Page 1

Pressure measurement

for research & industry

Druck Limited

Fir Tree Lane

Leicester LE6 0FH

England

Tel: 0116 231 7100

Trench Etched

Resonant Pressure Sensor

TERPS 8000 Series

User Manual

Groby

K0473

Druck Limited 2013

This document is the property of Druck Limited and may not, either in part or whole, be copied or otherwise

reproduced, communicated in any way to third parties, nor stored in any data processing system, without the express

written authority of Druck Limited.

Page 1 of 42 K0473 Issue 5

DO NOT PRINT THIS PAGE

Page 2

mendment Record

A

Iss No Date C/N No Originator Typed

1 20/12/10 N/A Robert Lee Robert Lee 156219 New document

2 24/06/11 26758 Robert Lee Robert Lee 165022

3 26/10/11

4 30/01/12 27572 Robert Lee Robert Lee 176971

5 08/11/12

Approvals

Engineering

Technical and operational accuracy

M COLE

Marketing

Customer/market suitability

I ABBOTT

27245

27300

28898

29134

Glenn Roles Glenn Roles 171244

Robert Lee Robert Lee 192333

Technical Communications

Compliance with style guidance and

presentation

G ROLES

Workflow

No.

Amendments

Delete two 80xx pressure ranges,

change power supply voltage from 5 to

6 Vdc.

Change Pascal to hector-Pascal, -

0.2mV/°C to -2mV/°C. Equations

changed on page 5. Pressure range

changed on page 4 25 to 40khz.

Page 11, 7.9b, add 5% of span after

`An applied pressure’.

Add Hastelloy versions and up-date

RS232/RS485.

Add section 6.5 Stored Coefficients and

appendix A

Page 2 of 42 K0473 Issue 5

DO NOT PRINT THIS PAGE

Page 3

Print Instructions

Finished Size: A5

•

• Print in colour on white throughout (covers + text), saddle stitched.

• Cover to 285 gsm, content to 100 gsm.

Translate into French, German, Italian, Spanish, Portuguese Brazilian, Simplified Chinese and Russian.

THIS HARDCOPY IS NOT TO BE USED AS CAMERA COPY.

Page 3 of 42 K0473 Issue 5

DO NOT PRINT THIS PAGE

Page 4

Page 4 of 42 K0473 Issue 5

DO NOT PRINT THIS PAGE

Page 5

GE

Measurement & Control

Trench Etched Resonant Pressure Sensor

8000 Series

User Manual - K0473

Page 6

© 2013 General Electric Company. All rights reserved.

Page 7

Safety • The manufacturer has designed this sensor to be safe when

operated using the procedures detailed in this manual. Do not

use this sensor for any other purpose than that stated.

• This publication contains operating and safety instructions

that must be followed for safe operation and to maintain the

sensor in a safe condition. The safety instructions are either

warnings or cautions issued to protect the user and the

equipment from injury or damage.

• Use qualified* personnel and good engineering practice for all

procedures in this publication.

Pressure WARNING:

Do not apply pressure greater the maximum safe working

pressure to the sensor.

Toxic Materials There are no known toxic materials used in this sensor.

Maintenance The sensor must be maintained using the manufacturer’s

procedures and these should be carried out by authorised service

agents or the manufacturer’s service departments.

Technical Advice For technical advice contact the manufacturer.

* A qualified technician must have the necessary technical

knowledge, documentation, special test equipment and tools

to carry out the required work on this equipment.

EC Directives This equipment complies with:

BS EN 61000-6-1:2007

BS EN 61000-6-2:2005

BS EN 61000-6-3:2007

BS EN 61000-6-4:2007

BS EN 61326-1:2006

This equipment complies with the requirement of the Pressure

Equipment Directive 97/23/EEC.

For further details see the Sales Data Sheet.

A full conformity certificate is available from the manufacturer.

Contact GE Measurement & Control:

www.ge-mcs.com

i K0473 Issue 5 - [EN] English

Page 8

Abbreviations

The following abbreviations are used in this manual.

Note: Abbreviations are the same in the singular and plural.

aAbsolute

ASCII American Standard Code for Information Interchange

atm Atmosphere

bps Bits per second

cmHg Centimetre of mercury

CR Carriage return

DC Direct current

EEPROM Electrically Erasable Programmable Read Only Memory

FS Full-scale

ftH

OFeet of water

2

hPa Hecto Pascal

inHg Inch of mercury

inH2OInches of water

kg Kilogram

2

kg/cm

kg/m

Kilogram per centimetre squared

2

Kilogram per metre squared

kPa Kilo Pascal

lb/ft2 Pounds per foot squared

LF Line feed

mA Milli Ampere

mbar Millibar

mbar a Millibar absolute

mHg Metre of mercury

mH

OMetres of water

2

mm Millimetre

mmHg Millimetre of mercury

mmH2O Millimetres of water

MW Mega ohm

MPa Megapascal

n/a Not applicable

[EN] English - K0473 Issue 5 ii

Page 9

Abbreviations (continued)

Pa Pascal

pc Personal computer

PIN Personal identification number

ppm Parts per million

psi Pound per square inch

RS232 Serial data communication standard

RS485 Serial data communication standard

TERPS Trench etched resonant pressure sensor

VVolt

VA Volt amp

°C Degrees centigrade

iii K0473 Issue 5 - [EN] English

Page 10

[EN] English - K0473 Issue 5 iv

Page 11

1Introduction

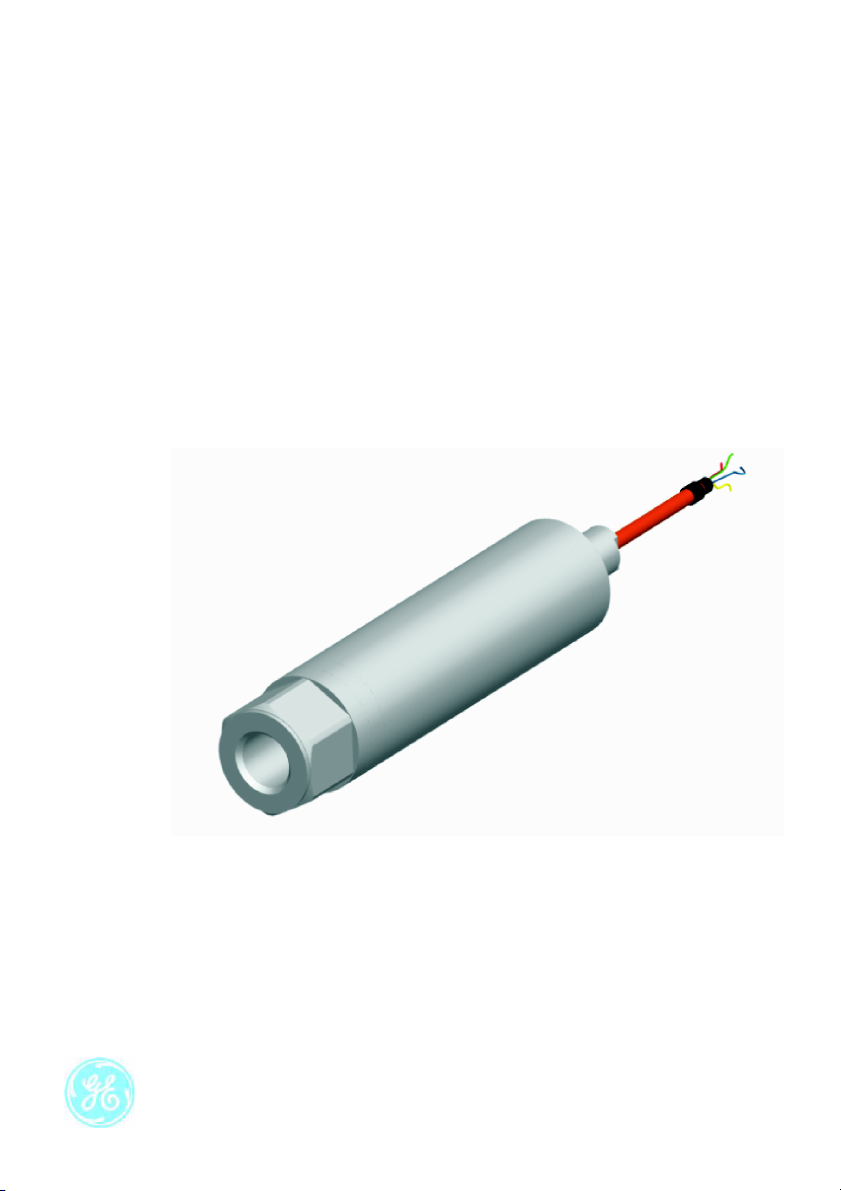

1.1 General The 8000 Series uses TERPS (trench etched resonant sensor)

technology. The RPS 8000 produces a frequency and diode voltage

output. The DPS 8000 includes a microprocessor to produce a serial

digital output.

Figure 1 TERPS General view

1.2 Configuration The following variables are specified at the time of ordering.

a. Pressure range

b. Pressure connector

c. Cable length

d. Option A - Increased accuracy

e. Accessories

i. User Manual (this publication)

ii. Calibration certificate.

1 K0473 Issue 5 - [EN] English

Page 12

2 Installation TERPS 8XXX is a harsh media isolated product. Isolation is achieved

by hermetically sealing the sensor chip in an oil filled chamber. The

weight of this oil gives a g-sensitivity as a pressure offset error.

To calibrate the TERPS 8XXX, the unit is mounted vertically with the

pressure port at the lowest point. Orientation other than this

produces a pressure offset error as specified in the datasheet. The

error is most noticeable at lower pressure ranges.

: The g-sensitivity will also create an error in a high vibration

Note

environment and the unit should be mounted accordingly.

TERPS 81XX is not a harsh media isolated product. There is

negligible change in offset due to mounting position and vibration.

Because the pressure media comes directly into contact with the

sensor chip, care must be taken to ensure the pressure media does

not damage the sensing chip.

2.1 Connecting

TERPS to

pressure source

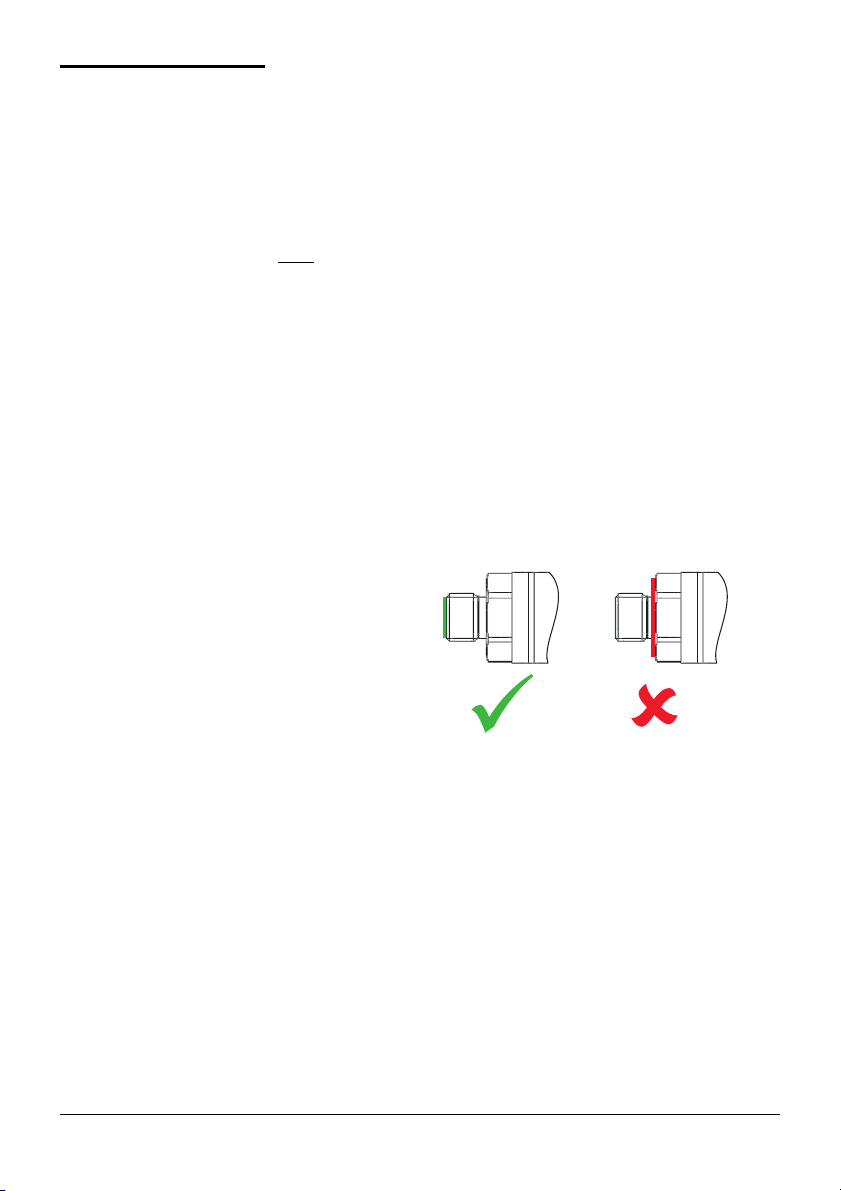

When mounting the sensor, seal the mating surfaces. Failure to

properly seal may affect performance or calibration accuracy.

Male threaded pressure connectors must not be sealed or

constrained against the face at the base of the thread. The forward

cone or flat face should always be used as indicated below.

Depth versions should not be used at hyperbaric pressures above

70 bar (approximately 700 m of water).

[EN] English - K0473 Issue 5 2

Page 13

3 TERPS media

compatibility

3.1 TERPS 81XX 0 to 3.5 bar: non-condensing dry gases compatible with silicon,

silicon dioxide, RTV adhesive, stainless steel 316L and glass.

3.2 TERPS 80XX- Ranges 0 to 200 bar: Fluids compatible with Stainless Steel 316L

and Hastelloy C276.

Ranges 201 to 350 bar: Liquids and group II gases compatible with

Stainless Steel 316L and Hastelloy C276.

Fluid classification complies with EC directive 67/548/EEC.

Statements comply with Pressure Equipment Directive 97/23/EC.

3.3 TERPS 82XX- Ranges 0 to 200 bar: Fluids compatible with Hastelloy C276.

Ranges 201 to 350 bar: Liquids and group II gases compatible with

Hastelloy C276.

Fluid classification complies with EC directive 67/548/EEC.

Statements comply with Pressure Equipment Directive 97/23/EC.

3.4 TERPS 83XX- Ranges 0 to 200 bar: Fluids compatible with Hastelloy C276.

Ranges 201 to 350 bar: Liquids and group II gases compatible with

Hastelloy C276.

Fluid classification complies with EC directive 67/548/EEC.

Statements comply with Pressure Equipment Directive 97/23/EC.

4 Pressure

containment

4.1 TERPS 81XX Ranges 0 to 3.5bar 7 bar maximum.

4.2 TERPS 8XXX- Ranges up to 7 bar: 70 bar maximum.

Ranges >7 to 100 bar: 200 bar maximum.

3 K0473 Issue 5 - [EN] English

Page 14

5 Applying power to

TERPS

5.1 Frequency and

diode versions:

5.2 RS485 and RS232

Versions

6 Measuring TERPS

6.1 Frequency and

diode version

6.2 Measuring the

Frequency

The TERPS sensor should be connected to stable power supply

between 6 and 28 V

Low jitter version require a less than 10 mA during normal

operation.

Low power versions require less than 3.5 mA during normal

operation.

During power-up the sensor draws more than current than above,

it is recommended that the power supply can supply a short term

peak of at least 20 mA.

The TERPS sensor should be connected to a stable power supply

between 11 and 28 V

at 32 mA.

The frequency and diode version of the TERPS sensor requires the

user to measure a frequency and a voltage to calculate pressure.

The TERPS sensor has a very high level of repeatability that needs

to be matched by the measurement system.

The frequency of the TERPS die is output as a TTL square wave

referenced to ground in the range of 25 to 40 kHz. The frequency of

the square wave needs to be measured to a better than 6.5 digits

(i.e. 30 KHz to better than 0.05 Hz) to allow the sensor to meet

quoted specification.

To make sure the calculated output is correct, the measurement

device should be regularly calibrated refer to the manufacturer’s

instructions against a traceable standard.

.

DC

. Current drawn is a nominal 16 mA peaking

DC

6.3 Measuring the

Diode Voltage

[EN] English - K0473 Issue 5 4

The diode signal is referenced to ground. It is a nominal 0.5 V at

room temperature, and changes with a nominal -2mV/°C. To

achieve the quoted specification of the sensor this signal must be

measured to better than 0.01mV.

To make sure the calculated output is correct, the measurement

device should be regularly calibrated refer to the manufacturer’s

instructions against a traceable standard.

: Best practice, when measuring a TERPS device, take both

Note

measurements together. Where this is not possible the

measurements should be taken as closely together as possible.

Control the environment in which the TERPS is situated so it is not

subjected to sudden changes in temperature and pressure.

Page 15

6.4 Calculating

Where:

P = Applied pressure (psi)

K

y

= Calibration coefficient

x = Pressure signal in Hz minus normalising factor X

y = Temperature signal in mV minus normalising factor Y

[]

[]

[]

)()()()(

)()()()(

)()()()(

32

23

22

22

12

21

02

20

31

13

21

12

11

11

01

10

30

03

20

02

10

01

00

00

yxKyxKyxKyxK

yxKyxKyxKyxK

yxKyxKyxKyxKP

⋅⋅+⋅⋅+⋅⋅+⋅⋅

+⋅⋅+⋅⋅+⋅⋅+⋅⋅

+⋅⋅+⋅⋅+⋅⋅+⋅⋅=

Pressure

During manufacture, a large number of pressures and

temperatures are applied to the sensor to build-up a mathematical

description of its behavior. This data is then used to generate a

polynomial equation that relates the measured outputs from the

sensor (bridge output and temperature output) to the applied

pressure.

nd

The following example assumes a 2

order temperature signal (T

3

). If other orders of fit are used, these

order pressure (P2) and a 3rd

equations will need to be expanded to suit.

This equation is in the form:

Therefore:-

The x variable is the pressure sensitive, measured output from the

sensor in Hz minus the normalising factor X.

The y variable is the temperature sensitive, measured output from

the sensor in mV minus the normalising factor Y.

The coefficients Kij, X and Y are printed on the top right-hand corner

of the calibration certificate supplied with the pressure sensor. A

sample set is shown below:

SN refers to the serial number of the unit, CS is a check sum of the

5 K0473 Issue 5 - [EN] English

data and can be ignored.

Page 16

6.5 Stored

Coefficients

The coefficients are also stored internally on a serial EEPROM. See

Appendix A for details on data format and communication

information.

The internal EEPROM is only available on some electrical connector

variants of the RPS 8000 series, see datasheet or calibration

certificate for electrical connection details.

7 Using RS485 and

Output is compensated pressure in user specified units.

RS232 versions

7.1 Serial Data

Communications

7.2 Applications The TERPS may be used as a single transducer directly connected

7.3 RS485

Connections

RS485 bi-directional digital communication, no handshaking, user

programmable baud rate between 300 and 9600 baud, 8 bit data,

1 stop bit. Format: ASCII text, pressure reading including pressure

units. User programmable reading rate from one reading per

second to one reading per 999999 seconds.

to a serial interface. It can also be part of a network of devices using

the programmed addressing facility. Each device on the network is

a slave with a master device controlling the communications.

The installed transducer is completely controlled by the serial

interface. The TERPS transducer contains its characteristic data in

an integral E

Stand Alone RS485 Electrical connections

RS485-B (or RS485 -)

+ve supply

0V supply

RS485-A (or RS485 +)

Transducer body (screen)

Notes

2

PROM.

:

• Other connectors available refer to manufacturer.

• For electrical connections refer to the sales data

sheet.

[EN] English - K0473 Issue 5 6

Page 17

Figure 2 RS485 Direct connections

Figure 3 RS485 Network connections

7.4 RS232

Connections

7 K0473 Issue 5 - [EN] English

Stand Alone RS232 Electrical connections

Tx

+ve supply

0V supply

Rx

Data ground (GRD) connects to 0V

Page 18

Figure 4 RS232 Direct connections

[EN] English - K0473 Issue 5 8

Page 19

7.5 Command

Summary

The following functions can be performed using the serial data link:

FUNCTION COMMAND

Measurement

Transmit pressure reading........................................ ...............R

Trigger new reading and transmit........................ ...............G

Read raw data................................................................ ...............Z

Information

Identity and set-up information............................. ...............I

General set-up

Set automatic transmission interval.................... ...............A

Set filter............................................................................. ...............F

Set device address........................................................ ...............N

Pressure measurement speed................................ ...............Q

Set output pressure units.......................................... ...............U

PIN Set-up

Digital output calibration........................................... ...............C

Set full-scale ................................................................... ...............H

User message................................................................ ...............M

Communication settings............................................ ...............O

Change PIN...................................................................... ...............P

Set offset........................................................................... ...............S

Command Terminators.............................................. ............... <CR>

.............................................. ............... <CRLF>

:

Notes

• Waiting 20 seconds after entering a valid command

has the same effect as <CR>.

• The backspace character deletes typing errors.

• Commands are processed on receipt of a <CR> or a

20 second time out.

• Adding a * before a command character causes a

text reply.

• All <LF> characters are removed from the incoming

string before processing, so <CR> = <CRLF>, number

of terminating characters set in ‘O’ command effects

the reply.

9 K0473 Issue 5 - [EN] English

Page 20

FUNCTION QUERY

General set-up

Automatic transmission interval?.......................... ...............A,?

Filter setting?.................................................. ............... F,?

Device address?............................................. ............... N,?

Pressure measurement speed?.............. ............... Q,?

Output pressure units?............................... ...............U,?

PIN Set-up

Digital output calibration........................... ............... C,?

Full-scale value?............................................ ...............H,?

User message?............................................... ...............M,?

Communication settings?......................... ............... O,?

PIN set? ............................................................. ...............P,?

Offset value?................................................... ...............S,?

Factory Set-up (Query only)

Crystal Reference Frequency................... ...............E,?

Load Calibration Coefficients.................. ...............L,?

Analogue/Digital Convertor Set-up...... ...............T,?

Transducer Type and Settings................. ...............V,?

Write to EEPROM........................................... ...............W,?

7.6Measuring

Pressure

7.7 Communication

Modes

The frequency output from the sensor is counted for a fixed nu mber

of cycles by the microprocessor. At atmospheric pressure this takes

a nominal 400 milliseconds. The output from the integral

temperature sensing diode takes 400 milliseconds for a single

conversion through the discrete converter. Measurement cycles

are continuous, each cycle delivers new values of frequency and

temperature.

The TERPS smart transducer operates in one of two operating

modes: direct and addressed. These modes are controlled by

sending the transducer an address number.

Direct mode

The valid address in direct mode is zero. In this mode, the

transducer continuously transmits data at an interval set by the

user. Before any command can be sent to the transducer, the data

stream must be stopped by sending a single byte character or back

space. The stop character is lost and not parsed with the

instruction.

Note: On shipment, sensors are set to direct mode as default.

Addressed mode

The valid address in addressed mode is a number between 1 and

32. In this mode, data has to be polled from the transducer using

the valid address. All devices on the network respond to the

address 0 for the G, R, I and Z commands. The reply timing depends

on the address of the sensor, each sensor delays response by a

[EN] English - K0473 Issue 5 10

Page 21

time equal to the message length times (it's address - 1) times a

character transmit time. For example sensor address 20 will delay

by a time to allow 19 sensors to reply with the same message

length. The command 0:I returns the sensor serial number only.

Special Note

Transducers are shipped with the following initial settings (unless alternatives

have been requested):

Units

PIN

Address

Long error messages

Communications set

Update rate

Filter

User message

-

mbar

-

000 (not set)

-

Direct mode

-

Present

-

9600, 8, N, 1

-

1 reading/second

-

disabled

-

none

7.8General

Command

Format

A sequence of single letter commands control the transducer.

Some commands require one or more numeric values to follow the

command letter. The correct number of parameters must be sent

for this particular command. A comma separates all command

fields. The transducer accepts upper-case or lower-case letters.

Single commands should be in the form:

Command, P1, P2......................................................... ...............Pn

Where, Command is a single letter command

P1 to Pn are the required numeric values in the form:

(-) mmm.ddd

or

(-)m.ddddE(-)xx

e.g. 123.456 or 1.23456E02

Example 1 - Single Command

A,3<CR> selects the output update of one

reading every 3 seconds

(alternative command - a,3<CRLF>)

Command Strings

The transducer also recognises a string of commands each

separated by a semicolon. After receiving a valid terminator, the

transducer accepts the command string.

Example 2 - Multiple Commands (Command String)

P, PIN, new PIN; U, units;A,5 <CRLF>

This command string sets the new PIN, the units in which the

pressure reading is transmitted and the interval between

transmissions.

: A command with the *prefix causes a reply to change to text.

Note

i.e., Command: *R

Reply: <Pressure value><pressure units>

11 K0473 Issue 5 - [EN] English

Page 22

Command String Limitations

A command string must not be more than thirty characters. The

transducer ignores all the commands in a string containing more

than thirty characters.

Network Mode Syntax

In this mode an address field must be added to the start of the

general format as follows:

Address: command,P1,P2.......................................... ...............Ppn

where:

‘Address’ is the address of the transducer to send the command

‘:’ is the end of the address field

‘command’ is the single letter instruction

‘P1’ to ‘Pn’ are the required numeric values

Example 3 - 1:R<CR>

Get device @ address 1 to transmit pressure

7.9 Error Message Error messages are generated from two sources:

a. User commands

In a command string, the transducer accepts correct commands

and rejects incorrect commands. An incorrect command causes

the transducer to send an error message related to the command.

Error Message Format

The form of the error message:

ERROR nn - where nn is a decimal number

Defined error numbers are detailed in Table 1, page 28.

b. Transducer fault

A transducer fault sends an error message blocking the

transmission of pressure data and sending the fault message in

place of data.

Error messages

An applied pressure, 5% of span out of the calibrated range,

causes:

*Over Pressure*

*Under Pressure*

A damaged transducer or no frequency output from the transducer

causes:

**** NO RPT ****

[EN] English - K0473 Issue 5 12

Page 23

8Command

Definitions

The commands have been defined for direct mode operation

(address 0). In the addressed mode an address field will be added

to the start of the command and reply. For example:

Get reading command

Command

direct : R<CR>

addressed : Address:R<CR>

: Address:*R<CR>

Reply

direct : Pressure value pressure units<CR>

addressed : Address:Pressure value pressure units<CR>

: Address*:<Pressure reading><units><CR>

8.1 Measurement

Commands

R - Get Reading This command polls the devices in the network for a reading.

Although used mainly in the addressed mode it can also be used in

direct mode.

Command: R<CR>

Reply: Pressure value pressure units<CR>

Result: A new pressure reading is transmitted.

Command: *R<CR>

Reply: <Pressure value> <pressure units><CR>

Result: A new pressure reading and the units of pressure measurement are

transmitted.

Query: n/a

G - Get New Reading and

Transmit

This command starts a new "measurement cycle" and, when

completed, transmits the reading.

Command: G<CR>

Reply: <Pressure reading>(CR)

Result: Transmission of the reading takes 1.5 times the current

measurement interval set by the Q command.

13 K0473 Issue 5 - [EN] English

Page 24

Command: *G<CR>

Reply: <Pressure reading>,<Units>(CR)

Result: Transmission of the reading takes 1.5 times the current

measurement interval set by the Q command.

Z - Read Raw Data This command sends the last complete "measurement cycle" of the

transducer as frequency and voltage.

Note: The frequency value is proportional to the applied pressure

and the voltage is proportional to the temperature sensed by

the diode.

Command: Z<CR>

Reply: <Frequency><Diode voltage>(CR)

Command: *Z<CR>

Reply: <Frequency (Hz)><Diode voltage (mV)>(CR)

Response: In direct mode changes between automatic transmission mode

(see A command) and transmission of the frequency and voltage. In

network mode sends the last complete "measurement cycle" of the

transducer as frequency and voltage.

Query: n/a

8.2 Information

Commands

I - Transducer Identity This command gets the identity and set-up data from the

transducer. Either formatting character can be used with this

command.

Command: I<CR>

Reply: <Unit type>, <Serial Number>,<Style>,<Range Unit

Number>,<Minimum Pressure>,<Maximum Pressure>,<Calibration

Date>,<Software Version>,<Transmission Interval>,<Units sent

Y/N>,<Measurement Speed>,<Filter Factor>,<Filter Step>,<User

Message>,<Units number>,<Pin set Y/N>,<User Zero Y/N>,<>(CR)

Command: *I<CR> or <I<CR>

Reply: "Device : Device type" (TERPS-1234)<CR>

"S/N : Transducer serial number"<CR>

"Range : Pressure range"<CR>

"Address : Transducer address"<CR>

<CR>

"Press any key to continue . . . "<CR>

Query: n/a

[EN] English - K0473 Issue 5 14

Page 25

8.3 General Set-up

Commands

A - Auto-send Reading This command sets the interval between each transmission. The

interval can be to one decimal place, i.e., 1.5 seconds. Entering a

negative number causes an error.

: Setting this interval to less than the measurement interval (Q

Note

Command), causes the output of the same reading twice or

more.

Command: A,nnnnnn<CR>

Where: ‘nnnnnn’ is a number between 0 and 999999. This is the interval in

seconds between successive transmissions.

Reply: None in network mode.

In direct mode: <Pressure reading>(CR)

<Pressure reading>(CR)

Result: A reading is transmitted every nnnnnn seconds in the format set in

the set-up commands. The interval input is non-volatile.

Command: *A,nnnnnn<CR>

Where: ‘nnnnnn’ is a number between 0 and 999999. This is the interval in

seconds between successive transmissions.

Reply: None in network mode.

In direct mode: <Pressure reading><Units>(CR)

<Pressure reading><Units>(CR)

Result: A reading is transmitted every nnnnnn seconds. The interval input

is nonvolatile.

Query: A,?

Reply: <Transmission interval set>,<Y if Units displayed, N if units not

displayed>(CR)

Query: *A,?

Reply: Interval = <Transmission interval set>(CR)

Units = <Yes if Units displayed, No if units not displayed>(CR)

15 K0473 Issue 5 - [EN] English

Page 26

F - Change Filter Settings This command sets the filter applied to the pressure reading (R

Command, network mode) or direct mode pressure reading.

Command: F, (Filter factor),(Filter step)

Where: The last two pressure readings are filtered using a % factor of the

sum of the two values. The filter step takes a value expressed as an

integer percentage of full-scale. If step = 0, then the filter is disabled.

If the percentage change between last pressure reading and the

current pressure reading exceeds the filter step value the current

reading passes through unfiltered.

The last two pressure readings are filtered using a % factor of the

sum of the two values,

. (1-F/100) + PN . F/100

P = P

o

Where

P = New returned pressure

Po = Last returned pressure

= New measured pressure

P

N

F = Filter factor as integer between 1 and 99

The filter step . . . . . .”

Reply: <None>

Result: A filtered value within the filter step band, this change is

non-volatile.

Query: F,?

Reply: <Filter Factor>,<Filter Step>

Query: *F,?

Reply: Filter Factor = <Filter Factor>

Filter Step = <Filter Step>

N - Set Device

(transducer) Address

This command sets the address of the transducer. A valid address

is a number between 0 and 32. Setting the address to zero causes

the transducer to go into direct mode. All other address settings

cause the transducer to go into network mode. This command has

a secondary function and uses N,0 or *N,0 to change the length of

error messages (where: 0 = direct mode).

Command: N, (new address)

Reply: (none)

Command: N,0

Reply: (none)

Result: Changes to short error messages.

where: 0 = direct mode

[EN] English - K0473 Issue 5 16

Page 27

Command: *N,0

Result: Changes to long error messages.

Example: Address 1 change to long error messages:1:*N,1

Query: N,?

Query: *N,?

Q - Set Measurement

Speed

Command: Q (speed setting)

Query: Q,?

Query: *Q,?

Reply: (none)

where: 0 = direct mode

Reply: <Device Address> (CR)

Reply: Device Address =<Device Address> (CR)

This command changes the rate of measuring by changing the

number of output cycles counted for each reading. The RPT

produces an output at 16000 cycles per second and by selecting

one of 6 settings (0 to 5), a sample rate can be made. The highest

rate (5) causes the most electrical noise.

: Increasing the Q speed may, for the next two seconds, cause

Note

reading errors or !020 No Frequency error message to be

returned.

Reply: (none)

Reply: <Measurement Speed>(CR)

Reply: Measurement Speed =<Measurement Speed>(CR)

Q

Command

Setting

2[1] 16000 360 530 1.0

[1] Default setting for the accuracy stated in the specification.

[2] This interval varies between minimum and maximum.

U - Set Units This command sets the units of pressure measurement.

17 K0473 Issue 5 - [EN] English

Resonant

Sensor

Cycles

Counted

0 64000 1400 2100 4.0

1 32000 710 1050 2.0

3 8000 180 260 0.50

4 4000 90 130 0.25

5 2000 50 75 0.25

Measurement Interval

milliseconds [2]

minimum maximum

G

Command

fixed

setting

Page 28

Either formatting character can be used with this command.

Command: U,nn<CR>

Where: ‘nn’ is a number between 0 and 24 used to select the required units.

Reply: <none>

Result: Changes the pressure units of the transmitted reading.

Query: U,?

Reply: <unit number> (CR)

Command: *U

Reply: (Interactive)

Current units are <Units> (<unit number>) (CR)

(CR)

0 - mbar<CR> 13 - mH

1 - Pa<CR> 14 - torr <CR>

2- kPa<CR>15- atm <CR>

3- MPa<CR>16- psi <CR>

4- hPa<CR>17- lb/ft2<CR>

5- bar<CR>18- inHg <CR>

2

6- kg/cm

<CR> 19 - inH2O04<CR>

7- kg/m2<CR> 20 - ftH2O04 <CR>

8 - mmHg<CR> 21 - mbar <CR>

9- cmHg<CR>22- inH

10-mHg<CR>23-ftH

11 - mmH

O<CR> 24 - mbar <CR>

2

12 - cmH2O<CR>

2

O <CR>

O20<CR>

2

O20<CR>

2

: mbar can be selected using code 0, 21 or 24.

Note

Result: Each of these non-volatile commands changes the pressure units

of the transmitted reading.

Query: *U,?

Reply: Units = <Units> (<unit number>) (CR)

[EN] English - K0473 Issue 5 18

Page 29

8.4 PIN Protected

Set-up

Commands

C - User Calibration This command allows the user to perform a two point calibration on

the output of the device. The calibration routine requires two

pressures to be applied within the operating extremes and in units

of pressure measurement set in the transducer. The software

calculates an offset and gain correction to all subsequent readings.

Command: C or *C

Reply: (Interactive)

Reply: Enter PIN’ => (enter PIN)

Reply: “Apply first pressure, then send <CR>” (when stable, send <CR>)

Reply: “Enter applied pressure (<units>)” =>(enter pressure value in

specified units) <CR>

Reply: “Apply second pressure, then send <CR>” (when stable, send <CR>)

Reply: “Enter applied pressure (<units>)” =>(enter pressure value in

specified units) <CR>

Reply: “Pressure gain = <new pressure gain>” (CR)

“Pressure offset = <new pressure offset>” (CR)

“Accept these values? (Y/N) =>(Enter Y or N)

(Y answered) “EEPROM updated” <CR>

(N answered) “Current settings left unchanged” <CR>

(If invalid data entered) “!023 Bad Cal Pres” <CR>

Command: *C,PIN,mode,?<CR>

Non-interactive calibration requires the C command to be used

twice, i.e. two calibration pressures must be entered for a straight

line fit.

Proceed as follows:

Command: *C,PIN,1,?<CR>

Where: ‘PIN‘ is the PIN of the transducer and ‘1‘ is the first pressure value.

Apply pressure 1, when stable send:

C,(PIN),1,<CR>

Note: Sending *C,PIN,1,?<CR> causes the current stored data for

pressure 1 to be sent.

Apply pressure 2, when stable send:

C,(PIN),2,<CR>

19 K0473 Issue 5 - [EN] English

Page 30

Query: C,PIN,mode?

original slope

Output reading

Applied pressure

0

12

3

4

0

1

2

3

4

new set-point

(span) using the

H command

new off-set

(zero) using the

S command

Reply: <Measured>,<Applied><Got first point (Yes/No)> (CR)

Query: *C,?

Reply: “Measured Pressure = <Measured>” (CR)

“Applied Pressure = <Applied>” (CR)

“First Point Done=<Yes/No>(CR)

8.5 H - Change Slope This command changes the slope of the output function of the

transducer.

The relationship between the applied pressure and the output

signal can be shown in graphic form:

[EN] English - K0473 Issue 5 20

Figure 4-1 Output to Applied Pressure Graph

:

Notes

• If S remains at 0 (the before value) and the H value is

changed, the slope "pivots" around zero.

• If H remains the same (slope) and the S value is

changed the whole slope goes higher or lower by the

S value.

Page 31

H and S Commands Proceed with caution when using these commands.

Do not use both commands together.

Use one command and then assess the result

before continuing.

Command: H,(PIN),(pressure)

Reply: <none>

Command: H,?

Reply: <slope>,<setpoint>(CR)

Command: *H,?

Reply: Slope =<slope>(CR)

Set At =<setpoint><Units>(CR)

Where: The slope is a gradient and set-point is the reading value entered for

an applied pressure.

M - User Message Th is comman d s et s a us er de fi ned message of 16 characters stored

in non-volatile memory. Only ASCII characters 32 to 128 are stored,

all others will be removed from the final string. ASCII 0 indicates the

end of message and stores this in memory but does not transmit

this character. The (CR) character is transmitted with the message

but not stored in memory. Attempting to store the colon character

causes an error '!022 Bad Message'.

Command: M,(PIN),(message)

*M,(PIN),(message)

Reply: <none>

Command: M,?

Reply: <message>(CR)

Command: *M,?

Reply: Message =<message>(CR)

21 K0473 Issue 5 - [EN] English

Page 32

O - Communication

Settings

This command sets the communications for the transducer. The

settings can be either interactive or non-interactive.

Where:

Baud rate: number between 0 and 6 or an actual rate.

Parity: set with a single letter:

I = ignore, N = None, O = Odd, E = Even

Character length: 7 or 8

Stop bits: 1 or 2

Software handshaking:Y or N (Yes or No)

Termination characters:1 or 2

(1 = transmitted lines must end in CR, received lines end in

either CR or LF).

(2 = transmitted lines must end in CRLF, received lines end in

CRCR or CRLF or LFLF or LFCR).

Command: O, PIN,n <CR>

where: O, (PIN), (Baud Rate), (Parity), (Character Length), (Stop Bits),

(Software Handshaking), (Number of Termination Characters)

Reply: <none>

Command: *O, PIN,n <CR>

where: O, (PIN), (Baud Rate), (Parity), (Character Length), (Stop Bits),

(Software Handshaking), (Number of Termination Characters)

Reply: <none>

Command: O,?

Reply: <Baud Rate>, <Parity -NIEO>, <Character Length>, <Stop Bits>,

<Software Handshaking - Y/N>, <Number of Termination

Characters> (CR)

Command: *O,?

Reply: Baud Rate = <Baud Rate>

Parity = <Parity -Ignore/None/Odd/Even (CR)

Data Bits = <Char Length> (CR)

Stop Bits = <Stop Bits> (CR)

Handshake = <Software Handshaking - Yes/No> (CR)

Term Chars = <Number of Termination Characters> (CR)

[EN] English - K0473 Issue 5 22

Page 33

Command: *O

Reply: (Interactive)

Enter PIN - >(Enter PIN)

0 - 19200 bps. (CR) 1 - 9600 bps. (CR)2 - 4800 bps. (CR)

3 - 2400 bps. (CR) 4 - 1200 bps. (CR)5 - 600 bps. (CR)

6 - 300 bps. (CR)

Select Baud rate (0 - 6) = >(enter selection)

Enter parity ([N]one/[I]gnore/[E]ven/[O]dd) = >(Enter parity)

Enter number of data bits (7/8) = >(Enter number of data bits)

Enter number of stop bits (1/2) = >(Enter number of stop bits)

Software Handshaking? (Y/N) = >(Enter Y or N)

Number of termination characters (1 = CR, 2 = CRLF) = >(Enter

number of termination characters)

Accept these values? (Y/N) = >(Enter Y or N)

If Y entered - EEPROM updated. (CR)

If N entered - Current settings unchanged. (CR)

Result: These settings take effect after switching off then on the power

supply for the transducer.

P - Change PIN This command sets the PIN of the transducer that must be used to

access the PIN protected settings. To change this setting the

current PIN must be used and can be integers between 0 and 999.

Command: P, (current PIN), (new PIN)

Where: PIN’ is the PIN of the transducer.

‘NewPIN’ is the replacement PIN.

Reply:

Result:

<none>

The PIN of the transducer changes to new PIN.

Command: *P, (current PIN), (new PIN)

Where:

Reply: <none>

Result: The PIN of the transducer changes to new PIN.

‘current PIN’ is the PIN of the transducer.

‘new PIN’ is the replacement PIN.

Command: P,?

Reply: (Y if PIN set, N if PIN not set) (CR)

23 K0473 Issue 5 - [EN] English

Page 34

S - Set Offset

Command: *P,?

Reply: Pin Set = (Yes if PIN set, No if PIN not set) (CR)

This command adds an offset value to the output of the transducer.

Command: S, (PIN), (pressure)

Reply:

Result: The transducer stores the value set with the S command in

<none>

non-volatile memory.

Command: S,?

Reply:

<Offset>,<Setpoint>(CR)

Command: *S,?

Reply:

Offset = <Offset><Units>(CR)

Set at = <Setpoint><Units>(CR)

The transducer stores the value entered as <Setpoint>. The H

command also uses this set-point value. To remove the set-point

send:

S,(PIN),(X)

This sets the stored set-point value to zero.

[EN] English - K0473 Issue 5 24

Page 35

8.6 Factory Set

Commands Query Only

The following command codes can only be accessed using a

factory PIN. These command codes can be queried by the user. The

transducer sends the data/settings stored in non-volatile memory

for the queried commands code.

E - Crystal Reference

Frequency

Command: n/a

Query: E,?

Query: *E,?

L - Load Calibration

Coefficients

Command: n/a

Query: L,?

This direct mode only command sets the measured frequency of

the crystal oscillator in non-volatile memory.

Reply: <Reference Frequency>(CR)

Reply: Reference Frequency = <Reference Frequency>kHz(CR)

This direct mode only command sets the calibration coefficients in

non-volatile memory.

Reply: <Coefficient0,0>,<Coefficient 0,1>,<Coefficient0,2>,<Coefficient

0,3>,<Coefficient 0,4>,<Coefficient 1,0>, ... ,<Coefficient

5,3>,<Coefficient 5,4>,<Frequency Offset>,<Diode

Offset>,<Calibration Date>(CR)

Reply: K[0][0] = <Coefficient 0,0> K[0][1] = <Coefficient 0,1>

K[0][2] = <Coefficient 0,2>(CR) K[0][3] = <Coefficient 0,3>

K[0][4] = <Coefficient 0,4> (CR) K[1][0] = <Coefficient 1,0> ...... ...

K[5][4] = <Coefficient 5,4>(CR)

(CR)

Frequency Offset (X) = <Frequency Offset> Diode Offset (Y)= <Diode

Offset>(CR)

Serial Number = <Serial Number> Calibration Date= <Calibration

Date>(CR)

Curve Fit = <X order> x <Y order>(CR)

(CR)

Type <CR> to continue(CR) (Waits 20 seconds or for CR)

25 K0473 Issue 5 - [EN] English

Page 36

T - Analogue/Digital

Converter Set-up

Command : n/a

This direct mode only command sets the internal analogue to

digital converter used to measure the ambient temperature value

in non-volatile memory.

Query: T,?

Reply: <Diode Calibration>(CR)

Query: *T,?

Reply: Diode Cal = <Diode Calibration>(CR)

V - Transducer Type

and Settings

Command: n/a

Query: V,?

Reply: <Type>,<Serial Number>,<Sensor Serial Number>,

Query: *V,?

Reply:

This command sets the transducer type, pressure range and serial

number in non-volatile memory.

Transducer data

Type: 5 character text string

Serial Number: ‘AA/1/2’ format

Sensor Serial Number: serial number is a 7 digit integer

Style: G for Gauge, A for Absolute

Pressure Unit Number: 0 to 24, see the U command

Minimum Pressure: real numbers in pressure units

Maximum Pressure: real numbers in pressure units

Direct mode only

<Style>,<Pressure Unit Number>,<Minimum Pressure>,

<Maximum Pressure>(CR)

Type = <Type>(CR)

Serial Number = <Serial Number>(CR)

Sensor SN = <Sensor Serial Number>(CR)

Style = <Style>(CR)

Minimum Pressure = <Minimum Pressure> <Pressure Units>(CR)

Maximum Pressure = <Maximum Pressure> <Pressure Units>(CR)

[EN] English - K0473 Issue 5 26

Page 37

W - Write to EEPROM This command sets the non-volatile memory, as listed below:

Address Meaning

-1 Wipe the first bank of the EEPROM.

-2 Wipe the second bank of the EEPROM.

-3 Wipe the both banks of the EEPROM.

-4 Wipe the calibration coefficients in both banks.

-5 Copy from bank 2 to bank 1.

-6 Copy from bank 1 to bank 2.

Command: n/a

Query: W,?

Reply:

<Byte 0>,<Byte 1>,<Byte 2>,<Byte 3>,<Byte 4>,

<Byte5>,<Byte 6>, ... ,<Byte 510>,<Byte 511>(CR)

Query: *W,?

Reply:

000=> <Byte 0>,<Byte 1>, ... ,<Byte 15>(CR)

010=> <Byte 16>,<Byte 17>, ... ,<Byte 31>(CR)

...

0F0=> <Byte 240>,<Byte 241>, ... ,<Byte 255>(CR)

(CR)

Send <CR> to continue(CR)

(Waits 20 seconds or for CR)

100=> <Byte 256>,<Byte 257>, ... ,<Byte 271>(CR)

...

1F0=> <Byte 496>,<Byte 497>, ... ,<Byte 511>(CR)

Send <CR> to continue(CR)

(Waits 20 seconds or for CR)

27 K0473 Issue 5 - [EN] English

Page 38

Table 1, Fault Finding

Error Message Probable cause Action

!001 Buf Overflow

!002 EEPROM Error Failure of non-volatile memory. Return to GE for repair or replacement.

!004 Bad

Command

!005 Bad Char Illegal character sent in a command string.

!006 Bad Param(s)

!008 Bad Format

!009 Miss’g Param

!010 Invalid PIN Incorrect PIN for the command sent. Check command string sent.

!011 Bad Value Out of range value sent to the transducer. Send in range value.

!012 Bad BUS Cmd

!013 Cal Error

!014 Press Range

!015 Under Press Pressure applied below calibrated limit.

!016 Over Press Pressure applied above calibrated limit.

!017 Bad Global

!018 Bad Response

!019 Timed Out

!021 Bad

Checksum

!022 Bad Message

!023 Bad Cal Pres

More than 30 characters sent without an end

of the line character.

Command character not recognised.

Invalid parameters sent in command string out of range, too long, wrong type etc.

Invalid formatting character sent in command

string or command is interactive.

At least one of the required parameters

missing from command string.

Command sent to transducer in Network

mode.

Corrupt calibration data detected, transducer

pressure measurement unreliable.

Corrupt calibration data detected, pressure

range not known, transducer pressure

measurement unreliable.

Command sent to the transducer as a global 0:

command not valid as a global command in

network mode.

Invalid value entered in response to a prompt

normally happens with inactive commands.

Key not pressed in the specified time period

(usually 20 seconds) normally happens with

inactive commands.

Error occurred in memory check sum.

Erroneous character detected in the middle of

a message.

Divide by zero error occurred in calibration

calculation.

Send 30 delete characters followed by an end of

line to clear the buffer.

Check command string sent.

Check the serial interface connection.

Check command string sent is valid.

Check the serial interface connection.

Check command string sent.

Check command string sent requires a valid

formatting character.

Check command string sent.

Send this command with transducer in Direct

mode.

Return to GE for recalibration.

Return to GE for recalibration.

Check for system fault where transducer is

installed.

Check for system fault where transducer is

installed.

Send the command to each transducer in turn,

using correct address in place of global 0.

Repeat command with valid values in response

to each prompt.

Repeat command, entering response in less than

20 seconds between each character and send

carriage return within the specified time.

Power cycle sensor, if fault remains return to GE

for repair or replacement.

Check and re-send message.

Check data and repeat calibration.

[EN] English - K0473 Issue 5 28

Page 39

9 Appendix A:

RPS 8000 Series

EEPROM format

The EEPROM device in the RPS 8000 Series is a Microchip 11LC040.

The datasheet can be found at:

http://www.microchip.com/wwwproducts/Devices.aspx?dDocName=en535102

Only the first 511 bytes of memory are defined as follows:

Table 2: EEPROM Data format

Address

(Dec) (Hex)

0 0000 1

2 0002 4

8 0008 16

40 0028 2

44 002C 1

45 002D 1

46 002E 1

52 0034 4

56 0038 4

64 0040 4

68 0044 4

72 0048 1

73 0049 1

80 0050 1

81 0051 1

128 0080 4

132 0084 4

136 0088 4

140 008C 4

144 0090 4

148 0094 4

152 0098 4

156 009C 4

160 00A0 4

164 00A4 4

168 00A8 4

172 00AC 4

Size

(Bytes)

Field Name

Data field format code 1 8 bit Integer

Serial Number 32-bit Integer

Product ID Code RPS 8000 ASCII Text

Transducer Type Identifier &h 1F40 16 bit Integer

Day of calibration - dd 8 bit Integer

Month of calibration - mm 8 bit Integer

Year of calibration - yy 8 bit Integer

Customer Offset term 0 32 bit IEEE

Customer Gain term 1 32 bit IEEE

Upper pressure range 32 bit IEEE

Lower pressure range 32 bit IEEE

Pressure units code 8 bit Integer

Sensor type Abs/Gauge 0 / 1 8 bit Integer

Number of pressure coefficients 8 bit Integer

Number of temperature coefficients 8 bit Integer

X - Frequency datum 32 bit IEEE

Y - Temperature datum 32 bit IEEE

K00 32 bit IEEE

K01 32 bit IEEE

K02 32 bit IEEE

K03 32 bit IEEE

K04 32 bit IEEE

K10 32 bit IEEE

K11 32 bit IEEE

K12 32 bit IEEE

K13 32 bit IEEE

K14 32 bit IEEE

Contents

(Default)

Format

29 K0473 Issue 5 - [EN] English

Page 40

Address

(Dec) (Hex)

176 00B0 4

180 00B4 4

184 00B8 4

188 00BC 4

192 00C0 4

196 00C4 4

200 00C8 4

204 00CC 4

208 00D0 4

212 00D4 4

216 00D8 4

220 00DC 4

224 00E0 4

228 00E4 4

232 00E8 4

236 00EC 4

240 00F0 4

244 00F4 4

248 00F8 4

252 00FC 4

510 01FE 2

Size

(Bytes)

Field Name

K20 32 bit IEEE

K21 32 bit IEEE

K22 32 bit IEEE

K23 32 bit IEEE

K24 32 bit IEEE

K30 32 bit IEEE

K31 32 bit IEEE

K32 32 bit IEEE

K33 32 bit IEEE

K34 32 bit IEEE

K40 32 bit IEEE

K41 32 bit IEEE

K42 32 bit IEEE

K43 32 bit IEEE

K44 32 bit IEEE

K50 32 bit IEEE

K51 32 bit IEEE

K52 32 bit IEEE

K53 32 bit IEEE

K54 32 bit IEEE

Check sum 16 bit Integer

Contents

(Default)

Format

Where the entries are in the following number formats:

8 bit Integer signed integer

16 bit Integer signed integer, MSB in lowest address

32 bit Integer signed integer, MSB in lowest address

ASCII Text series of ASCII characters

32 bit IEEE 4 byte IEEE-754 floating point number, lowest address holds sign and exponent,

highest address holds LSB of mantissa.

All un-used locations below 01FE Hex are filled with zero.

All un-used coefficients are populated with the value zero.

The check sum is calculated so that addition of all locations between 0 and 01FF Hex will sum to

1234 Hex.

The list of available values for 0048 Hex, pressure unit code are shown in Table 3.

[EN] English - K0473 Issue 5 30

Page 41

Table 3 RPS Pressure unit codes

Pressure

Code

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Units

Not defined

mBar

Bar

hPa

KPa

MPa

psi

mm H2O

in H2O

ft H2O

m H2O

mm Hg

in Hg

2

Kgf / cm

Atm

31 K0473 Issue 5 - [EN] English

Page 42

[EN] English - K0473 Issue 5 32

Loading...

Loading...