Page 1

GE

Sensing & Inspection Technologies

Druck PV 62x

pneumatic/hydraulic pressure stations

user manual - K0457

Page 2

Issue 1

Quick reference data

A1.1

PV 621: Pneumatic pressure station

-950 mbar to 20 bar (-13.5 to 300 psi)

PV 622: Pneumatic pressure station

-950 mbar to 100 bar (-13.5 to 1500 psi)

PV 623: Hydraulic pressure station

0 to 1000 bar (0 to 15000 psi)

A1.2

PV 62x + DPI 620 + PM 620

Recommended pressure modules (PM 620) *

PV 621 models 25 mbar to 20 bar (0.36 to 300 psi)

PV 622 models 25 mbar to 100 bar (0.36 to 1500 psi)

PV 623 models 70 to 1000 bar (1000 to 15000 psi)

*Caution: To prevent damage to the PM 620 module, only use it

within the specified pressure limit on the label.

A1.3

PV 62x pressure relief valves (PR V )

(Recommended options)

Parts: IO620-PRV-P1 to P5 (Pneumati c)

PV 621 models 1 to 30 bar (14.5 to 435 psi)

PV 622 models 1 to 100 bar (14.5 to 1500 psi)

Parts: IO620-PRV-H1 to H5 (Hydraulic)

PV 623 models 50 to 1000 bar (725 to 15000 psi)

Copyright © 2008 General Electric Company. All rights reserved.

Trademarks All product names are trademarks of their respective

companies.

ii

Page 3

Issue 1

Safety

General warnings

Pressure warnings

Before you use the instrument, make sure that you read and

understand all the related data. This includes: the applicabl e

local safety procedures, th is publication, and the instructions

for the accessories/options/ equipment you are using it with.

WARNING

• It is dangerous to ignore the specified limits for the

instrument or to use the instrument when it is not in its

normal condition. Use the applicable protection and

obey all safety precautions.

• Do not use the instrument in locations with explosive

gas, vapour or dust. There is a risk of an explosion.

• It is dangerous to attach an external sour ce of pressure

to a PV 62x series pressure st ation. Use only the

internal mechanisms to set and control the pressure in

the pressure station.

• Some liquid and gas mixtures are dangerous. This

includes mixtures that occur be cause of con t amination.

Make sure that the equipment is safe to use with the

necessary media.

Electrical warnings

• Pressurized gases and fluids are dangerous. Bef ore you

attach or disconnect pressure equipment, safely r elease

all the pressure.

• To prevent a dangerous release of pressure, make sure

that all the related pipes, hoses and equipment have the

correct pressure rating, are safe to use and are

correctly attached.

If you use the DPI 620 calibrator with your pressure station,

these warnings are also applicable:

• To prevent electrical shocks or damage to the DPI 620

calibrator, do not connect more than 30V between the

terminals, or between the terminals and the ground

(earth).

• This instrument uses a Lithium-Polymer (Li-Polymer)

battery pack. To prevent an ex plosion or fire, do not

short circuit, do not disassemble, keep it safe from

damage.

Continued

[EN] English - K0457 Safety iii

Page 4

Issue 1

1

1 1

• To prevent an explosion or fire, use only the GE

specified battery, power supply and battery charger .

• To make sure the display shows the correct data,

disconnect the test leads before you set the power to on

or change to another measure or source function.

Cautions

To prevent damage to the instrument, do not let dirt get

into the pressure mechanism. Before you attach

equipment, make sure it is clean.

To prevent damage to t he instrument wh en you move it,

hold the body of the pressure station or use the carry

strap (or specified accessories).

PV 621/PV 622 models only. Before you turn the

pressure/vacuum selector to + or -, release all the

pressure. Sudden high pressure in the pump

mechanism can cause damage.

PV 623 models only. Ice in the pressur e mechanism can

cause damage. If the temperature is less than 4°C

(39°F), drain all water from the instrument.

In its normal condition, the PV 623 model contains

hydraulic fluid. To make sure it does not spill out, seal

the system and put it on its side before you install a

PRV.

To prevent damage to the PM 620 module, only use it

within the specified pressure limit on the label.

Marks and symbols

on the instrument

Before you start an operation or procedure in this publication,

make sure that you have the necessary ski lls (if necessary, with

qualifications from an approved training est abl is hment) . Follow

good engineering practice at all times.

Complies with European Union directives

Read the manual Warning - refer to the

manual

PRV Pressure relief valve (Refer to Chapter 1; item )

Do not dispose of this product as household waste. Refer to

Chapter 6 (Maintenance procedures).

More marks and symbols are specified in this manual

iv Safety K0457 - [EN] English

Page 5

Issue 1

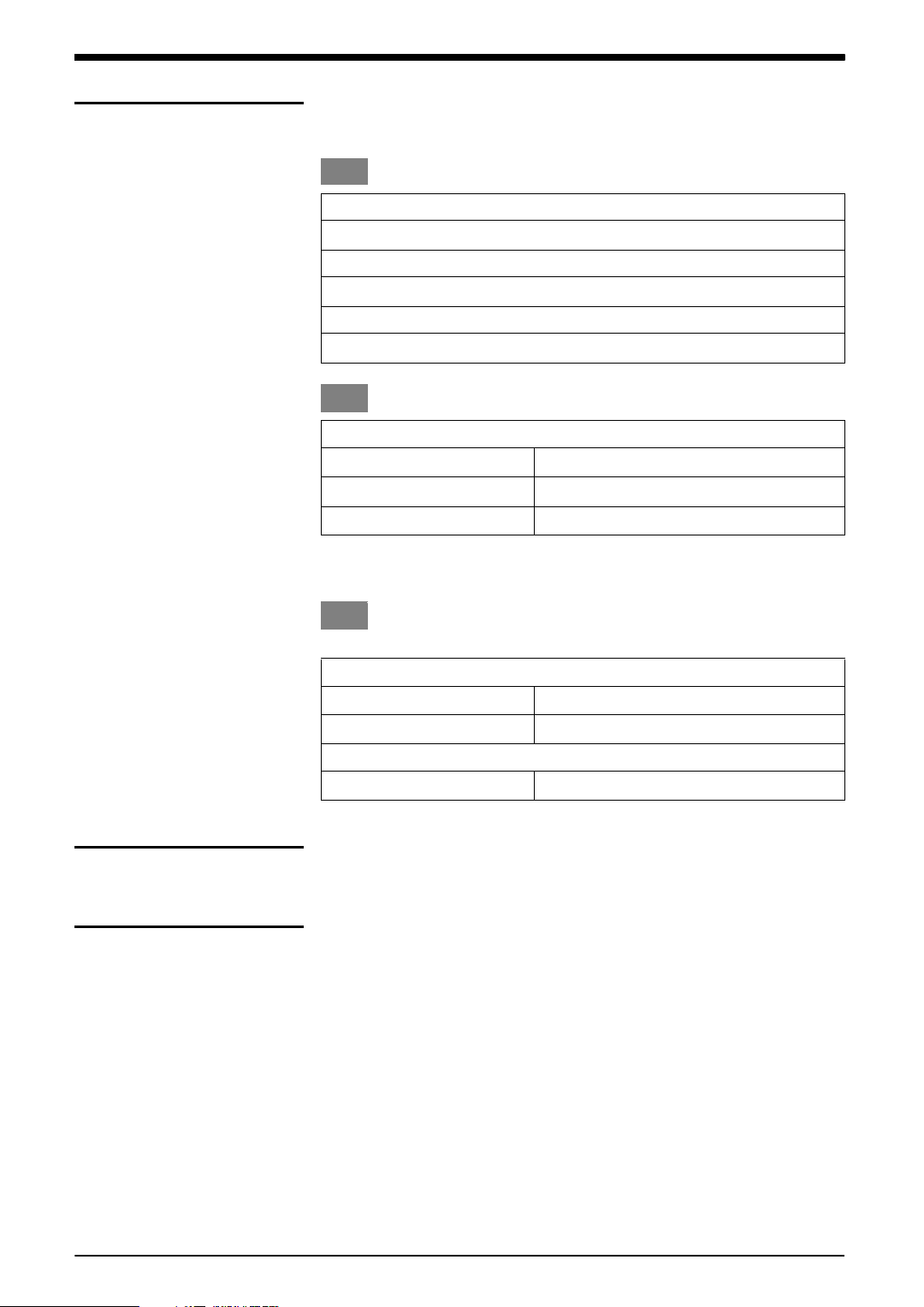

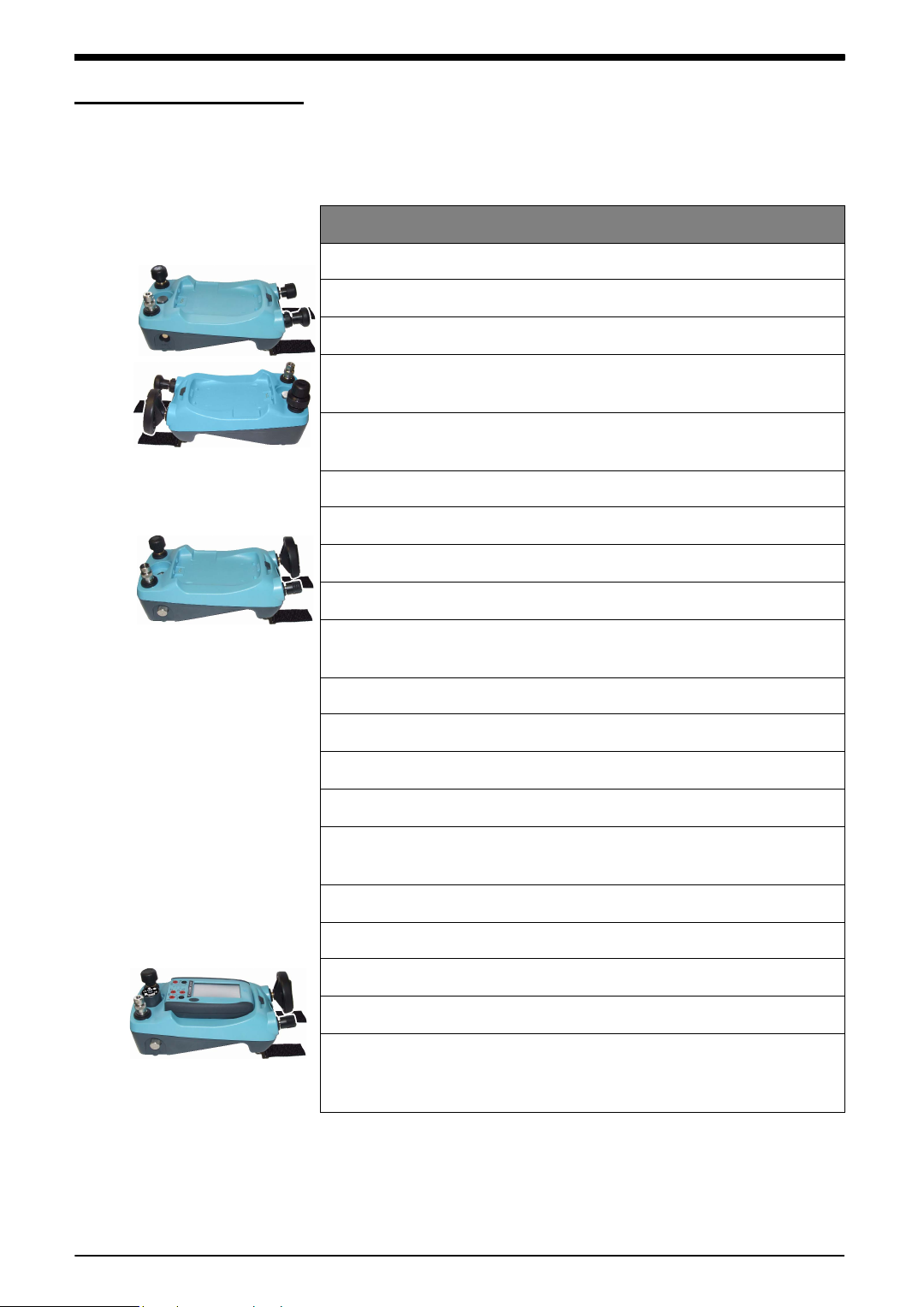

PV 622

PV 621

PV 623

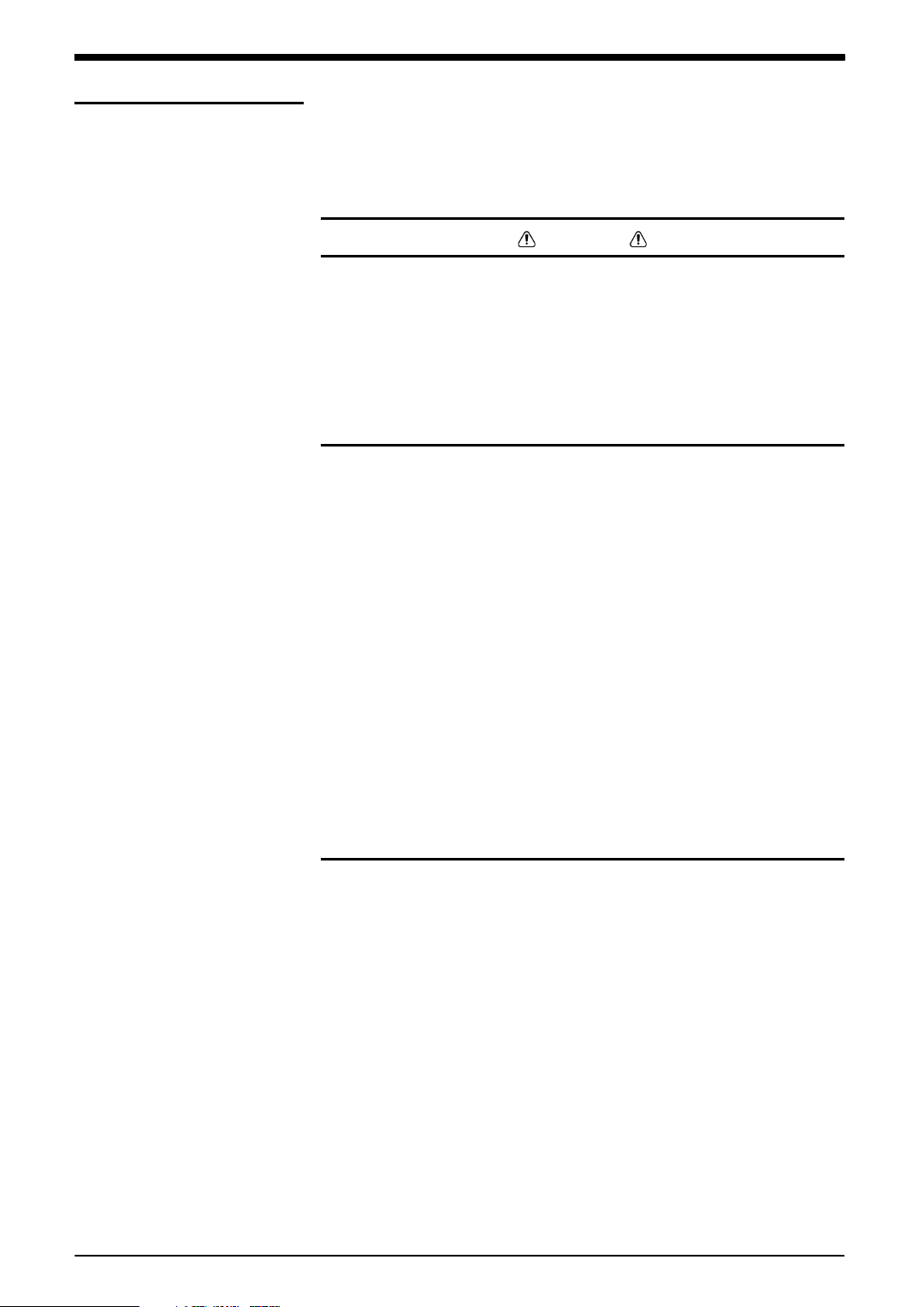

Pressure calibrator

DPI 620

PM 620

Overview

Other module options

There are three pressure stations in the PV 62x series:

• two pneumatic pressure stations to give you accurate and

controlled pressure and vacuum conditions:

PV 621: -950 mbar to 20 bar (-13.5 to 300 psi) version

PV 622: -950 mbar to 100 bar (-13.5 to 1500 psi) version

• one hydraulic pressure station to give you accurate and

controlled hydraulic pressure conditions:

PV 623: 0 to 1000 bar (15000 psi)

To give the attached equipment overpressure protection, there

are pressure relief valves (PRV) available for all the pressure

stations; refer to Secti on 1.5 (Ac cessories).

The pressure stations are part of a set of hand-held modules

that you can quickly put together to include a wide range of

calibrator functions.

Pressure calibrator (this user manual): You can use the

pressure stations on their own or you can attach the DPI 620

calibrator and a PM 620 module to make a fully integrated

pressure calibrator instrument.

Advanced modular calibrator, DPI 620 (user manual K0449): Optional item. This is a bat tery-powered ins trument for

electrical measure and source operations and HART®

communications. It also supplies the power and user interface

functions for all the add-on modules. You can use the

touch-screen to display up to six different parameters.

Pressure modules, PM 620 (this user manual): Optional

item. These modules attach to a pressure station (PV 62x) to

give the DPI 620 calibrator the necessary pressure

measurement functionality. They are fully interchangeable

“plug and play” modules with no initial set-up or user

calibration.

Software (user manual - K0449): The DPI 620 calibrator

includes the following sof tware:

• documenting software • HART® communications

software

Other accessories and options: For part numbers (P/N),

refer to Section 1.5 (Accessories).

[EN] English - K0457 Overview v

Page 6

Issue 1

PV 622

PV 621

PV 623

Pressure calibrator

Summary of functions

This table gives a summary of the available funct ions with the

PV 62x pressure stations.

PV 62x - pressure station functions

Function

Pneumatic pressure stations

*

PV 621: Pressure from vacuum (95%) to 20 bar (300 psi);

* PV 622: Pressure from vacuum (95%) to 100 bar (1500 psi)

Selector switch to change the pump operation from pressure

generator to vacuum generator

Needle point pressure release valve to control the release of

pressure.

Hydraulic pressure station

* PV 623: Hydraulic pressure from 0 to 1000 bar (15000 psi)

3

Internal hydraulic reservoir: 100 cm

Self sealing pressure module connection to prevent fluid leaks.

(6.1 in3)

Fast thermal stability for devices attached directly to the pressure

test connection (≤ one minute)

All pressure stations

“Quick fit” pressure adaptors for the device under test

** Pressure connecti on for a PM 620 mod ule

Volume adjuster to give accurate control of pressure conditions.

Latch mechanism to attach the DPI 620 calibrator to make a fully

integrated pressure calibrator instrument

** Pressure relief valves (PRV) to give overpressure protection.

** Pressure station + DPI 620 calibrator + PM 620 module

Measure pressure/Leak test

Documenting software

®

HART

communications software to set up and calibrate devices that use

the HART

* Refer to Chapter 7 (Specification)

** Optional item

(Highway Addressable Remote Transducer)

®

field communications protocol.

vi Summary of functions K0457 - [EN] English

Page 7

Issue 1

1

1 1

About this manual

This user manual is set up for you to use on a computer or

similar device that has the necessary software to read a

Portable Document Format (PDF) file.

It is supplied as a PDF on a compact disc (CD) but you can

copy or save the PDF onto a computer or similar device that

has the necessary PDF software.

To navigate between related items of information, the use r

manual includes cross references and links; for example:

• text cross references: ... Figure 1-1; Table 1-1; Chapter 1;

Section 1.5 (Accessories)

• some (but not all) symbols:

Note: If you move the PDF software cursor over an item that

has a link, the cursor symbol normally changes.

When you click (or tap ) on a lin k, your PDF software shows the

applicable page.

[EN] English - K0457 About this manual vii

Page 8

Issue 1

viii About this manual K0457 - [EN] English

Page 9

Issue 1

Table of Contents

Quick reference data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ii

Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Other module options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .v

Summary of functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Chapter 1: Instrument parts, accessories and options

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 PV 621 models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2.1 Pressure relief valve (PRV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2.2 Test port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.3 Pneumatic pressure release valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2.4 Volume adjuster . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.2.5 Selector (pressure/vacuum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2.6 Pump (pressure/vacuum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3 PV 622 models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.3.1 Pressure relief valve (PRV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.3.2 Test port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.3.3 Pneumatic pressure release valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.3.4 Pneumatic refill valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1.3.5 Volume adjuster wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1.3.6 Selector (pressure/vacuum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.3.7 Pump (pressure/vacuum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1.4 PV 623 models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1.4.1 Pressure relief valve (PRV) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1.4.2 Test port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.4.3 Hydraulic pressure release valve/ reservoir access. . . . . . . . . . . . . . . . . . . . . 1-9

1.4.4 Hydraulic refill valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

1.4.5 Volume adjuster wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

1.5 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

[EN] English - K0457 Table of Contents viii

Page 10

Issue 1

Chapter 2: Pneumatic pressure operation (PV 621)

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 Release the pressur e. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.3 Att ach/Remove the device under test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.3.1 Procedure (to attach) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.3.2 Procedure (to remove) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.4 Attach/Adjust a PRV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.4.1 Procedure (to attach) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.4.2 Procedure (to adjust) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.5 Vacuum or pressure operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.5.1 Vacuum procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.5.2 Pressure procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Chapter 3: Pneumatic pressure operation (PV 622)

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 Release the pressur e. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.3 Att ach/Remove the device under test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.3.1 Procedure (to attach) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.3.2 Procedure (to remove) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.4 Attach/Adjust a PRV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.4.1 Procedure (to attach) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.4.2 Procedure (to adjust) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.5 Vacuum or pressure operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

3.5.1 Vacuum procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3.5.2 Pressure procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

Chapter 4: Hydraulic pressure operation (PV 623)

4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.2 Fill the reservoir. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.3 Release the pressur e. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.4 Att ach/Remove the device under test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.4.1 Procedure (to attach) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.4.2 Procedure (to remove) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.5 Attach/Adjust a PRV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.5.1 Procedure (to attach) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.5.2 Procedure (to adjust) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

4.6 Pressure operat ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.6.1 Hydraulic pressure procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.6.2 Add more hydraulic fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.6.3 Drain hydraulic fluid from the device under test . . . . . . . . . . . . . . . . . . . . . . . 4-5

ix Table of Contents K0457 - [EN] English

Page 11

Issue 1

4.7 Drain all the hydraulic fluid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.7.1 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.7.2 Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

Chapter 5: Pressure calibrator operation (DPI 620)

5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 Parts and assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2.1 DPI 620 calibrator parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2.2 PM 620 module parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2.3 Assembly instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3 Measure pressure/vacuum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3.1 Procedure overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.3.2 DPI 620 calibrator: Set the pressure function. . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.3.3 DPI 620 calibrator: Set the pressure unit s . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

5.3.4 DPI 620 calibrator: Set up a Leak Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-5

5.3.5 DPI 620 calibrator: Set the PM 620 module to zero . . . . . . . . . . . . . . . . . . . .5-6

5.3.6 Example procedure: Gauge/indicator cal ibration . . . . . . . . . . . . . . . . . . . . . . 5-7

5.3.7 Example procedure: Transmitter calibration. . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.3.8 Example procedure: Switch test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Chapter 6: Maintenance procedures

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.2 Clean the unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.3 Drain the unit (PV 623 models). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.4 Leak test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.4.1 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

6.4.2 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Chapter 7: Specification

7.1 PV 62x models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

7.1.1 Pressure data (PV 62x models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.2 PM 620 modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.2.1 Pressure data (PM 620 modules). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

Customer service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Back cover

[EN] English - K0457 Table of Contents x

Page 12

Issue 1

xi Table of Contents K0457 - [EN] English

Page 13

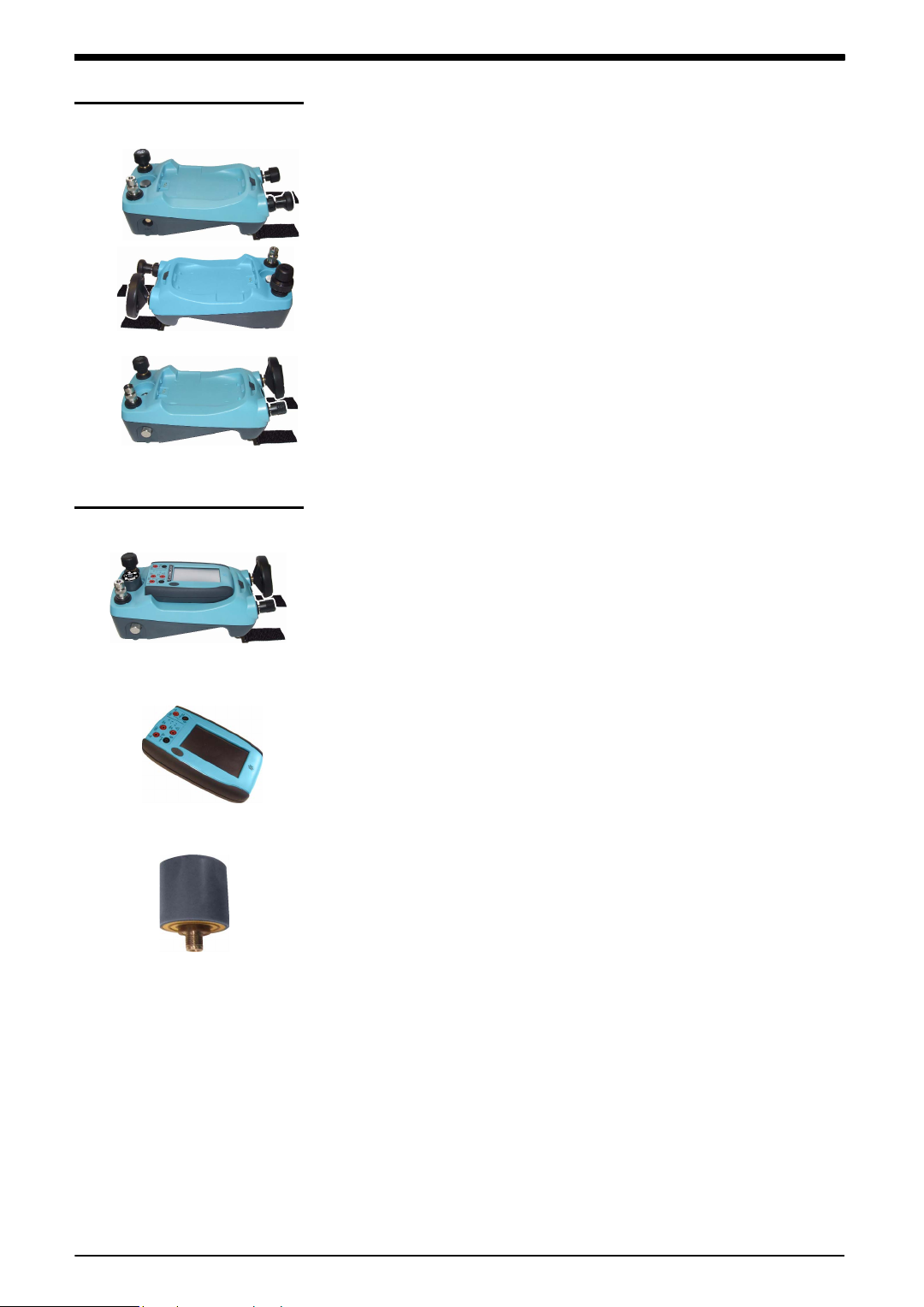

Chapter 1: Instrument parts,

Items 5, 9, 10: Not applicable

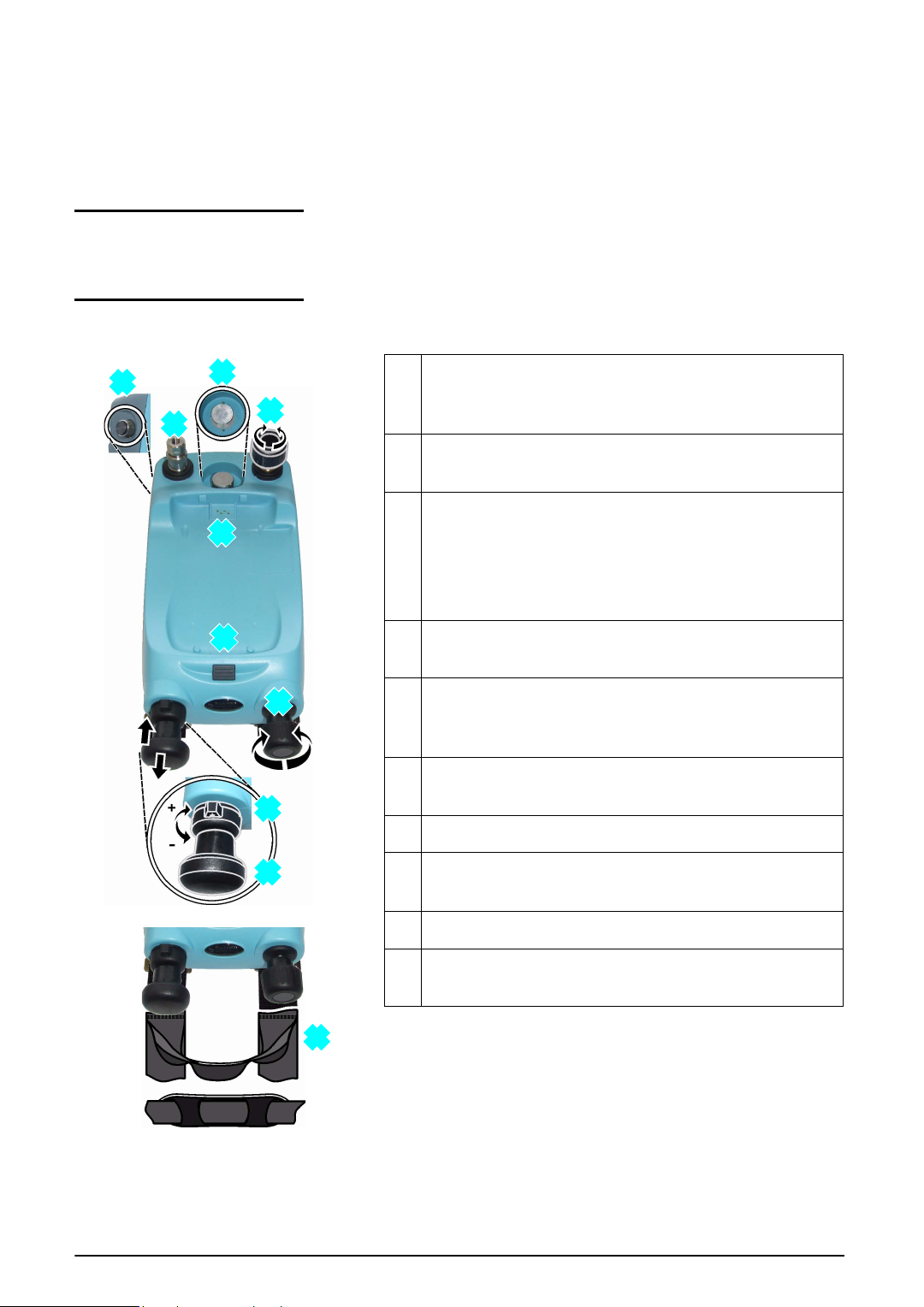

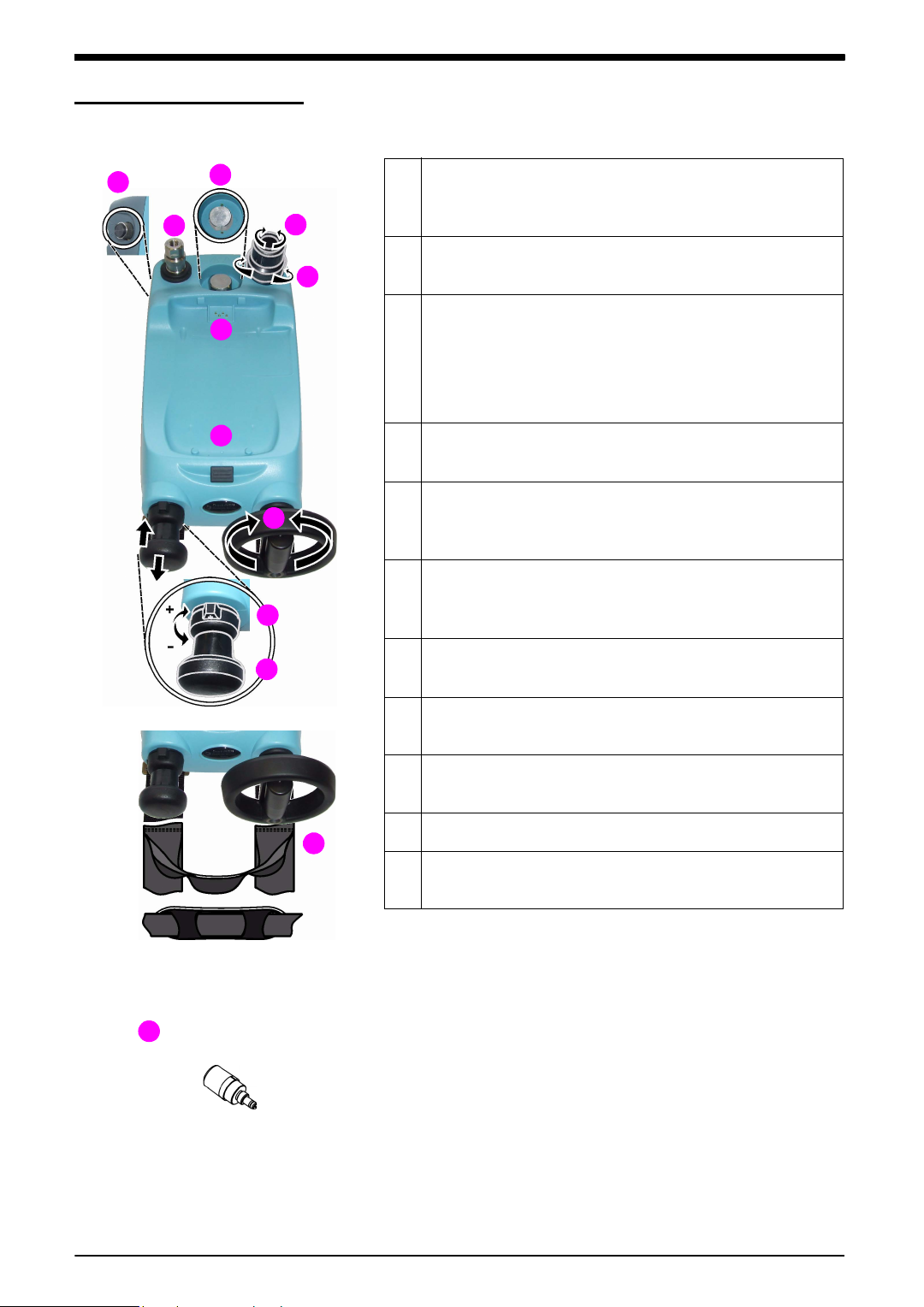

Figure 1-1: General views

1

2

3

4

6

7

8

11

12

13

1. Optional accessory: Pressure connection for a

pressure relief valve (PRV); see Section 1.2.1. A

blanking plug is standard.

2. Test port: Pressure connection (G1/8 or 1/8NPT) to

attach the device under test; see Section 1.2.2.

3. Pressure and electrical connections for a PM 620

module.

Seal the pressure connection with a blanking plug

(P/N IO620-BLANK) or a PM 620 module that has the

correct pressure rating.

4. Pneumatic pressure release valve to release pressure

in the system; see Section 1.2.3.

6. Moulded compartment for the DPI 620 calibrator with

electrical connections and a mechanism to hold it in

position.

7. Push-button mechanism to release the DPI 620

calibrator.

8. Pneumatic volume adjuster; see Section 1.2.4.

11. Pressure/vacuum selector to set the pump operation:

pressure (+), vacuum (-); see Section 1.2.5.

12. Pump mechanism; see Sect ion 1.2.6.

13. Carrying strap with a carry handle and a shoulder

strap.

accessories and options

1.1 Introduction

1.2 PV 621 models

This chapter gives a description of the different parts of each

instrument and the accessories/options available.

[EN] English - K0457 Instrument parts, accessories and options 1-1

Page 14

Issue 1

124

8

1.2.1 Pressure relief valve (PRV)

To give your attached devices overpressure prote ction (device

under test, PM 620 module), we recommend you use one of

our range of optional pneumatic PRVs; see Sect ion 1.5

(Accessories).

To attach or adjust a PRV, see Section 2.4.

1.2.2 Test port

To attach the device under test, the test port uses “Qui ck fit”

pressure adaptors; see Section 1.5 (Accessories). These are

easy to remove, change and install; see Section 2.3

(Attach/Remove the device under test).

1.2.3 Pneumatic pressure release valve

This is a needle point valve that lets you rel ease the pressure

or vacuum, or seal the system. You can also use it to control a

change in pressure conditi ons; f or example, to go to or t hrou gh

another test pressure.

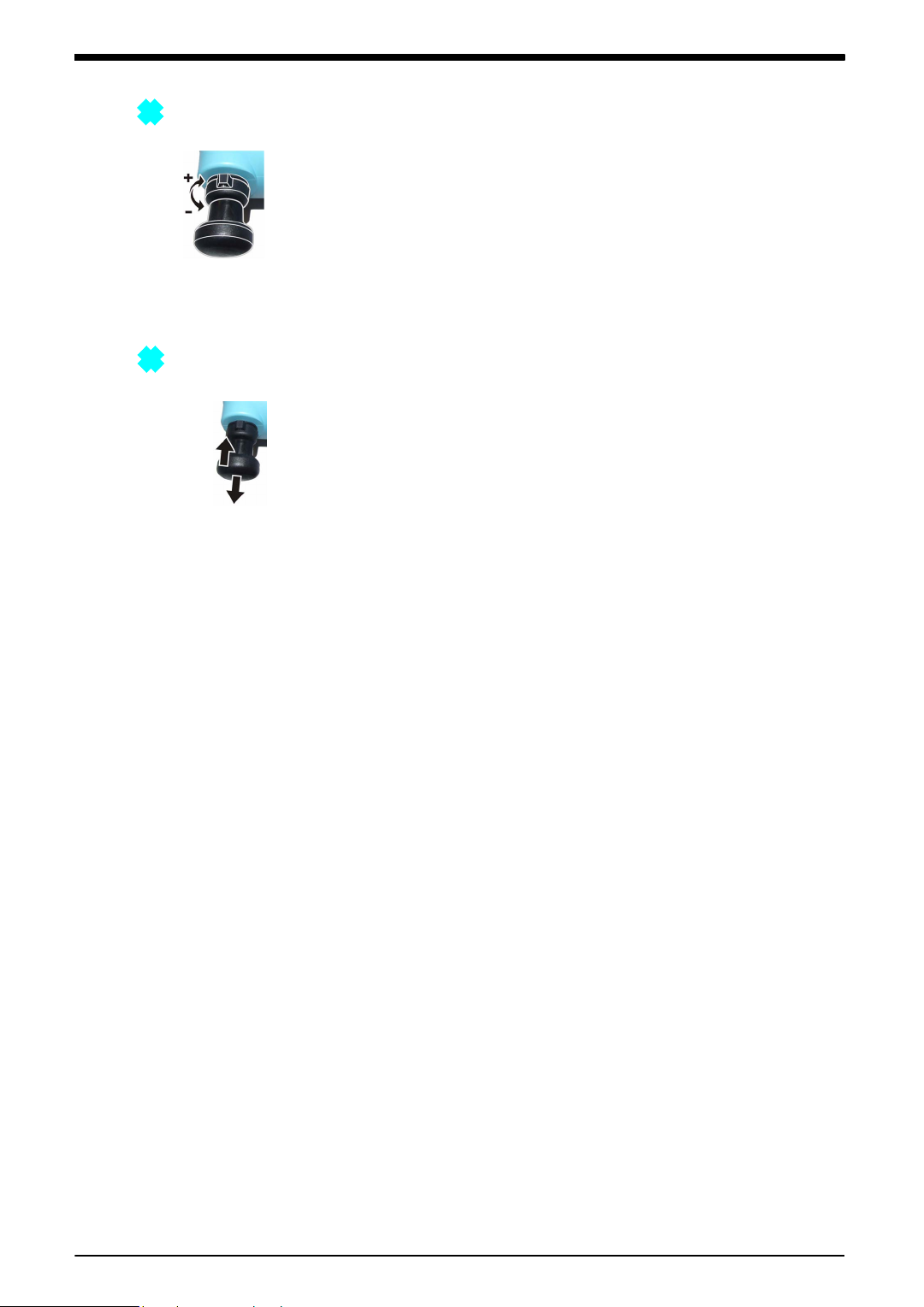

1.2.4 Volume adjuster

: Open : Close

This control increases or decreases the pressure/vacuum.

Before you seal the system (Section 1.2.3), turn this control to

the necessary position:

• for equal adjustment, turn it to the middl e of its range

• for maximum adjustment, turn it full y clockwise or

counterclockwise

When you have set the necessary pr essure or vacu um with t he

pump (Section 1.2.6), use the volume adjuster to make the last

adjustments.

1-2 Instrument parts, accessories and options K0457 - [EN] English

Page 15

1.2.5 Selector (pressure/vacuum)

11

12

Caution: Before you turn the pressure/vacuum selector

to + or -, release al l the pressur e. Sudden hi gh pressur e

in the pump mechanism can cause damage.

This control sets the operation of the instrument (pressure or

vacuum). To prevent a pressure leak, turn it fully clockwise or

counterclockwise.

Issue 1

+

: Pressure

1.2.6 Pump (pressure/vacuum)

When you have set the operation to pressure or vacuum

(Section 1.2.5), seal the system (Section 1.2.3) and use the

pump to set the necessary pressure or vacuum.

You can then make the last adjustments with the volume

adjuster (Section 1.2.4).

-

: Vacuum

[EN] English - K0457 Instrument parts, accessories and options 1-3

Page 16

Issue 1

Items 8, 10: Not applicable

Figure 1-2: General views

1

2

3

4

5

7

6

9

11

12

13

1. Optional accessory: Pressure connection for a

pressure relief valve (PRV); see Section 1.3.1. A

blanking plug is standard.

2. Test port: Pressure connection (G1/8 or 1/8NPT) to

attach the device under test; see Section 1.3.2.

3. Pressure and electrical connections for a PM 620

module.

Seal the pressure connection with a blanking plug

(P/N IO620-BLANK) or a PM 620 module that has the

correct pressure rating.

4. Pneumatic pressure release valve to release pressure

in the system; see Section 1.3.3.

5. Pneumatic refill valve. Close it to seal off all the

pressure and refill the pressure mechanism; see

Section 1.3.4.

6. Moulded compartment for the DPI 620 calibrator with

electrical connections and a mechanism to hold it in

position.

7. Push-button mechanism to release the DPI 620

calibrator.

9. Volume adjuster wheel with fold-in handle; see

Section 1.3.5.

11. Pressure/vacuum selector to set the pump operation:

pressure (+), vacuum (-); see Section 1.3.6.

12. Pump mechanism; see Sect ion 1.3.7.

13. Carrying strap with a carry handle and a shoulder

strap.

2

1.3 PV 622 models

1.3.1 Pressure relief valve (PRV)

To give your attached devices overpressure prote ction (device

under test, PM 620 module), we recommend you use one of

our range of optional pneumatic PRVs; see Sect ion 1.5

(Accessories).

To attach or adjust a PRV, see Section 3.4.

1-4 Instrument parts, accessories and options K0457 - [EN] English

Page 17

1.3.2 Test port

2

4

5

9

To attach the device under test, the test port uses “Qui ck fit”

pressure adaptors; see Section 1.5 (Accessories). These are

easy to remove, change and install; see Section 3.3

(Attach/Remove the device under test).

1.3.3 Pneumatic pressure release valve

This is a needle point valve that lets you release the pressure

or vacuum, or seal the system. You can also use it to control a

change in pressure conditi ons; f or example, to go to or t hrou gh

another test pressure.

Open Close

Note: To release all the pressure in the sy stem, you must open

the refill valve (Section 1.3.4) one turn and then open the

pressure release valve one turn.

Issue 1

1.3.4 Pneumatic refill valve

When the refill valve is open, you have full control to increase

or decrease the pressure/vacuum with the volume adjus ter

(Section 1.3.5).

If you increase pressure and the volume adjuster gets to the

limit of travel, cl ose the refill valve. This seals off all the

pressure in the test port and the pressure module connection.

You can then use the pump and volume adjuster to refill the

pressure mechanism (Section 1.3.5).

Note: To release all the pressure in the sy stem, you must open

the refill valve one turn and then open the pressure release

valve (Section 1.3.3) one turn.

1.3.5 Volume adjuster wheel

The refill valve (Section 1.3.4) sets the operation of the Volume

adjuster wheel: Full control or refill

Open (1 turn): Full control Close: Refill

[EN] English - K0457 Instrument parts, accessories and options 1-5

Page 18

Issue 1

1

2

2

+

3

+

-

1

Full control When the refill valve is open, you have full control to increase

or decrease the pressure/vacuum. Before you seal the system

(Section 1.3.3), turn the wheel to the necessary position:

• for equal adjustment, turn it to the middl e of its range

• for maximum adjustment, turn it full y clockwise or

counterclockwise

When you have set the applicable pressure or va cuum with the

pump (Section 1.3.7), use the volume adjuster.

At higher pressures, it is easier to turn the wheel if you fold in

the handle:

1. Pull the handle out from the recess t hat locks it in position.

2. Fold the handle back against the wheel.

Refill If you increase pressure and the volume adjuster gets to the

limit of travel, close the refill valve (Sec tion 1.3.4). Y ou can then

use the pump and volume adjuster to refill the pressure

mechanism:

1. Close the refill val ve and wind the vol u me adjuster fully

counterclockwise. There is no change in pressure to the

device under test or the PM 620 module (if applicable).

2. Refill the pressure mechanism with the pump (≈ 15 cycles)

and wind the volume adjuster clockwise until the pres sure

starts to increase.

3. Open the refill valve to get full control again.

1-6 Instrument parts, accessories and options K0457 - [EN] English

Page 19

1.3.6 Selector (pressure/vacuum)

11

12

Caution: Before you turn the pressure/vacuum selector

to + or -, release al l the pressur e. Sudden hi gh pressur e

in the pump mechanism can cause damage.

This control sets the operation of the instrument (pressure or

vacuum). To prevent a pressure leak, turn it fully clockwise or

counterclockwise.

Issue 1

+

: Pressure

1.3.7 Pump (pressure/vacuum)

When you have set the operation to pressure or vacuum

(Section 1.3.6), seal the system (Section 1.3.3) and use the

pump to set an applicable pressure or vacuum:

You can then make the last adjustments with the volume

adjuster (Section 1.3.5).

-

: Vacuum

[EN] English - K0457 Instrument parts, accessories and options 1-7

Page 20

Issue 1

Items 5, 8, 11, 12: Not applicable

Figure 1-3: General views

7

1

6

2

3

4

10

9

13

1. Optional accessory: Pressure connection for a

pressure relief valve (PRV); see Section 1.4.1. A

blanking plug is standard.

2. Test port: Pressure connection (G1/8 or 1/8NPT) to

attach the device under test; see Section 1.4.2.

3. Pressure and electrical connections for a PM 620

module.

PV 623 models only: The pressure connection seals

itself.

4. Hydraulic pressure release valve to release pressure

in the system.

It also gives access to the hydraulic fluid reservoir; see

Section 1.4.3.

6. Moulded compartment for the DPI 620 calibrator with

electrical connections and a mechanism to hold it in

position.

7. Push-button mechanism to release the DPI 620

calibrator.

9. Volume adjuster wheel with fold-in handle; see

Section 1.4.5.

10. Hydraulic refill valve. Close it to seal off all the

pressure and refill the pressure mechanism with fluid;

see Section 1.4.4.

13. Carrying strap with a carry handle and a shoulder

strap.

1

1.4 PV 623 models

1.4.1 Pressure relief valve (PRV)

To give your attached devices overpressure prote ction (device

under test, PM 620 module), we recommend you use one of

our range of optional hydraulic PRVs; see Section 1.5

(Accessories).

To attach or adjust a PRV, see Section 4.5.

1-8 Instrument parts, accessories and options K0457 - [EN] English

Page 21

1.4.2 Test port

2

4

10

To attach the device under test, the test port uses “Qui ck fit”

pressure adaptors; see Section 1.5 (Accessories). These are

easy to remove, change and install; see Section 4.4

(Attach/Remove the device under test).

1.4.3 Hydraulic pressure release valve/reservoir access

This valve lets you release the pressure or seal the system.

Open Close

Note: To release all the pressure in the sy stem, you must open

the refill valve (Section 1.4.4) one turn and then open the

pressure release valve one turn.

If you remove the valve (counterclockwise), you can also do

these operations:

Issue 1

• add hydraulic fluid to the reservoir; see Section 4.2

• drain all the hydraulic fluid from the instrument; see

Section 4.7

1.4.4 Hydraulic refill valve

When the refill valve is open, you have full control to increase

or decrease the pressure with the volume adjuster

(Section 1.4.5).

If you increase pressure and the volume adjuster gets to the

limit of travel, cl ose the refill valve. This seals off all the

pressure in the test port and the pressure module connection.

You can then use the volume adjuster to refill the pressure

mechanism (Section 1.4.5).

Note: To release all the pressure in the sy stem, you must open

the refill valve one turn and then open the pressure release

valve (Section 1.4.3) one turn.

Open (1 turn): Full control Close: Refill

[EN] English - K0457 Instrument parts, accessories and options 1-9

Page 22

Issue 1

9

1

2

+

2

+

-

1

1.4.5 Volume adjuster wheel

The refill valve (Section 1.4.4) sets the operation of the Volume

adjuster wheel: Full control or refill

Full control When the refill valve is open, you have full control to increase

or decrease the pressure.

At higher pressures, it is easier to turn the wheel if you fold in

the handle:

1. Pull the handle out from the recess t hat locks it in position.

2. Fold the handle back against the wheel.

Refill If you increase pressure and the volume adjuster gets to the

limit of travel, close the refill valve (Sec tion 1.4.4). Y ou can then

use the volume adjuster to refill the pressure mechanism:

1. Close the refill valve and then wind the volume adjus ter fully

counterclockwise and clockwise until the pressure starts to

increase.

The counterclockwise operation refills the pressure

mechanism without a change in pressure to the device

under test or the PM 620 module (if applicable).

2. Open the refill valve to get full control again.

1-10 Instrument parts, accessories and options K0457 - [EN] English

Page 23

1.5 Accessories

Figure 1-4: Accessories included

2

4

1

3

5

1. “Quick fit” pressure adaptors (G1/8 and 1/8NPT); easy

to remove, change and install

2. Carrying strap with a shoulder strap and a carry

handle

3. PV 623 models only: Refill bottle for hydraulic fluid

4. Safety and quick reference guide

5. CD with the user manual

Figure 1-5: Optional accessories f or

the PV 62x pressure stations

9

8

7

6

6. P/N IO620-CASE-3. Fabric carry case with a shoulder

strap and a large pocket for accessories. It can hold

one PV 62x pressure station; one DPI 620 calibrator;

one PM 620 module.

7. P/N IO620-CASE-4. Rigid trolley case to hold a set of

units: one DPI 620 calibrator; two PV 62x pressure

stations; MC 620 module carrier; all the related

accessories.

The case includes: an extendable handle;

7 double-step latches that lock the lid down onto a

neoprene o-ring; an automatic pressure equalisation

valve.

8. Pressure modules (PM 620); refer to Chapter 7

(Specification)

9. Pneumatic PRVs to give attached devices

overpressure protection; see Table 1-1

Table 1-1: Recommended PRVs (Pneumatic)

PRV P/N Recommended

for:

Factory setting Adjustable range

Bar PSI Bar PSI

IO620-PRV-P1

IO620-PRV-P2

IO620-PRV-P3

PV 621, PV 62217

30

15

100

435

0.4 to 1

3 to 7

15 to 30

6 to15

45 to 100

220 to 435

IO620-PRV-P4

IO620-PRV-P5

PV 622 only

60

100

870

1500

30 to 60

50 to 100

435 to 870

725 to 1500

Issue 1

[EN] English - K0457 Instrument parts, accessories and options 1-11

Page 24

Issue 1

10

10. Hydraulic P RV s to gi ve att ach ed devi ces ov erpr essure

protection; see Table 1-2.

Table 1-2: Recommended PRVs (Hydraulic)

PRV P/N Recommended

for:

Factory setting Adjustable range

Bar PSI Bar PSI

IO620-PRV-H1

IO620-PRV-H2

IO620-PRV-H3

IO620-PRV-H4

IO620-PRV-H5

PV 623 only

50

200

400

700

1000

725

3000

6000

10000

15000

10 to 50

50 to 200

200 to 400

300 to 700

600 to 1000

145 to 725

725 to 2900

2900 to 5800

4350 to 10000

8700 to 15000

11. Pneumatic hose kit rated to 400 bar (5800 psi) with

“Quick fit” connectors for the test port.

P/N IO620-HOSE-P1: 1 metre (≈ 39”)

P/N IO620-HOSE-P2: 2 metre (≈ 78”)

12. Hydraulic hose kit rated to 1000 bar (15000 psi) with

“Quick fit” connectors for the test port.

P/N IO620-HOSE-H1: 1 metre (≈ 39”)

P/N IO620-HOSE-H2: 2 metre (≈ 78”)

13. Pressure adaptor sets:

P/N IO620-BSP: G1/8, G1/4 male; G1/4, G3/8 and

G½ female

P/N IO620-NPT: 1/8NPT, ¼NPT male, ¼NPT , 3/8NPT,

and ½NPT female

P/N IO620-MET: M14 x 1.5 and M20 x 1.5 female

14. P/N IO620-BLANK. Blanking plug to seal the pressure

port for the PM 620 module.

15. P/N IO620-COMP. Comparator. Attach it to the test

port and then use it to compare the device under test

with a reference device.

Figure 1-5: Opt ional accessories f or

the PV 62x pressure stations

(Continued)

15

13

14

11

12

1-12 Instrument parts, accessories and options K0457 - [EN] English

Page 25

Chapter 2: Pneumatic pressure

1

13

4

2

operation (PV 621)

2.1 Introduction

2.2 Release the pressure

Chapter 1 gives a description of the different parts of the

instrument: to

This chapter gives examples of how to connect and use the

PV 621 pressure station to give the necessary pressure or

vacuum conditions.

Before you start:

• Read and understand the “Safety” section.

• Make sure that there is no damage to the instrument, and

that there are no missing items.

Note: Use only original p arts supplied by the manufacturer.

To release all the pressure in this instrument, open the

pressure release valve countercloc kwise (1 turn).

To control a change in pressure conditions (for example, to go

to or through another test pressure) use the volume adjuster

(Section 1.2.4) or open and close the pressure release valve.

2.3 Attach/Remove the device under test

WARNING: Pre ssurized gases and fluids are dangerous.

Before you attach or disconnect pressure equipment,

safely release all the pressure.

Caution: To prevent damage to the instrument, do not

let dirt get into the pressure mechanism. Before you

attach equipment, make sure it is clean.

The test port uses “Quick fit” pressur e adaptors; see

Section 1.5 (Accessories). These are easy to remove, change

and install (Section 2.3.1).

[EN] English - K0457 Pneumatic pressure operation (PV 621) 2-1

Page 26

Issue 1

3. Attach the adaptor to the device; if

necessary use one of the alternative

adaptors in Section 1.5 (Accessories),

then tighten to the applicable torque.

4. Re-attach the adaptor to the test port and

tighten it until it is hand tight only.

Step Procedure

Step Procedure

1. Remove the adaptor

2. Use an applicable seal for the pressure

connection:

a. NPT type: Use an applicable sealant

on the thread.

b. BSP (parallel) type: We recommend a

bonded seal at the bottom.

c. BSP (parallel) type, 100 bar

(1500 psi) or less: a bonded seal at

the top is permitted.

1

4

3

2

NPT

a.

c.

(G) / BSPP

P ≤ 100 bar

b.

(G) / BSPP

1

2.3.1 Procedure (to attach)

2.3.2 Procedure (to remove)

To remove a device, release the pressure first (Section 2.2).

You can then do steps 4, 3, and 1 in Section 2.3.1 but do the

operations in the opposite direction.

2.4 Attach/Adjust a

PRV

WARNING: Pre ssurized gases and fluids are dangerous.

Before you attach or disconnect pressure equipment,

safely release all the pressure.

Optional accessory; see Section 1.5 (Access ories). Use a

pneumatic pressure relief valve (PRV) to set a limit to the

pressure you can apply to the pressure device s attached to the

pressure station. The PR V i s set at the fact ory to operat e at the

maximum pressure specified on the label.

If the pressure in the instrument is more t han the relief pressure

set for the PRV, the PRV controls a slow release of the

unwanted pressure. The correct PRV helps prevent

overpressure and damage to the attached devices.

To adjust the PRV, see Section 2.4.2.

2-2 Pneumatic pressure operation (PV 621) K0457 - [EN] English

Page 27

Issue 1

1 2

a

b

c

d

2.4.1 Procedure (to attach)

2.4.2 Procedure (to adjust)

1. Steps (a) and (b): Remove the blanking pl ug or , if applicabl e,

the PRV you are using.

Note: Before you put it into storage, make sure it is clean and

dry.

2. Steps (c) and (d): Choose a clean, dry PRV with the correct

pressure value for the devices you are using and tighten it

into position (hand tight only).

Note: We only guarantee the pressure setting on the product

set at our factory.

The PRV is set at the factory to operate at the maximum

pressure specified on the label (on the plastic cap). For the

adjustable range, refer t o Table 1-1.

If necessary, use these steps to adjust the relief pressure:

1. Attach an applicable pressure indicator to the test port

(Section 2.3) or use a DPI 620 calibrator with a PM 620

module (Chapter 5).

2. Remove the plastic cap from the end of the PRV.

3. Loosen the locknut counterclockwise.

2.5 Vacuum or pressure operation

4. Set the necessary pressure with the pressure station (see

Section 2.5.2).

5. When the pressure in the pressure station is at th e new PRV

pressure, turn the adjustment screw until the PRV operates:

counterclockwise decreases the operating pressure

clockwise increases the operating pre ssure

6. Do steps 4 and 5 until the PRV operates at the correct

pressure. Then tighten the l ocknut an d pr ess the p las tic c ap

back into position.

After you correctly attach an applicable device to the test port

(Section 2.3), use these steps to set the necessary vacuum or

pressure. If applicable, attach the correct PRV (Section 2.4).

[EN] English - K0457 Pneumatic pressure operation (PV 621) 2-3

Page 28

Issue 1

1 2

3 4

+

-

5

1184128

1 2

3 4

+

-

5

1184128

2.5.1 Vacuum procedure

2.5.2 Pressure procedure

Step Procedure (Vacuum)

1. Set the pressure/vacuum selector to vacuum (-); fully

counterclockwise.

2. To do equal adjustments (up or down) at the end of

the procedure, turn the volume adjuster to the middle

of its range of operation.

To get the maximum vacuum, turn the volume adjuster fully

clockwise.

3. Seal the system.

4. Use the pump to set the maximum vacuum or set the

vacuum you want to adjust.

5. Adjust the vacuum: + decrease; - increase.

Step Procedure (Pressure)

1. Set the pressure/vacuum selector to pressure (+);

fully clockwise.

2. To do equal adjustments (up or down) at the end of

the procedure, turn the volume adjuster to the middle

of its range of operation.

3. Seal the system.

4. Use the pump to set the approximate pressure.

5. Adjust the pressure: + decrease; - increase.

2-4 Pneumatic pressure operation (PV 621) K0457 - [EN] English

Page 29

Chapter 3: Pneumatic pressure

1

13

5

4

5

4

2

operation (PV 622)

3.1 Introduction

3.2 Release the pressure

Chapter 1 gives a description of the different parts of the

instrument: to

This chapter gives examples of how to connect and use the

PV 622 pressure station to give the necessary pressure or

vacuum conditions.

Before you start:

• Read and understand the “Safety” section.

• Make sure that there is no damage to the instrument, and

that there are no missing items.

Note: Use only original p arts supplied by the manufacturer.

To release all the pressure in this instrument:

Step Procedure

1. Open the refill valve counterclockwise (1 turn).

2. Open the pressure release valve counterclockwise

(1 turn).

3.3 Attach/Remove the device under test

To control a change in pressure conditions (for example, to go

to or through another test pressure) use the volume adjuster

wheel (Section 1.3.5) or open and close the pressure rele ase

valve.

WARNING: Pre ssurized gases and fluids are dangerous.

Before you attach or disconnect pressure equipment,

safely release all the pressure.

Caution: To prevent damage to the instrument, do not

let dirt get into the pressure mechanism. Before you

attach equipment, make sure it is clean.

The test port uses “Quick fit” pressur e adaptors; see

Section 1.5 (Accessories). These are easy to remove, change

and install (Section 3.3.1).

[EN] English - K0457 Pneumatic pressure operation (PV 622) 3-1

Page 30

Issue 1

3. Attach the adaptor to the device; if

necessary use one of the alternative

adaptors in Section 1.5 (Accessories),

then tighten to the applicable torque.

4. Re-attach the adaptor to the test port and

tighten it until it is hand tight only.

Step Procedure

Step Procedure

1. Remove the adaptor

2. Use an applicable seal for the pressure

connection:

a. NPT type: Use an applicable sealant

on the thread.

b. BSP (parallel) type: We recommend a

bonded seal at the bottom.

c. BSP (parallel) type, 100 bar

(1500 psi) or less: a bonded seal at

the top is permitted.

1

4

3

2

NPT

a.

c.

(G) / BSPP

P ≤ 100 bar

b.

(G) / BSPP

1

3.3.1 Procedure (to attach)

3.3.2 Procedure (to remove)

To remove a device, release the pressure first (Section 3.2).

You can then do steps 4, 3, and 1 in Section 3.3.1 but do the

operations in the opposite direction.

3.4 Attach/Adjust a

PRV

WARNING: Pre ssurized gases and fluids are dangerous.

Before you attach or disconnect pressure equipment,

safely release all the pressure.

Optional accessory; see Section 1.5 (Access ories). Use a

pneumatic pressure relief valve (PRV) to set a limit to the

pressure you can apply to the pressure device s attached to the

pressure station. The PR V i s set at the fact ory to operat e at the

maximum pressure specified on the label.

If the pressure in the instrument is more t han the relief pressure

set for the PRV, the PRV controls a slow release of the

unwanted pressure. The correct PRV helps prevent

overpressure and damage to the attached devices.

To adjust the PRV, see Section 3.4.2.

3-2 Pneumatic pressure operation (PV 622) K0457 - [EN] English

Page 31

Issue 1

1 2

a

b

c

d

3.4.1 Procedure (to attach)

3.4.2 Procedure (to adjust)

1. Steps (a) and (b): Remove the blanking pl ug or , if applicabl e,

the PRV you are using.

Note: Before you put it into storage, make sure it is clean and

dry.

2. Steps (c) and (d): Choose a clean, dry PRV with the correct

pressure value for the devices you are using and tighten it

into position (hand tight only).

Note: We only guarantee the pressure setting on the product

set at our factory.

The PRV is set at the factory to operate at the maximum

pressure specified on the label (on the plastic cap). For the

adjustable range, refer t o Table 1-1.

If necessary, use these steps to adjust the relief pressure:

1. Attach an applicable pressure indicator to the test port

(Section 3.3) or use a DPI 620 calibrator with a PM 620

module (Chapter 5).

2. Remove the plastic cap from the end of the PRV.

3. Loosen the locknut counterclockwise.

3.5 Vacuum or pressure operation

4. Set the necessary pressure with the pressure station (see

Section 3.5.2).

5. When the pressure in the pressure station is at th e new PRV

pressure, turn the adjustment screw until the PRV operates:

counterclockwise decreases the operating pressure

clockwise increases the operating pre ssure

6. Do steps 4 and 5 until the PRV operates at the correct

pressure. Then tighten the l ocknut an d pr ess the p las tic c ap

back into position.

After you correctly attach an applicable device to the test port

(Section 3.3), use these steps to set the necessary vacuum or

pressure. If applicable, attach the correct PRV (Section 3.4).

[EN] English - K0457 Pneumatic pressure operation (PV 622) 3-3

Page 32

Issue 1

1

3

4

5 6

+

-

2

11

594

12

9

1

6

2

3

7

5

+

-

4

+

11

9

4

12

5

959129

3.5.1 Vacuum procedure

3.5.2 Pressure procedure

Step Procedure (Vacuum)

1. Set the pressure/vacuum selector to vacuum (-); fully

counterclockwise.

2. Open the refill valve (1 turn).

3. To do equal adjustments (up or down) at the end of the

procedure, turn the volume adjuster wheel to the

middle of its range of operation.

To get the maximum vacuum, turn the volume adjuster

wheel fully clockwise.

4. Seal the system.

5. Use the pump to set the maximum vacuum or set the

vacuum you want to adjust.

6. Adjust the vacuum: + decrease; - increase.

Step Procedure (Pressure)

1. Set the pressure/vacuum selector to pressure (+); fully

clockwise.

2. To do equal adjustments (up or down) at the end of the

procedure, turn the volume adjuster wheel to the

middle of its range of operation.

3. Seal the system.

4. Use the pump to set a pressure up to ≈ 20 bar

(300 psi).

5. Open the refill valve (1 turn). You now have full control

to increase (+) or decrease (-) the pressure with the

volume adjuster.

Note: At higher pressures, it is easier to turn the wheel if

you fold in the handle; see Section 1.3.5.

6. If you increase pressure and get to the limit of travel,

close the refill valve and wind the volume adjuster fully

counterclockwise.

There is no change in pressure to the device under test or

7. Refill the pressure mechanism with the pump

the PM 620 module (if applicable).

(≈ 15 cycles) and wind the volume adjuster clockwise

until the pressure starts to increase.

3-4 Pneumatic pressure operation (PV 622) K0457 - [EN] English

operation and then pump) until you get the necessary

pressure OR for full control, go back to step 5.

Continue this sequence (clockwise/counterclockwise

Page 33

Chapter 4: Hydraulic pressure

1

13

4 5

1

3

+

2

24494

operation (PV 623)

4.1 Introduction

4.2 Fill the reservoir

Chapter 1 gives a description of the different parts of the

instrument: to

This chapter gives examples of how to connect and use the

PV 623 pressure station to give the necessary hydraul ic

pressure conditions.

Before you start:

• Read and understand the “Safety” section.

• Make sure that there is no damage to the instrument, and

that there are no missing items.

Note: Use only original p arts supplied by the manufacturer.

Caution: Ice in the pressure mechanism can cause

damage. If the temperature is less than 4 °C (39°F), drai n

all water from the instrument.

The first time you want to use the hydraulic pressure station,

use this procedure to fill the reser voir:

Step Procedure

1. Use the applicable adaptor to attach the device

(Section 4.4).

[EN] English - K0457 Hydraulic pressure operation (PV 623) 4-1

2. Remove the hydraulic pressure release valve.

3. Use the refill bottle to add the necessary hydraulic

4. To remove air from the pressure mechanism, wind the

5. Seal the system and continue with the normal

* Refer to Chapter 7 (Specification)

*

but leave a small air gap.

fluid

volume adjuster through one full cycle

(counterclockwise then cloc k wis e).

pressure operation; see Section 4.6.

After a period of operation, if it is necessar y to add more fluid to

the reservoir, use this procedure again.

To add more fluid during a pressure procedure, refer to

Section 4.6.2.

To drain the hydraulic fluid, refer to Section 4.7.

Page 34

Issue 1

10

4

10

4

2

3. Attach the adaptor to the device; if

necessary use one of the alternative

adaptors in Section 1.5 (Accessories),

then tighten to the applicable torque.

4. Re-attach the adaptor to the test port and

tighten it until it is hand tight only.

Step Procedure

Step Procedure

1. Remove the adaptor

2. Use an applicable seal for the pressure

connection:

a. NPT type: Use an applicable sealant

on the thread.

b. BSP (parallel) type: We recommend a

bonded seal at the bottom.

c. BSP (parallel) type, 100 bar

(1500 psi) or less: a bonded seal at

the top is permitted.

1

4

3

2

NPT

a.

c.

(G) / BSPP

P ≤ 100 bar

b.

(G) / BSPP

4.3 Release the pressure

4.4 Attach/Remove the device under test

To release all the pressure in this instrument:

Step Procedure

1. Open the refill valve counterclockwise (1 turn).

2. Open the pressure release valve counterclockwise

(1 turn).

To control a change in pressure conditions (for example, to go

to or through another test pressure) use the volume adjuster

wheel (Section 1.4.5).

WARNING: Pre ssurized gases and fluids are dangerous.

Before you attach or disconnect pressure equipment,

safely release all the pressure.

Caution: To prevent damage to the instrument, do not

let dirt get into the pressure mechanism. Before you

attach equipment, make sure it is clean.

The test port uses “Quick fit” pressur e adaptors; see

Section 1.5 (Accessories). These are easy to remove, change

and install.

4.4.1 Procedure (to attach)

4-2 Hydraulic pressure operation (PV 623) K0457 - [EN] English

Page 35

Issue 1

1

3 4

a

b

c

d

1

1 2

4.4.2 Procedure (to remove)

4.5 Attach/Adjust a

PRV

To remove a device, release the pressure first (Section 4.3).

You can then do steps 4, 3, and 1 in Section 4.4.1 but do the

operations in the opposite direction.

WARNING: Pre ssurized gases and fluids are dangerous.

Before you attach or disconnect pressure equipment,

safely release all the pressure.

Caution: In its normal condition, the PV 623 model

contains hydraulic fluid. To make sure it does not spill

out, seal the system and put it on its side before you

install a PRV.

Optional accessory; see Section 1.5 (Access ories). Use a

hydraulic pressure relief val ve (PRV) to set a limit to the

pressure you can apply to the pressure device s attached to the

pressure station. The PR V i s set at the fact ory to operat e at the

maximum pressure specified on the label.

If the pressure in the instrument is more t han the relief pressure

set for the PRV, the PRV controls a slow release of the

unwanted pressure. The correct PRV helps prevent

overpressure and damage to the attached devices.

4.5.1 Procedure (to

4.5.2 Procedure (to

attach)

adjust)

To adjust the PRV, see Section 4.5.2.

1. Seal the system.

2. Put the instrument on its side.

3. Steps (a) and (b): Remove the blanking pl ug or , if applicabl e,

the PRV you are using. To collect possi ble drops of hy draulic

fluid, put it in a container.

Note: Before you put it into storage, make sure it is clean and

dry.

4. Steps (c) and (d): Choose a clean, dry PRV with the correct

pressure value for the devices you are using and tighten it

into position (hand tight only).

Note: We only guarantee the pressure setting on the product

set at our factory.

The PRV is set at the factory to operate at the maximum

pressure specified on the label (on the plastic cap). For the

adjustable range, refer t o Table 1-2.

If necessary, use these steps to adjust the relief pressure:

[EN] English - K0457 Hydraulic pressure operation (PV 623) 4-3

1. Attach an applicable pressure indicator to the test port

(Section 4.4) or use a DPI 620 calibrator with a PM 620

module (Chapter 5).

Page 36

Issue 1

1

4

2

3

+

-

+

4

9

10

9

10

9

10

2. Remove the plastic cap from the end of the PRV.

3. Set the necessary pressure with the pressure station (see

Section 4.6.1).

4. When the pressure in the pressure station is at th e new PRV

pressure, turn the adjustment screw until the PRV operates:

counterclockwise decreases the operating pressure

clockwise increases the operating pre ssure

5. Do steps 3 and 4 until the PRV operates at the correct

pressure. Then press the plastic cap back into position.

4.6 Pressure operation

After you correctly attach an applicable device to the test port

(Section 4.4), use these steps t o set the nec essar y pressur e. I f

applicable, attach the correct PRV (Section 4.5).

Note: To operate correctly, make sure the reservoir contains

the correct amount of hydraulic fluid; see Sect ion 4.2.

During the procedure, you can add more hydraulic fluid; see

Section 4.6.2. When the procedure is complete, you can then

drain this fluid back out of the device; see Section 4.6.3.

4.6.1 Hydraulic pressure procedure

Step Procedure

1. Seal the system.

2. Close the refill valve and then wind the volume

adjuster fully clockwise and counterclockwise until the

pressure starts to increase.

Continue the clockwise/counterclockwise sequence until

you get the necessary pressure OR for full control, go to

step 3.

3. For full control, open the refill valve (1 turn). You can

The counterclockwise operation refills the pressure

mechanism but there is no change in pressure to the

device under test or the PM 620 module (if applicable).

Note: At higher pressures, it is easier to turn the wheel if

you fold in the handle; see Section 1.4.5.

now increase (+) or decrease (-) the pressure with the

volume adjuster.

4. If you increase pressure and get to the limit of travel,

4-4 Hydraulic pressure operation (PV 623) K0457 - [EN] English

5. Continue to do steps 2 to 4 until you get the necessary

close the refill valve again and wind the volume

adjuster fully counterclockwise.

pressure.

Page 37

4.6.2 Add more hydraulic fluid

4 5

3

+

21

10

449

4

If the device under test has a large fluid capacity, you can add

hydraulic fluid during the pressure procedure.

Issue 1

Step Procedure

1. To seal off all the pressure in the test port and the

pressure module connection, close the refill valve.

2. Remove the hydraulic pressure release valve.

3. Use the refill bottle to add the necessary hydraulic

4. To remove air from the pressure mechanism, wind the

5. Seal the system and continue with the normal

* Refer to Chapter 7 (Specification)

*

but leave a small air gap.

fluid

Note: To prevent contamination use only one type of

hydraulic fluid in the instrument.

volume adjuster through one full cycle

(counterclockwise then clock wis e).

pressure procedure; see Section 4.6.1.

4.6.3 Drain hydraulic fluid from the device under test

If you add more hydraulic fluid during the pressure procedure,

drain this fluid out of the devic e when the pressure procedure i s

complete.

Note: If it is safe and there is no risk of contamination, you can

leave the hydraulic fluid inside the device.

Preparation To drain the device, we recommend these items:

[EN] English - K0457 Hydraulic pressure operation (PV 623) 4-5

• the applicable skin and eye protection

• a container that is large enough to hold the hydraulic fluid

and prevent contamination of the work surface

• applicable materials to make sure the instrument and the

Procedure 1. Release the pressure (Section 4.3).

area stay clean; see Chapter 6 (Maintenance procedures)

2. Remove the device (Section 4.4) but do not let fluid spill

onto the PV 62x instrument.

3. If necessary, drain the hydraulic fluid from the device under

test.

Note: To discard the hydraulic fluid, obey all the local health

and safety procedures.

Page 38

Issue 1

1 2

4

+

3

249

4.7 Drain all the hydraulic fluid

4.7.1 Preparation

4.7.2 Procedure

In some conditions, it is necessary to fully drain the hydraulic

fluid from your PV 62x pressure station; for example:

• if you are using water and the storage or operating

temperature is going to be less than 4°C (39°F)

• if there is a long period of storage

• if there is unwanted material in the hydraulic fluid

To drain the instrument, we recommend these items:

• the applicable skin and eye protection

• a container that is large enough to hold the hydraulic fluid

and prevent contamination of the work surface

• applicable materials to make sure the instrument and the

area stay clean; see Chapter 6 (Maintenance procedures)

Step Procedure (Drain all the fluid)

1. If applicable, release the pressure (Section 4.3) and

remove the device (Section 4.4).

Note: If it is attached, we also recommend you remove the

DPI 620 calibrator; see Chapter 5 (Pressure calibrator

operation (DPI 620)).

2. Remove the hydraulic pressure release valve.

3. Wind the volume adjuster wheel fully clockwise; this

moves the fluid out of the pressure mechanism.

4. Put a container below the instrument then tilt the instrument

up until all the fluid has come out. To discard the hydraulic

fluid, obey all the local health and safety procedures.

Note: Fluid comes out of the test port and the connection

for the pressure release valve.

5. To flush out fluids that contain unwanted material, refill the

system and repeat steps 3 and 4.

Note: To prevent contamination use only one type of

hydraulic fluid in the instrument.

4-6 Hydraulic pressure operation (PV 623) K0457 - [EN] English

Page 39

Chapter 5: Pressure calibrator

1

2 3

6

4

5

operation (DPI 620)

5.1 Introduction

5.2 Parts and assembly

5.2.1 DPI 620 calibrator parts

This section gives examples of how to connect and use the

pressure stations to do pressure calibrations with the DPI 620

calibrator and the applicable pressure modules (PM 620).

Before you start:

• Read and understand the “Safety” section.

• Do not use a damaged instrument.

Note: Use only original p arts supplied by the manufacturer.

To make a fully integrated pressure calibrator instrument, use

these items:

• a PV 62x pressure station; see Chapter 1 (Instrument pa rt s,

accessories and options)

• a DPI 620 calibrator; see Section 5.2.1

• an applicable PM 620 module for the pressure station; see

Section 5.2.2

Refer to the user manual - K0449: Druck DPI 620 Advanced

modular calibrator.

1. On or off button. Press and hold the button down until the

power comes on.

2. Channel 1 (CH1) connectors for electrical measure and

source operations; refer to the user manual - K0449

3. Isolated channel 2 (CH2) connectors for electrical measure

and source operations and a 24V loop power supply (24Vo);

refer to the user manual - K0449

4. Rubber pull-down cover for the USB type A connector; USB

mini-type B connector and +5V DC power input soc ket.

5. Colour display with touch-screen. The number of windows

you see on the display is set by the number of task selections

and external modules you are working with (maximum: 6).

T o make a selection, lightly tap on the applicable display area;

refer to the user manual - K0449

6. Sealed speaker unit.

[EN] English - K0457 Pressure calibrator operation (DPI 620) 5-1

Page 40

Issue 1

1

a

1

2

3

4

5

5.2.2 PM 620 module parts

5.2.3 Assembly instructions

Caution: To pr event damage to the PM 620 module, only

use it within the specified pressure limit on the label.

1. Pressure module (PM 620) with a pressure connection,

reference port (a) and a label. The label includes:

Pressure range. Example: 20 bar g (g: gauge; a: absolute);

serial number (S/ N); manufacturer: name, address, website

Table 5-1: Recommended pressure modules (PM 620)

PV 62x model PM 620 module range

PV 621 models 25 mbar to 20 bar (0.36 to 300 psi)

PV 622 models 25 mbar to 100 bar (0.36 to 1500 psi)

PV 623 models 70 to 1000 bar (1000 to 15000 psi)

Step Procedure

1. Lower the DPI 620 calibrator into the moulded

compartment.

2. Press on the bottom end of the calibrator until it

latches in position.

3. Attach a PM 620 module with the correct range

and type.

4. Tighten it until it is hand tight only.

When this symbol flashes at the top of the display,

it shows there is communication between the

module and the calibrator.

5. If applicable, attach one of the optional PRVs; see

Chapter 1 (Instrument parts, accessories

and options).

5-2 Pressure calibrator operation (DPI 620) K0457 - [EN] English

Page 41

Issue 1

TAP

2

1

3

A

3

C

B

A

B

C

1

D

D

1

E

TAP

E

5.3 Measure pressure/vacuum

5.3.1 Procedure overview

When the pressure calibrator assembly is complete

(Section 5.2), use the calibrator to measure the pressure or, if

applicable, the vacuum in the pressure station; for example: to

calibrate a gauge or indicator.

To use the pressure calibrator, complete these procedures:

• Set the calibrator functions you want to use on the displ a y:

a. Pressure function (P1): item ;

see Section 5.3.2

b. CH1: Channel 1 electrical function (input or output);

refer to the user manual - K0449

c. CH2: Channel 2 electrical function (input or output);

refer to the user manual - K0449

d. other functions (maximum: 6 functions);

refer to the user manual - K0449

• If necessary, change the Units for the function: item ;

see Section 5.3.3

• If necessary, set a Utility for the function: item

a. Max/Min/Avg; refer to the user manual - K0449

b. Switch Test; refer to the user manual - K0449

c. Leak Test; see Section 5.3.4

• If necessary, change the Settings for the pressure function:

item

a. Process (Tare, Alarm, Filter, Flow, Scaling);

refer to the user manual - K0449

b. Leak Test (Only wh en the Utility is set); see Section 5.3.4

c. Zero; see Section 5.3.5

• If necessary, change the Process for the CH1 and/or CH2

input functions: item

This includes: Tare, Alarm, Filter, Flow, Scaling; refer to the

user manual - K0449

[EN] English - K0457 Pressure calibrator operation (DPI 620) 5-3

Page 42

Issue 1

1

F

TAP

F

G

2

1

G

TAP

Channel SettingsTask Settings

Task SettingsSelect Function Channel Settings

1

2

3

4

86 7

5

• If necessary, change the Automation options for the CH1

and/or CH2 output functions: item

This includes: Nudge, Span Check, Percent Step,

Defined Step, Ramp; refer to the user manual - K0449

• If necessary, change the Configuration: item

This includes: Data Logging, Documenting, and Advanced

options; refer to the user manual - K0449

• When all the software selections are complete, make the

applicable pressure and electrical connections. Examples:

Gauge/indicator calibration (Section 5.3.6); Transmitter

calibration (Section 5.3.7); Switch test (Section 5.3.8)

5.3.2 DPI 620 calibrator: Set the pressure function

This example shows the sequence to set t he pressure funct ion.

It is a similar procedure for other functions; refer to the user

manual - K0449.

5-4 Pressure calibrator operation (DPI 620) K0457 - [EN] English

Page 43

5.3.3 DPI 620 calibrator: Set the pressure units

Channel SettingsTask Settings

TAP

2

1

3

4

5

6

Select Units Select Units

Channel Settings

Task Settings

7 8

Channel SettingsTask Settings

TAP

2

1

3

4

5

6

Select Utility Select Utility

Channel Settings

Task Settings

7 8

This example shows the sequence to set the pressure units. It

is a similar procedure for other units.

Issue 1

5.3.4 DPI 620 calibrator: Set up a Leak Test

To do a leak test, set the Utility to Leak Test and then set the

Leak Test options in Settings:

(1) Set the Utility

[EN] English - K0457 Pressure calibrator operation (DPI 620) 5-5

Page 44

Issue 1

2

1

3

4

Select Leak Test Select Test Time

Steps 5 and 6: Set the Test Time

+ Set the Wait Time (if necessary)

TAP the wind ow

(Maximise)

Select Settings

5

6

7

Start the test and let it

complete.

Go back to the Home window. Start the test

when the pressure system is set up.

Stop the test (with no results)

(2) Set the Leak Test

options

When you have set the Utility to Leak Test, you can set these

options:

Wait Time: The time before the test starts in

hours:minutes:seconds (hh:mm:ss)

Test Time: The period of the leak test in

hours:minutes:seconds (hh:mm:ss)

Note: To set the Leak Test options, you must have a PM 620

module correctly installed (Section 5.2.3).

5.3.5 DPI 620 calibrator: Set the PM 620 module to zero

5-6 Pressure calibrator operation (DPI 620) K0457 - [EN] English

Use this option to write a new zero pressure value to the

PM 620 module you are using. This option only affects gauge

type modules.

Note: To make a temporary adjustment for zero, you can use

the Tare function: Select Settings > Process > Tare (refer to the

user manual - K0449).

Page 45

Issue 1

21

3

4

Select Zero Accept the adjustment value

TAP the wind ow

(Maximise)

Select Settings

See the new reading and go back to the H ome

window.

5

2

1 3 4

5.3.6 Example procedure: Gauge/indicator calibration

1. Assemble the pressure calibrator with the correct PM 620

module and PRV (if applicable); see Section 5.2.3.

2. Set the applicable software options; see Section 5.3.1

(Procedure overview). This example shows one function:

• Pressure (P1) is set to measure the pressure supplied by

the pressure station.

3. To attach the device under test, use the specified

procedures for your PV 62x pressure station*.

[EN] English - K0457 Pressure calibrator operation (DPI 620) 5-7

Page 46

Issue 1

2

1

3

5

4

4. To s et the necessa ry pressure or vac uum for the calibrat ion,

use the specified procedures for your PV 62x pressure

station*.

* Reference • PV 621 models: see Chapter 2 (Pneumatic pressure

operation (PV 621))

• PV 622 models: see Chapter 3 (Pneumatic pressure

operation (PV 622))

• PV 623 models: see Chapter 4 (Hydraulic pressure

operation (PV 623))

5.3.7 Example procedure: Transmitter calibration

1. Assemble the pressure calibrator with the correct PM 620

module and PRV (if applicable); see Section 5.2.3.

2. Set the applicable software options; see Section 5.3.1

(Procedure overview). This example shows two func tions:

• Channel 2 (CH2) is set to measure current with 24V loop

power.

• Pressure (P1) is set to measure the pressure supplied by

the pressure station.

3. To attach the device under test, use the specified

procedures for your PV 62x pressure station*.

5-8 Pressure calibrator operation (DPI 620) K0457 - [EN] English

Page 47

* Reference • PV 621 models: see Chapter 2 (Pneumatic pressure

2

1

3

5

4

6

operation (PV 621))

• PV 622 models: see Chapter 3 (Pneumatic pressure

operation (PV 622))

• PV 623 models: see Chapter 4 (Hydraulic pressure

operation (PV 623))

4. Complete the electrical connections. This example shows

Channel 2 (CH2) set up to measure current with 24V loop

power.

5. To s et the necessa ry pressure or vac uum for the calibrat ion,

use the specified procedures for your PV 62x pressure

station*.

5.3.8 Example procedure: Switch test

Issue 1

1. Assemble the pressure calibrator with the correct PM 620

module and PRV (if applicable); see Section 5.2.3.

2. Set the applicable software options; see Section 5.3.1

(Procedure overview). This example shows one function:

• Pressure (P1) is set to measure the pressure. The Utility is

set to Switch Test.

[EN] English - K0457 Pressure calibrator operation (DPI 620) 5-9

3. To attach the device under test, use the specified

procedures for your PV 62x pressure station*.

Page 48

Issue 1