Page 1

GE Industrial

Sensing

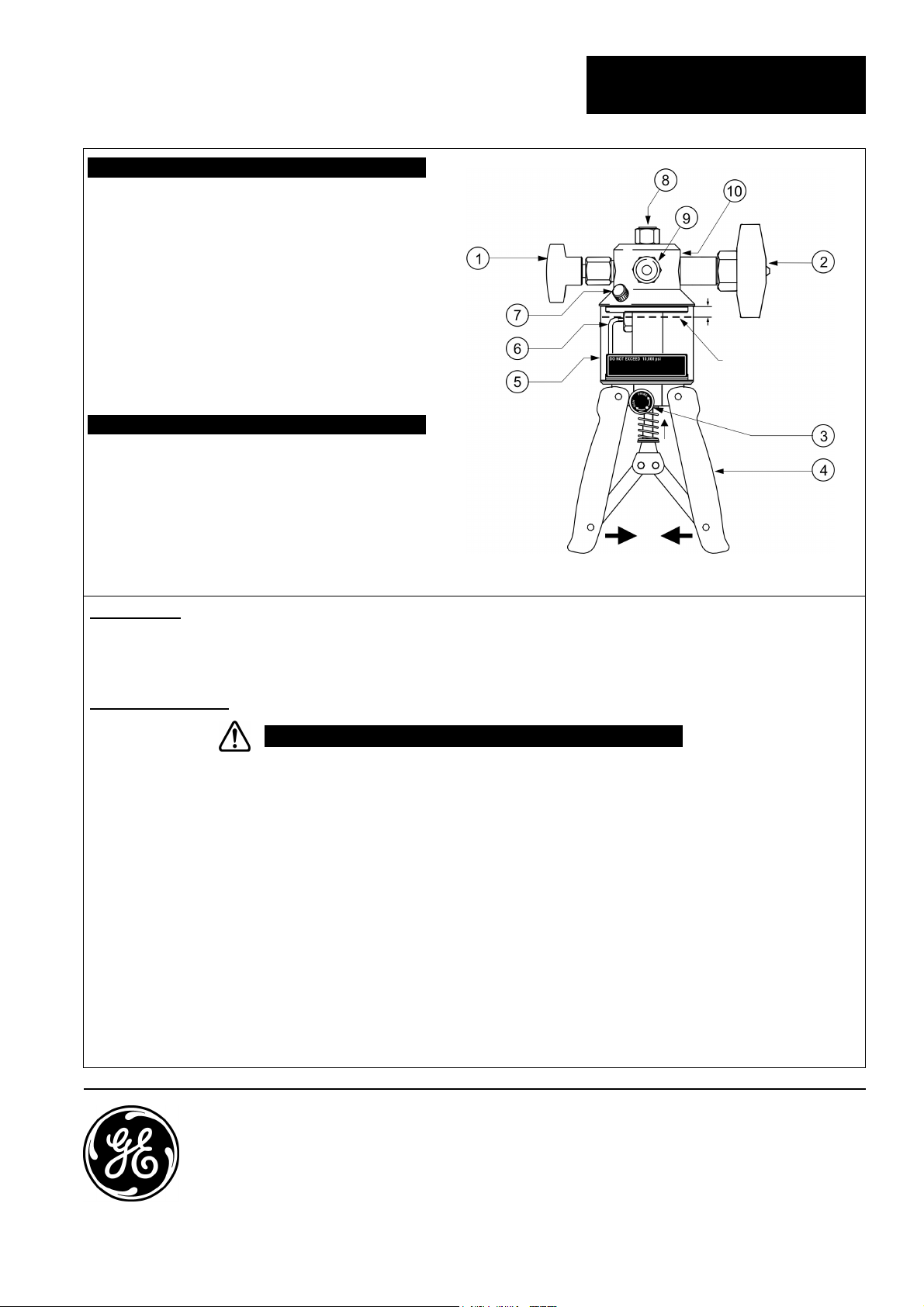

KEY

1. Pressure release valve

2. Fine adjust vernier

3. Prime/High pressure selector

4. Scissor handles

5. Reservoir: 6.1 cubic inch (100 cc)

6. Fluid inlet tube

7. Reservoir fill plug

8. 1/4” NPT female adapter

9. 1/4” NPT female adapter

10. Rear port for an optional pressure relief valve

DO NOT USE IT FOR OTHER FUNCTIONS

SPECIFICATION

Ranges: PV212-10K (0 to 10,000 psi)

PV212-15K (0 to 15,000 psi)

Pressure media: Low viscosity mineral-based

hydraulic oil, distilled water,

“Skydrol/Fyrquel” and brake fluid

versions available

Dimensions: 9”L x 6.25”W x 2.75”D

Weight: 3.2 lb

Druck PV212 series -

Hydraulic hand pumps

K409 Issue 1

1/4”

RECOMMENDED

FLUID LEVEL

DESCRIPTION

This system is a portable source of hydraulic pressure. Each pump includes a reservoir, and a volume control for fine

adjustment. To prevent damage to sensitive instruments, there are five pressure relief valves available for different

pressure ranges.

USER INSTRUCTIONS

WARNING - HIGH PRESSURE

• Uncontrolled release of high pressure is dangerous and may cause damage to equipment. Because the

internal pressure can get very high during operation, make sure that all the connections are made

correctly. DO NOT ignore the maximum operating pressure specified on the pump label.

• Before you connect a pressure component to the PV212, make sure that it is isolated from the pressure

supply and release the internal pressure slowly. DO NOT connect the pump to an external pressure source.

1. Remove the reservoir fill plug (7), fill the reservoir (5) to the indicated level, and replace the fill plug,

2. Connect a reference instrument to connection (8).

Note: Use PTFE tape to seal all NPT connections.

3. Connect the instrument under test to connection (9):

Use pressure-rated flexible hose or use the optional accessories to direct mount it.

4. Set the fine adjust vernier (2) to the midpoint of its travel:

Turn it fully clockwise, then four to six turns counterclockwise.

5. Open the pressure release valve (1):

Turn it fully clockwise and then one turn counterclockwise.

6. Squeeze the scissor handles (4) fully together and turn the selector (3) to the “Prime” position.

Web: www.gesensing.com

Page 2

Operating instructions for the Druck PV212 series - Hydraulic hand pumps

USER INSTRUCTIONS (continued)

7. Remove trapped air from the pump:

Squeeze the scissor handles (4) several times. Make sure that the fluid inlet tube (6) remains immersed in fluid at all

times.

8. Close the pressure release valve (1):

Turn it fully clockwise, and tighten to seal.

9. Prime the system:

Squeeze the scissor handles (4) together and then release them to get the fluid into the pump cylinder. Repeat this

operation until the system is fully primed, as indicated by pressure build-up on the reference instrument or the

instrument under test.

10. Set a pressure that is almost correct:

With the scissor handles (4) fully together, turn the selector (3) to the “High” position, and operate the scissor

handles (4).

!WARNING!

It is dangerous to ignore the maximum operating pressure specified on the pump label.

Note: At higher pressures, it is easier to use short handle strokes.

11. To adjust the pressure to the correct value, turn the fine adjust vernier (2) clockwise to increase the pressure or

counterclockwise to decrease the pressure.

Note: Initially, small pressure changes can occur (thermodynamic effects, the seals settle, the hoses expand). The

pressure will stabilize after a short time.

12. To fully release the pressure from the system, slowly turn the pressure release valve (1) counterclockwise one full

turn. This completes the procedure.

Note: Careful operation of the pressure release valve (1) gives a controlled release of pressure.

FAULT INVESTIGATION/MAINTENANCE

• When in operation, if the fluid level in the reservoir falls by a large amount, this can create a partial vacuum and

affect pump performance. To prevent this, loosen the fill plug (7) and let air into the reservoir.

• For seal replacement refer to the service kit IAS-A111-1 instructions.

2 of 2 K409 Issue 1

Loading...

Loading...