Page 1

Operating/Safety Instructions

Mode d’emploi et consignes de sécurité

Instrucciones de seguridad/operación

Model/Modèle/Modelo 670

Mini Saw Attachment

Instrument pour mini-scie

Acople de minisierra

For use with models 275, 285, 395, 398, 780

Pour utiliser avec les modèles 275, 285, 395, 398, 780

Para uso con los modelos 275, 285, 395, 398, 780

Consumer Information

Renseignement des consommateurs

Información para el consumidor

1-800-4-DREMEL www.dremel.com

5716 Dremel 2.625x4.25 6/18/02 10:29 AM Page 1

®

Page 2

Read and understand all

instructions.Failure to follow

all instructions listed below may result in personal

injury.

SAVE THESE INSTRUCTIONS

Keep hands away from

cutting area and blade.

Keep your second hand on motor housing. If

both hands are holding the tool,they cannot be cut

by the blade.Hold the tool firmly to prevent loss of

control. Figures in this manual illustrate typical

hand support of the tool. NEVER place your hand

behind the saw blade since kickback could cause

the saw to jump backwards over your hand.

If your application does not allow two-hand

control of the tool,keep your hand,fingers and

body positioned to either side of the saw blade,

but not in line with the saw blade. KICKBACK

could cause the saw to jump backwards. (See

“Causes and Operator Prevention of Kickback.”)

Advance the blade only in a direction where

the blade teeth are coming up through

the workpiece. “Climb cutting” or feeding the

blade into the material so that the teeth are

descending into the material, will cause the

blade to climb out of the material and to

Power Tool Safety Rules

!

WARNING

Safety Rules for Mini Saw Attachment

!

DANGER

jump uncontrollably in the direction of this

improper feed.

Be extremely careful when cutting round rods

or when approaching corners or the edge of

the workpiece.The blade can bind on the edge of

the workpiece and cause kickback.

Do not cut along a radius or curved line of cut.

Kickback will occur if a curved cutting motion is

attempted.

Do not reach underneath the work. The guard

cannot protect you from the blade below the work.

Check lower guard for proper closing before

each use. Never clamp or tie the lower guard

into the open position. If saw is accidentally

dropped,lower guard may be bent.Make sure the

guard moves freely and does not touch the blade

or any other part.

Check the operation of the lower guard spring.

If the guard and the spring are not operating

properly, they must be serviced before use.

Lower guard may operate sluggishly due to

damaged parts, gummy deposits, or a buildup of

debris. Disconnect the plug from power source.

Periodically remove the blade, clean the lower

guard and the hub area, or blow it clean with

compressed air.

Always observe that the lower guard is

covering the blade before placing the tool

down on bench or floor. An unprotected,

23

5716 Dremel 2.625x4.25 6/18/02 10:29 AM Page 2

Page 3

coasting blade will cause the saw to cut whatever

is in its path. Be aware of the time it takes for the

blade to stop after switch is turned off.

NEVER hold piece being cut in your hands or

across your leg. It is important to support the

work properly to minimize body exposure, blade

binding, or loss of control.

Always use blades with correct size and shape

arbor holes. Blades that do not match the

mounting hardware of the saw will run

eccentrically,causing loss of control.

Do not run the tool while carrying it at your side.

Lower guard may be opened by a contact with

your clothing. Accidental contact with the spinning

saw blade could result in serious personal injury.

Know how to turn slide switch “OFF” in an

emergency. If switch cannot turn “OFF” the tool

quickly,unplug the tool immediately.

CAUSES AND OPERATOR PREVENTION OF KICKBACK:

Kickback is a sudden reaction to a pinched, bound

or misaligned saw blade, causing an uncontrolled

saw to lift up and out of the workpiece toward

the operator.

When the blade is pinched or bound tightly by the

kerf closing down, the blade stalls and the motor

reaction drives the unit rapidly back toward

the operator.

If the blade becomes twisted or misaligned in the

cut,the teeth at the back edge of the blade can dig

into the top surface of the wood causing the blade

to climb out of the kerf and jump back toward

the operator.

Kickback is the result of tool misuse and/or

incorrect operating procedures or conditions and

can be avoided by taking proper precautions as

given below:

Maintain a firm grip with both hands on the tool

and position your body and arm to allow you to

resist KICKBACK forces. KICKBACK forces can be

controlled by the operator, if proper precautions

are taken.

When blade is binding, or when interrupting a

cut for any reason,turn off the tool and hold the

tool motionless in the material until the blade

comes to a complete stop. Never attempt to

remove the saw from the work or pull the tool

backward while the blade is in motion or

45

5716 Dremel 2.625x4.25 6/18/02 10:29 AM Page 4

Page 4

KICKBACK may occur. Investigate and take

corrective action to eliminate the cause of blade

binding. Wet lumber, green lumber or pressure-

treated lumber and most plastics require special

attention during cutting operation to prevent

KICKBACK. Avoid cutting nails. Inspect for and

remove all nails from lumber before cutting.

When restarting a saw in a workpiece, center

the saw blade in the kerf and check that saw

teeth are not engaged into the material. If saw

blade is binding,it may walk up or KICKBACK from

the workpiece as the tool is restarted.

Support panels to minimize the risk of blade

pinching and KICKBACK. Large panels tend to sag

under their own weight. Supports must be placed

under the panel on both sides,near the line of cut and

near the edge of the panel.

Do not use dull or damaged blade.Unsharpened

or improperly set blades produce narrow kerf

causing excessive friction, blade binding and

KICKBACK.

Use extra caution when making a “Pocket

Cut” into existing walls or other blind areas.

The protruding blade may cut objects that can

cause KICKBACK.

67

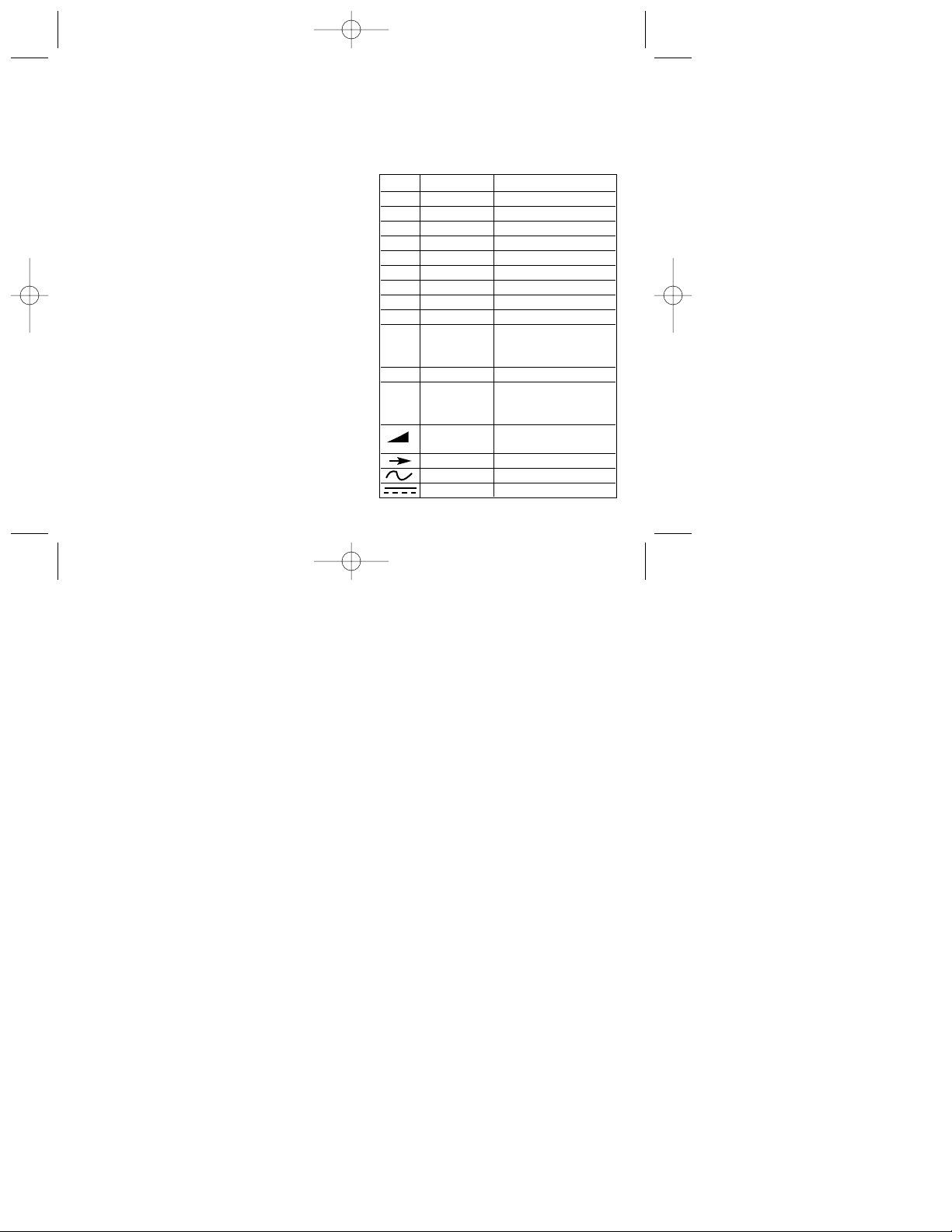

Symbols:

IMPORTANT: Some of the following symbols may

be used on your tool.Please study them and learn

their meaning. Proper interpretation of these

symbols will allow you to operate the tool better

and more safely.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

ø Diameter

Size of drill bits, grinding wheels,etc.

noNo load speed Rotational speed, at no load

.../min Revolutions or Revolutions, strokes, surface

reciprocation speed,orbits,etc.per minute

per/min.

O Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position

I, II, III, settings. Higher number means

greater speed

o Infinitely variable Speed is increasing

selector with off from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

5716 Dremel 2.625x4.25 6/18/02 10:29 AM Page 6

Page 5

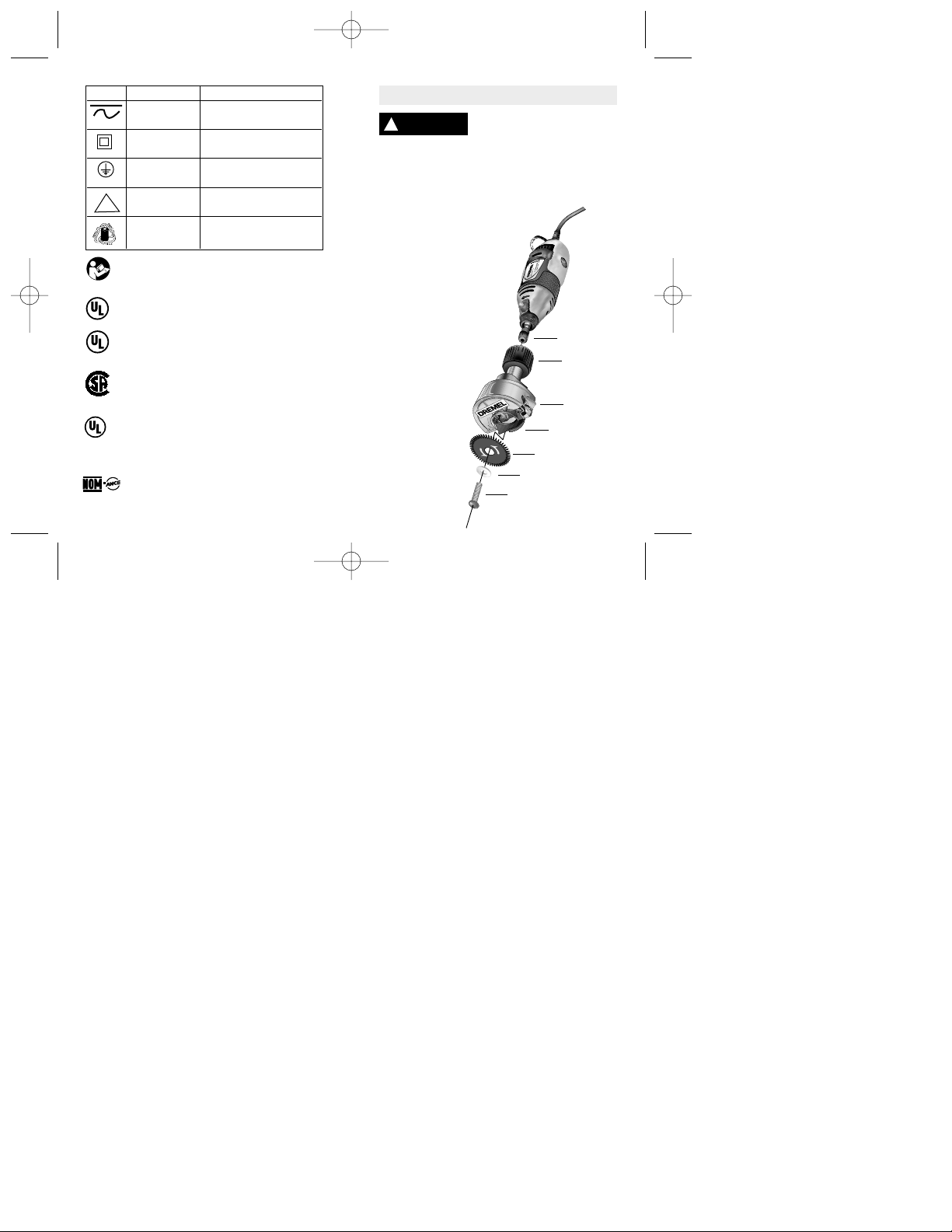

SawGuardExpl

This symbol designates that this tool is

listed by Underwriters Laboratories.

This symbol designates that this tool is

listed to Canadian Standards by

Underwriters Laboratories.

This symbol designates that this tool is

listed by the Canadian Standards

Association.

This symbol designates that this tool is

listed by Underwriters Laboratories, and

listed to Canadian Standards by

Underwriters Laboratories.

This symbol designates that this tool

complies to NOM Mexican Standards.

89

Symbol Name Designation/Explanation

Alternating or Type or a characteristic of current

direct current

Class II Designates Double Insulated

construction Construction tools

Earthing terminal Grounding terminal

Warning symbol Alerts user to

warning messages

Ni-Cad RBRC seal Designates Ni-Cad battery

recycling program

!

Disconnect the plug of your

rotary tool from the power

source before making any assembly,

adjustments or changing accessories. Make

sure switch is in the OFF position before

plugging in. Such preventive safety measures

reduce the risk of starting the tool accidentally.

Functional Description and Specifications

!

WARNING

Drive Adapter

Coupling

Directional

Guide

Lower Guard

Blade

Screw

Washer

For use with Dremel Models

275, 285,395,398 and 780.

Maximum Capacities:

Blade - 1-1/4" (31.8 mm)

Arbor Hole - .363" (9.22 mm)

Depth at 90° - 1/4"

Read Instruction Manual.

5716 Dremel 2.625x4.25 6/18/02 10:29 AM Page 8

®

C

®

CUS

®

Page 6

Disconnect the plug of your

rotary tool from the power

source before making any assembly,

adjustments or changing accessories. Such

preventive safety measures reduce the risk of

starting the tool accidentally.

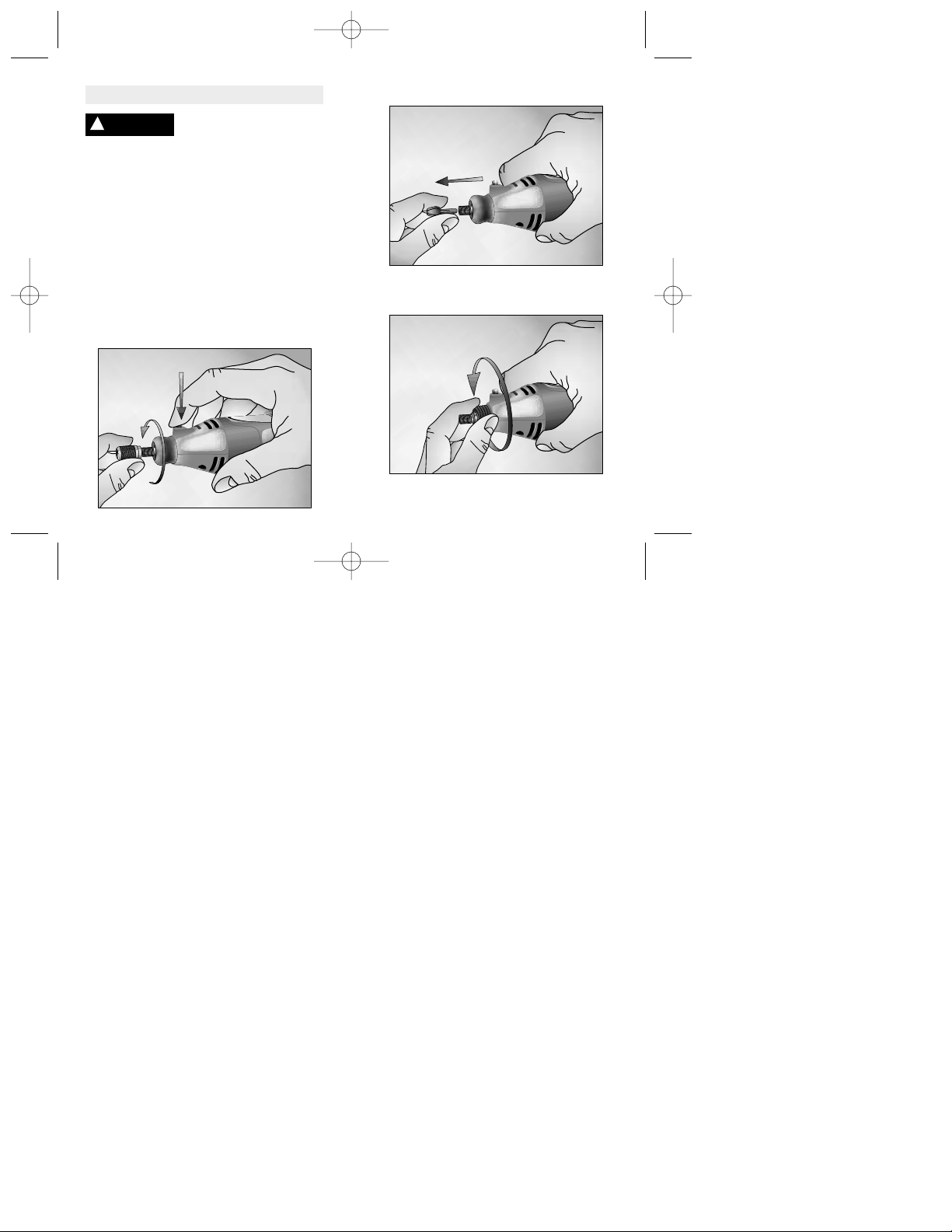

MINI SAW ATTACHMENT INSTALLATION

It is extremely important to carefully read and

follow the directions below to assemble the Mini

Saw Attachment to your rotary tool and ensure the

tool will function properly.

To properly attach the Mini Saw Attachment to the

rotary tool, THREE items must be removed from

the tool: the housing cap,collet nut and collet.

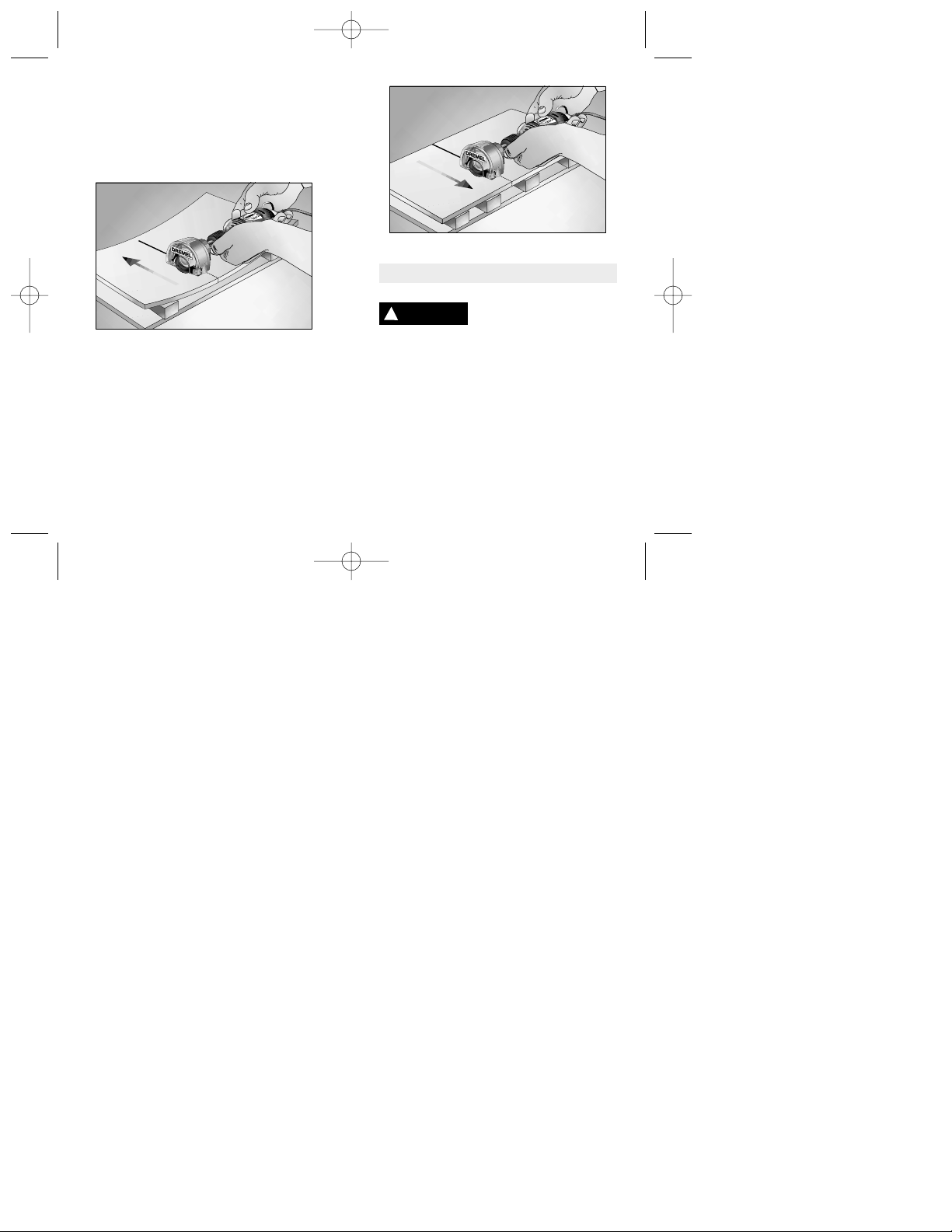

Step 1. Press the shaft lock button, unscrew and

remove the collet nut.

Assembly

!

WARNING

Step 2. Remove the collet.

10 11

Step 3. Unscrew the housing cap from the tool.

5716 Dremel 2.625x4.25 6/18/02 10:29 AM Page 10

Page 7

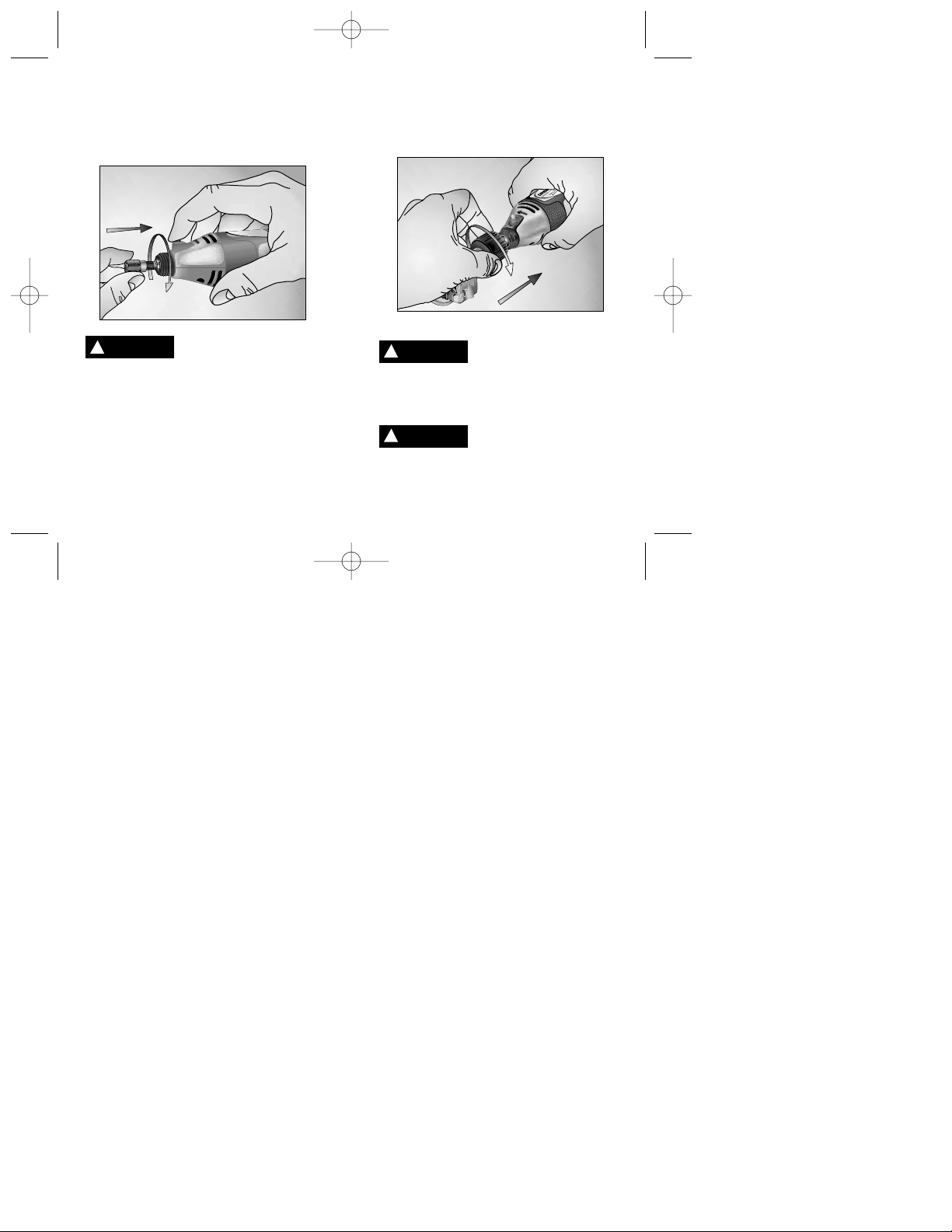

Note: If the collet nut and collet are not removed

from the motor shaft, the tool will not function

properly.

Step 4. Install the drive adapter on the motor shaft

and tighten.

To prevent damage to tool,

do not over tighten drive

adapter.Tighten the drive adapter finger tight and

then tighten an additional 1/3 turn with the wrench.

(Wrench is included with your rotary tool kit.)

!

CAUTION

12 13

Step 5. Screw the attachment onto your rotary tool

until the coupling is tight against the housing.Hand

tighten only.The attachment should be oriented on

your rotary tool so that the speed control switch on

the tool is easily accessible.

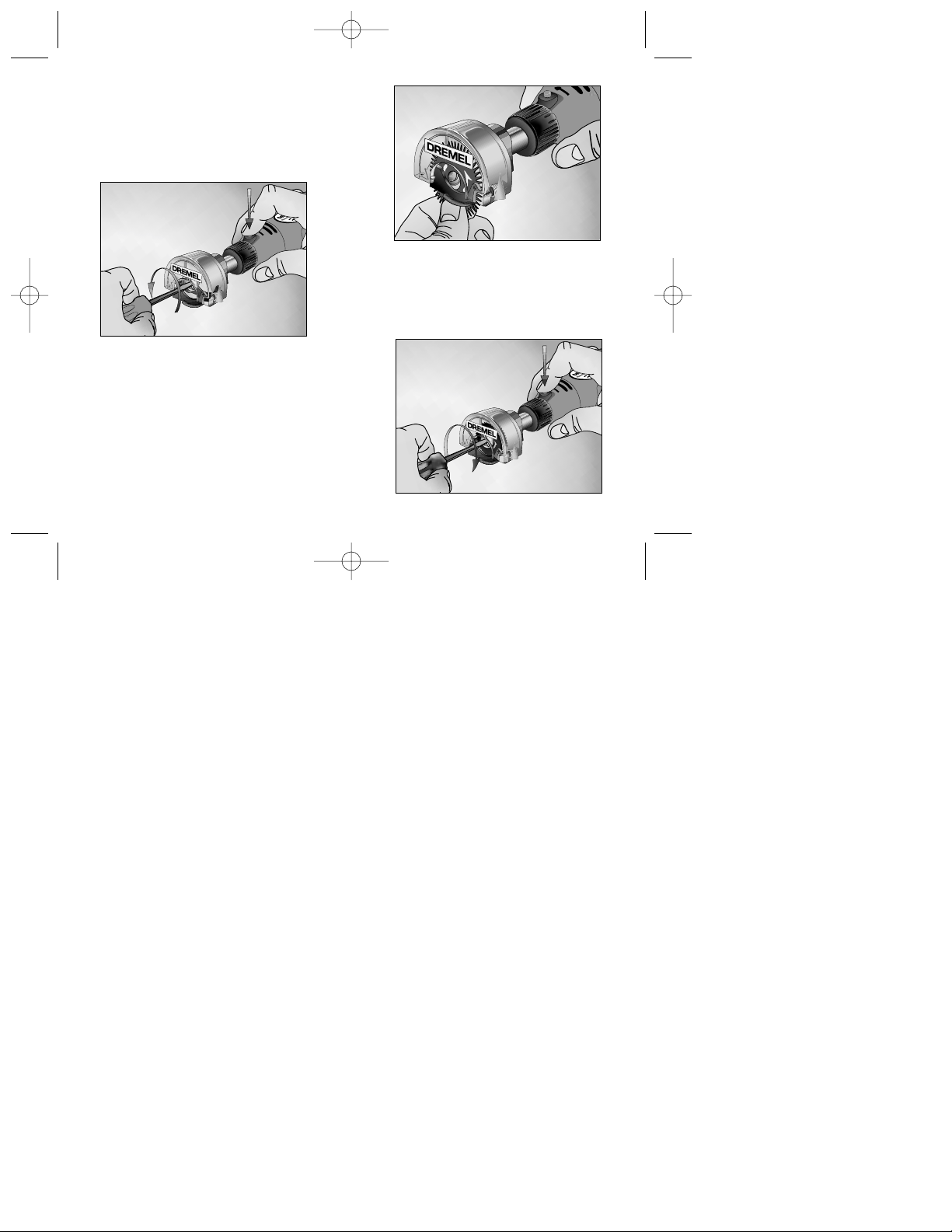

BLADE ASSEMBLY

Disconnect the plug of your

rotary tool from the power

source before making any assembly,

adjustments or changing accessories. Such

preventive safety measures reduce the risk of

starting the tool accidentally.

Always use Dremel Saw

Blades. Blades that do

not match mounting hardware will run

eccentrically,causing loss of control.

!

WARNING

!

WARNING

5716 Dremel 2.625x4.25 6/18/02 10:31 AM Page 12

Page 8

Step 4.Press the shaft lock button on your rotary

tool. Replace the washer and screw and tighten

securely.

Note: If washer is not used, screw will overtighten, and you will not be able to remove.

14 15

Step 1. Mount attachment onto your rotar y tool.

Be sure rotary tool is unplugged and the switch is

in the OFF position.

Step 2. Press the shaft lock button on your rotary

tool. Unscrew the screw from the mandrel and

remove washer.

Step 3. Pushing the guard foot up on the

attachment, place the blade onto the mandrel

arbor, making sure the arrows on the blade are

facing out and the blade is resting flat on the

shoulder of the mandrel arbor. Make sure the

blade teeth point in the same direction as arrows

on upper guard.

While retracting the lower guard, check operation

and condition, including the spring.

5716 Dremel 2.625x4.25 6/18/02 10:31 AM Page 14

Page 9

Always be sure that

hands or fingers do not

interfere with the free movement of the

lower guard.

Maintain a firm grip. Never force the rotary tool.

Use light and continuous pressure.

When cutting across the grain, the fibers of the

wood have a tendency to tear and lift.Advancing

the saw slowly minimizes this effect.

Clean lower guard

frequently to assure a

rapid return of lower guard.

This attachment is not

intended for abrasive cut

off wheels. Standard Dremel wheels will not

fit on mandrel.

!

WARNING

!

WARNING

16 17

TYPES OF CUTS

The saw blade provided with your attachment is

for both cross cuts and rip cuts. Ripping is

cutting lengthwise, with the grain of the wood.

Cross cutting is cutting against the grain.

Your rotary tool should be running at the set

speed before starting the cut, and turned off only

after completing the cut.

Primarily for use on wood or wood-like materials.

Other materials may cause blade to wear out

prematurely.Not for use on metal or masonr y.

DIRECTIONAL GUIDE

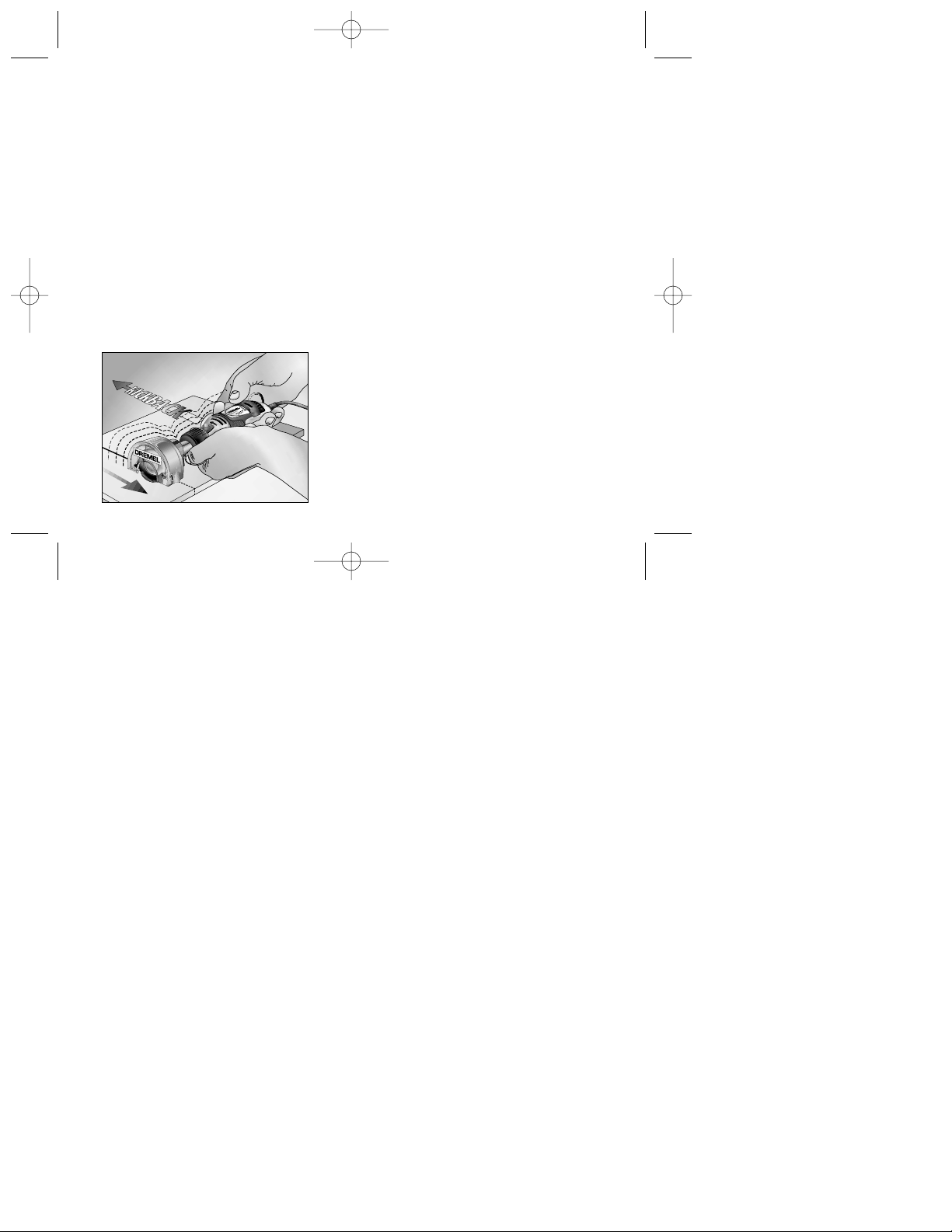

Feed direction for the rotary tool is right to left

only.

For a straight 90° cut, use the directional guide

on the left side of the guard to guide your cut.

This guide also shows feed direction. Make

sample cuts in scrap lumber to verify line of cut.

For minimum splintering,place the good side of

the material face down.

Maximum depth of cut is 1/4". Not for cutting

radii, curves or bevels.

Operating Instructions

!

WARNING

5716 Dremel 2.625x4.25 6/18/02 10:31 AM Page 16

Page 10

Figure 2

Feed Direction

SERVICE

Preventive maintenance

performed by unauthorized

personnel may result in misplacing of internal

components which could cause serious

hazard. We recommend that all tool service be

performed by a Dremel Service Facility.

TOOL LUBRICATION

Your saw attachment has been properly lubricated

and is ready to use.

Maintenance

!

WARNING

18 19

Support the panel or board close to the cut, as

shown in (Fig.2).Be sure that you cut through the

sheet or board only and not the table or work

bench.The two-by-fours used to raise and support

the work should be positioned so that the

broadest sides support the work and rest on the

table or bench. Do not support the work with the

narrow sides as this is an unsteady arrangement.

If the sheet or board to be cut is too large for a

table or work bench, use the supporting two-byfours on the floor and secure.

Figure1

Kickback

CUTTING LARGE SHEETS

Large sheets and long boards sag or bend,

depending on support. If you attempt to cut

without leveling and properly supporting the

piece, the blade will tend to bind, causing

KICKBACK and extra load on the rotary tool.(Fig. 1)

5716 Dremel 2.625x4.25 6/18/02 10:31 AM Page 18

Page 11

20 21

CLEANING

To avoid accidents always

disconnect the tool from

the power supply before cleaning or

performing any maintenance. The Mini Saw

Attachment may be cleaned most effectively with

a damp cotton swab or compressed dry air.

Always wear safety goggles when cleaning

tools with compressed air.

Ventilation openings and switch levers must be

kept clean and free of foreign matter. Do not

attempt to clean by inserting pointed objects

through openings.

Certain cleaning agents and

solvents damage plastic parts.

Some of these are: gasoline, carbon tetrachloride,

chlorinated cleaning solvents, ammonia and

household detergents that contain ammonia.

CARE OF BLADES

Blades become dull even from cutting regular

lumber.If you find yourself forcing the rotary tool

forward to cut instead of just guiding it through

the cut, chances are the blade is dull or coated

with wood pitch.

!

CAUTION

When cleaning gum and wood pitch from blade,

unplug the rotary tool and remove the blade.

Remember, blades are designed to cut, so

handle carefully. Wipe the blade with kerosene

or similar solvent to remove the gum and pitch.

A dull or damaged blade slows the speed of

cutting and places a heavier load on your rotary

tool, and can cause KICKBACK. Keep extra

blades on hand so you always have sharp,

efficient blades ready to replace a dull or

damaged one.

Use only Dremel Saw Blades with your saw

attachment.

!

WARNING

5716 Dremel 2.625x4.25 6/18/02 10:31 AM Page 20

Page 12

Lire et comprendre toutes

les instructions. Toute

négligence à suivre les instructions ci-dessous

peut causer des blessures corporelles.

GARDER CES INSTRUCTIONS

Garder les mains éloignées

de la zone de coupe et de la

lame.Garder l’autre main sur le bâti du moteur.

Si les deux mains tiennent l’outil,elles ne peuvent

pas être coupées par la lame. Tenir l’outil

solidement pour éviter toute perte de contrôle.Les

illustrations dans ce manuel montrent la prise des

mains sur l’outil. NE JAMAIS placer votre main

derrière la lame de la scie puisque le recul

pourrait la faire sauter vers l’arrière sur votre main.

Si l’usage que vous en faites ne permet pas de

la contrôler avec vos deux mains,gardez votre

main,vos doigts et votre corps d’un côté ou de

l’autre de la scie mais pas en face de la lame

de la scie. LE RECUL pourrait faire sauter la scie

vers l’arrière.(Voir « Les causes et la prévention du

recul par l’utilisateur.»)

Avancer la lame seulement dans la direction

où les dents de scie sont orientées vers la

pièce. « Une coupe tangentielle en a valant » en

amenant la scie dans le matériau de telle sorte

22 23

!

AVERTISSEMENT

Règles de sécurité pour les outils électriques

!

DANGER

Règles de sécurité instrument pour mini-scie

que les dents descendent dans le matériau, fera

monter la scie hors du matériau et la fera sauter

de façon incontrôlable en direction d’où on l’a

alimentée incorrectement.

Soyez extrêmement prudent quand vous

coupez des tiges rondes ou quand vous

approchez des coins ou du rebord de la pièce.

La lame peut gripper sur le rebord de la pièce et

provoquer un recul. Ne pas couper le long d’un

arrondi ou d’une ligne courbe. Un mouvement de

recul se produira si on tente d’effectuer un

mouvement de coupe courbe.

Ne pas mettre ses mains sous le travail. La

garde ne peut vous protéger de la lame

par-dessous.

Vérifier si la garde inférieure est fermée

correctement avant usage. Ne jamais brider

ou attacher la garde inférieure en

position ouverte. Si la scie est échappée

accidentellement, la garde inférieure peut être

pliée. Assurez-vous que la garde se déplace

librement et ne touche pas la lame ni aucune

autre pièce.

Vérifier le fonctionnement du ressort de la

garde inférieure. Si la garde et le ressort ne

fonctionnent pas correctement,ils doivent être

réparés avant usage. La garde inférieure peut

fonctionner difficilement à cause de pièces

endommagées, de dépôts gommeux ou de

5716 Dremel 2.625x4.25 6/18/02 10:34 AM Page 22

Page 13

24 25

l’accumulation de débris. Débrancher la fiche.

Enlever la lame périodiquement,nettoyer la garde

inférieure et la zone du moyeu ou souffler pour

nettoyer avec de l’air comprimé.

Toujours vérifier que la garde inférieure

recouvre la lame avant de placer l’outil sur

l’établi ou sur le sol. Une lame non protégée qui

tourne coupera tout ce qui est sur son chemin.

Sachez combien de temps il faut à la lame pour

s’arrêter après l’interruption du courant.

NE JAMAIS tenir une pièce à couper dans vos

mains ou de travers sur vos jambes. Il est

important de supporter votre travail correctement

afin de minimiser l’exposition du corps, le

grippage ou une perte de contrôle.

Toujours utiliser des lames de la bonne

grandeur et de la bonne forme d’alésage

central. Les lames qui ne s’ajustent pas avec les

ferrures de fixation de la scie tourneront

excentriquement causant une perte de contrôle.

Ne pas faire tourner la scie quand vous la

transportez à vos côtés. La garde inférieure

peut être ouverte au contact de vos vêtements.

Toucher accidentellement la lame de scie qui

tourne peut causer des blessures corporelles

sérieuses.

Sachez comment mettre l’interrupteur à

glissière à « ARRÊT » en cas d’urgence. Si

l’interrupteur N’ARRÊTE PAS l’outil rapidement,

débrancher le immédiatement.

CAUSES ET PRÉVENTION DU

RECUL PAR L’UTILISATEUR

Le recul est une réaction soudaine à une lame

de scie pincée, grippée ou mal alignée,

provoquant un mouvement incontrôlé qui

soulève la scie hors de la pièce de travail vers

l’utilisateur.

Quand la lame est pincée ou grippée solidement

par le trait qui se referme, la lame s’arrête et

la réaction du moteur repousse l’appareil

rapidement vers l’utilisateur.

5716 Dremel 2.625x4.25 6/18/02 10:34 AM Page 24

Page 14

26 27

Si la lame devient tordue ou mal alignée dans la

coupe, les dents de l’arête arrière de la lame

peuvent creuser dans la surface supérieure du

bois et provoquer la montée de la lame hors du

trait et sauter vers l’utilisateur.

Le recul est le résultat d’une mauvaise

utilisation de l’outil et/ou du mauvais usage

des procédures ou conditions d’utilisation et

peut être évité en prenant les précautions

ci-dessous :

Maintenir une prise solide avec les deux

mains sur l’outil et placer votre corps et vos

bras pour vous permettre de résister aux

forces de RECUL.Les forces du RECUL peuvent

être contrôlées par l’utilisateur si les mesures

de précautions sont prises.

Quand la lame grippe, ou quand vous

interrompez une coupe, quelle que soit la

raison,éteindre l’outil et le tenir sans bouger

dans le matériau jusqu’à l’arrêt complet de

la lame. Ne jamais tenter d’enlever la scie

du travail ou de reculer l’outil pendant que

la lame tourne sinon, un RECUL peut se

produire.Rechercher les raisons du grippage et

prendre les mesures correctives afin d’en

éliminer la cause. Du bois humide, du bois vert

ou du bois traité sous pression ainsi que la

plupart des plastiques nécessitent une attention

spéciale lors de la coupe afin de prévenir le

RECUL. Éviter de couper des clous. Rechercher

et enlever tous les clous du bois avant

de couper.

Lors du redémarrage de la scie dans une

pièce, centrer la lame dans le trait et

s’assurer que les dents de scie ne mordent

pas dans le matériau. Si la lame de scie

grippe,elle peut monter ou RECULER de la pièce

dès que l’outil redémarre.

Supporter les panneaux pour minimiser les

risques de pincement de lame et de RECUL.

Les grands panneaux ont tendance à s’affaisser

sous leur propre poids. Des supports doivent

être placés sous le panneau des deux côtés,

près de la ligne de coupe et près de l’arête du

panneau.

Ne pas utiliser de lame émoussée ou

endommagée. Des lames mal aiguisées ou mal

réglées produisent un trait étroit favorisant une

friction excessive, le grippa ge de la lame et le

RECUL.

Soyez doublement prudent quand vous faites

une découpe à l’emporte-pièce dans un mur

existant ou tout autre endroit aveugle. La lame

proéminente pourrait couper des objets qui

peuvent causer du RECUL.

5716 Dremel 2.625x4.25 6/18/02 10:34 AM Page 26

Page 15

28

29

Symboles :

IMPORTANT : Certains des symboles suivants

peuvent être utilisés sur votre outil. Veuillez les

étudier et apprendre leur signification. Une

bonne interprétation de ces symboles vous

permettra de faire une utilisation plus efficace et

plus sécuritaire.

Symbole Nom Désignation/Explication

V Volts Tension (Potentielle)

A Ampères Courant

Hz Hertz Fréquence (cycles par seconde)

W Watt Puissance

kg Kilogrammes Poids

min Minutes Temps

s Secondes Temps

ø Diamètre

La taille des mèches, des meules,etc.

noVitesse à vide Vitesse de rotation, à vide

.../min Tours ou Tours,coups, vitesse en surface,

mouvement orbites,etc. par minute

par minute

O

À la position « arrêt»

Vitesse zéro, couple zéro

1, 2, 3, ... Réglage du Vitesse,couple ou réglages de

I, II, III, sélecteur position. Le chiffre le plus élevé

indique la plus grande vitesse

o

Sélecteur variable à

La vitesse augmente à

l’infini avec « arrêt »

partir de 0

Flèche

Actionner dans le sens de la flèche

Courant alternatif Type ou caractéristique de courant

Courant continu Type ou caractéristique de courant

Ce symbole indique que cet outil est

approuvé par les Laboratoires des

Assureurs.

Ce symbole indique que cet outil est

approuvé aux Normes Canadiennes par

les Laboratoires des Assureurs.

Ce symbole indique que cet outil est

approuvé par l’Association Canadienne

de Normalisation.

Ce symbole indique que cet outil est

approuvé par les Laboratoires des Assureurs

et homologué selon les Normes Canadiennes

par les Laboratoires des Assureurs.

Ce symbole indique que cet outil se

conforme aux Normes Mexicaines NOM.

Symbole Nom Désignation/Explication

Courant alternatif Ty pe ou caractéristique de courant

ou continu

Construction Désigne des outils de

classe II construction à double isolation

Borne de terre Borne de mise à la terre

Symbole Alerte l’utilisateur aux

d’avertissement messages d’avertissement

Sceau NiCad Indique le programme de

RBRC recyclage de piles NiCad

!

Lire le livre d’instruction.

5716 Dremel 2.625x4.25 6/18/02 10:34 AM Page 28

®

C

®

CUS

®

Page 16

30 31

SawGuardExploded.ai

Débrancher la fiche de

votre outil rotatif de la

source d’alimentation avant d’effectuer un

assemblage, des ajustements ou des

changements d’accessoire. Assurez-vous que

l’interrupteur est à la position « ARRÊT» avant

de le brancher. Ces mesures préventives de

sécurité réduisent le risque de mettre l’outil en

marche accidentellement.

Description fonctionnelle et spécifications

!

AVERTISSEMENT

Adaptateur

d’entraînement

Coupleur

Guide

directionnel

Garde inférieure

Lame

Vis

Rondelle

Pour utilisation avec les

modèles de Dremel 275,

285, 395,398 et 780.

Capacité maximum :

Lame – 1-1/4 po (31,8 mm)

Alésage central –

0,363 po (9,22 mm)

Profondeur à 90° –

1/4 po (6,5 mm)

Débrancher la fiche de

votre outil rotatif de la

source d’alimentation avant d’effectuer

un assemblage, des ajustements ou de

changements d’accessoires. Ces mesures

préventives de sécurité réduisent le risque de

mettre l’outil en marche accidentellement.

INSTALLATION D’INSTRUMENTS

SUR LA MINI-SCIE

Il est extrêmement important de lire soigneusement

et de suivre les directions ci-dessous pour

assembler l’Instrument pour mini-scie à l’outil rotatif

et s’assurer que l’outil fonctionnera correctement.

Pour bien assembler l’Instrument de mini-scie à

l’outil rotatif,TROIS pièces doivent être enlevées de

l’outil : le capuchon du boîtier,l’écrou de la douille

et la douille.

Assemblage

!

AVERTISSEMENT

5716 Dremel 2.625x4.25 6/18/02 10:34 AM Page 30

Page 17

Étape 1. Presser le bouton de blocage, dévisser

et enlever l’écrou de la douille.

Étape 2. Enlever la douille.

Étape 3. Dévisser le capuchon du boîtier

de l’outil.

Note : Si l’écrou de douille et la douille ne

sont pas enlevés de l’arbre du moteur,l’outil

ne fonctionnera pas correctement.

32 33

5716 Dremel 2.625x4.25 6/18/02 10:35 AM Page 32

Page 18

34 35

Pour éviter d’endommager

l’outil, ne pas trop serrer

l’adaptateur d’entraînement. Serrer l’adaptateur

d’entraînement à la main puis,serrer de 1/3 de tour

additionnel avec une clé. (La clé est incluse dans

votre ensemble pour outil rotatif.)

Étape 5. Visser l’accessoire sur votre outil rotatif

jusqu’à ce que le coupleur soit serré contre le

boîtier. Serrer à la main seulement. L’accessoire

devrait être orienté sur votre outil rotatif de telle

sorte que le contacteur de régulateur de vitesse de

l’outil soit facilement accessible.

!

CAUTION

Étape 4. Poser l’adaptateur d’entraînement sur

l’arbre du moteur et serrer.

ASSEMBLAGE DE LA LAME

Débrancher la fiche de

votre outil rotatif de la

source d’alimentation avant d’effectuer un

assemblage, des ajustements ou de changer

des accessoires. Ces mesures préventives de

sécurité réduisent le risque de mettre l’outil en

marche accidentellement.

Toujours utiliser des lames

de scie Dremel. Des lames

qui ne s’ajustent pas aux ferrures de fixation

tourneront excentriquement, provoquant une

perte de contrôle.

!

AVERTISSEMENT

!

AVERTISSEMENT

5716 Dremel 2.625x4.25 6/18/02 10:35 AM Page 34

Page 19

36 37

Étape 1. Poser l’accessoire sur l’outil rotatif,

assurez-vous que l’outil rotatif n’est pas branché

et que l’interrupteur est à la position « ARRÊT ».

Étape 2.Presser sur le bouton de blocage de votre

outil rotatif. Dévisser la vis du mandrin et enlever

la rondelle.

Étape 3. En poussant la base de la garde vers le

haut sur l’équipement, placer la lame sur l’arbre

du mandrin, en s’assurant que les flèches sur la

lame pointent vers l’extérieur et que la lame

repose à plat sur l’épaulement de l’arbre du

mandrin. S’assurer que les dents de la lame

pointent dans la même direction que les flèches

de la garde supérieure.

Pendant le retrait de la garde inférieure, vérifier

le fonctionnement et l’état général, incluant

le ressort.

Étape 4.Presser le bouton de blocage de l’arbre sur

votre outil rotatif. Replacer la rondelle et la vis et

serrer de façon sécuritaire.

Note : Si la rondelle n’est pas utilisée,la vis sera

trop serrée et vous ne pourrez pas l’enlever.

5716 Dremel 2.625x4.25 6/18/02 10:35 AM Page 36

Page 20

GENRES DE COUPES

La lame de scie fournie avec votre instrument

est pour la coupe croisée et la refente. La

refente est la coupe sur le sens de la longueur,

avec le grain du bois. La coupe croisée est une

coupe en travers du grain du bois.

Votre outil rotatif devrait tourner à la vitesse

choisie avant de commencer la coupe, et mis en

position « arrêt » seulement après avoir complété

la coupe.

Principalement conçue pour être utilisée sur du

bois ou des matériaux semblables au bois.

D’autres matériaux peuvent provoquer l’usure de

la lame prématurément.Elle n’est pas conçu pour

être utilisé sur du métal ou de la maçonnerie.

GUIDE DIRECTIONNEL

La direction d’alimentation pour l’outil rotatif est

de droite à gauche seulement.

Pour une coupe nette de 90°, utiliser le guide

directionnel du côté gauche de la garde pour

guider votre coupe. Ce guide montre aussi la

direction de l’alimentation. Faites des coupes

d’essai dans du bois de rebut pour vérifier la

ligne de coupe. Pour un minimum d’écaillage,

placer le bon côté du matériau vers le bas.

Mode d’emploi

38 39

La profondeur maximum de la coupe est de

1/4 po. N’est pas conçu pour couper en arrondi,

des courbes ou des chanfreins.

Assurez-vous que les

mains ou les doigts

n’interfèrent pas avec le libre déplacement

de la garde inférieure.

Maintenez un prise solide. Ne jamais forcer

l’outil rotatif. Utiliser un pression légère et

continue.

Quand vous coupez en travers du grain, les

fibres du bois ont tendance à se déchirer et

monter. Une avance lente de la scie minimise

cet effet.

Nettoyer souvent la garde

inférieure pour s’assurer

qu’elle revienne rapidement en place.

Cet équipement n’est pas

conçu pour les meules à

découper. Les meules régulières Dremel ne

s’ajusteront pas sur le mandrin.

!

AVERTISSEMENT

!

AVERTISSEMENT

!

AVERTISSEMENT

5716 Dremel 2.625x4.25 6/18/02 10:35 AM Page 38

Page 21

40 41

Figure 1

Recul

LA COUPE DE GRANDES FEUILLES

Les grandes feuilles et longues planches

s’affaissent ou plient, selon le support. Si vous

essayez de couper sans mettre au niveau et sans

supporter correctement la pièce, la lame aura

tendance à plier,ce qui provoquera un RECUL et

une charge additionnelle sur l’outil rotatif (Fig.1).

Supporter le panneau ou la planche près de la

coupe tel qu’illustré dans (Fig. 2). Bien s’assurer

de couper seulement dans la feuille ou la planche

et non dans la table ou l’établi. Les colombages

utilisés pour surélever et supporter le travail

devraient être placés de telle sorte que les côtés

les plus larges supportent le travail et reposent sur

la table ou l’établi.Ne pas supporter le travail avec

le côté étroit puisque c’est un ensemble instable.

Si la feuille ou la planche à couper est trop grande

pour la table ou l’établi,utiliser les colombages sur

le plancher et les arrimer.

Figure 2

Direction

d’alimentation

SERVICE

L ’entretien préventif effectué

par du personnel non

autorisé peut résulter en un dérèglement des

organes internes, ce qui pourrait représenter

un danger important. Nous recommandons que

tout entretien d’outil soit effectué par un atelier

d’entretien Dremel.

LUBRIFICATION DE L’OUTIL

Votre équipement de scie a été correctement

lubrifié et est prêt pour utilisation.

Entretien

!

AVERTISSEMENT

5716 Dremel 2.625x4.25 6/18/02 10:35 AM Page 40

Page 22

42 43

NETTOYAGE

Pour éviter des accidents,

toujours débrancher l’outil

de la source d’alimentation avant le nettoyage.

L’instrument pour Mini-Scie peut être nettoyé

efficacement avec un coton-tige ou avec de l’air

comprimé.

Toujours porter des lunettes de sécurité lors

du nettoyage de l’outil avec de l’air comprimé

Les orifices de ventilation et leviers d’interrupteurs

doivent être propres et libres de tout produit

étranger. N’essayez pas de nettoyer en insérant

des objets pointus dans les orifices.

Certains agents nettoyants

et solvants endommagent

les pièces en plastiques. Parmi eux, il y a

l’essence, le tétrachlorure de carbone, les solvants

de nettoyage chlorés, l’ammoniaque et les

détergents d’entretien domestique qui contiennent

de l’ammoniaque.

L’ENTRETIEN DES LAMES

Les lames s’émoussent même en coupant du bois

ordinaire. Si vous vous rendez compte que vous

devez forcer l’outil rotatif pour couper au lieu de le

guider simplement dans sa coupe, il y a des

chances que la lame soit émoussée ou recouverte

de poix résine.

Quand vous nettoyez la gomme ou la poix résine

de la lame, débrancher l’outil rotatif et enlever la

lame. Souvenez-vous, les lames sont conçues

pour couper, donc manipuler avec précaution.

Essuyer la lame avec du kérosène ou un

solvant semblable pour enlever la gomme ou la

poix résine.

Une lame émoussée ou endommagée ralentit

la vitesse de coupe et place une charge

additionnelle sur votre outil rotatif et peut

provoquer un RECUL. Garder des lames

supplémentaires sous la main afin de toujours

avoir des lames aiguisées et efficaces pour

remplacer une lame émoussée ou endommagée.

Utiliser seulement des lames de scie Dremel avec

votre instrument de scie.

!

CAUTION

!

AVERTISSEMENT

5716 Dremel 2.625x4.25 6/18/02 10:37 AM Page 42

Page 23

45

el avance de la cuchilla de tal forma que los

dientes desciendan en el material, hará que la

cuchilla salte fuera del material y salte de manera

descontrolada en la dirección de este avance

inapropiado.

Sea extremamente cuidadoso cuando esté

cortando varas redondas o cuando se acerque

a las esquinas o al borde de la pieza de

trabajo. La cuchilla se puede enredar en el borde

de la pieza de trabajo y causar contragolpe.

No corte a través de un radio o de una línea de

corte curva. Un movimiento de corte curvo

producirá contragolpe. No acceda por debajo del

área de trabajo. La guarda no puede protegerlo

por debajo de la cuchilla.

Revise que la guarda inferior esté cerrada

antes de cada uso. Nunca sostenga o amarre

la guarda inferior en posición abierta. Si la

sierra se cae accidentalmente la guarda inferior se

puede doblar. Cerciórese de que la guarda se

mueva libremente y que no toque la cuchilla ni

ninguna otra parte.

Revise la operación del resorte de la guarda

inferior. Si la guarda y el resorte no están

operando de manera apropiada, deben ser

reparadas antes de su uso. La guarda inferior

puede operar lentamente debido a partes

averiadas, depósitos pegajosos o una

acumulación de residuos. Desconecte el cable de

la electricidad. Periódicamente quite la cuchilla,

Normas de seguridad de la herramienta eléctrica

Lea y entienda todas las

instrucciones. No seguir las

siguientes instrucciones puede resultar en

lesiones personales graves.

GUARDE ESTAS INSTRUCCIONES

Mantenga las manos lejos

del área de corte y de la

cuchilla. Sostenga con una mano la cubierta

del motor. Si ambas manos sostienen la

herramienta la cuchilla no las cortará.Sostenga la

herramienta firmemente para prevenir la pérdida

de control. Las figuras en este manual ilustran el

soporte típico de la herramienta.NUNCA ponga su

mano detrás de la cuchilla de la sierra ya que el

contragolpe puede causar que la herramienta

salte hacia atrás sobre su mano.

Si su aplicación no permite el control de la

herramienta con las dos manos, mantenga su

mano,dedos y cuerpo al lado de la cuchilla de

la sierra, pero no en línea con la misma. El

CONTRAGOLPE puede hacer que la sierra

salte hacia atrás (ver "Causas del contragolpe y

medidas de prevención del operador para evitarlo").

Avance la cuchilla sólo en la dirección en que

los dientes de la cuchilla estén pasando a

través de la pieza de trabajo. El corte forzado o

Normas de seguridad del acople de minisierra

!

ADVERTENCIA

!

PELIGRO

44

5716 Dremel 2.625x4.25 6/18/02 10:37 AM Page 44

Page 24

47

CAUSAS DEL CONTRAGOLPE Y MEDIDAS DE

PREVENCION DEL OPERADOR PARA EVITARLO:

El contragolpe es una reacción repentina de una

cuchilla de sierra apresada, ligada o desalineada,

causando que la sierra descontrolada se levante y

se salga de la pieza de trabajo hacia el operador.

Cuando la cuchilla está apresada o muy enredada

con el trozo que está cortando, la cuchilla se

atasca y la reacción del motor hace que la unidad

se mueva rápidamente hacia el operador.

Si la cuchilla se tuerce o se desalínea del corte,los

dientes en el borde posterior de la cuchilla pueden

penetrar la superficie de la madera ocasionando

que la cuchilla se salga del trozo de corte y salte

hacia el operador.

46

limpie la guarda inferior y el área del cubo, o

límpiela con aire comprimido.

Siempre fíjese que la guarda inferior esté

cubriendo la cuchilla antes de colocar la

herramienta en el banco o en el suelo. Una

cuchilla en reposo desprotegida hará que la sierra

corte cualquier cosa que esté a su paso. Preste

atención al tiempo que se demora la cuchilla en

parar después de que el interruptor se apaga.

NUNCA mantenga la pieza que está cortando

en sus manos o agarrada con sus piernas. Es

importante sostener la pieza de trabajo de manera

apropiada para minimizar la exposición del

cuerpo,evitar que se trabe la cuchilla o la pérdida

de control.

Siempre use cuchillas con orificios del eje de

tamaño y forma adecuados. Las cuchillas que

no concuerden con los tornillos y herramientas de

montaje de la sierra se moverán de manera

eccéntrica, causando la pérdida de control.

No corra mientras que esté cargando la

herramienta. La guarda inferior puede abrirse

por contacto con su ropa. El contacto accidental

con la cuchilla de la sierra en rotación puede

ocasionar lesiones personales graves.

Sepa cómo apagar el interruptor corredizo en

una emergencia. Si el interruptor no apaga la

herramienta rápido, desconecte la herramienta

inmediatamente.

5716 Dremel 2.625x4.25 6/18/02 10:37 AM Page 46

Page 25

49

que los dientes de la sierra no estén atascados

en el material. Si la cuchilla de la sierra se está

agarrando, puede levantarse o CONTRAGOLPEAR.

Sostenga los páneles para minimizar el riesgo

de que la cuchilla se trabe o CONTRAGOLPEE.

Los páneles grandes tienden a hundirse por

su propio peso. Los soportes deben colocarse

debajo del pánel en ambos lado, cerca de la línea

de corte y cerca del borde del pánel.

No use cuchillas sin filo o averiadas. Las

cuchillas sin filo o instaladas de manera

inapropiada producen un corte estrecho causando

fricción excesiva, traba de la cuchilla y

CONTRAGOLPE.

Sea extremamente cuidadoso cuando haga un

"corte de bolsillo" en una pared u otra área

ciega. La cuchilla sobresaliente puede cortar

objetos que pueden producir CONTRAGOLPE.

Símbolos:

IMPORTANTE: Algunos de los siguientes símbolos

pueden ser utilizados en su herramienta. Por favor

estúdielos y aprenda su significado. Su apropiada

interpretación le permitirá operar la herramienta

mejor y de manera más segura.

El contragolpe es el resultado del uso inapropiado

y/o los procedimientos o condiciones de operación

incorrectos y puede evitarse tomando las

precauciones adecuadas como se dan a

continuación:

Mantenga la herramienta agarrada

firmemente con ambas manos y su cuerpo y

brazo de tal manera que pueda resistir la

fuerza del CONTRAGOPLE. El operador puede

controlar la fuerza del CONTRAGOLPE si se toman

las precauciones adecuadas.

Cuando la cuchilla se esté trabando o cuando

el corte se esté interrumpiendo por cualquier

razón, apague la herramienta y manténgala

sin moverla en el material hasta que la

cuchilla pare completamente. Nunca intente

retirar la sierra o halar la herramienta

mientras que la cuchilla esté moviéndose ya

que puede haber un CONTRAGOLPE. Vea por

qué la cuchilla se está trabando pasa y tome

las acciones correctivas del caso. La madera

húmeda,verde,o tratada a presión y la mayoría de

los plásticos requieren atención especial durante

la operación de corte para prevenir el

CONTRAGOLPE. Evite cortar puntillas. Busque y

remueva todas las puntillas de la madera antes

de cortar.

Cuando comience a trabajar con la sierra de

nuevo, céntrela en el trozo de madera y revise

48

5716 Dremel 2.625x4.25 6/18/02 10:37 AM Page 48

Page 26

51

Este símbolo designa que esta

herramienta está listada por UL.

Este símbolo designa que esta

herramienta está listada en los

Estándares Canadienses por UL.

Este símbolo designa que esta

herramienta está listada por la

Asociación Canadiense de Estándares.

Este símbolo designa que esta

herramienta está listada por UL y en

los Estándares Canadienses por UL.

Este símbolo designa que esta

herramienta cumple con los

Estándares Mexicanos NOM.

Símbolo Nombre Designación/Explicación

Corriente alternante Tipo o una característica

odirecta de corriente

Construcción Designa aislado doble

clase II Herramientas de construcción

Terminal con Terminal con toma a tierra

polo a tierra

Símbolo de Alerta al usuario de

precaución mensajes de precaución

Sello Ni-Cad RBRC Designa el programa de reciclaje

de la batería Ni-Cad

!

Lea el Manual de instrucciones.

Símbolo Nombre Designación/Explicación

V Voltios Voltage (potencial)

A Amperios Corriente

Hz Hertz Frecuencia (ciclos por segundo)

W Vatios Energía

kg Kilogramos Peso

min Minutos Tiempo

s Segundos Tiempo

ø Diámetro

Tamaño de las brocas para taladro,

ruedas de esmeril, etc.

noVelocidad sin carga

Velocidad de rotación,sin

ninguna carga

.../min Revoluciones o Revoluciones, golpes, velocidad

alternaciones de superficie, órbitas,etc.

por minuto por/min.

O Posición "Off" Velocidad cero, cero torsión…

1, 2, 3, ... Selector de ajustes Ajustes de velocidad, torsión o

I, II, III posición.Un número mayor

significa mayor velocidad

o Selector variable La velocidad aumenta desde el

infinitamente con punto cero

"Off"

Flecha Acción en la dirección

de la flecha

Corriente alternante Tipo o una característica

de corriente

Corriente directa Tipo o una característica

de corriente

50

5716 Dremel 2.625x4.25 6/18/02 10:37 AM Page 50

®

C

®

CUS

®

Page 27

53

Desconecte su herramienta

rotatoria de la electricidad

antes de hacer cualquier ensamble, ajuste

o cambio de accesorios. Esta medida de

precaución reduce el riesgo de activar la

herramienta accidentalmente.

INSTALACION DEL ACOPLE DE MINISIERRA

Es extremamente importante leer y seguir

cuidadosamente las siguientes instrucciones para

ensamblar el Acople de minisierra en su

herramienta rotatoria y asegurar que la

herramienta funcione de manera apropiada.

Para instalar adecuadamente el Acople de

minisierra en la herramienta rotatoria, se deben

quitar tres elementos de la herramienta: la tapa de

la cubierta,la tuerca del collarín y el collarín.

Ensamble

!

ADVERTENCIA

52

SawGuardExploded.ai

Desconecte su herramienta

rotatoria de la electricidad

antes de hacer cualquier ensamble, ajuste o

cambio de accesorios. Cerciórese de que el

interruptor está en la posición "Off" antes de

enchufarlo.Esta medida de precaución reduce el

riesgo de activar la herramienta accidentalmente.

Descripción funcional y especificaciones

!

ADVERTENCIA

Adaptador del

mecanismo

de

transmisión

Acoplamiento

Guía

direccional

Guarda inferior

Cuchilla

Tornillo

Arandela

Para uso con los modelos

Dremel 275, 285, 395, 398 y

780.

Capacidades máximas:

Cuchilla - 1-1/4" (31.8 mm)

Agujero de arbor - .363"

(9.22 mm)

Profundidad a 90° - 1/4"

5716 Dremel 2.625x4.25 6/18/02 10:37 AM Page 52

Page 28

Paso 3. Desa tornille la tapa de la cubierta de la

herramienta.

55

Nota: si la tuerca del collarín y el collarín no se

remueven del eje del motor,la herramienta no

funcionará de manera apropiada.

Paso 1. Oprima el botón del seguro del eje,

desatornille y remueva la tuerca del collarín.

Paso 2.Remueva el collarín.

54

5716 Dremel 2.625x4.25 6/18/02 10:37 AM Page 54

Page 29

57

ENSAMBLE DE LA CUCHILLA

Desconecte su herramienta

rotatoria de la electricidad

antes de hacer cualquier ensamble, ajuste

o cambio de accesorios. Esta medida de

precaución reduce el riesgo de activar la

herramienta accidentalmente.

Siempre use Cuchillas

para sierra Dremel. Las

cuchillas que no concuerden con los tornillos

y herramientas de montaje de la sierra se

moverán de manera eccéntrica, causando la

pérdida de control.

!

ADVERTENCIA

!

ADVERTENCIA

Paso 4. Instale el adaptador de drive en el eje del

motor y apriete.

Para prevenir daño a la

herramienta, no apriete

demasiado el adaptador de drive. Apriete el

adaptador de drive con la mano y luego 1/3 de vuelta

con la llave (la llave está incluida en la caja del la

herramienta rotatoria).

Paso 5. Atornille el acople a su herramienta

rotatoria hasta que el acoplamiento esté apretado

contra la cubierta.Apriete con la mano únicamente.

El acople debe estar orientado en su herramienta

rotatoria de tal manera que el interruptor de control

de la velocidad quede a fácil acceso.

!

CAUTION

56

5716 Dremel 2.625x4.25 6/18/02 10:37 AM Page 56

Page 30

59

Paso 4. Oprima el botón del seguro del eje en su

herramienta rotatoria. Coloque la arandela y el

tornillo y apriete de manera segura.

Nota: Si no se usa la arandela, el tornillo

quedará demasiado apretado y no podrá

retirarlo.

Paso 1. Monte el acople en su herramienta

rotatoria. Cerciórese de que la herramienta

rotatoria esté desconectada y el interruptor en la

posición "Off".

Paso 2. Oprima el botón del seguro del eje en su

herramienta rotatoria.Afloje el tornillo del mandril

y remueva la arandela.

58

Paso 3. Empujando el pie de la guarda en el

acople hacia arriba,coloque la cuchilla en mandril

del árbol eje, cerciorándose de que las flechas en

la cuchilla queden hacia afuera y la cuchilla quede

plana en el hombro del mandril del árbol.

Asegúrese de que los dientes de la cuchilla

apunten en la misma dirección que las flechas en

la guarda superior.

Cuando la guarda inferior se contraiga, revise la

operación y las condiciones,incluyendo el resorte.

5716 Dremel 2.625x4.25 6/18/02 10:37 AM Page 58

Page 31

61

Asegúrese siempre de que

sus manos y dedos no

interfieran con el movimiento libre de la

guarda inferior.

Sostenga la herramienta firmemente. Nunca la

fuerce. Use luz y presión contínua.

Cuando corte a través de la fibra, las fibras de

la madera tienen la tendencia de rajarse y

levantarse. Avanzar despacio con la sierra

minimiza este efecto.

Limpie la guarda inferior

con frecuencia para

asegurar un retorno rápido de la misma.

Este acople no se debe

usar con los discos de

corte abrasivos. Los discos estándar Dremel

no se ajustarán en el mandril.

!

ADVERTENCIA

!

ADVERTENCIA

!

ADVERTENCIA

CORTE DE HOJAS GRANDES

Las hojas grandes y las tablas largas se hunden

o doblan dependiendo del soporte. Si intenta

cortar sin nivelar y sostener la pieza de manera

apropiada, la cuchilla tenderá a trabarse,

causando CONTRAGOLPE y presión extra en la

herramienta rotatoria (fig. 1).

60

TIPOS DE CORTE

La cuchilla de sierra que se incluye sirve para

hacer cortes cruzados y a lo largo. El corte a lo

largo se hace de acuerdo con la fibra de la

madera. El corte cruzado se hace contra la fibra

de la madera.

Su herramienta rotatoria debe estar funcionando a

la velocidad ajustada antes de comenzar el corte,

y debe apagarse sólo después de terminar el

corte.

Para uso primariamente en madera o materiales

similares. Otros materiales pueden causar

desgaste prematuro de la cuchilla. No se debe

usar en metal o mampostería.

GUIA DIRECCIONAL

La dirección de avance de la herramienta es de

derecha a izquierda únicamente.

Para un corte recto de 90°,use la guía direccional

al lado izquierdo de la guarda para guiar su corte.

Esta guía también muestra la dirección de avance

del corte. Haga cortes de prueba en pedazos de

madera de desperdicio para verificar la línea de

corte. Para minimizar que el material se astille,

ponga el lado bueno del material hacia abajo.

La profundidad máxima de corte es 1/4". No es

para cortar radios, curvas o biselados.

Instrucciones de operación

5716 Dremel 2.625x4.25 6/18/02 10:37 AM Page 60

Page 32

63

fig. 2

Dirección

del avance

SERVICIO

El mantenimiento preventivo

realizado por personal no

autorizado puede ocasionar la colocación

errada de componentes internos lo cual puede

causar serios peligros. Recomendamos que

todos los servicios para la herramienta sean

ejecutados por un Centro de servicio Dremel.

LUBRICACION DE LA HERRAMIENTA

Su acople de sierra ha sido lubricado

apropiadamente y está listo para su uso.

Mantenimiento

!

ADVERTENCIA

62

fig. 1

Contregolpe

Sostenga el pánel o la tabla cerca del corte,como

se muestra en la (fig. 2). Asegúrese de estar

cortando la hoja o la tabla únicamente y no la

mesa o el banco de trabajo. Los dos por cua tro

usados para levantar y sostener el trabajo deben

colocarse de tal forma que los lados más amplios

sostengan el trabajo y descansen sobre la mesa o

el banco. No sostenga el trabajo con los lado

estrechos ya que este ajuste es inestable. Si la

hoja o la tabla que se va a cortar es muy grande

para la mesa o el banco,use los soportes dos por

cuatro en el suelo y asegúrela.

5716 Dremel 2.625x4.25 6/18/02 10:37 AM Page 62

Page 33

65

Cuando limpie la goma o la resina de madera de

la cuchilla, desenchufe la herramienta rotatoria y

quite la cuchilla. Recuerde, las cuchillas están

diseñadas para cortar, por consiguiente

manipúlelas con cuidado. Limpie la cuchilla con

querosén o un solvente similar para quitar la goma

o resina.

Una cuchilla sin filo o averiada disminuye la

velocidad de corte y pone mayor presión en su

herramienta rotatoria, y puede causar

CONTRAGOLPE. Mantenga al alcance cuchillas

extras de tal manera que siempre cuente con

cuchillas afiladas y eficientes, listas para

reemplazar una desafilada o averiada.

Use únicamente Cuchillas para sierra Dremel con

su Acople de sierra.

LIMPIEZA

Para evitar accidentes

desconecte siempre la

herramienta de la electricidad antes de limpiar

o hacer mantenimiento. El acople de minisierra

puede limpiarse mejor con un copito húmedo o

con aire seco comprimido.

Siempre use gafas de seguridad cuando limpie

las herramientas con aire comprimido.

Las rejillas de ventilación y las palancas del

interruptor deben mantenerse limpias y libres de

material extraño. No intente limpiarlas insertando

objetos puntiagudos a través de las aberturas.

Ciertos agentes de limpieza

y solventes dañan las partes

plásticas. Algunos de estos son: gasolina,

tetracloruro de carbono, solventes de limpieza con

cloro, amoníaco y detergentes caseros que

contengan amoníaco.

CUIDADO DE LAS CUCHILLAS

Las cuchillas pierden el filo inclusive cortando

madera normal. Si ve que está forzando la

herramienta rotatoria para cortar en vez de

simplemente guiarla a través del corte, lo más

seguro es que la cuchilla esté desafilada o

cubierta con resina de la madera.

64

!

CAUTION

!

ADVERTENCIA

5716 Dremel 2.625x4.25 6/18/02 10:37 AM Page 64

Page 34

Notes/Notes/Notas Notes/Notes/Notas

6766

5716 Dremel 2.625x4.25 6/18/02 10:37 AM Page 66

Page 35

2610914192 Printed in U.S.A.

5716 Dremel 2.625x4.25 6/18/02 10:37 AM Page 68

®

Loading...

Loading...