Page 1

For English Parlez-vous français? ¿Habla español?

See page 2 Voir page 8 Ver página 14

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento

y seguridad

IMPORTANT: Read Before Using

IMPORTANT : Lire avant usage

IMPORTANTE: Leer antes de usar

Model Modèle Modelo 330

ROUTER ATTACHMENT

ACCESSOIRE DE TOUPILLAGE

COMPLEMENTO GUÍA

DM 2615302558 8/98 1/11/99 1:47 PM Page 1

Page 2

Read and understand all instructions. Failure to follow all instructions listed

below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

-2-

Work Area

Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust. Power tools

create sparks which may ignite the dust or

fumes.

Keep by-standers, children, and visitors away

while operating a power tool. Distractions can

cause you to lose control.

Electrical Safety

Double Insulated tools are equipped with a

polarized plug (one blade is wider than the

other.) This plug will fit in a polarized outlet

only one way. If the plug does not fit fully in

the outlet, reverse the plug. If it still does not

fit, contact a qualified electrician to install a

polarized outlet. Do not change the plug in

any way. Double Insulation eliminates the

need for the three wire grounded power cord and

grounded power supply system. Before plugging

in the tool, be certain the outlet voltage supplied

is within the voltage marked on the nameplate.

Do not use “AC only” rated tools with a DC

power supply.

Avoid body contact with grounded surfaces

such as pipes, radiators, ranges and

refrigerators. There is an increased risk of

electric shock if your body is grounded. If

operating the power tool in damp locations is

unavoidable, a Ground Fault Circuit Interrupter

must be used to supply the power to your tool.

Electrician’s rubber gloves and footwear will

further enhance your personal safety.

Don't expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord to

carry the tools or pull the plug from an outlet.

Keep cord away from heat, oil, sharp edges or

moving parts. Replace damaged cords

immediately. Damaged cords increase the risk

of electric shock.

When operating a power tool outside, use an

outdoor extension cord marked "W-A" or "W."

These cords are rated for outdoor use and

reduce the risk of electric shock.

Personal Safety

Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use tool while tired or under the

influence of drugs, alcohol, or medication. A

moment of inattention while operating power

tools may result in serious personal injury.

Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair,

clothing, and gloves away from moving parts.

Loose clothes, jewelry, or long hair can be caught

in moving parts. Keep handles dry, clean and free

from oil and grease.

Avoid accidental starting. Be sure switch is

“OFF” before plugging in. Carrying tools with

your finger on the switch or plugging in tools that

have the switch “ON” invites accidents.

Remove adjusting keys or wrenches before

turning the tool “ON”. A wrench or a key that is

left attached to a rotating part of the tool may

result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. Proper footing and balance

enables better control of the tool in unexpected

situations.

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety shoes,

hard hat, or hearing protection must be used for

appropriate conditions.

Tool Use and Care

Use clamps or other practical way to secure

and support the workpiece to a stable

platform. Holding the work by hand or against

your body is unstable and may lead to loss of

control.

Do not force tool. Use the correct tool for your

application. The correct tool will do the job

better and safer at the rate for which it is

designed.

Do not use tool if switch does not turn it “ON”

or “OFF”. Any tool that cannot be controlled with

the switch is dangerous and must be repaired.

Disconnect the plug from the power source

before making any adjustments, changing

accessories, or storing the tool. Such

preventive safety measures reduce the risk of

starting the tool accidentally.

Store idle tools out of reach of children and

other untrained persons. Tools are dangerous

!

WARNING

Power Tool Safety Rules

DM 2615302558 8/98 1/11/99 1:47 PM Page 2

Page 3

-3-

Safety Rules for Routers

in the hands of untrained users.

Maintain tools with care. Keep cutting tools

sharp and clean. Properly maintained tools, with

sharp cutting edges are less likely to bind and

are easier to control. Any alteration or

modification is a misuse and may result in a

dangerous condition.

Check for misalignment or binding of moving

parts, breakage of parts, and any other

condition that may affect the tools operation.

If damaged, have the tool serviced before

using. Many accidents are caused by poorly

maintained tools. Develop a periodic

maintenance schedule for your tool.

Use only accessories that are recommended

by the manufacturer for your model.

Accessories that may be suitable for one tool,

may become hazardous when used on another

tool.

Service

Tool service must be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified personnel

could result in a risk of injury. For example:

internal wires may be misplaced or pinched,

safety guard return springs may be improperly

mounted.

When servicing a tool, use only identical

replacement parts. Follow instructions in the

Maintenance section of this manual. Use of

unauthorized parts or failure to follow

Maintenance Instructions may create a risk of

electric shock or injury. Certain cleaning agents

such as gasoline, carbon tetrachloride, ammonia,

etc. may damage plastic parts.

Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring or its

own cord. Contact with a "live" wire will make

exposed metal parts of the tool "live" and

shock the operator. If cutting into existing walls

or other blind areas where electrical wiring may

exist is unavoidable, disconnect all fuses or

circuit breakers feeding this worksite.

Always make sure the work surface is free

from nails and other foreign objects. Cutting

into a nail can cause the bit and the tool to

jump and damage the bit.

Never hold the workpiece in one hand and

the tool in the other hand when in use.

Never place hands near or below cutting

surface. Clamping the material and guiding the

tool with both hands is safer.

Never lay workpiece on top of hard

surfaces, like concrete, stone, etc...

Protruding cutting bit may cause tool to jump.

Always wear safety goggles and dust mask.

Use only in well ventilated area. Using

personal safety devices and working in safe

environment reduces risk of injury.

After changing the bits or making any

adjustments, make sure the collet nut and

any other adjustment devices are securely

tightened. Loose adjustment device can

unexpectedly shift, causing loss of control,

loose rotating components will be violently

thrown.

Never start the tool when the bit is engaged

in the material. The bit cutting edge may grab

the material causing loss of control of the

cutter. Always hold the tool with two hands

during start-up. The reaction torque of the

motor can cause the tool to twist.

The direction of feeding the bit into the

material is very important and it relates to

the direction of bit rotation. When viewing

the tool from the top, the bit rotates

clockwise. Feed direction of cutting must

be counter-clockwise. NOTE: inside and

outside cuts will require different feed direction,

refer to section on feeding the router. Feeding

the tool in the wrong direction, causes the

cutting edge of the bit to climb out of the work

and pull the tool in the direction of this feed.

Always use the tool with the depth guide

securely attached and positioned flat

against material being cut. The guide

securely positioned on the material improves

the stability and control of your tool.

Never use dull or damaged bits. Sharp bits

must be handled with care. Damaged bits

can snap during use. Dull bits require more

force to push the tool, possibly causing the bit

to break.

Never touch the bit during or immediately

after the use. After use the bit is too hot to be

touched by bare hands.

Never lay the tool down until the motor has

come to a complete standstill. The spinning

bit can grab the surface and pull the tool out of

your control.

Do not use the tool for drilling purposes.

This tool is not intended to be used with drill

bits.

Never use bits that have a cutting diameter

greater than the opening in the base.

DM 2615302558 8/98 1/11/99 1:47 PM Page 3

Page 4

ATTACHMENT FOR USE WITH DREMEL

ROTARY TOOL MODELS 275, 285, 395,

245, 250, 270, 280, 370, 380, 398, AND

MODEL 850 FREE WHEELER

ATTENTION: This attachment will convert

Dremel Rotary Tool to a Router for freehand

routing, edging, grooving, and circular cuts.

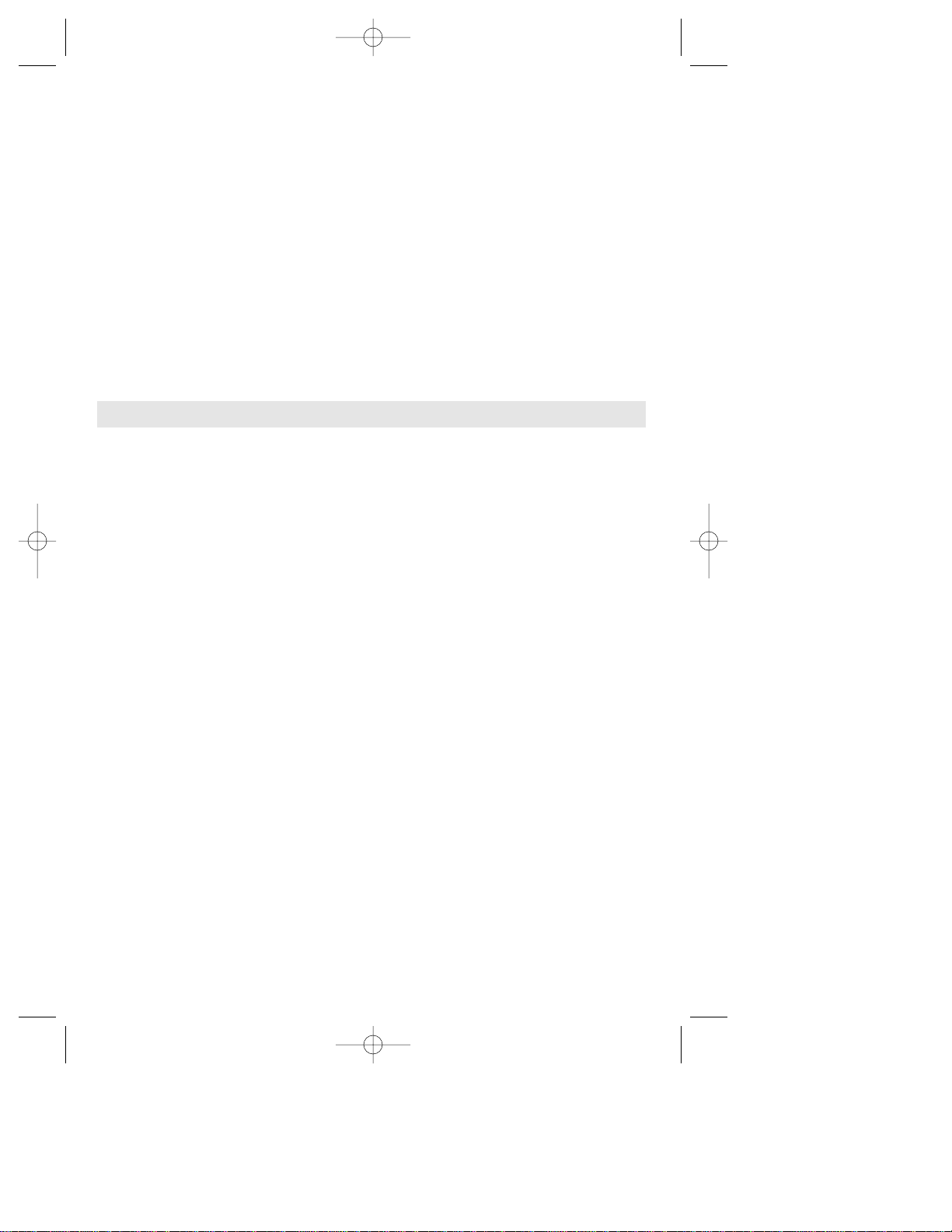

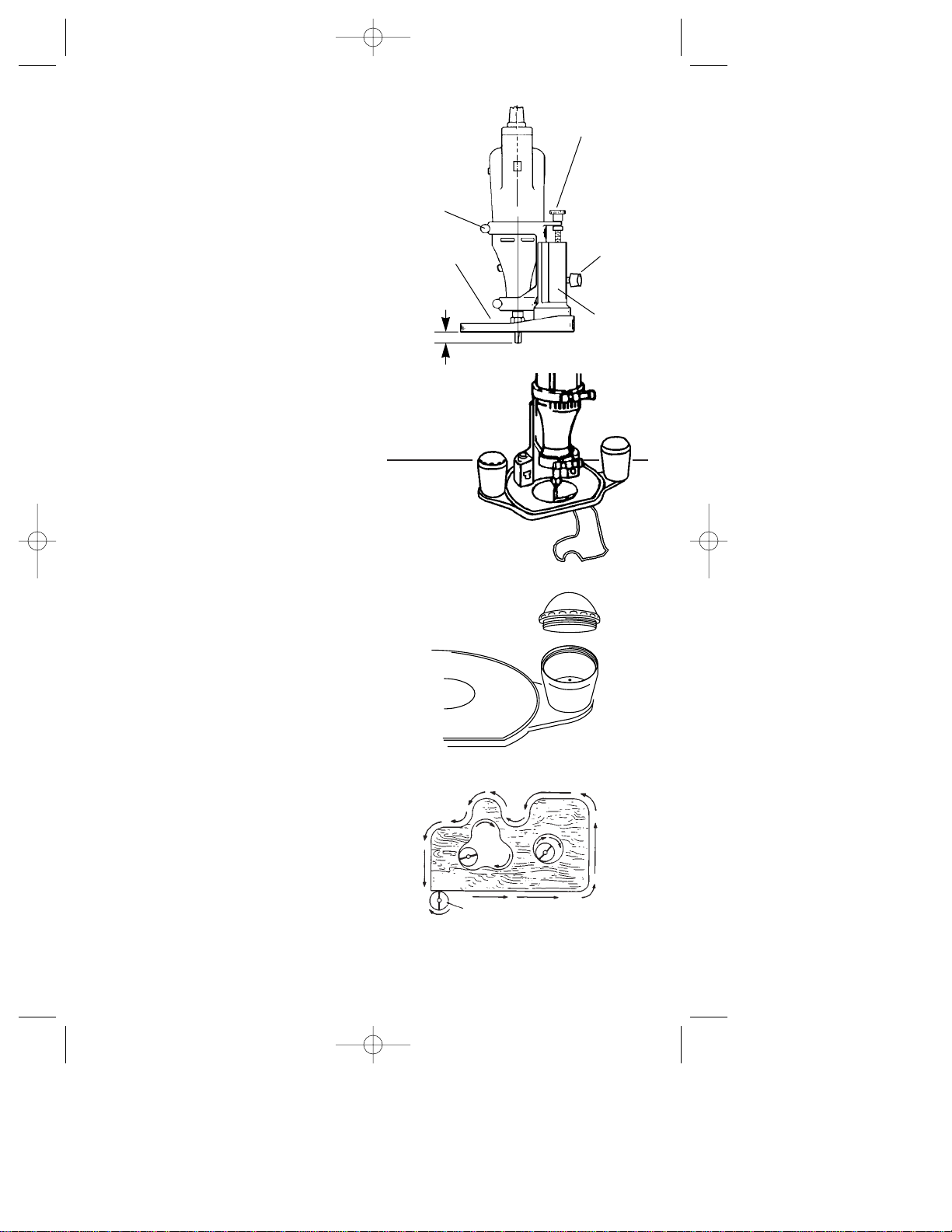

1. The router attachment comes assembled

ready for freehand or pilot bit routing. Type II

and III tools will fit in the UPPER and

LOWER CLAMPS without need for

bushings. When using type l, IV and V type

tools and model 398, the BLACK BUSHING

is used in the lower clamp. Assemble with

internal ledge down.

NOTE: When using Rotary Tool model 245,

270, 280, 370 and 380 the two GREY

BUSHINGS are required. Assemble the

large bushing in the upper clamp and the

small bushing in the lower clamp.

When using Rotary Tool model 250, only the

small grey bushing is required. Assemble

this bushing in the lower clamp.

2. Loosen the two CLAMP NUTS several

turns. Place the Rotary Tool in the clamps

making sure the nose of the tool is against

the ledge in the bottom of the lower clamp.

With the SWITCH and SPINDLE LOCK to

the front, secure the tool by tightening the

two clamp nuts.

NOTE: When using bushings, align the split

of the bushing to the split of the clamps.

Also be careful to seat the tool and bushings

properly.

3. Unplug the power cord from the electrical

outlet and remove the Rotary Tool from the

router to install a router bit. Fit the shank of

the ROUTER BIT into the collet allowing a

maximum of 5/8” to protrude below the

COLLET NUT. Use the spindle lock and

wrench to tighten the bit securely.

-4-

TWO GREY BUSHINGS

COLLET NUT

ROUTER BIT

DEPTH OF CUT

5/8”

UPPER

CLAMP

BLACK BUSHING

LOWER CLAMPS

DM 2615302558 8/98 1/11/99 1:47 PM Page 4

Page 5

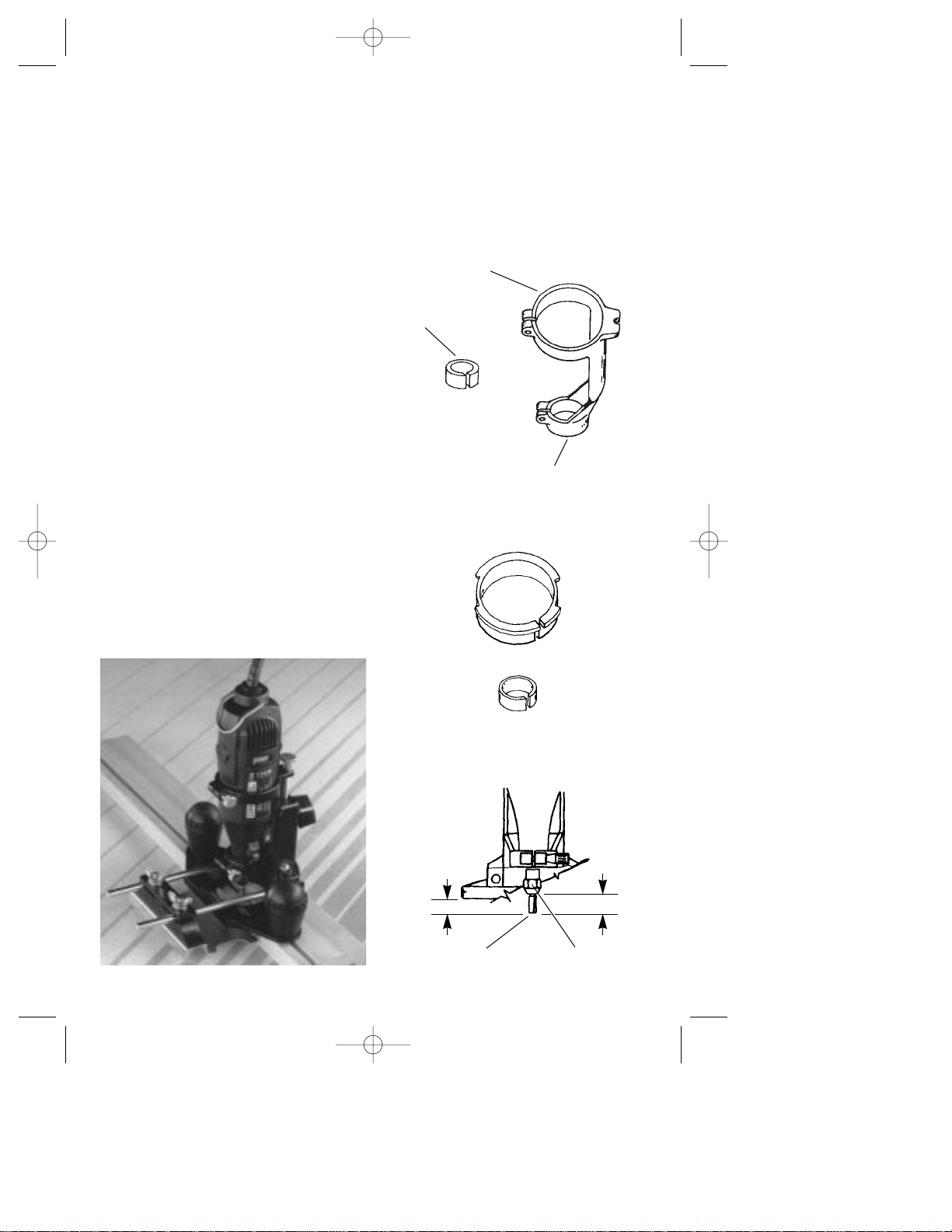

4. Loosen the CLAMP KNOB on HEIGHT

STAND and turn the DEPTH ADJUSTING

SCREW to set cutting depth. Depth of cut

will be the amount the bit extends below the

ROUTER BASE. After setting depth,

retighten clamp knob.

Adjustment markings on the back of

adjusting bracket are marked in inches and

millimeters. Each line on the fractional side

represents 1/16 of an inch. Each line on the

metric side represents one millimeter. View

the markings prior to starting your project.

Loosen the clamp knob and turn the

adjusting screw counterclockwise (raising

the adjusting bracket), set to desired depth

and tighten clamp knob. To insure proper

settings, rout and measure cut on scrap

material.

5. Used freehand, the router attachment will

help you carve letters, figures, patterns, or

perform pilot bit operations. Keep your

forearms on the bench for the best control

when freehand routing.

Use Dremel’s Wood Sign Layout Kit Model

10 for letter and number patterns. This kit

has three styles of letter patterns. (Old

English, Script, Block)

6. Router handles give better overall control

of the router attachment. The router handles

also serve as a router bit storage

compartment. By turning cap counterclockwise and placing rotary tool router bits

in the 1/8” holes (4 per handle), you can

store up to 8 bits. Replace handle by turning

in a clockwise fashion until tight.

7. The router spindle turns in a clockwise

direction when viewed from above. For best

control and quality of cut, feed the router

into the work in the direction that the bit will

tend to pull itself into the wood. (Incorrect

feed direction will result in the bit trying to

climb over the wood.) Feed the router in

direction shown in diagram. For example, if

cutting around the edge of a square piece,

move the router in a counterclockwise

direction. If routing the inside surface, as

shown, move in a clockwise direction. Feed

direction is extremely important when using

a pilot bit freehand on the edge of a

workpiece.

-5-

Make sculptured and

relief carved letters with

a Rotary Tool and

Router Attachment.

DEPTH ADJUSTING

SCREW

CLAMP

KNOB

HEIGHT

STAND

DEPTH OF CUT

ROUTER BASE

ADJUSTMENT

BRACKET

Feed directions for outside and inside routing. Note the

sequence of the cuts for routing around all four edges of a

rectangle or square board.

ROUTER FEED DIRECTION

BIT ROTATION

ROUT

END

GRAINS

FIRST

DM 2615302558 8/98 1/11/99 1:48 PM Page 5

Page 6

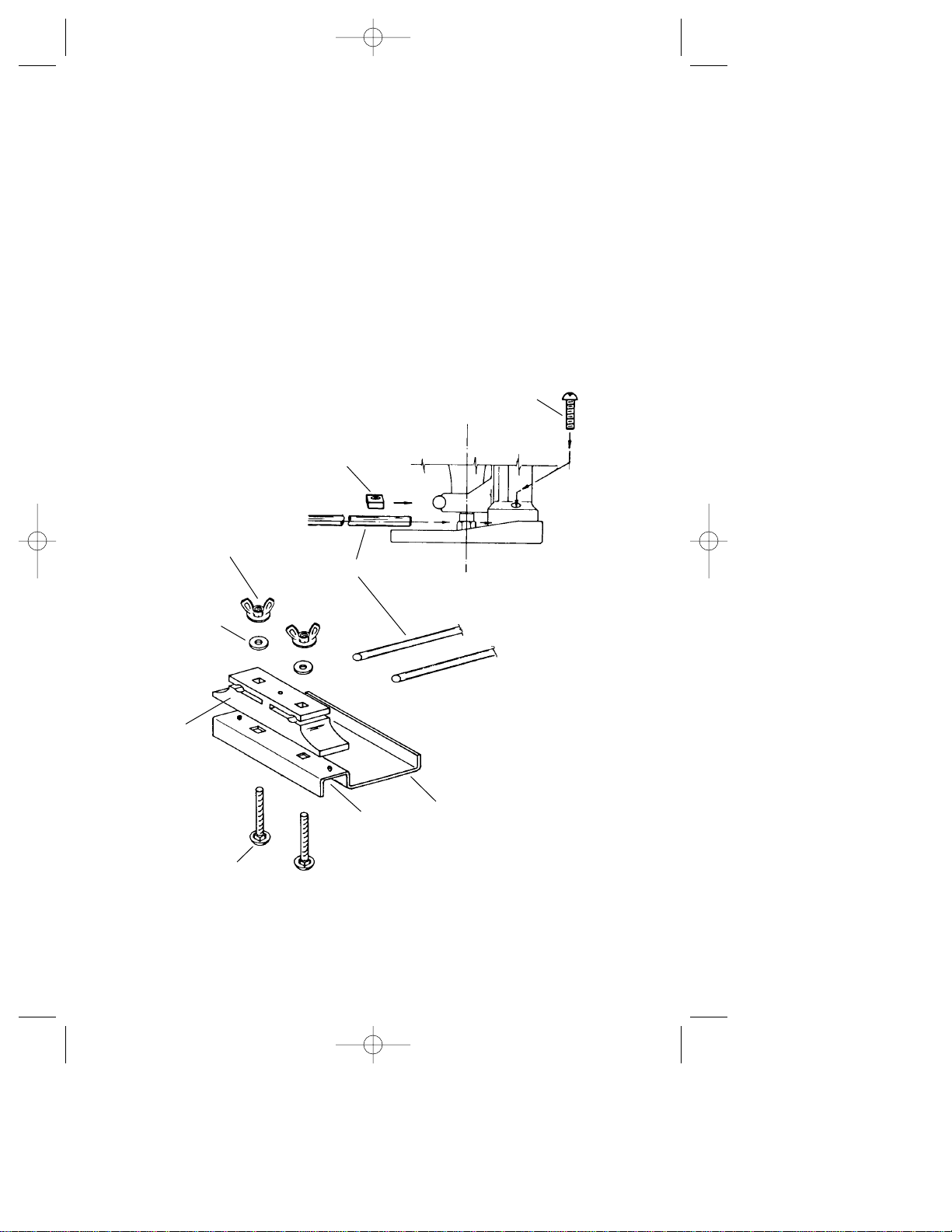

8. For EDGE GUIDE use, assemble GUIDE

RODS into height adjusting bracket and

secure using (2) #10-24 SQUARE NUTS and

(2) #10-24 x 3/4" phillip drive SCREWS.

Square nut will slide in slots above the guide

rods. Screws are assembled from the top

through holes down through nuts, and

against the rods. Fasten edge guide to edge

guide CARRIAGE BOLTS. Assemble

carriage bolts through square holes in EDGE

GUIDE and through EDGE GUIDE

BRACKET and secure using WASHER and

WING NUTS. (Be sure small DOWELS at the

ends of edge guide bracket locate in

corresponding holes in edge guide.) Slide

edge guide assembly on guide rods as

shown. Set edge guide at DESIRED

DISTANCE from cutter and tighten wing

nuts. (See Fig. 1 )

NOTE: Use the flat on the front of the router

base for edging or straight line routing.

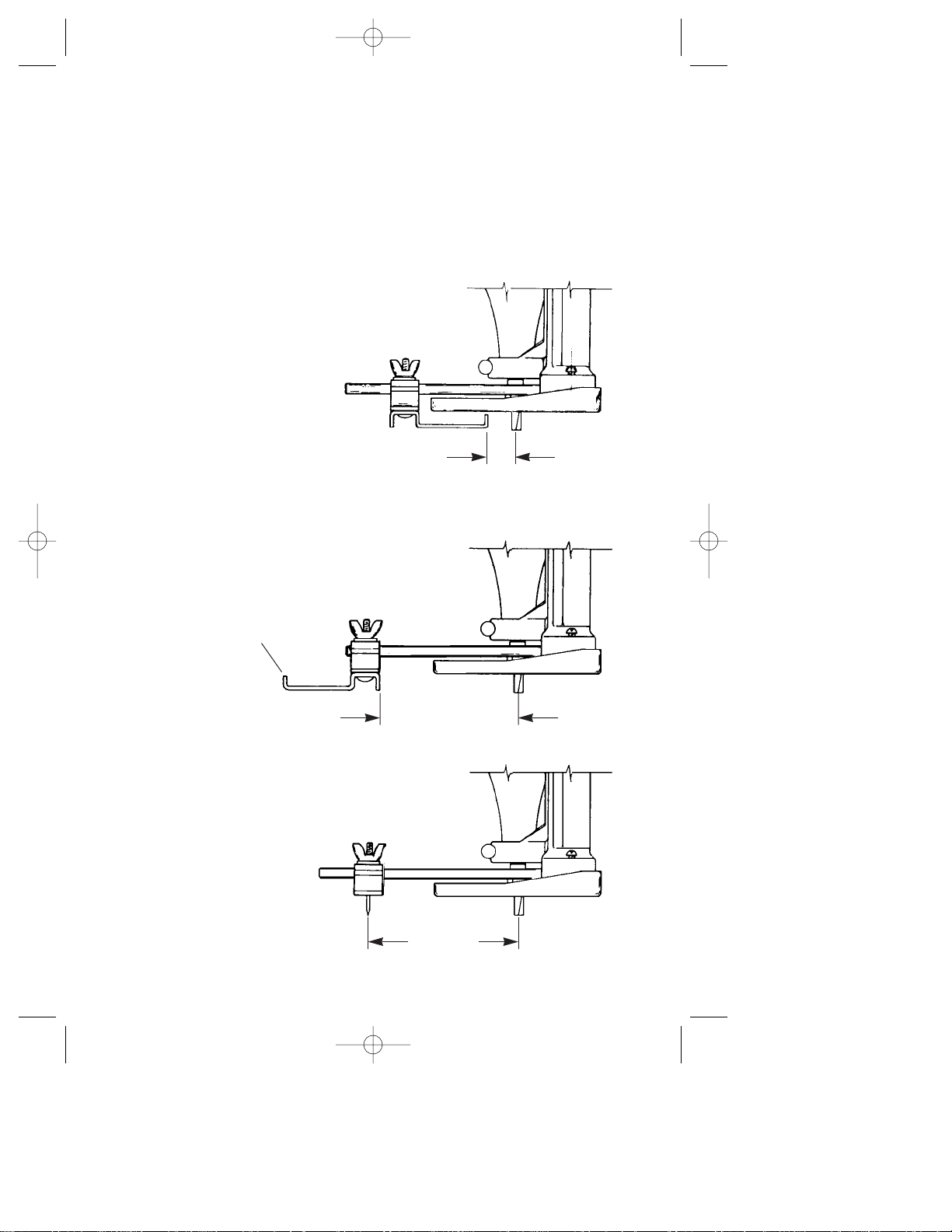

9. When edge guide settings are needed

at more than 1 3/4" from cutter, remove

edge guide assembly from guide rods. Turn

assembly around and assemble edge guide

bracket to guide rod from the opposite side.

You can now set edge guide at any distance

from cutter between 1 1/4" to 4". (See Fig. 2)

-6-

SQUARE NUTS

SCREWS

CARRIAGE BOLTS

WING NUTS

WASHERS

EDGE

GUIDE

BRACKET

GUIDE RODS

DOWELS

EDGE GUIDE

DM 2615302558 8/98 1/11/99 1:48 PM Page 6

Page 7

10. Edge guide is used for shaping edges,

cutting rabbets, dadoes, mortise, tongues,

grooves, slots, and chamfers. Remember to

feed so the cutter tends to pull the edge

guide against the wood. A consistent feed

rate gives a smooth cut.

11. In general, several shallow cuts should

be used when a deep groove is desired.

Maximum depth of cut will vary depending

on material used. Do not over feed to an

amount that the motor is noticeably slowed.

12. Certain circular cuts can be made using

the edge guide bracket. Radii from 1 11/16"

to 4" can be done. Remove the edge guide

and attach the edge guide bracket to the

guide rods. Use the finishing nail provided as

a compass point. Set the edge guide bracket

for the desired radius. Place the nail through

the hole in the bracket and place the nail at

the center of the desired radius to be cut.

-7-

DESIRED DISTANCE

OF LESS THAN 1 3/4"

EDGE GUIDE

RADIUS

Fig. 2

Fig. 1

DESIRED DISTANCE

1 1/4” TO 4”

DM 2615302558 8/98 1/11/99 1:48 PM Page 7

Page 8

-8-

Vous devez lire et comprendre toutes les instructions. Lenon-respect, même partiel,

des instructions ci-après entraîne un risque de choc életrique, d'incendie et/ou de

blessures graves.

CONSERVEZ CES INSTRUCTIONS

AVERTISSEMENT

!

AIRE DE TRAVAIL

Veillez à ce que l'aire de travail soit propre et bien

éclairée. Le désordre et le manque de lumière favorisent

les accidents.

N'utilisez pas d'outils électriques dans une

atmosphère explosive, par exemple enprésence de

liquides, de gaz ou de poussières inflammables. Les

outils électriques créent des étincelles qui pourraient

enflammer les poussières ou les vapeurs.

Tenez à distance les curieux, les enfants et les

visiteurs pendant que vous travaillezavec un outil

électrique. Ils pourraient vous distraire et vous faire

faire une fausse manoeuvre.

SÉCURITÉ ÉLECTRIQUE

Les outils à double isolation sont équipés d'une fiche

polarisée (une des lames est pluslarge que l'autre),

qui ne peut se brancher que d'une seule façon dans

une prise polarisée. Si la fiche n'entre pas

parfaitement dans la prise, inversez sa position ; si

elle n'entre toujours pasbien, demandez à un

électricien qualifié d'installer une prise de courant

polarisée. Ne modifiez pas la fiche de l'outil. La

double isolation élimine le besoin d'un cordon

d'alimentationà trois fils avec mise à la terre ainsi que

d'une prise de courant mise à la terre. Avant de brancher

l'outil, assurez-vous que la tension de la prise

correspond, à celle indiquée sur la plaque signalétique.

N'utilisez pas d'outils prévus pour courant alternatif

seulement avec une source de courant continu.

Évitez tout contact corporel avec des surfaces mises à

la terre (tuyauterie, radiateurs, cuisinières,

réfrigérateurs, etc.). Le risque de choc électrique est

plus grand si votre corps est encontact avec la terre.Si

l'utilisation de l'outil électrique dans un endroit humide

est inévitable, un disjoncteur de fuite à la terre doit être

utilisé pour alimenter votre outil. Des chaussures et des

gants en caoutchouc d'électricien contribueront à

accroître davantage votre sécurité personnelle.

N'exposez pas les outils électriques à la pluie ou à

l'eau. La présence d'eau dans un outil électrique

augmente le risque de choc électrique.

Ne maltraitez pas le cordon. Ne transportez pas l'outil

par son cordon et ne débranchez pas la fiche en tirant

sur le cordon. N'exposez pas le cordon à la chaleur, à

des huiles, à des arêtes vives ou à des pièces en

mouvement. Remplacez immédiatement un cordon

endommagé. Un cordon endommagé augmente le

risque de choc électrique.

Lorsque vous utilisez un outil électrique à l'extérieur,

employez un prolongateur pour l'extérieur marqué «

W-A » ou « W ». Ces cordons sont faits pour être utilisés

à l'extérieur et réduisent le risque de choc électrique.

SÉCURITÉ DES PERSONNES

Restez alerte, concentrez-vous sur votre travail et

faites preuve de jugement. N'utilisez pas un outil

électrique si vous êtes fatigué ou sous l'influence de

drogues, d'alcool ou de médicaments. Un instant

d'inattention suffit pour entraîner des blessures graves.

Habillez-vous convenablement. Ne portez ni

vêtements flottants ni bijoux. Confinez les cheveux

longs. N'approchez jamais les cheveux, les vêtements

ou les gants des pièces en mouvement. Des vêtements

flottants, des bijoux ou des cheveux longs risquent

d'être happés par des pièces en mouvement. Gardez les

poignées sèches, propres et exemptes d'huile et de

graisse.

Méfiez-vous d'un démarrage accidentel. Avant de

brancher l'outil, assurez-vous que son interrupteur est

sur ARRÈT. Le fait de transporter un outil avec le doigt

sur la détente ou de brancher un outil dont l'interrupteur

est en position MARCHE peut mener tout droit à un

accident.

Enlevez les clés de réglage ou de serrage avant de

démarrer l'outil. Une clé laissée dans une pièce

tournante de l'outil peut provoquer des blessures.

Ne vous penchez pas trop en avant. Maintenez un bon

appui et restez en équilibre entout temps. Un bonne

stabilité vous permet de mieux réagir à une situation

inattendue.

Utilisez des accessoires de sécurité. Portez toujours

des lunettes ou une visière. Selon les conditions, portez

aussi un masque antipoussière, des bottes de sécurité

antidérapantes, un casque protecteur et/ou un appareil

antibruit.

UTILISATION ET ENTRETIEN DES OUTILS

Immobilisez le matériau sur une surface stable au

moyen de brides ou de toute autre façon adéquate. Le

fait de tenir la pièce avec la main ou contre votre corps

offre une stabilité insuffisante et peut amener un

dérapage de l'outil.

Ne forcez pas l'outil. Utilisez l'outil approprié à la

tâche. L'outil correct fonctionne mieux et de façon plus

sécuritaire. Respectez aussi la vitesse de travail qui lui

est propre.

Règles de Sécurité Générales

DM 2615302558 8/98 1/11/99 1:48 PM Page 8

Page 9

-9-

N'utilisez pas un outil si son interrupteur est bloqué.

Un outil que vous ne pouvez pas commander par son

interrupteur est dangereux et doit être réparé.

Débranchez la fiche de l'outil avant d'effectuer un

réglage, de changer d'accessoire oude ranger l'outil.

De telles mesures préventives de sécurité réduisent le

risque de démarrage accidentel de l'outil.

Rangez les outils hors de la portée des enfants et

d'autres personnes inexpérimentées. Les outils sont

dangereux dans les mains d'utilisateurs novices.

Prenez soin de bien entretenir les outils. Les outils de

coupe doivent être toujours bien affûtés et propres.

Des outils bien entretenus, dont les arêtes sont bien

tranchantes, sont moins susceptibles de coincer et plus

faciles à diriger.Toute altération ou modification

constitue un usage erroné et peut causer un danger.

Soyez attentif à tout désalignement ou coincement des

pièces en mouvement, à tout bris ou à toute autre

condition préjudiciable au bon fonctionnement de

l'outil. Si vous constatez qu'un outil est endommagé,

faites-le réparer avant de vous en servir. De nombreux

accidents sont causés par des outils en mauvais état.

Élaborez un calendrier d'entretien périodique de votre

outil.

N'utilisez que des accessoires que le fabricant

recommande pour votre modèle d'outil. Certains

accessoires peuvent convenir à un outil, mais être

dangereux avec un autre.

RÉPARATION

La réparation des outils électriques doit être confiée à

un réparateur qualifié. L'entretien ou la réparation d'un

outil électrique par un amateur peut avoir des

conséquences graves. Ainsi, des fils internes peuvent

être mal placés ou pincés, des ressorts de rappel de

protecteur peuvent être montés erronément.

Pour la réparation d'un outil, n'employez que des

pièces de rechange d'origine. Suivez les directives

données à la section « Réparation » de ce manuel.

L'emploi de pièces non autorisées ou le non-respect des

instructions d'entretien peut créer un risque de choc

électrique ou de blessures. Certains agents nettoyants

tels qu'essence, tétrachlorure de carbone, ammoniac,

etc., peuvent abîmer les pièces en plastique.

Tenez l'outil par les surfaces isolées de prise en

exécutant une opération lorsque l'outil de coupe peut

venir en contact avec des fils cachés ou son propre

cordon. Le contact avec un fil sous tension rendra les

parties métalliques exposées de l'outil sous tension et

causera des secousses électriques à l'opérateur. Pour

couper dans des murs existants ou autres endroits

aveugles pouvant dissimuler des fils électriques,

débranchez tous les fusibles ou les disjoncteurs

alimentant ce lieu de travail.

Assurez-vous toujours que la surface de travail est

exempte de clous et autres objets étrangers. La coupe

dans un clou peut faire sauter la lame et l'outil, et ainsi

abîmer la lame.

Ne tenez jamais le matériau d'une main et l'outil de

l'autre lorsque vous en faites usage. Ne placez jamais

les mains sous la surface de coupe ou à proximité de

celle-ci. Il est plus sûr de cramponner le matériau et de

guider l'outil des deux mains.

Ne posez jamais le matériau sur des surfaces dures

telles que le béton, la pierre, etc. ... La lame de coupe

en saillie peut faire sauter l'outil.

Portez toujours des lunettes de sécurité et un masque

anti-poussières. N'utilisez l'outil qu'à un endroit bien

aéré. L'utilisation de dispositifs de sécurité personnelle

et le travail dans un environnement sûr réduisent les

risques de blessures.

Après avoir changé les lames ou effectué quelque

réglage que ce soit, assurez-vous que l'écrou de la

douille et tout autre dispositif de réglage sont bien

serrés. Un dispositif de réglage lâche peut bouger

soudainement et causer ainsi une perte de contrôle avec

projection violente des composants en rotation.

Ne mettez jamais l'outil en marche alors que la lame

est enfoncée dans le matériau. Le tranchant de la lame

peut se coincer dans le matériau et vous faire perdre le

contrôle du couteau. Tenez toujours le couteau des

deux mains durant la mise en marche. Le couple de

réaction du moteur peut faire tordre l'outil.

Le sens d'introduction de la lame dans le matériau

est très important, et il est lié au sens d'introduction

de la lame. Lorsque vous regardez l'outil depuis le

dessus, la lame tourne en sens horaire. Le sens

d'introduction du couteau doit être anti-horaire.

REMARQUE : Les coupes intérieures et extérieures

nécessiteront des sens de déplacement différents référez-vous à la section consacrée au sens de

déplacement de la toupie. Si l'outil est introduit dans le

mauvais sens, le tranchant de la lame peut sortir du

matériau et tirer l'outil dans le sens de cette

introduction.

Utilisez toujours l'outil avec le guide de profondeur

fixé solidement et placé à plat contre le matériau à

couper. Le guide positionné solidement sur le matériau

améliore la stabilité et le contrôle de votre outil.

N'utilisez jamais de lames émoussées ou abîmées.

Les lames affilées doivent être maniées soigneusement.

Les mèches abîmées peuvent se rompre brusquement

durant l'usage. Les lames émoussées nécessitent plus

de force pour pousser l'outil, causant éventuellement un

bris de la lame.

Ne touchez jamais la lame durant ou immédiatement

après l'usage. Après usage, la lame est trop chaude

pour être touchée à main nue.

Ne posez jamais l'outil avant que le moteur ne se soit

arrêté complètement. La lame en rotation peut saisir la

surface et vous faire perdre le contrôle de l'outil.

N'utilisez pas l'outil pour percer. Cet outil n'est pas

destiné à être utilisé avec des mèches de perceuse.

N’utilisez jamais des fers dont le diamètre de coupe est

supérieur à celui de l’ouverture pratiquée dans la base.

Règles de sécurité concernant les toupies

DM 2615302558 8/98 1/11/99 1:48 PM Page 9

Page 10

ACCESSOIRE POUR USAGE AVEC LES OUTILS

ROTATIFS DREMEL MODÈLES 275, 285, 395, 245,

250, 270, 280, 370, 380, 398 ET 850 RECHARGEABLE.

ATTENTION : Cet accessoire permet de transformer

l’outil rotatif Dremel en toupie pour l’exécution de figures

à main levée, de feuillures, de rainures et de cercles.

1. L’accessoire de toupillage est vendu assemblé et prêt

pour le toupillage à main levée ou à l’aide de fers guidés.

Les outils de type II et III se glissent dans les

SUPPORTS SUPÉRIEUR et INFÉRIEUR sans faire appel

à un manchon. Dans le cas des outils de type I, IV, V et

398, le MANCHON NOIR est utilisé dans le support

inférieur. L’introduire en place avec le rebord intérieur en

bas.

REMARQUE : Avec les outils rotatifs modèles 245, 270,

280, 370 et 380, il faut faire appel aux deux MANCHONS

GRIS. Introduire le grand manchon dans le support

supérieur et le petit dans le support inférieur.

Avec l’outil rotatif modèle 250, seul le petit manchon gris

est requis. L’installer dans le support inférieur.

2. Desserrer de plusieurs tours les deux ÉCROUS DE

SERRAGE. Placer l’outil rotatif dans les supports en

s’assurant que le nez de l’outil repose contre le rebord

situé au fond du support inférieur. Orienter le

COMMUTATEUR et le BLOCAGE DE L’ARBRE vers

l’avant, puis fixer l’outil en place en serrant les deux

écrous de serrage.

REMARQUE : Lorsque les manchons sont employés, en

aligner la fente sur celle des supports. Prendre soin de

loger bien à fond l’outil et ses manchons.

3. Pour installer un fer à toupie, débrancher le cordon

d’alimentation de la prise de courant et détacher l’outil

rotatif de la base de toupillage. Glisser la queue du FER

À TOUPIE dans le mors en s’assurant qu’un maximum

de 16 mm (5/8") dépasse l’ÉCROU DE MORS. Enfoncer

le blocage de l’arbre et serrer le fer en place à l’aide

d’une clé.

-10-

DEUX MANCHONS GRIS

ÉCROU DE MORS

FER DE TOUPIE

PROFONDEUR DE COUPE

16 MM (5/8”)

SUPPORT

SUPÉRIEUR

MANCHON NOIR

SUPPORT INFÉRIEUR

DM 2615302558 8/98 1/11/99 1:48 PM Page 10

Page 11

4. Pour régler la profondeur de coupe, desserrer LE

BOUTON DE SERRAGE de la COLONNE et tourner la VIS

DE RÉGLAGE DE PROFONDEUR. La profondeur de

coupe correspond à la projection du fer au-delà de la

BASE DE TOUPILLAGE. Une fois la profondeur réglée,

resserrer le bouton de serrage.

Les marques de réglage au dos du support de réglage

sont indiquées en pouces et en millimètres. Chaque ligne

du côté fractionnaire représente 1/16 de pouce. Chaque

ligne du côté métrique représente un millimètre.

Reportez-vous aux marquages avant de commencer

votre projet. Desserrez le bouton de la bride et tournez la

vis de réglage en sens anti-horaire (en levant le support

de réglage), réglez à la profondeur désirée et serrez le

bouton de la bride. Pour assurer des réglages

appropriés, toupillez et mesurez la coupe sur des

matériaux de rebut.

5. L’accessoire de toupillage s’utilise à main levée pour

graver des lettres, des figures ou des patrons et pour

usiner à l’aide de fers guidés. Pour assurer la meilleur

maîtrise possible de l’outil lors du toupillage à main

levée, toujours garder les avant-bras sur l’établi.

L’ensemble Dremel pour panneaux en bois modèle 10

comporte des patrons permettant de graver des lettres et

des chiffres dans trois styles distincts (Old English,

Script, Block).

6. Les poignées de toupillage assurent une meilleure

maîtrise de l’accessoire. Elles servent aussi pour le

rangement des fers de toupie : il suffit d’en tourner le

couvercle à droite pour ouvrir le compartiment. Des

trous de 3,2 mm (1/8") (4 dans chaque poignée)

permettent d’y ranger un maximum de 8 fers. Refermer

la poignée en serrant le couvercle en place.

7. Vu du dessus, l’arbre de la toupie tourne à droite.

Pour assurer la plus grande maîtrise de l’outil et la plus

grande qualité des toupillages, avancer la toupie de

manière à ce que le fer ait tendance à s’engager dans le

bois. (Avancé dans l’autre sens, le fer aura tendance à

vouloir marcher le long du bois.) Avancer la toupie dans

le sens indiqué par le schéma ci-contre. Pour usiner les

bords d’une pièce carrée, par exemple, avancer la toupie

dans le sens antihoraire (rotation à gauche). Pour usiner

des rebords intérieurs, comme l’illustre le schéma,

avancer la toupie dans le sens horaire (rotation à droite).

Le sens de l’avance est extrêmement important lors du

toupillage à main levée avec un fer guidé le long des

bords d’une pièce.

-11-

VIS DE RÉGLAGE DE

PROFONDEUR

BOUTON DE

SERRAGE

COLONNE

PROFONDEUR DE COUPE

BASE DE

TOUPILLAGE

SUPPORT DE

RÉGLAGE

Sens de l’avance pour le toupillage intérieur et extérieur.

Noter la séquence de coupe pour le toupillage des quatre

bords d’une pièce carrée ou rectangulaire.

SENS D’AVANCE DE LA TOUPIE

ROTATION DE FER

TOUPILLE

R LES

BOUTS

EN

PREMIER

Sculpter et graver des

lettres à l’aide d’un outil

rotatif et de l’accessoire

de toupillage.

DM 2615302558 8/98 1/11/99 1:48 PM Page 11

Page 12

8. Pour utiliser le GUIDE, introduire les TIGES DU GUIDE

dans le support de réglage de profondeur et les fixer en

place à l’aide de deux (2) ÉCROUS CARRÉS no 10-24 et

de deux (2) VIS no 10-24 x 3/4" à empreinte cruciforme.

Les écrous carrés doivent se loger dans les fentes

situées au-dessus des tiges du guide. Les vis sont

passées par le dessus, traversant d’abord les trous, puis

les écrous, pour venir s’appuyer contre les tiges. Fixer le

guide à l’aide des BOULONS DE CARROSSERIE. Passer

ces derniers dans les trous carrés du GUIDE, puis dans

le SUPPORT DU GUIDE et les fixer en place à l’aide de

RONDELLES et d’ÉCROUS À AILETTES. (S’assurer que

les petites SAILLIES dans le support du guide se

glissent dans les trous correspondants du guide.) Glisser

de la manière illustrée l’assemblage du guide sur les

tiges. Régler le guide à la DISTANCE CHOISIE par

rapport au fer, puis serrer les vis à ailettes (se reporter à

la fig. 1).

REMARQUE : Pour toupiller un rebord ou en ligne droite,

utiliser la partie plate à l’avant de la base de toupillage.

9. Pour régler le guide à plus de 45 mm (1 3/4") du fer,

détacher le guide de ses tiges. Le retourner, puis le

glisser en place sur les tiges, mais en sens inverse. Le

guide pourra alors être réglé à une distance de 45 à 100

mm (1 1/4" à 4") (se reporter à la fig. 2).

-12-

ÉCROUS CARRÉS

VIS

BOULONS DE

CARROSSERIE

ÉCROUS À AILETTES

RONDELLES

SUPPORT

DU GUIDE

TIGES DU GUIDE

SAILLIES

GUIDE

DM 2615302558 8/98 1/11/99 1:48 PM Page 12

Page 13

10. Le guide sert à usiner les bords ainsi qu’à exécuter

les feuillures, les rainures, les mortaises, les tenons et

les chanfreins. Ne pas oublier d’avancer l’outil pour que

le fer tire le guide contre le bois. Une vitesse d’avance

constante assure un résultat uniforme.

11. Règle générale, il est préférable d’exécuter plusieurs

rainures à faible profondeur plutôt qu’une seule rainure

profonde. La profondeur maximale de la coupe variera

en fonction du matériau. Ne pas avancer l’outil si

rapidement que l’on remarquerait un ralentissement du

moteur.

12. Certaines rainures circulaires peuvent être exécutées

à l’aide du support de guide. On peut exécuter une

courbe dont le rayon se situe entre 43 et 100 mm (1

11/16" et 4"). Détacher le guide, puis installer seulement

son support sur les tiges. Utiliser le clou à finir fourni

comme pointe de compas. Régler le support de guide au

rayon choisi. Passer le clou dans le support et le placer

au centre de la courbe à exécuter.

-13-

DISTANCE CHOISIE DE

MOINS DE 45 MM (1 3/4)

GUIDE

RAYON

Fig. 2

Fig. 1

DISTANCE CHOISIE DE

45 À 100 MM (1 1/4” À 4”)

DM 2615302558 8/98 1/11/99 1:48 PM Page 13

Page 14

-14-

Lea y entienda todas las instrucciones. El incumplimiento de todas las instrucciones

indicadas a continuación puede dar lugar a sacudidas eléctricas, incendios y/o lesiones

personales graves.

CONSERVE ESTAS INSTRUCCIONES

AREA DE TRABAJO

Mantenga el área de trabajo limpia y bien iluminada.

Las mesas desordenadas y las áreas oscuras invitan a

que se produzcan accidentes.

No utilice herramientas mecánicas en atmósferas

explosivas, tales como las existentes en presencia de

líquidos, gases o polvos inflamables. Las

herramientas mecánicas generan chispas y éstas

pueden dar lugar a la ignición del polvo o los vapores.

Mantenga a las personas que se encuentren

presentes, a los niños y a los visitantes alejados al

utilizar una herramienta mecánica. Las distracciones

pueden hacer que usted pierda el control.

SEGURIDAD ELÉCTRICA

Las herramientas con aislamiento doble están

equipadas con un enchufe polarizado (un terminal es

más ancho que el otro). Este enchufe entrará en un

tomacorriente polarizado solamente de una manera.

Si el enchufe no entra por completo en el

tomacorriente, déle la vuelta. Si sigue sin entrar,

póngase en contacto con un electricista competente

para instalar un tomacorriente polarizado. No haga

ningún tipo de cambio en el enchufe. El aislamiento

doble elimina la necesidad del sistema de cordón de

energía de tres hilos conectado a tierra y la fuente de

energía conectada a tierra. Antes de enchufar la

herramienta, asegúrese de que la tensión del

tomacorriente suministrada se encuentre dentro del

margen de la tensión especificada en la placa del

fabricante. No utilice herramientas con capacidad

nominal "AC solamente" ("AC only") con una fuente de

energía DC.

Evite el contacto del cuerpo con las superficies

conectadas a tierra tales como tuberías, radiadores,

estufas de cocina y refrigeradores. Hay mayor riesgo

de que se produzcan sacudidas eléctricas si su cuerpo

está conectado a tierra. Si la utilización de la herramienta

mecánica en lugares húmedos es inevitable, se debe

usar un interruptor de circuito para fallos a tierra para

suministrar la energía a la herramienta. Los guantes de

goma para electricista y el calzado antideslizante

aumentarán más la seguridad personal.

No exponga las herramientas mecánicas a la lluvia ni

a situaciones húmedas. La entrada de agua en una

herramienta mecánica aumentará el riesgo de que se

produzcan sacudidas eléctricas.

No abuse del cordón. Nunca use el cordón para llevar las

herramientas ni para sacar el enchufe de un

tomacorriente. Mantenga el cordón alejado del calor, el

aceite, los bordes afilados o las piezas móviles. Cambie

los cordones dañados inmediatamente. Los cordones

dañados aumentan el riesgo de que se produzcan

sacudidas eléctricas.

Al utilizar una herramienta mecánica a la intemperie,

utilice un cordón de extensión para intemperie

marcado "W-A" o "W". Estos cordones tienen capacidad

nominal para uso a la intemperie y reducen el riesgo de

que se produzcan sacudidas eléctricas.

SEGURIDAD PERSONAL

Manténgase alerta, fíjese en lo que está haciendo y

use el sentido común cuando utilice una herramienta

mecánica. No use la herramienta cuando esté

cansado o se encuentre bajo la influencia de drogas,

alcohol o medicamentos. Un momento de distracción

al utilizar herramientas mecánicas puede dar lugar a

lesiones personales graves.

Vístase adecuadamente. No se ponga ropa holgada ni

joyas. Sujétese el pelo. Mantenga el pelo, la ropa y

los guantes alejados de las piezas móviles. La ropa

holgada, las joyas o el pelo largo pueden quedar

atrapados en las piezas móviles. Mantenga los mangos

secos, limpios y libres de aceite y grasa.

Evite el arranque accidental. Asegúrese de que el

interruptor esté en la posición "OFF" (apagado) antes

de enchufar la herramienta. El llevar las herramientas

con el dedo en el interruptor o el enchufar herramientas

que tengan el interruptor en la posición "ON" (encendido)

invita a que se produzcan accidentes.

Quite las llaves de ajuste o de tuerca antes de

encender la herramienta. Una llave de ajuste o de

tuerca que se deje puesta en una pieza giratoria de la

herramienta puede ocasionar lesiones personales.

No intente alcanzar demasiado lejos. Mantenga un

apoyo de los pies y un equilibrio adecuados en todo

momento. El apoyo de los pies y el equilibrio adecuados

permiten un mejor control de la herramienta en

situaciones inesperadas.

Utilice equipo de seguridad. Use siempre protección

de los ojos. Se debe utilizar una máscara antipolvo,

zapatos de seguridad antideslizantes, casco o protección

de los oídos según lo requieran las condiciones.

UTILIZACION Y CUIDADO DE LAS HERRAMIENTAS

Utilice abrazaderas u otro modo práctico de fijar y

soportar la pieza de trabajo a una plataforma estable.

La sujeción de la pieza de trabajo con la mano o contra

el cuerpo resulta inestable y puede ocasionar pérdida de

control.

No fuerce la herramienta. Use la herramienta correcta

para la aplicación que desea. La herramienta correcta

hará el trabajo mejor y con más seguridad a la capacidad

nominal para la que está diseñada.

No utilice la herramienta si el interruptor no la

enciende o apaga. Toda herramienta que no se pueda

controlar con el interruptor es peligrosa y debe ser

reparada.

Desconecte el enchufe de la fuente de energía antes

de hacer cualquier ajuste, cambiar accesorios o

guardar la herramienta. Estas medidas de seguridad

preventivas reducen el riesgo de arrancar la herramienta

accidentalmente.

Guarde las herramientas que no esté usando fuera del

alcance de los niños y otras personas no capacitadas.

ADVERTENCIA

!

Normas de seguridad para herramientas mecánicas

DM 2615302558 8/98 1/11/99 1:48 PM Page 14

Page 15

-15-

Las herramientas son peligrosas en las manos de los

usuarios no capacitados.

Mantenga las herramientas con cuidado. Conserve las

herramientas de corte afiladas y limpias. Las

herramientas mantenidas adecuadamente, con bordes

de corte afilados, tienen menos probabilidades de

atascarse y son más fáciles de controlar. Toda alteración

o modificación constituye un uso incorrecto y puede

tener como resultado una situación peligrosa.

Compruebe la desalineación o el atasco de las piezas

móviles, la ruptura de piezas y cualquier otra

situación que pueda afectar el funcionamiento de las

herramientas. Si la herramienta está dañada, haga

que realicen un servicio de ajustes y reparaciones a la

herramienta antes de usarla. Muchos accidentes son

causados por herramientas mantenidas

deficientemente. Establezca un programa de

mantenimiento periódico para la herramienta.

Utilice únicamente accesorios que estén

recomendados por el fabricante de su modelo. Los

accesorios que pueden ser adecuados para una

herramienta pueden volverse peligrosos cuando se

utilizan en otra herramienta.

SERVICIO

El servicio de ajustes y reparaciones de una

herramienta debe ser realizado únicamente por

personal de reparaciones competente. El servicio o

mantenimiento realizado por personal no competente

podría ocasionar un peligro de que se produzcan

lesiones. Por ejemplo: Los cables internos pueden

colocarse mal o pellizcarse, los resortes de retorno de

los protectores de seguridad pueden montarse

inadecuadamente.

Al realizar servicio de ajustes y reparaciones de una

herramienta, utilice únicamente piezas de repuesto

idénticas. Siga las instrucciones que aparecen en la

sección Mantenimiento de este manual. El uso de

piezas no autorizadas o el incumplimiento de las

instrucciones de Mantenimiento puede ocasionar un

peligro de que se produzcan sacudidas eléctricas o

lesiones. Ciertos agentes de limpieza, tales como

gasolina, tetracloruro de carbono, amoníaco, etc.,

pueden dañar las piezas de plástico.

Sujete siempre la herramienta por las superficies de

agarre aisladas al realizar una operación en la que la

herramienta de corte pueda entrar en contacto con

cables ocultos o con su propio cordón. El contacto con

un cable con corriente transmitirá corriente a las piezas

metálicas al descubierto y hará que el operador reciba

sacudidas eléctricas. Si el corte en paredes existentes u

otras áreas ciegas donde puedan existir cables

eléctricos es inevitable, desconecte todos los fusibles o

cortacircuitos que alimentan el lugar de trabajo.

Asegúrese siempre de que la superficie de trabajo no

tenga clavos ni otros objetos extraños. El corte de un

clavo puede hacer que la broca y la herramienta salten y

que la broca se dañe.

Nunca tenga la pieza de trabajo en una mano y la

herramienta en la otra al utilizarla. Nunca ponga las

manos cerca o debajo de la superficie de corte. Es

más seguro fijar con abrazaderas el material y guiar la

herramienta con ambas manos.

Nunca ponga la pieza de trabajo sobre superficies

duras, tales como hormigón, piedra, etc... la broca de

corte que sobresale podrá hacer que la herramienta

salte.

Use siempre gafas de seguridad y máscara antipolvo.

Use la herramienta únicamente en un área bien

ventilada. La utilización de dispositivos de seguridad

personal y el trabajar en un entorno seguro reducen el

riesgo de que se produzcan lesiones.

Después de cambiar las brocas o de hacer ajustes,

asegúrese de que la tuerca del portaherramienta y

otros dispositivos de ajuste estén apretados

firmemente. Un dispositivo de ajuste flojo puede

desplazarse inesperadamente, causando pérdida de

control, y los componentes giratorios flojos saldrán

despedidos violentamente.

Nunca arranque la herramienta cuando la broca esté

acoplada en el material. El borde de corte de la broca

puede engancharse en el material, causando pérdida de

control de la cortadora. Sujete siempre la herramienta

con las dos manos durante el arranque. El par de

reacción del motor puede hacer que la herramienta se

tuerza.

El sentido de avance de la broca en el material es

muy importante y está relacionado con el sentido de

giro de la broca. Al mirar a la herramienta desde

arriba, la broca gira en el sentido de las agujas del

reloj. El sentido de avance de corte debe ser en

contra de las agujas del reloj. NOTA: Los cortes

interiores y exteriores requerirán un sentido de avance

distinto; consulte la sección sobre avance de la

fresadora. El hacer avanzar la herramienta en sentido

incorrecto hace que el borde de corte de la broca se

salga de la pieza de trabajo y tire de la herramienta en el

sentido de este avance.

Use siempre la herramienta con la guía de

profundidad colocada firmemente y posicionada

plana contra el material que se está cortando. El

posicionamiento firme de la guía sobre el material

mejora la estabilidad y el control de la herramienta.

Nunca use brocas desafiladas o dañadas. Las brocas

afiladas se deben manejar con cuidado. Las brocas

dañadas pueden romperse bruscamente durante el uso.

Las brocas desafiladas requieren más fuerza para

empujar la herramienta, con lo que es posible que la

broca se rompa.

Nunca toque la broca durante ni inmediatamente

después de la utilización. Después del uso, la broca

está demasiado caliente como para tocarla con las

manos desnudas.

Nunca deje la herramienta hasta que el motor se haya

detenido por completo. La broca que gira puede

engancharse en la superficie y tirar de la herramienta

haciendo que usted pierda el control.

No utilice la herramienta para taladrar. Esta

herramienta no está diseñada para uso con brocas

taladradoras.

Nunca utilice brocas que tengan un diámetro de corte

mayor que la abertura de la base.

Normas de seguridad para fresadoras

DM 2615302558 8/98 1/11/99 1:48 PM Page 15

Page 16

COMPLEMENTO PARA UTILIZAR CON LA

HERRAMIENTA GIRATORIA DREMEL. MODELOS 275,

265, 395, 245, 250, 270, 280, 370, 380, 398 Y

MODELO 850 DE PIÑÓN LIBRE

ATENCIÓN: este complemento convertirá la herramienta

giratoria Dremel en una guía para el uso a mano alzada

en remates de esquinas, realización de hendiduras y

cortes circulares.

1. El complemento guía se entrega instalado y listo para

trabajos guiados a mano alzada o con broca dirigida. Las

herramientas de tipo II y III se acoplan a las FIJACIONES

SUPERIOR e INFERIOR sin necesidad de cojinetes.

Cuando se utilicen las herramientas de tipo I, IV, V y

398, se usa el COJINETE NEGRO con la fijación inferior.

Efectúe el montaje con el saliente interno hacia abajo.

NOTA: al usar las herramientas giratorias de los modelos

245, 270, 280 y 380, son necesarios los dos COJINETES

GRISES. Monte el cojinete grande en la fijación superior

y el pequeño en la fijación inferior.

Si utiliza la herramienta giratoria del modelo 250, sólo

necesitará el cojinete gris pequeño. Móntelo en la fijación

inferior.

2. Afloje las dos TUERCAS DE FIJACIÓN varias veces.

Sitúe la herramienta giratoria en las fijaciones

asegurándose de que la punta de la herramienta se

encuentra frente al saliente de la parte de abajo de la

fijación inferior. Con el INTERRUPTOR y EL BLOQUEO

DE EJE hacia adelante, fije la herramienta apretando las

dos tuercas de fijación.

NOTA: mientras use los cojinetes, alinee el corte de cada

cojinete con el corte de las fijaciones. Además, confirme

que la herramienta y los cojinetes quedan perfectamente

ajustados.

3. Desenchufe el cable de alimentación de la toma de

pared y saque la herramienta giratoria de la guía para

instalar una broca de guía. Introduzca la caña de la

BROCA GUÍA en el portabrocas, permitiendo que la

TUERCA DEL PORTABROCAS sobresalga un máximo de

5/8" por debajo. Aplique el bloqueo del eje y la llave para

fijar correctamente la broca.

-16-

DOS COJINETES GRISES

TUERCA DEL

PORTABROCAS

BROCA GUÍA

PROFUNDIDAD DE CORTE

5/8”

FIJACIÓN

SUPERIOR

COJINETE NEGRO

FIJACIONES INFERIORES

DM 2615302558 8/98 1/11/99 1:48 PM Page 16

Page 17

4. Afloje la TUERCA DE FIJACIÓN del SOPORTE DE

ALTURA y gire el TORNILLO DE AJUSTE DE

PROFUNDIDAD para establecer la profundidad del corte.

La profundidad del corte será la distancia que la broca

sobresale por debajo de la BASE DE LA GUÍA. En cuanto

haya fijado esta medida, vuelva a apretar la tuerca de

fijación.

Las marcas de ajuste que se encuentran en la parte

posterior de la abrazadera de ajuste están marcadas en

pulgadas y en milímetros. Cada línea del lado con

fracciones representa un 1/16 de pulgada. Cada línea del

lado con unidades métricas representa un milímetro.

Fíjese en las marcas antes de comenzar su proyecto.

Afloje el pomo de fijación y gire el tornillo de ajuste en

sentido antihorario (subiendo la abrazadera de ajuste),

realice el ajuste a la profundidad deseada y vuelva a

apretar el pomo de fijación. Para asegurarse de que el

ajuste sea adecuado, frese material de desecho y mida el

corte.

5. Utilizado a mano alzada, el complemento guía le

ayudará a tallar letras, figuras, patrones o realizar

operaciones de broca dirigida. Apoye los antebrazos en

el banco para obtener un mejor control durante este tipo

de operaciones.

Si necesita un patrón para letras o números, utilice el Kit

de diseño de señales en madera de Dremel, modelo 10.

Este juego ofrece 3 estilos de patrones de letra (Old

English, Script y Block).

6. El mango de guía permite un mejor control general del

complemento guía. Este mango también sirve de

compartimento para guardar brocas de guía. Si gira la

tapa en el sentido antihorario, y coloca las brocas de la

herramienta giratoria en los orificios de 1/8" (4 por cada

mango), podrá colocar hasta 8 brocas. Vuelva a colocar

el mango girándolo en el sentido horario hasta que

quede apretado.

7. Observado desde arriba, el eje de la guía gira en el

sentido horario. Para lograr un mejor control y calidad

del corte, haga avanzar la guía en la dirección en la que

la broca tiende a entrar en la madera por sí sola (si la

dirección del avance es incorrecta, la broca tratará de

salir de la madera). Haga avanzar la guía en el sentido

mostrado en la figura. Por ejemplo, si está cortando

alrededor del borde de una pieza cuadrada, mueva la

guía en el sentido antihorario. Si va a moverse por la

superficie interior, según se muestra, avance en el

sentido horario. La dirección de avance es muy

importante al usar una broca dirigida a mano alzada en el

borde de una pieza de trabajo.

-17-

Hacer escultura y tallar

letras con la

herramienta giratoria y

el complemento guía.

TORNILLO DE AJUSTE

DE PROFUNDIDAD

TUERCA DE

FIJACIÓN

SOPORTE

DE ALTURA

PROFUNDIDAD

DE

CORTE

BASE DE GUÍA

ABRAZADERA

DE AJUSTE

Direcciones de avance para las operaciones guiadas por el

exterior y el interior. Observe el orden de los cortes para el

trabajo alrededor de los cuatro lados de un tablero

rectangular o cuadrado.

DIRECCIÓN DE AVANCE DE LA PIEZA DE TRABAJO

ROTACIÓN DE LA BROCA

FRESAR

CONTRAHILO

PRIMERO

DM 2615302558 8/98 1/11/99 1:48 PM Page 17

Page 18

8. Para el GUIADO DE BORDES, monte unas VARILLAS

GUÍA en la abrazadera de ajuste de altura y fíjelas usando

unas (2) TUERCAS CUADRADAS nº10-24 y (2)

TORNILLOS philips #10-24 x 3/4". Las tuercas

cuadradas se deslizarán por unas ranuras situadas sobre

las varillas de guía. Los tornillos se montan desde los

orificios superiores, a través de las tuercas anteriores y

apretando las varillas. Fije la guía de bordes a los

PERNOS DE CARRO de dicha guía. Monte los pernos del

carro a través de los orificios cuadrados de la GUÍA DE

BORDE y a través de la ABRAZADERA de ésta. A

continuación, utilice las ARANDELAS y las TUERCAS DE

MARIPOSA para fijar estos elementos (tenga en cuenta

que los pequeños salientes del extremo de la abrazadera

de la guía de borde se corresponden con los orificios de

la guía de borde) Deslice el conjunto de guía de borde

sobre las varillas como se muestra en la figura. Coloque

la guía de borde a la DISTANCIA DESEADA desde el

cortador y apriete las tuercas de mariposa (fig. 1).

NOTA: aproveche la superficie lisa frontal de la base guía

para operaciones en línea recta o bordeados.

9. Si necesitan ajustes de la guía de bordes por encima

de las 1 3/4" del cortador, separe el conjunto de guía de

bordes de las varillas guía. Gire el conjunto y vuelva a

montar la abrazadera guía de borde en la varillas guía

desde el lado opuesto. A continuación, podrá fijar la guía

de borde a cualquier distancia desde el cortador, entre

1 1/4" y 4" (fig. 2).

-18-

TUERCAS CUADRADAS

TORNILLOS

PERNOS DE CARRO

TUERCAS DE MARIPOSA

ARANDELAS

ABRAZADER

A DE GUÍA

DE BORDE

VARILLAS GUÍA

SALIENTES

GUÍA DE BORDE

DM 2615302558 8/98 1/11/99 1:48 PM Page 18

Page 19

10. La guía de bordes sirve para dar forma a bordes,

cortar, hacer frisos, muescas, ranuras y chaflanes.

Recuerde hacer avanzar la herramienta de manera que el

cortador tienda a apretar la guía de borde contra la

madera. Para lograr unos cortes suaves, es conveniente

aplicar una velocidad regular de avance.

11. En general, suelen usarse varios cortes de

golondrina para realizar una muesca muy profunda. La

profundidad máxima del corte varía en función del

material utilizado. La velocidad del motor debe ser

moderada.

12 La abrazadera de la guía de bordes permite hacer

algunos cortes circulares. Pueden efectuarse a radios

entre 1 11/16" hasta 4". Extraiga la guía de borde y fije la

abrazadera de guía de borde a las varillas guía. Como

aguja de compás use la aguja de acabado que se

proporciona y sitúela al radio deseado. Coloque la aguja

a través del orificio de la abrazadera y sitúela en el centro

del radio que vaya a cortar.

-19-

DISTANCIA DESEADA

INFERIOR A 1 3/4”

GUÍA DE BORDE

RADIO

Fig. 2

Fig. 1

DISTANCIA DESEADA

ENTRE 1 1/4” Y 4”

DM 2615302558 8/98 1/11/99 1:48 PM Page 19

Page 20

-20-

9

20

2

12

4

3

10

11

15

16

8

18

19

7

7

6

1

5

13

14

11

21

17

ROUTER ATTACHMENT MODEL 330

COMPLEMENTO GUÍA MODELO 330

DM 2615302558 8/98 1/11/99 1:48 PM Page 20

Page 21

Code No. Part No. *Description

01 2615302324 *Router Base

02 529495170 *Depth Adjustment Bracket

03 529495270 *Tool Holder

04 529495370 *Depth Adjustment Screw

05 529495470 *Edge Guide Bracket

06 529495570 *Edge Guide

07 529495670 *Carriage Bolt #10 - 24 x 1 1/4 3 Req’d.

08 529495770 *Guide Rod 2 Req’d.

09 2615302325 *Router Bit Storage Handle 2 Req’d.

10 2615297532 *Clamp Knob

11 529422770 *Washer 3/16 I.D. 3 Req’d.

12 529496070 *Bracket Mounting Screw (#8 x 1”) 2 Req’d.

13 529496170 *Type One Bushing

14 529496270 *Small Body Bushing Set of Two

15 529496370 *Rod Clamp Screw #10 - 24 x 3/4 R.D. H.D. 2 Req’d.

16 529496470 *Square Nut #10 - 24 x 3/8 x 1/8 3 Req’d.

17 529496570 *Compass Point Nail

18 529422370 *Clamp Screw Nut 2 Req’d.

19 529420570 *Clamp Screw #6 - 32 x 3/4 Hex H.D. M.S. 2 Req’d.

20 0326578 *Storage Knob Mounting Screw - (#2 x 1/2”) 2 Req’d.

21 529495970 *Wing Nut #10-24 2 Req’d

-21-

*Available in hardware stores.

DM 2615302558 8/98 1/11/99 1:48 PM Page 21

Page 22

-22-

N˚ de rep. N˚ de pièce *Description

01 2615302324 *Base de toupillage

02 529495170 *Support de réglage de profondeur

03 529495270 *Support d’outil

04 529495370 *Vis de réglage de profondeur

05 529495470 *Support de guide

06 529495570 *Guide de toupie

07 529495670 *Boulon de carrosserie n˚ 10 - 24 x 1 1/4 3 requis

08 529495770 *Tige de guide 2 requises

09 2615302325 *Poignée de toupie avec rangement d’accessoires 2 requises

10 2615297532 *Bouton de serrage

11 529422770 *Rondelle à diam. int. de 3/16 2 requises

12 529496070 *Vis de montage du support (n˚ 8 x 1”) 2 requises

13 529496170 *Manchon de type I

14 529496270 *Manchons pour petite carcasse, jeu de 2

15 529496370 *Vis de serrage de tige n˚ 10 - 24 x 3/4 à tête ronde 2 requises

16 529496470 *Écrou carré n˚ 10 - 24 x 3/4 x 1/8 3 requis

17 529496570 *Clou servant de pointe de compas

18 529422370 *Écrou de la vis de serrage 2 requis

19 529420570 *Vis de serrage n˚ 6 - 32 x 3/4 à tête bombée 2 requises

20 0326578 *Vis de montage des poignées à rangement (n˚ 2 x 1/2”) 2 requises

21 529495970 *Écrous à ailettes #10-24 2 requises

*En vente dans les quincailleries

DM 2615302558 8/98 1/11/99 1:48 PM Page 22

Page 23

-23-

N˚ de código N˚ de pieza *Descripción

01 2615302324 *Base de guía

02 529495170 *Abrazadera de ajuste de profundidad

03 529495270 *Soporte de herramienta

04 529495370 *Tornillo de ajuste de profundidad

05 529495470 *Abrazadera de guía de borde

06 529495570 *Guía de borde

07 529495670 *Perno de carro n˚10 - 24 x 1 1/4” (3 nec.)

08 529495770 *Varilla guía (2 nec.)

09 2615302325 *Compartimento para guardar brocas de guía (2 nec.)

10 2615297532 *Tuerca de fijación

11 529422770 *Arandela de 3/16 I.D. (3 nec.)

12 529496070 *Tornillo de montaje de abrazadera (n˚8 x 1) (2 nec.)

13 529496170 *Cojinete de tipo uno

14 529496270 *Cojinete pequeño, juego de dos

15 529496370 *Tornillo de fijación de varilla n˚ 10 - 24 x 3/4 RD HD (2 nec.)

16 529496470 *Tuerca cuadrada n˚10 - 24 x 3/8 x 1/8 (3 nec.)

17 529496570 *Aguja de punta de compás

18 529422370 *Tuerca de tornillo de fijación (2 nec.)

19 529420570 *Tornillo de fijación n˚6 - 32 x 3/4 Hex H.D. M.S. (2 nec.)

20 0326578 *Tornillo de montaje de mango de almacenamiento

21 529495970 *Tuerca de mariposa #10-24 2 requises

*Puede adquirirse en ferreterìas.

DM 2615302558 8/98 1/11/99 1:48 PM Page 23

Page 24

UNITED STATES

ÉTATS-UNIS

ESTADOS UNIDOS

Dremel Service Center OR Dremel Service Center

4915 Twenty-First Street 4631 E. Sunny Dunes

Racine, Wisconsin 53406 Palm Springs, CA 92264

1-800-437-3635 1-800-275-2052

CANADA OUTSIDE CONTINENTAL

Giles Tool Agency

UNITED STATES

6520 Lawrence Av. East À L’EXTÉRIEUR DU TERRITOIRE

Scarborough, Ont.

CONTINENTAL DES ÉTATS-UNIS

Canada M1C 4A7 FUERA DE LOS TERRITORIOS

1-800-285-3476

CONTINENTALES DE LOS EE.UU.

See your local distributor or write to

Dremel, 4915 Twenty-First St.

Racine, Wisconsin 53406

ORDER BY PART NUMBER, NOT CODE NUMBER

COMMANDEZ PAR LE NUMÉRO DE LA PIÉCE—NON PAR LE NUMÉRO DE CODE

ORDERNE POR NUMERO DE PIEZA, NO POR NUMERO DE CODIGO

WRITE FOR CURRENT PRICES

NO C.O.D.'S

ÈCRIVEZ POUR OBTENIR LES PRIX

COURANTS PAS DE P.S.L.

ESCRIBA PARA OBTENER PRECIOS

ACTUALES - NO SE HACEN ENVIOS CONTRA REEMBOLSO

2615302558 8/98 Printed in U.S.A

DM 2615302558 8/98 1/11/99 1:48 PM Page 24

Loading...

Loading...