Page 1

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

231

P.O. Box 1468 Racine, Wisconsin 53401

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations

et les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

1-800-4-DREMEL (1-800-437-3635) http://www.dremel.com

For English Version

See page 2

Version française

Voir page 9

Versión en español

Ver la página16

Page 2

Power Tool Safety Rules

!

WARNING

Read and understand all instructions. Failure to follow all instructions listed

below may result in electric shock, fi re and/or serious personal injury.

SA VE THESE INSTRUCTIONS

Work Area

Keep your work area clean and well lit.

Cluttered benches and dark areas invite

accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

fl ammable liquids, gases, or dust. Power

tools create sparks which may ignite the

dust or fumes.

Keep by-standers, children, and visitors

away while operating a power tool.

Distractions can cause you to lose control.

Electrical Safety

Double-insulated tools are equipped

with a polarized plug (one blade is wider

than the other). This plug will fi t in a

polarized outlet only one way. If the plug

does not fi t fully in the outlet, reverse

the plug. If it still does not fi t, contact a

qualifi ed electrician to install a polarized

outlet. Do not change the plug in any

way. Double Insulation

need for the three-wire grounded power

cord and grounded power supply system.

Before plugging in the tool, be certain the

outlet voltage supplied is within the voltage

marked on the nameplate. Do not use “AC

only” rated tools with a DC power supply.

Avoid body contact with grounded

surfaces such as pipes, radiators,

ranges and refrigerators. There is an

increased risk of electric shock if your body

is grounded. If operating the power tool in

damp locations is unavoidable, a Ground

Fault Circuit Interrupter must be used to

supply the power to your tool. Electrician’s

rubber gloves and footwear will further

enhance your personal safety.

Don't expose power tools to rain or wet

conditions. Water entering a power tool

will increase the risk of electric shock.

Do not abuse the cord. Never use the cord

to carry the tools or pull the plug from

an outlet. Keep cord away from heat, oil,

sharp edges or moving parts. Replace

damaged cords immediately. Damaged

cords increase the risk of electric shock.

When operating a power tool outside, use

an outdoor extension cord marked “W-A”

eliminates the

or “W.”

use and reduce the risk of electric shock.

These cords are rated for outdoor

Personal Safety

Stay alert, watch what y ou are doing and

use common sense when operating a

power tool. Do not use tool while tired or

under the infl uence of drugs, alcohol, or

medication.

operating power tools may result in serious

personal injury.

Dress properly. Do not wear loose

clothing or jewelry. Contain long hair.

Keep your hair, clothing, and gloves away

from moving parts. Loose clothes, jewelry,

or long hair can be caught in moving parts.

Keep handles dry , clean and free from oil and

grease.

Avoid accidental starting. Be sure switch

is “OFF” before plugging in. Carrying tools

with your fi nger on the switch or plugging

in tools that have the switch “ON” invites

accidents.

Remove adjusting keys or wrenches

before turning the tool “ON”. A wrench or

a key that is left attached to a rotating part of

the tool may result in personal injury.

Do not overreach. Keep proper footing

and balance at all times. Proper footing and

balance enables better control of the tool in

unexpected situations.

Use safety equipment. Always wear eye

protection. Dust mask, non-skid safety

shoes, hard hat, or hearing protection must

be used for appropriate conditions.

A moment of inattention while

Tool Use and Care

Use clamps or other practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand or

against your body is unstable and may lead

to loss of control.

Do not force tool. Use the correct tool for

your application. The correct tool will do the

job better and safer at the rate for which it is

designed.

Do not use tool if switch does not turn

it “ON” or “OFF”. Any tool that cannot be

controlled with the switch is dangerous and

must be repaired.

2

Page 3

Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing the tool.

Such preventive safety measures reduce the

risk of starting the tool accidentally.

Store idle tools out of reach of children

and other untrained persons.

dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting

tools sharp and clean.

tools, with sharp cutting edges are less likely

to bind and are easier to control. An y alteration

or modifi cation is a misuse and may result in

a dangerous condition.

Check for misalignment or binding of

moving parts, breakage of parts, and

any other condition that may affect tool

operation. If damaged, have the tool

serviced before using.

caused by poorly maintained tools. Dev elop a

periodic maintenance schedule for your tool.

Properly maintained

Many accidents are

Tools are

Safety Rules for Router/Shaper Tables

Use only accessories that are

recommended by the manufacturer

for your model. Accessories that may

be suitable for one tool may become

hazardous when used on another tool.

Service

Tool service must be performed only

by qualifi ed repair personnel. Service

or maintenance performed by unqualifi ed

personnel could result in a risk of injury. For

example: internal wires may be misplaced or

pinched, safety guard return springs may be

improperly mounted.

When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual.

Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk

of electric shock or injury. Certain cleaning

agents such as gasoline, carbon tetrachloride,

ammonia, etc. may damage plastic parts.

Read and understand the tool manual

and these instructions for the use of this

table with your router. Failure to follow all

instructions listed below may result in serious

personal injury.

Position the tool with the switch in “easy”

reach so you are not blindly searching for

it. Power tool switches and controls need to

be within your zone in emergency situations.

Fully assemble and tighten all the fasteners

required for this table and mounting the

tool. Do not use the router table until all

assembly and installation steps have been

completed. Also remember to occasionally

check the table clamps and tool to make sure

it is still tight. A loose table is unstable and

may shift in use and cause serious injury.

Make certain the tool is not plugged into

a wall outlet when installing into the table,

making adjustments or changing bits.

Accidental start-up of the tool can cause

injury.

Before operating make sure the entire unit

is placed on a solid, fl at, level surface.

Serious injury could occur if tool is unstable

and tips.

Be certain tool is fully and securely clamped

in the collar, periodically check the base

fastener or clamping tightness. Adjustment

devices must be securely tightened.

Tighten as necessary as the motor can

loosen from the base due to vibration

and may drop or fall unexpectedly when

positioned upside down in a table.

After changing the bits or making any

adjustments, make sure the collet nut

and any other adjustment devices are

securely tightened. Loose adjustment

devices can unexpectedly shift, causing loss

of control, and loose rotating components

will be violently thrown.

Do not use the router table without the

overhead guard.

keeping your hands away from the spinning

blade in case of unintended contact with bit.

Never place your fi ngers under the guard

or near the spinning bit. Never hold the

workpiece on the out-feed side of bit.

Pressing the workpiece against the outfeed side of the fence may cause material

binding and possible kickback pulling your

hand back into the bit.

Router bits are intended for wood, wood

products and plastic only. Not for cutting

or shaping metals. Be sure the workpiece

does not contain nails, etc. before routing.

Cutting a nail or the like will cause the carbides

The guard will aid in

3

Page 4

to be dislodged, fl y toward the operator side,

and possibly strike you or bystanders.

Match the appropriate bit and its speed

to your application. Do not use bits that

have a cutting diameter that exceeds the

capacity of the tool. Overloading the tool

can lead to personal injury or tool failure.

Position and securely clamp the router

bit in the collet before making any cuts.

If the bit becomes loose during operation,

it may fl y up and away from table possibly

striking you or bystanders.

Never use dull or damaged bits. Sharp

bits must be handled with care. Damaged

bits can snap during use. Dull bits require more

force to push the workpiece, possibly causing

the bit to break or material to kick back.

The router table is primarily designed to

cut fl at, straight and squared materials,

we do not recommend cutting material

that is warped, wobbly or otherwise

unstable. If the material is slightly

curved cut the material with the concave

side against the table or fence. Cutting

the material with the concave side up or

away from table may cause the warped or

wobbly material to roll; causing you to lose

control; kickbac k and serious personal injury

may result.

Never start the tool when the bit is

engaged in the material. The bit cutting

edge may grab the material causing loss of

control of the workpiece.

Feed the workpiece against the rotation of

the bit. The bit rotates counter-clockwise

as viewed from the top of table. Feeding

the work in the wrong direction will cause the

workpiece to “climb” up on the bit and may

lead to loss of control during operation.

Use push sticks and other jigs to hold

down the workpiece and keep your hands

away from the spinning blade. Router

cuts are blind cuts but the bit still protrudes

through the table and you must be aware

of the position of your hands relative to the

spinning bit.

Use of auxiliary in-feed and out-feed

supports is strongly suggested for long

or wide workpieces. Long workpieces can

fl ip offthe table or cause the table to tip over if

notfully supported.

Use the adjustable fence in straight

cutting applications. When routing along

an entireedge of the work, the fence and

adjustable support wedge will help maintain

stability.

Do not place material between router

bitand the fence while routing the edge.

This placement may cause the material to

become wedged, making kickback possible.

Never touch the bit during or immediately

after use. Contact with a spinning bit will

cause injury and after use the bit is too hot to

be touched by bare hands.

Do not use the table as workbench or

worksurface. The table is not intended to be

used as a workbench or work surface other

than for routing material. Using it for purposes

other than routing may cause damage and

make it unsafe to use in routing.

Never stand on the table or use as ladder

or scaffolding. Serious injury could occur

if the table is tipped or the cutting tool is

accidentally contacted. Do not store materials

on or near the table such that it is necessary to

stand on the table or its stand to reach them.

Use only Dremel replacement parts and

accessories. Any others ma y create a hazard.

Shaper/Router Table, Model 231

ATTACHMENT FOR USE WITH DREMEL ROTARY MODELS

100, 200, 300, 400XPR, 275, 285, 395, 398, 800, 4000, 8200

ATTENTION:

manual carefully before using your Dremel

Shaper/Router Table. Retain instructions for

future reference. This attachment will convert

Read entire instruction

Dremel Rotary Tools to a Shaper/Router

Table for edge forming, routing, grooving,

shaping, sanding edges, jointing, etc

4

Page 5

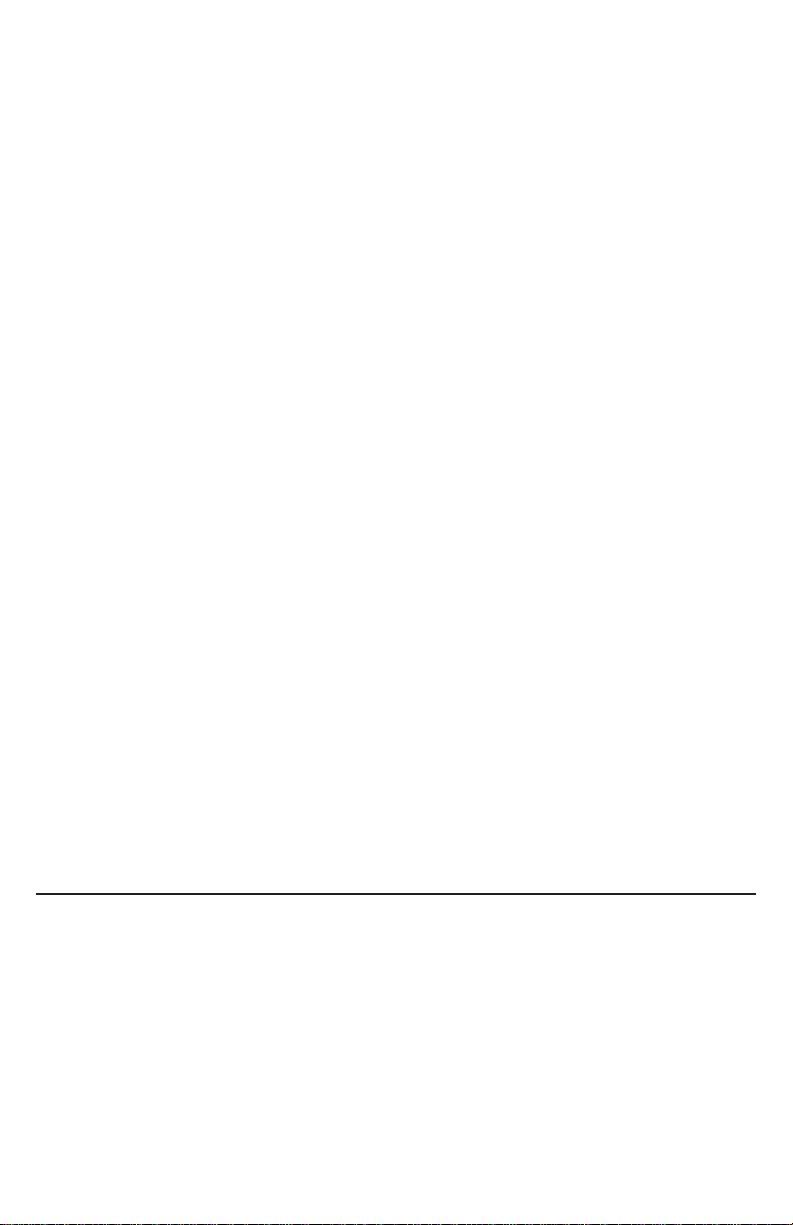

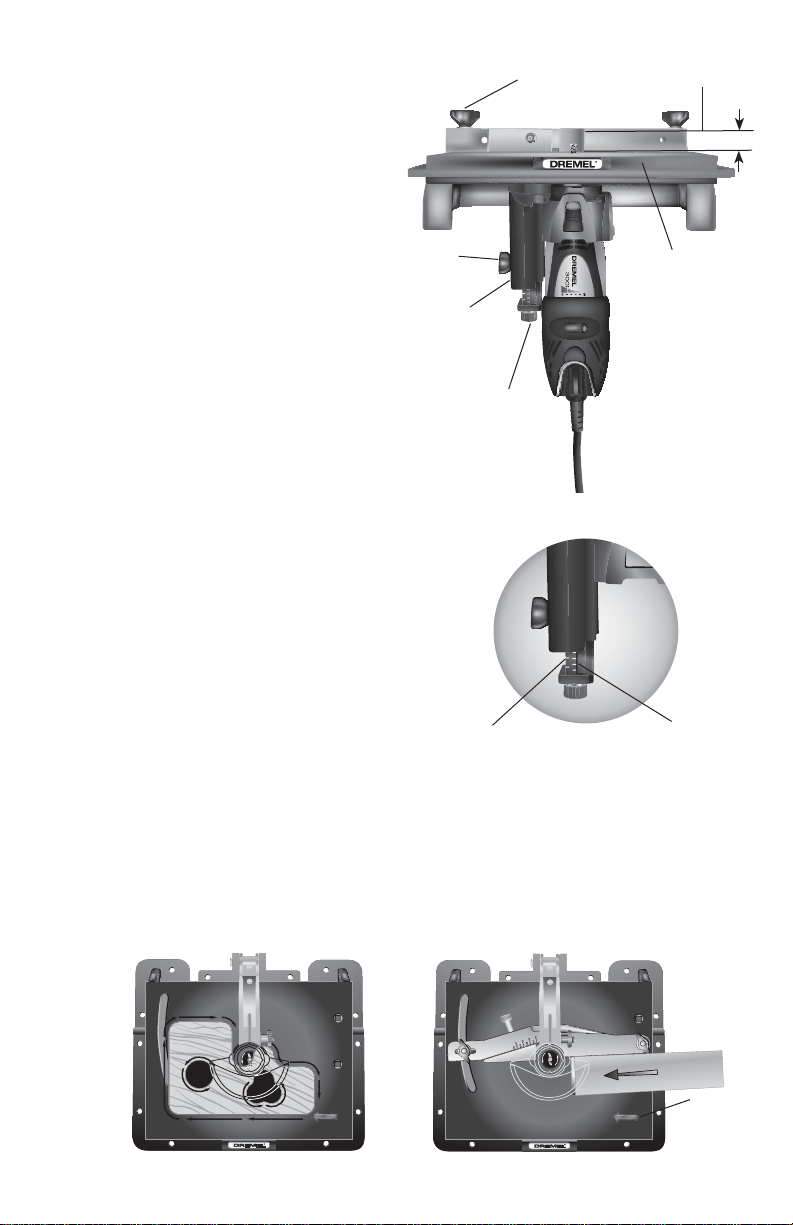

Mount T able to Workbench

The SHAPER/ROUTER TABLE comes

assembled ready to mount to the workbench.

After determining table location, predrill the

bench using a 1/8" diameter drill at the four

mounting hole locations. Secure table to the

bench using the (4) #10 x 1" wood screws,

and washers. (Included with the Shaper/

Router T ab le). (See Fig. 1)

Alternative mounting option: To make your

shaper table more portable, mount to piece

of 2" x 4". Then easily clamp to your work

bench as shown in Fig. 1.

Install Rotary Tool to Table

1. Loosen the clamp knob and turn depth

adjustment knob to lower tool holder .

2. With the Rotary Tool unplugged from a

power source, remove the threaded

housing cap off of tool and set housing cap

aside. The housing cap must be reinstalled

when not using Shaper/Router table.

3. Place tool into attachment with shaft lock

button and on/off button facing forward.

4. Thread locking nut clockwise onto the

threaded portion of your Rotary Tool and

securely tighten with the provided

wrench (See Fig. 2).

Fig. 1

Fig. 2

(4) #10 x 1"Wood

Screws &

Washers

Use 2' x 4" as

alternative

mounting option

Guard

Fence

!

WARNING

manual before using this accessory.

Read and understand these

instructions and the tool

Clamp

Knob

5

Depth

Adjustment

Screw

On/off switch

must face

forward so

that turning off

tool is readily

accessible

Page 6

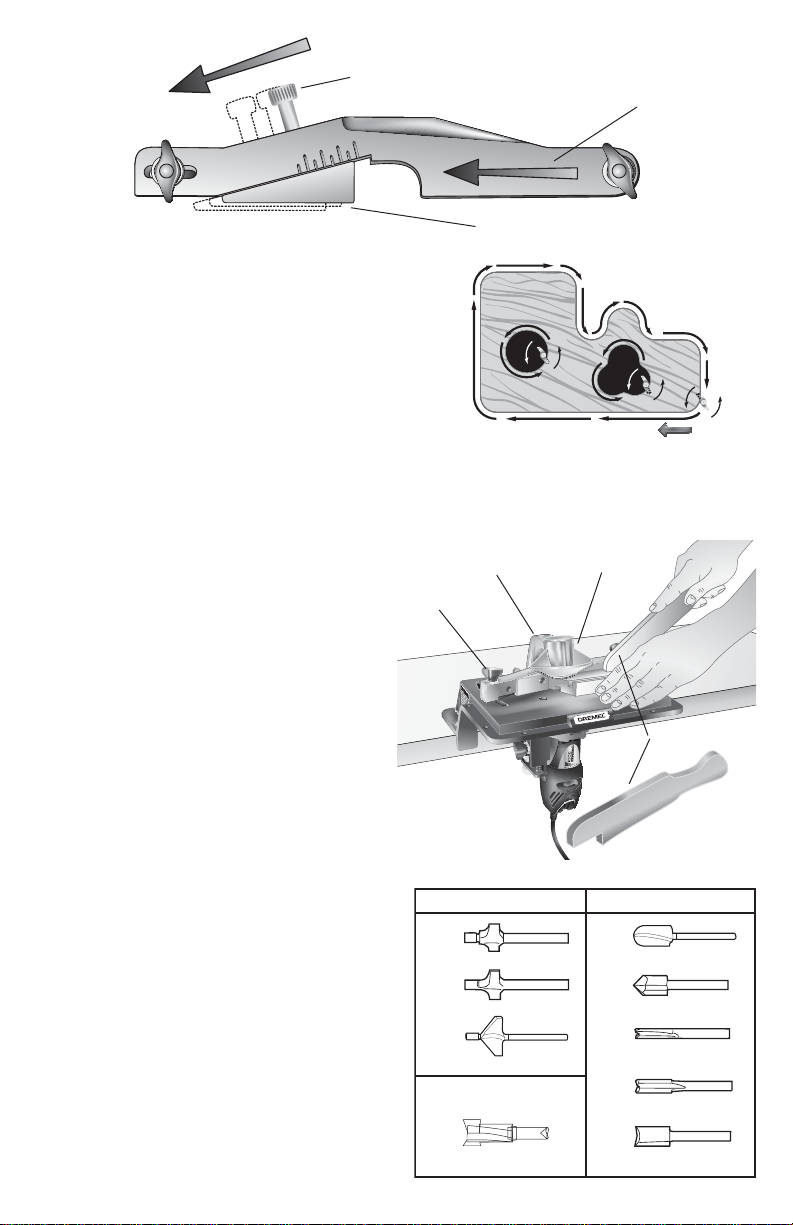

1. When installing router bits, be sure the

Installing Router Bits

power cord is unplugged, then remove

the tool from the Shaper/Router Table. Fit

the router bit shank into the collet allowing

a maximum of 5/8" to protrude past the

collet nut. Use the shaft button on your

rotary tool and wrench to secure the bit.

(See Fig. 3)

2. Loosen the clamp knob and turn the

depth adjustment screw to set cutting

depth. Depth of cut will be the amount the

bit extends above the shaper/router

table.

Cutting Depth Adjustment

Adjustment markings on the side of the

tool holder facing outward are marked in

inches and millimeters. View the markings

prior to starting your project. Turn the depth

adjustment screw to set desired depth. To

ensure proper settings, rout and measure

cut on scrap material. (See Fig. 4)

Fig. 3

Clamp

Knob

Holder

Assembly

Large Knob

Tool

Depth

Adjustment

Screw

Depth of Cut

5/8"

Table

The router spindle turns in a counter

Router Feed Direction

clockwise direction when viewed from abov e

the table. For best control and quality of cut,

feed the work into the bit in the direction that

the bit will tend to pull the work to the fence.

(Incorrect feed direction will result in the bit

trying to pull the wood through faster than

you want. This is called climb cutting.) Feed

the workpiece from right to left as shown.

Feed direction is extremely important when

using a pilot bit freehand on the edge of a

workpiece as well as when using the fence

with all bits. (See Fig. 5)

Routing T able Tips

1. Wrong Direction – Hard to control.

2. Feeding too fast – Overloads motor.

3. Dull bit – Overloads motor.

4. Cutting too large or deep in one pass –

Overloads motor.

5. Feeding too slow – Leav es friction b urns

on work.

Fig. 5

Fig. 4

Millimeters

in 5mm increments

Depth Adjustment Markings

Inches in 1/8 inch

increments

Direction

Feed Direction Without Fence Feed Direction With Fence

6

Feed

Arrow

Page 7

Fig. 6 Fence

Clamp Screw Nut

Routing Using the Fence

1. Unplug the rotary tool before making any

fence adjustments or bit changes. Feed

the work against the rotation of the bit

as shown. (See Fig. 7) Most fence cutting

is done with the support wedge adjusted

to the right, where it is in line with the

fence. (See Fig. 6)

2. Center cylinder of the guard can be

adjusted up when making cuts using the

fence. Loosen thumb nut, lift the cylinder

up and secure by tightening thumb nut.

(See Fig. 8)

3. When shaping small pieces or when

fi nishing the cut on narrow, long pieces,

use a push stick. Use 1/4" x 2" x 8" piece

of lumber notched as shown to make

this push stick. (See Fig. 8) It will enable

you to keep your hands away from the

cutting area.

4. To cut a straight groove, install the bit

and set the depth of cut using the depth

adjustment screw as shown in Fig. 3.

Loosen large knob on left end of fence

and swing fence assembly to proper

distance from bit to give desired groove

location. Retighten large knob. Take a

trial cut on scrap lumber to check depth

and location of groove.

5. When planing the entire edge of a

workpiece, the support wedge may be

adjusted to support the workpiece on the

left side of the table. Take a trial cut

about 2" long and measure the amount of

stock removed. Turn rotary tool off.

Loosen clamp screw nut and slide wedge

to left until wedge contacts cut edge of

workpiece. Retighten clamp screw nut.

Workpiece will now have support on

both sides of the router bit.

When removing more than 1/16" of

mater ial from a long edge, if the support

wedge is not adjusted properly, the edge

will not be planed evenly.

Feed Direction

Support Wedge

Fig. 7

Feed Direction for Streight Cuts

with Fence

Fig. 8

Thumb Nut

Center Cylinder

(not shown)

Large Knob

Piloted Router Bits

612

615

618

Keyhole Bit

655

Router Bits

617

640

650

652

654

Push Stick

7

Page 8

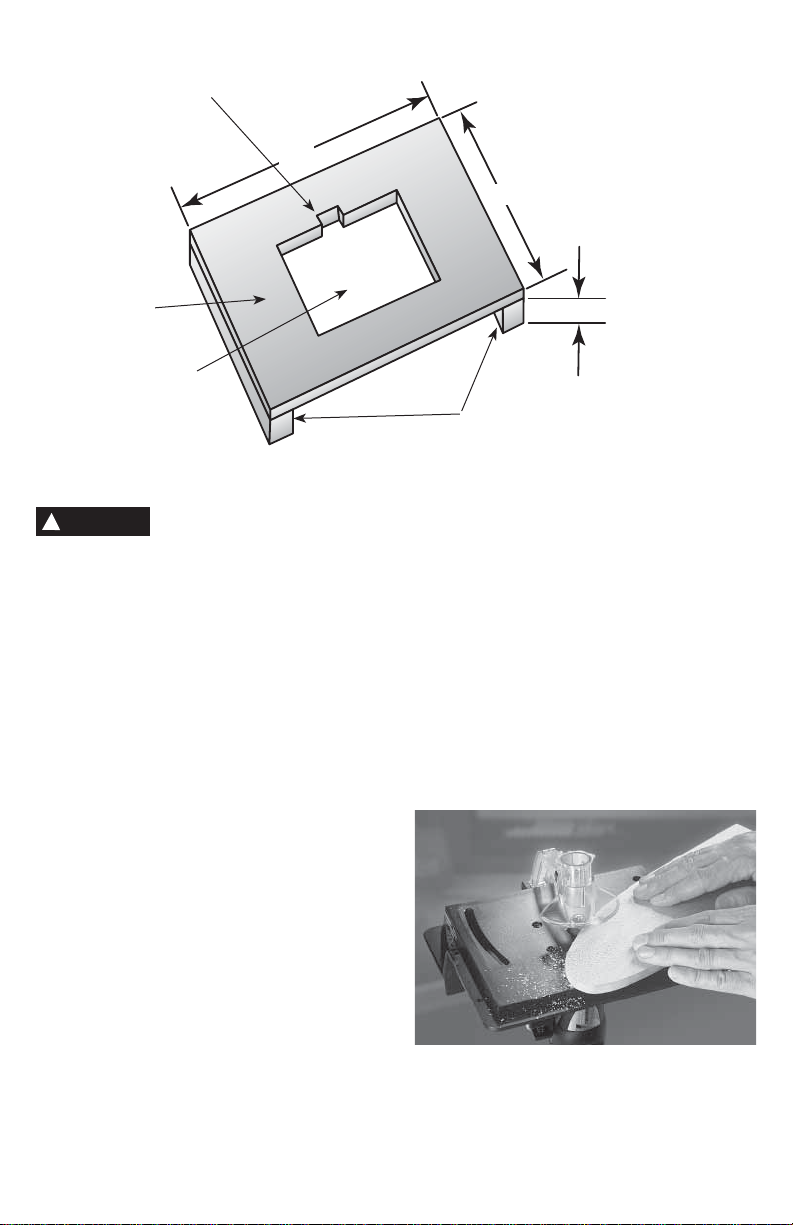

Fig. 9

1-1/2" Slot to Clear Guard

16"

12"

3/8" Plywood

Rectangular Hole

to Fit Over Table

!

WARNING

accessory and fence while routing or

sanding edge. This placement may cause

material to wedge making kickback possible.

Do not place material

between router bit or

Routing Using Pilot Bits

1. When bits with pilots are to be used,

move the fence back only enough to allow

the amount of cut to be made. Keeping

the fence close to the bit allows the fence

to serve as a rear guard. In special cases

when the fence must be remo ved from the

table, adjust the center cylinder of the

guard down to provide protection from

revolving cutter.

2. Only piloted bits can be used without the

fence. The workpiece should be kept

between the cutter and the operator, and

fed from right to left.

3. Feed the workpiece past the cutter

without stopping and with a consistent

speed. A change in feed or a dwell wil

cause an irregular cut.

1-1/2"

1-1/2" High Supports

on Both Ends Will Rest on Bench

secure using (8) #10 wood screws, 1/2" in

length. Support the table at both ends by

securing 1-1/2" high lumber supports to the

plywood base. (See Fig. 9)

(Hardware not included)

Drum Sanding

The Shaper/Router Table is also ideal for

drum sanding irregular shaped parts as

shown. Use Drum Sander 407 (1/2") or 430

(1/4"), with or without the fence assembly.

(See Fig. 10)

Fig. 10

Expanded T able Work Surface

The shaper/router table is designed to easily

expand the size of the working surface. Use

3/8" thick solid core plywood. Cut a rectangular

hole in the plywood to fi t over the table and

8

Page 9

Conseils de sécurité pour les outils électriques

!

AVERTISSEMENT

électrique, un incendie et/ou des blessures personnelles graves..

Maintenir le lieu de travail propre et bien

éclairé. Des établis encombrés et des endroits

sombres sont la cause d’accidents.

Ne pas utiliser d’outils électriques dans des

atmosphères explosives ou en présence de

liquides, gaz et poussière infl ammables. Les

outils électriques créent des étincelles qui peuvent

enfl ammer la poussière ou les vapeurs.

Maintenir les spectateurs, les enfants et les

visiteurs à l’écart lors de l’utilisation d’un outil

électrique. Les distractions peuvent causer une

perte du contrôle.

Sécurité électrique

Les outils à double isolation sont équipés

d’une fi chepolarisée (une des broches est plus

large que l’autre).Cette fi che s’adaptera dans

une prise polarisée d’uneseule manière. Si

la fi che ne s’adaptait pasparfaitement dans la

prise, l’inverser. Si elle nes’adapte toujours

pas, communiquer avec unélectricien qualifi é

pour faire installer une prisepolarisée. Ne pas

modifi er la fi che d’une manièrequelconque. La

double isolation

électrique à trois fi ls pour mise à la terre et d’un

système d’alimentation électrique mis à la terre.

Avant de brancher l’outil, s’assurer que la tension

fournie à la prise correspond à la tension indiquée

sur la plaque signalétique. Ne pas utiliser d’outils

étiquetés «CA seulement» avec une alimentation

électrique à courant continu.

Éviter tout contact du corps avec des objets mis

à la terre comme tuyaux, radiateurs, cuisinières

et réfrigérateurs. Il existe un risque accru de

décharge électrique si votre corps est mis à la

terre. Si le fonctionnement de l’outil électrique

dans des endroits humides ne peut être évité, un

circuit comportant un interrupteur de fuite à la terre

doit être utilisé pour alimenter l’outil. Des gants et

des chaussures encaoutchouc pour électriciens

amélioreront encore votresécurité personnelle.

Ne pas laisser les outils électriques exposés à

la pluie ou à l’humidité. L’eau pénétrant dans un

outil électrique augmentera le risque de décharge

électrique. Éviter d’endommager le cordon.

Ne jamais utiliser le cordon pour transporter

l’outil ou débrancher la fi che de la prise. Maintenir

le cordon à l’écart de chaleur , d’huile, des bords

coupants ou de pièces mobiles. Remplacer les

cordons endommagés immédiatement. Les

cordons endommagés augmentent le risque de

décharge électrique.

Veuillez lire et bien comprendre toutes les directives. Si les directives

indiquées cidessous ne sont pas respectées, il peut en résulter une décharge

VEUILLEZ CONSERVER CES DIRECTIVES

Lieu de travail

élimine le besoin d’un cordon

Lors de l’utilisation d’un outil électrique à

l’extérieur, utiliser un cordon de rallonge électrique

pour l’extérieur, étiqueté «W-A» ou «W». Ces

cordons sont étalonnés pour usage à l’extérieur

et réduisent les risques de décharge électrique.

Soyez alerte, faites attention à ce que vous faites

et faites usage de bon sens lors de l’utilisation

d’un outil électrique. N’utilisez pas un outil si

vous êtes fatigué ou sous l’infl uence de drogue,

alcool ou médicament. Un moment d’inattention

lors de l’usage d’outils électriques peut résulter en

de graves blessures personnelles.

Habillez-vous adéquatement. Ne portez pas

de vêtements lâches ou de bijouterie. Retenez

les cheveux longs. Maintenez les cheveux,

les vêtements et les gants à l’écart de pièces

mobiles. Des vêtements lâches, de la bijouterie

ou des cheveux longs peuvent se prendre dans les

pièces mobiles. Maintenir les poignées propres,

sèches et exemptes de graisse et d’huile.

Éviter toute mise en marche accidentelle.

S’assurer que le contacteur est sur «OFF» (arrêt)

avant de brancher l’outil. Le fait de transporter

des outils avec le doigt sur le contacteur ou de

brancher des outils avec le contacteur en position

«ON» (marche) est souvent la cause d’accidents.

Enlever les clés de réglage avant de mettre

l’outil en marche. Une clé restée attachée sur une

pièce rotative de l’outil peut causer des blessures

personnelles.

Ne pas s’étirer pour atteindre. Maintenir un bon

équilibre en tout temps. Un bon équilibre assure

un meilleur contrôle de l’outil dans des situations

inattendues.

Utiliser l’équipement de sécurité. Toujours

porter des lunettes protectrices. Des masques

anti-poussières, des chaussures de sécurité

antidérapantes, un casque ou une protection

antibruit doit être utilisé selon les conditions.

Utilisation et entretien de l’outil

Utiliser une bride de fi xation ou toute autre pince

de travail pour maintenir et soutenir la pièce de

travail d’une manière stable. Le fait de tenir la

pièce à la main ou contre le corps est instable et

peut causer une perte du contrôle.

Ne pas forcer l’outil. Utiliser le bon outil en

fonction de l’application. Le bon outil fera un

meilleur travail et plus sécuritairement pour lequel

il a été conçu.

9

Sécurité personnelle

Page 10

Ne pas utiliser l’outil si le contacteur «MARCHE/

ARRÊT» ne fonctionne pas. T out outil qui ne peut

être contrôlé par le contacteur est dangereux et

doit être réparé.

Débrancher la fi che de la prise d’alimentation

avant d’effectuer tout réglage, changement

d’accessoires ou rangement de l’outil. Des

mesures de sécurité préventives réduisent le

risque de mise en marche accidentelle de l’outil.

Ranger les outils hors d’atteinte des enfants

et d’autres personnes non formées. Les outils

sont dangereux dans les mains d’un utilisateur

inexpérimenté.

Entretenir les outils avec soin. Maintenir les

outils de coupe bien affûtés et propres. Des

outils adéquatement maintenus avec des bords

de coupe tranchants risquent moins de coincer et

sont plus faciles à contrôler. Toute altération ou

modifi cation est un mésusage et peut résulter en

une situation dangereuse.

Vérifi er le mauvais alignement ou le coincement

des pièces mobiles, le bris des pièces ainsi

que toute autre condition qui peut affecter le

fonctionnement de l’outil. S’il est endommagé,

faire réparer l’outil avant de l’utiliser. De

nombreux accidents sont causés par des outils mal

Directives de sécurité pour les tables à façonner/toupiller

entretenus. Mettre au point un calendrier

d’entretien périodique pour votre outil.

Utiliser uniquement les accessoires qui sont

recommandés par le fabricant pour le modèle.

Les accessoires qui conviennent pour un outil

peuvent devenir dangereux lorsqu’ils sont utilisés

sur un autre.

Service d’entretien

Le service d’entretien de l’outil doit être effectué

uniquement par du personnel de réparation

qualifi é. Le service ou l’entretien effectué par

du personnel inexpérimenté peut résulter en des

risques de blessure. Par exemple : le câblage

interne peut être mal placé ou pincé, les ressorts

de retour des gardes de sécurité peuvent être mal

montés.

Lors de tout service d’entretien d’un outil,

utiliser uniquement des pièces de rechange

identiques. Suivre les directives indiquées dans

la section «Entretien» de ce manuel. L’utilisation

de pièces non autorisées ou le fait de ne pas

suivre les directives d’entretien peut causer un

risque de décharge électrique ou des blessures.

Certains agents de nettoyage commel’essence,

le tétrachlorure de carbone, l’amoniaque, etc.

peuvent endommager les pièces en plastique.

Veuillez lire et comprendre le manuel de l’outil

et ses directives pour l’usage de cette table

avec votre toupie. Si les directives indiquées ci-

dessous ne sont pas respectées, il peut en résulter

de graves blessures personnelles.

Placer l’outil pour que le contacteur soit à «facile

à atteindre» pour éviter d’avoir à le rechercher à

tâtons. Les contacteurs et les commandes d’outils

électriques doivent être dans votre zone visuelle

pour les utiliser en situations d’urgence.

Assembler complètement et serrer toutes les

fi xations requises pour cette table et pour

monter l’outil. Ne pas utiliser la table à toupiller

avant que toutes les étapes d’assemblage et

d’installation aient été terminées. N’oubliez

pas de vérifi er de temps en temps les brides de

fi xation de l’outil pour vous assurer qu’elles sont

bien serrées. Une table desserrée est instable

et peut se déplacer lors de l’usage et causer de

graves blessures.

S’assurer que l’outil n’est pas branché dans

la prise murale lors de l’installation de la

table, lors d’ajustements ou de changement

de mèches. Une mise en marche accidentelle de

l’outil peut causer des blessures.

Avant l’usage, s’assurer que l’unité en entier

est placée sur une surface plate, stable et de

niveau. De graves blessures peuvent se produire

si l’outil est instable et s’il bascule.

S’assurer que l’outil est bien bridé dans le

collier de maintien, en vérifi ant périodiquement

la fi xation de la base ou le serrage de la bride.

Les dispositifs d’ajustement doivent être serrés

fermement. Serrer au besoin car le moteur peut

se desserrer de l a base à la suite de vibrations

et peut basculer ou tomber soudainement lorsqu’il

est monté à l’envers dans une table.

Après avoir changé les mèches ou avoir effectué

tout ajustement, s’assurer que l’écrou de pince

ainsi que les autres dispositifs d’ajustement

sont bien serrés. Des dispositifs d’ajustement

desserrés peuvent causer un déplacement

inattendu, une perte de contrôle, et des éléments

rotatifs peuvent être projetés violemment.

Ne pas utiliser la table à toupiller sans le garde

supérieur. Ce garde aidera à maintenir vos mains

à l’écart de la lame en mouvement dans le cas de

contact inattendu avec la mèche.

Ne jamais placer les doigts sous le garde ou

près de la mèche en mouvement. Ne jamais

tenir la pièce de travail par le côté de sortie

d’alimentation de la mèche. En appuyant sur la

pièce de travail contre le côté de sortie de la mèche,

le matériau risque de se coincer et causer un recul

qui pourrait forcer votre main vers la mèche.

Les mèches à toupiller sont conçues pour usage

uniquement avec du bois, des produits de bois et

de plastique. Ne pas couper ou former de métaux.

10

Page 11

S’assurer que la pièce de travail ne contient

aucun clou, etc. avant le toupillage. Le fait de

couper un clou ou autre pièce métallique risque

de causer le dégagement des pointes de carbure

et les projeter vers l’utilisateur ou toute autre

personne.

Faire correspondre la mèche et sa vitesse à votre

application. Ne pas utiliser de mèches ayant un

diamètre de coupe excédant le rendement de

l’outil. Une surcharge de l’outil peut causer des

blessures personnelles ou une défaillance de

l’outil.

Placer et brider sécuritairement la mèche à

toupiller dans la pince avant d’effectuer toute

coupe. Si la mèche se desserre au cours de

l’usage, elle peut être projetée de la table et vous

heurter ou d’autres personnes.

Ne jamais utiliser de mèches émoussées

ou endommagées. Les mèches tranchantes

doivent être manipulées avec soin. Des mèches

endommagées peuvent casser lors de l’usage. Des

mèches émoussées exigent plus de force pour

pousser la pièce de travail, risquant de casser la

mèche ou de faire sauter la pièce.

La table à toupiller est principalement conçue

pour couper des pièces plates, droites ou

carrées; nous ne recommandons pas de couper

des matériaux gondolés, mous ou instables.

Si la pièce est légèrement incurvée, la couper

avec le côté concave contre la table ou le guide.

Le fait de couper la pièce avec le côté concave ou

incurvé vers le haut peut causer un déplacement

de la pièce, résultant en une perte du contrôle, un

recul de la pièce et des blessures personnelles

graves peuvent en résulter.

Ne jamais démarrer l’outil lorsque la mèche

est prise dans la pièce. Le bord d’attaque de la

mèche peut agripper la pièce et causer une perte

du contrôle de la pièce.

Alimenter la pièce de travail contre la rotation

de la mèche. La mèche tourne dans le sens antihoraire, vu du dessus de la table. L’alimentation

de pièce dans la mauvaise direction risque de

causer un déplacement de la pièce sur la mèche et

résulter en une perte du contrôle lors de la coupe.

Utiliser des pièces et autres dispositifs pour

maintenir la pièce et garder vos mains à

l’écart de la lame en mouvement. Les travaux

de toupillage sont des coupes aveugles, mais

la mèche dépasse de la table et vous devez être

conscient de la position de vos mains en fonction

de celle de la mèche.

L’usage de supports d’alimentation auxiliaires

est fortement suggéré pour les pièces de travail

longues ou surdimensionnées. Les pièces

surdimensionnées peuvent tomber de la table ou

causer un basculement de la table si elles ne sont

pas totalement soutenues.

Utiliser un guide ajustable pour les applications

de coupe droite. Lors de toupillage le long du

bord de la pièce de travail, le guide et le coin de

support ajustable aidera à maintenir la stabilité.

Ne placer aucune pièce entre la mèche de la

toupie et le guide lors du toupillage d’un bord.

Ceci peut causer un coincement de la pièce et

risque de causer un recul.

Ne jamais toucher la mèche pendant l’usage

ou immédiatement après. Tout contact avec une

mèche en mouvement causera des blessures et

après l’usage, la mèche est trop chaude pour être

touchée à mains nues.

Ne pas utiliser la table comme établi ou surface

de travail. La table n’est pas conçue pour être

utilisée comme un établi ou une surface de travail

autre que pour le toupillage de pièces. Le fait de

l’utiliser pour des usages autre que le toupillage

peut l’endommager et compromettre sa sécurité

lors du toupillage.

Ne jamais monter sur la table ou l’utiliser

comme échelle ou échafaudage. Des blessures

graves pourraient se produire si la table bascule

ou si l’outil est mis en marche accidentellement.

Ne pas ranger de matériaux sur ou près de la table

pour éviter qu’il soit nécessaire de s’appuyer sur la

table ou son support pour les atteindre.

Utiliser uniquement des pièces de rechange et

des accessoires Dremel. T ous les autres peuvent

causer un risque.

Table à façonner/toupiller, modèle 231

ACCESSOIRE POUR USAGE AVEC OUTIL ROTATIF DREMEL MODELES

100, 200, 300, 400XPR, 275, 285, 395, 398, 800, 4000, ET 8200

ATTENTION: Lire les directives complètes de ce

manuel avant d’utiliser la table à façonner/toupiller

Dremel. Conserver ces directives pour vous y

reporter à l’avenir . Cet accessoire transformera

votre outil rotatif Dremel en une table à façonner/

toupiller pour faire des bordures, toupiller , rainurer,

façonner, poncer des bords et faire des joints, etc.

11

Page 12

Montage de la table sur un établi

La table à façonner/toupiller est livrée assemblée,

prête au montage sur un établi. Après avoir

déterminé l’emplacement de la table, prépercer

l’établi avec un foret d’un diamètre de 1/8 po aux

quatre emplacements des trous de montage. Fixer

la table à l’établi avec (4) vis à bois No. 10 x 1

po et rondelles (Incluses avec la table à façonner/

toupiller). (Voir fi gure 1.)

Autre option de montage : Pour rendre votre

table à façonner plus portative, montez-la sur un

morceau de 2 x 4 po puis, bridez-la aisément sur

votre établi comme illustré à la fi gure 1.

Montage de l’outil rotatif dans la table

1. Desserrer le bouton de maintien et tourner

lebouton de réglage de la profondeur pour

abaisserle porte-outils inférieur.

2. Après avoir débranché l’outil rotatif de sa source

d’alimentation électrique, retirez le capuchon

fi leté de protection de l’outil et mettez-le de

côté. Le capuchon de protection doit être

réinstallé lorsque vous n’utilisez pas la table de

la toupie/machine à façonner.

3. Placez l’outil dans l’équipement de façon que

le bouton de verrouillage de l’arbre et le bouton/

l’interrupteur de marche/arrêt soient orientés

tous les deux vers l’avant.

4. Enfi lez l’écrou de blocage dans le sens des

aiguilles d’une montre sur la partie fi letée de

votre outil rotatif et serrez solidement avec la

clé fournie (voir fi gure 2)

!

AVERTISSEMENT

ainsi que le manuel de l’outil avant d’utiliser cet

accessoire.

Veuillez lire et bien

comprendre ces directives

fi g. 1

fi g. 2

Bouton de

maintien

réglage de la

(4) vis à bois No.

et rondelles

Vis de

profondeur

10 x 1 po

Utiliser un 2 x 4 po

comme autre

option de montage

Garde

Guide

L’interrupteur de

marche/arrêt doit

être orienté vers

l’avant de façon

qu’il soit facile

d’éteindre l’outil

en cas de besoin.

12

Page 13

Mise en place des mèches de toupie

1. Lors de la mise en place de mèches de toupie,

s’assurer de débrancher le cordon d’alimentation,

puis enlever l’outil de la table à façonner/

toupiller. Placer la tige de la mèche à toupie

dans la pince en laissant dépasser un maximum

de 5/8 po de l’écrou de pince. Utiliser le bouton

de la broche de votre outil rotatif et une clé pour

serrer fermement la mèche. (Voir fi gure 3.)

2. Desserrer le bouton de maintien et tourner

la vis de réglage de profondeur pour ajuster

la profondeur de coupe. La profondeur de

coupe sera la longueur de la mèche qui

dépassera au-dessus de la table à façonner/

toupiller.

Réglage de la profondeur de coupe

Les marques de réglage sur le côté extérieur

du porteoutils sont calibrées en pouces et en

millimètres. Examiner les marques avant de

commencer votre projet. Tourner la vis de réglage

de profondeur pour régler la profondeur voulue.

Pour assurer les bons réglages, effectuer un essai

de coupe et mesurer la profondeur sur une pièce

de rebut. (Voir fi gure 4.)

Direction d’alimentation de la toupie

L’arbre de la toupie tourne dans une direction

antihoraire vue du dessus de la table. Pour assurer

le meilleur contrôle et une bonne qualité de la

coupe, pousser la pièce à travailler vers la mèche,

dans la direction où la mèche aura tendance à

tirer sur le travail vers le guide. (Une direction

d’alimentation incorrecte aura tendance à tirer

sur le bois plus rapidement que vous le désirez,

et la mèche aura tendance à grimper sur le bois.)

Alimenter la pièce de la droite vers la gauche,

comme illustré. La direction d’alimentation est

extrêmement importante lors de l’utilisation d’une

mèche pilote à main levée sur le bord d’une pièce

ainsi que lors de l’usage d’un guide avec toutes les

autres mèches. (Voir fi gure 5.)

Conseils pour table à toupiller

1. Mauvaise direction – Diffi cile à contrôler.

2. Alimentation trop rapide – Surcharge du moteur .

3. Mèche émoussée – Surcharge du moteur.

4. Coupe trop longue ou trop profonde pour

un seul passage – Surcharge du moteur.

5. Alimentation trop lente – Marque des brûlures

de friction sur la pièce.

fi g. 3

Grand bouton

Bouton de

maintien

Ensemble

porte-outils

Vis de réglage

de profondeur

fi g. 4

Millimètres

par intervalles

de 5mm

Marques de réglage de profondeur

Profondeur de

la coupe

5/8 po

Table

Pouces par

intervalles

de 1/8 po

fi g. 5

Direction d’alimentation sans guide Direction d’alimentation avec guide

13

Flèche de

direction

d’alimentation

Page 14

fi g. 6 Guide

Écrou de la vis de maintien

Direction d’alimentation

Coin de support

1. Débrancher l’outil rotatif avant d’effectuer tout

Toupillage avec le guide

réglage du guide ou tout changement de

mèche. Alimenter le travail contre la rotation

de la mèche, comme illustré. (Voir fi gure 7.)

La plupart des coupes avec guide sont

effectuées avec le coin de support ajusté à

droite, aligné avec le guide. (Voir fi gure 6.)

2. Le cylindre central du garde peut être ajusté

vers le haut lors de coupes effectuées avec

le guide. Desserrer l’écrou à oreilles, relever le

cylindre et le sécuriser en serrant l’écrou à oreilles.

(Voir fi gure 8.)

3. Lors du façonnage de petites pièces ou lors de

la fi nition d’une coupe sur des pièces longues et

étroites, utiliser un poussoir. Utiliser un morceau

de bois de 1/4 x 2 x 8 po, encoché comme

illustré pour fabriquer ce poussoir. (Voir fi gure

8.) Il vous permettra de maintenir vos mains à

l’écart de la zone de coupe.

4. Pour couper une rainure droite, monter la

mèche et régler la profondeur de coupe avec la

vis de réglage de profondeur, comme illustré

à la fi gure 3. Desserrer le grand bouton du côté

gauche du guide et placer l’ensemble du guide

à la distance voulue de la mèche pour obtenir

l’emplacement voulu de la rainure. Resserrer

le grand bouton. Faire une coupe d’essai sur

un morceau de bois de rebut pour vérifi er la

profondeur et l’emplacement de la rainure.

5. Lors du rabotage d’un bord d’une pièce de

travail, le coin de support peut être ajusté pour

supporter la pièce de travail du côté gauche de

la table. Faire une coupe d’essai d’environ 2

po. de long et mesurer la quantité de bois

enlevée. Arrêter l’outil rotatif. Desserrer l’écrou

de la vis de maintien et glisser le coin vers

la gauche jusqu’à ce qu’il entre en contact avec

le bord coupé de la pièce de travail. Resserrer

l’écrou de la vis de maintien. La pièce de travail

sera maintenant supportée des deux côtés de la

mèche.

Lorsque l’on enlève plus de 1/16 po. d’un bord

long, si le coin de support n’est pas ajusté

comme il faut, le bord ne sera pas raboté

uniformément.

fi g. 7

Direction d’alimentation pour

coupe droite avec guide

fi g. 8

Cylindre central

Grand bouton

Mèches pilotes

612

615

618

Mèche pour trou

de serrure

655

Écrou à oreilles

(non illustré)

Poussoir

Mèches de toupie

617

640

650

652

654

14

Page 15

fi g. 9

Fente de 1-1/2 po pour

permettre le passage

Contreplaqué

de 3/8 po.

Trou rectangulaire

pour adapter sur

la table

du garde

16 po.

12 po.

1-1/2 po.

Supports de 1-1/2 po de haut aux deux

extrémités, à placer sur l’établi

!

AVERTISSEMENT

ou accessoire et le guide lors de toupillage ou du

ponçage de bords. Ceci peut faire coincer la pièce

et causer un recul.

Ne pas placer de pièce

entre la mèche de la toupie

Toupillage avec des mèches pilotes

1. Lorsque des mèches avec pilotes doivent être

utilisées, reculer le guide suffi samment pour

permettre d’effectuer la coupe prévue. Le fait

de maintenir le guide près de la mèche permet

au guide de servir de protecteur arrière. Dans

certains cas où le guide doit être enlevé de la

table, ajuster le cylindre central du garde vers

le bas pour fournir la protection de la mèche en

mouvement.

2. Seules des mèches pilotes peuvent être utilisées

sans le guide. La pièce de travail doit être

maintenue entre la mèche et l’usager et

alimentée de la droite vers la gauche.

3. Alimenter la pièce de travail jusqu’à la mèche

sans vous arrêter et à une vitesse constante. Un

changement d’alimentation ou un ralentissement

causera une coupe irrégulière.

Agrandissement de la surface

de travail de la table

La table à façonner/toupiller est conçue pour

agrandir aisément la surface de travail. Utiliser une

planche de contreplaqué de 3/8 po d’épaisseur.

Découper un trou rectangulaire dans la planche

pour l’adapter au-dessus de la table et la sécuriser

avec (8) vis à bois No. 10, de 1/2 po. de long. Soutenir

la table aux deux extrémités en sécurisant un

morceau de bois de 1-1/2 po. de haut pour soutenir

la base en contreplaqué.

(Boulonnerie non comprise)

(Voir fi gure 9.)

Ponceuse à tambour

La table à façonner/toupiller est aussi idéale

pour le ponçage au tambour de pièces de formes

irrégulières, comme illustré. Utiliser le tambour

de ponçage 407 (1/2 po) ou 430 (1/4 po) avec ou

sans le guide. (Voir fi gure 10.)

fi g. 10

15

Page 16

Reglas de seguridad de la herramienta eléctrica

!

ADVERTENCIA

Lea y entienda todas las instrucciones. No seguir las siguientes instrucciones

puede resultar en una descarga eléctrica, fuego y/o lesiones personales graves.

GUARDE ESTAS INSTRUCCIONES

Area de trabajo

Mantenga su área de trabajo limpia y bien

iluminada. Bancos desordenados y áreas oscuras

promueven accidentes.

No opere herramientas eléctricas en ambientes

explosivos, como en presencia de líquidos

inlfamables, gases o polvo. Las herramientas

eléctricas crean chispas las cuales pueden encender

el polvo o los gases.

Mantenga a las personas, niños y visitantes

lejos mientras que opere una herramienta

eléctrica. Las distracciones pueden hacer que

pierda el control.

Seguridad eléctrica

Las herramientas doblemente aisladas están

equipadas con un enchufe polarizado (una

clavija es más ancha que la otra). Este enchufe

funcionará en un toma de corriente polarizados

únicamente de una manera. Si el enchufe no entra

completamente voltéelo. Si aún no entra, llame a

un electricista califi cado para que instale un toma

de corriente polarizado. No cambie el enchufe de

ninguna manera. El aislamiento

necesidad de un cable tripolar con toma de tierra y

de un sistema de suministro eléctrico con toma de

tierra. Antes de enchufar la herramienta, cerciórese

de que el voltaje de suministro esté dentro del voltaje

marcado en la placa. No use herramientas clasifi cadas

"sólo AC" con suministros de energía DC.

Evite el contacto del cuerpo con superfi cies con

toma de tierra tales como tubos, radiadores,

fogones y neveras. Hay un mayor riesgo de una

descarga eléctrica si su cuerpo está haciendo

contacto a tierra. Si no se puede evitar la operación

de la herramienta en una área húmeda, se debe usar

un Interruptor que regula la falla de la toma de tierra

para suministrar la energía a su herramienta. El

uso de guantes y calzado de caucho de electricista

mejorará su seguridad personal.

No exponga las herramientas eléctricas a la

lluvia o a la humedad. El agua que entre a una

herramienta eléctrica incrementará el riesgo de

descarga eléctrica.

No abuse del cable. Nunca lo use para sujetar

las herramientas o lo hale para desenchufarlas.

Mantenga el cable alejado del calor, aceite,

bordes afi lados o partes en movimiento.

Reemplace inmediatamente un cable en mal

estado. Los cables dañados aumentan el riesgo de

descargas eléctricas.

Cuando opere una herramienta eléctrica a la

intemperie, use una extensión para trabajo

externo marcada “W-A” o “W.”

doble elimina la

Estas extensiones

están clasifi cadas para uso al aire libre y reducen el

riesgo de descarga eléctrica.

Seguridad personal

Manténgase atento, observe lo que está

haciendo y aplique su sentido común cuando

esté operando una herramienta eléctrica. No

use la herramienta cuando esté cansado o bajo

los efectos de drogas, bebidas alcohólicos o

medicamentos. Un momento de desatención

mientras que esté operando una herramienta

eléctrica puede causar lesiones personales serias.

Vístase de manera apropiada. No use ropa

amplia o joyas. Cójase el cabello largo.

Mantenga su cabello, ropa y guantes lejos de

las partes en movimiento. La ropa suelta, joyas

o el cabello largo pueden quedar atrapados en las

partes en movimiento. Mantenga las manijas secas,

limpias y libres de aceite y grasa.

Evite el encendido accidental. Asegúrese que

el interruptor está “APAGADO (OFF)” antes de

enchufar. Sujetar las herramientas con su dedo en

el interruptor o enchufar herramientas que tengan

el interruptor “ENCENDIDO (ON)” promueve

accidentes.

Quite las llaves de ajuste o cualquier objeto

antes de encender la herramienta. Una llave

o herramienta que sea dejada en una parte

rotatoria de la herramienta puede causar lesiones

personales.

No se estire demasiado. Manténgase bien

apoyado en sus pies y en equilibrio en todo

momento. Un apoyo y equilibrio adecuados

permiten un mejor control de la herramienta en

situaciones inesperadas.

Use un equipo de seguridad. Siempre use

protección para sus ojos.Máscara para el polvo,

zapatos con suela antideslizante de seguridad,

casco o protección para sus oídos deben ser

usados para asegurar condiciones adecuadas.

Uso y cuidado de la herramienta

Use abrazaderas o cualquier otra manera

práctica de asegurar y apoyar la pieza de trabajo

a una plataforma estable. Sostener el trabajo con

las manos o contra su cuerpo resulta inestable y

puede conducir a la pérdida de control.

No fuerce la herramienta. Use la herramienta

apropiada para cada aplicación. La herramienta

apropiada hará el trabajo mejor y de manera más

segura al ritmo para el cual fue diseñada.

No use la herramienta si el interruptor no apaga

o prende la herramienta. Cualquier herramienta

16

Page 17

que no puede ser controlada con el interruptor es

peligrosa y debe ser reparada.

Desconecte el enchufe antes de hacer cualquier

ajuste, de cambiar accesorios o de guardar

la herramienta. Estas medidas de seguridad

preventivas reducen el riesgo de encender la

herramienta de manera accidental.

Guarde las herramientas que no estén en uso

lejos del alcance de los niños y personas sin

entrenamiento. Las herramientas son peligrosas

en las manos de usuarios sin entrenamiento.

Cuide las herramientas. Mantenga las

herramientas para cortar afi ladas y limpias. Las

herramientas mantenidas de manera apropiada, con

bordes afi lados son menos propensas a doblarse

y más fáciles de controlar. Cualquier alteración o

modifi cación consiste en un uso inapropiado y

puede causar una situación peligrosa.

Revise que no haya partes en movimiento

desalineadas o dobladas, partes quebradas,

o cualquier otra condición que pueda afectar

la operación de la herramienta. Si está

dañada, la herramienta debe ser reparada

antes de ser usada. Muchos accidentes son

causados por herramientas que no han sido

Normas de seguridad para mesas para buril/moldeador

Lea y entienda el manual de la herramienta y estas

instrucciones para el uso de la mesa con su buril.

No seguir todas las instrucciones a continuación

puede resultar en lesiones personales graves.

Coloque la herramienta con el interruptor a un

fácil acceso de tal manera que no esté buscándolo

ciegamente. Los interruptores y controles de

electricidad de la herramienta deben estar dentro de

su alcance en caso de una emergencia.

Ensamble completamente y apriete todos los

seguros requeridos para esta mesa y para montar

la herramienta. No use la mesa para el buril

hasta que todos los pasos para la instalación y

el ensamble hayan sido completados. T ambién

recuerde revisar ocasionalmente las abrazaderas

de la mesa y la herramienta para asegurarse de

que todavía estén apretadas. Una mesa suelta es

inestable y puede moverse durante el uso causando

lesiones graves.

Cerciórese de que la herramienta no esté enchufada

mientras que la instale en la mesa, haga ajustes

o cambie de brocas. El encendido accidental de la

herramienta puede casuar lesiones.

Antes de operar, cerciórese de que la unidad entera

esté en una superfi cie fi rme, plana y nivelada.

Pueden presentarse lesiones graves si la herramienta

está inestable y se tambalea.

Asegúrese de que la herramienta esté bien

asegurada en el collar, periódicamente revise el

seguro de la base y que las abrazaderas estén

apretadas. Las piezas de ajuste deben estar

17

mantenidas adecuadamente. Desarrolle un

calendario de mantenimiento periódico para su

herramienta.

Use únicamente accesorios recomendados

por el fabricante de su modelo. Los accesorios

adecuados para una herramienta pueden resultar

peligrosos si se usan en otra.

Reparación

La reparación de la herramienta debe ser

realizada únicamente por personal califi cado.

La reparación o el mantenimiento realizados por

personal no califi cado puede causar el riesgo de

lesiones. Por ejemplo, los cables internos pueden

ser mudados de lugar o chuzados, los resortes

que retornan la barrera pueden ser montados

inadecuadamente.

Cuando repare una herramienta use únicamente

repuestos idénticos. Siga las instrucciones en

la sección de mantenimiento de este manual. El

uso de repuestos no autorizados o no seguir las

Instrucciones de mantenimiento pueden ocasionar

el riesgo de descarga eléctrica o lesiones. Ciertos

agentes limpiadores como gasolina, tetracloruro

de carbono, amoniaco, etc., pueden estropear las

partes plásticas.

apretadas de manera segura.

necesario para que el motor no se suelte de la base

debido a la vibración y pueda caerse inesperadamente

cuando se coloque al revés en la mesa.

Después de cambiar las brocas o hacer cualquier

ajuste, asegúrese de que la tuerca del collarín y

cualquier otra pieza de ajuste estén apretadas de

manera segura. Las piezas de ajuste sueltas pueden

moverse inesperadamente, causando la pérdida de

control, y los componentes rotatorios sueltos serán

arrojados violentamente.

No use la mesa para el buril sin la protección

superior. La protección le ayudará a mantener

sus manos lejos de la cuchilla giratoria en caso de

contacto involuntario con la broca.

Nunca ponga sus dedos bajo la protección o cerca

de la broca girando. Nunca sostenga la pieza

de trabajo por el lado que la broca va a hacer el

agujero.

contraria a la salida de la broca puede causar que el

material se trabe y retroceda empujando su mano

hacia la broca.

Las brocas buriladoras son diseñadas para madera,

y productos de madera y plástico únicamente. No

para cortar o dar forma a metales. Asegúrese de

que la pieza de trabajo no tenga puntillas, etc.

antes de burilar. Hacer un corte en una puntilla

causará que los carburos se desprendan, vuelen

hacia el operador y posiblemente lo golpeen a usted

o a alguien cerca.

Presionar la pieza de trabajo en dirección

Apriete tanto como sea

Page 18

Elija la broca apropiada y su velocidad de

acuerdo con su aplicación. No use brocas que

tengan un diámetro de corte que exceda la

capacidad de la herramienta. Sobrecargar la

herramienta puede causar lesiones personales o

falla de la herramienta.

Coloque y sujete de manera segura la broca

buriladora en el collarín antes de empezar

cualquier corte. Si la broca se afl oja durante su

operación puede volar y posiblemente golpearlo a

usted o a alguien cerca.

Nunca use brocas sin fi lo o dañadas. Las brocas

afi ladas deben manejarse con cuidado. Las

brocas dañadas pueden romperse durante su

uso. Las brocas sin fi lo requieren más fuerza

para empujar la herramienta, ocasionando la

posibilidad de que la broca se quiebre o que el

material retroceda.

La mesa para el buril está diseñada

primordialmente para cortar materiales planos,

rectos y cuadrados, no recomendamos cortar

material deformado, poco fi rme o inestable. Si

el material es ligeramente curvo córtelo con el

lado cóncavo contra la mesa o la barrera. Cortar

el material con el lado cóncavo hacia arriba puede

hacer que el material deforme o inestable dé

vueltas, haciendo que pierda el control, retroceda

y cause lesiones personales graves.

Nunca encienda la herramienta cuando la broca

esté engranada en el material. El fi lo de la broca

de corte puede agarrar el material causando la

pérdida de control de la pieza de trabajo.

Avance con la pieza de trabajo en contra de la

rotación de la broca. El eje del buril gira en

sentido contrario de las manecillas del reloj

cuando se ve desde encima de la mesa. Avanzar

en una dirección contraria causará que la pieza de

trabajo trate de montarse en la broca y cause la

pérdida de control durante la operación.

Use palos de presión o cualquier otra guía

para sostener la pieza de trabajo y mantener

sus manos alejadas de la cuchilla girando. Los

cortes del buril son cortes ciegos pero la broca

sale de todas maneras a través de la mesa y usted

debe estar consciente de la posición de sus manos

con respecto a la broca girando.

El uso de apoyos auxiliares para avanzar es

fuertemente aconsejado en piezas largas o

anchas. Las piezas largas pueden salirse de la

mesa o causar que la mesa se voltee si no está

apoyada fi rmemente.

Use la barrera ajustable para cortes rectos.

Cuando burile a lo largo de todo el borde de una

pieza, la barrera y la cuña de apoyo ajustable le

ayudarán a mantener la estabilidad.

No coloque el material entre la broca buriladora

y la barrera mientras que burile el borde. Esta

posición puede causar que el material se bloquee

haciendo posible que rebote.

Nunca toque la broca durante o inmediatamente

después de su uso. El contacto con una broca

girando causará lesiones y después de su uso la

broca está muy caliente para ser tocada con las

manos.

No use la mesa como banco de trabajo o

superfi cie de trabajo para otra cosa que no sea

para burilar. El uso para propósitos diferentes a

burilar puede causar daños y volverla peligrosa

para burilar.

Nunca se pare en la mesa o la use como escalera

o andamio. Lesiones graves pueden ocurrir si la

mesa se voltea o la herramienta de corte se toca

accidentalmente. No mantenga materiales sobre o

cerca de la mesa de tal manera que sea necesario

pararse en la mesa o en su pie para alcanzarlos.

Use sólo repuestos y accesorios Dremel.

Cualquier otro puede ocasionar peligros.

Mesa para moldeador/buril, modelo 231

ACCESORIO PARA USAR CON LOS MODELOS ROTATORIOS DE DREMEL

100, 200, 300, 400XPR, 275, 285, 395, 398, 800, 4000, Y 8200

ATENCION: Lea cuidadosamente el Manual de

Instrucciones completo antes de usar su mesa para

Moldeador/Buril Dremel. Guarde las instrucciones

para futura consulta. Este accesorio convertirá su

herramienta rotatoria Dremel en una mesa para

Moldeador/Buril para bordear, burilar, acanalar,

moldear, lijar bordes, articular, etc.

18

Page 19

Montar la tabla al banco de trabajo

La mesa para moldeador/buril viene ensamblada

y lista para montar en el banco de trabajo. Después

de determinar la ubicación de la mesa, perfore

previamente el banco usando una broca de 1/8" de

diámetro en la posición de los cuatro agujeros de

montaje. Asegure la mesa al banco usando los (4)

tornillos # 10 x 1" y las arandelas (incluidos con

la mesa para moldeador/buril) (vea la fi gura 1).

Opción alternativa para montaje: para hacer su

mesa para moldeador/buril más portátil, monte

la pieza de 2" x 4". Después asegure fácilmente su

banco de trabajo como se muestra en la fi gura 1.

Instalar la herramienta rotatoria a la mesa

1. Afl oje la perilla de la abrazadera y gire la perilla

de ajuste de profundidad para bajar el soporte de

la herramienta.

2. Con la herramienta rotativa desenchufada

de una fuente de alimentación, retire la

tapa de la carcasa roscada de la herramienta

y ponga dicha tapa de la carcasa a un lado. La

tapa de la carcasa debe ser reinstalada cuando

no se esté utilizando la mesa de perfi ladora /

fresadora.

3. Coloque la herramienta en el aditamento con el

botón de cierre del eje y el botón de encendido

y apagado orientados hacia delante.

4. Enrosque la tuerca de fi jación en el sentido de

las agujas del reloj en la porción roscada de su

herramienta rotativa y apriétela de manera

segura con la llave de tuerca suministrada (vea

la fi gura 2).

!

ADVERTENCIA

de la herramienta antes de usar el accesorio.

Lea y entienda estas

instrucciones y el manual

fi g. 1

fi g. 2

Perilla de la

abrazadera

Tornillo de

ajuste de

profundidad

(4) tornillos para

madera

y arandelas #10 x 1"

Use una tabla

2" x 4" como opción

alternativa de

montaje

Protección

Barrera

El interruptor

de encendido y

apagado debe

estar orientado

hacia delante con

el fi n de brindar

acceso fácil

para apagar la

herramienta

19

Page 20

1. Cuando instale las brocas buriladoras, asegúrese

Instalar las brocas del buril

de que el cable eléctrico esté desenchufado y

retire la herramienta de la mesa para moldeador/

buril. Encaje la espiga de la broca buriladora en

el collarín permitiendo que salga un máximo de

5/8" debajo de la tuerca del collarín. Use el

seguro del eje en su herramienta rotatoria y la

llave para apretar la broca de manera segura

(vea la fi gura 3).

2. Afl oje la perilla de la abrazadera en el soporte

de profundidad y gire el tornillo de ajuste

de profundidad para ajustar la profundidad de

corte. La profundidad de corte será la cantidad

que la broca se extiende encima de la mesa

para moldeador/buril.

Ajustar la profundidad de corte

Las marcas de ajuste en la parte lateral hacia

afuera del soporte de la herramienta vienen en

pulgadas y milímetros. Observe las marcas antes

de comenzar su proyecto. Gire el tornillo de

ajuste de profundidad para ajustar la profundidad

deseada. Para asegurar un ajuste apropiado, burile

y mida el corte en un material de desperdicio (vea

la fi gura 4).

Cómo avanzar el buril

El eje del buril gira en dirección contraria a las

manecillas del reloj cuando se ve desde arriba de

la mesa. Para mejor control y calidad de corte,

mueva la madera hacia la broca en la dirección en

que la broca tiende a dirigir la pieza hacia la barrera.

(Avanzar en una dirección contraria causará que la

broca trate de tirar la madera más rápido de lo que

usted quiere. Esto se llama corte montado). Mueva

la pieza de trabajo de derecha a izquierda como se

muestra. La dirección de avance es extremamente

importante cuando use una broca piloto a pulso en

el borde de una pieza de trabajo, así como también

cuando use la barrera con cualquier broca (vea la

fi gura 5).

Claves para el uso de la mesa para burilar

1. Dirección incorrecta – Difícil de controlar.

2. Avance muy rápido – Sobrecarga del motor.

3. Broca sin fi lo – Sobrecarga del motor.

4. Corte muy largo o profundo en una sola pasada

- Sobrecarga del motor.

5. Avance muy despacioso – Deja marcas de

quemaduras por fricción en el trabajo.

fi g. 3

Perilla grande

Perilla

de la

abrazadera

Estructura del

soporte de la

herramienta

Tornillo de

ajuste de

profundidad

fi g. 4

Milímetros con

incrementos

de 5 mm

Marcas de ajuste de profundidad

Profundidad

de corte

5/8"

Table

Pulgadas con

incrementos de

1/8 de pulgada

fi g. 5

Dirección de avance sin la barrera Dirección de avance con la barrera

20

Flecha de

dirección

de avance

Page 21

fi g. 6 Barrera

Tuerca del tornillo de la

abrazadera

Cuña de apoyo

Dirección de avance

1. Desenchufe la herramienta rotatoria antes de

Burilar usando la barrera

hacer cualquier ajuste a la barrera o antes de

cambiar las brocas. Mueva el trabajo en contra de la

rotación de la broca como se muestra (vea

la fi gura 7). La mayoría de corte con la barrera

se hace con la cuña de apoyo ajustada hacia la

derecha, donde está alineada con la barrera

(vea la fi gura 6).

2.

El cilindro central de la protección puede ser

ajustado hacia arriba cuando se hacen cortes

usando la barrera. Afl oje la tuerca de mariposa,

levante el cilindro y asegúrelo apretando la tuerca

de mariposa (vea la fi gura 8).

3. Cuando esté moldeando piezas pequeñas o

cuando le esté dando acabado a cortes en piezas

estrechas y largas use

piezas de madera de 1/4" x 2" x 8" con muescas

como se muestra para hacer estos palos de

presión

sus manos lejos del área de corte.

4.

ajuste la profundidad de corte usando el tornillo

de ajuste de profundidad como se muestra en

la fi gura 3. Afl oje la perilla grande en el

extremo izquierdo de la barrera gire la estructura

de la barrera a la distancia apropiada de la

broca para lograr la posición deseada de la

canal. Vuelva a apretar la perilla grande. Haga

un corte de prueba en madera de desperdicio

para revisar la profundidad y la posición de

la canal.

5. Cuando alise el borde entero de una pieza

de trabajo, la cuña de apoyo puede ser

ajustada para sostener la pieza de trabajo en

el lado izquierdo de la mesa. Haga un corte

de prueba de aproximadamente 2" de longitud

y mida la cantidad de madera removida. Apague

la herramienta rotatoria. Afl oje la tuerca del

tornillo de la abrazadera y deslice la cuña hacia

la izquierda hasta que toque el borde de corte

de la pieza de trabajo. Vuelva a apretar la tuerca

del tornillo de la abrazadera. La pieza de trabajo

tiene ahora el soporte en ambos lados de la

broca buriladora.

Cuando quite más de 1/16" de material de un

borde largo, si la cuña de apoyo no está

ajustada de manera apropiada, el borde no será

aplanado uniformemente.

(vea la fi gura 8).

Para cortar una canal recta, instale la broca y

palos de presión.

Le permitirán mantener

Use

fi g. 7

Dirección de avance para cortes

rectos con barrera

fi g. 8

Tuerca de

mariposa (no

Cilindro central

se muestra)

Perilla grande

Brocas buriladoras

piloteadas

612

615

618

Broca de calar

655

Palo de presión

Brocas buriladoras

617

640

650

652

654

21

Page 22

fi g. 9

Ranura de 1-1/2" para

desmontar la protección

Triplex de 3/8"

Agujero rectangular

para ajustarse

encima de la mesa

16"

12"

1-1/2"

Soportes altos de 1-1/2" en ambos

extremos que descansan en el banco

!

ADVERTENCIA

el accesorio y la barrera mientras que burile o

lije el borde. Esta posición puede causar que el

material se bloquee haciendo posible que rebote.

No coloque el material

entre la broca buriladora o

Burilar usando brocas piloteadas

1. Cuando se deben usar brocas con pilotos,

mueva la barrera hacia atrás únicamente lo

sufi ciente como para hacer el corte. Mantener

la barrera cerca de la broca permite que la

barrera sirva como protección trasera. En

casos especiales cuando se debe quitar la

barrera de la mesa, ajuste el cilindro central de

la barrera hacia abajo para proteger en contra

de la cortadora giratoria.

2. Sólo se deben usar brocas piloteadas sin la

barrera. La pieza de trabajo se debe mantener

entre la cortadora y el operador, y se debe

avanzar de derecha a izquierda.

3. Avance con la pieza de trabajo hasta pasar la

cortadora sin parar y a una velocidad constante.

Un cambio en el avance o una extensión causará

un corte irregular.

Superfi cie extendida de la mesa de trabajo

La mesa para moldeador/buril está diseñada para

ampliar el tamaño de la superfi cie de trabajo. Use

triplex con alma gruesa sólida de 3/8". Haga un

agujero rectangular en el triplex para que se ajuste

sobre la mesa y asegure usando (8) #10 tornillos

para madera, de 1/2" de longitud. Sostenga la

mesa en ambos extremos asegurando apoyos de

madera de 1-1/2" de altura a la base del triplex

(vea la fi gura 9).

Tornillos y piezas metálicas no incluidas

Lijado con tambor

La mesa para moldeador/buril también es ideal

para lijar con tambor partes con formas irregulares

como se muestra. Use la lijadora de tambor 407

(1/2") ó 430 (1/4"), con o sin la estructura de la

barrera (vea la fi gura 10).

fi g. 10

22

Page 23

MODEL 231

2

16

7

6

15

10

9

15

19

18

17

11

1

4

3

8

5

7

14

7

13

12

23

Page 24

ORDER BY PART NUMBER, NOT CODE NUMBER

CODE NO. PART NO. DESCRIPCION

01 2610914499 Guard

02 2610914500 Sleeve

03 2610914501 Wedge

04 2610914502 Fence

05 2610914503 Base

06 2615294999 Pin

07 2615294956 Carriage Bolt 4 Required

08 2615296105 Wedge Clamp Screw 1 Required

09 2615296106 Mounting Screw 4 Required

10 2615294227 Washer 3/16" 7 Required

11 2610914504 Depth Bracket

12 2615294953 Depth Adjustment Screw

13 2610923360 Tool Holder

14 2615294964 Square Nut

15 2610915058 Large Knob 3 Required

16 2615297202 Thumb Nut

17 2615294960 Bracket Screw 2 Required

18 2610910326 Washer #9 1 Required

19 2615294223 Clamp Screw Nut 1 Required

WRITE FOR CURRENT PRICES

NO C.O.D.’S

24

Page 25

MODÈLE 231

2

16

7

6

15

10

9

15

19

18

17

11

1

4

3

8

5

7

14

7

13

12

25

Page 26

COMMANDER PAR NUMÉRO DE PIÈCE, NON PAS PAR NUMÉRO DE CODE

NO. NO.

DE CODE DE PIÈCE DESCRIPTION

01 2610914499 Garde

02 2610914500 Manchon

03 2610914501 Coin

04 2610914502 Guide

05 2610914503 Base

06 2615294999 Goupille

07 2615294956 Boulons mécaniques – 4 requis

08 2615296105 Vis de maintien du coin – 1 requise

09 2615296106 Vis de montage – 4 requises

10 2615294227 Rondelles de 3/16 po. – 7 requises

11 2610914504 Support de profondeur

12 2615294953 Vis de réglage de profondeur

13 2610923360 Porte-outils

14 2615294964 Écrou carré

15 2610915058 Grands boutons – 3 requis

16 2615297202 Écrou à oreilles

17 2615294960 Vis du support – 2 requises

18 2610910326 Rondelle No. 9 – 1 requise

19 2615294223 Écrou de vis de maintien – 1 requise

ÉCRIVEZ POUR OBTENIR LES PRIX COURANTS

AUCUN ENVOI CONTRE REMBOURSEMENT

26

Page 27

MODELO 231

2

16

7

6

15

10

9

15

19

18

17

11

1

4

3

8

5

7

14

7

13

12

27

Page 28

ORDENE USANDO EL NUMERO DE PARTE, NO EL NUMERO DEL CODIGO

CODIGO NO. PARTE NO. DESCRIPCION

01 2610914499 Protección

02 2610914500 Manga

03 2610914501 Cuña

04 2610914502 Barrera

05 2610914503 Base

06 2615294999 Alfiler

07 2615294956 Tornillo de carrocería – se requieren 4

08 2615296105 Tornillo de la abrazadera de la cuña – se requiere 1

09 2615296106 Tornillo de montaje – se requieren 4

10 2615294227 Arandela de 3/16" – se requieren 7

11 2610914504 Soporte de profundidad

12 2615294953 Tornillo de ajuste de profundidad

13 2610923360 Soporte de la herramienta

14 2615294964 Tuerca cuadrada

15 2610915058 Perilla grande – se requieren 3

16 2615297202 Tuerca de mariposa

17 2615294960 Tornillo de soporte – se requieren 2

18 2610910326 Arandela #9 – se requiere 1

19 2615294223 Tuerca del tornillo de la abrazadera – se requiere 1

ESCRIBA PARA PEDIR PRECIOS ACTUALES

NO COBROS CONTRA ENTREGA

UNITED STATES

Dremel Service Center

4915 Twenty-First Street

Racine, Wisconsin 53406

1-800-437-3635

CANADA

Giles Tool Agency

47 Granger Av.

Scarborough, Ont.

Canada M1K 3K9

1-416-287-3000

See your local distributor or

write to:

Dremel, 4915 Twenty-First St. Racine, Wisconsin 53406

2610914511 8/10 Printed in Taiwan

Consultez votre distributeur local

et écrivez à:

ÉTATS-UNIS

OR

28

ESTADOS UNIDOS

Dremel Service Center

4631 E. Sunny Dunes

Palm Springs, CA 92264

1-800-275-2052

OUTSIDE CONTINENTAL

UNITED STATES

À L’EXTÉRIEUR DU TERRITOIRE

CONTINENTAL DES ÉTATS-UNIS

FUERA DE LOS 48 ESTADOS

CONTIGUOS

Visite su distribuidor local o

escriba a: