Dremel 2222 User guide

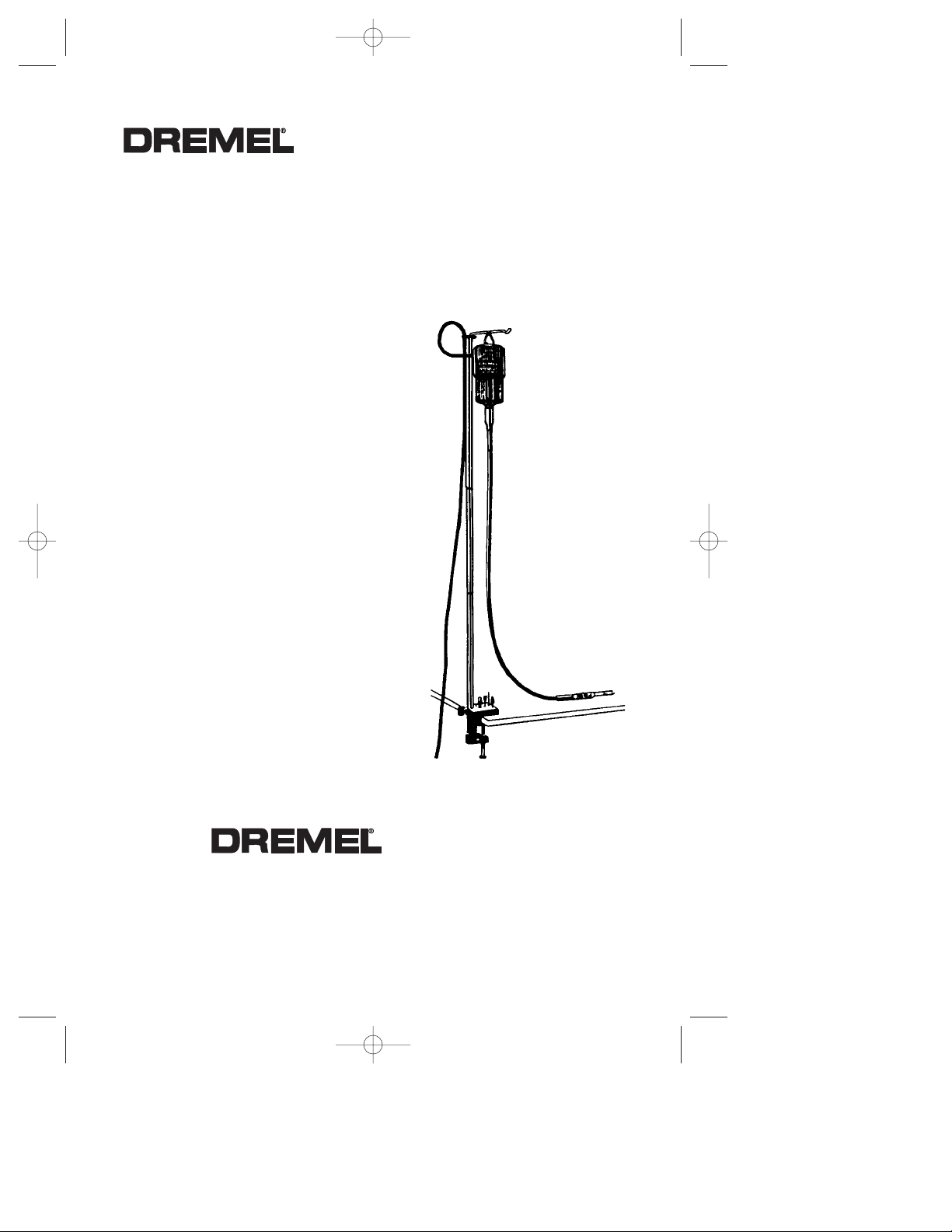

Flex Shaft Tool Stand

Owner’s Manual Model 2222

HONESTLY NOW … Have you read

this OWNER’S MANUAL?

• Safety

• Assembly

• Operation

• Service Parts

Parlez-vous français?

Voir page 6

¿Habla español?

Vea página 10

2615302568 3/99 ©1999 S-B Power Tool Co. PRINTED IN U.S.A.

P.O. Box 1468

Racine, Wisconsin 53401

1-800-437-3635

http://www.dr emel.com

DM 2615302568 3/99 3/17/99 2:45 PM Page 1

-2-

Read and understand all instructions. Failure to follow all

instructions listed below, may result in electric shock, fire and/or

serious personal injury.

SAVE THESE INSTRUCTIONS

!

WARNING

Safety Rules for Flex Shaft Rotary Tools

Accessories must be rated for at least

the speed recommended on the tool

warning label. Wheels and other

accessories running over rated speed can

fly apart and cause injury.

Hold tool by insulated gripping surfaces

when performing an operation where

the cutting tool may contact hidden

wiring or its own cord. Contact with a

"live" wire will make exposed metal parts

of the tool "live" and shock the operator. If

cutting into existing walls or other blind

areas where electrical wiring may exist is

unavoidable, disconnect all fuses or

circuit breakers feeding this worksite.

Do not operate the flexible shaft with a

sharp bend. Over bending the shaft can

generate excessive heat on the jacket or

hand piece. The recommended minimum

is 6" radius.

Always disconnect the power cord from

the power source before making any

adjustments or attaching any

accessories. You may unexpectedly

cause the tool to start leading to serious

personal injury.

Be aware of the switch location, when

placing the tool down or when picking

the tool up. You may accidentally activate

the switch.

Always hold the hand piece firmly in

your hands during the start-up. The

reaction torque of the motor, as it

accelerates to full speed, can cause the

shaft to twist.

Always wear safety goggles and dust

mask. Use only in well ventilated area.

Using personal safety devices and

working in safe environment reduces risk

of injury.

After changing the bits or making any

adjustments, make sure the collet nut

and any other adjustment devices are

securely tightened. Loose adjustment

device can unexpectedly shift, causing

loss of control, loose rotating components

will be violently thrown.

Do not reach in the area of the spinning

bit. The proximity of the spinning bit to

your hand may not always be obvious.

Allow brushes to run at operating

speed for at least one minute before

using wheel. During this time no one is

to stand in front or in line with the

brush. Loose bristles or wires will be

discharged during the run-in time.

Wire and bristle brushes must never be

operated at speeds greater than

15,000/min. Direct the discharge of the

spinning wire brush away from you.

Small particles and tiny wire fragments

may be discharged at high velocity during

the “cleaning” action with these brushes

and may become imbedded in your skin.

Bristles or wires will be discharged from

the brush at high speeds.

Carefully handle both the tool and

individual grinding wheels to avoid

chipping or cracking. Install a new

wheel if tool is dropped while grinding.

Do not use a wheel that may be

damaged. Fragments from a wheel that

bursts during operation will fly away at

great velocity possibly striking you or

bystanders.

Never use dull or damaged bits. Sharp

bits must be handled with care.

Damaged bits can snap during use. Dull

bits require more force to push the tool,

possibly causing the bit to break.

DM 2615302568 3/99 3/17/99 2:45 PM Page 2

-3-

Use clamps to support workpiece

whenever practical. Never hold a small

workpiece in one hand and the tool in

the other hand while in use. Allow for

sufficient space, at least 6", between

your hand and the spinning bit. Round

material such as dowel rods, pipes or

tubing have a tendency to roll while being

cut, and may cause the bit to “bite” or

jump toward you. Clamping a small

workpiece allows you to use both hands

to control the tool.

Inspect your workpiece before cutting.

When cutting irregularly shaped

workpieces, plan your work so it will

not slip and pinch the bit and be torn

from your hand. For example, if carving

wood, make sure there are no nails or

foreign objects in the workpiece. Nails or

foreign objects can cause the bit to jump.

Never start the tool when the bit is

engaged in the material. The bit cutting

edge may grab the material causing loss

of control of the cutter.

Avoid bouncing and snagging the

wheel, especially when working

corners, sharp edges etc. This can

cause loss of control and kick-back.

The direction of feed with the bit into

the material when carving, routing or

cutting is very important. Always feed

the bit into the material in the same

direction as the cutting edge is exiting

from the material (which is the same

direction as the chips are thrown).

Feeding the tool in the wrong direction,

causes the cutting edge of the bit to climb

out of the work and pull the tool in the

direction of this feed.

If the workpiece or bit becomes

jammed or bogged down, turn the tool

“OFF” by the switch. Wait for all

moving parts to stop and unplug the

tool, then work to free the jammed

material. If the switch to the tool is left

“ON” the tool could restart unexpectedly

causing serious personal injury.

Do not leave a running tool unattended,

turn power off. Only when tool comes to

a complete stop it is safe to put it down.

Do not grind or sand near flammable

materials. Sparks from the wheel could

ignite these materials.

Do not touch the bit or collet after use.

After use the bit and collet are too hot to

be touched by bare hands.

Regularly clean the tool's air vents by

compressed air. Excessive accumulation

of powdered metal inside the motor

housing may cause electrical failures.

Do not allow familiarity gained from

frequent use of your rotary tool to

become commonplace. Always

remember that a careless fraction of a

second is sufficient to inflict severe injury.

Do not alter or misuse tool. Any

alteration or modification is a misuse and

may result in serious personal injury.

This product is not intended for use as

a dental drill, in human or veterinary

medical applications. Serious injury may

result.

When using the steel saws, cutoff

wheels, high speed cutters or tungsten

carbide cutters, always have the work

securely clamped. Never attempt to

hold the work with one hand while

using any of these accessories. The

reason is that these wheels will grab if

they become slightly canted in the groove,

and can kickback causing loss of control

resulting in serious injury. Your second

hand should be used to steady and guide

the hand holding the tool. When a cutoff

wheel grabs, the wheel itself usually

breaks. When the steel saw, high speed

cutters or tungsten carbide cutter grab, it

may jump from the groove and you could

lose control of the tool.

DM 2615302568 3/99 3/17/99 2:45 PM Page 3

-4-

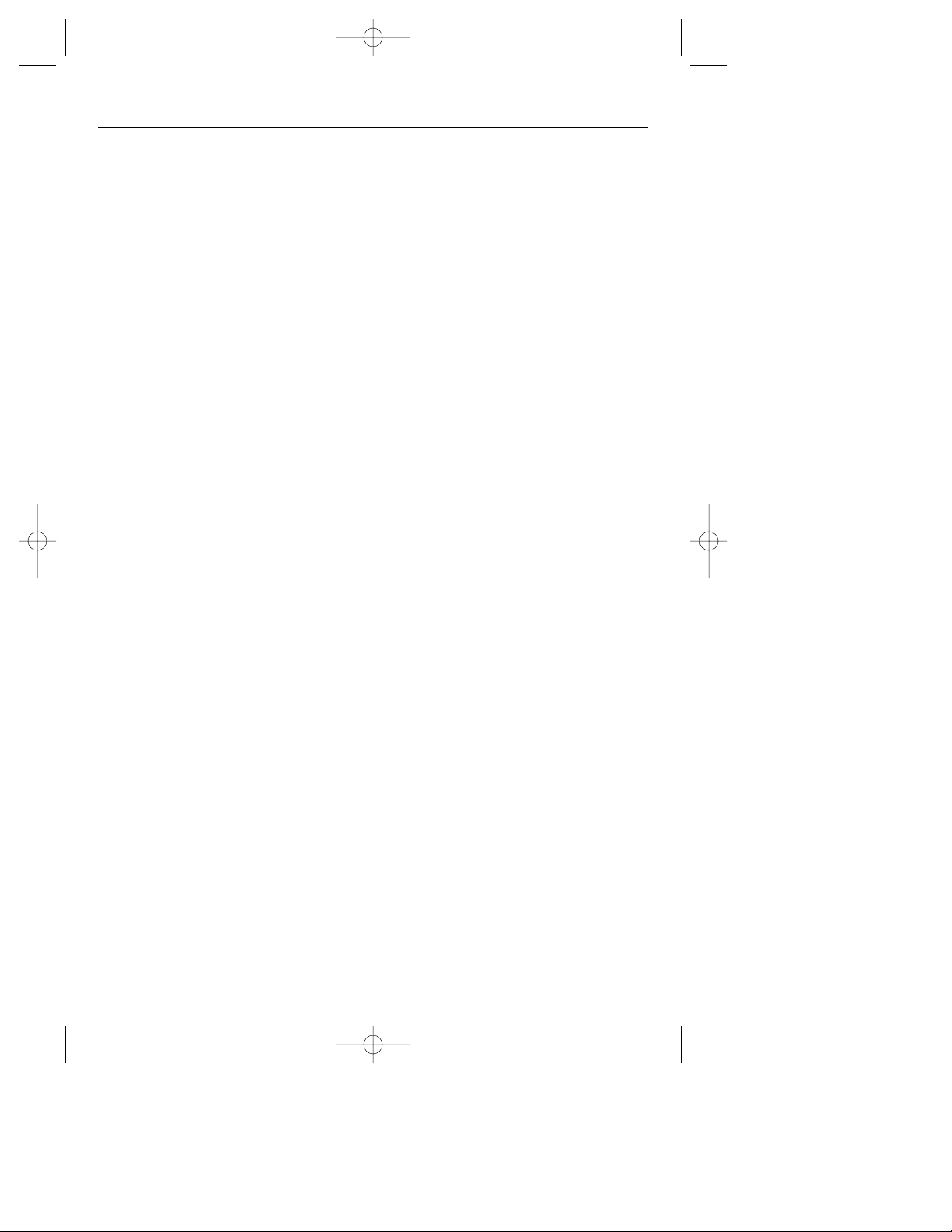

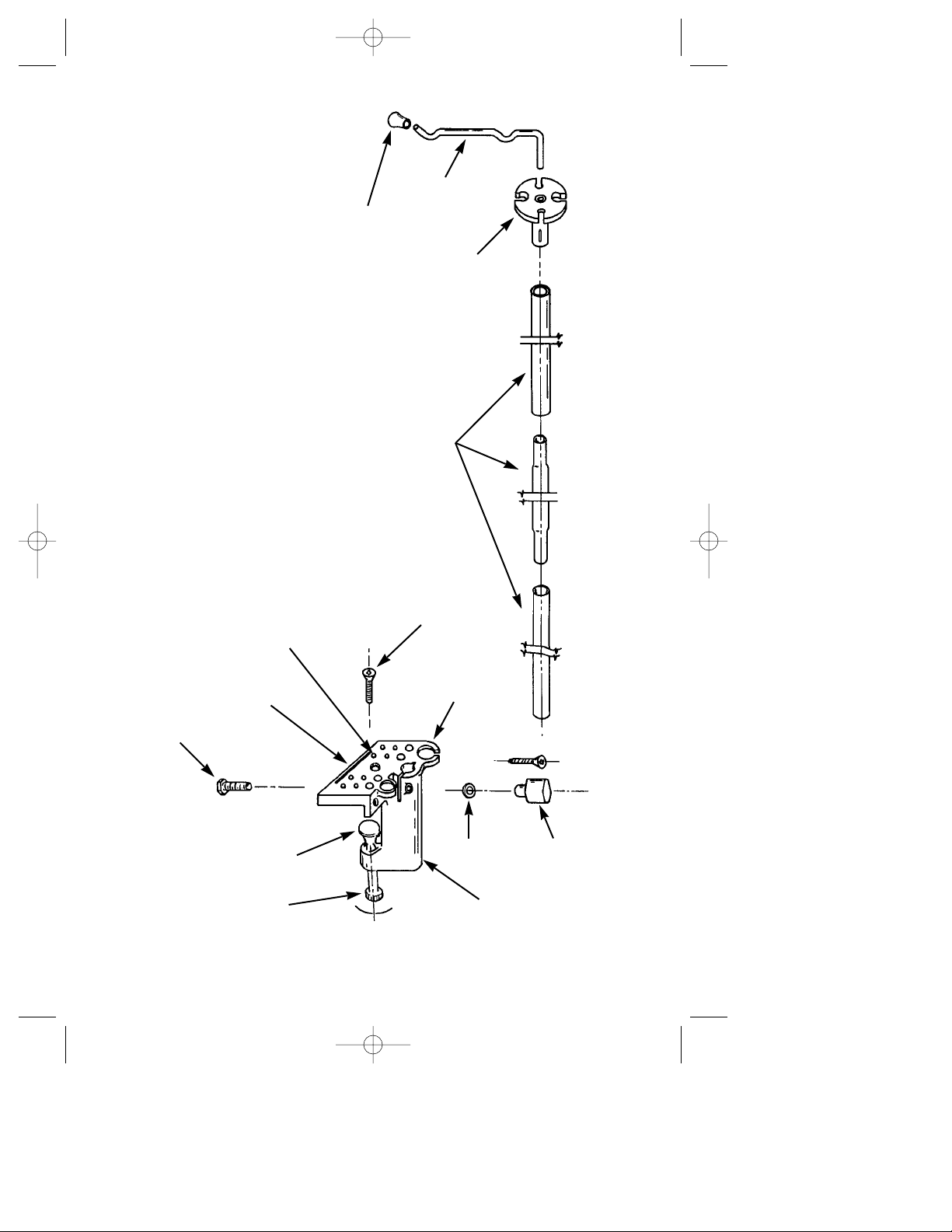

1. Assembly HEXAGON HEAD SCREW

thru housing allowing its HEXAGON

HEAD to fit into hexagon receptacle.

Secure with washer and CLAMP

KNOB. Leave loose for now. Tighten

after assembly of tubes. (Step 4)

2. Assemble the three Tubes to each

other. The center tube is reduced in

size at both ends. Rap the ends of the

tube assembly with a soft head

hammer to ensure a tight assembly.

3. The CORD HOLDER and hanger wire

bushing are one piece. Assemble this

part in one end of the tube assembly.

4. Insert the tube assembly, with the

CARD HOLDER up (away from clamp

screw) in the 5/8” hole in the clamp

housing. Let the tube extend below

the housing by a small amount, and

secure its location by tightening the

CLAMP KNOB.

5. Place the CLAMP HOUSING on a

work bench and secure by tightening

the CLAMP SCREW. Any bench can

be used with a thickness of 1-3/4” or

less. Screw holes are provided for

permanent installation. Use (3) #10 x

1-1/4” long FLAT HEAD WOOD

SCREWS: two from the front and one

from the top. Use this permanent

installation when possible. Pre-drill

with an 1/8” drill for maximum rigidity.

6. Assemble the rubber RETAINING

CAP on the HANGER WIRE. This cap

will keep the power tool hanger wire

contained on the hanger wire when

starting the motor. Insert the hanger

wire into the cord holder. Hanger wire

is free to rotate 360°.

7. Hang a Moto-Tool with flex shaft

attachment or Moto-Flex tool on the

hanger wire. The Heavy Duty MotoFlex tool must be placed on the

outside. Height of the tool from the

bench can be adjusted using the

clamp knob. The Flex-Shaft Hanger

stand can accommodate two tools at

the same time. Push the power cord

into one of the slots on the rim of the

cord holder. Be sure to have some

slack in the cord to allow free

movement of the hanger wire.

8. Clamp housing has HOLES FOR

CUTTER and WRENCH STORAGE.

Holes for both 1/4” and 1/8” diameter

shanks are provided. A RING is

provided for controlling the hand

piece when not in use.

ATTACHMENT FOR USE WITH ALL ROTARY TOOLS, FLEX SHAFT TOOLS AND

HEAVY DUTY FLEX SHAFT TOOLS.

Assembly and Operation Instructions

DM 2615302568 3/99 3/17/99 2:45 PM Page 4

-5-

CLAMP HOUSING

WRENCH SLOT

HEXAGON HEAD

SCREW

CLAMP BUTTON

CLAMP SCREW

WASHER

FLAT HEAD

WOOD SCREW (3)

CORD

HOLDER

HANGER

WIRE

RETAINING

CAP

TUBE

CUTTER

STORAGE HOLES

HAND PIECE

RETAINING RING

CLAMP KNOB

DM 2615302568 3/99 3/17/99 2:45 PM Page 5

Loading...

Loading...