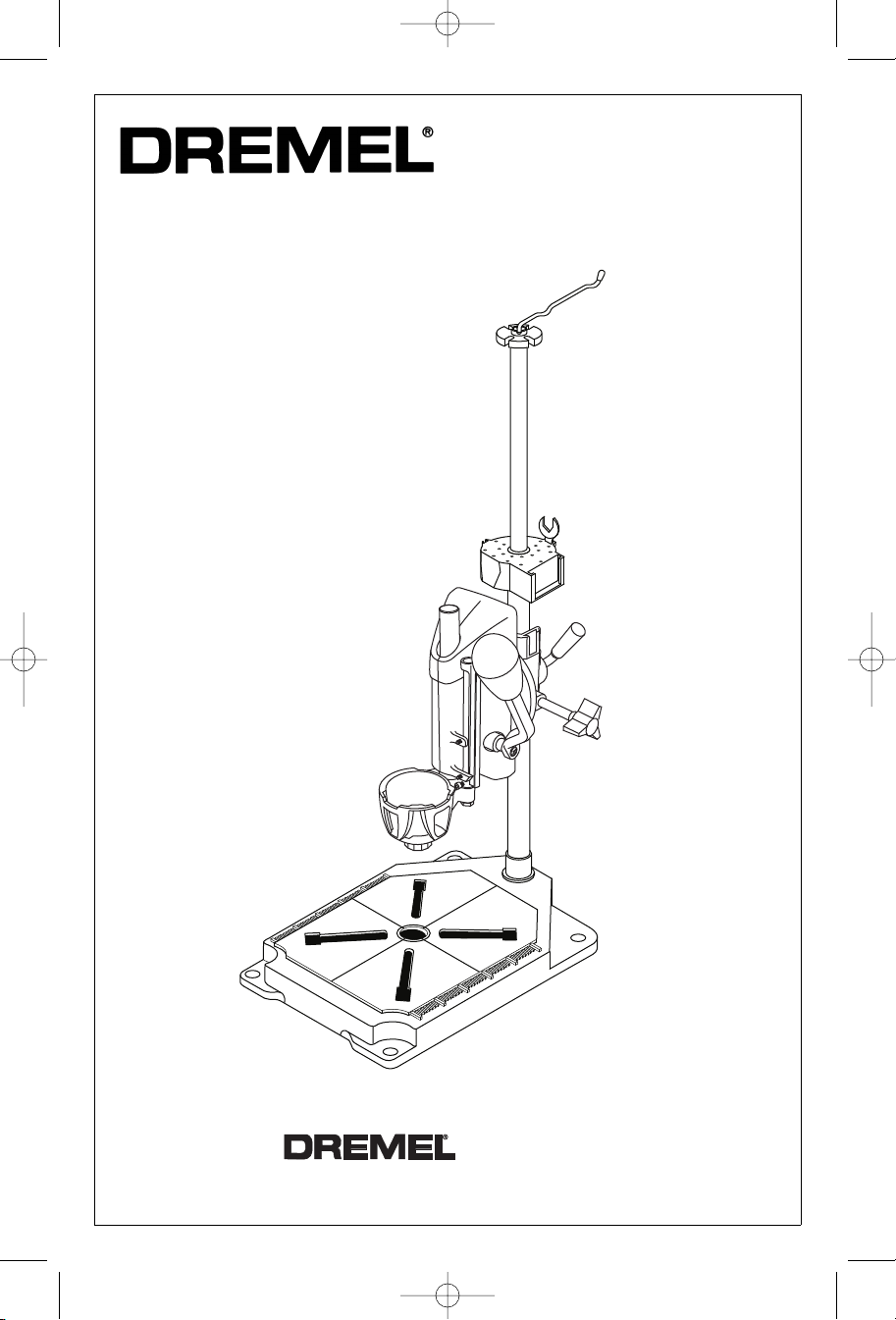

Page 1

DM 2610921728 8-05E 8/23/05 9:15 AM Page 1

Owner’s Manual

Manual Contents

Power Tool Safety Rules . . . . . . . . . . . . . . . . . . . . . . .2

Safety Rules for Drill Press . . . . . . . . . . . . . . . . . .3 - 4

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 5

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 8

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Parts Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . .10-11

Parlez-vous français? Voir page . . . . . . . . . . . . . .12

Habla español? Ver página . . . . . . . . . . . . . . . . . . .25

¿

Work Station

MODEL 220

Form No. 2610921728 08/05

4915 21st Street

Racine, WI 53406

1-800-437-3635

http://www.dremel.com

Page 2

DM 2610921728 8-05E 8/23/05 9:15 AM Page 2

Power Tool Safety Rules

!

WARNING

Keep your work area clean and well lit.

Cluttered benches and dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust.

tools create sparks which may ignite the dust

or fumes.

Keep bystanders, children, and visitors

away while operating a power tool.

Distractions can cause you to lose control.

Double Insulated tools are equipped with

a polarized plug (one blade is wider than

the other.) This plug will fit in a polarized

outlet only one way. If the plug does not

fit fully in the outlet, reverse the plug. If it

still does not fit, contact a qualified electrician to install a polarized outlet. Do not

change the plug in any way.

Insulation eliminates the need for the three

wire grounded power cord and grounded

power supply system. Before plugging in the

tool, be certain the outlet voltage supplied is

within the voltage marked on the nameplate.

Do not use “AC only” rated tools with a DC

power supply.

Avoid body contact with grounded surfaces such as pipes, radiators, ranges

and refrigerators.

of electric shock if your body is grounded. If

operating the power tool in damp locations is

unavoidable, a Ground Fault Circuit

Interrupter must be used to supply the power

to your tool. Electrician’s rubber gloves and

footwear will further enhance your personal

safety.

Don't expose power tools to rain or wet

conditions.

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil,

sharp edges or moving parts.

damaged cords immediately. Damaged

cords increase the risk of electric shock.

When operating a power tool outside, use

an outdoor extension cord marked "W

or "W."

use and reduce the risk of electric shock.

Read and understand all instructions. Failure to follow all instructions listed below, may result in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or

medication.

Power

Electrical Safety

Double

There is an increased risk

ater entering a power tool will

W

Replace

These cords are rated for outdoor

operating power tools may result in serious

personal injury.

Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep

your hair, clothing, and gloves away from

moving parts.

long hair can be caught in moving parts.

Keep handles dry, clean and free from oil and

grease.

Avoid accidental starting. Be sure switch

is “OFF” before plugging in.

with your finger on the switch or plugging in

tools that have the switch “ON” invites accidents.

Remove adjusting keys or wrenches

before turning the tool ON.

key that is left attached to a rotating part of

the tool may result in personal injury.

Do not overreach. Keep proper footing

and balance at all times.

balance enables better control of the tool in

unexpected situations.

Use safety equipment. Always wear eye

protection.

shoes, hard hat, or hearing protection must

be used for appropriate conditions.

Use clamps or other practical way to

secure and support the workpiece to a

stable platform.

or against your body is unstable and may

lead to loss of control.

Do not force tool. Use the correct tool for

your application.

job better and safer at the rate for which it is

designed.

Do not use tool if switch does not turn it

ON or OFF

trolled with the switch is dangerous and must

be repaired.

Disconnect the plug from the power

source before making any adjustments,

-A"

changing accessories, or storing the tool.

Such preventive safety measures reduce the

risk of starting the tool accidentally.

2

Personal Safety

A moment of inattention while

Loose clothes, jewelry, or

Carrying tools

A wrench or a

Proper footing and

Dust mask, non-skid safety

Tool Use and Care

Holding the work by hand

The correct tool will do the

.

Any tool that cannot be con

-

Page 3

DM 2610921728 8-05E 8/23/05 9:15 AM Page 3

Store idle tools out of reach of children

and other untrained persons.

dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting

tools sharp and clean.

tained tools, with sharp cutting edges are

less likely to bind and are easier to control.

Any alteration or modification is a misuse

and may result in a dangerous condition.

Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tools

operation. If damaged, have the tool

serviced before using.

are caused by poorly maintained tools.

Develop a periodic maintenance schedule

for your tool.

Use only accessories that are recommended by the manufacturer for your

Accessories that may be suitable for

model.

Tools are

Properly main-

Many accidents

Safety Rules for Drill Press

Unplug tool before setting up in table,

making adjustments or changing bits.

Accidental start-up of the tool can cause

injury.

Securely fasten table to a stable platform

or workbench

platforms or workbenches may shift or tip

causing loss of control and injury.

Securely fasten tool to table before operating.

tend to walk down from clamp and tool may

fall while bit is still spinning.

Know how to shut off the tool! Position the

tool so that switch is readily accessible to

quickly shut off in an emergency.

Route the cord away from the bit or cutting area.

may result in a shock, burn or electrocution.

Wear eye protection and dust mask. Use

only in well-ventilated area. Using personal

safety devices and working in safe environment reduces risk of injury.

Do not wear gloves, necktie or loose

clothing during operation of the tool.

back long hair or use a hair net. Clothing or

hair can become caught in the spinning bit

and injury may occur.

Match the appropriate bit and its speed to

your application. Do not use bits that

have a cutting diameter that exceed the

capacity of the tool.

intended primarily for light duty use on wood.

. During operation unstable

If tool loosens during operation it will

Cutting into live electrical wires

Tie

The drill press stand is

one tool, may become hazardous when

used on another tool.

Service

T

ool service must be performed only by

qualified repair personnel.

maintenance performed by unqualified personnel could result in a risk of injury. For

example: internal wires may be misplaced

or pinched, safety guard return springs may

be improperly mounted.

When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual.

Use of unauthorized parts or failure to follow

Maintenance Instructions may create a risk

of electric shock or injury. Certain cleaning

agents such as gasoline, carbon tetrachloride, ammonia, etc. may damage plastic

parts.

Overloading the tool can lead to personal

injury or tool failure.

Never use dull or damaged bits. Sharp

bits must be handled with care.

bits can snap during use. Dull bits require

more force to push the workpiece, possibly

causing the bit to break.

Always make sure the workpiece is free

from nails and other foreign objects.

Cutting into a nail will damage the bit and can

cause the workpiece to jump causing loss of

control.

Before operation clamp workpiece or

brace against column. Never hold a small

workpiece in one hand and bring the drill

down.

to use both hands to control the tool.

Securing workpiece will prevent spinning or

climbing on the drill during operation.

Use a “V” block for supporting round

stock such as tubes or rods when drilling.

Round material such as dowel rods, pipes or

tubing have a tendency to roll while being

cut, and may cause the bit to "bite" or the

workpiece to jump toward you.

You must set and lock tool head into the

desired position and depth of cut when

performing operations other than drilling.

Bring the workpiece to the tool and allow

for sufficient space, at least 150 mm (6"),

between your hand and the spinning bit.

Contact with the spinning bit will cause injury.

Clamping the workpiece allows you

Service or

Damaged

3

Page 4

DM 2610921728 8-05E 8/23/05 9:15 AM Page 4

Safety Rules for Drill Press (continued)

This Drill Press was designed for drilling,

sanding, brushing, polishing or grinding

applications, other applications may present

hazards that cannot be adequately guarded.

If the side of

to perform the work, for example a sanding

drum, the workpiece must be positioned on

the side of the accessory that rotates against

the feed direction of the workpiece. Placing

the workpiece on the side of the accessory

where the feed direction and accessory

rotation are same may cause the workpiece

to be pulled by the rotating accessory and

lead to loss of control during operation.

Never start the tool when the bit is

engaged in the material.

edge may grab the material causing loss of

control of the workpiece.

Do not reach in the area of the spinning

bit.

The proximity of the spinning bit to your

hand may not always be obvious. Workpiece

could shift or your hand could slip during

operation.

!

WARNING

grinding, drilling, and other construction

activities contains chemicals known to

cause cancer, birth defects and other

reproductive harm. Some examples of

these chemicals are:

any rotating accessory is used

The bit cutting

Some dust created by

power sanding, sawing,

• Lead from lead-based paints,

• Crystalline silica from bricks and cement

• Arsenic and chromium from chemically-

After changing the bits or making any

adjustments, make sure the collet nut and

any other adjustment devices are securely tightened.

unexpectedly shift, causing loss of control,

loose rotating components will be violently

thrown.

Never touch the bit during or immediately

after the use.

cause injury and after use the bit is too hot to

be touched by bare hands.

Do not leave a running tooling unattended, turn power off.

to a complete stop it is safe to remove workpiece and clean the stand.

THINK SAFETY! Safety is a combination of

operator COMMON SENSE and ALERTNESS at all times when the tool is being

used.

Use only grinding wheels, sanding

disks/drums and drill bits when using the tool

in the Work Station and any other accessory

will cause injury to the user.

and other masonry products, and

treated lumber.

Loose adjustment device can

Contact with a spinning bit will

Only when tool comes

Assembly

ATTACHMENT FOR USE WITH DREMEL

ROTARY MODELS 275, 285, 295, 300, 395,

398, 400, 780 AND 800.

ATTENTION:

manual carefully before using your Dremel

Workstation. Retain instructions for future

reference. Your Dremel Workstation 220 will

convert rotary tools to a drill press for drilling,

to a tool holder for sanding or polishing, or to

a flex shaft tool stand.

1. Assemble the tube to the base and

secure with hex bolt and square nut.

Read this entire instruction

2. Insert the square nut (short end first)

into the tube support assembly and

install the height adjustment lever. Slide

the press onto the larger section of the

tube and tighten.

3. Install the crow’s nest onto the larger

section of the tube with small holes

facing up.

4. Install the cord holder.

Install the hanger wire and cap.

5.

6. If desired, base may be secured to a

workbench using the appropriate size

hardware (not supplied).

4

Page 5

DM 2610921728 8-05E 8/23/05 9:15 AM Page 5

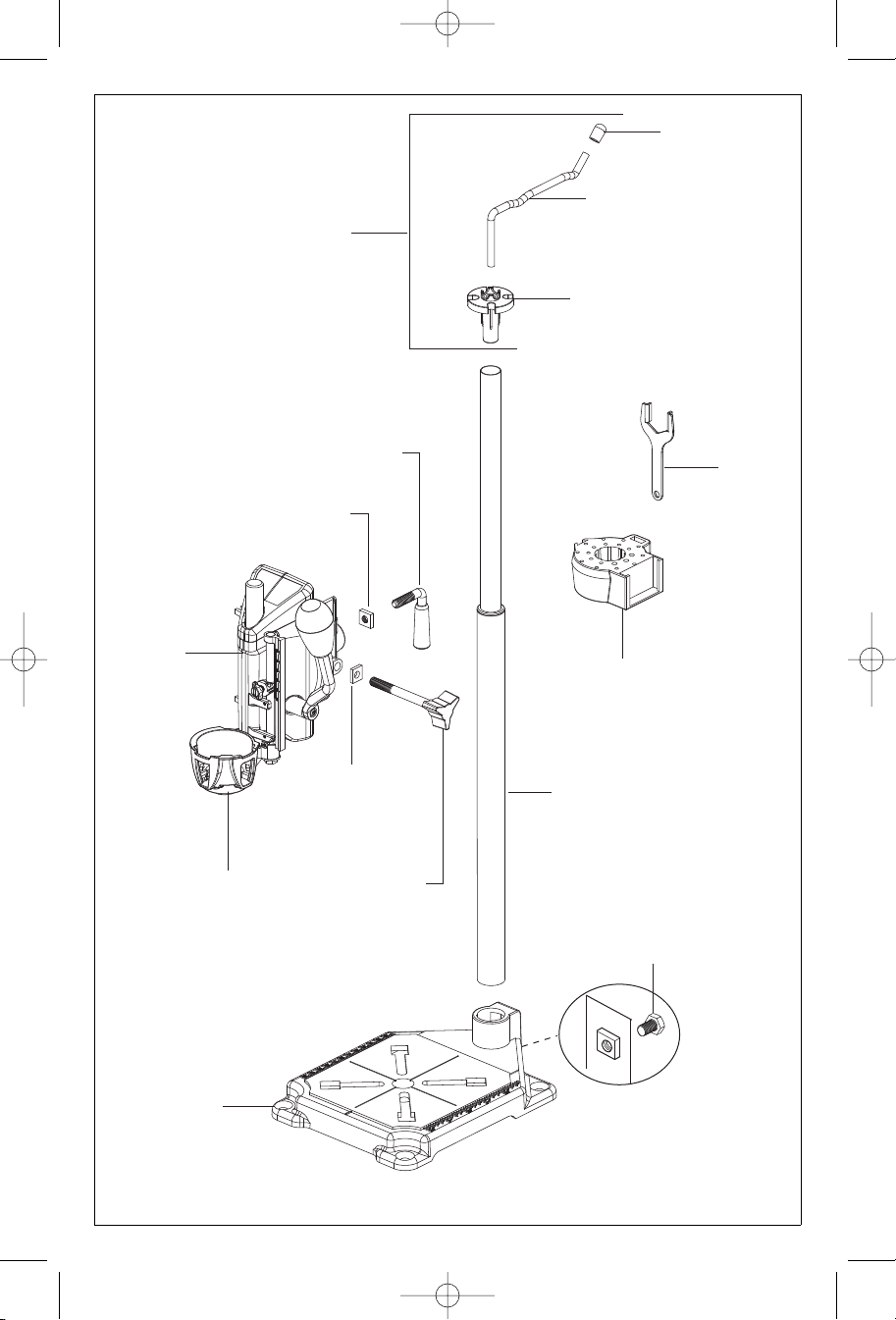

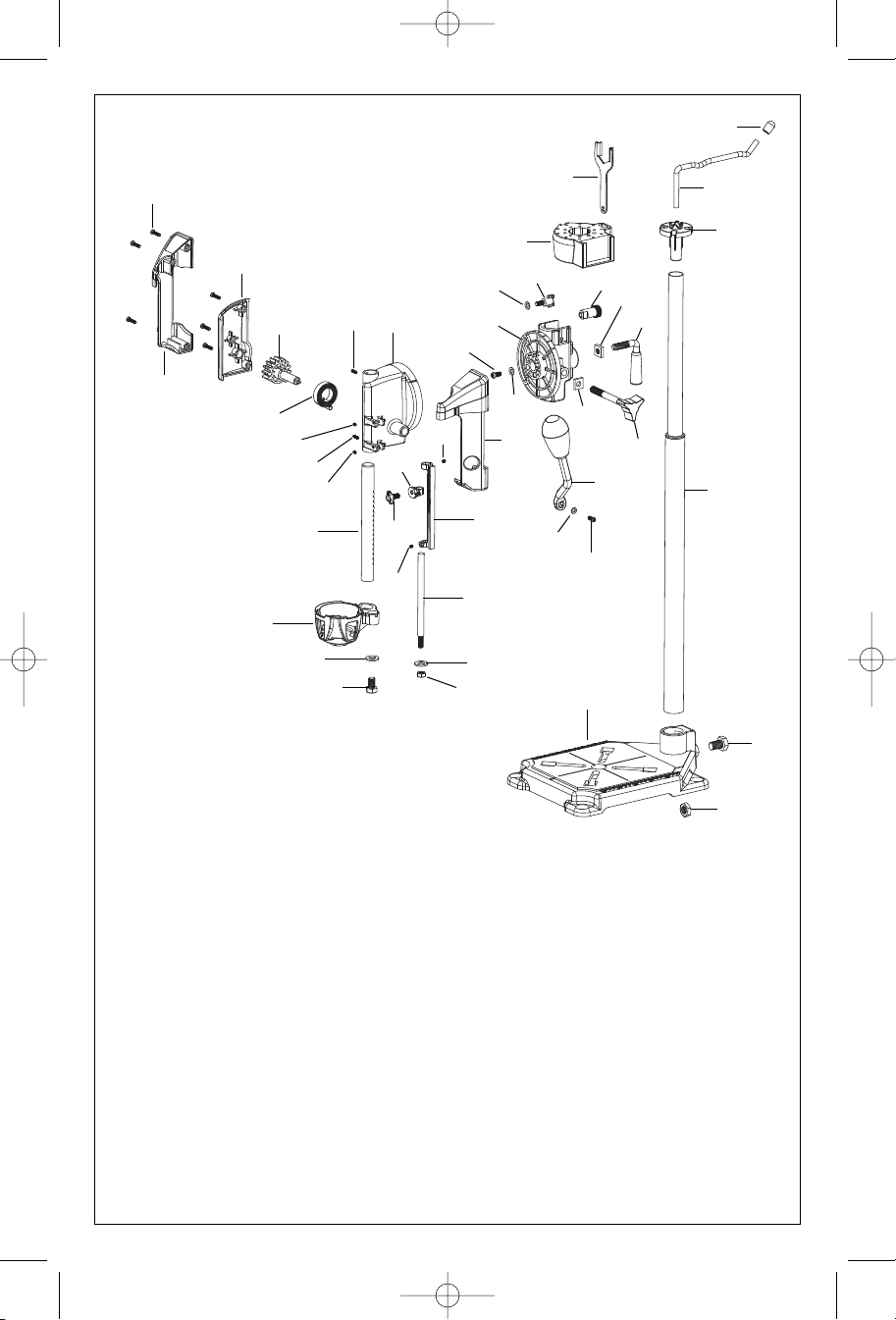

Cap

Drill Press

Assembly

Hanger

Height

Adjustment Lever

Square Nut

(assembled to inside of

tube support assembly)

Hanger W

Cord Holder

Crow’s Nest

ire

Wrench

Tool Holder

Base

Square Nut

(assembled to

inside of drill

press)

Angle Lock

Knob

Tube Assembly

Figure 1. Work Station 220 Components

5

Base Hex Bolt

Page 6

DM 2610921728 8-05E 8/23/05 9:15 AM Page 6

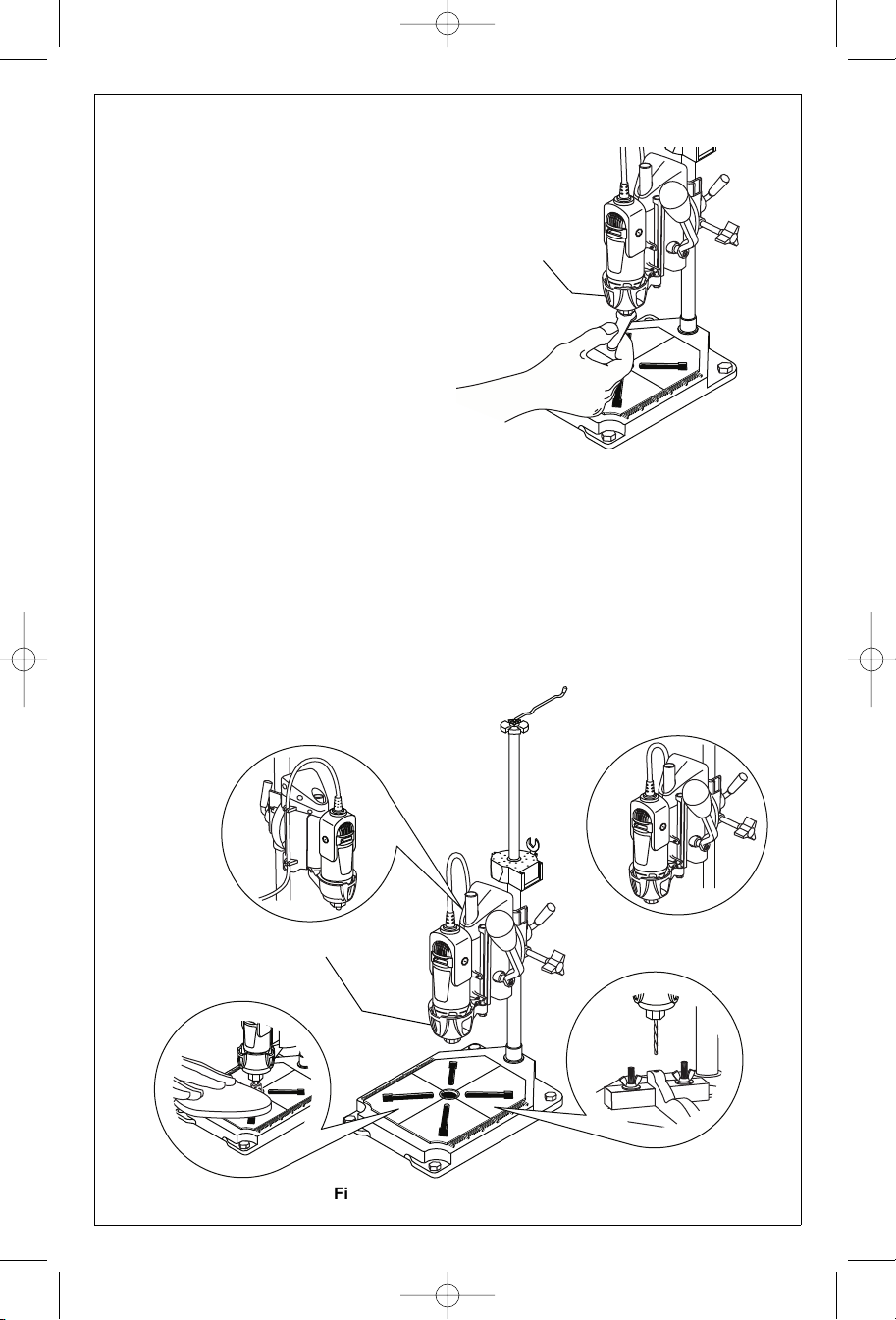

Operation

IMPORT

only one tool at time. Do not hang a tool on

hanger assembly when another tool is

mounted in the press.

The Crow’s Nest tool storage will hold the following tools:

• Drill bit set (Model 628 or 631)

• Rotary tool wrench

• Mounting wrench

• Bits with shank size less than or equal to 1/8"

• Rotary tool collets

NOTE: The drill bits are held in the tool by a

collet system. The bit may be installed before

or after the rotary tool is installed in the drill

press.

ANT!Work Station is for use with

(Models 480, 481, 482, 483)

1. Depress and hold the shaft lock button

while rotating the collet nut and shaft.

Continue to rotate the collet nut and

shaft until the lock engages and holds

the shaft (Figure 2).

2. Use the wrench from your Dremel

Rotary Tool and turn the collet nut counterclockwise to loosen it.

3. Release the shaft lock button.

Figure 2. Loosening/Tightening Collet

4. Insert the drill bit into the collet as deep

5. Re-engage the shaft lock button and tight-

Shaft Lock

Button

as possible to ensure proper gripping of

the bit and to minimize run out. Do not

insert the bit so far that the flutes touch

the collet or collet nut to avoid chipping

or cracking the bit.

en the collet nut; first by hand, then using

the wrench until bit is held securely.

Cord should be

positioned to

the side when

drill press is

used.

Clamp Nut

Figure 3. Installing Rotary Tool

6

Page 7

DM 2610921728 8-05E 8/23/05 9:15 AM Page 7

6. Remove nose cap from rotary tool.

7. Insert the rotary tool into the press with

the shaft lock to the front. Clamp the tool

to the tool bracket by tightening the clamp

nut Figure 3).

NOTE: Model 398 mounts with shaft lock to

the back and cord to the right. Models 400

and 800 mount with shaft lock to the right.

NOTE: When clamping rotary tool in holder,

make sure tool is seated properly and vent

openings are not covered.

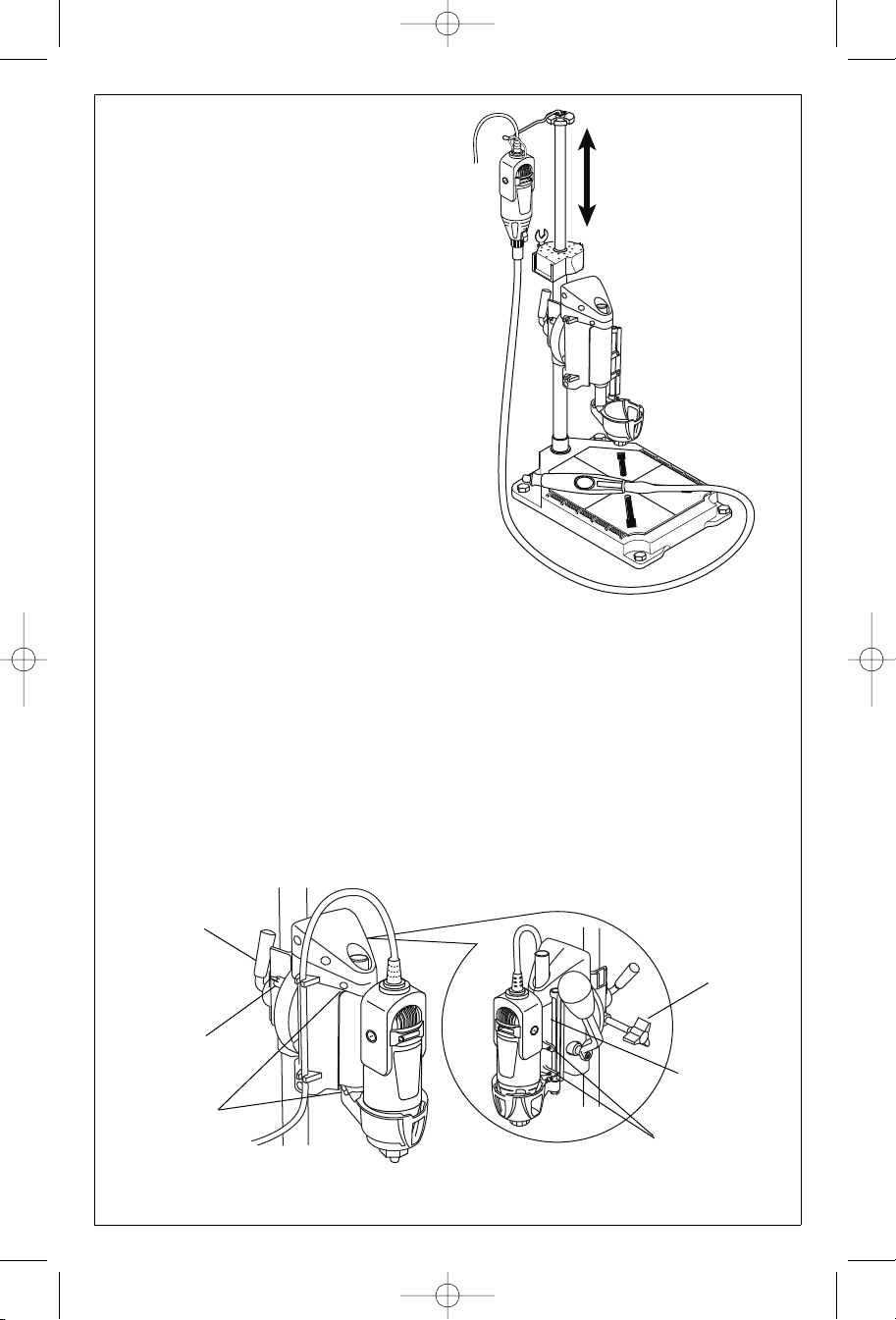

8. Twist the top tube counterclockwise to

loosen and enable the tube to be adjusted up or down. After desired height is

achieved, turn tube clockwise to tighten it

(Figure 4).

NOTE: Tube should not be extended when

tool is being used in tool holder.

Insert the cord into the cord clips (Figure

2). Holder will keep cord away from the

work area. Make sure there is sufficient

slack to keep the cord from being pulled

taut when the full stoke of the press is

used.

9. The Depth Stop is used when you wish

to drill holes to a measured depth. A

scale on the press housing is provided

for your convenience.

Set the depth stop adjustment to the

desired depth and tighten depth stop

lock knob (Figure 5). Four set screws

are also provided on the depth gauge

and left side of the housing assembly

(See Figure 5). These screws allow for

micro adjustments to the drill press. Use

1.5mm allen wrench to make adjustments. Be carefull not to overtighten set

screws.

10. The small and large Angle Lock knobs

are used to secure the tool either verti-

Height

Adjustment

Lever

urn tube counter-

T

clockwise to loosen,

adjust tube up or

down, turn tube clockwise to tighten.

NOTE: T

not be extended when

tool is being used in

tool holder.

ube should

Figure 4. Adjusting Tube Height

cally or at a 90° angle. Tool may be used

at a 15°, 30°, 45°, 60°, 75° or 90° angle

for sanding, polishing or wire wheel

application.

Loosen the large and small knobs and

rotate the tool, then securely tighten

both angle lock knobs.

11. The Height Adjustment Lever is used to

secure the press on the tube at the proper height.

Loosen the lever and move the

press/tool assembly to the desired position, then tighten the height adjustment

lever.

Large Angle

Lock Knob

Small Angle

Lock Knob

Set Screws

Depth Stop

Adjustment

Lock Knob

Set Screws

Figure 5. Setting Depth and Height Adjustments

7

Page 8

DM 2610921728 8-05E 8/23/05 9:15 AM Page 8

Operation (continued)

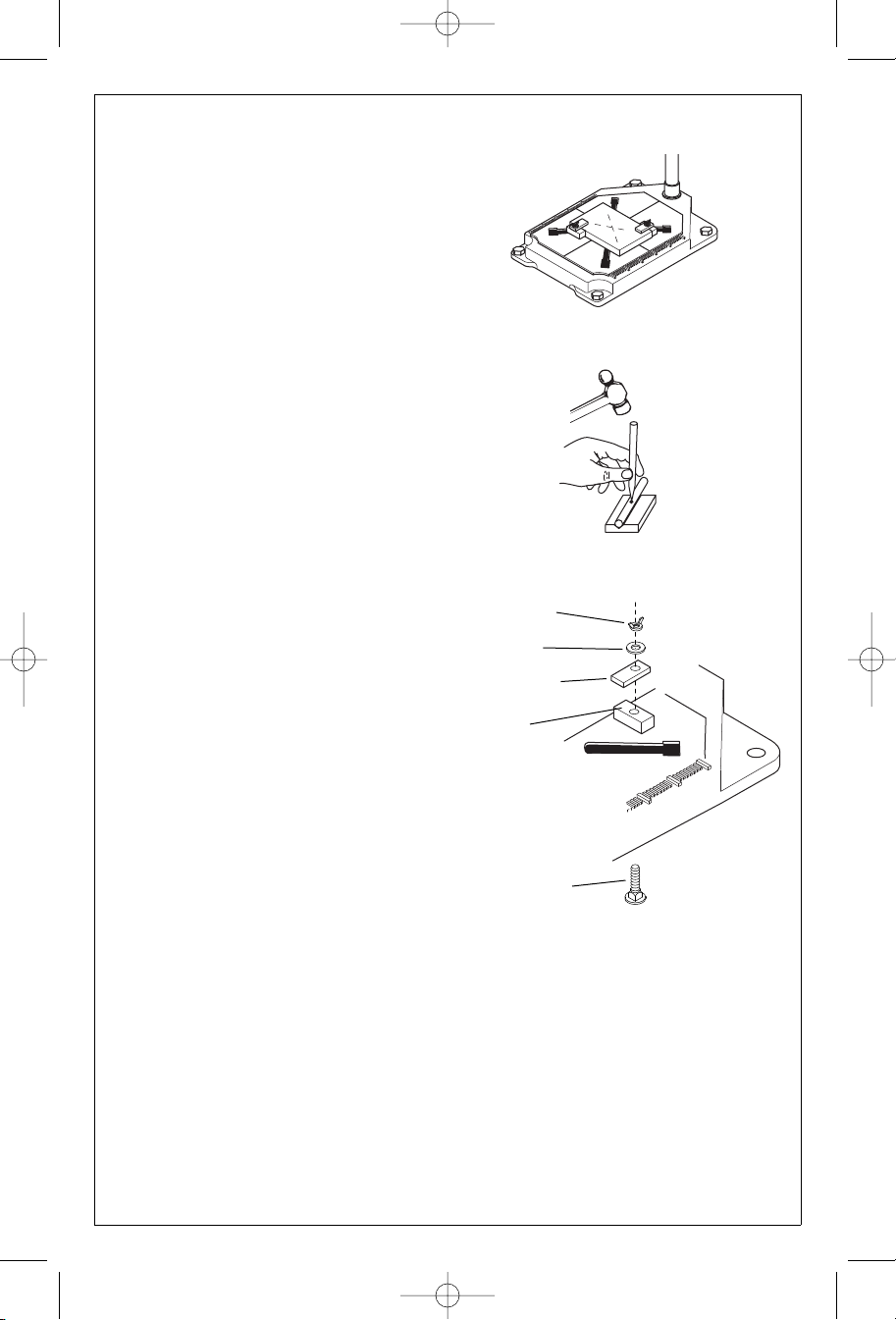

12. Mark the hole locations on the workpiece and center punch at these loca

tions. Center punching will prevent walking of the drill point and ensure proper

hole location. The benefits of center

punching are less drill breakage and

better hole size tolerance.

13. Secure the workpiece to the base before

drilling. This will keep the workpiece

from climbing the drill bit or spinning.

The benefit is safety and better quality

work. Hold down clamps (not included)

are very good for holding workpieces, or

use a small utility vise for holding the

workpiece when drilling (Figure 6).

14. Loosen the Height Adjustment Lock

lever 1/2 turn and move the press on the

tube until drill bit tip is near the workpiece. (A maximum of 1/4" between drill

bit tip and workpiece is recommended.)

Retighten lock lever.

15. Grasp the Press Handle and pull down

to drill hole.

-

Figure 6. Workpiece Hold Downs

Clamps (not supplied)

Figure 7. Round Workpiece

Helpful hints

When drilling round pieces, use a “V” block or

vise. To drill a hole in the center of a round

piece, a center punch mark is necessary

(Figure 7). Use center punch to make center

punch mark (not included).

Avoid force feeding to such an extent that the

motor speed is noticeably reduced. Also,

feed carefully when approaching point of

breakthrough. This will avoid making ragged

breakthrough edges.

For accurate drilling, lower the tool to a location where the end of the drill bit is within 1/4"

of the workpiece before advancing the handle for feeding the drill. Using minimum

stroke and center punching at the location to

be drilled will ensure accurate drilling.

Making optional hold down clamps for

your Work Station 220

Hold down clamps can be fabricated out of

wood, steel or aluminum, depending on your

application.

1. Cut or saw material to desired length,

width and height.

2. Drill a hole using a 5/16" or 21/64" drill

bit in the desired location, through the

clamp.

3. Mount the hold down clamps using a

5/16"-18 x 1-1/2" or 2" length carriage

Wing Nut

Washer

Hold Down

Spacer

Carriage Bolt

Figure 8. Making Optional Hold

Down Clamps

bolts with matching washers and wing

nuts.

4. Mount to base by sliding the head of the

carriage bolt up through the bottom of

the base with the wing nuts on top.

When using hold down clamps on workpieces larger than 1/4" in thickness, always

use a spacer block to support the back side

of the clamp (Figure 8). For the best support,

the spacer block should be cut about 1/8"

shorter in height than the workpiece.

8

8

Page 9

DM 2610921728 8-05E 8/23/05 9:15 AM Page 9

Dremel Limited Warranty

Your Dremel product is warranted against defective material or workmanship for a period of

one year from date of purchase. In the event of a failure of a product to conform to this written warranty, please take the following action:

1. DO NOT return your product to the place of purchase.

2. Carefully package the product by itself, with no other items, and return it, freight prepaid,

along with:

A. A copy of your dated proof of purchase (please keep a copy for yourself).

B. A written statement about the nature of the problem.

C. Your name, address and phone number to:

UNITED STATES

Dremel Service Center Dremel Service Center

4915 21st Street OR 4631 E. Sunny Dune

Racine, WI 53406 Palm Springs, CA 92264

CANADA OUTSIDE

Giles Tool Agency CONTINENTAL UNITED STATES

6520 Lawrence Av. East See your local distributor or write to

Scarborough, Ont Dremel, 4915 21st Street

Canada M1C 4A7 Racine, WI 53406

We recommend that the package be insured against loss or in transit damage for which we

cannot be responsible.

This warranty applies only to the original registered purchaser. DAMAGE TO THE PRODUCT RESULTING FROM TAMPERING, ACCIDENT, ABUSE, NEGLIGENCE, UNAUTHORIZED REPAIRS OR ALTERATIONS, UNAPPROVED ATTACHMENTS OR OTHER

CAUSES UNRELATED TO PROBLEMS WITH MATERIAL OR WORKMANSHIPARE NOT

COVERED BY THIS WARRANTY.

No employee, agent, dealer or other person is authorized to give any warranties on behalf

of Dremel. If Dremel inspection shows that the problem was caused by problems with material or workmanship within the limitations of the warranty, Dremel will repair or replace the

product free of charge and return product prepaid. Repairs made necessary by normal

wear or abuse, or repair for product outside the warranty period, if they can be made, will

be charged at regular factory prices.

DREMEL MAKES NO OTHER WARRANTY OF ANY KIND WHATEVER, EXPRESSED OR

IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE WHICH EXCEED THE ABOVE MENTIONED OBLIGATION ARE

HEREBY DISCLAIMED BY DREMEL AND EXCLUDED FROM THIS LIMITED WARRANTY.

This warranty gives you specific legal rights and you may also have other rights which vary

from state to state. The obligation of the warrantor is solely to repair or replace the product. The

warrantor is not liable for any incidental or consequential damages due to any such alleged

defect. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitations or exclusion may not apply to you.

For prices and warranty fulfillment in the continental United States, contact your local Dremel

distributor.

9

Page 10

DM 2610921728 8-05E 8/23/05 9:15 AM Page 10

Parts Diagram

1

3

7

6b

6a

8

10

11

asher

6b

16

15

6a

Assembly

4

2

5

6a

9

Ref. Part No. Description

1 2610921769 Screw (6)

2 2610929316 Outer Shell-Left

3 2610928604 Housing Cover

4 2610930418 Pinion

5 2610928594 Torsion Spring

6a 2610933097 Small Set Screw (4)

6b 2610935514 Large Set Screw (2)

7 2610928605 Main Housing

8 2610928596 Rack

9 2610928607 Tool Holder

10 2610921755 Washer

11 2610921738 Hex Bolt

12 2610921768 Hex Nut

2610921767

13

14 2610921766 Depth Rod

15 2610933108 Knob

16 2610928717 Stop piece

17 2610928598 Depth Gauge

18 2610933939 Screw

19 2610933107 Washer

20 2610928597

21 2610921716 Angle Lock Knob

22 2610923737 Square Nut

23 2610929317 Outer Shell Right

24 2610921756 Screw

W

Handle

28

27

25

39

26

32

33

34

24

6a

25

23

22

21

20

17

19

18

14

13

12

Ref. Part No. Description

25 2610921980 Washer (2)

26 2610921749 Wing Knob

27 2610921722 Crow’s Nest

28 2610917207 Wrench

29 2615297527 Grommet

30 2615297529 Hanger

31 2610923471 Cord Holder

32 2610921746 Pin

2610921747 Square Nut

33

34 2610921719 Height Adjustment

35 2610921736 Extension Tube

36 2610921732 Hex Bolt

2610

37

2610921710

38

39 2610921745 Shaft Support

101010

38

921731

Assembly

Assembly

Square Nut

Assembly

Base

29

30

31

35

36

37

Page 11

DM 2610921728 8-05E 8/23/05 9:15 AM Page 11

NOTES

11

Page 12

Mode d'emploi

Table des Matières

Consignes de sécurité pour les outils

Électroportatifs . . . . . . . . . . . . . . . . .13 - 14

Consignes de sécurité pour les Perceuses

Sensitives . . . . . . . . . . . . . . . . . . . .14 - 15

Assemblage . . . . . . . . . . . . . . . . . . . .16 - 17

Utilisation . . . . . . . . . . . . . . . . . . . . . .18 - 21

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Schéma des Pièces . . . . . . . . . . . . .23 - 24

Habla español? Ver página . . . . . . . . . .25

¿

Poste de Travail

MODÈLE 220

4915 21st Street

Racine, WI 53406

1-800-437-3635

http://www.dremel.com

Page 13

Règles de Sécurité Générales

!

AVERTISSEMENT

d'incendie et/ou de blessures graves.

Veillez à ce que l'aire de travail soit propre

et bien éclairée. Le désordre et le manque

de lumière favorisent les accidents.

N'utilisez pas d'outils électriques dans

une atmosphère explosive, par exemple

enprésence de liquides, de gaz ou de

poussières inflammables. Les outils élec-

triques créent des étincelles qui pourraient

enflammer les poussières ou les vapeurs.

Tenez à distance les curieux, les enfants

et les visiteurs pendant que vous travaillezavec un outil électrique. Ils pour-

raient vous distraire et vous faire faire une

fausse manoeuvre.

Sécurité Électrique

Les outils à double isolation sont équipés

d'une fiche polarisée (une des lames est

pluslarge que l'autre), qui ne peut se

brancher que d'une seule façon dans une

prise polarisée. Si la fiche n'entre pas parfaitement dans la prise, inversez sa position ; si elle n'entre toujours pasbien,

demandez à un électricien qualifié d'installer une prise de courant polarisée. Ne

modifiez pas la fiche de l'outil. La double

isolation élimine le besoin d'un cordon

d'alimentationà trois fils avec mise à la terre

ainsi que d'une prise de courant mise à la

terre. Avant de brancher l'outil, assurez-vous

que la tension de la prise correspond, à celle

indiquée sur la plaque signalétique. N'utilisez

pas d'outils prévus pour courant alternatif

seulement avec une source de courant

continu.

Évitez tout contact corporel avec des surfaces mises à la terre (tuyauterie, radiateurs, cuisinières, réfrigérateurs, etc.). Le

risque de choc électrique est plus grand si

votre corps est encontact avec la terre.Si l'utilisation de l'outil électrique dans un endroit

humide est inévitable, un disjoncteur de fuite

à la terre doit être utilisé pour alimenter votre

outil. Des chaussures et des gants en

caoutchouc d'électricien contribueront à

accroître davantage votre sécurité

personnelle.

N'exposez pas les outils électriques à la

pluie ou à l'eau. La présence d'eau dans un

outil électrique augmente le risque de choc

électrique.

Ne maltraitez pas le cordon. Ne transportez pas l'outil par son cordon et ne

débranchez pas la fiche en tirant sur le

Vous devez lire et comprendre toutes les instructions. Lenon-respect,

même partiel, des instructions ci-après entraîne un risque de choc életrique,

CONSERVEZ CES INSTRUCTIONS

Aire de Travail

cordon. N'exposez pas le cordon à la

chaleur, à des huiles, à des arêtes vives

ou à des pièces en mouvement.

Remplacez immédiatement un cordon

endommagé. Un cordon endommagé aug-

mente le risque de choc électrique.

Lorsque vous utilisez un outil électrique à

l'extérieur, employez un prolongateur

pour l'extérieur marqué « W-A » ou « W ».

Ces cordons sont faits pour être utilisés à

l'extérieur et réduisent le risque de choc électrique. Reportez-vous aux Dimensions

recommandées des cordons de rallonge »

dans la section Accessoires de ce manuel.

Sécurité des Personnes

Restez alerte, concentrez-vous sur votre

travail et faites preuve de jugement.

N'utilisez pas un outil électrique si vous

êtes fatigué ou sous l'influence de

drogues, d'alcool ou de médicaments. Un

instant d'inattention suffit pour entraîner des

blessures graves.

Habillez-vous convenablement. Ne portez

ni vêtements flottants ni bijoux. Confinez

les cheveux longs. N'approchez jamais

les cheveux, les vêtements ou les gants

des pièces en mouvement. Des vêtements

flottants, des bijoux ou des cheveux longs

risquent d'être happés par des pièces en

mouvement. Gardez les poignées sèches,

propres et exemptes d'huile et de graisse.

Méfiez-vous d'un démarrage accidentel.

Avant de brancher l'outil, assurez-vous

que son interrupteur est sur ARRÈT.

fait de transporter un outil avec le doigt sur la

détente ou de brancher un outil dont l'interrupteur est en position MARCHE peut mener

tout droit à un accident.

Enlevez les clés de réglage ou de serrage

avant de démarrer l'outil. Une clé laissée

dans une pièce tournante de l'outil peut

provoquer des blessures.

Ne vous penchez pas trop en avant.

Maintenez un bon appui et restez en

équilibre entout temps. Un bonne stabilité

vous permet de mieux réagir à une situation

inattendue.

Utilisez des accessoires de sécurité.

Portez toujours des lunettes ou une

visière. Selon les conditions, portez aussi un

masque antipoussière, des bottes de sécurité antidérapantes, un casque protecteur

et/ou un appareil antibruit.

Le

13

Page 14

Utilisation et Entretien des Outils

Immobilisez le matériau sur une surface

stable au moyen de brides ou de toute

autre façon adéquate.

pièce avec la main ou contre votre corps

offre une stabilité insuffisante et peut amener

un dérapage de l'outil.

Ne forcez pas l'outil. Utilisez l'outil approprié à la tâche. L'outil correct fonctionne

mieux et de façon plus sécuritaire.

Respectez aussi la vitesse de travail qui lui

est propre.

N'utilisez pas un outil si son interrupteur

est bloqué. Un outil que vous ne pouvez pas

commander par son interrupteur est dangereux et doit être réparé.

Débranchez la fiche de l'outil avant d'effectuer un réglage, de changer d'accessoire oude ranger l'outil. De telles mesures

préventives de sécurité réduisent le risque

de démarrage accidentel de l'outil.

Rangez les outils hors de la portée des

enfants et d'autres personnes inexpérimentées. Les outils sont dangereux dans les

mains d'utilisateurs novices.

Prenez soin de bien entretenir les outils.

Les outils de coupe doivent être toujours

bien affûtés et propres. Des outils bien

entretenus, dont les arêtes sont bien tranchantes, sont moins susceptibles de coincer

et plus faciles à diriger.Toute altération ou

modification constitue un usage erroné et

peut causer un danger.

Soyez attentif à tout désalignement ou

coincement des pièces en mouvement, à

Le fait de tenir la

tout bris ou à toute autre condition préjudiciable au bon fonctionnement de l'outil.

Si vous constatez qu'un outil est endommagé, faites-le réparer avant de vous en

De nombreux accidents sont causés

servir.

par des outils en mauvais état. Élaborez un

calendrier d'entretien périodique de votre

outil.

N'utilisez que des accessoires que le fabricant recommande pour votre modèle

d'outil. Certains accessoires peuvent con-

venir à un outil, mais être dangereux avec un

autre.

Réparation

La réparation des outils électriques doit

être confiée à un réparateur qualifié.

L'entretien ou la réparation d'un outil électrique par un amateur peut avoir des conséquences graves. Ainsi, des fils internes

peuvent être mal placés ou pincés, des

ressorts de rappel de protecteur peuvent être

montés erronément.

Pour la réparation d'un outil, n'employez

que des pièces de rechange d'origine.

Suivez les directives données à la section

« Réparation » de ce manuel. L'emploi de

pièces non autorisées ou le non-respect des

instructions d'entretien peut créer un risque

de choc électrique ou de blessures. Certains

agents nettoyants tels qu'essence, tétrachlorure de carbone, ammoniac, etc., peuvent abîmer les pièces en plastique.avant

l’entretien ; avant de changer les lames, les

mèches, les couteaux, etc.

Consignes de Sécurité pour les outils Électroportatifs

Débranchez l'outil avant de le monter sur

une table, de faire des réglages ou de

changer d'embout.

en cas de démarrage intempestif de l'outil.

Fixez fermement la table sur une plateforme ou un établi stable.

bilité pendant l'utilisation, la plate-forme ou

l'établi risque de bouger ou de basculer causant ainsi une perte de contrôle et des

blessures.

Fixez fermement l'outil à la table avant

utilisation.

tilisation il aura tendance à sortir tout seul de

la bride et il risque de tomber avec l'embout

toujours en rotation.

Sachez arrêter votre outil! Positionnez-le

de manière à ce que l'interrupteur soit facile

ment accessible pour pouvoir arrêter l'outil

rapidement en cas d'urgence.

Éloignez le cordon de l'embout et de la

zone de coupe.

Si l'outil se desserre pendant l'u-

Il y a risque de blessure

En cas d'insta-

Il y a risque de choc,

brûlure ou électrocution si on coupe un cordon sous tension.

Portez une protection oculaire et un

masque à poussière.

dans un endroit bien ventilé. L'utilisation

d'équipements de protection personnelle et

le fait de travailler dans un endroit sûr

réduisent le risque de blessures.

Ne pas porter de gants, de cravate ou de

vêtements amples quand vous utilisez

l’outil.

Nouer les cheveux longs ou utiliser

un filet à cheveux. Les vêtements ou les

cheveux risquent d’être happés par le foret

(ou fer) en rotation, ce qui pourrait résulter

en blessures.

Le type et la vitesse de l'embout doivent

-

être adaptés à la tâche. N'utilisez pas

d'embouts dont le diamètre de coupe

dépasse la capacité de l'outil.

perceuse sensitive est prévu principalement

pour effectuer de travaux légers dans du

14

Utilisez uniquement

Le pied de

Page 15

Consignes de Sécurité pour les outils Électroportatifs (suite)

bois. Si on surcharge l'outil, il y a risque de

blessure corporelle ou de panne.

Il ne faut jamais utiliser d'embouts

abîmés ou émoussés. Soyez prudents

quand vous manipulez des embouts

affûtés.

casser pendant l'utilisation. Les embouts

émoussés nécessitent plus d'effort pour

pénétrer dans la pièce, ce qui risque

éventuellement de les casser.

Assurez-vous que la pièce ne contient ni

clous ni autres objets étrangers.

coupez un clou, vous abîmerez l'embout et la

pièce risque de rebondir et de causer une

perte de contrôle.

Avant utilisation, bridez la pièce ou

appuyez-la contre la colonne. Il ne faut

jamais tenir une petite pièce dans une

main et abaisser la perceuse.

pièce vous permet d'utiliser les deux mains

pour mieux maîtriser l'outil. Fixer la pièce

l'empêche de tourner ou d'être avalée par

l'embout pendant le perçage.

Utilisez un vé pour supporter les pièces

rondes telles que les tubes ou les tiges

pendant le perçage.

telles que les goujons, les tuyaux ou les

tubes ont tendance à rouler pendant la

coupe. L'embout risque ainsi de mordre

dans la pièce ou la pièce risque de rebondir

vers vous.

Il faut régler la tête de l'outil et la profondeur de coupe à la position désirée et

l'y fixer quand vous effectuez des

opérations autres que le perçage.

Amenez la pièce à l'outil et laissez

suffisamment d'espace entre votre main

et l'embout en rotation (au moins 150 mm

(6 po).

rotation, vous vous blesserez.

Cette perceuse à colonne a été conçue pour

des opérations de perçage, de ponçage, de

brossage, de polissage et de meulage. Son

utilisation dans des opérations autres que

celles-ci risque de présenter des dangers

inévitables.

Si le côté d’un

rotation, un tambour de ponçage par exemple,

est utilisé pour réaliser le travail, il faut faire

avancer la pièce sur le côté de l’accessoire

qui tourne en direction opposée au sens

d’avance de la pièce. Le fait de faire avancer

la pièce sur le côté de l’accessoire qui tourne

dans la même direction que le sens d’avance

Les embouts abîmés risquent de

Si vous

Brider la

Les pièces rondes

Si vous touchez l'embout en

quelconque accessoire en

de la pièce risque de causer l’entraînement

de la pièce par l’accessoire en rotation et de

mener à une perte de contrôle pendant

l’opération.

Ne démarrez jamais l'outil avec l'embout

engagé dans le matériau.

l'embout risque de happer la pièce et de

causer une perte de contrôle.

N'approchez pas les mains de la zone du

fer en rotation.

que votre main est proche de l'embout en

rotation. La pièce risque de bouger ou votre

main risque de glisser pendant l'utilisation.

!

AVERTISSEMENT

ou le perçage à la machine ainsi que

d'autres activités du bâtiment produisent

certaines poussières qui contiennent des

produits chimiques, lesquels peuvent

causer des cancers, des déformations

congénitales ou d'autres troubles

reproductifs. Ces produits chimiques sont

par exemple :

• Le plomb provenant des peintures à base

de plomb ;

• Les cristaux de silice provenant des

briques, du ciment et d'autres produits de

maçonnerie et

• L'arsenic et le chrome provenant des bois

traités chimiquement.

Après avoir changé d'embout ou effectué

un réglage, assurez-vous que l'écrou de

douille ainsi que tous les autres dispositifs de réglage sont fermement serrés.

Les dispositifs de réglage mal serrés risquent

de bouger de manière inattendue, résultant

en une perte de contrôle. Toute pièce en

rotation mal serrée sera éjectée violemment.

Il ne faut jamais toucher l'embout pendant

ou immédiatement après utilisation.

vous touchez l'embout en rotation, vous vous

blesserez. Après utilisation, l'embout est trop

chaud pour qu'on puisse le toucher à mains

nues.

Ne laissez pas un outil en rotation sans

surveillance. Arrêtez-le.

sécurité, attendez l'arrêt complet de l'embout

avant d'enlever la pièce et de nettoyer le pied

de perceuse.

PENSEZ À LA

résulte du BON SENS et de la VIGILANCE

constante de l'utilisateur pendant utilisation

de l'outil.

Il n'est pas toujours évident

SÉCURITÉ!

Le tranchant de

Le ponçage, le

sciage, le meulage

Si

Pour votre

La sécurité

15

Page 16

Assemblage

CET ACCESSOIRE CONVIENT AUX OUTILS ROTATIFS DREMEL MODELES 275,

285, 295, 300, 398, 400, 780 ET 800.

ATTENTION:

entièrement et attentivement avant d'utiliser

votre poste de travail Dremel. Conservez ces

instructions pour vous y reporter ultérieurement. Votre poste de travail Dremel 220 permet de convertir des outils rotatifs en

perceuse sensitive pour percer. Il peut

également servir de porte-outil pour poncer

ou polir ou même de pied pour outil muni

d'un arbre flexible.

1. Assemblez le tube sur le socle et fixezle avec le boulon 6 pans et l'écrou carré.

Veuillez lire ce mode d'emploi

2. Enfoncez l'écrou carré (bout court en premier) dans le support d’ensemble du

tube et installez la manette de réglage

de la hauteur. Faites glisser le coulisseau sur la section la plus large du tube

et serrez.

3. Installez le porte-embout sur la section la

plus large du tube avec les petits trous

tournés vers le haut.

4. Installez la pince du cordon.

5. Installez le crochet en métal et son

capuchon.

6. Si on le désire, on peut fixer le socle sur

un établi à l'aide de vis de taille appropriée (non fournies).

16

Page 17

Ensemble du crochet

Manette

de Réglage de la

hauteur

Écrou Carré

(Assemblé à l’intérieur du support

d’ensemble du tube)

Capuchon

Crochet en métal

Pince du cordon

Clé

Coulisseau

Porte-outil

Socle

Écrou Carré

(assemblé à l'intérieur

du coulisseau)

Bouton de

blocage de

l'angle

Figure 1. Poste de T

ravail Mod

17

Porte-embout

Ensemble du tube

le 220 Composant

è

Boulon 6 pans

du socle

Page 18

Utilisation

IMPORT

utilisé qu'avec un seul outil à la fois. Il ne faut

pas accrocher un outil sur le crochet quand

un autre outil est monté sur le coulisseau.

Le porte-embout permet de ranger les outils

suivants :

• Jeu de forets (Modèle 628)

• Clé de l'outil rotatif

• Clé de montage

• Embouts avec queue d'un diamètre

inférieur ou égal à 1/8 po

• Douilles pour l'outil rotatif

(Modèles 480, 481, 482, 483)

REMARQUE: Les embouts rotatifs sont

retenus dans l'outil par un système de douille.

On peut installer l'embout soit avant soit

après avoir installé l'outil rotatif sur le pied de

perceuse sensitive.

1. Appuyez sur le bouton de blocage de l'arbre et maintenez-le enfoncé tout en tournant l'écrou de douille et l'arbre.

Continuez de tourner l'écrou de douille et

l'arbre jusqu'à ce que le blocage s'enclenche et bloque l'arbre (Figure 2).

2. À l'aide de la clé fournie avec votre outil

rotatif Dremel, tournez la douille en sens

anti-horaire pour la desserrer.

Le poste de travail ne peut être

ANT!

Bouton de

blocage de

l'arbre

Figure 2. Desserrage/ serrage

de la Douille

3. Lâchez le bouton de blocage de l'arbre.

4. Enfoncez le foret dans la douille aussi loin

que possible afin de pouvoir le pincer correctement et de minimiser le battement.

N'enfoncez pas le foret si profond que les

cannelures touchent la douille ou l'écrou

de douille afin d'éviter de l'ébrécher ou de

le fêler.

5. Ré-enclenchez le bouton de blocage de

l'arbre et serrez l'écrou de douille, d'abord

à la main puis avec la clé jusqu'à ce que

le foret soit maintenu fermement.

Il faut positionner le

cordon sur le

côté quand

on utilise la

perceuse

sensitive.

Écrou de pince

Figure 3. Montage de l'outil Rotatif

18

Page 19

Utilisation (suite)

6. Retirez le capuchon de l’outil rotatif.

7. Insérez l’outil rotatif dans le coulisseau

avec le blocage de l'arbre dirigé vers

l'avant. Bridez l'outil dans la pince du

porte-outil en serrant l'écrou de la pince.

REMARQUE : le modèle 398 se monte avec

le blocage de l’arbre à l’arrière et le cordon à

droite. Les modèles 400 et 800 se montent

avec le blocage de l’arbre à droite.

REMARQUE: Quand vous serrez l'outil rotatif

dans le porte-outil, assurez-vous qu'il est assujetti correctement et que les ouïes de ventilation ne sont pas masquées.

8. Faites pivoter le tube supérieur en sens

anti-horaire pour le desserrer, ce qui permet de le régler vers le haut ou vers le bas.

Quand vous avez atteint la hauteur

désirée, tournez le tube en sens horaire

pour le serrer (Figure 4).

REMARQUE: Il ne faut pas déployer le tube

quand l'outil est monté dans le porte-outil.

Enfoncez le cordon dans la pince du cordon (Figure 2), ce qui le maintient éloigné

de la zone de travail. Assurez-vous qu'il y

a assez de mou dans le cordon pour qu'il

ne soit pas tendu quand la perceuse sensitive est en bout de course.

9. Utilisez la butée de profondeur quand vous

voulez percer des trous d'une profondeur

donnée. Le boîtier du coulisseau est muni

d'une échelle pour vous faciliter la tâche.

Réglez la butée de profondeur à la profondeur désirée et serrez le bouton de

blocage de la profondeur (Figure 5).

Quatre vis de pression sont également

fournies sur l’échelle de profondeur et le

côté gauche du boîtier (cf. figure 5). Ces vis

permettent le microréglage du coulisseau.

Utilisez une clé Allen de 1,5 mm pour

effectuer les réglages. Faites attention de

ne pas trop serrer les vis de pression.

Manette de

Réglage

de la Hauteur

Bouton de

verrouillage des

petits angles

Vis de

pression

Figure 5. Réglage de la Profondeur et de la Hauteur

ournez le tube en sens

T

anti-horaire pour le

desserrer, réglez le tube

vers le haut ou vers le bas,

tournez le tube en sens

horaire pour le serrer.

REMARQUE: Il ne faut pas

déployer le tube quand

l'outil est monté dans le

porte-outil.

Figure 4. Réglage de la hauteur du tube

10. Les boutons de verrouillage des petits

angles et des grands angles servent à

fixer l’outil soit dans la position verticale,

soit à un angle de 90 °. L'outil peut

être utilisé à 15°, 30°, 45°, 60°, 75° ou

90° pour poncer, pour polir ou pour le

travail à la brosse métallique.

Desserrez le petit bouton et le grand

bouton et faites pivoter l'outil puis

resserrez fermement les deux boutons

de blocage de l'angle.

11. Utilisez la manette de réglage de hauteur pour bloquer le coulisseau sur le

tube à la hauteur appropriée.

Bouton de

verrouillage

des grands

angles

Bouton de

Blocage de la

butée de

Profondeur

Vis de

pression

19

Page 20

Desserrez la manette et déplacez

l'ensemble du coulisseau et de l'outil

pour l'amener à la position désirée puis

resserrez la manette de réglage de la

hauteur.

12. Repérez la position des trous sur la

pièce et marquez les centres d'un coup

de pointeau, ce qui empêchera la pointe

du foret de glisser et assurera que le

trou est percé au bon endroit. Les avantages du coup de pointeau sont un

moindre risque de casser le foret et une

meilleure précision dans le diamètre du

trou.

13. Fixez la pièce sur le socle avant de

percer. Ceci évitera qu'elle soit avalée

par le foret ou qu"elle tourne avec lui.

L'avantage du bridage est l'amélioration

de la sécurité et de la qualité. Des

brides (non fournies) conviennent

parfaitement mais vous pouvez

également utiliser un petit étau pour

tenir la pièce lors du perçage (Figure 6).

14.Desserrez le levier de blocage du

réglage de la hauteur d'un 1/2 tour et

déplacez le coulisseau le long du tube

afin d'amener la pointe du foret à proximité de la pièce. (On recommande un

maximum de 1/4 po entre la pointe du

foret et la pièce) Resserrez le levier de

blocage.

15.Saisissez le levier du coulisseau

et abaissez-le pour percer le trou.

Figure 6. Brides de Pièces

(non fournies)

Figure 7. Pièce Ronde

Conseils Utiles

Pour percer dans des pièces rondes, utilisez

un vé ou un étau. Pour percer un trou au centre d'une pièce ronde, il est nécessaire d'en

marquer le centre d'un coup de pointeau

(Figure 7). (Pointeau non compris).

Évitez de forcer au point où la vitesse du

moteur est réduite de matière notable. Il faut

également pousser doucement quand le

foret est prêt à déboucher. Cela évitera de

déchiqueter le bord du trou quand on

débouche.

Pour améliorer la précision du perçage,

abaissez l'outil de manière à amener la

pointe du foret à 1/4 po ou moins de la pièce

avant d'abaisser le levier qui fait avancer le

foret. La précision du perçage sera assurée

si on minimise la course et si on marque le

centre du trou d'un coup de pointeau là où on

désire percer.

20

Page 21

Fabrication de Brides Optionnelles pour

votre Poste de Travail 220

On peut fabriquer les brides en bois, en

aluminium ou en acier suivant la tâche à

effectuer.

1. Coupez ou sciez la pièce à la longueur,

largeur et hauteur désirées.

2. Percez un trou débouchant dans la bride

à l'aide d'un foret de 5/16 po ou de 21/64

po à l'endroit désiré.

3. Montez les brides à l'aide de boulons de

carrosserie de 5/16 -18 x 1-1/2 po ou 2

po de long et de rondelles et écrous

papillon correspondants.

4. Montez-les sur le socle en glissant la

tête du boulon de carrosserie par le

dessous du socle avec les écrou-papillons

sur le dessus.

Quand on utilise les brides sur des pièces

d'épaisseur supérieure à 1/4 po, il faut toujours placer une cale d'épaisseur pour supporter l'arrière de la bride (Figure 8). Pour

supporter la bride au mieux, il convient de

couper la cale épaisseur environ 1/8 po plus

court que la hauteur de la pièce.

Écrou à ailettes

Rondelle

Bride

Cale

Boulon

de carrosserie

Figure 8. Fabrication de Brides

en Option

21

Page 22

Garantie limitée de Dremel

Votre produit Dremel est garanti contre les vices de matière et de main d'œuvre pour une période

de d'un an à partir de la date d'achat. Au cas ou un produit n'est pas conforme à cette garantie

écrite, il convient d'agir comme suit :

1. NE rapportez PAS votre produit là où vous l'avez acheté.

2. Emballez le produit seul avec soin, sans rien d'autre, et renvoyez-le en port payé accompagné des documents suivants:

A. Une copie de votre preuve d'achat datée (veuillez conserver une copie pour vous-même).

B. Une description écrite du problème.

C. Votre nom, adresse et numéro de téléphone à l'attention de:

ÉTATS-UNIS

Dremel Service Center Dremel Service Center

4915 21st Street OU 4631 E. Sunny Dune

Racine, WI 53406 Palm Springs, CA 92264

CANADA EN DEHORS DES ÉTATS AMÉRICAINS

Giles Tool Agency CONTINENTAUX

6520 Lawrence Av. East Contactez votre distributeur local

Scarborough, Ont ou écrivez à

Canada M1C 4A7 Dremel, 4915 21st Street

Nous vous recommandons d'assurer votre envoi contre la perte ou les dégâts de transport,

lesquels ne peuvent en aucun cas engager notre responsabilité.

Cette garantie ne s'applique qu'à l'acheteur inscrit d'origine. LES DÉGÂTS AU PRODUIT

RÉSULTANT DE MODIFICATIONS, D'ACCIDENT, D'UN MAUVAIS TRAITEMENT, D'UNE

NÉGLIGENCE, DE RÉPARATIONS NON AUTORISÉES, DE L'UTILISATION D'ACCESSOIRES

NON HOMOLOGUÉS OU D'AUTRES CAUSES NON LIÉES À DES VICES DE MATIÈRE OU

DE MAIN D'OEUVRE NE SONT PAS COUVERTS PAR CETTE GARANTIE.

Aucun employé, agent ou distributeur ni qui que ce soit d'autre n'est autorisé à donner aucune

garantie de la part de Dremel. Si l'inspection par Dremel démontre que le problème a été causé

par un vice de matière ou de main d'œuvre dans les limites de la garantie, Dremel réparera ou

remplacera le produit sans frais et le renverra en port payé. Les réparations nécessitées par

l'usure normale ou un mauvais traitement et les réparations du produit en dehors de la période

de garantie, si elles sont possibles, seront effectuées au coût usine normal.

DREMEL NE FAIT AUCUNE AUTRE GARANTIE D'AUCUNE SORTE, EXPLICITE OU IMPLICITE,

ET TOUTES LES GARANTIES IMPLICITES QUE LE PRODUIT EST COMMERCIALISABLE ET

QU'IL CONVIENT À UN USAGE PARTICULIER SAUF COMME EXPRESSÉMENT MENTIONNÉ

CI-DESSUS SONT EXPRESSÉMENT DÉCLINÉES ET EXCLUES DE CETTE GARANTIE

LIMITÉE.

Cette garantie vous donne des droits spécifiques et il se peut que vous ayez d'autres recours légaux

qui varient d'état à état. Le devoir du garant se limite à la réparation ou au remplacement du produit. Le garant ne saurait être tenu pour responsable des dommages directs ou indirects causés par

le vice supposé. Certains états n'admettent pas l'exclusion ou la limitation des dommages directs ou

indirects. Les limitations ou exclusions mentionnées ci-dessus ne s'appliquent donc pas forcément

à vous.

Pour vous renseigner sur les prix ou l'exécution de la garantie dans les états américains continentaux, contactez votre distributeur Dremel.

Racine, WI 53406

22

Page 23

Schéma des pièces

29

1

3

4

6b

7

2

5

6a

6b

16

6a

8

15

6a

9

10

11

Ref. No. de piece Description

1 2610921769 Vis (6)

2 2610929316 Coque extérieure –

3 2610928604 Couvercle de boîtier

4 2610930418 Pignon

5 2610928594 Ressort de torsion

6a 2610933097 Petite vis de pression (4)

6b 2610933514 Grande vis de pression (2)

7 2610928605 Boîtier principal

8 2610928596 Support

9 2610928607 Porte-outil

10 2610921755 Rondelle

11 2610921738 Boulon 6 pans

12 2610921768 Écrou 6-pans

13 2610921767 Rondelle

14 2610921766 Tige de profondeur

15 2610933108 Bouton

16 2610928717 Pièce de butée

17 2610928598 Échelle de profondeur

18 2610933939 Vis

19 2610933107 Rondelle

20 2610928597 Ensemble de poignée

21 2610921716 Bouton de blocage

22 2610923737 Écrou carré

23 2610929317 Coque extérieure –

côté gauche

de l'angle

côté droit

28

27

26

25

32

33

34

25

24

22

6a

23

21

20

17

19

18

14

13

12

Ref. No. de piece Description

24 2610921756 Vis

25 2610921980 Rondelle (2)

26 2610921749 Bouton à ailettes

27 2610921722 Porte-embouts

28 2610917207 Clé

29 2615297527 Capuchon

30 2615297529 Crochet

31 2610923471 Pince pour cordon

32 2610921746 Goupille

33 2610921747 Écrou carré

2610921719

34

2610921736 Ensemble de tube de

35

2610921732 Boulon 6 pans

36

2610921731 Écrou carré

37

38 2610921710 Ensemble de socle

39 2610921745 Support d’arbre

23

38

Ensemble de réglage

de la hauteur

rallonge

30

31

35

36

37

Page 24

REMARQUES

24

Page 25

Manual del Usuario

Contenido del Manual

Normas de seguridad para Herramientas

Mecánicas . . . . . . . . . . . . . . . . . . . . .26 - 27

Normas de Seguridad para el Taladro de

Columna . . . . . . . . . . . . . . . . . . . . . .27 - 28

Montaje . . . . . . . . . . . . . . . . . . . . . . .29 - 30

Utilización . . . . . . . . . . . . . . . . . . . . .31 - 34

Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Diagrama de Piezas . . . . . . . . . . . . .36 - 37

Parlez-vous français? Voir page . . . . . .12

Estación de Trabajo

MODELO 220

4915 21st Street

Racine, WI 53406

1-800-437-3635

http://www.dremel.com

Page 26

Normas de seguridad para Herramientas Mecánicas

!

ADVERTENCIA

tricas, incendios y/o lesiones personales graves.

Lea y entienda todas las instrucciones. El incumplimiento de todas las

instrucciones indicadas a continuación puede dar lugar a sacudidas eléc-

CONSERVE ESTAS INSTRUCCIONES

Area de Trabajo

Mantenga el área de trabajo limpia y bien

iluminada. Las mesas desordenadas y las

áreas oscuras invitan a que se produzcan

accidentes.

No utilice herramientas mecánicas en

atmósferas explosivas, tales como las

existentes en presencia de líquidos,

gases o polvos inflamables. Las

herramientas mecánicas generan chispas y

éstas pueden dar lugar a la ignición del polvo

o los vapores.

Mantenga a las personas que se

encuentren presentes, a los niños y a los

visitantes alejados al utilizar una

herramienta mecánica. Las distracciones

pueden hacer que usted pierda el control.

Seguridad Eléctrica

Las herramientas con aislamiento doble

están equipadas con un enchufe

polarizado (un terminal es más ancho que

el otro). Este enchufe entrará en un

tomacorriente polarizado solamente de

una manera. Si el enchufe no entra por

completo en el tomacorriente, déle la

vuelta. Si sigue sin entrar, póngase en

contacto con un electricista competente

para instalar un tomacorriente polarizado.

No haga ningún tipo de cambio en el

enchufe. El aislamiento doble elimina la

necesidad del sistema de cordón de energía

de tres hilos conectado a tierra y la fuente de

energía conectada a tierra. Antes de

enchufar la herramienta, asegúrese de que

la tensión del tomacorriente suministrada se

encuentre dentro del margen de la tensión

especificada en la placa del fabricante. No

utilice herramientas con capacidad nominal

"AC solamente" ("AC only") con una fuente

de energía DC.

Evite el contacto del cuerpo con las

superficies conectadas a tierra tales

como tuberías, radiadores, estufas de

cocina y refrigeradores. Hay mayor riesgo

de que se produzcan sacudidas eléctricas si

su cuerpo está conectado a tierra. Si la

utilización de la herramienta mecánica en

lugares húmedos es inevitable, se debe usar

un interruptor de circuito para fallos a tierra

para suministrar la energía a la herramienta.

Los guantes de goma para electricista y el

calzado antideslizante aumentarán más la

seguridad personal.

No exponga las herramientas mecánicas

a la lluvia ni a situaciones húmedas. La

entrada de agua en una herramienta

mecánica aumentará el riesgo de que se

produzcan sacudidas eléctricas.

No abuse del cordón. Nunca use el cordón

para llevar las herramientas ni para sacar el

enchufe de un tomacorriente. Mantenga el

cordón alejado del calor, el aceite, los bordes

afilados o las piezas móviles. Cambie los

cordones dañados inmediatamente. Los

cordones dañados aumentan el riesgo de

que se produzcan sacudidas eléctricas.

Al utilizar una herramienta mecánica a la

intemperie, utilice un cordón de

extensión para intemperie marcado "WA" o "W". Estos cordones tienen capacidad

nominal para uso a la intemperie y reducen

el riesgo de que se produzcan sacudidas

eléctricas. Consulte "Tamaños

recomendados de los cordones de

extensión" en la sección Accesorios de este

manual.

Seguridad Personal

Manténgase alerta, fíjese en lo que está

haciendo y use el sentido común cuando

utilice una herramienta mecánica. No use

la herramienta cuando esté cansado o se

encuentre bajo la influencia de drogas,

alcohol o medicamentos. Un momento de

distracción al utilizar herramientas

mecánicas puede dar lugar a lesiones

personales graves.

Vístase adecuadamente. No se ponga

ropa holgada ni joyas. Sujétese el pelo.

Mantenga el pelo, la ropa y los guantes

alejados de las piezas móviles. La ropa

holgada, las joyas o el pelo largo pueden

quedar atrapados en las piezas móviles.

Mantenga los mangos secos, limpios y libres

de aceite y grasa.

Evite el arranque accidental. Asegúrese

de que el interruptor esté en la posición

"OFF" (apagado) antes de enchufar la

herramienta. El llevar las herramientas con

el dedo en el interruptor o el enchufar

herramientas que tengan el interruptor en la

posición "ON" (encendido) invita a que se

produzcan accidentes.

Quite las llaves de ajuste o de tuerca

antes de encender la herramienta. Una

llave de ajuste o de tuerca que se deje

puesta en una pieza giratoria de la

herramienta puede ocasionar lesiones

personales.

26

Page 27

No intente alcanzar demasiado lejos.

Mantenga un apoyo de los pies y un

equilibrio adecuados en todo momento.

El apoyo de los pies y el equilibrio

adecuados permiten un mejor control de la

herramienta en situaciones inesperadas.

Utilice equipo de seguridad. Use siempre

protección de los ojos.

máscara antipolvo, zapatos de seguridad

antideslizantes, casco o protección de los

oídos según lo requieran las condiciones.

Se debe utilizar una

Utilización y Cuidado de las Herramientas

Utilice abrazaderas u otro modo práctico

de fijar y soportar la pieza de trabajo a

una plataforma estable. La sujeción de la

pieza de trabajo con la mano o contra el

cuerpo resulta inestable y puede ocasionar

pérdida de control.

No fuerce la herramienta. Use la

herramienta correcta para la aplicación

que desea. La herramienta correcta hará el

trabajo mejor y con más seguridad a la

capacidad nominal para la que está

diseñada.

No utilice la herramienta si el interruptor

no la enciende o apaga. Toda herramienta

que no se pueda controlar con el interruptor

es peligrosa y debe ser reparada.

Desconecte el enchufe de la fuente de

energía antes de hacer cualquier ajuste,

cambiar accesorios o guardar la

herramienta. Estas medidas de seguridad

preventivas reducen el riesgo de arrancar la

herramienta accidentalmente.

Guarde las herramientas que no esté

usando fuera del alcance de los niños y

otras personas no capacitadas. Las

herramientas son peligrosas en las manos

de los usuarios no capacitados.

Mantenga las herramientas con cuidado.

Conserve las herramientas de corte

afiladas y limpias. Las herramientas

mantenidas adecuadamente, con bordes de

corte afilados, tienen menos probabilidades

de atascarse y son más fáciles de controlar.

Toda alteración o modificación constituye un

uso incorrecto y puede tener como resultado

una situación peligrosa.

Compruebe la desalineación o el atasco

de las piezas móviles, la ruptura de

piezas y cualquier otra situación que

pueda afectar el funcionamiento de las

herramientas. Si la herramienta está

dañada, haga que realicen un servicio de

ajustes y reparaciones a la herramienta

antes de usarla. Muchos accidentes son

causados por herramientas mantenidas

deficientemente. Establezca un programa de

mantenimiento periódico para la

herramienta.

Utilice únicamente accesorios que estén

recomendados por el fabricante de su

modelo. Los accesorios que pueden ser

adecuados para una herramienta pueden

volverse peligrosos cuando se utilizan en

otra herramienta.

Servicio

El servicio de ajustes y reparaciones de

una herramienta debe ser realizado

únicamente por personal de reparaciones

competente. El servicio o mantenimiento

realizado por personal no competente podría

ocasionar un peligro de que se produzcan

lesiones. Por ejemplo: Los cables internos

pueden colocarse mal o pellizcarse, los

resortes de retorno de los protectores de

seguridad pueden montarse

inadecuadamente.

Al realizar servicio de ajustes y

reparaciones de una herramienta, utilice

únicamente piezas de repuesto idénticas.

Siga las instrucciones que aparecen en la

sección Mantenimiento de este manual.

El uso de piezas no autorizadas o el

incumplimiento de las instrucciones de

Mantenimiento puede ocasionar un peligro

de que se produzcan sacudidas eléctricas o

lesiones. Ciertos agentes de limpieza, tales

como gasolina, tetracloruro de carbono,

amoníaco, etc., pueden dañar las piezas de

plástico.

Normas de Seguridad para el Taladro de Columna

Desenchufe la herramienta antes de

realizar la instalación en la mesa, hacer

ajustes o cambiar brocas. Un arranque

accidental de la herramienta puede causar

lesiones.

Sujete firmemente la mesa a una plataforma estable o un banco de trabajo estable.

Durante la utilización de la herramienta, las

plataformas inestables o los bancos de tra

bajo inestables pueden desplazarse o inclinarse, causando pérdida de control

y lesiones.

-

Sujete firmemente la herramienta a la

mesa antes de utilizarla. Si la herramienta

se afloja durante su utilización, tenderá a

desplazarse hacia abajo de la abrazadera y

podría caerse mientras la broca aún esté

girando.

¡Sepa cómo apagar la herramienta!

Posicione la herramienta de manera que se

pueda obtener acceso fácilmente al interrup

tor para apagar rápidamente la herramienta

en una emergencia.

27

-

Page 28

Normas de Seguridad para el Taladro de Columna (continuación)

Encamine el cordón alejándolo de la

broca o del área de corte. Si se realiza un

corte en cables eléctricos que tengan corriente, el resultado podría ser una descarga

eléctrica, quemaduras o electrocución.

Use protección de los ojos y una máscara

antipolvo.

mente en un área bien ventilada. La utilización de dispositivos de seguridad personal y trabajar en un entorno seguro reducen el

riesgo de lesiones.

No use guantes, corbata o ropa holgada

durante la utilización de la herramienta.

Sujétese el pelo largo detrás de la cabeza o

use una red para el pelo. La ropa o el pelo

pueden quedar atrapados en la broca que

gira y se podrían producir lesiones.

Escoja la broca apropiada y la velocidad

adecuada para la aplicación que vaya a

realizar. No use brocas que tengan un

diámetro de corte que exceda la capacidad de la herramienta. La base de soporte

del taladro de columna está diseñada principalmente para uso de servicio ligero en

madera. Si se sobrecarga la herramienta, el

resultado puede ser lesiones personales o

fallo de la herramienta.

No use nunca brocas desafiladas o

dañadas. Las brocas afiladas se deben

manejar con cuidado. Las brocas dañadas

pueden romperse bruscamente durante el

uso. Las brocas desafiladas requieren más

fuerza para empujar la pieza de trabajo, con

lo que es posible que la broca se rompa.

Asegúrese siempre de que la pieza de trabajo no tenga clavos ni otros objetos

extraños. Si se realiza un corte en un clavo,

se dañará la broca y dicho corte puede hacer

que la pieza de trabajo salte, causando pérdida de control.

Antes de utilizar la herramienta, fije con

abrazaderas la pieza de trabajo o sujétela

contra la columna. No sostenga nunca

una pieza de trabajo pequeña en una

mano y baje el taladro. La sujeción de la

pieza de trabajo con abrazaderas le permite

usar las dos manos para controlar la herramienta. La sujeción firme de la pieza de

trabajo evitará que ésta gire o trepe por el taladro durante la utilización de la herramienta.

Use un bloque en "V" para soportar mate

rial redondo, tal como tubos o varillas,

cuando taladre.

como espigas de unión, tuberías o tubos,

tiene tendencia a rodar mientras está siendo

cortado y podría hacer que la broca "muerda" o que la pieza de trabajo salte hacia

usted.

Utilice la herramienta única-

El material redondo, tal

Usted debe ajustar y fijar la cabeza de la

herramienta en la posición y la profundidad de corte deseadas cuando realice

operaciones distintas al taladrado. Traiga

la pieza de trabajo hacia la herramienta y

deje suficiente espacio, al menos 150 mm

(6"), entre la mano y la broca que gira. El

contacto con la broca que gira causará

lesiones.

Este taladro de columna se diseñó para

realizar aplicaciones de taladrado, lijado,

cepillado, pulido o amolado; otras aplicaciones

pueden presentar peligros contra los que no

se puede tener una protección adecuada.

Si el lado de

usa para realizar el trabajo, como por ejemplo

el lado de un tambor de lijar, la pieza de

trabajo se debe posicionar en el lado del

accesorio que gira contra el sentido de

avance de la pieza de trabajo. Si la pieza de

trabajo se coloca en el lado del accesorio en

el que el sentido de avance de la pieza de

trabajo y el sentido de giro del accesorio son

el mismo, el resultado podría ser que el

accesorio que gira tire de la pieza de trabajo

y cause pérdida de control durante la

operación.

No arranque nunca la herramienta cuando

la broca esté acoplada en el material. El

borde de corte de la broca podría enganchar

el material, causando pérdida de control de

la pieza de trabajo.

No ponga la mano en el área de la broca

que gira. Es posible que la proximidad de la

mano a la broca que gira no siempre sea

obvia. La pieza de trabajo podría

desplazarse o la mano podría resbalar

durante la operación.

!

ADVERTENCIA

aserrado, amolado y taladrado mecánicos, así como por otras actividades de

construcción, contienen sustancias

químicas que se sabe que causan cáncer,

defectos de nacimiento y otros daños

sobre la reproducción. Algunos ejemplos

de estas sustancias químicas son:

• Plomo procedente de pinturas a base de

plomo,

• Sílice cristalina procedente de ladrillos y

cemento y otros productos de mam-

-

postería, y

• Arsénico y cromo procedentes de

madera de construcción tratada químicamente.

cualquier accesorio que gira se

Ciertos tipos de polvo

generados por el lijado,

28

Page 29

Después de cambiar las brocas o hacer

cualquier ajuste, asegúrese de que la

tuerca del portaherramienta y todos los

demás dispositivos de ajuste estén

firmemente apretados. Un dispositivo de

ajuste que esté flojo se puede desplazar

inesperadamente, causando pérdida de

control, y los componentes que giren

estando flojos serán lanzados violentamente.

No toque nunca la broca durante el uso

de la herramienta o inmediatamente

después de su uso. El contacto con una

broca que gira causará lesiones y después

Montaje

ADITAMENTO PARA UTILIZARSE CON

LOS MODELOS GIRATORIOS DREMEL

275, 285, 295, 300, 398, 400, 780 Y 800.

ATENCIÓN:

al de instrucciones completo antes de utilizar

la estación de trabajo Dremel. Retenga las

instrucciones para referencia futura. La

estación de trabajo Dremel 220 convertirá

las herramientas giratorias en un taladro de

columna para taladrar, en un portaherramienta para lijar o pulir, o en una base de

soporte para una herramienta de eje flexible.

1. Monte el tubo en la base y sujételo

firmemente con el perno de cabeza

hexagonal y la tuerca cuadrada.

Lea detenidamente este manu-

del uso la broca está demasiado caliente

para tocarla con las manos desnudas.

No deje desatendido herramental que

esté en marcha; apáguelo. Solamente

cuando la herramienta se ha detenido por

completo es seguro retirar la pieza de

trabajo y limpiar la base de soporte.

¡PIENSE EN LA SEGURIDAD! La seguridad

es una combinación de SENTIDO COMÚN

del operador y de que éste se mantenga

ALERTA en todo momento cuando se esté

usando la herramienta.

2. Introduzca la tuerca cuadrada (el

extremo corto primero) en el ensamblaje del soporte del tubo e instale la palanca de ajuste de la altura. Deslice la

prensa por la sección más grande del

tubo y apriétela.

3. Instale el nido de pájaro en la sección

más grande del tubo con los agujeros

pequeños orientados hacia arriba.

4. Instale el portacordón.

5. Instale el alambre del colgador y la tapa.

6. Si se desea, la base se puede sujetar

firmemente a un banco de trabajo usando los herrajes de tamaño apropiado (no

suministrados).

29

Page 30

Ensamblaje del

Colgador

Palanca de

ajuste de la altura

Tuerca cuadrada (instalada en

el interior del ensamblaje del

soporte del tubo)

apa

T

Alambre del Colgador

Portacordón

Llave de

tuerca

Prensa

taladradora

Portaherramienta

Tuerca cuadrada

(montada en el

interior del taladro

de columna)

Pomo de

fijación del

ángulo

Base

Figura 1. Componentes de la Estación de Trabajo 220

Nido de pájaro

Ensamblaje del tubo

Perno de cabeza

hexagonal de la

base

30

Page 31

Utilización

¡IMPORTANTE! La estación de trabajo está

diseñada para utilizarse solamente con una

herramienta a la vez. No cuelgue una herramienta en el ensamblaje del colgador cuando otra herramienta esté montada

en la prensa.

El área de almacenamiento de herramientas

en el nido de pájaro tiene capacidad para las

herramientas siguientes:

• Juego de brocas taladradoras (modelo 628)

• Llave de tuerca para herramientas

giratorias

• Llave de tuerca de montaje

• Brocas con tamaño de vástago menor

o igual a 1/8"

• Portaherramientas para herramientas

giratorias (modelos 480, 481, 482, 483)

NOTA: Las brocas taladradoras se sujetan

en la herramienta mediante un sistema de

portaherramienta. La broca se puede instalar

antes o después de instalar la herramienta

giratoria en el taladro de columna.

1. Oprima y mantenga oprimido el botón de

fijación del eje a la vez que gira la tuerca

del portaherramienta y el eje. Continúe

girando la tuerca del portaherramienta y

el eje hasta que el cierre se acople y mantenga sujeto el eje (Figura 2).

Botón de

fijación

del eje