Page 1

Technical Service Manual

Isolette® Infant Incubator

C2000

Revision J

6016.036

man 223

Because you care

Page 2

Revisions

Isolette® Infant Incubator

Service Manual

Revision Letter Pages Affected Date

Original Issue March, 1998

A 1 November, 1998

B vii, 1-4, 2-7, 2-8A, 2-8D,

2-12, 2-19, 4-4, 4-5, 4-8

and 4-12

C 2-2, 2-8, 2-8B, 2-8C, 5-1,

5-2, 6-30 through 6-34, 636, 6-38, 6-40 through 642, 6-44 through 6-46, 670, 6-71, 6-74 through 677, 6-97A, 6-97B, 7-3

D 4-6, 4-7, 6-2, 6-51 November, 1999

E Cover, Warranty, A, B, ii

through vi, viii through x,

1-3, 2-9, 2-11, 3-2, 3-5, 37 through 3-9, 3-13, 3-14,

3-16, 3-30, 4-3, 5-4

through 5-18, 6-1, 6-4

through 6-6, 6-52 through

6-55, 6-55A through 655D, 6-56, 6-57, 6-57A

through 6-57F, 6-58, 659, 7-4 through 7-24

February, 1999

May, 1999

March, 2000

FAll May, 2001

G All September, 2002

H All pages with Hill ROM;

front and back Covers

I Front and back covers April, 2006

J Back cover October, 2006

Isolette® Infant Incubator (Model C2000) Service Manual Page i

December, 2004

Page 3

Revisions

© 2006 by Draeger Medical Systems, Inc. ALL RIGHTS RESERVED.

No part of this text shall be reproduced or transmitted in any form or by

any means, electronic or mechanical, including photocopying,

recording, or by any information or retrieval system without written

permission from Draeger Medical Systems, Inc.

The information in this manual is confidential and may not be disclosed

to third parties without the prior written consent of Draeger Medical

Systems, Inc.

Eleventh Edition

First Printing 1998

Printed in the USA

Air-Shields® is a registered trademark of Draeger Medical Systems,

Inc.

Allen™ is a trademark of Industrial Fasteners, Inc.

Critter Covers® is a registered trademark of Hill-Rom Services, Inc.

Dow Corning® is a registered trademark of Dow Corning Corporation.

Isolette® is a registered trademark of Draeger Medical Systems, Inc.

Keystone® is a registered trademark of Keystone Electronics Corp.

Kleenaseptic® is a registered trademark of Predicted Environments,

Inc.

Loctite® is a registered trademark of Loctite Corporation.

Microsoft Windows® is a registered trademark of Microsoft Corporation.

Nylok® is a registered trademark of Nylok Fastener Corporation.

Oilite® is a registered trademark of Beemer Precision, Incorporated.

Teflon® is a registered trademark of E. I. du Pont and de Nemours and

Company.

Velcro® is a registered trademark of Velcro Industries, BV (a Dutch

corporation).

Page ii Isolette® Infant Incubator (Model C2000) Service Manual

Page 4

Revisions

The information contained in this manual is subject to change without

notice. Draeger Medical Systems, Inc. makes no commitment to update

or keep current, the information contained in this manual.

The only product warranty intended by Draeger Medical Systems, Inc.

is the express, written warranty accompanying the bill of sale to the

original purchaser. Draeger Medical Systems, Inc. makes no other

warranty, express or implied, and in particular, makes no warranty of

merchantability or fitness for a particular purpose.

Isolette® Infant Incubator (Model C2000) Service Manual Page iii

Page 5

Revisions

NOTES:

Page iv Isolette® Infant Incubator (Model C2000) Service Manual

Page 6

Table of Contents

Chapter 1: Introduction

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Chapter 2: Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Chapter 3: Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Chapter 4: Removal, Replacement, and Adjustment Procedures. . . . . 1 - 3

Chapter 5: Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Chapter 6: General Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Chapter 7: Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

Technical Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9

Operating Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Oval Access Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Mattress Tilt Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Pedestal Stand Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Oxygen Control System (Optional) . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Humidity System (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Weighing Platform (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 11

Physical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 11

Electrical Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 13

Oxygen Control Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 14

Isolette® Infant Incubator (Model C2000) Service Manual Page v

Page 7

Table of Contents

Humidity Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 14

Scale Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 15

Regulations, Standards, and Codes . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 15

Model Identification and Series Changes . . . . . . . . . . . . . . . . . . . . . . . . .1 - 16

Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 18

Warning and Caution Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 24

Chapter 2: Troubleshooting Procedures

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

Initial Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 5

Function Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 6

Final Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 24

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 25

High and Low Air and Skin Temperature Alarms. . . . . . . . . . . . . . . . .2 - 25

Alarm and System Prompt Messages . . . . . . . . . . . . . . . . . . . . . . . . .2 - 26

System Failure Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 33

Diagnostic Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 35

Entering the System Configuration Menu . . . . . . . . . . . . . . . . . . . . . .2 - 35

Entering the Diagnostic Information Menu. . . . . . . . . . . . . . . . . . . . . .2 - 37

System Test Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 40

System Test (1 of 3) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 40

System Test (2 of 3) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 42

System Test (3 of 3) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 43

Key Check Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 45

Data Summary Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 46

Data Summary (1 of 2) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 46

Data Summary (2 of 2) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 48

There Is No Power, and Power Failure Alarm Does Not Activate. . . . . . .2 - 51

Variable Height Adjustable (VHA) Pedestal/Stand Does Not Move Up or Down2 52

Skin Set Temperature Cannot Be Achieved or Maintained. . . . . . . . . . . . 2 - 54

Oxygen Concentration is Low . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 56

Page vi Isolette® Infant Incubator (Model C2000) Service Manuall

Page 8

Table of Contents

Oxygen Concentration is High . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 58

Hood Does Not Tilt or Close Properly . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 60

Controller Failure #1—EEPROM Circuitry Failure . . . . . . . . . . . . . . . . . . 2 - 63

Controller Failure #2—Ambient Air Probe Failure . . . . . . . . . . . . . . . . . . 2 - 64

Controller Failure #4—Controller Cooling Fan Failure . . . . . . . . . . . . . . . 2 - 65

Controller Failure #5—Display Test Failure . . . . . . . . . . . . . . . . . . . . . . . 2 - 66

Controller Failure #7—Power Supply Voltage Failure . . . . . . . . . . . . . . . 2 - 67

Controller Failure #8—RAM Test Failure . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 68

Controller Failure #9—Real-Time Clock Failure. . . . . . . . . . . . . . . . . . . . 2 - 69

Controller Failure #10—Watchdog Timer Failure . . . . . . . . . . . . . . . . . . . 2 - 70

Controller Failure #11—Relay Test Failure . . . . . . . . . . . . . . . . . . . . . . . 2 - 71

Controller Failure #13—Heater Circuit Failure Detected . . . . . . . . . . . . . 2 - 72

Controller Failure #14—Low Heater Current Detected. . . . . . . . . . . . . . . 2 - 73

Heater Thermocouple Does Not Work Properly . . . . . . . . . . . . . . . . . . . . 2 - 74

Humidity Heater Draws Too Much Current. . . . . . . . . . . . . . . . . . . . . . . . 2 - 76

Motor Fails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 77

Communication Between the Sensor Module and the Controller Fails . . 2 - 78

Sensor Module Is Out of Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 80

A Stuck Key Is Detected. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 81

Unit Fails the Non-Volatile Memory (NVM) Integrity Test. . . . . . . . . . . . . 2 - 82

Access Panel Assembly Does Not Latch Properly . . . . . . . . . . . . . . . . . . 2 - 83

Iris Entry Port Does Not Open or Close Properly . . . . . . . . . . . . . . . . . . . 2 - 85

Access Door Does Not Operate or Latch Properly. . . . . . . . . . . . . . . . . . 2 - 86

Heat Shield Does Not Latch Properly. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 88

Mattress Tray Does Not Tilt Properly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 90

Mattress Tray Is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 92

Air Intake Is Not Working Properly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 94

X-ray Tray Does Not Operate Properly . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 96

Sensor Module Lock Does Not Secure the Sensor Module (Units Equipped With

the Sensor Module Lock Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 98

Incubator Takes Longer Than One Hour to Warm Up to the Air Set Temperature2

Isolette® Infant Incubator (Model C2000) Service Manual Page vii

Page 9

Table of Contents

- 99

Air Set Temperature Cannot Be Maintained . . . . . . . . . . . . . . . . . . . . . .2 - 101

Low Air Temperature Alarm or High Air Temperature Alarm Does Not Sound When

Air Temperature Drops or Rises Out of Specification . . . . . . . . . . . . . . .2 - 102

Low Skin Temperature Alarm or High Skin Temperature Alarm Does Not Sound

When Skin Temperature Drops or Rises Out of Specification . . . . . . . . 2 - 103

When Skin Probes are Disconnected, Connect Skin 1 Probe Alarm Does Not

Sound . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 104

Incubator’s Air Temperature Exceeds Air Set Temperature by 1.5 C or Greater, or

Infant’s Skin Temperature Exceeds Skin Set Temperature by 1.0 C or Greater2 105

Humidity System Is Not Working Properly . . . . . . . . . . . . . . . . . . . . . . .2 - 106

Power Failure Alarm Sounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 108

Skin 1 Probe Does Not Work Properly . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 109

Oxygen System Is Not Working Properly (Units Equipped With an Oxygen System

Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 112

Poor Air Circulation Exists Within the Incubator . . . . . . . . . . . . . . . . . . .2 - 113

Sensor Module Assembly Fails. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 114

Remove Skin 2 Probe Alarm Sounds . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 115

Scale Is Not Working Properly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 116

Oxygen System’s Cal Fail System Prompt Message Appears . . . . . . . .2 - 119

Chapter 3:

Theory of Operation

Controller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 3

Variable Height Adjustable Pedestal/Stand Assembly . . . . . . . . . . . . . . . .3 - 7

Hood/Shell Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 8

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 17

Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 17

Sensor Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 17

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 21

Impeller Movement Detector (IMD) P.C. Board . . . . . . . . . . . . . . .3 - 22

Fan Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 23

Heater Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 24

Page viii Isolette® Infant Incubator (Model C2000) Service Manuall

Page 10

Humidity Heater Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 24

Air System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 29

Overall Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 29

Air Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 31

Skin Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 32

Oxygen Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 32

Humidity Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 33

Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 33

Weighing Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 33

Trend Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 33

Interface Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 34

RS-232 Serial Port Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 35

Chapter 4: Removal, Replacement, and Adjustment Procedures

Table of Contents

Skin Temperature Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 5

Sensor Module Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 8

Oxygen Sensor Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 9

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 9

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 10

Controller Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 11

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 11

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 11

Hood Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 14

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 14

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 14

Check Valve Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 16

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 16

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 18

Isolette® Infant Incubator (Model C2000) Service Manual Page ix

Page 11

Table of Contents

Mattress, Mattress Tray, and X-ray Tray. . . . . . . . . . . . . . . . . . . . . . . . . .4 - 20

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 20

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 21

Impeller Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 22

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 22

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 23

Motor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 24

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 24

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 27

Access Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 29

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 29

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 31

Adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 32

Iris Entry Port Sleeve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 33

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 33

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 33

Access Door Latch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 35

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 35

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 37

Access Door and Access Door Pivot Hinges . . . . . . . . . . . . . . . . . . . . . . 4 - 38

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 38

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 39

Electroluminescent (EL) Display Front Panel . . . . . . . . . . . . . . . . . . . . . .4 - 41

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 41

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 42

Electroluminescent (EL) Central Processing Unit (CPU) P.C. Board, EL Display

Faceplate, and EL Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 43

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 43

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 44

Controller Fan Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 45

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 45

Page x Isolette® Infant Incubator (Model C2000) Service Manuall

Page 12

Table of Contents

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 46

Interface/Power Supply Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 47

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 47

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 48

Power Supply P.C. Board Assembly and Interface P.C. Board Assembly4 - 49

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 49

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 50

Air Intake Microfilter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 51

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 51

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 51

Heater Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 52

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 52

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 54

Impeller Movement Detection Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 55

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 55

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 58

AC Wiring Harness Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 60

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 60

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 62

Sensor Module-To-Controller Cable Assembly . . . . . . . . . . . . . . . . . . . . 4 - 65

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 65

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 67

Access Panel Pawl Latch and Knob Assembly . . . . . . . . . . . . . . . . . . . . 4 - 70

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 70

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 71

Iris Entry Port Retaining Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 73

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 73

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 73

Access Door Cuff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 74

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 74

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 74

Isolette® Infant Incubator (Model C2000) Service Manual Page xi

Page 13

Table of Contents

Access Door Gasket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 76

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 76

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 76

Pivot/Hook Lock Assembly Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 77

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 77

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 78

Heat Shield Latch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 80

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 80

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 81

Heat Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 82

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 82

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 83

Mattress Tilt Knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 84

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 84

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 87

Mattress Tilt Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 90

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 90

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 93

Sensor Module Lock (Models with Sensor Module Lock Only). . . . . . . . .4 - 94

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 94

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 95

Access Grommet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 96

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 96

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 97

Upper Transition Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 98

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 98

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 98

Chapter 5:

Parts List

Service Parts Ordering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 5

Recommended Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 7

Page xii Isolette® Infant Incubator (Model C2000) Service Manuall

Page 14

Table of Contents

Incubator Hood and Shell Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 10

High Dual Access Hood Assembly with Left & Right Iris Ports

(P/N 83 200 77-R) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 14

High Front Access Hood Assembly with Two Access Doors and Left & Right Iris

Ports (P/N 83 200 71-R) (Series 00 Model) . . . . . . . . . . . . . . . . . . . . . . . 5 - 18

High Front Access Hood Assembly with Two Access Doors and Left & Right Iris

Ports (P/N 83 200 78) (Series 01 Model) . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 22

High Dual Access Hood Assembly with One Access Door and One Iris Port (Series

00 Model) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 27

High Dual Access Hood Assembly with Left Iris Port and Right Access Door (P/N

83 200 79) (Series 01 Model Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 31

High Dual Access Hood Assembly with Left & Right Access Doors (P/N 83 200 73)

(Series 00 Model Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 35

High Dual Access Hood Assembly with Left & Right Access Doors (P/N 83 200 80-

R) (Series 01 Model Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 39

High Front Access Hood Assembly with Left & Right Access Doors (P/N 83 200 74)

(Series 00 Model Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 43

High Front Access Hood Assembly with Left & Right Access Doors (P/N 83 200 81)

(Series 01 Model Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 47

High Front Access Panel Assembly (P/N 83 300 70-R) (Series 00 Model Only)5 52

Replacement High Front Access Panel Assembly (P/N 83 300 76-R) (Series 01

Model Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 56

High Rear Access Panel Assembly (P/N 83 300 71-R) (Series 00 Model Only)5 60

Replacement High Rear Access Panel Assembly (P/N 83 300 77-R) (Series 01

Model Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 64

Shell Assembly (Series 00, 01, and 02 Models Only) . . . . . . . . . . . . . . . 5 - 68

Top Shell Assembly and Barn Door Shell Assembly (Series 00, 01, and 02 Model

Only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 72

Shell Assembly (Series 03 Model Only) . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 76

Top Shell Assembly (Series 03 Model Only) . . . . . . . . . . . . . . . . . . . . . . 5 - 80

Impeller Movement Detector P.C. Board Assembly . . . . . . . . . . . . . . . . . 5 - 83

Controller Assembly—Model C2C-2 (P/N 83 006 76) . . . . . . . . . . . . . . . 5 - 84

Controller Enclosure Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 86

Isolette® Infant Incubator (Model C2000) Service Manual Page xiii

Page 15

Table of Contents

Electroluminescent Display Front Panel Assembly. . . . . . . . . . . . . . . . . .5 - 88

Interface/Power Supply Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 89

Sensor Module Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 90

Fixed-Height Pedestal Stand Assembly (Series 00 Model Only) . . . . . . .5 - 92

Fixed-Height Pedestal Stand Assembly (Series 01 and Higher Models Only)5 - 97

Variable Height Adjustable Pedestal Stand Assembly . . . . . . . . . . . . . .5 - 101

Hood/Shell Assembly and Pedestal Stand Assembly Attachment . . . . . 5 - 106

Front and Rear Foot Switch Assemblies. . . . . . . . . . . . . . . . . . . . . . . . .5 - 108

Check Valve Assembly Replacement Kit (P/N 83 900 16) . . . . . . . . . . .5 - 110

Scale Assembly (P/N 83 600 50) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 112

IV Pole Assembly (P/N 83 444 00) (Accessory) . . . . . . . . . . . . . . . . . . .5 - 114

High Monitor Shelf Assembly (P/N 83 442 00) (Accessory) . . . . . . . . . . 5 - 116

Swivel Drawer Assembly, Small (P/N 83 441 00) and Large

(P/N 83 440 00) (Accessory). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 118

Humidity System Assembly (P/N 83 610 70/80/90) (Accessory) . . . . . .5 - 122

Humidity System Assembly (P/N 83 613 70/80/81/90) (Accessory) (Series 02 Mod-

el Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 126

Evaporator Reservoir Assembly (Accessory) (Series 02 Model Only) . .5 - 129

Oxygen System Assembly (P/N 83 620 60 and 83 621 20/21/22) (Accessory)5 133

Ventilator Tube Support (P/N 83 001 05) (Accessory) . . . . . . . . . . . . . .5 - 136

Oxygen Tank Bracket Assembly (P/N 83 443 00) (Accessory). . . . . . . . 5 - 137

Chapter 6: General Procedures

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 3

Steam Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 4

Cleaning Hard to Clean Spots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 4

Disinfecting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 4

Using Cleaning Agents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 4

Skin Temperature Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 4

Access Door Gaskets and Tubing Access Ports . . . . . . . . . . . . . . .6 - 4

Controller, Shell, and Pedestal Stand . . . . . . . . . . . . . . . . . . . . . . .6 - 5

Page xiv Isolette® Infant Incubator (Model C2000) Service Manuall

Page 16

Table of Contents

Hood, Sensor Module, and Heat Shields. . . . . . . . . . . . . . . . . . . . . 6 - 5

Heater Radiator and Fan Impeller . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 6

Mattress Tray, Main Deck, Heater/Impeller Cover, and Mattress Tilt Bars6

- 6

Air Intake Microfilter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 7

Humidity Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 7

Component Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 8

P.C. Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 8

Lubrication Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 9

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 10

Preventive Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 11

Preventive Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 12

Installation and Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 13

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 13

Assembling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 13

Setting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 16

Oxygen Sensor Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 20

Room Air—21% Oxygen Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 20

100% Oxygen Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 21

Oxygen Concentration Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 23

Weighing Scale Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 25

Current Leakage Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 27

Set-Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 27

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 27

Disassembly and Assembly for Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 28

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 28

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 32

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 32

Filling the Humidity Reservoir. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 34

Updating the Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 35

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 35

Isolette® Infant Incubator (Model C2000) Service Manual Page xv

Page 17

Table of Contents

Tool and Supply Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 36

Chapter 7: Accessories

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 3

Weighing Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 5

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 7

Oxygen System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 8

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 8

100% Calibration Fixture Installation . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 13

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 14

Humidity System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 15

Preparing the Shell Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 15

Installing the Humidity System (Series 00 and 01 Models) . . . . . . . . .7 - 17

Installing the Humidity System (Series 02 Models) . . . . . . . . . . . . . . .7 - 19

Removing the Humidity System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7 - 21

Page xvi Isolette® Infant Incubator (Model C2000) Service Manuall

Page 18

Chapter 1

Introduction

Chapter Contents

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Chapter 2: Troubleshooting Procedures . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Chapter 3: Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 3

Chapter 4: Removal, Replacement, and Adjustment Procedures. . . . . 1 - 3

1

Chapter 5: Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Chapter 6: General Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Chapter 7: Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 4

Typographical Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

Technical Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9

Operating Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Oval Access Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Mattress Tilt Mechanism . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Pedestal Stand Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Oxygen Control System (Optional) . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Humidity System (Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Weighing Platform (Optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 10

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 11

Isolette® Infant Incubator (Model C2000) Service Manual Page 1 - 1

Page 19

Chapter 1: Introduction

Physical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 11

Electrical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 13

Oxygen Control Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 14

Humidity Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 14

Scale Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 15

Regulations, Standards, and Codes . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 15

Model Identification and Series Changes . . . . . . . . . . . . . . . . . . . . . . . . .1 - 16

Safety Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 18

Warning and Caution Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 24

Page 1 - 2 Isolette® Infant Incubator (Model C2000) Service Manual

Page 20

Purpose

This manual provides requirements for the Isolette® Infant Incubator

normal operation and maintenance. It also includes parts lists (in

chapter 5) for ordering replacement components.

Audience

This manual is intended for use by only facility-authorized personnel.

Failure to observe this restriction can result in severe injury to people

and serious damage to equipment.

Organization

This manual contains seven chapters.

Purpose

Chapter 1: Introduction

1

Chapter 1: Introduction

In addition to a brief description of this service manual, chapter 1 also

provides a product overview.

Chapter 2: Troubleshooting Procedures

Repair analysis procedures are contained in this chapter. Use these

procedures to gather information, identify the maintenance need, and

verify the effectiveness of the repair.

Chapter 3: Theory of Operation

This chapter describes the application of the mechanical, electrical, and

hydraulic systems employed in this product.

Chapter 4: Removal, Replacement, and Adjustment

Procedures

Chapter 4 contains the detailed maintenance procedures determined

necessary in chapter 2.

Isolette® Infant Incubator (Model C2000) Service Manual Page 1 - 3

Page 21

Organization

Chapter 1: Introduction

Chapter 5: Parts List

This chapter contains the warranty, part-ordering procedure, and

illustrated parts lists.

Chapter 6: General Procedures

Cleaning, preventive maintenance, and other general procedures are

described in this chapter.

Chapter 7: Accessories

A list of additional products, that can be used in conjunction with the

Isolette® Infant Incubator, is available in chapter 7. Installation

procedures for these accessories are also included.

Page 1 - 4 Isolette® Infant Incubator (Model C2000) Service Manual

Page 22

Typographical Conventions

This manual contains different typefaces and icons designed to improve

readability and increase understanding of its content. Note the following

examples:

• Standard text—used for regular information.

• Boldface text—emphasizes a word or phrase.

• NOTE:—sets apart special information or important instruction

clarification.

• The symbol below highlights a WARNING or CAUTION:

Figure 1-1. Warning and Caution

– A WARNING identifies situations or actions that may affect

patient or user safety. Disregarding a warning could result

in patient or user injury.

Typographical Conventions

Chapter 1: Introduction

1

– A CAUTION points out special procedures or precautions

that personnel must follow to avoid equipment damage.

• The symbol below highlights an ELECTRICAL SHOCK HAZARD

WARNING:

Figure 1-2. Electrical Shock Hazard Warning

• The symbol below indicates WARNING: CONSULT

ACCOMPANYING DOCUMENTS:

Figure 1-3. Warning: Consult Accompanying Documents

• The symbol below indicates WARNING: HOT SURFACE:

Isolette® Infant Incubator (Model C2000) Service Manual Page 1 - 5

Page 23

Typographical Conventions

Chapter 1: Introduction

Figure 1-4. Warning: Hot Surface

• The symbol below indicates WEIGHT LOAD:

Figure 1-5. Weight Load

• The symbol below indicates DANGER: EXPLOSION HAZARD—DO

NOT USE IN THE PRESENCE OF FLAMMABLE ANESTHETICS:

Figure 1-6. Danger: Explosion Hazard—Do Not Use in the Presence of Flammable

Anesthetics

Page 1 - 6 Isolette® Infant Incubator (Model C2000) Service Manual

Page 24

Technical Definitions

This manual contains different technical terms. Note the following

definitions:

• Incubator temperature—The air temperature at a point 4" (10 cm)

above and centered over the mattress surface.

• Control temperature—The temperature controller’s set point

selected by the user.

• Average incubator temperature—The average of the maximum

and minimum incubator temperatures achieved during temperature

equilibrium.

• Incubator temperature equilibrium—The condition reached when

the average incubator temperature does not vary more than 1 °C

over a period of one hour. These measurements are taken at the

control temperatures of 90 °F (32 °C) and 97 °F (36 °C).

Technical Definitions

Chapter 1: Introduction

1

• Temperature uniformity—The amount by which the average

temperature of each of four points 4" (10 cm) above the mattress

surface differs from the average incubator temperature at incubator

temperature equilibrium.

• Temperature rise time—The time required for the incubator

temperature to rise 20 °F (11 °C), when the air control temperature

is at least 22 °F (12 °C) above the ambient temperature.

• Temperature overshoot—The amount by which incubator

temperature exceeds average incubator temperature at incubator

temperature equilibrium as a result of an increase in control

temperature. Additionally, the incubator temperature equilibrium

shall be restored within 15 min as a result of an increase in control

temperature value.

• Temperature correlation: Incubator temperature versus control

temperature—The amount the air temperature indicator at incubator

temperature equilibrium differs from the control temperature.

• Temperature correlation: Temperature indicator versus control

temperature—The amount the air temperature indicator in air mode

at incubator temperature equilibrium differs from the control

temperature.

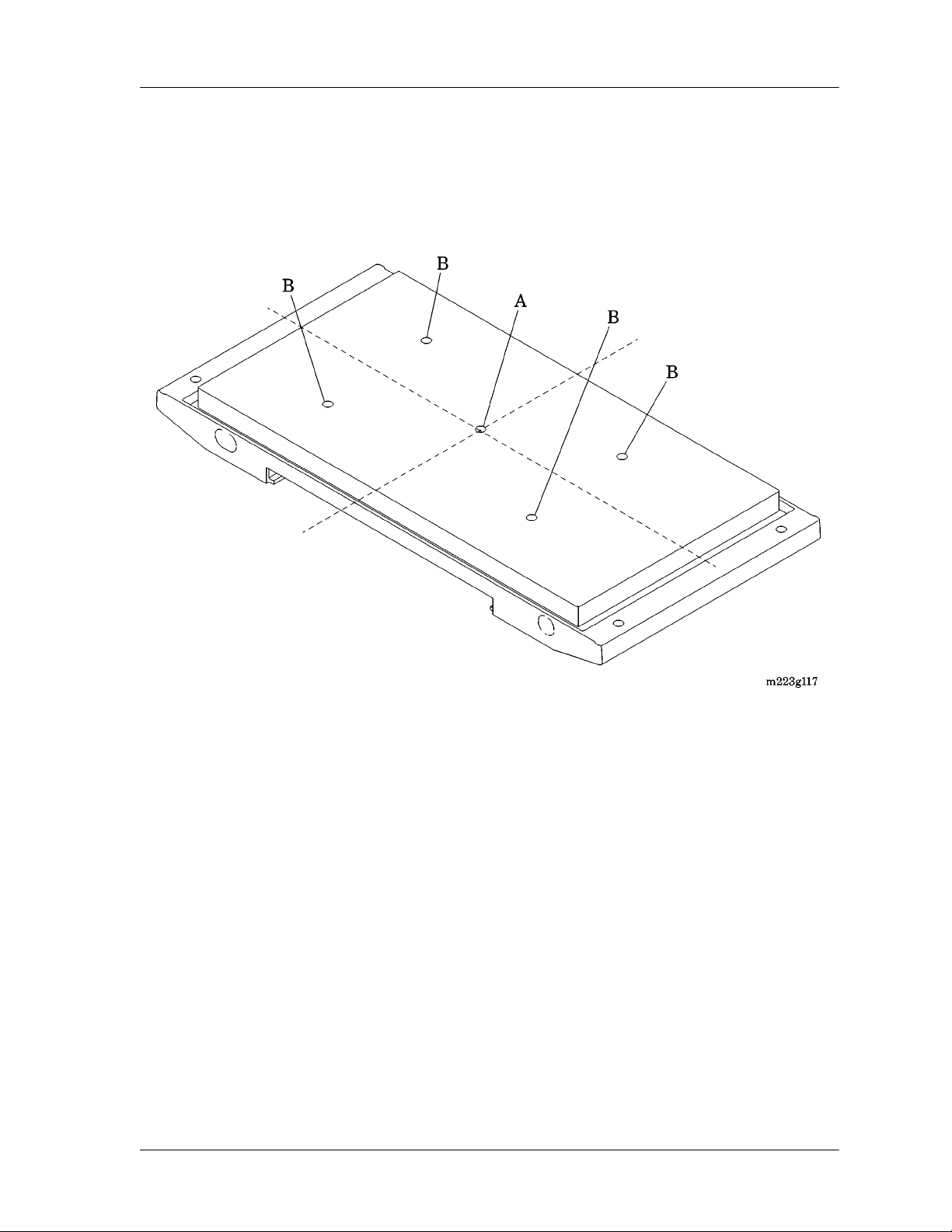

• Measurement points—Measurements are taken at five points in a

plane parallel to and 4" (10 cm) above the mattress surface: One

point (A) is 4" (10 cm) above the center of the mattress, and the

Isolette® Infant Incubator (Model C2000) Service Manual Page 1 - 7

Page 25

Technical Definitions

Chapter 1: Introduction

remaining four points (B) are the centers of four areas formed by

lines that divide both the width and length into two parts (see figure

1-7 on page 1-8).

Figure 1-7. Measurement Points

Page 1 - 8 Isolette® Infant Incubator (Model C2000) Service Manual

Page 26

Introduction

Overview

The Model C2000 Isolette® Infant Incubator provides a therapeutic

environment for the care for low birth-weight neonates. The Model

C2000 Isolette® Infant Incubator provides the following features:

Introduction

Chapter 1: Introduction

1

• Data trending—The unit graphically trends critical data, such as air

temperature, skin temperature, heater power, oxygen, and humidity,

for intervals of 12 to 24 hours, and up to seven days for weight

changes.

• Thermal performance—The unit’s thermal management capabilities

provide a patented dual-air curtain that reduces radiant heat loss

from the infant by warming the surface of the inner hood.

• Bi-directional airflow—Bi-directional airflow minimizes temperature

fluctuations within the incubator when the access doors are opened.

A microprocessor controller quickly and accurately regulates

temperature, humidity, and oxygen levels within the incubator.

• Low operating sound levels—The unit’s low operating sound levels

ensure a developmentally-supportive environment for infants.

• Centralized care for multiple births—The unit allows for co-bedding,

enabling the caregiver to monitor and care for multiple births. The

incubator mattress provides the needed space to care for two

infants and enough room for both to grow comfortably.

• Integrated x-ray cassette tray—Located beneath the mattress, the xray cassette tray slides out smoothly to avoid disturbing the baby.

• Infant access—By using the front and side access, two clinicians

can simultaneously care for an infant while he or she remains in the

incubator, reducing handling and adverse stimulation.

• Servo-controlled oxygen—Oxygen delivery is simplified by selecting

and controlling whole hood oxygen concentrations from 21% to

65%. Calibration can be performed in room air or in 100% oxygen.

The process can be done while the caregiver monitors the infant,

without interfering with the thermal environment.

• Servo-controlled humidity—The front-loading humidity reservoir

requires filling only once every 24 hours. The caregiver can set the

desired relative humidity, minimizing the infant’s evaporative heat

loss.

Isolette® Infant Incubator (Model C2000) Service Manual Page 1 - 9

Page 27

Introduction

Chapter 1: Introduction

Operating Precautions

For additional operating precautions for the Isolette® Infant Incubator

and its accessories, refer to the Isolette® Infant Incubator User Manual.

Features

Oval Access Doors

Dual access doors are provided with a quiet latch.

Mattress Tilt Mechanism

A mattress tilt mechanism is provided, and is continuously variable from

0° to 12° from either end.

Pedestal Stand Assembly

The pedestal stand assembly is available in two models: fixed height

and variable height adjustable.

Oxygen Control System (Optional)

The oxygen control system monitors and controls the oxygen

concentration level within the incubator hood environment.

Humidity System (Optional)

The humidity system monitors and controls the humidity level within the

incubator hood environment.

Weighing Platform (Optional)

A weighing platform located under the mattress measures the weight of

the infant.

Page 1 - 10 Isolette® Infant Incubator (Model C2000) Service Manual

Page 28

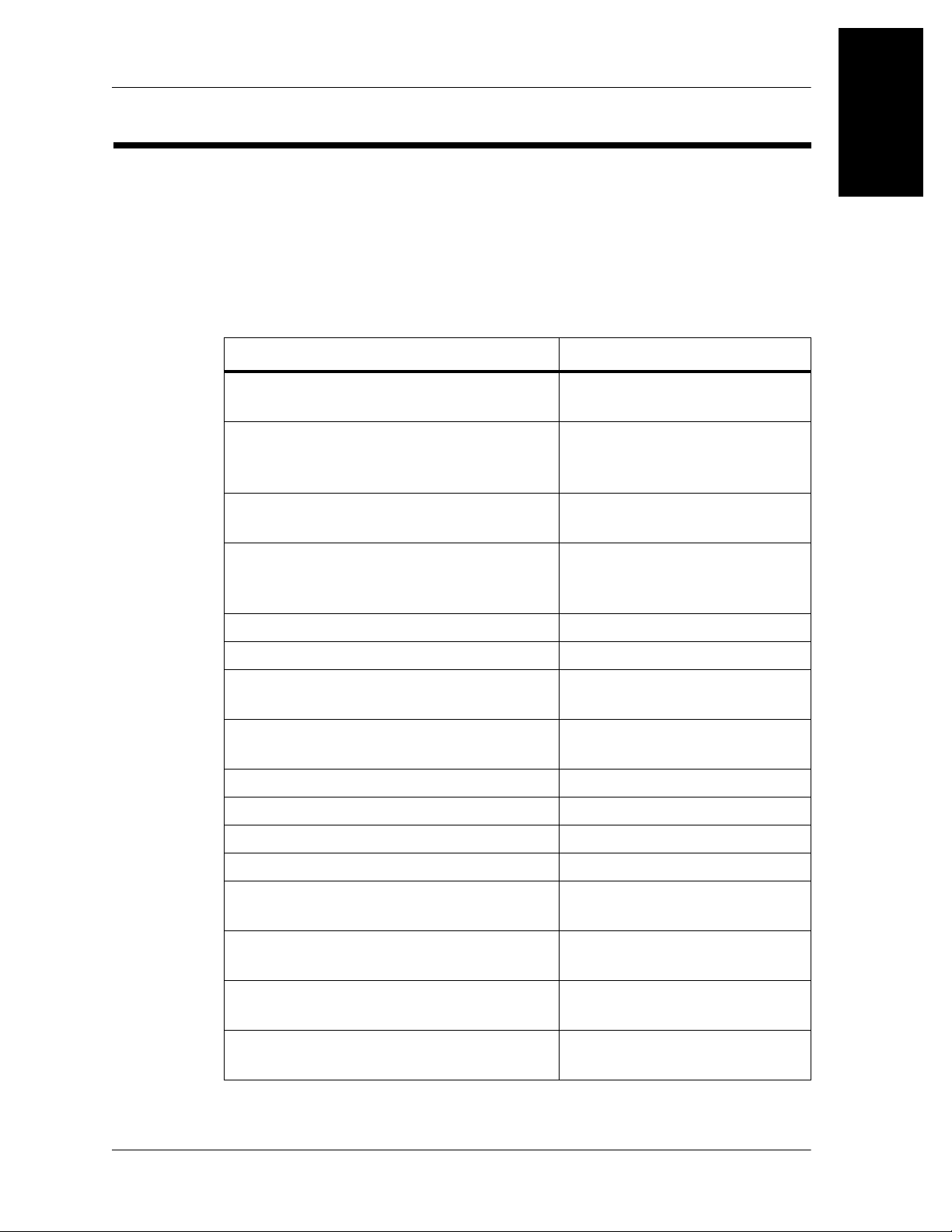

Specifications

Physical Description

For the physical specifications of the Model C2000 Isolette® Infant

Incubator, see table 1-1 on page 1-11.

Specifications

Chapter 1: Introduction

1

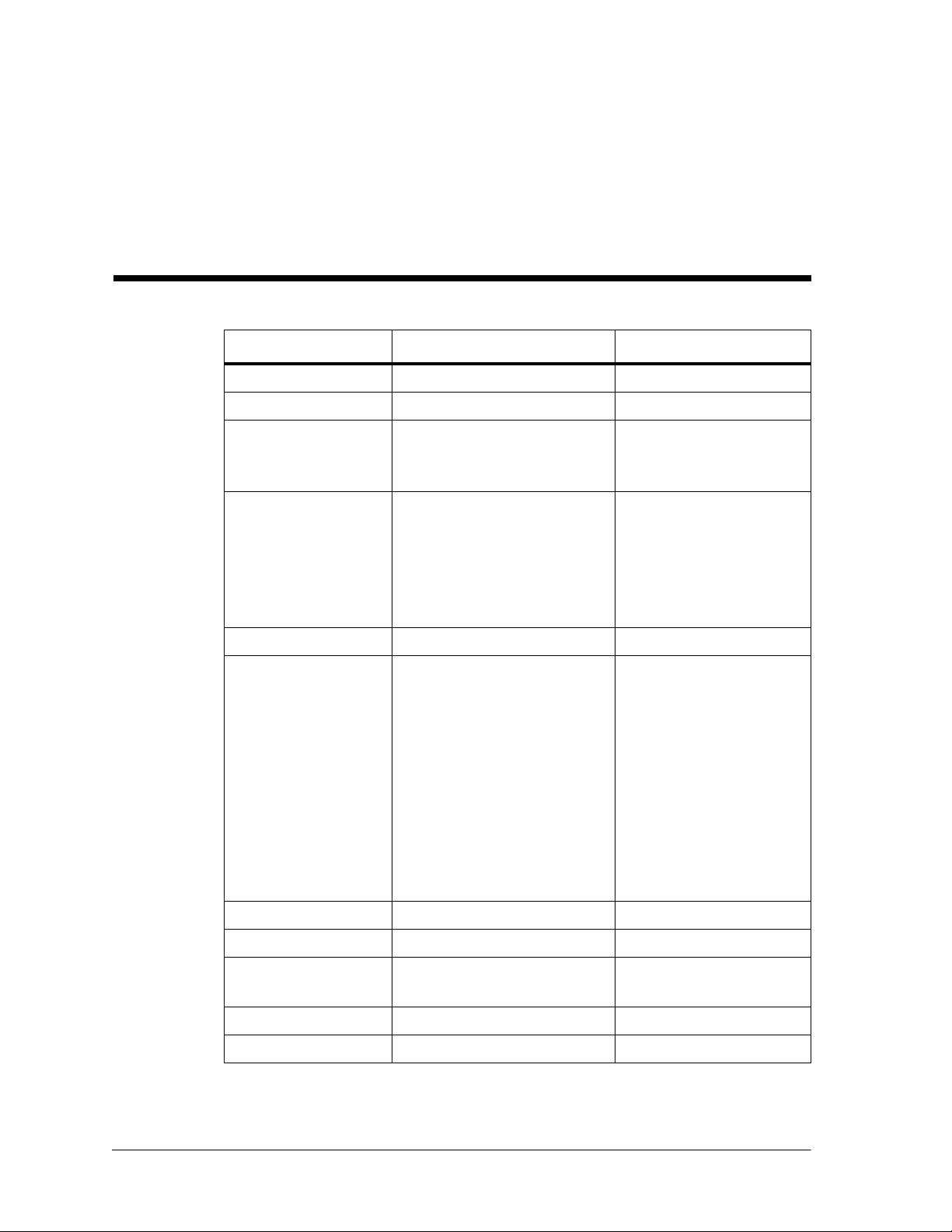

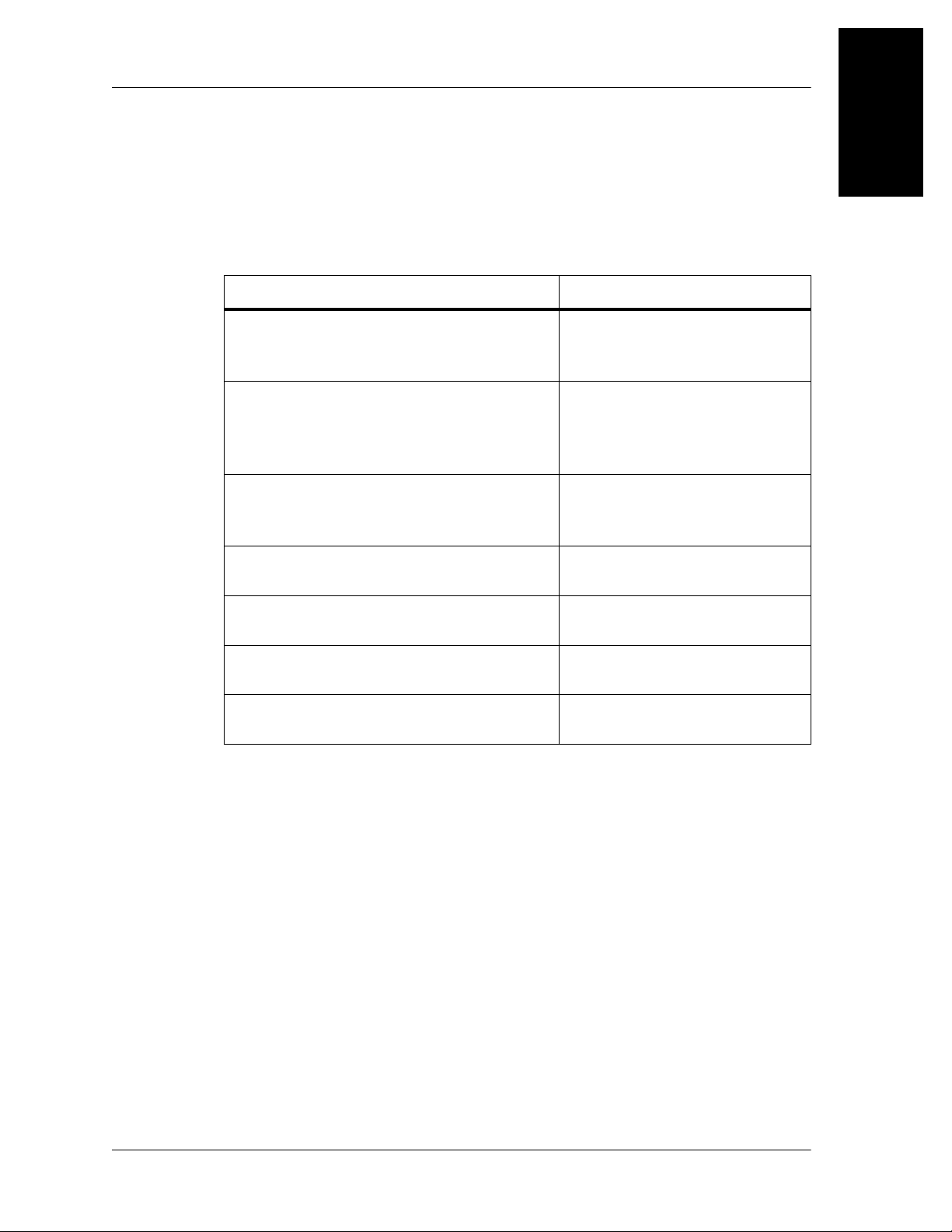

Table 1-1. Physical Specifications

Feature Dimension

Height from floor (fixed pedestal stand

model)

Height from floor (variable height

adjustable model)

Mattress to floor (fixed pedestal stand

model)

Mattress to floor (variable height

adjustable model)

Depth < 23½" (59.69 cm)

Overall width with tilt knobs < 41" (104 cm)

Weight (fixed pedestal stand model

without options or accessories)

Weight (variable height adjustable

model without options or accessories)

IV pole maximum static load 10.4 lb (4.7 kg)

Monitor shelf maximum static load 25 lb (11 kg)

56" ± ½" (142 cm ± 12.7 mm)

52½" ± ½" to 60" ± ½"

(133.35 cm ± 12.7 mm to

152 cm ± 12.7 mm)

39¾" ± ½" (100.97 cm ±

12.7 mm)

35½" ± ½" to 43½" ± ½"

(90.17 cm ± 12.7 mm to

110.49 cm ± 12.7 mm)

195 lb (88 kg)

200 lb (91 kg)

Mattress tray width 31" (79 cm)

Mattress tray depth 16" (41 cm)

Mattress Trendelenburg/Reverse

Trendelenburg tilt

Environmental temperature operating

range

Storage temperature -4 °F (-20 °C) to 140 °F

Air Mode temperature range 68 °F (20 °C) to 98.6 °F

Isolette® Infant Incubator (Model C2000) Service Manual Page 1 - 11

Continuously variable to 12°

±1°

68 °F (20 °C) to 86 °F

(30 °C)

(60 °C)

(37.0 °C)

Page 29

Specifications

Chapter 1: Introduction

Feature Dimension

Air Mode temperature range in

Temperature Override Mode

98.6 °F (37.0 °C) to 102.2 °F

(39.0 °C)

Skin Mode temperature range 93.2 °F (34.0 °C) to 98.6 °F

(37.0 °C)

Skin Mode temperature range in

Temperature Override Mode

Temperature rise time, typical at 72 F

93.2 °F (34.0 °C) to 100.4 °F

(38.0 °C)

< 35 minutes

(22 C) ambient

Temperature variability < 0.5 C maximum

Temperature overshoot < 0.5 C maximum

Temperature uniformity < 0.8 °C

Correlation of the indicated air temper-

≤ 0.8 °C

ature to the actual incubator temperature after temperature equilibrium is

reached

Page 1 - 12 Isolette® Infant Incubator (Model C2000) Service Manual

Page 30

Electrical Description

For Isolette® Infant Incubator electrical specifications, see table 1-2 on

page 1-13.

Table 1-2. Electrical Specifications

Feature Dimension

Specifications

Chapter 1: Introduction

1

Power requirements of an incubator

with a fixed height pedestal stand

(100V and 120V models)

Power requirements of an incubator

with a variable height adjustable (VHA)

pedestal stand (100V and 120V models)

Power requirements of an incubator

with a fixed height or a VHA pedestal

stand (220V and 240V models)

Convenience outlets (100V and 120V

models)

Convenience outlets (220V and 240V

models)

Chassis current leakage (110V and

120V models)

Chassis current leakage (220V and

240V models)

100V/120V ± 10%, 50/60 Hz,

630 W maximum

100V/120V ± 10%, 50/60 Hz,

1900 W maximum

220V or 240V ± 10%,

50/60 Hz, 2376 W maximum

100V/120V ± 10%, 50/60 Hz,

500 W maximum

220V or 240V, 500 W

maximum

300 μA or less

500 μA or less

Isolette® Infant Incubator (Model C2000) Service Manual Page 1 - 13

Page 31

Specifications

Chapter 1: Introduction

Oxygen Control Description

For Isolette® Infant Incubator oxygen control specifications, see table

1-3 on page 1-14.

Oxygen display range 18% to 100%

Oxygen display resolution 1% oxygen

Table 1-3. Oxygen Control Specifications

Feature Dimension

Oxygen display accuracy (100%

calibration)

Oxygen display accuracy (21% calibration)

Oxygen set resolution 1%

Oxygen setpoint range 21% to 65%

Humidity Description

For Isolette® Infant Incubator humidity specifications, see table 1-4 on

page 1-14.

Feature Dimension

Operating range 5% to 99% relative humidity

Storage range 0% to 99% RH, non-con-

± 3%

± 5%

Table 1-4. Humidity Specifications

(RH), non-condensing

densing

Operating time without refilling > 24 hours maximum at 85%

RH

Humidity control accuracy at 10% to

± 6% RH

80% at 68 F (20 C) to 104 F (60 C)

Maximum humidity level at the incuba-

> 85% RH

tor’s set temperature of 102 F (39 C)

Humidity setpoint range 30% to 95% RH

Page 1 - 14 Isolette® Infant Incubator (Model C2000) Service Manual

Page 32

Scale Description

For Isolette® Infant Incubator scale specifications, see table 1-5 on

page 1-15.

Weight display range 0 kg (0 lb) to 7 kg (15 lb)

Weight display resolution 1 g or 1 oz

Weight display accuracy ± 2 g (0.07 oz) ≤ 2 kg (4.4 lb)

Specifications

Chapter 1: Introduction

1

Table 1-5. Scale Specifications

Feature Dimension

or

± 5 g (0.18 oz) ≥ 5 kg (11 lb)

Weight zeroing limit during infant

weighing

Regulations, Standards, and Codes

The Model C2000 Isolette® Infant Incubator meets the following

specifications:

• IEC 601-1

• IEC 601-2-19

• UL-2601

• With respect to the International Electrotechnical Commission (IEC)

601-1, the incubator is Class 1, Type BF.

• On the variable height adjustable model, the mode of operation is

continuous operation with short-time loading.

> 3.5 kg (7.7 lb)

Isolette® Infant Incubator (Model C2000) Service Manual Page 1 - 15

Page 33

Model Identification and Series Changes

Chapter 1: Introduction

Model Identification and Series Changes

For Isolette® Infant Incubator model identification, see table 1-6 on

page 1-16.

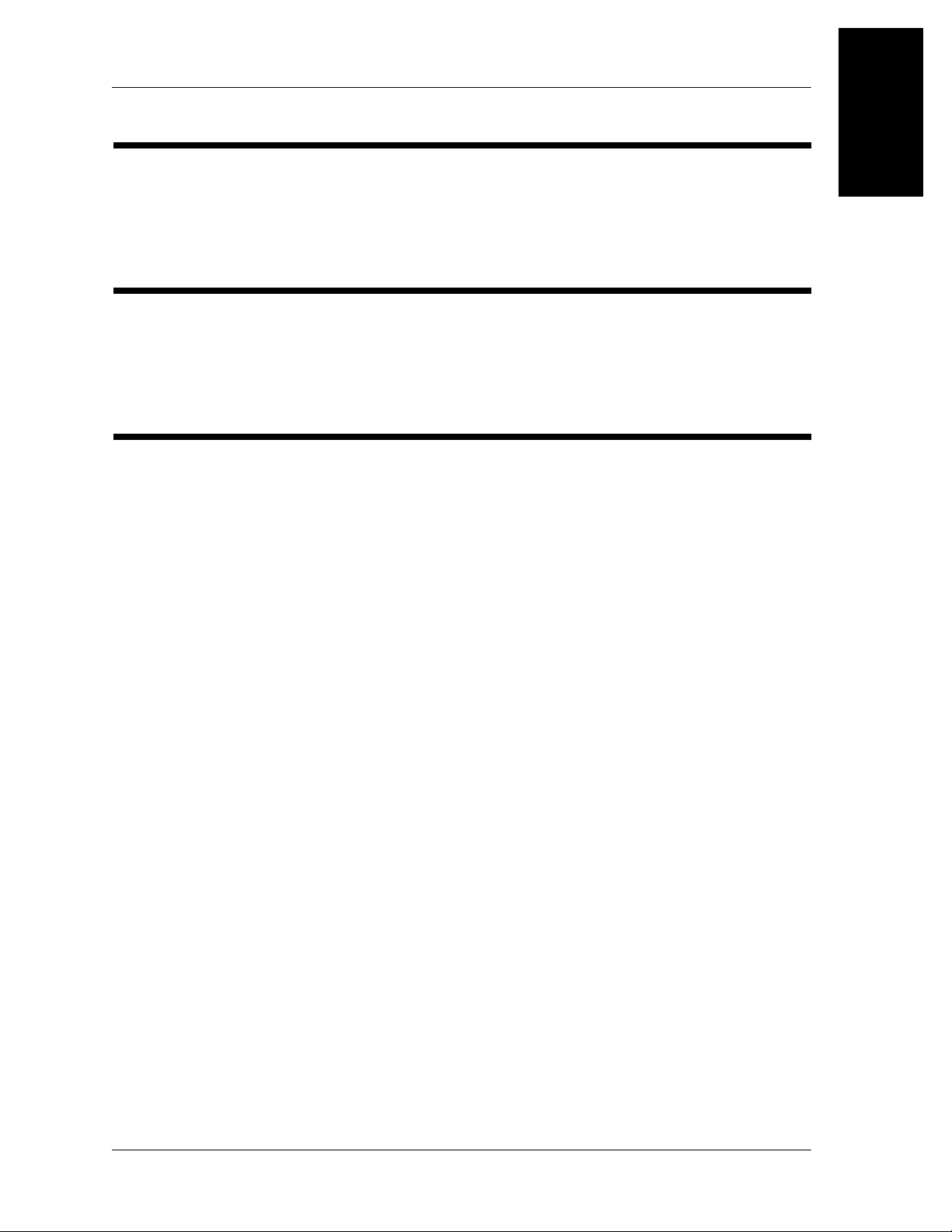

Table 1-6. Model Identification

Model/Series

Number

Description

C2000 Isolette® Infant Incubator

For Isolette® Infant Incubator hood/shell assembly series identification,

see table 1-7 on page 1-16.

Table 1-7. Series Identification for the Hood/Shell Assembly

Model/Series

Number

Description

C2HS-1, C2HS1-400 Isolette® Infant Incubator hood/shell assem-

bly with panel slide latches

C2HS01, C2HS-1,

C2HS-1400

Isolette® Infant Incubator hood/shell assembly with pawl latches

C2HS-02 Isolette® Infant Incubator hood/shell assem-

bly with hood lock

C2HS-03 Isolette® Infant Incubator hood/shell assem-

bly with modification 170

For Isolette® Infant Incubator controller series identification, see table

1-8 on page 1-16.

Table 1-8. Series Identification for the Controller

Model/Series

Number

Description

C2C-2-00 Isolette® Infant Incubator controller

For Isolette® Infant Incubator fixed height pedestal stand assembly

series identification, see table 1-9 on page 1-17.

Page 1 - 16 Isolette® Infant Incubator (Model C2000) Service Manual

Page 34

Model Identification and Series Changes

Chapter 1: Introduction

Table 1-9. Series Identification for the Fixed Height Pedestal Stand

Assembly

1

Model/Series

Number

C2STD1-00 Isolette® Infant Incubator fixed height pedes-

tal stand assembly with upper and lower column extrusion

C2STD1-01 Isolette® Infant Incubator fixed height pedes-

tal stand assembly with upper and lower column weldment

C2STD2-00 Isolette® Infant Incubator fixed height pedes-

tal stand assembly

For Isolette® Infant Incubator variable height adjustable pedestal stand

assembly series identification, see table 1-10 on page 1-17.

Table 1-10. Series Identification for the

Variable Height Adjustable Stand Assembly

Model/Series

Number

C2VHA-1-00 Isolette® Infant Incubator variable height

adjustable pedestal stand assembly

Description

Description

For Isolette® Infant Incubator humidity system series identification, see

table 1-11 on page 1-17.

Table 1-11. Series Identification for the Humidity System

Model/Series

Number

C2RH-1-00 Isolette® Infant Incubator humidity system

C2RH-1-01 Isolette® Infant Incubator humidity system

C2RH-2-00 Isolette® Infant Incubator humidity system

with manifold assembly

Isolette® Infant Incubator (Model C2000) Service Manual Page 1 - 17

Description

Page 35

Safety Tips

Chapter 1: Introduction

Safety Tips

WARNING:

Only facility-authorized personnel should troubleshoot the Model C2000

Isolette® Infant Incubator. Troubleshooting by unauthorized personnel

could result in personal injury or equipment damage.

WARNING:

Do not use the incubator if it fails to function as described. Personal

injury or equipment damage could occur. Refer the unit for servicing by

qualified personnel.

WARNING:

To prevent personal injury or damage to the variable height adjustable

pedestal stand when transporting, employ a person of sufficient

strength to adequately control the incubator.

WARNING:

A dirty air intake microfilter may affect oxygen concentrations and/or

cause carbon dioxide build-up. Check the filter routinely, and change it

at least every 3 months or when it is visibly dirty. Failure to do so could

result in infant injury.

WARNING:

Two people are required to lift the hood assembly. Failure to use at

least two people could result in personal injury or equipment damage.

WARNING:

Allow 45 minutes for the heater assembly to cool. Failure to do so could

result in personal injury.

WARNING:

Follow the product manufacturer’s instructions. Failure to do so could

result in personal injury or equipment damage.

Page 1 - 18 Isolette® Infant Incubator (Model C2000) Service Manual

Page 36

Safety Tips

Chapter 1: Introduction

WARNING:

Make sure that the oxygen supply to the incubator is turned off and that

the incubator is disconnected from the oxygen supply when performing

cleaning procedures. A fire and explosion hazard exists when cleaning

in an oxygen-enriched environment.

WARNING:

Failure to clean the heater radiator and fan impeller could result in

sufficient lint build-up to reduce airflow, which will affect temperature

control and cause high oxygen concentrations. Infant injury could occur.

WARNING:

Only facility-authorized personnel should perform preventive

maintenance on the Model C2000 Isolette® Infant Incubator.

Preventive maintenance performed by unauthorized personnel could

result in personal injury or equipment damage.

1

WARNING:

Make sure that the oxygen supply to the incubator is turned off and that

the incubator is disconnected from the oxygen supply when performing

maintenance procedures. A fire and explosion hazard exists when

performing maintenance procedures in an oxygen-enriched

environment.

WARNING:

The hood/shell assembly must attach to the pedestal/stand using the

screws provided. Failure to do so could result in the hood/shell

assembly separating from the pedestal stand when sufficiently tilted,

particularly with the hood open. Personal injury or equipment damage

could occur.

WARNING:

To keep the incubator from sliding when parked on an incline, the

pedestal stand’s front locking casters must be facing down the incline

and locked.

Isolette® Infant Incubator (Model C2000) Service Manual Page 1 - 19

Page 37

Safety Tips

Chapter 1: Introduction

WARNING:

For the 21% oxygen calibration, the unit must be equipped with a

standard sensor module lock. Failure to use a standard sensor module

could result in incorrect calibration. Infant injury could occur.

WARNING:

For the 100% oxygen calibration procedure, the incubator hood must

be equipped with the 100% calibration fixture. Failure to use the 100%

calibration fixture could result in incorrect calibration. Infant injury could

occur.

WARNING:

Oxygen flow rates cannot be used as an accurate indication of oxygen

concentration in an incubator. Continuously monitor the oxygen

concentrations with a calibrated oxygen analyzer. Failure to do so could

result in personal injury or equipment damage.

WARNING:

Ensure all sensor leads are properly routed. Use cable management

clips to avoid entanglement and possible infant injury.

SHOCK HAZARD:

Ensure that the building power source is compatible with the electrical

specifications shown on the right side of the incubator and the variable

height adjustable pedestal stand. For proper grounding reliability,

connect the power cord only to a properly marked, three-wire, hospitalgrade or hospital-use receptacle. Do not use extension cords.

SHOCK HAZARD:

Unplug the unit from its power source. Failure to do so could result in

personal injury or equipment damage.

SHOCK HAZARD:

Unplug the power cord from the controller assembly. Failure to do so

could result in personal injury or equipment damage.

Page 1 - 20 Isolette® Infant Incubator (Model C2000) Service Manual

Page 38

Safety Tips

Chapter 1: Introduction

SHOCK HAZARD:

Do not expose the unit to excessive moisture. Personal injury or

equipment damage could occur.

CAUTION:

When using the variable height adjustable pedestal stand, always lower

the incubator to its lowest position prior to transport for optimum

stability. Failure to do so could result in personal injury or equipment

damage.

CAUTION:

Replace both oxygen sensor cells at the same time. Failure to do so

could result in equipment damage.

CAUTION:

When reconnecting the rear panel connectors, connect the sensor

module-to-connector cable assembly to the sensor module connector

only. Do not connect the sensor module cable to the RS-232

connector. Equipment damage could occur.

1

CAUTION:

Always replace Nylok®1 screws; do not reuse them. Equipment

damage could occur.

CAUTION:

Use caution when lowering the shell assembly in place on the shell

bottom. Ensure that no cables are pinched and that the extrusion

bumper fits properly. Failure to do so could result in equipment

damage.

CAUTION:

Do not use harsh cleansers, such as scouring pads or heavy-duty

grease removers or solvents, such as acetone. Equipment damage

could occur.

1. Nylok® is a registered trademark of Nylok Fastener Corporation.

Isolette® Infant Incubator (Model C2000) Service Manual Page 1 - 21

Page 39

Safety Tips

Chapter 1: Introduction

CAUTION:

Some chemical cleaning agents may be conductive and/or leave a

residue that may enable a build-up of conductive dust or dirt. Do not

permit cleaning agents to contact electrical components. Do not spray

cleaning solutions onto any of these surfaces. Equipment damage

could occur.

CAUTION:

When cleaning the interior of the incubator shell, prevent liquids from

entering the motor shaft opening. Equipment damage could occur.

CAUTION:

Do not use alcohol for cleaning. Alcohol can cause crazing of the clear

acrylic hood.

CAUTION:

Do not expose the hood assembly to direct radiation from germicidal

lamps. Ultraviolet radiation from these sources can cause cracking of

gaskets, fading of paint, and crazing of the clear acrylic hood.

CAUTION:

To prevent component damage, ensure that your hands are clean, and

only handle the P.C. board by its edges.

CAUTION:

When handling electronic components, wear an antistatic strap. Failure

to do so could result in component damage.

CAUTION:

For shipping and storage, place the removed P.C. board in an antistatic

protective bag. Equipment damage can occur.

CAUTION:

Do not use silicone-based lubricants. Equipment damage could occur.

Page 1 - 22 Isolette® Infant Incubator (Model C2000) Service Manual

Page 40

Safety Tips

Chapter 1: Introduction

CAUTION:

When removing the equipment from the cartons, take care not to

scratch or otherwise damage unprotected surfaces.

CAUTION:

Before lifting the incubator hood for cleaning, ensure that all mounted

accessories have been removed to prevent possible interference with

the raised hood.

CAUTION:

To avoid equipment damage, use only distilled or sterile distilled water.

Sterile water alone is not an acceptable substitute for distilled water.

CAUTION:

Use only the programming cable assembly (P/N 83 930 70) to install

the software update. Using a standard RS-232 cable assembly could

result in equipment damage.

1

CAUTION:

To prevent damage to the collar that secures the evaporator assembly

to the shell assembly, be careful not to twist the evaporator assembly

around the horizontal axis when installing its tubing.

Isolette® Infant Incubator (Model C2000) Service Manual Page 1 - 23

Page 41

Warning and Caution Labels

Chapter 1: Introduction

Warning and Caution Labels

Figure 1-8. Warning and Caution Labels

Page 1 - 24 Isolette® Infant Incubator (Model C2000) Service Manual

Page 42

Chapter 2

Troubleshooting Procedures

Chapter Contents

Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

Initial Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 5

Function Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 6

Final Actions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 24

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 25

High and Low Air and Skin Temperature Alarms . . . . . . . . . . . . . . . . 2 - 25

Alarm and System Prompt Messages. . . . . . . . . . . . . . . . . . . . . . . . . 2 - 26

System Failure Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 33

2

Diagnostic Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 35

Entering the System Configuration Menu . . . . . . . . . . . . . . . . . . . . . . 2 - 35

Entering the Diagnostic Information Menu . . . . . . . . . . . . . . . . . . . . . 2 - 37

System Test Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 40

System Test (1 of 3) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 40

System Test (2 of 3) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 42

System Test (3 of 3) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 43

Key Check Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 45

Data Summary Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 46

Data Summary (1 of 2) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 46

Data Summary (2 of 2) Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 48

There Is No Power, and Power Failure Alarm Does Not Activate . . . . . . 2 - 51

Variable Height Adjustable (VHA) Pedestal/Stand Does Not Move Up or

Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 52

Skin Set Temperature Cannot Be Achieved or Maintained . . . . . . . . . . . 2 - 54

Isolette® Infant Incubator (Model C2000) Service Manual Page 2 - 1

Page 43

Chapter 2: Troubleshooting Procedures

Oxygen Concentration is Low . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 56

Oxygen Concentration is High . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 58

Hood Does Not Tilt or Close Properly . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 60

Controller Failure #1—EEPROM Circuitry Failure . . . . . . . . . . . . . . . . . . 2 - 63

Controller Failure #2—Ambient Air Probe Failure. . . . . . . . . . . . . . . . . . .2 - 64

Controller Failure #4—Controller Cooling Fan Failure . . . . . . . . . . . . . . .2 - 65

Controller Failure #5—Display Test Failure . . . . . . . . . . . . . . . . . . . . . . .2 - 66

Controller Failure #7—Power Supply Voltage Failure. . . . . . . . . . . . . . . . 2 - 67

Controller Failure #8—RAM Test Failure . . . . . . . . . . . . . . . . . . . . . . . . .2 - 68

Controller Failure #9—Real-Time Clock Failure . . . . . . . . . . . . . . . . . . . .2 - 69

Controller Failure #10—Watchdog Timer Failure . . . . . . . . . . . . . . . . . . .2 - 70

Controller Failure #11—Relay Test Failure. . . . . . . . . . . . . . . . . . . . . . . . 2 - 71

Controller Failure #13—Heater Circuit Failure Detected. . . . . . . . . . . . . . 2 - 72

Controller Failure #14—Low Heater Current Detected . . . . . . . . . . . . . . . 2 - 73

Heater Thermocouple Does Not Work Properly . . . . . . . . . . . . . . . . . . . . 2 - 74

Humidity Heater Draws Too Much Current . . . . . . . . . . . . . . . . . . . . . . . .2 - 76

Motor Fails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 77

Communication Between the Sensor Module and the Controller Fails. . . 2 - 78

Sensor Module Is Out of Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 80

A Stuck Key Is Detected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 81

Unit Fails the Non-Volatile Memory (NVM) Integrity Test . . . . . . . . . . . . .2 - 82

Access Panel Assembly Does Not Latch Properly . . . . . . . . . . . . . . . . . .2 - 83

Iris Entry Port Does Not Open or Close Properly . . . . . . . . . . . . . . . . . . .2 - 85

Access Door Does Not Operate or Latch Properly . . . . . . . . . . . . . . . . . .2 - 86

Heat Shield Does Not Latch Properly . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 88

Mattress Tray Does Not Tilt Properly . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 90

Mattress Tray Is Damaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 92

Air Intake Is Not Working Properly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 94

X-ray Tray Does Not Operate Properly . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 96

Sensor Module Lock Does Not Secure the Sensor Module

(Units Equipped With the Sensor Module Lock Only) . . . . . . . . . . . . . . . .2 - 98

Page 2 - 2 Isolette® Infant Incubator (Model C2000) Service Manual

Page 44

Chapter 2: Troubleshooting Procedures

Incubator Takes Longer Than One Hour to Warm Up to the Air Set

Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 99

Air Set Temperature Cannot Be Maintained. . . . . . . . . . . . . . . . . . . . . . 2 - 101

Low Air Temperature Alarm or High Air Temperature Alarm Does Not Sound

When Air Temperature Drops or Rises Out of Specification . . . . . . . . . 2 - 102