Page 1

MANUAL DOUGH DIVIDER MDF820

INDEX

TO GET THE BEST PERFORMANCE OUT OF YOUR MACHINE, PLEASE READ THE

MANUAL, CAREFULY.

CHAPTER 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1 MACHINE’S MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 BREAK DOWN SITUATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 PACKAGE CONDITION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CHAPTER 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.1 GENERAL SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.2 MACHINE’S PARTICULARITIES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 INCORRECT USE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

CHAPTER 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 TOTAL DIMENSIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3.2 TECHNICAL SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3.3 SECURITY SYSTEMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

CHAPTER 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

4.1 TRANSPORT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 PLACEMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CHAPTER 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.1 FUNCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

CHAPTER 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

CLEANING THE MACHINE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CHAPTER 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

7.1 SECURITY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.2 SPECIAL CARE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.2.1 CARES TO HAVE WITH MOVABLE PIECES . . . . . . . . . . . . . . . . . . . . 11

7.2.2 HYGIENE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Page 2

CHAPTER 1

GENERAL DESCRIPTION

The usage and maintenance manual of the machine is important and must be kept in a safe

place.

It’s obligatory to read the machine’s usage manual, before using it for the first time and it should

be consulted every time a maintenance or usage doubt appears.

1.1.- MACHINE’S MANUAL

• Before using the manual dough divider read these instructions and specially the security

chapter.

• This manual must be kept where all machine users can easily consult it and in a safe place,

avoiding water, dough, sun, etc.

1.2.- BREAK DOWN SITUATIONS

THE MANUFACTURER IS NOT RESPONSIBLE FOR THE MACHINE’S BREAK DOWN,

ACCORDING TO THE FOLLOWING SITUATIONS:

• Improper, erroneous or irrational use of the machine;

• Non conformable use of the national and international laws;

• Incorrect installation of the machine;

• Insufficient maintenance;

• Non authorized alterations or interventions;

• Use of pieces of the machine that are not original;

• Not following the instructions manual.

1.3.- PACKAGE CONDITION

Before unwrapping the machine’s package, verify if it was damaged while being transported.

In case of damage, please contact the manufacturer.

2006/04/04

2

Page 3

CHAPTER 2

USING THE MACHINE

2.1.- GENERAL SPECIFICATIONS

The manual dough divider is a volumetric divider of bread dough.

2.2.- MACHINE’S PARTICULARITIES

The 20 unit manual divider DMF 820 divides dough into 20 equal weight portions, obtaining

rolled portions, or ball form, with the minimum weight if 45g and maximum of 400g.

Model MDF820

Total

[g]

Minimum weight 900 45

Maximum weight 8000 400

2.3.- INCORRECT USAGE

This machine was specially made to divide volumetrically the dough usually used in the bakery

industry.

Other use of the machine is considered incorrect and dangerous.

The manufacturer can’t be responsible for any damages made to the machine or people that are

improperly using it.

It is not recommend to use other kinds of dough than the bread dough.

Division

[g]

2006/04/04

3

Page 4

CHAPTER 3

TECHNICAL INFORMATION

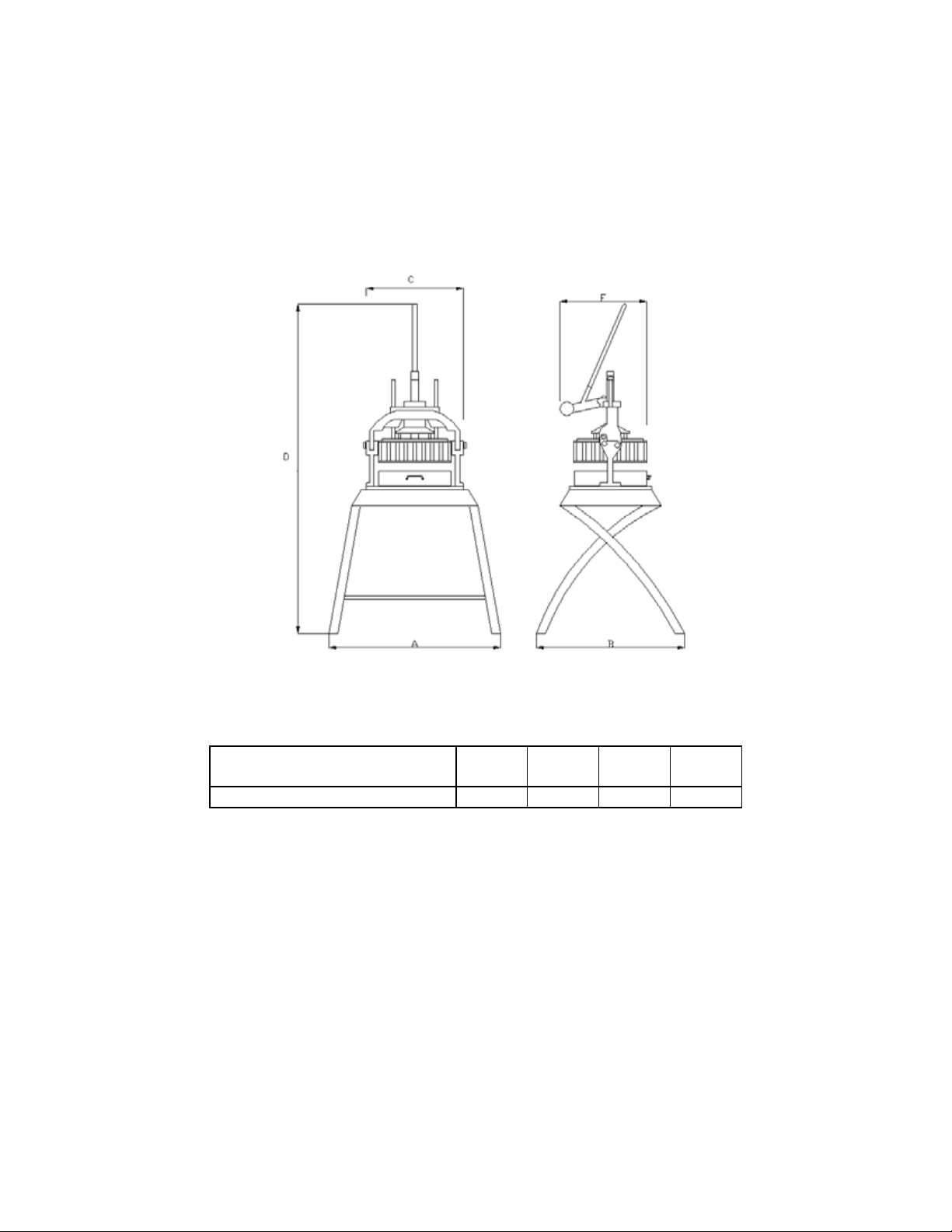

3.1.- TOTAL DIMENSIONS

Figure 2 shows the machine’s total dimension.

Figure 2

Total dimensions of the manual divider:

Model

DMF820

A

[mm]B[mm]C[mm]D[mm]

630 610 700 1920

3.2.- TECHNICAL SPECIFICATIONS

• Superior structure completely made in solid cast iron, gives the machine a compact, stable,

resistant, robust and lasting structure.

• The star of the divider is completely made of stainless steel.

• The press is made of POM-C which is in accordance with the food standards.

• The plates are made of stainless steel AISI304, proper for contact with food products, see

figure 3.

2006/04/04

4

Page 5

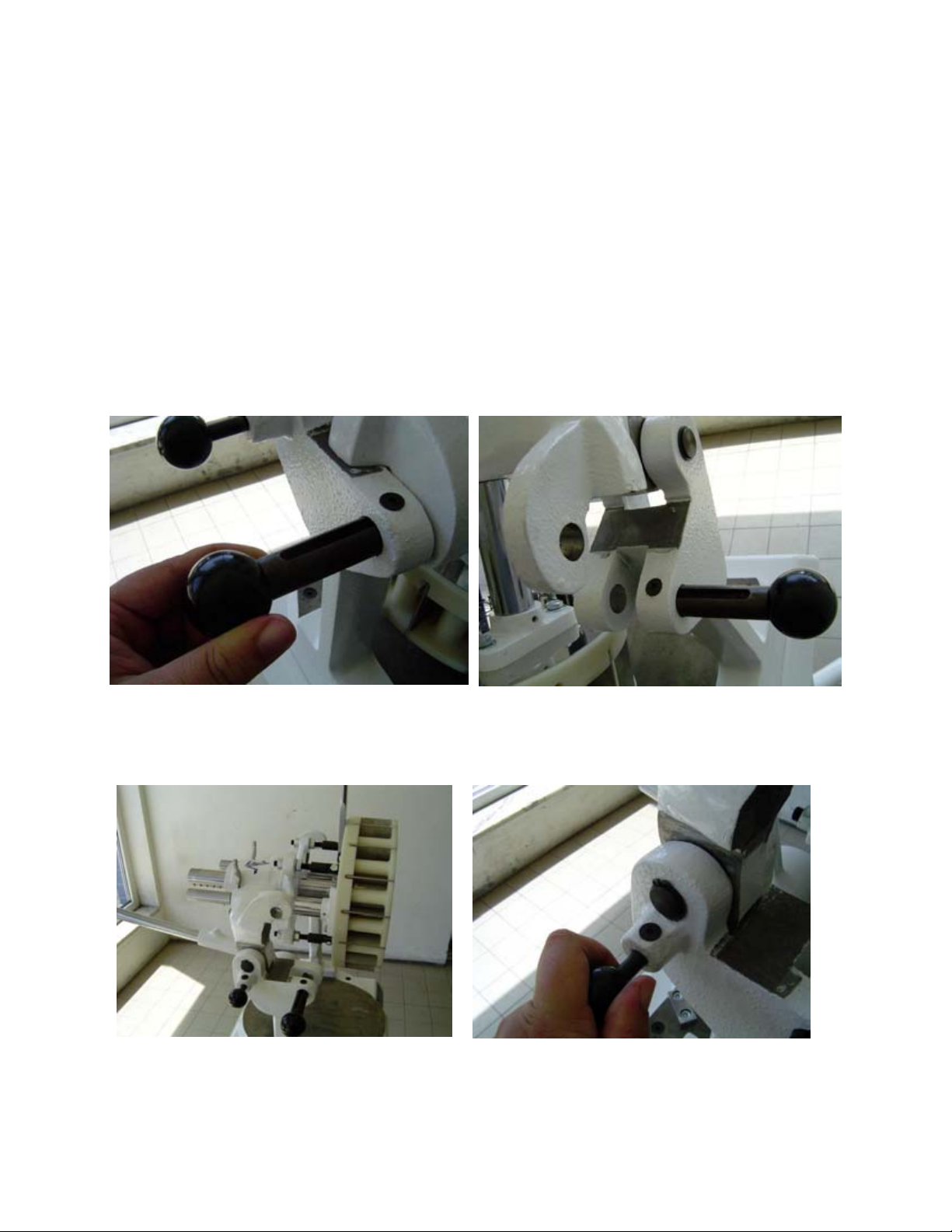

Figure 3

• Sliding blades are made of stainless steel.

• High resistance painting, which facilitates cleaning of the machine.

• Easy opening of the head allows easy cleaning of the machine

3.3.- SECURITY SYSTEMS

The division and cutting process of the dough is totally mechanical.

The area where the cutting blade is found, is closed with the stainless steel plate when the

dough is being pressed and divided.

This plate is also used to transport the dough after being divided.

Warning: The 2.5 mm width blades can cause injury if in contact with skin.

It is preferable to use gloves while cleaning the press and the blades.

2006/04/04

5

Page 6

CHAPTER 4

TRANSPORT AND PLACEMENT

4.1.- TRANSPORT

The machine’s weight is described in the following grid:

Models Weight [kg]

DMF820

The machine can be lifted, as shown in the example in figure 4, with adequate cables, ropes,

chains or hooks that support the machine’s weight in accordance with the drawing above.

185

Figure 4

4.2.- PLACEMENT

An incorrect installation of the machine could cause material and personal damage, which the

manufacturer is not responsible for.

The ground surface on which the machine is placed on to work, should be perfectly rigid, flat and

horizontally levelled, to avoid the loss of balance and tumbling of the machine, while it’s working.

The manual dough divider doesn’t need to be fixed to the ground surface , since it has non-stick

supports positioned under each leg (see figure 5).

Figure 5

2006/04/04

6

Page 7

CHAPTER 5

FUNCTIONING WITH THE MANUAL DOUGH DIVIDER

5.1.- FUNCTIONS

• First, place the correct amount of dough on the top of the previously powdered plate with

flour flatten the dough with your hands as much as possible in order to fill most of the plate’s

area.

• Position the plate that collects the dough on top of the solid cast iron board, placing it

perfectly under the press and on the back side of the table (figure 6)

Figure 6

• Unlock the blades so it could go down (figure7).

Figure 7

• Push the lever A down in figure 8, with the right hand and press strongly on the dough to

flatten it even more (figure 8).

2006/04/04

7

Page 8

A

Figure 8

• Without letting go of lever A, with your left hand push right to lever B in figure 9, which has

the function of releasing the star blade. Press lever A again to lower the star some (figure 9).

B

Figure 9

• Now, the dough is perfectly divided into 20 portions with equal weight.

• Lift lever A , to the initial position of rest, and take out the plate with the bread perfectly

weighed.

• This is the end of the process. To divide more dough, repeat the same process.

2006/04/04

8

Page 9

CHAPTER 6

MAINTENANCE

6.1.- CLEANING THE MACHINE

Every day, at the end of each working period, it’s necessary to clean the press thoroughly, verify

that there’s no accumulated dough between the star and the groove of the press.

Also clean the stainless plate that collects the remaining dough.

Be careful to clean the flour left on the machine, that way you can get a correct cleaning of the

machine when you proceed in the following way:

• Take out the stainless plate and clean it.

• Push the lateral left and right safety pins that fasten the columns to the machine’s frame

support (figure10)

Figure 10

• Lift the machine’s head and press the pin in figure 11 to keep the machine open.

Figure 11

2006/04/04

9

Page 10

• Close the cutting blades’ locks (figure 12).

Figure 12

• Unlock the lever B in figure 9 and push lever A in figure 8, to take out the pressing cutting

blade and proceed to it’s cleaning.

Figure 13

• Clean the blades thoroughly, with a smooth clothe moistened in water. Never use corruptive

cleaning products that may destroy the cutting blade.

• To use the machine again, proceed to the previous steps in an inverse form.

WARNING:

DON’T USE ANY TYPE OF OILS TO LUBRICATE THE MACHINE. IF YOU USE

OILS, THE FLOUR AND DOUGH WILL REMAIN ON THE MACHINE CAUSING

BREAK DOWNS.

2006/04/04

10

Page 11

CHAPTER 7

SECURITY

7.1.- SECURITY INSTRUCTIONS

• After the machine is delivered, verify its integrity.

• Please contact a qualified technician authorized by the manufacturer. The repairing of the

machine should be done by an agent assistant authorized by the manufacturer and use

original pieces.

This manual is part of the machine and must accompany it at all times.

7.2.- SPECIAL CARE

7.2.1.- Cares to have with movable pieces

All transmissions are potentially dangerous, do not place your hands near the movable pieces

while the machine is working, because you can hurts yourself.

Don’t let anyone near the machine while it is working.

7.2.2.- Hygiene

The materials that contact the food products are perfectly harmless and non-toxic (stainless

steel AISI304 e POM-C).

2006/04/04

11

Page 12

LIMITED WARRANTY

(Continental United States Of America

And Canada Only)

Doyon Equipment Inc. guarantees to the original purchaser only that

its product are free of defects in material and workmanship, under

normal use.

This warranty does not cover any light bulbs, thermostat calibration or

defects due to or resulting from handling, abuse, misuse, nor shall it

extend to any unit from which the serial number has been removed or

altered, or modifications made by unauthorized service personnel or

damage by flood, fire or other acts of God. Nor will this warranty

apply as regards to the immersion element damaged by hard water.

The extent of the manufacturer’s obligation under this warranty shall

be limited to the replacement or repair of defective parts within the

warranty period. The decision of the acceptance of the warranty will

be made by Doyon Equipment service department, which decision

will be final.

The purchaser is responsible for having the equipment properly

installed, operated under normal conditions with proper supervision

and to perform periodic preventive maintenance.

If any parts are proven defective during the period of one year from

date of purchase, Doyon Equipment Inc. hereby guarantees to

replace, without charge, F.O.B. Linière, Quebec, Canada, such part

or parts.

Doyon Equipment Inc will pay the reasonable labor charges in

connection with the replacement parts occurring within one year from

purchase date. Travel over 50 miles, holiday or overtime charges are

not covered. After one year from purchase date, all labor and

transportation charges in connection with replacement parts will be

the purchaser’s responsibility.

Doyon Equipment Inc. does hereby exclude and shall not be liable to

purchaser for any consequential or incidental damages including, but

not limited to, damages to property, damages for loss of use, loss of

time, loss of profits or income, resulting from any breach or warranty.

In no case, shall this warranty apply outside Canada and continental

United States unless the purchaser has a written agreement from

Doyon Equipment Inc.

2006/04/04

12

Loading...

Loading...