Page 1

ÉQUIPEMENT DOYON INC.

1255, rue Principale

Linière, Qc, Canada G0M 1J0

Tel.: 1 (418) 685-3431

Canada: 1 (800) 463-1636

US: 1 (800) 463-4273

FAX: 1 (418) 685-3948

Internet: http://www.doyon.qc.ca

e-mail: doyon@doyon.qc.ca

JA8 SCHLOTZSKY EBAKE

Serial number:

Page 2

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

DANGER

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK

CAREFULLY FOLLOW THESE INSTRUCTIONS

TABLE OF CONTENTS

(table des matières : page suivante)

DESCRIPTION________________________________________________________________ A-1

Introduction________________________________________________________________ A-1

Construction _______________________________________________________________ A-1

Shipping __________________________________________________________________ A-1

Installation warnings_________________________________________________________ A-2

Distances to respect __________________________________________________________ A-2

Installation_________________________________________________________________ A-3

Ebake front panel control - button key description and parts list _______________________ A-3

Ebake Programmable control - Operating modes ___________________________________ A-3

Manual mode _______________________________________________________________ A-3

Program mode______________________________________________________________ A-3

Over ride mode ____________________________________________________________ A-11

Troubleshooting ____________________________________________________________ A-3

Oven maintenance and cleaning _______________________________________________ A-14

Warranty

JA8Schlotsky's EBAKE1 [BOOK].doc 09/12

Page 3

A-1

SECTION A:

DESCRIPTION

INTRODUCTION

The manufacturer suggests to read this manual carefully.

This Jet Air oven is manufactured with first quality material by experienced technicians. Proper

installation and maintenance will guarant ee a reliable service for years to come.

A nameplate fixed to the front or right side of the oven specifies the model number, serial number,

voltage and amperage.

Drawings and replacement parts numbers are included in this manual. The electrical diagram is affixed

in the control panel at the back of the oven.

ATTENTION

DOYON is not responsible for damages to the property or the equipment caused

by personnel who is not certified by known organisations. The customer is

responsible for finding qualified te chnicians in electricity and plumbing for the

installation of the oven.

CONSTRUCTION

You just bought the most advanced oven in the world, "DOYON" technology at its best. This oven is

manufactured using the highest quality components and material.

The oven gives a perfect uniform baking with its unique Jet Air convection system. The DOYON oven

is designed with parts that are easy to find.

SHIPPING

For your safety, this equipment has been verified by qualified technicians and carefully crated before

shipment. The freight company assumes full responsibility concerning the delivery in good condition of

the equipment in accepting to transport it.

IMPORTANT

RECEPTION OF THE MERCHANDISE

Take care to verify that the received equipment is not damaged before signing the delivery receipt. If a

damage or a lost part is noticed, write it clearly on the receipt. If it is noticed after the carrier has left,

contact immediately the freight company in order that they do their inspection.

We do not assume the responsibility for damages or losses that may occur d uring transportation.

Page 4

DESCRIPTION

A-2

INSTALLATION WARNINGS

POWER FAILURE WARNING

WHEN YOU HAVE A POWER FAILURE, SHUT OFF THE OVEN POWER SWITCH TO

PROTECT THE ELECTRONIC COMPONENTS WHEN THE POWER COMES BACK.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN THE VICINITY OF THIS OR ANY APPLIANCE.

INSTALLATION AND SERVICE

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

Installation and service must be done by specialised technicians. Contact a certified electrician and

plumber for set up.

The oven must be connected to the utility and electrically grounded in conformity to the effective

local regulations. If these are not established, the oven must be connected according to the Canadian

Electrical Code (CSA-C22.1-XX) or National Electrical Code (NFPA 70-XX). Refer to last edition

year for XX. Installation must also allow proper access for service (24 inches each side and back).

The ovens must be installed with a proper ventilation according with the local building code.

DISTANCES TO RESPECT

A) Back and sides of the oven: 1 inch.

B) Top of the oven: a clearance of 12 inches to the ceiling must exist to permit adequate venting.

C) Floor: 4 inches minimum.

D) Sides of the oven: do not install other than easily removable equipment for service and

maintenance (not closer than 1 inch).

E) It is recommended to have a certain length of water pipe, electric cable between oven and

wall to help gain access for service.

Page 5

A-3

INSTALLATION

IN GENERAL

Take off the packaging material with care. Take off all the material used for packing and accessories.

If the equipment is delivered with casters, always lock them after installation and use flexible wire.

It must also be installed with restraining device (chain comes with the oven) to guard against

transmission of strain to the gas supply and connectors.

1. To the electrician

Electrical supply installation must be in accordance with the electrical rating on the nameplate.

WARNING

The electrician must make sure that the supply cable does not come in contact

with the oven top which becomes hot.

2. To the plumber

This equipment is to be installed to comply with the applicable federal, state or local plumbing

codes.

Connect the steam system (1/4 NPT) to the cold water distribution network.

We highly recommend to use a water softener to eliminate minerals in the water.

We suggest you to use CUNO # CFS6135 (Doyon part number PLF240).

WARNING

Do not adjust the needle valves, it has been done at the factory.

Page 6

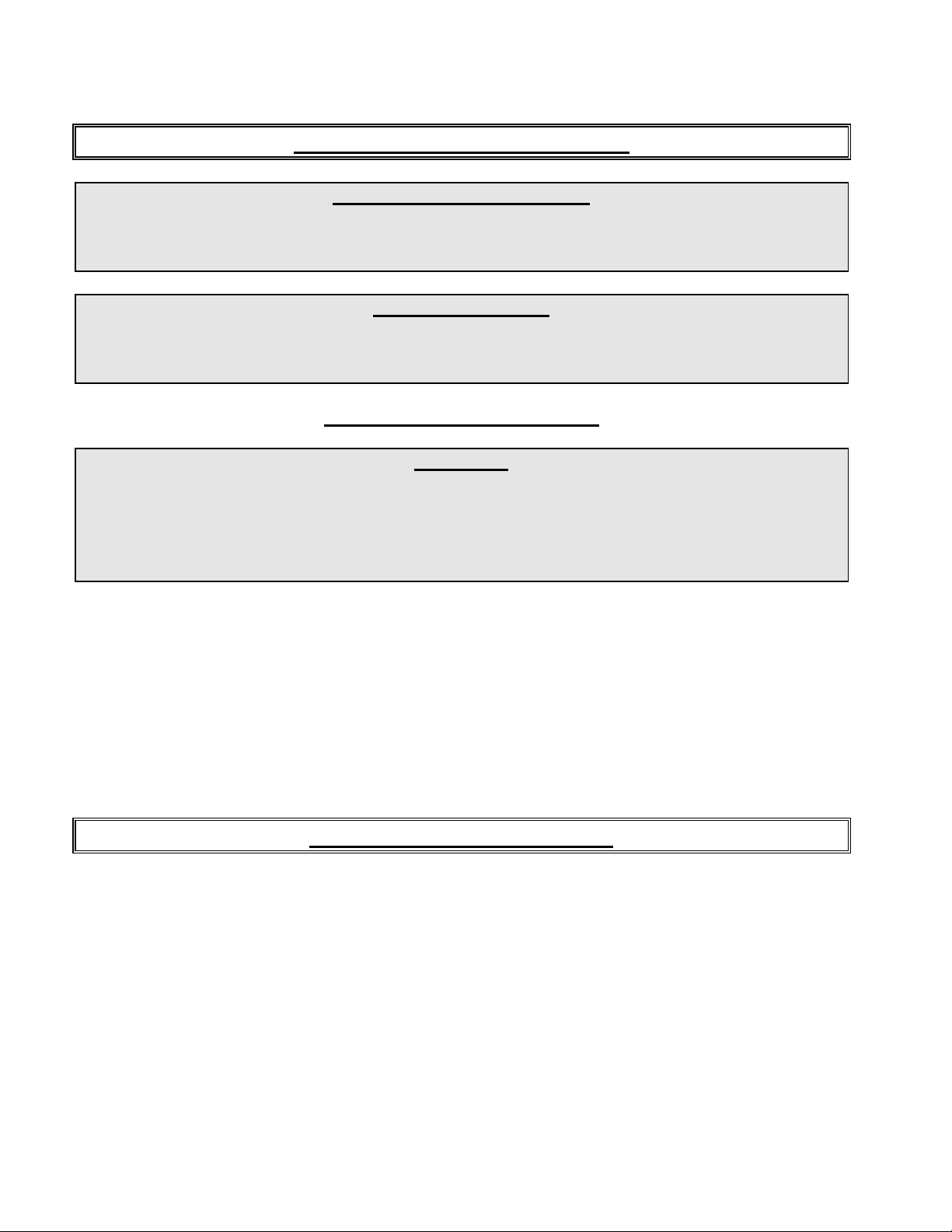

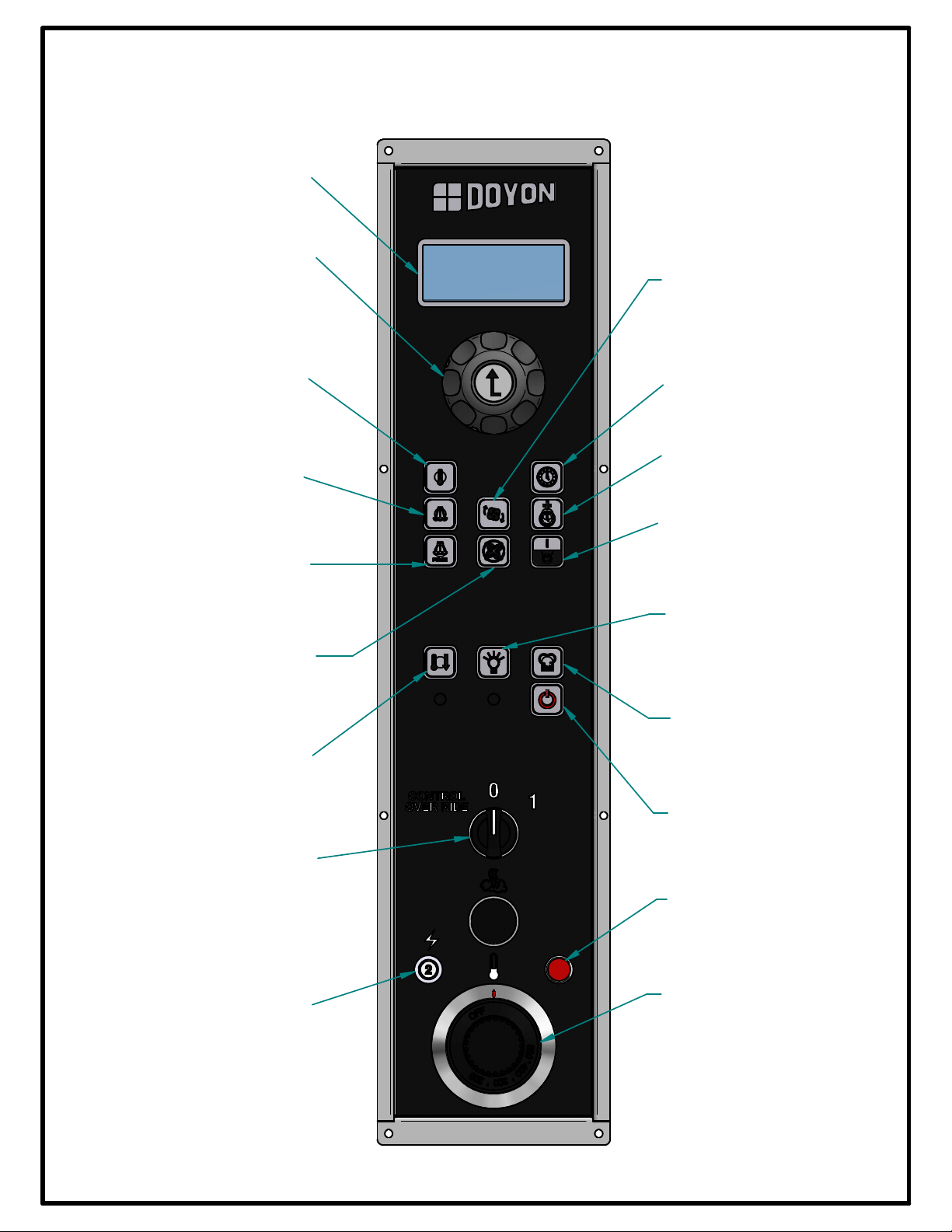

EBAKE CONTROL PANEL SCHLOTZSKY OVEN

PANNEAU CTRL. EBAKE FOUR SCHLOTZSKY

DISPLAY/

AFFICHAGE

ROTARY PUSH KNOB/

BOUTON POUSSOIR

ROTATIF

FAN SPEED & CYCLE/

VITESSE & CYCLE

DU VENTILATEUR

TEMPERATURE/

TEMPÉRATURE

SHOT STEAM/

VAPEUR UNIQUE

PUSLE STEAM/

VAPEUR PULSÉ

FAN OFF DELAY/

DELAI VENTILATEUR

AUTO COOL DOWN/

REFROIDISSEUR AUTO

CONTROL OVERRIDE/

CONTRÔLE BY-PASS

TIMER/

MINUTERIE

ADD BAKE TIME/

AJOUT TEMPS CUISSON

TIMER START/STOP/

MARCHE/ARRÊT

MINUTERIE

LIGHT/

LUMIÈRE

PROGRAM MENU/

MENU PROGRAMME

POWER/

MISE EN MARCHE

OVERRIDE ON/

OVERRIDE ON

BREAKER/

DISJONCTEUR

I:\Dessins\PANNEAU CONTRÔLE\50009033.dft

THERMOSTAT/

THERMOSTAT

Page 7

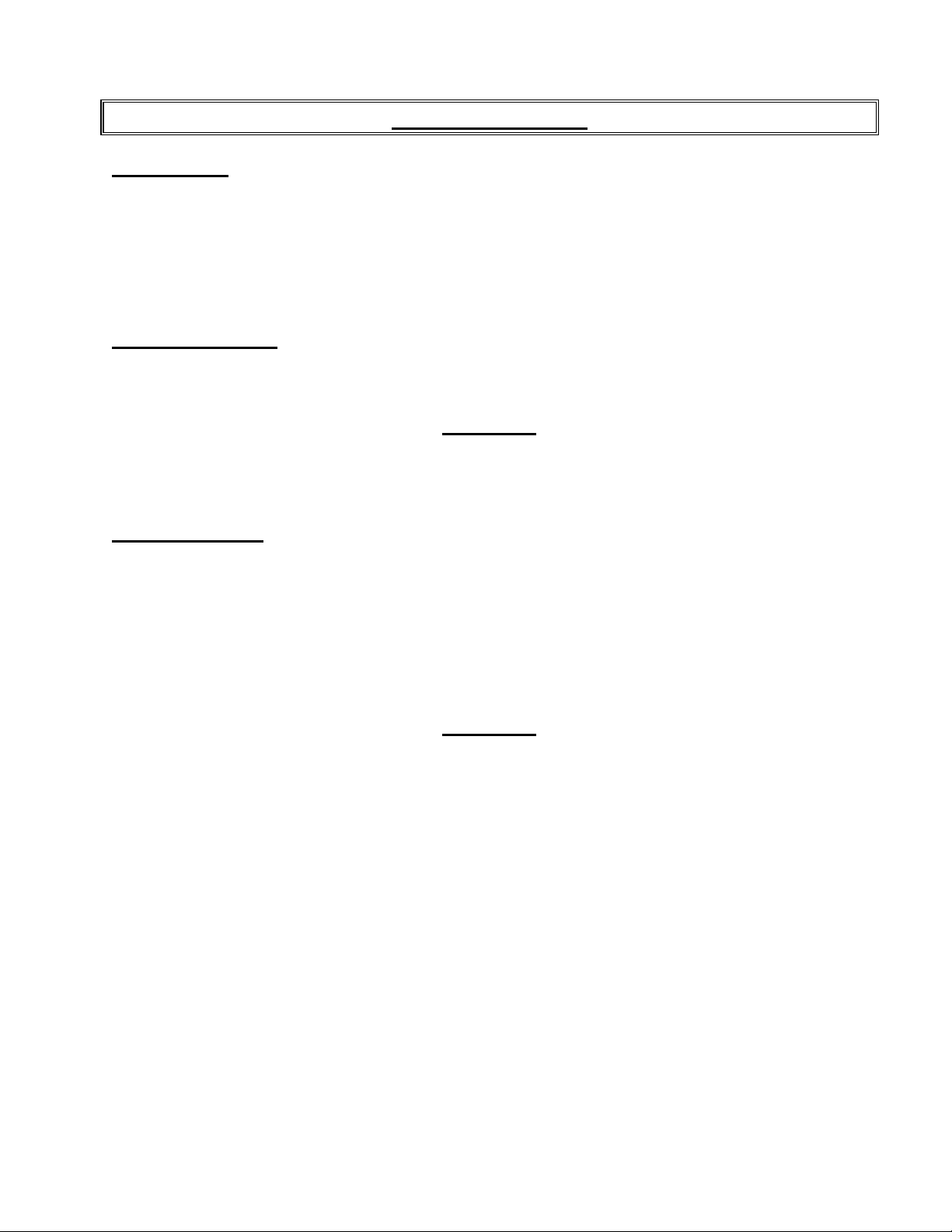

EBAKE CONTROL PANEL SCHLOTZSKY OVEN

PANNEAU CTRL. EBAKE FOUR SCHLOTZSKY

1

12

2

3

4

13

11

5

14

6

10

7

15

8

N° CODE DESCRIPTION FRANÇAISE ENGLISH DESCRIPTION QTY

1 50010432 PANNEAU CTRL. FOUR STD. CONTROL PANEL STD. OVEN 1

2 ET229 MEMBRANE FOUR CTRL. EBAKE SCHLOTZSKY OVERLAY EBAKE CTRL. SCHLOTZSKY OVEN 1

3 ELT801 BOUTON POUR CONTROLEUR EBAKE KNOB FOR EBAKE CONTROL 1

4 ET223 ÉTIQUETTE ENTRER POUR ELT801 ENTER STICKER FOR ELT801 1

5 ELI403 SÉLECTEUR 3 POS. NOIR BLACK SELECTOR 3 POS. 1

6 ELP400 BOUTON POUSSOIR (NOIR) BLACK PUSH−BUTTON 1

7 ELB098 DISJONCTEUR 2A 2A BREAKER 1

8 ELT620 PLAQUE DE THERMOSTAT THERMOSTAT BEZEL 1

9 ELT552 BOUTON DE THERMOSTAT 550°F KNOB 550°F 1

10 ELL650 LAMPE TÉMOIN ROUGE 250 V RED PILOT LIGHT 250V 1

11 ELL405 BLOCK CONTACT NO CONTACT BLOC NO 4

12 ELT800 CONTRÔLE PROGRAMMABLE EBAKE EBAKE PROGRAMMABLE CONTROL 1

13 ELI413 BASE AVEC 2NO BASE WITH 2NO 1

14 ELI406 BASE AVEC 1NO BASE WITH 1NO 1

15 ELT544 THERMOSTAT 550°F 550°F THERMOSTAT 1

I:\Dessins\PANNEAU CONTRÔLE\50009033.dft

9

Page 8

A-6

EBAKE PROGRAMMABLE CONTROL - OPERATING MODES

The Doyon Ebake controller has two operation modes Manual and Programmable.

MANUAL: to use all functions without using a recipe program.

PROGRAMMABLE : to use with a recipe program.

Program capacity

? Program #1 is always used as the default Manual Cooking mode setting (single stage).

? Programs #2 to #99 can have up to 8 stages each recipe.

OVEN START UP

Turn on the main power switch. The controller will power up and display:

? OFF, PRESS POWER KEY TO START.

Press the red POWER key, the oven will go ON. The display will read PREHEAT and the oven will heat to reach the

MANUAL preset temperature. Then, the oven will display READY and the alarm will beep 5 times. This will mean that

the oven is at the desired temperature.

To turn the oven OFF, press the red POWER key and hold it for 3 seconds. The oven will run on COOL DOWN mode

until it reaches 200°F and then, it will automatically turn OFF. At this moment, the display will show : OFF, PRESS

POWER KEY TO START.

DOOR SWITCH

? If the door is opened :

? Display scrolls recipe NAME and DOOR OPEN.

? All functions are turned OFF (unless in Cool Down mode, then the fan remains on).

? All timers pause until the door is closed.

Page 9

A-7

MANUAL MODE

This mode is used to work in a single st age.

Turn the dial until MANUAL is highlighted, press the dial to confirm.

COOL DOWN FUNCTION

For fast cool down, press on the COOL DOWN key, the fan will remain ON while the door is open.

Note: if the oven reaches 200°F, it will turn OFF automatically. Display will show: OFF, PRESS POWER KEY TO

START.

LIGHT KEY FUNCTION

Press the LIGHT key to turn lights ON/OFF.

TEMPERATURE FUNCTION

To change the temperature set point, press on . Display will show actual temperature set point. Turn the dial to select

the desired temperature set point (by increments of 5 degrees) and press

note that the new set point will automatically be saved after exiting if the dial is not pressed after changing the setting. If

the dial is not pressed or turned within 3 seconds, the last set temperature will be saved.

to confirm and exit the setting mode. Also,

TIMER FUNCTION

To change the time setting, press on

(by increments of 15 sec.) and press to confirm and exit setting. If the dial is not pressed or turned within 3 seconds,

the last set time will be saved.

Press on timer START/STOP key to start the timer countdown. At the end of the countdown, display will show BAKE

DONE. If needed, you can add 1 minute by pressing the ADD TIME key. It will automatically add 1 minute without

changing the original time setting. If more then one minutes is needed turn the dial to desired add time and press

When th e countdown is finished, the display will show BAKE DONE.

Also, at any time during the countdown, the time can be paused by pressing on the TIMER START/STOP key or

cancelled by pressing and holding the START/STOP key for 3 seconds.

When the door is open, the timer pauses and the display indicates DOOR OPEN until the door is closed.

? If the remaining time is less than 60 minutes, it will be displayed as MM:SS

? If the remaining time is 60 minutes or more, it will be displayed as HH:MM

Note: Timer in MANUAL mode is only a reminder.

Display wills show time setting. Turn the dial to select the desired timer se tting

.

FAN OFF DELAY FUNCTION

By pressing on the FAN OFF DELAY key, the fan remains OFF for a period of time before starting working in normal

reversing fan mode. After pressing FAN OFF DELAY key, the display will show NONE. Turn the dial to select HIGH

(5 minutes on electric oven and 45 seconds on gas) or LOW (3 minutes on electric oven and 30 seconds on gas) fan off

delay and press

If the dial is not pressed or turned within 3 seconds, the last set FAN OFF DELAY will be saved.

.

Page 10

A-8

To cancel fan off delay, press the FAN OFF DELAY key, turn the dial to NONE and press

STEAM FUNCTION

Steam output can be turned ON only if oven temperature is >= (250°F /121°C).

? Pressing PULSE STEAM key : It will create continuous steam injections. If pressed again, it will

cancel the pulse steam function. When active, the display scrolls recipe name and pulse steam.

? Pressing SHOT STEAM key : A single steam injection will inject for duration of preset time. The

display will toggle the recipe name and the steam. Following the steam injection you will have

automatically a FAN OFF DELAY of 30 seconds.

? Note: When pressing the SHOT STEAM key, it will force the fan ON.

FAN SPEED & CYCLE FUNCTION

You can change the fan speed & cycle time. There are 2 different fan speed setting available STD & LOW and 3

different fan cycles setting available STD (2.5 min ON - 25 sec. OFF), MED (1.5 min ON - 25 sec OFF) and LOW (20

sec ON - 45 sec OFF). Default speed & fan cycle is STD. To select a different fan speed or cycle then STD turn the dial

to desire fan speed & cycle type and press

This function will change the fan speed and the reversing time cycle of the fan, creating a different air flow.

.

Page 11

A-9

PROGRAMMED COOKING MODE

This mode is used to work with 1 to 8 stages recipe programs.

To select a programmed recipe, turn the dial until name or number of product is highlighted. Press

program. The oven will preheat to the programmed temperature. Display will show READY and the alarm will beep 5

times when the oven is at the desired temperature.

Press on START /STOP key to start the programmed recipe. The timer will countdown. At the end of the recipe, display

will show BAKE DONE. If needed, you can add time pressing the BAKE MORE TIME key. It will automatically add 1

minute without changing the original time setting. If more then one minute is needed after pressing the BAKE MORE

TIME key, turn the dial to desire add time and press

DONE. Press on START/STOP key to stop the recipe.

Also, at any time during the countdown, the recipe can be paused by pressing on the START/STOP timer key or

canceled by pressing and holding the key for 3 seconds.

When the door is open, the timer pauses and the display shows DOOR OPEN until the door is closed.

To see current stage information during baking process, press on the TIMER key. It will display recipe name, stage

number, stage status and time reminder.

Note: During a programmed recipe, the keys SHOT & PULSE STEAM, FAN CYCLE, FAN OFF DELAY are not

functional. All those functions need to be set in the recipe program.

when the countdown is finished, the display will show BAKE

Cook Program Structure

Each recipe name can have maximum of 15 characters. Up to 10 characters will show a fixe recipe name on the display.

If more then 10, the recipe name will scroll on the display and when timer is activate the recipe name will be fixe and

show only the 10 first characters.

Each recipe can have preheat temps, core probe, cook stage, cook & hold function. Each stage has the following

programmable parameters:

Optional Core probe: If enable monitoring or cooking temperature.

Time: the time duration of the current stage.

Oven temperature: the oven set point for current stage.

Steam: shot or pulse steam injected into the oven chamber.

Fan off delay: 0 to 60 second can be programmed after the shot steam injection.

Fan off delay: duration of the fan OFF

Fan speed: LOW/HIGH

Fan cycle: the cycle time between fan ON/OFF

Entering the Programming mode

to select product

Press the PROGRAM KEY . If the control is protected by a password, the display reads ENTER CODE. Use the dial to enter the

4 digits code. Select the number and press to go to the next number. After the last number confirmation, you will enter program

mode.

Programming a product recipe

Note : the control can hold up to 99 recipes. Each recipe can have up to 8 stages.

Rotate the dial to the desired recipe and press .

To edit a new or existing name:

Turn the dial to the edit name or option name and press .

-EDIT NAME: Use dial to select each letter and press to step to the next letter.

-OPTION NAME: Select one of the library listed product name.

Page 12

A-10

After product name is edited, you will enter to the following recipe programming mode.

1-PREHEAT

If no preheat needed: Use the dial to step on next programming function.

If preheat needed: Turn the dial to select preheat and press .Use the dial to select YES and press . Rotate the dial to

set the desire preheat temperature and press to exit and save preheat function.

2-STAGE PROGRAMMING

Turn the dial to the product stage 1 and press . Display will show the following programming process.

a) Set stage timer: Turn the dial to select desired current stage cooking time and press . Note if core probe is set to cooking the

b) Set temperature: Turn the dial to set the current stage temperature and press .

c) Steam: If no steam is needed, press to skip steam function and go to FAN speed.

cook time function will be disabled and you will start with set temperature instead of set Time.

If steam is needed, rotate the dial to select YES and press . Use the dial to select SHOT or PULSE and press . If

SHOT is selected, rotate the dial to select LOW (+/- 100 ml) or HIGH (+/- 120 ml) steam and press .

If a steam SHOT delay is needed, rotate the dial to set the fan off delay and press .

If pulse is selected, rotate the dial to select STD (+/-15 ml every 30 sec), HI (+/-15 ml every 20 sec) or MED (+/-15 ml every

15 sec) pulse and press .

d) Fan delay: If no fan delay is needed, press of the dial to skip to fan cycle. If fan delay is needed, rotate the dial to select LOW

(3 minutes) or HIGH (5 minutes) and press . If a fan off delay is needed, press to step to fan cycle.

e) Fan Speed: If fan speed STD is ok, press . If LOW fan speed, is desired, Turn the dial to select LOW and press .

f) Fan cycle: If standard fan cycle STD (2.5min ON - 25sec OFF) is ok, press . If need of a different fan cycle is needed, rotate the

You have now completed 1 stage program. If another stage is needed, select stage 2 and follow same process as stage 1. If a 2nd stage

dial to select MED(1.5min ON - 25sec OFF) or LOW(20min ON - 45sec OFF) and press .

is not needed, turn the dial to exit and the recipe will be registered.

Page 13

A-11

OVER RIDE MODE

The over ride mode gives you the possibility to bypass the programmable controler and use the oven

temporarely in manual temperature and steam operation, in the case the programmable controler is

out of fonction.

The fan will run only one direction instead of having the reversing fan system every 3 minutes as

normal, when use with the programmable control.

Also, the steam system will be not automatic preset time like the normal operation.

HOW TO USE MANUAL OVER RIDE FUNCTION

1. Turn the selector to over ride.

2. Set the mechanical temperature controler dial to the desire temperature, when the red light switch

off it means that the temperature is reached and ready to bake.

3. To use the steam you need to press and hold the black manual steam button for the time you need

the steam, in over ride there is no preset time on the steam.

Page 14

A-12

erature drops when

loading and needs a certain amount

This is normal. The opening of the door produces an

important loss of heat. The rack loaded with cold

pastries need a large amount of heat to get back to its

rature. The same thing happens with

domestic ovens. You will realize that your oven can

provide an excellent baking quality for any kind of

Inside the electrical box located at the back of the unit,

Check the breaker behind the unit in the electrical

TROUBLESHOOTING

BEFORE CALLING FOR SERVICE

ANSWERS TO MOST FREQUENT QUESTIONS

Always cut off the main power before replacing any parts. Take care of water and electric

wire supply system when pulling the oven.

WARNING: Always disconnect the power supply to the appliance before cleaning, doing

preventive maintenance or servicing.

WARNING: Contact the factory, the factory representative or a local service company to perform

maintenance and repair.

Convection blower and (rack lift/rotating system on CA only)are on the top of the oven. These

components are sealed and don’t require lubrication.

Electric Control parts, water manual shut off valve are behind the control panel and back of the

aplliance.

BEFORE CALLING FOR SERVICE ANSWERS TO MOST FREQUENT QUESTIONS

Questions Solutions

The oven temp

of time before it stabilizes.

original tempe

products you want to bake.

The oven does not turn on. Check the breakers of the building.

Check the breaker on the front panel.

Check if the door is tightly closed.

check if the breaker of the convection blower is ON

The oven does not produce heat. Make sure the control is adjusted to a temperature high

enough to turn on the heat.

2. If the oven blower is not on

box.

If it does not start up again, contact our company or a

certified technician.

Page 15

A-13

n air intake is not

Verify the temperature of the oven by using an oven

thermometer and make sure that it is even with the

Verify if water manual shut off valve located at the back

Verify if line screen filter is clean (First, turn the water

manual shut off valve OFF and bleed the line by having

f display show CONTROL

COMPARTMENT OVER TEMP

Turn off or disconnect appliance from power supply and

Uneven baking. Verify that hot air diffuser and convectio

block. Do not use foil on the grills.

thermostat setting.

Verified the airflow output adjustment.

If steam device of the oven does not

work properly.

Check if the water supply valve (of the building) is open.

of the unit is open.

Steam injection is not permitted if actual

oven temperature is below 250F

The oven must be idling at temperature over 350F for at

least 15 minutes to get a good amount of steam

the appliance injecting water.)

Check the solenoid valve.

I

ERROR

If CAVITY PROBE ERROR

DISPLAY and the oven turn OFF

Check if control compartment cooling fan work.

Check if cooling fan inlet is clean.

have service by a qualified technician.

check cavity probe connection

Replace the cavity probe

call for service

Page 16

A-14

Clean the inside of the oven and the proofer

Take out the grills (the grills of the oven could

silicone base oven protector. It avoids food

316 Silicone base protector and lubricant for

Brasso or equivalents. They are copper

OVEN MAINTENANCE AND CLEANING

MAINTENANCE OF THE OVEN

• It is recommended to use a water filter and to clean or replace it regularly to avoid accumulation

of minerals inside the unit.

• Once a year or as needed, clean the reservoir of the proofer

(see parts description for localisat ion).

Questions Solutions

We recommend and sell:

with water and soap.

be cleaned with "Easy-Off").

After cleaning the inside of the oven, apply a

Dirt Buster III: Action foam cleaner

CHEMCO

Part number: NEB201

We recommend and sell:

from sticking to the metal.

Clean the oven windows with products like

cleaners but good for this use

Clean the oven exterior with a stainless steel

cleaner.

oven

Dow Corning

Part number : EXS400

We recommend and sell:

Wright's: Cream copper cleaner

J.A. Wright & Co.

Part number : EXC300

We recommend and sell:

Stainless steel cleaner

SANY or CURTIS (comestible)

Part number : NES201

Page 17

NOTES

Page 18

LIMITED WARRANTY

(Continental United States Of America And Canada Only)

Doyon Equipment Inc. guarantees to the original purchaser only that its product are

free of defects in material and workmanship, under normal use.

This warranty does not cover any light bulbs, thermostat calibration or defects due to

or resulting from handling, abuse, misuse, nor shall it extend to any unit from which

the serial number has been removed or altered, or modifications made by

unauthorised service personnel or damage by flood, fire or other acts of God. Nor will

this warranty apply as regards to the immersion element dama ged by hard water.

The extent of the manufacturer’s obligation under this warranty shall be limited to the

replacement or repair of defective parts within the warranty period. The decision of

the acceptance of the warranty will be made by Doyon Equipment service

department, which decision will be final.

The purchaser is responsible for having the equipment properly installed, operated

under normal conditions with proper supervision and to perform periodic preventive

maintenance.

If any parts are proven defective during the period of one year from date of purchase,

Doyon Equipment Inc. hereby guarantees to replace, without charge, F.O.B. Linière,

Quebec, Canada, such part or parts.

Doyon Equipment Inc will pay the reasonable labour charges in connection with the

replacement parts occurring within one year from purchase date. Travel over 50

miles, holiday or overtime charges are not covered. After one year from purchase

date, all labour and transportation charges in connection with replacement parts will

be the purchaser’s responsibility.

Doyon Equipment Inc. does hereby exclude and shall not be liable to purchaser for

any consequential or incidental damages including, but not limited to, damages to

property, damages for loss of use, loss of time, loss of profits or income, resulting

from any breach or warranty.

In no case, shall this warranty apply outside Canada and continental United States

unless the purchaser has a written agreement from Doyon Equipment Inc.

Loading...

Loading...