Doosan P425WCU-EX-T2, HP375WCU-EX-T2, XP375WCU-EX-T2 Electronic Service Manual

ELECTRONIC SERVICE MANUAL

COMPRESSOR MODELS

P425WCU-EX-T2 (F66)

HP375WCU-EX-T2 (F67)

XP375WCU-EX-T2 (F65)

P425WCU-EX-T2 (G02)

HP375WCU-EX-T2 (G03)

XP375WCU-EX-T2 (G04)

Doosan Infracore Portable Power

1293 Glenway Drive

Statesville, N.C. 28625

DoosanPortablePower.com

Book: 46673131 (06-2015) Rev A

2

TABLE OF CONTENTS

Electronic Service Manual

TITLE PAGE

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

COMPRESSOR OPERATION SEQUENCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

COMPRESSOR DIAGNOSTIC CODE TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . 15

ELECTRICAL CIRCUIT TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

E

LECTRICAL COMPONENT LOCATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

ELECTRICAL PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

SY

STEM SCHEMATICS AND WIRING DIAGRAMS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3

TABLE OF CONTENTS

Electronic Service Manual

TITLE PAGE

4

General Information

46673131 Rev. A 5

Electronic Service Manual General Information

Operational Theory

The P425/XP375/HP375WCU-EX-T2 compressor has an electronic system using the Titan

controller to provide discharge air pressure control and package monitoring functions. The

electrical system connects all the necessary switches, sensors, and transducers to the Titan

controller.

Titan Controller

The Titan controller is the heart of the compressor monitoring and control system and

provides data collection, package monitoring, and control functions for compressor

operations. The Titan controller is a microprocessor-based controller with analog and digital

inputs and outputs.

The Titan controller is mounted on the liftbail in the middle of compressor.

The first function of the Titan controller is to scan all inputs at a fixed interval. The analog

values are compared to preset minimum and maximum values and an ALERT or FAULT is

issued when a value is out of range. The various ALERTS and FAULTS are listed in the

Compressor Diagnostic Code Troubleshooting section.

The second function of the Titan controller is compressor discharge pressure control. The

Titan monitors the regulation system air pressure and varies the engine throttle to maintain

the setpoint discharge air pressure. The setpoint pressure is set by adjusting the pressure

regulator.

The third function of the Titan controller is to communicate diagnostic and control information

between the Titan, Micro-Port display, and other optional controllers via the J1939 CAN

network.

Temperature Sensors and Pressure Transducers

The electronics system uses temperature sensors and pressure transducers to monitor the

compressor operation. The temperature sensors used to measure compressor temperatures

are thermistor type devices. The resistance output of the temperature sensor changes with a

corresponding temperature change of the parameter being monitored. The Titan controller

receives the resistance value of the sensor and converts it to a temperature value. The Titan

uses the temperature value to ensure the parameter being monitored is within its operating

limits and relays the value to the Micro-Port display for operator viewing.

The pressure sensors used to measure compressor pressures are transducer type devices.

These sensors have an output signal range of 0.5 VDC to 4.5 VDC, where 0.5 VDC

corresponds to 0 PSI and 4.5 VDC corresponds to the maximum PSI rating for a particular

transducer. Pressure sensors are provided with 5 VDC excitation voltage from the Titan

controller. Also, the sensor return or ground connects to the Titan controller. The output

voltage of the pressure sensor changes with a corresponding pressure change of the

parameter being monitored. The Titan controller receives the voltage of the sensor and

converts it to a pressure value. The Titan uses the pressure value to ensure the parameter

being monitored is within its operating limits and relays the value to the Service Air Pressure

gauge display for operator viewing.

6 46673131 Rev. A

General Information Electronic Service Manual

The Titan controller scans digital inputs such as switch contacts. Inputs are 24 VDC, 12 VDC,

or 0 VDC. Digital inputs with 24 VDC or 12 VDC represent a closed switch contact. Digital

inputs with 0 VDC represent an open switch contact.

The Titan controller provides 12 VDC digital outputs to control solenoids, relays, and other

devices. Outputs are 12 VDC ON and 0 VDC OFF and are current limited and short circuit

protected.

The Titan controller has 12 VDC digital (ON/OFF) type outputs.

Micro-Port Display

The Micro-Port displays compressor and engine operational information to the operator. The

Micro-Port display can be navigated by using the UP, DOWN, and ENTER buttons on the

Keypad.

The Micro-Port display is connected to the J1939 CAN network for communication with other

devices on the network.

J1939 CAN Network

The J1939 CAN network is a twisted pair of wires located in the compressor and engine

harnesses. These wires are the network link between all electronic control modules. The

wires are color coded yellow and dark green. The yellow wire is referred to as CAN High (+)

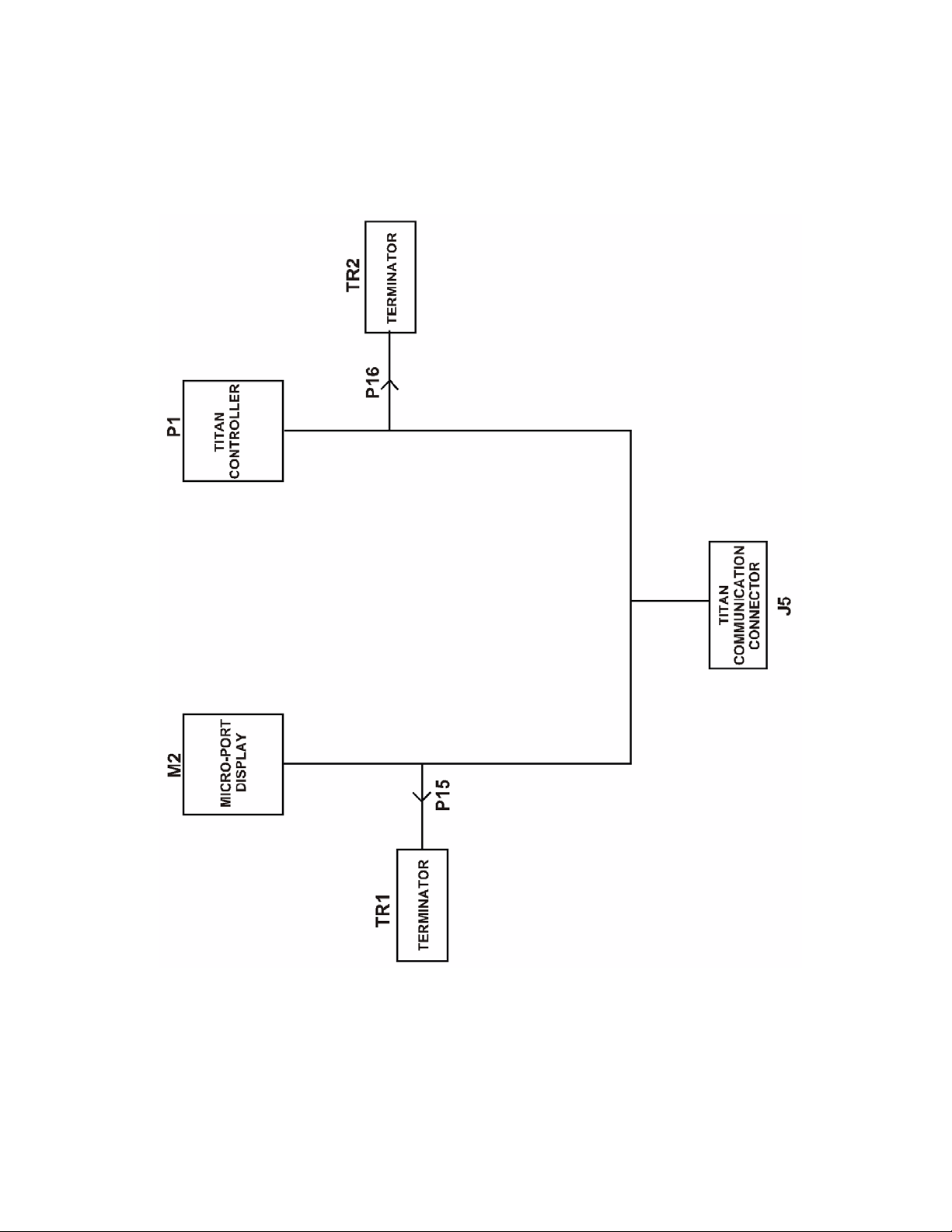

and the dark green wire is referred to as CAN Low (-). Figure 1-2 shows the connection layout

of the CAN network.

Located on each end of the J1939 CAN network are termination resistors (terminator). The

terminators prevent reflections on the transmission line and must be in place for the network

to function properly.

Electrical System

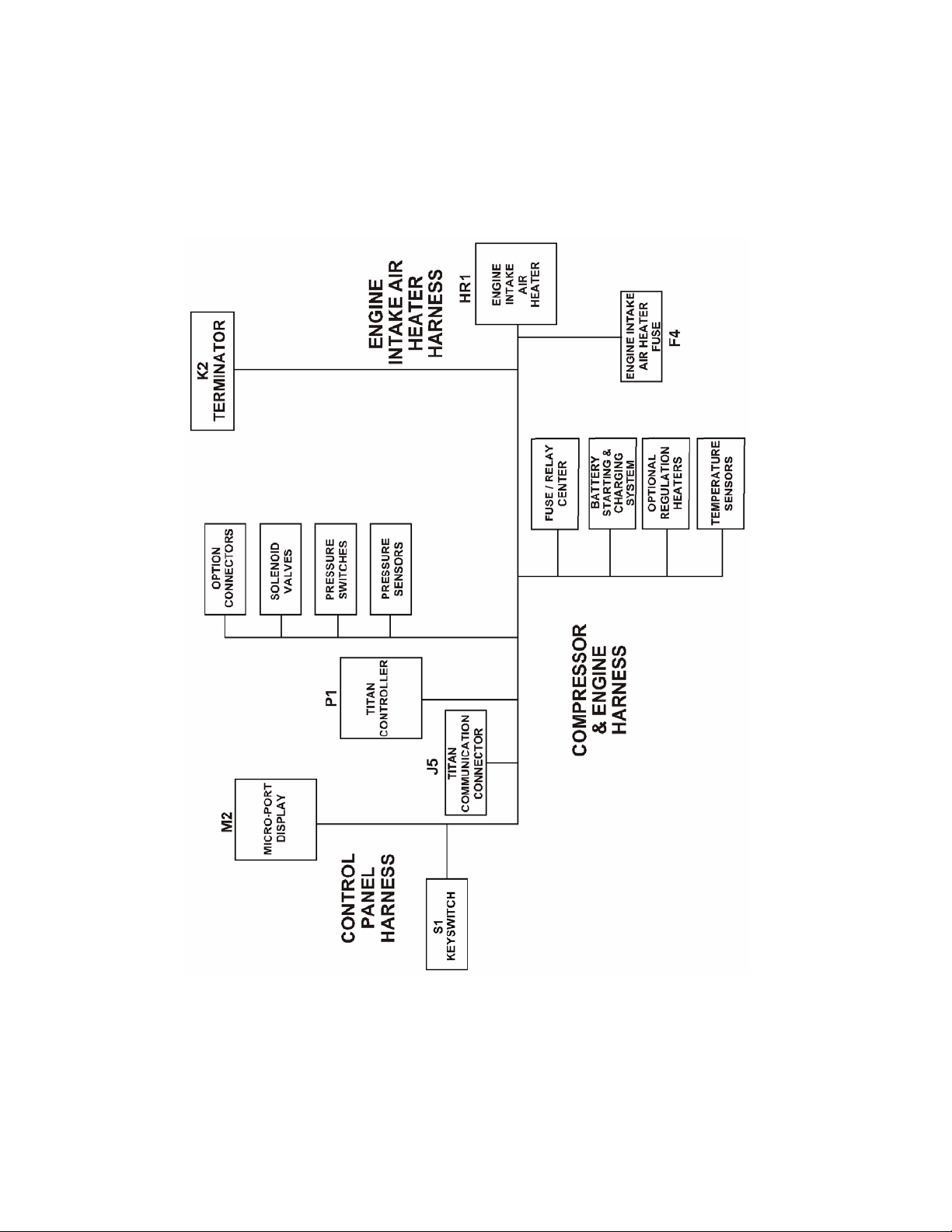

The electrical system consists of the wiring harnesses and associated electrical devices such

as relays, switches, sensors, and solenoids. There are three wiring harnesses on this

compressor:

• Compressor and Engine Harness

• Engine Intake Air Heater Harness

Figure 1-3 shows the connection layout of the harness system.

The electrical circuits are protected by fuses. A fuse should only be replaced with one of the

same rating. Installing a larger rated fuse could lead to wiring harness damage.

46673131 Rev. A 7

Electronic Service Manual General Information

Figure 1-2 : J1939 CAN BUS CONNECTION LAYOUT

8 46673131 Rev. A

General Information Electronic Service Manual

Figure 1-3 : HARNESS SYSTEM CONNECTION LAYOUT

46673131 Rev. A 9

Electronic Service Manual General Information

10 46673131 Rev. A

Compressor Operation Sequence

46673131 Rev. A 11

Electronic Service Manual Compressor Operation Sequence

Power On

When the Keyswitch is in the ON position:

1. Key ON/OFF signal (12 VDC) supplied to Titan controller.

2. Titan controller energizes Switched Power Relay (FB1-K3).

3. Micro-Port display and gauges will initialize.

4. Gauge backlights power ON.

5. Regulation heaters (if equipped) are energized ON if ambient temperature is

below 45°F. Engine intake heaters are energized if ambient temperature is

below 60°F.

Start

When the Keyswitch is in the START position:

1. Unloader Solenoid Valve (L2) is closed (de-energized).

2. Engine Starter is energized.

When the engine speed reaches 1000 RPM (engine start declared):

1. Engine starter is de-energized.

2. Engine speed is set to 1500 RPM.

When the engine speed is greater than 1100 RPM:

1. Unloader Solenoid Valve (L2) is opened (energized).

Loading

When the Start/Run Valve is pressed:

1. Engine speed is set to 2200 RPM.

12 46673131 Rev. A

Electronic Service Manual Compressor Operation Sequence

Shutdown

Close the service valves(s). Allow the compressor to run at idle speed for 3 to 5 minutes to

allow cool down. Do not use E-Stop (if equipped) to stop machine unless it is an emergency.

When the Keyswitch is moved to the OFF position:

1. Keyswitch signal (12VDC) from Titan is de-engerized.

2. The engine will shut down.

3. The Titan controller and Switched Power Relay (FB1-K3) de-energize.

4. Micro-Port display, gauges, and Compressor Control System will turn OFF.

46673131 Rev. A 13

Electronic Service Manual Compressor Operation Sequence

14 46673131 Rev. A

Compressor Diagnostic Code

Troubleshooting

46673131 Rev. A 15

Electronic Service Manual Compressor Diagnostic Code Troubleshooting

General

A thorough analysis of the problem is the key to successful troubleshooting. The

more information known about a problem, the faster and easier the problem can be

solved.

Troubleshooting charts are included to act as a guide to the troubleshooting

process.

The charts are organized so the easiest and most logical things are performed first.

It is not possible to include all the solutions to problems that can occur or list all

possible problems.

The charts are designed to stimulate a thinking process that will lead to the solution

of a problem.

Basic Troubleshooting Steps

• Collect all facts concerning the problem.

• Analyze the problem thoroughly.

• Relate the symptoms to the basic electrical/electronic systems and

components.

• Consider any recent repairs that could relate to the problem.

16 46673131 Rev. A

Compressor Diagnostic Code Troubleshooting Electronic Service Manual

General Measuring Guidelines

Since the electrical system uses sealed connectors and splices, access of test

points can be difficult. It is recommended a test probe kit be used to access the

signals to prevent damage to wires and connectors. Back-probing connectors and

insulation piercing test probes can cause damage that can cause future failures.

Measuring Voltage

A digital voltmeter is recommended to make measurements. Voltage

measurements are made by connecting the Red (+) lead to the desired signal and

the Black (-) lead to the common. The test lead connections must be secure or

incorrect readings will result. Do NOT use chassis ground or other metal

connection. Circuit common will be any of the brown wires or battery Negative.

IMPORTANT INFORMATION

DO NOT USE MACHINE FRAME, SHEET METAL, PIPING, OR OTHER METAL

COMPONENTS AS COMMON OR GROUND WHEN MAKING VOLTAGE OR

FREQUENCY MEASUREMENTS.

Measuring Resistance

Extra care must be taken when making resistance measurements. Test probe

connections are crucial to correct readings. Ensure the test probe makes a solid

connection with the wire(s) or connector pin(s) under test. The test probe kit may

help with these types of measurements. Electrical system must be powered OFF

while making resistance measurements.

Measuring Frequency

Frequency is measured in the same manner as voltage, but the meter is set for HZ

or frequency. Good connections are important or false readings will occur.

Measuring Duty Cycle

To measure duty cycle, set up the meter as if measuring frequency or voltage.

Select the % or duty cycle function and take the measurements.

46673131 Rev. A 17

Electronic Service Manual Compressor Diagnostic Code Troubleshooting

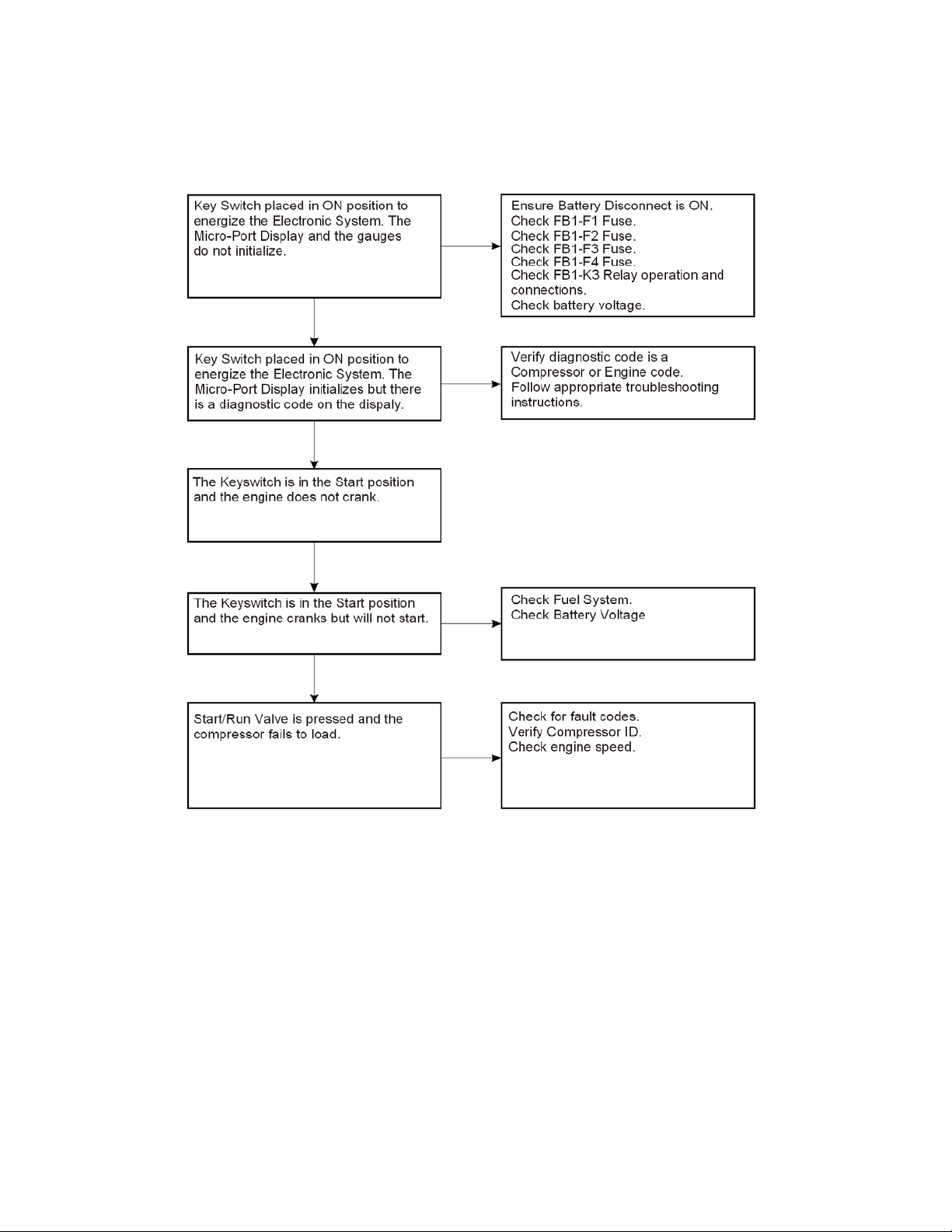

Troubleshooting Flow Chart

18 46673131 Rev. A

Compressor Diagnostic Code Troubleshooting Electronic Service Manual

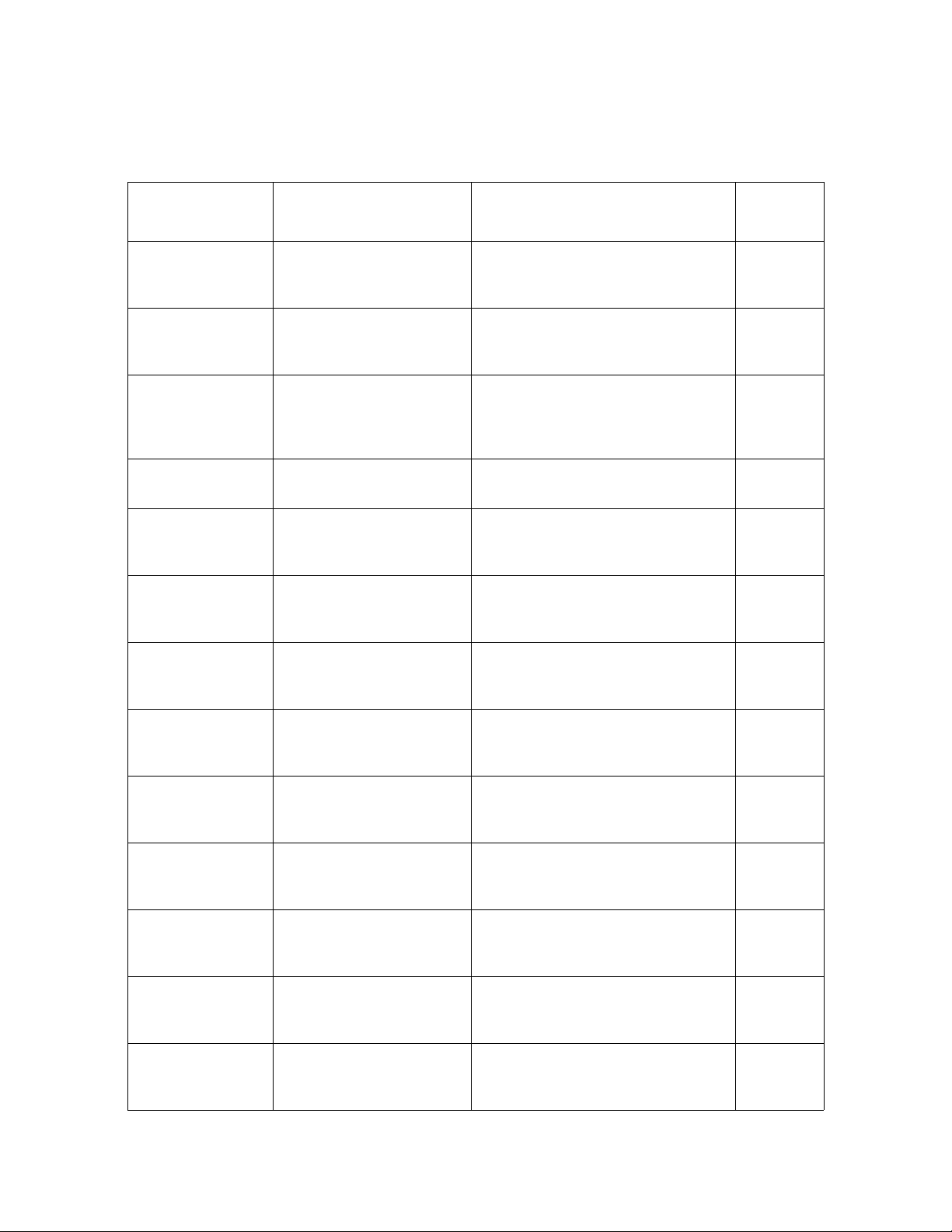

Compressor Diagnostic Codes

LCD Display Display Name Description

CPR CODE 1

LOW ENGINE

SPEED

CPR CODE 2

HIGH ENGINE

SPEED

CPR CODE 3

WAIT 30 SEC

RETRY START

CPR CODE 4

OUT OF FUEL

CPR CODE 12

FUEL LEVEL

LOW

CPR CODE 16

HIGH ENGINE

TEMP

Low Engine Speed Engine speed less than 1100

RPM for 30 seconds.

High Engine Speed Engine speed greater than 2350

RPM for 30 seconds.

Engine Crank Timeout Engine crank attempt longer

than 15 seconds above 50°F or

longer than 30 seconds below

32°F.

Out of Fuel Fuel level in tank below usable

limit.

Low Fuel Level Fuel level in tank approaching

empty.

High Engine

Temperature

Engine coolant temperature

greater than 212°F (Engine

derate begins).

Code

Type

FAULT

FAULT

FAULT

FAULT

ALERT

ALERT

CPR CODE 17

HIGH ENGINE

TEMP

CPR CODE 18

LOW OIL

PRESSURE

CPR CODE 29

ENGINE

SHUTDOWN?

CPR CODE 30

HIGH AIREND

TEMP

CPR CODE 32

AIREND DISC

TEMP SENSOR

CPR CODE 33

SEP TANK

PRES SENSOR

CPR CODE 34

HIGH PRES AT

START

High Engine

Temperature

(Shutdown)

Low Oil Pressure Low engine oil pressure. Open

Engine Shutdown

Unknown

High Airend Discharge

Temperature

Airend Discharge

Temperature Sensor

Separator Tank

Pressure Sensor

High Separator Tank

Pressure At Start

Engine coolant temperature

greater than 215°F in 3 seconds

(Engine Shutdown).

for 3 seconds.

Engine stopped without an

engine diagnostic code.

Airend discharge temperature

greater than or equal to 251°F. 3

seconds.

Airend Discharge Temperature

Sensor reading out of range.

Separator Tank Pressure

Sensor reading out of range.

Separator tank pressure greater

than 20 psi at crank attempt.

FAULT

FAULT

FAULT

FAULT

FAULT

FAULT

ALERT

46673131 Rev. A 19

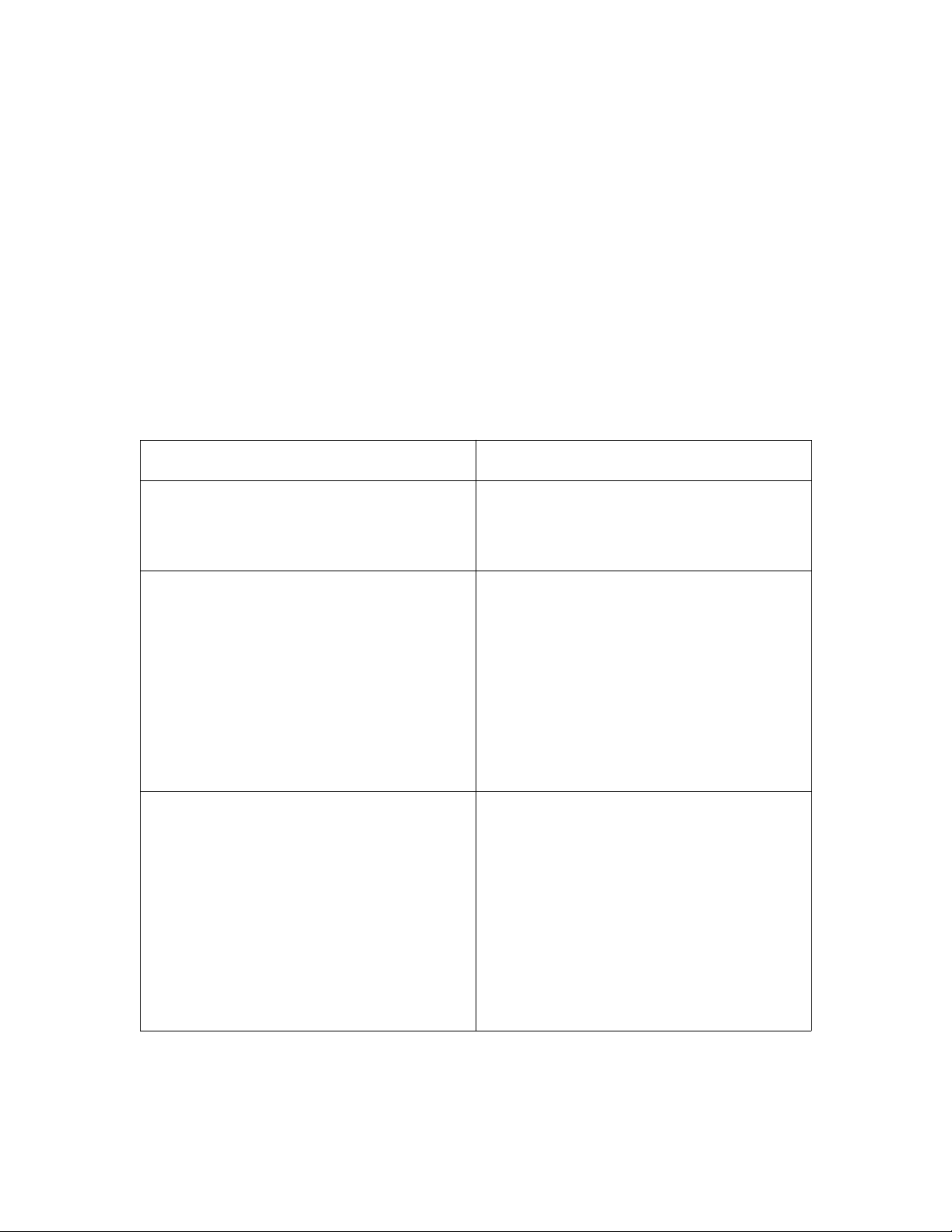

Electronic Service Manual Compressor Diagnostic Code Troubleshooting

LCD Display Display Name Description

CPR CODE 36

SAFETY V ALVE

OPEN

CPR CODE 38

AIR FILTERS

RESTRICTED

CPR CODE 39

LOW SYSTEM

VOLTAGE

CPR CODE 42

FUEL LEVEL

SENSOR

CPR CODE 50

HIGH SEP

TANK TEMP

CPR CODE 51

COMPRESSOR

ID INVALID

Safety Valve Open Safety relief valve on separator

Intake Air Filters

Restricted

Low System Voltage/

Alternator Not Charging

Fuel Level Sensor Fuel Level Sensor reading out of

High Separator Tank

Temperature

Compressor ID Invalid The Titan controller and Engine

tank opened.

Intake filters restricting air flow. ALERT

Electrical system voltage below

13.3 VDC for 30 seconds or

more.

range.

Separator tank temperature

greater than or equal to 251°F.

for 3 seconds.

T achometer with MidPort display

do not have a valid compressor

ID.

Code

Type

FAULT

ALERT

ALERT

FAULT

FAULT

CPR CODE 52

IQ FILTERS

RESTRICTED

CPR CODE 53

SEP TANK

TEMP SENSOR

CPR CODE 58

AMBIENT

TEMP SENSOR

CPR CODE 73

AUTOSTART

CTRL COMMS

CPR CODE 76

CPR CTRL

COMMS

IQ Filters Restricted IQ filters restricted past usable

level. 3 seconds.

Separator Tank

Temperature Sensor

Ambient Temperature

Sensor

AutoStart Controller

Communication

Compressor Controller

Communication

Separator Tank Temperature

Sensor reading out of range.

Ambient Temperature Sensor

reading out of range.

Communication between Titan

controller and AutoStart

controller not functional.

Communication between Titan

controller and Engine

T achometer with MidPort display

not functional.

FAULT

FAULT

ALERT

ALERT

ALERT

20 46673131 Rev. A

Compressor Diagnostic Code Troubleshooting Electronic Service Manual

COMPRESSOR CODE 1

Low Engine Speed

Explanation

The Titan controller has received an engine speed value less than 1100 RPM for

30 seconds from the engine.

Effect

Code 1 is a FAULT condition and will shut down the compressor. CPR CODE 1

LOW ENGINE SPEED will be shown on the Micro-Port display.

Troubleshooting Steps

Action Result

Step 1:

Check Micro-Port display for active

engine diagnostic codes.

Step 2:

Start and run the compressor at idle.

Check Micro-Port display to verify the

engine target (RPM). If the engine

coolant temperature is below 100°F,

the engine target (RPM) will be 1500

RPM. If the engine coolant

temperature is 100°F or above, the

engine target (RPM) will be 1400

RPM.

Step 3:

Check the engine fuel system for

restrictions.

If active engine diagnostic codes are

present, resolve the issues.

If the engine target (RPM) is 1500 for

cold idle or 1400 for hot idle, the

electronic system is commanding the

engine to run at the correct speed.

Proceed to Step 3.

If the fuel filters are dirty or have not

been changed during regular service,

replace fuel filters.

If dirty fuel has been used, add clean

fuel and replace fuel filters.

If air has gotten into the fuel system,

bleed the fuel system.

If fuel hoses are damaged, replace

fuel hoses.

46673131 Rev. A 21

Electronic Service Manual Compressor Diagnostic Code Troubleshooting

Action Result

Step 4:

If Steps 1 thru 3 checkout OK, refer to

the engine manufacturer service

dealer.

22 46673131 Rev. A

Compressor Diagnostic Code Troubleshooting Electronic Service Manual

COMPRESSOR CODE 2

High Engine Speed

Explanation:

The Titan controller has measured an engine speed value greater than 2350 RPM

for 30 seconds.

Effect:

Code 2 is a FAULT condition and will shut down the compressor. CPR CODE 2

HIGH ENGINE SPEED will be shown on the Micro-Port display.

Troubleshooting Steps

Action Result

Step 1:

Check Micro-Port display for active

engine diagnostic codes.

Step 2:

Start and run the compressor at idle.

Press the Start/Run Valve after

warmup of engine for 3 minutes or

reaching engine coolant temperature

of 150°F. Check Micro-Port display to

verify the engine target (RPM) is 2200.

Step 3:

If Steps 1 and 2 checkout OK, refer to

the engine manufacturer service

dealer.

If active engine diagnostic codes are

present, resolve the issues.

If the engine target (RPM) is 2200, the

electronic system is commanding the

engine to run at the correct speed.

Proceed to Step 3.

46673131 Rev. A 23

Electronic Service Manual Compressor Diagnostic Code Troubleshooting

COMPRESSOR CODE 3

Engine Crank Timeout

Explanation:

The electronic system has attempted to start the compressor longer than 15

seconds above 50°F ambient or longer than 30 seconds below 32°F ambient.

Effect:

Code 3 is a FAULT condition and will prevent further cranking. CPR CODE 3 WAIT

30 SEC RETRY START will be shown on the Micro-Port display. Operator must

wait 30 seconds before electronic system will allow another start attempt.

Troubleshooting Steps

Action Result

Step 1:

Wait 30 seconds before attempting to

start compressor.

Step 2:

Check the engine fuel system for

restrictions.

Step 3:

If ambient temperature is below 10°F,

verify Cold Weather Kit is functioning

(if equipped).

After 30 seconds, the electronic

system will allow another 15 or 30

second start attempt depending on

ambient temperature.

If the fuel filters are dirty or have not

been changed during regular service,

replace fuel filters.

If dirty fuel has been used, add clean

fuel and replace fuel filters.

If air has gotten into the fuel system,

bleed the fuel system.

If fuel hoses are damaged, replace

fuel hoses.

If Cold Weather Kit is not functioning,

repair as needed.

If Cold Weather Kit is not installed, it is

required to start compressor in

ambient temperatures below 10°F.

24 46673131 Rev. A

Compressor Diagnostic Code Troubleshooting Electronic Service Manual

COMPRESSOR CODE 4

Out Of Fuel

Explanation:

The Titan controller has detected a condition from U1 Fuel Level Sensor indicating

the fuel level in the tank is below a usable limit.

Effect:

Code 4 is a FAULT condition and will shut down the compressor. CPR CODE 4

OUT OF FUEL will be displayed on the Micro-Port display.

Troubleshooting Steps

Action Result

Step 1:

Check fuel level in tank.

Step 2:

Check all harness connections

between Titan and U1 Fuel Level

Sensor.

Step 3:

Remove fuel level sensor from fuel

tank. With the fuel level sensor

connected to the harness, turn the

sensor upside down so float will go to

the top. Turn the Keyswitch to the ON

position to energize the compressor

electronic system. Verify the fuel level

on the gauge is FULL and CPR CODE

4 clears from the Micro-Port display.

Step 4:

With the fuel level sensor still removed

from the tank and the compressor

electronic system energized, tilt the

fuel sensor so the float will move

down. Verify the fuel level gauge is

moving down the scale.

If the fuel level is low, add fuel.

If harness connections are loose or

damaged, repair harness as needed.

If CPR CODE 4 clears and the fuel

level gauge shows FULL, the fuel level

sensor is operating properly.

If CPR CODE 4 does not clear and the

fuel level gauge shows EMPTY,

replace U1 Fuel Level Sensor.

If the float in the fuel level sensor

appears to be sticking while moving,

replace U1 Fuel Level Sensor.

46673131 Rev. A 25

Electronic Service Manual Compressor Diagnostic Code Troubleshooting

Action Result

Step 5:

If Step s 1 thru 4 checkout OK, replace

Titan controller.

26 46673131 Rev. A

Compressor Diagnostic Code Troubleshooting Electronic Service Manual

COMPRESSOR CODE 12

Low Fuel Level

Explanation:

The Titan controller has detected a condition from U1 Fuel Level Sensor indicating

the fuel level in the tank is approaching empty.

Effect:

Code 12 is an ALERT condition and will not shut down the compressor. CPR

CODE 12 FUEL LEVEL LOW will be shown on the Micro-Port display.

Troubleshooting Steps

Action Result

Step 1:

Check fuel level in tank.

Step 2:

Check all harness connections

between Titan and U1 Fuel Level

Sensor.

Step 3:

Remove fuel level sensor from fuel

tank. With the fuel level sensor

connected to the harness, turn the

sensor upside down so float will go to

the top. Turn Keyswitch to the ON

position to energize the compressor

electronic system.Verify the fuel level

on the gauge is FULL and CPR CODE

12 clears from the Micro-Port display.

Step 4:

With the fuel level sensor still removed

from the tank and the compressor

electronic system energized, tilt the

fuel sensor so the float will move

down. Verify the fuel level gauge is

moving down the scale.

If the fuel level is low, add fuel.

If harness connections are loose or

damaged, repair harness as needed.

If CPR CODE 12 clears and the fuel

level gauge shows FULL, the fuel level

sensor is operating properly.

If CPR CODE 12 does not clear and

the fuel level gauge shows EMPTY,

replace U1 Fuel Level Sensor.

If the float in the fuel level sensor

appears to be sticking while moving,

replace U1 Fuel Level Sensor.

46673131 Rev. A 27

Loading...

Loading...