Page 1

DOOSAN PUMA MX Series

FANUC Series 31i-Model A5

Programming Examples Manual

tim.markoski@gmail.com

Revision

(0

2012)

2.1

7/17/

Page 2

- 1 -

DISCLAIMER OF WARRANTY:

This user manual and the accompanying files are sold or supplied "as is" and without warranties as to

performance of merchantability or any other Warranties whether expressed or implied.

While every effort has been made to verify the accuracy of the content provided, it is the responsibility

of those programming and operating Doosan MX Series Multi-Tasking CNC Machining Centers to

abide by standards of safe programming, setup and operation of any CNC Machine Tool.

Because the various machine configurations, programming methods, individual work pieces and

setup/operator skill levels all effect the actual operation of the machine,

NO WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE IS OFFERED.

The user must assume the entire risk of using the information provided in this manual and

accompanying files.

Any typographical errors should be brought to the attention of AmTTech immediately.

South Texas

10010 Houston Oaks Dr.

Houston, TX 77064

(832) 912-2000

North Texas

3301 Pleasant Valley Ln.

Arlington, TX 76015

(832) 912-2000

Service & Support

Service Support Center: (888) 823-2967

Page 3

- 2 -

TABLE OF CONTENTS

Standard Turning

Pg 3

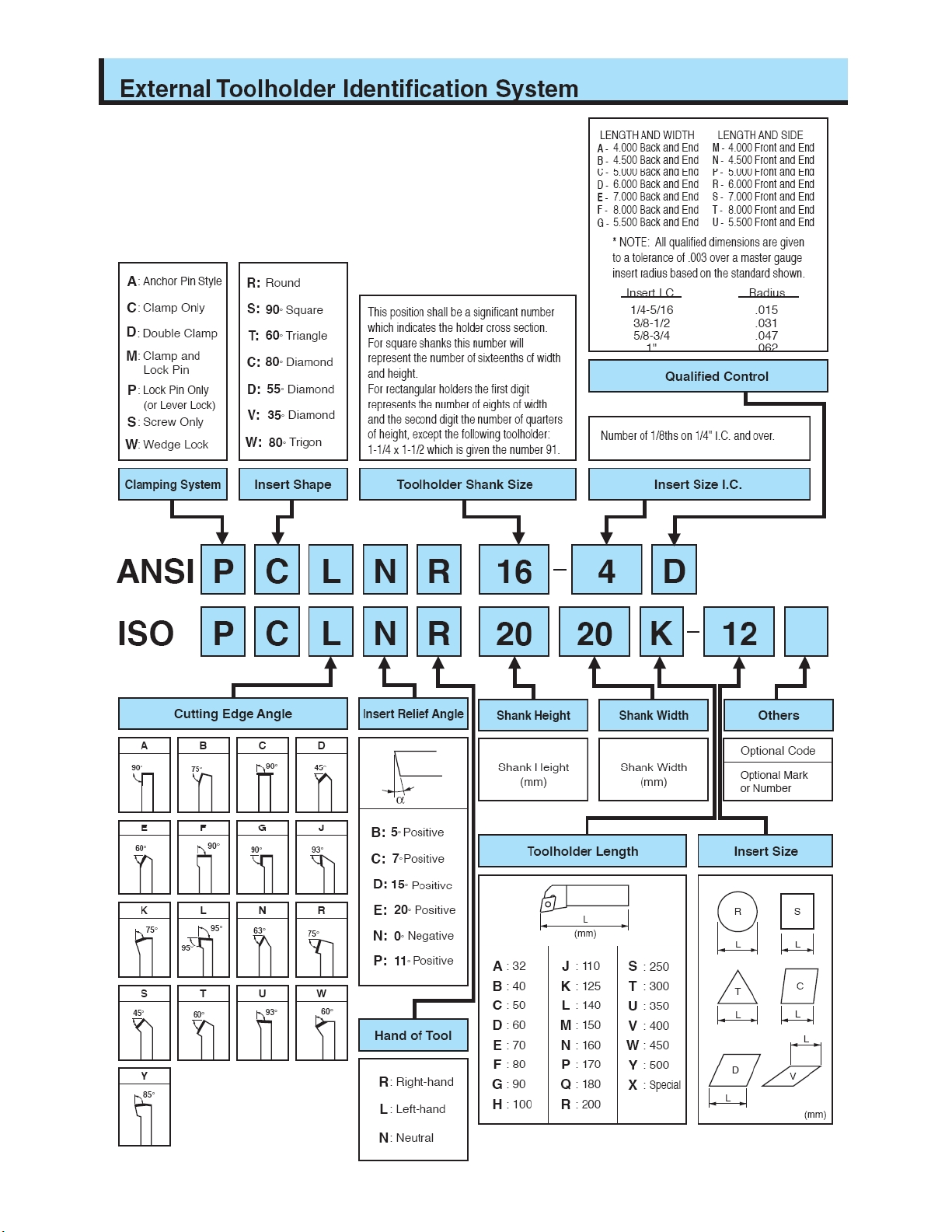

ANSI/ISO Holder Identification Pg 4

Insert Identification Pg 5

B-Axis Spindle Function – G490 Pg 9

Programming Example #1 - Upper Pg 10

Programming Example #2 - Lower Pg 13

Pinch Turning

Pg 16

Programming Example #3 – Upper & Lower Pg 17

Simultaneous Turning

Pg 20

Programming Example #4 - Upper & Lower w/Part Transfer Pg 20

Advanced Turning

Pg 25

B-Axis Spindle Function – G400 Pg 26

Programming Example #5 - Upper Pg 28

Programming Example #6 - Upper Pg 31

Advanced Drilling

Pg 34

Programming Example #7 - Upper Pg 34

Programming Example #8 - Upper Pg 36

Programming Example #9 - Upper Pg 38

B-Axis Spindle Tilt Function – G368/G369

- Upper Pg 40

Programming Example #10 - Upper Pg 41

Advanced Milling

Pg 43

Programming Example #11 – Upper (C-Axis/Y-Axis) Pg 43

Programming Example #12 – Upper (C-Axis) Pg 46

Advanced 5-Axis Operations

Pg 51

Programming Example #13 – Upper (5-Axis Milling) Pg 51

Doosan TCP Mode for 5-Axis Machining G700/G701

Pg 53

CAM System Post-Processor Information Pg 55

APT Cutter Location File Generated by CAM System

Pg 56

NC Code File Generated by CAM System Post-Processor

Pg 61

Miscellaneous

Pg 66

Servo Driven Tail Stock Pg 66

Macro-B OD Jaw Program Pg 66

Page 4

- 3 -

DOOSAN PUMA MX Series – Standard Turning

The Doosan Puma MX Series is a powerful Multi-Task Machining Center.

Its core is built upon the concepts a standard CNC Turning Center.

As such, it handles standard CNC Turning quite well.

The basic differences in programming are not in the tool path motion but in the following:

Preparation and positioning before a Turning Operation

Tool Changes and Offsets

End of an Operation/Preparation for the next operation.

By standardizing the NC Code data in these areas, we can come up with a basic skeleton or outline

for all machining operations. This standardization will aid in the creation of a Post-Processor for any

given CAM system that a user may have for generating NC programs.

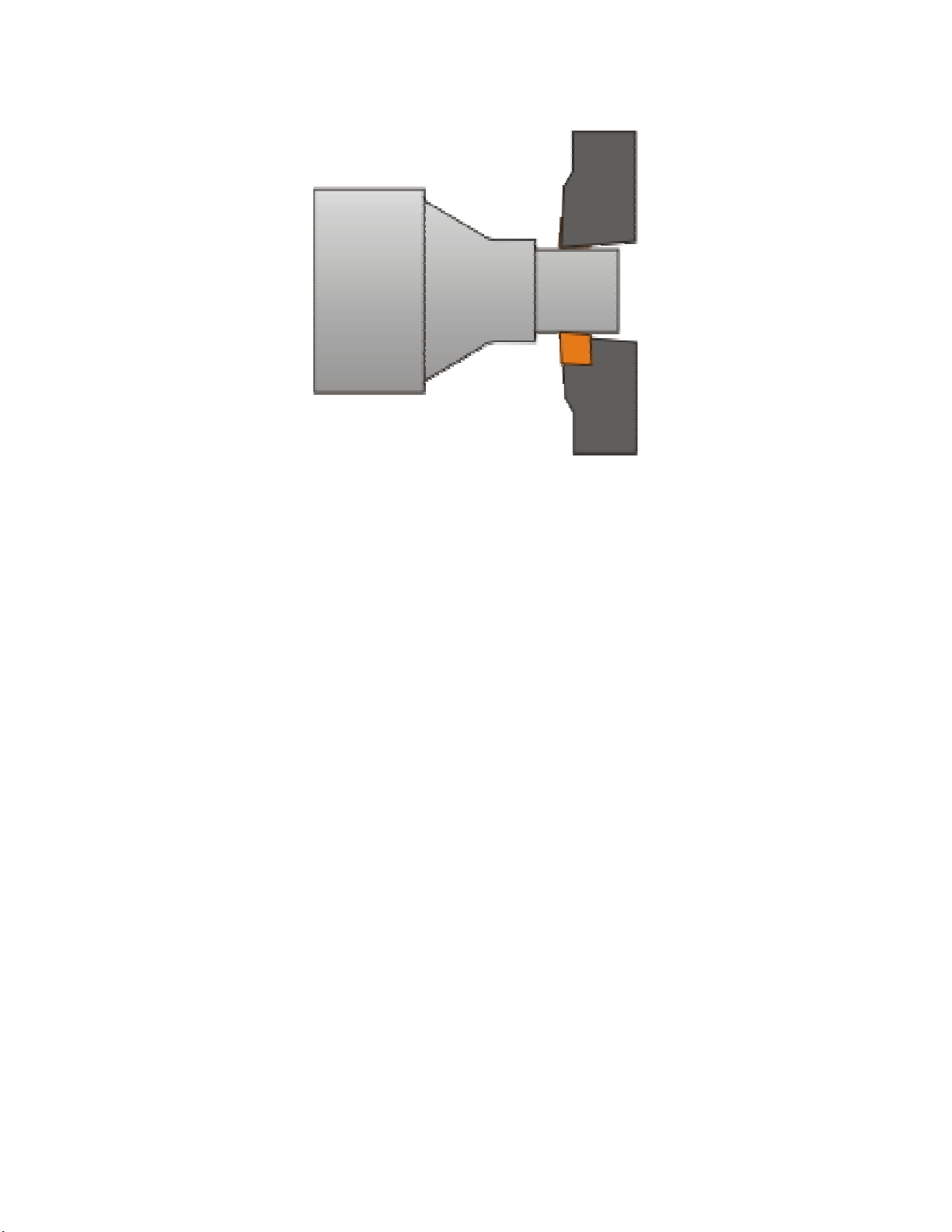

As ANSI/ISO Stick Tooling is well established for CNC Turning Operations, the first four examples in

this user manual will be using this standard stick tooling along with the proper CAPTO® C6 holder

and adapters for that tooling.

As all Doosan Puma MX Series Multi-Task Machining Center have the common element of the

Nutating B-Axis Head, our first standard turning example will be done using the B-Axis Head for all

operations. We will then progress to using the Lower Turret independently and then integrate it into

synchronized operations using both the Upper B-Axis Head and the Lower Turret.

Page 5

- 4 -

Page 6

- 5 -

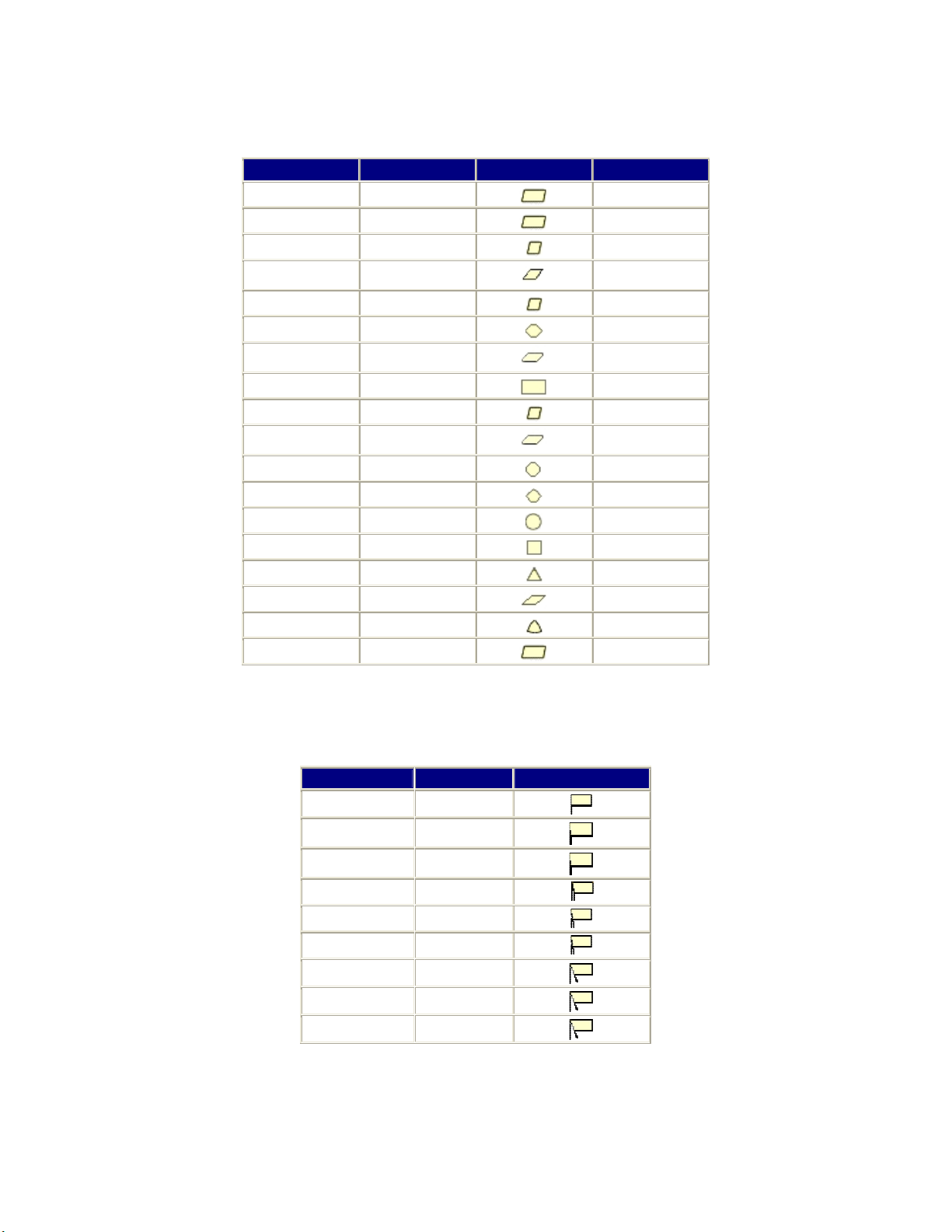

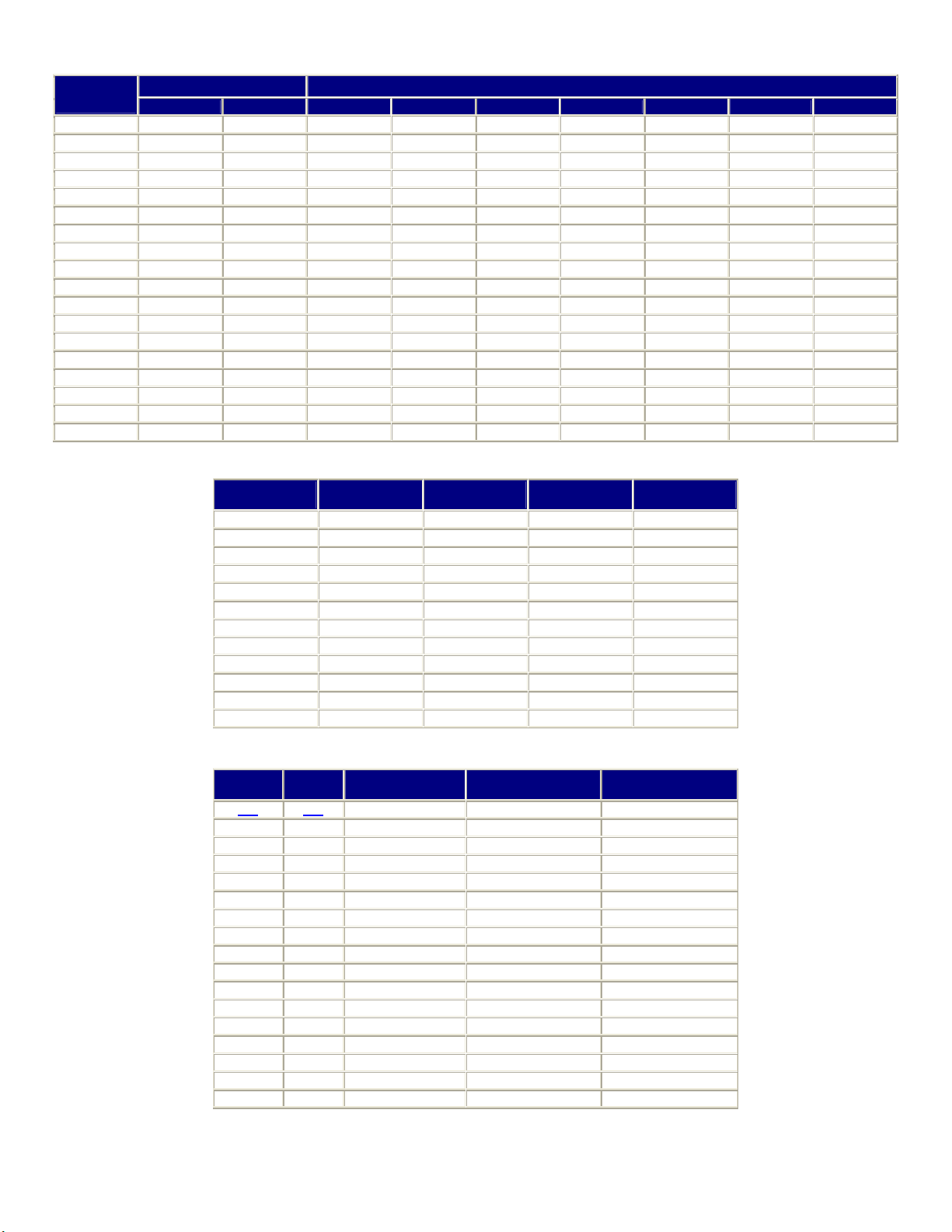

Insert Designation Chart

Shape

(e.g. "CNMG432" / "CCMT32.51")

Code Letter

Description

Diagram

Nose Angle

A

85° parallelogram

85°

B

82° parallelogram

82°

C

80° diamond

80°

D

55° diamond

55°

E

75° diamond

75°

H

hexagon

120°

K

55° parallelogram

55°

L

rectangle

90°

M

86° diamond

86°

N

55° parallelogram

55°

O

octagon

135°

P

pentagon

108°

R

round

full radius

S

square

90°

T

triangle

60°

V

35° diamond

35°

W

trigon

80°

X

sp. parallelogram

85°

Clearance or Relief Angle

(e.g. "CNMG432" / "CCMT32.51")

Code Letter

Angle

Diagram

N

0°

A

3°

B

5°

C

7°

P

11°

D

15°

E

20°

F

25°

G

30°

Page 7

- 6 -

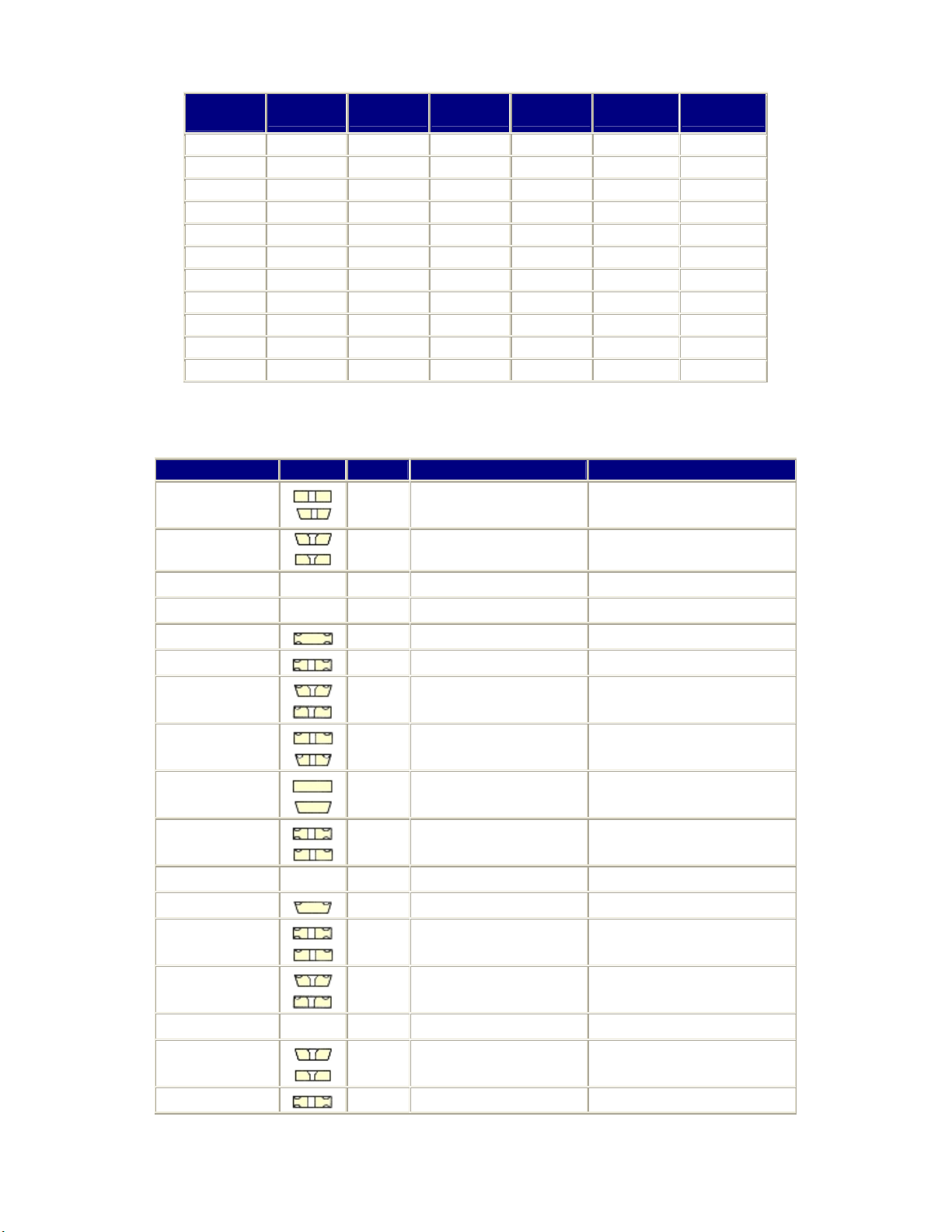

Tolerance

(e.g. "CNMG432" / "CCMT32.51")

Code

Letter

Cornerpoint

(inches)

Thickness

(inches)

Inscribed

Circle (in)

Cornerpoint

(mm)

Thickness

(mm)

Inscribed

Circle (mm)

A

.0002"

.001"

.001"

.005mm

.025mm

.025mm

C

.0005"

.005"

.001"

.013mm

.025mm

.025mm

E

.001"

.001"

.001"

.025mm

.025mm

.025mm

F

.0002"

.005"

.0005"

.005mm

.025mm

.013mm

G

.001"

.001"

.001"

.025mm

.13mm

.025mm

H

.0005"

.001"

.0005"

.013mm

.025mm

.013mm

J

.002"

.001"

.002-.005"

.005mm

.025mm

.05-.13mm

K

.0005"

.001"

.002-.005"

.013mm

.025mm

.05-.13mm

L

.001"

.001"

.002-.005"

.025mm

.025mm

.05-.13mm

M

.002-.005"

.005"

.002-.005"

.05-.13mm

.13mm

.05-.15mm

U

.005-.012"

.001"

.005-.010"

.06-.25mm

.13mm

.08-.25mm

Hole / Chipbreaker

(e.g. "CNMG432" / "CCMT32.51")

Code Letter

Diagram

Hole

Hole Shape

Chipbreaker Type

A

Yes

Cylindrical

None

B

Yes

70-90° double countersink

None

D

Yes

Cylindrical

None

E

No

None

F

No

Double-sided

G

Yes

Cylindrical

Double-sided

H

Yes

70-90° single countersink

Single-sided

M

Yes

Cylindrical, or dbl countersink

Single-sided

N

No

None

P

Yes

Cylindrical

Hi-double positive

Q

Yes

40-60° double countersink

None

R

No

Single-sided

S

Yes

Cylindrical

Hi-double positive

T

Yes

40-60° double countersink

Single-sided

U

Yes

40-60° double countersink

Double-sided

W

Yes

40-60° double countersink

None

Z

Yes

Cylindrical

Double-sided hi-double positive

Page 8

- 7 -

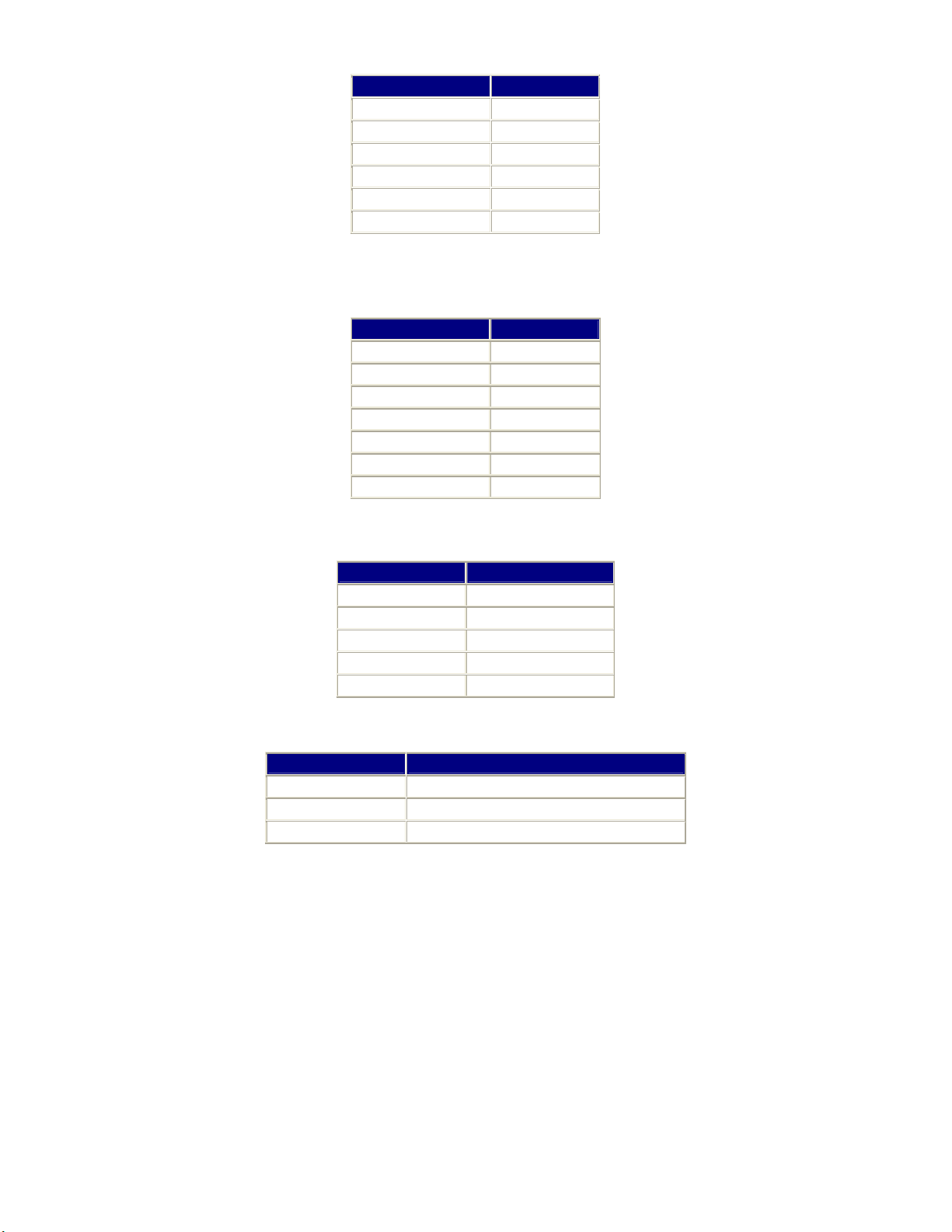

Size

(e.g. "CNMG432" / "CCMT32.51")

Inscribed Circle Size

ISO Code No. (metric cutting edge length) by shape code letter of insert

ANSI

Code No.

decimal in.

fractional in.

CDRSTVW

0.5

.0625"

1/16

1.2

.15625"

5/32

1.5

.1875"

3/16

04 (4mm)

5mm

04 (4mm)

04 (4mm)

8mm

8mm

S3

1.8

.21875"

7/32

2

.25"

1/4

06 (6mm)

07 (7mm)

06 (6mm)

06 (6mm)

11 (11mm)

11 (11mm)

04 (4mm)

2.5

.3125"

5/16

08 (8mm)

9mm

07 (7mm)

07 (7mm)

13 (13mm)

13 (13mm)

05 (5mm)

3

.375"

3/8

09 (9mm)

11 (11mm)

09 (9mm)

09 (9mm)

16 (16mm)

16 (16mm)

06 (6mm)

3.5

.4375"

7/16

11mm

13mm

11 (11mm)

11 (11mm)

19 (19mm)

19mm

7mm

4

.5"

1/2

12 (12mm)

15 (15mm)

12 (12mm)

12 (12mm)

22 (22mm)

22 (22mm)

08 (8mm)

4.5

.5625"

9/16

14mm

17mm

14 (14mm)

14 (14mm)

24mm

24mm

9mm

5

.625"

5/8

16 (16mm)

19 (9mm)

15 (15mm)

15 (15mm)

27 (27mm)

27 (27mm)

10 (10mm)

5.5

.6875"

11/16

17mm

21mm

17 (17mm)

17 (17mm)

30mm

30mm

11mm

6

.75"

3/4

19 (19mm)

23 (23mm)

19 (19mm)

19 (19mm)

33 (33mm)

33 (33mm)

13 (13mm)

6.5

.8125"

13/16

7

.875"

7/8

22mm

27mm

22 (22mm)

22 (22mm)

38mm

38mm

15mm

81"1

25 (25mm)

31 (31mm)

25 (25mm)

25 (25mm)

44 (44mm)

44 (44mm)

17 (17mm)

10

1.25"

1-1/4

32 (32mm)

38mm

31 (31mm)

31 (31mm)

54 (54mm)

54 (54mm)

21 (21mm)

1.26"

32 (32mm)

Thickness

(e.g. "CNMG432" / "CCMT3

2.5

1")

ANSI

Code No.

ISO

Code No.

Decimal

Value

Fractional

Value

Millimeter

Value

1010.0625"

1/16

1.59mm

T1

0.078"

5/64

1.98mm

1.5020.094"

3/32

2.38mm

T2

0.109"

7/64

2.78mm

2030.125"

1/8

3.18mm

2.5T30.156"

5/32

3.97mm

3040.187"

3/16

4.76mm

05

0.219"

7/32

5.56mm

4060.25"

1/4

6.35mm

5070.313"

5/16

7.9mm

6090.375"

3/8

9.53mm

8

0.5"

1/2

12.7mm

Radius

(e.g. "CNMG432" / "CCMT32.51")

ANSI

Code No.

ISO

Code No.

Decimal

Value

Fractional

Value

Millimeter

Value

Null

Null

Wiper flat

Wiper flat

Wiper flat

VM0000

0.2000.004"

0.1mm

X

0.004"

0.1mm

0.5

0.008"

0.2mm

0000.008"

0.2mm

Y

0.008"

0.2mm

1040.016"

1/64

0.4mm

05

0.020"

0.5mm

2080.031"

1/32

0.8mm

10

0.040"

1.02mm

3120.047"

3/64

1.2mm

4160.062"

1/16

1.6mm

5200.078"

5/64

2mm

6240.094"

3/32

2.4mm

7290.109"

7/64

2.9mm

8320.125"

1/8

3.2mm

Page 9

- 8 -

Wiper Lead Angle

(e.g. "SEKN42AFTN")

Code Letter

Angle

A

45°

D

60°

K

60°

E

75°

L

75°

P

0°

Wiper Clearance Angle

(e.g. "SEKN42AFTN")

Code Letter

Angle

C

7°

D

15°

E

20°

F

25-26°

G

30°

N

0°

P

11°

Cutting Edge Preparation

(e.g. "SEKN42AFTN")

Code Letter

Edge Preparation

F

sharp

E

honed

T

T-land

S

honed T-land

X

special chamfer

Cutting Direction

(e.g. "SEKN42AFTN")

Code Letter

Direction

R

right-hand cutting only

L

left-hand cutting only

N

both right-hand and left-hand cutting

Page 10

- 9 -

B-Axis Spindle Function - G490

Automatic Milling Spindle Orientation

(G490)

The B-Axis Head Spindle contains a curvic-coupling on the front

face.

This allows for the possible indexing of the milling spindle in 30˚ increments.

The Doosan Puma MX series has two functions in commanding for milling spindle

orientation.

The G490 function automatically unclamps the milling spindle and orients to the designated

degree of rotation. After orientation, t h e milling spindle is automatically

clamped.

The other function (M279) is needed to command unclamping (M101) for the milling

spindle

before commanding orientation and to command clamping (M100) after

commanding

orientation. But this is only for maintenance by an authorized Service Engineer

.

Command

Format

G490 S

G490

: automatic milling spindle orientation

command

S

: orientation degree of milling

spindle

S0

→0˚

S300

→30˚

S1800→180

˚

S3600→360

˚

Note:

G490 S0 is automatically invoked during a Tool Change Sequence.

It is not required to command G49 S0 prior to a Tool Change Sequence.

However, all examples using the B-Axis Head will show this commanded explicitly

for clarity.

Page 11

- 10 -

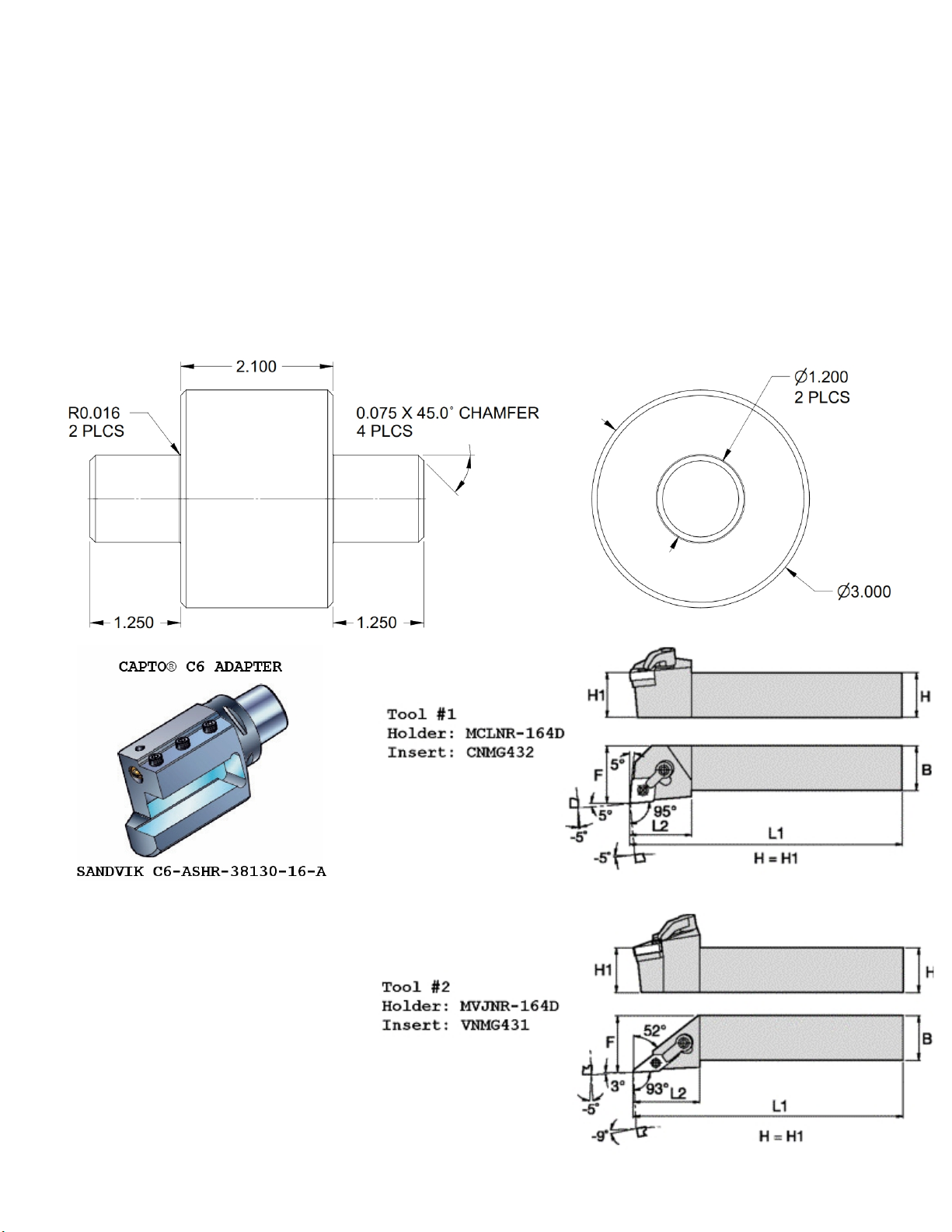

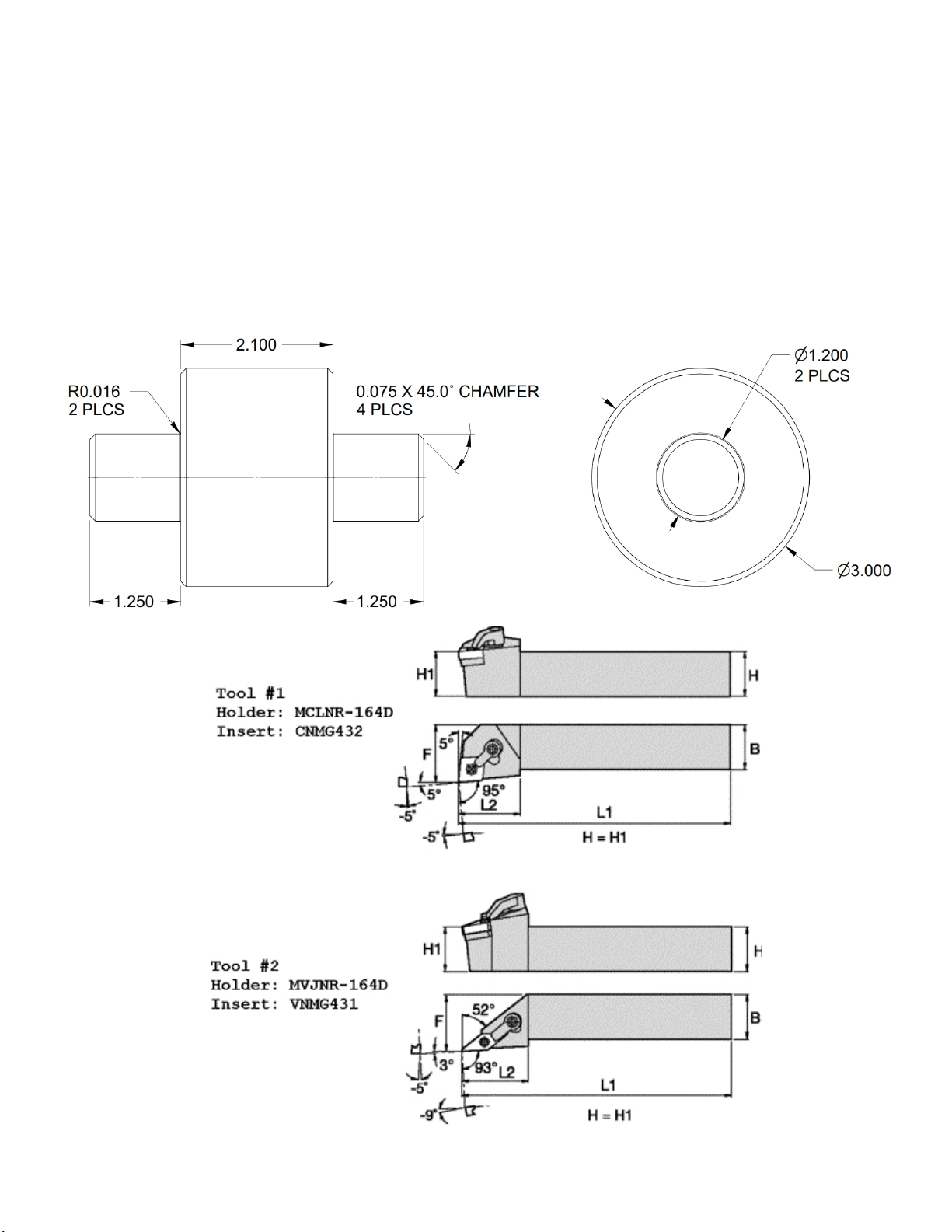

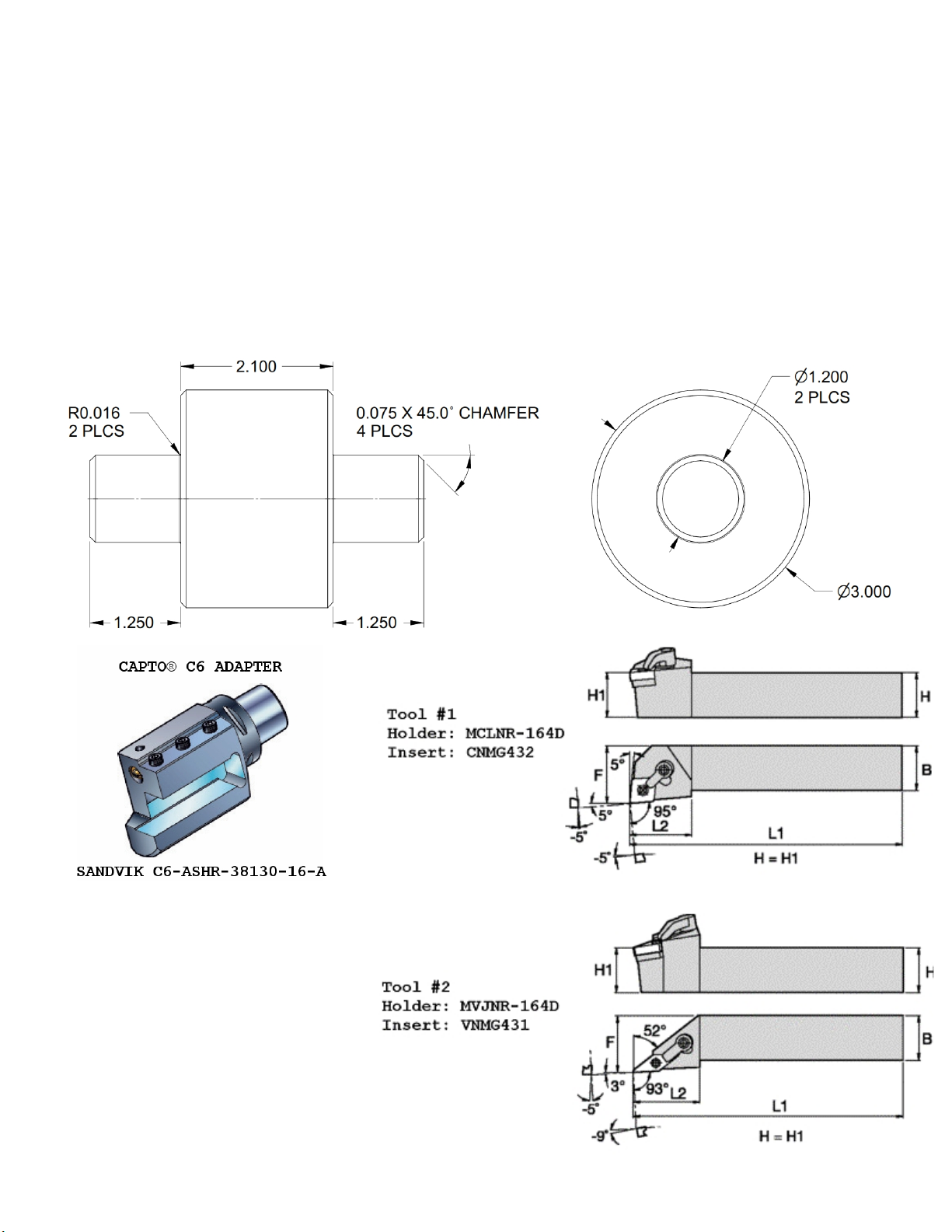

EXAMPLE #1 – STANDARD TURNING – UPPER UNIT ONLY

MATERIAL : AISI 4140 ALLOY STEEL - 275 HB

STOCK : 3.5 DIA ROUND BAR X 4.85 LONG

PROJECTION: 2.5 MINIMUM FROM JAW FACE

ADAPTERS : SANDVIK C6-ASHR-38130-16-A (2)

HOLDERS : MCLNR-164D (1), MVJNR-164D (1)

INSERTS : CNMG-432 (1), VNMG-431 (1)

SPINDLE : LEFT MAIN

WORK COORD: G54

ORIGIN : X0.0 = SPINDLE CENTERLINE, Z0.0 = FINISHED FACE

PROCESS : FACE, ROUGH & FINISH TURN HALF OF PART

Page 12

- 11 -

%

O0001(MX-EXAMPLE #1 – UPPER UNIT ONLY)

(PREPARATION FOR START OF PROGRAM)

(INITIALIZE - RAPID, ZX PLANE, TNR COMP CANCEL, TLO CANCEL, CYCLE CANCEL, UPR FEED)

N1 G00 G18 G40 G49 G80 G99

N2 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N3 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N4 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N5 G490 S0 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL CHANGE)

N6 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N7 M01

(PREPARATION FOR START OF OPERATION)

N8 G54 (WORK COORDINATE SELECTION)

N9 M06 T01001 (SANDVIK C6-ASHR-38130-16-A - MCLNR-164D - CNMG432)

N10 T02000 (STAGE NEXT TOOL)

N11 G490 S0 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL)

N12 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N13 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N14 M138 (SHOWER BED COOLANT ON)

N15 M126 (COOLANT THROUGH TOOL ON)

N16 M34 (LEFT SPINDLE C-AXIS MODE OFF)

N17 M261 (SPINDLE WINDING LOW - REPLACES M41)

N18 G50 S2500 (MAXIMUM RPM CAP)

N19 G96 S500 M03 P11 (CONSTANT CUTTING SPEED MODE - 500 FPM - LEFT SPINDLE CLOCKWISE)

(FACE = ROUGH & FINISH)

N20 G00 X3.7 Z0.01

N21 G01 X-0.0625 F0.018

N22 G00 Z0.11

N23 X3.7

N24 Z0.0

N25 G01 X-0.0625 F0.01

N26 G00 Z0.1

(OD CANNED ROUGH)

N27 G00 X3.5

N28 G00 Z0.0615

N29 G71 U0.125 R0.03

N30 G71 P31 Q40 U0.02 W0.01 F0.018

N31 G00 X0.8903

N32 G01 X1.1817 Z-0.0842

N33 G03 X1.2 Z-0.1063 R0.0313

N34 G01 Z-1.125

N35 G01 X2.7875

N36 G03 X2.8317 Z-1.1342 R0.0313

N37 G01 X2.9817 Z-1.2092

N38 G03 X3.0 Z-1.2313 R0.0313

N39 G01 Z-2.225

N40 G01 X3.5

N41 G00 Z0.1

(TOOL CHANGE PREPARATION)

N42 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N43 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N44 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N45 T01000 (CANCEL OFFSET FOR CURRENT TOOL)

N46 M139 (SHOWER BED COOLANT OFF)

N47 M127 (COOLANT THROUGH TOOL OFF)

N48 M05 P11 (LEFT SPINDLE STOP)

N49 G490 S0 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL CHANGE)

N50 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N51 M01

Page 13

- 12 -

(PREPARATION FOR START OF OPERATION)

N52 G54 (WORK COORDINATE SELECTION)

N53 M06 T02002 (SANDVIK C6-ASHR-38130-16-A - MVJNR-164D - VNMG431)

N54 T01000 (STAGE NEXT TOOL)

N55 G490 S0 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL)

N56 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N57 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N58 M126 (COOLANT THROUGH TOOL ON)

N59 M34 (LEFT SPINDLE C-AXIS MODE OFF)

N60 M262 (SPINDLE WINDING HIGH- REPLACES M42)

N61 G50 S2500 (MAXIMUM RPM CAP)

N62 G96 S600 M03 P11 (CONSTANT CUTTING SPEED MODE - 600 FPM - LEFT SPINDLE CLOCKWISE)

(OD FINISH)

N63 G00 X3.5 Z0.1

N64 X1.0408 Z0.0661

N65 G01 X0.9701 Z0.0308 F0.006

N66 X1.1908 Z-0.0796

N67 G03 X1.2 Z-0.0906 R0.0156

N68 G01 Z-1.125

N69 X2.8187

N70 G03 X2.8408 Z-1.1296 R0.0156

N71 G01 X2.9908 Z-1.2046

N72 G03 X3.0 Z-1.2156 R0.0156

N73 G01 Z-2.205

N74 X3.0707 Z-2.1697

N75 G00 X3.5 Z0.1

(END PROGRAM/TOOL CHANGE PREPARATION)

N76 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N77 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N78 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N79 T02000 (CANCEL OFFSET FOR CURRENT TOOL)

N80 M139 (SHOWER BED COOLANT OFF)

N81 M127 (COOLANT THROUGH TOOL OFF)

N82 M05 P11 (LEFT SPINDLE STOP)

N83 G490 S0 (EXPLICIT SPINDLE ORIENTATION FOR TOOL CHANGE)

N84 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N85 M30

%

Page 14

- 13 -

EXAMPLE #2 – STANDARD TURNING – LOWER UNIT ONLY

MATERIAL : AISI 4140 ALLOY STEEL - 275 HB

STOCK : 3.5 DIA ROUND BAR X 4.85 LONG

PROJECTION: 2.5 MINIMUM FROM JAW FACE

ADAPTERS : N/A

HOLDERS : MCLNR-164D (1), MVJNR-164D (1)

INSERTS : CNMG-432 (1), VNMG-431 (1)

SPINDLE : LEFT MAIN

WORK COORD: G54

ORIGIN : X0.0 = SPINDLE CENTERLINE, Z0.0 = FINISHED FACE

PROCESS : FACE, ROUGH & FINISH TURN HALF OF PART

Page 15

- 14 -

%

O0002(MX-EXAMPLE #2 - LOWER)

(PREPARATION FOR START OF PROGRAM)

(INITIALIZE - RAPID, ZX PLANE, TNR COMP CANCEL, CYCLE CANCEL, UPR FEED)

N1 G00 G18 G40 G80 G99

N2 G00 G28 U0.0 (ZERO RETURN X-AXIS)

N3 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

(PREPARATION FOR START OF OPERATION)

N4 G54 (WORK COORDINATE SELECTION)

N5 T01001 (MCLNR-164D - CNMG432)

N6 M138 (SHOWER BED COOLANT ON)

N7 M08 (COOLANT ON)

N8 M34 (LEFT SPINDLE C-AXIS MODE OFF)

N9 M261 (SPINDLE WINDING LOW - REPLACES M41)

N10 G50 S2500 (MAXIMUM RPM CAP)

N11 G96 S500 M03 P11 (CONSTANT CUTTING SPEED MODE - 500 FPM - LEFT SPINDLE CLOCKWISE)

(FACE = ROUGH & FINISH)

N12 G00 X3.7 Z0.01

N13 G01 X-0.0625 F0.018

N14 G00 Z0.11

N15 X3.7

N16 Z0.

N17 G01 X-0.0625 F0.01

N18 G00 Z0.1

(OD CANNED ROUGH)

N19 G00 X3.5

N20 G00 Z0.0615

N21 G71 U0.125 R0.03

N22 G71 P23 Q32 U0.02 W0.01 F0.018

N23 G00 X0.8903

N24 G01 X1.1817 Z-0.0842

N25 G03 X1.2 Z-0.1063 R0.0313

N26 G01 Z-1.125

N27 G01 X2.7875

N28 G03 X2.8317 Z-1.1342 R0.0313

N29 G01 X2.9817 Z-1.2092

N30 G03 X3.0 Z-1.2313 R0.0313

N31 G01 Z-2.225

N32 G01 X3.5

N33 G00 Z0.1

(TOOL CHANGE PREPARATION)

N34 G00 G28 U0.0 (ZERO RETURN X-AXIS)

N35 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N36 T01000 (CANCEL OFFSET FOR CURRENT TOOL)

N37 M139 (SHOWER BED COOLANT OFF)

N38 M09 (COOLANT THROUGH TOOL OFF)

N39 M05 P11 (LEFT SPINDLE STOP)

N40 M01

(PREPARATION FOR START OF OPERATION)

N41 G54 (WORK COORDINATE SELECTION)

N42 T02002 (MVJNR-164D - VNMG431)

N43 M08 (COOLANT ON)

N44 M34 (LEFT SPINDLE C-AXIS MODE OFF)

N45 M262 (SPINDLE WINDING HIGH- REPLACES M42)

N46 G50 S2500 (MAXIMUM RPM CAP)

N47 G96 S600 M03 P11 (CONSTANT CUTTING SPEED MODE - 600 FPM - LEFT SPINDLE CLOCKWISE)

Page 16

- 15 -

(OD FINISH)

N48 G00 X3.5 Z0.1

N49 X1.0408 Z0.0661

N50 G01 X0.9701 Z0.0308 F0.006

N51 X1.1908 Z-0.0796

N52 G03 X1.2 Z-0.0906 R0.0156

N53 G01 Z-1.125

N54 X2.8187

N55 G03 X2.8408 Z-1.1296 R0.0156

N56 G01 X2.9908 Z-1.2046

N57 G03 X3.0 Z-1.2156 R0.0156

N58 G01 Z-2.205

N59 X3.0707 Z-2.1697

N60 G00 X3.5 Z0.1

(END PROGRAM/TOOL CHANGE PREPARATION)

N61 G00 G28 U0.0 (ZERO RETURN X-AXIS)

N62 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N63 T02000 (CANCEL OFFSET FOR CURRENT TOOL)

N64 M139 (SHOWER BED COOLANT OFF)

N65 M09 (COOLANT THROUGH TOOL OFF)

N66 M05 P11 (LEFT SPINDLE STOP)

N67 T12000 (INDEX TO EMPTY TOOL FOR LOWER TURRET CHUCK CLEARANCE)

N68 G00 G54 Z0.0 (POSITION LOWER TURRET FOR WORKING ENVELOPE CLEARANCE)

N69 M30

%

Page 17

- 16 -

PINCH TURNING – SYNCHRONIZED UPPER & LOWER

Pinch Turning

is a way to employ 2 independent and opposing tools on a CNC lathe in order to cut

more quickly. When Pinch Turning, one tool follows 180° of spindle rotation behind the other.

Each opposing tool is only engaged in the cut for 180° of spindle rotation.

The Doosan Puma MX Series T & ST configurations fully support Pinch Turning.

The feed rate that is calculated for each tool is doubled.

The tools cut at the same time but are 180° out of phase so that the amount of time needed for the

Pinch Turned Operation is 50% less than a standard turning operation.

The tools used in Pinch Turning must be identical in configuration.

The opposing tools should both share the same orientation (Right or Left Handed), clearance and

relief angles, and most importantly, the inserts used must be identical.

Pinch Turning is also referred to as Balanced Turning.

It can be used for either roughing or finishing.

With Pinch Turning, both the opposing tools use the same programmed path.

However, each program is independent and is a separate control system.

These different control systems are typical classified as Upper & Lower and are synchronized during

automatic operation. This synchronization is achieved by the use of Wait Codes (M900-M999) that

are placed strategically within the NC code. A Wait Code is included on a line of NC Code where we

wish to begin the synchronization. The same wait code is placed at the corresponding point in the NC

Code for the opposing tool. When the Upper and Lower Control Systems reach the same point, both

Upper and Lower Tools will begin their motion at the same time.

If either Control System reaches a Wait Code before the other Control System, that Control System

will wait for the other system to “catch up” before beginning synchronized operations.

Page 18

- 17 -

EXAMPLE #3 – STANDARD TURNING – SYNCHRONIZED UPPER & LOWER

MATERIAL : AISI 4140 ALLOY STEEL - 275 HB

STOCK : 3.5 DIA ROUND BAR X 4.85 LONG

PROJECTION: 2.5 MINIMUM FROM JAW FACE

ADAPTERS : SANDVIK C6-ASHR-38130-16-A (2)

HOLDERS : MCLNR-164D (2), MVJNR-164D (2)

INSERTS : CNMG-432 (2), VNMG-431 (2)

SPINDLE : LEFT MAIN

WORK COORD: G54

ORIGIN : X0.0 = SPINDLE CENTERLINE, Z0.0 = FINISHED FACE

PROCESS : FACE WITH UPPER, PINCH TURN ROUGH & FINISH TURN HALF OF PART

Page 19

- 18 -

%

O0003(MX-EXAMPLE #3 - UPPER)

(PINCH TURN SYNCHRONIZED WITH LOWER TURRET)

N1 G00 G18 G40 G49 G80 G99

N2 G00 G28 U0.0 V0.0

N3 G00 G28 W0.0

N4 G00 G28 B0.0

N5 G490 S0

N6 G00 B-90.0

N7 M01

N8 G54

N9 M06 T01001

N10 T02000

N11 G490 S0

N12 G00 G28 W0.0

N13 G00 G28 B0.0

N14 M138

N15 M126

N16 M34

N17 M261

N18 G50 S2500

N19 G96 S500 M03 P11

(FACE = ROUGH & FINISH)

N20 G00 X3.7 Z0.01

N21 G01 X-0.0625 F0.018

N22 G00 Z0.11

N23 X3.7

N24 Z0.

N25 G01 X-0.0625 F0.01

(OD CANNED ROUGH)

N28 G00 Z0.0615

N29 G71 U0.125 R0.03

N30 G71 P31 Q40 U0.02 W0.01 F0.036

N31 G00 X0.8903

N32 G01 X1.1817 Z-0.0842

N33 G03 X1.2 Z-0.1063 R0.0313

N34 G01 Z-1.125

N35 G01 X2.7875

N36 G03 X2.8317 Z-1.1342 R0.0313

N37 G01 X2.9817 Z-1.2092

N38 G03 X3.0 Z-1.2313 R0.0313

N39 G01 Z-2.225

N40 G01 X3.5

N41 G00 Z0.1

N42 G00 G28 U0.0 V0.0

N43 G00 G28 W0.0

N44 G00 G28 B0.0

N45 T01000

N46 M139

N47 M127

N48 M05 P11

N49 G490 S0

N50 G00 B-90.0

N51 M01

%

O0003(MX-EXAMPLE #3 - LOWER)

(PINCH TURN SYNCHRONIZED WITH B-AXIS HEAD)

N1 G00 G18 G40 G80 G99

N2 G00 G28 U0.0

N3 G00 G28 W0.0

N4 G54

N5 T01001

N6 M138

N7 M08

N8 M34

N9 M261

N10 G50 S2500

N11 G96 S500 M03 P11

(OD CANNED ROUGH)

N13 G00 Z0.0615

N14 G71 U0.125 R0.03

N15 G71 P16 Q25 U0.02 W0.01 F0.036

N16 G00 X0.8903

N17 G01 X1.1817 Z-0.0842

N18 G03 X1.2 Z-0.1063 R0.0313

N19 G01 Z-1.125

N20 G01 X2.7875

N21 G03 X2.8317 Z-1.1342 R0.0313

N22 G01 X2.9817 Z-1.2092

N23 G03 X3.0 Z-1.2313 R0.0313

N24 G01 Z-2.225

N25 G01 X3.5

N26 G00 Z0.1

N27 G00 G28 U0.0

N28 G00 G28 W0.0

N29 T01000

N30 M139

N31 M09

N32 M05 P11

N33 M01

N26 G00 Z0.1

N27 G00 X3.5 M900 (SYNC POINT)

N12 G00 X3.5

00 (SYNC POINT)

Z0.1 M9

Page 20

- 19 -

N52 G54

N53 M06 T02002

N54 T01000

N55 G490 S0

N56 G00 G28 W0.0

N57 G00 G28 B0.0

N58 M126

N59 M34

N60 M262

N61 G50 S2500

N62 G96 S600 M03 P11

(OD FINISH)

N63 G00 X3.5 Z0.1 M901 (SYNC POINT)

N64 X1.0408 Z0.0661

N65 G01 X0.9701 Z0.0308 F0.012

N66 X1.1908 Z-0.0796

N67 G03 X1.2 Z-0.0906 R0.0156

N68 G01 Z-1.125

N69 X2.8187

N70 G03 X2.8408 Z-1.1296 R0.0156

N71 G01 X2.9908 Z-1.2046

N72 G03 X3.0 Z-1.2156 R0.0156

N73 G01 Z-2.205

N74 X3.0707 Z-2.1697

N75 G00 X3.5 Z0.1

N76 G00 G28 U0.0 V0.0

N77 G00 G28 W0.0

N78 G00 G28 B0.0

N79 T02000

N80 M139

N81 M127

N82 M05 P11

N83 G490 S0

N84 G00 B-90.0

N85 M30

%

N34 G54

N35 T02002

N36 M08

N37 M34

N38 M262

N39 G50 S2500

N40 G96 S600 M03 P11

(OD FINISH)

N41 G00 X3.5 Z0.1 M901 (SYNC POINT)

N42 X1.0408 Z0.0661

N43 G01 X0.9701 Z0.0308 F0.012

N44 X1.1908 Z-0.0796

N45 G03 X1.2 Z-0.0906 R0.0156

N46 G01 Z-1.125

N47 X2.8187

N48 G03 X2.8408 Z-1.1296 R0.0156

N49 G01 X2.9908 Z-1.2046

N50 G03 X3.0 Z-1.2156 R0.0156

N51 G01 Z-2.205

N52 X3.0707 Z-2.1697

N53 G00 X3.5 Z0.1

N54 G00 G28 U0.0

N55 G00 G28 W0.0

N56 T02000

N57 M139

N58 M09

N59 M05 P11

N60 T12000

N61 G00 G54 Z0.0

N62 M30

%

Page 21

- 20 -

EXAMPLE #4 – STANDARD TURNING

SIMULTANEOUS UPPER & LOWER OPERATION

USING LEFT & RIGHT SPINDLES WITH PART TRANSFER

MATERIAL : AISI 4140 ALLOY STEEL - 275 HB

STOCK : 3.5 DIA ROUND BAR X 4.85 LONG

PROJECTION: 2.5 MINIMUM FROM JAW FACE

ADAPTERS : SANDVIK C6-ASHR-38130-16-A (2)

HOLDERS : MCLNR-164D (2), MVJNR-164D (2)

INSERTS : CNMG-432 (2), VNMG-431 (2)

SPINDLES : LEFT MAIN W/UPPER, RIGHT MAIN W/LOWER

WORK COORD: G54=LEFT MAIN W/UPPER, G55=RIGHT MAIN W/LOWER

ORIGIN : X0.0 = SPINDLE CENTERLINE, Z0.0 = FINISHED FACE

PROCESS : FACE, ROUGH & FINISH TURN 1ST HALF OF PART – LEFT MAIN w/UPPER

: FACE, ROUGH & FINISH TURN 2ND HALF OF PART – RIGHT MAIN w/LOWER

: STOP, REMOVE FINISHED PART FROM RIGHT SPINDLE

: TRANSFER PART FROM LEFT SPINDLE TO RIGHT SPINDLE

: LOAD NEW STOCK AND CONTINUE SIMULTANEOUS OPERATION

Page 22

- 21 -

Page 23

- 22 -

%

O0004(MX-EXAMPLE #4 - UPPER)

(TURN ON LEFT MAIN SPINDLE WITH B-AXIS HEAD)

(TURN SIMULTANEOUSLY WITH LOWER TURRET)

(ON RIGHT MAIN SPINDLE)

N1 G00 G18 G40 G49 G80 G99

N2 G00 G28 U0.0 V0.0

N3 G00 G28 W0.0

N4 G00 G28 B0.0

N5 G490 S0

N6 G00 B-90.0

N7 M01

N8 G54

N9 M06 T01001

N10 T02000

N11 G490 S0

N14 M138

N15 M126

N16 M34

N17 M261

N18 G50 S2500

N19 G96 S500 M03 P11

(FACE = ROUGH & FINISH)

N20 G00 X3.7 Z0.01 M900 (SYNC POINT)

N21 G01 X-0.0625 F0.018

N22 G00 Z0.11

N23 X3.7

N24 Z0.

N25 G01 X-0.0625 F0.01

N26 G00 Z0.1

(OD CANNED ROUGH)

N27 G00 X3.5 M901 (SYNC POINT)

N28 G00 Z0.0615

N29 G71 U0.125 R0.03

N30 G71 P31 Q40 U0.02 W0.01 F0.036

N31 G00 X0.8903

N32 G01 X1.1817 Z-0.0842

N33 G03 X1.2 Z-0.1063 R0.0313

N34 G01 Z-1.125

N35 G01 X2.7875

N36 G03 X2.8317 Z-1.1342 R0.0313

N37 G01 X2.9817 Z-1.2092

N38 G03 X3.0 Z-1.2313 R0.0313

N39 G01 Z-2.225

N40 G01 X3.5

N41 G00 Z0.1

N42 G00 G28 U0.0 V0.0

N43 G00 G28 W0.0

N44 G00 G28 B0.0

N45 T01000

N46 M139

N47 M127

N48 M05 P11

N49 G490 S0

N50 G00 B-90.0

N51 M01

%

O0004 (MX-EXAMPLE #4 - LOWER)

(TURN ON RIGHT MAIN SPINDLE WITH LOWER TURRET)

(TURN SIMULTANEOUSLY WITH B-AXIS HEAD)

(ON LEFT MAIN SPINDLE)

N1 G00 G18 G40 G80 G99

N2 G00 G28 U0.0

N3 G00 G28 W0.0

N4 G55

N5 T01001

N6 M138

N7 M08

N10 G50 S2500

N11 G96 S500 M03 P21

(FACE = ROUGH & FINISH)

N12 G00 X3.7 Z-0.01 M900 (SYNC POINT)

N13 G01 X-0.0625 F0.018

N14 G00 Z-0.11

N15 X3.7

N16 Z0.

N17 G01 X-0.0625 F0.01

N18 G00 Z-0.1

(OD CANNED ROUGH)

N19 G00 X3.5 Z-0.1 M901 (SYNC POINT)

N20 G00 Z-0.0615

N21 G71 U0.125 R0.03

N22 G71 P23 Q33 U0.02 W-0.01 F0.036

N23 G00 X0.8903

N24 G01 X1.1817 Z0.0842

N25 G02 X1.2 Z0.1063 R0.0313

N26 G01 Z1.125

N27 G01 X2.7875

N28 G02 X2.8317 Z1.1342 R0.0313

N29 G01 X2.9817 Z1.2092

N30 G02 X3.0 Z1.2313 R0.0313

N31 G01 Z2.225

N32 G01 X3.5

N33 G00 Z-0.1

N34 G00 G28 U0.0

N35 G00 G28 W0.0

N36 T01000

N37 M139

N38 M09

N39 M05 P21

N40 M01

N13 G00 G28 B0.0

N9 M161

N12 G00 G28 W0.0

N8 M134

Page 24

- 23 -

N52 G54

N53 M06 T02002

N54 T01000

N57 G00 G28 B0.0

N58 M126

N59 M34

N60 M262

N61 G50 S2500

N62 G96 S600 M03 P11

(OD FINISH)

N63 G00 X3.5 Z0.1 M902 (SYNC POINT)

N64 X1.0408 Z0.0661

N65 G01 X0.9701 Z0.0308 F0.012

N66 X1.1908 Z-0.0796

N67 G03 X1.2 Z-0.0906 R0.0156

N68 G01 Z-1.125

N69 X2.8187

N70 G03 X2.8408 Z-1.1296 R0.0156

N71 G01 X2.9908 Z-1.2046

N72 G03 X3.0 Z-1.2156 R0.0156

N73 G01 Z-2.205

N74 X3.0707 Z-2.1697

N75 G00 X3.5 Z0.1

N76 G00 G28 U0.0 V0.0

N77 G00 G28 W0.0

N78 G00 G28 B0.0

N79 T02000

N80 M139

N81 M127

N82 M05 P11

N83 G490 S0

N84 G00 B-90.0

N85 M903 (SYNC POINT)

N86 M30

%

N41 G55

N42 T02002

N43 M08

N46 G50 S2500

N47 G96 S600 M03 P21

(OD FINISH)

N48 G00 X3.5 Z-0.1 M902 (SYNC POINT)

N49 X1.0408 Z-0.0661

N50 G01 X0.9701 Z-0.0308 F0.012

N51 X1.1908 Z0.0796

N52 G02 X1.2 Z0.0906 R0.0156

N53 G01 Z1.125

N54 X2.8187

N55 G02 X2.8408 Z1.1296 R0.0156

N56 G01 X2.9908 Z1.2046

N57 G02 X3.0 Z1.2156 R0.0156

N58 G01 Z2.205

N59 X3.0707 Z2.1697

N60 G00 X3.5 Z-0.1

N61 G00 G28 U0.0

N62 G00 G28 W0.0

N63 T02000

N64 M139

N65 M09

N66 M05 P21

N67 T12000 (EMPTY TOOL STATION)

N68 G00 G54 Z0.0

N69 M903 (SYNC POINT)

M00

(PROGRAM STOP BEFORE PART TRANSFER)

(LEFT & RIGHT SPINDLE MUST BE STOPPED)

(PRIOR TO THIS TRANSFER)

(** OPEN JAWS ON RIGHT SPINDLE AND REMOVE **)

(** FINISHED PART FROM RIGHT SPINDLE **)

(** BLOW OUT JAWS TO PREPARE FOR TRANSFER **)

(** MANUALLY CLOSE JAWS ON RIGHT SPINDLE **)

(** PRESS CYCLE START TO BEGIN TRANSFER **)

(** FROM LEFT SPINDLE TO RIGHT SPINDLE **)

N56 G00 G28 W0.0

N45 M162

N55 G490 S0

N44 M134

Page 25

- 24 -

(** BEGIN PART TRANSFER **)

G97 (ENTER RPM MODE)

M34 (C-AXIS MODE OFF – LEFT SPINDLE)

M134 (C-AXIS MODE OFF – RIGHT SPINDLE)

M19 (ORIENT THE LEFT)

M119 (ORIENT THE RIGHT)

M131 (ALLOW THE RIGHT TO OPEN)

M169 (OPEN RIGHT JAWS)

G04 U1.0 (WAIT A SECOND)

G54 G98 G00 A0.5 (RAPID TO 0.5 AWAY)

M86 (TORQUE SKIP)

G31 P99 A-

2.3F5

0.0 (FEED ONTO THE PART)

(MODIFY A-AXIS VALUE PER PART/JAWS)

M87 (TORQUE SKIP CANCEL)

M168 (CLOSE RIGHT JAWS)

G04 U1.0 (WAIT A SECOND)

M31 (ALLOW THE LEFT TO OPEN)

M69 (OPEN LEFT JAWS)

G04 U1.0 (WAIT A SECOND)

G00 G28 G53 A0.0 (GO HOME)

M05 P21 (PREVENT ALARM)

M05 P11 (PREVENT ALARM)

(** END PART TRANSFER **)

N70 M00

(** BLOW OUT LEFT SPINDLE JAWS **)

(** LOAD STOCK FOR NEXT PART **)

(** IN LEFT SPINDLE **)

N71 M30

%

Page 26

- 25 -

DOOSAN PUMA MX Series – Advanced Turning

With all of our previous examples we have focused on standard ANSI/ISO Stick Tooling.

On a standard CNC Turning Center, stick tooling is designed to be used in a specific orientation.

Multi-Task CNC Machining Centers, like the Doosan Puma MX Series, allow users to create efficient

CNC Operations by orienting tooling to positions previously impossible to achieve with Standard CNC

Turning Centers.

Specific Tooling Adapters have been designed to support Multi-Task CNC Machining Centers.

These tools provide the user with the ability to be used as either Right Handed or Left Handed as well

as tilting them to provide optimal chip clearance.

Example #5 is a modified version of Example #1.

Example #5 will use two CAPTO® C6 Holder/Adapters specifically designed for Multi-Task CNC

Machining Centers. Additionally, we will now use a new programming code that allows us to use the

Nutating B-Axis Head to tilt to an angle that provides for the most efficient machining operation.

Page 27

- 26 -

B-Axis Spindle Tilt Function - G400

Page 28

- 27 -

B-Axis Spindle Tilt Function - G400

IMPORTANT NOTE:

A B C D

When a tool is touched off in a manner that is normal to its cutting position as shown in figures A & B,

the tool length is measured by the Q-Setter, including any tool nose radius built into the insert. A high

degree of accuracy can be achieved without issue with this method because the reference point

shown in figure B is included in the X and Z measurement.

When a tool is touched off in a manner that is NOT normal to its cutting position (Figures C & D),

The calculations from within G400 project the theoretical position of the tool based on the information

defining the tool.

This definition includes the measured tool length of X and the described R

value in the tool offset register.

A higher degree of accuracy will be achieved with G400 if the radius of the tool is known.

For example, A 0.0313 radius cannot be assumed with a CNMG432 insert. Typically, tool

manufacturers use a +0 -.005 tolerance band for radii. It is common for the actual radii to be -0.003.

When using G400 with a turning tool, it is best to start with a radius of minus (-) 0.003 of the

published radius in R of the offset page.

EXAMPLE:

An ID Boring Bar or Grooving Tool is only used at B-90.0.

Simply touch off the tool in the orientation it will be cutting.

The program should have an explicit command for positioning the B-Axis Angle.

However, if you choose to use G400 in such a case, there are some facts users should be aware of.

It is permissible to touch off ID Boring and Grooving Tools at B0.

However, the Tool Nose Radius at the Touch-Off point MUST be entered in the Offset R-Field.

Also, using J11 or J12 on a G400 command line requires a G490 S____ command PRIOR to the

G400 line in order for compensation applied to be accurate. Using G490 S____ AFTER the G400 line

will orient the spindle but your compensation will NOT be accurate.

Please reference the Doosan Programming Manual page 14-4.

Due to the added complexity involved in touching off at B0 for ID tooling that is only used at B-90.0 ,

The use of G400 is discouraged in favor of the traditional method of touching off at the B-Axis Angle

used in the operation.

Page 29

- 28 -

EXAMPLE #5 – ADVANCED TURNING – UPPER UNIT ONLY

MATERIAL : AISI 4140 ALLOY STEEL - 275 HB

STOCK : 3.5 DIA ROUND BAR X 4.85 LONG

PROJECTION: 2.5 MINIMUM FROM JAW FACE

ADAPTERS : SANDVIK C6-DCMNN-00115-12 (1), SANDVIK C6-DDMNL-0013-1504 (1)

INSERTS : CNMG-432 (1), DNMG-431 (1)

SPINDLE : LEFT MAIN

WORK COORD: G54

ORIGIN : X0.0 = SPINDLE CENTERLINE, Z0.0 = FINISHED FACE

PROCESS : FACE, ROUGH & FINISH TURN HALF OF PART

Q-SETTER : TOUCH OFF BOTH TOOLS IN X ONLY AT B0.0

TOOL #3

ADAPTER : C6-DCMNN-00115-12

INSERT : CNMG432

ORIENTATION : G490 S1800

B-AXIS TILT : -45.0

TOOL #4

ADAPTER : C6-DDMNL-0013-1504

INSERT : DNMG431

ORIENTATION : G490 S1800

B-AXIS TILT : -20.0

Page 30

- 29 -

%

O0005(MX-EXAMPLE #5 - UPPER - G400)

(PREPARATION FOR START OF PROGRAM)

(INITIALIZE - RAPID, ZX PLANE, TNR COMP CANCEL, TLO CANCEL, CYCLE CANCEL, UPR FEED)

N1 G00 G18 G40 G49 G80 G99

N2 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N3 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N4 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N5 G490 S0 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL CHANGE)

N6 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N7 M01

(PREPARATION FOR START OF OPERATION)

N8 G54 (WORK COORDINATE SELECTION)

N9 M06 T03003 (SANDVIK C6-DCMNN-00115-12 - CNMG432)

N10 T04000 (STAGE NEXT TOOL)

N11 G490 S1800 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL)

N12 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N13 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N14 M138 (SHOWER BED COOLANT ON)

N15 M126 (COOLANT THROUGH TOOL ON)

N16 M34 (LEFT SPINDLE C-AXIS MODE OFF)

N17 M261 (SPINDLE WINDING LOW - REPLACES M41)

N18 G400 B-45.0 J2.0 R3.0 K3.0 W3.0 (ENGAGE G400 TOOL POINT CONTROL)

(B-45.0 = ANGLE OF HEAD TILT)

(J2.0 = ORIENTATION AND LOCK B-AXIS SPINDLE AT 180.0 DEGREES & LOCKED)

(R3.0 = CUTTING QUADRANT #3)

(K3.0 = IMAGINARY TOOL NOSE ORIENTATION #3)

(W3.0 = TOOL OFFSET REGISTER #3)

N19 G50 S2500 (MAXIMUM RPM CAP)

N20 G96 S500 M04 P11 (CONSTANT CUTTING SPEED MODE - 500 FPM - LEFT SPINDLE COUNTER-CLOCKWISE)

(FACE = ROUGH & FINISH)

N21 G00 X3.7 Z0.01

N22 G01 X-0.0625 F0.018

N23 G00 Z0.11

N24 X3.7

N25 Z0.

N26 G01 X-0.0625 F0.01

N27 G00 Z0.1

(OD CANNED ROUGH)

N28 G00 X3.5

N29 G00 Z0.0615

N30 G71 U0.125 R0.03

N31 G71 P32 Q41 U0.02 W0.01 F0.018

N32 G00 X0.8903

N33 G01 X1.1817 Z-0.0842

N34 G03 X1.2 Z-0.1063 R0.0313

N35 G01 Z-1.125

N36 G01 X2.7875

N37 G03 X2.8317 Z-1.1342 R0.0313

N38 G01 X2.9817 Z-1.2092

N39 G03 X3.0 Z-1.2313 R0.0313

N40 G01 Z-2.225

N41 G01 X3.5

N42 G00 Z0.1

Page 31

- 30 -

(TOOL CHANGE PREPARATION)

N43 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N44 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N45 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N46 T03000 (CANCEL OFFSET #399 FOR CURRENT TOOL USING G400)

N47 M139 (SHOWER BED COOLANT OFF)

N48 M127 (COOLANT THROUGH TOOL OFF)

N49 M05 P11 (LEFT SPINDLE STOP)

N50 G490 S0 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL CHANGE)

N51 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N52 M01

(PREPARATION FOR START OF OPERATION)

N53 G54 (WORK COORDINATE SELECTION)

N54 M06 T04004 (SANDVIK C6-DDMNL-0013-1504 - DNMG431)

N55 T03000 (STAGE NEXT TOOL)

N56 G490 S1800 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL)

N57 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N58 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N59 M126 (COOLANT THROUGH TOOL ON)

N60 M34 (LEFT SPINDLE C-AXIS MODE OFF)

N61 M262 (SPINDLE WINDING HIGH- REPLACES M42)

N62 G400 B-20.0 J2. R3. K3. W4. (ENGAGE G400 TOOL POINT CONTROL)

(B-20.0 = ANGLE OF HEAD TILT)

(J2.0 = ORIENTATION AND LOCK B-AXIS SPINDLE AT 180.0 DEGREES & LOCKED)

(R3.0 = CUTTING QUADRANT #3)

(K3.0 = IMAGINARY TOOL NOSE ORIENTATION #3)

(W4.0 = TOOL OFFSET REGISTER #4)

N63 G50 S2500 (MAXIMUM RPM CAP)

N64 G96 S600 M03 P11 (CONSTANT CUTTING SPEED MODE - 600 FPM - LEFT SPINDLE CLOCKWISE)

(OD FINISH)

N65 G00 X3.5 Z0.1

N66 X1.0408 Z0.0661

N67 G01 X0.9701 Z0.0308 F0.006

N68 X1.1908 Z-0.0796

N69 G03 X1.2 Z-0.0906 R0.0156

N70 G01 Z-1.125

N71 X2.8187

N72 G03 X2.8408 Z-1.1296 R0.0156

N73 G01 X2.9908 Z-1.2046

N74 G03 X3.0 Z-1.2156 R0.0156

N75 G01 Z-2.205

N76 X3.0707 Z-2.1697

N77 G00 X3.5 Z0.1

(END PROGRAM/TOOL CHANGE PREPARATION)

N78 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N79 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N80 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N81 T04000 (CANCEL OFFSET #399 FOR CURRENT TOOL USING G400)

N82 M139 (SHOWER BED COOLANT OFF)

N83 M127 (COOLANT THROUGH TOOL OFF)

N84 M05 P11 (LEFT SPINDLE STOP)

N85 G490 S0 (EXPLICIT SPINDLE ORIENTATION FOR TOOL CHANGE)

N86 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N87 M30

%

Page 32

- 31 -

EXAMPLE #6 – ADVANCED TURNING – UPPER UNIT ONLY

MATERIAL : AISI 4140 ALLOY STEEL - 275 HB

STOCK : 3.5 DIA ROUND BAR X 4.85 LONG

PROJECTION: 2.5 MINIMUM FROM JAW FACE

ADAPTERS : SANDVIK C6-DCMNN-00115-12 (1), SANDVIK C6-DDMNL-0013-1504 (1)

INSERTS : CNMG-432 (1), DNMG-431 (1)

SPINDLE : RIGHT MAIN

WORK COORD: G55

ORIGIN : X0.0 = SPINDLE CENTERLINE, Z0.0 = FINISHED FACE

PROCESS : FACE, ROUGH & FINISH TURN HALF OF PART

Q-SETTER : TOUCH OFF BOTH TOOLS IN X ONLY AT B0.0

TOOL #3

ADAPTER : C6-DCMNN-00115-12

INSERT : CNMG432

ORIENTATION : G490 S1800

B-AXIS TILT : 45.0

TOOL #4

ADAPTER : C6-DDMNL-0013-1504

INSERT : DNMG431

ORIENTATION : G490 S0

B-AXIS TILT : 20.0

Page 33

- 32 -

%

O0006(MX-EXAMPLE #6 - UPPER - G400)

(PREPARATION FOR START OF PROGRAM)

(INITIALIZE - RAPID, ZX PLANE, TNR COMP CANCEL, TLO CANCEL, CYCLE CANCEL, UPR FEED)

N1 G00 G18 G40 G49 G80 G99

N2 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N3 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N4 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N5 G490 S0 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL CHANGE)

N6 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N7 M01

(PREPARATION FOR START OF OPERATION)

N8 G55 (WORK COORDINATE SELECTION)

N9 M06 T03003 (SANDVIK C6-DCMNN-00115-12 - CNMG432)

N10 T04000 (STAGE NEXT TOOL)

N11 G490 S1800 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL)

N12 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N13 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N14 M138 (SHOWER BED COOLANT ON)

N15 M126 (COOLANT THROUGH TOOL ON)

N16 M134 (RIGHT SPINDLE C-AXIS MODE OFF)

N17 M161 (SPINDLE WINDING LOW - REPLACES M41)

N18 G400 B45.0 J2.0 R4.0 K4.0 W3.0 (ENGAGE G400 TOOL POINT CONTROL)

(B45.0 = ANGLE OF HEAD TILT)

(J2.0 = ORIENTATION AND LOCK B-AXIS SPINDLE AT 180.0 DEGREES & LOCKED)

(R4.0 = CUTTING QUADRANT #4)

(K4.0 = IMAGINARY TOOL NOSE ORIENTATION #4)

(W3.0 = TOOL OFFSET REGISTER #3)

N19 G50 S2500 (MAXIMUM RPM CAP)

N20 G96 S500 M03 P21 (CONSTANT CUTTING SPEED MODE - 500 FPM - RIGHT SPINDLE CLOCKWISE)

(FACE = ROUGH & FINISH)

N21 G00 X3.7 Z-0.01

N22 G01 X-0.0625 F0.018

N23 G00 Z-0.11

N24 X3.7

N25 Z0.

N26 G01 X-0.0625 F0.01

N27 G00 Z-0.1

(OD CANNED ROUGH)

N28 G00 X3.5

N29 G00 Z-0.0615

N30 G71 U0.125 R0.03

N31 G71 P32 Q41 U0.02 W-0.01 F0.018

N32 G00 X0.8903

N33 G01 X1.1817 Z0.0842

N34 G02 X1.2 Z0.1063 R0.0313

N35 G01 Z1.125

N36 G01 X2.7875

N37 G02 X2.8317 Z1.1342 R0.0313

N38 G01 X2.9817 Z1.2092

N39 G02 X3.0 Z1.2313 R0.0313

N40 G01 Z2.225

N41 G01 X3.5

N42 G00 Z-0.1

Page 34

- 33 -

(TOOL CHANGE PREPARATION)

N43 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N44 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N45 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N46 T03000 (CANCEL OFFSET #399 FOR CURRENT TOOL USING G400)

N47 M139 (SHOWER BED COOLANT OFF)

N48 M127 (COOLANT THROUGH TOOL OFF)

N49 M05 P11 (LEFT SPINDLE STOP)

N50 G490 S0 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL CHANGE)

N51 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N52 M01

(PREPARATION FOR START OF OPERATION)

N53 G55 (WORK COORDINATE SELECTION)

N54 M06 T04004 (SANDVIK C6-DDMNL-0013-1504 - DNMG431)

N55 T03000 (STAGE NEXT TOOL)

N56 G490 S1800 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL)

N57 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N58 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N59 M126 (COOLANT THROUGH TOOL ON)

N60 M134 (RIGHT SPINDLE C-AXIS MODE OFF)

N61 M162 (SPINDLE WINDING HIGH- REPLACES M42)

N62 G400 B20.0 J1. R4. K4. W4. (ENGAGE G400 TOOL POINT CONTROL)

(B20.0 = ANGLE OF HEAD TILT)

(J1.0 = ORIENTATION AND LOCK B-AXIS SPINDLE AT 0.0 DEGREES & LOCKED)

(R4.0 = CUTTING QUADRANT #4)

(K4.0 = IMAGINARY TOOL NOSE ORIENTATION #4)

(W4.0 = TOOL OFFSET REGISTER #4)

N63 G50 S2500 (MAXIMUM RPM CAP)

N64 G96 S600 M03 P21 (CONSTANT CUTTING SPEED MODE - 600 FPM - RIGHT SPINDLE CLOCKWISE)

(OD FINISH)

N65 G00 X3.5 Z-0.1

N66 X1.0408 Z-0.0661

N67 G01 X0.9701 Z-0.0308 F0.006

N68 X1.1908 Z0.0796

N69 G02 X1.2 Z0.0906 R0.0156

N70 G01 Z1.125

N71 X2.8187

N72 G02 X2.8408 Z1.1296 R0.0156

N73 G01 X2.9908 Z1.2046

N74 G02 X3.0 Z1.2156 R0.0156

N75 G01 Z2.205

N76 X3.0707 Z2.1697

N77 G00 X3.5 Z-0.1

(END PROGRAM/TOOL CHANGE PREPARATION)

N78 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N79 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N80 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N81 T04000 (CANCEL OFFSET #399 FOR CURRENT TOOL USING G400)

N82 M139 (SHOWER BED COOLANT OFF)

N83 M127 (COOLANT THROUGH TOOL OFF)

N84 M05 P11 (LEFT SPINDLE STOP)

N85 G490 S0 (EXPLICIT SPINDLE ORIENTATION FOR TOOL CHANGE)

N86 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N87 M30

%

Page 35

- 34 -

EXAMPLE #7 – ADVANCED DRILLING – UPPER UNIT ONLY

MATERIAL : AISI 4140 ALLOY STEEL - 275 HB

STOCK : 3.5 DIA ROUND BAR X 4.85 LONG

PROJECTION: 2.5 MINIMUM FROM JAW FACE

ADAPTERS : SANDVIK C6 ER32 COLLET HOLDER

TOOL : 0.75 SOLID CARBIDE THRU COOLANT DRILL

SPINDLE : LEFT MAIN

WORK COORD: G54

ORIGIN : X0.0 = LEFT MAIN SPINDLE CENTERLINE, Z0.0 = FINISHED FACE

PROCESS : DRILL THRU HOLE

Q-SETTER : TOUCH OFF TOOL IN X ONLY AT B0.0

TOOL #5

ADAPTER : SANDVIK C6 ER32 COLLET HOLDER

TOOL : 0.75 SOLID CARBIDE THRU COOLANT DRILL

ORIENTATION : G490 S0

B-AXIS TILT : -90.0

Page 36

- 35 -

%

O0007(MX-EXAMPLE #7 - UPPER - G400 STD DRILL)

(PREPARATION FOR START OF PROGRAM)

(INITIALIZE - RAPID, ZX PLANE, TNR COMP CANCEL, TLO CANCEL, CYCLE CANCEL, UPR FEED)

N1 G00 G18 G40 G49 G80 G99

N2 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N3 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N4 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N5 G490 S0 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL CHANGE)

N6 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N7 M01

(PREPARATION FOR START OF OPERATION)

N8 G54 (WORK COORDINATE SELECTION)

N9 M06 T05005 (SANDVIK C6 ER32 COLLET HOLDER - 0.75 SOLID CARBIDE THRU COOLANT DRILL)

N10 T06000 (STAGE NEXT TOOL)

N11 G490 S0 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL)

N12 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N13 M138 (SHOWER BED COOLANT ON)

N14 M126 (COOLANT THROUGH TOOL ON)

N15 M34 (LEFT SPINDLE C-AXIS MODE OFF)

N16 M261 (SPINDLE WINDING LOW - REPLACES M41)

N17 G400 B-90.0 J1.0 (ENGAGE G400 TOOL POINT CONTROL)

(B-90.0 = ANGLE OF HEAD TILT)

(J1.0 = ORIENTATION AND LOCK B-AXIS SPINDLE AT 0.0 DEGREES & LOCKED)

N18 G50 S2500 (MAXIMUM RPM CAP)

N19 G97 S500 M03 P11 (DIRECT RPM MODE - 500 RPM - LEFT SPINDLE CLOCKWISE)

(ID CENTERLINE DRILL)

N20 G00 Z4.0

N21 X0.0

N22 Z0.1

N23 G01 Z-4.8 F0.006

N24 G00 Z4.0

(END PROGRAM/TOOL CHANGE PREPARATION)

N25 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N26 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N27 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N28 T05000 (CANCEL OFFSET FOR CURRENT TOOL)

N29 M139 (SHOWER BED COOLANT OFF)

N30 M127 (COOLANT THROUGH TOOL OFF)

N31 M05 P11 (LEFT SPINDLE STOP)

N32 G490 S0 (EXPLICIT SPINDLE ORIENTATION FOR TOOL CHANGE)

N33 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N34 M30

%

Page 37

- 36 -

EXAMPLE #8 – ADVANCED DRILLING – UPPER UNIT ONLY

MATERIAL : AISI 4140 ALLOY STEEL - 275 HB

STOCK : 3.5 DIA ROUND BAR X 4.85 LONG

PROJECTION: 2.5 MINIMUM FROM JAW FACE

ADAPTERS : SANDVIK C6 ER32 COLLET HOLDER

TOOL : 0.75 SOLID CARBIDE THRU COOLANT DRILL

SPINDLE : B-AXIS HEAD

WORK COORD: G54

ORIGIN : X0.0 = LEFT MAIN SPINDLE CENTERLINE, Z0.0 = FINISHED FACE

PROCESS : DRILL THRU HOLE

Q-SETTER : TOUCH OFF TOOL IN X ONLY AT B0.0

TOOL #5

ADAPTER : SANDVIK C6 ER32 COLLET HOLDER

TOOL : 0.75 SOLID CARBIDE THRU COOLANT DRILL

ORIENTATION : G490 S0

B-AXIS TILT : -90.0

Page 38

- 37 -

%

O0008(MX-EXAMPLE #8 - UPPER - G400 LIVE DRILL)

(PREPARATION FOR START OF PROGRAM)

(INITIALIZE - RAPID, ZX PLANE, TNR COMP CANCEL, TLO CANCEL, CYCLE CANCEL, UPR FEED)

N1 G00 G18 G40 G49 G80 G99

N2 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N3 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N4 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N5 G490 S0 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL CHANGE)

N6 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N7 M01

(PREPARATION FOR START OF OPERATION)

N8 G54 (WORK COORDINATE SELECTION)

N9 M06 T05005 (SANDVIK C6 ER32 COLLET HOLDER - 0.75 SOLID CARBIDE THRU COOLANT DRILL)

N10 T06000 (STAGE NEXT TOOL)

N11 G490 S0 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL)

N12 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N13 M138 (SHOWER BED COOLANT ON)

N14 M126 (COOLANT THROUGH TOOL ON)

N15 M35 (LEFT SPINDLE C-AXIS MODE ON)

N16 M89 (C-AXIS CLAMP)

N17 G400 B-90.0 J0.0 (ENGAGE G400 TOOL POINT CONTROL)

(B-90.0 = ANGLE OF HEAD TILT)

(J0.0 = B-AXIS SPINDLE UNLOCKED)

N18 M101

N19 G50 S500 (MAXIMUM RPM CAP)

N20 G97 S500 M03 P12 (DIRECT RPM MODE - 500 RPM - B-AXIS SPINDLE CLOCKWISE)

(ID CENTERLINE DRILL)

N21 G00 Z4.0

N22 X0.0

N23 Z0.1

N24 G01 Z-4.8 F0.006

N25 G00 Z4.0

(END PROGRAM/TOOL CHANGE PREPARATION)

N26 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N27 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N28 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N29 T05000 (CANCEL OFFSET FOR CURRENT TOOL)

N30 M139 (SHOWER BED COOLANT OFF)

N31 M127 (COOLANT THROUGH TOOL OFF)

N32 M05 P12 (B-AXIS SPINDLE STOP)

N33 M34 (LEFT SPINDLE C-AXIS MODE OFF)

N34 G490 S0 (EXPLICIT SPINDLE ORIENTATION FOR TOOL CHANGE)

N35 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N36 M30

%

Page 39

- 38 -

EXAMPLE #9 – ADVANCED DRILLING – UPPER UNIT ONLY

MATERIAL : AISI 4140 ALLOY STEEL - 275 HB

STOCK : 6.0 OD X 3.0 ID X 6.0 LONG

PROJECTION: 3.5 MINIMUM FROM JAW FACE

ADAPTERS : SANDVIK C6 ER32 COLLET HOLDER

TOOL : 0.75 SOLID CARBIDE THRU COOLANT DRILL

SPINDLE : B-AXIS HEAD

WORK COORD: G54

ORIGIN : X0.0 = LEFT MAIN SPINDLE CENTERLINE, Z0.0 = FINISHED FACE

PROCESS : DRILL OD HOLE PATTERN

Q-SETTER : TOUCH OFF TOOL IN X ONLY AT B0.0

TOOL #5

ADAPTER : SANDVIK C6 ER32 COLLET HOLDER

TOOL : 0.75 SOLID CARBIDE THRU COOLANT DRILL

ORIENTATION : LIVE TOOL - M101 (UNCLAMPED)

B-AXIS TILT : 0.0

Page 40

- 39 -

%

O0009(MX-EXAMPLE #9 - UPPER - LIVE DRILL)

(PREPARATION FOR START OF PROGRAM)

(INITIALIZE - RAPID, ZX PLANE, TNR COMP CANCEL, TLO CANCEL, CYCLE CANCEL, UPR FEED)

N1 G00 G18 G40 G49 G80 G99

N2 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N3 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N4 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N5 G490 S0 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL CHANGE)

N6 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N7 M01

(PREPARATION FOR START OF OPERATION)

N8 G54 (WORK COORDINATE SELECTION)

N9 M06 T05005 (SANDVIK C6 ER32 COLLET HOLDER - 0.75 SOLID CARBIDE THRU COOLANT DRILL)

N10 T06000 (STAGE NEXT TOOL)

N11 M101 (LIVE B-AXIS SPINDLE - UNCLAMPED)

N12 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N13 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N14 M138 (SHOWER BED COOLANT ON)

N15 M126 (COOLANT THROUGH TOOL ON)

N16 M35 (LEFT SPINDLE C-AXIS MODE ON)

N17 G00 G28 H0.0 (ZERO RETURN C-AXIS)

N18 G97 S500 M03 P12 (DIRECT RPM MODE - 500 RPM - B-AXIS SPINDLE CLOCKWISE)

(OD DRILL HOLE PATTERN)

N19 G00 C0.0

N20 G00 X8.0 Z1.0

N21 Z-1.0

N22 X6.2 (POSITION TO R-PLANE FOR PECK CYCLE)

N23 G87 X2.675 R0.0 Q625 F0.006 M89 (OD PECK DRILL START W/C-AXIS CLAMP – 0.0625 PECK)

N24 C45.0 Q625 M89 (INDEX TO C45.0 - PECK DRILL W/C-AXIS CLAMP – 0.0625 PECK)

N25 C90.0 Q625 M89 (INDEX TO C90.0 - PECK DRILL W/C-AXIS CLAMP – 0.0625 PECK)

N26 C135.0 Q625 M89 (INDEX TO C135.0 - PECK DRILL W/C-AXIS CLAMP – 0.0625 PECK)

N27 C180.0 Q625 M89 (INDEX TO C180.0 - PECK DRILL W/C-AXIS CLAMP – 0.0625 PECK)

N28 C225.0 Q625 M89 (INDEX TO C225.0 - PECK DRILL W/C-AXIS CLAMP – 0.0625 PECK)

N29 C270.0 Q625 M89 (INDEX TO C270.0 - PECK DRILL W/C-AXIS CLAMP – 0.0625 PECK)

N30 C315.0 Q625 M89 (INDEX TO C315.0 - PECK DRILL W/C-AXIS CLAMP – 0.0625 PECK)

N31 G80 M90 (PECK CYCLE CANCEL - UNCLAMP C-AXIS)

N32 G00 X8.0

N33 G00 Z1.0

(END PROGRAM/TOOL CHANGE PREPARATION)

N34 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N35 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N36 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N37 T05000 (CANCEL OFFSET FOR CURRENT TOOL)

N38 M139 (SHOWER BED COOLANT OFF)

N39 M127 (COOLANT THROUGH TOOL OFF)

N40 M05 P12 (B-AXIS SPINDLE STOP)

N41 M34 (LEFT SPINDLE C-AXIS MODE OFF)

N42 G490 S0 (EXPLICIT SPINDLE ORIENTATION FOR TOOL CHANGE)

N43 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N44 M30

%

Page 41

- 40 -

B-Axis Spindle Tilt Function – G368/G369

Page 42

- 41 -

EXAMPLE #10 – ADVANCED DRILLING – UPPER UNIT ONLY

MATERIAL : AISI 4140 ALLOY STEEL - 275 HB

STOCK : 6.0 OD X 3.0 ID X 6.0 LONG

PROJECTION: 3.5 MINIMUM FROM JAW FACE

ADAPTERS : SANDVIK C6 ER32 COLLET HOLDER

TOOL : 0.75 SOLID CARBIDE THRU COOLANT DRILL

SPINDLE : B-AXIS HEAD

WORK COORD: G54

ORIGIN : X0.0 = LEFT MAIN SPINDLE CENTERLINE, Z0.0 = FINISHED FACE

PROCESS : DRILL OD HOLE PATTERN

Q-SETTER : TOUCH OFF TOOL IN X ONLY AT B0.0

TOOL #5

ADAPTER : SANDVIK C6 ER32 COLLET HOLDER

TOOL : 0.75 SOLID CARBIDE THRU COOLANT DRILL

ORIENTATION : LIVE TOOL - M101 (UNCLAMPED)

B-AXIS TILT : -45.0

Page 43

- 42 -

%

O0010(MX-EXAMPLE #10 - UPPER - LIVE DRILL)

(PREPARATION FOR START OF PROGRAM)

(INITIALIZE - RAPID, ZX PLANE, TNR COMP CANCEL, TLO CANCEL, CYCLE CANCEL, UPR FEED)

N1 G00 G18 G40 G49 G80 G99

N2 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N3 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N4 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N5 G490 S0 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL CHANGE)

N6 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N7 M01

(PREPARATION FOR START OF OPERATION)

N8 G54 (WORK COORDINATE SELECTION)

N9 M06 T05005 (SANDVIK C6 ER32 COLLET HOLDER - 0.75 SOLID CARBIDE THRU COOLANT DRILL)

N10 T06000 (STAGE NEXT TOOL)

N11 M101 (LIVE B-AXIS SPINDLE - UNCLAMPED)

N12 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N13 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N14 M138 (SHOWER BED COOLANT ON)

N15 M126 (COOLANT THROUGH TOOL ON)

N16 M35 (LEFT SPINDLE C-AXIS MODE ON)

N17 G00 G28 H0.0 (ZERO RETURN C-AXIS)

N18 G97 S500 M03 P12 (DIRECT RPM MODE - 500 RPM - B-AXIS SPINDLE CLOCKWISE)

N19 G00 C0.0

N20 G00 X8.0 Z4.0 (POSITION TO SAFE CLEARANCE)

N21 G368 X4.95 Z-0.525 D0 B-45.0 (ESTABLISH NEW WORKPLANE FOR B-AXIS SPINDLE)

N22 G00 X0.0 Y0.0 Z0.7425 (POSITION TO NEW X0,Y0 POINT ON TILTED PLANE - 0.7425 ABOVE POINT)

(CURRENT POSITION IS THE THEORETICAL PART CORNER)

N23 Z0.1 (POSITION TO R-PLANE FOR PECK CYCLE)

(OD DRILL HOLE PATTERN)

N24 G83 Z-2.0 R0.0 Q625 F0.006 M89 (TILTED OD PECK DRILL START W/C-AXIS CLAMP – 0.0625 PECK)

N25 C45.0 Q625 M89 (INDEX TO C45.0 - PECK DRILL W/C-AXIS CLAMP – 0.0625 PECK)

N26 C90.0 Q625 M89 (INDEX TO C90.0 - PECK DRILL W/C-AXIS CLAMP – 0.0625 PECK)

N27 C135.0 Q625 M89 (INDEX TO C135.0 - PECK DRILL W/C-AXIS CLAMP – 0.0625 PECK)

N28 C180.0 Q625 M89 (INDEX TO C180.0 - PECK DRILL W/C-AXIS CLAMP – 0.0625 PECK)

N29 C225.0 Q625 M89 (INDEX TO C225.0 - PECK DRILL W/C-AXIS CLAMP – 0.0625 PECK)

N30 C270.0 Q625 M89 (INDEX TO C270.0 - PECK DRILL W/C-AXIS CLAMP – 0.0625 PECK)

N31 C315.0 Q625 M89 (INDEX TO C315.0 - PECK DRILL W/C-AXIS CLAMP– 0.0625 PECK)

N32 G80 M90 (PECK CYCLE CANCEL - UNCLAMP C-AXIS)

N33 G00 Z10.0 (POSITION TO SAFE CLEARANCE ON G368 WORKPLANE)

N34 G369 (G368 PLANE ROTATION CANCEL)

(END PROGRAM/TOOL CHANGE PREPARATION)

N35 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N36 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N37 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N38 T05000 (CANCEL OFFSET FOR CURRENT TOOL)

N39 M139 (SHOWER BED COOLANT OFF)

N40 M127 (COOLANT THROUGH TOOL OFF)

N41 M05 P12 (B-AXIS SPINDLE STOP)

N42 M34 (LEFT SPINDLE C-AXIS MODE OFF)

N43 G490 S0 (EXPLICIT SPINDLE ORIENTATION FOR TOOL CHANGE)

N44 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N45 M30

%

Page 44

- 43 -

EXAMPLE #11 – ADVANCED C-AXIS/Y-AXIS MILLING – UPPER UNIT ONLY

MATERIAL : AISI 4140 ALLOY STEEL - 275 HB

STOCK : 4.0 OD X 6.0 LONG

PROJECTION: 3.5 MINIMUM FROM JAW FACE

ADAPTERS : SANDVIK C6 ER32 COLLET HOLDER THRU COOLANT

TOOL : 0.75 SOLID CARBIDE END MILL

SPINDLE : B-AXIS HEAD

WORK COORD: G54

ORIGIN : X0.0 = LEFT MAIN SPINDLE CENTERLINE, Z0.0 = FINISHED FACE

PROCESS : MILL HEX FLATS WITH BOTTOM OF TOOL

Q-SETTER : TOUCH OFF TOOL IN X ONLY AT B0.0

TOOL #6

ADAPTER : SANDVIK C6 ER32 COLLET HOLDER - THRU COOLANT

TOOL : 0.75 SOLID CARBIDE END MILL

ORIENTATION : LIVE TOOL - M101 (UNCLAMPED)

B-AXIS TILT : 0.0

Page 45

- 44 -

%

O0011(MX-EXAMPLE #11 - UPPER - LIVE MILL)

(PREPARATION FOR START OF PROGRAM)

(INITIALIZE - RAPID, ZX PLANE, TNR COMP CANCEL, TLO CANCEL, CYCLE CANCEL, UPR FEED)

N1 G00 G18 G40 G49 G80 G99

N2 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N3 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N4 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N5 G490 S0 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL CHANGE)

N6 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N7 M01

(PREPARATION FOR START OF OPERATION)

N8 G54 (WORK COORDINATE SELECTION)

N9 M06 T06006 (SANDVIK C6 ER32 COLLET HOLDER THRU COOLANT - 0.75 SOLID CARBIDE END MILL)

N10 T07000 (STAGE NEXT TOOL)

N11 M101 (LIVE B-AXIS SPINDLE - UNCLAMPED)

N12 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N13 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N14 M138 (SHOWER BED COOLANT ON)

N15 M126 (COOLANT THROUGH TOOL ON)

N16 M35 (LEFT SPINDLE C-AXIS MODE ON)

N17 G00 G28 H0.0 (ZERO RETURN C-AXIS)

N18 G97 S1500 M03 P12 (DIRECT RPM MODE - 500 RPM - B-AXIS SPINDLE CLOCKWISE)

N19 G00 C0.0

N20 G00 X8.0 Z4.0 (POSITION TO SAFE CLEARANCE)

N21 M89 (C-AXIS CLAMP)

N22 G00 Z1.0

(POSITION TO START POINT)

N23 X6.0

N24 Z-0.25

N25 Y-2.5

(MILL HEX FLAT AT C0.0)

N26 G01 X3.5 F0.0075

N27 Y2.5

N28 G00 X6.0

N29 M90 (C-AXIS UNCLAMP)

(MILL HEX FLAT AT C45.0)

N30 G00 C45.0

N31 M89 (C-AXIS CLAMP)

N32 Y-2.5

N33 G01 X3.5 F0.0075

N34 Y2.5

N35 G00 X6.0

N36 M90 (C-AXIS UNCLAMP)

(MILL HEX FLAT AT C90.0)

N37 G00 C90.0

N38 M89 (C-AXIS CLAMP)

N39 Y-2.5

N40 G01 X3.5 F0.0075

N41 Y2.5

N42 G00 X6.0

N43 M90 (C-AXIS UNCLAMP)

Page 46

- 45 -

(MILL HEX FLAT AT C135.0)

N44 G00 C135.0

N45 M89 (C-AXIS CLAMP)

N46 Y-2.5

N47 G01 X3.5 F0.0075

N48 Y2.5

N49 G00 X6.0

N50 M90 (C-AXIS UNCLAMP)

(MILL HEX FLAT AT C180.0)

N51 G00 C180.0

N52 M89 (C-AXIS CLAMP)

N53 Y-2.5

N54 G01 X3.5 F0.0075

N55 Y2.5

N56 G00 X6.0

N57 M90 (C-AXIS UNCLAMP)

(MILL HEX FLAT AT C225.0)

N58 G00 C225.0

N59 M89 (C-AXIS CLAMP)

N60 Y-2.5

N61 G01 X3.5 F0.0075

N62 Y2.5

N63 G00 X6.0

N64 M90 (C-AXIS UNCLAMP)

(MILL HEX FLAT AT C270.0)

N65 G00 C270.0

N66 M89 (C-AXIS CLAMP)

N67 Y-2.5

N68 G01 X3.5 F0.0075

N69 Y2.5

N70 G00 X6.0

N71 M90 (C-AXIS UNCLAMP)

(MILL HEX FLAT AT C315.0)

N72 G00 C315.0

N73 M89 (C-AXIS CLAMP)

N74 Y-2.5

N75 G01 X3.5 F0.0075

N76 Y2.5

N77 G00 X6.0

N78 M90 (C-AXIS UNCLAMP)

(POSITION TO SAFE CLEARANCE)

N79 G00 Z4.0

N80 G00 Y0.0

(END PROGRAM/TOOL CHANGE PREPARATION)

N81 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N82 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N83 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N84 T06000 (CANCEL OFFSET FOR CURRENT TOOL)

N85 M139 (SHOWER BED COOLANT OFF)

N86 M127 (COOLANT THROUGH TOOL OFF)

N87 M05 P12 (B-AXIS SPINDLE STOP)

N88 M34 (LEFT SPINDLE C-AXIS MODE OFF)

N89 G490 S0 (EXPLICIT SPINDLE ORIENTATION FOR TOOL CHANGE)

N90 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N91 M30

%

Page 47

- 46 -

EXAMPLE #12 – ADVANCED C-AXIS MILLING – UPPER UNIT ONLY

MATERIAL : AISI 4140 ALLOY STEEL - 275 HB

STOCK : 4.0 OD X 6.0 LONG

PROJECTION: 3.5 MINIMUM FROM JAW FACE

ADAPTERS : SANDVIK C6 ER32 COLLET HOLDER THRU COOLANT

TOOL : 0.75 SOLID CARBIDE END MILL

SPINDLE : B-AXIS HEAD

WORK COORD: G54

ORIGIN : X0.0 = LEFT MAIN SPINDLE CENTERLINE, Z0.0 = FINISHED FACE

PROCESS : MILL HEX FLATS WITH SIDE OF TOOL – C-AXIS POLAR INERPOLATION

Q-SETTER : TOUCH OFF TOOL IN X ONLY AT B0.0

TOOL #6

ADAPTER : SANDVIK C6 ER32 COLLET HOLDER - THRU COOLANT

TOOL : 0.75 SOLID CARBIDE END MILL

ORIENTATION : LIVE TOOL - M101 (UNCLAMPED)

B-AXIS TILT : -90.0

Page 48

- 47 -

%

O0012(MX-EXAMPLE #12 - UPPER - G400 LIVE MILL)

(PREPARATION FOR START OF PROGRAM)

(INITIALIZE - RAPID, ZX PLANE, TNR COMP CANCEL, TLO CANCEL, CYCLE CANCEL, UPR FEED)

N1 G00 G18 G40 G49 G80 G99

N2 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N3 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N4 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N5 G490 S0 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL CHANGE)

N6 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N7 M01

(PREPARATION FOR START OF OPERATION)

N8 G54 (WORK COORDINATE SELECTION)

N9 M06 T06006 (SANDVIK C6 ER32 COLLET HOLDER THRU COOLANT - 0.75 SOLID CARBIDE END MILL)

N10 T07000 (STAGE NEXT TOOL)

N11 G490 S0 (EXPLICIT B-AXIS SPINDLE ORIENTATION FOR TOOL)

N12 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N13 M138 (SHOWER BED COOLANT ON)

N14 M126 (COOLANT THROUGH TOOL ON)

N15 M35 (LEFT SPINDLE C-AXIS MODE ON)

N16 G00 G28 H0.0 (ZERO RETURN C-AXIS)

N17 G00 C0.0

N18 G400 B-90.0 J0.0 (ENGAGE G400 TOOL POINT CONTROL)

(B-90.0 = ANGLE OF HEAD TILT)

(J0.0 = B-AXIS SPINDLE UNLOCKED)

N19 G00 X8.0 Z4.0 (POSITION TO SAFE CLEARANCE POINT)

N20 M101

N22 G00 X5.0 Z1.0 (POSITION TO CLEARANCE POINT)

(MILL HEX WITH HELICAL CLIMB MILL CONTOUR WITH CUTTER RADIUS COMPENSATION)

N23 G12.1 (POLAR COORDINATE INTERPOLATION MODE ON)

N24 G98 (UNIT PER MINUTE FEED)

N25 G01 X3.3198 C2.125 F100.0

N26 Z0.1

N27 G01 Z0. F30.0

N28 G41 X2.5762 C2.0761

N29 G03 X2.6702 C1.9375 R0.375

N30 G01 X4.6910 C0.1875 Z-0.0087

N31 G02 X4.7914 C0. Z-0.0095 R0.375

N32 X4.6910 C-0.1875 Z-0.0104 R0.375

N33 G01 X2.6702 C-1.9375 Z-0.0191

N34 G02 X2.0208 C-2.125 Z-0.0208 R0.375

N35 G01 X-2.0208 Z-0.0296

N36 G02 X-2.6702 C-1.9375 Z-0.0313 R0.375

N37 G01 X-4.6910 C-0.1875 Z-0.04

N38 G02 X-4.7914 C0. Z-0.0408 R0.375

N39 X-4.6910 C0.1875 Z-0.0417 R0.375

N40 G01 X-2.6702 C1.9375 Z-0.0504

N41 G02 X-2.0208 C2.125 Z-0.0521 R0.375

N42 G01 X2.0208 Z-0.0608

N43 G02 X2.6702 C1.9375 Z-0.0625 R0.375

N44 G01 X4.6910 C0.1875 Z-0.0712

N45 G02 X4.7914 C0. Z-0.072 R0.375

N46 X4.6910 C-0.1875 Z-0.0729 R0.375

N47 G01 X2.6702 C-1.9375 Z-0.0816

N48 G02 X2.0208 C-2.125 Z-0.0833 R0.375

N49 G01 X-2.0208 Z-0.0921

N50 G02 X-2.6702 C-1.9375 Z-0.0938 R0.375

N51 G01 X-4.6910 C-0.1875 Z-0.1025

N21 G97 S1500 M03 P12 (DIRECT RPM MODE - 1500 RPM - B-AXIS SPINDLE CLOCKWISE)

Page 49

- 48 -

N52 G02 X-4.7914 C0. Z-0.1033 R0.375

N53 X-4.6910 C0.1875 Z-0.1042 R0.375

N54 G01 X-2.6702 C1.9375 Z-0.1129

N55 G02 X-2.0208 C2.125 Z-0.1146 R0.375

N56 G01 X2.0208 Z-0.1233

N57 G02 X2.6702 C1.9375 Z-0.125 R0.375

N58 G01 X4.6910 C0.1875 Z-0.1337

N59 G02 X4.7914 C0. Z-0.1345 R0.375

N60 X4.6910 C-0.1875 Z-0.1354 R0.375

N61 G01 X2.6702 C-1.9375 Z-0.1441

N62 G02 X2.0208 C-2.125 Z-0.1458 R0.375

N63 G01 X-2.0208 Z-0.1546

N64 G02 X-2.6702 C-1.9375 Z-0.1563 R0.375

N65 G01 X-4.6910 C-0.1875 Z-0.165

N66 G02 X-4.7914 C0. Z-0.1658 R0.375

N67 X-4.6910 C0.1875 Z-0.1667 R0.375

N68 G01 X-2.6702 C1.9375 Z-0.1754

N69 G02 X-2.0208 C2.125 Z-0.1771 R0.375

N70 G01 X2.0208 Z-0.1858

N71 G02 X2.6702 C1.9375 Z-0.1875 R0.375

N72 G01 X4.6910 C0.1875 Z-0.1962

N73 G02 X4.7914 C0. Z-0.197 R0.375

N74 X4.6910 C-0.1875 Z-0.1979 R0.375

N75 G01 X2.6702 C-1.9375 Z-0.2066

N76 G02 X2.0208 C-2.125 Z-0.2083 R0.375

N77 G01 X-2.0208 Z-0.2171

N78 G02 X-2.6702 C-1.9375 Z-0.2188 R0.375

N79 G01 X-4.6910 C-0.1875 Z-0.2275

N80 G02 X-4.7914 C0. Z-0.2283 R0.375

N81 X-4.6910 C0.1875 Z-0.2292 R0.375

N82 G01 X-2.6702 C1.9375 Z-0.2379

N83 G02 X-2.0208 C2.125 Z-0.2396 R0.375

N84 G01 X2.0208 Z-0.2483

N85 G02 X2.6702 C1.9375 Z-0.25 R0.375

N86 G01 X4.6910 C0.1875 Z-0.2587

N87 G02 X4.7914 C0. Z-0.2595 R0.375

N88 X4.6910 C-0.1875 Z-0.2604 R0.375

N89 G01 X2.6702 C-1.9375 Z-0.2691

N90 G02 X2.0208 C-2.125 Z-0.2708 R0.375

N91 G01 X-2.0208 Z-0.2796

N92 G02 X-2.6702 C-1.9375 Z-0.2813 R0.375

N93 G01 X-4.6910 C-0.1875 Z-0.29

N94 G02 X-4.7914 C0. Z-0.2908 R0.375

N95 X-4.6910 C0.1875 Z-0.2917 R0.375

N96 G01 X-2.6702 C1.9375 Z-0.3004

N97 G02 X-2.0208 C2.125 Z-0.3021 R0.375

N98 G01 X2.0208 Z-0.3108

N99 G02 X2.6702 C1.9375 Z-0.3125 R0.375

N100 G01 X4.6910 C0.1875 Z-0.3212

N101 G02 X4.7914 C0. Z-0.322 R0.375

N102 X4.6910 C-0.1875 Z-0.3229 R0.375

N103 G01 X2.6702 C-1.9375 Z-0.3316

N104 G02 X2.0208 C-2.125 Z-0.3333 R0.375

N105 G01 X-2.0208 Z-0.3421

N106 G02 X-2.6702 C-1.9375 Z-0.3438 R0.375

N107 G01 X-4.6910 C-0.1875 Z-0.3525

N108 G02 X-4.7914 C0. Z-0.3533 R0.375

N109 X-4.6910 C0.1875 Z-0.3542 R0.375

N110 G01 X-2.6702 C1.9375 Z-0.3629

N111 G02 X-2.0208 C2.125 Z-0.3646 R0.375

N112 G01 X2.0208 Z-0.3733

N113 G02 X2.6702 C1.9375 Z-0.375 R0.375

N114 G01 X4.6910 C0.1875 Z-0.3837

N115 G02 X4.7914 C0. Z-0.3845 R0.375

N116 X4.6910 C-0.1875 Z-0.3854 R0.375

N117 G01 X2.6702 C-1.9375 Z-0.3941

Page 50

- 49 -

N118 G02 X2.0208 C-2.125 Z-0.3958 R0.375

N119 G01 X-2.0208 Z-0.4046

N120 G02 X-2.6702 C-1.9375 Z-0.4063 R0.375

N121 G01 X-4.6910 C-0.1875 Z-0.415

N122 G02 X-4.7914 C0. Z-0.4158 R0.375

N123 X-4.6910 C0.1875 Z-0.4167 R0.375

N124 G01 X-2.6702 C1.9375 Z-0.4254

N125 G02 X-2.0208 C2.125 Z-0.4271 R0.375

N126 G01 X2.0208 Z-0.4358

N127 G02 X2.6702 C1.9375 Z-0.4375 R0.375

N128 G01 X4.6910 C0.1875 Z-0.4462

N129 G02 X4.7914 C0. Z-0.447 R0.375

N130 X4.6910 C-0.1875 Z-0.4479 R0.375

N131 G01 X2.6702 C-1.9375 Z-0.4566

N132 G02 X2.0208 C-2.125 Z-0.4583 R0.375

N133 G01 X-2.0208 Z-0.4671

N134 G02 X-2.6702 C-1.9375 Z-0.4688 R0.375

N135 G01 X-4.6910 C-0.1875 Z-0.4775

N136 G02 X-4.7914 C0. Z-0.4783 R0.375

N137 X-4.6910 C0.1875 Z-0.4792 R0.375

N138 G01 X-2.6702 C1.9375 Z-0.4879

N139 G02 X-2.0208 C2.125 Z-0.4896 R0.375

N140 G01 X2.0208 Z-0.4983

N141 G02 X2.6702 C1.9375 Z-0.5 R0.375

N142 G01 X4.6910 C0.1875 Z-0.5087

N143 G02 X4.7914 C0. Z-0.5095 R0.375

N144 X4.6910 C-0.1875 Z-0.5104 R0.375

N145 G01 X2.6702 C-1.9375 Z-0.5191

N146 G02 X2.0208 C-2.125 Z-0.5208 R0.375

N147 G01 X-2.0208 Z-0.5296

N148 G02 X-2.6702 C-1.9375 Z-0.5313 R0.375

N149 G01 X-4.6910 C-0.1875 Z-0.54

N150 G02 X-4.7914 C0. Z-0.5408 R0.375

N151 X-4.6910 C0.1875 Z-0.5417 R0.375

N152 G01 X-2.6702 C1.9375 Z-0.5504

N153 G02 X-2.0208 C2.125 Z-0.5521 R0.375

N154 G01 X2.0208 Z-0.5608

N155 G02 X2.6702 C1.9375 Z-0.5625 R0.375

N156 G01 X4.6910 C0.1875 Z-0.5712

N157 G02 X4.7914 C0. Z-0.572 R0.375

N158 X4.6910 C-0.1875 Z-0.5729 R0.375

N159 G01 X2.6702 C-1.9375 Z-0.5816

N160 G02 X2.0208 C-2.125 Z-0.5833 R0.375

N161 G01 X-2.0208 Z-0.5921

N162 G02 X-2.6702 C-1.9375 Z-0.5938 R0.375

N163 G01 X-4.6910 C-0.1875 Z-0.6025

N164 G02 X-4.7914 C0. Z-0.6033 R0.375

N165 X-4.6910 C0.1875 Z-0.6042 R0.375

N166 G01 X-2.6702 C1.9375 Z-0.6129

N167 G02 X-2.0208 C2.125 Z-0.6146 R0.375

N168 G01 X2.0208 Z-0.6233

N169 G02 X2.6702 C1.9375 Z-0.625 R0.375

N170 G01 X4.6910 C0.1875

N171 G02 X4.7914 C0. R0.375

N172 X4.6910 C-0.1875 R0.375

N173 G01 X2.6702 C-1.9375

N174 G02 X2.0208 C-2.125 R0.375

N175 G01 X-2.0208

N176 G02 X-2.6702 C-1.9375 R0.375

N177 G01 X-4.6910 C-0.1875

N178 G02 X-4.7914 C0. R0.375

N179 X-4.6910 C0.1875 R0.375

N180 G01 X-2.6702 C1.9375

N181 G02 X-2.0208 C2.125 R0.375

N182 G01 X2.0208

N183 G02 X2.6702 C1.9375 R0.375

Page 51

- 50 -

N184 G03 X2.8632 C1.8275 R0.375

N185 G01 G40 X3.3198 C2.125

N186 Z0.1

N187 Z2.0 F100.0

N188 G13.1 (POLAR COORDINATE INTERPOLATION MODE OFF)

N189 G99 (UNIT PER REVOLUTION FEED)

N190 G00 X8.0 Z4.0 (POSITION TO SAFE CLEARANCE POINT)

N191 C0.0

(END PROGRAM/TOOL CHANGE PREPARATION)

N192 G00 G28 U0.0 V0.0 (ZERO RETURN X-AXIS & Y-AXIS)

N193 G00 G28 W0.0 (ZERO RETURN Z-AXIS)

N194 G00 G28 B0.0 (ZERO RETURN B-AXIS)

N195 T06000 (CANCEL OFFSET FOR CURRENT TOOL)

N196 M139 (SHOWER BED COOLANT OFF)

N197 M127 (COOLANT THROUGH TOOL OFF)

N198 M05 P12 (B-AXIS SPINDLE STOP)

N199 M34 (LEFT SPINDLE C-AXIS MODE OFF)

N200 G490 S0 (EXPLICIT SPINDLE ORIENTATION FOR TOOL CHANGE)

N201 G00 B-90.0 (EXPLICIT B-AXIS POSITIONING FOR TOOL CHANGE)

N202 M30

%

Page 52

- 51 -

EXAMPLE #13 – ADVANCED 5-AXIS OPERATIONS – UPPER UNIT ONLY

MATERIAL : AISI 4140 ALLOY STEEL - 275 HB

STOCK : 3.5 OD X 7.75 LONG FORGING

3D MODEL : PARASOLID FILE O0013.X_T

PROJECTION: 3.5 MINIMUM FROM JAW FACE

ADAPTERS : SANDVIK C6 ER32 COLLET HOLDER THRU COOLANT

TOOL : 0.75 SOLID CARBIDE END MILL

SPINDLE : B-AXIS HEAD

WORK COORD: G54

ORIGIN : X0.0 = LEFT MAIN SPINDLE CENTERLINE, Z0.0 = FINISHED FACE

PROCESS : MILL 37.5° FACE FEATURES WITH SIDE OF TOOL – 5-AXIS CONTINUOUS

Q-SETTER : TOUCH OFF TOOL IN X ONLY AT B0.0

TOOL #6

ADAPTER : SANDVIK C6 ER32 COLLET HOLDER - THRU COOLANT

TOOL : 0.75 SOLID CARBIDE END MILL

ORIENTATION : LIVE TOOL - M101 (UNCLAMPED)

B-AXIS TILT : CONTINUOUS 5-AXIS WITH TCP MODE (G700)

Page 53

- 52 -

Page 54

- 53 -

Advanced 5-Axis Operations:

The MX-Series has both a Nutating (Articulating) head and a Rotary Axis (C1 Left Main Spindle ,C2

Right Main Spindle). The C-Axis(C1 & C2) is mechanically independent of the B-Axis head.

If we do not use TCP (Tool Center Point) mode then we are required to use the traditional method of

calculating X, Y, Z, C and B. In a CAM system, the part will remain static and the system will create

5-axis toolpath vectors around the desired geometry. These vectors represent the centerline axis of

the cutting tool and are used to calculate the required position and angles.

The tip of the tool will have XYZ positions based relative to the origin of the part in the CAM system.

On a machine like the MX-Series, the C axis angle would be calculated first.

This is necessary to align a tool vector to the ZX plane as the B-Axis only rotates in this plane.

Once that angle of rotation is known, the CAM system then calculates the X,Y positions required

based on the C axis rotation. Since the Z-axis is the centerline of the C axis rotation, the Z axis

position isn't effected by the C axis rotation. We now have the new X, Y, Z and C known within the

CAM system.

The CAM system next calculates the B-Axis angle based on the toolpath vectors.

Since all tools have differing lengths, the position of the B-Axis head needs to be adjusted based on

those tools lengths and B-Axis angle. The only coordinates effected by the length of the tool and the

B-Axis rotation are X & Z. Our next step is to calculate new X & Z coordinates based on the distance

from the tip of the tool to the center of rotation of the B-axis head. This process would need to be

repeated for every toolpath point.

All of these calculations are typically handled within the Post-Processor of the CAM system.

The Post-Processor is the last step in the process as it formats any work done in a CAM system to a

useable NC Code file that will operate a CNC Machine Tool.

Doosan TCP Mode for 5-Axis Machining - G700/G701

Page 55

- 54 -

As one can plainly see, this is a complicated process.

Fanuc TCP Mode is designed for Nutating (Articulating) heads to simplify multi-axis programming by

having the machine itself control the position of the tip of the tool during based on the specific tool

gage length. Using the Q-Setter, with the B-Axis at 0.0 and touching off in the X-axis only, establishes

that gage length. With TCP mode, the relationship between the tool center point (control point) and

the workpiece stays constant,

Doosan has further enhanced the TCP functionality of the MX-Series by also applying it to the C-Axis

Rotary Axis. This results in simplified programming and a more efficient toolpath motion kinematically