Doosan P185WDOU-T4F, P185WDO-T4F Operation And Maintenance Manual

OPERATION and MAINTENANCE

PDF versions of the Parts Manual and the Electronic Service Manual

are available for download at:

http://www.doosanportablepower.com/en/aftermarket/parts/online-parts-manuals

MANUAL

COMPRESSOR MODEL

P185WDOU-T4F (F89)

Doosan Infracore Portable Power

1293 Glenway Drive

tesville, N.C. 28625

Sta

DoosanPortablePower.com

P/N: 46680186 (10-2015) Rev A

TABLE OF CONTENTS

Operation & Maintenance Manual

TITLE

PAGE

FOREWORD ..........................................................................................................................9

Information..................................................................................................................................... 10

SAFETY ...............................................................................................................................13

Safety Precautions ......................................................................................................................... 14

Compressed Air..........................................................................................................................14

ExhaustSystem......................................................................................................................... 15

Materials.................................................................................................................................... 16

Battery....................................................................................................................................... 17

Radiator ..................................................................................................................................... 17

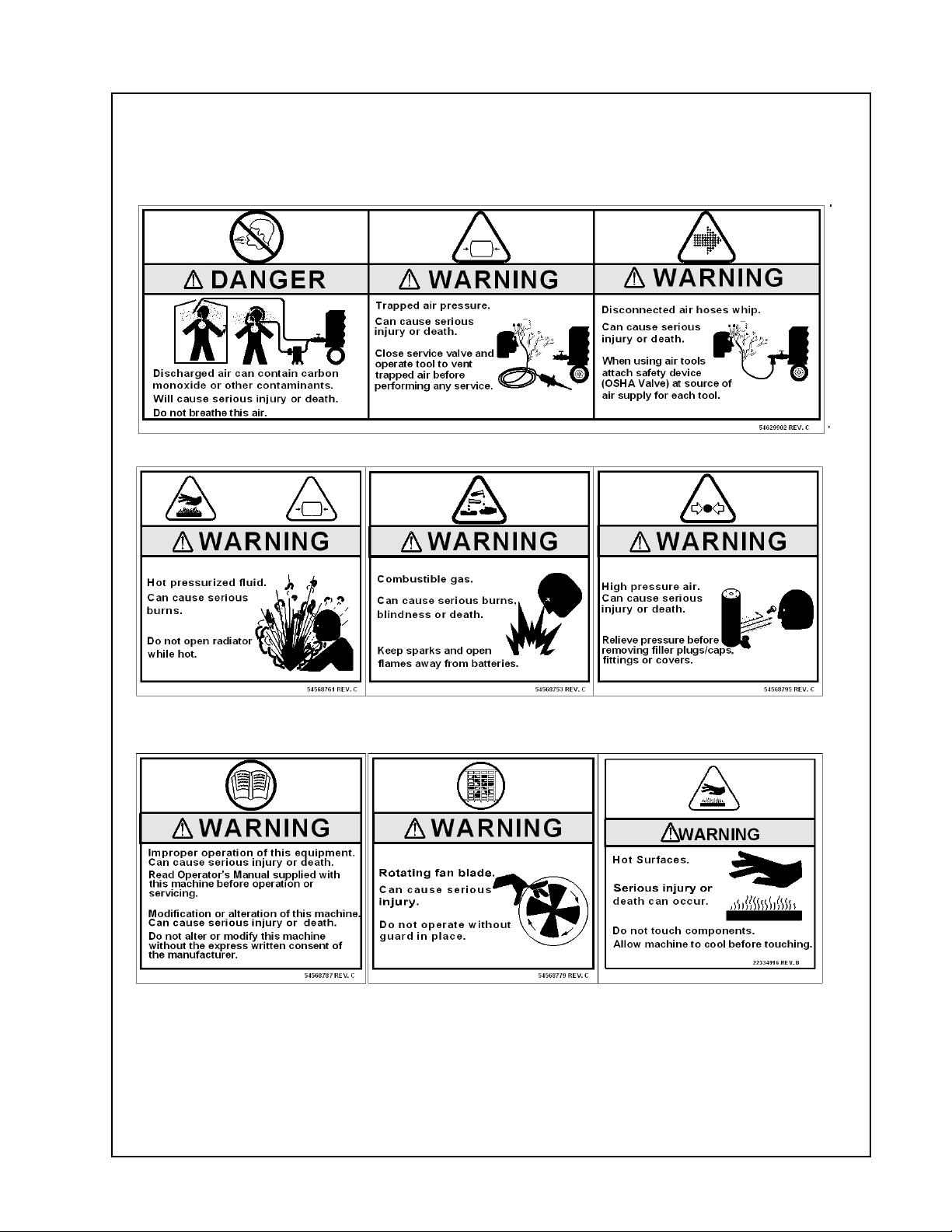

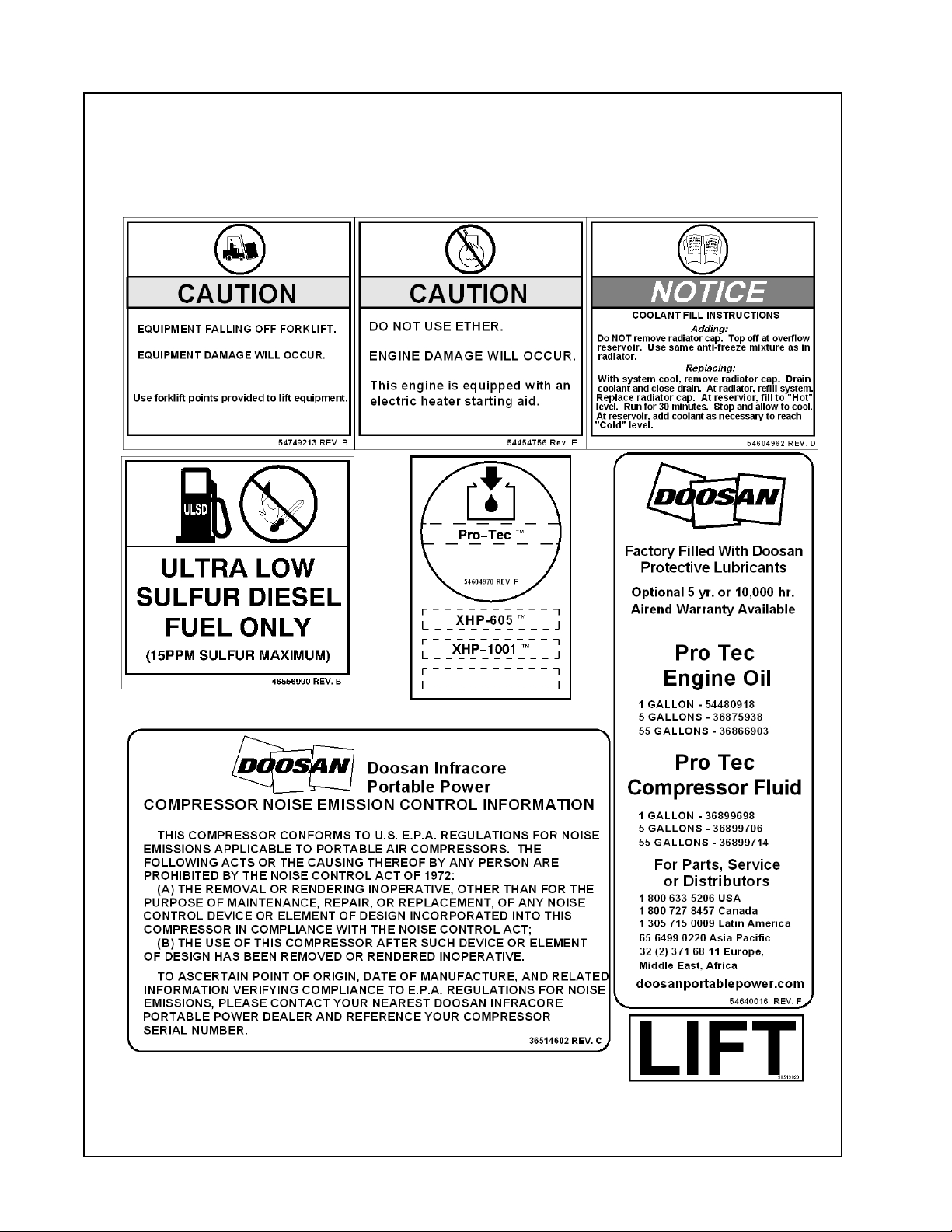

Decals....................................................................................................................................... 19

Decals................................................................................................................................. 21

NOISE EMISSION................................................................................................................25

Noise Emission............................................................................................................................... 26

Introduction .................................................................................................................................... 26

Maintenance Schedule.................................................................................................................... 27

Noise Emission Warranty ............................................................................................................... 29

Maintenance Log ............................................................................................................................ 30

GENERAL DATA .................................................................................................................33

General Data Information................................................................................................................ 34

OPERATING INSTRUCTIONS ............................................................................................37

Control/Gauge Panel ...................................................................................................................... 38

Auto Power Off ............................................................................................................................... 40

Quick View Screens........................................................................................................................ 41

Fault and Alert ............................................................................................................................... 41

Service Interval Set Up ................................................................................................................... 44

Display Setup ................................................................................................................................. 46

TABLE OF CONTENTS

Operation & Maintenance Manual

TITLE

Language and Units........................................................................................................................ 47

Compressor ID................................................................................................................................ 48

Utility Package Set-Up (no running gear)........................................................................................ 48

Before Starting ............................................................................................................................... 48

Starting........................................................................................................................................... 50

Shutdown ....................................................................................................................................... 51

Pressure Regulator Adjustment Instructions ................................................................................. 52

PAGE

ENGINE OPERATION..........................................................................................................53

Engine Operation and Maintenance................................................................................................ 54

SAFETY..................................................................................................................................... 54

Instructions ................................................................................................................................ 55

GeneralRepair........................................................................................................................... 57

Environmental Pollution .............................................................................................................. 58

Engine Management................................................................................................................... 59

Preventionof Pollution................................................................................................................ 60

Start and Shutdown.................................................................................................................... 61

Break-in Period of Engine............................................................................................................ 62

Inspectionafter Starting the Engine ............................................................................................. 63

Operation in Winter..................................................................................................................... 64

RegularInspection...................................................................................................................... 65

Checking the Engine Oil........................................................................................................ 66

Replacementof EngineOil.................................................................................................... 68

Coolant ................................................................................................................................ 70

Checking the Coolant...................................................................................................... 71

Replenishment of Coolant............................................................................................... 74

Replacementof Coolant.................................................................................................. 75

FuelSystem ................................................................................................................... 76

LUBRICATION .....................................................................................................................79

Compressor Oil Chart..................................................................................................................... 80

MAINTENANCE ...................................................................................................................83

General Information........................................................................................................................ 84

Compressor Oil Filters.................................................................................................................... 87

Receiver Separator System ............................................................................................................ 88

TABLE OF CONTENTS

Operation & Maintenance Manual

TITLE

Scavenge Line ................................................................................................................................ 89

Exterior Finish Care........................................................................................................................ 89

Field Replacement of Exterior Decals............................................................................................. 91

PAGE

TROUBLESHOOTING .........................................................................................................95

Introduction .................................................................................................................................... 97

Troubleshooting Chart.................................................................................................................... 98

Diagnostic Codes ..........................................................................................................................105

TABLE OF CONTENTS

Operation & Maintenance Manual

TITLE

PAGE

FOREWORD

9

Operation & Maintenance Manual FOREWORD

Information

The contents o

Infracore Portable Power (herein referred to as “Portable Power”), and should not be

reproduced without the prior written permission of Portable Power.

Nothing con

representation, expressed or implied, regarding the Portable Power products described

herein. Any such warranties or other terms and conditions of sale of products shall be in

accordanc

available upon request.

This manual contains instructions and technical data to cover all routine operation and

schedule

outside the scope of this manual and should be referred to an authorized Portable Power

Service department.

All comp

should be:

onents, accessories, pipes, and connectors added to the compressed air system

• of good quality, procured from a reputable manufacturer and, wherever possible,

• clearly rated for a pressure at least equal to the compressor safety valve setting.

• compatible with the compressor oil.

•accom

f this manual are considered to be proprietary and confidential to Doosan

tained in this document is intended to extend any promise, warranty or

e with the standard terms and conditions of sale for such products, which are

d maintenance tasks by operation and maintenance staff. Major overhauls are

be of a t

ype approved by Portable Power.

panied with instructions for safe installation, operation, and maintenance.

Details of approved equipment are available from the Portable Power Service departments.

The use of repair parts other than those included within the approved parts list may c reate

rdous conditions over which Portable Power has no control. Therefore, Portable Power

haza

cannot be held responsible for equipment in which non-approved repair parts are installed.

Portable Power reserves the right to make changes and improvements to products without

ice and without incurring any obligation to make such changes or add such improvements

not

to products sold previously.

The intended uses of this compressor are outlined below and examples of unapproved

age are also given. However, Portable Power cannot anticipate every application or work

us

situation that may arise. If in doubt, consult supervision.

This compressor has been designed and supplied for above ground operation to be used for

ompression of normal ambient air containing no additional gases, vapors, or particles within

c

the ambient temperature range specified in the General Data Section of this manual.

10

FOREWORD Operation & Maintenance Manual

This compressor should not be used:

• For direct or indirect human consumption of the compressed air.

• Outside the am

bient temperature range specified in the General Data Section of

this manual.

• When an actual or foreseeable risk of hazardous levels of flammable gases or

vapors exist

s.

• With other than Portable Power approved components.

• With guards, controls, or switches missing or disabled.

• For storag

e or transportation of materials inside or on the enclosure.

Portable Power accepts no responsibility for errors in translation of this manual from the

original English version.

You, as th

e customer, are expected to provide certain service and maintenance items. Your

Portable Power dealer will provide all other more detailed service and maintenance items on

a special preventive maintenance schedule for each compressor. It is very important that the

minimum

service and maintenance requirements explained in this manual be performed at

the required intervals. Exceeding these intervals may reduce the reliability of the compressor.

The purpose of this manual is to train the operator with functions, operation, and basic

e and maintenance requirements of the compressor. During the preparation of this

servic

manual, every effort was made to ensure the accuracy and adequacy of the contents.

Your Portable Power dealer will assist with setup and initial startup of the compressor and

lso provide brief operating and service instructions. Before starting the compressor,

will a

this manual and instructions should be carefully read to obtain a thorough knowledge of the

duties to be performed. Please take pride in the compressor, keep it clean and in good

anical condition.

mech

To enable proper maintenance records, Portable Power provides a Noise Emission Control

Maintenance Log in the Noise Emission Section of this manual. The Noise Emission Section

tains a recommended Maintenance schedule and provides space in the log for the

con

technician to note what service and maintenance was done, by whom, where, and when.

11

12

SAFETY

13

Operation & Maintenance Manual SAFETY

Safety Precautions

Never operate

the Operation and Maintenance Manual shipped from the factory with this compressor.

Ensure the operator reads and understands the decals and consults the manuals before

operation o

Ensure all maintenance personnel are adequately trained, competent, and have read the

manuals.

Ensure all

The specification of this compressor is such that the compressor is not suitable for use in

flammable gas risk areas. If such an application is required, all local regulations, codes of

practice

and reliable manner, additional equipment such as gas detection, exhaust spark arrestors,

and intake (shut-off) valves may be required, dependent on local regulations or the degree

of risk i

A weekly visual check must be made of all fasteners/fixing screws securing mechanical parts.

In particular, safety-related parts such as coupling hitch, drawbar components, wheels, tires,

and lif

All components which are loose, damaged, or unserviceable must be rectified without delay.

Air discharged from this compressor may contain carbon monoxide or other contaminants

which

, and site rules must be observed. To ensure the compressor can operate in a safe

nvolved.

ting bail should be checked for total security.

will cause serious injury or death. Do not breathe discharged air.

the compressor without first observing all safety warnings and carefully reading

r performing maintenance.

protective covers are in place and the canopy/doors are closed during operation.

This compressor produces loud noise with the doors open or service valve vented. Extended

exposure to loud noise can cause hearing loss. Always wear hearing protection when doors

pen or service valve is vented.

are o

Never inspect or service the compressor without first disconnecting battery cable(s) to

prevent accidental starting.

not use petroleum products (solvents or fuels) under high pressure as this can penetrate

Do

the skin and result in serious illness. Wear eye protection while cleaning the compressor

with compressed air to prevent debris from injuring eye(s).

otating fan blade can cause serious injury. Do not operate without fan guard in place.

R

Use care to avoid contacting hot surfaces (engine exhaust manifold and piping, air receiver,

and air discharge piping, etc.).

Never operate the compressor with guards, covers, or screens removed. Keep hands, hair,

clothing, tools, blow gun tips, etc. well away from moving parts.

Compressed Air

Compressed air can be dangerous if incorrectly handled. Prior to performing maintenance

or service on the compressor, ensure all pressure is vented from the system and the

compressor cannot be started accidentally.

14

Ensure the compressor is operating at the rated pressure and the rated pressure is known

to all relevant personnel.

SAFETY Operation & Maintenance Manual

All air pressure equipment installed in, or connected to, the compressor must have safe

working pressure ratings of at least the compressor safety valve setting.

If more than on

valves and isolation valves must be fitted and controlled by work procedures, to ensure one

compressor cannot accidentally be pressurized or over pressurized by another.

Compressed a

or mask.

Compressed air can cause serious injury or death. Relieve pressure before removing filler

plugs/caps

Air pressure can remain trapped in air supply line which can result in serious injury or death.

Always carefully vent air supply line at tool or vent valve before performing any service or

maintena

Discharged air contains a very small percentage of compressor lubricating oil and care

should be taken to ensure downstream equipment is compatible.

If disch

must be provided.

When using compressed air, always use appropriate personal protective equipment.

All pre

inspected, be free from defects, and be replaced according to the manual instructions.

Avoid bodily contact with compressed air.

arged air is to be ultimately released into a confined space, adequate ventilation

ssure containing parts, especially flexible hoses and their couplings, must be regularly

e c ompressor is connected to one common downstream plant, effective check

ir must NOT be used for a direct feed to any form of breathing apparatus

, fittings, or covers.

nce.

The sa

operation.

Whenever the compressor is stopped, air will flow back into the compressor from downstream

devi

service valve to prevent reverse flow in the event of an unexpected shutdown when the

service valve is open.

Dis

flow restrictor to each hose at the s ource of supply or branch line in accordance with OSHA

Regulation 29CFR Section 1926.302(b).

Ne

fety valve located in the separator tank must be checked periodically for correct

ces or systems unless the service valve is closed. Install a check valve at the compressor

connected air hoses whip and can cause serious injury or death. A lways attach a safety

ver allow the compressor to sit stopped with pressure in the separator tank or piping.

Exhaust System

Hot engine exhaust gas and hot exhaust system surfaces are produced during and after

compressor operation. Avoid contact with exhaust gas and hot exhaust system surfaces.

Keep flammable and combustible materials away. Do not operate compressor on, under, or

near flammable or combustible materials.

15

Operation & Maintenance Manual SAFETY

Materials

The following substances may be produced during the operation of this compressor:

• brake lining dust

• engine exhau

Ensure tha

all times.

The following substances are used in the manufacture of this compressor and may be

hazardou

t adequate ventilation of the cooling system and exhaust gases is maintained at

s to health if used incorrectly:

• compressor oil

• preservative grease, lubricating grease

•rustpr

• battery electrolyte

eventative

st fumes

Avoid inhalation of material substances.

Avoid

ingestion, skin contact, and inhalation of fumes.

16

SAFETY Operation & Maintenance Manual

Should compressor oil come into contact with the eyes, irrigate with water for at least 5

minutes.

Should compre

physician if large amounts of compressor oil are ingested or if compressor oil is inhaled.

Never give fluids or induce vomiting if the patient is unconscious or having convulsions.

Safety data s

Do NOT start or operate this compressor in a confined area. Avoid breathing exhaust fumes

when working on or near the compressor.

This compre

filters, and batteries which may require proper disposal when performing maintenance or

service tasks. Contact local authorities for proper disposal of these materials.

ssor oil come into contact with the skin, wash off immediately. Consult a

heets for compressor and engine oils should be obtained from the oil supplier.

ssor may include such materials as oil, diesel fuel, antifreeze, brake fluid, oil/air

Battery

A batter

explosive. Avoid contact with skin, eyes, and clothing. In case of contact, flush area

immediately with water.

y contains sulfuric acid and can produce gases which are corrosive and potentially

Do not attempt to jump start a frozen battery since this may cause the

battery to explode.

cise extreme caution when using an external method to jump start

Exer

a unit. Verify the electrical systems on the weak battery system and

the external jump system are the same voltage type system, 12VDC

4VDC. Connect the Positive (+) terminal of the external system to

or 2

the Positive (+) terminal on the weak system. Connect the Negative (-)

terminal of the external system to the Negative (-) terminal of the weak

tem. Always disconnect the two systems in reverse order.

sys

Radiator

Hot engine coolant and steam can cause injury. Ensure the Radiator Pressure Cap is

removed with due care and attention.

o not remove the pressure cap from a HOT radiator. Allow radiator to cool before removing

D

pressure cap.

17

Operation & Maintenance Manual SAFETY

Hot engine coolant and steam can cause injury. When adding coolant

or antifreeze solution to the engine radiator, stop the engine and allow

radiator to cool prior to releasing the Radiator Pressure Cap. Using a

cloth to protect the hand, slowly release the pressure cap, absorbing

any released f uid with the cloth. Do not remove the pressure cap

until all excess f uid is released and the engine cooling system fully

depressurized.

Follow th

e instructions provided by the antifreeze supplier when adding

or draining the antifreeze solution. It is advisable to wear personal

protective equipment to prevent skin and eye contact with the antifreeze

solutio

n.

The potential for higher temperatures is present when the exhaust

treatment system undergoes regeneration. Refer to Engine

after

Manual for further safety instructions and information on the exhaust

aftertreatment system and controls.

18

SAFETY Operation & Maintenance Manual

Decals

Decals are located on the compressor to point out potential safety hazards. Read and follow

these instructions. If you do not understand these instructions, inform your supervisor.

(Red Background)

Indicates the presence of a hazard which WILL cause serious injury,

death, or p

Indicates the presence of a hazard which CAN cause serious injury,

death, o

roperty damage, if ignored.

(Orange Background)

r property damage, if ignored.

(Yellow Background)

Indicates the presence of a hazard which WILL or CAN cause injury or

prope

rty damage, if ignored.

19

Operation & Maintenance Manual SAFETY

(Blue Background)

Indicates important set-up, operating, or maintenance information.

FREE SAFETY DECALS

To promote communication of Safety Warnings on products

manufactured by the Portable Power Division in Statesville, N.C., Safety

Decals are available FREE of charge. Safety Decals are identif ed by the

decal heading: DANGER, WARNING, CAUTION, NOTICE.

Decal part numbers are located in the lower right hand corner of each

decal and are also listed in the compressor Parts Manual. Submit orders

for Safety Decals to the Statesville Parts Service Dept. The no charge

order should contain only Safety Decals.

Help promote product safety! Ensure decals are present on the

compressor. Replace decals that are not readable.

20

SAFETY Operation & Maintenance Manual

Decals

21

Operation & Maintenance Manual SAFETY

22

SAFETY Operation & Maintenance Manual

23

24

NOISE EMISSION

25

Operation & Maintenance Manual NOISE EMISSION

Noise Emission

This section p

Compressor Noise Emission Control Information

Note: The a

with the U.S. Environmental Protection Agency.

Portable Power reserves the right to make changes or add improvements without notice

and witho

products sold previously.

The Purchaser is urged to include the above provisions in any agreement for any resale

of this c

Federal law prohibits the following acts or the causing thereof:

(1) The removal or rendering inoperative by any persons, other than for purposes of

mainte

any new compressor for the purpose of noise control prior to its sale or delivery to the ultimate

purchaser or while it is in use; or (2) the use of the compressor after such device or element

of des

ompressor.

nance, repair, or replacement, of any device or element of design incorporated into

ign has been removed or rendered inoperative by any person.

ertains only to compressors distributed within the United States.

Tampering with noise control system prohibited.

bove information applices only to compressors that are built in compliance

ut incurring any obligation to make s uch changes or add such improvements to

Among those acts included in the prohibition against tampering are these:

1. Removal or rendering inoperative any of the following:

he engine exhaust system or parts thereof

a. t

b. the air intake system or parts thereof

c. enclosure or parts thereof

2. Re

3. Operation of the compressor with any of the enclosure doors open.

moval of any of the following:

a. fan shroud

b. vibration mounts

. sound absorption material

c

Introduction

The compressor for which this Maintenance Log is provided conforms to U.S. E.P.A.

Regulations for Noise Emissions, applicable to Portable Air Compressors.

26

NOISE EMISSION Operation & Maintenance Manual

The purpose of this book is to provide (1) the Maintenance Performance Schedule for all

required noise emission controls and (2) space so that the purchaser or owner can record

what maintena

detailed instructions on the maintenance items are given on following page.

nce was done, by whom, where and when. The Maintenance Schedule and

27

Operation & Maintenance Manual NOISE EMISSION

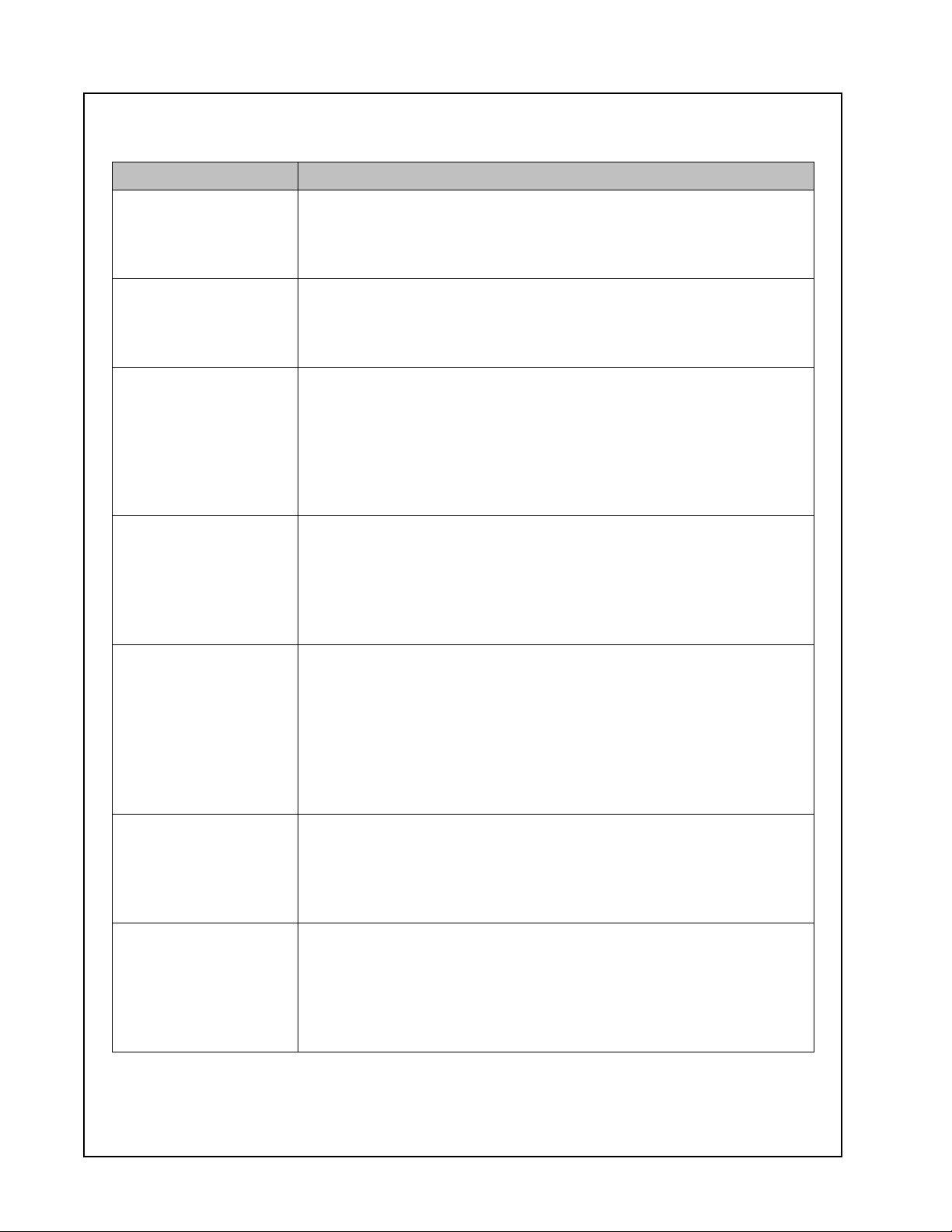

Maintenance Schedule

PERIOD DESCRIPTION

As Detected

As Detecte

Daily

100 HOURS FASTENERS

d

COMPRESSED AIR LEAKS

Correct all compressed air leaks during the first shutdown period

after disco

and efficiency loss, shut down immediately and correct the leak(s).

SAFETY AND CONTROL SYSTEMS

Repair or replace all safety and control systems or circuits as

malfunction occurs. No compressor should be operated with either

system bypassed, disabled, or nonfunctional.

ACOUSTIC MATERIALS

In daily inspections, observe these materials. Maintain all acoustic

materi

replace all sections that have: 1) sustained damage, 2) have

partially separated from panels to which they were attached, 3) are

missi

storage conditions.

All fasteners such as hinges, nuts, bolts, clamps, screws, rivets,

and latches should be inspected for looseness after each 100

hours of operation. They should be retightened, repaired, or if

missing, replaced immediately to prevent subsequent damage and

noise emission increase.

very. If severe enough to cause serious noise problems

al as nearly as possible in its original condition. Repair or

ng, or have otherwise deteriorated due to severe operating or

0HOURS

10

100 HOURS AIR INTAKE AND ENGINE EXHAUST

250 HOURS COOLING SYSTEMS

CLOSURE PANELS

EN

Enclosure panels should be inspected at 100 hour operational

intervals. All panels that are warped, punctured, torn, or otherwise

eformed, such that their noise containment function is reduced,

d

should be repaired or replaced before the next operation interval.

Doors, access panels, and hatch closures especially, should be

checked and adjusted at this time to ensure continuous seating

between gasket or acoustic material and the mating frame.

Engine and compressor air intake and engine exhaust systems

should be inspected after each 100 hours of operation for loose,

damaged, or deteriorated components. Repairs or replacements

should be made before the next period of use.

All components of the cooling system for engine water and

compressor oil should be inspected every 250 hours of use.

Any discrepancies found should be corrected before placing the

compressor back in operation. Unrestricted airflow over the radiator

and oil cooler must be maintained at all times during operation.

28

NOISE EMISSION Operation & Maintenance Manual

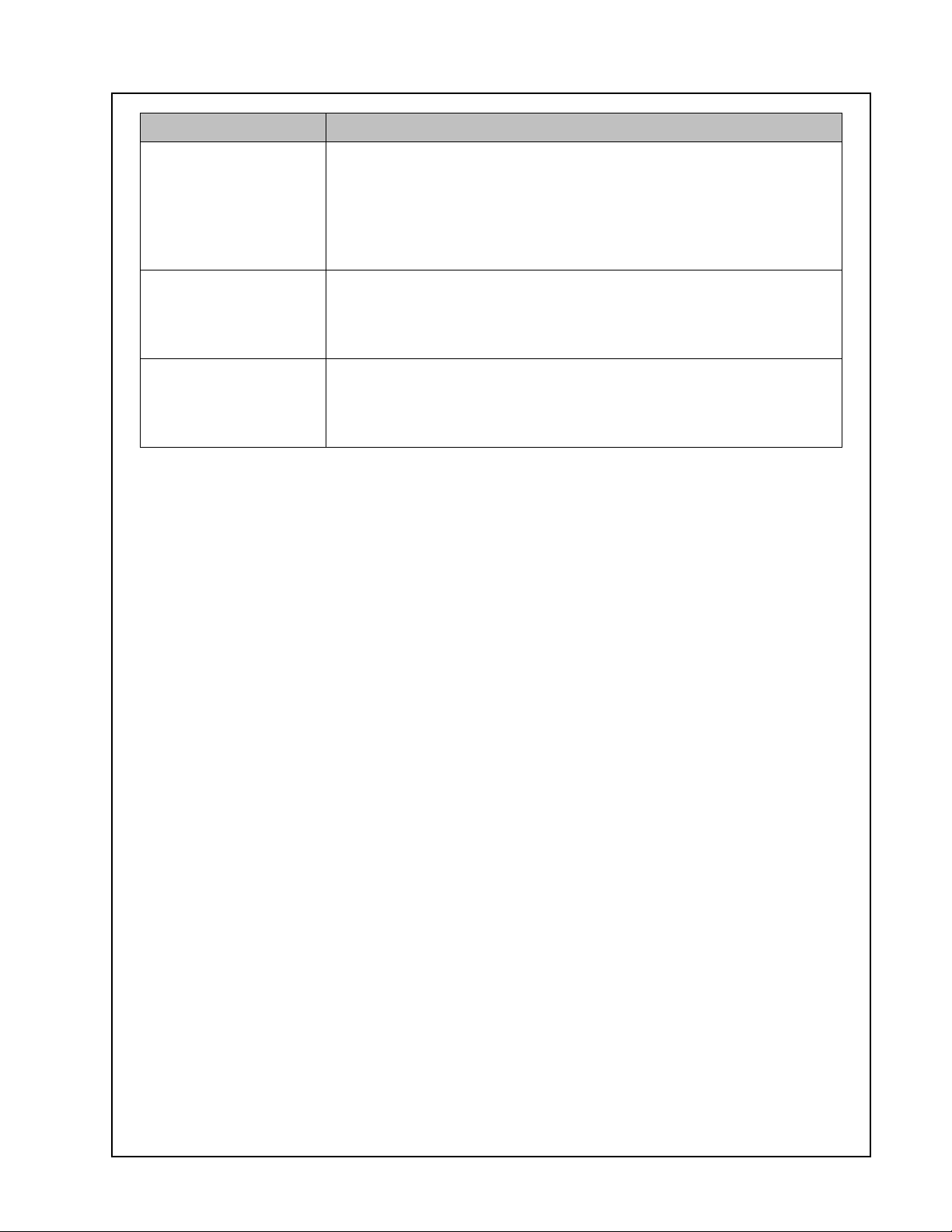

PERIOD DESCRIPTION

250 HOURS ISOLATION MOUNTS

Engine/airend isolation mounts should be inspected after each

250 hours of o

the molded rubber or with bent or broken bolts due to operation

or storage in severe environments should be replaced with

equivalent

See Operator Manual ENGINE OPERATION

Inspect and maintain engine condition and operation as

recommended in the manuals supplied by the engine

manufacturer.

peration. Those mounts with cracks or splits in

parts.

See Oper

ator Manual

FUELS AN

D LUBRICANTS

Use only the types and grades of fuels and lubricants

recommended in the Operator and Maintenance Manual and

Engine

Manual.

29

Operation & Maintenance Manual NOISE EMISSION

Noise Emission Warranty

The manufactu

this air compressor was designed, built and equipped to conform at the time of sale to the

first retail purchaser, with all applicable U.S. EPA Noise Control Regulations.

This w arrant

compressor. Defects in the design, assembly or in any part, component, or system of

the compressor which, at the time of sale to the first retail purchaser, caused noise

emissions t

compressor.(40CFR204.58-1)

rer warrants to the ultimate purchaser and each subsequent purchaser that

y is not limited to any particular part, component, or system of the air

o exceed Federal Standards are covered by this warranty for the life of air

30

NOISE EMISSION Operation & Maintenance Manual

Maintenance Log

COMPRESSOR MODEL:

SERIAL NO:

USER UNIT NO:

UNIT IDENTIFICATION DEALER / DISTRIBUTOR INFORMATION

Engine Make & Model:

Serial No:

Purchaser or Owner:

Address: Date Purchased:

The Noise Co

system of any compressor manufactured and sold under the above regulations, specifically

the following acts or the causing thereof:

(1) the rem

maintenance, repair, or replacement, of any device or element of design incorporated into

new compressor for the purpose of noise control prior to its sale or delivery to the ultimate

purchase

of design has been removed or rendered inoperative by any person.

ntrol Act of 1972 (86 Stat. 1234) prohibits tampering with the noise control

oval or rendering inoperative by any persons, other than for purposes of

r or while it is in use; or (2) the use of the compressor after such device or element

Purchased From:

31

32

Loading...

Loading...