Doosan P158LE, P180LE, P222LE Operator Manual

65.99897-8076C

Operation &

Maintenance Manual

GENERATOR DIESEL ENGINE

P158LE / -1 / - 2 / -S / -III

P180LE / -1 / -S / -II

P222LE / -1 / -S / -II

POWER UNIT DIESEL ENGINE

PU158TI

PU180TI

PU222TI

FOREWORD

This manual is designed to serve as an instruction for Diesel generator engine and Power Unit engine of

DOOSAN series (P158LE /P180LE /P222LE, PU158TI/ PU180TI/ PU222TI).

The engines are 4 strokes, 2 valves per cylinder, V-type, and direct injection mode and thus, are also satisfying

with various features required as generator and power unit engine such as quiet operation, economical fuel

consumption, durability in high speed operation and so forth.

We are very confident that these engine series are quite superior to any high speed engines in economy and

efficiency. However, high performance and long life cycle will be accomplished when a proper handling and

administration of periodic inspections and maintenance should be observed. Readers are desired to know for

your reference that those kinds of maintenance matters are explained here in detail by means of figures and

diagrams.

In this manual, the following symbols are used to indicate the type of service operations to be performed.

Removal Adjustment

Installation Cleaning

Disassembly Pay close attention-Important

Reassembly Tighten to specified torque

Align the marks Use special tools of manufacturer's

Directional Indication Lubricate with oil

Inspection Lubricate with grease

Measurement

If you have any question or recommendation in connection with this manual, please do not hesitate to contact

our head office, dealers or authorized service shops near by your location for any services.

For the last, the contents of this instruction manual may be changed without prior notice for some quality

improvement. Thank you.

Doosan Infracore Co., Ltd.

Jan. 2008

CONTENTS

1. Safety Regulations & Engine Specifications

1.1. Safety regulations ............................................................................................................................... 1

1.2. Engine Specification ........................................................................................................................... 5

1.3. Engine Assembly .............................................................................................................................. 11

2. Technical Information

2.1. Engine Model and Serial Number ..................................................................................................... 19

2.2. Engines Characteristic ...................................................................................................................... 20

2.3. Troubleshooting ................................................................................................................................ 41

2.4. Operation tip ..................................................................................................................................... 51

3. Disassembly and Reassembly of Major Components

3.1. Engine Disassembly ......................................................................................................................... 52

3.2. Inspection ......................................................................................................................................... 62

3.3. Engine Reassembly .......................................................................................................................... 81

3.4. Breaking-In ....................................................................................................................................... 98

4. Commissioning and Operation

4.1. Preparations ..................................................................................................................................... 99

4.2. Starting ............................................................................................................................................. 99

4.3. Running in ...................................................................................................................................... 100

4.4. During operation ............................................................................................................................. 100

4.5. Shutting down ................................................................................................................................. 100

4.6. Maintenance and Care ................................................................................................................... 101

5. Maintenance of Major Components

5.1. Fuel Injection System ..................................................................................................................... 105

5.2. Cooling System .............................................................................................................................. 126

5.3. Lubricating System ......................................................................................................................... 129

5.4. Turbo Charger ................................................................................................................................ 131

5.5. Installation ...................................................................................................................................... 140

5.6. Air Cleaner ...................................................................................................................................... 143

5.7. Tightening Cylinder Head Bolts ...................................................................................................... 145

5.8. V-belts ............................................................................................................................................ 146

6. Special Tool List

z

Appendix

z

Parts & After Service Center

z

Worldwide Network

................................................................................................................................. 149

1. Safety Regulations & Engine Specifications

1.1. Safety Regulations

1.1.1. General notes

Handling diesel engines and the necessary resources is no problem when the personnel commissioned

with operation and maintenance are trained accordingly and use their common sense.

This summary is a compilation of the most important regulations, These are broken down into main

sections which contain the information necessary for preventing injury to persons, damage to property

and pollution. In addition to these regulations those dictated by the type of engine and its site are to be

observed also.

IMPORTANT :

If despite all precautions, an accident occurs, in particular through contact with

caustic acids, fuel penetrating the skin, scalding from oil, antifreeze being splashed

in the eyes etc, consult a doctor immediately.

1.1.2. Regulations designed to prevent accidents

1) During commissioning, starting and operation

z

Before putting the engine into operation for the first time, read the operating instructions carefully

and familiarize yourself with the “critical” points, If you are unsure, ask your DHI representative.

z

For reasons of safety we recommend you attach a notice to the door of the engine room

prohibiting the access of unauthorized persons and that you draw the attention of the operating

personal to the fact that they are responsible for the safety of persons who enter the engine room.

z

The engine must be started and operated only by authorized personnel. Ensure that the engine

cannot be started by unauthorized persons.

z

When the engine is running, do not get too close to the rotating parts. Wear close-fitting clothing.

z

Do not touch the engine with bare hands when it is warm from operation risk of bums.

z

Exhaust gases are toxic. Comply with the instructions for the installation of DHI Diesel engines

which are to be operated in enclosed spaces. Ensure that there is adequate ventilation and air

extraction.

z

Keep vicinity of engine, ladders and stairways free of oil and grease. Accidents caused by slipping

can have serious consequences.

- 1 -

Safety Regulations & Engine Specifications

2) During maintenance and care

z

Always carry out maintenance work when the engine is switched off. If the engine has to be

maintained while it Is running, e.g. changing the elements of change-over filters, remember that

there is a risk of scalding. Do not get too close to rotating parts.

z

Change the oil when the engine is warm from operation.

CAUTION :

There is a rise of burns and scalding. Do not touch oil drain plug or oil filters with

bare hands.

z

Take into account the amount of oil in the sump. Use a vessel of sufficient size to ensure that the

oil will not overflow.

z

Open the coolant circuit only when the engine has cooled down. If opening while the engine is still

warm is unavoidable, comply with the instructions in the chapter “Maintenance and Care”.

z

Neither tighten up nor open pipes and hoses (lube oil circuit, coolant circuit and any additional

hydraulic oil circuit) during the operation. The fluids which flow out can cause injury.

z

Fuel is inflammable. Do not smoke or use naked lights in its vicinity. The tank must be filled only

when the engine is switched off.

z

When using compressed air, e.g. for cleaning the radiator, wear goggles.

z

Keep service products (anti-freeze) only in containers which can not be confused with drinks

containers.

z

Comply with the manufacturer’s instructions when handling batteries.

CAUTION :

Accumulator acid is toxic and caustic. Battery gases are explosive.

3) When carrying out checking, setting and repair work

z

Checking, setting and repair work must be carried out by authorized personnel only.

z

Use only tools which are in satisfactory condition. Worn open-end wrench slip. which could lead to

Injury.

z

When the engine is hanging on a crane, no-one must be allowed to stand or pass under it. Keep

lifting gear in good condition.

z

When working on parts which contain asbestos, comply with the notes at the end of this chapter.

z

When checking injectors do not put your hands under the jet of fuel. Do not inhale atomized fuel.

z

When working on the electrical system disconnect the battery earth cable first. Connect it up

again last in prevent short circuits.

Safety Regulations & Engine Specifications

- 2 -

1.1.3. Regulations designed to prevent damage to engine and premature wear

1) Never demand more of the engine than it was designed to yield for its intended purpose.

z

Detailed information on this can be found in the sales literature. The injection pump must not be

adjusted without prior written permission of DHI.

2) If faults occur, find the cause immediately and have it eliminated in order to prevent more serious of

damage.

3) Use only genuine DHI spare parts. DHI will accept no responsibility for damage resulting from the

installation of other parts which are supposedly “just as good”.

4) In addition to the above, note the following points.

z

Never let the engine run when dry, i.e. without lube oil or coolant.

z

Use only DHI-approved service products (engine oil , anti-freeze and anticorrosion agent).

z

Pay attention to cleanliness. The Diesel fuel must be free of water. See “Maintenance and care”.

z

Have the engine maintained at the specified intervals.

z

Do not switch off the engine immediately when it is warm, but let it run without load for about 5

minutes so that temperature equalization can take place.

z

Never put cold coolant into an overheated engine. See “Maintenance and care”.

z

Do not add so much engine oil that the oil level rises above the max. marking on the dipstick. Do

not exceed the maximum permissible tilt of the engine. Serious damage to the engine may result

if these instructions are not adhered to.

z

Always ensure that the testing and monitoring equipment (for battery charge, oil pressure, coolant

temperature) function satisfactorily.

z

Comply with instructions for operation of the alternator. See “Commissioning and operation”.

z

Do not let the raw water pump run dry, If there is a risk of frost, drain the pump when the engine is

switched off.

1.1.4. Regulations designed to prevent pollution

1) Engine oil, filter elements, fuel filters

z

Take old oil only to an oil collection point.

z

Take strict precautions to ensure that oil does not get into the drains or into the ground. The

drinking water supply could be contaminated.

z

Filter elements are classed as dangerous waste and must be treated as such.

2) Coolant

z

Treat undiluted anti-corrosion agent and / or antifreeze as dangerous waste.

z

When disposing of spent coolant comply with the regulations of the relevant local authorities.

1.1.5. Notes on safety in handling used engine oil

Prolonged or repeated contact between the skin and any kind of engine oil decreases the skin.

Drying, irritation or inflammation of the skin may therefore occur. Used engine oil also contains

dangerous substances which have caused skin cancer in animal experiments. If the basic rules of

hygiene and health and safety at work are observed, health risks are not to the expected as a result of

handling used engine oil.

- 3 -

Safety Regulations & Engine Specifications

Health precautions :

z

Avoid prolonged or repeated skin contact with used engine oil.

z

Protect your skin by means of suitable agents (creams etc.) or wear protective gloves.

z

Clean skin which has been in contact with engine oil.

-

Wash thoroughly with soap and water, A nailbrush is an effective aid.

-

Certain products make it easier to clean your hands.

-

Do not use petrol, Diesel fuel, gas oil, thinners or solvents as washing agents.

z

After washing apply a fatty skin cream to the skin.

z

Change oil-soaked clothing and shoes.

z

Do not put oily rags into your pockets.

Ensure that used engine oil is disposed of properly.

- Engine oil can endanger the water supply -

For this reason do not let engine oil get into the ground, waterways, the drains or the sewers.

Violations are punishable.

Collect and dispose of used engine oil carefully. For information on collection points please contact the

seller, the supplier or the local authorities.

1.1.6. General repair instructions

1. Before performing service operation, disconnect the grounding cable from the battery for reducing

the chance of cable damage and burning due to short-circuiting.

2. Use covers for preventing the components from damage or pollution.

3. Engine oil and anti-freeze solution must be handled with reasonable care as they cause paint

damage.

4. The use of proper tools and special tools where specified is important to efficient and reliable service

operation.

5. Use genuine DOOSAN parts necessarily.

6. Used cotter pins, gaskets, O-rings, oil seals, lock washer and self-lock nuts should be discarded and

new ones should be prepared for installation as normal function of the parts can not be maintained if

these parts are reused.

7. To facilitate proper and smooth reassemble operation, keep disassembled parts neatly in groups.

Keeping fixing bolts and nut separate is very important as they vary in hardness and design

depending on position of installation.

8. Clean the parts before inspection or reassembly. Also clean oil ports, etc. using compressed air to

make certain they are free from restrictions.

9. Lubricate rotating and sliding faces of parts with oil or grease before installation.

10. When necessary, use a sealer on gaskets to prevent leakage.

11. Carefully observe all specifications for bolts and nuts torques.

12. When service operation is completed, make a final check to be sure service has been done

property.

Safety Regulations & Engine Specifications

- 4 -

1.2. Engine Specification

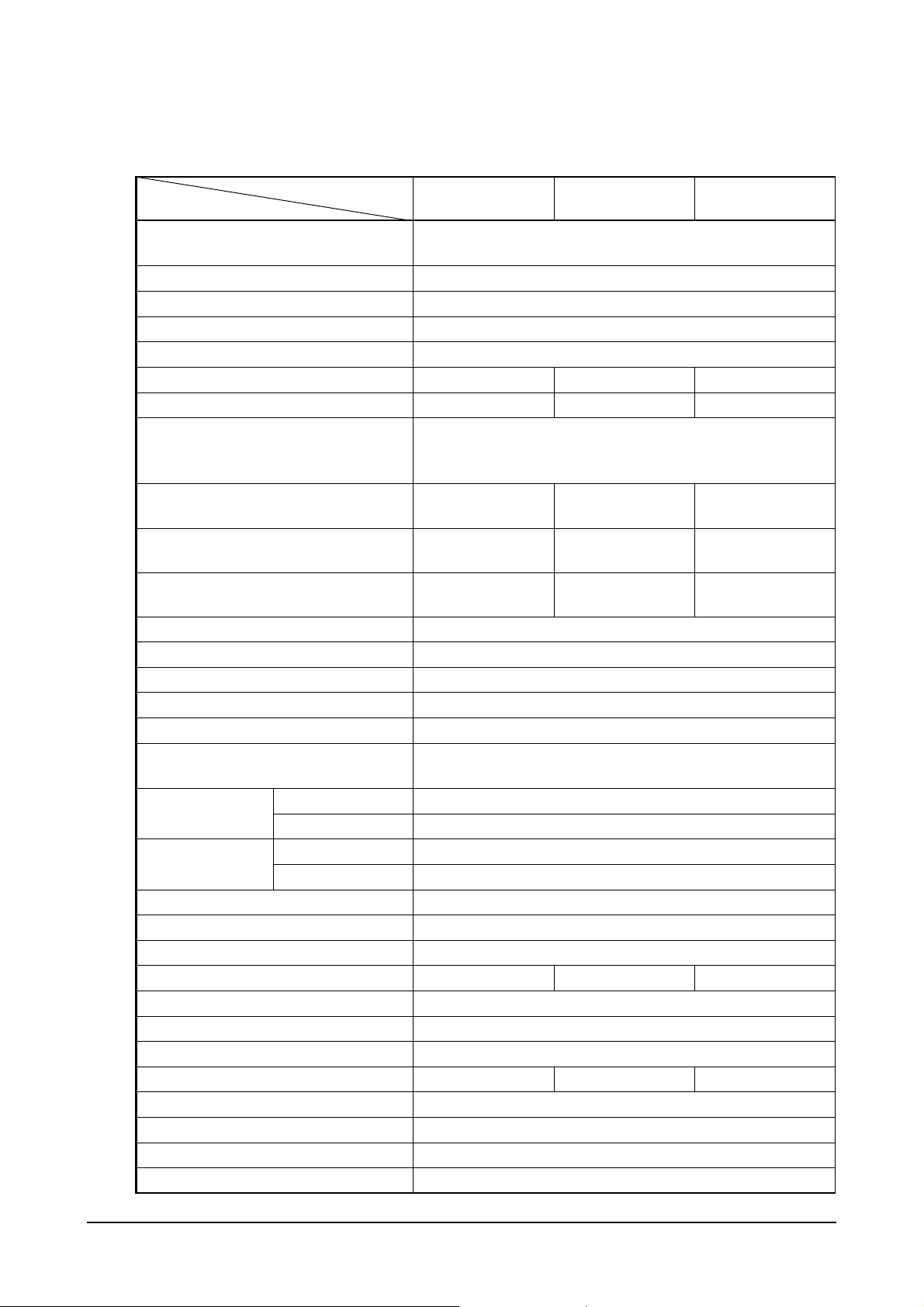

1.2.1. Specification for generator engine

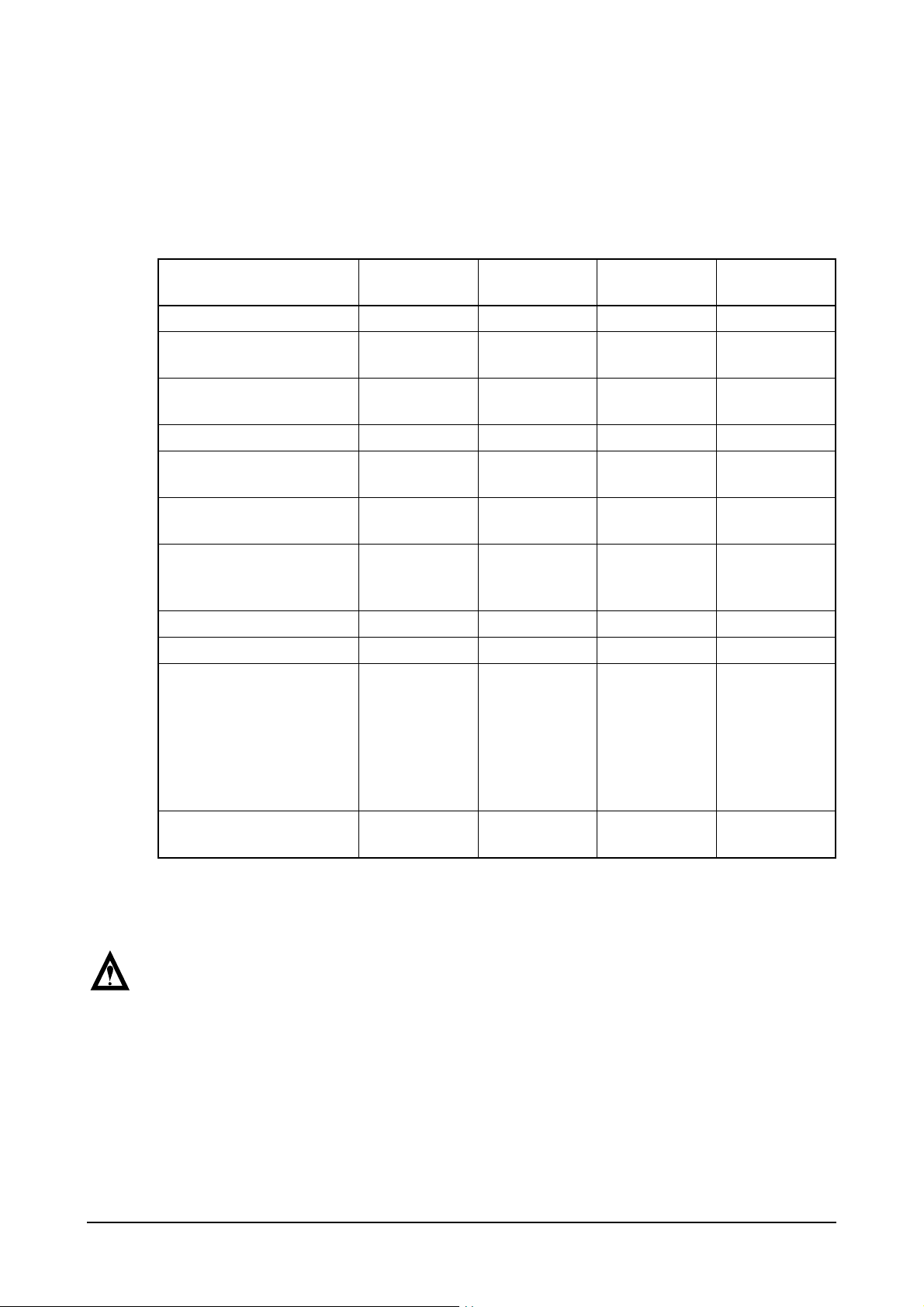

Engine Model

Items

Engine type

P158LE series P180LE series P222LE series

Water-cooled, 4 cycle Vee type

Turbo charged & intercooled

Combustion chamber type Direct injection type

Cylinder liner type Wet type, chromated or casting liner

Timing gear system Gear driven type

No. of piston ring Compression ring 2, oil ring 1

No. of cylinder-bore × stroke (mm) 8 – 128 × 142 10 – 128 × 142 12 – 128 × 142

Total piston displacement (cc) 14,618 18,273 21,927

P158LE/-1/-2, P180LE/-1, P222LE/-1 => 15.0 : 1

Compression ratio

P158LE-S/-III, P180LE-S/-II, P222LE-S/-II => 14.6 : 1

P222LE-II(EAYQD) => 14.0 : 1

Engine dimension

(length × width × height) (mm)

Engine dry weight (kg)

Fuel injection order

1,484 × 1,389 × 1,161.5

P158LE/-1/-2 : 950

P158LE-S/-III : 961

1-5-7-2-6-3-4-8

1,557 × 1,389 × 1,248 1,717 × 1,389 × 1,288

P180LE/-1 : 1,175

P180LE-S/-II : 1,188

1-6-5-10-2-7-3-8-4-9

P222LE/-1 : 1,575

P222LE-S/-II : 1,591

1-12-5-8-3-10-6-7-

2-11-4-9

Injection pump type Bosch in-line P type

Governor type Electrical type

Injection nozzle type Multi-hole type

Fuel injection pressure (kg/cm

Compression pressure (kg/cm

Intake and exhaust valve clearance

(at cold) (mm)

Open at 24

2

)285

2

) 28 (at 200 rpm)

0.3 / 0.4

°

(B.T.D.C)

Intake valve

Close at 36

Open at 63

°

(A.B.D.C)

°

(B.B.D.C)

Exhaust valve

Close at 27

°

(A.T.D.C)

Lubrication method Fully forced pressure feed type

Oil pump type Gear type

Oil filter type Full-flow, cartridge type

Lubricating oil capacity (max./min.) (lit) 21 / 17 35 / 28 40 / 33

Oil cooler type Water cooled

Water pump Centrifugal type driven by belt

Cooling Method Pressurized circulation

Cooling water capacity (engine only) (lit)

Thermostat type Wax pallet type (71 ~ 85

20 21 23

°

C)

Alternator voltage – capacity (V – A) 24 – 45

Starting Motor voltage – output (V – kW)

24 – 7.0

Battery capacity (V – AH) 24 – 200

- 5 -

Safety Regulations & Engine Specifications

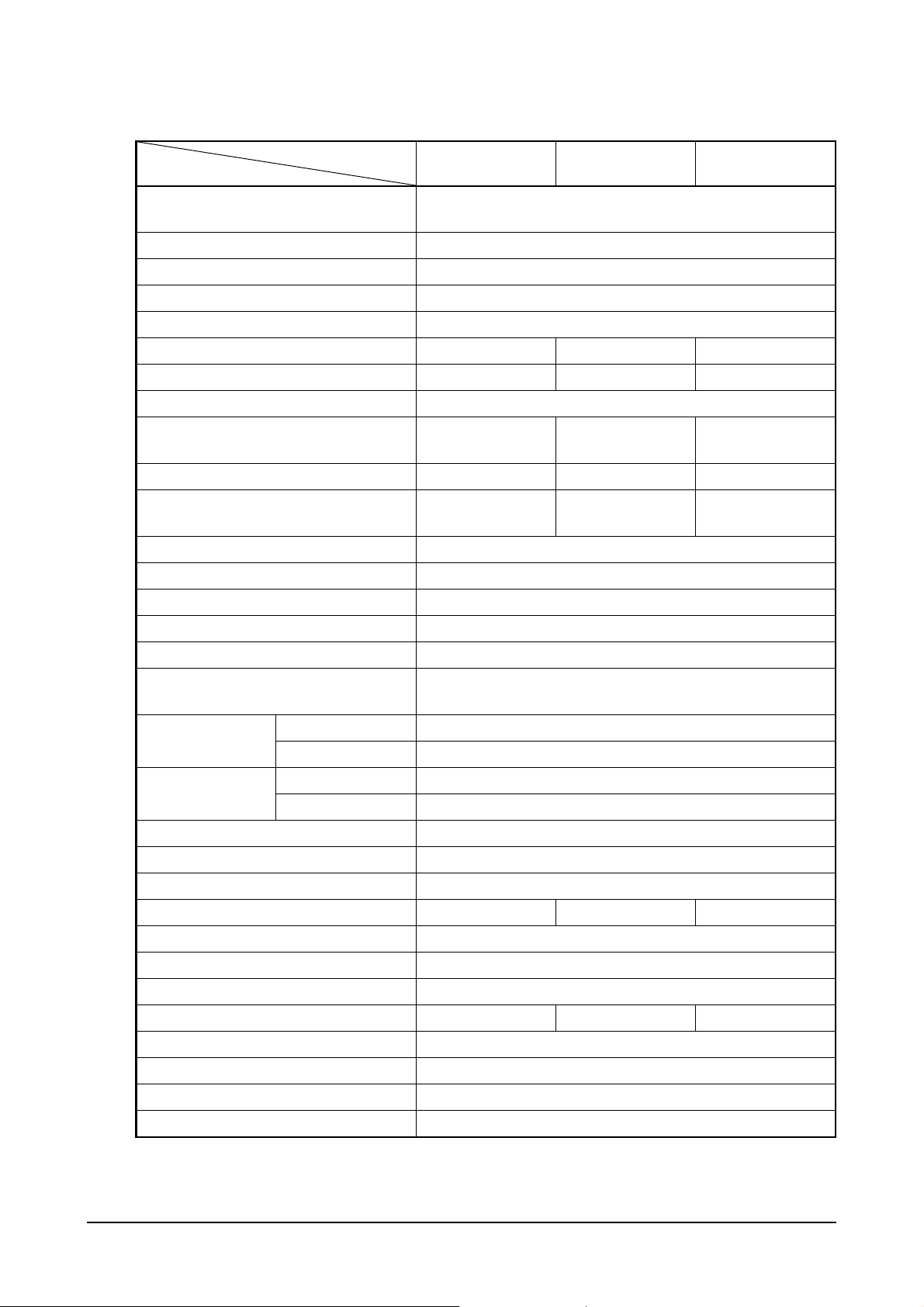

1.2.2. Specification for power unit engine

Engine Model

Items

Engine type

PU158TI PU180TI PU222TI

Water-cooled, 4 cycle Vee type

Turbo charged & intercooled

Combustion chamber type Direct injection type

Cylinder liner type Wet type, chromated or casting liner

Timing gear system Gear driven type

No. of piston ring Compression ring 2, oil ring 1

No. of cylinder-bore × stroke (mm) 8 – 128 × 142 10 – 128 × 142 12 – 128 × 142

Total piston displacement (cc) 14,618 18,273 21,927

Compression ratio 15 : 1

Engine dimension

(length × width × height) (mm)

1,484 × 1,389 × 1,161.5

1,557 × 1,389 × 1,248 1,717 × 1,389 × 1,288

Engine dry weight (kg) 950 1,175 1,575

Fuel injection order 1-5-7-2-6-3-4-8

1-6-5-10-2-7-3-8-4-9

1-12-5-8-3-10-6-7-

2-11-4-9

Injection pump type Bosch in-line P type

Governor type Mechanical type

Injection nozzle type Multi-hole type

2

Fuel injection pressure (kg/cm

Compression pressure (kg/cm

Intake and exhaust valve clearance

(at cold) (mm)

Open at 24

)285

2

) 28 (at 200 rpm)

0.3 / 0.4

°

(B.T.D.C)

Intake valve

Close at 36

Open at 63

°

(A.B.D.C)

°

(B.B.D.C)

Exhaust valve

°

Close at 27

(A.T.D.C)

Lubrication method Pressurized circulation

Oil pump type Gear type

Oil filter type Full-flow, cartridge type

Lubricating oil capacity (max./min.) (lit) 21 / 17 35 / 28 40 / 33

Oil cooler type Water cooled

Water pump Centrifugal type driven by belt

Cooling Method Pressurized circulation

Cooling water capacity (engine only) (lit)

Thermostat type Wax pallet type (71 ~ 85

Alternator voltage – capacity (V – A) 24 – 45

Starting Motor voltage – output (V – kW)

Battery capacity (V – AH) 24 – 200

Safety Regulations & Engine Specifications

20 21 23

°

C)

24 – 7.0

- 6 -

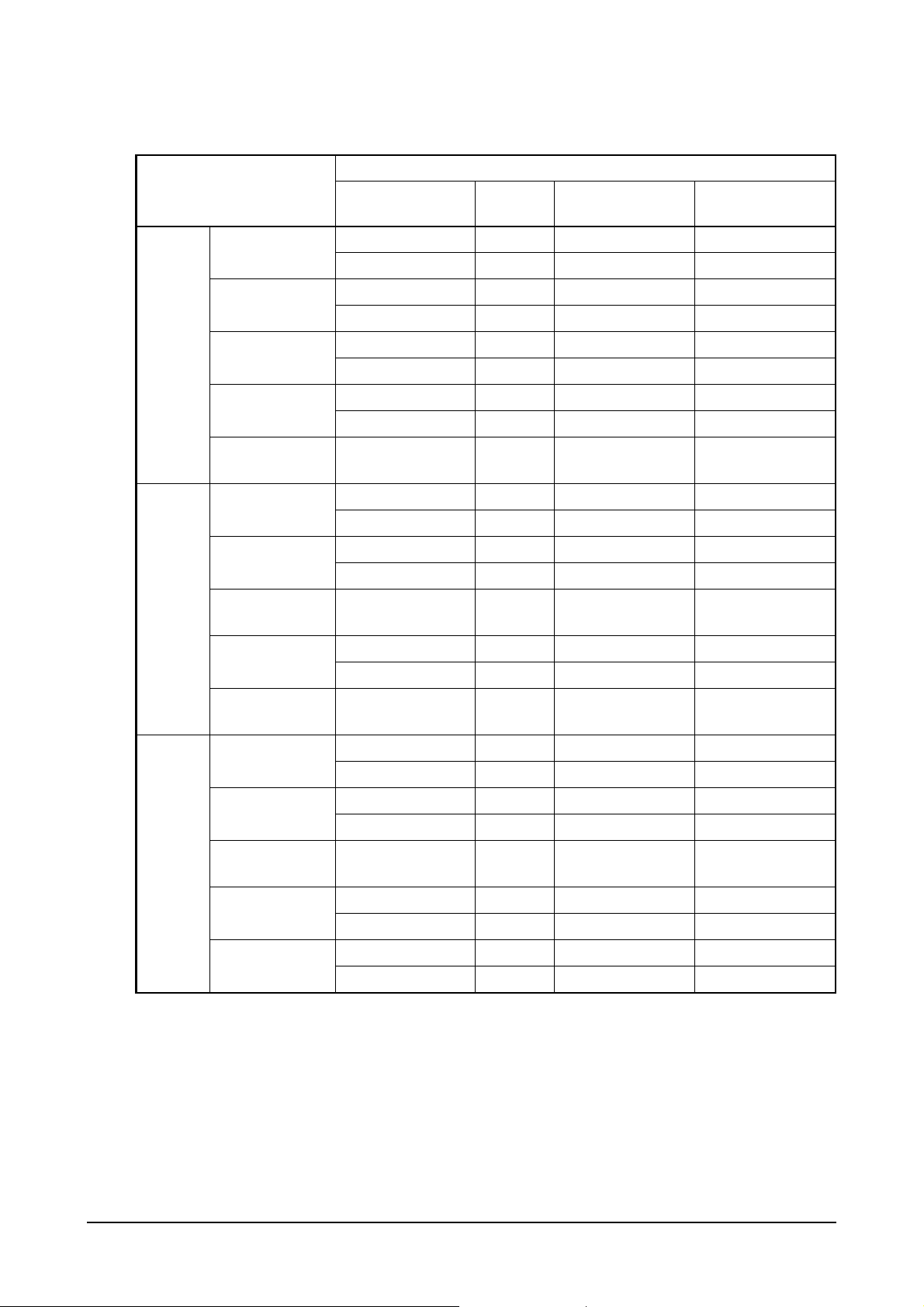

1.2.3. Engine power for generator

Engine model

P158LE-2

(EAZOC/QC)

Production tolerance : ±5%

Condition

HZ

50 HZ(1,500 rpm) 16 399 PS(293 kW) 437 PS(321 kW)

60 HZ(1,800 rpm) 16 470 PS(346 kW) 510 PS(375 kW)

Timing

(BTDC)

Prime Stand by

P158LE

P180LE

P158LE-1

(EAZOB/QB)

P158LE

(EAZOA/QA)

P158LE-S

(EAZOG/H/QG)

P158LE-III

(EAZOF)

P180LE-1

(EASOB/QB)

P180LE

(EASOA/QA)

P180LE

(EASOC)

P180LE-S

(EASOE/F/QE)

P180LE-II

(EASOD)

P222LE-1

(EAYOB/QB)

50 HZ(1,500 rpm) 16 444 PS(327 kW) 492 PS(362 kW)

60 HZ(1,800 rpm) 16 498 PS(366 kW) 546 PS(402 kW)

50 HZ(1,500 rpm) 16 494 PS(363 kW) 563 PS(414 kW)

60 HZ(1,800 rpm) 16 547 PS(402 kW) 623 PS(458 kW)

50 HZ(1,500 rpm) 12 546 PS(402 kW) 600 PS(441 kW)

60 HZ(1,800 rpm) 16 600 PS(441 kW) 654 PS(481 kW)

60 HZ(1,800 rpm) 16 – 690 PS(508 kW)

50 HZ(1,500 rpm) 16 548 PS(403 kW) 601 PS(442 kW)

60 HZ(1,800 rpm) 16 617 PS(454 kW) 677 PS(498 kW)

50 HZ(1,500 rpm) 16 602 PS(443 kW) 674 PS(496 kW)

60 HZ(1,800 rpm) 16 676 PS(497 kW) 734 PS(540 kW)

60 HZ(1,800 rpm) 18 695 PS(511 kW) 764 PS(562 kW)

50 HZ(1,500 rpm) 16 615 PS(452 kW) 674 PS(496 kW)

60 HZ(1,800 rpm) 16 705 PS(519 kW) 771 PS(567 kW)

60 HZ(1,800 rpm) 16 – 827 PS(608 kW)

50 HZ(1,500 rpm) 16 696 PS(512 kW) 752 PS(553 kW)

60 HZ(1,800 rpm) 16 765 PS(563 kW) 850 PS(625 kW)

P222LE

(EAYOA/QA)

P222LE

* Note : All data are based on operation without cooling fan at ISO 3046

P222LE

(EAYOC)

P222LE-S

(EAYOE/F/QE)

P222LE-II

(EAYOD/QD)

50 HZ(1,500 rpm) 16 723 PS(532 kW) 781 PS(574 kW)

60 HZ(1,800 rpm) 16 803 PS(591 kW) 883 PS(649 kW)

60 HZ(1,800 rpm) 18 803 PS(591 kW) 898 PS(660 kW)

50 HZ(1,500 rpm) 20 750 PS(552 kW) 820 PS(603 kW)

60 HZ(1,800 rpm) 19 850 PS(625 kW) 927 PS(682 kW)

50 HZ(1,500 rpm) 13 – 886 PS(652 kW)

60 HZ(1,800 rpm) 19 – 1000 PS(736 kW)

- 7 -

Safety Regulations & Engine Specifications

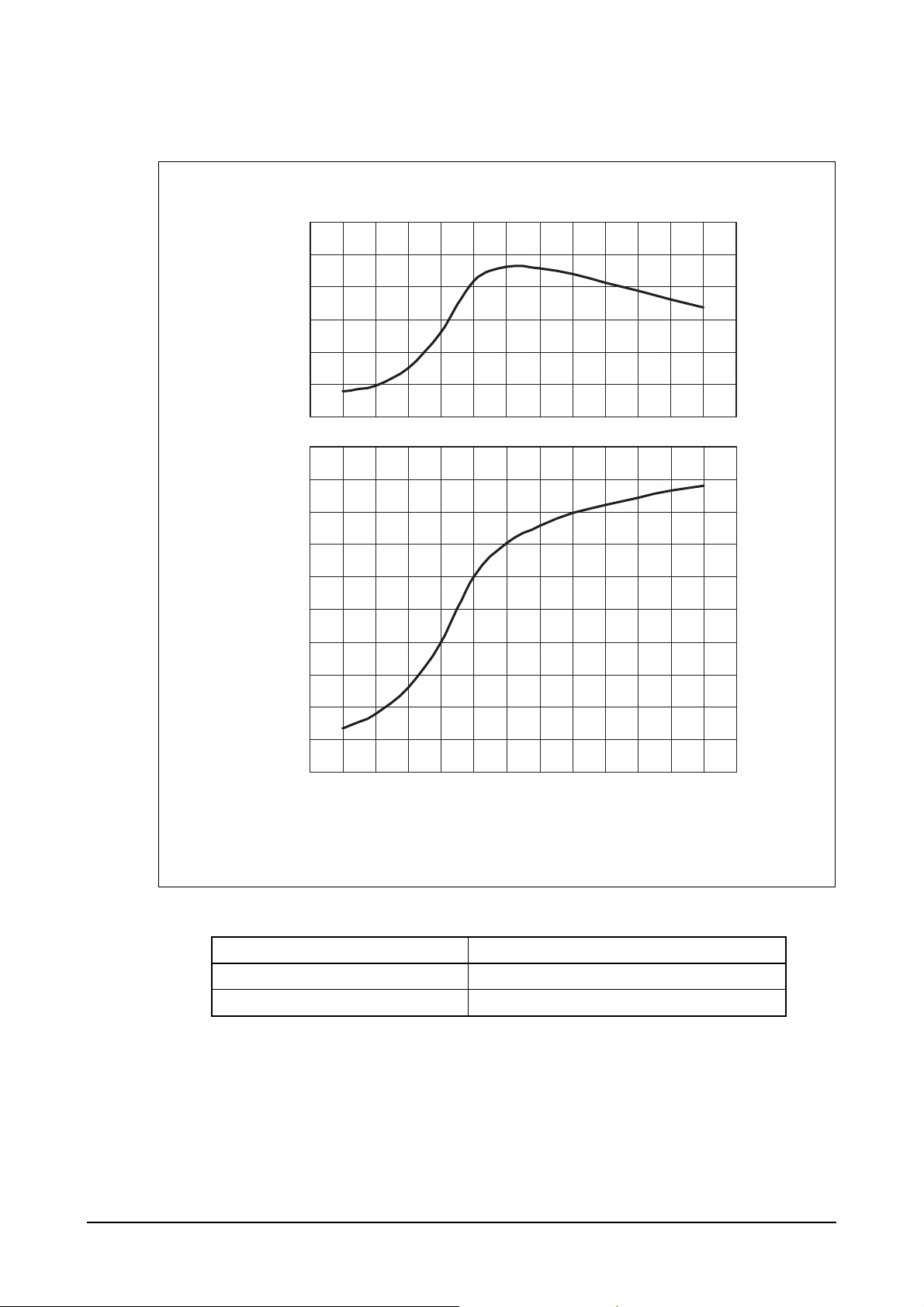

1.2.4. Engine performance curve

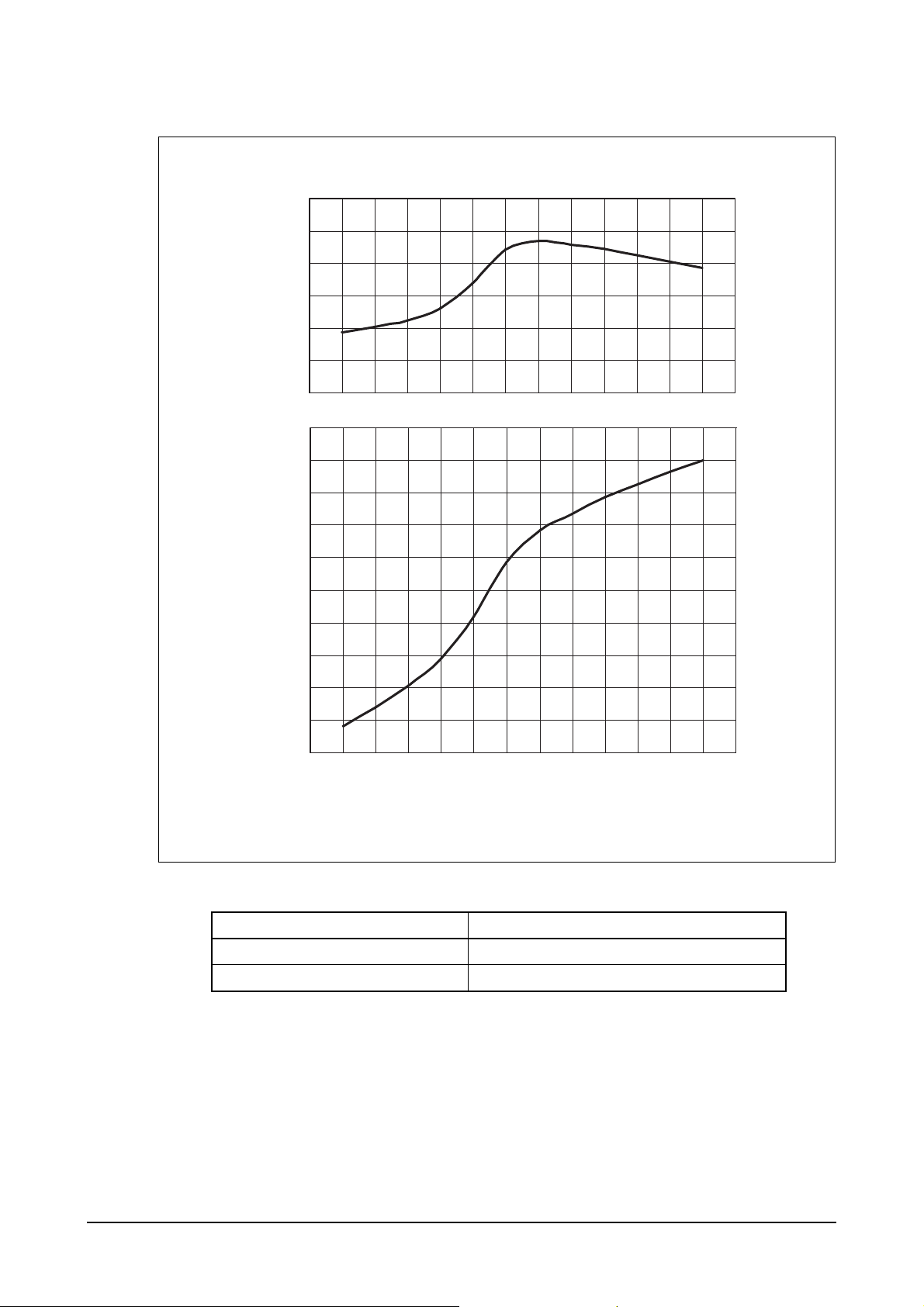

1) PU158TI engine

250

225

m)

200

.

175

Torque (kg

150

125

100

600

550

500

450

400

350

Power (PS)

300

250

200

150

100

900 1,000

1,000

1,200 1,300 1,400 1,500 1,600 1,700 1,800 1,900 2,000 2,100 2,200

Engine Speed (rpm)

Performance ISO 3046, DIN 6270B

Output (max.) 397 kW (540 PS) / 2,100 rpm

⋅

Torque (max) 2,117 N

m (216 kg⋅m) / 1,500 rpm

EH5OM001

Safety Regulations & Engine Specifications

- 8 -

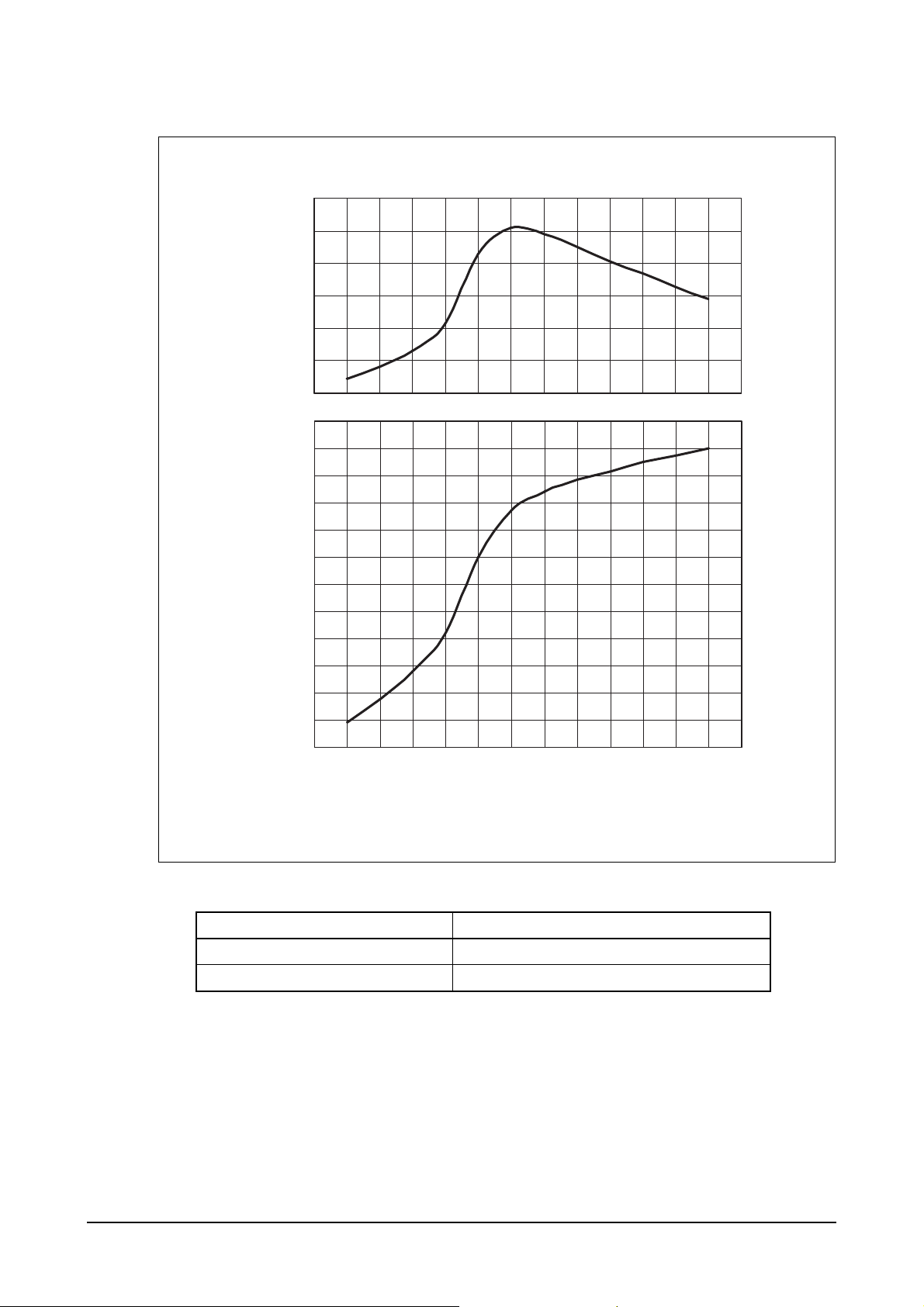

2) PU180TI engine

275

250

m)

225

.

200

Torque (kg

175

150

125

700

650

600

550

500

450

Power (PS)

400

350

300

250

200

900 1,000

1,000

1,200 1,300 1,400 1,500 1,600 1,700 1,800 1,900 2,000 2,100 2,200

Engine Speed (rpm)

Performance ISO 3046, DIN 6270B

Output (max.) 478 kW (650 PS) / 2,100 rpm

Torque (max) 2,303 N

⋅

m (235 kg⋅m) / 1,500 rpm

EH5OM002

- 9 -

Safety Regulations & Engine Specifications

3) PU222TI engine

350

325

m)

300

.

275

Torque (kg

250

225

200

850

800

750

700

650

600

550

Power (PS)

500

450

400

350

300

250

900 1,000

1,000

1,200 1,300 1,400 1,500 1,600 1,700 1,800 1,900 2,000 2,100 2,200

Engine Speed (rpm)

Performance ISO 3046, DIN 6270B

Output (max.) 588 kW (800 PS) / 2,100 rpm

Torque (max) 3,205 N

⋅

m (327 kg⋅m) / 1,500 rpm

EH5OM003

Safety Regulations & Engine Specifications

- 10 -

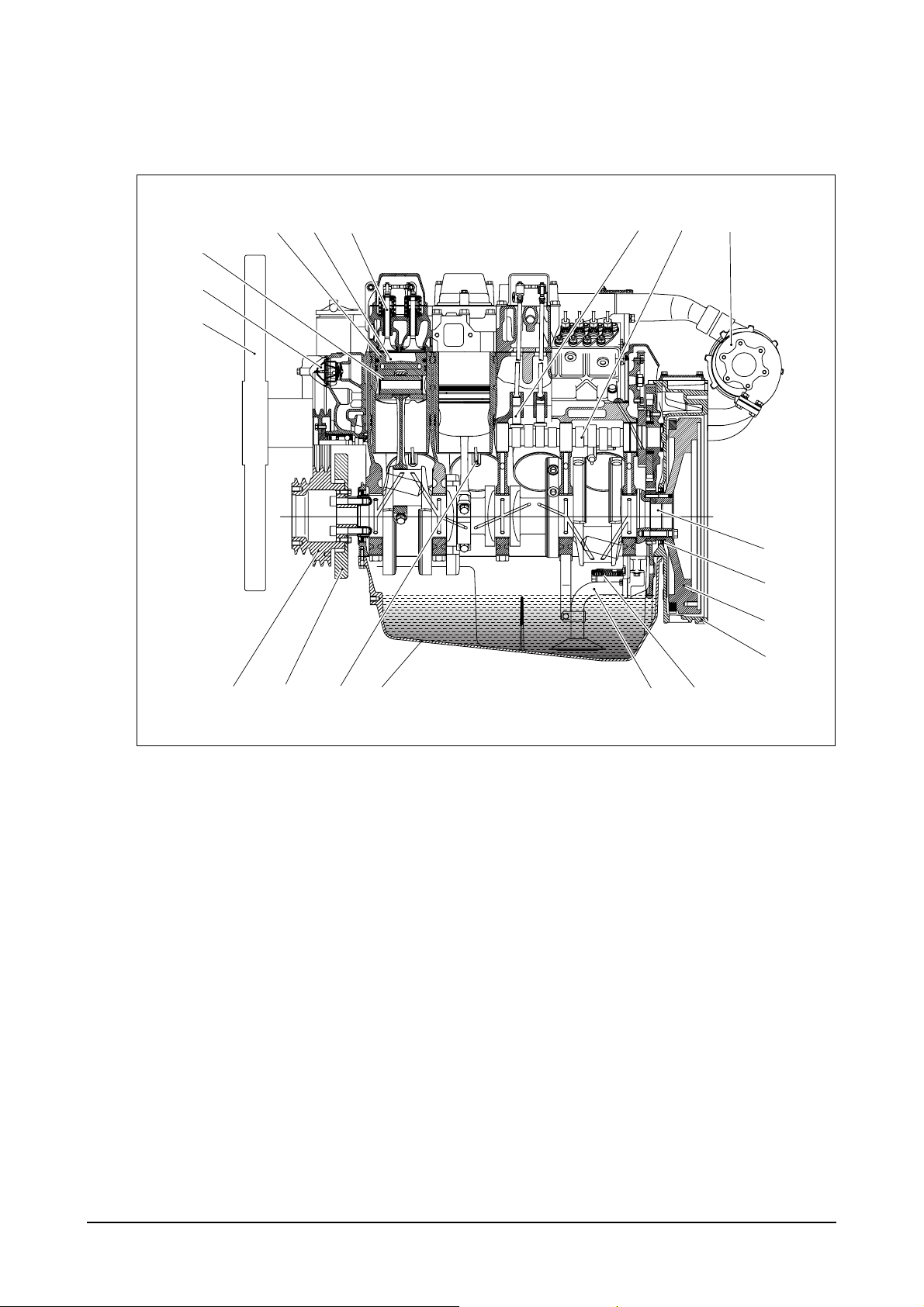

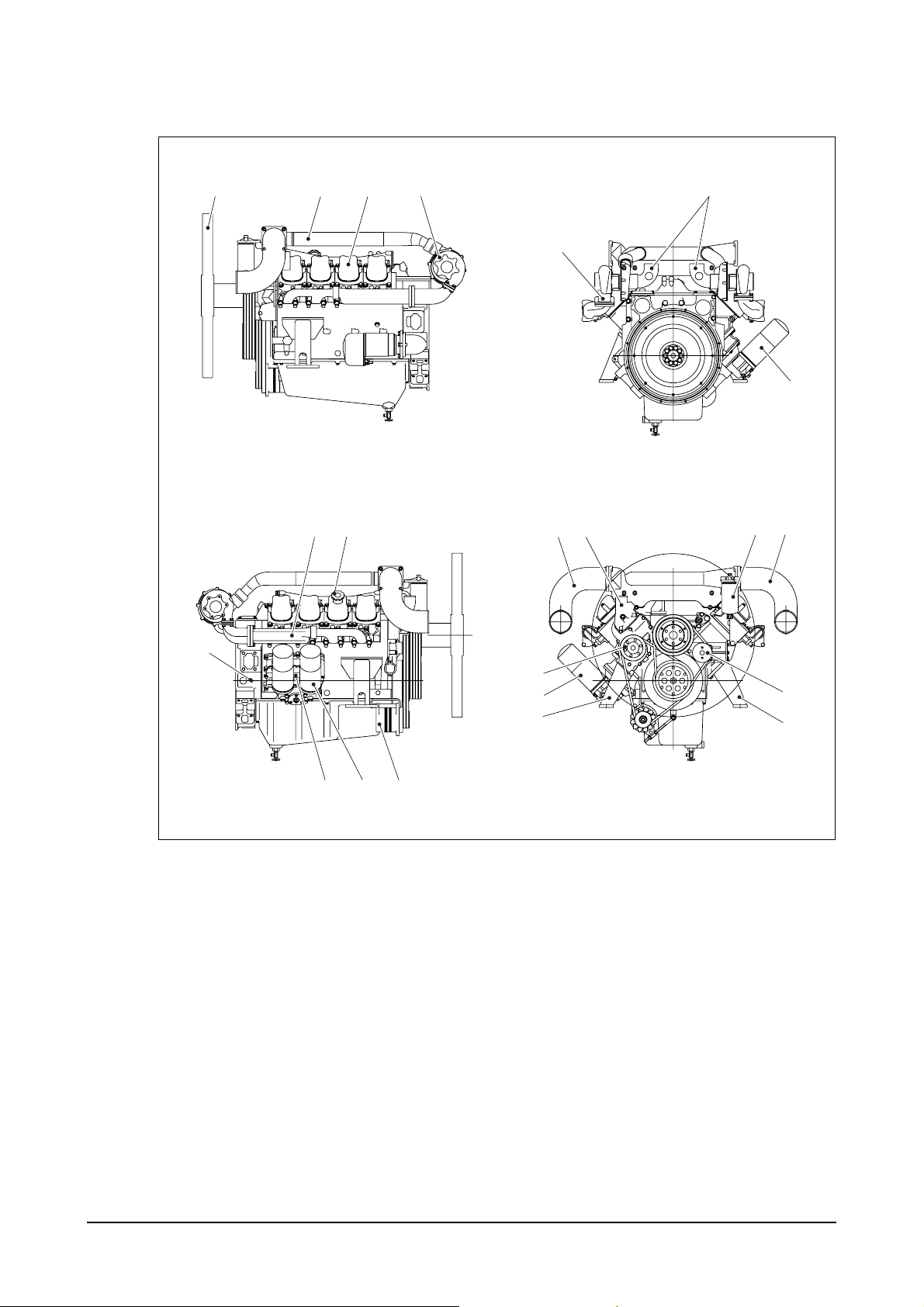

1.3. Engine Assembly

1.3.1. Engine sectional view (Longitudinal)

12 3

7

8

9

45 6

19

18

17

16

1110

10. Crank shaft pulley

12 13

1. Piston 11. Vibration damper

2. Combustion camper 12. Oil spray nozzle

3. Valve 13. Oil pan

4. Tappet 14. Oil suction pipe

5. Cam shaft 15. Oil pump relief valve

6. Turbocharger 16. Flywheel housing

7. Piston pin 17. Flywheel

8. Thermostat 18. Oil seal

9. Cooling fan 19. Crank shaft

14 15

EA6O1004

- 11 -

Safety Regulations & Engine Specifications

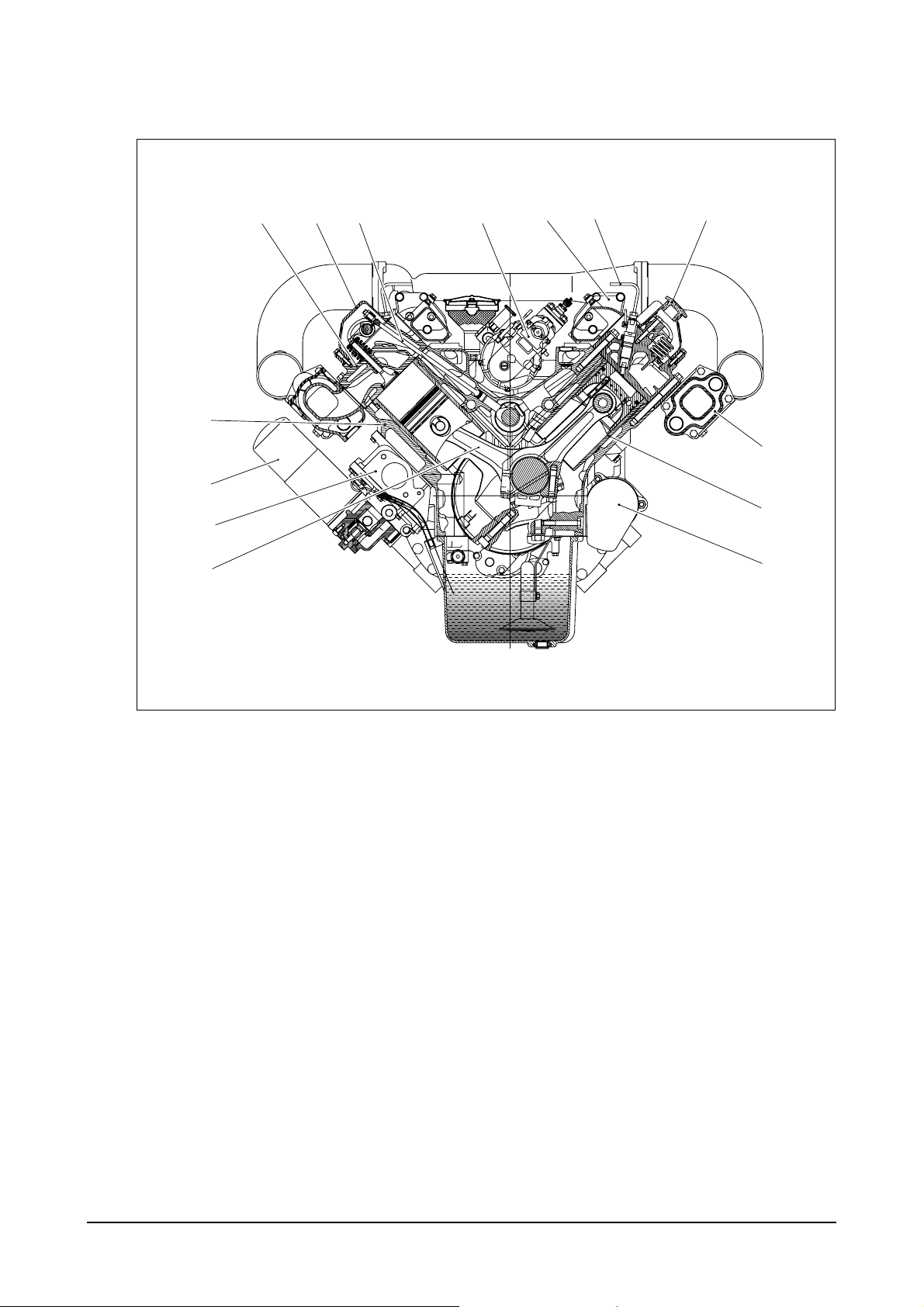

1.3.2. Engine sectional view (Cross)

10

11

12

3

4

56 7

8

12

9

13

14

1. Cylinder head 8. Cylinder block

2. Cylinder head cover 9. Oil filter

3. Push rod 10. Oil cooler

4. Injection pump 11. Connecting rod

5. Intake manifold 12. Exhaust manifold

6. Injection pipe 13. Cylinder liner

7. Oil filler cap 14. Starter

EA6O1005

Safety Regulations & Engine Specifications

- 12 -

1.3.3. Engine assembly views

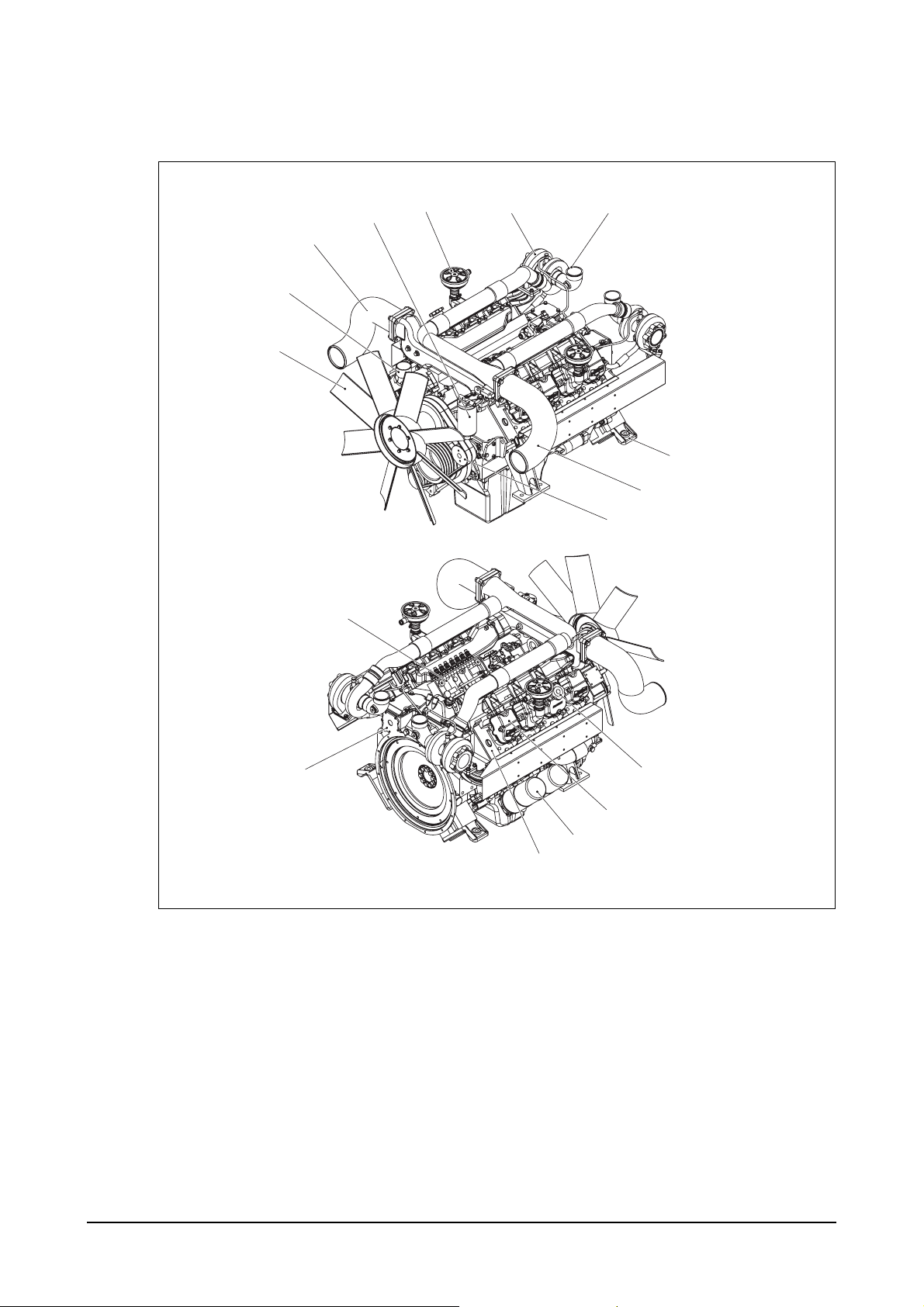

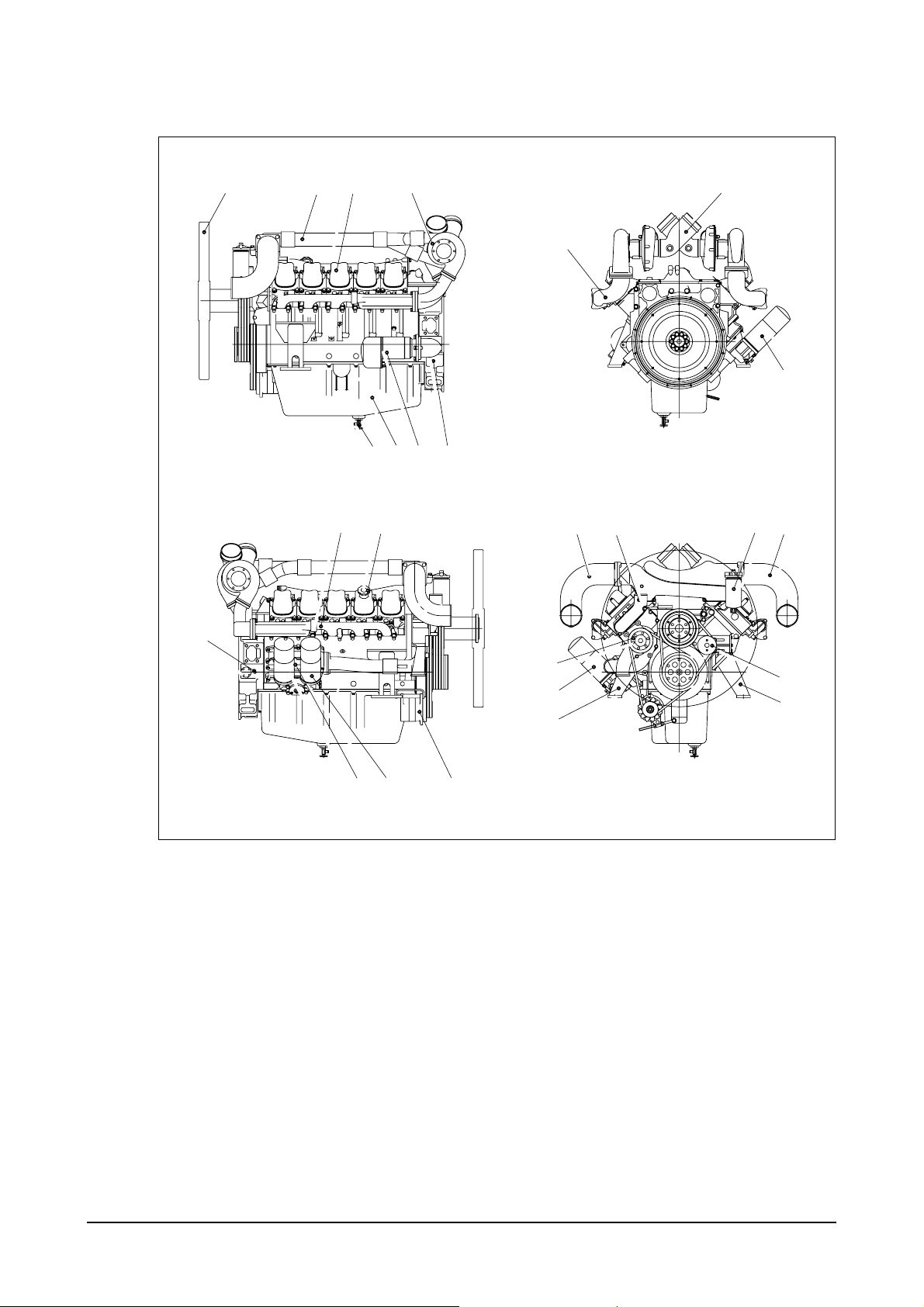

1) PU158TI : Power unit engine

4

5

67

3

2

1

8

9

10

11

12

16

15

14

13

1. Cooling fan 9. Air pipe

2. Water outlet (Turbocharger to inter cooler)

3. Air pipe 10. Idle pulley

(Intercooler to intake manifold) 11. Injection pump

4. Fuel filter 12. Fly wheel housing

5. Breather 13. Cylinder head

6. Turbo charger 14. Oil filter

7. Air pipe 15. Cylinder head cover

(

Air cleaner to turbocharger)

16. Oil filler cap

8. Mounting bracket

EH5OM004

- 13 -

Safety Regulations & Engine Specifications

2) PU180TI : Power unit engine

5

6

7

4

3

2

1

8

9

10

11

12

13

17

16

15

14

1. Cooling fan 9. Air pipe

2. Water outlet (Turbocharger to inter cooler)

3. Air pipe 10. Starter

(Intercooler to intake manifold) 11. Idle pulley

4. Fuel filter 12. Injection pump

5. Breather 13. Fly wheel housing

6. Turbo charger 14. Cylinder head

7. Air pipe 15. Oil filter

(

Air cleaner to turbocharger)

16. Oil filler cap

8. Mounting bracket 17. Cylinder head cover

EH5OM005

Safety Regulations & Engine Specifications

- 14 -

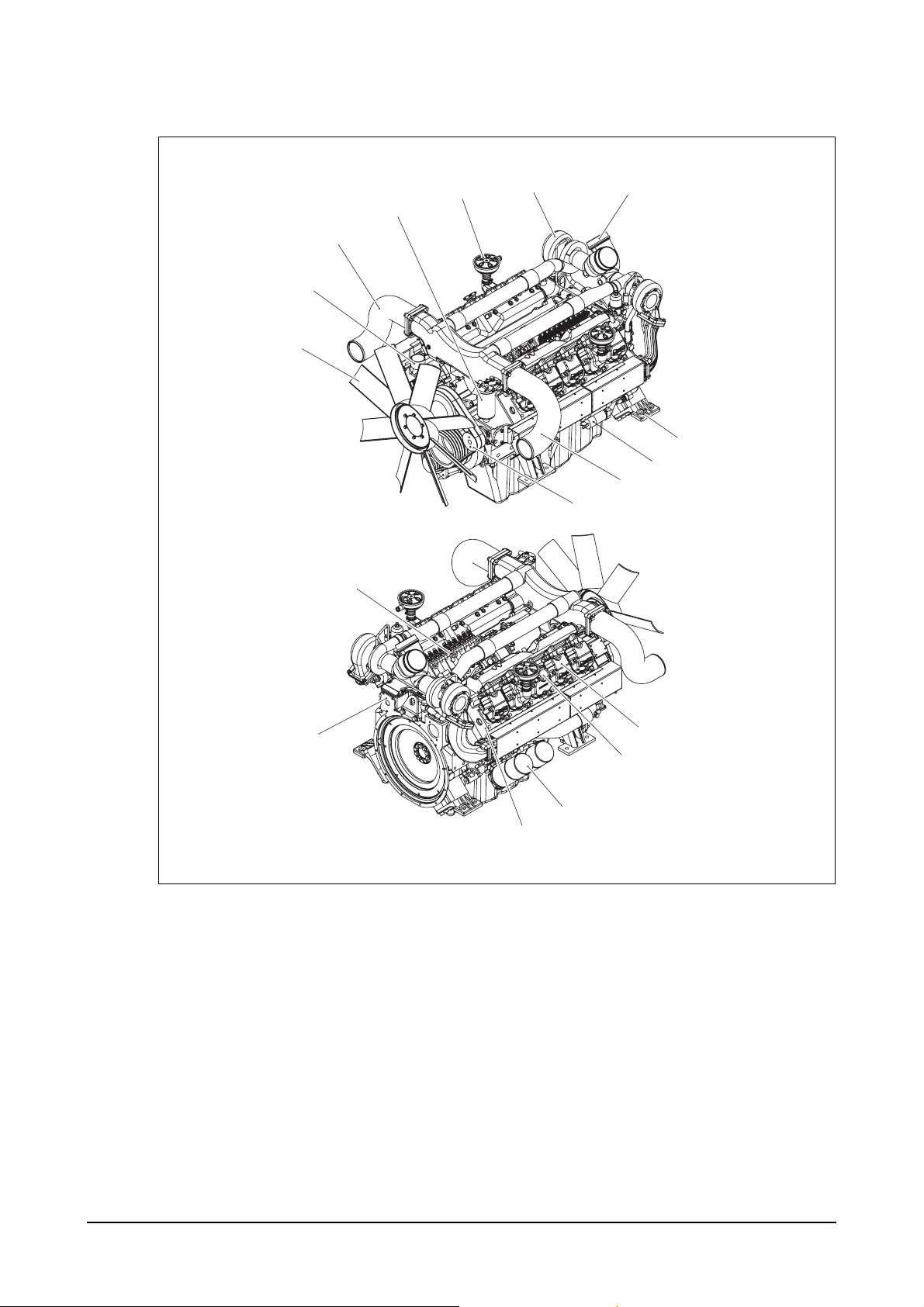

3) PU222TI : Power unit engine

5

6

7

4

3

2

1

8

9

10

11

12

16

15

14

13

1. Cooling fan 9. Air pipe

2. Water outlet (Turbocharger to inter cooler)

3. Air pipe 10. Idle pulley

(Intercooler to intake manifold) 11. Injection pump

4. Fuel filter 12. Fly wheel housing

5. Breather 13. Cylinder head

6. Turbo charger 14. Oil filter

7. Air pipe 15. Oil filler cap

(

Air cleaner to turbocharger)

16. Cylinder head cover

8. Starter

EH5OM006

- 15 -

Safety Regulations & Engine Specifications

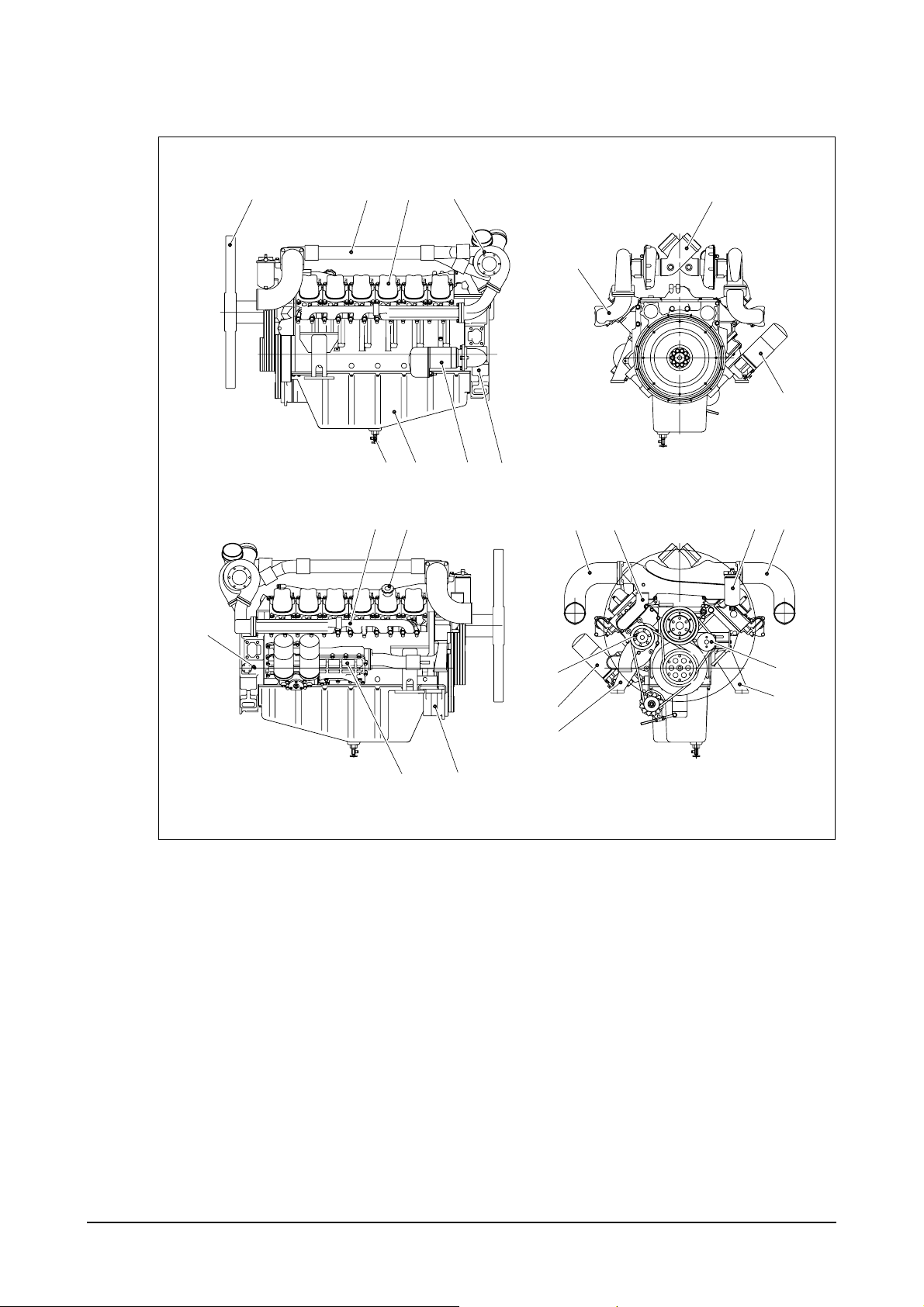

4) P158LE : Generator engine

234

910

14

18 17

151

191620

23

16

22

21

22

121116 13

EA6O1001

1. Cooling fan 10. Oil filler cap 18. Air pipe

2. Air pipe 11. Pick up sensor (Air cleaner to turbocharger)

3. Cylinder head cover 12. Oil cooler 19. Fuel filter

4. Turbocharger 13. Alternator 20. Air pipe

5. Oil drain valve 14. Exhaust elbow (Turbocharger to inter cooler)

6. Oil pan 15. Air pipe 21. Idle pulley

7. Starter (Air cleaner to turbocharger) 22. Engine mounting bracket

8. Flywheel housing 16. Oil filter 23. Water pump

9. Exhaust manifold 17. Cooling water outlet

Safety Regulations & Engine Specifications

- 16 -

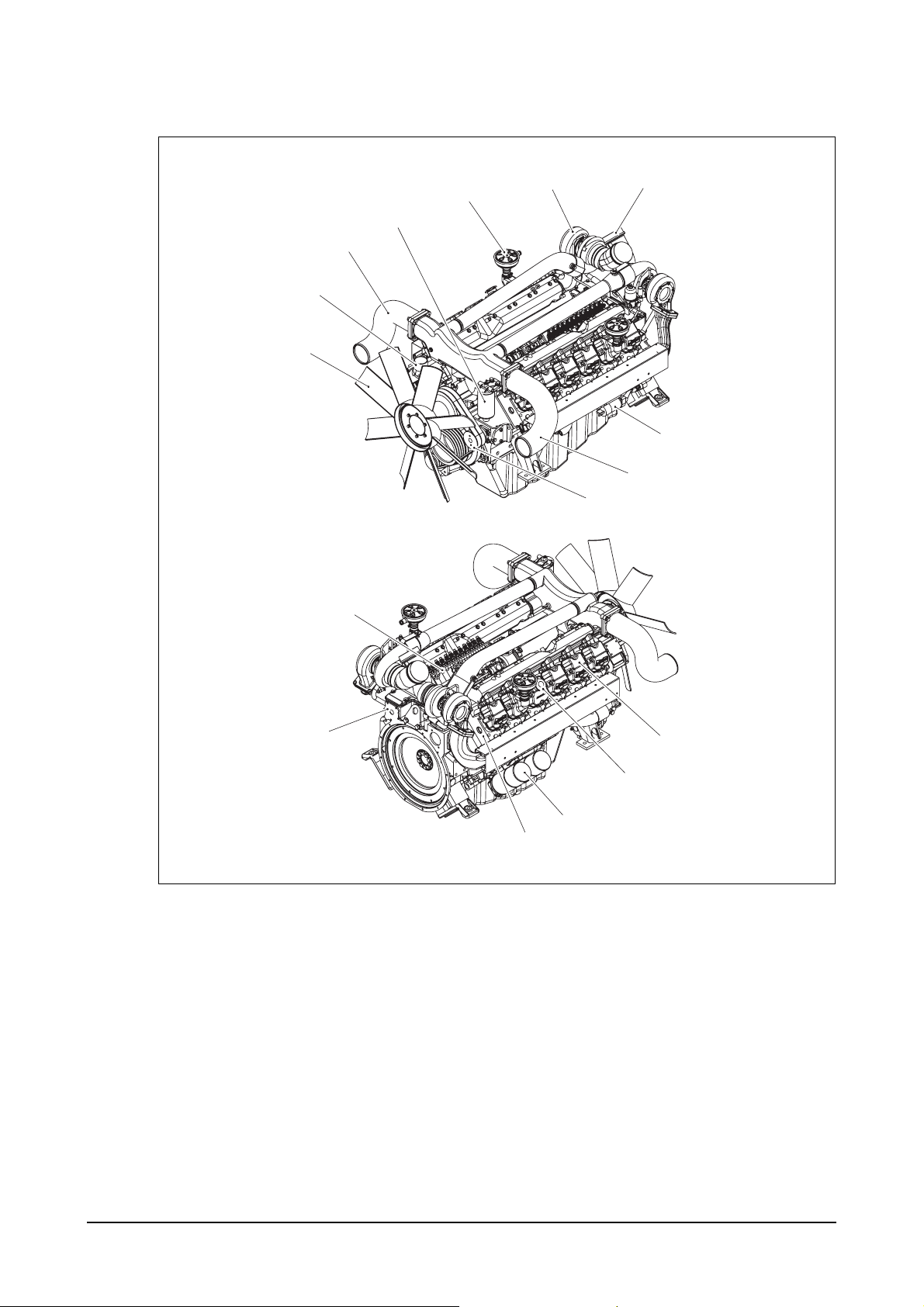

5) P180LE : Generator engine

123

4

5

67 8

910

14

18 17

15

16

19 20

11

23

21

16

22

22

12 16 13

EA6O1002

1. Cooling fan 10. Oil filler cap 18. Air pipe

2. Air pipe 11. Pick up sensor (Air cleaner to turbocharger)

3. Cylinder head cover 12. Oil cooler 19. Fuel filter

4. Turbocharger 13. Alternator 20. Air pipe

5. Oil drain valve 14. Exhaust elbow (Turbocharger to inter cooler)

6. Oil pan 15. Air pipe 21. Idle pulley

7. Starter (Air cleaner to turbocharger) 22. Engine mounting bracket

8. Flywheel housing 16. Oil filter 23. Water pump

9. Exhaust manifold 17. Cooling water outlet

- 17 -

Safety Regulations & Engine Specifications

6) P222LE : Generator engine

11

123

4

56 7 8

910 18 17 1920

15

14

16

23

16

21

22

22

12

13

EA6O1003

1. Cooling fan 10. Oil filler cap 18. Air pipe

2. Air pipe 11. Pick up sensor (Air cleaner to turbocharger)

3. Cylinder head cover 12. Oil cooler 19. Fuel filter

4. Turbocharger 13. Alternator 20. Air pipe

5. Oil drain valve 14. Exhaust elbow (Turbocharger to inter cooler)

6. Oil pan 15. Air pipe 21. Idle pulley

7. Starter (Air cleaner to turbocharger) 22. Engine mounting bracket

8. Flywheel housing 16. Oil filter 23. Water pump

9. Exhaust manifold 17. Cooling water outlet

Safety Regulations & Engine Specifications

- 18 -

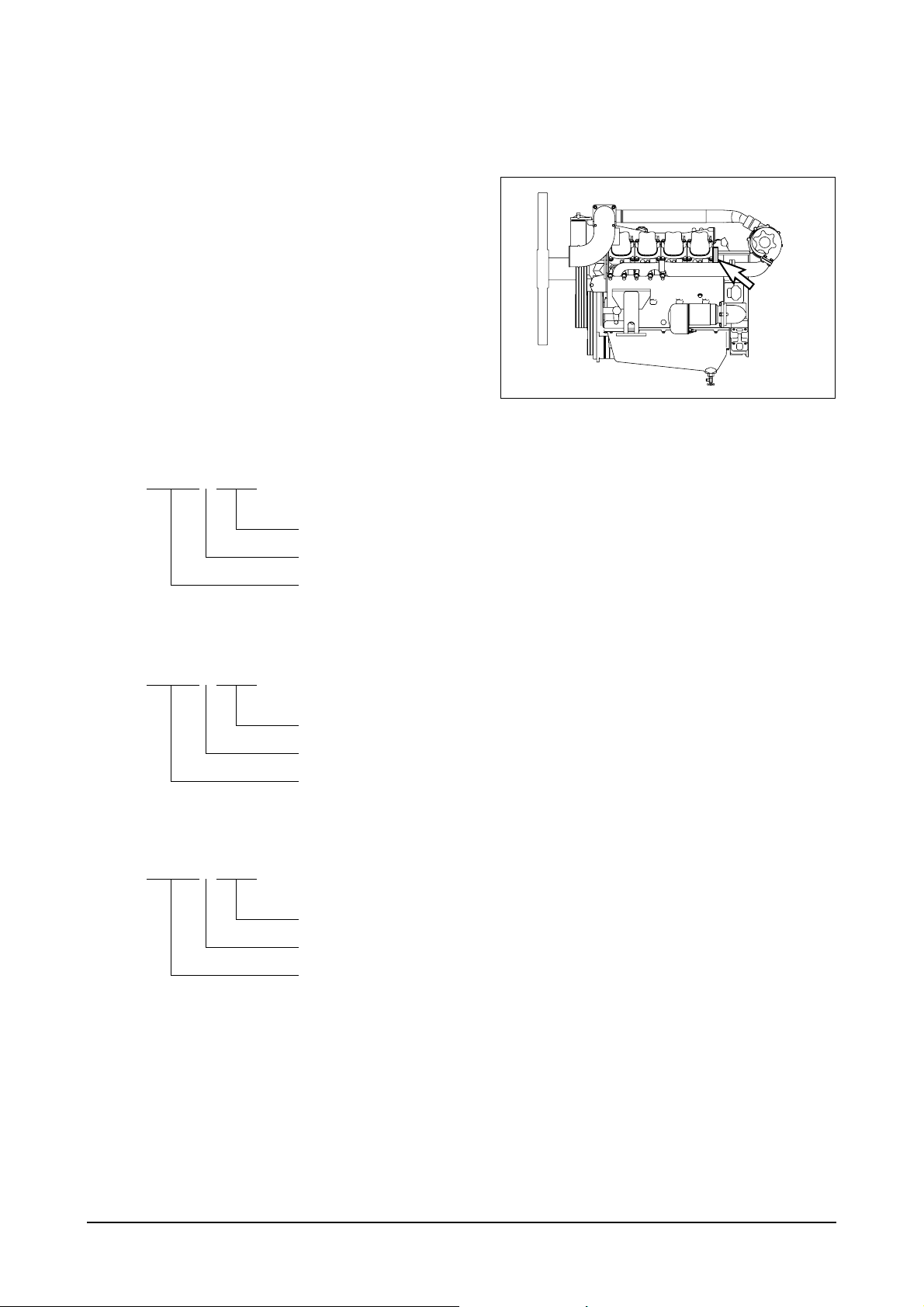

2. Technical Information

2.1. Engine Model and Serial Number

z

The engine model and serial number is

located on the engine as illustrated. These

numbers are required when requesting

warranty and ordering parts. They are also

referred to as engine model and serial

number because of their location.

z

Engine serial No. (example 1 : P158LE)

EAZOA 8 00001

Serial No.

Production Year(2008)

Engine

number

EA6O1006

Engine Model Suffix

z

Engine serial No. (example 2 : P180LE)

EASOA 8 00001

Serial No.

Production Year(2008)

Engine Model Suffix

z

Engine serial No. (example 3 : P222LE)

EAYOA 8 00001

Serial No.

Production Year(2008)

Engine Model Suffix

- 19 -

Technical Information

z

Engine serial No. (example 4 : PU158TI)

EAZPA 8 00001

Serial No.

Production Year(2008)

Engine Model Suffix

z

Engine serial No. (example 5 : PU180TI)

EASPA 8 00001

Serial No.

Production Year(2008)

Engine Model Suffix

z

Engine serial No. (example 6 : PU222TI)

EAYPA 8 00001

Serial No.

Production Year(2008)

Engine Model Suffix

2.2. Engines Characteristic

z

The generator engine(P158LE/P180LE/P222LE) and power unit engine(PU158TI/PU180TI/PU222TI)

series are V-type liquid-cooled 8/10/12-cylinder four-stroke Diesel engines with direct injection.

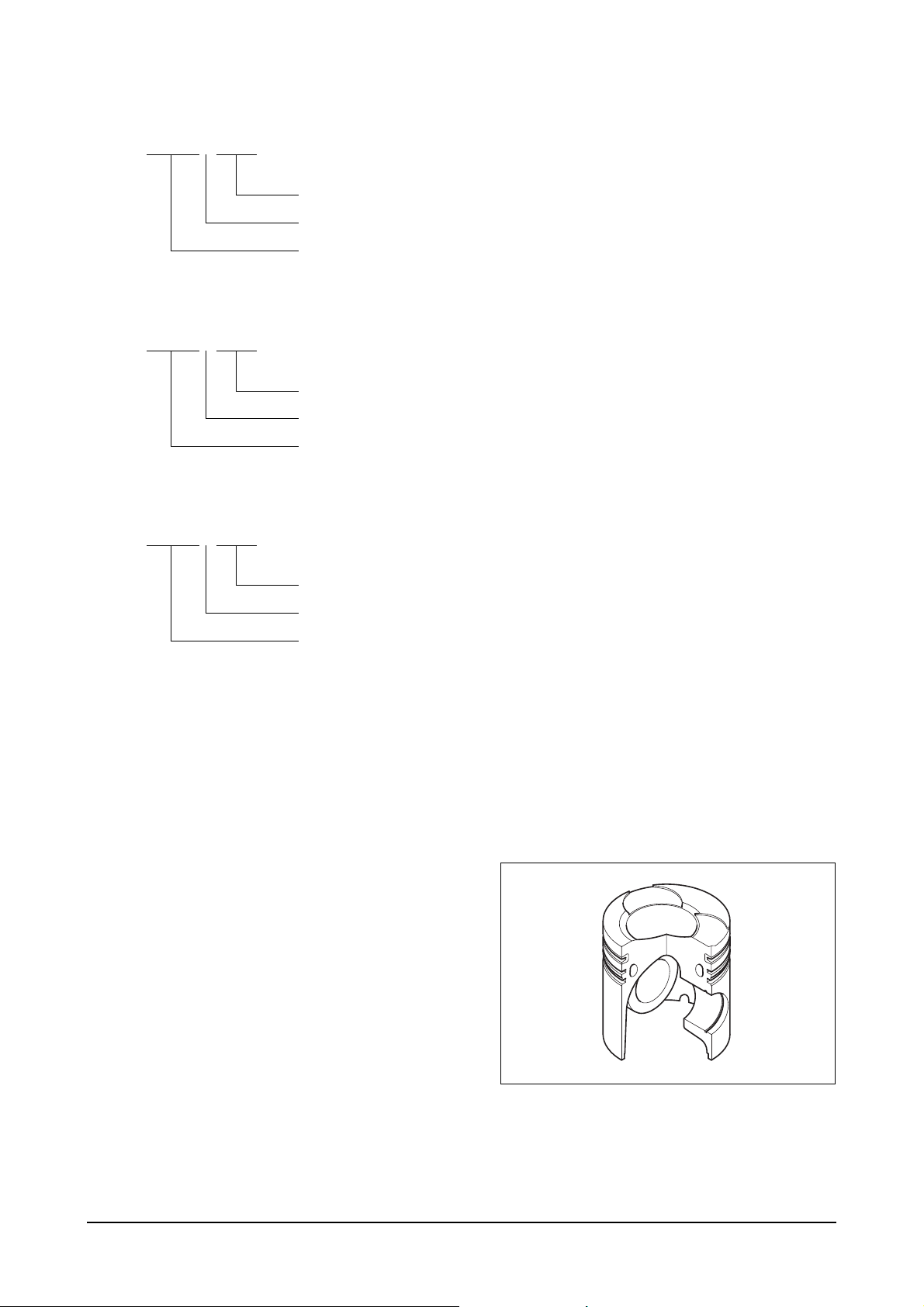

2.2.1. Oil gallery cooling type piston

z

Oil gallery cooling is used for the piston

of the engine.

z

When thermal loading is high, piston

cooling by means of an oil gallery in the

crown is normally necessary to prevent

crown cracking and ring sticking. The

design of the gallery, the design and

location of the oil spray nozzle and the

quantity of oil flowing in the gallery are

critical in order to achieve the desired

temperature reduction.

z

The cross section shape of the gallery should be designed to achieve sufficient oil movement to

maximize cooling efficiency.

ED7OM007

Technical Information

- 20 -

2.2.2. Engine block

z

The cylinder block is a single piece of alloy cast iron. To increase its stiffness, it is extended to a level

below the crankshaft center line. The engine has replaceable wet cylinder liners and individual

cylinder heads with strung-in valve seat rings and replaceable valve guides.

2.2.3. Piston / Connecting rod / Crank assembly

z

The forged crankshaft has screwed-on counterweights. Radial seals with replaceable wearing rings

on crankshaft and flywheel are provided to seal the crankcase penetrations.

z

The connecting rods are die-forged, diagonally split and can be removed through the top of the

cylinders together with the pistons. Crankshaft and connecting rods run in steel-backed lead bronze

ready-to fit type bearings.

2.2.4. Engine timing

z

Camshaft, oil pump and injection pump are driven by a gear train arranged at the flywheel end.

2.2.5. Valves

z

The overhead valves are actuated via chilled cast iron tappets, push rods and rocker arms from the

camshaft.

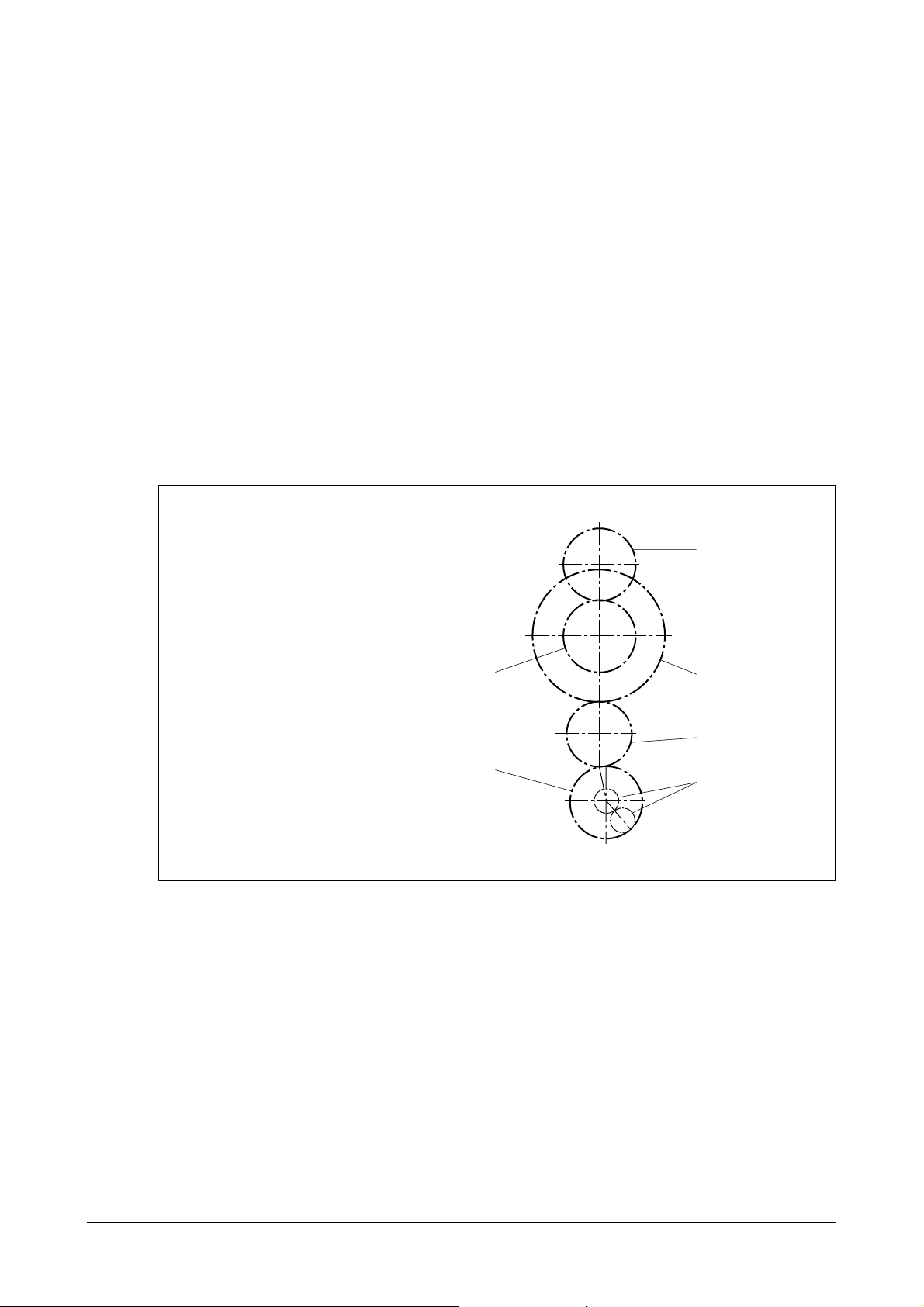

1. Crankshaft gear

2. Oil pump drive gear

3. Oil pump impeller gears

4. Camshaft drive gear

5. Injection pump drive gear

6

5

2

4

1

3

EA6O3001

- 21 -

Technical Information

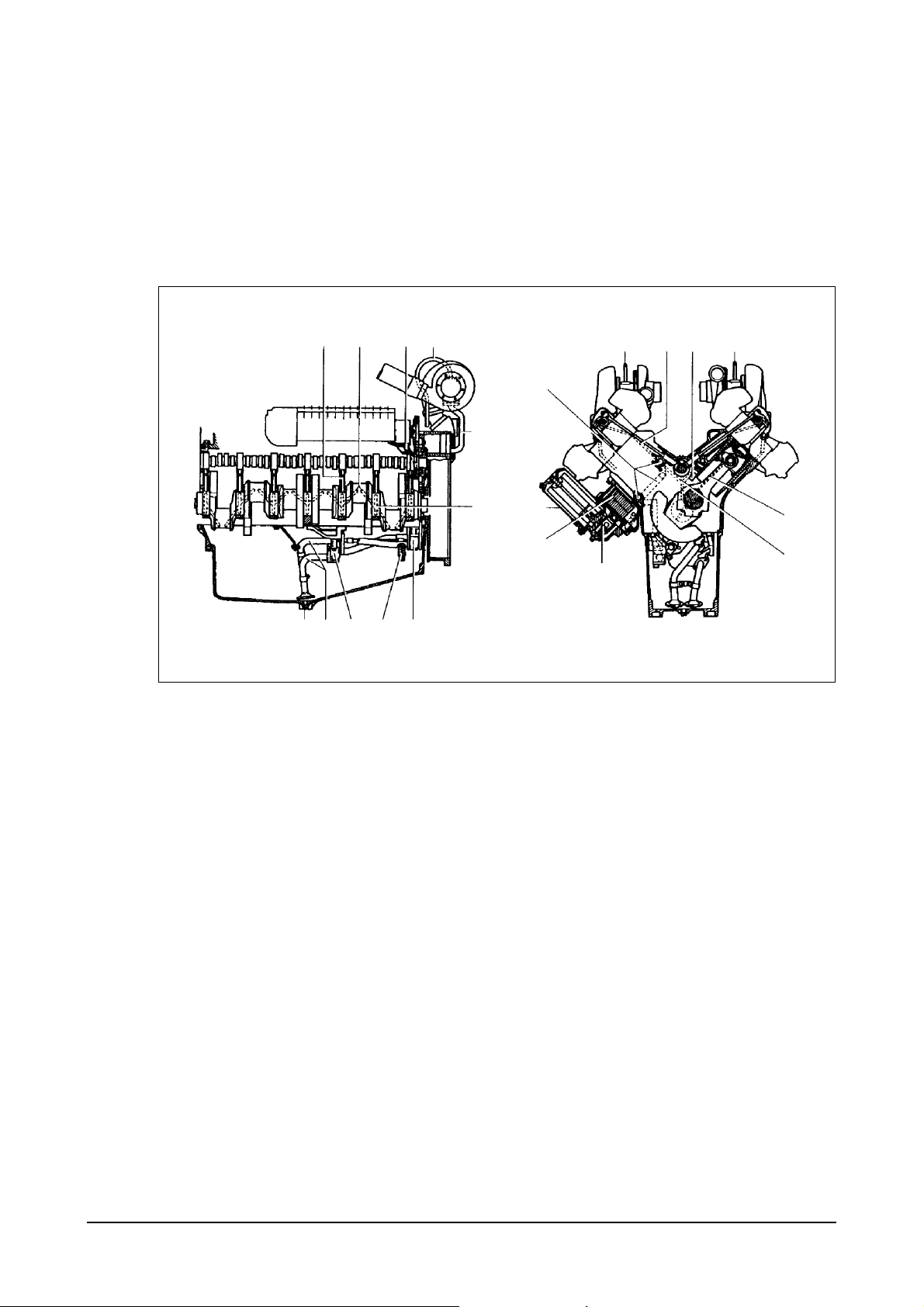

2.2.6. Engine lubrication

z

The engine is equipped with force-feed lubrication.

The pressure is produced by a gear pump whose drive gear is in direct mesh with the crankshaft

gear at the flywheel end.

z

The oil pump draws the oil from the oil sump and delivers it through the oil cooler and oil filter to the

main distributor gallery and from there to the main bearings, big-end bearings and camshaft bearings

as well as to the small-end bearings and the rocker arms.

10 15 17

8

17 13 14 17

7

18

9

2

16

1

1. Oil suction pipes 10. Ports for big end bearing lubrication

2. Oil pumps 11. Small end bearing lubrication

3. Oil relief valves 12. Camshaft bearing lubrication

4. Oil cooler 13. Rocker arm lubrication

5. Oil filter 14. Spray nozzle

6. Bypass valve 15. Injection pump lubrication

7. Main oil galleries 16. Oil drain plug

8. Oil gallery to crankshaft 17. Lube oil pipes to turbochargers

9. Ports for main bearing lubrication 18. Oil return from turbochargers

3

2

5

4

6

11

12

EA6O3002

Technical Information

- 22 -

z

The injection pump and the turbocharger are also connected to the engine lubricating system. The

cylinder walls and timing gears are splash-lubricated.

Each cylinder has an oil jet provided for cooling the underside of the pistons.

The lube oil is cleaned in a full-flow oil filter. Depending on the agreed extent of delivery and the

design of the engine, the lube oil circuit can be equipped with oil pressure monitors (advance

warning and cut-off function) which shut the engine down in the event of a sudden loss of pressure.

(1) Oil cooler

An oil cooler is provided between the oil filter and the crankcase. This cooler is of the flat tube

type with turbulence inserts and operated by the coolant.

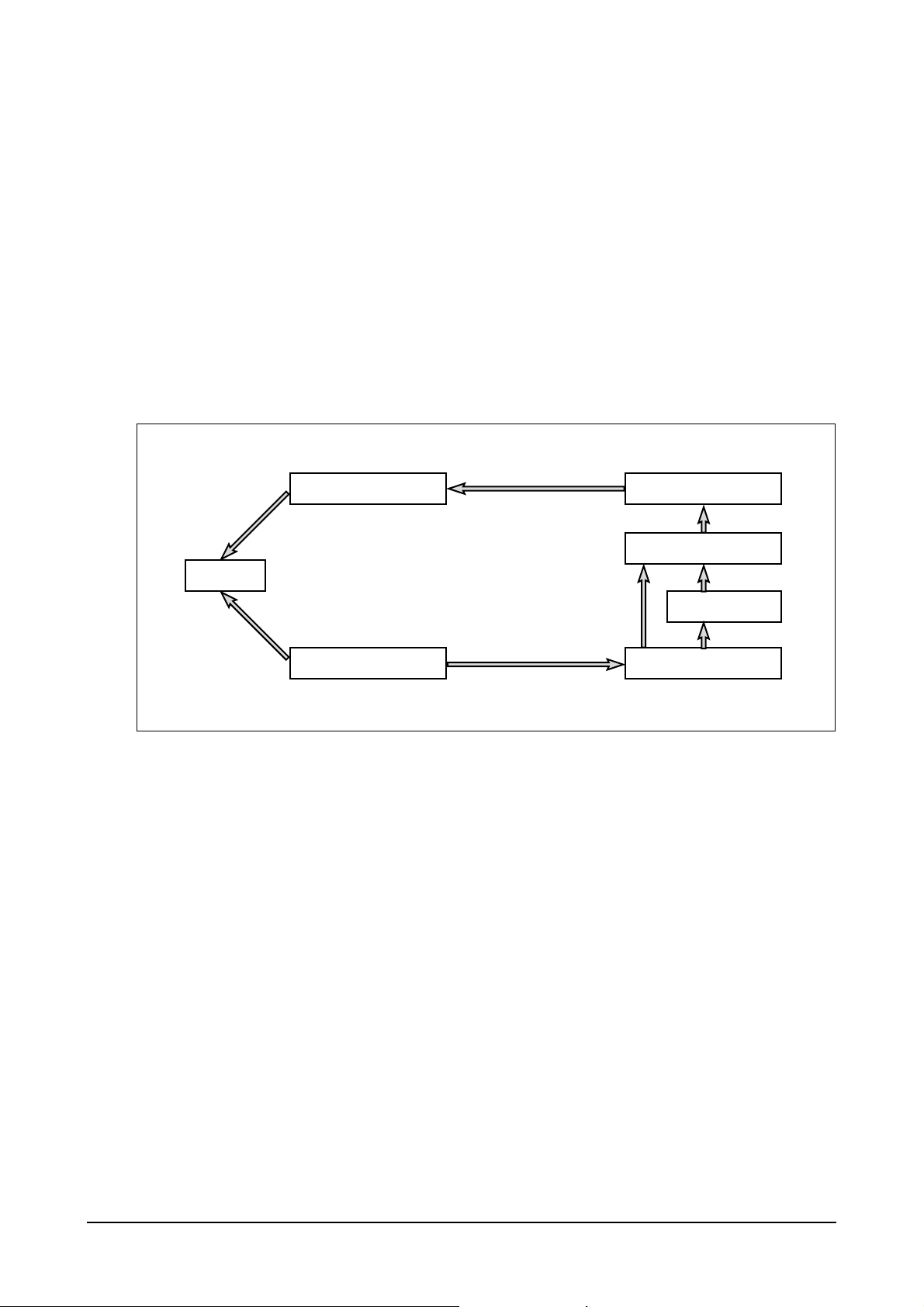

2.2.7. Engine cooling system

Radiator

Thermostat

Water pump

Coolant pipe

Cylinder head

Oil cooler

Coolant pipe

EA6M1001

- 23 -

Technical Information

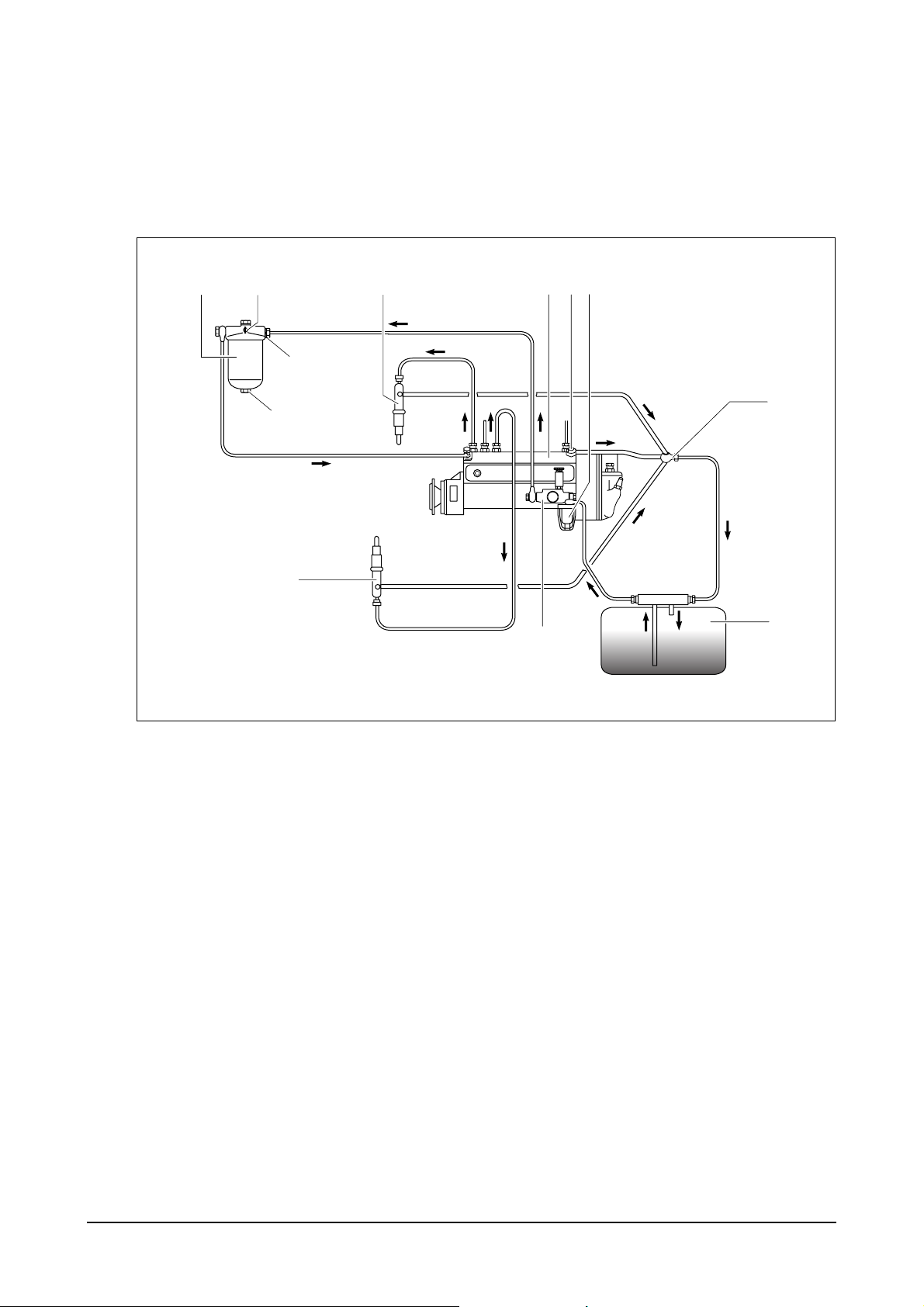

2.2.8. Fuel system

The fuel is delivered by the fuel lift pump via the fuel filter to the injection pump and from there to the

injectors.

The fuel is sprayed into the cylinder through nozzles fitted in screw-fit injections in the cylinder heads.

Excessive fuel delivered and leak fuel from the injectors flow through the return pipe back to the tank.

4

4b

7

682

5

9

4a

7

1

10

EA6O3003

1. Fuel tank 5. Fuel pipe connector

2. Strainer 6. Injection pump

3. Fuel Filter 7. Injector

4. Fuel filter assembly 8. Fuel pressure relief valve

4a. Fuel water drain plug 9. Fuel return pipe

4b. Air bleeding plug

10. Fuel feed pump

(for fuel filter)

Technical Information

- 24 -

If Diesel fuel which contains moisture is used the injection system and the cylinder liners / pistons will be

damaged. This can be prevented to same extent by filling the tank as soon as the engine is switched off

while the fuel tank is still warm (formation of condensation is prevented). Drain moisture from storage

tanks regularly. Installation of a water trap upstream of the fuel filter is also advisable.

z

Fuel oil selection chart

General Fuel

Classification

Gravity, °API

#)

Flash Point

Min. °F (°C)

Viscosity, Kinematic

cST 100 °F (40 °C )

Cloud Point °F

#)

Sulfur Content

wt%, Max.

Carbon Residue

on 10 %, wt%, Max.

ASTM

Test

No. 1

ASTM 1-D

No. 2

ASTM 2-D

D 287 40 ~ 44 33 ~ 37 0.815 ~ 0.855

D 93 100 (38) 125 (52) 131 (55)

D 445 1.3 ~ 2.4 1.9 ~ 4.1 1.8 ~ 10

D 2500 See NOTE 1) See NOTE 1) See NOTE 1)

D 129 0.5 0.5 0.15

D 524 0.15 0.35 0.1

Accelerated Stability

Total Insolubles

mg/100 ml, Max.

#)

D 2274 1.5 1.5

Ash, wt%, Max. D 482 0.01 0.01

Cetane Number, Min.

+)

D 613 45 45 > 45

Distillation

Temperature, °F (°C)

IMP, Typican

10 % Typical

50 % Typical

+)

90 %

End Point

#)

#)

#)

#)

D 86

350(177)

385(196)

45(218)

500(260) Max.

550(288) Max.

375(191)

430(221)

510(256)

625(329) Max.

675(357) Max.

DIN 51601

680(360)

Water & Sediment

%, Max.

D 1796 0.05 0.05 0.05

#) Not specified In ASTM D 975

+) Differs from ASTM D 975

NOTE :

The cloud point should be -12

°

C (10 °F) below the lowest expected fuel temperature

to prevent clogging of fuel fitters by crystals.

- 25 -

Technical Information

2.2.9. Injection pump

No alterations must be made to the injection pump. If the lead seal is damaged the warranty on the

engine will become null and avoid.

z

Faults

We strongly recommend that any faults developing in the injection pump should be taken care of by

authorized specialist personnel.

z

Bleeding the fuel system

Bleeding the fuel filter is by releasing the bleed screws and operating the manual primer.

The suction chamber of the injection pump is continuously bled via the relief valve during operation If

the suction chamber is completely empty, e.g., when fitting a new pump, filling and bleeding it is by

actuating the manual primer.

z

Fuel lift pump

The fuel lift pump is operated by the injection pump camshaft via the roller tappet.

z

Strainer

After every 200 hours of operation the fuel strainer connected upstream of the fuel lift pump should

be cleaned.

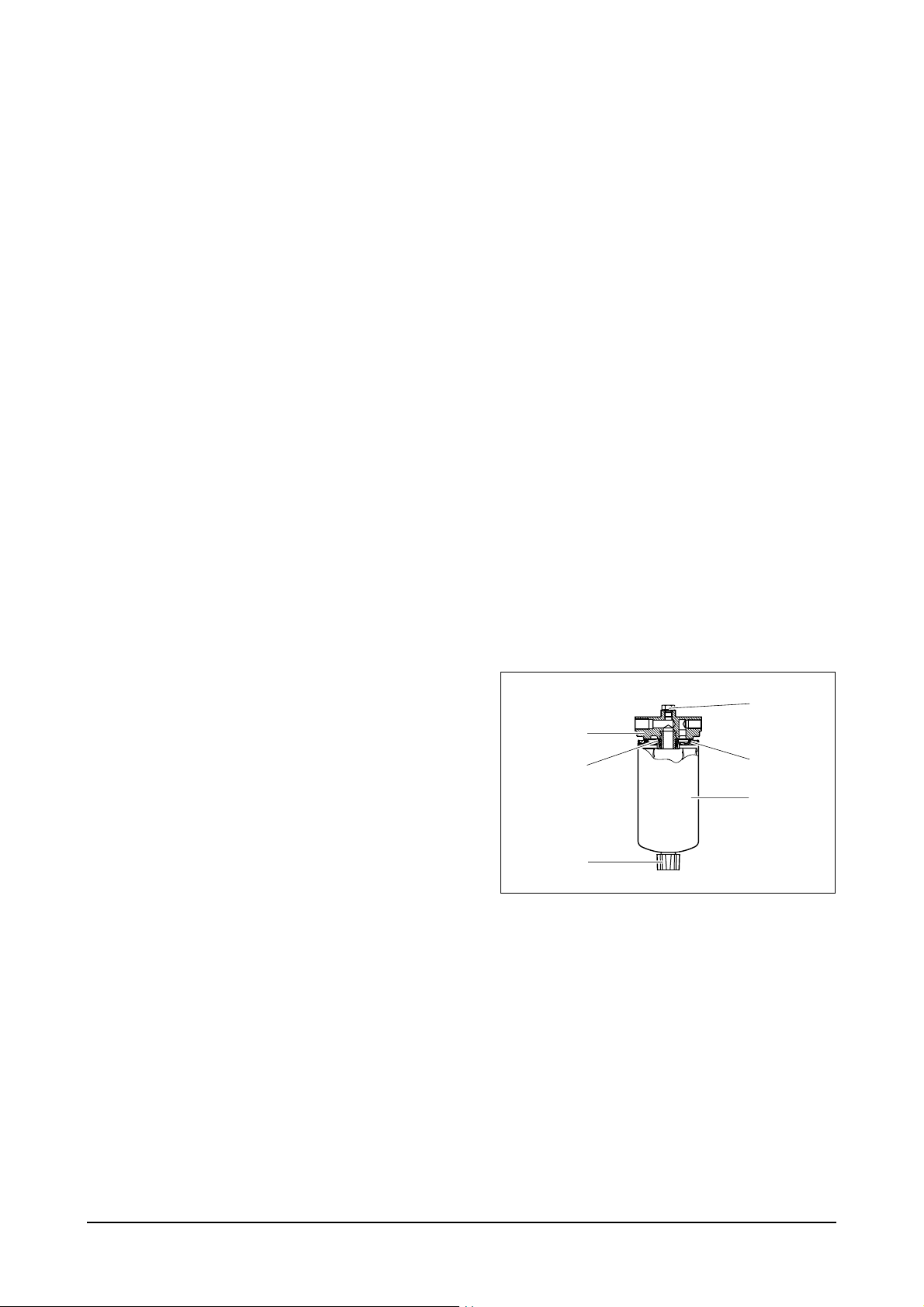

2.2.10. Fuel filter

z

After every 1,200 hour of operation,

drain the water and sediment from the

fuel-water separator.

z

Shut off the engine. Use your hand to

open the drain valve(6).

Turn the valve counter clockwise

approximately 2 ~ 3 turns until draining

occurs. Drain the filter sump of water

until close fuel is visible.

z

Turn the valve clockwise to close the

drain valve. Do not over tighten the

valve, overtightening can damage the

threads.

1

3

4

6

5

2

EA2O4009

Technical Information

- 26 -

2.2.11. Replacement of fuel filter

z

Clean the area around the fuel filter head(3).

z

Remove the fuel filter(2).

z

Remove the fuel filter thread adapter seal ring(4).

Use a clean lint free cloth to clean the gasket surface of the fuel filter head(3).

z

Install the new thread adapter seal ring(4)supplied with the new filter.

Use clean oil to lubricate the filter seal(5), and fill the new filter with clean fuel.

z

Install the filter on the filter head(5).

Tighten the filter until the gasket contacts the filter head surface.

Tighten the filter on additional one-half to three-fourths of a turn, on as specified by the filter

manufacturer.

NOTE :

Mechanical over tightening of the filter can distort the thread or damage the filter

element seal.

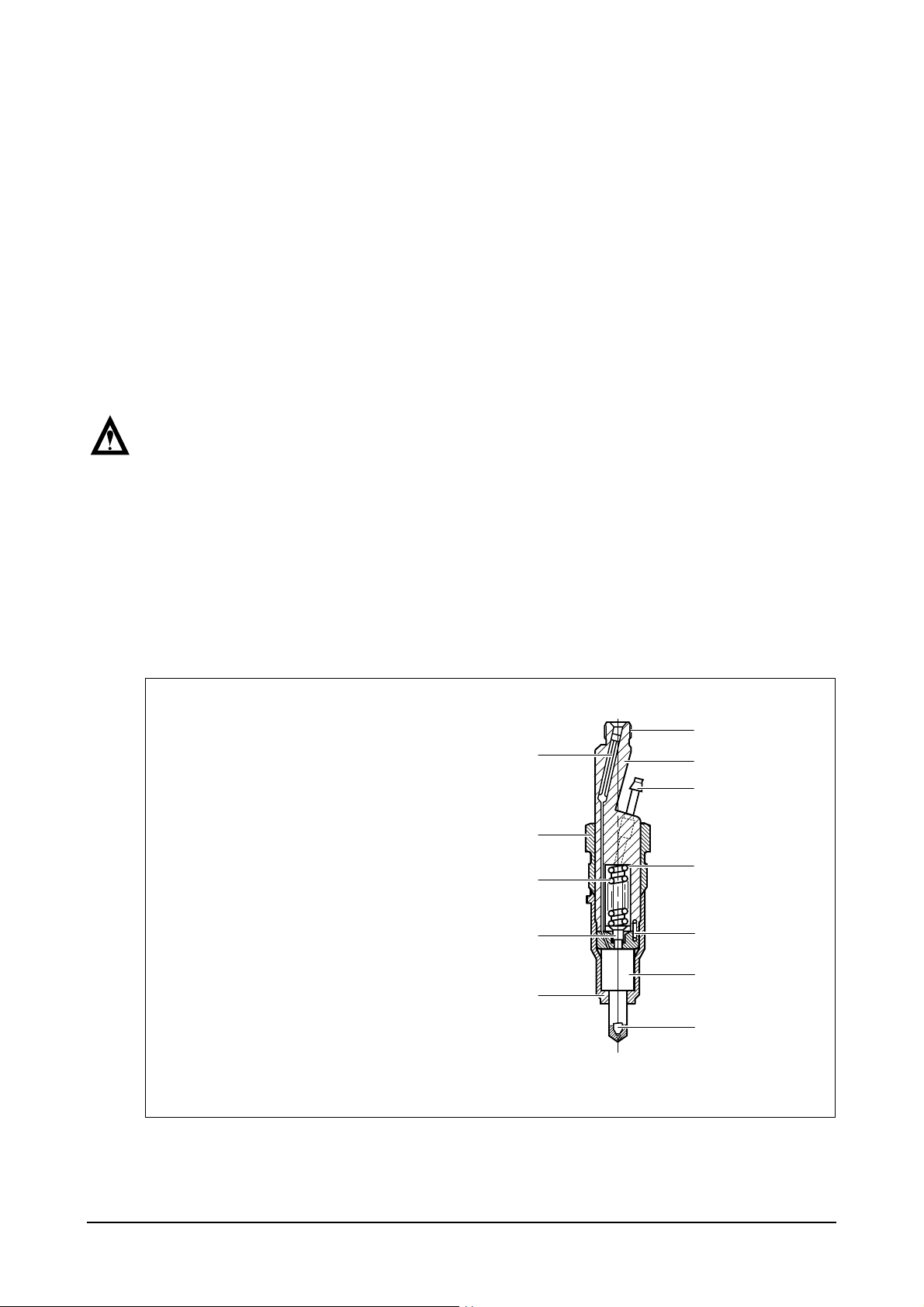

2.2.12. Injector maintenance

The injectors are designed to spray the fuel delivered by the injection pump directly into the spherical

combustion chamber in the piston crown.

The injector consists of the nozzle and the nozzle holder.

A copper gasket fitted to the injector ensures gas-tight seating and good heat dissipation.

The opening pressure of the nozzle is adjusted by means of shims at the compression spring.

1. Rod type filter

2. Cap nut

3. Compression spring

4. Compression pin

5. Cap nut for fixed nozzle

6. Nozzle needles

7. Connect hole for fuel delivery

8. Nozzle holder

9. Connect tube for overflow

10. Shim

11. Pin

12. Nozzle bush

7

1

2

3

4

5

8

9

10

11

12

6

EA6O5006

- 27 -

Technical Information

Loading...

Loading...