Doosan MD Series, L Series, V Series, L034, L034TI Installation Instructions Manual

...

PREFACE

•

General information

This installation instruction is designed as a guide for the proper installation of DOOSAN

(Doosan Infracore Ltd. hereafter DOOSAN) marine diesel engines and to create conditions for

faultless operation of the entire system and to prevent installation related malfunctions and

possible consequential damage to the engine.

•

Scope

This installation instruction applies to all DOOSAN engines for marine propulsion and marine

generator.

•

Warranty

Warranty claims against DOOSAN Marine Engines will be accepted only if this installation

instruction has been complied with.

If any modification to the engine installation intended by DOOSAN is planned, DOOSAN must be

informed in writing, and a new inspection may necessary.

We reserve the right to make technical modifications in the course of further development.

•

Validity

DOOSAN reserves the right to make changes at any time, without notice, in specifications and

models and also to discontinue models. The right is also reserved to change any specifications or

parts at any time without noticing any obligation to equip same on models manufactured prior to

date of such change.

The continuing accuracy of this manual cannot be guaranteed.

All illustrations used in this manual may not depict actual models or equipment and are intended

as representative views for reference only.

- a -

•

Marine engine Recommendation on applications

The engine must be able to achieve rated engine speed when operated under fully

loaded conditions;

Secondary drive loads must be considered engine horse power which could be available to

drive the primary load. Therefore any such parasitic load requirements must be deducted when

sizing an engine for the primary load.

The engine must be used in accordance with the application guidelines for that

particular rating;

It is important to choose the proper engine rating to provide the optimum performance in a

given application. Ratings below show DOOSAN marine engine guidelines on applications.

(1) Heavy duty

•

Operation hours : Unlimited per year

•

Average load application : Up to 90%

•

Percentages of time at full load : Up to 80%

•

Typical gear box ratio : 2.5 ~ 6

(Application: Fishing trawler, Tug boat, Pushing vessel, Cago boat, Freighter, Ferry)

(2) Medium duty

•

Operation hours : Up to 3,000hr per year

•

Average load application : Up to 70%

•

Percentages of time at full load : Up to 30%, 4hrs per 12 hour operation period

•

Typical gear box ratio : 2 ~ 3.5

(Application:

Fishing boat, Pilot boat, Escort boat, Passenger boat, Ferry, Cruising Vessel

)

(3) Light duty

•

Operation hours : Up to 1,000hr per year

•

Average load application : Up to 50%

•

Percentages of time at full load : Up to 20%, 2hrs per 12 hour operation period

•

Typical gear box ratio : 1 ~ 2.5

(Application:

Fishing boat, Pilot boat, Escort boat, Passenger boat, Ferry, Cruising Vessel

)

- b -

•

Other country regulation

Other country may apply additional internal regulation. Please follow their appropriate advice.

Korea : KR = Korean Resister of Shipping

Sweden : Navigation Office

Finland : Navigation Office

Norway : DNV = Det Norske Veritas

USA : ABS = American Bureau of shipping

Indonesia : BKI = Biro Klasifikasi Indonesia

USA : NMMA = National Marine Manufacturers Association

England : LR = Lloyds Register of Shipping

France : BV = Bureau Veritas

Germany : GL = Germanisher Lloyd

Italy : RINA = Regislro Italiano Navale

Bulgaria : BKP = Bulgarian Register of Shipping

China : CCS = China Classification Society

China Rep.(Taiwan) : CR = China Corporation Register of Shipping

Spain : FN = Fidenavis

Croatia : CRS = Croatian Register of shipping

India : IRS = Indian Register of Shipping

Japan : NK = Nippon Kaiji Kyokai

Poland : PRS = Polski Register Statkow

Portugal : RP = Rinave Portuguesa

Rumania : RNR = Registrul Naval Roman

Russia : MRS = Russian Maritime Register of Sipping

Turkey : TL = Turk Loydu Vakfi

- c -

CONTENTS

CHAPTER 1 Engine Room .............................................................................................................1

1.1. Engine Room Ventilation 1.4. Power Rating

1.2. Engine Foundation 1.5. Inclinations

1.3. Max. Permissible Engine Inclination

CHAPTER 2 Engine Mounting .......................................................................................................6

2.1. Flexible Mounting 2.3. Arrangement of Engine and Reduction Gear

2.2. Solid Mounting

CHAPTER 3 Front Power Take off...............................................................................................13

3.1. Marine Installation Requirements 3.3. Belt Drives

3.2. Front Power Take-off Clutches

CHAPTER 4 Exhaust System.......................................................................................................18

4.1. Marine Installation Requirements 4.4. Direction of Exhaust Outlet

4.2. Dry Exhaust Systems(without sea 4.5. Permissible Back Pressure

water injection) 4.6. Designing the Exhaust System

4.3. Wet Exhaust System(with sea water 4.7. Measuring the Pressure Drop

injection)

CHAPTER 5 Intake System ..........................................................................................................30

5.1. Air Intake 5.4. General Note on Air Guidance

5.2. Engine Room Ventilation 5.5. Clear Cross Section

5.3. Radiant Heat to be Removed

CHAPTER 6 Cooling System .......................................................................................................35

6.1. Marine Installation Requirements 6.5. Engine Coolant

6.2. Selection of Piping Materials 6.6. Sea Water Lines

6.3. Cooling Circuit 6.7. Keel Cooler

6.4. Engine Cooling System

CHAPTER 7 Lubricating System .................................................................................................55

7.1. Marine Installation Requirements 7.3. Lube Oil Drain Pump

7.2. Engine Blow- by Gas Vent 7.4. Oil Dipstick Level Gauge

CHAPTER 8 Fuel System ...........................................................................................................57

8.1. Fuel Circuit 8.2. Fuel Tank

- a.4 -

CHAPTER 9 Propulsion System..................................................................................................64

9.1. Marine Gear Ratio Selection 9.5. Designing of the Propeller

9.2. How to Select the Right Propeller System 9.6. Propeller Tip Clearance

9.3. Propeller selection 9.7. Propeller Rotation in Twin Engine Applications

9.4. Power Drive with Fixed Pitch Propeller

CHAPTER 10 Electrical System...................................................................................................75

10.1. Electric Circuit 10.2. Electric Components

•

Appendix ....................................................................................................................................81

•

Part & After service center

•

Applications for DOOSAN Engine

- a.5 -

CHAPTER 1 ENGINE ROOM

When installing the engine, ensure that there is sufficient space for regular maintenance work

and possible engine overhaul after prolonged periods of operation. It must be possible to carry

out the following jobs on engine and gearbox without obstruction;

•

Removing heat exchanger and inter-cooler for cleaning

•

Exchanging starter, alternator and water pump

•

Filling up with fuel, oil and coolant

•

Checking oil and coolant level

•

Changing fuel, oil and air filter

•

Setting valves, re-tightening cylinder head bolts

•

Draining oil and coolant

•

Re-tightening and exchanging V - belts

•

Maintenance and exchange of battery

•

Exchanging injection nozzles

•

Changing the sea water pump impeller

•

Changing the reduction gear

1.1. Engine Room Ventilation

Calculation of the air requirements for the dissipation of convection and radiation heat can be

simplified the following formula:

where

•

m Air mass flow rate in kg/h

•

Q Convection and radiation in MJ/h

C

p

Specific heat capacity of air = 1 kJ/(kg x degree)

Δt Difference in temperature between heated waste air and cold intake air in degrees Celsius

In order to obtain the air volume flow (m

3

/h) the air mass flow (kg/h) must be divided by the air

density, which depends on the temperature.

Air density as a function of the temperature at the air pressure of 0.98kg/cm

2

(1000 mbar).

- 1 -

•

•

m =

Q x 1000

C

p

x Δt

Temperature in ˚C Density in kg/m

3

0 1.28

10 1.23

20 1.19

30 1.15

40 1.11

50 1.08

The before-mentioned formula is based on the assumption that the engine room is a heat-tight

system, i.e. for the sake of simplicity it is assumed that no thermal energy whatever is

dissipated through the hull to the ambient air or water.

In practice, however, such heat losses are likely to occur and depend on the following factors:

•

Size and surface area of the engine room

•

Difference in temperature between the engine room and the ambient air

•

Hull material (thermal conductivity) and hull thickness

•

Heat dissipation via pipes (e.g. exhaust pipes)

This heat transfer is therefore hard to estimate qualitatively.

Note : The difference of engine room and ambient air temperature (

Δ

t) would be better

below than 15

˚

C, but should not exceed maximum 20

˚

C.

Δt = (Air temperature of engine room) - (Ambient temperature)

<Conversion table of physical units >

•

Temperature

t(degree Celsius) = T(Kelvin) - 273

T(Kelvin) = t (degree Celsius ) +273

t (degree Fahrenheit) = 1.8 x t (degree Celsius) + 32

•

Pressure

1 kilo-Pascal (kPa) = 10 millibar (mbar)

1 hecto-Pascal (hPa) = 1 millibar (mbar)

•

Energy flow

Mega - Joule/hour (MJ/h) x

1000

= Kilocalories/hour (kcal/h)

4.187

Mega - Joule/hour (MJ/h) x

1

= Kilowatt (kW)

3.6

- 2 -

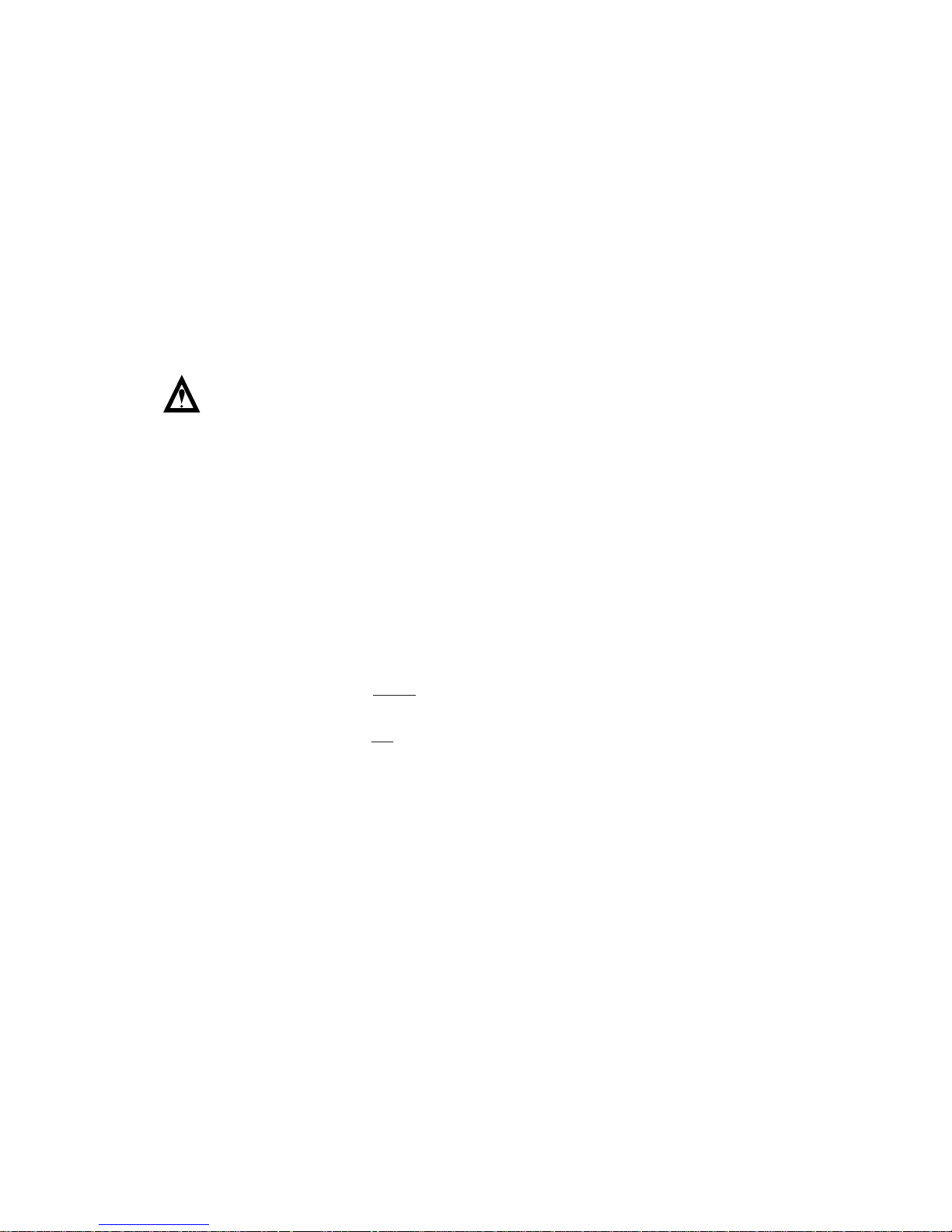

1.2. Engine Foundation

Requirements for the engine foundation are as following;

•

The foundation in the vessel should be able to take up propeller thrust in both directions

(ahead & astern) and transmit it on to the hull.

•

The weight of the drive system as well as all dynamic forces that occur in rough seas must

be safely taken up.

•

The torsion of the hull owing to rough seas and the load status must not be transferred to

the engine. The engine foundation is to be connected to the hull on an area as large as

possible

EB0O1001

Engine bed

Stringer

Engine mounting bracket

EB0O9007

•

Transverse cross bracing on the engine

bed and stringers should be used to

prevent lateral engine movement on solid

mounted systems.

•

In order to properly support the weight of

the engine and marine gear, a six-point

mounting system is recommended on all

DOOSAN marine engines.

When using a six-point mounting system,

the engine should be aligned using the

mounts at the front and at the marine gear

at first. Once the alignment is complete,

the next flywheel housing mounts should

be added.

- 3 -

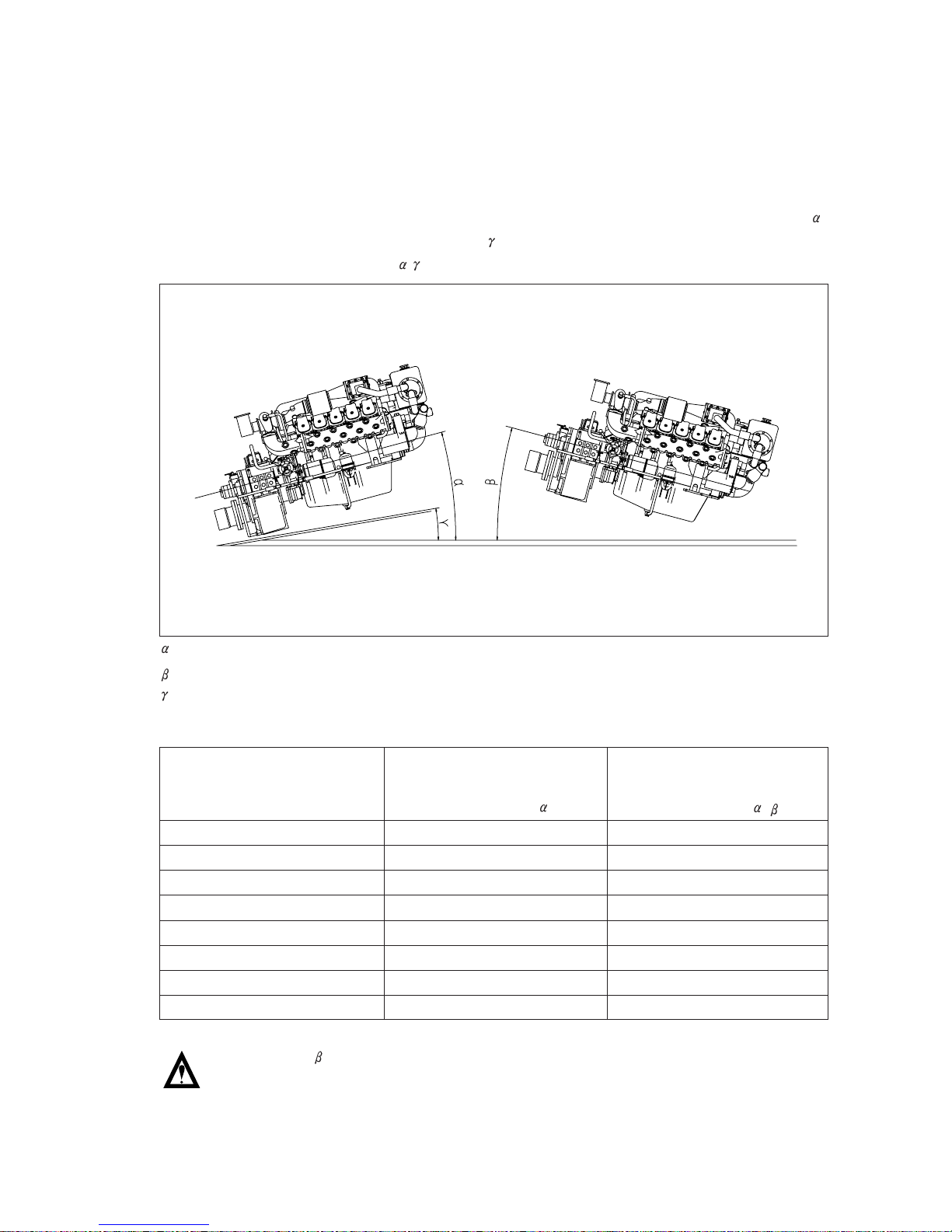

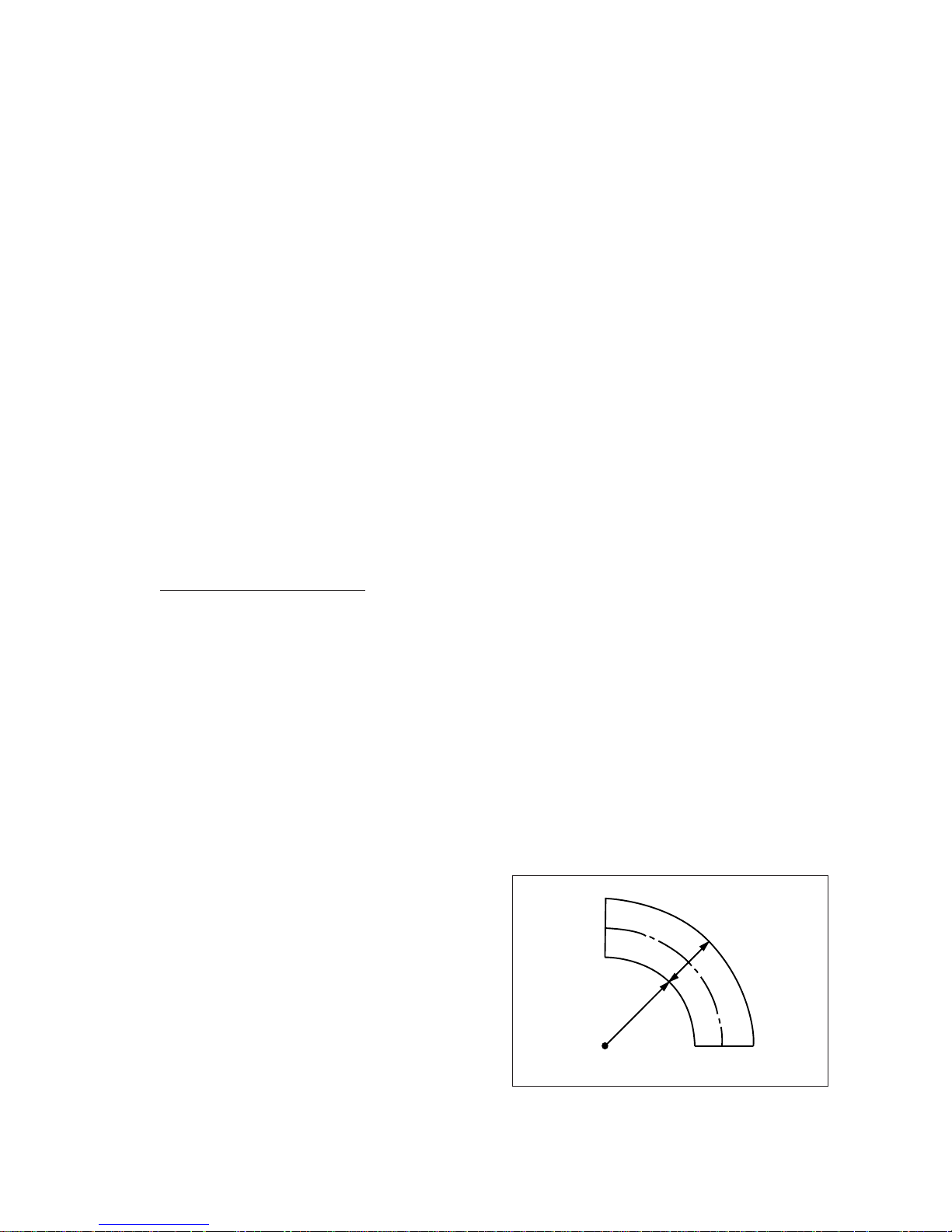

1.3. Max. Permissible Engine Inclination

The installation angle of the engine is an important factor in the construction of the sub-frame.

When the engine is to be installed in longitudinal direction, The maximum permissible inclination

must not be exceeded. The maximum permissible inclination is defined as the largest angle that

occurs in driving operation, ie, installation inclination plus the ship’s maximum trim angle.

The maximum installation angle of the engine is the maximum permissible inclination angle ( )

of the boat less the angle of the maximum trim( ) while the vessel is in motion. ie, the maximum

installation angle of the engine is( - ).

= max. permissible vessel inclination angle ; angle towards the flywheel end

= angle towards the non flywheel end

= trim of the vessel

<The maximum angles of inclination for the various engine are shown in below table>

Note : angle

The angle of 5˚toward the non-flywheel and must occur only while the vessel

is in motion.

- 4 -

Water line

EB0O1003

Max. oil pan permissible Max. angle of

Engine model angle of inclination engine installation

to the rear : ( ) inclination : ( - )

L034 / L034TI 20

˚

5

˚

L066TI 30

˚

5

˚

L136 / L136T 17

˚

5

˚

L136TI / L086TI 17

˚

5

˚

L196T / L196TI / L126TI 17

˚

5

˚

V158TI 17

˚

5

˚

V180TI 25

˚

5

˚

V222TI 25

˚

5

˚

If the installation angle of the engine is greater than that listed upper, the engine may occur

any engine damage. That is, connecting rods begin to dip into the oil in oil pan. So, this may

also cause high oil consumption, low power and the breather gas increasing and more

smokes. We recommend the engine installation angle to install below 6 degree for DOOSAN

marine engines.

1.4 Power Rating

Diesel engines are to be so designed that when running at rated speed their rated power can

be delivered as a continuous power. Continuous power means the net brake power which an

engine is capable of delivering continusously between the maintenance intervals stated by the

engine manufacturer.

To determine the power of all engines used on board ships with an unlimited range of service,

the following ambient conditions are to be used:

Engine driving generators are to be capable of developing 10% for a short period.(15minutes)

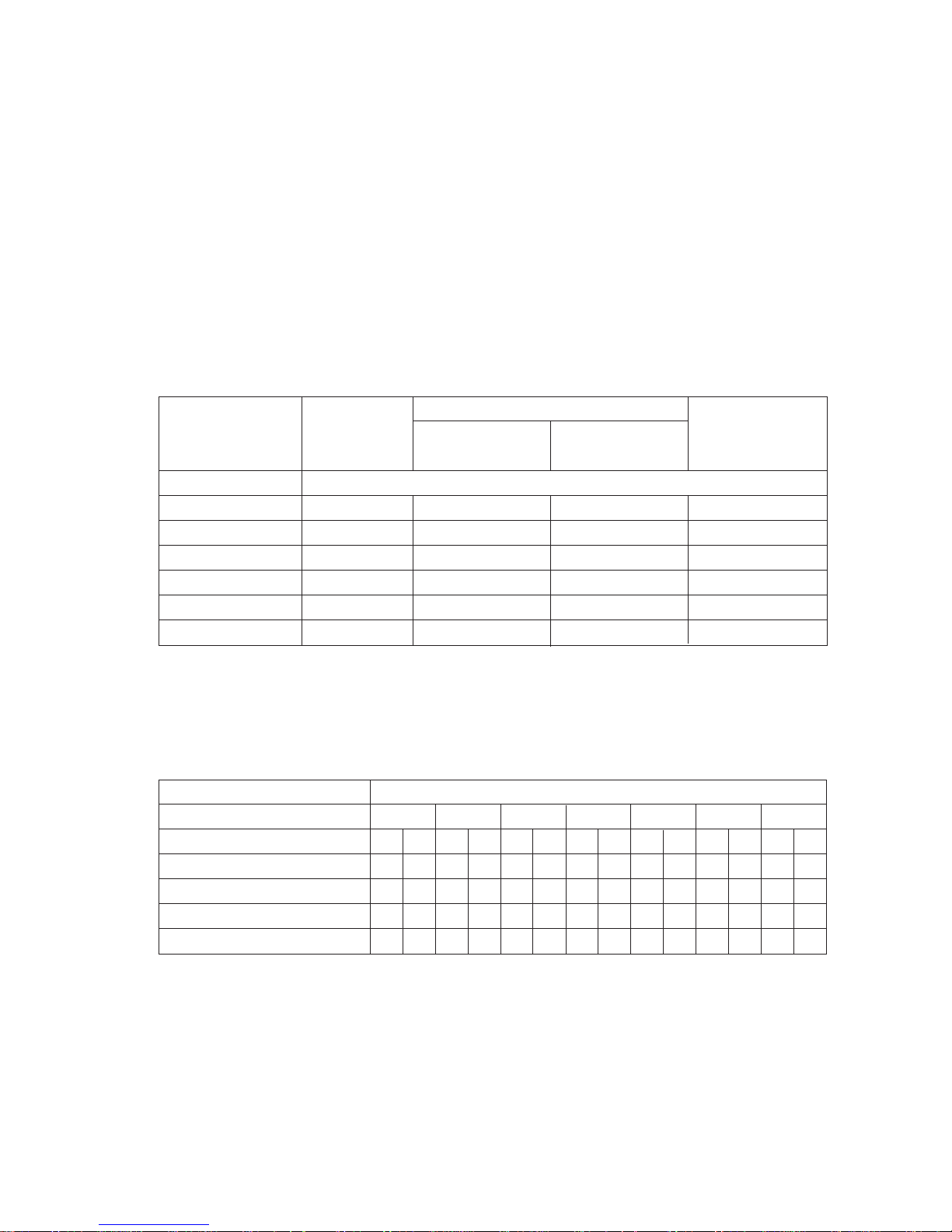

1.5 Inclinations

All components and systems shall be capable to operate in the following trim and pitch

positions.

1) Athwartships and for - and - aft inclinations may occur simultaneously.

2) Where the length of the ship exceeds 100m, the fore - and - aft static angle of inclination

may be taken as : (500)˚/L where L = length of ship(m).

3) In ships for the carrige of liquefied gases and of chemicals the emergency power supply

must also remain operable with the ship flooded to a final athwartships inclination up to

maximum 30˚.

- 5 -

Classification Barometric

Temperatures

Relative

societies pressure

Intake air

Seawater/

humidity

charge air coolant

DNV According to ISO3046/1

BV 1,000 mbar 45

˚C

32

˚C

60%

GL 1,000 mbar 45

˚C

32

˚C

60%

LR 1,000 mbar 45

˚C

32

˚C

60%

RINA Propuision 1,000 mbar 15

˚C

15

˚C

-

RINA Aux. service 1,000 mbar 45

˚C

30

˚C -

KR 1,000mbar 45

˚C

32

˚C

60%

Angle of inclination

1)

Installation ABS BV DNV GL LR RINA KR

Stat. Dyn. Stat. Dyn. Stat. Dyn. Stat. Dyn. Stat. Dyn. Sta. Dyn. Sta. Dyn.

Main and AUX athwartships

15 22.5 15 22.5 15 22.5 15 22.5 15 22.5 15 22.5 15 22.5

For - and - aft 5 7.5 5 7.5 5 7.5 5 7.5 52)7.5 5 7.5 5 7.5

Emergency athwartships

3)

22.5 22.5 22.5 22.5 22.5 22.5 22.5 22.5 22.5 22.5 22.5 22.5 22.5 22.5

For - and - aft 10 10 10 10 10 10 10 10 10 10 10 10 10 10

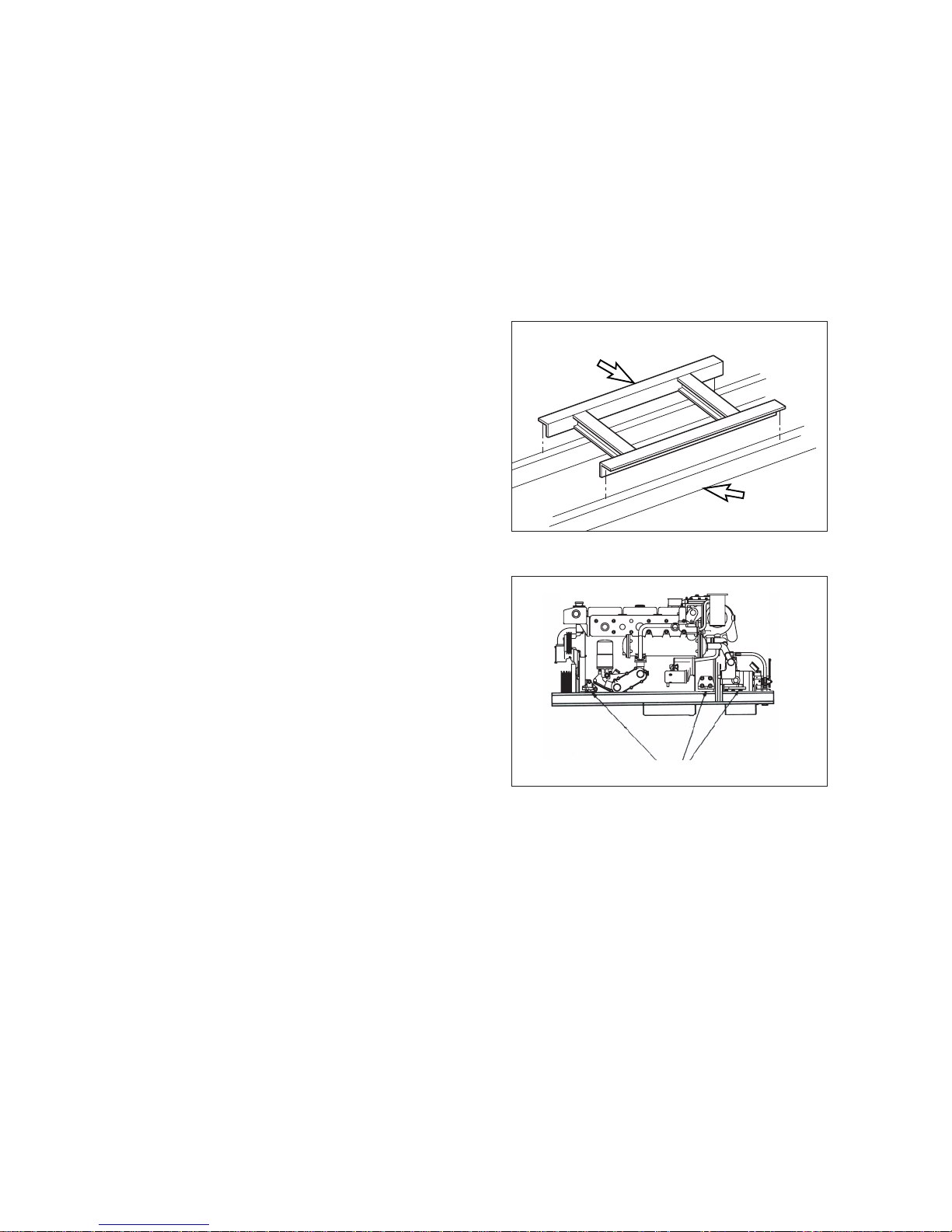

CHAPTER 2 ENGINE MOUNTING

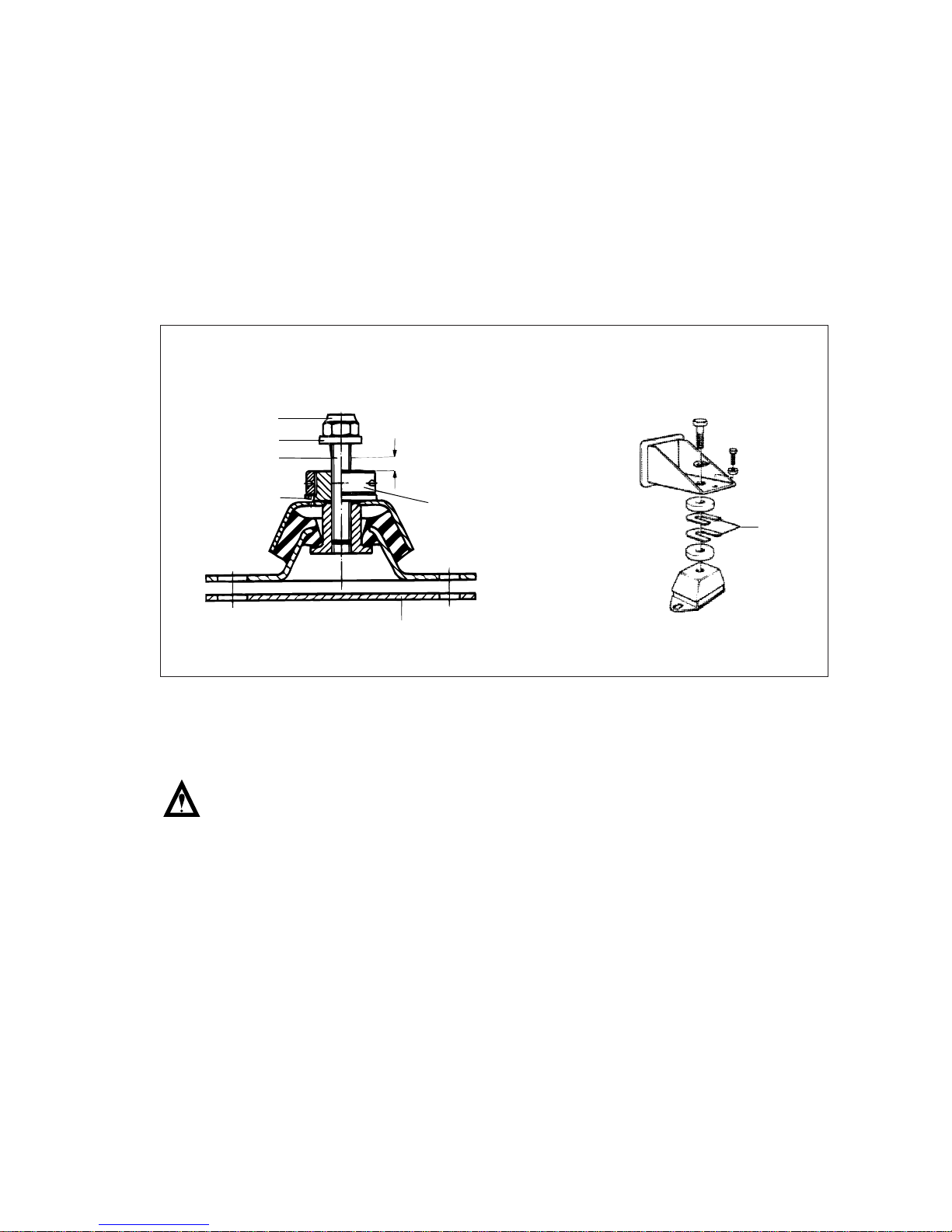

2.1. Flexible Mounting

Flexible mounting will generally be chosen for yachts and small boats because it reduces

vibration and noise levels.

Flexible engine mounts use the rubber isolators to absorb engine vibration before it is

transmitted to the hull. This will reduce noise and vibration in the boat. There are wide variety

of flexible mounts available on the market. Any mounts selected must hold the engine in

alignment and provide for acceptable mounting life. The isolator manufacturer should be

consulted for further recommendations.

The engine should be installed with sufficient clearance on all sides so that the allowable

engine movement will not cause structural or component damage.

Note : If the reduction gear must be mounted prior to installation in the hull, the

engine and reduction gear should be mounted on base rails and the whole

system installed together.

- 6 -

1

2

3

4

5

6

max. 10mm

EHO9001S

1. Mounting nut

2. Washer

3. Threaded pin

4. Clamp sleeve

5. Height adjustment

6. Shim

( manufactured as required)

Shims

2.2. Solid Mounting

The solid mounting engine is usually done by using brass or steel shims, pourable choking

compound and pads. The use of pourable choking compounds is the simplest and preferred

ways to solid mount the engine.

When using a choking compound, the alignment of the reduction gear and propeller shaft is

accomplished using jacking screws between the support brackets and the engine bed. The

mounting bolts can be loosely put into place at this point or a hole can be drilled through the

choking compound later. The jacking screws, mounting bolts and bottom of the engine bracket

should be coated with a grease or anti-bonding substance to allow them to be removed later.

Temporary dams are put on the engine bed and should extend approximately 13mm (0.5”)

above the bottom of the engine beds. The choking compound is poured in to fill the space

between the bracket and engine bed. Once the compound has solidified, the jacking screws

can be removed or left in place and the final mounting bolts are torqued down.

When using jacking screws on wood or fiberglass engine beds, steel plates should be used

under the jacking screws to prevent damage to the engine bed.

The choking compound manufacturer should be consulted for further recommendations.

- 7 -

EB0O2001

Engine

bracket

Chocking

compound

Temperary

dam

13mm(0.5")

Engine

bed

Jacking

screw

If a front power take-off clutch is used, it is a good practice to support the clutch. The clutch

available from DOOSAN marine Vee Series Models must be supported to avoid over stressing

the nose of the crankshaft due to the overhung weight.

- 8 -

EB0O2002

Fabreeka

washer

Steel tubing

approx. 0.8mm(1/32")

shorter than total

thickness of

fabreeka pads and

support bracker

13mm(1/2") fabreeka pad

Engine bad

4.8mm(3/16") steel plate

same length and

width as

fabreeka pads

Fabreeka type washers and pads consist of

layers of rubber impregnated canvas and

will provide a small amount of flexibility for

minor misalignment and a degree of

protection from shock loading. A steel plate

is required between the nut and Fabreeka

pad to protect the pad from wear and should

be the same size as the pad. It is still

necessary to use brass or steel shims to

align the engine and gear with the shafting.

Clutch support

EB0O2003

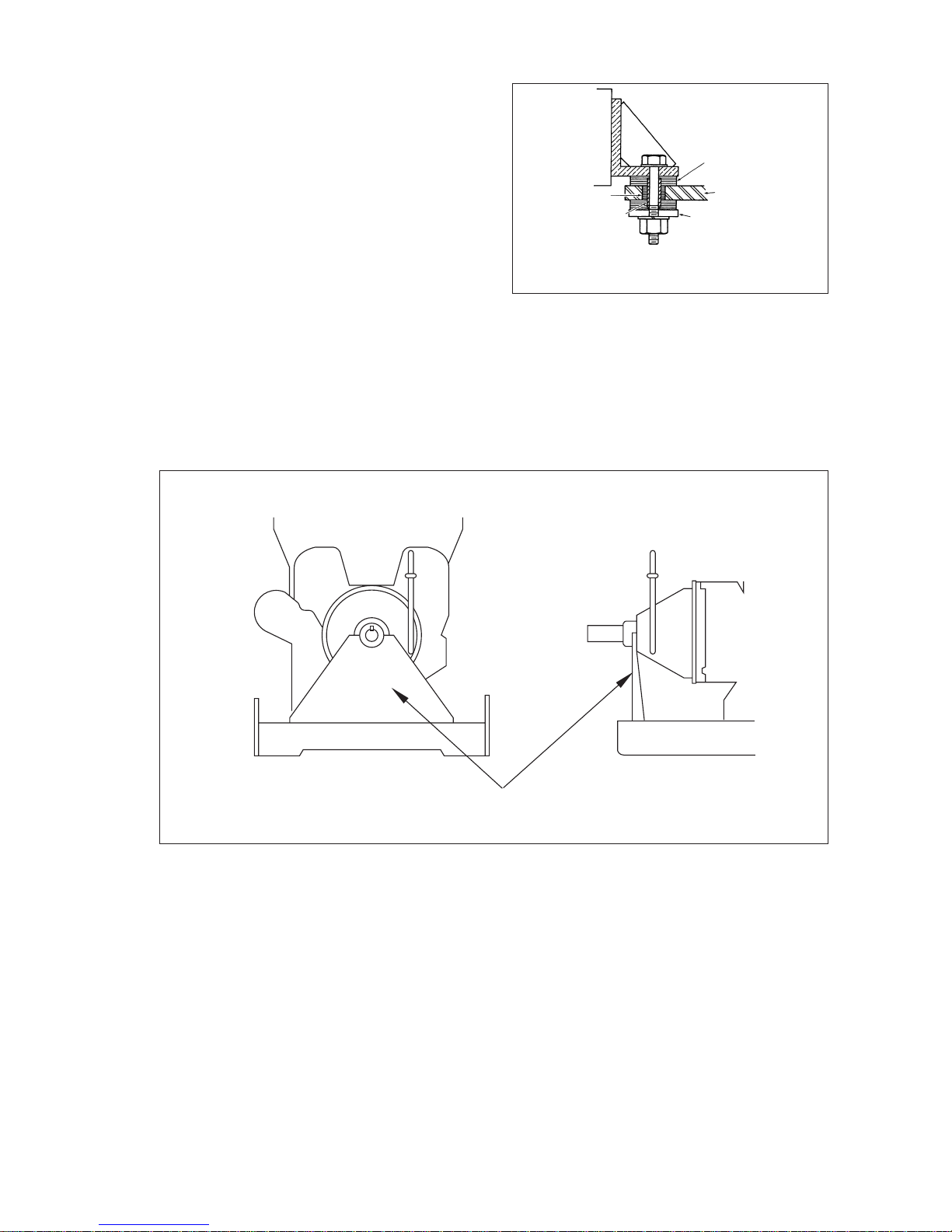

2.3. Arrangement of Engine and Reduction Gear

2.3.1. Engine and flanged-on reversing reduction gear

Engine and reduction gear can be constitute a unit. Propeller thrust is taken up by a

reduction gear thrust bearing.

In order to isolate engine vibration and prevent it from being transferred to the hull through the

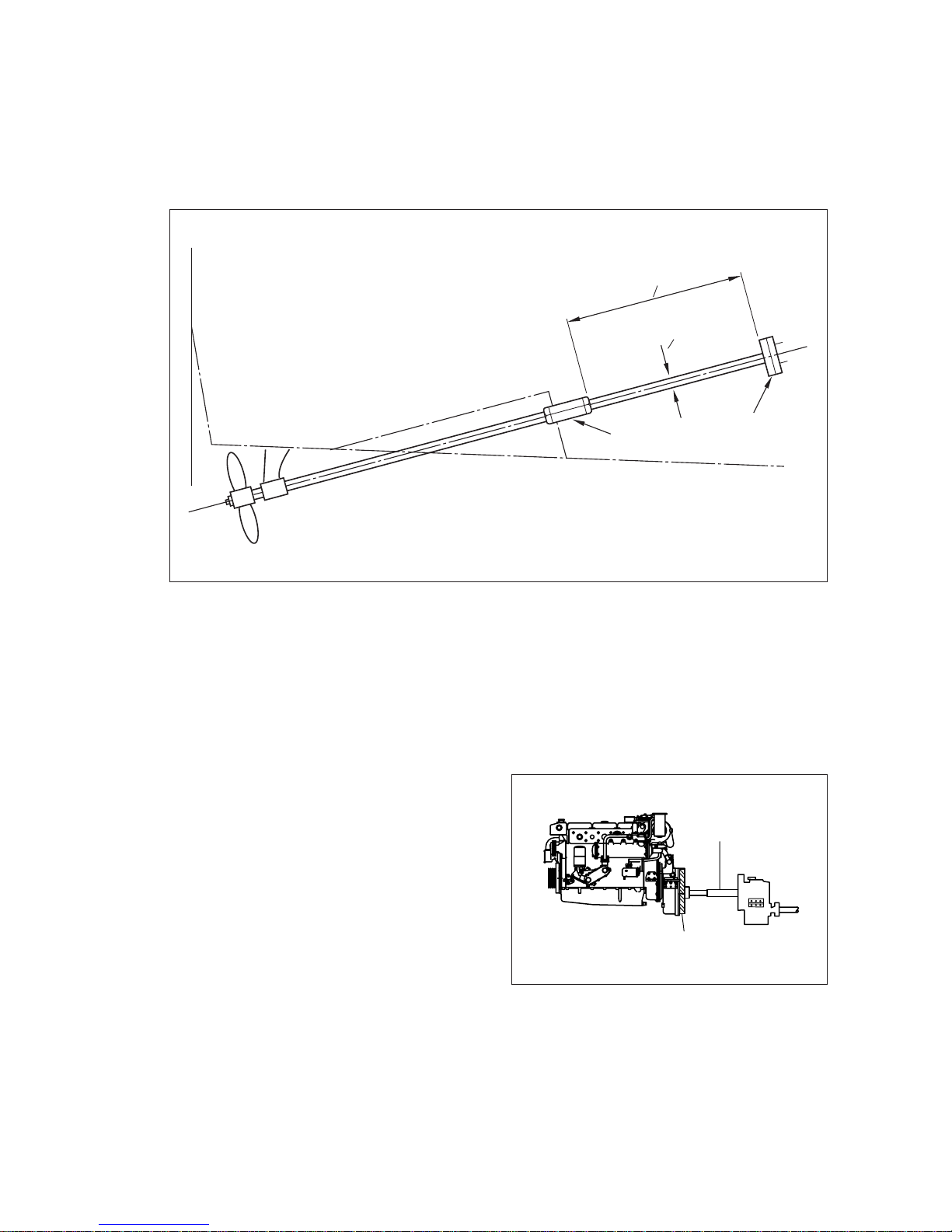

propeller shaft, DOOSAN recommends that the distance from the reduction gear output flange

to a fixed stuffing box or first fixed bearing should be a minimum of 20 times the shaft

diameter. If the distance is less than this, a flexible coupling may be necessary to isolate the

engine vibration.

2.3.2. Engine and detached reduction gear

- 9 -

Stuffing box

Min. Shaft length

20 x o

Output flange

EB0O2004

o

Sliding shaft

Flexible coupling

EB0O9008

The reduction gear is installed separately

from the engine, taking up propeller thrust

via a thrust bearing. A constant velocity

joint, or a pair of universal joints, and

sliding shaft must be used to allow for the

relative motion between the flexible

mounted engine and the fixed reduction

gear.

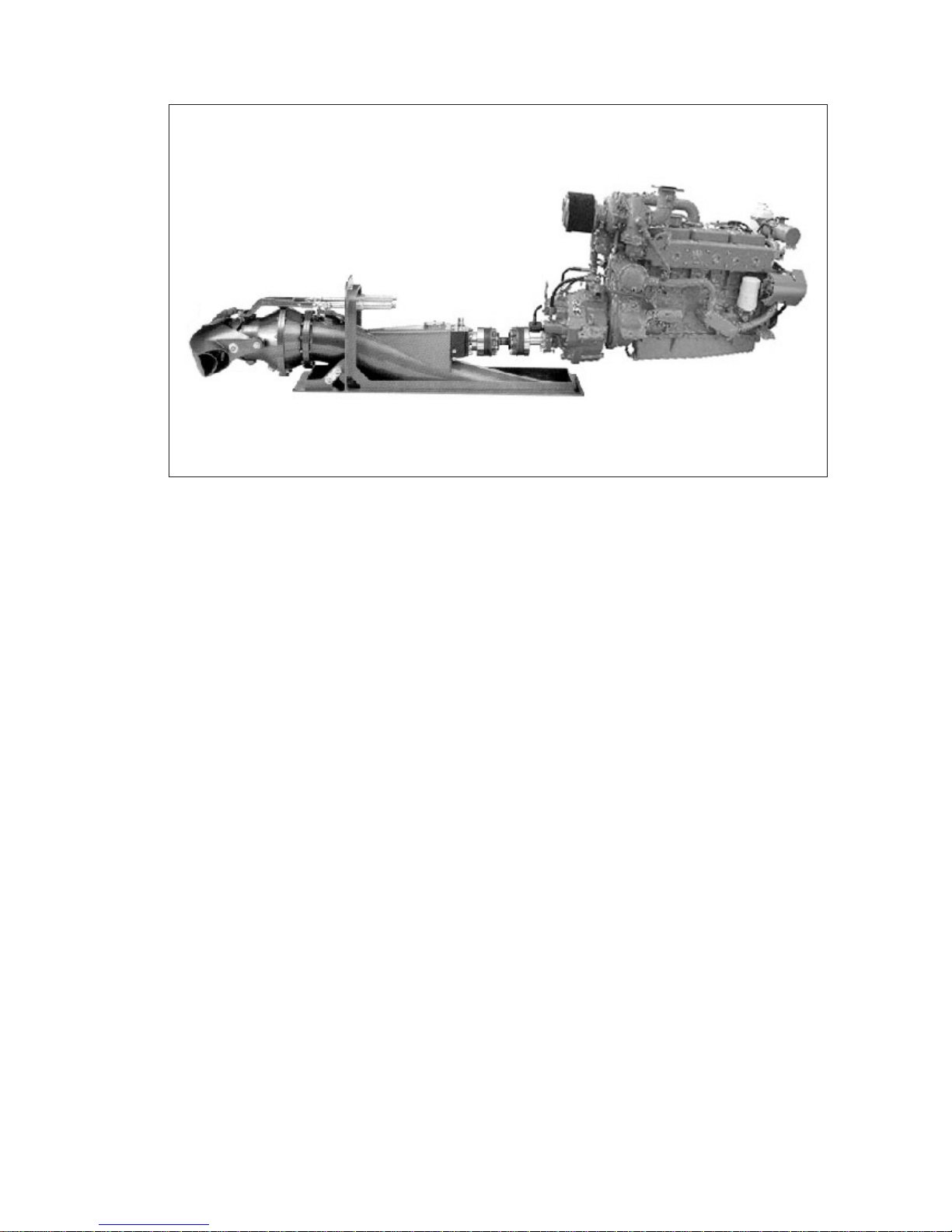

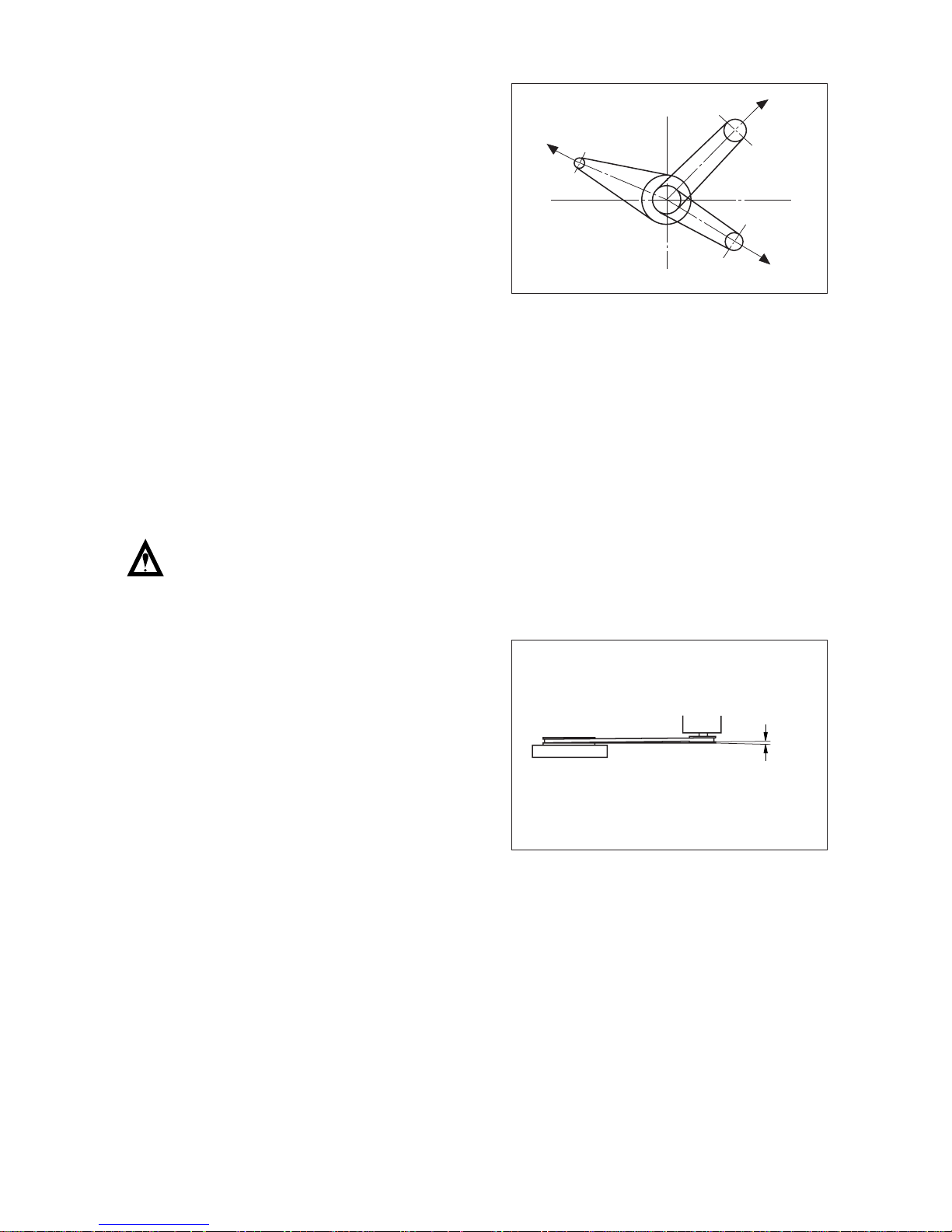

2.3.3. V - type drive

2.3.4. Jet type drive

More and more civilian and military boats, such as rescue boats, pilot boats, transport boats,

taxi boats, police boats and patrol boats, are using waterjets for propulsion. The waterjet

offers many benefits, which include giving the boat greater availability and maneuverability.

The waterjet also minimizes the draught of the boat and enables it to operate in shallow

water, as well as reducing the risk of personal injury during rescue and diving operations.

To obtain good economy from a waterjet installation, the jet unit and the engine should be

correctly matched to the full load service speed of the boat. The differences between a good

and a poor match are enormous with regard to fuel efficiency and overall performance of the

boat. A correctly sized and installed waterjet gives very small torque variations and creates

no engine overload, regardless of the boats loading conditions and speed. The jet is always

rotating in one direction, but the reversing of the boat is done by changing the jet stream

direction with a reverse deflector, which further reduces the load variations on the engine.

Waterjet has excellent characteristics when it comes to general maneuverability and comfort.

Superior control of the boat is achieved across the complete speed range, with small turning

radius and quick stops. The boat can rotate within its own length and with two jets the bot

can also move sideways. The lack of need of underwater rudder can make the vessel less

course stable, it is therefore important that the hull and the maneuvering control system is

correctly designed for the use of waterjets.

A waterjet installation has no underwater appendages which reduces the drag of the hull and

increases the overall efficiency in speeds above 20 - 30 knots depending on type of waterjets.

In comparison with conventional propeller system the inboard noise, vibration and the hydro-

acoustic noise is reduced as well.

Jet-type drives work according to the principle of jet propulsion. A jet of water is generated

whose thrust sets the vessel in motion.

- 10 -

EB0O2006

2

2

Engine and reduction gear is installed

separately and connected via an elastic

coupling and a universal joint. If universal

joints are to be used, it is important to

remember that it is necessary to have the

exact same angle at each joint under all

operating conditions in order for the

system to work properly.

The drive-line component manufacturer should always be consulted for more details on the

installation of their product.

2.3.5. The alignment of propeller

The alignment of the engine and marine transmission with the propeller shafting is essential

to minimize vibration, noise, power loss and stress in the driveline components.

While aligning the engine and gear, check both the propeller shaft flange bore and face. The

shaft and gear flanges should fit together without deflecting either the engine or the shaft

from its operating position. This will allow the propeller shaft flange and reduction gear output

flange to mate properly without over stressing the driveline components.

The shaft should then be rotated 180

˚

and checked again. The propeller shaft flange bore

and face alignment should not be done before the vessel is in the water and, on a solid

mounted engine, should be rechecked after the vessel has been in the water and loaded to

its normal operating condition.

Engine, gearbox and propeller shaft must be aligned in such a way that radial and angular

offset of all components remain within the pre-set tolerances.

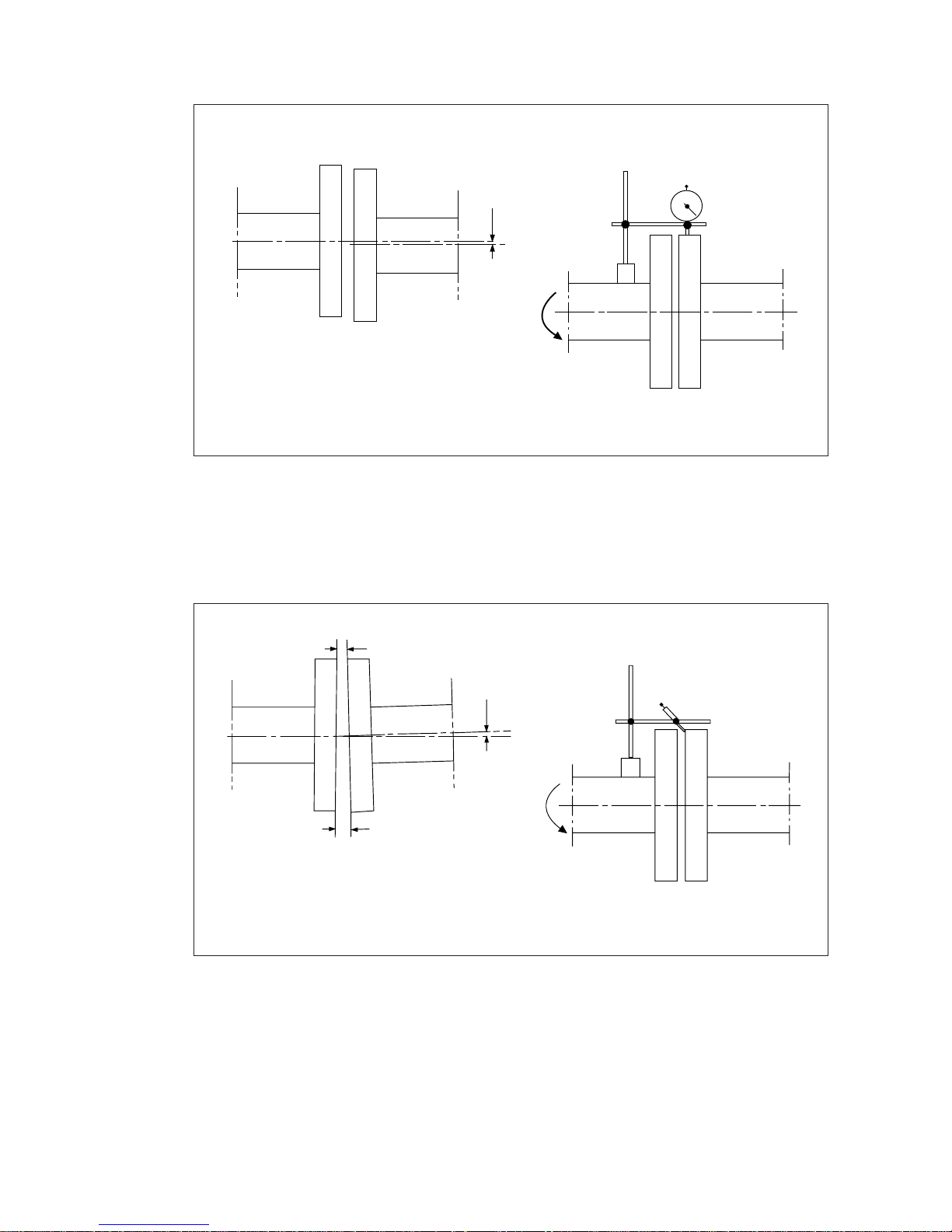

(1) Radial offset check

The feeler of the dial indicator runs on the peripheral surface of the fixed flange. The

shaft end with the dial indicator placed on it must be turned. The reading must not vary

by more than 2 x 0.5 mm = 1.0 mm.

- 11 -

EB0O2009

(2) Angular offset check

The feeler of the dial indicator runs on the front side of the fixed flange. The shaft end

with the dial indicator placed on it is to be turned.

The feeler must contact the mating surface. A 360

˚

turn is required for each check. The

max. Permissible angular offset must not be exceeded at any measuring point.

- 12 -

x

1

2

EB0O9009

1. Flange (e.g. gearbox output shaft)

2. Flange (e.g. propeller shaft)

1

2

X

3

X + max. 0.1mm

EB0O9010

1. Flange (e.g. gearbox output shaft)

2. Flange (e.g. propeller shaf)

Radial offset : x = max. 0.1 mm relative to a 200 mm flange diameter

or : x = max. 0.05 mm relative to a 100 mm flange diameter

CHAPTER 3 FRONT POWER-TAKE-OFF

3.1. Marine Installation Requirements

•

Belt-driven accessories must be mounted on the engine when a flexible mounting system is

used.

•

Brackets used to mount accessories must provide adequate strength to hold the static and

dynamic load of the accessory and avoid resonant vibration within the normal operating

range of the engine.

•

Variance in accessory loads must be considered when selecting accessory drive location

and capacity. Design service factors given in the installation recommendations should be

used when determining accessory loads.

•

Belt-driven equipment must be held in alignment to a tolerance of 1 mm in 200 mm (1/16

inch in 12 inches).

•

The total power taken off at the front of the crankshaft cannot exceed the maximum capacity

of the FPTO clutch and the total power absorbed from the engine may not exceed the

specified value of each model.

•

All exposed rotating components must have a protective guard.

3.2. Front Power Take-off Clutches

More power may be taken from a direct drive at the front of the crankshaft than any other

accessory drive location. Many DOOSAN marine engines can be fitted with FPTO clutch for

driving accessories such as a winch, fire pump, hydraulic pumps or generator.

All direct driven equipment will have some effect on torsional vibration. Excessive torsional

vibration in a system can result in excessive noise, gear failure, main bearing wear or, in the

most severe cases, crankshaft failures.

The total power taken off at the front of the crankshaft cannot exceed the capacity of the

FPTO clutch and the total required power from the engine may not exceed the values in the

list below.

This is the maximum amount of power that can be transmitted through the particular clutch.

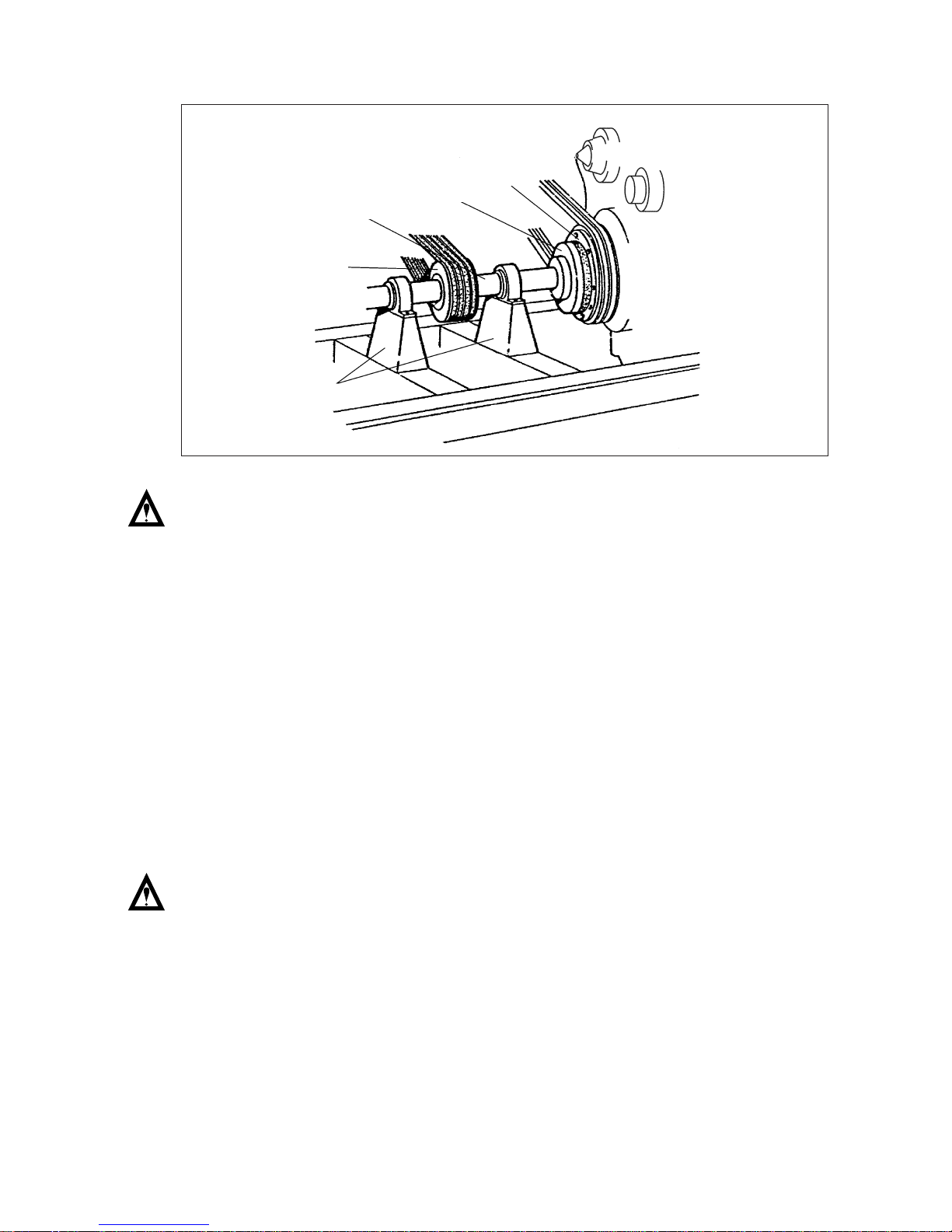

3.2.1. For maximum FPTO power

- 13 -

Engine

Crank pulley

Pillow blocks

Fiexible coupling

Driveshaft

V-pulley

EA4O7001

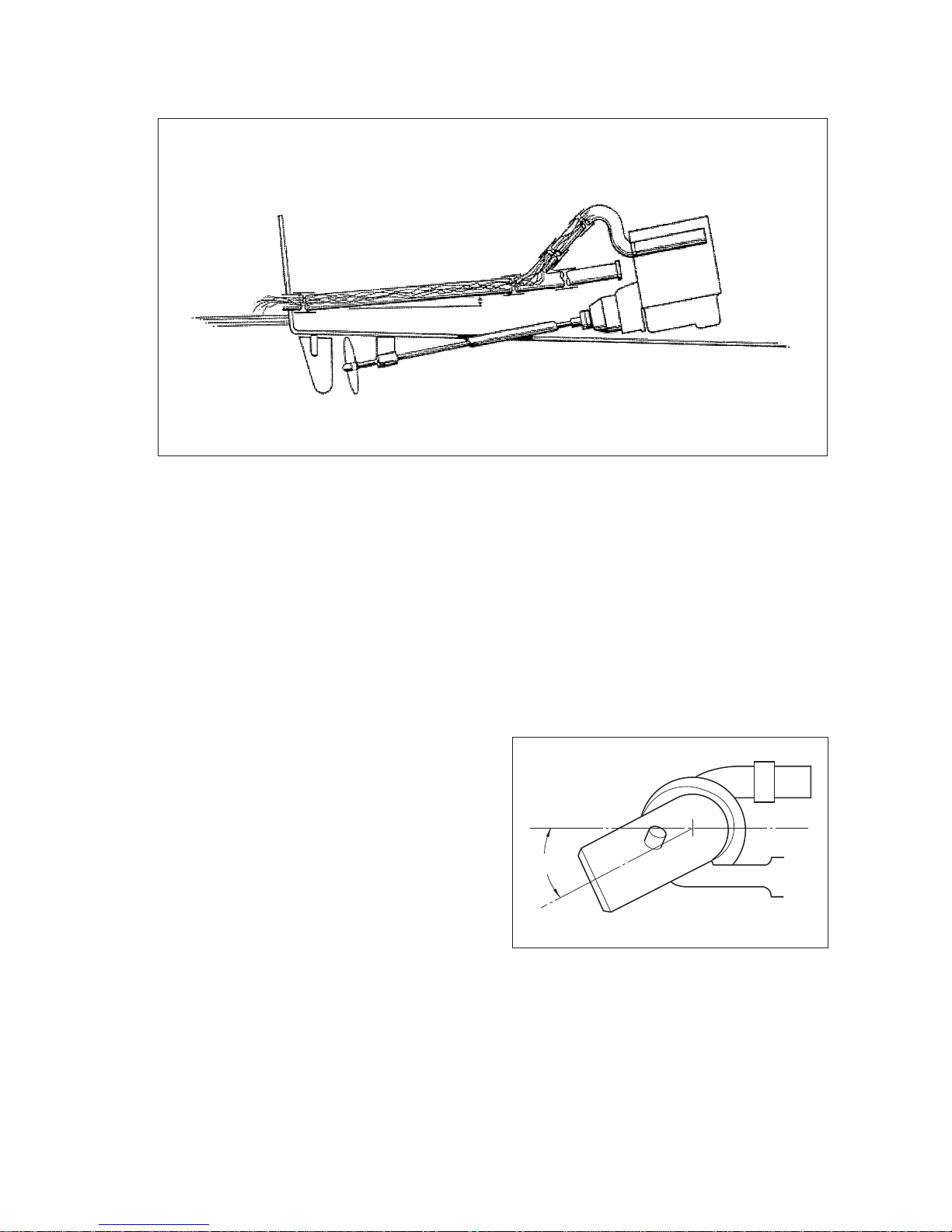

For front power take-off in engine, install a

flexible coupling to the engine front crank

shaft pulley and connect drive shaft and V-

pulley by supporting them with two pillow

blocks as shown in Fig. It is a standard

procedure to support driveshaft and V-

pulley with two pillow blocks by using

flexible coupling for connection to engine.

DOOSAN recommends you this type to

use front power take-off. (FPTO).

When the front PTO is installed, be sure to take deflection reading. Radial run-out should be

no more than 0.02 mm.

Be sure to limit the front PTO output within the maximum allowable horsepower as specified

for each model in figure below.

(Load represents when there is no propeller load)

Note : Upper listed loads represent allowable maximum torque.

3.2.2. For small cross drive power

- 14 -

Model Load(kW) rpm

L034 15 2,200

L034TI 31 2,600

L066TI 65 1,500

L136 60 1,800

L136T 72 1,400

L136TI 88 1,200

L086TI 120 1,600

Model Load(kW) rpm

MD196T 115 1,600

MD196TI 122 1,400

L126TI 132 1,600

V158TI 176 1,400

V180TI 220 1,600

V222TI 265 1,600

Engine

Crank

pulley

V-pulley, PTO

L

MAX. 170mm

(6.7 in) dia.

EA4O7002

(No supporting bearing on front side of

PTO pulley)

DOOSAN does not recommend this type

arrangement, which is not standard

procedure. However, If the FPTO as in

figure have to apply the drive arrangement,

the distance between the coupling end

face of engine pulley and the centerline

through pulley groove is not greater than

60 mm. The distance is indicated as “L” in

the figure.

<Driven loads by V-belt>

(L = Max. 60mm)

(Load represents when the propeller is running with engine)

Note : Upper listed loads represent allowable maximum torque.

3.3. Belt Drives

DOOSAN marine engines usually have belt drives for an alternator, sea water pump and at

least one or two free(grooves of) drive pulleys for other accessories. Many engines also have

crankshaft pulleys available for driving accessories. All of DOOSAN marine engine drives are

available with either A or B type V-belts that are designed to ISO 3046 standards.

If two power take-offs are at the same time, make sure that the resultant radial forces are as

small as possible.

The combination of companion flange and V-belt pulley can be used for such a multi power

take-off, as shown in below figure. It is advisable to shield V-belts and flanges properly, to

avoid accidents.

- 15 -

Model Load(kW) rpm

L034 12 2,200

L034TI 20 2,600

L066TI 38 1,800

L136 35 1,800

L136T 40 1,400

L136TI 50 1,200

L086TI 70 2,000

Model Load(kW) rpm

MD196T 68 1,600

MD196TI 74 1,400

L126TI 80 1,600

V158TI 95 1,400

V180TI 115 1,600

V222TI 125 1,600

Marine continuous rating

Engine speed (r.p.m)

Output (PS)

(g/PS

.

h)

500

170

160

150

400

300

200

100

1000 1500 2000 2500

1. Max. Power available

intermittant USE only

2. Propulsion curve

Fuel consumption

Max. FPTO

power

1

2

EB0O3001

Additionally, the total power(Load) required

by the propeller and FPTO cannot exceed

curve #1 on the power curve at any given

rpm. If the propeller is engaged, this

means that the max. power available at the

front is equal to the distance between

curves #1 and #2.

Note : New belts require a run-in period of 10 ~ 15 minutes under tension and should then

be retensioned. This allows for the initial stretch of the belt and will help prevent it

from jumping the pulley.

Brackets used to mount accessories must provide adequate strength to hold the

static and dynamic load of the accessory and avoid resonant vibration within the

normal operating range of the engine.

If a bracket has a natural frequency within the operating range of the engine, operation at that

speed will result in resonant vibration and failure of the bracket. So DOOSAN has no control

over the design or material of the component, they are not responsible for any damage

resulting from the failure of a non-DOOSAN supplied part.

When accessories are mounted on the engine, the mounting bracket should be attached to a

basic part of the engine such as the cylinder block or cylinder head whenever possible.

Accessories should not be mounted where they must be removed for normal engine

maintenance or where they are supported through a gasketed joint.

Note : Variance in accessory loads must be considered when selecting accessory drive

location and capacity. Design service factors given in the installation

recommendations should be used when determining accessory loads.

Since engine-driven accessories will have experience fluctuations in the load during normal

operation, the rated load of the accessories should be multiplied by a design service factor

when determining the load imposed on the engine by the accessory.

The direction as well as the load is important when considering belt driven accessories. The

load capacity of crankshaft pulleys and other drive locations will vary at different angles due to

the loading capability of the bearings.

- 16 -

Pillow blocks

V-pulley

Drive shaft

Crank pulley

Engine

EB0O3002

Flexible coupling

Note : Belt driven equipment must be

held in alignment to a tolerance of

1 mm in 200 mm (1/16 inch in 12

inches).

EB0O3003

A

B

C

EB0O3004

Crankshaft pulley

Accessory

1 mm in 200 mm

(1/16" in 12")

If two or more accessories are being

driven from a single multigroove pulley,

the accessories should be arranged to

have opposing belt pulls so that the

resulting force on the drive shaft is kept to

a minimum.

Additional pulley grooves or increasing

the belt size may exceed the safe loading

of the crankshaft or drive location.

Therefore the overloading should not be

allowed to prevent any malfunction.

Any device rigidly attached to the front of

the crank, other than an approved option,

must be analyzed for the effects on crank

bending, side-pull loading, mean and

vibratory torques, and the capability of

the crank bolted joint capacity.

Misalignment between the belt-driven

equipment and the engine will result in

bending forces on the shafts involved,

wearing of the belt, belt jumping and can

result in bearing or belt failure. This can

usually be checked with a straight edge.

- 17 -

CHAPTER 4 EXHAUST SYSTEM

The purpose of the exhaust system is to carry the exhaust gas from the engine to the

atmosphere with minimal flow restriction. Marine applications have two types of exhaust

systems, wet and dry.

4.1. Marine Installation Requirements

•

Thermal insulation or guards must be installed on dry exhaust systems.

•

Dry exhaust piping must not be installed near combustible material.

•

The exhaust system components must not impose excessive stresses on the exhaust

manifold or turbocharger due to weight, inertia, relative motion of the components or

dimensional change due to thermal growth.

•

The exhaust system must automatically prevent the entrance of water into the engine or

turbocharger whether it is from spray, rain, washing or any other source.

•

The exhaust gas must be dispersed so that it does not detrimentally affect the air cleaner

function, the engine ambient environment or the crew or passengers.

4.2. Dry Exhaust Systems (without sea water injection)

Depending on the temperature, the standard value for longitudinal expansion of steel pipes is

1 mm per meter and 100

˚

C.

It is not permissible to channel exhaust gases of several engines into one system. Multi-

engine systems are required to have a separate exhaust system for each and every engine to

prevent exhaust gases from penetrating from one running engine into another one.

For V-type engines it is recommended that the exhaust gases of both cylinder rows be

combined via an Y-pipe type.

Owing to high exhaust temperatures of several hundred degrees Celsius, exhaust pipes heat

up. For reasons of safety the pipes must be fitted with suitable anti-heat protection.

In order to prevent the engine room from heating up too much, a fireproof fuel and lubricating-

oil-repellent insulation is recommended.

To minimize exhaust gas back pressure, avoid sharp turns and manifolds.

- 18 -

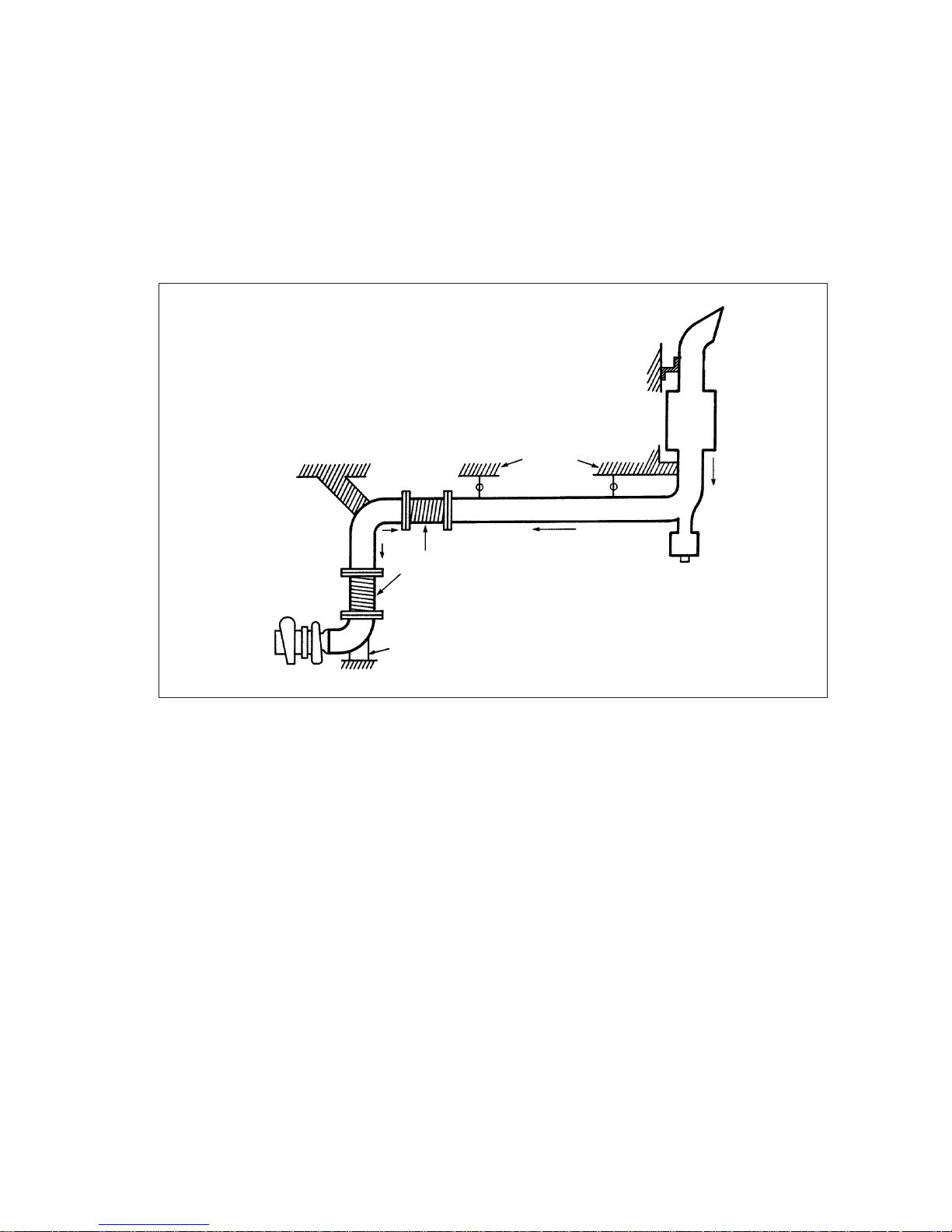

R

d

EHO1202I

Design pipe bends with large radius only

(R/d

≥

1.5). If silencers are installed, ensure

that the max. permissible exhaust gas back

pressure is not exceeded.

Any bends in the exhaust system should be

made as smooth as possible. Sharp bends

can drastically increase the exhaust back

pressure.

Dry exhaust systems use steel or iron pipe for the exhaust piping, stainless steel flexible

sections, and steel for the mufflers. Due to the high exhaust temperatures and the thermal

conductivity of the metal components they can be very dangerous unless certain precautions

are taken.

One more flexible exhaust connection must under initial tension be installed between the

engine and the exhaust system.

A flexible exhaust connection must be installed in the exhaust piping within 1.2 m (4 feet) of

the engine exhaust outlet.

If the exhaust system has both long vertical and horizontal sections, separate flexible exhaust

sections must be used to absorb the thermal growth in each direction. The horizontal flexible

sections should be installed as far away from the vertical piping as possible to avoid collecting

soot and condensation in the bellows.

If water enters the turbocharger or engine it will damage the turbocharger and, if it enters the

exhaust manifold, may cause a hydraulic lock and engine failure upon start-up.

Condensation water collects in the exhaust system and under any circumstances water (rain,

spray) must not penetrate into the exhaust system of the engine.

- 19 -

EB0O4001

Flexible

support

Flexible

support

Muffler

Solid

support

Flexible

connection

Arrow show the directions of thermal expansion.

Solid support

to engine

The actual exhaust piping size may vary depending upon the complexity of the routing and the

silencer used in the system.

The below table is showed the MINIMUM dry exhaust outlet pipe diameters for various engine

models and ratings when total exhaust piping length is below 5m. Add the diameter additional

5mm every 5m increasing. The actual exhaust piping size may vary depending upon the

complexity of the routing and the silencer used in the system.

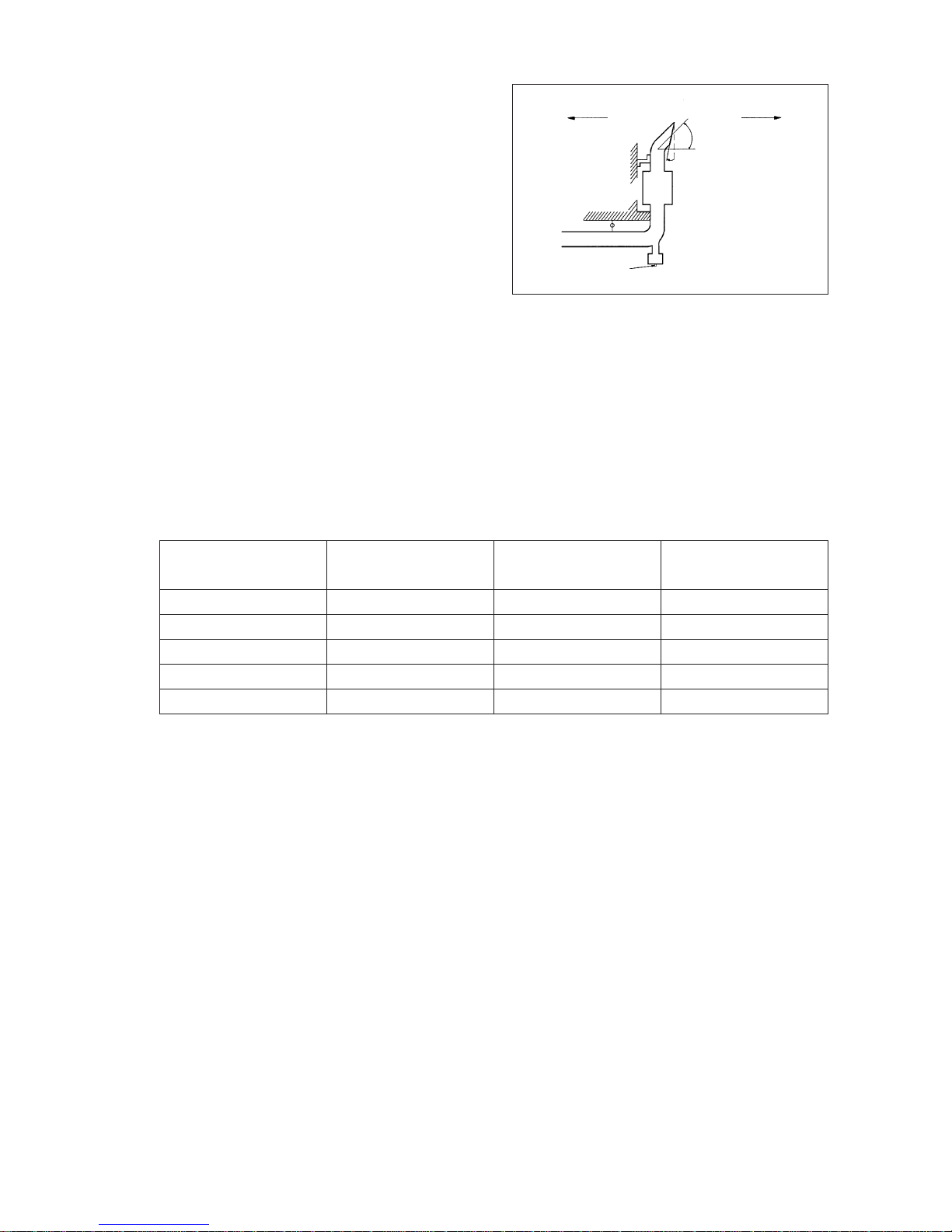

4.3. Wet Exhaust System (with sea water injection)

In a wet exhaust, sea water is sprayed into the exhaust pipe. Heat is transferred from the

exhaust gases to the sea water and the exhaust gas temperature drops low enough.

A pipe bend (swan neck) is required in the exhaust pipe system followed by a downward

sloping exhaust pipe to prevent water from penetrating into the engine. The pipe bend must be

mounted immediately downstream of the engine. Following picture shows an example of a

swan neck for sea water injection into the exhaust pipe.

The diameter of the exhaust pipe

behind the sea water inlet must be 25% larger than that of the pipe bend.

Any bends in

the exhaust system should be made as smooth as possible. Sharp bends can greatly increase

the back pressure and should be avoided.

- 20 -

EB0O4002

Bow

45

o

Stern

Drain

Condensation trap

For this reason the water collector with a

drainage device must be installed near the

engine if long exhaust pipes are laid at an

ascending angle.

This can usually be accomplished in a dry

exhaust system by using a 45 degrees or

greater bend at the top of the piping. The

pipe should also have a slight overhang to

make the entrance of water more difficult.

The exhaust outlet should face the stern of

the boat so that any water that comes over

the bow will not enter the exhaust system.

Engine model

Minimum dry exhaust

Engine model

Minimum dry exhaust

inner diameter(mm) inner diameter(mm)

L034 76 MD196T / TI 115

L034TI 76 L126TI 115

L066TI 76 V158TI 145

L136 / T / TI 76 V180TI 145

L086TI 115 V222TI 145

<Schematic diagram for sea water injection>

Wet exhaust system

(Engine should be mounted above water line)

1. The water cooling exhaust elbow : sea water cools elbow, then discharges through

peripheral slot at discharge end of elbow into exhaust pipe.

2. The rubber exhaust hose flexible connection : must be oil and heat resistant.

3. Backwater surge chamber : prevents sea water surging into engine exhaust when vessel at

rest with stern exposed to oncoming waves.

4. Exhaust pipe : should have slight downward gradient toward discharge end.

5. End cover plate : available for inspection and cleanup purposes

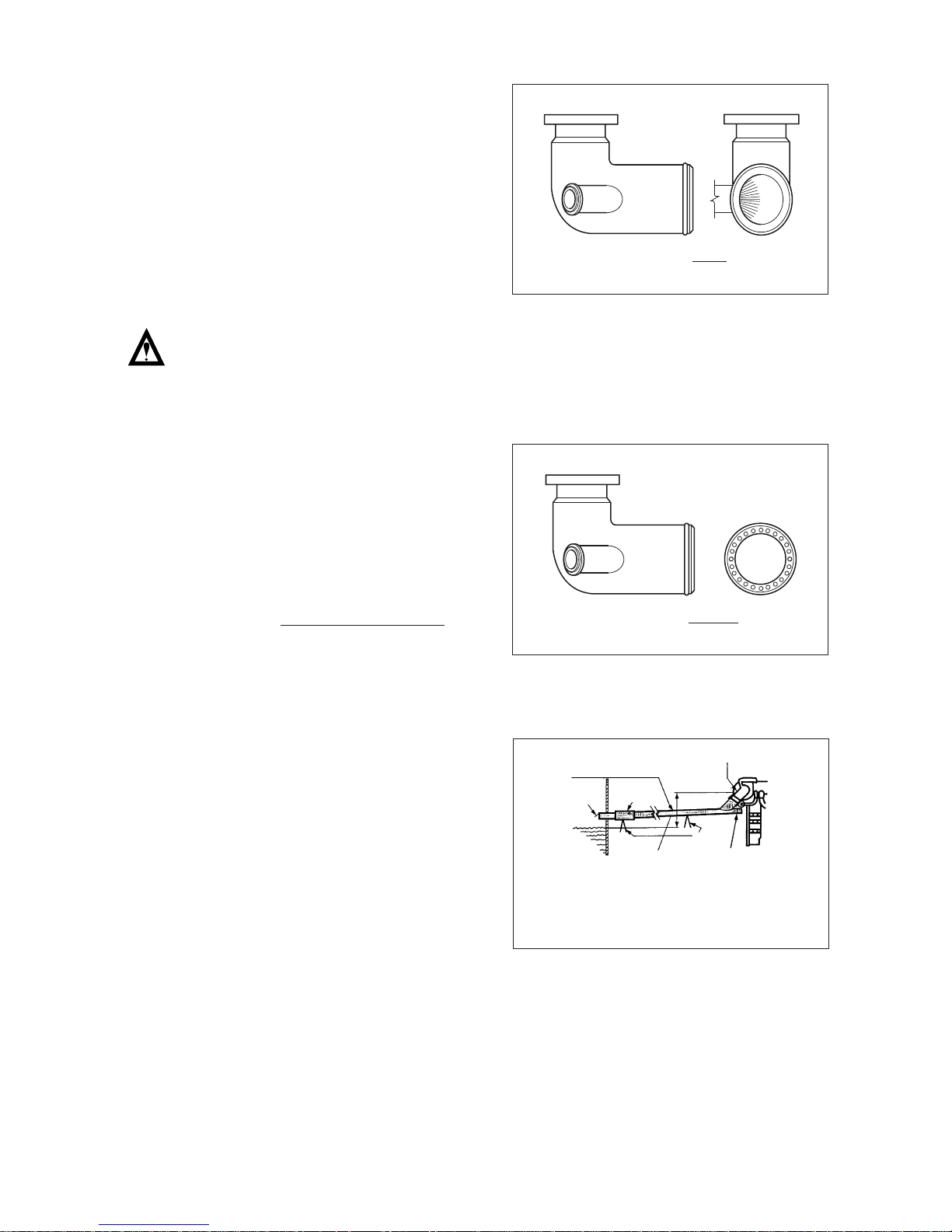

4.3.1. Design of water injection

In a wet exhaust system, sea water is

sprayed into the exhaust pipe at some

point downstream of the turbocharger.

If a water injection elbow is used, the

elbow should be directed downward at a

minimum of 15 degrees to prevent the

water being injected from getting back

into the turbocharger and should have a

pipe tap (1/8”) for exhaust restriction

measurements. Heat is transferred from

the exhaust gases to the sea water and

the exhaust gas temperature drops low

enough to allow the use of hard rubber

hose, fiberglass tube or other corrosion

resistant materials downstream of the

water injection.

- 21 -

EB0O4003

1

2

2

2

2

2

3

4

5

Slope(2 )

o

Exhaust discharge piping must have

adequate slope to avoid water entering

engine.

15O MIN

EB0O4006

Note : The surface temperature of the

exhaust piping should not exceed

93

˚

C (200˚F) under any operating

conditions.

DOOSAN recommends using evenly

distributed holes with an 8 mm (0.31 in)

diameter with the number of holes being

dependent upon the sea water flow. The

following equation can be used to

determine the number of holes:

No. of holes =

Lit./min(sea water flow)

10

4.3.2. Location of water injection

- 22 -

EB0O4004

BAD

Wherever water is injected in the exhaust

system, it is important that an even spray

pattern is achieved. If the spray pattern is

uneven, parts of the exhaust piping may

not be sufficiently cooled. This can result in

failure of the exhaust piping system due to

overheating and a possible safety hazard

from high surface temperatures.

EB0O4005

GOOD

If the engine is installed at a deep position

and the exhaust gas outlet at the system is

located just above or even below the water

line, a pipe bend (swan neck) must be

integrated into the pipe. This prevents

water from flowing into the engine when

the ship reverses or the water is rough.

Therefore, all exhaust outlets should be

located above the loaded water line.

A flapper valve may also be installed at the

exhaust outlet to help prevent water from

entering the exhaust system while the boat

is at rest.

EB0O4007

Supports

1. Water jacket exhaust elbow

2. Surge pipe

3. Exhaust piping

4. Water muffler

5. Flapper valve

6. Supporters

Waterline

12"(300mm)Minimum

1

2

3

4

5

6

2 Downward slope

o

Loading...

Loading...