Doosan Ingersoll Rand P425 WIP, Ingersoll Rand HP375 WIR, Ingersoll Rand XP375 WIR Operation & Maintenance Manual

Revised (09-12)

Doosan purchased Bobcat Company from Ingersoll-Rand Company in

2007. Any reference to Ingersoll-Rand Company or use of trademarks,

service marks, logos, or other proprietary identifying marks belonging

to Ingersoll-Rand Company in this manual is his torical or nominative

in nature, and is not meant to suggest a current affiliation between

Ingersoll-Rand C

ompany and Doosan

Company or the products of

e

ith

er.

OPERATION & MAINTENANCE MANUAL

COMPRESSOR MODELS

P425 WIR

XP375 WIR

HP375 WIR

Code: C

This manual contains important safety information.

Do not destroy this manual.

This manual must be available to the personnel who operate and maintain this machine.

Doosan Infracore Portable Power

P.O. Box 868 - 501 Sanford Ave

Mocksville, N.C. 27028

www.doosanportablepower.com

Book: 23209307 (01/08) Rev C

2

TABLE OF CONTENTS

Operating & Maintenance Manual

TITLE PAGE

FOREWORD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Foreword. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

NOISE EMISSION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

NOISE EMISSION CONTROL MAINTENANCE LOG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Noise Emission Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

A. Compressed Air Leaks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

B. Safety and Control Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

C. Acoustic Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

D. Fasteners. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

E. Enclosure Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

F. Air Intake and Engine Exhaust. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

G. Cooling Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

H. Isolation Mounts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

I. Engine Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

J. Fuels and Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Compressed Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Radiator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Safety Chains/Connections and Their Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

GENERAL ARRANGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

General Arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Compressor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Lubricating Oil Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3

TABLE OF CONTENTS

Operating & Maintenance Manual

TITLE PAGE

OPERATING INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Prior to Starting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Diagnostic/Auto Shutdown (Standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Starting the Machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Push After Warm Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Dual Pressure when Fitted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Stopping the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Emergency Stopping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Re-Starting After an Emergency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Monitoring During Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Decommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Engine Serial Number Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Fuels, Lubricants and Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Diesel Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Required Fuel Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Sulfur Content: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Bio-Diesel Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Handling and Storing Bio-Diesel Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Diesel Fuel Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Minimizing the Effect of Cold Weather on Diesel Engines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Diesel Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Diesel Engine Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Supplemental Coolant Additives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Coolant Drain Intervals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Operating in Warm Temperature Climates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Lubrication and Maintenance Service Interval Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Lubrication & Maintenance/Daily. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Daily Pre-starting Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Changing Engine Oil and Replacing Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

To change engine oil and oil filter: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Cleaning Crankcase Vent Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Replacing Fuel Filter Elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Checking Belt Tensioner Spring Tension and Belt Wear (Automatic Tensioner). . . . . . . . . . . . 66

Checking Belt Wear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Checking Tensioner Spring Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Checking Engine Electrical Ground Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Replenishing Supplemental Coolant Additives (SCAs) Between Coolant Changes . . . . . . . . . 67

Replacing Fan and Alternator Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Bleeding the Fuel System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

At Fuel Injection Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

At Fuel Injection Nozzles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Do Not Modify Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

General Troubleshooting Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4

TABLE OF CONTENTS

Operating & Maintenance Manual

TITLE PAGE

Precautions for Welding on Engines Equipped with Electronic Engine Control Unit (ECU). . . . 70

Displaying of Diagnostic Trouble Codes (DTCs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Intermittent Fault Diagnostics (With Electronic Controls). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Suggestions for diagnosing intermittent faults:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Possible causes of intermittent faults: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Engine Storage Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Preparing Engine for Long Term Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Removing Engine from Long Term Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Engine Crankcase Oil Fill Quantities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Lubrication and Maintenance Records. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Using Lubrication and Maintenance Records. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Emission System Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Emissions Control System Certification Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Productive Shutdown System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Scavenge Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Compressor Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Compressor Oil Separator Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Compressor Oil Cooler and Engine Radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Air Filter Elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Cooling Fan Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Fuel System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Fuel Filter Water Separator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Charge Air Cooler Pipework . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Electrical System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Pressure System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Tyres/Tyre/Tire Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Running Gear/Wheels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Engine Lubricating Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Engine Lubricating Oil Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Engine Oil Filter Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Compressor Lubricating Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Compressor Oil Filter Element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Running Gear Wheel Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Speed and Pressure Regulation Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

MACHINE SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Machine Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Wedge to Engine Interface - IR Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Harness System Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

J1939 CAN Communications Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

5

TABLE OF CONTENTS

Operating & Maintenance Manual

TITLE PAGE

SERVICE TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Service Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Electronic Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Service Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Electrical Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

FAULT FINDING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Fault Finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Options - Lubricator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Prior to Starting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Fault Finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

6

TABLE OF CONTENTS

Operating & Maintenance Manual

TITLE PAGE

7

8

Foreword

Book: 23209307 (1-7-08) Rev C 9

Operating & Maintenance Manual Foreword

Foreword

The contents of this manual are considered to be proprietary and confidential to Doosan

Infracore Portable Power (herein referred to as “Portable Power”), and should not be

reproduced without the prior written permission of Portable Power.

Nothing contained in this document is intended to extend any promise, warranty or

representation, expressed or implied, regarding the products described herein. Any such

warranties or other terms and conditions of sale of products shall be in accordance with the

standard terms and conditions of sale for such products, which are available upon request.

This manual contains instructions and technical data to cover all routine operation and

scheduled maintenance tasks by operation and maintenance staff. Major overhauls are

outside the scope of this manual and should be referred to authorized Portable Power Service

Department.

The design specification of this machine has been certified as complying with EC directives.

As a result:

a. Any machine modifications are strictly prohibited, and will invalidate EC

certification.

b. A unique specification for USA/Canada is adopted and tailored to the territory.

All components, accessories, pipes and connectors added to the compressed air system

should be:

• of good quality, procured from a reputable manufacturer and, wherever possible, be

of a type approved by Portable Power.

• clearly rated for a pressure at least equal to the machine maximum allowable working

pressure.

• compatible with the compressor lubricant/coolant.

• accompanied with instructions for safe installation, operation and maintenance.

Details of approved equipment are available from the Portable Power Service Departments.

The use of repair parts/lubricants/fluids other than those included within the Portable Power

approved parts list may create hazardous conditions over which Portable Power has no

control. Therefore Portable Power cannot be held responsible for equipment in which non–

approved repair parts are installed.

Portable Power reserves the right to make changes and improvements to products without

notice and without incurring any obligation to make such changes or add such improvements

to products sold previously.

The intended uses of this machine are outlined below and examples of unapproved usage are

also given, however Portable Power cannot anticipate every application or work situation that

may arise.

IF IN DOUBT CONSULT SUPERVISION.

10 Book: 23209307 (1-7-08) Rev C

Foreword Operating & Maintenance Manual

This machine has been designed and supplied for use only in the following specified

conditions and applications:

• Compression of normal ambient air containing no known or detectable additional

gases, vapors or particles.

• Operation within the ambient temperature range specified in the GENERAL

INFORMATION section of this manual.

UNITS MANUFACTURED IN NORTH AMERICA: Generation of electricity at 120V (1ph) at 60

Hertz.

UNITS MANUFACTURED IN EUROPE: Generation of electricity not applicable.

The use of the machine in any of the situation types listed in table 1:–

a) Is not approved by Portable Power,

b) May impair the safety of users and other persons, and

c) May prejudice any claims made against Portable Power.

TABLE 1

Use of the machine to produce compressed air for:

a) direct human consumption

b) indirect human consumption, without suitable filtration and purity checks.

Use of the machine outside the ambient temperature range specified in the GENERAL

INFORMATION SECTION of this manual.

This machine is not intended and must not be used in potentially explosive atmospheres,

including situations where flammable gases or vapors may be present.

Use of the machine fitted with non Portable Power approved components/lubricants/ fluids.

Use of the machine with safety or cont ro l components missing or disabled.

Use of the machine for storage or transportation of materials inside or on the enclosure

except when contained within the toolbox.

GENERATOR

Use of the generator to supply load(s) greater than those specified.

Use of unsafe or unserviceable electrical equipment connected to the generator.

Use of electrical equipment:

(a) Having incorrect voltage and/or frequency ratings.

(b) Containing computer equipment and/or similar electronics.

The company accepts no responsibility for errors in translation of this manual from the original

English version.

Book: 23209307 (1-7-08) Rev C 11

12 Book: 23209307 (1-7-08) Rev C

Decals

Book: 23209307 (1-7-08) Rev C 13

Operating & Maintenance Manual Decals

DECALS

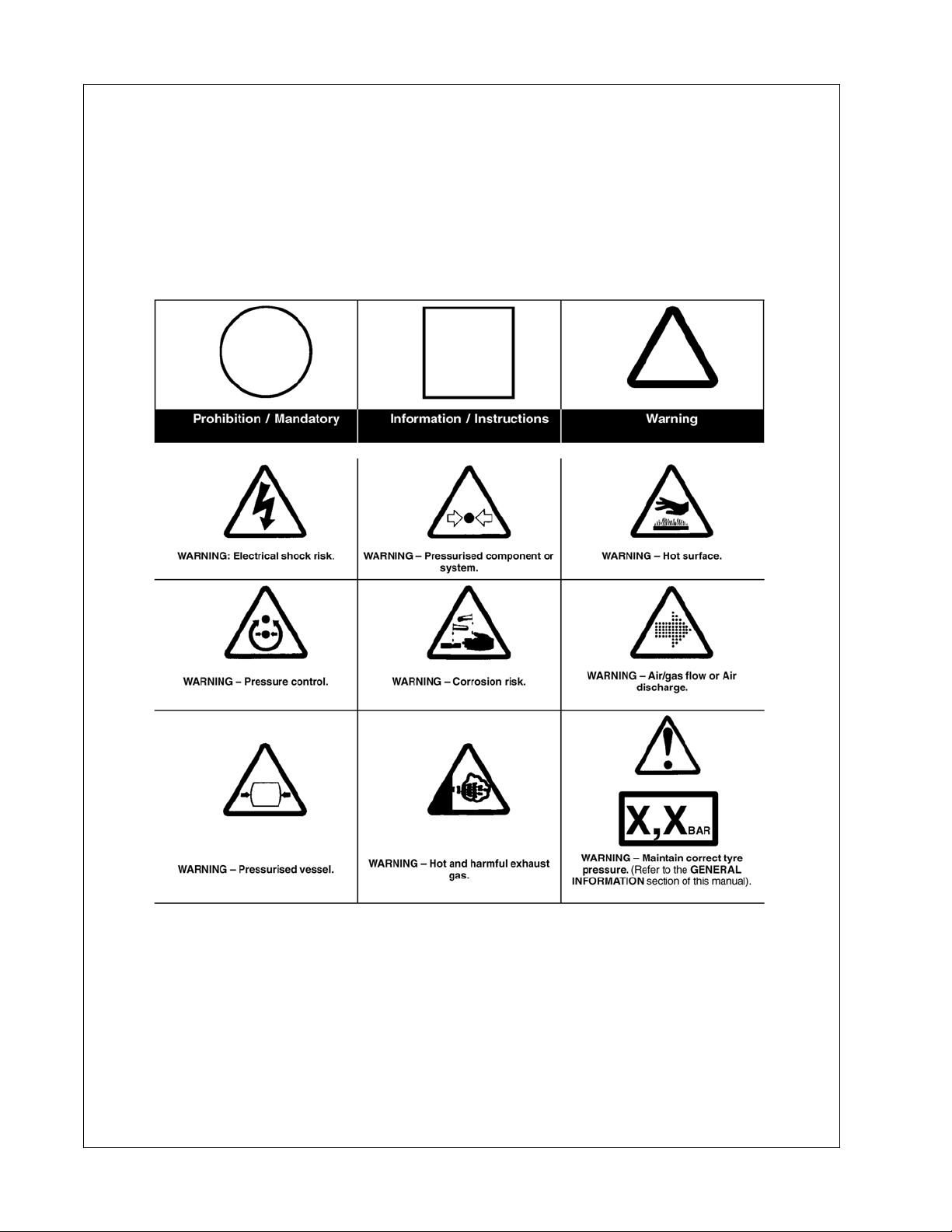

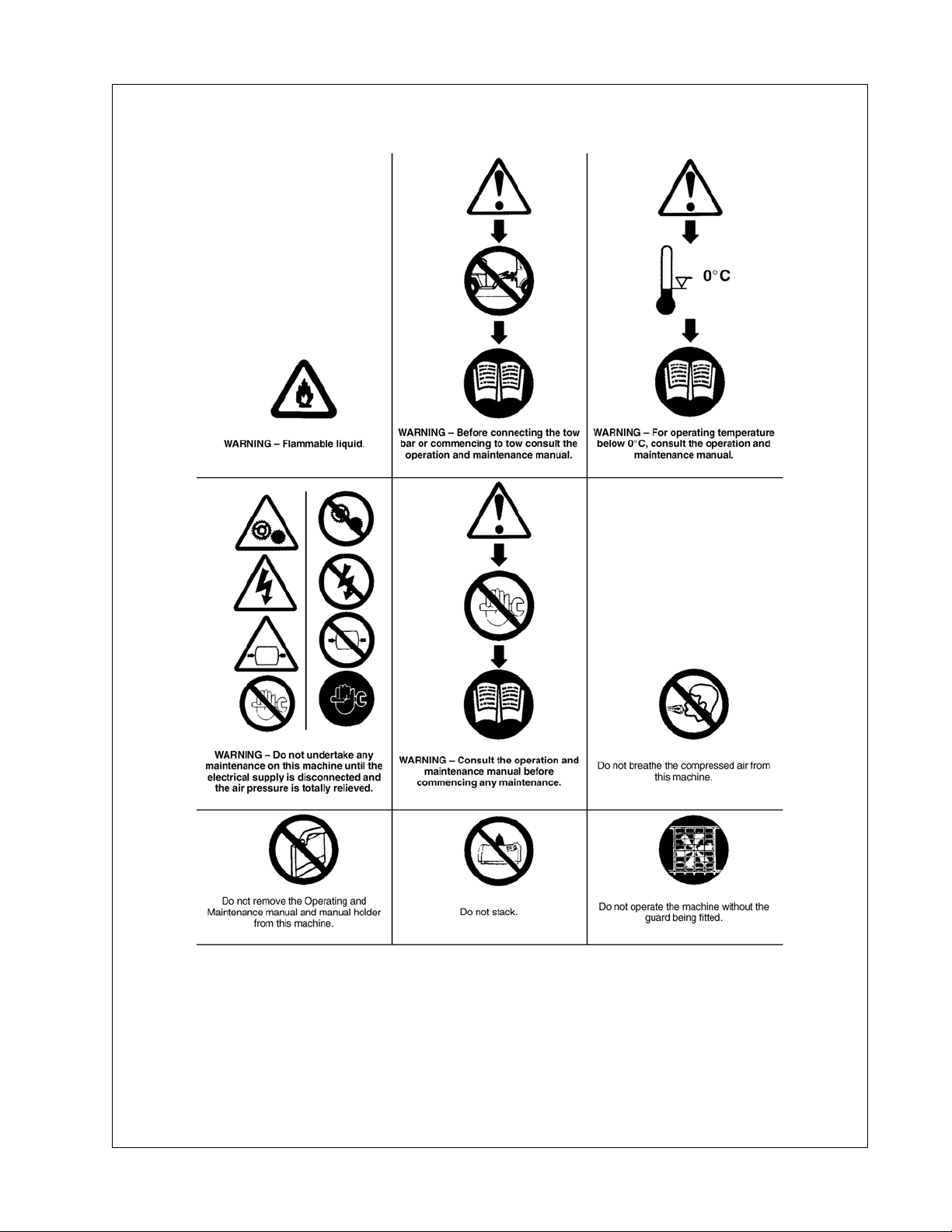

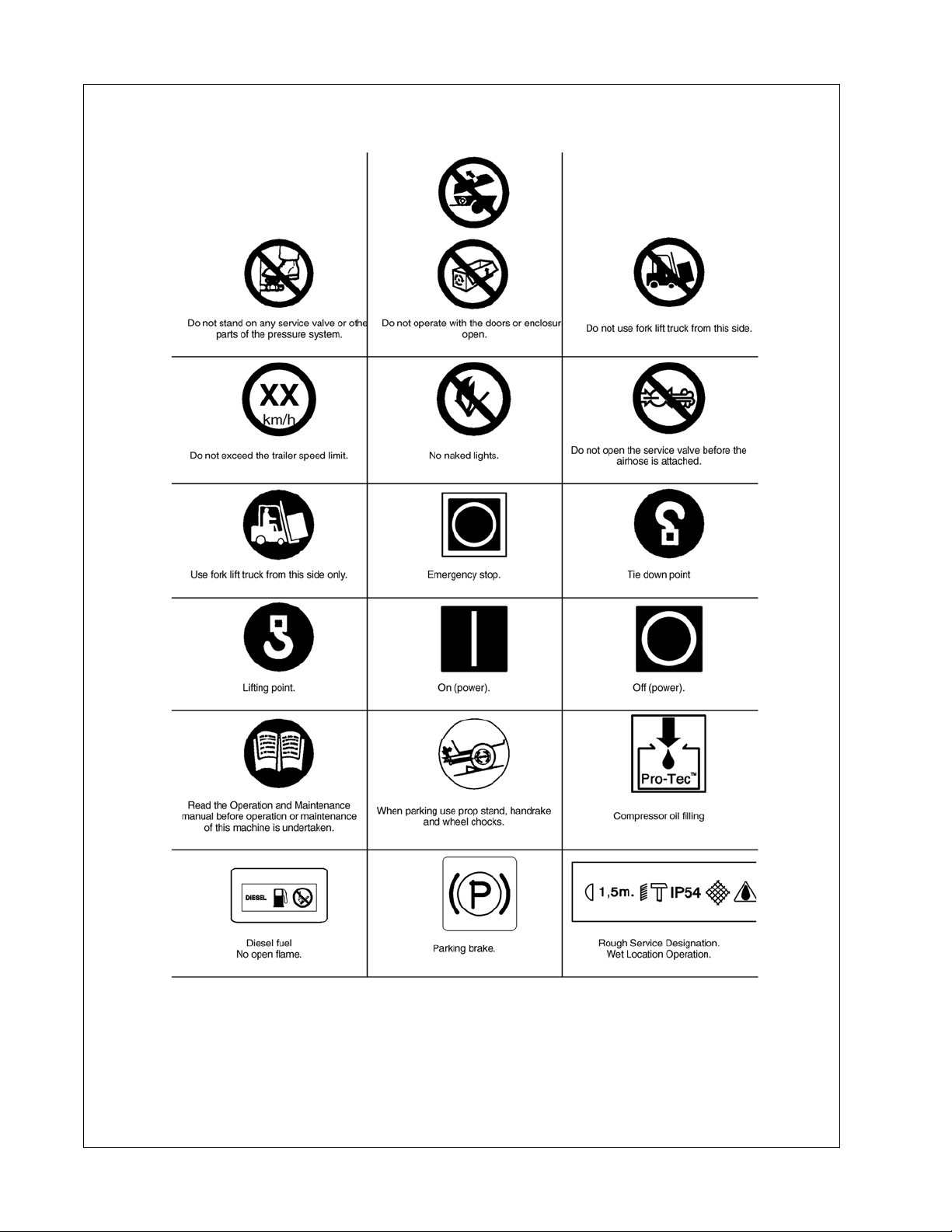

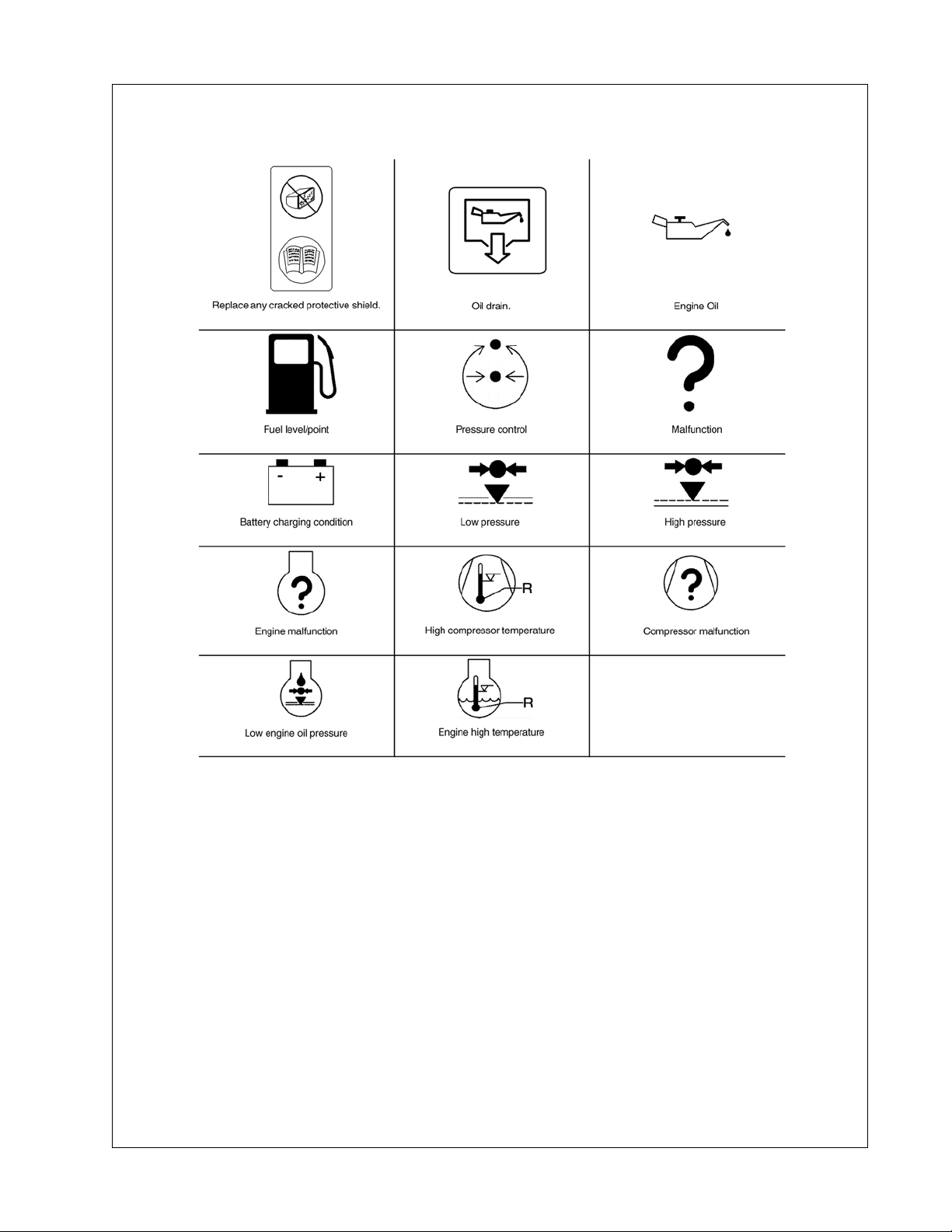

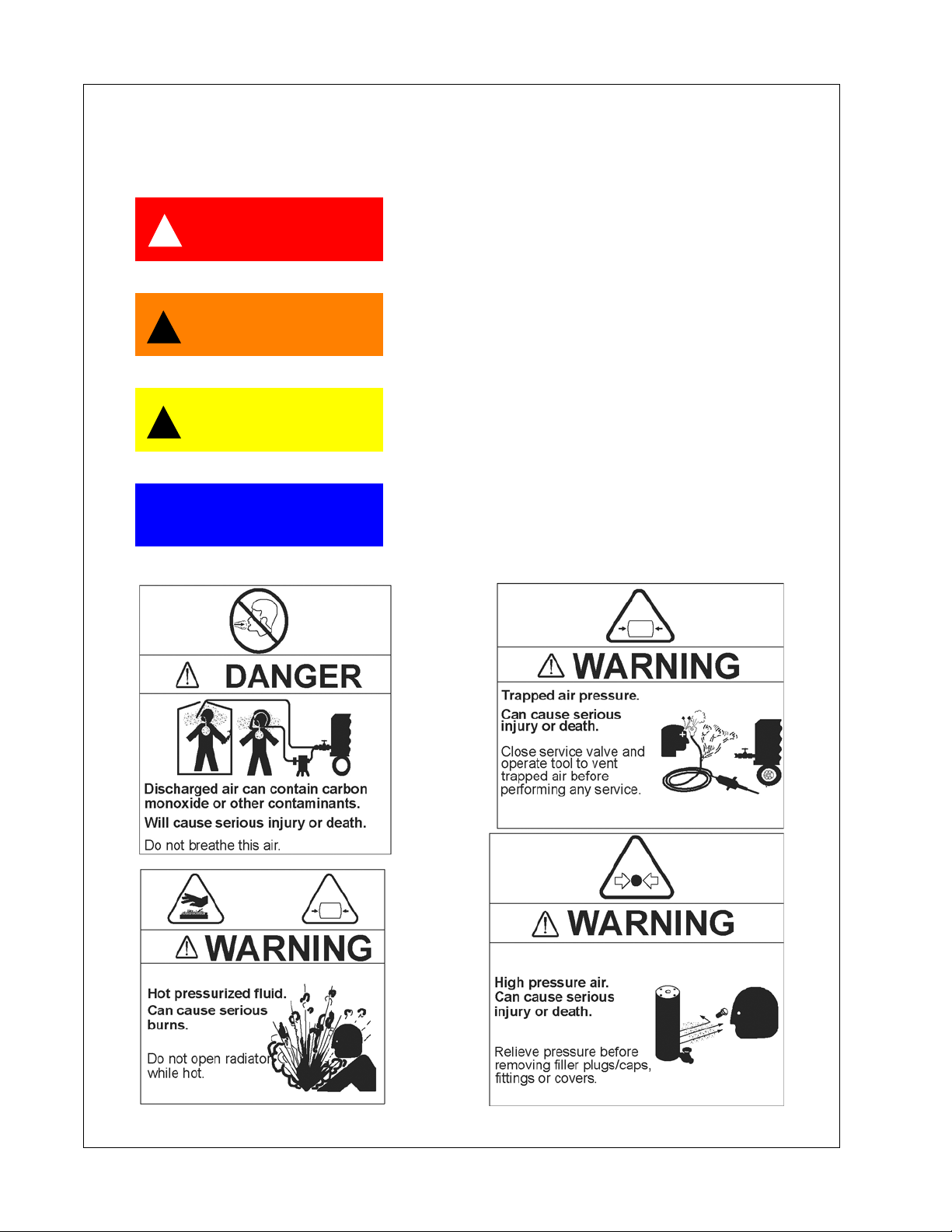

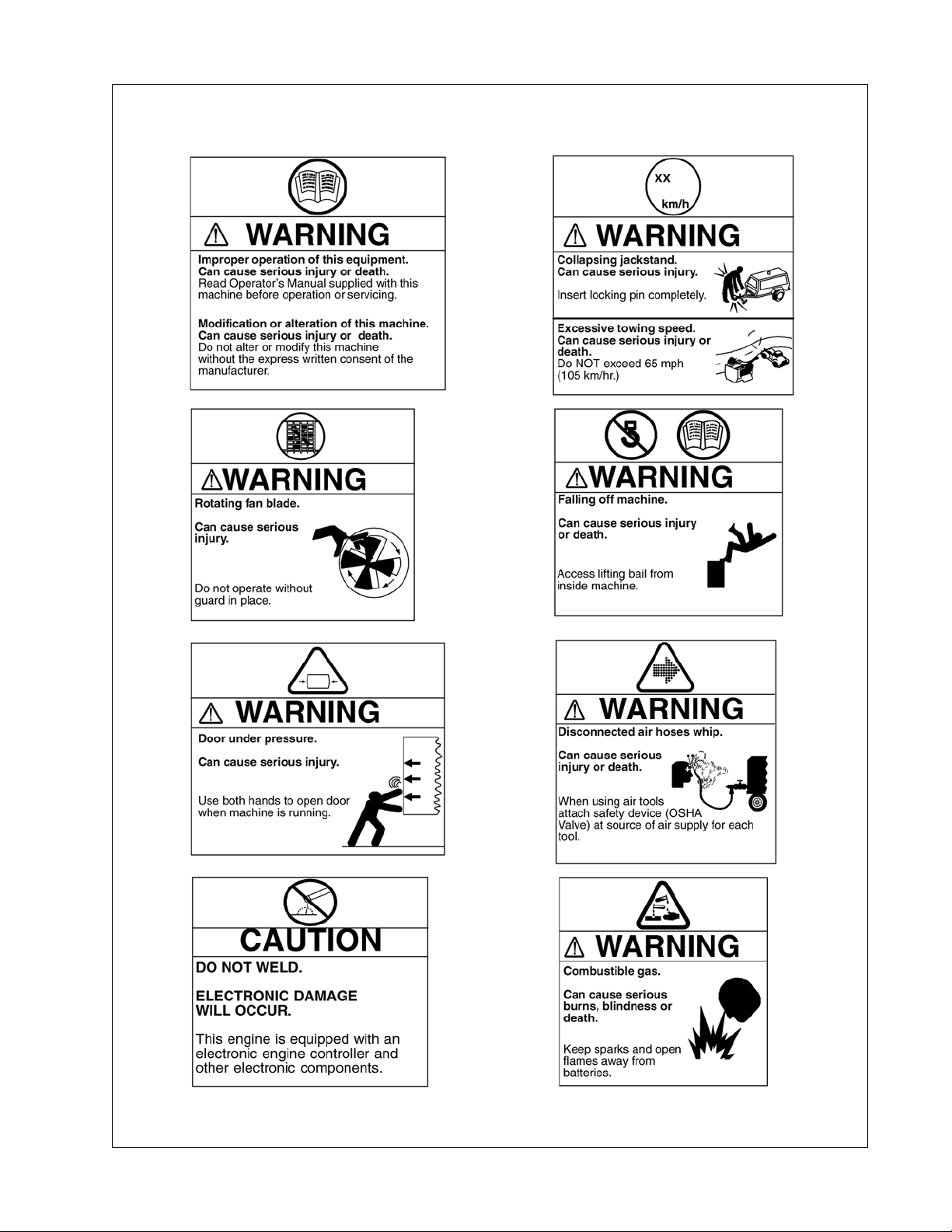

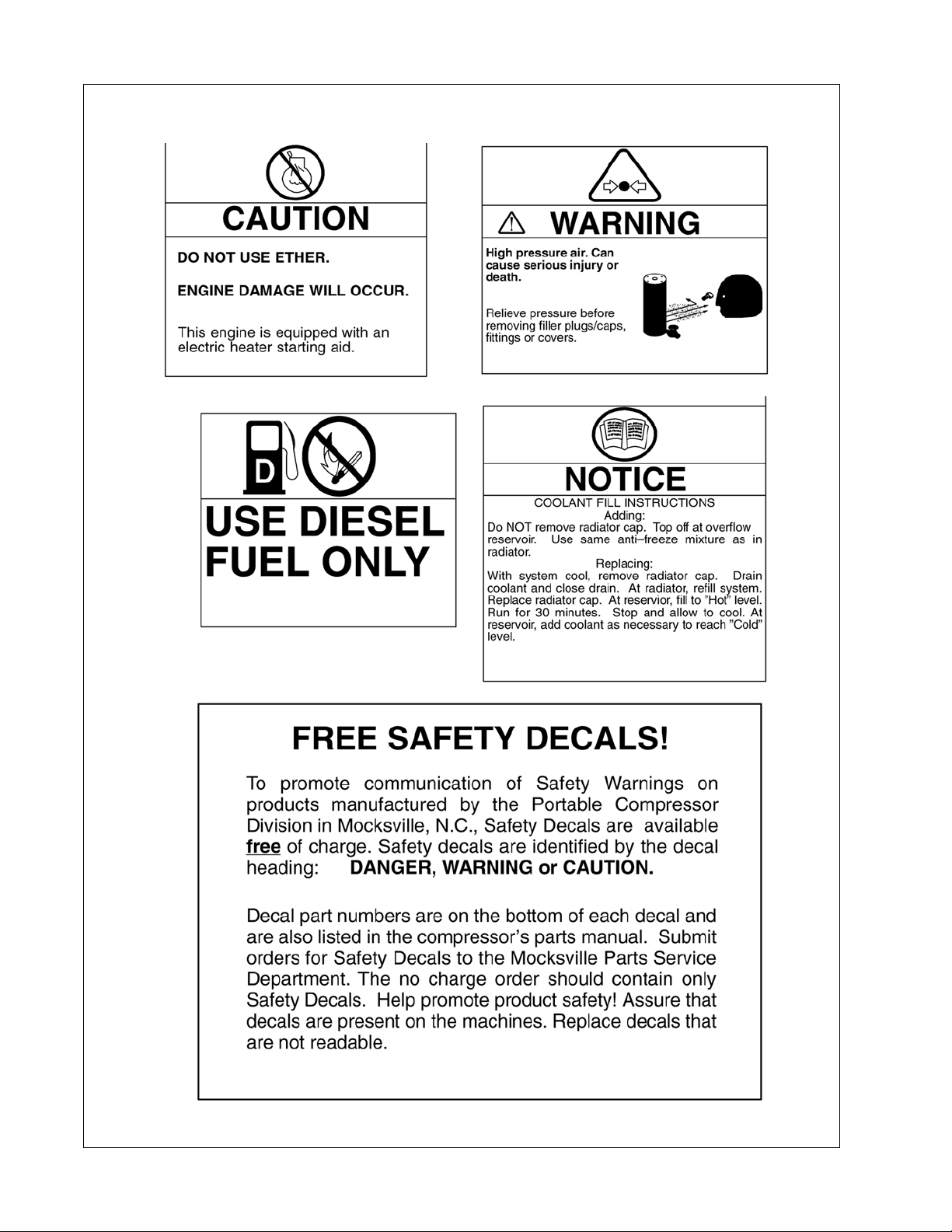

Look for these signs on machines manufactured in Europe, which point out potential

hazards to the safety of you and others. Read and understand thoroughly. Heed

warnings and follow instructions. If you do not understand, inform your supervisor.

GRAPHIC FORM AND MEANING OF ISO SYMBOLS

14 Book: 23209307 (1-7-08) Rev C

Decals Operating & Maintenance Manual

Book: 23209307 (1-7-08) Rev C 15

Operating & Maintenance Manual Decals

16 Book: 23209307 (1-7-08) Rev C

Decals Operating & Maintenance Manual

Book: 23209307 (1-7-08) Rev C 17

Operating & Maintenance Manual Decals

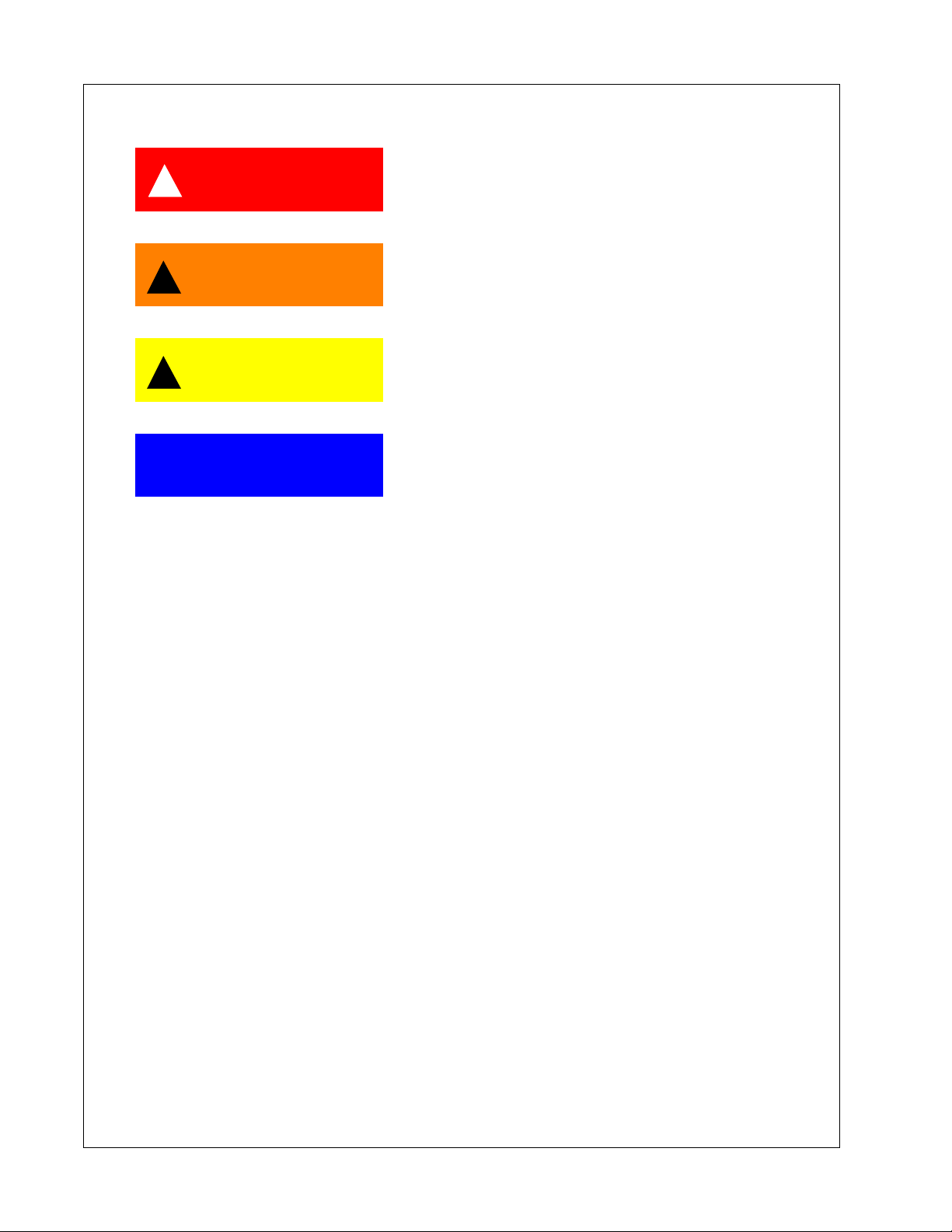

Look for these signs on machines manufactured in North America, which point out

potential hazards to the safety of you and others. Read and understand thoroughly.

Heed warnings and follow instructions. If you do not understand, inform your

supervisor

Indicates the presence of a hazard which WILL cause

!

DANGER

(Red Background)

!

WARNING

(Orange Background)

!

CAUTION

(Yellow Background)

NOTICE

serious injury, death or property damage, if ignored.

Indicates the presence of a hazard which CAN cause

serious injury, death or property damage, if ignored.

Indicates the presence of a hazard which WILL or can

cause injury or property damage, if ignored.

Indicates important set-up, operating or maintenance

information.

(Blue Background)

18 Book: 23209307 (1-7-08) Rev C

Decals Operating & Maintenance Manual

Book: 23209307 (1-7-08) Rev C 19

Operating & Maintenance Manual Decals

20 Book: 23209307 (1-7-08) Rev C

Decals Operating & Maintenance Manual

This section pertains only to machines distributed within the United States.

!

WARNING

TAMPERING WITH NOISE CONTROL SYSTEM PROHIBITED

Federal law prohibits the following acts or the causing thereof:

(1) The removal or rendering inoperative by any persons, other than for purposes of

maintenance, repair, or replacement, of any device or element of design incorpo rated into any

new compressor for the purpose of noise control prior to its sale or delivery to the ultimate

purchaser or while it is in use; or (2) the use of the compressor after such device or element

of design has been removed or rendered inoperative by any person.

Among those acts included in the prohibition against tampering are these:

1. Removal or rendering inoperative any of the following:

a. the engine exhaust system or parts thereof

b. the air intake system or parts thereof

c. enclosure or parts thereof

2. Removal of any of the following:

a. fan shroud

b. vibration mounts

c. sound absorption material

3. Operation of the compressor with any of the enclosure doors open.

Compressor Noise Emission Control Information

A. The removal or rendering inoperative, other than for the purpose of

maintenance, repair, or replacement of any noise control device or element of

design incorporated into this compressor in compliance with the noise control

act;

B. The use of this compressor after such device or element of design has been

removed or rendered inoperative.

NOTE: the above information applies only to units that are built in

compliance with the U.S. Environmental Protection Agency.

Portable Power reserves the right to make changes or add improvements without notice and

without incurring any obligation to make such changes or add such improvements to products

sold previously.

The Purchaser is urged to include the above provisions in any agreement for any resale of this

compressor.

Book: 23209307 (1-7-08) Rev C 21

Operating & Maintenance Manual Decals

22 Book: 23209307 (1-7-08) Rev C

Noise Emission

Book: 23209307 (1-7-08) Rev C 23

Operating & Maintenance Manual Noise Emission

NOISE EMISSION CONTROL MAINTENANCE LOG

COMPRESSOR MODEL_________________________

SERIAL NO. __________________________________

USER UNIT NO. _______________________________

UNIT IDENTIFICATION

ENGINE MAKE & MODEL:

SERIAL NO:_________________ __________________________________

PURCHASER OR OWNER:__________ __________________________________

ADDRESS: ____________________ DATE PURCHASED:_______________

The Noise Control Act of 1972 (86 Stat. 1234) prohibits tampering with the noise control

system of any compressor manufactured and sold under the above regulations, specifically

the following acts or the causing thereof:

(1) The removal or rendering inoperative by any persons, other than for purposes of

maintenance, repair, or replacement, of any device or element of design incorpo rated into any

new compressor for the purpose of noise control prior to its sale or delivery to the ultimate

purchaser or while it is in use; or (2) the use of the compressor after such device or element

of design has been removed or rendered inoperative by any person.

DEALER OR DISTRIBUTOR FROM

WHOM PURCHASED:

Noise Emission Warranty

The manufacturer warrants to the ultimate purchaser and each subsequent purchaser that this

air compressor was designed, built and equipped to conform at the time of sale to the first retail

purchaser, with all applicable U.S. EPA Noise Control Regulations.

This warranty is not limited to any particular part, component, or system of th e air compressor.

Defects in the design, assembly or in any part, component, or system of the compressor

which, at the time of sale to the first retail purchaser, caused noise emissions to exceed

Federal Standards are covered by this warranty for the life of the air compressor.

(40FR204.58-1).

24 Book: 23209307 (1-7-08) Rev C

Noise Emission Operating & Maintenance Manual

Introduction

The unit for which this Maintenance Log is provided conforms to U.S. E.P.A. Regulations for

Noise Emissions, applicable to Portable Air Compressors.

The purpose of this book is to provide (1) the Maintenance Performance Schedule below for

all required noise emission controls and (2) space so that the purchaser or owner can record

what maintenance was done, by whom, where and when. Detailed instructions on the

maintenance items below are given on following page.

Maintenance Schedule

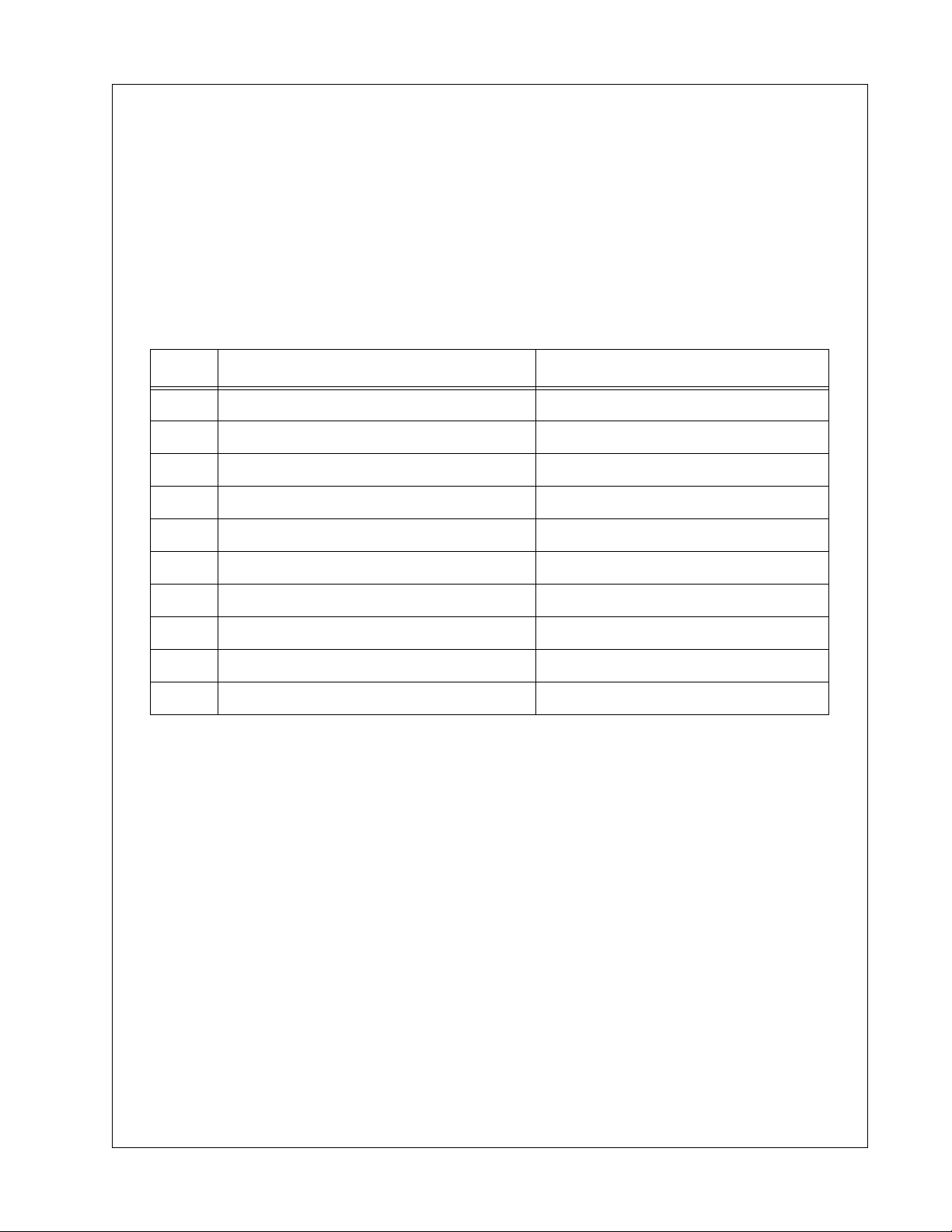

ITEM AREA PERIOD

A. COMPRESSED AIR LEAKS AS DETECTED

B. SAFETY AND CONTROL SYSTEMS AS DETECTED

C. ACOUSTIC MATERIALS DAILY

D. FASTENERS 100 HOURS

E. ENCLOSURE PANELS 100 HOURS

F. AIR INTAKE & ENGINE EXHAUST 100 HOURS

G. COOLING SYSTEMS 250 HOURS

H. ISOLATION MOUNTS 250 HOURS

I. ENGINE OPERATION SEE OPERATOR’S MANUAL

J. FUELS & LUBRICANTS SEE OPERATOR’S MANUAL

A. Compressed Air Leaks

Correct all compressed air leaks during the first shutdown period after discovery. If severe

enough to cause serious noise problems and efficiency loss, shut down immediately and

correct the leak(s).

B. Safety and Control Systems

Repair or replace all safety and control systems or circuits as malfunction occurs. No

compressor should be operated with either system bypassed, disabled, or nonfunctional.

C. Acoustic Materials

In daily inspections, observe these materials. Maintain all acoustic material as nearly as

possible in its original condition. Repair or replace all sections that have: 1) sustained damage,

2) have partially separated from panels to which they were attached, 3) are missing, or have

otherwise deteriorated due to severe operating or storage conditions.

Book: 23209307 (1-7-08) Rev C 25

Operating & Maintenance Manual Noise Emission

D. Fasteners

All fasteners such as hinges, nuts, bolts, clamps, screws, rivets, and latches should be

inspected for looseness after each 100 hours of operation. They should be retightened,

repaired, or if missing, replaced immediately to prevent subsequent damage and noise

emission increase.

E. Enclosure Panels

Enclosure panels should also be inspected at 100 hour operational intervals. All panels that

are warped, punctured, torn, or otherwise deformed, such that their noise containment

function is reduced, should be repaired or replaced before the next operation interval. Doors,

access panels, and hatch closures especially, should be checked and adjusted at this time to

insure continuous seating between gasket or acoustic material and the mating frame.

F. Air Intake and Engine Exhaust

Engine and compressor air intake and engine exhaust systems should be inspected after each

100 hours of operation for loose, damaged, or deteriorated components. Repairs or

replacements should be made before the next period of use.

G. Cooling Systems

All components of the cooling system for engine water and compressor oil shou ld be inspected

every 250 hours of use. Any discrepancies found should be corrected before placing the unit

back in operation. Unrestricted airflow over the radiator and oil cooler must be maintained at

all times during operation.

H. Isolation Mounts

Engine/airend isolation mounts should be inspected after each 250 hours of operation. Those

mounts with cracks or splits in the molded rubber, or with bent or broken b olts due to operation

or storage in severe environments, all should be replaced with equivalent parts.

I. Engine Operation

Inspect and maintain engine condition and operation as recommended in the manuals

supplied by the engine manufacturer.

J. Fuels and Lubricants

Use only the types and grades of fuels and lubricants recommended in the Portable Power

Engine Manufacturer’s Operator and Maintenance Manuals.

26 Book: 23209307 (1-7-08) Rev C

Noise Emission Operating & Maintenance Manual

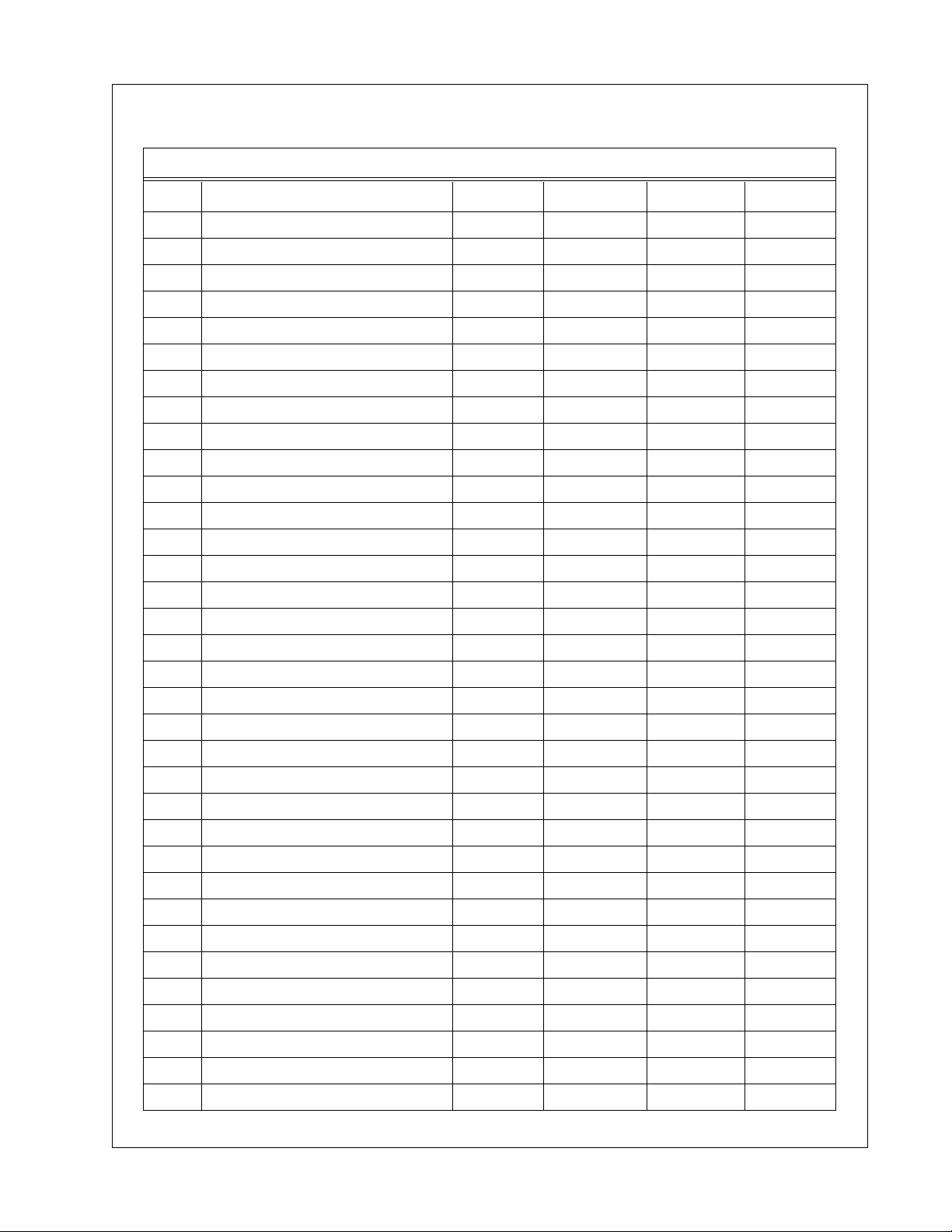

MAINTENANCE RECORD FOR NOISE EMISSION CONTROL AND EXTENDED WARRANTY

ITEM NO. DESCRIPTION OF WORK OR COMMENTS HOURMETER

READING

MAINT/ INSPECT

DATE

LOCATION CITY/

STATE

WORK DONE

BY (NAME)

Book: 23209307 (1-7-08) Rev C 27

28 Book: 23209307 (1-7-08) Rev C

Safety

Book: 23209307 (1-7-08) Rev C 29

Operating & Maintenance Manual Safety

Safety

Indicates the presence of a hazard which WILL cause

!

DANGER

(Red Background)

!

WARNING

(Orange Background)

!

CAUTION

(Yellow Background)

NOTICE

(Blue Background)

serious injury, death or property damage, if ignored.

Indicates the presence of a hazard which CAN cause

serious injury, death or property damage, if ignored.

Indicates the presence of a hazard which WILL or can

cause injury or property damage, if ignored.

Indicates important set-up, operating or maintenance

information.

General Information

Never operate unit without first observing all

safety warnings and carefully reading the

operation and maintenance manual shipped

from the factory with this machine.

Ensure that the operator reads and

understands the decals and consults the

manuals before maintenance or operation.

Ensure that the Operation and Maintenance

manual, and the manual holder, are not

removed permanently from the machine.

Ensure that maintenance personnel are

adequately trained, competent and have

read the maintenance manuals.

Make sure that all protective covers are in

place and that the canopy/doors are closed

during operation.

The specification of this machine is such that

the machine is not suitable for use in

flammable gas risk areas. If such an

application is required then all local

regulations, codes of practice and site rules

must be observed. To ensure that the

machine can operate in a safe and reliable

manner, additional equipment such as gas

detection, exhaust spark arrestors, and

intake (shut-off) valves may be required,

dependant on local regulations or the degree

of risk involved.

A weekly visual check must be made on all

fasteners/fixing screws securing mechanical

parts. In particular, safety-related parts such

as coupling hitch, drawbar components,

road-wheels, and lifting bail should be

checked for total security.

All components which are loose, damaged or

unserviceable, must be rectified without

delay.

Air discharged from this machine may

contain carbon monoxide or other

contaminants which will cause serious injury

or death. Do not breathe this air.

This machine produces loud noise with the

doors open or service valve vented.

Extended exposure to loud noise can cause

hearing loss. Always wear hearing protection

when doors are open or service valve is

vented.

Never inspect or service unit without first

30 Book: 23209307 (1-7-08) Rev C

Loading...

Loading...