Doosan Infracore P250WDO-T4F, Infracore HP210WDO-T4F Operation And Maintenance Manual

OPERATIONandMAINTENANCE

MANUAL

COMPRESSORSMODEL:

P250/HP210WDO-T4F(G91)

DoosanInfracorePortablePower

1293GlenwayDrive

Statesville,N.C.28625

DoosanPortablePower.com

P/N:46720670(2018)RevC

iii

TABLEOFCONTENTS

Operation&MaintenanceManual

TITLE

........................................................................................................................................................iii

PAGE

FOREWORD..........................................................................................................................9

Information.....................................................................................................................................10

DRAWBARINSTRUCTIONS...............................................................................................13

InstructionKitForDrawbar............................................................................................................14

SAFETY...............................................................................................................................17

SafetyPrecautions.........................................................................................................................18

CompressedAir..........................................................................................................................19

ExhaustSystem.........................................................................................................................20

Materials....................................................................................................................................20

Battery.......................................................................................................................................21

CoolantSystem..........................................................................................................................22

Transport...................................................................................................................................22

Decals.............................................................................................................................................23

NOISEEMISSION................................................................................................................27

NoiseEmission...............................................................................................................................28

CompressorNoiseEmissionControlInformation..........................................................................28

MaintenanceLog............................................................................................................................29

NoiseEmissionWarranty............................................................................................................29

Introduction................................................................................................................................30

MaintenanceSchedule................................................................................................................30

GENERALDAT A.................................................................................................................33

GeneralDataInformation................................................................................................................34

ExpendableServiceParts...........................................................................................................34

OPERATINGINSTRUCTIONS............................................................................................37

ControlPanel..................................................................................................................................38

Control/GaugePanel..................................................................................................................38

QuickViewScreens........................................................................................................................40

5

TABLEOFCONTENTS

Operation&MaintenanceManual

TITLE

FaultandAlert...........................................................................................................................41

ServiceIntervalSetup.................................................................................................................43

LanguagesandUnits..................................................................................................................45

DisplaySetup.............................................................................................................................46

DisplayCompressorandDisplaySoftwareInformation.................................................................46

DisplayCompressorandDisplaySoftwareInformation.................................................................47

BeforeTowing.................................................................................................................................48

Towing.......................................................................................................................................50

SettingUp..................................................................................................................................50

BeforeStarting...........................................................................................................................51

Starting......................................................................................................................................52

Shutdown...................................................................................................................................53

PressureRegulatorAdjustmentInstructions.................................................................................54

ENGINEOPERATION..........................................................................................................55

EngineOperationandMaintenance................................................................................................56

Safety........................................................................................................................................57

Instructions................................................................................................................................58

GeneralRepair...........................................................................................................................60

EnvironmentalPollution..............................................................................................................61

EngineManagement...................................................................................................................62

PreventionofPollution................................................................................................................63

PAGE

StartandShutdown........................................................................................................................64

Break-inPeriodofEngine............................................................................................................65

InspectionafterStartingtheEngine.............................................................................................67

OperationinWinter.....................................................................................................................68

RegularInspection.........................................................................................................................69

CheckingtheEngineOil..............................................................................................................70

ReplacementofEngineOil..........................................................................................................72

Coolant...........................................................................................................................................76

CheckingtheCoolant..................................................................................................................77

ReplenishmentofCoolant...........................................................................................................83

ReplacementofCoolant..............................................................................................................84

LUBRICATION.....................................................................................................................87

Lubrication.....................................................................................................................................88

CompressorOilChart.................................................................................................................89

MAINTENANCE...................................................................................................................91

GeneralInformation........................................................................................................................92

6

TABLEOFCONTENTS

Operation&MaintenanceManual

TITLE

CompressorOilFilters....................................................................................................................95

ReceiverSeparatorSystem.........................................................................................................96

ScavengeLine................................................................................................................................97

ExteriorFinishCare....................................................................................................................97

FieldReplacementofExteriorDecals..........................................................................................98

PreventiveMaintenanceSchedule.................................................................................................100

TROUBLESHOOTING.......................................................................................................103

Introduction...................................................................................................................................104

TroubleshootingChart................................................................................................................105

DiagnosticCodes......................................................................................................................1 10

CompressorDiagnosticCodes......................................................................................................111

APPENDIXA......................................................................................................................115

Warranty........................................................................................................................................116

................................................................................................................................................1 16

................................................................................................................................................1 16

................................................................................................................................................1 17

PAGE

RevisionHistory............................................................................................................................119

7

8

Foreword

9

Operation&MaintenanceManual

Information

TheContentsOfThisManualAreConsideredT oBeProprietaryAndCondentialToDoosan

InfracorePortablePower(HereinReferredT oAs“PortablePower”),AndShouldNotBe

ReproducedWithoutThePriorWrittenPermissionOfPortablePower.

NothingContainedInThisDocumentIsIntendedT oExtendAnyPromise,WarrantyOr

Representation,ExpressedOrImplied,RegardingThePortablePowerProductsDescribed

Herein.AnySuchWarrantiesOrOtherTermsAndConditionsOfSaleOfProductsShall

BeInAccordanceWithTheStandardT ermsAndConditionsOfSaleForSuchProducts,

WhichAreAvailableUponRequest.

ThisManualContainsInstructionsAndT echnicalDataT oCoverAllRoutineOperationAnd

ScheduledMaintenanceT asksByOperationAndMaintenanceStaff.MajorOverhaulsAre

OutsideTheScopeOfThisManualAndShouldBeReferredT oAnAuthorizedPortable

PowerServiceDepartment.

AllComponents,Accessories,Pipes,AndConnectorsAddedT oTheCompressedAir

SystemShouldBe:

•OfGoodQuality,ProcuredFromAReputableManufacturerAnd,Wherever

Possible,BeOfATypeApprovedByPortablePower.

Foreword

•ClearlyRatedForAPressureAtLeastEqualT oTheCompressorSafetyV alve

Setting.

•CompatibleWithTheCompressorOil.

•AccompaniedWithInstructionsForSafeInstallation,Operation,AndMaintenance.

DetailsOfApprovedEquipmentAreAvailableFromThePortablePowerService

Departments.TheUseOfRepairPartsOtherThanThoseIncludedWithinTheApproved

PartsListMayCreateHazardousConditionsOverWhichPortablePowerHasNo

Control.Therefore,PortablePowerCannotBeHeldResponsibleForEquipmentInWhich

Non-ApprovedRepairPartsAreInstalled.

PortablePowerReservesTheRightT oMakeChangesAndImprovementsT oProducts

WithoutNoticeAndWithoutIncurringAnyObligationToMakeSuchChangesOrAddSuch

ImprovementsT oProductsSoldPreviously.

TheIntendedUsesOfThisCompressorAreOutlinedBelowAndExamplesOfUnapproved

UsageAreAlsoGiven.However,PortablePowerCannotAnticipateEveryApplicationOr

WorkSituationThatMayArise.IfInDoubt,ConsultSupervision.

ThisCompressorHasBeenDesignedAndSuppliedForAboveGroundOperationToBe

UsedForCompressionOfNormalAmbientAirContainingNoAdditionalGases,V apors,Or

ParticlesWithinTheAmbientTemperatureRangeSpeciedInTheGeneralDataSection

OfThisManual.

10

Foreword

ThisCompressorShouldNotBeUsed:

•ForDirectOrIndirectHumanConsumptionOfTheCompressedAir.

•OutsideTheAmbientT emperatureRangeSpeciedInTheGeneralDataSection

OfThisManual.

•WhenAnActualOrForeseeableRiskOfHazardousLevelsOfFlammableGases

OrVaporsExists.

•WithOtherThanPortablePowerApprovedComponents.

•WithGuards,Controls,OrSwitchesMissingOrDisabled.

•ForStorageOrTransportationOfMaterialsInsideOrOnTheEnclosure.

PortablePowerAcceptsNoResponsibilityForErrorsInTranslationOfThisManualFrom

TheOriginalEnglishVersion.

You,AsTheCustomer,AreExpectedT oProvideCertainServiceAndMaintenanceItems.

YourPortablePowerDealerWillProvideAllOtherMoreDetailedServiceAndMaintenance

ItemsOnASpecialPreventiveMaintenanceScheduleForEachCompressor.ItIsVery

ImportantThatTheMinimumServiceAndMaintenanceRequirementsExplainedInThis

ManualBePerformedAtTheRequiredIntervals.ExceedingTheseIntervalsMayReduce

TheReliabilityOfTheCompressor.

Operation&MaintenanceManual

ThePurposeOfThisManualIsT oTrainTheOperatorWithFunctions,Operation,AndBasic

ServiceAndMaintenanceRequirementsOfTheCompressor.DuringThePreparationOfThis

Manual,EveryEffortWasMadeT oEnsureTheAccuracyAndAdequacyOfTheContents.

YourPortablePowerDealerWillAssistWithSetupAndInitialStartupOfTheCompressor

AndWillAlsoProvideBriefOperatingAndServiceInstructions.BeforeStartingThe

Compressor,ThisManualAndInstructionsShouldBeCarefullyReadToObtainAThorough

KnowledgeOfTheDutiesT oBePerformed.PleaseT akePrideInTheCompressor,KeepIt

CleanAndInGoodMechanicalCondition.

ToEnableProperMaintenanceRecords,PortablePowerProvidesANoiseEmissionControl

MaintenanceLogInTheNoiseEmissionSectionOfThisManual.TheNoiseEmission

SectionContainsARecommendedMaintenanceScheduleAndProvidesSpaceInThe

LogForTheTechnicianToNoteWhatServiceAndMaintenanceWasDone,ByWhom,

Where,AndWhen.

11

12

DrawbarInstructions

13

Operation&MaintenanceManual

InstructionKitForDrawbar

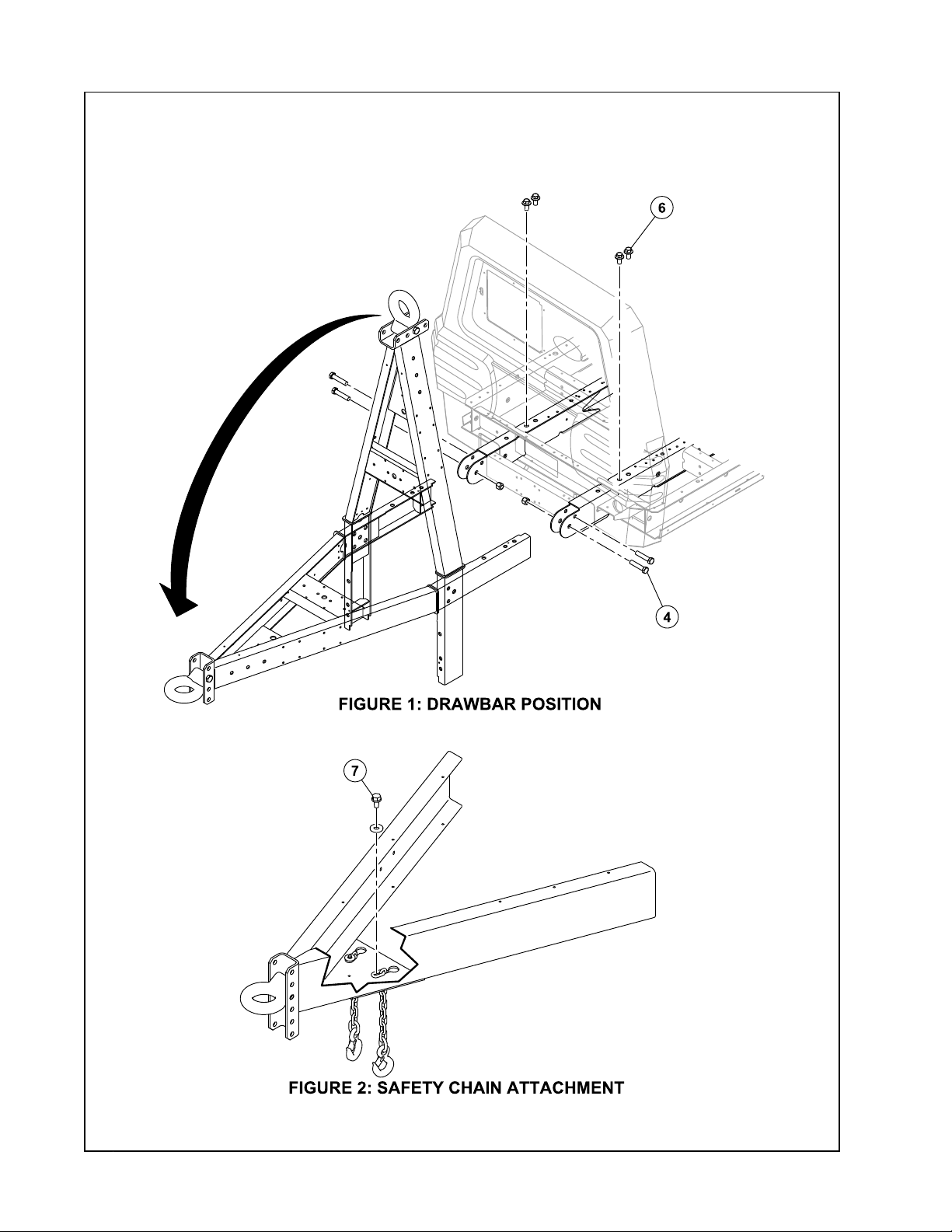

ToConvertfromShippingPositiontoT owingPosition

DrawbarInstructions

14

DrawbarInstructions

TheFollowingToolsareRequired:

Ratchet

13mmSockettotRatchet

TorqueWrenchsetto68footpounds(9.4kg-meters)

16mmSockettotT orqueWrench

5-inchExtensionforT orqueWrench

HardwareIncluded:

(4)12mmBoltswithPre-appliedThreadLock.

(2)8mmTaptiteBolts

(2)Washers

(2)SafetyChainsarezippedtiedtoDrawbar.

1.RemoveHardwareboxfromCompressorT oolbox.

2.OpenboxandremovethebagcontainingHardware,andAssemblyinstructions.

3.UsingtheJack,raisethefrontoftheUnitsotheLegsareapproximately1-inch

abovetheground.

Operation&MaintenanceManual

4.RemovethetemporaryRetainingBoltsfrombothsidesoftheFrameattheDrawbar

connection(SeeFigure1).

5.CarefullylowertheDrawbartotheLevelposition.

6.InstalltheFourBolts(withPre-appliedThreadLock)tothefourpointsinsidethe

EnclosureandT orqueto68pounds(9.4kg-meters)(SeeFigure1).

7.InstallSafetyChainsbyslidingthesecondlinkofoneChainintotheslotinDrawbar

Plate.FastenChaintoPlateusingT aptiteandWasher.RepeatfortheotherSafety

Chain(SeeFigure2)

SupporttheDrawbaratthePintleEye:

1.PullthePinoutoftheJacklocatedattheFrontoftheEnclosure.RemovetheJack

byslidingifOfftheMountingTube.RelocateandinstalltheJacktotheMounting

TubeonthesideoftheDrawbar.

15

16

Safety

17

Operation&MaintenanceManualSafety

SafetyPrecautions

Neveroperatethecompressorwithoutrstobservingallsafetywarningsandcarefullyreading

theOperationandMaintenanceManualshippedfromthefactorywiththiscompressor.

Ensuretheoperatorreadsandunderstandsthedecalsandconsultsthemanualsbefore

operationorperformingmaintenance.

Ensureallmaintenancepersonnelareadequatelytrained,competent,andhavereadthe

manuals.

Ensureallprotectivecoversareinplaceandthecanopy/doorsareclosedduringoperation.

Thespecicationofthiscompressorissuchthatthecompressorisnotsuitableforusein

ammablegasriskareas.Ifsuchanapplicationisrequired,alllocalregulations,codesof

practice,andsiterulesmustbeobserved.T oensurethecompressorcanoperateinasafe

andreliablemanner,additionalequipmentsuchasgasdetection,exhaustsparkarrestors,

andintake(shut-off)valvesmayberequired,dependentonlocalregulationsorthedegree

ofriskinvolved.

Aweeklyvisualcheckmustbemadeofallfasteners/xingscrewssecuringmechanicalparts.

Inparticular,safety-relatedpartssuchascouplinghitch,drawbarcomponents,wheels,tires,

andliftingbailshouldbecheckedfortotalsecurity.

Allcomponentswhichareloose,damaged,orunserviceablemustberectiedwithoutdelay.

Airdischargedfromthiscompressormaycontaincarbonmonoxideorothercontaminants

whichwillcauseseriousinjuryordeath.Donotbreathedischargedair.

Thiscompressorproducesloudnoisewiththedoorsopenorservicevalvevented.Extended

exposuretoloudnoisecancausehearingloss.Alwayswearhearingprotectionwhendoors

areopenorservicevalveisvented.

Neverinspectorservicethecompressorwithoutrstdisconnectingbatterycable(s)to

preventaccidentalstarting.

Donotusepetroleumproducts(solventsorfuels)underhighpressureasthiscanpenetrate

theskinandresultinseriousillness.Weareyeprotectionwhilecleaningthecompressor

withcompressedairtopreventdebrisfrominjuringeye(s).

Rotatingfanbladecancauseseriousinjury .Donotoperatewithoutfanguardinplace.

Usecaretoavoidcontactinghotsurfaces(engineexhaustmanifoldandpiping,airreceiver,

andairdischargepiping,etc.).

Etherisanextremelyvolatile,highlyammablegas.Whenitisspeciedasastartingaid,

usesparingly.DonotuseEtheriftheenginehasglowplugsorinletheaterstartingaids.

Enginedamagewillresult.

Neveroperatethecompressorwithguards,covers,orscreensremoved.Keephands,hair,

clothing,tools,blowguntips,etc.wellawayfrommovingparts.

18

SafetyOperation&MaintenanceManual

CompressedAir

Compressedaircanbedangerousifincorrectlyhandled.Priortoperformingmaintenance

orserviceonthecompressor,ensureallpressureisventedfromthesystemandthe

compressorcannotbestartedaccidentally.

Ensurethecompressorisoperatingattheratedpressureandtheratedpressureisknown

toallrelevantpersonnel.

Allairpressureequipmentinstalledin,orconnectedto,thecompressormusthavesafe

workingpressureratingsofatleastthecompressorsafetyvalvesetting.

Ifmorethanonecompressorisconnectedtoonecommondownstreamplant,effectivecheck

valvesandisolationvalvesmustbettedandcontrolledbyworkprocedures,toensureone

compressorcannotaccidentallybepressurizedoroverpressurizedbyanother.

Compressedairmustnotbeusedforadirectfeedtoanyformofbreathingapparatusor

mask.

Compressedaircancauseseriousinjuryordeath.Relievepressurebeforeremovingller

plugs/caps,ttings,orcovers.

Airpressurecanremaintrappedinairsupplylinewhichcanresultinseriousinjuryordeath.

Alwayscarefullyventairsupplylineattoolorventvalvebeforeperforminganyserviceor

maintenance.

Dischargedaircontainsaverysmallpercentageofcompressorlubricatingoilandcare

shouldbetakentoensuredownstreamequipmentiscompatible.

Ifdischargedairistobeultimatelyreleasedintoaconnedspace,adequateventilation

mustbeprovided.

Whenusingcompressedair,alwaysuseappropriatepersonalprotectiveequipment.

Allpressurecontainingparts,especiallyexiblehosesandtheircouplings,mustberegularly

inspected,befreefromdefects,andbereplacedaccordingtothemanualinstructions.

Avoidbodilycontactwithcompressedair.

Thesafetyvalvelocatedintheseparatortankmustbecheckedperiodicallyforcorrect

operation.

Wheneverthecompressorisstopped,airwillowbackintothecompressorfromdownstream

devicesorsystemsunlesstheservicevalveisclosed.Installacheckvalveatthecompressor

servicevalvetopreventreverseowintheeventofanunexpectedshutdownwhenthe

servicevalveisopen.

Disconnectedairhoseswhipandcancauseseriousinjuryordeath.Alwaysattachasafety

owrestrictiontoeachhoseatthesourceofsupplyorbranchlineinaccordancewithOSHA

Regulation29CFRSection1926.302(b).

Neverallowthecompressortositstoppedwithpressureintheseparatortankorpiping.

19

Operation&MaintenanceManualSafety

ExhaustSystem

Hotengineexhaustgasandhotexhaustsystemsurfacesareproducedduringandafter

compressoroperation.Avoidcontactwithexhaustgasandhotexhaustsystemsurfaces.

Keepammableandcombustiblematerialsaway.Donotoperatecompressoron,under,or

nearammableorcombustiblematerials.

Thepotentialforhighertemperaturesispresentwhentheexhaustaftertreatmentsystem

undergoesregeneration.Refertoenginemanualforfurthersafetyinstructionsand

informationontheexhaustaftertreatmentsystemandcontrols.

Materials

THefollowingsubstancesmaybeproducedduringtheoperationofthiscompressor:

•BrakeLiningDust

•EngineExhaustFumes

AvoidInhalationOfMaterialSubstances.

Ensurethatadequateventilationofthecoolingsystemandexhaustgasesismaintainedat

alltimes.

Thefollowingsubstancesareusedinthemanufactureofthiscompressorandmaybe

hazardoustohealthifusedincorrectly:

•Antifreeze

•CompressorOil

•EngineOil

•PreservativeGrease,LubricatingGrease

•RustPreventative

•DieselFuel

•BatteryElectrolyte

20

SafetyOperation&MaintenanceManual

AvoidIngestion,SkinContact,AndInhalationOfFumes.

Shouldcompressoroilcomeintocontactwiththeeyes,irrigatewithwaterforatleast5

minutes.

Shouldcompressoroilcomeintocontactwiththeskin,washoffimmediately.Consulta

physicianiflargeamountsofcompressoroilareingestedorifcompressoroilisinhaled.

Nevergiveuidsorinducevomitingifthepatientisunconsciousorhavingconvulsions.

Safetydatasheetsforcompressorandengineoilsshouldbeobtainedfromtheoilsupplier.

Donotstartoroperatethiscompressorinaconnedarea.Avoidbreathingexhaustfumes

whenworkingonornearthecompressor.

Thiscompressormayincludesuchmaterialsasoil,dieselfuel,antifreeze,brakeuid,oil/air

lters,andbatterieswhichmayrequireproperdisposalwhenperformingmaintenanceor

servicetasks.Contactlocalauthoritiesforproperdisposalofthesematerials.

Battery

Abatterycontainssulfuricacidandcanproducegaseswhicharecorrosiveandpotentially

explosive.Avoidcontactwithskin,eyes,andclothing.Incaseofcontact,usharea

immediatelywithwater.

DoNotAttemptToJumpStartAFrozenBatterySinceThisMayCauseIt

ToExplode.

Exerciseextremecautionwhenusinganexternalmethodtojumpstartaunit.Verifythe

electricalsystemsontheweakbatterysystemandtheexternaljumpsystemarethesame

voltagetypesystem,12VDCOr24VDC.Connectthepositive(+)terminaloftheexternal

systemtothepositive(+)terminalontheweaksystem.Connectthenegative(-)terminal

oftheexternalsystemtothenegative(-)terminaloftheweaksystem.Alwaysdisconnect

thetwosystemsinreverseorder.

21

Operation&MaintenanceManualSafety

CoolantSystem

Hotenginecoolantandsteamcancauseinjury.Ensurethereservoircapisremovedwith

duecareandattention.

Donotremovereservoircapwhileradiatorishot.Allowradiatortocoolbeforeremoving

reservoircap.

Hotenginecoolantandsteamcancauseinjury.Whenaddingcoolant

orantifreezesolutiontotheengineradiator,stoptheengineand

allowradiatortocoolpriortoreleasingthereservoircap.Usinga

clothtoprotectthehand,slowlyreleasethereservoircap,absorbing

anyreleaseduidwiththecloth.Donotremovethereservoircap

untilallexcessuidisreleasedandtheenginecoolingsystemfully

depressurized.

Followtheinstructionsprovidedbytheantifreezesupplierwhenadding

ordrainingtheantifreezesolution.Itisadvisabletowearpersonal

protectiveequipmenttopreventskinandeyecontactwiththeantifreeze

solution.

Transport

Whenloadingortransportingthecompressor,ensurethespeciedliftingandtiedownpoints

areused.

Whenloadingortransportingthecompressor,ensurethetowingvehicle,itssize,weight,

towinghitch,andelectricalsupplyareallsuitabletoprovidesafeandstabletowingatspeeds

either,uptothelegalmaximumforthecountryinwhichitisbeingtowed,orasspecied

forthecompressormodeliflowerthanthelegalmaximum.Donotexceedgrossvehicle

weightrating.

Beforetowingthecompressor,ensure:

•Thetiresandtowinghitchareinaserviceableconditionandtiresareproperlyinated.

•Thecanopyissecure.

•Allancillaryequipmentisstoredinasafeandsecuremanner.

•Thebrakesandlightsarefunctioningcorrectlyandmeetnecessaryroadtrafcrequirements.

•Breakawaycables/safetychainsareconnectedtothetowingvehicle.

22

SafetyOperation&MaintenanceManual

Thecompressormustbetowedinalevelattitudeinordertomaintaincorrecthandling,

braking,andlightingfunctions.Thiscanbeachievedbycorrectselectionandadjustmentof

thevehicletowinghitchand,onvariableheightrunninggear,adjustmentofthedrawbar.

1.Ensurewheels,tires,anddrawbarconnectorsareinsafeoperatingconditionanddrawbar

isproperlyconnectedbeforetowing.

2.Whenparking,alwaysusethehandbrakeand,ifnecessary,suitablewheelchocks.

SafetyChains/BreakawayCableAndTheirAdjustment(WhereFitted).

Ensurebreakawaycableissecurelycoupledtothetowedcompressorandalsotoa

substantialanchoragepointonthetowingvehicle.

Ensurecablelengthisasshortaspossible,whilestillallowingenoughslacknessforthe

towedcompressortoarticulatewithoutthebrakebeingapplied.

Attachsafetychainstothetowingvehicleatsubstantialanchoragepointsofsuitablestrength.

Ensureeffectivechainlengthisasshortaspossiblewhilestillallowingnormalarticulationof

thetowedcompressorandproperoperationofthebreakawaycable.

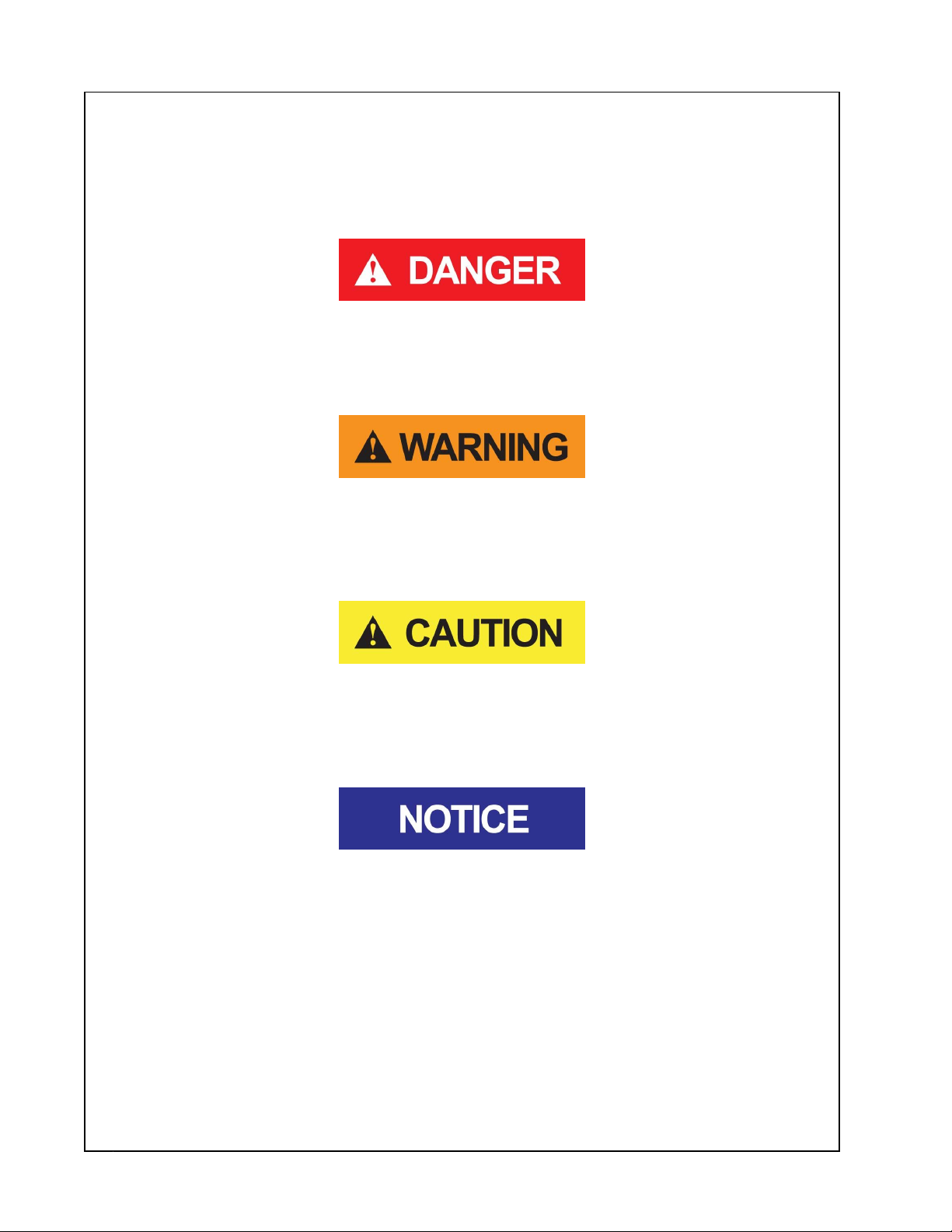

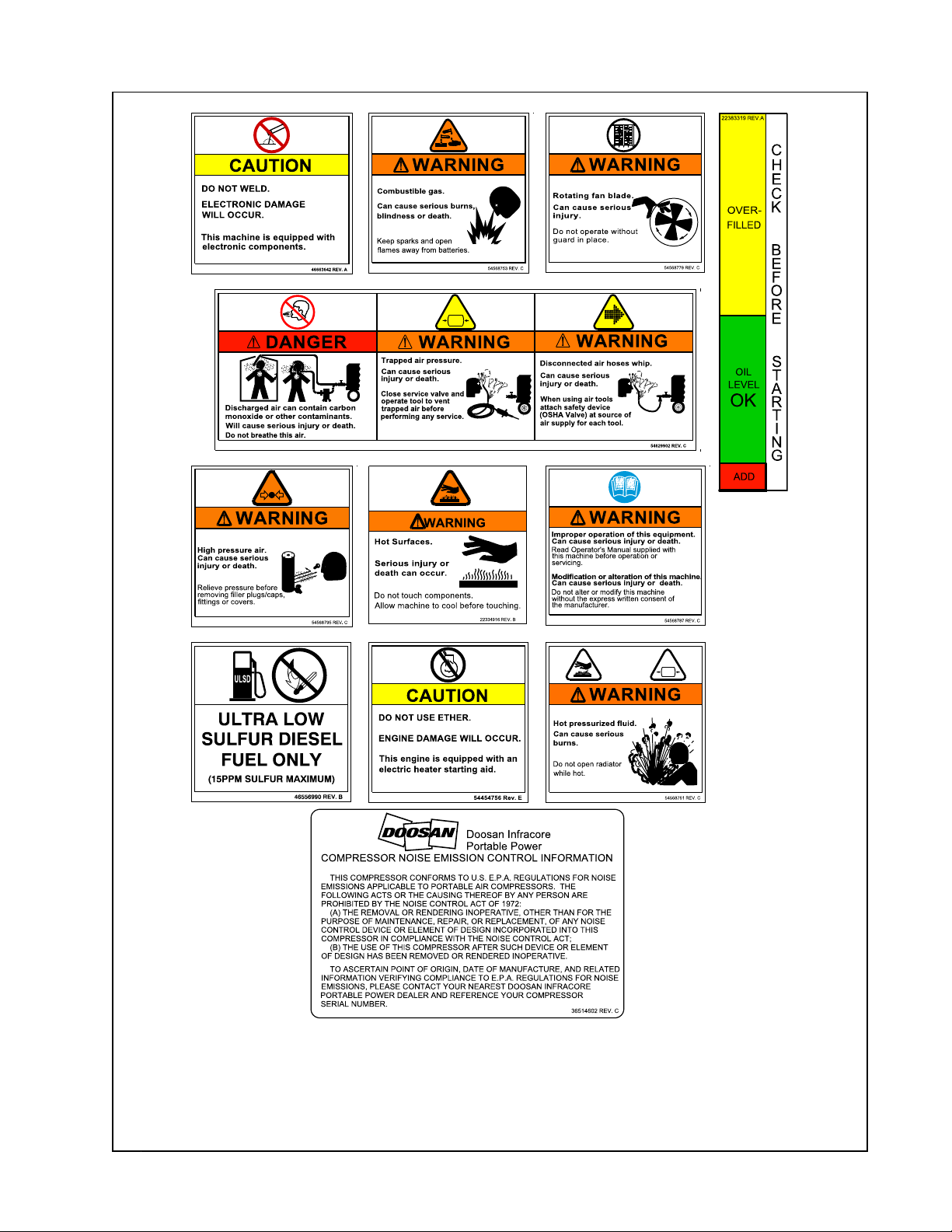

Decals

FreeSafetyDecals

TopromotecommunicationofSafetyWarningsonproducts

manufacturedbythePortablePowerDivisioninStatesville,N.C.,Safety

DecalsareavailableFREEofcharge.SafetyDecalsareidentiedby

thedecalheading:DANGER,WARNING,CAUTION,NOTICE.

Decalpartnumbersarelocatedinthelowerrighthandcornerofeach

decalandarealsolistedinthecompressorPartsManual.Submitorders

forSafetyDecalstotheStatesvillePartsServiceDept.Thenocharge

ordershouldcontainonlySafetyDecals.

Helppromoteproductsafety!Ensuredecalsarepresentonthe

compressor.Replacedecalsthatarenotreadable.

23

Operation&MaintenanceManualSafety

Decalsonthefollowingpagescontainexamplesofdecalsavailable

forthisequipment.

Decalsarelocatedonthecompressortopointoutpotentialsafetyhazards.Readandfollow

theseinstructions.Ifyoudonotunderstandtheseinstructions,informyoursupervisor.

(RedBackground)

IndicatesthepresenceofahazardwhichWILLcauseseriousinjury,

death,orpropertydamage,ifignored.

(OrangeBackground)

IndicatesthepresenceofahazardwhichCANcauseseriousinjury,

death,orpropertydamage,ifignored.

(YellowBackground)

IndicatesthepresenceofahazardwhichWILLorCANcauseinjuryor

propertydamage,ifignored.

(BlueBackground)

Indicatesimportantset-up,operating,ormaintenanceinformation.

24

SafetyOperation&MaintenanceManual

25

26

NoiseEmission

27

Operation&MaintenanceManual

NoiseEmission

ThisSectionPertainsOnlyToCompressorsDistributedWithinTheUnitedStates.

TamperingWithNoiseControlSystemProhibited.

FederalLawProhibitsthefollowingActsortheCausingThereof:

(1)theremovalorrenderinginoperativebyanypersons,otherthanforpurposesof

maintenance,repair,orreplacement,ofanydeviceorelementofdesignincorporatedinto

anynewcompressorforthepurposeofnoisecontrolpriortoitssaleordeliverytotheultimate

purchaserorwhileitisinuse;or(2)theuseofthecompressoraftersuchdeviceorelement

ofdesignhasbeenremovedorrenderedinoperativebyanyperson.

Amongthoseactsincludedintheprohibitionagainsttamperingarethese:

1.Removalorrenderinginoperativeanyofthefollowing:

NoiseEmission

A.TheEngineExhaustSystemorPartsthereof

B.TheAirIntakeSystemorPartsthereof

C.EnclosureorPartsthereof

2.Removalofanyofthefollowing:

A.FanShroud

B.VibrationMounts

C.SoundAbsorptionMaterial

3.OperationoftheCompressorwithanyoftheEnclosureDoorsOpen.

CompressorNoiseEmissionControlInformation

A.Removalorrenderinginoperative,otherthanforthepurposeofmaintenance,repair,

orreplacementofanynoisecontroldeviceorelementofdesignincorporatedintothis

CompressorincompliancewiththeNoiseControlAct.

B.TheuseofthisCompressoraftersuchdeviceorelementofdesignhasbeenremoved

orrenderedinoperative.

Note:TheAboveInformationAppliesOnlyToCompressorsThatAreBuiltIn

ComplianceWithTheU.S.EnvironmentalProtectionAgency .

Portablepowerreservestherighttomakechangesoraddimprovementswithoutnotice

andwithoutincurringanyobligationtomakesuchchangesoraddsuchimprovementsto

productssoldpreviously.

Thepurchaserisurgedtoincludetheaboveprovisionsinanyagreementforanyresale

ofthisCompressor.

28

NoiseEmission

Operation&MaintenanceManual

MaintenanceLog

COMPRESSORMODEL:

SERIALNO:

USERUNITNO:

UNITIDENTIFICA TIONDEALER/DISTRIBUTORINFORMATION

EngineMake&Model:

SerialNo:

PurchaserorOwner:

Address:DatePurchased:

TheNoiseControlActOf1972(86Stat.1234)ProhibitsTamperingwiththeNoiseControl

SystemofanyCompressorManufacturedandSoldUnderTheAboveRegulations,

SpecicallyTheFollowingActsortheCausingThereof:

(1)TheRemovalOrRenderingInoperativebyanypersons,otherthanforPurposesOf

Maintenance,Repair,orReplacement,ofanyDeviceorElementofDesignIncorporatedinto

newCompressorforthepurposeofNoiseControlpriortoitsSaleorDeliverytotheUltimate

Purchaserorwhileitisinuse;or(2)theuseoftheCompressoraftersuchDeviceorElement

ofDesignhasbeenremovedorrenderedinoperativebyanyperson.

PurchasedFrom:

NoiseEmissionWarranty

TheManufacturerWarrantstotheUltimatePurchaserandeachSubsequentPurchaserthat

thisAirCompressorwasDesigned,BuiltandEquippedtoconformatthetimeofSaletothe

FirstRetailPurchaser,withallapplicableU.S.EP ANoiseControlRegulations.

ThisWarrantyisnotLimitedtoanyParticularPart,Component,orSystemoftheAir

Compressor.DefectsintheDesign,AssemblyorinanyPart,Component,orSystemof

theCompressorwhich,atthetimeofSaletotheFirstRetailPurchaser,causedNoise

EmissionstoExceedFederalStandardsarecoveredbythisWarrantyFortheLifeofAir

Compressor.(40CFR204.58-1)

29

Operation&MaintenanceManual

Introduction

TheCompressorforwhichthisMaintenanceLogisprovidedconformsT oU.S.EPA

RegulationsforNoiseEmissions,applicabletoPortableAirCompressors.

Thepurposeofthisbookistoprovide(1)TheMaintenancePerformanceScheduleforall

RequiredNoiseEmissionControlsand(2)SpacesothatthePurchaserorOwnercanrecord

whatMaintenancewasdone,bywhom,whereandwhen.TheMaintenanceScheduleand

DetailedInstructionsontheMaintenanceItemsaregivenonthefollowingpage.

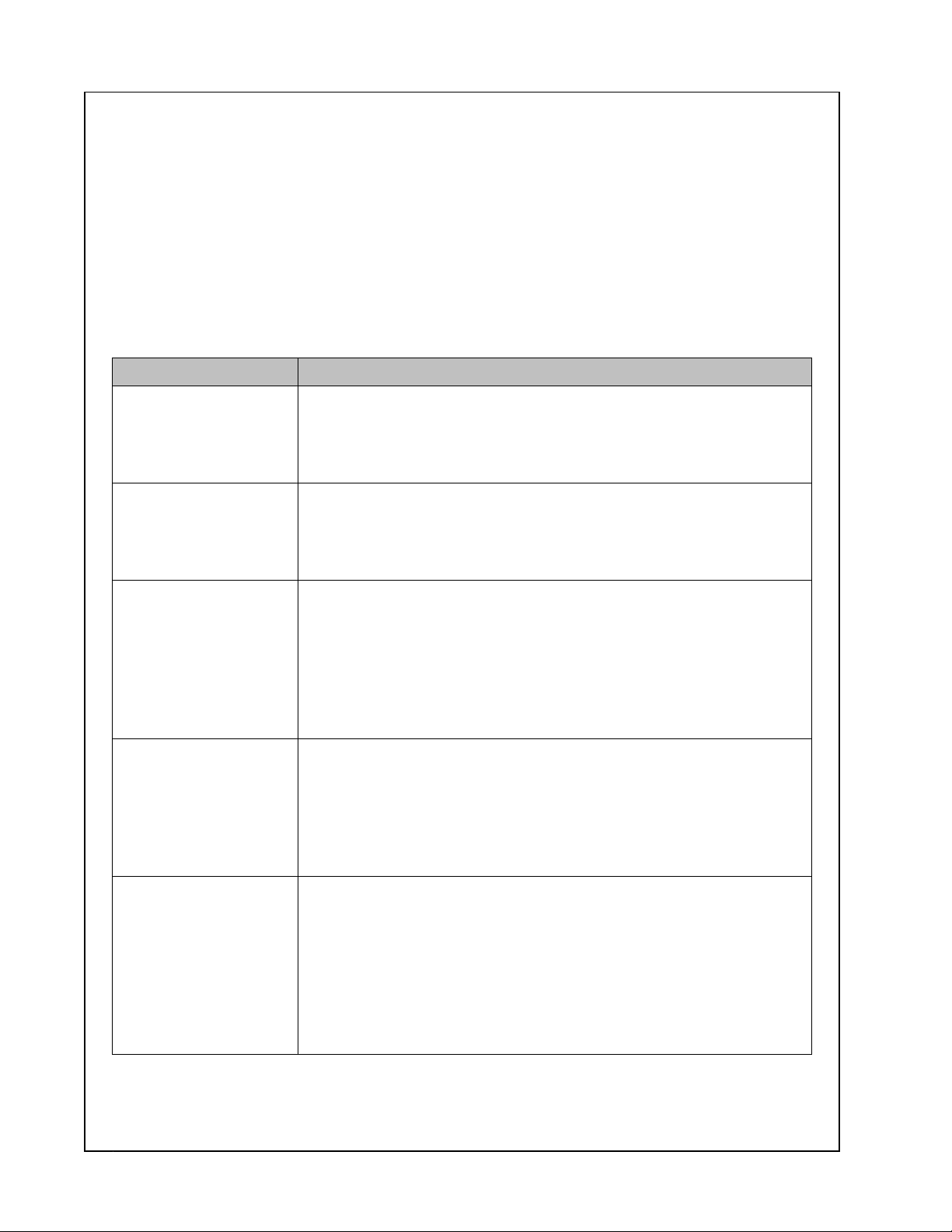

MaintenanceSchedule

PERIODDESCRIPTION

NoiseEmission

AsDetected

AsDetected

Daily

100HOURSFASTENERS

COMPRESSEDAIRLEAKS

Correctallcompressedairleaksduringtherstshutdownperiod

afterdiscovery.Ifsevereenoughtocauseseriousnoiseproblems

andefciencyloss,shutdownimmediatelyandcorrecttheleak(s).

SAFETYANDCONTROLSYSTEMS

Repairorreplaceallsafetyandcontrolsystemsorcircuitsas

malfunctionoccurs.Nocompressorshouldbeoperatedwitheither

systembypassed,disabled,ornonfunctional.

ACOUSTICMA TERIALS

Indailyinspections,observethesematerials.Maintainallacoustic

materialasnearlyaspossibleinitsoriginalcondition.Repairor

replaceallsectionsthathave:1)sustaineddamage,2)have

partiallyseparatedfrompanelstowhichtheywereattached,3)are

missing,orhaveotherwisedeterioratedduetosevereoperatingor

storageconditions.

Allfastenerssuchashinges,nuts,bolts,clamps,screws,rivets,

andlatchesshouldbeinspectedforloosenessaftereach100

hoursofoperation.Theyshouldberetightened,repaired,orif

missing,replacedimmediatelytopreventsubsequentdamageand

noiseemissionincrease.

100HOURSENCLOSUREP ANELS

Enclosurepanelsshouldbeinspectedat100houroperational

intervals.Allpanelsthatarewarped,punctured,torn,orotherwise

deformed,suchthattheirnoisecontainmentfunctionisreduced,

shouldberepairedorreplacedbeforethenextoperationinterval.

Doors,accesspanels,andhatchclosuresespecially,shouldbe

checkedandadjustedatthistimetoensurecontinuousseating

betweengasketoracousticmaterialandthematingframe.

30

Loading...

Loading...