Doosan G70WJD-2A-T3, G145WJD-2A-T3, G25WMI-2A-T2, G185WJD-2A-T3, G240WJD-2B-T3 Installation, Operation & Maintenance Manual

...

OPERATION, MAINTENANCE

MANUAL

G10WMI-2D-T2 (B63)

G25WMI-2A-T2 (B54)

G40WMI-2A-T2 (B50)

G60WJD-2A-T2 (B55)

G70WJD-2A-T3 (D63)

G80

G90WJD-2A-T3 (C24)

G125

G145WJD-2A-T3 (C27)

G185WJD-2A-T3 (C28)

G240WJD-2B-T3 (C31)

G240WCU-2C-T3 (D97)

G290WCU-3B-T3 (C38)

G290WCU-3C-T3 (D77)

G450WCU-2B-T2 (C34)

G450WCU-2C-T2 (D96)

G570WCU-2B-T2 (C37)

G570WCU-2C-T2 (D78)

GENERATOR MODELS

This manual contains important safety information.

Do not destroy this manual.

This manual must be available to the personnel who operate and maintain this machine.

Doosan Infracore Portable Power

1293 Glenway Drive

Statesville, N.C. 28625

www.doosanportablepower.com

Book: 22637300 (8-2-2010) Rev H

2

TABLE OF CONTENTS

Operation & Maintenance Manual

TITLE PAGE

DRAWBAR NOTICE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SAFETY SYMBOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

HAZARDOUS SUBSTANCE PRECAUTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

GENERAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

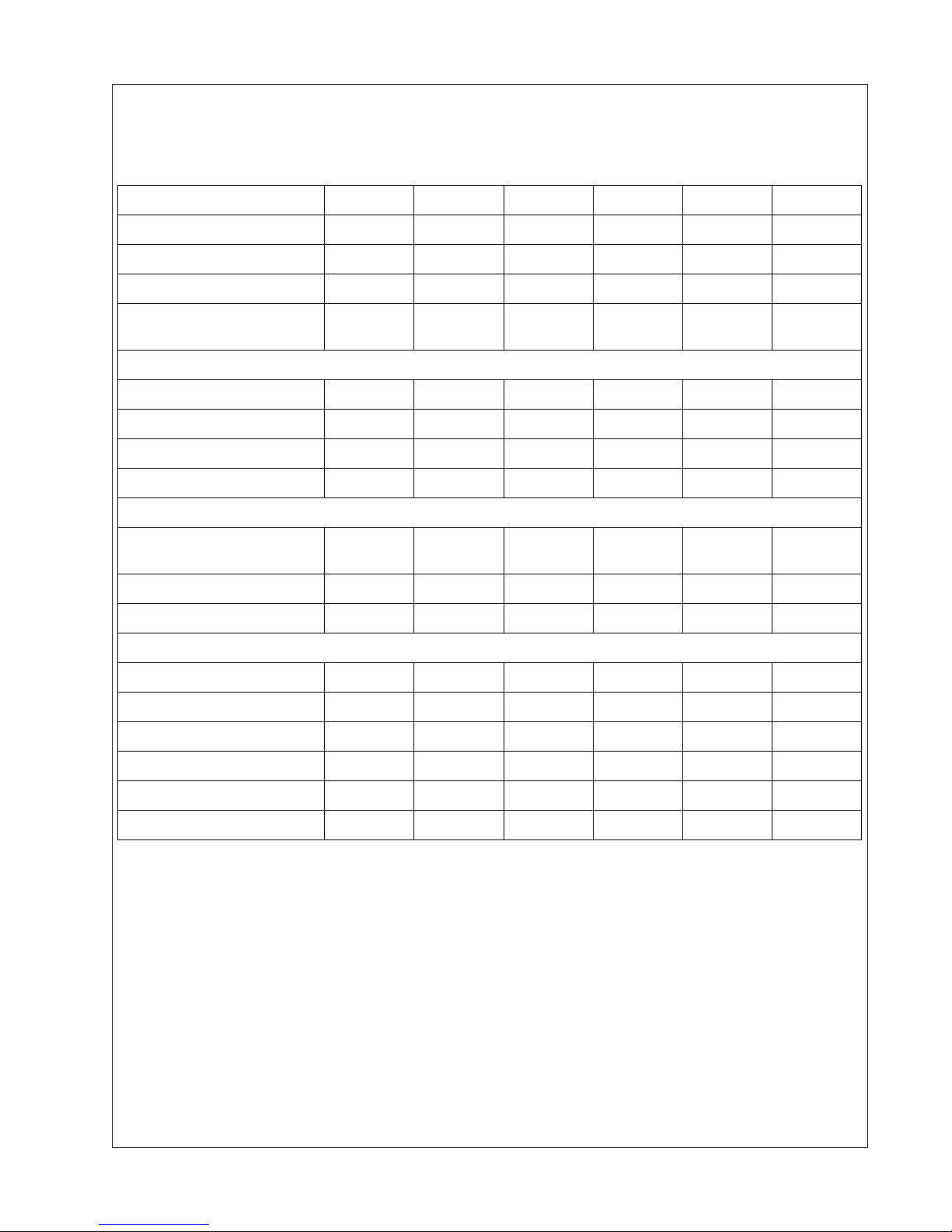

Unit Model: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Unit Model: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Unit Model: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Consumables Service Parts:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Consumable Service Parts:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Expendable Service Parts: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

OPERATING INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

BEFORE TOWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

TOWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

SETTING UP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

DISCONNECT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

BEFORE STARTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

STARTING (AUTOSTART MODELS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

STOPPING (AUTOSTART MODELS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

REMOTE STARTING AND STOPPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

DIAGNOSTICS/AUTO SHUTDOWN (AUTOSTART MODELS). . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

ENGINE CONTROLS and INSTRUMENTS (AUTOSTART MODELS) . . . . . . . . . . . . . . . . . . . . . . 35

CUSTOMER - DIAGNOSTIC GAUGE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

STARTING (KEY START MODELS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

STOPPING (KEYSTART MODELS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

DIAGNOSTICS and AUTO SHUTDOWN (KEYSTART MODELS). . . . . . . . . . . . . . . . . . . . . . . . . . 40

ENGINE CONTROLS and INSTRUMENTS (Keystart Models) . . . . . . . . . . . . . . . . . . . . . . . . . 41

GENERATOR SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

MONITOR SWITCHES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

CIRCUIT BREAKERS - Flip to Reset (if equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

RECEPTACLES (if equipped) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

PROTECTION/REGULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

VOLTAGE SELECTION/ADJUSTMENTS G25 thru G185 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

SWITCH POSITION - 120/208V 3 Phase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

SWITCH POSITION - 277/480V 3 Phase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

SWITCH POSITION - 120/240 1Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

VOLTAGE SELECTION/ADJUSTMENTS G240 thru G570 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

120/208V 3 Phase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

277/480V 3 Phase. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

BASIC DIGITAL CONTROLS OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3

TABLE OF CONTENTS

Operation & Maintenance Manual

TITLE PAGE

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Scheduled Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

ADJUSTMENT INSTRUCTIONS and TESTING PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . 71

ACCESSING COMPARTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

VOLTAGE REGULATOR ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

OVERCURRENT RELAY ADJUSTMENT (Set Dial on the OCR Relay) . . . . . . . . . . . . . . . . . . . . . 72

POWER BYPASS SWITCH FOR ENGINE ECU SERVICE. . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

PACKAGE PREVENTIVE MAINTENANCE SCHEDULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

ALTERNATOR INSTALLATION AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . 75

SAFETY MEASURES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

INSTALLATION - COMMISSIONING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

SERVICING-MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

TECHNICAL CHARACTERISTICS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

4

Drawbar Notice

22637300 5

Operation & Maintenance Manual Drawbar Notice

Drawbar Notice

This machine may have been shipped from the factory with the drawbar positioned upright. To

convert from shipping position to towing position, the following tools are required:

Tool Required:

Ratchet, 24mm socket and an 18mm socket to fit ratchet

Torque wrench set to 166 ft-lbs (226 Nm) and 67 ft-lbs. (91 Nm)

24mm socket and an 18mm socket to fit torque wrench

Hardware included: (1) 16mm nut, (2) Washers, (2) Safety Chains

1. Remove hardware box from generator.

2. Open box and remove the bag containing hardware, safety chains and assembly

instructions.

3. Using the jack, raise the front of the unit so that the end of the drawbar is

approximately 1 inch above the ground.

4. While holding the drawbar, carefully remove the temporary retaining bolt that holds

the drawbar to the top of the enclosure (See Fig. 1).

5. Carefully lower drawbar to the Level Position.

6. Install the bolt (that was removed in Step 4) with the washers and nut from the

included hardware to secure the end of the drawbar underneath the unit and torque to

166 ft-lbs (226 Nm). Also torque the drawbar pivot bolt to 166 ft-lbs. (226 Nm). See

Figure 2).

7. Install safety chains by first removing the longest bolt used to attach the hitch then

insert the last link of one chain onto the bolt. Slide one spa cer back on the bo lt and pu t

the assembly back into the hitch. Slide the other spacer onto th e bolt, th en the last link

of the other safety chain washer. Tighten the nut to 67 ft-lbs (91 Nm).

6 22637300

Safety Symbols

22637300 7

Operation & Maintenance Manual Safety Symbols

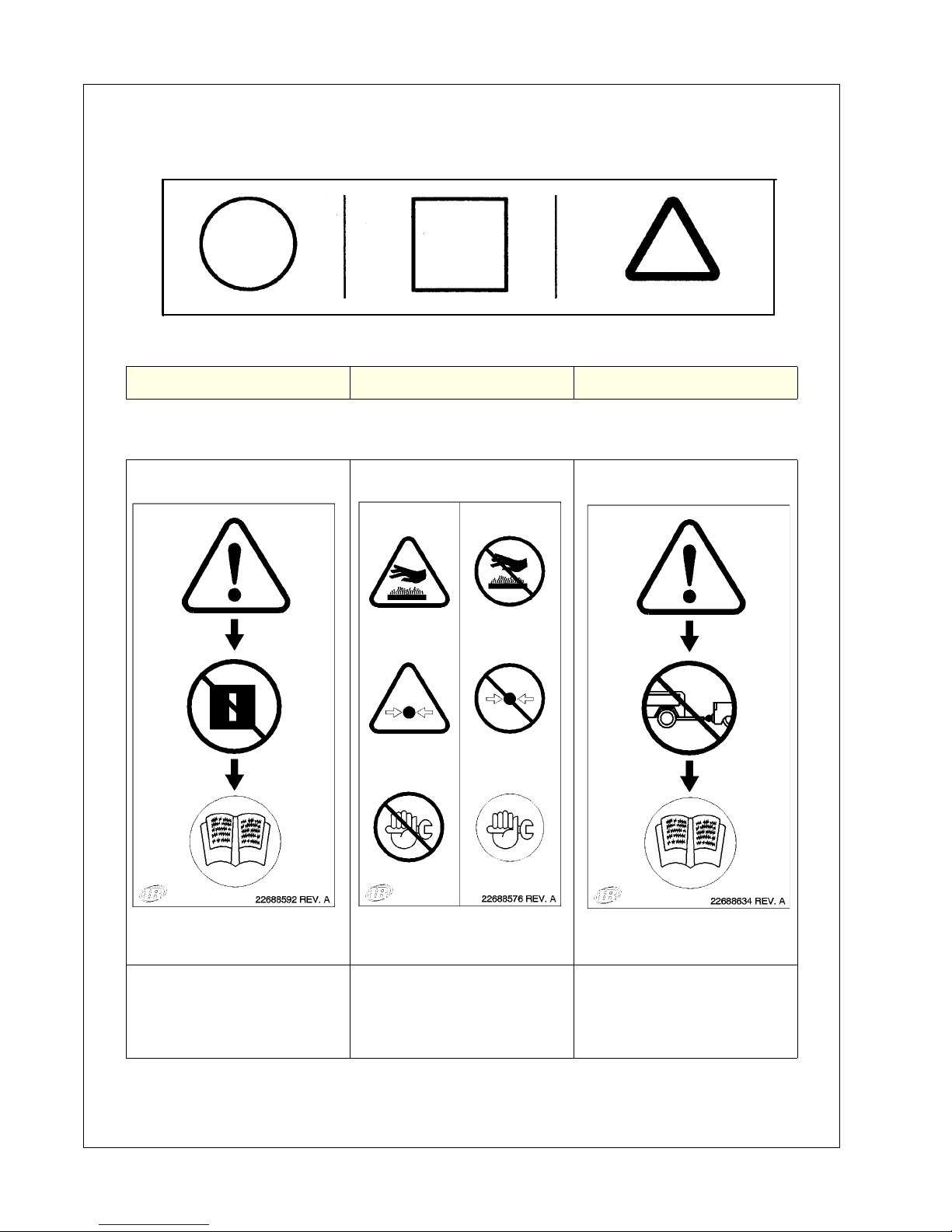

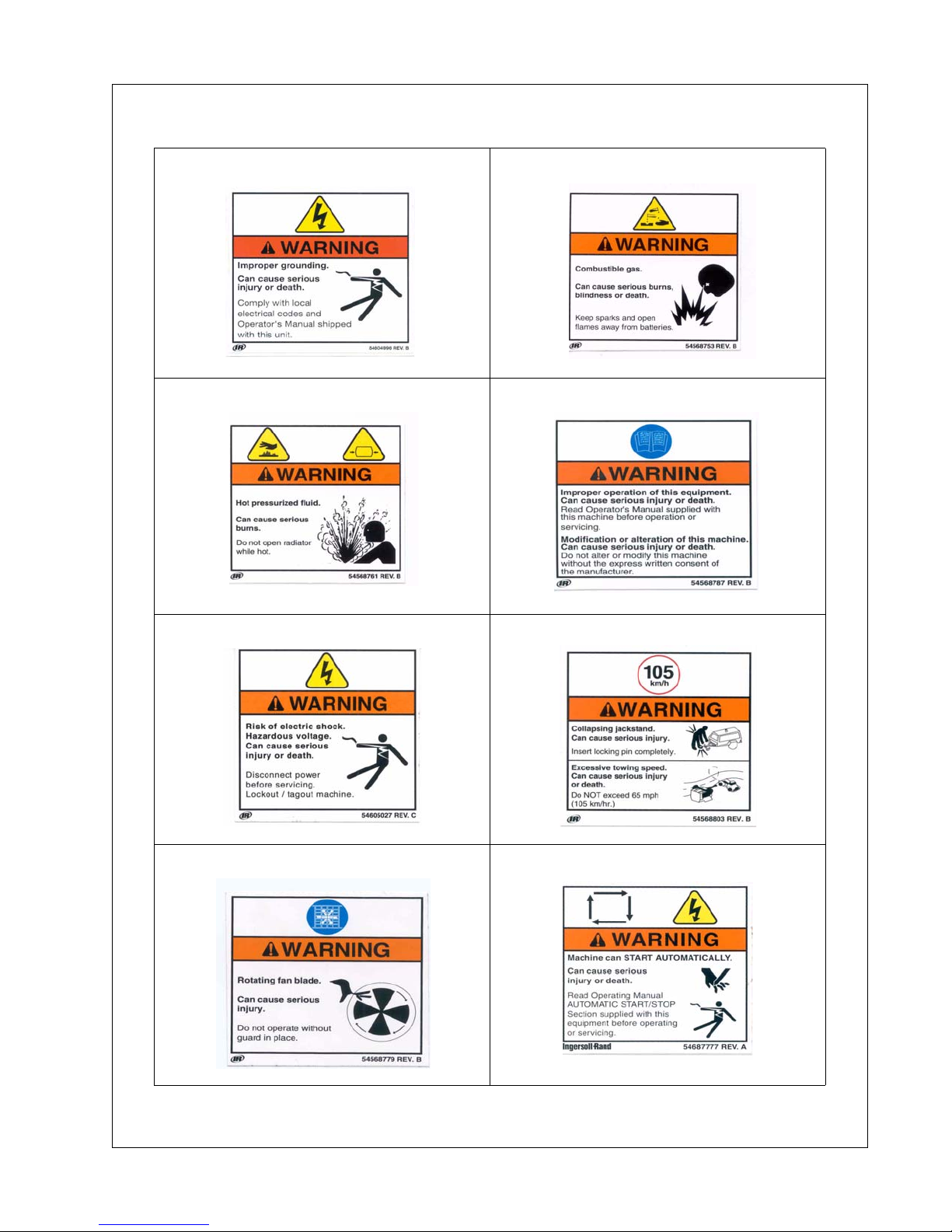

Symbols below point out potential safety hazards and provide important information about this

machine. Read and understand. Heed warnings and follow instructions. If you do not

understand, inform your supervisor.

Prohibition/ Mandatory Information/Instructions WARNING

WARNING - Read the

operator’s manual before

operating this machine.

WARNING - Do not open

radiator until radiator is

cool and pressure is

WARNING - Read the

operator’s manual before

towing machine.

relieved.

8 22637300

Safety Symbols Operation & Maintenance Manual

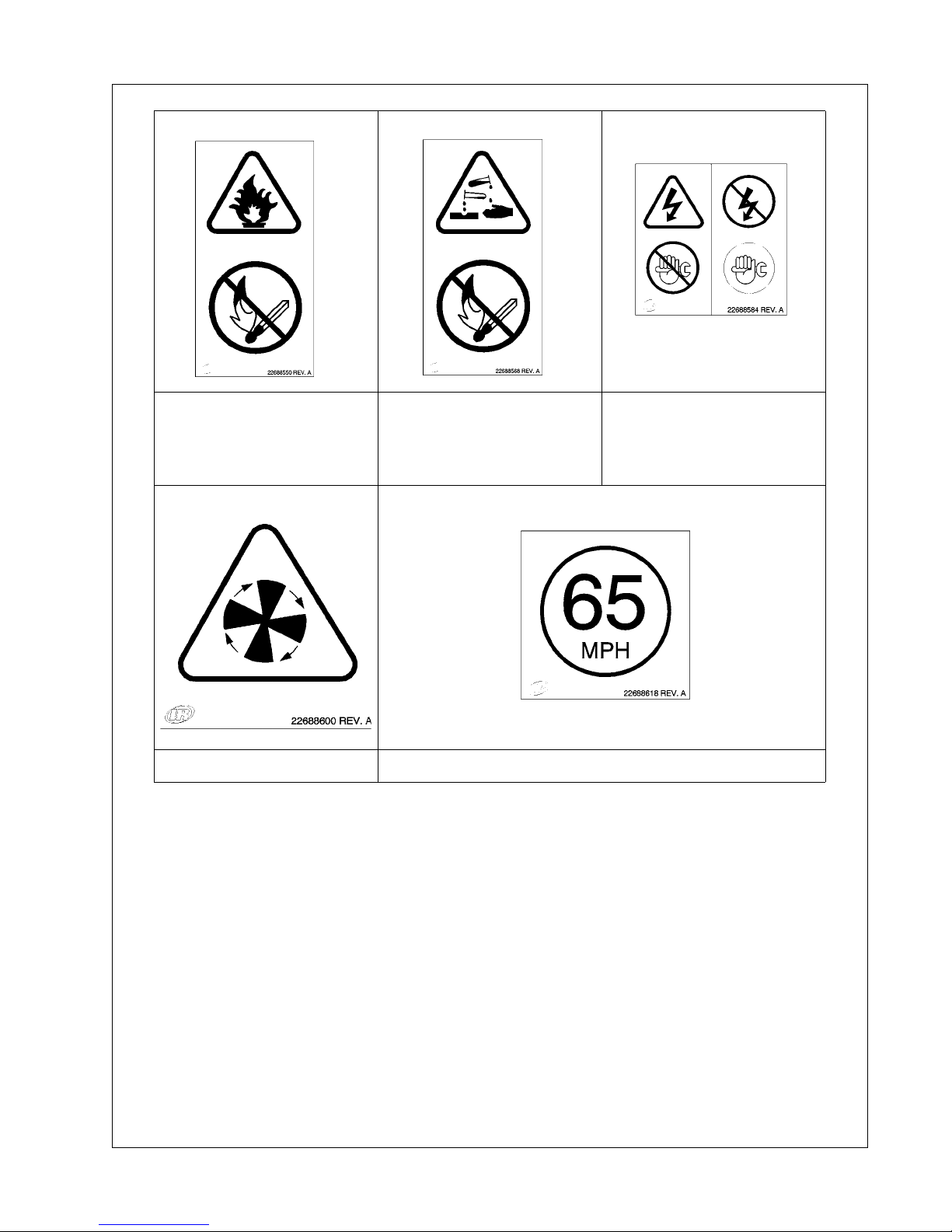

WARNING - Diesel fuel is

flammable. No open

flames or sparks.

WARNING - Battery

contains acid. Gases are

flammable. No open

flames or sparks.

WARNING - Do not

perform maintenance until

all electrical power has

been disconnected.

WARNING - Rotating fan. 65 MPH maximum towing speed.

22637300 9

Operation & Maintenance Manual Safety Symbols

Safety Symbols

Look for these signs on machines manufactured in North America, which point out

potential hazards to the safety of you and others. Read and understand thoroughly.

Heed warnings and follow instructions. If you do not understand, inform your

supervisor.

Safety Decals area available free of charge.

Safety decals are identified by the decal heading:

DANGER, WARNING or CAUTION

Decal part numbers are on the bottom of each decal and are listed

in the parts manual. Help promote product safety! Assure that

decals are present on the machines. Replace decals that are not

legible.

10 22637300

Safety Symbols Operation & Maintenance Manual

22637300 11

Always use genuine replacement parts!

12 22637300

Safety

22637300 13

Operation & Maintenance Manual Safety

Safety

!

DANGER

This machine is not designed for operating life-sustaining equipment. It

is equipped with a safety shutdown system that will cause the machine to

stop operating whenever a shutdown condition is present.

!

DANGER

Never operate the engine of this machine inside a building without

adequate ventilation. Avoid breathing exhaust fumes when working on

on near the machine.

!

WARNING

A battery contains sulfuric acid and can give off gases which are

corrosive and potentially explosive. Avoid contact with skin, eyes, and

clothing. In case of contact, flush area immediately with water.

!

WARNING

Improper operation of this equipment can cause severe injury or death.

Read Operator’s Manual supplied with this machine before operation or

service.

Modification or alteration of this machine CAN result in severe injury or

death. Do not alter or modify this machine without the express written

consent of the manufacturer.

14 22637300

Safety Operation & Maintenance Manual

!

CAUTION

Exercise extreme caution when using booster battery. To jump battery,

connect ends of one booster cable to the positive (+) terminal of each

battery. Connect one end of other cable to the negative (-) terminal of the

bosster battery and other end to a ground connection away from dead

battery (to avoid a spark occurring near any explosive gases that may be

present). After starting unit, always disconnect cables in reverse order.

!

WARNING

Never inspect or service unit without first disconnecting battery cable(s)

to prevent accidental starting.

Wear eye protection while cleaning unit with compressed air, to prevent

debris from injuring eyes.

!

WARNING

HOT PRESSURIZED FLUID - Remove cap slowly to relieve PRESSURE

from HOT radiator. Protect skin and eyes. HOT water or steam and

chemical additives can cause serious personal injury.

22637300 15

Operation & Maintenance Manual Safety

!

WARNING

Flammable Fuels - Do not fill tank when engine is running.

Do not smoke or use an open flame in the vicinity of the generator set or

fuel tank.

Do not permit smoking, open flame, or sparks to occur near the battery,

fuel, cleaning solvents or other flammable substances and explosive

gases.

Do not operate Genset if fuel has been spilled inside or near the unit.

!

WARNING

Electrical Shock -

Do not operate electrical equipment while standing in water, on wet

ground or with wet hands or shoes.

Use extreme caution when working on electrical components. Battery

voltage (12V/24V DC) is present unless the battery cables have been

disconnected. Higher voltage (potentially 480V) is possibly present at all

times.

Always treat electrical circuits as if they were energized.

Disable Start Control before attempting any repair service, disconnect all

leads to electrical power requirements and disconnect battery to prevent

start up.

GROUNDING

!

WARNING

Depending upon your application, it may be MANDATORY to ground this unit to earth or to

NOT ground this unit to earth. Comply with local electrical codes and Operation Manual.

16 22637300

Safety Operation & Maintenance Manual

!

WARNING

The Generator Set can produce high voltages, which can cause severe

injury or death to personnel and damage to equipment. The Generator Set

should have proper internal and external ground when required by the

National Electric Code.

The Generator Set is internally grounded neutral to the frame of the

Generator Set. This internal ground connection is essential for proper

Generator Set performance and personal protection.

External grounding consists of connecting the generator neutral to a

solid earth ground, and is the responsibility of the operator, when

grounding is required by National Electrical Code, Article 250, and other

local codes as applicable. Several methods are employed to externally

ground portable generator sets, depending on the intended use and code

requirements. In all cases, a continuous length of splice-free copper

cable, no smaller than AWG#8, shall be used for the external ground

conductor, when grounding is required.

A qualified, licensed electrical contractor, knowledgeable in local codes,

should be consulted.

The Generator Set has two main applications:

(1) If the Generator Set is supplying electrical power to portable equipment, the vehicle frame

shall NOT be grounded to earth per National Electrical Code, Article 250-34(b). All other

provisions of the Article shall be complied with.

(2) If the Generator Set is connected to a temporary or fixed distribution system (such as a

building), grounding of the vehicle frame is required at the service entrance to the building, per

National Electrical Code, Article 250-20 (b).

If the Generator Set is supplying power to more than one temporary or fixed wiring system, a

separate ground cable must be connected from the generator neutral to each distribution

systems ground as detailed above.

!

WARNING

Failure to properly ground the Generator Set can result in severe injury

or death.

IF USED AS ALTERNATE POWER SUPPLY

Connect only after the main service entrance switch has been DISCONNECTED and

LOCKED OPEN. In addition, circuit overload protection must be provided in accord ance with

National Electrical Codes and local regulations.

22637300 17

Operation & Maintenance Manual Safety

!

WARNING

TOWING -

Do not tow this unit in excess of 65 mph (104 km/hr).

Do not tow this unit with a vehicle whose towing capacity is less than the

gross vehicle weight.

Steps for determining correct load limit -

1. Locate the statement “The weight of cargo should never exceed

xxx kg or xxx lbs” on your vehicle’s placard.

2. This figure equals the available amount of cargo and luggage l oad

capacity.

3. Determine the combined weight of luggage and cargo being loaded

on the vehicle. That weight may not safely exceed the available cargo

and luggage load capacity.

Always make sure the wheels, tires and towbar connectors are in safe

operating condition and tow bar is properly connected before towing.

Chock the wheels of the unit when it is not connected to the tow vehicle.

Do not store or transport material or equipment in or on the unit.

!

WARNING

Drawbar/Hitch Hookup -

Safety chains must be crossed under drawbar and attached to towing

vehicle to prevent drawbar from dropping to ground in event of coupling

failure.

18 22637300

Safety Operation & Maintenance Manual

!

WARNING

If the drawbar is removed from this machine, use new OEM fasteners,

thread locking compound and torque per the tables included in this

manual, when re-installing the drawbar.

!

WARNING

Voltage Selection - Do not turn Voltage Selector Switch while engine is

running. Voltage selection, adjustment and electrical connections shall

be performed only by qualified personnel.

!

CAUTION

Welding -

Prior to any welding, disconnect alternator relays, diagnostic circuit

board, voltage regulator circuit board, meters, circuit breakers and

battery cables. Open all circuit breakers, and remove any external

connections (except grounding rod). Connect the welding ground as

close as possible to the area being welded.

!

WARNING

Electrical Loading -

Never make electrical connections with the unit running.

Before placing the unit in operation, verify the electrical rating of the

Generator Set and do not exceed generator set ratings.

22637300 19

Operation & Maintenance Manual Safety

!

CAUTION

Use extreme care to avoid contacting hot surfaces (engine exhaust

manifold and piping).

HAZARDOUS SUBSTANCE PRECAUTION

Ensure that adequate ventilation of the cooling system and exhaust gases is maintained at all

times.

The following substances are used in the manufacture of this machine and may be hazardous

to health if used incorrectly.

Avoid ingestion, skin contact and breathing fumes for the following substances: Antifreeze,

Engine Lubricating Oil, Preservative Grease, Rust Preventative, Diesel Fuel and Battery

Electrolyte.

The following substances may be produced during the operation of this machine and may be

hazardous to health:

• Avoid build-up of engine exhaust fumes in confined spaces.

• Avoid breathing exhaust fumes.

• Avoid breathing brake lining dust during maintenance.

• Always operate in a well ventilated area.

20 22637300

General Data

22637300 21

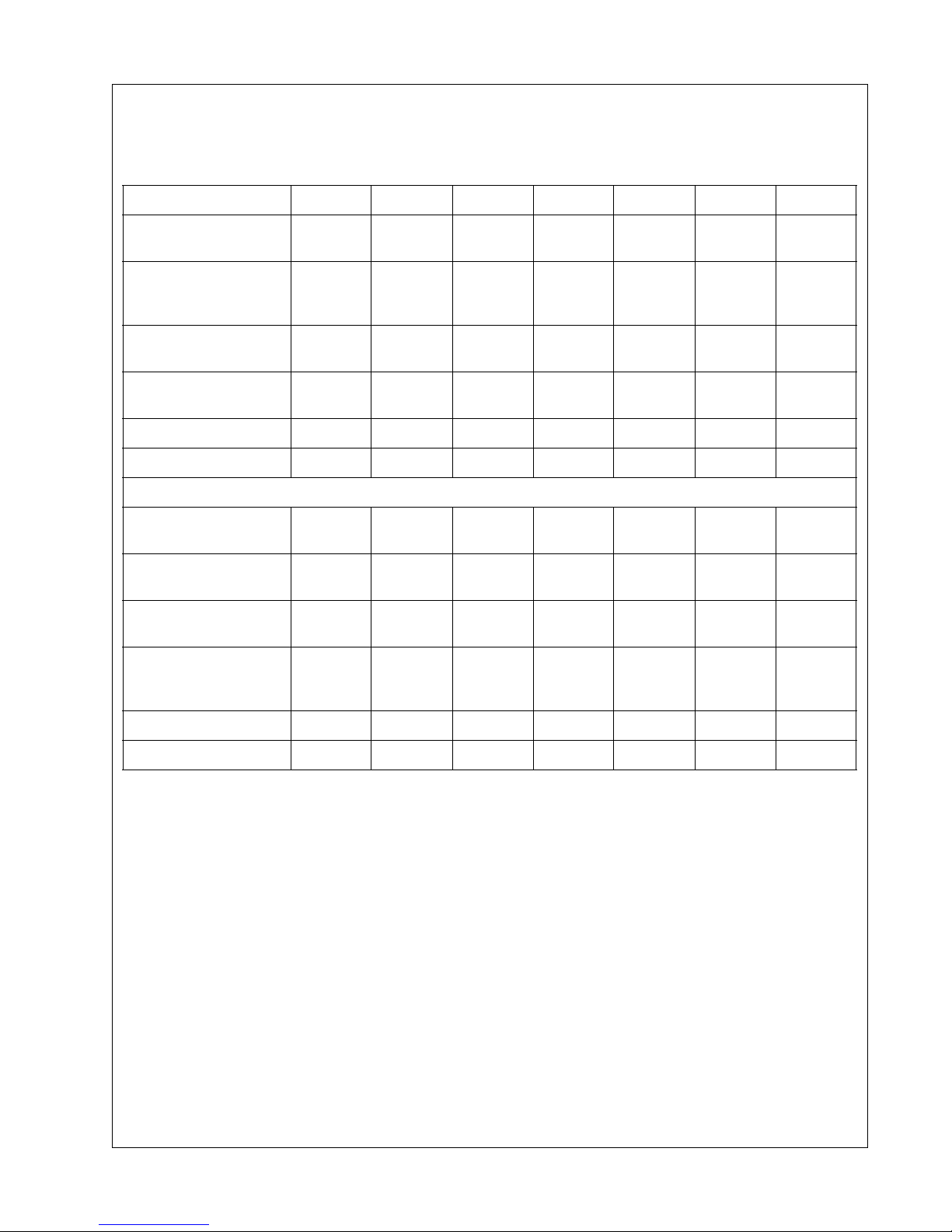

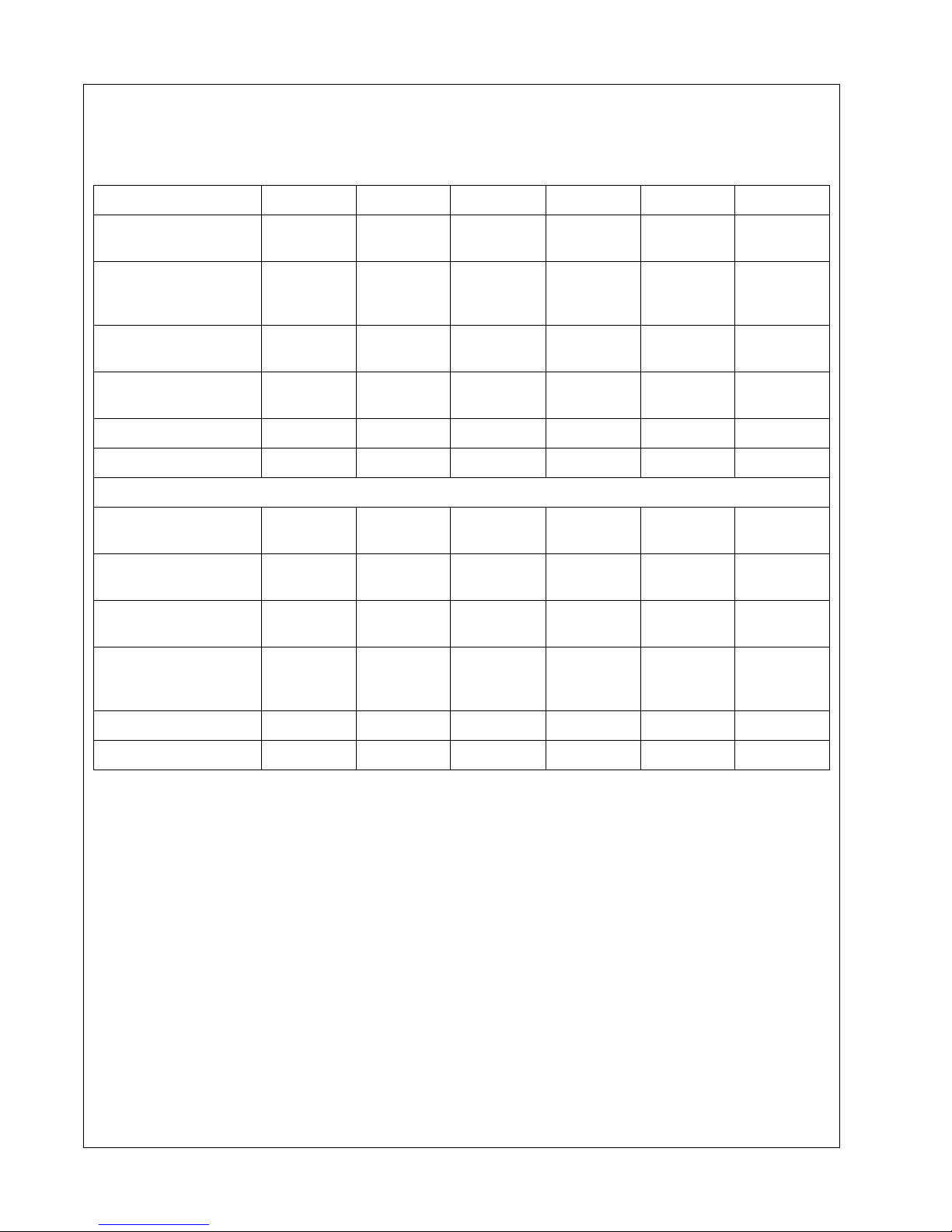

Operation & Maintenance Manual General Data

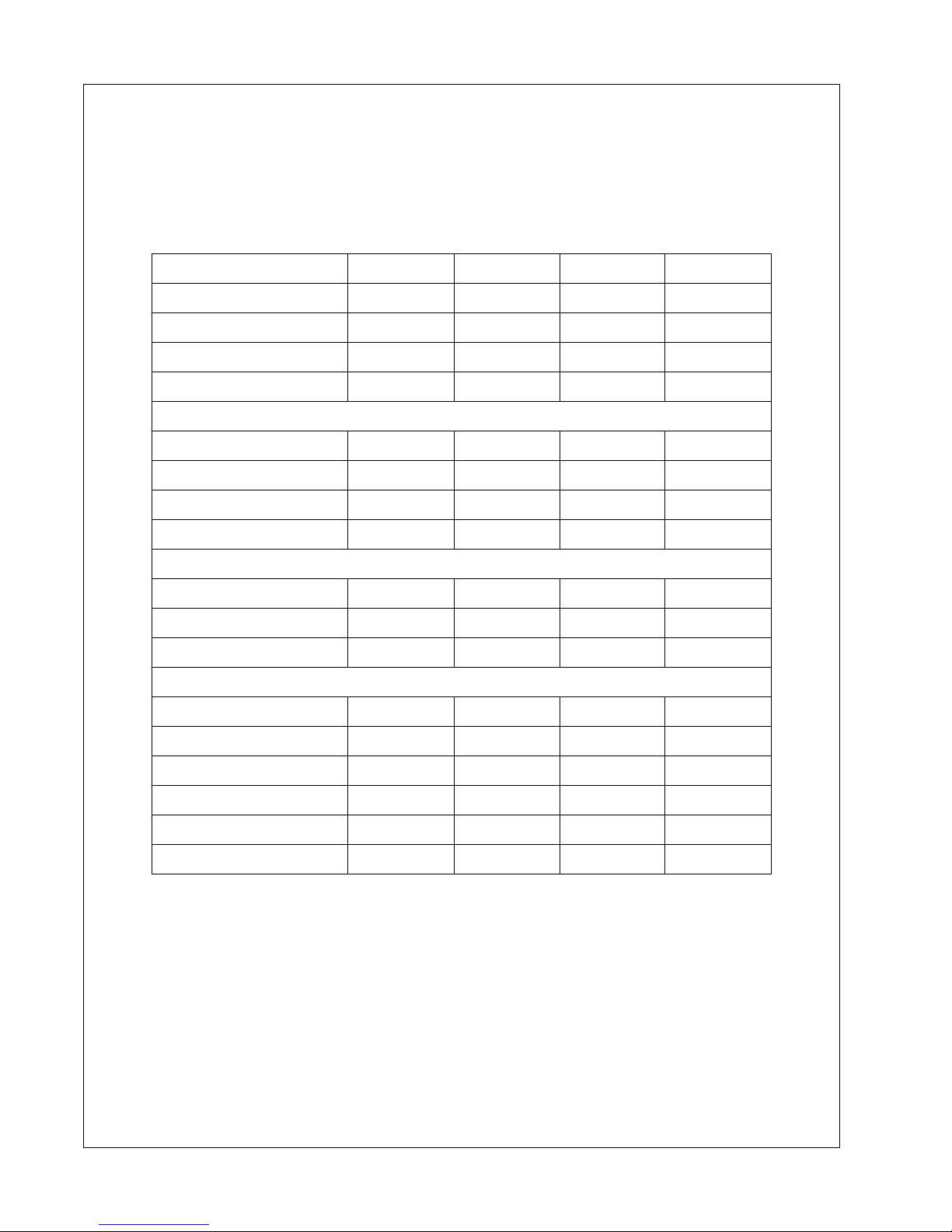

General Data

Unit Model:

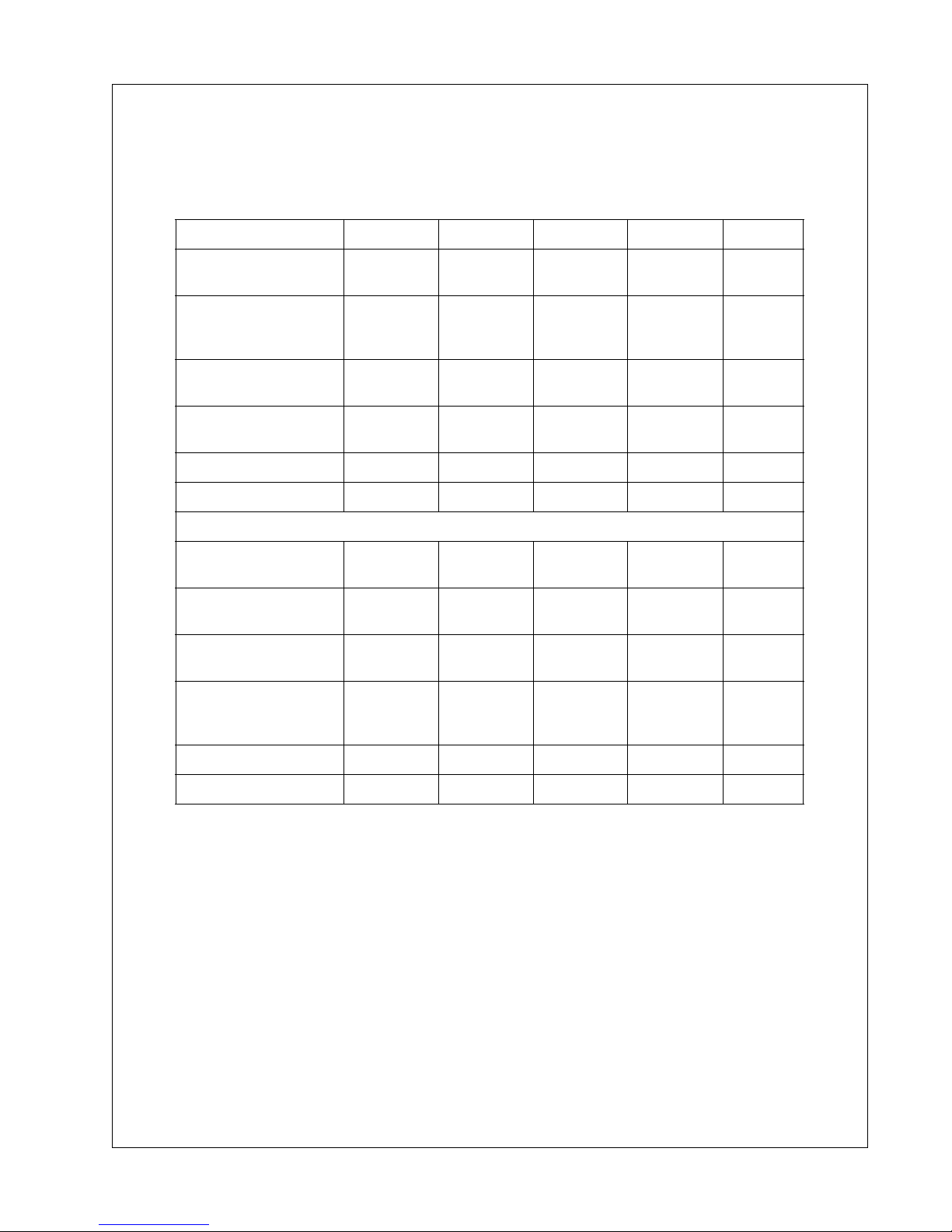

UNIT MODEL G10A G25B, G25C G40B, G40C G60

Engine Speed - RPM 1800 1800 1800 1800

ENGINE Diesel Diesel Diesel Diesel

Manufacturer IR IR IR JD

Model 3IRL2N 4IRQ2N 4IRS2N 5030TF270

FLUID CAPACITIES

Engine Crankcase Lubricant .98 1.7 gal 2.64 gal 2.96 gal

Fuel Tank 21 36 gal 47 gal 103 gal

Radiator & Engine Coolant 2.0 4 gal 5 gal 6 gal

Electrical System 12VDC 12VDC 12VDC 12VDC

RUNNING GEAR

Tire Size ST175/80D13 ST205/75D15 ST205/75D15 ST205/75D15

Inflation Pressure (Cold) 50 psi 50 psi 50 psi 50 psi

Towing Speed (Maximum) 65 mph 65 mph 65 mph 65 mph

UNIT MEASUREMENTS/ WEIGHTS (w/running gear)

Overall length (inches) 121 131 143 156

Overall width (inches) 56 60 66 69

Overall height (inches) 43 67 72 85

Track width (inches) 48 50 56 60

Weight (with fuel) 1708 lbs 2588 lbs 3508 lbs 4658 lbs

Weight (less fuel) 1529 lbs 2420 lbs 3078 lbs 3895 lbs

22 22637300

General Data Operation & Maintenance Manual

Unit Model:

UNIT MODEL G70A G80A G90A G125 G145B G185

Engine Speed - RPM 1800 1800 1800 1800 1800 1800

ENGINE Diesel Diesel Diesel Diesel Diesel Diesel

Manufacturer JD JD JD JD JD JD

Model 4045

TF285E

FLUID CAPACITIES

Engine Crankcase Lubricant 3.57 gal 3.57 gal 3.57 gal 3.57 gal 3.57 gal 8.59 gal

Fuel Tank 103 gal 103 gal 190 gal 145 gal 190 gal 255.3 gal

Engine Coolant Only 6 gal 6 gal 3.1 gal 5.3 gal 3.1 gal 3.1 gal

Electrical System 12VDC 12VDC 12VDC 12VDC 12VDC 12VDC

RUNNING GEAR

Tire Size ST205/

75D15

Inflation Pressure (Cold) 50 PSI 50 PSI 50 PSI 50 psi 50 psi 50 psi

Towing Speed (Maximum) 65 mph 65 mph 65 mph 65 mph 65 mph 65 mph

UNIT MEASUREMENTS/ WEIGHTS (w/running gear)

Overall length (inches) 156 156 165 166 166 204

Overall width (inches) 69 69 71 72 72 76

Overall height (inches) 85 85 84 80 84 95

Track width (inches) 60 60 63 64 63 61.7

4045

TF275

ST205/

75D15

4045

HF285

ST205/

75D15

6068

TF275-123

ST205

75D15

4045

HF485

ST205

75D15

6068

HF285

9.50-16.5

LT/E

Weight (with fuel) 5105 lbs 5174 lbs 6466 lbs 5632 lbs 7220 lbs 9166 lbs

Weight (less fuel) 4435 lbs 4478 lbs 5004 lbs 4518 lbs 5758 lbs 7205 lbs

22637300 23

Operation & Maintenance Manual General Data

Unit Model:

UNIT MODEL G240 G290 G450 G570

Engine Speed - RPM 1800 1800 1800 1800

ENGINE Diesel Diesel

Manufacturer JD Cummins Cummins Cummins

Model 6068HF485 QSL9G3 QSX15 QSX15

FLUID CAPACITIES

Engine Crankcase Lubricant

(gal)

Fuel Tank (gal) 255.3 gal 389.5 gal 652 652

Engine Coolant Only (gal) 3.1 gal 2.91 gal 15 15

Electrical System VDC 12VDC 24VDC 24VDC 24VDC

RUNNING GEAR

Tire Size 9.50-16.5 LT/E 9.50-16.5 LT/E 9.50 -16.5 LT/E 9.50 -16.5 LT/E

Inflation Pressure (Cold) psi 50 PSI 50 PSI 75 75

Towing Speed (Maximum) 65 mph 65 mph 65 mph 65 mph

UNIT MEASUREMENTS/ WEIGHTS

Overall length (in/mm) 204 221 261/6626 261/6626

Overall width (in/mm) 76 78 86/2181 86/2181

Overall height (in/mm) 95 111 120/3042 120/3042

Track width (in/mm) 65 68.5 74/ 74/

Weight (with fuel) lbs 9678 lbs 11,957 lbs 18271 18573

Weight (less fuel) lbs 7717 lbs 8989 lbs 13868 14170

8.59 gal 7 gal 24 24

24 22637300

General Data Operation & Maintenance Manual

Consumables Service Parts:

For Models: G10A G25B G40B G60 G 70A G80A G125

Air Cleaner Element

(Engine) primary

Air Cleaner Element

(Engine) secondary optional

Engine Oil Filter

Element

Fuel Water Separator

Element

Engine Fuel Element 85426815 85426823 22712475 22556138 22969257 22206197 22206197

Inline Fuel Filter NA NA NA NA NA NA NA

MAINTENANCE KITS

250 hour Maintenance

Kit (without fluids)

250 hour Maintenance

Kit (& engine fluids)

500 hour Maintenance

Kit (without fluids)

500 hour Maintenance

Kit (& Engine fluids

fluids)

36890135 35393685 35393685 54471834 54471834 54471834 54717145

NA NA NA NA 54471842 NA 54717152

85426849 85426856 22712467 22545867 22206148 22206148 22206148

54525530 54525530 54525530 54525530 22969265 54525530 54468178

44003929 44003945 44000404 44003960 44029098 44003986 44003986

44003648 44003663 44000388 44003705 44029072 44003721 44003747

44003937 44003952 44000412 44003978 44029106 44003994 44004000

44003655 44003671 44000396 44003713 44029080 44003739 44003754

Protec Eng Fluid - 5 gal 54480918 54480918 54480918 54480918 54480918 54480918 54480918

Protec Eng Fluid -1 gal 36875938 36875938 36875938 36875938 36875938 36875938 36875938

22637300 25

Operation & Maintenance Manual General Data

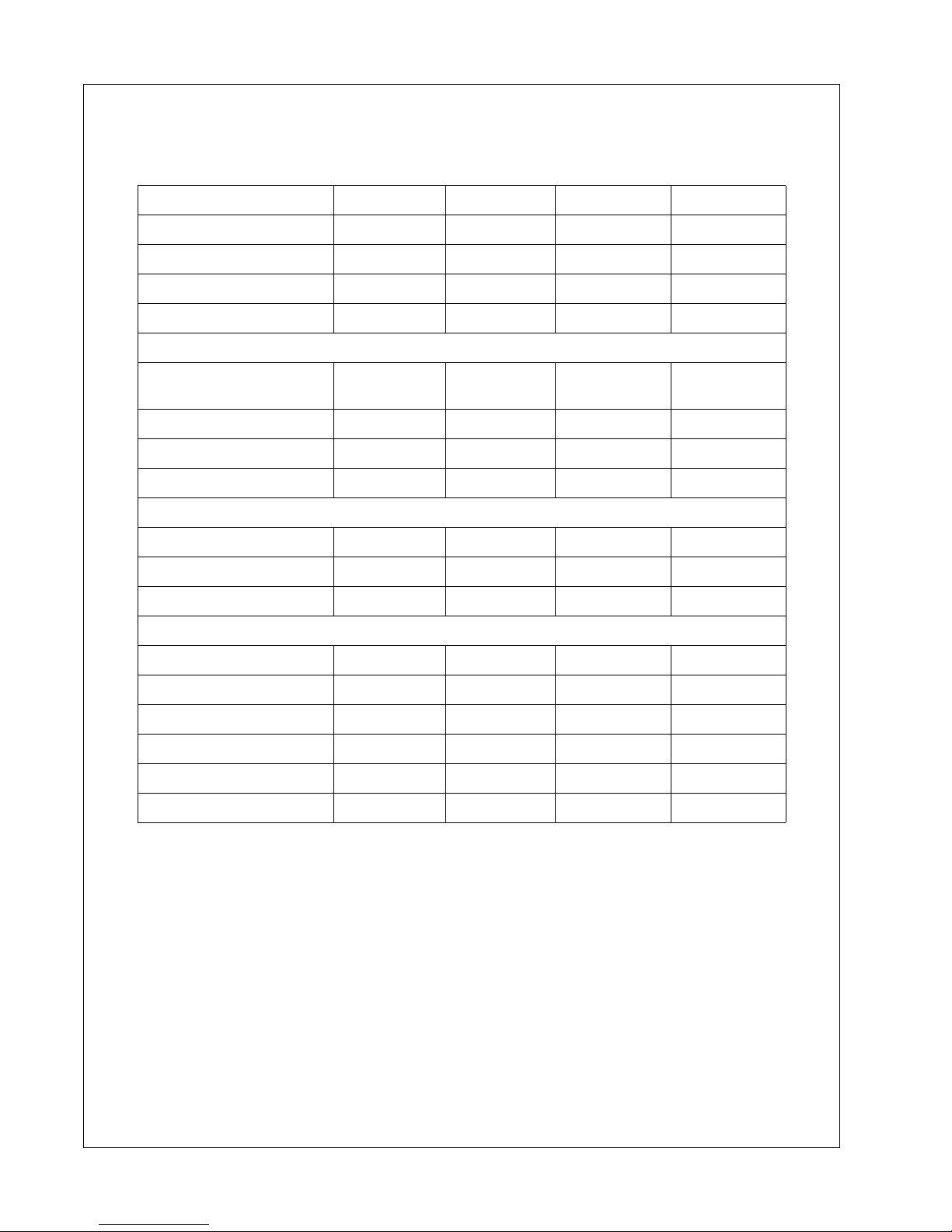

Consumable Service Parts:

For Models: G450 G570

Air Cleaner Element

(Engine) primary

Air Cleaner Element

(Engine) secondary optional

Engine Oil Filter

Element

Fuel Water Separator

Element

Engine Fuel Element 54662036 54662036

MAINTENANCE KITS

250 hour Maintenance

Kit (without fluids)

250 hour Maintenance

Kit (& engine fluids)

500 hour Maintenance

Kit (without fluids)

500 hour Maintenance

Kit (& Engine fluids

fluids)

36864361 36864361

36864379 36864379

54662028 54662028

22201396 22201396

44020279 44020295

44020212 44020238

44020287 44020303

44020220 44020246

Protec Eng Fluid - 5 gal 54480918 54480918

Protec Eng Fluid -1 gal 36875938 36875938

26 22637300

General Data Operation & Maintenance Manual

Expendable Service Parts:

For Models: G90A G145B G185 G240 G290

Air Cleaner Element

(Engine) primary

Air Cleaner Element

(Engine) secondary optional

Engine Oil Filter

Element

Fuel Water Separator

Element

Engine Fuel Element 22206197 22 969257 22969257 22969257 22765325

MAINTENANCE KITS

250 hour Maintenance

Kit (without fluids)

250 hour Maintenance

Kit (& engine fluids)

500 hour Maintenance

Kit (without fluids)

500 hour Maintenance

Kit (& Engine fluids

fluids)

54471834 54717145 54717145 22119168 89288971

NA 54717152 54717152 22119176 89288989

22206148 22206148 22206148 22206148 22177737

54525530 22969265 22969265 22969265 22637904

TBD 44016038 44016038 44016038 44020253

TBD 44016004 44016004 44016004 44020196

TBD 44016046 44016046 44016020 44020261

TBD 44016012 44016012 44016053 44020204

Protec Eng Fluid - 5 gal TBD 54480918 54480918 54480918 54480918

Protec Eng Fluid -1 gal TBD 36875938 36875938 36875938 36875938

22637300 27

28 22637300

Operating Instructions

22637300 29

Operation & Maintenance Manual Operating Instructions

Operating Instructions

Never operate unit without first observing all safety warnings and carefully reading the

operation and maintenance manual shipped from the factory with this machine.

BEFORE TOWING

!

WARNING

Failure to follow these instructions can cause severe injury or death.

!

CAUTION

- Position the tow vehicle to align its hitch with the pintle eye or coupler.

- Engage the parking brake and chock the wheels of the tow vehicle.

- Stand to the side and ensure pin is FULLY inserted (secure) in tube of

jack.

- Crank jack to lower pintle eye coupler onto the hitch and to raise foot off

the ground. Pull pin from tube of jack. Fold jack handle down and forward.

Swing up jack tube and FULLY insert pin in tube.

- Connect machine towing lights to tow vehicle.

- Remove chocks from tow vehicle wheels.

Steps for determining correct load limit -

1. Locate the statement “The weight of cargo should never exceed xxx kg or xxx lbs” on

your vehicle’s placard.

2. This figure equals the available amount of cargo and luggage load capacity.

3. Determine the combined weight of luggage and cargo being loaded on the vehicle.

That weight may not safely exceed the available cargo and luggage load capacity.

30 22637300

Loading...

Loading...