Page 1

1Electrical System

Page 2

Page 3

SP001038

ELECTRICAL SYSTEMSP001038

Electrical

System

Edition 1

Electrical System

SP001038

Page 1

Page 4

MEMO

Electrical System

Page 2

SP001038

Page 5

SP001038

Page 3

Electrical System

Table of Contents

Electrical System

Safety Precautions ............................................... 7

Applicable Models ................................................ 7

Introduction........................................................... 9

Electrical Supply System .................................... 10

Engine Starting Circuit........................................ 12

Start Operation .............................................................. 12

After Start ...................................................................... 14

Engine Preheating System ................................. 16

Engine Stop ........................................................ 18

Charging System ................................................ 20

Monitoring System.............................................. 21

Instrument Panel ........................................................... 22

Monitoring System Schematic....................................... 24

Operation............................................................ 26

Instruments.................................................................... 26

Warning and Indicator Lights.............................. 28

Indication of Warning Lights .......................................... 28

Indication of Multifunction Gauge and

Letter Information Area.................................................. 29

Initial Operation .................................................. 31

Mode Selector Switch......................................... 31

Graphic Information Area Display....................... 32

Overview ....................................................................... 32

Main Menus for the Graphic Display Area..................... 33

Menu Selector Buttons .................................................. 33

Main Menu.......................................................... 34

Language ...................................................................... 34

Set Clock ....................................................................... 35

Filter/Oil Info .................................................................. 35

Adjust Display................................................................ 36

Page 6

SP001038

Electrical System

Page 4

Set Password ................................................................ 37

Special Menu...................................................... 38

Entering/Accessing and Exiting/Escaping Menus ......... 38

Special Menu Selections ............................................... 39

Electronic Hydraulic Control System (e-EPOS).. 56

Control System Schematic ............................................ 56

Power Mode Control........................................... 58

Operation ....................................................................... 60

Power Mode Control - Circuit Diagram............... 62

Work Mode Control............................................. 64

Operation ....................................................................... 65

Work Mode Control - Circuit Diagram................. 66

Engine Control System....................................... 67

Engine Control Dial............................................. 68

Engine Control Circuit Diagram .......................... 69

Automatic Deceleration Control

(Auto Idle Control) .............................................. 70

Engine Overheat Protection System .................. 72

Power Boost Mode ............................................. 74

Operation ....................................................................... 74

Power Boost Control - Circuit Diagram ......................... 76

Automatic Travel Speed Control......................... 78

Automatic Travel Speed Control - Circuit Diagram ....... 80

Self-diagnostic Function .....................................81

e-EPOS Controller......................................................... 81

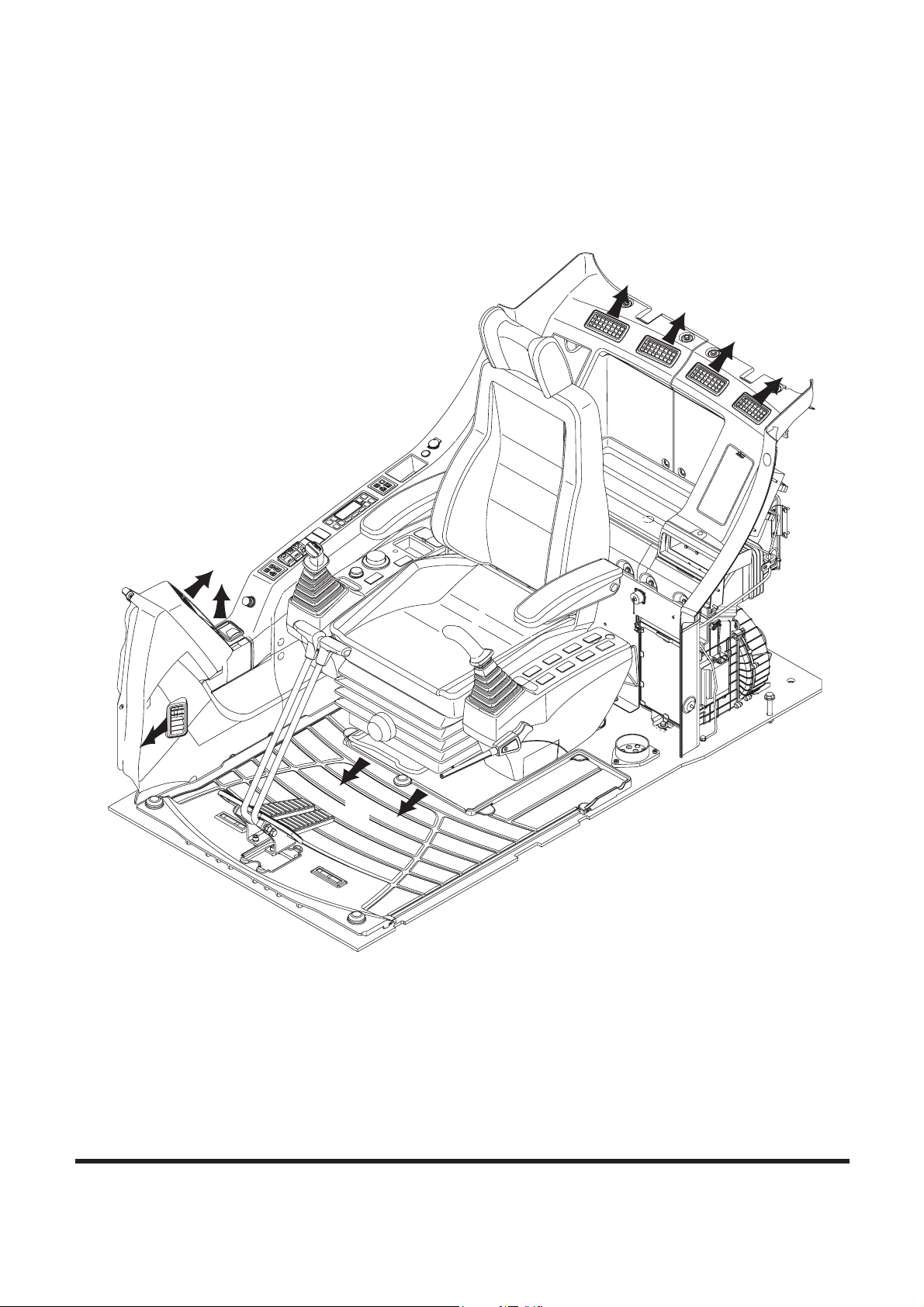

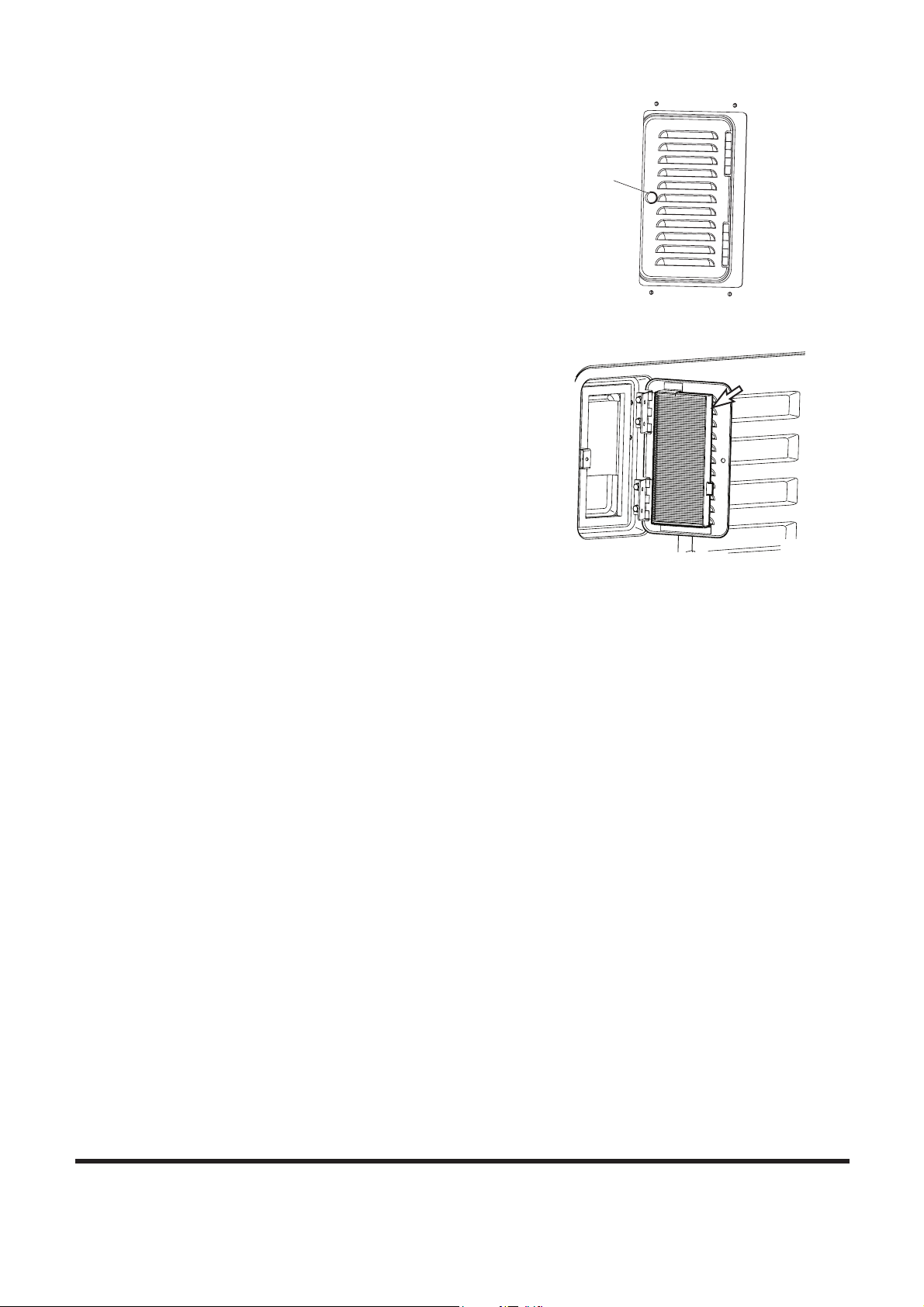

Air Conditioner System....................................... 83

Outline ........................................................................... 83

Internal and External Filters .......................................... 84

Air-Conditioning System Layout .................................... 86

Air Conditioner/heater Circuit Diagram.......................... 87

Air Conditioner/heater Unit ............................................ 88

Ambient Air Temperature Sensor .................................. 93

Page 7

SP001038

Page 5

Electrical System

Sun Sensor.................................................................... 94

Control Panel................................................................. 94

Compressor ................................................................. 102

Receiver Dryer ............................................................ 102

Troubleshooting................................................ 103

Weight of R134a Gas Used In Machines ......... 105

Refrigerant System Repairs ............................. 106

Refrigerant Safe Handling Procedures........................ 106

Repair and Replacement Procedure ........................... 107

Refrigerant Recovery .................................................. 109

Vacuuming Refrigerant System................................... 109

Leakage Check ........................................................... 111

Refrigerant Charging ................................................... 111

Inspecting System For Leakage .................................. 113

Wiper System ................................................... 114

Wiper Circuit................................................................ 114

Wiper operation ........................................................... 115

Lighting System ................................................ 118

Lighting System Circuit Diagram ................................. 118

Kind of Light ................................................................ 119

Operation ..................................................................... 119

Audio Controller................................................ 120

Audio Controller Circuit Diagram................................. 120

Page 8

MEMO

Electrical System

Page 6

SP001038

Page 9

SP001038

Page 7

Electrical System

SAFETY PRECAUTIONS

APPLICABLE MODELS

The contents of this section apply to the following models and

serial number ranges.

CAUTION!

Follow all safety recommendations and safe shop practices

outlined in the front of this manual or those contained

within this section.

Always use tools and equipment that are in good working

order.

Use lifting and hoisting equipment capable of safely

handling load.

Remember, that ultimately safety is your own personal

responsibility.

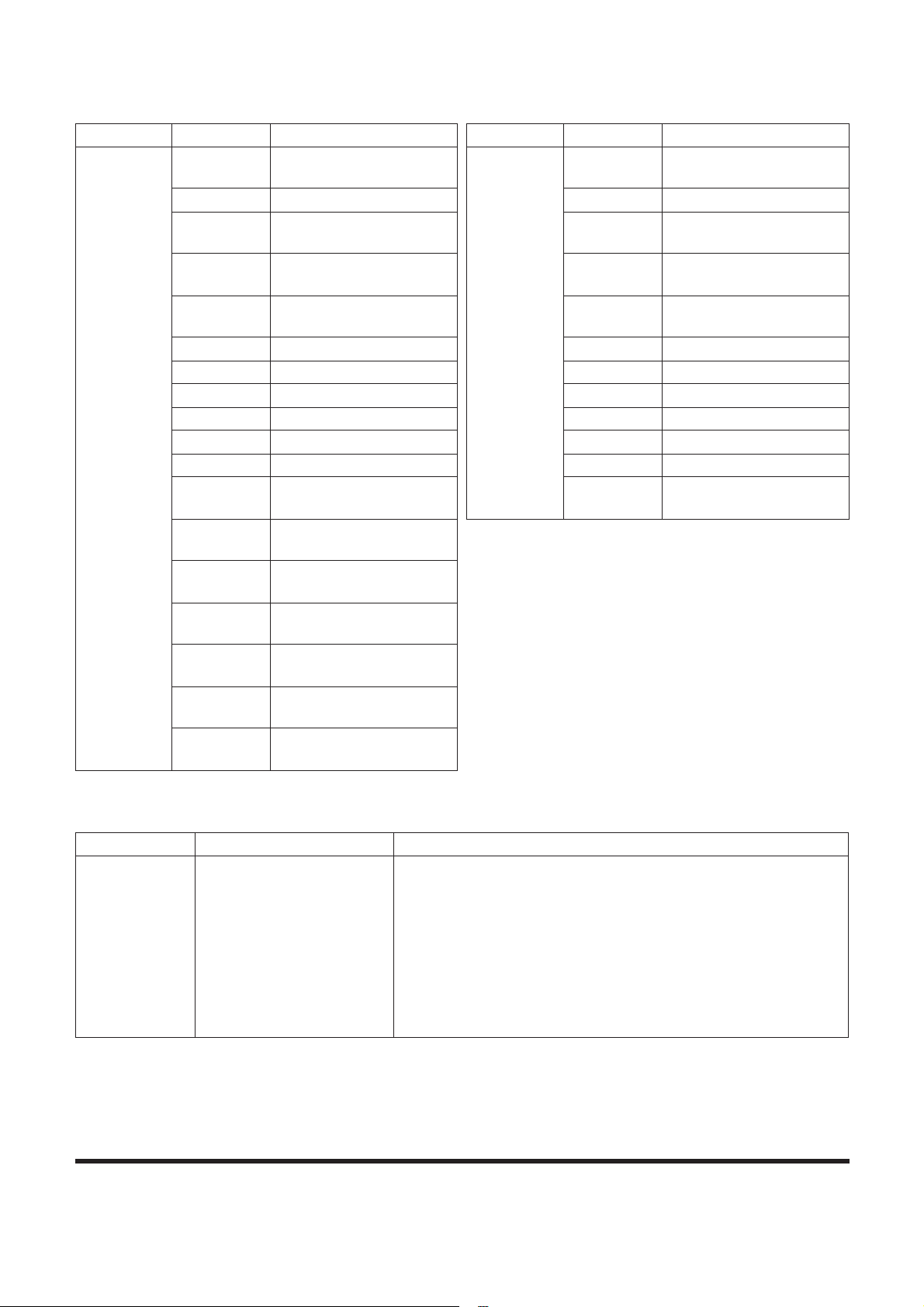

MODEL SERIAL NUMBER RANGE

DX140LC 5001 and Up

DX180LC 5001 and Up

Page 10

Page 8

SP001038Electrical System

Page 11

SP001038

Page 9

Electrical System

INTRODUCTION

The electrical system for this equipment is DC 24 volts. The

rated voltage for all electric components is 24 volts with the

exception of the stereo and the air-conditioning control actuator.

The system contains two 12 volt batteries connected in series

and a three phase AC generator with a rectifier. The electric

wiring used in the system is easily identifiable by the insulator

color. The color symbols used in the electrical system are listed

in the following chart.

Electric Wire Color

NOTE: RW: Red wire with White stripe

R - Base Color, W - Stripe Color

NOTE: 0.85G: Nominal sectional area of wire core less

insulator = 0.85 mm

2

Symbol Color

W White

G Green

Or Orange

B Black

L Blue

Lg Light green

R Red

Gr Gray

P Pink

Y Yellow

Br Brown

V Violet

Page 12

SP001038Electrical System

Page 10

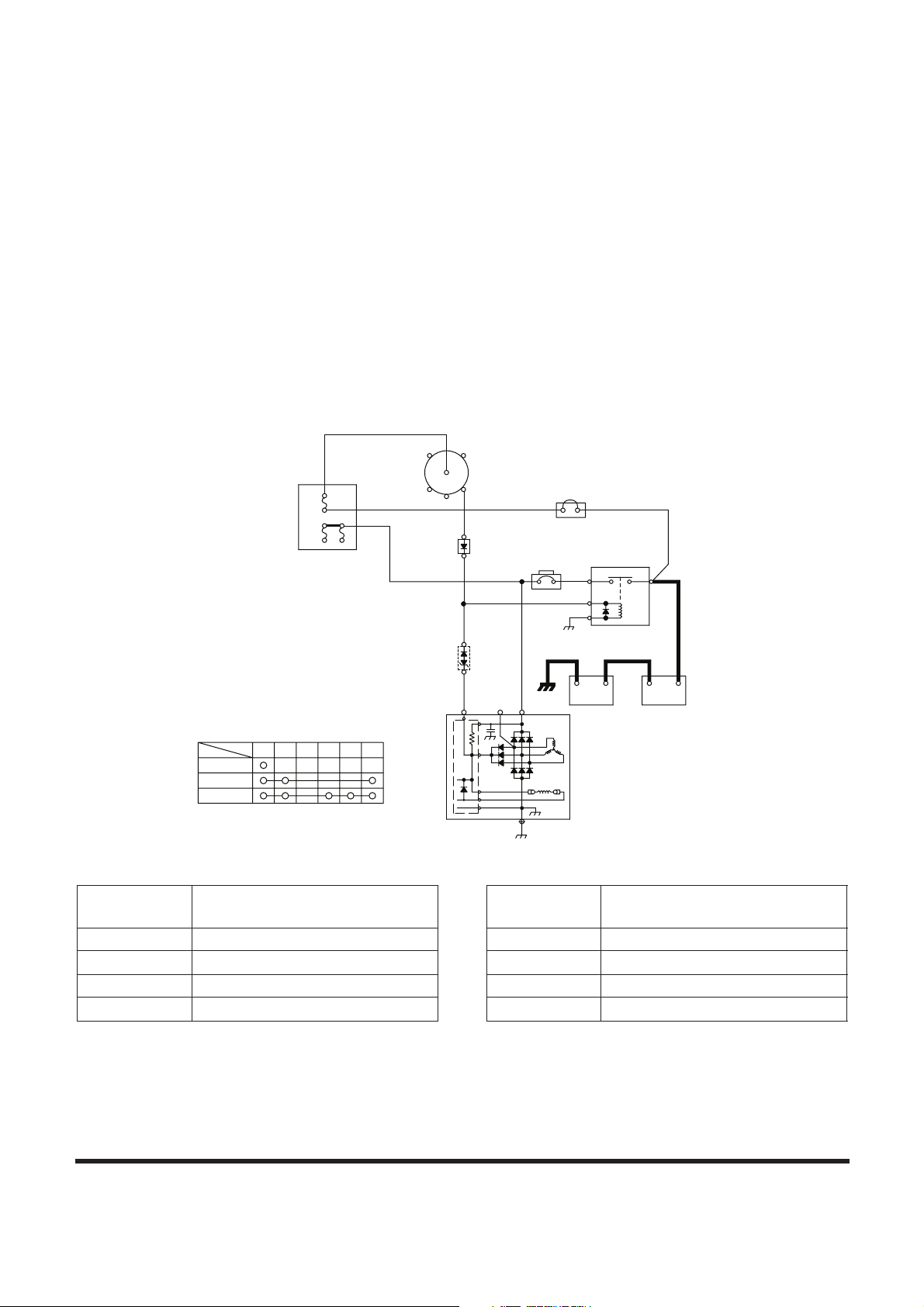

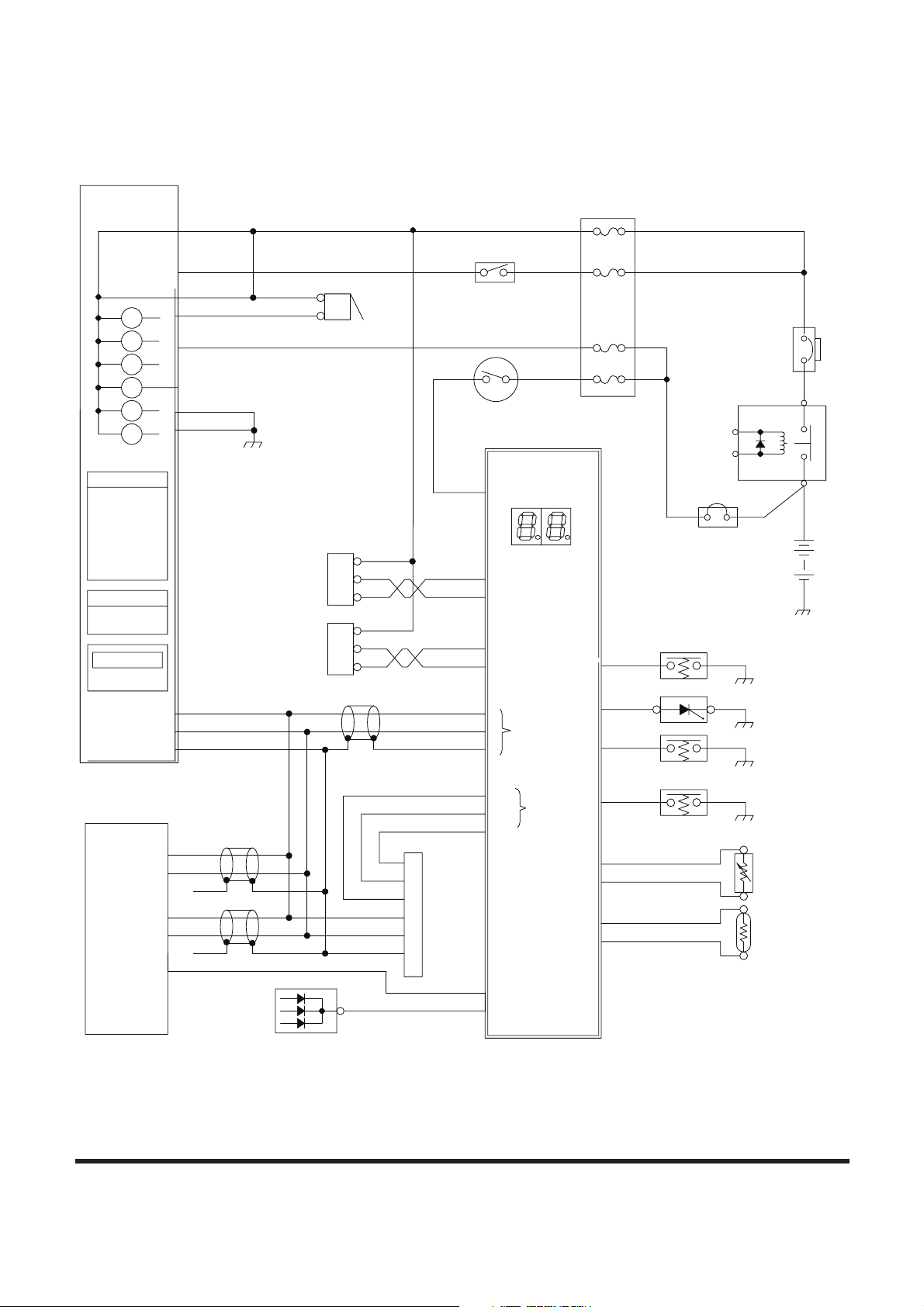

ELECTRICAL SUPPLY SYSTEM

The electric power circuit supplies electric current to each

electric component. It consists of a battery, battery relay, starter

switch, circuit breaker, fusible link and fuse box.

The negative terminal of the battery is grounded to the vehicle

body.

Even when the starter switch (5) is in the "OFF" position, electric

current is supplied to the following components through battery

(1) o fusible link (3) o fuse box (6).

1. Terminal "1" of DC-DC converter (for memory backup of

stereo)

2. Terminal "B" of starter switch

3. Hour meter

4. Engine controller

5. Fuel feeder pump switch

6. Terminal "6" of wiper motor

7. Terminal "13" of wiper controller

8. Terminal "CN6-11" of instrument panel

9. Terminal "CN9-6" of air conditioner panel

10. Cabin light

When the starter switch (5) is in the "ON or START" positions,

the current flows from the battery (1) o fusible link (3) o fuse

box (6) o "B" terminal of starter switch (5) o "BR" terminal of

starter switch (5) o "BR" terminal of battery relay (2) which

activates the coil of the battery relay and the electric supply

system is energized.

When the battery relay's contacts are connected, all electric

devices can be operated.

While the engine is not running, the electric power for all electric

devices are supplied by the battery. Once the engine is started

the power is supplied from the alternator (7).

Page 13

SP001038

Page 11

Electrical System

TRIO DIODE

0.5 uF

8

START

ON

OFF

STARTER SWITCH CONNECTION

TML

PST

B BR R1 R2 C ACC

F+

F-

E

REG.

I(L)

FIELD

GRD

7

12V 100AH

R(I)

P(R)

B+

8

B(B+)

-

E

BR

4

B

12V 100AH

1

+ - +

2

A

6

R2

ACC

R1

B

BR

C

5

0.5G

3

FG007233

Figure 1 ELECTRIC POWER CIRCUIT DIAGRAM

Reference

Number

Description

1 Battery

2 Battery Relay

3 Fusible Link

4 Circuit Breaker

5 Starter Switch

6 Fuse Box

7 Alternator

8 Diode

Reference

Number

Description

Page 14

SP001038Electrical System

Page 12

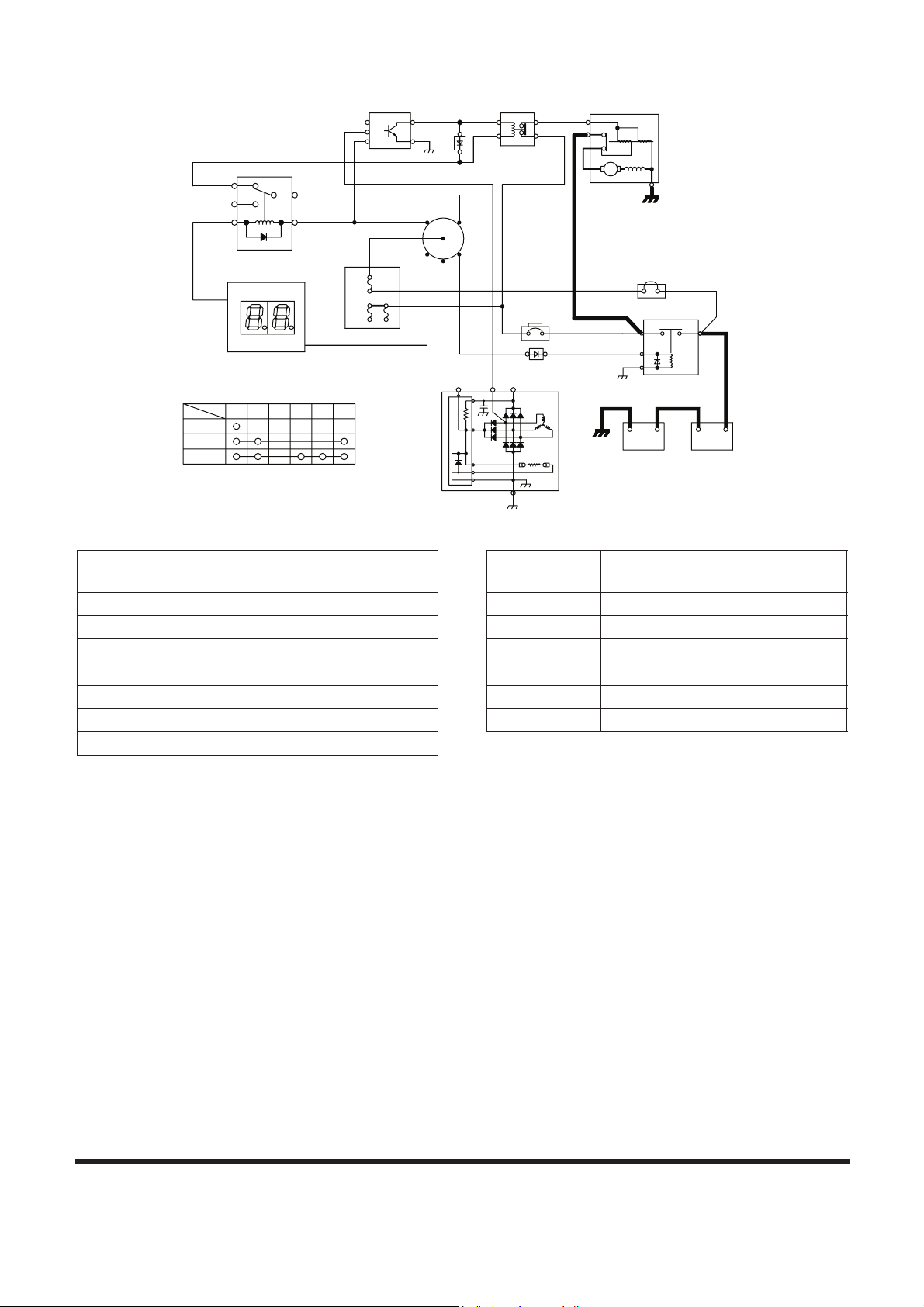

ENGINE STARTING CIRCUIT

Start Operation

When the starter switch is turned to the "START" position, the

"S" and "E" terminals of the starter controller (7) are connected.

At this time the contacts in the starter relay (8) are closed by the

current flow from the battery (1) o fusible link (3) ofuse box (6)

o "B" terminal of starter switch (5) o "C" terminal of starter

switch (5) o "30" terminal of starter relay (12) - "87a" terminal o

"C" terminal of starter relay (8) - "D" terminal o "S" terminal of

starter controller (7) - "E" terminal o ground.

When the contact point "B" and "PP" of starter relay (8) are

connected, the pinion gear of the starter (9) is pushed forward

and makes contact with the ring gear of the flywheel and the

internal contacts of the starter are connected. The current flows

from the battery (1) o "A" terminal of the battery relay (2) o "B"

terminal of the battery relay (2, Figure 3) o "B" terminal of the

starter (9). The starter motor is rotated and the engine is started.

If the instrument panel has the password function activated ,

input number should match the set number, otherwise the start

circuit closes and the engine does not start.

NOTE: If the security system is "LOCKED," a four-digit

password will be required to start the engine. If the

system is "UNLOCKED," no password will be

required and this display screen will not appear.

In the event the security system is locked, current

flows from battery (1)

o

fusible link (3) ofuse box

(6)

o

"B" terminal of starter switch (5) o "ACC"

terminal of starter switch (5)

o

"86" terminal of starter

relay (12)

o

"85" terminal of starter relay (12)

o

"CN1-15" terminal of e-EPOS (13) o ground. This

current flow causes the coil in starter relay (12) to be

activated, opening contacts at "87a" terminal. This

prevents starter relay (8) from functioning.

C

H

C

E

F

H

02/05 [MO] 11:30

E/G SPEED

0

RPM

FG001445

ENTER

PASSWORD

Figure 2

Page 15

SP001038

Page 13

Electrical System

TRIO DIODE

0.5 uF

CN1-15

TML

STARTER SWITCH CONNECTION

ON

START

OFF

PST

F-

E

GRD

R2BRB R1 ACCC

13

CN2-1

6

P(R)

R(I)

B(B+)

REG.

I(L)

F+

FIELD

B+

11

4

12

85 86

30

87a

87

P

N

B

C

BR

R2

R1

ACC

B

5

E

S

11

D

C B

PP

7 8

2

-10+ -

1

BR

E

B

A

+

3

A

B

C

9

FG007234

Figure 3 STARTER CIRCUIT (1) - WHILE STARTING

Reference

Number

Description

1 Battery

2 Battery Relay

3 Fusible Link

4 Circuit Breaker

5 Starter Switch

6 Fuse Box

7 Starter Controller

8 Starter Relay

9 Starter

10 Alternator

11 Diode

12 Starter Relay 2

13 e-EPOS Controller

Reference

Number

Description

Page 16

SP001038Electrical System

Page 14

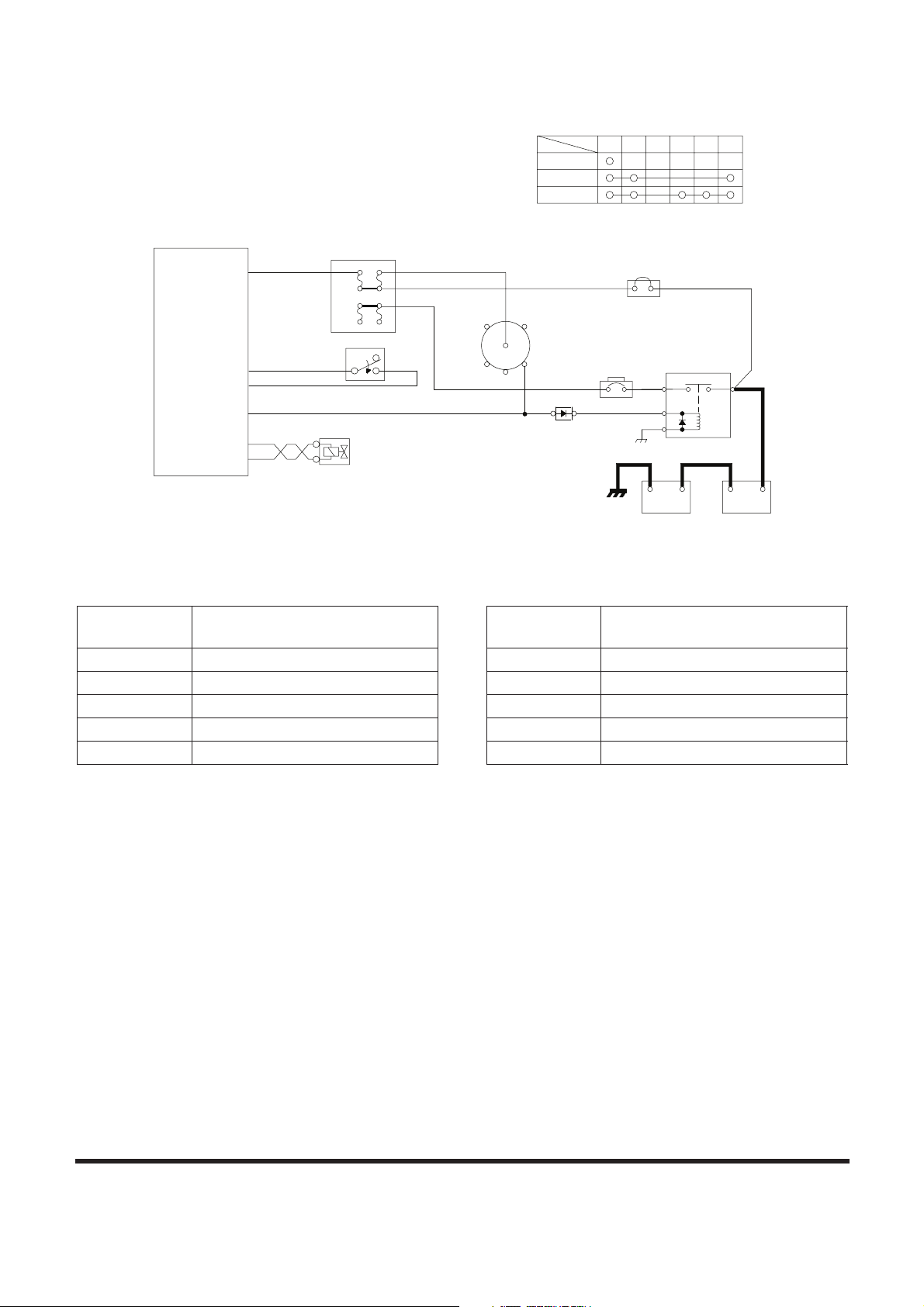

After Start

Once the engine has been started, the belt driven alternator (10)

generates a current.

The output generated by the alternator (10) is a square wave

pulse voltage through the "P" terminal and the frequency of the

pulse voltage is proportional to the rotation of the alternator.

The starter controller (7) monitors the frequency of the output

current. Once the frequency is equivalent to 500 rpm, it is

sensed and the connection between "S" and "E" terminals and

the connection between "B" and "PP" terminals are opened. As

a result the rotation of the starter (9) is stopped. Once the engine

is running, the starter (9) will not operate even if the starter

switch (5) is moved to the start position, preventing possible

damage to the starter.

Page 17

SP001038

Page 15

Electrical System

Operation of the Start Circuit (2) - Immediately After Start

FG007237

TRIO DIODE

0.5 uF

ACC

85 86

STARTER SWITCH CONNECTION

ON

START

TML

OFF

PST

BRB

CN1-15

ACCR2R1 C

R2

CN2-1

R1

B

C

BR

87

87a

P

30

B

E

N

S

C B

D PP

+- + -

E

B

BR

A

B

A

C

12

13

10

6

11

4

5

7

11

8

1

2

3

9

F-

E

GRD

P(R)

R(I)

I(L)

REG.

F+

B+

B(B+)

FIELD

igure 4 OPERATION OF START CIRCUIT (2) - IMMEDIATELY AFTER START

Reference

Number

Description

1 Battery

2 Battery Relay

3 Fusible Link

4 Circuit Breaker

5 Starter Switch

6 Fuse Box

7 Starter Controller

8 Starter Relay

9 Starter

10 Alternator

11 Diode

12 Starter Relay 2

13 e-EPOS Controller

Reference

Number

Description

Page 18

SP001038Electrical System

Page 16

ENGINE PREHEATING SYSTEM

An air heater (8) is installed in the intake manifold of the engine.

When the starter switch (5) is turned "ON," the current flows

from the battery (1) o fusible link (3) o fuse box (6) o "B"

terminal of starter switch (5) o "BR" terminalof starter switch (5)

o "1-39" terminal of engine controller (12), causing current to

flow though "1-16" terminal of engine controller (12) o "C and

D" terminals of preheat relay (7) o "1-04" terminals of engine

controller (12) o ground.

This current flow causes the coil in preheat relay (7) to be

activated, closing contacts.

When the contacts of the preheat relay (7) are closed, the

heating coils of the air heating device (8) are heated by current

flowing from the battery (1) o battery relay (2) o preheat relay

(7) o air heater (8) o ground.

The duration of the heating cycle depends on the temperature of

engine coolant. The preheat indicator light in the instrument

panel (9) will turn "ON" during preheating cycle.

The preheat relay (7) is controlled by the engine controller (12)

and operates only at temperatures of 10°C (50°F) and below.

The longer the preheating period, the lower the temperature of

coolant is.

Page 19

SP001038

Page 17

Electrical System

(1)

12

1-07

1-13

D

+

H

ON

OFF

START

11

1-40

1-34,35

7

C

PREHEAT

L5

CN4-4,5,6

CN2-1

CN7-4,5,6

CN6-1,2

9

6

2

STARTER SWITCH CONNECTION

-

200A

B

TML

PST

B BR R1

-

1

+

R1

R2

ACC

B

C

BR

5

E

10

BR

B

ACCR2 C

- +

A

4

3

FG007137

Figure 5 ENGINE PREHEAT CIRCUIT

Reference

Number

Description

1 Battery

2 Battery Relay

3 Fusible Link

4 Circuit Breaker

5 Starter Switch

6 Fuse Box

7 Preheat Relay

8 Air Heater

9 Preheat Indicator Light

10 Diode

11 e-EPOS Controller

12 Engine Controller

Reference

Number

Description

Page 20

SP001038Electrical System

Page 18

ENGINE STOP

When starter switch (5) is turned "ON" the engine controller (8)

is activated. The engine controller monitors and controls the

engine including the injector solenoid (9). It controls the fuel

deliver rate and the injection timing for each cylinder.

NOTE: There is an individual injector solenoid (9) for each of

the six cylinders. Only one soleniod is shown in

Figure 7.

When starter switch (5) is turned "OFF," the engine controller

stops suppling power to the injector solenoid (9). This stops fuel

from being injexted into the engine cylinder, thus stopping the

engine.

In the event that the engine can be shut down using the starter

switch (5), an emergency stop switch (10) is provided to shut

down engine. To activate the emergancy stop switch, move it to

the "I" (EMERGENCY STOP) position.

The emergency stop switch (10) is in its "O" (OFF) position

during normal operation. The switch must be moved and held in

the "I" (EMERGENCY STOP) position until the engine stops.

When released it will automatically move back to the "O" (OFF)

position.

FG001344

O

I

Figure 6 ENGINE EMERGENCY STOP

SWITCH

Page 21

SP001038

Page 19

Electrical System

9

1

+- -+

2

1-19

1-45

1-39

8

0.5G

10

3

R2

4

R1

BR

7

ACC

5

B

C

BR

E

A

2

B

3

BR

STARTER SWITCH CONNECTION

6

START

ON

TML

OFF

PST

B ACCR1 R2 C

FG001473

Figure 7 ENGINE STOP CIRCUIT

Reference

Number

Description

1 Battery

2 Battery Relay

3 Fusible Link

4 Circuit Breaker

5 Starter Switch

6 Fuse Box

7 Diode

8 Engine Controller

9 Injector Solenoid

10 Emergency Stop Switch

Reference

Number

Description

Page 22

SP001038Electrical System

Page 20

CHARGING SYSTEM

When the starter switch (5) is turned to the "ON" position, an

initial excited current flows to the field coil of the alternator (7)

through the battery relay (2) and circuit breaker (4). When the

engine is started from this condition the alternator (7) starts

charging. The current flows from the "B(B+)" terminal of

alternator (7) o circuit breaker (4) o battery relay (2) obattery

(1).

The alternator also supplies electric current to other electrical

components. When the alternator (7) starts to operate, a current

flows from the "R(I)" terminal of alternator o diode (8) o battery

relay (2) coil securing a path for the charging current to the

battery (1). Thus preventing the possibility of a high voltage build

up and possible damage to the electric system.

TRIO DIODE

0.5 uF

8

START

ON

OFF

STARTER SWITCH CONNECTION

TML

PST

B BR R1 R2 C ACC

F+

F-

E

REG.

I(L)

FIELD

GRD

7

12V 100AH

R(I)

P(R)

B+

8

B(B+)

-

E

BR

4

B

12V 100AH

1

+ - +

2

A

6

R2

ACC

R1

B

BR

C

5

0.5G

3

FG007238

Figure 8 CHARGING CIRCUIT

Reference

Number

Description

1 Battery

2 Battery Relay

3 Fusible Link

4 Circuit Breaker

5 Starter Switch

6 Fuse Box

7 Alternator

8 Diode

Reference

Number

Description

Page 23

SP001038

Page 21

Electrical System

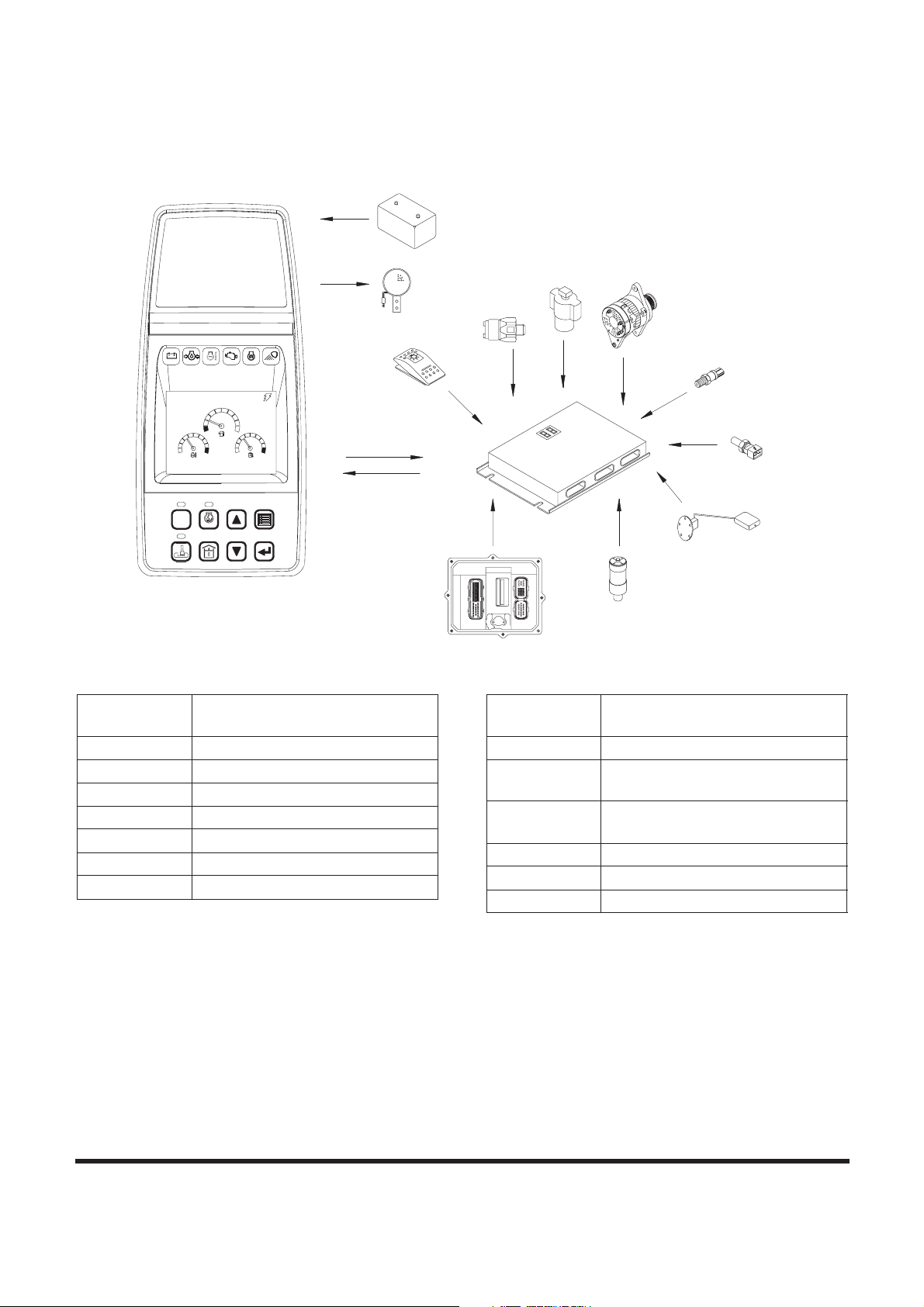

MONITORING SYSTEM

The monitoring system displays the various data and warning

signals onto the instrument panel by processing the information

gathered from the e-EPOS controller. It displays information

selected by the operator.

E

B

+

-

R

C

H

E

F

H

C

POWER

1

5

2

3

6

7

AUTO

4

ESC

8

E/G SPEED

02/05 [MO] 11:30

1700

RPM

CHECK

1

2

8

3

4

5

7

9

10

11

12

13

6

FG000547

Figure 9

Reference

Number

Description

1 Instrument Panel

2 Battery

3 Light Switch

4 Return Filter Switch

5 Pilot Filter Switch

6 e-EPOS Controller

7 Alternator

8 Warning Buzzer

9

Pump Discharge Pressure

Sensor

10

Hydraulic Oil Temperature

Sensor

11 Fuel Sensor

12 Air Cleaner Indicator

13 Engine Controller

Reference

Number

Description

Page 24

SP001038Electrical System

Page 22

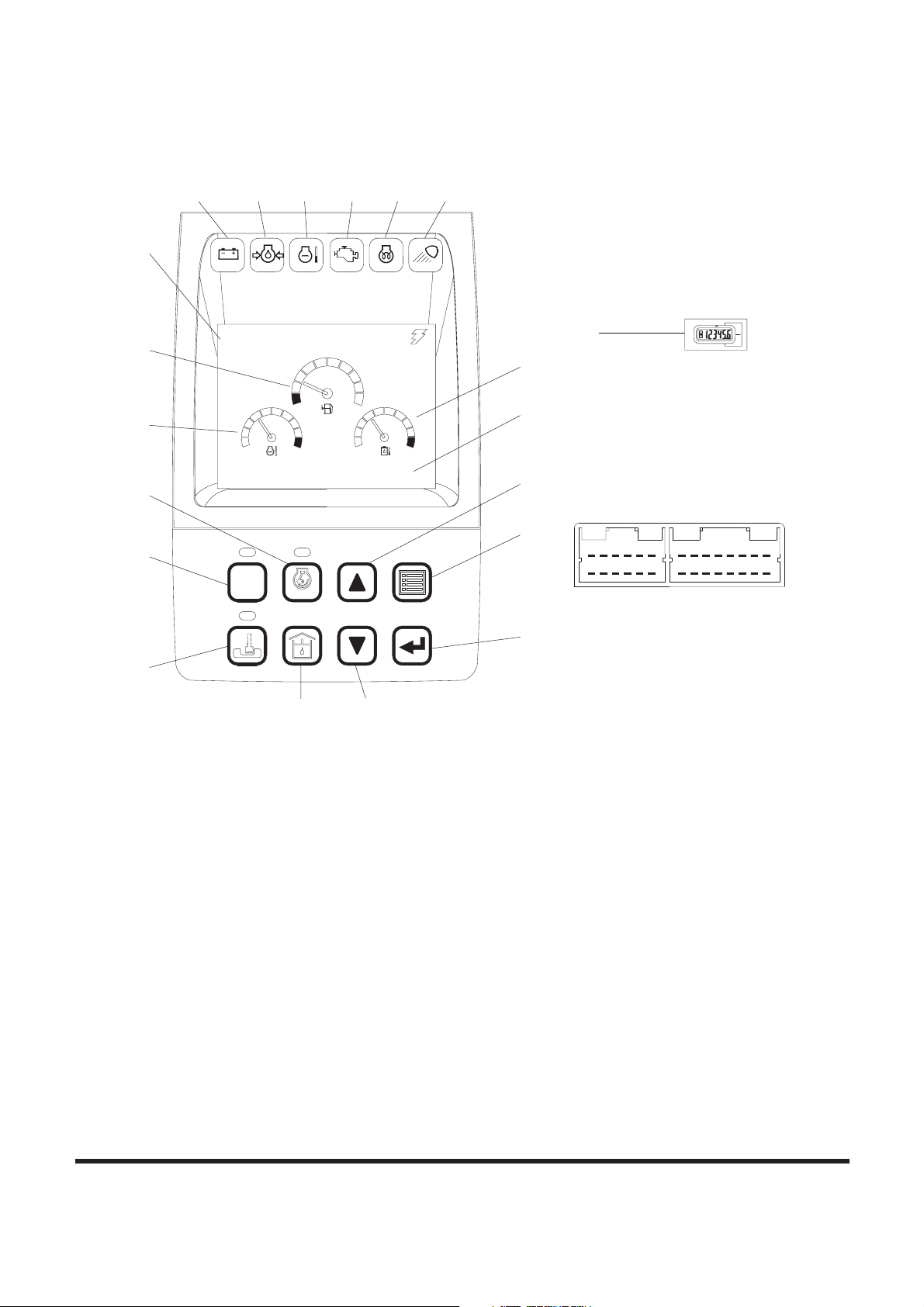

Instrument Panel

C

H

E

F

H

C

POWER

1

5

2

3

6

7

AUTO

4

ESC

8

FG000548

E/G SPEED

02/05 [MO] 11:30

1700

RPM

CHECK

7 8 9 10 11 12

5

1

2

15

13

14

3

6

4

17

19

20

16 18

(CN7)

< CONNECTOR AND TERMINAL NO.>

12

6 5114

10 14

8 7

1516

2 1

8 739 12

5 4 3 2 1

1011 9

6

13

(CN6)

AMP 040 28P

1

Figure 10

Page 25

SP001038

Page 23

Electrical System

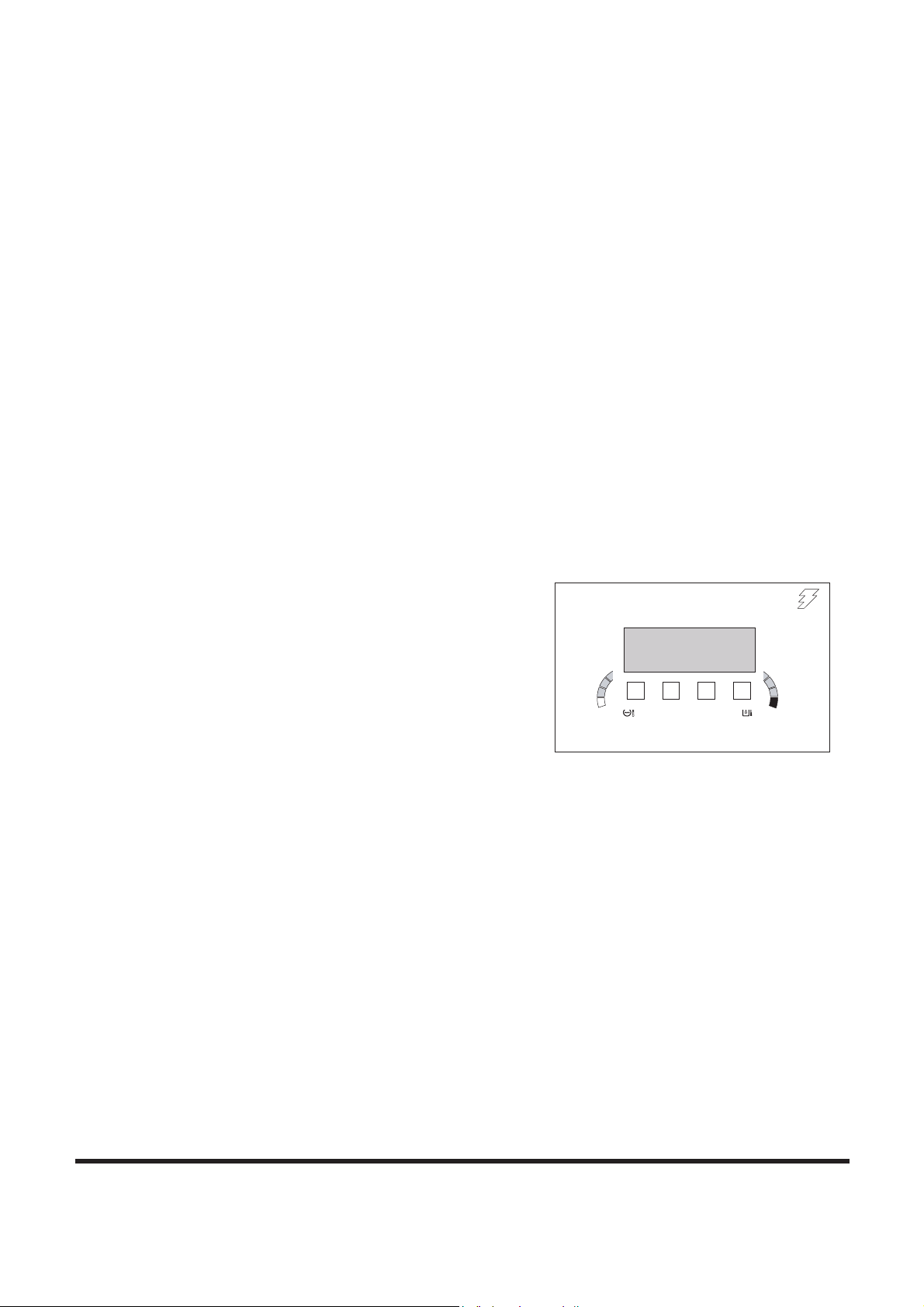

When the engine starter switch is turned to the "I" (ON) position,

all gauge bands, switch/button indicator lights and indicator/

warning lights will turn "ON" and the alarm buzzer will sound

about two seconds.

During this functional check, a LOGO will appear on the multi

function gauge in the graphic information area

Gauges Warning Lights Mode Selector Switches

1. Fuel Gauge

2. Engine Coolant Temperature

Gauge

3. Hydraulic Oil Temperature

Gauge

4. Multifunction Gauge and

Letter Information Area

5. Digital Clock

6. Hour Meter

7. Charge Warning Light

8. Engine Oil Pressure Warning

Light

9. Coolant Temperature

Warning Light

10. Engine Check Warning Light

11. Preheat Indicator Light

12. Work Light Indicator Light

13. Power Mode Selector Switch

and Indicator

14. Work Mode Selector Switch

and Indicator

15. Auto Idle Switch and

Indicator

16. Flow Adjusting Switch

17. Up Button Switch

18. Down Button Switch

19. Display Selector Switch

20. Selector Button Switch

Page 26

SP001038Electrical System

Page 24

Monitoring System Schematic

B

SIG

SIG

1-35

1-34

1-53

1-52

L5

L6

WARNING LAMP

L1 : CHARGE

L5 : PREHEAT

L2 : ENG OIL PRESS

L4 : E/G WARNING

L3 : W/T OVER HEAT

WATER TEMPERATURE

LCD DISPLAY PANEL

L6 : WORK LAMP

GRAPHIC DISPLAY

FUEL LEVEL

CN7-4

CN7-5

CN7-6

CN6-10

CN6-9

4

2

1

3

6

5

14

R(I)

CN4-1

CN2-14

CN3-8

CN3-7

CN3-10

CN3-9

CAN A

-

+

CN4-4

CN3-3

CN3-4

CN4-6

CN4-5

CN4-2

CN4-3

+

-

CN2-1

CN3-2

CN3-1

CN5-3

CN2-17

CN2-18

CN5-7

E

BR

A

L1

L3

L2

L4

ILL.

CN6-3

CN6-1

CN6-2

CN6-12

CN6-11

+

-

R2 B

13

21

6

5

20

14

18

7

8

11

10

12

9

15

1

4

2

3

19

17

16

CN5-2

1-56

TxD

RxD

GND

FG007141

Figure 11

Page 27

SP001038

Page 25

Electrical System

Reference

Number

Description

1 Instrument Panel

2 Pilot Buzzer

3 Light Switch

4 Starter Switch

5 Front Pump Pressure Sensor

6 Rear Pump Pressure Sensor

7 Hydraulic Oil Temperature

Sensor

8 Fuel Sensor

9 Pedal Pressure Switch (Optional)

10 Air Cleaner Indicator

11 Pilot Filter Switch

12 Return Filter Switch

13 Alternator

14 e-EPOS Controller

15 Battery

16 Battery Relay

17 Circuit Breaker

18 Fusible Link

19 Fuse Box

20 Check Connector

21 Engine Controller

Reference

Number

Description

Page 28

SP001038Electrical System

Page 26

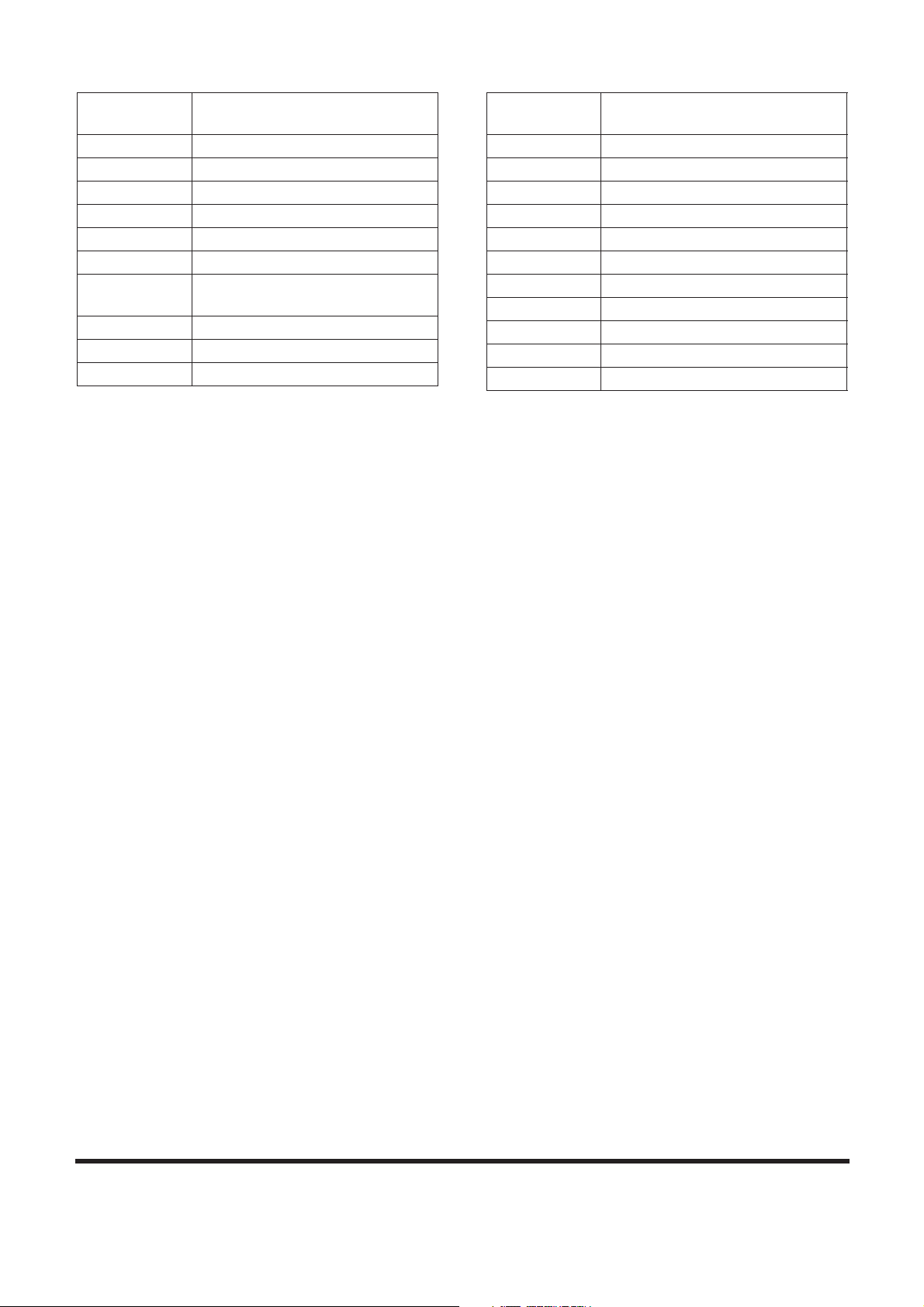

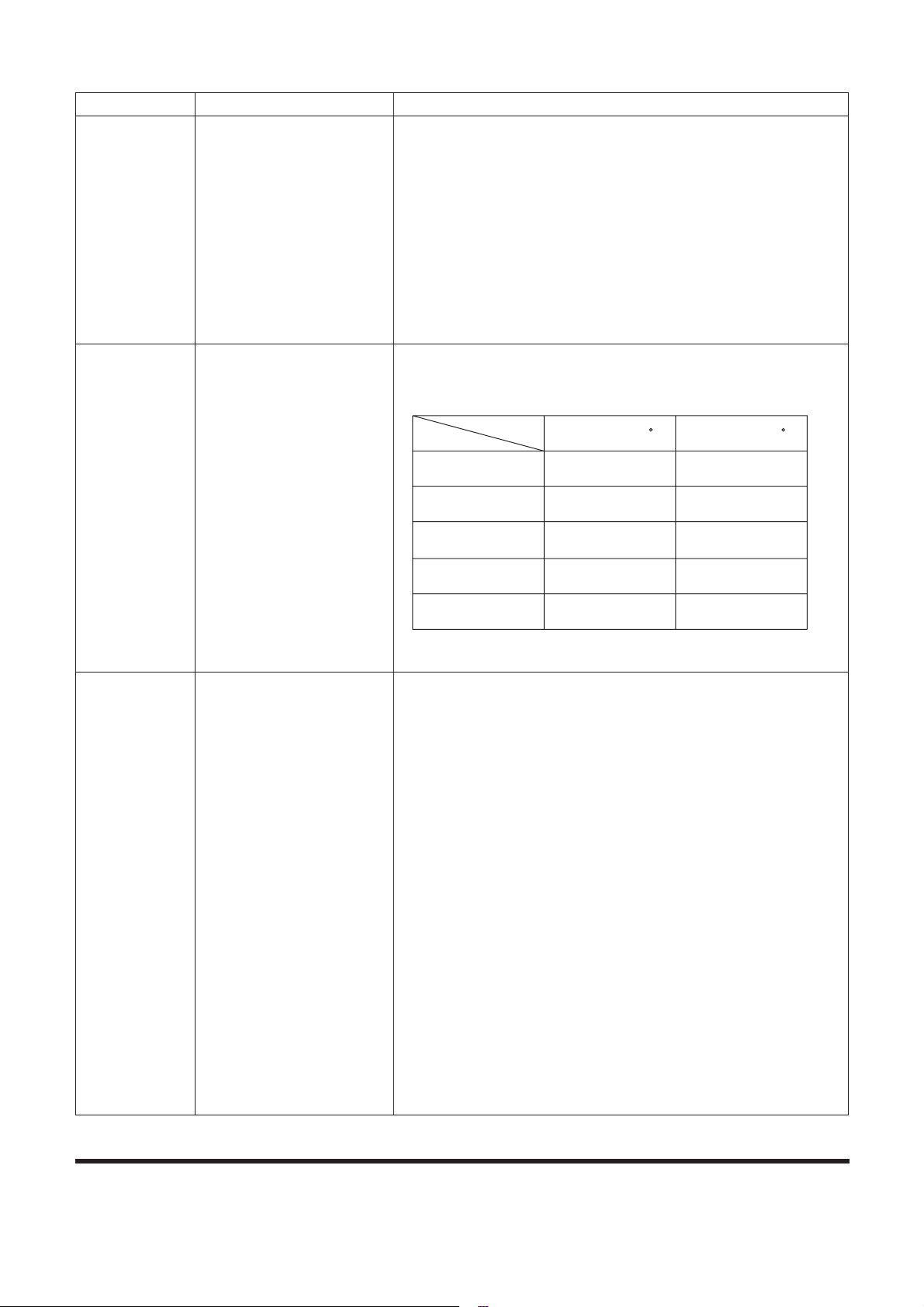

OPERATION

Instruments

Function Display

Sensor Specification

Input Terminal Input Specification

Coolant

Temperature

ECU-CAN

Communication

Fuel Level

CN3-7

CN3-8

1/10 LCD (Red Zone)

Blinking o over 5K ohms

FULL o under 525 ohms

Hydraulic Oil

Temperature

CN3-9

CN3-10

40°C (104°F) o 1,397 ohms

50°C (122°F) o 1,139 ohms

60°C (140°F) o 881 ohms

94°C (201°F) o 190 ohms

96°C (205°F) o 177 ohms

(When reading increase)

Flow

Adjusting

(Output

Terminal)

CN1-19

CN1-20

48.5 l/min o610 mA

57 l/min o583 mA

66 l/min o555 mA

78.5 l/min o466 mA

(Default Set)

108 l/min o343 mA

114 l/min o290 mA

C

H

FG000550

Blue

White Red

107°C

102°C

41°C

61°C

E

F

FG000552

Blue

Red Full

1/10

C

H

FG000551

Blue

White Red

96°C

94°C

40°C

50°C

FG009964

78.5

96.5

106.5

108

(None)

48.5

57

66

69

90

114

114

Page 29

SP001038

Page 27

Electrical System

Tachometer

ECU-CAN

Communication

N = 162 f / 60

N = Engine speed (rpm)

f = Frequency of engine

speed sensor (Hz)

Voltmeter CN2-14 0 - 32 VDC

Main pump

discharge

pressure

(front pump)

CN3-1

CN3-2

V = 0.00816 x P + 1.0

V: Sensor output voltage (V)

P: Displayed pressure (Bar)

Main pump

discharge

pressure

(rear pump)

CN3-3

CN3-4

Function Display

Sensor Specification

Input Terminal Input Specification

E/G SPEED

1700

RPM

FG000049

BATTERY

28.0

VOLT

FG000050

FRONT PUMP

320

BAR

FG000051

REAR PUMP

313

BAR

FG000052

Page 30

SP001038Electrical System

Page 28

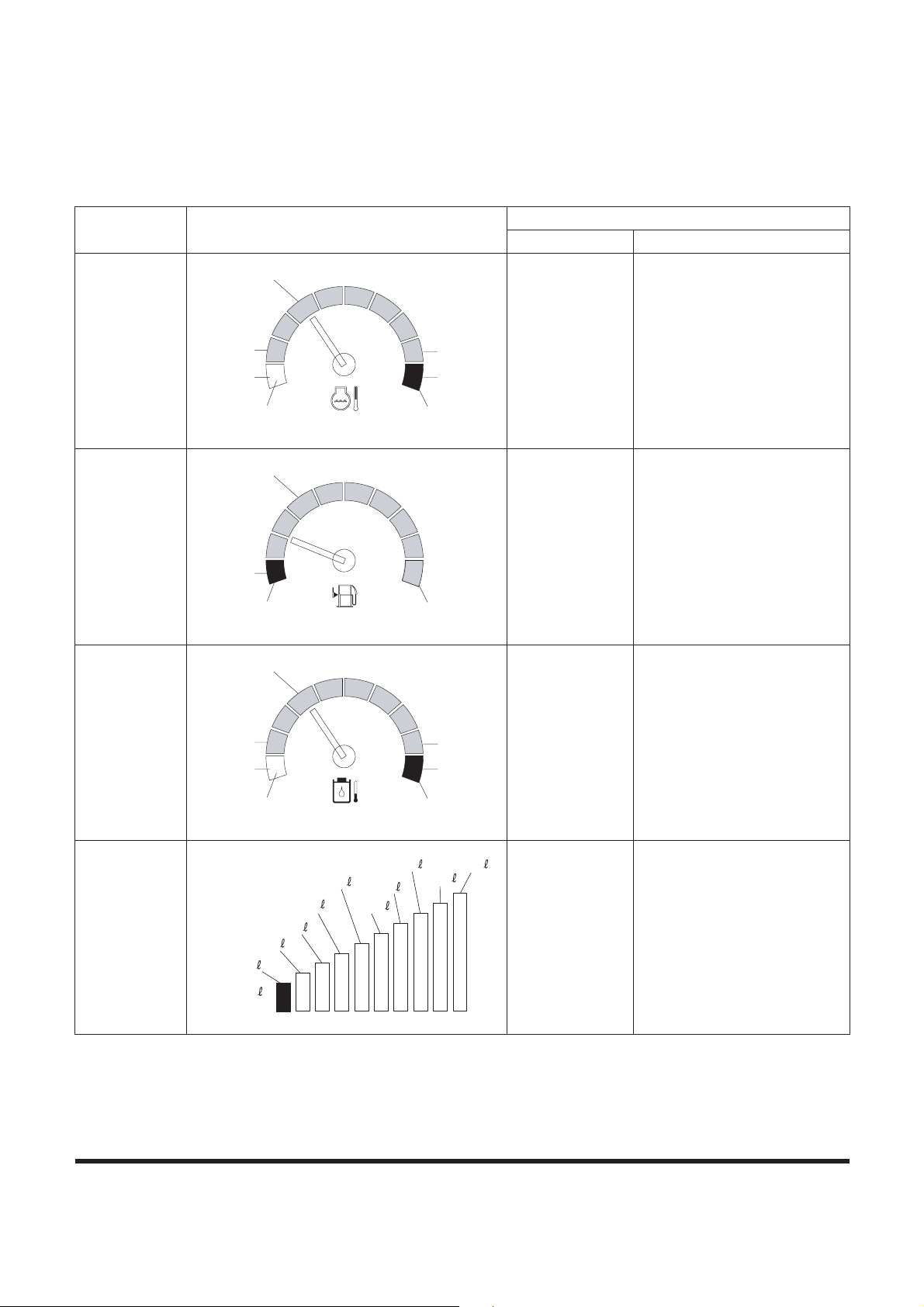

WARNING AND INDICATOR

LIGHTS

Indication of Warning Lights

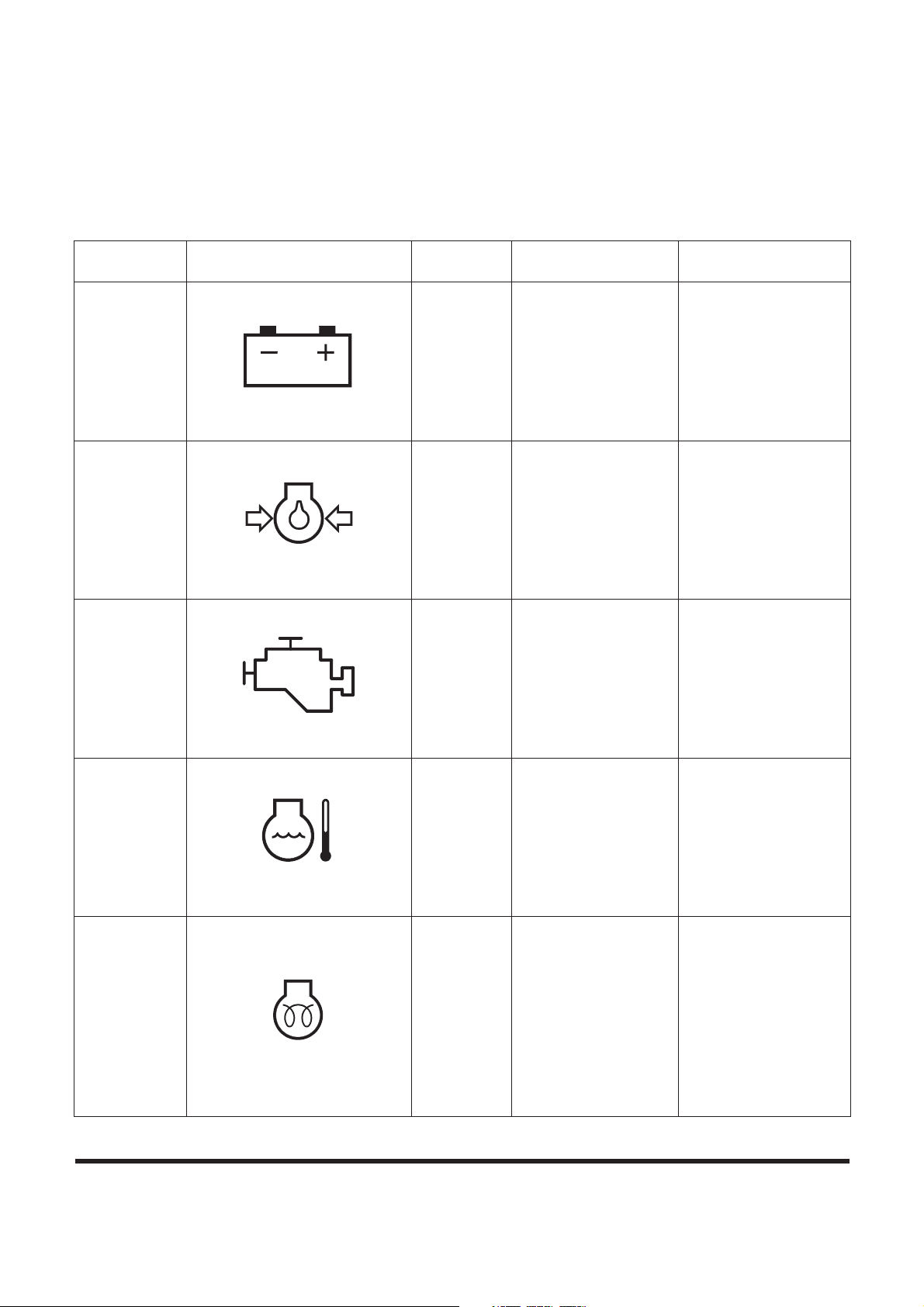

Description Symbol

Input

Terminal

Operation Remarks

Charge CN2 - 14

It lights in case of no

charge [voltage of

"R(I)" terminal is

below 12 ±1V] or

overcharge [voltage

of "R(I)" terminal is

above 33(V)].

Normally, it lights

when starting engine

and is out after engine

starts.

Engine Oil

Pressure

ECU-CAN

Communic

ation

It lights when engine

oil pressure is below

the reference.

After starting engine,

if engine oil pressure

is insufficient after 8

seconds, a warning

buzzer will sound.

Engine

Check

ECU-CAN

Communic

ation

It lights in case of

failure in engine

system.

Coolant

Temperature

ECU-CAN

Communic

ation

It lights when engine

coolant temperature

sensor resistant is

below about 128

ohms.

Preheating CN5-2

It lights during

preheating ("CN5-2"

terminal voltage is

below 2V) and turns

"OFF" after

completion of

preheating.

Preheating period

depends on coolant

temperature.

No preheating at

above 10°C

10 sec preheating at

5°C

20 sec preheating at

below 0°C

HAOA610L

HAOA620L

CHECK

FG000045

HAOD350L

HAOA639L

Page 31

SP001038

Page 29

Electrical System

Indication of Multifunction Gauge and

Letter Information Area

Work Light CN2 - 6

It lights when work

light turns "ON" (24V

applied).

Description Symbol

Input

Terminal

Operation Remarks

HB4O2003

Description Symbol

Input

Terminal

Operation Remarks

Hydraulic Oil

Temperature

CN3-9

CN3-10

When hydraulic oil

temperature is above

about 96°C.

Fuel

Exhausted

CN3-7

CN3-8

When fuel is almost

exhausted.

Air Cleaner CN2-17

When air cleaner is

clogged.

Return Filter CN5-3

When return filter

pressure is above

about 1.50 kg/cm²

(21 psi)

FG000056

FG000057

FG000053

FG000054

Page 32

SP001038Electrical System

Page 30

Pilot Filter CN2-18

When pilot filter

pressure is above

about 1 kg/cm² (14

psi)

Overload

Warning

CN3-5

CN3-6

Warning buzzer also

starts when boom

pressure sensor

output voltage is

about 2.7V while

overload warning

switch is "ON."

It flickers in case of

2.71V and above and

lights continuously in

case of 2.8V and

above (and warning

buzzer also starts).

Boost CN2-2

It lights when boost is

selected.

Breaker CN2-10

It lights when breaker

is selected.

Shear CN2-9

It lights when shear is

selected.

FG000055

FG000253

FG000554

FG00147

0

FG001471

Page 33

SP001038

Page 31

Electrical System

INITIAL OPERATION

NOTE: Refer to method for setting clock in operation manual

for setting time.

MODE SELECTOR SWITCH

Power Mode / Trenching Mode Switch

NOTE:

When the engine speed is below 1,000 rpm, the output

current of E.P.P.R valve is fixed to be 600 ±60mA.

Auto Idle Switch

Item Input (Terminal) Output (Operation and initial setting mode)

Initial

Operation

When "CN6-1,2" is applied

battery voltage (starter switch

shifts from "OFF" to "ON"

! LCD, all of LED and warning lights are turned

"ON" and turned "OFF" after about 2 seconds.

! Warning buzzer is activated and turned "OFF"

after about 2 seconds.

! Power mode: Standard mode.

! Work Mode: Digging mode.

! Auto Idle: High Output (Activation).

! Display: Indicating coolant temperature, Fuel

level, Hydraulic oil temperature, Engine speed.

! Clock: Current time display.

Operation Mode

Output Check

(Operation

mode display

LED)

e-EPOS Output

Electromagnetic

Proportional Pressure

Reducing Valve (E.P.P.R

Valve) Current (mA)

Swing Priority

Solenoid Valve

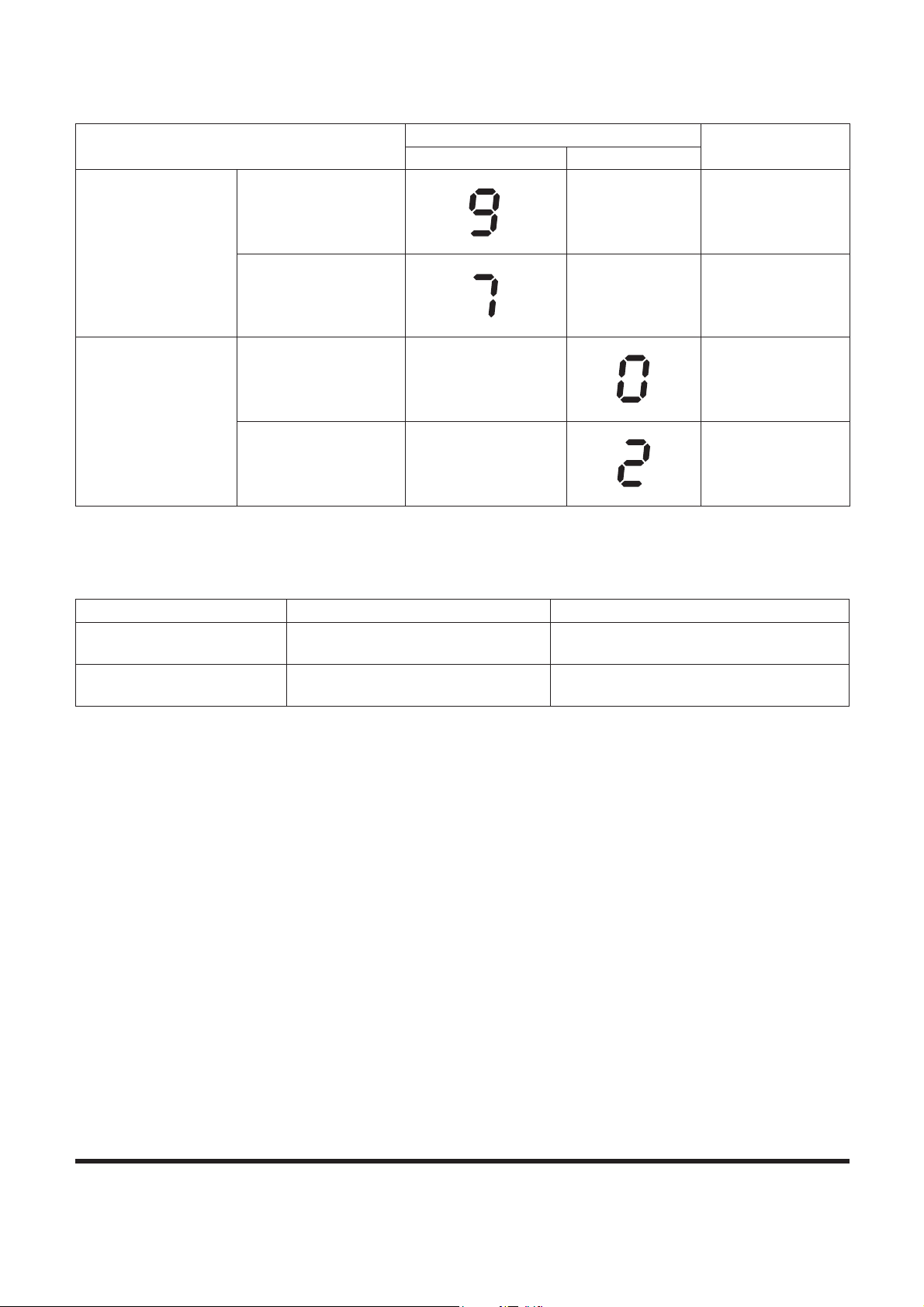

7-Segment

Display

Power

Mode

Power Mode ON

No-load: 150 ±20mA

Load: Variable output

(Max. current: 600 ±20mA)

- 9 x

Standard Mode OFF

No-load: 250 ±20mA

Load: Variable output

(Max. current: 600 ±60mA)

- 7 x

Work

Mode

Trenching Mode OFF - ON x 2

Digging Mode ON - OFF x 0

Operation Mode Output Check (Operation mode display LED)

Auto Idle

Activation ON

Cancellation OFF

Page 34

SP001038Electrical System

Page 32

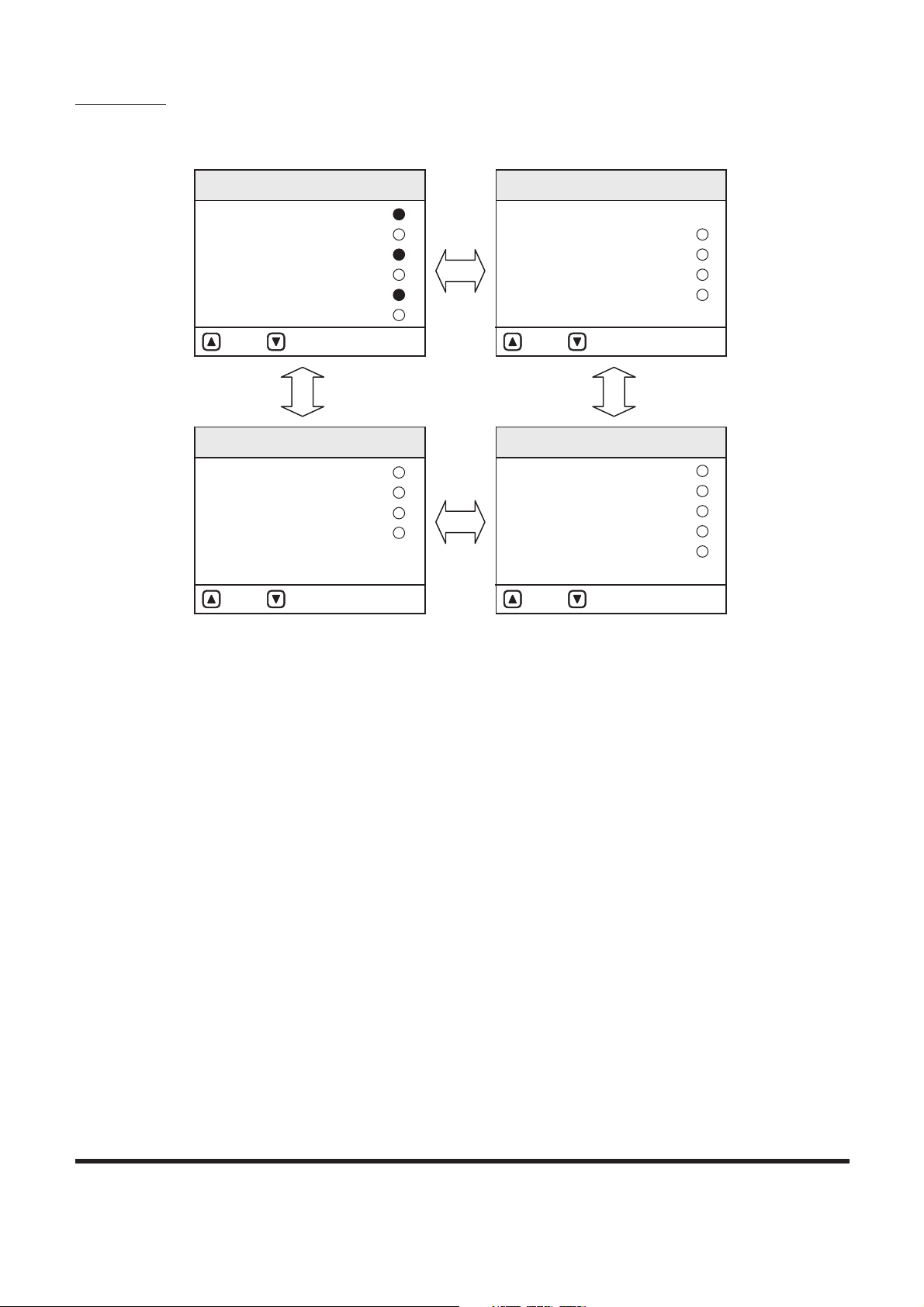

GRAPHIC INFORMATION AREA

DISPLAY

Overview

Many kinds of condition of machine are displayed on the letter

information display department. The information display

department is divided into two menus. One is main menu for

user and the other is special menu for specialist. These menus

can be moved from normal display mode by the combination of

selector buttons.

C

H

E

F

H

C

POWER

1

5

2

3

6

7

AUTO

4

ESC

8

FG000557

E/G SPEED

02/05 [MO] 11:30

1700

RPM

CHECK

5

1

4

3

2

Figure 12

Selector Buttons Graphic Display Area

1. Up Arrow Button

2. Down Arrow Button

3. Enter Button

4. Escape Button

5. Letter Information Display Department

Page 35

SP001038

Page 33

Electrical System

Main Menus for the Graphic Display Area

1. Main menu: Language setting, Time setting, Filter/Oil

information, Brightness adjustment, Password

2. Special menu: Information of machine status, failure

information, Information of machine operation.

Menu Selector Buttons

1. Up Arrow Button ( , 1 on Figure 12): Move the cursor to

up, left and previous screen.

2. Down Arrow Button ( , 2 on Figure 12): Move the cursor

to down, right and next screen.

3. Enter Button ( , 3 on Figure 12): Move the menu to

selected mode. When setting the menu, this button is used

to function as the selector button.

4. Escape Button (ESC, 4 on Figure 12): Move a screen to

previous menu or main menu.

Page 36

SP001038Electrical System

Page 34

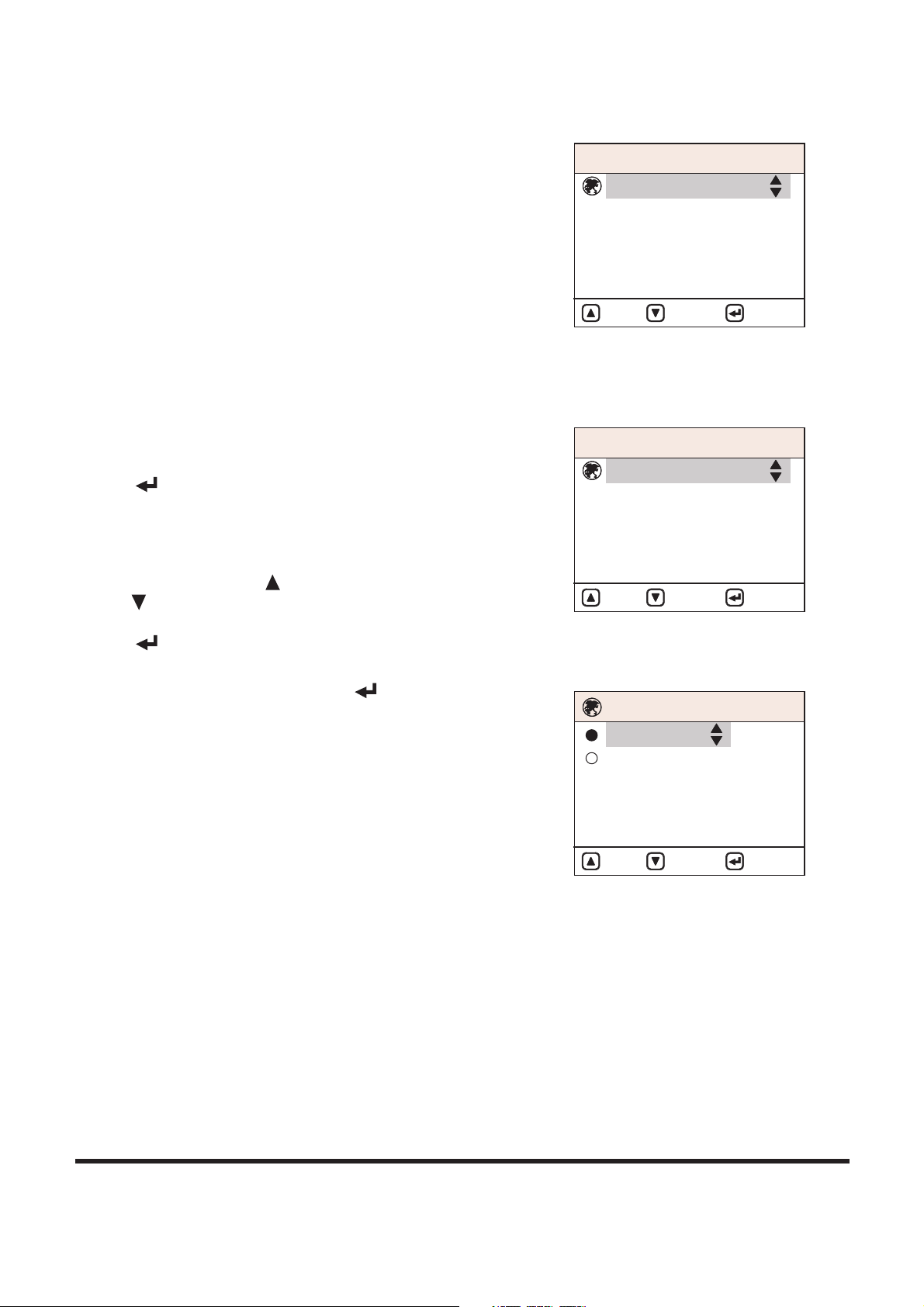

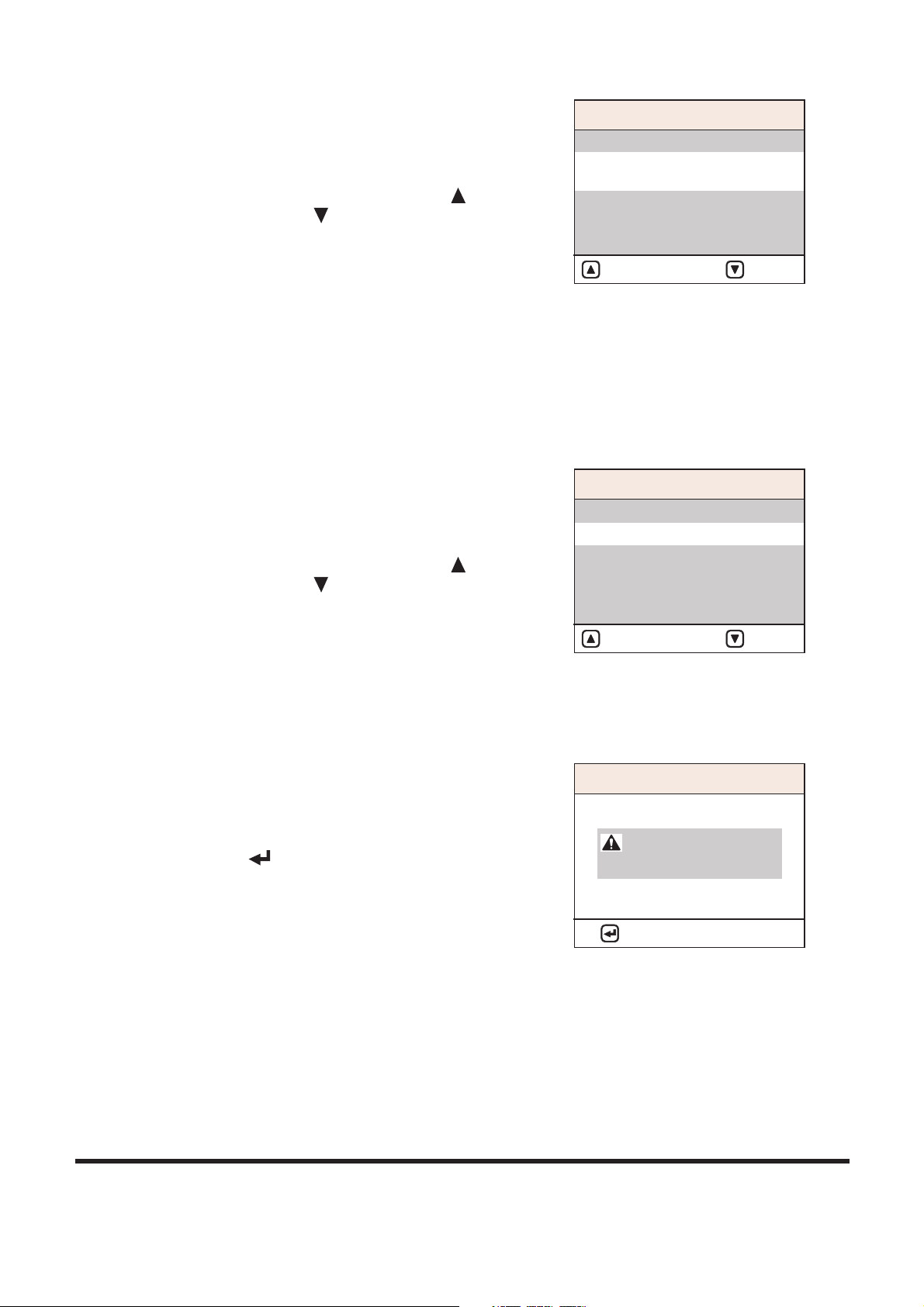

MAIN MENU

When the "ESC" button is pressed for more than 3 seconds, the

main menu screen is displayed.

Main menu offers sub-menus (language setting, time setting, or

filter/oil information, brightness adjustment, password) to the

operator.

Refer to the "Operation and Maintenance Manual" for details.

Language

Put the cursor on Language in the main menu and put the Enter

Button ( , 3 on Figure 12) and the language select view

appears.

The default language is Korean, but it will memorize and use the

newly set language.

Use the Up Arrow Button ( , 1 on Figure 12) or Down Arrow

Button ( , 2 on Figure 12) to move cursor to a language to be

selected on the Language Select display and press the Enter

Button ( , 3 on Figure 12) and the selected language is

indicated in the right bottom of the screen.

At this point pressing the Enter Button ( , 3 on Figure 12) or

the Escape Button (ESC, 4 on Figure 12) more than 1 second

brings the main menu with changed language and then pressing

the ESC button again shows the default view.

Without pressing a button more than 20 seconds, the default

view appears.

MA I N ME N U

1. Language

4. Adjust Display

5. Set Password

2. Set Clock

3. Filter / Oil Info

: UP : D OWN : SELE CT

FG0000 72

Figure 13

MA I N ME N U

1. Language

4. Adjust Display

5. Set Password

2. Set Clock

3. Filter / Oil Info

: UP : D OWN : SELE CT

FG0000 72

Figure 14

1. Korean

2. English

: UP : D OWN : SELE CT

FG0007 83

Figure 15

LA N G UAG E

Page 37

SP001038

Page 35

Electrical System

Set Clock

It is used to adjust time of the digital clock.

Pressing the Enter Button ( , 3 on Figure 12) in the Main

Menu after putting cursor on Set Clock brings Set Clock display.

Without pressing a button more than 20 seconds, the default

view appears.

Please refer to the Operation Manual for detailed information on

Time Setting.

Filter/Oil Info

This mode displays total operating hours of filters and oils.

After changing the filter and oil, reset the operating hour and

then the operating hours until the next service interval can be

easily checked.

MA I N ME N U

1. Language

4. Adjust Display

5. Set Password

2. Set Clock

3. Filter / Oil Info

: UP : D OWN : SELE CT

FG0000 75

Figure 16

SE T CLO C K

:

+

: : MOVE

FG0000 76

0 6 : 0 5

2004 0 6 / 29

Figure 17

MA I N ME N U

1. Language

4. Adjust Display

5. Set Password

2. Set Clock

3. Filter / Oil Info

: UP : D OWN : SELE CT

FG0000 77

Figure 18

FI LTE R / O I L I N FO

: UP : D OWN : RESE T

FG0000 78

1. Fuel F ilter

Hrs : 002 5

Figure 19

Page 38

SP001038Electrical System

Page 36

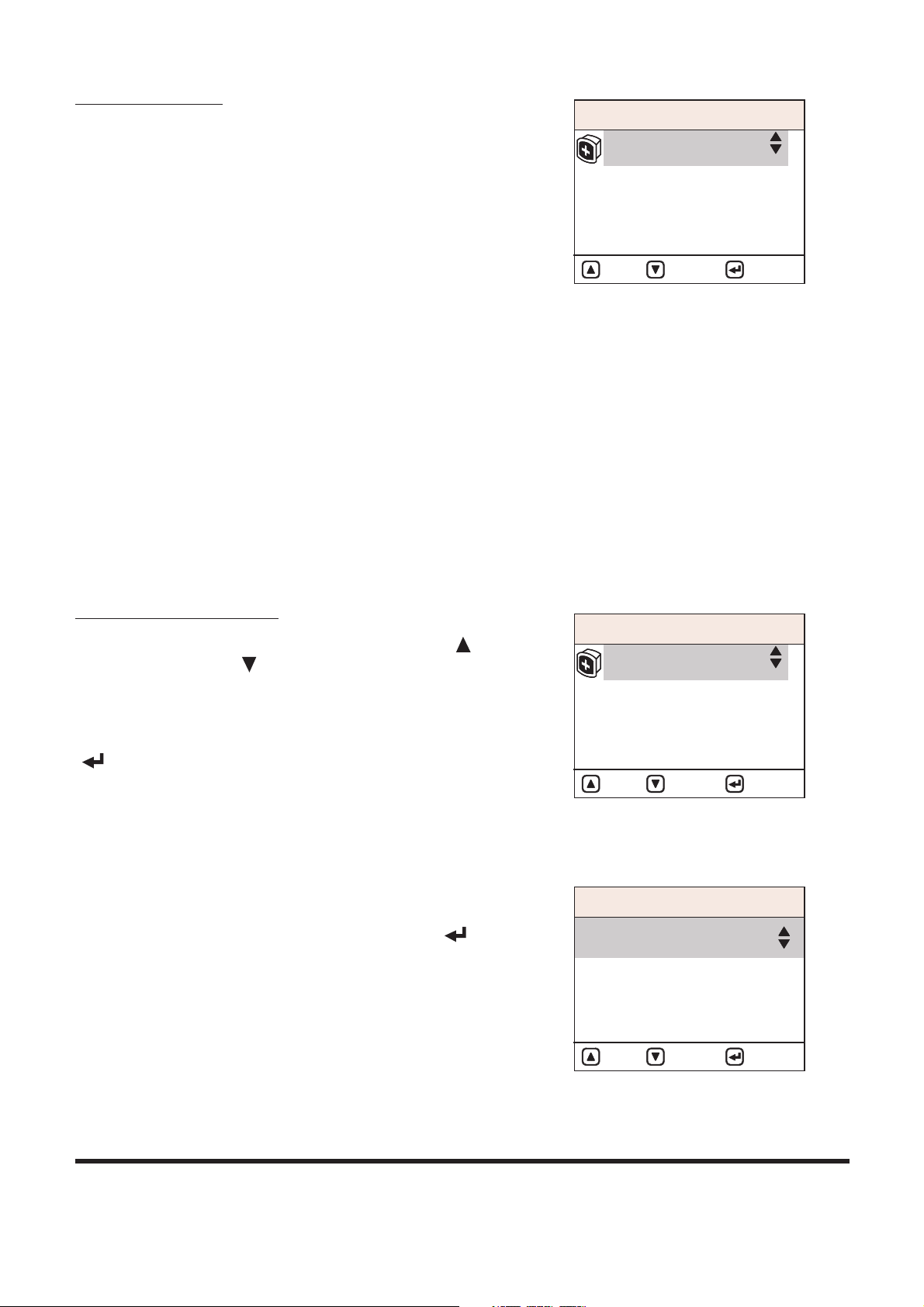

Menu Display Order and Icon Explanation

Adjust Display

Pressing the Enter Button ( , 3 on Figure 12) in the main

menu after putting cursor on Adjust Display brings Adjust

Display.

Screen brightness can be adjusted using the Up Arrow Button

( , 1 on Figure 12) or the Down Arrow Button ( , 2 on Figure

12).

The default brightness is set to 50%.

1. Fuel Filter 2. Air Cleaner 3. Engine Oil Filter 4. Hyd. Oil Filter

5. Pilot Filter 6. Engine Oil 7. Hydraulic Oil 8. Coolant Water

FG001358

Figure 20

MA I N ME N U

1. Language

4. Adjust Display

5. Set Password

2. Set Clock

3. Filter / Oil Info

: UP : D OWN : SELE CT

FG0000 80

Figure 21

Ad j u st D i sp l a y

:

+

+

:

FG0000 81

50 %

LC D T ES T

LC D T ES T

LC D T ES T

Figure 22

Page 39

Set Password

1. Language

4. Adjust Display

5. Set Password

2. Set Clock

3. Filter / Oil Info

: UP : D OWN : SELE CT

FG0002 27

Figure 23

This menu is used to apply (lock), release, or change password.

Please refer to the Operation Manual for detailed information on

Password Setting.

MA I N ME N U

Electrical System

SP001038

Page 37

Page 40

SP001038Electrical System

Page 38

SPECIAL MENU

In this menu, many types of operating conditions and functions

can be accessed and displayed, including the e-EPOS

controller. This menu is mainly used for machine testing and

failure diagnostics.

The special menu offers three sub-menus:

1. Machine status.

2. Failure information.

3. Information on machine operation.

Entering/Accessing and Exiting/Escaping

Menus

Entering/Accessing Menus

When normal mode screen is displayed, if the enter button ( ,

3) and escape button (ESC, 4) are pressed simultaneously for

more than 3 seconds, normal mode screen (Figure 25) will be

changed to special menu screen (Figure 26).

Normal Mode Screen

NOTE: Normal mode screen can display many kinds of

display mode by selecting, for example, engine

speed (RPM), battery voltage (VOLT), front pump

pressure (BAR), rear pump pressure (BAR) and so

on by selecting.

1

5

POWER

3

2

6

7

AUTO

4

ESC

8

FG001402

3

4

2

1

Figure 24

C

H

C

E

F

H

02/05 [MO] 11:30

E/G SPEED

1700 RPM

FG000043

Figure 25

Page 41

SP001038

Page 39

Electrical System

Special Menu Screen

NOTE: Displayed language on the special menu screen

consists of Korean and English.

If any language except for Korean is selected during

language selection mode of main menu, only English

will be displayed on special menu screen.

Exiting/Escaping Menus

1. If escape button (ESC, 4 on Figure 24) is pressed for more

than 1 second, the special menu screen will be returned to

the normal mode screen.

2. If this special menu is "ON" without any activity, for more

than 20 seconds, it will turn to the normal mode screen.

3. After the turning starter switch to the "OFF" position, turn it

back to the "ON" position, and the normal mode screen

displayed once again.

Special Menu Selections

Submenu Selection Method

Various sub-menus can be selected by pressing "Up ( , 1 on

Figure 24)" and "Down ( , 2 on Figure 24)" button.

Move the cursor to desired menu and a selected menu will be

inverse displayed.

When the selected menu is inverse displayed, press the "Enter

( , 3 on Figure 24)" button for menu selection.

Information of Machine Status

1. Entering Sub-menus: When cursor is located on "Machine

Info" of special menu screen, press "Enter ( , 3 on

Figure 24)" button and the "Machine Info" will be displayed.

2. Exiting Sub-menus: If escape button (ESC, 4 on Figure 24)

is pressed for more than 1 second, display will be turned to

previous screen.

SP E C IAL ME N U

1. Machine Info

2. Failure Info

3. Operating Hrs

: UP : D OWN : SELE CT

FG0005 58

Figure 26

SP E C IAL ME N U

1. Machine Info

2. Failure Info

3. Operating Hrs

: UP : D OWN : SELE CT

FG0005 58

Figure 27

MA C H INE I NF O

1. Analogue Input State

2. Digital Input State

3. Digital Output State

: UP : D OWN : SELE CT

FG0005 59

Figure 28

Page 42

SP001038Electrical System

Page 40

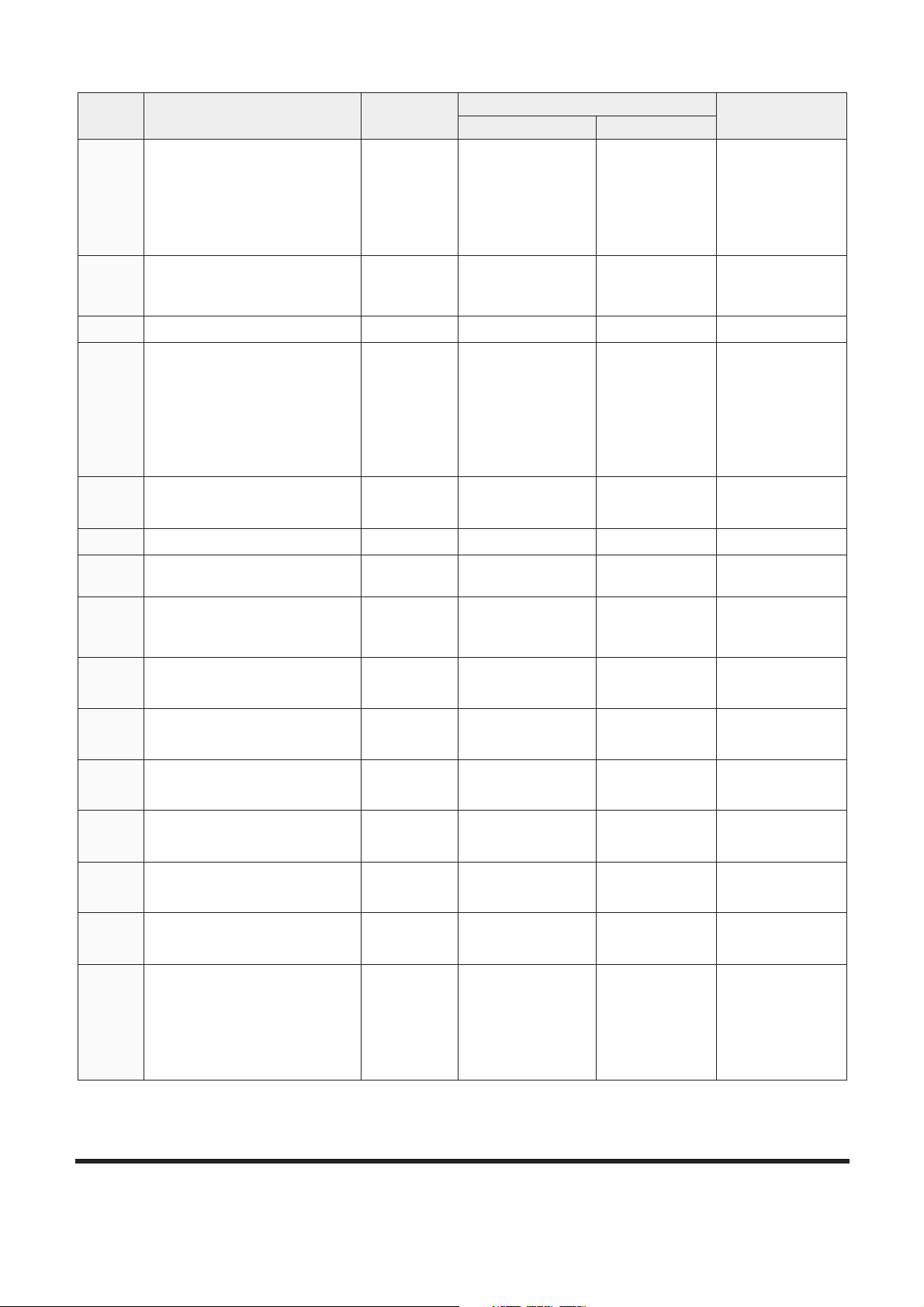

Analog Inputs Description

Submenu Selections

Analog Input Items Display Remark

1. Pump P/V mA Current in pump proportional valve.

2. Cooling Fan P/V mA N.A.

3. Flow Control P/V mA N.A.

4. Dial mV Indicating dial voltage.

5. TPS mV N.A.

6. E/G Control Motor mV N.A.

7. Boom Pressure BAR Boom cylinder head pressure.

8. Pilot Gear Pump Press BAR N.A.

9. Boost Pressure BAR Pump pressure for boost.

10. Intake Manifold Temperature °C Temperature of air incoming to

intake manifold.

11. E/G Oil Pressure BAR Engine oil pressure.

12. Fuel Temperature °C Fuel temperature.

13. E/G Oil Temperature °C Engine oil temperature.

14. Load At Cur. Spd % Current load ratio of equipment.

FG008126

AN A L OG I N PUT S T ATE

: UP : DOWN Page:3/3

1. Pump P/V

2. Cooling Fan P/V

3. Flow Control P/V

4. Dial

5. TPS

6. E/G Control Motor : N.A

7. Boom Pressure

8. Pilot Gear Pump Press.

9. Boost Pressure

11. E/G Oil Pressure

14. Load at Cur. Spd : 000 %

AN A L OG I N PUT S T ATE

AN A L OG I N PUT S T ATE

10. Intake Manifold Temp.

12. Fuel Temp.

13. E/G Oil Temp.

: 000mA

: 000mA

: N.A

: N.A

: 000mV

: 000mA

: 000 C

: 000 C

: 000 C

: 000BAR

: 000BAR

: 000BAR

Figure 29

: UP : DOWN Page:1/3 : UP : DO WN Pag e:2/3

Page 43

SP001038

Page 41

Electrical System

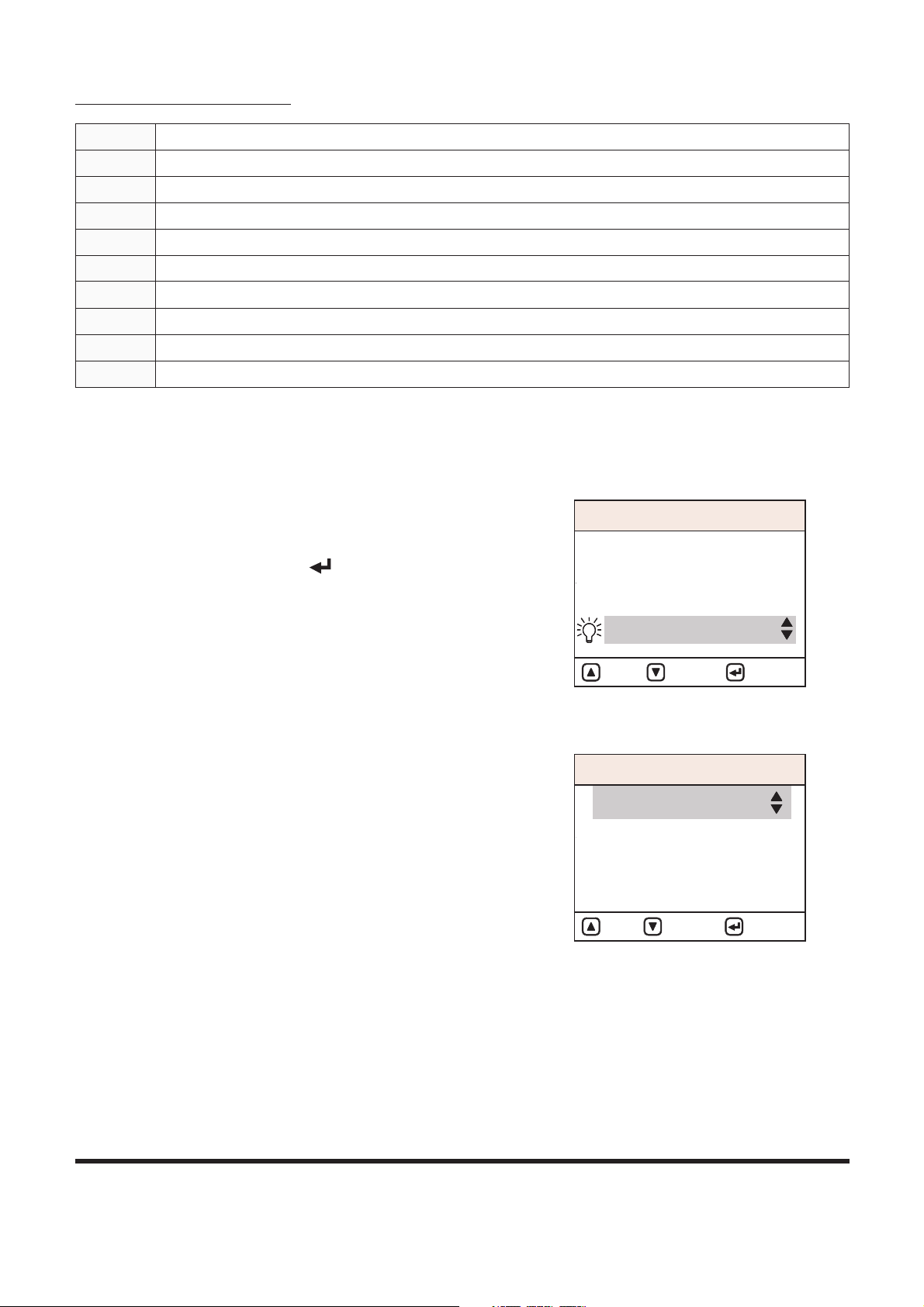

Digital Inputs Descriptions

Digital Inputs Items Mark Remark

1. Alternator

ON / OFF

Lights up when output at alternator

"R(I)" terminal is above 12 ±1V.

2. Travel Select SW N.A. (only for wheel type equipment)

3. High Speed Sel. SW (M)

Lights up when the travel speed

selector switch is set to the "I"

position.

4. High Speed Sel. SW (A)

Lights up when the travel speed

selector switch is set to the "II"

position.

5. Pressure SW (Py)

Lights up when the pressure switch

(Py) is "ON."

6. Pressure SW (Px)

Lights up when the pressure switch

(Px) is "ON."

7. E/G Oil Press. SW N.A. (only for mechanical engine)

8. Air Cleaner Clogged

Lights up when the air cleaner

indicator contact is "ON."

9. Return Filter Clogged

Lights up when the return filter

pressure switch is "ON."

10. Pilot Filter Clogged

Lights up when the pilot filter

pressure switch is "ON."

11. OWD Warning SW

Lights up when the overload

warning selector switch is "ON."

12. Brake Oil Press. SW N.A. (only for wheel type equipment)

13. Pedal Press. SW

Lights up when the pedal pressure

switch is ON.

14. One Way Sel. SW

Lights up when the selector switch is

turned to breaker.

15. Two-way Sel. SW

Lights up when the Selector Switch

is turned to "SHEAR."

16. Power Max. SW

Lights up when the boost button is

"ON" with the Select switch turned

to "BOOST."

17. Breaker SW

Lights up when the boost button is

"ON" with the selector switch turned

to "BREAKER."

18. Preheat Select N.A.

19. Quick Coupler

Lights up when the Quick Coupler

switch is "ON."

20. F and R Lever N.A. (only for wheel type equipment)

21. Preheat Select

Lights up during preheating (CN5-2)

terminal voltage is below 2V.

22. Reverse Fan SW N.A.

23. Pilot Cutoff SW N.A.

Page 44

Menu Select

: UP : DOW N Page:1/ 4

: UP : DOW N Page:3/ 4

1. Alte rna tor

2. Travel Select SW

3. High Sp eed Sel. SW (M)

4. High Sp eed Sel. SW (A)

5. Pres sur e SW (Py)

6. Pres sur e SW (Px)

:

:

:

:

:

:

19. Qui ck Coupler

20. F&R Le ver

21. Pre hea t Select

22. Rev ers e Fan SW

23. Pil ot Cutoff S W

:

:

:

:

: N.A

7. E/G Oil Pr ess. SW

8. Air Cle aner Clogged

9. Retu rn Filter Clogged

10. Pil ot Filter Clogged

11. OWD Warning SW

12. Bra ke Oil Press. SW

: N.A

:

:

:

:

: N.A

13. Ped al Press. SW

14. One Way Sel. SW

15. Two Way Sel. SW

16. Pow er Max. SW

17. Bre ake r SW

18. Pre hea t Select

:

:

:

:

:

: N.A

DI G I TA L INP U T STAT E

DI G I TA L INP U T STAT E DI G I TA L INP U T STAT E

Figure 30

DI G I TA L INP U T STAT E

: UP : DOW N Page:2/ 4

: UP : DOW N Page:4/ 4

FG008136

Page 42

SP001038Electrical System

Page 45

SP001038

Page 43

Electrical System

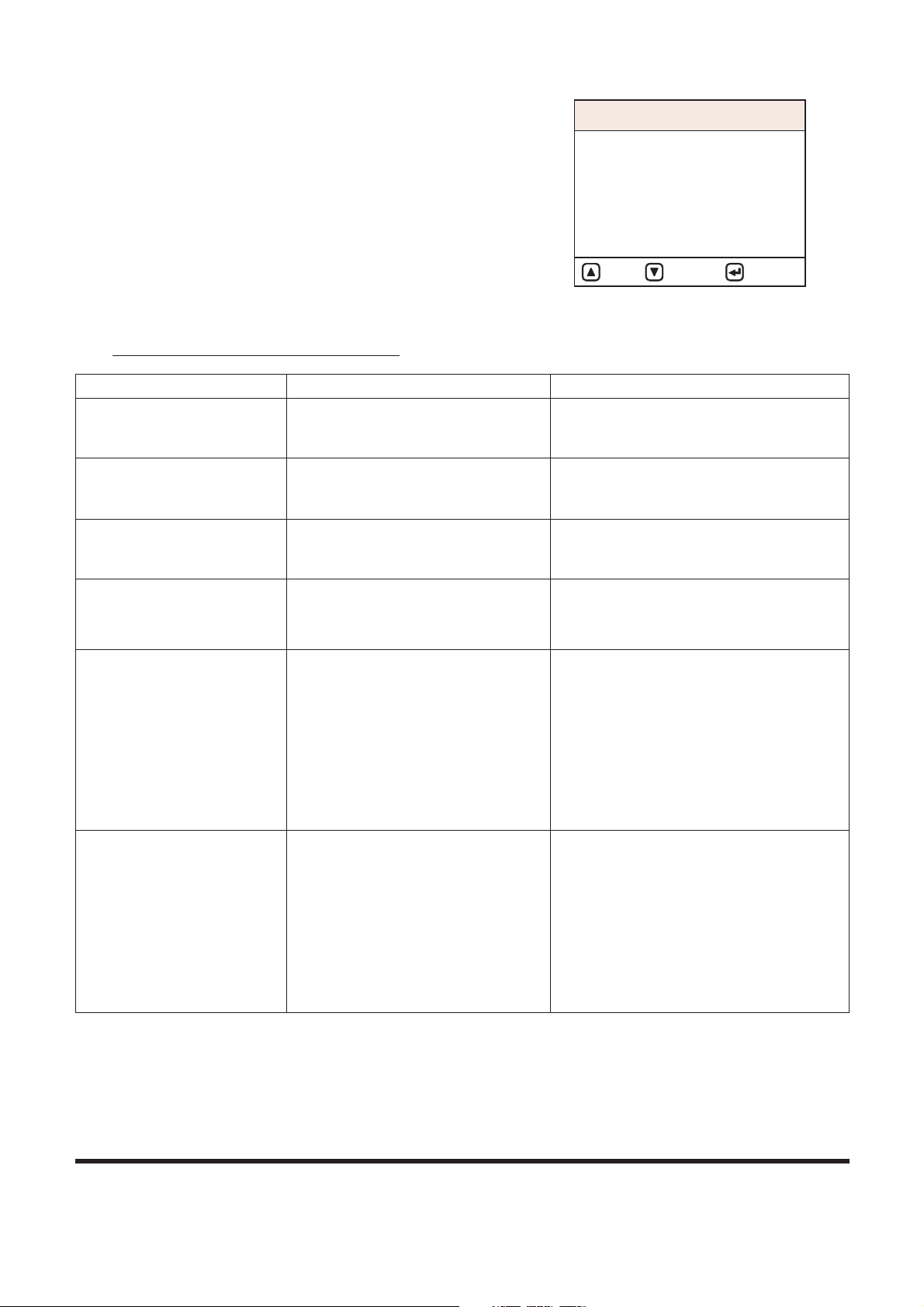

Digital Outputs Descriptions

Menu Select

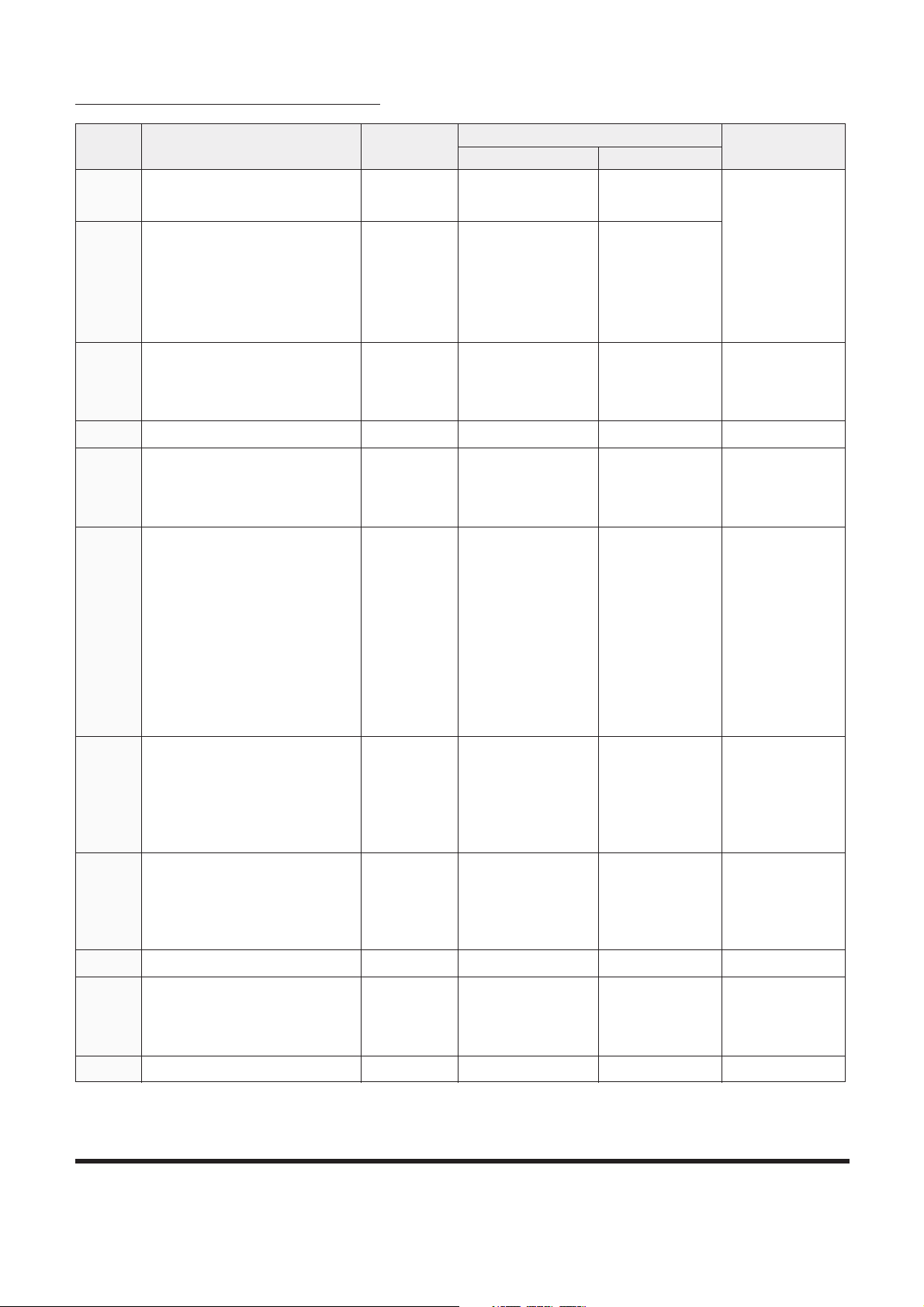

Failure Information

1. Entering Sub-menus: When a cursor is located in "Failure

Info" of special menu screen press enter button ( , 3 on

Figure 24) and "Failure Info" screen is displayed.

2. Exiting Sub-menus: If escape button (ESC, 4 on Figure 24)

is pressed for more than 1 second, this information screen

will be returned to previous screen.

* Real-time Failure:

Current status of failure is displayed.

* Failure Log:

Memorized record of past failure is displayed.

* Delete Fail Log:

This mode is used to delete all of the

memorized record of past failure.

Digital Outputs Items Mark Remark

1. Relief Press. Up S/V

ON / OFF

Lights up when the relief press up

solenoid valve is "ON."

2. High Speed S/V

Lights up when the high speed

solenoid valve is "ON."

3. Swing Priority S/V

Lights up when the swing priority

solenoid valve is "ON."

4. Reverse Fan S/V N.A.

5. Starter Relay When the starter relay is "ON."

6. After Heat Relay N.A.

: UP : DOWN Page:1 /1

FG0039 30

1. R elief Press. Up S/V

2. H igh Speed S/V

3. S wing Priority S/V

4. R everse Fan S/V

5. S tarter Relay

6. Afterheat Relay

:

:

:

: N. A

:

: N. A

DI G I TA L O U TPU T STATE

Figure 31

SP E C IAL ME N U

1. Machine Info

2. Failure Info

3. Operating Hrs

: UP : D OWN : SELE CT

FG0005 63

Figure 32

FA I L URE I NF O

1. Realtime Fail

2. Failure Log

3. Delete Fail Log

: UP : D OWN : SELE CT

FG0005 64

Figure 33

Page 46

SP001038Electrical System

Page 44

A. Current failure information

Current status of failure is displayed (Failure code,

failure contents).

When a number of failures are produced, failure

information can be checked using "UP" ( , 1 on

Figure 24) or "DOWN" ( , 2 on Figure 24) button.

* 1/2: A serial number of current failure/ total quantity

of failure.

* Vxxx-xx: Vxxx is a unique code and xx is a FMI

(Failure Mode Identifier) number.

- V: Machine related failure code

- E: Engine related failure code

Refer to the failure information code for unique codes

and FMI numbers.

This example shows one of two failures.

B. Past failure information

Memorized record of past failure is displayed (Failure

code, failure contents).

When a number of failures are produced, failure

information can be checked using "UP" ( , 1 on

Figure 24) or "DOWN" ( , 2 on Figure 24) button.

NOTE: " Number: xxx ": "xxx" means that the

totally counted number of the same failure.

" Period:xxxxxHrxxm ": It indicates the

period for which machine has operated

until a failure takes place. (For more than

two occurrences of the same failure, until

the first occurrence time.)

C. Failure record deletion

This mode is used to delete the memorized record of

past failure. If this mode is selected, all records will

be deleted.

When "YES" ( , 3 on Figure 24) button is pressed,

the memorized record will be deleted.

At this time, deletion signal will be displayed and the

screen will move to previous menu after deletion.

This screen will be displayed during 3 seconds.

RE A LT I M E FA I L

: UP : DOWN

FG0005 65

1/ 2 CO DE : V2 04 -0 5

2/ 2 CO DE : E0 11 - 04

Re li ef Pr es su r e Up S / V

Cu rr en t b el ow no rm al (C UR RE N T

BE LO W N OR MA L or o p en c ir c ui t)

Figure 34

: UP : DOWN

FG0005 66

1/ 2 CO DE : V2 04 -0 5

2/ 2 CO DE : E0 11 - 04

Pe ri od : 00 25 4H r 2 9m N um be r: 0 8

Re li ef Pr es su r e Up S / V

Cu rr en t b el ow no rm al (C UR RE N T

BE LO W N OR MA L or o p en c ir c ui t)

Figure 35

DELETE FAIL LOG

ESC: No

FG0005 67

: Yes

Al l Fai l Lo g wil l be

DE L E TED .

Figure 36

FA I L URE L OG

Page 47

SP001038

Page 45

Electrical System

Input your password with one of No. 1 - 8 switches.

When "NO" (ESC, 4 on Figure 24) button is pressed,

the screen will recover to previous menu without

deletion.

Delete Completed screen will appear 3 seconds and

the screen will move to Failure Info screen.

It has been shown 3 seconds upon deleting Fail Log.

The screen shown on the left will appear 3 seconds in

case of wrong password input and then Enter

Password screen appears again.

It has been shown 3 seconds in case of password

failure.

ESC: No

FG0005 69

: Yes

DE L ET E D!! !

DELETE FAIL LOG

Figure 38

ESC: No

FG0005 70

: Yes

PASSWORD ERR !!!

DELETE FAIL LOG

Figure 39

DELETE FAIL LOG

Figure 37

ENTER PASSWD

: Yes

ESC: No

FG0005 68

Page 48

SP001038Electrical System

Page 46

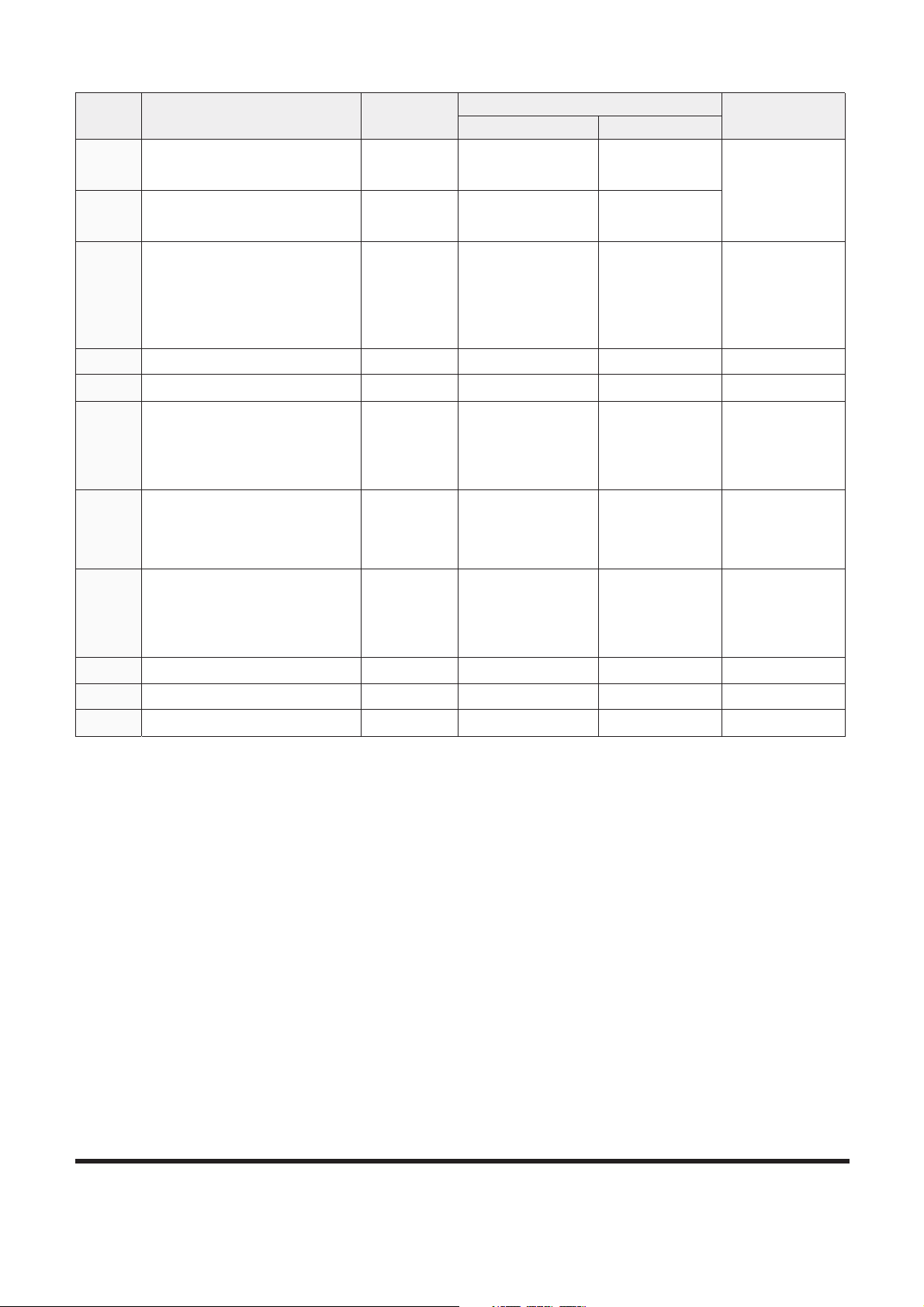

Failure Information Code at Machine Side

Code Failure Component

Measuring

Points

Correct Value

Remarks

Active Passive

V201

Gauge Panel

Communication Error

CN7-4

CN7-5

- R 60 ±5 :

It is a

composite

resistance of

CAN line. This

value has to be

measured by

connected

condition of

CAN line.

V202

Ecu Communication Error

CN4-4

CN4-5

- R 60 ±5 :

V210

Pump P/V

CN1-10

CN1-21

-

R 18 ±2 :

(25°C (77°F))

Pump

proportional

pressure

reducing valve.

V211

Cooling Fan P/V - -

N.A.

V212

Flow Control P/V

CN1-19

CN1-20

-

R 14 ±2 :

(25°C (77°F))

Flow control

proportional

pressure

reducing valve.

V213

Relief Pressure Up S/V

CN1-1

CN1-11

V = V_volt (Note

4.)

R 26.2 ±2 :

(25°C (77°F))

Breaker/boost/

shear selector

switch has to

be selected as

a boost

function and

the boost

switch on the

right-hand

joystick is "ON"

status.

V214

High Speed S/V

CN1-1

CN1-12

V = V_volt

R 26.2 ±2 :

(25°C (77°F))

Voltage is only

measured

when the

pressure

switch (Py) is

turned "ON."

V215

Swing Priority S/V

CN1-1

CN1-13

V = V_volt

R 26.2 ±2 :

(25°C (77°F))

Work mode

has to be

selected as a

trenching

mode.

V216

Reverse Fan Speed S/V - -

N.A.

V217

Starter Relay

CN1-1

CN1-15

V = V_volt -

It has to be

measured in

engine start up

state.

V218

After Heat Relay - -

N.A.

Page 49

SP001038

Page 47

Electrical System

NOTE: 1. Active value: Starter switch has to be turned "ON"

Measuring points between component and wire

harness have to be connected.

2. Passive value: Starter switch has to be turned

"OFF"

Measuring points between component and wire

harness have to be disconnected.

3. Measuring points are engine controller's points and

passive value is each component's value.

4. V#batt: Source power of equipment.

V220

Front Pump Press. Sensor

CN3-1

CN3-2

V = IV -

It has to be

measured in

engine stop

state.

V221

Rear Pump Press. Sensor

CN3-3

CN3-4

V = IV -

V222

Hyd. Oil Temperature Sensor

CN3-9

CN3-10

-

R 2.45 r25

k: (25°C

(77°F))

R 320 ±32 :

(80°C (176°F))

V223

Water Temperature Sensor - -

N.A.

V224

Engine Speed Sensor - -

N.A.

V225

Fuel Level Sensor

CN3-7

CN3-8

-

Empty: 5 r25

k:

Full: 320 ±32

:

V226

Alternator Potential

CN2-14

CN1-8

V = 2 ±1V -

It has to be

measured in

engine stop

state.

V227

Dial

CN3-16

CN3-7

-

R 1.0 r3

k:

R 4.0 ±1.5

k:

V228

Tps (Wheel) - -

N.A.

V229

Parking Brake Press. Sensor - -

N.A.

V230

E/g Control Motor Sensor - -

N.A.

Code Failure Component

Measuring

Points

Correct Value

Remarks

Active Passive

Page 50

SP001038Electrical System

Page 48

Failure Information Code at Engine Side

Code Failure Component

Measuring

Points

Current Valve

Remarks

Active Passive

E011

Coolant temperature sensor

2-26

2-15

-

R 186 ±5 :

(100°C

(212°F))

E012

Fuel temperature sensor

2-26

2-35

-

R 186 ±5 :

(100°C

(212°F))

E013

Boost air temperature sensor

2-36

2-25

-

R 186 ±5 :

(100°C

(212°F))

E014

Boost air pressure sensor

2-33

2-34

V 1,071 ±58mV

(at 23°C (73°F)

and absolute

pressure 1bar)

-

It has to be

measured in

engine running

state.

E017

E/G oil temperature sensor

2-28

2-24

-

R 186 ±5 :

(100°C

(212°F))

E018

E/G oil pressure sensor

2-32

2-27

V 2,318 ±80mV

(at 23°C (73°F)

and absolute

pressure 3bar)

-

It has to be

measured in

engine running

state.

E021

Battery voltage

1-03

1-06

V = V#volt

(Note 4.)

-

E022

Fuel pressure sensor

3-09

3-10

V 1,833 ±28mV

(at 23°C (73°F)

and absolute

pressure 300bar)

-

It has to be

measured in

engine running

state.

E032

Fuel pressure monitoring

MPROP

2-14

2-12

-

R 2.60 ±3.15

:

(20°C (68°F))

E037

CAN module

1-53 and

1-52

1-35 and

1-34

-

R 60 ±5 :

(20°C (68°F))

It is a composite

resistance of

CAN line.

This value has

to be measured

by connected

condition of

CAN line.

E038

Engine overspeed - -

E039

Main relay (ECU) - -

E041

Redundant shutoff path - -

Abnormal

engine stop.

E042

E/G speed (Crankshaft)

2-23

2-19

-

R 860 ±6 :

(20°C (68°F))

E043

E/G speed (Camshaft)

2-09

2-10

- -

Page 51

SP001038

Page 49

Electrical System

E044

Engine speed sensor - -

Synchronizing

error between

crank shaft

speed sensor

and cam shaft

speed sensor.

E045

EEPROM - -

Data storing

error when

engine stop.

E046

Recovery - -

E047

Monitoring of PRV - -

When the

pressure sensor

of common rail

or

high-pressure

pump has a

defect.

E048

Power supply

1-03

1-06

V = V#volt -

E049

Booster voltage C1 - -

E051

Booster voltage C2 ($6, 2

and 4)

- -

E058

Solenoid power stage 1

3-13

3-04

-

R 0.31 ±0.42

:

(20°C (68°F))

E059

Solenoid power stage 2

3-11

3-06

- -

E061

Solenoid power stage 3

3-05

3-12

- -

E062

Solenoid power stage 4

3-03

3-14

- -

E063

Solenoid power stage 5

3-01

3-16

- -

E064

Solenoid power stage 6

3-02

3-15

- -

E066

Preheat light (E/G: Lowside

Power stage 2)

1-56

1-06

- -

E072

Preheat relay (E/G: Highside

Power stage 1)

1-13

1-07

V = V#volt

R 40 ±5 :

(25°C (77°F))

Voltage is only

measured when

afterheat

function is

operating

status.

Code Failure Component

Measuring

Points

Current Valve

Remarks

Active Passive

Page 52

SP001038Electrical System

Page 50

NOTE: 1. Active value: Starter switch has to be turned "ON"

Measuring points between component and wire

harness have to be connected.

2. Passive value: Starter switch has to be turned

"OFF"

Measuring points between component and wire

harness have to be disconnected.

3. Measuring points are engine controller's points and

passive value is each component's value.

4. V#batt: Source power of equipment.

E083

Fuel HI pressure pump

(E/G: Current controlled

Highside power stage 1)

- - -

Fuel metering

unit error of

high-pressure

pump.

E091

System start-up test for

shutoff path

- - -

Power supply

error

Engine

controller error.

E092

Monitoring of misfire cylinder

1

- - -

Injector error

Speed signal

error of cam

shaft speed

sensor or crank

shaft speed

sensor.

E093

Monitoring of misfire cylinder

2

- - -

E094

Monitoring of misfire cylinder

3

- - -

E095

Monitoring of misfire cylinder

4

- - -

E096

Monitoring of misfire cylinder

5

- - -

E097

Monitoring of misfire cylinder

6

- - -

E098

Monitoring of misfire multiple

cylinder

- - -

E099

Monitoring of overrun - - -

E101

Engine speed redundant - - -

Code Failure Component

Measuring

Points

Current Valve

Remarks

Active Passive

Page 53

SP001038

Page 51

Electrical System

FMIs (Failure Mode Identifier)

Information of Machine Operation

Accumulated operation hour of each mode and status is

displayed.

1. Operating Hour Information

A. Entering Sub-menus: When a cursor is located in

"Operating Hrs" of special menu screen (Figure 40)

press enter button ( , 3 on Figure 24) and

"Operating Hrs" screen will be displayed (Figure 41).

B. Information screen of machine operation (Figure 41).

FMI 0

Above normal range (DATA VALID but ABOVE NORMAL OPERATIONAL RANGE)

FMI 1

Below normal range (DATA VALID but BELOW NORMAL OPERATIONAL RANGE)

FMI 2

Incorrect signal (DATA ERRATIC, INTERMITTENT OR INCORRECT)

FMI 3

Voltage above normal (VOLTAGE ABOVE NORMAL OR SHORTED TO HIGH SOURCE)

FMI 4

Voltage below normal (VOLTAGE BELOW NORMAL OR SHORTED TO LOW SOURCE)

FMI 5

Current below normal (CURRENT BELOW NORMAL OR OPEN CIRCUIT)

FMI 6

Current above normal (CURRENT ABOVE NORMAL OR GROUNDED CIRCUIT)

FMI 8

Abnormal signal (ABNORMAL FREQUENCY OR PULSE WIDTH OR PERIOD)

FMI 11

Failure mode not identifiable (ROOT CAUSE NOT KNOWN - Malfunction)

FMI 31

NOT AVAILABLE OR CONDITION EXISTS

SP E C IAL MEN U

1. Machine Info

2. Failure Info

3. Operating Hrs

: UP : DOW N : SELECT

FG0005 71

Figure 40

OP E R AT I N G H O U RS

Reset Hours

Operating Hours

: UP : D OWN : SELECT

FG0005 72

Figure 41

Page 54

C. Operating Hours Screen

: UP : DO WN : SELECT

FG0005 73

1. Powe r

2. Tr enching

3. Au to idle

4. Travel speed

I speed

I I speed

: 00042 Hr

: 00003 Hr

: 00005 Hr

: 00007 Hr

: 00001 Hr

OP E R AT I N G H O U RS

Figure 42

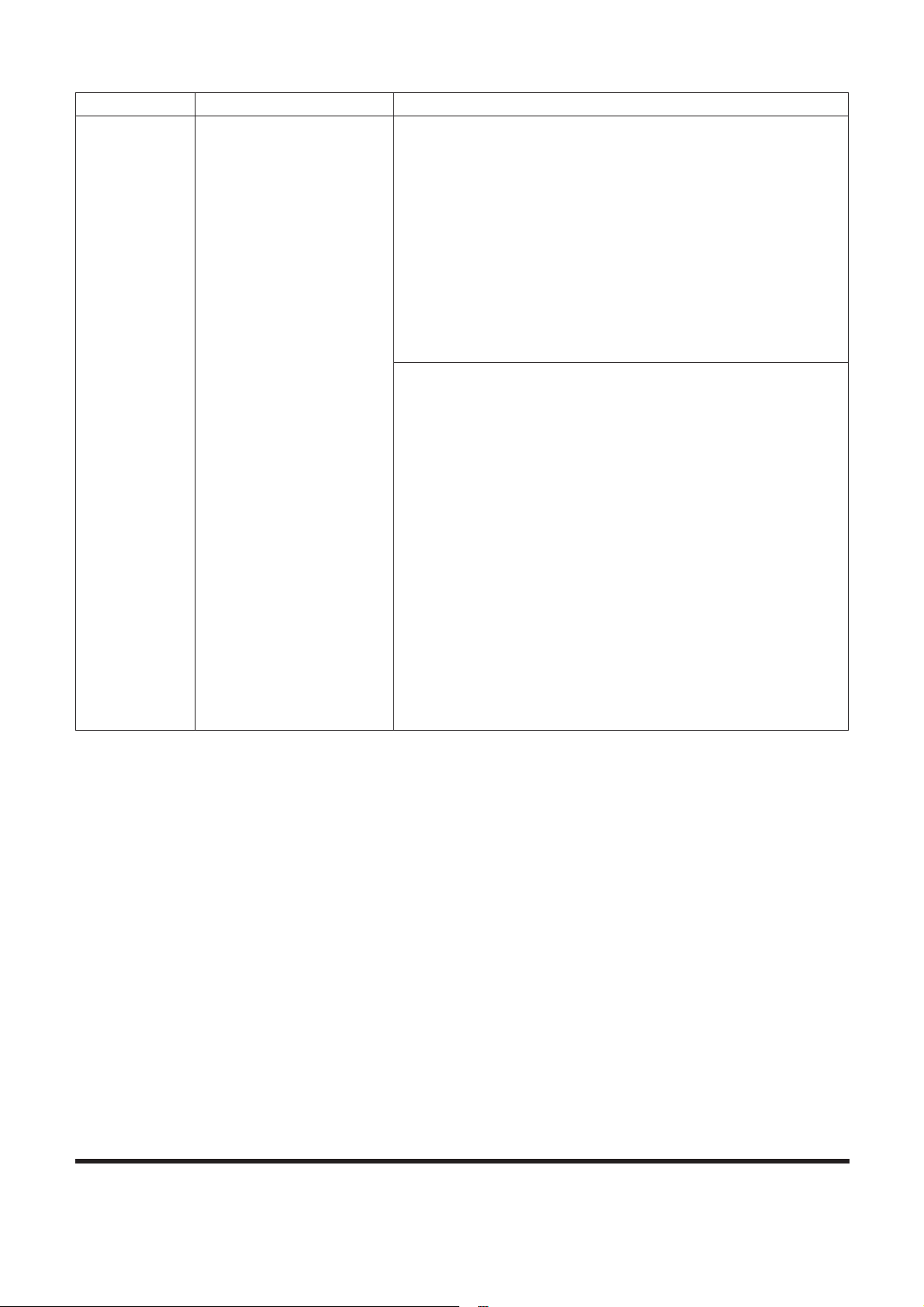

Item Information Contents Detection Method

Power Mode Operation hours used power mode

are displayed.

Power mode switch (Instrument panel) "ON" status and Alternator signal

(CN2-14) is "HI"

Trenching Mode Operation hours used trenching

mode are displayed.

Trenching mode switch (Instrument

panel) - "ON" status and Alternator

signal (CN2-14) is "HI"

Auto Idle Operation hours used auto idle

status are displayed.

Auto idle switch (Instrument panel) "ON" status and Alternator signal

(CN2-14) is "HI"

Travel Speed:

-1st

- 2nd

Operation hours used low speed

and high speed are displayed.

1st: High speed s/v "OFF" status

2nd: High speed s/v and travel pressure

switch "Py" (control valve) - "ON" status.

Hydraulic Oil Temperature

Distribution (°C (°F))

Temperature of hydraulic oil is

classified 6 steps. And operation

hours of each step are displayed

Under 30°C (87°F)

31 - 50°C (88 - 123°F)

51 - 75°C (124 - 168°F)

76 - 85°C (169 - 186°F)

86 - 95°C (187 - 203°F)

Over 96°C (204°F)

The resistance delivered from

temperature sensor of hydraulic oil is

classified 6 steps. And operation hours

of each step are displayed. (Alternator

output HI status)

Coolant Temperature

Distribution (°C (°F))

Temperature of coolant is classified

6 steps. And operation hours of

each step are displayed.

Under 40°C (105°F)

41 - 60°C (106 - 141°F)

61 - 85°C (142 - 186°F)

86 - 95°C (187 - 204°F)

96 - 105°C (205 - 222°F)

Over 106°C (223°F)

The resistance delivered from coolant

sensor is classified 6 steps. And

operation hours of each step are

displayed. (Alternator output HI status)

D. Exiting Sub-menus: If escape button (ESC, 4 on

Figure 24) is pressed for more than 1 second, this

information screen will be returned to previous

screen.

Information contents of operation hour

Page 52

SP001038Electrical System

Page 55

SP001038

Page 53

Electrical System

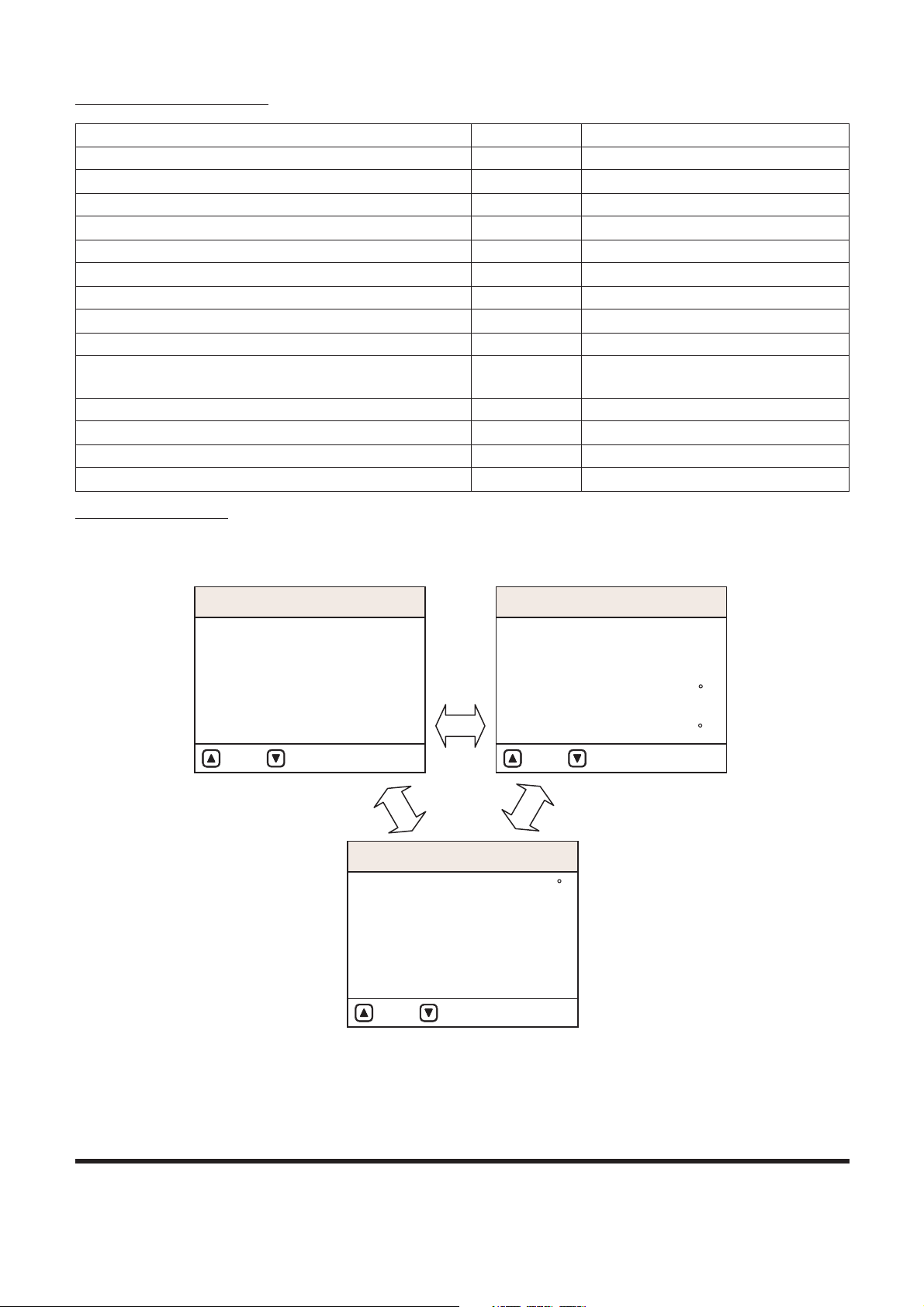

Menu Selection of Operation Hour Information

Example of Machine Operation Info Screen

2. Operation hour reset

A. Entering Sub-menus: When cursor is located in

"Reset Hrs" of information screen of operating hours

press enter button ( , 3 on Figure 24) and

"Machine Operation Info" screen will be displayed.

1. Power Mode

2. Trenching Mode

3. Auto Idle

4. Travel Speed 1st, 2nd

5. Hydraulic Oil Temperature Distribution

6. Coolant Temperature Distribution

FG000574

Figure 43

FG0005 75

OP E R AT I N G H O U RS

: UP : DOWN P age:1/3 : UP : DO WN Page:2/3

: UP : DOWN Page:3/3

1. Powe r

2. Tr enching

3. Au to idle

4. Tr avel speed

I Sp eed

I I S pee d

: 00042 Hr

: 00003 Hr

: 00005 Hr

: 00007 Hr

: 00001 Hr

5. Hyd. Oi l Temp. [ C]

30

31 - 50

51 - 75

86 - 95

96

: 00003 Hr

: 00005 Hr

: 00008 Hr

76 - 85 : 00000 Hr

: 00007 Hr

: 00001 Hr

6. Cool ant Temp. [ C]

40

41 - 60

61 - 85

86 - 95

96 - 105

1 06

: 00003 Hr

: 00005 Hr

: 00000 Hr

: 00000 Hr

: 00007 Hr

: 00001 Hr

OP E R AT I N G H O U RS

OP E R AT I N G H O U RS

Figure 44

Reset Hrs

Operating Hrs

: UP : DO WN : Yes

FG0005 78

OP E R AT I NG H O URS

Figure 45

Page 56

SP001038Electrical System

Page 54

B. Reset screen of operation hour

C. Exiting Sub-menus: If escape button (ESC, 4 on

Figure 24) is pressed for more than 1 second, this

information screen will be returned to previous

screen.

NOTE: When "YES" ( , 3 on Figure 24) button is

pressed, operation hours will reset.

At this time, resetting signal will be displayed

and the screen will move to previous menu after

resetting.

NOTE: When "NO" (ESC, 4) button is pressed, the

screen will recover to previous menu without

resetting.

Machine Operation Info Screen

1. If you press the YES" ( , 3 on Figure 24) button,

password entrance screen appears.

2. When right password is input, machine operation periods

will be deleted and Reset Completed screen will appear 3

seconds.

3. If you press the "NO" (ESC, 4) button, the previous screen

appears without resetting operation periods.

ESC: No

FG0005 76

: Yes

OP E R AT I NG H O URS

ENTER PASSWD

Figure 47

ESC: No

FG0005 77

: Yes

DE L E TED ! ! !

OP E R AT I NG H O URS

Figure 48

ESC: No

FG0010 86

: Yes

PASSWORD ERR !!!

OP E R AT I NG H O URS

Figure 49

OP E R AT I NG H O URS

Figure 46

Al l Ope r ati n g

Ho u r s w i ll b e

DE L E TED .

: Yes

ESC: No

FG0005 79

Page 57

Electrical System

SP001038

Page 55

Page 58

SP001038Electrical System

Page 56

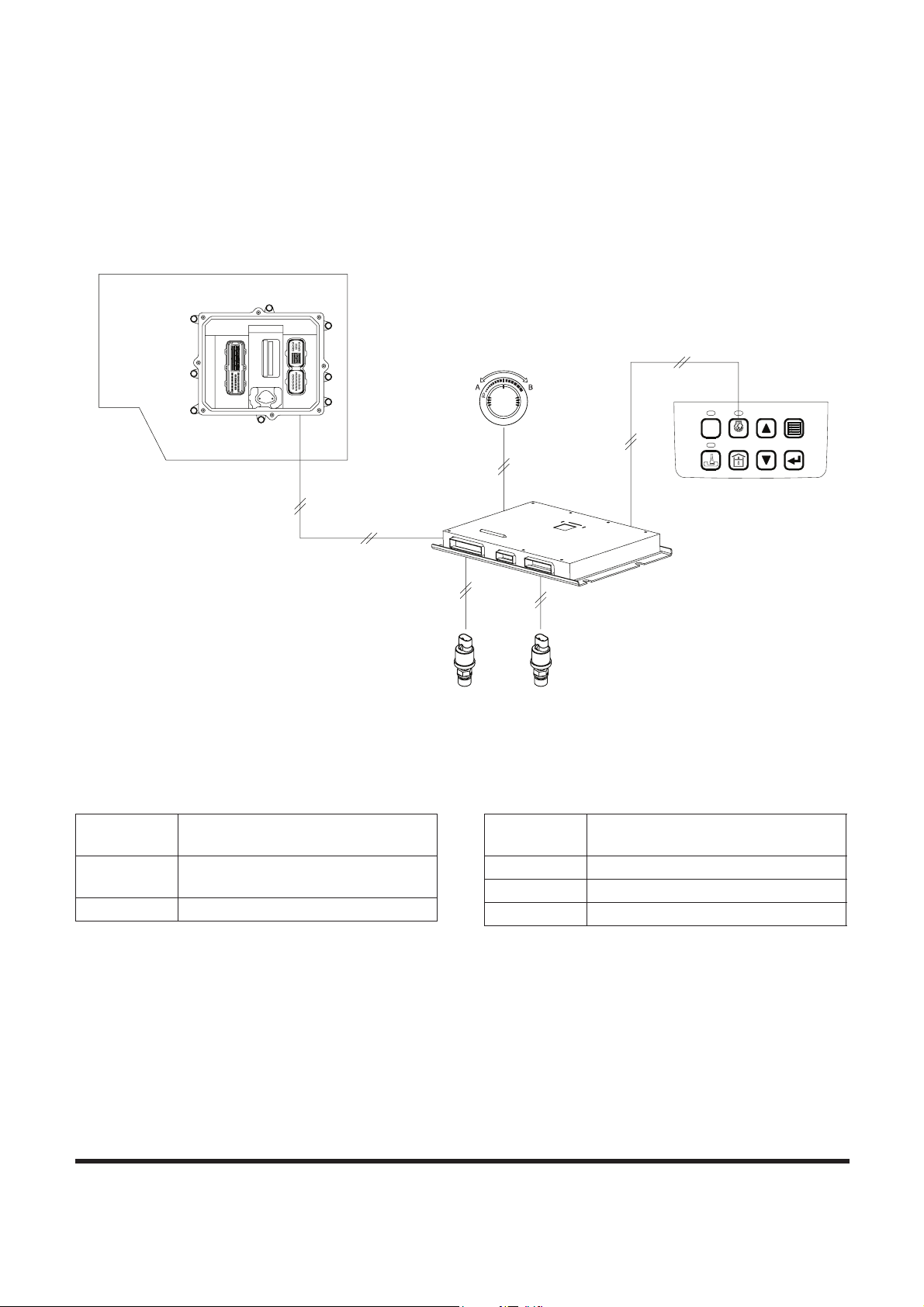

ELECTRONIC HYDRAULIC

CONTROL SYSTEM (e-EPOS)

Control System Schematic

Work Mode

Auto Idle

Machine Info

E/G

E/G speed order

FG000795

POWER UP

C

H

E

F

H

C

POWER

152

3

6

7

AUTO

4

ESC

8

E/G SPEED

02/05 [MO] 11:30

1700

RPM

CHECK

5

44

3

8

8

7 7

16

6 6

11 12 14

13

15

109

2

17 21 19 18 22 20

23

1

Figure 50

Page 59

SP001038

Page 57

Electrical System

Reference

Number

Description

1 Instrument Panel

2 e-EPOS Controller

3 Engine Controller (ECU)

4 Main Pump

5 Aux Pump

6 Control Valve

7 Pressure Switch

8 Pump Pressure Sensor

9

Electromagnetic Proportional

Pressure Reducing Valve

(Attachment)

10

Electromagnetic Proportional

Pressure Reducing Valve (Mode

Control)

11 Solenoid Valve (Boost)

12 Solenoid Valve (Swing Priority)

13 Solenoid Valve (High Speed)

14 Solenoid Valve (Breaker)

15 Travel Motor

16 Main Relief Valve

17 Engine Control Dial

18

Breaker/Boost/Shear Selector

Switch

19 Auto Travel Selector Switch

20

Boost Switch

(Right Work Lever)

21 Sensor

22 Aux Mode Switch

23 Aux Mode Resistor

Reference

Number

Description

Page 60

SP001038Electrical System

Page 58

POWER MODE CONTROL

POWER

1

5

2

3

6

7

AUTO

4

ESC

8

E/G

FG000796

1

10

5

4

66

3

17

23 22

4

2

Figure 51

Reference

Number

Description

1

Instrument Panel (Power Mode

Selector Switch)

2 e-EPOS Controller

3 Engine Controller (ECU)

4 Main Pump

5 Aux Pump

6 Control Valve

10 Electromagnetic Proportional

Pressure Reducing Valve (Mode

Control)

17 Engine Control Dial

22 Aux Mode Switch

23 Aux Mode Resistor

Reference

Number

Description

Page 61

SP001038

Page 59

Electrical System

The power mode switch permits the selection of the appropriate

engine power depending on the working condition. One of the

two, Power Mode or Standard Mode, setting can be selected.

When the engine starter switch is turned "ON," the power mode

is automatically defaulted to standard mode. The desired mode

can be selected by pressing the selector button on the

instrument panel. When the power mode is selected, the

indicator light will turn "ON" to display the selected mode.

The quantity of oil discharged by the pump and the engine

speed are determined by the mode selected by the operator.

The pump output in each mode is determined by the mode

selection and is listed in the following table

Mode Standard Mode Power Mode

Output (%) Approximately 85% 100%

Page 62

SP001038Electrical System

Page 60

Operation

1. Power Mode

This mode should be selected for high speed work. In this

mode the engine output is most efficiently utilized due to

the discharged oil volume being controlled based on the

equivalent horsepower curve at various loaded pressures.

The e-EPOS controller compares the target engine speed

with the actual engine speed and controls the signal to the

E.P.P.R. (Electromagnetic Proportional Pressure

Reducing) valve which in turn varies the pump output

quantity.

If the load increases, the engine speed will fall below the

rated speed. When this occurs, the controller senses this

decrease and immediately reduces the pump discharge

volume to maintain the engine speed at the rated level.

On the other hand, if the load is decreased the controller

increases the discharge volume of the pump to maintain

the engine speed at the rated level.

By repeating these control operations, the engine speed is

maintained at the rated speed so that maximum power can

be generated.

In Power Mode, the e-EPOS controller receives engine

speed signals from the engine control dial and the engine

controller (ECU) and converts it to an operating signal

current and is then transferred to the pump's E.P.P.R

valve. At this time the E.P.P.R. valve converts the electric

signal to the corresponding control pressure and sends it

to the two pumps, adjusting the pump discharge volume to

the desired level.

ARO0260L

Figure 52

B D

CA

FG0 00 58 0

Figure 53

Reference

Number

Description

A Engine Horsepower (hp)

B Engine Speed (rpm)

C Pump Discharge Volume (lpm)

D Pump Discharge Pressure

(kg/cm2)

Reference

Number

Description

Page 63

SP001038

Page 61

Electrical System

2. Standard Mode

Standard Mode is used for general work. When this mode

is selected it will reduce noise and fuel consumption in

comparison with Power Mode. The current to the E.P.P.R.

valve is shut off and pump discharge volume is controlled

by pump regulator.

3) Operation in case of failure in the control system (Aux

mode operation

Though it is impossible to control current of the E.P.P.R

(Electromagnetic Proportional Pressure Reducing) Valve

controlling the discharge volume of pump due to fault in control

system, the machine can be operated in the aux mode.

Upon turning "ON" the aux mode switch, the E.P.P.R Valve

controlling the discharge volume of pump comes into contact

with the aux mode resistor to let current of a certain value flow.

At this time, the discharge volume of pump follow the control by

the pump regulator, nearly at quantity roughly similar to that in

the standard mode.

B D

CA

FG0005 81

Figure 54