Doosan DL550-5 Operation & Maintenance Manual

Operation &

Maintenance

Manual

WHEEL LOADER

950106-01245NA-1

July 2014

DL550-5

Serial Number 10001 and Up

Operation & Maintenance Manual

DL550-5 WHEEL LOADER

Serial Number 10001 and Up

DOOSAN and the DOOSAN logo are registered

trademarks of DOOSAN Corporation in the United

States and various other countries around the

world.

Copyright DOOSAN 2014

950106-01245NA-1

July 2014

Copyright Doosan 2011 Operation and Maintenance Manual

Table of Contents

Foreword ....................................................................................0-1

Safety Messages ............................................................................... 0-2

AEM Safety Manual (North America Only) ........................................ 0-3

Product Information............................................................................ 0-4

Product Identification ......................................................................... 0-5

Federal Emission Control Systems.................................................... 0-6

Safety..........................................................................................1-1

Safety Decals..................................................................................... 1-2

General ............................................................................................ 1-14

Operation ......................................................................................... 1-25

Maintenance .................................................................................... 1-38

Transportation.................................................................................. 1-53

Environment and Circumstances ..................................................... 1-55

Operating Controls....................................................................2-1

Component Locations ........................................................................ 2-2

Operator's Area.................................................................................. 2-5

Steering Console and Pedals ............................................................ 2-6

Front Instrument Panel .................................................................... 2-17

Multifunction Gauge and Graphic Information Display..................... 2-22

Right Side Switch Panel................................................................... 2-52

Left Side Electric Steering Control Unit (Optional)........................... 2-69

Various Cabin Locations .................................................................. 2-72

Heater and Air Conditioner Operation.............................................. 2-76

Stereo/CD Player (Optional) ............................................................ 2-82

Seat Adjustment W/Air Suspension (Standard) ............................... 2-83

Seat Adjustment W/Air Suspension and Heater .............................. 2-86

DL550-5

Table of Contents

I

Seat Belt .......................................................................................... 2-88

Door Side Latch ............................................................................... 2-89

Arm Rest.......................................................................................... 2-90

Fuse Box/Relay................................................................................ 2-91

Wheel Chocks.................................................................................. 2-94

Operation....................................................................................3-1

To Operate a New Wheel Loader ...................................................... 3-1

Starting and Stopping Engine ............................................................ 3-2

Emission Control System................................................................. 3-13

Machine Travel ................................................................................ 3-18

If Engine Stalls While Traveling ....................................................... 3-21

Working in Water ............................................................................. 3-21

Towing ............................................................................................. 3-22

F/R (Forward/Reverse) Travel Control System................................ 3-24

Machine Shut Down......................................................................... 3-25

Operation of Attachment .................................................................. 3-27

Bucket Angle Indicator ..................................................................... 3-27

Adjustment of Bucket Position Switch.............................................. 3-28

Operation Under Abnormal Conditions ............................................ 3-29

Long Term Storage .......................................................................... 3-34

Auto Grease System (Optional) ....................................................... 3-36

Inspection, Maintenance and Adjustment...............................4-1

Maintenance Information ................................................................... 4-1

Machine Setup Position for Maintenance .......................................... 4-5

Maintenance Handling Access........................................................... 4-7

Handling Oil, Fuel, DEF (AdBlue) Coolant....................................... 4-10

Electrical System Maintenance........................................................ 4-14

Recommend Fuel, Coolant, and Lubricant ...................................... 4-15

Preventive Maintenance .................................................................. 4-22

Table of Recommended Lubricants ................................................. 4-24

Transmission Oil .............................................................................. 4-27

Axle Oils........................................................................................... 4-28

DL550-5Table of Contents

II

Fluid Capacities ............................................................................... 4-29

Lubrication and Service Chart.......................................................... 4-30

Maintenance Intervals...................................................................... 4-34

10 Hour / Daily Service .................................................................... 4-36

50 Hour / Weekly Service ................................................................ 4-46

250 Hour / Monthly Service.............................................................. 4-51

500 Hour / 3 Month Service ............................................................. 4-62

1,000 Hour / 6 Month Service .......................................................... 4-72

1,500 Hour / 9 Month Service .......................................................... 4-87

2,000 Hour / Yearly Service ............................................................. 4-89

12,000 Hour / 6 Year Service........................................................... 4-95

Standard Bolt Torque Chart ............................................................. 4-96

Electrical System ............................................................................. 4-97

Engine Cooling System.................................................................... 4-98

Handling of Accumulator................................................................ 4-101

Hydraulic Pressure Checks............................................................ 4-103

Long Term Storage ........................................................................ 4-108

Parking Brake Adjustment ............................................................. 4-109

Severe Conditions Maintenance .................................................... 4-111

Tires ............................................................................................... 4-112

Transmission Recalibration............................................................ 4-115

Transportation ...........................................................................5-1

Transporting Machine ........................................................................ 5-1

Lifting Machine................................................................................... 5-5

Troubleshooting ........................................................................6-1

Braking............................................................................................... 6-1

Electrical System ............................................................................... 6-2

Engine................................................................................................ 6-2

DL550-5

Hydraulic System............................................................................... 6-5

Steering.............................................................................................. 6-7

Travel System.................................................................................... 6-8

Table of Contents

III

Specification ..............................................................................7-1

General Specifications ....................................................................... 7-1

Working Range and Dimensions ....................................................... 7-2

Working Capacities ............................................................................ 7-4

Approximate Weight of Workload Materials....................................... 7-5

Index ...........................................................................................8-1

IV

DL550-5Table of Contents

This Operation & Maintenance Manual was written to give owner

or operator instructions on safe operation and maintenance of

DOOSAN equipment. READ AND UNDERSTAND THIS

OPERATION AND MAINTENANCE MANUAL BEFORE

OPERATING YOUR DOOSAN EQUIPMENT. Keep this manual

in the cabin so it is always available. If it is lost, order another

one from your DOOSAN distributor.

ur

If there are any questions, contact yo

This manual may illustrate options and accessories not installed

on your equipment.

Any modification made without written authorization or approval

om

DOOSAN can create a safety hazard.

fr

DOOSAN distributor.

1Foreword

Always replace parts with genuine DOOSAN parts or

authorized replacement parts.

DOOSAN

DL550-5

Foreword

0-1

SAFETY MESSAGES

Safety messages and safety decals included in this manual and

on the machine provide instructions how to operate, service and

maintain the machine. Safety messages and safety decals

indicate potential hazards and describe safety precautions

required to avoid hazards. Operator and maintenance personnel

should read and understand these safety messages and decals

before beginning operation or maintenance.

SAFETY ALERT SYMBOL

Be Prepared - Get to Know All Operating and Safety

Instructions.

This is a Safety Alert Symbol. Wherever it appears in this

manual

alert to the potential for personal injury or accidents.

Always observe safety precautions and follow

recommended procedures.

Signal Words

or on safety decals on the machine, you must be

The signal words "DANGER", "WARNING", "CAUTION" are

throughout safety messages and safety decals in this

used

manual or on the machine. They indicate an existence of, and

the relative seriousness of, a hazard. All three indicate that a

safety risk is involved. Observe the precautions indicated

whenever a Safety Alert Symbol is present, no matter which

signal word appears next to it.

DANGER

DANGER - This signal word is used on safety messages and

safety labels and indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING

WARNING - This signal word is used on safety messages and

safety labels and indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION

CAUTION - This signal word is used on safety messages

and safety labels and indicates a potentially hazardous

situation which, if not avoided, could result in minor or

moderate injury.

0-2

DL550-5Foreword

Other Signal Words

Figure 1

In addition to safety signal words, the following signal words are

used

to indicate proper and effective use of machine.

IMPORTANT

This signal word identifies procedures which must be

followed to avoid damage to machine.

NOTE: Th

e word "NOTE" identifies information for effective

use.

AEM SAFETY MANUAL

(NORTH AMERICA ONLY)

The AEM Safety Manual delivered with the machine gives

general safety information.

The AEM Safety Manual must be read and understood before

beginn

ing operation or maintenance and is not intended to

replace the Operation & Maintenance Manual delivered with the

machine.

DL550-5

Foreword

0-3

PRODUCT INFORMATION

Intended Use

The machine is intended to be used under normal conditions for

applications described in this manual. If it is used for other

purposes, or in potentially hazardous environments, special

precautions must be followed and the machine must be

equipped for such use. Examples include, but are not limited:

falling object guards, work lights, etc. Do not engage in

prohibited uses as described in this manual. Contact your

DOOSAN distributor for further information.

Machine Capacity

Do not exceed machine capacity by modifying machine or using

unapproved attachments.

Exceeding machine capacity can ad

performance characteristics such as: stability, system

certifications such as brakes and steering, the Roll-over

Protective Structure (ROPS) and can result in death or serious

injury. Contact your DOOSAN distributor for further information.

versely affect machine

Engine and Emission Control System

Maintenance

Proper inspection, maintenance and repair is essential to

keeping engine and machine systems properly operating. This

includes proper inspection and maintenance of the machine's

emission control system. This could include machine and engine

components, such as an EGR (Exhaust Gas Recirculation)

system, fuel system, turbocharger, electrical system, air intake

system and/or cooling system.

As a heavy-duty off-road diesel engine owner, you are

sp

onsible for performing required maintenance. The required

re

maintenance procedures are outlined in this Operation &

Maintenance Manual, or Shop Manual. Do not remove, alter, or

render inoperative, any emission control system.

0-4

DL550-5Foreword

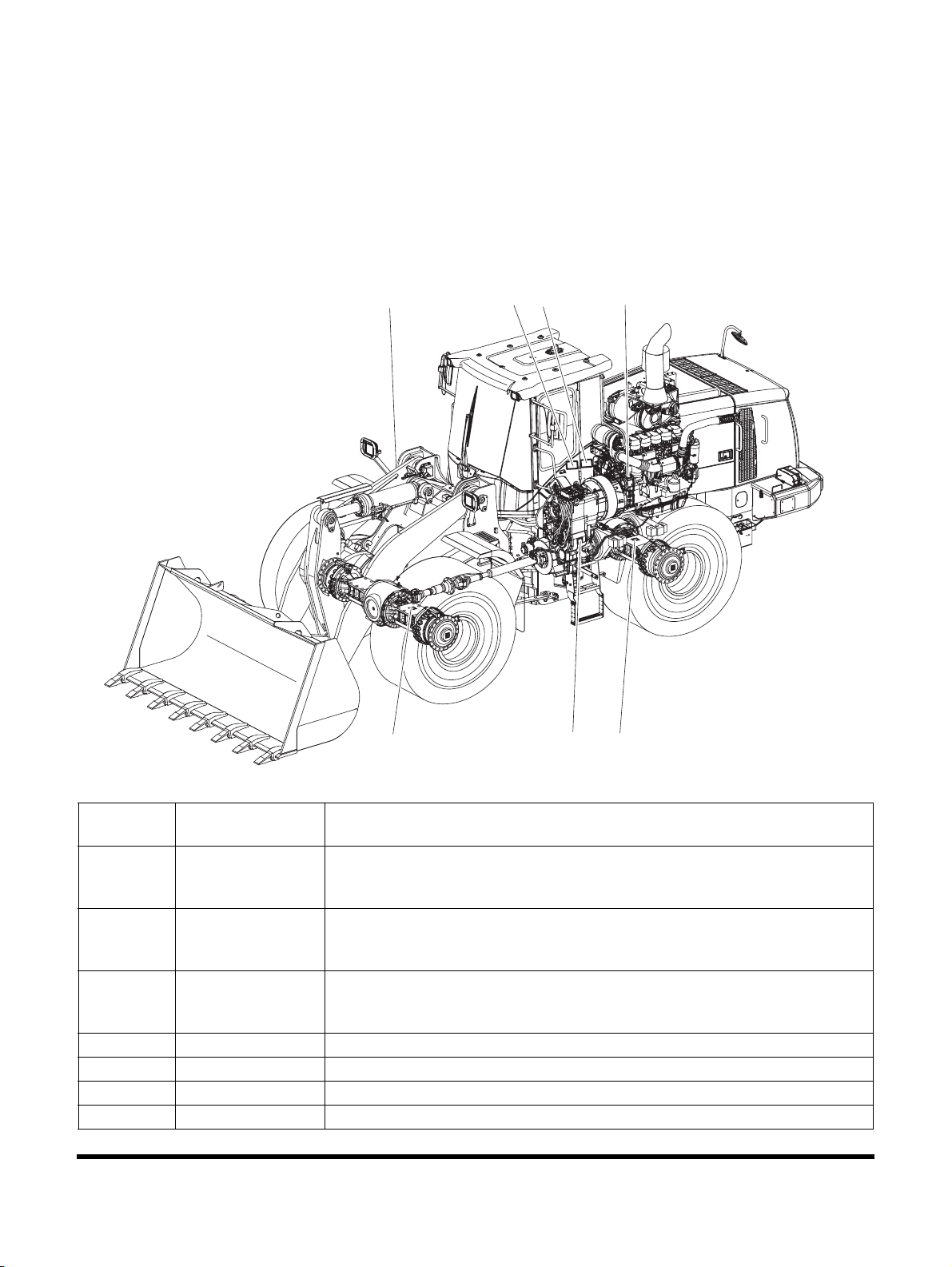

PRODUCT IDENTIFICATION

567

1324

WL1300045

Figure 2

Reference

Number

Description

1 Product Plate

The manufacturer's name and address, machine PIN.

Operating weight, year of manufacture, year of delivery and position of CE

mark (EU/EEA countries only) (stamped into right side).

2 Specification

Label operating weight, overall length, overall width, overall height, ground

clearance engine output, tire, turning radius, bucket capacity, dumping

reach, dumping clearance (only available for some regions).

3Cabin

The manufacturer's name and address, cabin part number, machine model

designation, operating weight, cabin serial number, ROPS/FOPS standard

number.

4 Engine The engine type designation and number.

5 Front Axle The manufacturer's name and address and front drive axle CIN.

6 Transmission The manufacturer's name and address and transmission CIN.

7 Rear Axle The manufacturer's name and address and rear drive axle CIN.

With the aid of the product plates, shown below, it is possible to

identify the machine and its components. The Product

Identification Number (PIN) indicates the model designation,

engine code and serial number of the machine. The Component

Identification Number (CIN) indicates the serial number of the

component. Make a note of the identification numbers.

When ordering spare parts, and in all telephone inquiries or

rr

espondence, the PIN and CIN, of the machine, must always

co

be referenced.

DL550-5

Foreword

0-5

FEDERAL EMISSION CONTROL SYSTEMS

Emission Control System Warranty

Statement

General Warranty Provisions

The emission control systems of your new Scania Engines

"Scania" in

using genuine parts, and were certified as being in conformity

with federal emission control regulations. Scania warrants to the

original owner, and to each subsequent owner, of a new Scania

industrial diesel engine.

1. Was designed, built and equipped so as to conform at the

dustrial diesel engine were designed, built and tested

time of sale

213 of the Clean Air Act, 42 U.S.C. section 7547, for their

full useful life and designed, built and equipped so as to

conform with all applicable regulations adopted by the

California Air Resources Board pursuant to its authority

under Chapters 1 and 2, Part 5, Division 26 of the

California Health and Safety Code, and:

with all applicab

le regulations under Section

2. Is free from defects in material and workmanship which

cause such engine to fail to conform to applicable

uld

wo

regulations for its warranty period or otherwise cause the

failure of a warranted part to be identical in all material

respects to the part as described in the engine

manufacturer's application for certification.

Where a warrantable condition exis

heavy-duty off-road engine at no cost to you including diagnosis,

parts, and labor.

Warranty Period

This warranty shall apply for one of the following periods,

whichever

• 3,000 hours of operation as determined by a device to

• Five years

Each engine is equipped with a device to

If that device fails to account for hours of use because of defects

in materials or workmanship, the engine shall be warranted for a

period of five years. The warranty period shall begin on the date

the engine is delivered to the first ultimate purchaser who, in

good faith, purchases the engine for purposes other than

imminent resale.

occurs first:

me

asure hours of use, or

ts, Scania w

measure hours of use.

ill repair your

0-6

DL550-5Foreword

The Warranty on Emission-related Parts Shall be

Interpreted as Follows:

1. Any warranted part which is not schedu

as required maintenance in Scania's written instructions for

maintenance and use of the engine by owner shall be

warranted for the warranty period defined above. If any

such part fails during the period of warranty coverage, it

shall be repaired or replaced by the engine manufacturer

according to Subsection (4) below. Any such part repaired

or replaced under the warranty shall be warranted for the

remaining warranty period.

2. Any warranted part which is scheduled only for regular

tion in Scania's written instructions for maintenance

c

inspe

and use of the engine by owner shall be warranted for the

warranty period defined above. A statement in such written

instructions to the effect of "repair or replace as necessary"

shall not reduce the period of warranty coverage. Any such

part repaired or replaced under warranty shall be

warranted for the remaining warranty period.

3. Any warranted part which is scheduled for replacement as

ed maintenance in Scania's written instructions for

quir

re

maintenance and use of the engine by owner shall be

warranted for the period of time before the first scheduled

replacement point for that part. If the part fails before the

first scheduled replacement, the part shall be repaired or

replaced by the engine manufacturer according to

Subsection below. Any such part repaired or replaced

under warranty shall be warranted for the remainder of the

period before the first scheduled replacement point for the

part.

led for replacement

4. Repair or replacement of any warranted part under the

rr

anty provisions of this article shall be performed at no

wa

charge to the owner at a warranty station.

5. Notwithstanding the provisions of Subsection

warranty services or repairs shall be provided at all

manufacturer distribution centers that are franchised to

serve the subject engines.

6. The owner shall not be charged for diagnostic labor that

leads to

defective provided that such diagnostic work is performed

at a warranty station.

7. The engine manufacturer shall be liable for damages to

other en

under warranty of any warranted part.

8. Throughout the engine's warranty period defined above,

the en

warranted parts sufficient to meet the expected demand for

such parts.

9. Any replacement part, as defined in Section 1900 (b), Title

13

the performance of any maintenance or repairs and must

be provided without charge to the owner.

the determination that a warranted part is in fact

gine components proximately caused by a failure

gine manufacturer shall maintain a supply of

of the California Code of Regulations, may be used in

(4) above,

DL550-5

Foreword

0-7

It is not necessary for replacement parts to be the same

brand or by the same manufacturer as the original part sold

with the engine. Such use shall not reduce the warranty

obligations of the engine manufacturer.

10. Add-on or modified parts, as defined in Section 1900 (b),

Title 13

exempted by the California Air Resources Board may not

be used. The use of any nonexempt add-on or modified

parts shall be grounds for disallowing a warranty claim

made according to this article. The engine manufacturer

shall not be liable under this article to warrant failures of

warranted parts caused by the use of a nonexempt add-on

or modified part.

of the California Code of Regulations, that are not

11. The Executive Officer of th

Board may request, and in such case, the engine

manufacturer shall provide, any documents which describe

that manufacturer's warranty procedures or policies.

Parts Covered by the Warranty

The following is a list of parts considered to be part of the

sion Control Systems covered by the Emission Warranty

Emis

for Scania industrial engines which were built to conform to

federal and California emission control regulations:

1. Fuel injection system

2. Air Induction System:

3. Exhaust manifold system

4. Smoke puff limiter (included in ECU)

5. Oil fill cap

6. EGR system (when applicable):

A. Cooler

B. EGR valve

7. Exhaust brake (when applicable)

e Califor

nia Air Resources

8. NOx sensors:

A. NOx sensor, engine out

B. NOx sensor, tail pipe

9. DOC (when applicable)

10. SCR System:

A. DEF (AdBlue) tank

B. DEF (AdBlue) tank level, temperature and quality

se

nsor

s

C. DEF (AdBlue) hose

D. DEF (AdBlue) injector

E. DEF (AdBlue) injector pressure and temperature

se

0-8

nsor

s

DL550-5Foreword

F. Evaporator

G. SCR catalyst inlet temperature sensor

H. SCR catalyst including the ammon

I. SCR control unit (EEC3)

11. Miscellaneous items used in the abov

A. Electronic control unit (ECU), sensors, wiring

har

nesses.

B. Hoses, belts, connectors, assemblies, clamps, fittings

tu

bing, sealing gaskets or devices and mounting

hardware.

C. Pulleys, belts and idlers.

D. Emission control information label

ia-slip catalyst

e systems:

IMPORTANT

This list does not include all expendable maintenance

parts.

• Expendable emission related parts requiring

scheduled

first scheduled replacement point.

• Emission related parts scheduled for inspection

and rep

considered expendable and if repaired or

replaced under warranty shall be warranted for

the remaining warranty period.

maintenance are warranted until their

lacement only as necessary are not

See Specific Warranty Exclusions below.

General Warranty Limitations

To retain the dependability of the exhaust emis

originally built into your Scania industrial diesel engine, it is

essential that engine is installed according to Scania installation

instructions and emission certificates. Your engine is designed

to operate on diesel fuel only. Use of any other fuel can result in

your engine no longer operating in compliance with state or

federal emissions requirements. The use of alternative fuels

shall not void the warranties on any engine certified if the fuel is

approved for use.

e responsible for the

In addition, as the engine owner, yo

performance of all scheduled maintenance listed in your owner's

manual, and all necessary repairs, on your new Scania industrial

diesel engine. Scania may deny a warranty claim if the engine or

part has failed because of abuse, neglect, improper

maintenance or unapproved modifications.

Receipts covering the performance o

be retained in the event questions arise concerning

maintenance.

u ar

f

regular maintenance must

sion control

DL550-5

Foreword

0-9

The receipts must be transferred to each subsequent owner of

the engine with the emission warranted engine. Scania cannot,

however, deny warranty solely for the lack of receipts or for your

failure to ensure the performance of all scheduled maintenance.

The Warranty covers the cost of diagnosis, repair and

replacem

systems performed by an authorized Scania distributor or dealer

using genuine Scania parts. You may elect to have

maintenance, replacement or repair of these components and

systems performed by any repair establishment or individual

without invalidating the Warranty.

The use of other than Scania repla

invalidate the warranty on other components unless such parts

cause damage to warranted parts. However, the cost of such

services or parts will not be covered by the Warranty.

You are responsible for initiating the warranty process. The

Californ

heavy-duty off-road engine to an authorized Scania dealer as

soon as a problem exists. The warranty repairs must be

completed by the dealer as expeditiously as possible.

ent parts and services of warranted components and

c

ement parts also does not

ia Air Resources Board suggests that you present your

WARNING

AVOID DEATH OR SERIOUS INJURY

Use of replacement parts which are not of equivalent

quality

systems. Accordingly, it is recommended that only Scania

repair or replacement parts be used for maintenance, repair

or replacement of emission control systems.

If other than Scania parts are used for maintenance, repair

or replac

such parts are warranted by their manufacturer to be

equivalent to genuine Scania parts.

Specific Warranty Exclusions

This warranty does not cover:

1. Malfunctions in any part cause

2. Engine installation, including cooling system, intake

may impair the effectiveness of emission control

ement, the owner should obtain assurance that

d

by any of the following:

misuse, abuse, improper adjustments, modifications,

alteration, tampering, disconnection, improper or

inadequate maintenance, or use of fuels not recommended

for the engine as described in the Operator's Manual.

m and exhaust system installation, that is not

syste

completed according to the Scania installation instructions

and emissions certificate for this engine type.

3. Damage resulting from accidents, acts of nature or

events beyond the control of Scania.

0-10

other

DL550-5Foreword

4. The replacement of expendable maintenance items such

as filters, hoses, belts, oil, thermostat, exhaust system and

coolant made about scheduled maintenance services once

these parts have been replaced.

5. Replacement items which are not genuine Scania parts or

not auth

6. Inconvenience, loss of use of the engine or commercial

loss.

7.

Any engine on which the actual use cannot be accurately

determin

hours of use unrelated to defects in materials or

workmanship.

orized by Scania.

ed because of a failure of the device to track

8. Any engine operating outsid

Customer Support

If you do not receive the warranty service to which you believe

re entitled under the Warranty provisions, or if you need

you a

additional support or information concerning the Warranty,

contact your DOOSAN or SCANIA engine distributor.

e th

e United States.

Catalytic Converter

WARNING

AVOID DEATH OR SERIOUS INJURY

The SCR catalytic converter contains vanadium pentoxide,

a chemica

The SCR converter is fitted in the silencer and does not

constitute a health hazard during normal use and handling.

When performing work on the SCR catalytic converter which can

resu

Such work includes, for example, opening the silencer

machining and scrapping the catalytic converter.

l known to the State of California to cause cancer.

lt in exposure to dust, safety precautions must be taken.

Safety precautions when working on the SCR-system.

• Inhalation: If dust is inhaled, the person must be provided

th fresh air immediately. Then seek immediate medical

i

w

attention.

• Eye contact: Rinse eyes with water im

persists, seek immediate medical attention.

• Skin contact: Wash with water and soap. Remove

contamin

• Ingestion: If large amounts have been ingested, drink

plenty o

medical attention.

DL550-5

ated clothes.

f water and induce vomiting. Then seek immediate

mediately. If irritation

Foreword

0-11

Environmental hazards

• Vanadium pentoxide is toxic to water organisms and can

cause de

Environmental protection measures

trimental long term effects to water environment.

• The SCR catalytic converter is a man

contains vanadium pentoxide, a hazardous substance.

Before disposing of, or scrapping, a used SCR catalytic

converter, it must be tested for any hazardous

characteristics (ignitability, corrosiveness, reactivity, acute

hazardousness, and toxicity), as those categories are

described in 22 CCR 66261.30. If the spent SCR catalytic

converter exhibits hazardous characteristics and is being

disposed of, it will be considered by the State of California

to be a hazardous waste subject to Title 22, California

Code of Regulations. Before disposing of hazardous

waste, review and follow all pertinent federal and California

requirements.

• Vanadium pentoxide is a liste

product - P120 - pursuant to 22 CCR 66261.33 (e).

According to the State of California, commercial chemical

products that are discarded or intended to be discarded

are hazardous wastes and are subject to all provisions of

Title 22, California Code of Regulations. Before disposing

of vanadium pentoxide, review and follow all pertinent

federal and California requirements.

• If the SCR catalytic converter

any dust spillages from the catalyst must be collected and

tested for the presence of vanadium pentoxide before

proper disposal. Dust spillages should also be tested for

any hazardous characteristics (ignitability, corrosiveness,

reactivity, acute hazardousness, and toxicity), as those

categories are described in 22 CCR 66261.30, before

proper disposal. If the dust contains either vanadium

pentoxide or exhibits hazardous characteristics and is

being disposed of, it will be considered by the State of

California to be a hazardous waste subject to Title 22,

California Code of Regulations. Before disposing of

hazardous waste, review and follow all pertinent federal

and California requirements.

is opened for maintenance,

ufactured article that

d com

mercial chemical

• Do not dispose of the used SCR catalytic converter or its

nstitu

co

sanitary sewers.

Additional considerations when working

• Perform work on the SCR catalytic converter in a well

ve

protect you from splashing or spraying of reductant or

coolant.

• When engine is running, the exhaust system parts can

reach such hig

injury. Make sure that exhaust system temperature has

cooled before starting to work.

0-12

ent parts into any waterways, storm drains or

on the

ntilated area. Use protective goggles and gloves to

h temperatures there is a risk of personal

SCR-system

DL550-5Foreword

• The SCR system is heated by water from the engine

cooling system. The cooling system runs at high-pressure

and when the engine is hot the coolant is hot. Do not open

any coolant hoses without first stopping the coolant flow in

the hose.

• A P3 type respirator/filter mask or

musk, protective goggles and gloves must be used for any

work where there is a risk of exposure to dust from the

SCR catalytic converter.

• Dispose the SCR catalytic converter properly after

machining in

• Eating, drinking or smoking while s

permitted.

• Any dust from the SCR catalytic converter must be

re

moved using a vacuum cleaner with microfilter to

minimize exposure.

• Make sure that work surface is cleaned after completed

rk; Vacuum first then swab.

wo

• Make sure you clean your hands after working with SCR

cata

lytic converter to avoid ingestion.

• Work done on the SCR catalytic converter may generate

waste

considered by the State of California to be a

hazardous waste subject to Title 22, California Code of

Regulations. Before disposing of hazardous waste, review

and follow all applicable federal and California

requirements.

a disposable container.

a type FFP3 fine dust

ervicing is not

California Emission Control Warranty

Statement

Your Warranty Rights and Obligations

The California Air Resources Board is pleased to explain the

emission control system warranty on your 2011 engine. In

California, new heavy-duty off-road engines must be designed,

built, and equipped to meet the State's stringent anti-smog

standards. Scania CV AB must warrant the emission control

system on your engine for the periods of time listed below

provided there has been no abuse, neglect or improper

maintenance of your engine.

Your emission control system may include parts such as the

fu

el-

injection system and the air induction system. Also included

may be hoses, belts, connectors and other emission-related

assemblies.

Where a warrantable condition exists, Sc

your heavy-duty off-road engine at no cost to you including

diagnosis, parts and labor.

ania C

V AB will repair

DL550-5

Foreword

0-13

Manufacturer's Warranty Coverage

The 2011 and later heavy-duty off-road engines are warranted

for a period of five years or 3,000 hours of operation, whichever

occurs first. If any emission-related part on your engine is

defective, the part will be repaired or replaced by Scania CV AB.

Owner's Warranty Responsibilities

• As the heavy-duty off-road engine owner, you are

responsible for the performance of the required

maintenance listed in your owner's manual. Scania CV AB

recommends that you retain all receipts covering

maintenance on your heavy-duty off-road engine, but

Scania CV AB cannot deny warranty solely for the lack of

receipts or for your failure to ensure the performance of all

scheduled maintenance.

• As the heavy-duty off-road engine owner, you should

er be aware that Scania CV AB may deny you

v

howe

warranty coverage if your heavy-duty off-road engine or a

part has failed because of abuse, neglect, improper

maintenance or unapproved modifications.

• Your engine is designed to operate on Diesel fuel only.

any other fuel can result in your engine no longer

Use of

operating in compliance with California's emissions

requirements.

• You are responsible for initiating the warranty process. The

ARB su

engine to a Scania CV AB dealer as soon as a problem

exists. The warranty repairs must be completed by the

dealer as expeditiously as possible.

• If you have any questions regarding your warranty rights

and resp

1-210-403-0007.

ggests that you present your heavy-duty off-road

onsibilities, you should contact Scania USA, Inc at

0-14

DL550-5Foreword

2Safety

DL550-5

Safety

1-1

SAFETY DECALS

Safety decals are attached to the machine to alert the operator

or maintenance person about potential hazards, the

consequences of potential injury, and instructions and/or actions

required to avoid the hazard. The location of the safety decals

and the description of the decals are reviewed in the following

section. Please become familiarized with all safety decals and

their messages.

Make sure that all the safety decals are in their correct location

legible. Clean or replace the safety decals if they are

and

damaged, missing, or the texts and pictorials are not legible.

When you clean the safety decals, use a soft cloth, water, and

soap. Do not use solvent, gasoline, or other harsh chemicals to

clean the safety decals because this could loosen the adhesive

that secures the decals to the machine. Remember, if a safety

decal is attached to a part that is replaced, install a new safety

decal on the replacement part.

This machine uses safety decals with and without text. The type

umber of safety decals can vary depending upon

n

and

geographical regions and machine models.

Safety Decals With Text

Safety decals with text consist of a signal wor

text message panel. In some cases, a pictorial panel may not be

part of the safety decal.

d, pictorial and a

1-2

DL550-5Safety

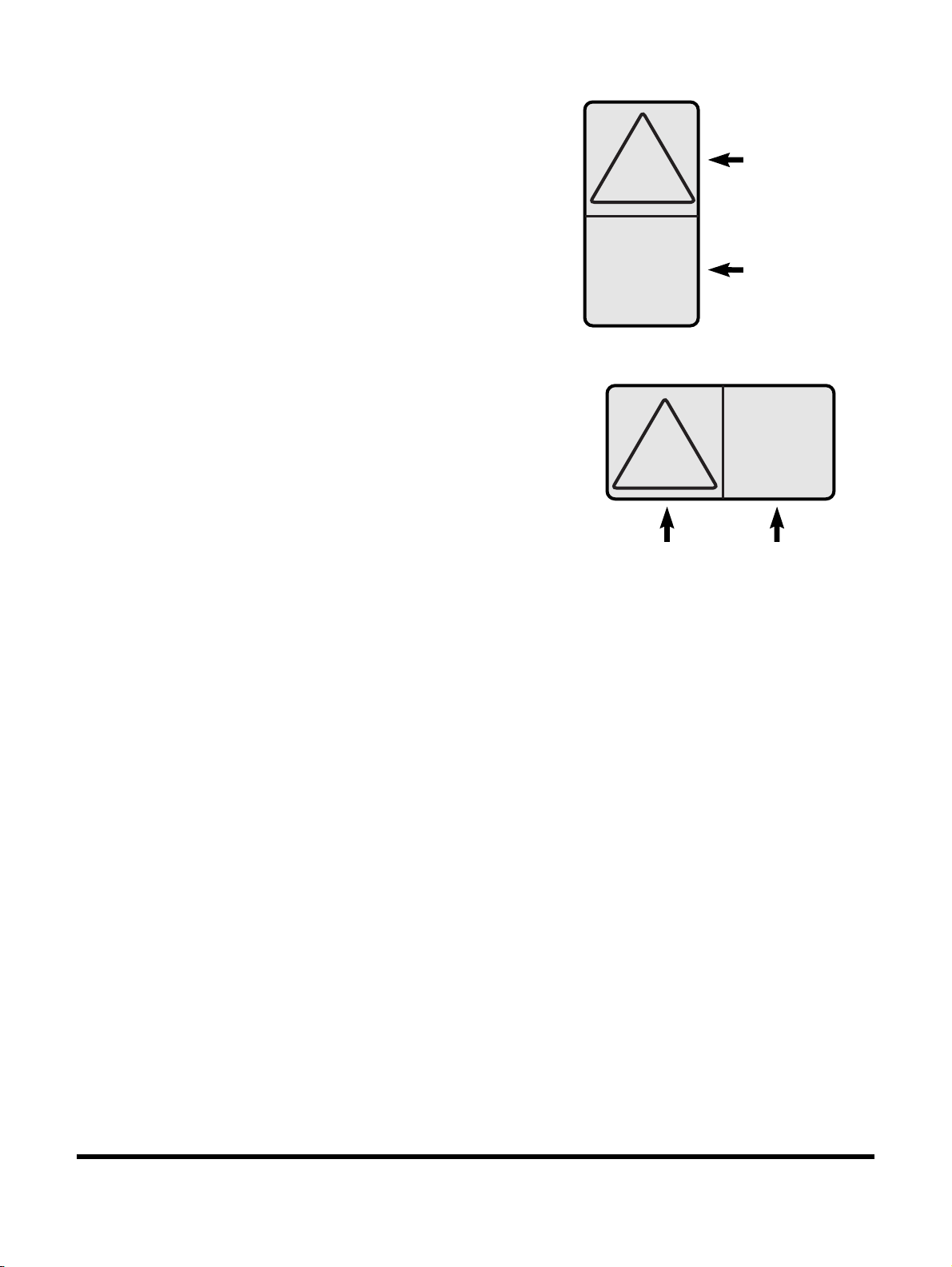

Safety Decals Without Text (No-Text)

Horizontal Configuration

Vertical Configuration

Hazard

Panel

Avoidance

Panel

Hazard

Panel

Avoidance

Panel

FG018723

Figure 1

Safety decals without text consist of a safety sig

n and safety

information panel. The safety sign panel is located at the top or

left side and the safety information panel is located at the bottom

or right side of the decal depending on its configuration. The

safety sign panel uses a black triangular band and a pictorial to

identify the hazard and the potential consequences of the failure

to follow instructions. The safety information panel uses

pictorials and/or prohibition signs to identify the actions

necessary to avoid the hazard.

DL550-5

Safety

1-3

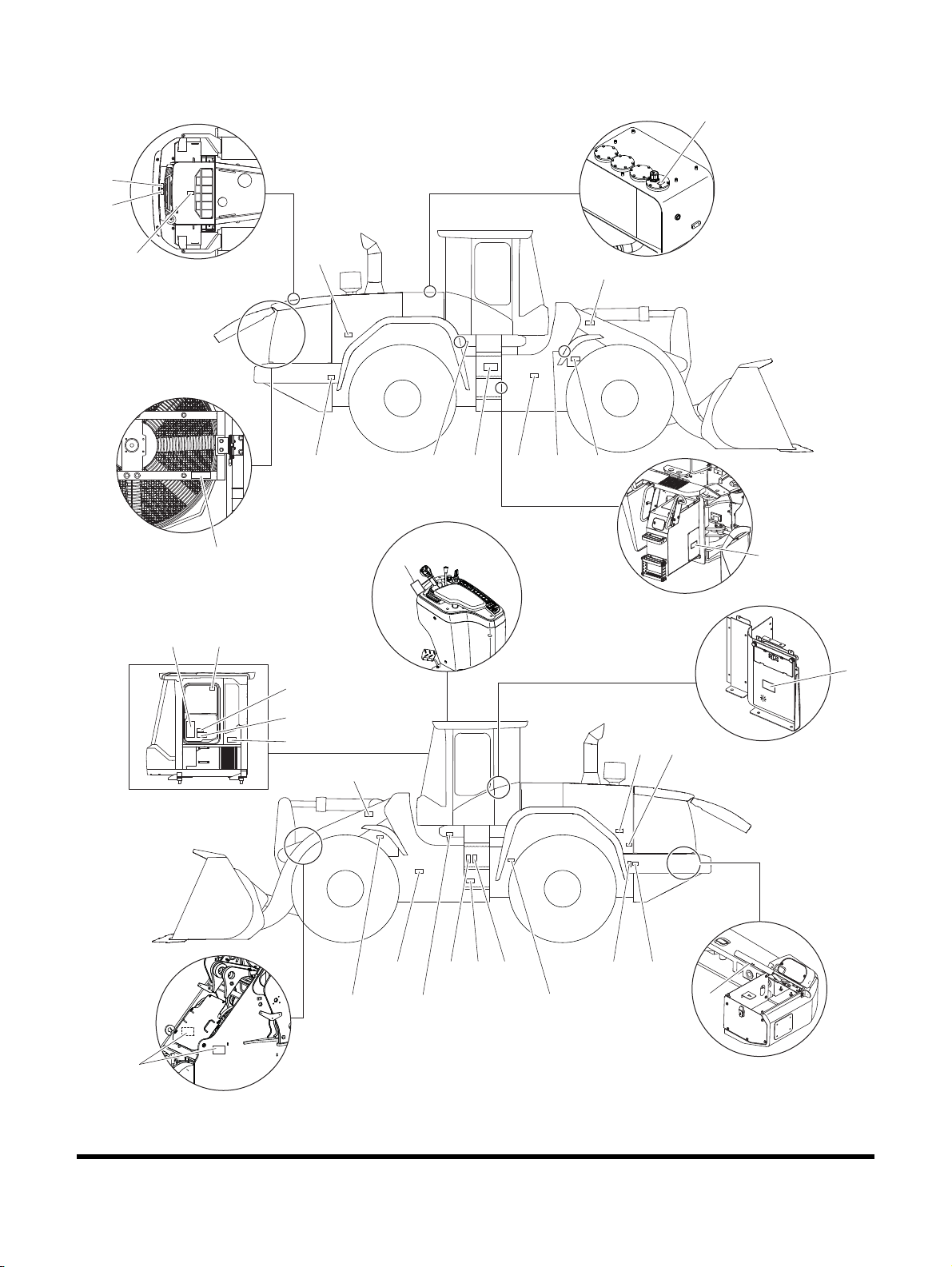

12

16

13

15

2319 20 14

19

11

(Steering)

9

10

11

(Pilot)

814 18

11

(Brake)

19

7

12

617

9

6

13

10

11(LIS)

21

22

WL1400801

5

24 2

3

1

4

Figure 2

Information and Location for Safety Decals

1-4

DL550-5Safety

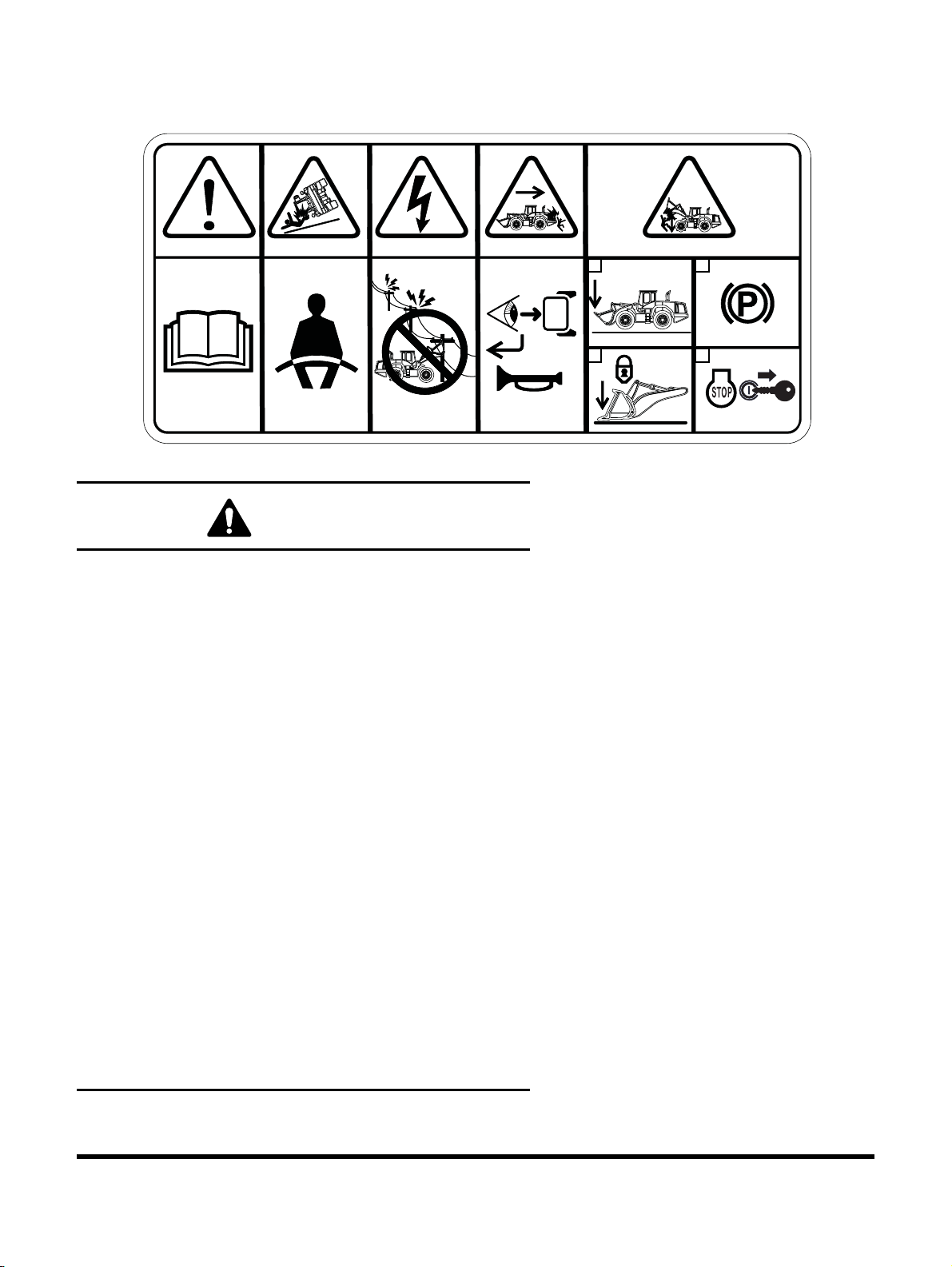

Safety Decal

1. General Hazard (950205-04644A)

WARNING

12

34

950205-04644A

WL1400812

AVOID DEATH OR SERIOUS INJURY

• Never use wheel loader without instructions.

• Read Operation & Maintenance Manual before

operat

ion.

• Always fasten your seat belt.

• Explosion or electrocution can occur if machine

contac

ts utility lines or pipes. Check for overhead or

underground lines before operating.

• Keep bystanders out of travel path and always look in

direction of travel.

the

• Ensure mirrors and rear view camera are clean and

working prop

erly.

• Sound the horn to alert bystanders before operating

• Never operate machine from outside the operator's

positio

n.

• TO LEAVE THE WHEEL LOADER:

1) Lower the attachment to the ground and make

sure all co

ntrols are in neutral.

2) Engage the parking brake.

3) Set pilot cutoff switch to OFF position.

4) Stop the engine and remove the key.

DL550-5

Safety

1-5

2. Emergency Exit (950205-04643)

WL1400805

WL1400813

IMPORTANT

If the primary exit is blocked, use right side window for

secondary exit.

3. Operating Load (950205-04915)

WARNING

AVOID DEATH OR SERIOUS INJURY

• Do not exceed Rated Operating Capacity (ROC).

950205-04643

ROC

• Do not travel or turn with lift arms raised.

• Load unload and turn on flat level ground.

• See Operating & Maintenance Manual for more

information.

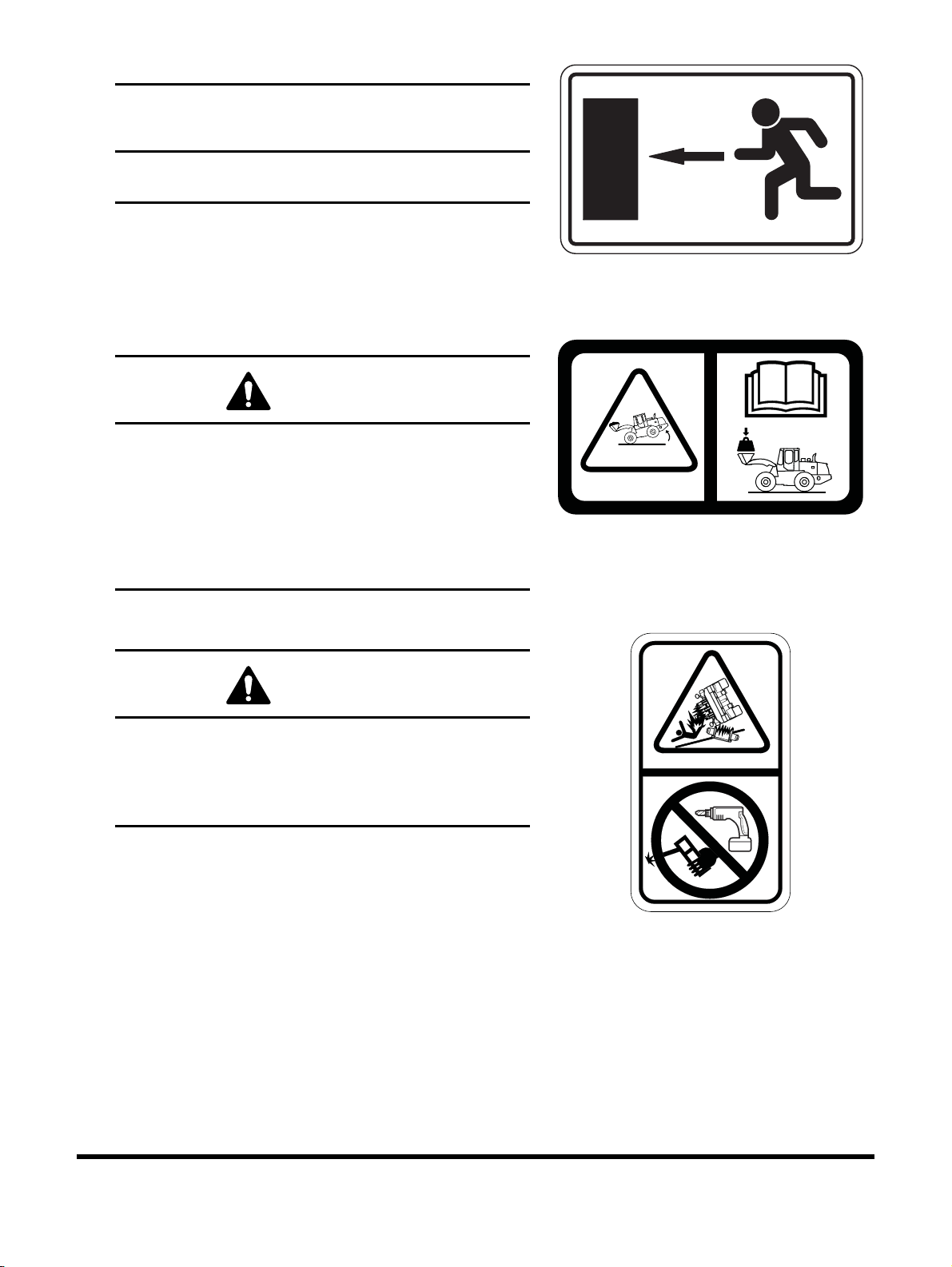

4. ROPS Warning (950205-04645)

WARNING

AVOID DEATH OR SERIOUS INJURY

• Do not weld on or drill holes in the protective

structure.

• Replacing ROPS, if damaged or modified.

Refer to See “Roll-over Protective Structure (ROPS)/

Falling Object Protective Structure (FOPS)” on page 2-23

for more information.

950205-04645

950205-04915

WL1400814

1-6

DL550-5Safety

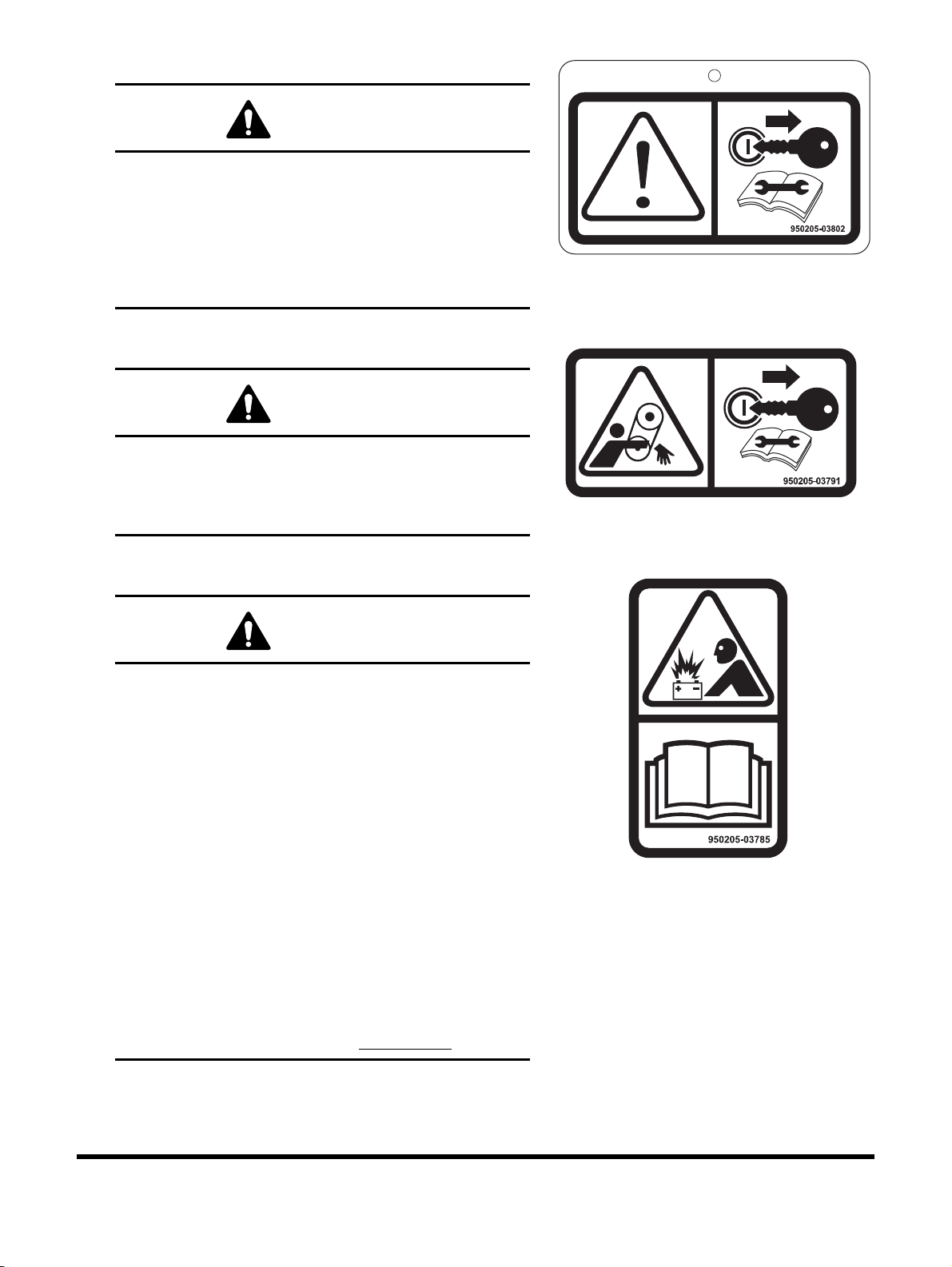

5. Warning Tag - "Do Not Operate" (950205-03802)

WARNING

AVOID DEATH OR SERIOUS INJURY

• Stop engine and remove the key.

• Attach "DO NOT OPERATE" warning tag to the

controls before servicing the machine.

• Do not operate when performing inspection or

maintenance.

6. Entanglement in Rotating Parts (950205-03791)

WARNING

ROTATING PARTS CAN CAUSE DEATH OR

SERIOUS INJURY

EX1301177

Keep away from belt and rotating parts. Stop engine

before servicing.

7. Battery Explosion (950205-03785)

WARNING

AVOID DEATH OR SERIOUS INJURY

• Read and follow instructions in Operation &

Maintenance Manual for battery maintenance.

• Keep arcs, sparks, flames, and lighted tobacco

away.

• Do not store metal tools or flammable materials

on or around batteries.

• Wear safety goggles and rubber gloves when

working with batteries.

• If battery acid contact occurs:

1) Flush your skin with water immediately and

apply baking soda or lime to neutralize the

acid.

EX1301181

EX1301183

DL550-5

2) Flush your eyes with water for 10 ~ 15

minutes.

3) Get medical attention immediately

.

Safety

1-7

8. Articulated Frame Lock (950205-01688B)

WL1400806

WL1400807

WARNING

AVOID DEATH OR SERIOUS INJURY

• Install articulated frame lock before servicing or

transporting.

9. Crush Hazard (950205-01687A)

WARNING

CRUSHING HAZARD CAN CAUSE SERIOUS INJURY

OR DEATH

• Keep out of this area unless articulated frame

lock is installed.

• Install articulated frame lock before servicing or

transporting.

950205-01688B

950205-01687A

10. Work Equipment (950205-01692A)

WARNING

AVOID DEATH OR SERIOUS INJURY

• Moving a lift arm control or failure of a part can

cause lift arm to drop.

• Never reach under or stand under raised lift arm

unless the lift arm is properly secured.

11. Pressurized Gas and Fluid (950205-03782)

WARNING

AVOID DEATH OR SERIOUS INJURY

• Heat or impact can cause the accumulator to

explode.

• Keep away from flame.

• Do not weld on or drill into accumulator.

950205-01692A

WL1400808

EX1301187

1-8

DL550-5Safety

Loading...

Loading...