Doosan DL250-3 Shop Manual

Shop Manual

DL250-3 Wheel Loader

Serial Number 10001 and Up

DOOSAN and the DOOSAN logo are registered

trademarks of DOOSAN Corporation in the United

States and various other countries around the

world.

950106-00985E

July 2012

Original Instructions Copyright DOOSAN 2012

1Table of Contents

Safety

Wheel Loader Safety ............................................................................ SP002397

Specifications

Specification for DL250-3 ..................................................................... SP002778

General Maintenance

General Maintenance Instructions........................................................ SP002454

Standard Torques................................................................................. SP002404

Drivetrain

Transmission and Torque Converter (ZF 4WG-190)............................ SP002779

Transmission Error Codes (ZF) ............................................................ SP002423

Axle (ZF-MT-L 3085 II) ......................................................................... SP002780

Driveshaft.............................................................................................. SP002663

Brake

Service Brake ....................................................................................... SP002781

Brake Supply Valve .............................................................................. SP002427

Charging Block ..................................................................................... SP002428

Parking Brake ....................................................................................... SP002429

Brake Pedal Valve ................................................................................ SP002430

Accumulator.......................................................................................... SP002782

Steering

Power Steering System ........................................................................ SP002599

Priority Valve......................................................................................... SP002600

Emergency Steering............................................................................. SP002601

Table of Contents

Page I

Frame

Articulation Center ................................................................................ SP002783

Counterweight....................................................................................... SP002784

Tank

Oil Tank ................................................................................................ SP002664

Fuel Tank.............................................................................................. SP002785

Hydraulics

Main Pump............................................................................................ SP002440

Main Control Valve ............................................................................... SP002786

Load Isolation System .......................................................................... SP002787

Cooling System..................................................................................... SP002788

Pilot System.......................................................................................... SP002445

Hydraulic Schematic DL250-3 .............................................................. SP002789

Electrical System

Air Conditioner...................................................................................... SP002447

Electrical System .................................................................................. SP002662

Electrical Schematic DL200-3 / DL220-3 / DL250-3............................. SP002666

Table of Contents

Page II

1Safety

SP002397

WHEEL LOADER SAFETYSP002397

Wheel Loader

Safety

Edition 3

Wheel Loader Safety

SP002397

Page 1

MEMO

Wheel Loader Safety

Page 2

SP002397

Table of Contents

Wheel Loader Safety

Safety Instructions ................................................ 5

Applicable Models ................................................ 5

Safety Messages .................................................. 6

Safety Decals ....................................................... 7

General................................................................. 8

Transportation .................................................... 19

Operation............................................................ 21

Maintenance ....................................................... 39

Environment and Circumstances........................ 54

Wheel Loader Safety

SP002397

Page 3

MEMO

Wheel Loader Safety

Page 4

SP002397

SAFETY INSTRUCTIONS

WARNING

AVOID DEATH OR SERIOUS INJURY

Instructions are necessary before operating or servicing

machine. Read and understand the Operation and

Maintenance Manual and signs (decals) on machine. Follow

warnings and instructions in the manuals when making

repairs, adjustments or servicing. Check for correct

function after adjustments repairs or service. Untrained

operators and failure to follow instructions can cause death

or serious injury.

APPLICABLE MODELS

The contents of this section apply to the following models and

serial number ranges.

MODEL SERIAL NUMBER RANGE

DL200-3 10001 and Up

DL220-3 10001 and Up

DL250-3 10001 and Up

Wheel Loader Safety

SP002397

Page 5

SAFETY MESSAGES

Safety messages and safety decals included in this manual and

on the machine provide instructions how to operate, service and

maintain the machine. Safety messages and safety decals

indicate potential hazards and describe safety precautions

required to avoid hazards. Operator and maintenance personnel

should read and understand these safety messages and decals

before beginning operation or maintenance.

SAFETY ALERT SYMBOL

Be Prepared - Get to Know All Operating and Safety

Instructions.

This is a Safety Alert Symbol. Wherever it appears in this

manual or on safety decals on the machine, you must be

alert to the potential for personal injury or accidents.

Always observe safety precautions and follow

recommended procedures.

Signal Words

The signal words "DANGER", "WARNING", "CAUTION" are

used throughout safety messages and safety decals in this

manual or on the machine. They indicate an existence of, and

the relative seriousness of a hazard. All three indicate that a

safety risk is involved. Observe the precautions indicated

whenever a Safety Alert Symbol is present, no matter which

signal word appears next to it.

DANGER

DANGER - This signal word is used on safety messages and

safety labels and indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING

WARNING - This signal word is used on safety messages and

safety labels and indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION

CAUTION - This signal word is used on safety messages

and safety labels and indicates a potentially hazardous

situation which, if not avoided, could result in minor or

moderate injury.

Page 6

SP002397Wheel Loader Safety

Other Signal Words

In addition to safety signal words, the following signal words are

used to indicate proper and effective use of machine.

IMPORTANT

This signal word identifies procedures which must be

followed to avoid damage to machine.

NOTE: The word "NOTE" identifies information for effective

use.

SAFETY DECALS

Location of safety labels (decals) can vary from unit to unit.

Refer to appropriate Operation and Maintenance Manual, and

parts manual for your unit.

Always replace damaged or faded decals.

Wheel Loader Safety

SP002397

Page 7

GENERAL

Safe Operation is Operator's Responsibility

Only trained and authorized personnel should operate and

maintain the machine.

Follow all safety rules, regulations and instructions when

operating or performing maintenance on machine.

• Do not operate machine if you are under the

influence of drugs or alcohol. An operator who is

taking prescription drugs must get medical advice to

determine if he or she can safely operate the

machine.

• When working with other personnel on a work site, be

sure that all personnel know the nature of work and

understand all hand signals that are to be used.

• Be sure that all guards and shields are installed in

their proper location. Have guards and shields

repaired or replaced immediately if damaged.

• Be sure that you understand the use and

maintenance of all safety features such as pilot cutoff

switch and seat belt. Use them always.

• Never remove, modify or disable any safety features.

Always keep them in good operating condition.

• Always check for and know the location of

underground and overhead utility lines before working.

• Failure to use and maintain safety features according

to instructions in this manual, Safety Manual and

Shop Manual can result in death or serious injury.

Know Your Machine

Know how to operate your machine. Know the purpose of all

controls, gauges, signals, indicators and monitor displays. Know

the rated load capacity, speed range, braking and steering

characteristics, turning radius and operating clearances. Keep in

mind that rain, snow, ice, loose gravel, soft ground, slopes etc.,

can change operating capabilities of your machine.

Proper Work Tools and Attachments

Only use work tools and attachments that are recommended by

DOOSAN for use on DOOSAN machines. When installing and

using optional attachments, read instruction manual for

attachment, and general information related to attachments in

this manual. Because DOOSAN cannot anticipate, identify or

test all attachments that owners may want to install on their

machines, contact DOOSAN for written authorization and

approval of attachments, and their compatibility with optional

kits.

Page 8

SP002397Wheel Loader Safety

Attachments and attachment control systems that are

compatible with the machine are required for safe and reliable

machine operation. Do not exceed maximum operating weight

(machine weight plus attachment) that is listed on ROPS

certification plate.

Make sure that all guards and shields are in place on machine

and on work tool. Depending on type or

equipment, there is a potential that work

interfere with the cabin or other parts of

unfamiliar work equipment, check if there

interference, and operate with caution.

While you are performing any maintenance, testing, or

adjustments to attachments, stay clear of the following areas:

cutting edges, pinch points, and crushing surfaces.

Never use attachment as a work platform or manlift.

Contact your DOOSAN distributor about auxiliary hydraulic kits

for attachments installation. If you are in doubt about the

compatibility of a particular attachment with the machine, consult

your DOOSAN distributor.

combination of work

equipment could

machine. Before using

is any potential of

Pressurized Fluids

Pressurized air or fluids can cause debris and/or fluids to be

blown out. This could result in death or serious injury.

Immediately after operations are stopped, coolant, engine oil,

and hydraulic oil are at their highest temperatures and the

radiator and hydraulic tank are still under pressure. Always wait

for temperature to cool down. Follow specified procedures when

attempting to remove caps, drain oil or coolant, or replacing

filters. Always wait for temperature to cool down, and follow

specified procedures when performing these operations. Failure

to do so can result in death or serious injury.

When pressurized air and/or pressurized water is used for

cleaning, wear protective clothing, protective shoes, and eye

protection. Eye protection includes goggles or a protective face

shield.

Pressure can be trapped in a hydraulic system and must be

relieved before maintenance is started.

Releasing trapped pressure can cause sudden machine

movement or attachment movement. Use caution if you

disconnect hydraulic lines or fittings.

High-pressure oil that is released can cause a hose to whip or oil

to spray. Fluid penetration can result in death or serious injury. If

fluid enters skin or eyes, get immediate medical attention from a

physician familiar with this injury.

FG018457

Figure 1

Obey all local laws and regulations for disposal of liquids.

To prevent hot coolant from spraying out, stop engine and wait

for coolant to cool. Using gloves, slowly loosen cap to relieve

pressure.

Wheel Loader Safety

SP002397

Page 9

Flying or Falling Objects

On work sites where there is a potential hazard that flying or

falling objects can come in contact with operator's cabin, select

and use a guard to match operating conditions for additional

operator protection.

Working in mines, tunnels, deep pits, and loose or wet surfaces,

can produce hazard of falling rocks or flying objects. Additional

protection for operator's cabin may be required such as a Falling

Object Protective Structure (FOPS) or window guards. Contact

your DOOSAN distributor for information on available protective

guards.

To prevent personnel from being struck by flying objects, keep

personnel out of work area.

HAOA110L

Figure 2

Personal Protective Equipment (PPE)

Do not wear loose clothing and accessories. Secure long hair.

These items can snag on controls or on other parts of equipment.

Do not wear oily clothes. They are highly flammable.

Do not forget that some risks to your health may not be

immediately apparent. Exhaust gases and noise pollution may not

be visible, but these hazards can cause disabling or permanent

injuries. Breathing masks and/or ear protection may be required.

Wear a hard hat, safety shoes, safety goggles, mask, leather

gloves, earplugs and other protective equipment, as required.

While working on machine, never use inadequate tools. They

could break or slip, or they may not adequately perform intended

functions.

Correction of Machine Problems

If any machine problems are found during operation and

maintenance (noise, vibration, smell, incorrect gauges, smoke,

oil leakage, etc.), or if any abnormal warming alerts are

displayed on display monitor, stop the machine immediately and

take the necessary corrective actions. Do not operate the

machine until problem has been corrected.

HAOA100L

Figure 3

HAOA020L

Figure 4

Page 10

SP002397Wheel Loader Safety

Crushing and Cutting

Keep objects away from moving fan blades. Fan blades can

throw and cut objects.

Do not use a wire rope that is kinked or frayed, or a wire rope

with any loss of diameter. Wear leather gloves when handling a

wire rope.

When striking a loose retainer pin, it can fly out and can cause a

serious injury. Make sure that area is clear of personnel when

striking a retainer pin. To avoid injury to your eyes, wear safety

goggles when striking a retainer pin.

Do not put your hand, arm or any other part of your body

between movable parts. If going between movable parts is

necessary, always position and secure work equipment so it

cannot move. Properly support equipment before performing

any work or maintenance under raised equipment.

If control levers are operated, clearance between machine and

work equipment will change and this may lead to serious

damage or can result in death or serious injury. Stay clear of

areas that may have a sudden change in clearance with

machine movement or equipment movement. Stay clear of all

rotating and moving parts. Unless instructed, never attempt

adjustments while machine is moving or while engine is running.

Do not depend on hydraulic cylinders to support raised

equipment. Equipment can fall if a control is moved, or if a

hydraulic line breaks, is loosened or disconnected.

If it is necessary to remove guards to perform maintenance,

always install guards after maintenance is completed.

Always have at least two people working together if the engine

must be running during service. One person needs to remain in

the operator's seat, ready to work the controls to stop the

machine or stop engine, if necessary.

HDO1010L

Figure 5

Wheel Loader Safety

SP002397

Page 11

Hot Coolant and Oils - Burn Prevention

Do not touch any part of an operating engine. Immediately after

operations are stopped, coolant, engine oil, and hydraulic oil are

at their highest temperatures. The radiator and hydraulic tank

are still under pressure. Always wait for temperature to cool

down. Attempting to remove caps, drain oil or coolant, or

replacing filters may lead to serious burns, if done when hot.

Relieve all pressure in air system, hydraulic oil system,

lubrication system, fuel system, and cooling system, before any

lines, fittings or related items are disconnected.

To prevent hot oil or coolant from spraying out, stop engine and

wait for oil and coolant to cool. Using gloves, slowly loosen cap

to relieve pressure.

FG019095

Figure 6

FG019096

Figure 7

Fire and Explosion Prevention

All fuels, most lubricants and some coolant mixtures are

flammable and can cause a fire resulting in death or serious

injury, and property damage. Flammable fluids that are leaking

or spilled onto hot surfaces or onto electrical components can

cause fire.

Inspect for and remove all flammable materials such as spilled

fuel and oil, and debris from machine. Do not allow any

flammable materials to accumulate on machine.

Always observe the following:

• Add fuel, oil, antifreeze and hydraulic fluid to machine

only in a well ventilated area. Machine must be

parked with controls, lights and switches turned

"OFF." Engine must be "OFF" and any flames,

glowing embers, auxiliary heating units or spark

causing equipment must be extinguished, or turned

"OFF" and kept well clear of machine.

• Dust that is generated from repairing or grinding

nonmetallic hoods or nonmetallic fenders can be

toxic, flammable and explosive. Repair these

components in a well ventilated area away from

flames or sparks and wear a dust mask when

grinding painted parts.

HDO1015I

Figure 8

FG018458

Figure 9

Page 12

SP002397Wheel Loader Safety

Maintenance

The machine and some attachments have components that

reach high temperatures under normal operating conditions. The

primary source of high temperatures are the engine and exhaust

system. If damaged or incorrectly maintained, the electrical

system can be a source of arcs or sparks.

Flammable debris (leaves, straw, etc.) must be removed

regularly. If flammable debris is allowed to accumulate, it can

cause a fire hazard. Clean machine often to avoid this

accumulation. Flammable debris in an engine compartment is a

potential fire hazard.

The operator's area, engine compartment and engine cooling

system must be inspected every day and cleaned. This is

necessary to prevent fire hazards and overheating.

Operation

Do not use machine where exhaust, arcs, sparks or hot

components can contact flammable material, explosive dust or

gases.

Do not operate machine near any flame.

Exhaust shields (if equipped) protect hot exhaust

from oil spray or fuel spray in case of a break in

components

a line, hose, or

seal. Exhaust shields must be correctly installed and maintained

properly.

Electrical

Check all electrical wiring and connections for damage daily.

Keep battery terminals clean and tight. Repair or replace any

damaged parts or wires that are loose or frayed. Clean all

electrical connections and tighten all electrical connections.

Never check battery charge by placing a metal object across

terminal posts. Use a voltmeter or a hydrometer.

Battery gas can explode and can result in death or serious

injury. Follow procedures in this manual for connecting battery

and for jump-starting. Do not jump-start or charge a frozen or

damaged battery. Keep all flames and sparks away from

batteries. Do not smoke in battery charging area.

Improper jumper cable connections can cause an explosion that

can result in death or serious injury. Refer to Operation and

Maintenance Manual for proper procedure in this manual.

Do not charge a frozen battery. This can cause an explosion.

After market radios or other electric operated equipment in cabin

must have a fuse in the electrical circuit.

Wheel Loader Safety

SP002397

Page 13

Hydraulic System

Check hydraulic tubes, hoses and fittings for damage, wear or

for leaks. Hydraulic lines and hoses must be properly routed and

have adequate support and secure clamps. Leaks can cause

fires. Never use a flame or bare skin to check for leaks.

Tighten or replace any parts that show leakage.

Check that all hose and tube clamps, guards, and cushions are

securely attached. If they are loose, they can vibrate during

operation and rub against other parts. This can cause damage

to hoses and cause high-pressure oil to spray on hot surfaces,

causing a fire and death or serious injury.

Always clean fluid spills. Do not use gasoline or diesel fuel for

cleaning parts. Use commercial nonflammable solvents.

X

X

HDO1045I

Figure 10

Fueling

Use caution when you are refueling a machine.

Fuel is flammable and can catch fire if it is brought close to a

flame.

Stop engine and let it cool before adding fuel. Do not smoke

while you are refueling a machine. Do not refuel a machine near

flames or sparks. Fill fuel tank outdoors.

Keep fuel and other fluid reservoir caps tight and do not start

engine until caps have been secured.

Store fuels and lubricants in properly marked containers away

from unauthorized personnel. Store oily rags and any flammable

materials in protective containers.

Static electricity can produce dangerous sparks at fuel filling

nozzle. In very cold, dry weather or other conditions that could

produce a static discharge, keep tip of fuel nozzle in constant

contact with neck of fuel filling nozzle, to provide a ground and

prevent sparks.

Always place plastic fuel containers on the ground before filling.

ARO1050S

Figure 11

Page 14

SP002397Wheel Loader Safety

Never Use Ether Starting Aids

Do not use ether or starting fluids on any engine that has glow

plugs, or an electric grid type manifold heater. These starting

aids can cause an explosion and result in death or serious

injury.

Use procedures in this manual for connecting battery and for

jump-starting.

Welding and Grinding

Always clean machine and attachment, disconnect battery

switch, and disconnect wiring from electronic controllers before

welding. Cover rubber hoses, battery and all other flammable

parts. Keep a fire extinguisher near machine when welding.

Toxic dust or gas can be produced when grinding or welding

painted parts. Grinding or welding painted parts must be done in

a well ventilated area. Wear a dust mask when grinding painted

parts.

FG018458

Figure 12

Dust generated from repairing nonmetallic parts such as hoods,

fenders or covers can be flammable or explosive.

Repair such components in a well ventilated area away from

flames or sparks.

Do not weld on lines or on tanks that contain flammable fluids.

Do not flame cut lines or tanks that contain flammable fluid.

Clean any such lines or tanks thoroughly with a nonflammable

solvent before welding or flame cutting.

If a Fire Occurs

If a fire occurs:

• Do not attempt to move machine or continue

operations.

• Turn starter switch to "O" (OFF) position to stop

engine.

• Use handrails and steps to get off machine.

• Immediately call for help or fire station.

• When using a fire extinguisher, always aim

extinguisher at base of fire.

• If an optional fire extinguishing system is in place, be

familiar with its operating procedures.

FG018459

Figure 13

NOTE: Depending on job conditions, other

Wheel Loader Safety

procedures could be necessary if a fire

occurs.

SP002397

Page 15

Fire Extinguisher and First-Aid Kit

(Emergency Medical Kit)

To be prepared in the event of a fire:

• Be sure that fire extinguishers have been provided

and read labels to ensure that you know how to use

them. It is recommended that an appropriately sized

(2.27 kg [5 lb] or larger) multipurpose A/B/C fire

extinguisher be mounted in cabin. Check and service

fire extinguisher at regular intervals and make sure

that all work site crew members are adequately

trained in its use.

• Inspect fire extinguisher and service fire extinguisher

regularly.

• Follow instructions on extinguisher instruction plate.

• Keep a first aid kit in storage compartment (Figure

15) and keep another kit at work site. Check kit

periodically and keep it properly supplied.

• Keep emergency numbers for doctor, ambulance

service, hospital and fire department readily

available.

HDO1009L

Figure 14

Electrical System and Electrical Shock

Never short across starter terminals or across batteries.

Shorting could damage electrical system and engine neutral

start system.

When engine is running or immediately after it has stopped, high

voltage is generated at injector terminal and inside engine

controller, so there is a potential for an electrical shock. Never

touch injector terminal or inside of engine controller.

NOTE:If it is necessary to touch injector terminal or inside

engine controller, contact your DOOSAN distributor.

FG026170

Figure 15

Page 16

SP002397Wheel Loader Safety

Rollover Protective Structure (ROPS)

The operator's cabin is a ROPS certified structure for protecting

the seat belted operator. It absorbs the impact energy of a

rollover impact. Do not allow machine weight (mass) to exceed

certified value on certification plate. If weight is exceeded, the

ROPS structure will not be able to fulfill its safety function.

Do not increase machine weight beyond certified value by

modifying machine or by installing attachments on machine. If

weight limit of protective equipment is exceeded, protective

equipment will not be able to protect operator, and this can

result in death or serious injury. Always observe the following:

• This machine is equipped with a protective structure.

Do not remove protective structure and perform

operations without it.

• Never modify the operator's cabin by welding,

grinding, drilling holes or adding attachments unless

instructed by DOOSAN in writing. Changes to the

cabin can cause loss of operator protection from

rollover and falling objects, and result in death or

serious injury.

• When protective structure is damaged or deformed

by falling objects or by rolling over, its strength will be

reduced and it will not be able to adequately protect

the operator. Contact your DOOSAN distributor if you

have any questions about the ROPS. Never repair a

damaged ROPS cabin.

• Always wear your seat belt when operating machine.

ROPS Certification

This DOOSAN machine has an operator's cabin that meets

ROPS requirements. The seat belt must be worn for rollover

protection.

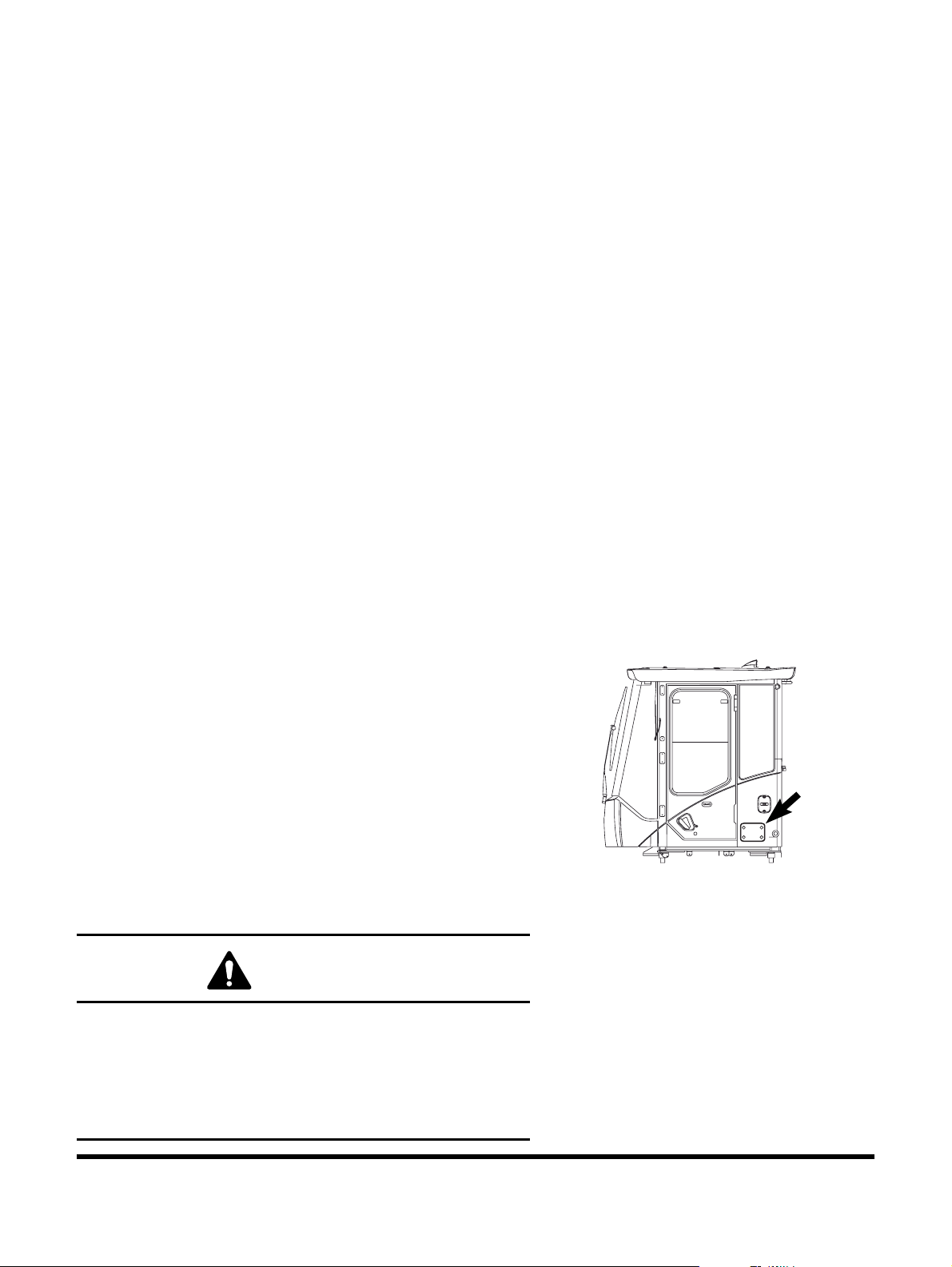

The ROPS certification plate (Figure 16) is found on the back of

the cabin on most models. It may vary slightly in its location on

some models.

Check the ROPS cabin, mounting, and hardware for damage.

Never modify the ROPS cabin. Replace the cabin and hardware

if damaged. See your DOOSAN distributor for parts.

ROPS - Rollover Protective Structure complies with

ISO 3471:2008.

WARNING

AVOID DEATH OR SERIOUS INJURY

Never modify the operator cabin by welding, grinding,

drilling holes or adding attachments unless instructed in

writing by DOOSAN. Changes to the cabin can cause loss

of operator protection from rollover and falling objects, and

can result in death or serious injury.

FG020110

Figure 16

Wheel Loader Safety

SP002397

Page 17

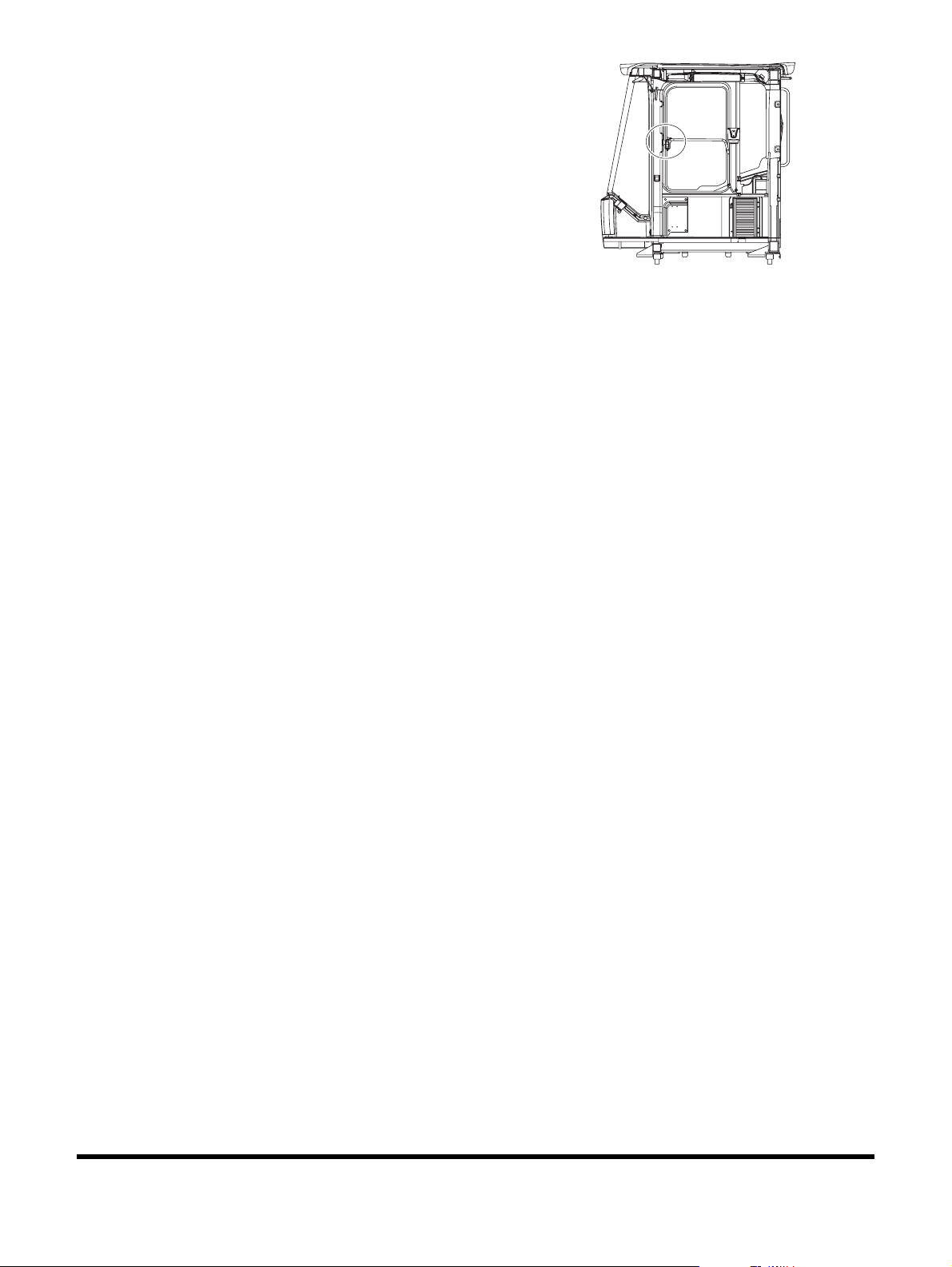

Emergency Exit from Operator's Station

If the primary exit is blocked, the window on the right side may

be used as an alternate exit. Open the window and exit the

machine through the window.

Door Catch

FG022692

Figure 17

Page 18

SP002397Wheel Loader Safety

TRANSPORTATION

Obey State and Local Over-the-Road Laws

and Regulations

Check federal, state and local laws and regulations regarding

weight, width and length of a load before making preparations

for transporting on public roads or highways.

The hauling vehicle, trailer and load must be in compliance with

applicable regulations for the shipping route.

Partial disassembly of the machine may be necessary to meet

travel restrictions or particular conditions at work site. See Shop

Manual for information on partial disassembly.

Refer to Operation and Maintenance Manual for information on

loading, unloading and towing.

The machine can be disassembled into parts for transporting.

Contact your DOOSAN distributor for assistance with

disassembly.

Loading and Unloading

To prevent machine tipping or rollover when loading or

unloading machine, always do the following:

• Perform loading and unloading only on firm and level

ground. Maintain a safe distance from edge of road or

drop-off.

• Never use work equipment to load or unload

machine. The machine may fall or tip over.

• Always use loading ramps of adequate strength and

capacity. Be sure that ramps are wide, and long

enough to provide a safe loading slope. Take steps to

prevent ramps from moving out of position or coming off.

• Clean ramp surfaces so they are free of grease, oil,

ice and loose materials. Remove dirt from machine

tires. On a rainy day, be careful since ramp surfaces

can be slippery.

• Turn auto idle switch "OFF."

• Run engine at low speed and travel slowly.

• When on ramps, do not operate any control lever

except for shift lever.

• Never correct your steering on ramps. If necessary,

drive off ramps, correct machine direction, then drive

back onto ramps.

• For machines equipped with a cabin, always lock

door after loading machine to prevent door from

suddenly opening during transportation.

Wheel Loader Safety

SP002397

Page 19

Transporting Machine

When transporting machine on a trailer or truck, do the following:

• The weight, transportation height, and overall length

of machine may change depending on work

equipment attached to it. Always check the machine

dimensions and work equipment's dimensions before

transporting.

• When passing over bridges or structures on private

land, check that structure is strong enough to support

weight of machine. Before traveling on public roads,

check with appropriate authorities and follow their

instructions.

Page 20

SP002397Wheel Loader Safety

OPERATION

Always make sure that the machine is properly maintained.

Before Engine Starting

Machine Condition

Every day before starting engine for first time, perform the

following checks and repair machine before operating, as

necessary. If these checks are not properly done death or

serious injury could result.

• Check coolant, fuel, and hydraulic tank oil levels, and

check for clogged air cleaner and damage to

electrical wiring.

• Check operation of gauges, cameras (if equipped)

and angle of mirrors, and check that pilot cutoff

switch is set to "O" (OFF) position.

• Check that pedals move freely, and pilot control lever

(s) returns to "NEUTRAL" when released.

• Check that attachment is properly attached and

locked.

IMPORTANT

Only use Ultra Low Sulfur Diesel (ULSD) fuel and

API-CJ-4/ACEA-E9 grade engine oil.

Make sure that the machine is equipped with a lighting system

that is adequate for job conditions and check that lights are

working properly.

Before performing checks, move machine to an area where

there are no obstructions, and operate slowly. Do not allow

personnel near machine.

Know maximum operating dimensions of your machine.

Work Site

Before starting operations, thoroughly check work area for any

hazards, such as underground utility lines, overhead electrical

lines, unstable ground, excessive slopes, etc.

Before starting engine and moving machine, make sure that no

one is underneath machine, around machine, or on machine.

Know width and length of your machine and work equipment to

maintain proper clearance when you operate machine or work

equipment near fences or near boundary obstacles.

Figure 18

WARNING

No Entry

FG013735

Wheel Loader Safety

SP002397

Page 21

Know appropriate work site hand signals and personnel that are

authorized to give hand signals. Follow hand signals from only

one person.

If you need to operate on a street, protect pedestrians and cars

by designating a person for work site traffic duty or by erecting

fences and posting "No Entry" signs around work site.

Erect barricades or fences, post "No Entry" signs, and take other

steps to prevent people from coming close to or entering work

site. If people come too close to a moving machine, they may be

struck or caught by machine, and this can result in death or

serious injury.

Check Tire Pressure and Condition

Maintain tire pressure but do not overinflate. Inspect tires and

wheels daily. When inflating tires, follow procedures in

Maintenance Section, which include using an extension to avoid

standing in front of or over a tire. Do not change a tire unless you

understand proper tire maintenance procedures and are using

proper equipment.

Refer to Operation and Maintenance Manual.

Mounting/Dismounting

Before getting on or off machine, if there is any oil, grease, or

mud on handrails or steps, wipe it off immediately. Always keep

these parts clean. Repair any damage and tighten any loose

bolts.

Never jump on or off machine. In particular, never get on or off a

moving machine. These actions can result in death or serious

injury.

When getting on or off machine, always face machine. Maintain

three-point contact (both feet and one hand or one foot and both

hands) with handrails and steps to ensure that you support

yourself securely.

Never hold onto any control levers when getting on or off

machine.

Securely latch door. If you grip handrail inside door when

moving on platform outside of door, and door latch is not

securely engaged, door may move and cause you to fall

resulting in death or serious injury.

Use points marked by arrows in diagram when getting on or off

machine.

Do not carry tools or supplies when you mount or dismount the

machine.

HA3O1003

Figure 19

Page 22

SP002397Wheel Loader Safety

Cleaning

Remove all straw, wood chips, leaves, grass, paper and other

flammable debris accumulated in engine compartment,

and around battery. Remove

handrails, and steps.

Do not leave tools or spare parts in operator's cabin. Vibration of

machine during operation can cause tools or spare parts to fall

and damage or break control levers or switches. Tools and

spare parts can also get caught in spaces between control

levers and cause accidental movement of work equipment

causing death or serious injury.

When entering operator's cabin, always remove all mud and oil

from your shoes. If you operate travel pedal with mud or oil stuck

to your shoes, your foot could slip off the control, or dirt and

debris may interfere with proper operation of control levers.

After using ashtray, make sure that any matches or cigarettes

are properly extinguished, and be sure to close ashtray.

Clean window glass and working lights for good visibility.

Do not stick suction pads to window glass. Suction pads act as a

lens and can cause fire.

Never bring flammable or explosive items into operator's cabin.

Do not leave cigarette lighters laying around operator's cabin. If

temperature inside operator's cabin becomes too high, there is a

potential hazard that lighter could explode.

any dirt from window glass, mirrors,

mufflers

Secure all loose items such as lunch boxes, and other items that

are not a part of the machine itself.

Operator Station

Inspect condition of seat belt and mounting hardware. Replace

any parts that are worn or damaged. Do not use a seat belt

extension on a retractable seat belt.

Adjust seat so full pedal travel can be achieved with operator's

back against back of seat.

Keep all windows and doors closed on machine.

Adjust operator's seat to a position where it is easy to perform

operations, and check that there is no damage or excessive

wear to seat belt or mounting clamps.

Never reach in through a window to work a control. Do not try to

operate the machine unless in operator's seat with the seat belt

fastened.

Adjust and clean mirrors so area to rear of machine can be seen

clearly from operator's seat.

When standing up from operator's seat, always place pilot cutoff

switch in "O" (OFF) position. If you accidentally move work

equipment levers when they are not locked, the machine could

suddenly move and cause damage, death or serious injury.

Wheel Loader Safety

SP002397

Page 23

Seat Belt

Check seat belt daily for correct function.

Inspect seat belt system more often if machine is exposed to

severe environmental conditions or applications. Conduct the

following inspections and replace seat belt system as

necessary:

1. Check webbing. If system is equipped with a retractor, pull

webbing completely out and inspect full length of webbing.

Look for cuts, wear, fraying, dirt and stiffness.

2. Check buckle and latch for correct operation.

3. Make sure latch plate is not excessively worn,

buckle is not damaged or casing is broken.

4. Check retractor web storage device (if equipped) by

extending webbing and checking that it spools out and

retracts correctly.

5. Check webbing in areas exposed to ultraviolet (UV) rays

from sun or extreme dust or dirt. If original color of webbing

in these areas is extremely faded and/or webbing is

packed with dirt, webbing strength may be reduced.

NOTE: Contact your DOOSAN distributor for seat belt

system replacement parts.

deformed or

WARNING

AVOID DEATH OR SERIOUS INJURY

Failure to properly inspect and maintain seat belt and

seat belt system can cause lack of operator restraint

and can result in death or serious injury.

Before fastening seat belt, check that there is no

problem in belt mounting bracket. If it is worn or

damaged, replace seat belt immediately. Fasten seat

belt so it is not twisted.

Always wear seat belt when operating machine.

Page 24

SP002397Wheel Loader Safety

Loading...

Loading...