Page 1

SB2088E02

Sep. 2011

DE08TS Diesel Engine

Disassembly & Assembly

D100, D120, D150

D110S-5, D130S-5, D160S-5

Page 2

Page 3

Important Safety Information

WARNING

Most accidents involving product operation, maintenance and repair are caused by failure to observe basic safety

rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an

accident occurs. Aperson must be alert to potential hazards. This person should also have the necessary training,

skills and tools to perform these functions properly.

Improper operation, Iubrication, maintenance or repair of this product can be dangerous and could result

in injury or death.

Do not operate or perform any Iubrication, maintenance or repair on this product, until you have read and

understood the operation, Iubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard warnings are not

heeded, bodily injury or death could occur to you or other persons.

The hazards are identified by the "Safety Alert Symbol" and followed by a "Signal Word" such as "WARNING" as

shown below.

The meaning of this safety alert symbol is as follows :

Attention! Become Alert! Your Safety is Involved.

The Message that appears under the warning, explaining the hazard, can be either written or pictorially presented.

Operations that may cause product damage are identified by NOTICE labels on the product and in this publication.

DOOSAN cannot anticipate every possible circumstance that might involve a potential hazard. The warnings in this

publication and on the product are therefore not all inclusive. If a tool, procedure, work method or operating

technique not specifically recommended by DOOSAN is used, you must satisfy yourself that it is safe for you and

others. You should also ensure that the product will not be damaged or made unsafe by the operation, Iubrication,

maintenance or repair procedures you choose.

The information, specifications, and illustrations in this publication are on the basis of information available at the

time it was written. The specifications, torques, pressures, measurements, adjustments, illustrations, and other

items can change at any time. These changes can affect the service given to the product.

Obtain the complete and most current information before starting any job. DOOSAN dealers have the most current

information available.

1 of 76

Page 4

Page 5

Index

Air Cleaner Assembly ...........................................24

Air Cleaner Elements.............................................25

Air Compressor (if equipped).................................72

Alternator ...............................................................12

Camshaft And Camshaft Bearing ..........................61

Connecting Rod Bearings......................................48

Cooling Water Pipe................................................41

Crankshaft..............................................................69

Crankshaft Pulley...................................................63

Cylinder Head ........................................................49

Cylinder Head Cover..............................................34

Cylinder Liners.......................................................57

Electric Starting Motor............................................11

Engine And Transmission........................................5

Exhaust Manifold ...................................................33

Fan Assembly ........................................................26

Fan Belts................................................................26

Flywheel.................................................................64

Flywheel Housing...................................................68

Fuel Filter...............................................................18

Fuel Injection Lines................................................17

Fuel Injection Nozzle Assembly.............................20

Fuel Injection Pump ...............................................13

Fuel Pump..............................................................19

Fuel Strainer ..........................................................18

Intake Manifold.......................................................31

Muffler....................................................................22

OIl Cooler...............................................................39

Oil Filter..................................................................38

Oil Pan ...................................................................34

Oil Pump ................................................................42

Pistons ...................................................................53

Radiator .................................................................28

Rocker Shaft ..........................................................46

Rocker Shaft And Push Rods ................................45

Timing Gear Case..................................................60

Timing Gear Case Cover .......................................58

Timing Gears .........................................................58

Water Pump...........................................................35

Water Temperature Regulator ...............................27

Disconnect batteries before performance of any

service work

WARNING

Page 6

Page 7

Engine

2

5

4

7

6

3

8

1

Remove Engine And

Transmission

A10999 & D40999 - 02

Tools Needed A

Link Bracket 1

IEED002P

Start By :

a. Remove overhead guard.*

Remove floorplate.*

b.

Remove hood.*

c.

Remove air cleaner.

d.

e. Remove universal joint.*

This operation is in the Vehicle Systems,

*

Disassembly And Assembly Manual.

1. Drain the coolant from the radiator.

5. Remove bolts (4), washers and nuts that hold

coolant reservoir on the frame. Set coolant

reservoir (5) aside.

IEED003P

6. Disconnect two hoses (6) from the fuel tank.

7. Disconnect wiring harness (7) from fuel sender.

IEED001P

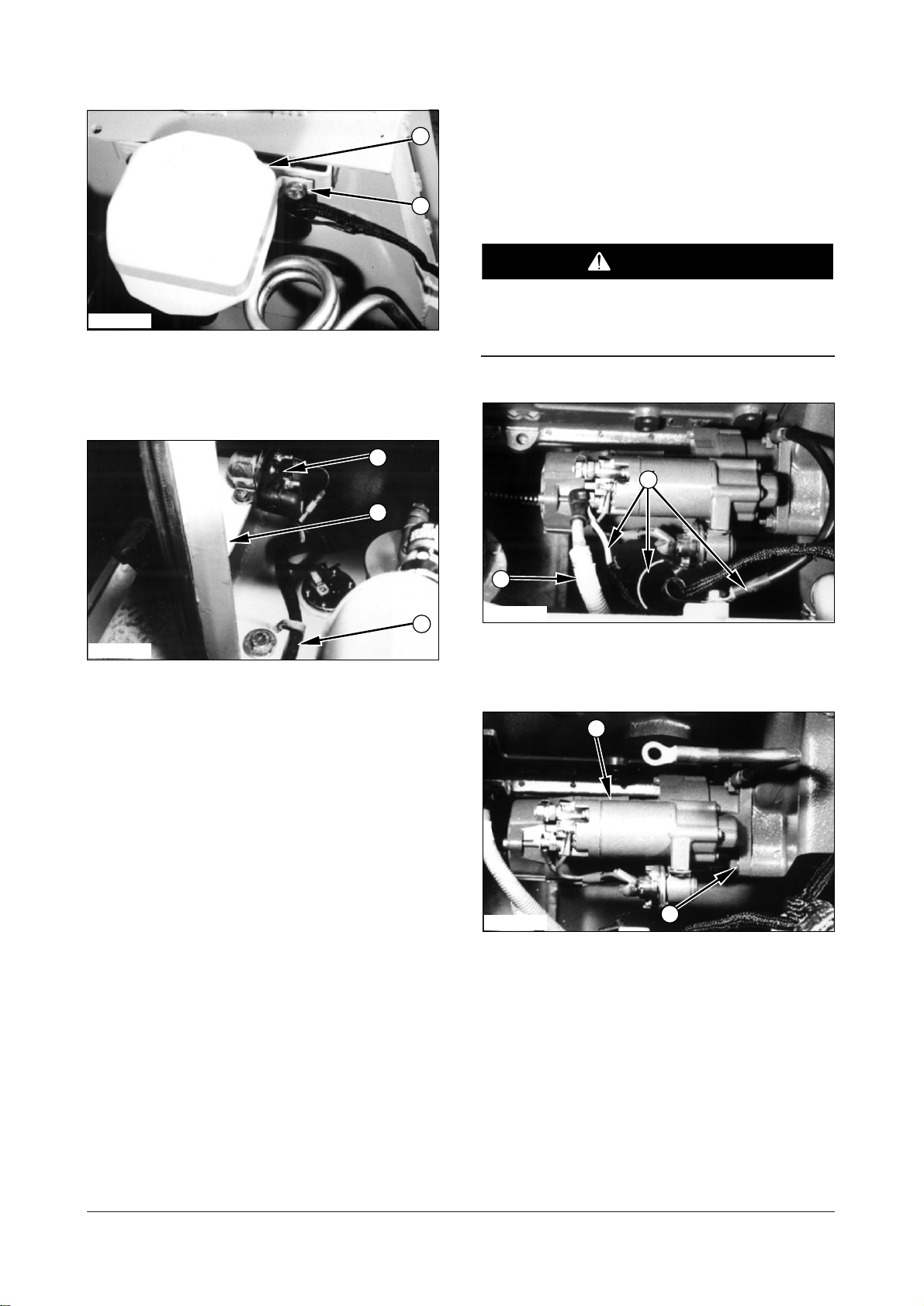

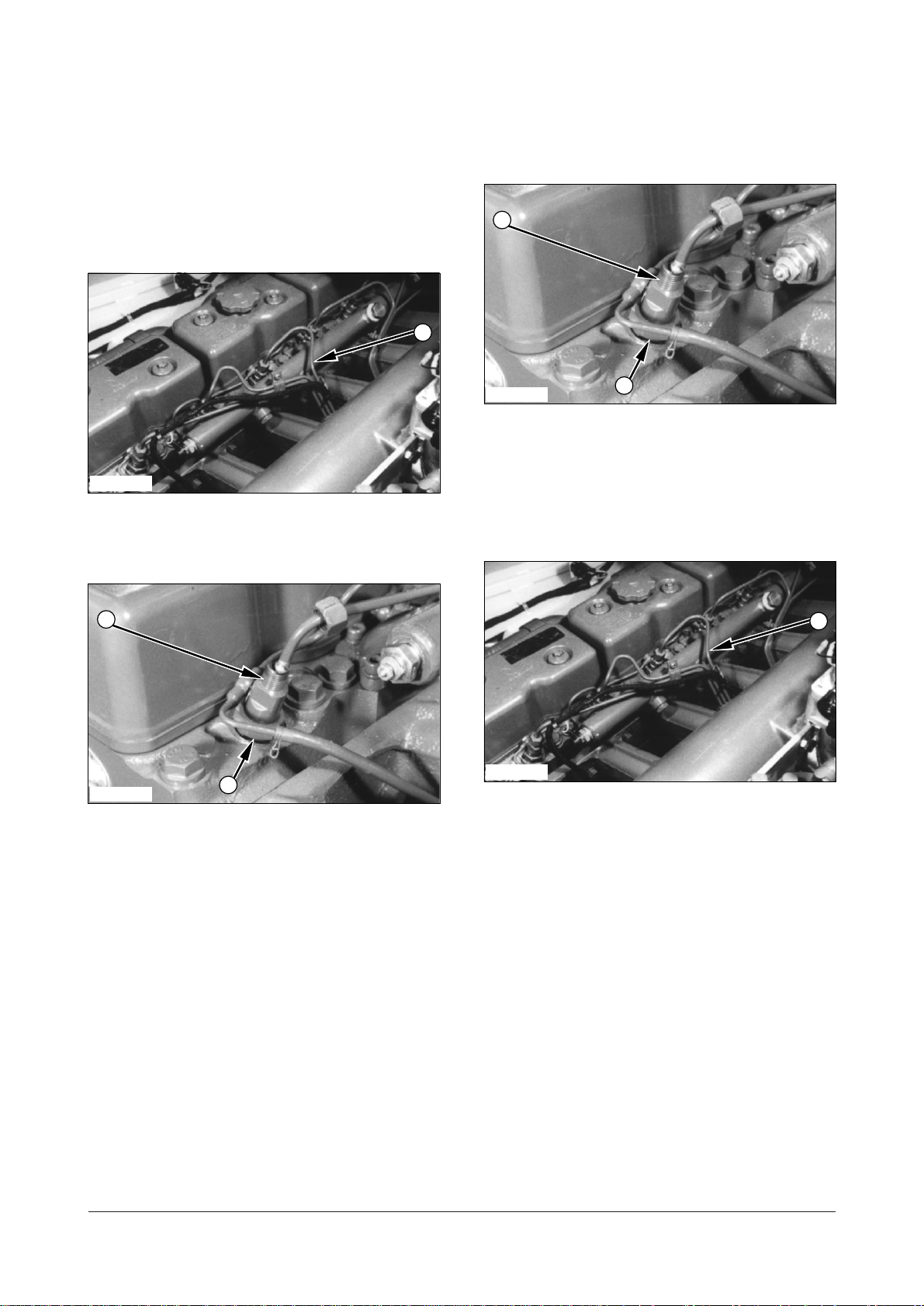

2. Remove engine harness assembly (1) from the

clips of bonnet assembly (3).

3. Remove screws, washers and circuit breaker (2)

from bonnet assembly (3).

4. Remove bolt and washer that hold bonnet

assembly. Remove bonnet assembly (3) from the

frame.

DE08TS Diesel Engine Disassembly and Assembly

5 of 76

IEED004P

8. Remove tube (8) from the tube of air compressor

(if equipped).

Page 8

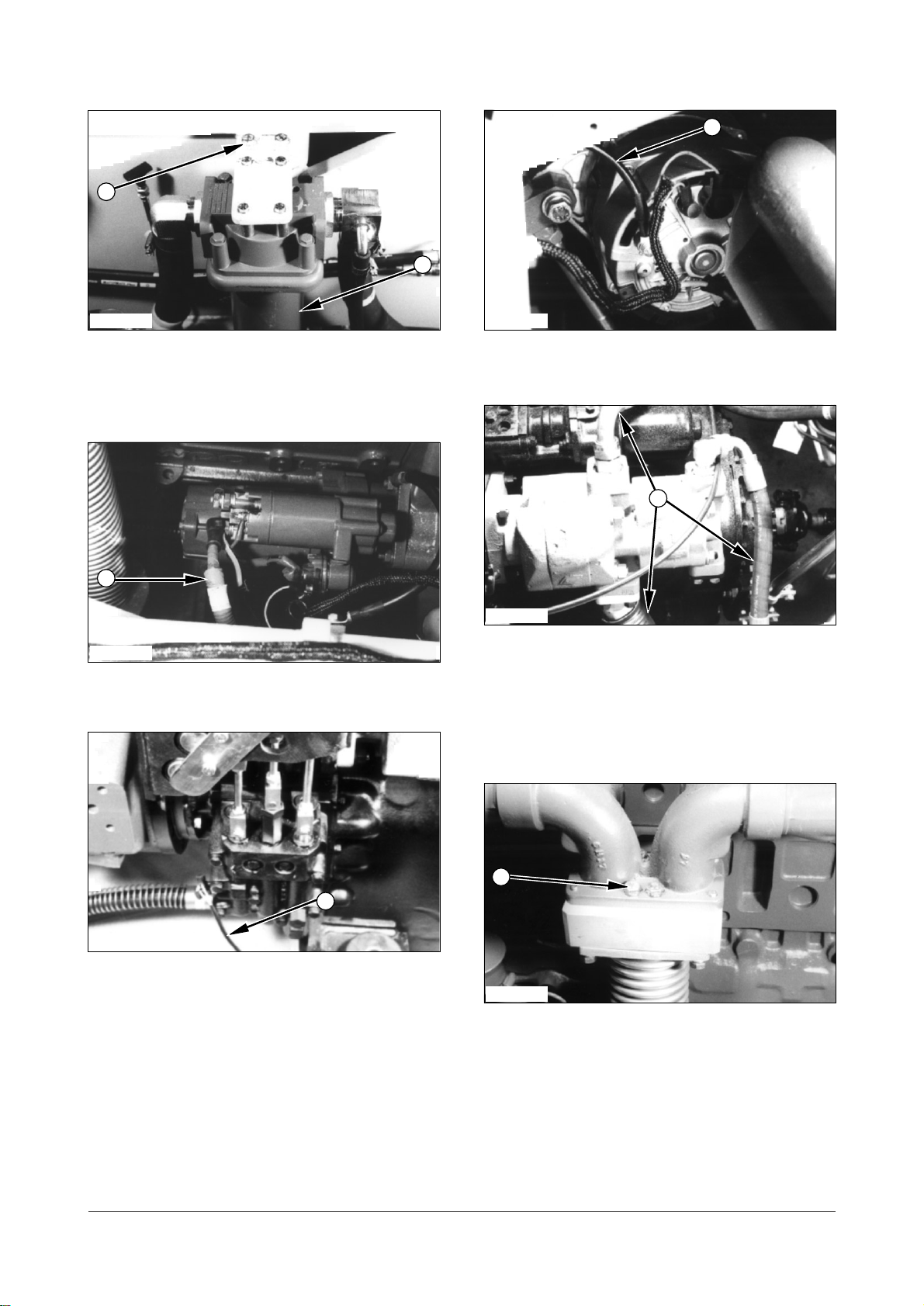

IEED005P IEED008P

9

11

14

15

12

10

13

9. Remove two bolts washers (9) and hydraulic filter

assembly (10). Set hydraulic filter assembly (10)

aside.

IEED006P

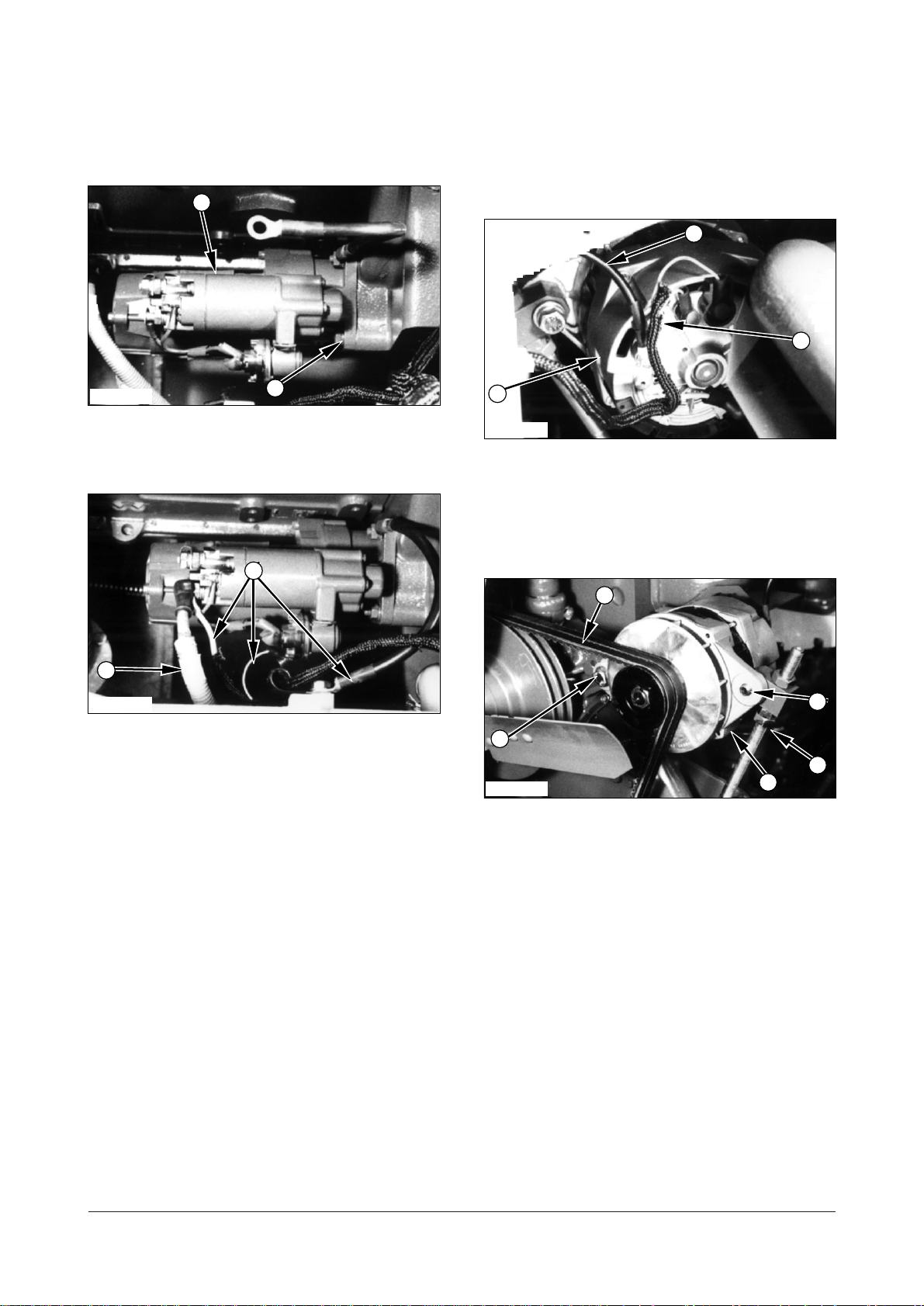

10. Disconnect battery cable (11) from the starting

motor.

12. Disconnect ground cable (13) from the alternator.

IEED009P

13. Disconnect three hoses (14) from the hydraulic

pump.

NOTE : Plug and cap all hydraulic connectors and hoses

to avoid debris and contamination from entering the

system.

IEED007P

11. Disconnect transmission neutral switch connector

IEED010P

(12).

14. Remove bolts (15) and washers that hold the

muffler expansion on exhanst manifold of the

engine.

DE08TS Diesel Engine Disassembly and Assembly

6 of 76

Page 9

IEED011P IEED014P

17

16

21

18

22

A

20

19

15. Disconnect two transmission cooling hoses (16)

from the transmission.

16. Disconnect transmission oil temperature switch

wiring (17).

IEED012P

17. Disconnect two engine cooling hoses (18 ) from

the engine.

19. Remove bolts (21), washers and nuts from the

two transmission support.

NOTE : At this point, make a final check to be sure all

removals and disconnections have been made from

the engine and the transmission.

IEED015P

20. Install the tool (A) to the transmission. Fasten tool

(A) to the engine and transmission as shown.

21. Remove engine and transmission (22) from the

lift truck.

22. Put the engine and transmission on an

acceptable engine stand. Remove tool (A).

IEED013P

18. Remove bolts (19), washers, nuts from the two

engine support (20), one on both side of the

engine.

DE08TS Diesel Engine Disassembly and Assembly

7 of 76

Page 10

IEED016P IEED017P

25

23

A

22

24

25

23

24

21

23. Support transmission (24) with fasten a strap and

remove twenty bolts(23) and washers. Remove

transmission (24) from engine (25).

Install Engine And Transmission

A10999 & C40999 - 03

Tools Needed A B

Link Bracket 1

Eye Bolt 1

3. Install the tool (A) to the transmission.

4. Fasten tool (A) to engine and transmission (22) as

shown.

IEED014P

5. Put the engine and transmission in position on the

lift truck. Make an alignment of supports with the

frame.

6. Install bolts (21), washers and nuts that hold the

transmission support to the frame.

Tightenbolts (21) to atorque of

(540

590 lbft).

730800 Nm

IEED016P

1. Put transmission (24) in position in engine (25).

2. Install bolts (23) and washers that hold

transmission to the engine. Tighten bolts (23) to

torque of

DE08TS Diesel Engine Disassembly and Assembly

55 10 Nm (40 7 lbft).

8 of 76

Page 11

IEED013P

20

19

18

17

16

15

14

IEED011P

7. Install bolts (19), washers and nuts that hold

engine support (20) to the frame. Tighten bolts (19)

to a torque of

IEED012P

280 Nm (205 lbft).

8. Connect two engine cooling hoses (18) and tighten

the hose clamps.

9. Connect two transmission cooling hoses (16) to

transmission.

10. Connect transmission oil temperature switch

connector (17).

IEED010P

11. Install bolts (15) and washers that hold the muffler

expansion to exhaust manifold of the engine.

IEED009P

12. Connect three hydraulic hoses (14) to the

hydraulic pump.

DE08TS Diesel Engine Disassembly and Assembly

9 of 76

Page 12

IEED008P

13

11

9

10

8

7

6

12

IEED005P

13. Connect ground cable (13) to the alternator.

IEED007P

14. Connect transmission neutral switch connector

(12).

16. Put hydraulic filter assembly (10) in position on

the frame. Install bolts (9) and washers.

IEED004P

17. Install tube (8) to the air compressor (if

equipped).

IEED006P

IEED003P

15. Connect battery cable(11) to the starting motor.

18. Connect wiring harness (7) to the fuel sender.

19. Connect two fuel hoses (6) and tighten the hose

clamp.

DE08TS Diesel Engine Disassembly and Assembly

10 of 76

Page 13

Electric Starting Motor

1

2

4

3

5

4

2

3

1

WARNING

Remove Electric Starting Motor

A61564 - 02

IEED002P

20. Put the coolant reservoir with bracket (5) in

position on the frame. Install bolts (4) and

washers that hold coolant reservoir (5).

IEED001P

21. Put bonnet assembly (3) in position on the frame.

Install the bolts and washers. Tighten the bolts to

a torque of

200 N..m (150 lb..ft).

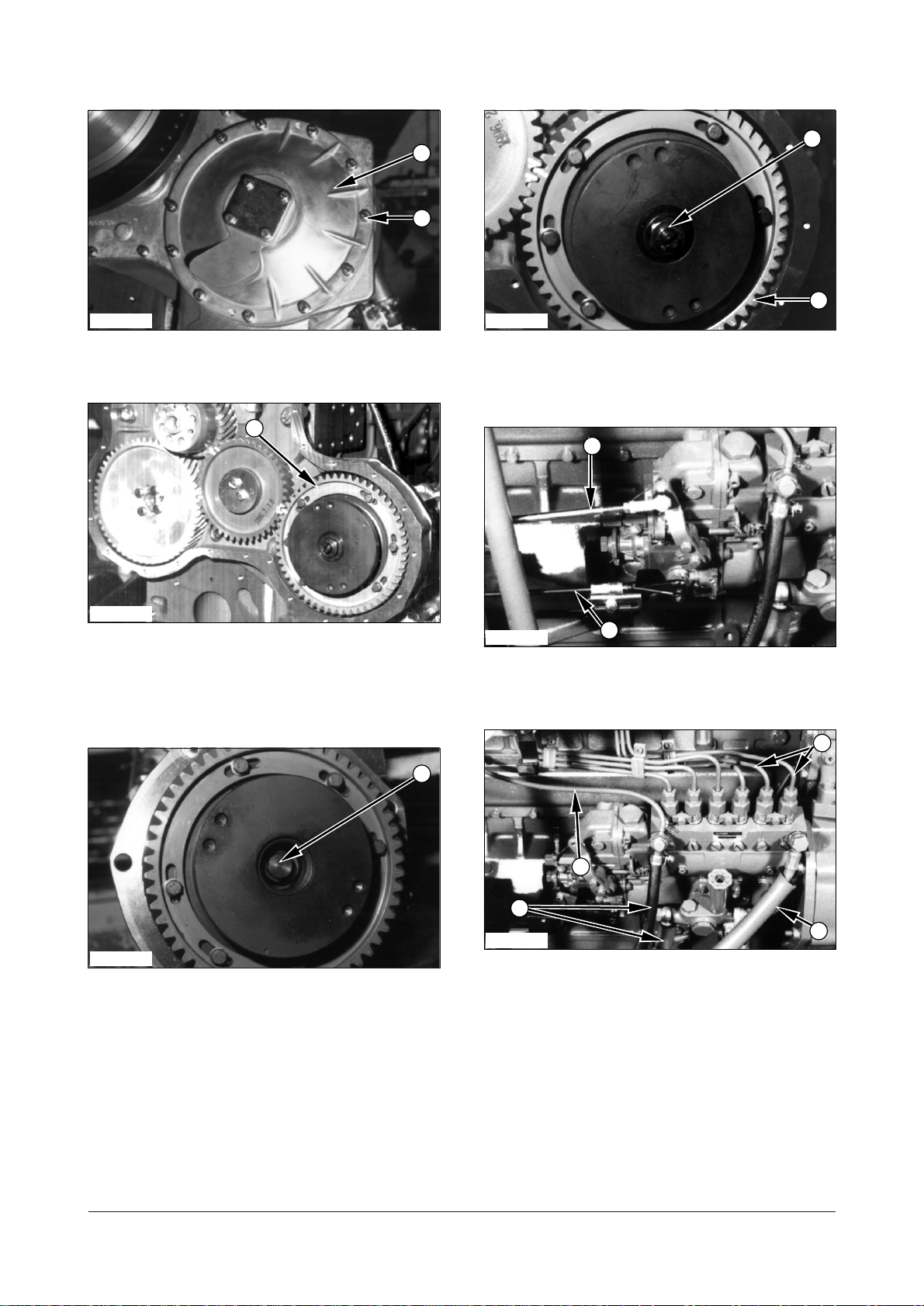

Disconnect the battery before the starting motor

is removed

IEED018P

1.

Put identification on the starting motor and

solenoid wires. Disconnect wirings (1) and battery

cable (2).

22. Install the screws and washers that hold circuit

breaker (2).

23. Clear engine harness assembly (1).

24. Fill the cooling system. See the Maintenance

Guide for the correct level.

End By :

a. Install universal joint.

b. Install air cleaner.

c. Install hood.

d. Install floorplate.

e. Install overhead guard.

IEED019P

2. Remove mounting nuts (3) and then remove

starting motor (4) from the lift truck.

DE08TS Diesel Engine Disassembly and Assembly

11 of 76

Page 14

Install Electric Starting Motor

1

54653

2

6

4

3

1

2

A61564 - 03

IEED019P

Alternator

Remove Alternator B31018 - 02

1. Put starting motor (4) in position on the flywheel

housing and install nuts (3) that hold it.

IEED018P

2. Connect wirings (2) to the starting motor and

solenoid. Connect battery positive cable (1).

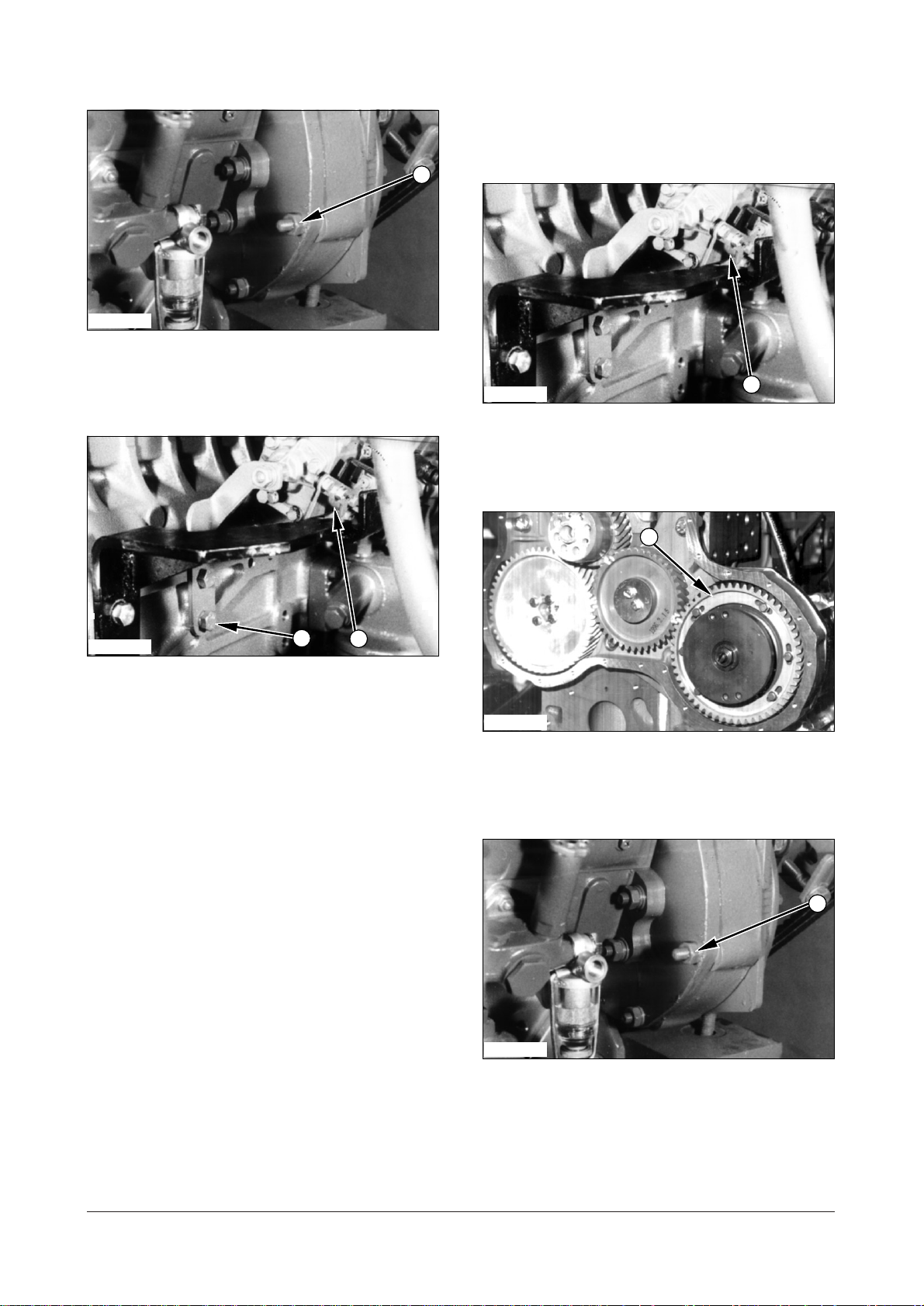

IEED020P

1. Put identification on all wires (1) and the

disconnect them from alternator (6).

2. Disconnect ground cable (2) from alternator (6).

IEED021P

3. Loosen nuts (4) and then remove belt (3) from the

alternator.

4. Remove bolts (5) from the alternator’s bracket to

remove alternator (6).

DE08TS Diesel Engine Disassembly and Assembly

12 of 76

Page 15

Install Alternator B31018 - 03

1

6

5

3

4

1

2

6

2

546

5

3

IEED021P

1. Put alternator (6) in position on its bracket and

install bolts (5) that hold it.

2. Install fan belt (3) on the alternator and tighten nuts

(4).

Fuel Injection Pump

Remove Fuel Injection Pump

A25663 - 02

Start By :

a. Remove air compressor (if equipped).

b. Remove intake manifold.

IEED020P

3. Connect all wires (1) to their respective positions.

4. Connect ground cable (2) to alternator (6).

IEED022P

1. Remove two bolts (1) and washers.

2. Remove bolt (2), washers, spacer (3) and lifting

bracket (4).

IEED166P

3. Remove bolts (5) and washers that hold the

tension adjusting bracket on the timing gear case.

4. Remove the idle pulley and V-belt tension

adjusting bracket assembly (6) and gasket.

Discard the gasket.

DE08TS Diesel Engine Disassembly and Assembly

13 of 76

Page 16

IEED023P

12

8

7

9

1414141513

10

11

9

IEED118P

5. Remove bolts (7), washers and cover (8).

IEED024P

6. Make an alignment of the timing marks on fuel

injection pump gear (9) and the idle gear or put a

mark of identification on the gears for correct

installation.

8. Remove nut (11) and injection pump coupling and

gear (9) from the injection pump.

IEED025P

9. Disconnect accel rod (12) and engine stop cable

(13).

IEED026P

IEED117P

10. Disconnect five hoses (14) and tubes (15) from

7. Remove nut (10) from the injection pump coupling.

DE08TS Diesel Engine Disassembly and Assembly

14 of 76

the injection pump.

Page 17

17

IEED027P

16

16

18

17

9

11. Remove four nuts (16) and washers that hold the

injection pump in place. Remove the gasket and

discard it.

Install Fuel Injection Pump

A25663 - 03

IEED028P

1. Install the new gasket in position on the timing

gear case. Put fuel injection pump (17) in position

on the timing gear case.

IEED028P

12. Support injection pump (17). Remove two bolts

(18) and washers that hold injection pump (17) on

the block. Remove injection pump (17).

IEED024P

2. Make sure the timing marks or the marks that were

put on the fuel injection pump gear (9) and the idle

gear are in alignment.

IEED027P

3. Install four nuts (16) and washers that hold the fuel

injection pump on the timing gear case.

DE08TS Diesel Engine Disassembly and Assembly

15 of 76

Page 18

141414

15

12

13

18

8

7

10

IEED118P

11

9

IEED028P

4. Put the fuel injection pump drive coupling and gear

(9) in position. Make an alignment of the key and

the groove (slot) in the coupling.

5. Install nut (11) that hold the injection pump drive

coupling and gear (9) in place. Tighten nut (11) to

a torque of

IEED117P

130 Nm (96 lbft).

6. Install nut (10) into the injection pump coupling.

8. Install bolts (18) and washers that hold the

injection pump on the block.

IEED026P

9. Connect three hoses (14) and tube (15) to the

injection pump.

IEED025P

10. Connect accel cable (12) and engine stop cable

IEED023P

(13) to the injection pump.

7. Install cover (8), bolts (7) and washers.

DE08TS Diesel Engine Disassembly and Assembly

16 of 76

Page 19

1

1

IEED166P

5

6

3

4

1

2

11. Install the new gasket on the timing gear case.

12. Put the idle pulley and V-belt tension adjusting

bracket assembly (6) on the timing gear case and

install bolts (5) and washers.

Fuel Injection Lines

Remove Fuel Injection Lines

A23525 - 02

IEED029P

1. Disconnect fuel injection lines (1) from the fuel

injection nozzle assemblies and the fuel injection

pump.

IEED022P

13. Install lifting bracket (4), spacer (3), washers and

bolts (2) on the block.

14. Install two bolts (1) and washers.

End By :

a. Install air compressor (if equipped).

b. Install intake manifold.

Install Fuel Injection Lines

A23525 - 03

IEED029P

2. Connect fuel injection lines (1) to the fuel injection

pump and the fuel injection nozzle assemblies.

Tighten the fuel line nuts toa torque of

16 to20 Nm (12 to 15 lbft).

DE08TS Diesel Engine Disassembly and Assembly

17 of 76

Page 20

Fuel Filter

2

1

3

4

1

2

2

1

Remove Fuel Filter A21357SE - 02

Fuel Strainer

Remove & Install Fuel Strainer

A21357PR - 01

IEED030P

1. Loosen bolt (1). Remove bowl (2).

2. Remove fuel filter.

Install Fuel Filter A21357SE - 03

IEED030P

1. Install a new gasket in the filter bowl.

IEED031P

1. Remove bolt (1) and washers and disconnect fuel

line (2) that connected the fuel tank.

2. Remove bolt (3), washers and fuel strainer (4) from

the injection pump.

3. Install fuel strainer (4) in reverse order of removal.

2. Put a new fuel filter element in position.

3. Put filter bowl (2) in position and tighten bolt (1)

that holds the bowl in position.

DE08TS Diesel Engine Disassembly and Assembly

18 of 76

Page 21

Fuel Pump

2

1

2

1

3

4

3

4

Remove Fuel Pump A21663 - 02

IEED032P

1. Disconnect fuel inlet line (1) and fuel outlet line (2)

from the fuel pump.

Install Fuel Pump A21663 - 03

IEED033P

1. Put fuel pump (4) in position on the engine block

with nuts (3) that hold it.

IEED033P

2. Remove three nuts (3) that hold fuel pump (4) to

the injection pump. Remove fuel pump (4).

IEED032P

2. Connect fuel outlet line (2) and fuel inlet line (1) to

the fuel pump.

DE08TS Diesel Engine Disassembly and Assembly

19 of 76

Page 22

Fuel Injection Nozzle

1

1

2

3

2

3

Assembly

Remove Fuel Injection Nozzle

Assembly A28999 - 02

IECD029P

1. Disconnect fuel lines (1) from the fuel injection

nozzles.

Install Fuel Injection Nozzle

Assembly A28999 - 03

IEED034P

1. Install the new seal rings in the nozzle hole of the

cylinder head.

2.Put fuel injection nozzles (2) in position. Install nuts

(3) and tighten them to a torque of

(52

7 lbft).

7010 Nm

IEED034P

2. Remove nuts (3) and then remove fuel injection

nozzles (2).

3. Remove the seals from the nozzle holders of the

cylinder head and discard it.

IEED029P

3. Connect fuel lines (1) to the injection nozzles and

then tighten the nuts to a torque of

30 Nm (22 lbft).

DE08TS Diesel Engine Disassembly and Assembly

20 of 76

Page 23

Disassemble & Assemble Fuel

1

1

6

4

2

3

5

7

6

4

2

3

5

7

Injection Nozzle Assembly

A28999 - 06

Start By :

a. Remove fuel injection nozzle assembly

IEED035P

1. Remove union nut (1) from the nozzle assembly.

IEED036P

4. Install shims (7), spring (6), guide (5) and

intermediate washer (4) to the nozzle holder.

5. Install needle valve (3) into fuel nozzle (2) and

install the fuel nozzle.

IEED036P

2. Remove fuel nozzle (2), needle valve (3),

intermediate washer (4), guide (5), spring (6) and

shims (7) from the nozzle holder.

3. Check all parts for damage. If damaged, use new

parts for replacement.

NOTE : The following steps are for assembling the

fuel injection nozzle assembly.

IEED035P

6. Install union nut (1) and tighten to a torque of

7010 Nm (527 lbft).

End By :

a. Install fuel injection nozzle assembly.

DE08TS Diesel Engine Disassembly and Assembly

21 of 76

Page 24

Muffler

2

8

15

12

11

14

13

5

9

10

4

5

6

7

3

1

Remove Muffler A32570 - 02

IEED037P

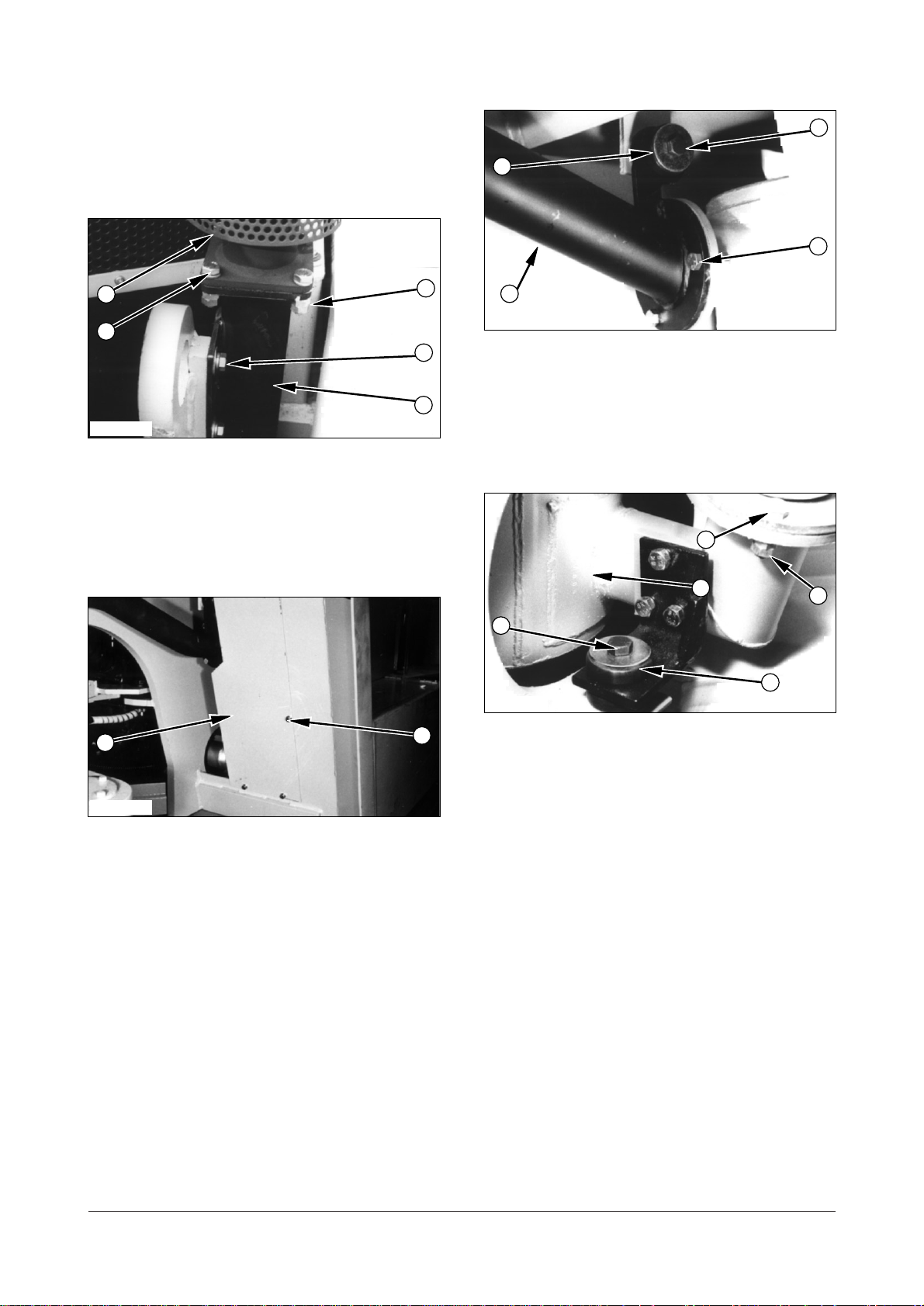

1. Remove four bolts (1), washers and nuts (2) that

hold muffler tube assembly (3) on tube assembly

(5).

2. Remove two bolts (4) and washers that hold tube

assembly (5) on the frame.

IEED039P

4. Remove three bolts (8), washers and nuts.

5. Support tube assembly (5) and remove bolt (9),

washers, rubber mounts (10), shims and nuts that

hold tube assembly (5) on the frame. Remove tube

assembly (5).

IEED038P

3. Remove five bolts (6), washers and cover (7) from

the frame.

IEED040P

6. Remove three bolts (11), washers and nuts (12).

7. Remove bolt (13), washers, rubber mounts (14),

shims and nuts that hold mount bracket of muffler

assembly (15) on the frame. Remove muffler

assembly (15).

DE08TS Diesel Engine Disassembly and Assembly

22 of 76

Page 25

Install Muffler A32570 - 02

15

12

111413

8

5

9

10

2

4

5

3

1

6

7

IEED038P

IEED040P

1. Put the muffler assembly (15) in position on the

frame. Install bolt (13), washers, rubber mounts

(14), shims and nuts that hold muffler assembly

(15) on the frame. Tighten bolt (13) to a torque of

7590 Nm (5565 lbft).

2. Install three bolts (11), washers and nuts (12).

IEED039P

3. Put the tube assembly (5) in position in place.

Install three bolts (8), washers and nuts.

5. Install five bolts (6), washers and cover (7) to the

frame.

IEED037P

6. Install two bolts (4) and washers that hold tube

assembly (5) on the frame.

7. Put muffler tube assembly (3) in position on tube

assembly (5). Install bolts (1), washers and nuts

that hold muffler tube assembly (3).

4. Install bolt (9), washers, rubber mounts (10), shims

and nuts that hold tube assembly (5) to the frame.

Tighten bolt (9) to a torque of

7590 Nm (55

65 lbft).

DE08TS Diesel Engine Disassembly and Assembly

23 of 76

Page 26

Air Cleaner Assembly

1

2

4

3

4

1

2

4

4

3

Remove Air Cleaner Assembly

A31999 - 02

IEED041P

1. Loosen hose clamps (1) and disconnect hoses (2)

from air cleaner (4).

Install Air Cleaner Assembly

A31999 - 03

IEED042P

1. Put air cleaner assembly (4) in position and install

bolts (3) and nuts that hold it. Tighten bolts (3) to a

torque of

Loctite No. 242.

5565 Nm (4045 lbft) with

IEED042P

2. Remove bolts (3) and nuts, and then remove air

cleaner assembly (4).

IEED041P

2. Install hoses (2) and tighten all hose clamps (1).

DE08TS Diesel Engine Disassembly and Assembly

24 of 76

Page 27

Air Cleaner Elements

2

1

4

6

7

5

4

5

3

2

1

3

6

7

Remove Air Cleaner Elements

A31330 - 02

IEED043P

1. Loosen bolt (1) and remove clamp (2) and element

cover (3)

Install Air Cleaner Elements

A31330 - 03

IEED045P

1. Put inner element filter (7) in position inside the

cleaner assembly and then install nut (6) that hold

it.

IEED044P

2. Remove nut (4) and outer filter element (5) from

the cleaner assembly.

IEED045P

3. Remove nuts (6) and then remove inner filter

element (7) from the cleaner assembly.

IEED044P

2. Install outer filter element (5) in position and install

nut (4) that hold it.

IEED043P

3. Install element cover (3) with the clamp (2) that

hold it and tighten the bolt (1).

DE08TS Diesel Engine Disassembly and Assembly

25 of 76

Page 28

Fan Assembly

2

2

3

1

1

2

3

1

1

1

2

1

Remove Fan Assembly

A51342 - 02

Start By :

a. Remove radiator

Remove Fan Belts A51087 - 02

IEED047P

1. Loosen bolts (1) and nuts (2) on the alternator

bracket and idle pulley. Move the alternator in

toward the engine. Remove belt (3).

IEED046P

1. Remove six bolts (2) and then remove fan

assembly (1).

Install Fan Assembly A51342-03

IEED046P

1. Put the fan assembly (1) in position and install the

six bolts (2) that hold it.

Install Fan Belts A51087 - 03

IEED047P

1. Put belt (3) in position on the pulleys.

Move the alternator away from the engine to tighten

the belt. Tighten bolts (1) and nuts (2). See

Specifications for the correct belt tension.

End By :

a. Install radiator

DE08TS Diesel Engine Disassembly and Assembly

26 of 76

Page 29

Water Temperature Regulator

1

2

1

2

4

3

4

3

Remove Water Temperature

Regulator A56581 - 02

IEED048P

1. Drain the coolant below the level of the water

temperature regulator.

2. Loosen clamps (1) to disconnect two hoses (2)

from the regulator.

Install Water Temperature

Regulator A56581 - 03

IEED049P

1. Put water temperature regulator (4) in position as

shown.

IEED049P

3. Loosen clamp (3) and remove water temperature

regulator (4).

IEED048P

2. Put water temperature regulator (4) in place and

connect hoses (2).

3. Tighten the hose clamps (1).

4. Fill the cooling system. See Maintenance Guide for

the correct level.

DE08TS Diesel Engine Disassembly and Assembly

27 of 76

Page 30

Radiator

1

2

6

8

7

10

9

11

12

3

5

4

Remove Radiator A52670 - 02

Tools Needed A

Link Bracket 2

Start By :

a. Remove hood

IEED050P

1. Drain the coolant from the radiator.

2. Loosen clamps (1) and remove air cleaner hose

(2).

IEED053P

5. Disconnect over flow hose (6) from the radiator.

6. Loosen hose clamp (7) and disconnect top

radiator hose (8).

NOTICE

Plug and cap all cooling hoses to avoid debris from

entering the system.

IEED054P

7. Loosen hose clamp (9) and disconnect hose (10).

8. Disconnect transmission cooling hose (11) from

the radiator.

IEED051P

3. Remove strap (3) from top cover (5).

4. Remove four bolts (4) and washers that hold top

cover (5) on the frame. Remove top cover (5) from

the frame.

IEED055P

9. Disconnect transmission cooling hose (12) from

the radiator.

DE08TS Diesel Engine Disassembly and Assembly

28 of 76

Page 31

IEED056P

13

14

13

14

15

16

17

15

16

17

17

A

10. Install tool (A) and fasten a hoist.

11. Remove bolts (13), washers, rubbers (14), shims

and bolt that hold the radiator on the frame (both

side).

Install Radiator A52670 - 03

Tools Needed A

Link Bracket 2

IEED058P

1. Install tool (A) and fasten a hoist as shown. Put

radiator (17) in position on the lift truck.

IEED057P

12. Remove nuts (15), washers, rubbers (16), shims and

bolt that hold radiator (17) on the frame (both side).

Remove radiator (17) from the lift truck.

IEED057P

2. Install bolt, shims, rubbers (16), washers and nuts

(15) that hold radiator (17) on the frame. Tighten

nuts (15) and bolt to a torque of

65 lbft).

IEED056P

7590 Nm (55

3. Install bolt, shims, rubbers (14), washers and nuts

(13) that hold the radiator on the frame. Tighten

nuts (13) and bolt to a torque of

65 lbft).

DE08TS Diesel Engine Disassembly and Assembly

29 of 76

7590 Nm (55

Page 32

IEED055P

12

10911

3

5

4

1

2

6

8

7

IEED051P

4. Connect transmission cooling hose (12) on the

radiator.

IEED054P

5. Connect hose (10) on the radiator and tighten hose

clamp (9).

6. Connect transmission cooling hose (11) on the

frame.

9. Put top cover (5) in position on the frame. Install

bolts (4) and washers that hold top cover (5) on

the frame.

10. Install strap (3).

IEED050P

11. Install air cleaner hose (2) and tighten hose

clamps (1).

12. Fill the cooling system. See the Maintenance

Guide for the correct level.

End By :

a. Install hood.

IEED053P

7. Connect top radiator hose (8) and tight hose clamp

(7).

8. Connect radiator overflow hose (6).

DE08TS Diesel Engine Disassembly and Assembly

30 of 76

Page 33

Intake Manifold

2

7

10

12

9

8

6

5

3

4

1

Remove Intake Manifold

A325491N - 02

Start By :

a. Remove hood

IEED059P

IEED061P

3. Loosen clamp (5) and disconnect hose (6) from the

air compressor (if equipped).

1. Loosen hose clamps (1) and remove air cleaner

outlet hose (2).

IEED060P

2. Remove four bolts (3), washers and mount bracket

and fuel filter assembly (4) from the intake

manifold. Set the mount bracket and fuel filter

assembly aside to theframe.

IEED062P

4. Remove six nozzle pipes (7) and disconnect fuel

return hose (8).

5. Disconnect cooling temperature harness (9) from

the cooling water pipe.

6. Support intake manifold (12) with fasten a strap.

Remove ten bolts (10), washers and two nuts that

hold intake manifold (12) to the cylinder head.

7. Remove intake manifold (12).

8. Remove the intake manifold gasket and discard it.

DE08TS Diesel Engine Disassembly and Assembly

31 of 76

Page 34

Assemble Intake Manifold

7

10

12

9

8

6

5

3

4

2

1

A325491N - 03

IEED062P

1. Install new intake manifold gasket on the cylinder

head by aligning its openings with the intake port in

the cylinder head.

2. Put the intake manifold (12) in position on the

cylinder head. Install bolts (10), washers and nuts

that hold intake manifold (12).

IEED060P

6. Put the mount bracket and fuel filter assembly (4)

in position on the intake manifold. Install bolts (3)

and washers that hold the mount bracket and fuel

filter assembly (4).

3. Connect fuel return hose (8) and install six nozzle

pipes (7).

4. Connect cooling temperature harness (9).

IEED061P

5. Connect hose (6) to the air compressor (if

equipped) and tighten clamp (5).

IEED059P

7. Install air cleaner outlet hose (2) and tighten hose

clamps (1).

DE08TS Diesel Engine Disassembly and Assembly

32 of 76

Page 35

Exhaust Manifold

1

1

2

5

3

4

2

5

3

4

Remove Exhaust Manifold

A32549ES - 02

IEED010P

Install Exhaust Manifold

A32549EX - 03

IEED063P

1. Check the seal ring on the jointing face of the

exhaust manifold and replace it if needed.

1. Remove four bolts (1) and washers from the

exhaust manifold.

IEED063P

2. Remove twelve nuts (2) and washers that hold the

exhaust manifold on the cylinder head. Remove

exhaust manifold (3), heat screens (4) and (5) and

gaskets from the cylinder head.

2. Put the new gaskets, heat screens (4 and 5) and

exhaust manifold (3) in position on the cylinder

head. Install nuts (2) and washers that hold the

exhaust manifold. Tighten nuts (2) to a torque of

45 Nm (33 lbft).

IEED010P

3. Install eight bolts (1) and washers.

DE08TS Diesel Engine Disassembly and Assembly

33 of 76

Page 36

Cylinder Head Cover

2

1

2

1

1

2

1

2

Oil Pan

Remove Cylinder Head Cover

IEED064P

1. Remove bolts (1) and washers that hold cylinder

head cover (2) onto the cylinder head.

2. Remove cylinder head cover (2) with gasket.

Inspect the cylinder head cover gasket for wear or

damage and replace if required.

Install Cylinder Head Cover

Remove Oil Pan A43591-02

1. Put the lift truck in position up on the blocks.

2. Drain the oil from the oil pan (2).

IEED065P

3. Remove all bolts (1) and washers from around the

oil pan and then remove oil pan (2) from the

engine block. Check gasket for damage.

Install Oil Pan A43591-03

IEED064P

IEED065P

1. Fix the new gasket to the jointing face of cylinder

head cover (2).

2. Position cylinder head cover (2) on the cylinder

head, then install bolts (1) and tighten them torque

to

20 Nm (15 lbft).

DE08TS Diesel Engine Disassembly and Assembly

34 of 76

1. Remove the gasket residue on the fixing surface of

the timing gear case, case cover and the cylinder

block using a scraper.

2. Coat the new gasket fixing surface with silicon

grease.

3. Put a new gasket in position on oil pan if

necessary. Put oil pan (2) in position on the engine

with bolts (1) and washers that hold it. Tighten the

bolts (1) to a torque of

4. Fill the engine with oil to the correct level. See the

operation And Maintenance Manual for further

information.

5. Remove the lift truck from the blocks.

20 Nm (15 lbft).

Page 37

Water Pump

1

1

3

2

3

2

Remove & Install Water Pump

A53663-01

Start By :

a. Remove fan assembly

b. Remove radiator

IEED067P

c. Remove alternator

IEED066P

1. Remove hose (1) from the water pump.

5. Install the new gasket on the engine.

6. Put water pump (3) in position and install bolts (2)

and washers that hold it. Tighten bolts (2) to a

torque of

IEED066P

20 Nm (15 lbft).

7. Connect hose (1) to the water pump.

End By :

a. Install fan assembly.

b. Install alternator.

c. Install radiator.

IEED067P

2. Remove six bolts (2) and washers that hold water

pump (3) on the engine.

3. Remove water pump (3) from the engine.

4. Remove the gasket and discard it.

NOTE : Use the following steps to install the water

pump.

DE08TS Diesel Engine Disassembly and Assembly

35 of 76

Page 38

Disassemble Water Pump

A

5

6

7

1

4

2

3

A53663-07

Tools Needed A B C

Gear Puller 1

Pliers 1

Drive Group 1

Start By :

a. Remove water pump

IEED070P

4. Remove snap ring (5) with tool (B).

IEED068P

1. Remove flange (1) using tool (A).

IEED069P

2. Remove three screws (2) that hold pump cover (3)

on the pump housing.

NOTE : Before unscrewing the screws (2) slight

impacts on them are necessary to loosen the loctite

connection.

3. Remove pump cover (3) and gasket (4) and

discard it.

IEED071P

5. Put the water pump in position on a press. Install

tool (C) and remove shaft assembly (6) from the

impeller and the water pump housing.

IEED072P

6. Remove seals (7) from the water pump housing if

they are damaged.

DE08TS Diesel Engine Disassembly and Assembly

36 of 76

Page 39

IEED073P

8

9

8

9

7

6

5

IEED072P

7. Put shaft assembly (8) in position in a press. Install

Tool (A) to remove bearing (9) from the shaft.

Assemble Water Pump A53663

Tools Needed A B

Pliers 1

Drive Group 1

2. Install seal (7) in the housing.

IEED071P

3. Put the water pump housing in position on a press

and install shaft assembly (6) in the housing.

IEED073P

1. Put shaft bearing (9) in position in a press. Make

sure there is support for the inner race of the

bearing. Push shaft into bearing (9).

IEED070P

4. Install snap ring (5) over the bearings with tool (A).

DE08TS Diesel Engine Disassembly and Assembly

37 of 76

Page 40

IEED071P

6

4

2

3

1

2

1

5. Install impeller (10) on the shaft with tool (B) and a

press. The clearance between the impeller blade

and pump body have not to exceed

(.0138 in)

.

0.35 mm

Oil Filter

Remove & Install Oil Filter

A42357-01

IEED074P

1. Remove four bolts (1) and washers that hold oil

filter assembly (2) on the block.

2. Remove oil filter assembly (2) from the block.

IEED069P

6. Install cover (3) and gasket (4) on the pump housing.

7. Install three screws (2) that hold cover (3).

Tighten the screws (2) to a torque of

lb

ft).

IEED068P

22 N m (16

3. Remove the gasket from the block and discard it.

4. Install the oil filter assembly (2) in reverse order of

removal.

8. Install flange (1) on the shaft with tool (B) and a

press.

End By :

a. Install water pump.

DE08TS Diesel Engine Disassembly and Assembly

38 of 76

Page 41

Disassemble & Assemble Oil

1

1

326

5

3

4

7

2

Filter A42357

Tools Needed A

Filter Wrench 1

Start By :

a. Remove oil filter

IEED075P

4. Assemble the oil filter assembly in reverse order of

disassembly.

End By :

a. Install oil filter.

Oil Cooler

Remove & Install Oil Cooler

1. Remove filter (1) on the filter head using tool (A).

IEED076P

2. Remove plug (2), seal ring (3), shim (4), spring (5)

and valve plunger (6) from the filter head.

IEED077P

1. Loosen clamps (1) and disconnect hoses (2) from

the oil cooler.

IEED078P

2. Remove PCV valve (3) and O-ring from the cooler

housing.

IEED167P

3. Remove relief valve assembly (7) with seal ring

from the filter head.

DE08TS Diesel Engine Disassembly and Assembly

39 of 76

Page 42

IEED079P

5

5

3

7

4

2

6

6

1

6

IEED081P

3. Remove two bolts (5), nuts (6) and washers that

hold oil cooler (7) on the block.

4. Remove oil cooler assembly (7).

5. Remove the gasket from the block and discard it.

6. Install the oil cooler in reverse order of removal.

Disassemble & Assemble Oil

Cooler

Start By :

a. Remove oil cooler

3. Inspect the condition of gasket (3). Replace gasket

(3) with new if needed.

IEED082P

4. Remove four bolts (4) and washers that hold

element in oil cooler housing.

5. Remove element (5) from oil cooler housing.

IEED080P

1. Remove eight bolts (1) and washers that hold

cover (2) on the oil cooler housing.

2. Remove cover (2) from the oil cooler housing.

IEED083P

6. Remove two gaskets (6) from the oil cooler

housing and discard it.

DE08TS Diesel Engine Disassembly and Assembly

40 of 76

Page 43

IEED084P

11

1

2

3

4

5

4

1

9

7

8

10

IEED086P

7. Remove plug (7), seal-ring (8), pin (9), spring (10)

and ball (11) from the oil cooler housing.

8. Assemble the oil cooler in reverse order of

disassembly.

End By :

a. Install oil cooler.

Cooling Water Pipe

Remove & Install Cooling Water

Pipe

2. Loosen clamp (2) and disconnect hose (3) from the

cooling pipe.

IEED087P

3. Remove six bolts (4) and washers that hold cooling

pipe (5) on the cylinder head.

NOTE : For purpose of reassembly, the torque for

bolts (4) is

20 Nm (15 lbft).

4. Remove cooling water pipe (5).

5. Remove gasket and discard it.

6. Install the cooling water pipe (5) in reverse order of

removal.

IEED085P

1. Disconnect two wirings (1) from the cooling water

pipe.

DE08TS Diesel Engine Disassembly and Assembly

41 of 76

Page 44

Oil Pump

2

1

5

6

3

4

7

8

Remove Oil Pump A41663-02

Start By :

a. Remove oil pan

IEED088P

1. Remove bolts (1), washers and tube assembly (2).

IEED090P

5. Remove bolts (5), washers and suction tube

assembly (6).

6. Remove the gasket and discard it

2. Remove the gaskets and discard it.

IEED089P

3. Remove bolts (3), washers and tube assembly (4).

4. Remove the gasket and discard it.

IEED091P

7. Remove two bolts (7) and washers that hold oil

pump (8) in place.

8. Remove oil pump assembly (8) from the engine.

DE08TS Diesel Engine Disassembly and Assembly

42 of 76

Page 45

Install Oil Pump A41663-03

7

3

4

8

5

6

2

1

IEED089P

IEED091P

1. Put oil pump assembly (8) in position on No.7

bearing cap, by tapping slightly with a plastic

hammer.

2. Install bolts (7) and washers that hold the oil pump

in place and tighten bolts (7) to a torque of

(32 lb

ft).

44 Nm

3. Bend the lock washer towards bolt (7) to prevent

from loosening.

IEED090P

5. Install new gasket on tube assembly (4).

6. Put tube assembly (4) in place and install bolts (3)

and washers that hold tube assembly (4). Tighten

bolts (3).

IEED088P

7. Install new gasket on tube assembly (2).

8. Put tube assembly (2) in place and install bolts (1)

and washers that hold tube assembly (2). Tighten

bolts (1).

End By :

4. Put suction tube assembly (6) in place and install

a. Install oil pan.

new gasket, bolts (5) and washers that hold

suction tube assembly (6).

DE08TS Diesel Engine Disassembly and Assembly

43 of 76

Page 46

Disassemble & Assemble Oil

5

4

1

6

8

9

10

7

2

3

Pump A41663-06

Start By :

a. Remove oil pump

IEED092P

1. Bend washer (1) that lock nut (2) on the shaft of

drive gear.

2. Remove washer (1), nut (2) and oil pump drive

gear (3).

IEED094P

6. Check the conditions of bushing (6) in the rear

cover. Replace with a new one if worn or

damaged.

NOTE : For the purpose of reassembly, tighten nut

(2) to a torque of

127 N m (94 lb ft).

3. Remove wooden roof key from the shaft.

IEED093P

4. Remove four bolts (4) and nuts that hold rear cover

(5) on the pump housing.

NOTE : For the purpose of reassembly, tighten bolts

(4) and nuts to a torque of

22 N m (16 lb ft).

5. Remove rear cover (5).

IEED095P

7. Remove plug (7), valve plunger (8) and spring (9)

from the rear cover.

IEED096P

8. Remove two pump gears (10) from the pump

housing.

DE08TS Diesel Engine Disassembly and Assembly

44 of 76

Page 47

IEED097P

12

2

1

3

2

1

3

11

NOTE : Mark front cover (11) for the purpose of

reassembly.

9. Remove front cover (11) from the pump housing.

10. Check the conditions of bushings (12) in the front

cover. Replace with new ones if worn or

damaged.

NOTE : Assemble the oil pump in reverse order of

removal.

End By :

a. Install oil pump.

Rocker Shaft & Push Rods

Remove Rocker Shaft & Push

Rods A17744 & A17702-02

Start By :

a. Remove head cover

IEED098P

1. Remove bolts (2) and washers from the rocker

shaft assembly. Remove rocker shaft assembly (1)

from the cylinder head.

2. Remove twelve push rods (3).

Install Rocker Shaft & Push

Rods A17744 & 17702-03

IEED098P

1. Install push-rods (3) coated with engine oil in the

cylinder head.

2. Install rocker arm shaft assembly (1) and align the

end of the rocker arm adjust screw with the push

rod, then tighten bracket bolts (2).

3. Adjust valve clearance as following procedure ;

DE08TS Diesel Engine Disassembly and Assembly

45 of 76

Page 48

a. Bring the TDC mark on the crankshaft pulley

1

2

4

3

into alignment with the gear case by turning the

crankshaft, then check the state of the rocker

arms on No. 1 cylinder to see in which cylinder

the poston is at the top dead center (TDC) on

compression stroke.

Rocker Shaft

Disassemble Rocker Shaft

A17744-07

NOTE : When both the intake and exhaust valve

rocker arms are in free state, it indicates that the

piston in that cylinder is at the top dead center on

compression stroke.

b. Perform valve clearance adjustment operation

commencing with the valves on the cylinder in

which the poston is at the top dead center on

compression stroke. Insert a feeler gauge of

specified thickness into the clearance between

the valve stem end and rocker arm and adjust

the clearance with the adjust screw. Fully

tighten the rock nut when a correct adjustment

is obtained.

Valve clearance (Cold)

(mm)

Intake 0.3

Exhaust 0.3

c. When adjustment of the valve on the No.1

cylinder is completed, turn the crankshaft one

full turn and adjust the clearances of the valve

on remaining cylinders.

123456

IE I E I E I E IEI E

Tools Needed A

Drive Group 1

Start By :

a. Remove rocker shaft and push rods

IEED099P

1. Remove circlip (1) and washer from both end of

the rocker shaft.

#1

#6

I:Intake valve E : Exhaust valve.

NOTE : Adjust the clearance of the valves marked

with '

in the table when the piston in No. 1 cylinder

is held at the top dead center on compression stroke.

Conversely, adjust the clearance of the valves

marked with '

in the table when the piston in No. 6

cylinder is held at the top dead center on

compression stroke.

End By :

a. Install head cover.

IEED100P

2. Remove rocker arms (2), brackets (3) and springs

(4) from both side of the rocker shaft.

DE08TS Diesel Engine Disassembly and Assembly

46 of 76

Page 49

Assemble Rocker Shaft A17744-08

5

Tools Needed A

Driver Group 1

6

7

IEED001S

3. Remove nut (5) and adjusting screw (6) from the

rocker arm.

4. If a replacement is needed, remove bushing (7)

with tool (A) and a press.

IEED002S

5. Support the rocker arm shaft on V-blocks at its

ends and check the amount of run-out at the

center part using a dial indicator. If a slight amount

of run-out is noticeable, correct with a bench press

without applying heat. Replace the rocker arm

shaft if the amount of run-out is 0.3 mm (.012 in).

5

6

7

IEED001S

1. If replacement was needed, make an alignment of

oil hole in the bushing with the oil hole in the rocker

arm. Install new bushing (7) in the rocker arm with

tool (A) and a press.

NOTE : Check the bore dimension of the bushing in

the rocker arm after installation. It must be within the

tolerance given in the specifications.

NOTICE

Do not turn the adjusting screw too far into the rocker

arms. Damage to the valve can be the result after the

rocker shaft and push rods have been installed in the

engine.

2. Install adjusting screw (6) and nut (5) in the rocker

arm.

6. Measure the diameter of the rocker shaft at both of

the rocker arm locations. The diameter must be

23.959 to 23.978 mm (.9432 to .9440 in).

NOTE : The maximum permissible clearance

between the rocker arm bearings and shaft is 0.25

mm (.0099 in.).

DE08TS Diesel Engine Disassembly and Assembly

47 of 76

Page 50

IEED100P

4

2

3

1

2

1

3. Install springs (4), brackets (3) and rocker arms (2)

in their original positions.

Connecting Rod Bearings

Remove Connecting Rod

Bearings A14078-02

Start By :

a. Remove oil pump

IEED101P

IEED099P

4. Install washer and circlip (1) on both end of the

rocker shaft.

End By :

a. Install rocker shaft and push rods.

1. Remove two bolts (1). Remove connecting rod cap

(2).

NOTE : Put identification on the bearings for correct

installation.

2. Remove the lower bearing half from the cap.

3. Push the connecting rod away from the crankshaft

and remove the upper bearing half.

4. Do Steps 1 through 4 for the other connecting rod

bearings.

DE08TS Diesel Engine Disassembly and Assembly

48 of 76

Page 51

Install Connecting Rod Bearings

1

A14078-03

9. Put the connecting rod cap in position and install

the bolts. Tighten the nuts to a torque of

(133 lb

ft).

180 Nm

NOTE : When installing undersize bearings, have the

crankshaft journals and crankpins ground to size

indicated in the below table :

IEED101P

1. Make sure all parts are clean and free of all dirt

and foreign material.

2. Put clean engine oil on the bearings and the

crankshaft journals.

NOTE : If the same bearings are used, install as per

identification.

3. Put the upper bearing halves in position on the

connecting rods. Make an alignment of the tabs on

the bearings and the grooves (slots) in the

connecting rods.

4. Put the connecting rods in position on the

crankshaft.

Outside diameter of

Bearing Size

Standard 83.96683.988 70.97170.990

Undersize 0.25 83.716

Undersize 0.50 83.466

Undersize 0.75 83.216

Undersize 1.00 82.966

crank journals after

grinding (mm)

83.738 70.72170.740

83.488 70.47170.490

83.238 70.22170.240

82.988 69.97169.990

Outside diameter of

crankpins after

grinding (mm)

10. Tighten main bearing cap bolts to a torque of 300

N

m (220 lbft).

11. Do steps 6 through 9 for the other connecting rod

caps.

End By :

a. Install oil pump.

Cylinder Head

5. Install the lower bearing halves on the caps. Make

an alignment of the tabs on the bearings and the

grooves (slots) in the caps.

NOTE : Make an alignment of the number on the cap

with the correct number on the connecting rod.

6. Put clean engine oil on the connecting rod bolt

threads. Install all bolt one of the connecting rod

caps.

7. Use Plastigage to check the bearing clearance of

the connecting rods. Install connecting rod cap (1)

and tighten the bolts to a torque of

lb

ft).

180 Nm (133

8. Remove the connecting rod cap and measure the

Plastigage. The bearing clearance for new rod

bearings must be

.0029 in.)

.

0.035 to 0.075 mm (.0010 to

Remove Cylinder Head A17429-02

Tools Needed A

Link Bracket 1

Start By :

a. Remove air cleaner

b. Remove intake manifold

c. Remove exhaust manifold

d. Remove cylinder head cover

e. Remove rocker shaft and push rods

DE08TS Diesel Engine Disassembly and Assembly

49 of 76

Page 52

IEED102P

1

2

3

3

2

A

2

A

1. Remove bolts (1) that hold the cylinder head on

the block.

Install Cylinder Head A17429-03

Tools Needed A

Link Bracket 1

NOTE : Clean the bolt holes on the cylinder block

with compressed air and throughly clean the upper

face of the cylinder block.

IEED104P

1. Install new cylinder head gasket (3) on the cylinder

block by aligning the holes with the dowels.

IEED103P

Typical Example

2. Install tool (A) in the cylinder head, and then fasten

a hoist. Remove cylinder head assemblies (2).

IEED104P

3. Remove cylinder head gasket (3) and discard it.

IEED103P

Typical Example

2. Install tool (A) on the cylinder head. Fasten a hoist

and put cylinder head (2) in position on the cylinder

block.

DE08TS Diesel Engine Disassembly and Assembly

50 of 76

Page 53

IEED102P

121

2

3

4

3. Remove tool (A) and the hoist. Put engine oil on

the bolt threads and then install bolts (1) that hold

the cylinder head in place.

4. Tighten bolts (1) as follows :

a. Tighten all bolts in number sequence to a torque of

100 Nm (74 lbft).

b. Tighten all bolts in number sequence to a torque of

180 Nm (133 lbft).

Disassemble Cylinder Head

A17429-07

Tools Needed A B C

Valve Spring Compressor 1

Valve Spring Tester 1

Valve Guide Installer 1

Start By :

a. Remove cylinder head

c. Again tighten all bolts in number sequence to a

torque of

220 Nm (163 lbft).

NOTE : After engine has run at normal temperature

of operation for a very short time, tighten all bolts

again to the final torque. Rocker shaft assembly has

to be removed and valves have to be adjusted again.

End By :

a. Install rocker shaft and push rods.

b. Install cylinder head cover.

c. Install exhaust manifold.

d. Install intake manifold.

e. Install air cleaner.

IEED105P

1. Apply cylinder number mark to the head of each

valve.

2. Install tool (A) on the cylinder head.

3. Compress the valve springs and remove valve

cotters (1), spring retainer (2) and springs (3).

IEED106P

4. Remove valve (4), stem seal and spring seat.

DE08TS Diesel Engine Disassembly and Assembly

51 of 76

Page 54

5

B

3

IEED003S

4. Remove valve guide (5) using tool (C).

5. Do steps 1 through 4 again for the remainer of the

valves.

6. Carefully remove carbon from lower face of

cylinder head to prevent scratching of valve seat

faces.

IEED004S

7. Replace valve (4) with valve guide if reduction in

diameter of the valve stem due to wear, is beyond

the below specified limit.

IEED107P

8. Check the spring force with tool (B) and replace

springs (3) if measured valve is beyond the below

limit.

Description

Intake Valve 41 65.5

Exhaust

Valve

Outer 41 62.7

Inner 38 27.2

Spring Set

Length(mm)

Nominal(kg)

73.5 65.5

63.9 62.7

30.0 27.2

Limit for

Use(kg)

4

Assemble Cylinder Head

A17429-08

Tools Needed A B C D

Valve Compressor 1

Valve Keeper Inserter 1

Valve Guide Installer 1

Stem Seal Installer 1

Description Nominal Limit for use

Intake Valve 8.95

Exhaust Valve 8.935

8.97 8.93

8.955 8.91

IEED003S

5

1. Install valve guide (5) with tool (C) in the cylinder

head.

DE08TS Diesel Engine Disassembly and Assembly

52 of 76

Page 55

WARNING

IEED106P

4

1

2

3

1

2. Press in new valve stem seal in valve guide using

tool (D) if they were removed.

3. Put clean engine oil on the valve stems.

4. Install spring seat and valve (4) into the cylinder

head.

Valve cotters (1) can be thrown from valve (4)

when tool (A) is released if they are not in their

correct position on the valve stem.

Remove tool (A) and hit the top of the valve with a

7.

plastic hammer to be sure the locks are in their

correct position on the valve.

8. Do steps 1 through 7 again for the remainder of

the valves.

End By :

a. Install cylinder head.

Pistons

4

1

IEED005S

IEED105P

5. Install springs (3) and spring retainer (2).

The close coil of spring (3) must be mext to the head.

23 2

NOTICE

Remove Pistons A14615-02

Start By :

a. Remove cylinder head

b. Remove oil pan plate

c. remove oil pump

IEED101P

1. Remove the ring of carbon from the top inner

surface of the cylinder liner.

2. Turn the crankshaft until the connecting rod

bearing cap to be removed is at bottom center.

Remove connecting rod bearing cap (1) from the

connecting rod.

6. Use tool (A) and put springs (3) under

compression. Use tool (B) and install valve cotters

(1) that hold the springs (3) in place.

DE08TS Diesel Engine Disassembly and Assembly

53 of 76

Page 56

IEED108P

3

A

3

1

3. Push the piston and connecting rod away from the

crankshaft until the piston rings are above the

cylinder liner. Remove piston (3) and the

connecting rod from the engine.

4. Do Steps 2 and 3 for the remainder of the pistons.

Install Pistons A14615-03

Tools Needed A

Ring Compressor 1

4. Use tool (A) and put piston (3) and the connecting

rod in the same cylinder from which it was

removed. Make sure the identification “FRONT” on

the piston is toward the front of the engine.

IEED101P

NOTICE

When connecting rod caps are installed, make sure the

number on the side of the cap is next to and respective

with the number on the side of the connecting rod. The

identification numbers must be opposite to the camshaft

when the piston and connecting rod are installed.

IEED109P

1. Turn the crankshaft until the bearing journal for the

piston to be installed is at bottom center.

2. Put clean engine oil on the crankshaft journal and

on the inside of the cylinder liner. Put clean engine

oil on the piston rings and connecting rod bearings.

3. Move the rings on the piston until the ring openings

are approximately 90

apart.

NOTICE

Never install the ring compressor on the piston

unless the cylinder liner is used as a guide. Damage

to the piston rings can be the result.

5. Put connecting rod bearing cap (1) in position and

install the nuts that hold it in place. Tighten the

nuts to a torque of

180 Nm (133 lbft).

6. Follow the same above procedure for installation of

the remainder of the pistons.

End By :

a. Install oil pan plate.

b. Install cylinder head.

c. Install oil pump.

DE08TS Diesel Engine Disassembly and Assembly

54 of 76

Page 57

Disassemble Pistons A14615-07

2

3

4

2

1

565

5

6

Tools Needed A B C

Pliers 1

Pliers 1

Drive Group 1

Start By :

a. Remove piston

IEED110P

NOTE : Put identification on all parts for correct

assembly.

1. Remove rings (1) from piston (2) with tool (A).

IEED112P

4. Remove bushing (6) with tool group (C) from

connecting rod (5).

5. See Specifications for use of the parts again.

Assemble Pistons A14615-08

Tools Needed A B C D

Driver Group 1

Piston Ring Groore Cleaner 1

Pliers 1

Pliers 1

IEED112P

IEED111P

1. Install the bushing in connecting rod (5) with tool

2. Remove retaining ring (3) from both side of the

piston with tool (B).

group (A) and a press. Make the new bushing to

the correct size with one.

See SPECIFICATIONS.

3. Remove pin (4) and connecting rod (5) from piston

(2).

DE08TS Diesel Engine Disassembly and Assembly

55 of 76

Page 58

IEED113P

3

4

2

5

2

1

Typical Example

2. When the oil pistons are used, clean the piston

grooves with tool (B) before the rings are installed.

NOTE : The concave area (the part that makes the

curve to the inside) in the piston is toward one side of

the piston. Install the piston on the connecting rod

with the concave area toward the side which has the

connecting rod and cap identification on it.

IEED111P

IEED110P

4. Install a retaining ring (3) on both side of the piston

(2) with tool (C).

5. Install rings (1) on the piston with tool (D).

NOTE : See Specifications for piston ring location.

End By :

a. Install pistons.

3. Slide connecting rod (5) inside the piston. Install

pin (4) in the piston and the connecting rod.

DE08TS Diesel Engine Disassembly and Assembly

56 of 76

Page 59

Cylinder Liners

Remove And Install Cylinder

Liners A11552-01

Start By :

a. Remove pistons

b. Remove crankshaft

1. Pull out cyliner liner (1) using the cylinder liner

extractor or by hand carefully so as not to damage

the cylinder bore.

2. Do step 1 for the other cylinder liners.

3. Number cylinder liners (1) according to installed

position.

4. Install the cylinder liners (1) in reverse order of

removal.

End By :

a. Install pistons.

b. Install crankshaft.

Timing Gear Case Cover

Remove Timing Gear Case Cover

A17198-02

Start By :

a. Remove oil pan

b. Remove crankshaft pulley

1. Remove bolts (1) and washers that hold timing

gear case cover (2) to the timing gear case.

Remove timing gear case cover (2) from the timing

gear case.

2. Remove lip type seal (3) from timing gear case

cover (2).

57 of 76

DE08TS Diesel Engine Disassembly and Assembly

IEED006S

IEED114P

IEED115P

2

3

1

1

Page 60

Install Timing Gear Case Cover

A17198-03

1. Install lip type seal (3) with tool group (A) with the

lip of the seal toward the inside of the timing gear

case cover.

2. Make sure the gasket is in position between the

timing gear case and cover.

3. Put the timing gear case cover (2) in position on

the timing gear case and install bolts (1) that hold it

to the case.

End By :

a. Install crankshaft pulley.

b. Install oil pan.

Timing Gears

Remove Timing Gears A16387-02

Start By :

a. Remove timing gear case cover

NOTE : Make an alignment of the timing marks on

the fuel injection pump gear and idle gear, crankshaft

gear and idle gear and camshaft gear and idle gear

or put a mark of identification on the gears for correct

installation.

1. Remove bolts (1) and thrust washer (2). Remove

idler gear (3). Remove the bushings from the

inside gear if damaged.

2. Remove nut (4) from injection pump coupling.

Tools Needed A

Puller Group 1

58 of 76

DE08TS Diesel Engine Disassembly and Assembly

Tools Needed A

Drive Group 1

IEED116P

IEED117P

IEED114P

2

1

IEED115P

3

3

1

2

4

Page 61

3. Remove nut (5) and injection pump coupling and

gear (6) from injection pump.

4. Remove six bolts (7) and washers that hold

injection pump gear (8) in place and remove

injection pump gear (8).

5. Remove four bolts (9), washers that hold camshaft

gear in place.

6. Remove camshaft gear (10) from camshaft.

Install Timing Gears A16387-03

1. Put camshaft gear (10) in position on the camshaft

and install washers and bolts (9). Tighten bolts (9)

to a torque of 22 Nm (16 lbft).

2. Put injection pump gear (8) in position on coupling

and install washers and bolts (7).

3. Spread the end of bolts (7).

59 of 76

DE08TS Diesel Engine Disassembly and Assembly

IEED118P

IEED120P

IEED119P

Tools Needed A

Dial Indicator 1

IEED121P

5

6

7

8

9

10

IEED120P

9

7

8

10

Page 62

4. Put fuel injection pump drive coupling and gear (6)

in position. Make an alignment of the key and the

groove (slot) in the coupling.

5. Install nut (5) that hold the injection pump drive

coupling and gear (6) in place. Tighten nut (5) to a

torque of 130 Nm (96 lbft).

6. Install nut (4) into the injection pump coupling.

7. Put idler gear (3) in position on the idler gear pin,

so that the marks on the idler gear are aligned with

marks on the camshaft gear, crankshaft gear and

the injection pump gear respectively.

8. Install thrust washer (2) and bolts (1) that hold the

idler gear. Tighten the bolts to a torque of 40 Nm

(30 lbft).

9. When installing the timing gears in position, check

the amount of backlash between gears using tool

(A). If the amount of backlash is beyond the

specified value(below table) correct it.

End By :

a. Install timing gear case cover.

Timing Gear Case

Remove Timing Gear Case

A17198-02

Start By :

a. Remove timing gears

b. Remove fuel injection pump

c. Remove oil pan

1. Remove bolts (1) and then remove timing gear

case (2) from the cylinder block.

2. Remove gasket from the timing gear case.

60 of 76

DE08TS Diesel Engine Disassembly and Assembly

Backlash

Camshaft gear and idler gear 0.160.28

Crankshaft gear and idler gear 0.160.28

Injection pump drive gear and idler gear 0.160.28

IEED122P

IEED118P

5

6

IEED117P

4

1

2

IEED116P

3

1

2

Page 63

Install Timing Gear Case

A17198-03

1. Install a new gasket on the timing gear case.

2. Put timing gear case (2) in position on the cylinder

block and install bolts (1) that hold it.

End By :

a. Install oil pan.

b. Install fuel injection pump.

c. Install timing gears.

Camshaft & Camshaft

Bearing

Remove Camshaft & Camshaft

Bearing A17174 & 17078 - 02

Start By :

a. Remove rocker shaft and push rods

b. Remove timing gear cover

1. Remove four bolts (1), washers that hold camshaft

gear (2) in place.

2. Remove camshaft gear (2) from the camshaft.

3. Remove bolts (3), washers and flange (4) from the

camshaft.

61 of 76

DE08TS Diesel Engine Disassembly and Assembly

IEED124P

IEED123P

1

2

4

3

IEED122P

1

2

Page 64

4. Remove camshaft assembly (5) by carefully sliding

it out from the block. Do not force shaft as damage

can occur to the camshaft bearings.

5. Check the conditions of thrust washer (6) and

replace thrust washer (6) if needed.

6. Remove camshaft bushes (7) from the block if

necessary.

Install Camshaft And Camshaft

Bearing A17174 & A17078-03

NOTE : Make an alignment of the oil holes in the

bearing with the oil holes in the engine block.

1. Install a new bushes (7) in place in block if

removed.

2. Install thrust washer (6). Make an alignment of the

hole in the washer and the dowel in the camshaft.

62 of 76

DE08TS Diesel Engine Disassembly and Assembly

IEED126P

IEED125P

5

6

7

IEED126P

7

IEED165P

6

Page 65

3. Clean engine oil to the cams and journals of the

camshaft and the camshaft bushes, then install

camshaft (5) in position in the cylinder block.

NOTE : When installing camshaft, exercise care not

to scratch camshaft bearings.

4. Put flange (4) in place and install washers and

bolts (3) that hold the flange.

5. Put camshaft gear (2) in position on the camshaft

and install washers and bolt (1) that hold camshaft

gear (2) in the camshaft.

End By :

a. Install timing gears.

b. Install rocker shaft and push rods.

Crankshaft Pulley

Remove Crankshaft Pulley

A12660-02

Start By :

a. Remove fan belts

1. Remove eight bolts (1) and thrust washer (2) that

hold crankshaft in place. Remove crankshaft pulley

(3).

2. Remove eight bolts (4) and washers and separate

the crankshaft pulley and vibration damper (5).

63 of 76

DE08TS Diesel Engine Disassembly and Assembly

IEED127P

IEED128P

1

3

5

4

2

IEED124P

4

3

IEED123P

1

2

IEED125P

5

6

Page 66

Install Crankshaft Pulley

A12660-03

1. Put vibration damper (5) in position on the

crankshaft pulley. Install washers and bolts (4) that

hold them.

2. Put crankshaft pulley (3) in position on the

crankshaft. Install thrust washer (2) and bolts (1)

that hold crankshaft pulley. Tighten bolts (1) to a

torque of 130 Nm (96 lbft).

Flywheel

Remove Flywheel

Start By :

a. Separation of engine and transmission

1. Remove bolts (1) that hold adapter (2) in place.

2. Remove adapter (2) from the flywheel housing.

3. Remove eight bolts (3) and washers that hold

adapter and ring gear assembly (4) on the

flywheel.

4. Remove adapter and ring gear assembly (4) from

the flywheel.

64 of 76

DE08TS Diesel Engine Disassembly and Assembly

IEED129P

IEED130P

IEED127P

IEED128P

1

3

5

2

2

3

4

1

4

Page 67

5. Remove bolts (5) and washers that hold adapter

(6) on the flywheel.

6. Remove adapter (6) from the flywheel.

7. Remove two bolts (7) and washers that hold

bushing on adapter (6).

8. Replace bushing (8) with new one if they was

worn or damaged.

9. Remove two bolts opposite each other and install

two M14x1.5 guide bolts in the flywheel.

10. Remove the remainder of bolts (9) and then

remove flywheel (10).

11. Remove flywheel ring gear (11) with a brass

punch. If necessary, put a little heat on the

flywheel ring gear.

Install Flywheel A13366-03

1. Heat ring gear (11) to a maximum temperature of

246(475). Install the ring gear so the chamfer

on the gear teeth is next to the starter pinion when

the flywheel is installed.

65 of 76

DE08TS Diesel Engine Disassembly and Assembly

IEED131P

11

IEED132P

IEED133P

Tools Needed A

Dial Indicator Group 1

IEED007S

5

686109

7

11

IEED007S

Page 68

2. Install two M14x1.5 guide bolts in opposite holes of

the crankshaft flange.

3. Install enough bolts (9) with Loctite No.271 to hold

flywheel (10) in position. Remove guide bolts.

4. Install remainder of bolts (9). Tighten bolts (9) to a

torque of 180 Nm (133 lbft).

Typical Example

5. Check the flywheel face runout as follows:

a. Install tool group (A) as shown. Move the

crankshaft the same way before the indicator is

read so the crankshaft end clearance

(movement) is always removed.

b. Set the dial indicator to read 0.0 mm (.000 in.).

c. Turn the flywheel and read the indicator every 90

d. The difference between the lower and higher

measurements taken at all four points must not

be more than 0.20mm (.008in.) which is the

maximum permissible face runout (axial

eccentricity) of the flywheel.

Typical Example

6. Check the pilot bore runout of the flywheel as follows:

a. Install tool group (A) as shown.

b. Set the dial indicator to read 0.0 mm (.000 in.).

c. Turn the flywheel and read the indicator at 90

intervals.

d. The difference between the lower and higher

measurements taken at all four points must not be

more than 0.30 mm (.0.12 in.) which is the maximum

pilot bore runout (eccentricity) of the flywheel.

Typical Example

7. Check the outside diameter runout of the flywheel

as follows:

a. Install tool group (A) at top dead center of the

flywheel as shown. Mount the dial indicator to

the flywheel housing or the engine block.

b. Set the dial indicator to read 0.0 mm (.000 in.).

c. Turn the flywheel and read the indicator every 90

d. The difference between the lower and higher

measurements taken at all four points must not

be more than 0.30 mm (.012 in.) which is the

maximum permissible outside diameter runout

(eccentricity) of the flywheel.

66 of 76

DE08TS Diesel Engine Disassembly and Assembly

IEED134P

IEED135P

IEED136P

IEED133P

10

AAA

9

Page 69

8. Install bushing (8) in position on adapter (6) and

tighten bolts (7) to a torque of 124 Nm (106

35 lbin).

9. Put the anti-seize compound (FEL-PRO C5-A)

inside of bushing (8).

10. Put adapter (6) in position and install bolts (5) and

washers that hold adapter (6) on the flywheel.

Tighten bolts (5) to a torque of 5510 Nm (40

7 lbft).

11. Put the adapter and ring gear assembly (4) in

position and install bolts (3) and washers that

hold adapter and ring gear assembly (4) on the

flywheel. Tighten bolts (3) to a torque of

5510 Nm (407 lbft).

12. Put adapter (2) in position and install bolts (1) that

hold adapter (2) on the flywheel housing. Tighten

bolts (1) to a torque of 55 10 Nm (40 7 lbft).

End By :

a. Connection engine and transmission.

67 of 76

DE08TS Diesel Engine Disassembly and Assembly

IEED131P

5

6

IEED130P

3

4

IEED132P

8

6

7

IEED129P

2

1

Page 70

Flywheel Housing

Remove Flywheel Housing

A11453-02

Start By :

a. Remove flywheel

b. Remove electric starting motor

1. Fasten tool (A) and a hoist to the flywheel housing.

Remove bolts (2) to remove housing (1)

NOTE : Flywheel housing is put in a location with

dowels.