Page 1

MARINE

CONTROL UNITS

Elite Control

EN

Installation and Operating Manual ........2

WARNING

Cancer and Reproductive Harm

www.P65Warnings.ca.gov

Elite Control Series

L-5507 | Form No. 341204 20200325 | ©2020 Dometic Corporation

Page 2

Contents Elite Control

Service Center & Dealer Locations

Visit: www.dometic.com

Read these instructions carefully. These instructions

MUST stay with this product.

Contents

1 Explanation of Symbols and Safety

Instructions ............................ 2

1.1 Recognize Safety Information .............2

1.2 Understand Signal Words ................2

1.3 Supplemental Directives .................3

1.4 General Safety Messages ................3

2 Intended Use ........................... 3

3 General Information ..................... 3

3.1 Tools and Materials .....................3

3.2 Display Features .......................4

4 Specifications .......................... 4

4.1 Product Dimensions ....................4

8 Troubleshooting .......................25

9 Disposal .............................. 30

10 Warranty Information ................... 30

1 Explanation of Symbols and Safety Instructions

This manual has safety information and instructions to

help you eliminate or reduce the risk of accidents and

injuries.

1.1 Recognize Safety Information

This is the safety alert symbol. It is used to alert

you to potential physical injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

4.2 Cable Length ..........................5

4.3 Available System Inputs ..................5

4.4 Operational Specifications ...............5

5 Wiring Diagrams ........................ 6

6 Installation ............................. 8

6.1 Choosing a Display Panel Location. . . . . . . . .8

6.2 Preparing the Wall ......................8

6.3 Installing an Optional Sensor .............8

6.4 Mounting the Display Panel ..............9

6.5 Testing the Display ......................9

7 Operation .............................. 9

7.1 Understanding the Heating and Cooling

Cycles ..............................10

7.2 Choosing the Control Operation ......... 11

7.3 Using the Control Display Panel ..........13

7.4 Programming the Control ...............14

1.2 Understand Signal Words

A signal word will identify safety messages and property

damage messages, and also will indicate the degree or

level of hazard seriousness.

DANGER!

Indicates a hazardous situation that, if not avoided,

will result in death or serious injury.

WARNING

Indicates a hazardous situation that, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a hazardous situation that, if not avoided,

could result in minor or moderate injury.

NOTICE: Used to address practices not related to

physical injury.

Indicates additional information that is not related

I

to physical injury.

7.5 Navigation Tree .......................24

2

EN

Page 3

Elite Control Intended Use

1.3 Supplemental Directives

To reduce the risk of accidents and injuries, please

observe the following directives before proceeding to

install or operate this appliance:

• Read and follow all safety information and

instructions.

• Read and understand these instructions before

installing and operating this product.

• The installation must comply with all applicable local

or national codes, including the latest edition of the

following standards:

– ANSI/NFPA70, National Electrical Code (NEC)

– American Boat and Yacht Council (ABYC)

1.4 General Safety Messages

WARNING: ELECTRICAL SHOCK, FIRE, AND/

OR EXPLOSION HAZARD. Failure to obey the

following warnings could result in death or

serious injury:

• Use only Dometic replacement parts and

components that are specifically approved for use

with the appliance.

• Avoid improper installation, adjustment, alteration,

service, or maintenance of the appliance. Service

and maintenance must be done by a qualified service

person only.

This manual provides all necessary information for the

proper installation and operation of the Elite Control

display panel. Poor installation and misunderstood

operating parameters will result in unsatisfactory

performance and possible failure. The manufacturer

accepts no liability for damage in the following cases:

• Faulty assembly or connection

• Damage to the product resulting from mechanical

influences and excess voltage

• Alterations to the product without express permission

from the manufacturer

• Use for purposes other than those described in the

operating manual

Dometic Corporation reserves the right to modify

appearances and specifications without notice.

3 General Information

This section provides information on the tooling, parts,

and display features for the Elite Control.

The images used in this document are for reference

I

purposes only. Components and component

locations may vary according to specific product

models. Measurements may vary ±0.38 in. (10 mm).

The Elite Control models have the same features,

installation procedure, and functionality.

• Do not modify this product in any way. Modification

can be extremely hazardous.

• This product should be installed in a controlled,

indoor environment.

2 Intended Use

The Elite Control is a user-friendly 5-volt logic and

micro controller-based unit designed for use with direct

expansion (DX), reverse-cycle air-conditioning systems,

and chilled-water systems (CW). The 5 button display

panel has 33 programmable parameters, automatic and

manual fan speeds, standard and optional sensor inputs,

and fits both Vimar® Idea and Eikon switch bezels.

EN

3.1 Tools and Materials

Dometic recommends that the following tools and

materials be used while installing the appliance:

Recommended Tools

Phillips-head Screwdriver Saw

Safety Glasses

Included Parts Quantity

Screws 4

Elite Control 1

3

Page 4

Specifications Elite Control

Additional Parts

Required for CW Installations (not included)

Water Inlet Temperature Sensor X

Optional Parts

Outside Air Temperature (OAT) Sensor X X

Inside Air Temperature Sensor X X

Auxiliary Electric Heater

Room Temperature/Relative Humidity

Combination Sensor

Seawater Low-Limit Temperature Sensor

Pump Sentry Water Sensor X

1

Additional parts are not included with the standard control package.

2

Available in soware revision C39 and newer.

1

2

2

2

DX CW

X X

X X

X

The maximum length for the display and sensor

I

cables is 75 (22.9 m).

3.2 Display Features

This section explains the function of the buttons and

indicators on the Elite Control display.

Indicator Indicator Name Function

Displays the inside, set

point, outside, and water

temperatures

Indicates the fan speed as

high, medium, or low

Located below the fan speed

indicator, the LED illuminates

when active

Located above the COOL

mode indicator, the LED

illuminates when active.

• The COOL or HEAT mode

LED also lluminates to

indicate which cycle is

active

When only this indicator is lit, it

indicates the COOL-only mode

is active

• When only this indicator is

lit, it indicates the HEATonly mode is active

• When the indicator is

flashing, indicates the

AUXILIARY HEAT mode is

active

AUTO

AUTO

Temperature LED

Display

Fan Speed

Automatic Fan

Mode

Automatic Mode

Cool Mode

Heat Mode

1

1 Elite Control Display

Button Button Name Function

Power

Up

Down

Fan

Mode

Toggles between ON and OFF

mode

Raises the temperature set

point by 1 °F (0.6 °C)

Lowers the temperature set

point by 1 °F (0.6 °C)

Cycles through the different

fan speeds

Selects one of the

four operating modes

(AUTOMATIC, COOL, HEAT,

or DEHUMIDIFICATION) when

the system is in the ON mode

Dehumidification

Mode

Indicates DEHUMIDIFICATION

mode is active

1

If parameter P-13 for the auxiliary heat is enabled, it can also be selected and the

display will show A-H.

4 Specifications

The following table lists the Elite Control dimensions,

cables, system inputs, and operational specifications.

4.1 Product Dimensions

Display Panel Dimensions

for the Idea Bezel

Display Panel Dimensions

for the Eikon Bezel

Cut-Out Dimensions for

the Idea Bezel

Cut-Out Dimensions for

the Eikon Bezel

4.4 in. x 3.0 in.

(112 mm x 76 mm)

4.5 in. x 2.9 in.

(114 mm x 74 mm)

2.3 in. x 3.5 in.

(58 mm x 89 mm)

1.9 in. x 2.8 in.

(48 mm x 71 mm)

4

EN

Page 5

Elite Control Specifications

4.2 Cable Length

Display Cable

Self-Contained

Inside Air Temperature

Sensor (optional)

OAT Sensor (optional) 15.0 (4.6 m) Standard

All custom cable lengths

are supplied in standard

5 (1.5 m) increments

15.0 (4.6 m) Standard

7.0 (2.1 m) Standard

75.0 (22.9 m) Maximum

4.3 Available System Inputs

Water Inlet

Temperature Sensor

(CW Installations Only)

High Refrigerant Pressure 1

1

4.4 Operational Specifications

Set Point Operating

Range

Ambient Temperature

Operating Range

Displayed

Sensor Accuracy ± 2°F @ 77°F (±1°C @ 25°C)

Low Voltage Limit

100–120 V

Low Voltage Limit

200–240 V

Low Voltage Processor

Reset

Universal Line Voltage 100–240 VAC

Frequency 50 Hz or 60 Hz

Fan Output

65 °F to 85 °F (18 °C to 29 °C )

5°F to 150°F (-15°C to 66°C)

95 VAC

195 VAC

50 VAC

6 A @ 115 VAC

6 A @ 230 VAC

Inside Air Temperature

Sensor (optional)

Low Refrigerant Pressure

(optional)

OAT Sensor (optional) 1

Pump Sentry Water

Sensor (optional)

(DX Installations Only)

Room Temperature/

Relative Humidity

Combination Sensor

(optional)

Valve Output 5 A @ 115/230 VAC

1

1

1

1

For CW Only:

Auxiliary Electric

Heater Output

(using compressor

output L1 and L2)

External Triac 26 A

External Q-Relay 30 A Maximum

Pump Output

Compressor Output

Minimum Operating

Temperature

Maximum Ambient

Operating Temperature

Maximum Rh Conditions 99% Non-condensing

30 A Maximum

1/4 HP @ 115 VAC

1/2 HP @ 230 VAC

1 HP @ 115 VAC

2 HP @ 230 VAC

0°F (-18°C)

180°F (82°C)

EN

Power Consumption < 5 W

5

Page 6

Wiring Diagrams Elite Control

5 Wiring Diagrams

WARNING: ELECTRIC SHOCK HAZARD.

Turn power OFF before performing any electrical

installation or maintenance activities. Failure to obey

this warning could result in death or serious injury.

Figure 2 and Figure 3 provide examples of the DX and

CW Wiring for the Elite Control.

Display Jacks (for 8- or 6-pin display and cables)

Inside Temperature Sensor Jack

Not Active

Optional Water-Out Temperature Sensor

Optional Outside Air Temperature Sensor

Low-Pressure

Switch

Optional

DC Blower

High-Pressure

Switch

0-10 VDC

GND

JP5 Temperature Sensor Selection Jumper

JP2 Low Pressure Switch Jumper

Gate Terminals to

Auxiliary Heat Relay

Pump or

Pump Relay Panel

Reversing Valve or

Electric Heat

2 DX Wiring Diagram

Comp L1

Pump L1

Pump L2

Compressor

Fan Run

Capacitor

Comp L2

Fan

Run Capacitor

Ground

L2

Fan L1

L2

L1

2

5

AC

1

6

Start Relay

4

L1

Start

Capacitor

6

EN

Page 7

Elite Control Wiring Diagrams

Optional

DC Blower

JP1 System Selection Jumper

JP5 Temperature Sensor Selection Jumper

0-10 VDC

GND

SMX DISPLAYS ONLY

COM

For Humidistat

COM

For Changeover Switch

L2

L1

L2

Display Jacks (for 8- or 6-pin display and cables)

Inside Temperature Sensor Jack

Required Water Inlet Temperature Sensor

Optional Water-Out Temperature Sensor

Optional Outside Air Temperature Sensor

Ground

L1

AC

Water Valve

3 CW Wiring Diagram

L2

Electric Heat Strip

L1

Fan Run

Capacitor

Fan

L2

L1

EN

7

Page 8

Installation Elite Control

6 Installation

WARNING: ELECTRIC SHOCK HAZARD.

Turn power OFF before performing any electrical

installation or maintenance activities. Failure to

obey this warning could result in death or serious

injury.

NOTICE: Failure to obey the following notices could

result in damage to the product:

• Do not locate the display panel in direct sunlight,

near any heat-producing appliances, or in a bulkhead

where temperatures radiating from behind the panel

may affect performance.

• Do not mount the display in the supply-air stream or

above or below a supply-air or return-air grille.

• Do not mount the display behind a door, in a corner,

under a stairwell, or any place where there is no freely

circulating air.

• Do not staple sensor cables during installation.

• Do not use a screw gun and do not over-tighten the

screws when mounting the display. Either method

may damage the display.

The system’s display built-in temperature sensor

I

is located in the control’s display panel. An

optional inside air temperature sensor is required if

installing the display panel in a cabinet, enclosed

space, or any area where the accurate sensing of

the room temperature would be impaired.

6.2 Preparing the Wall

Cut the cabin wall to fit the display panel, according to

the bezel being used.

w

q

4 Idea Bezel Cutout Dimensions

2.3 in. (58 mm)

q

3.8 in. (97 mm)

w

w

q

r

2.4 in. (61 mm)

e

3.5 in. (89 mm)

r

e

e

This section describes how to install an Elite Control.

6.1 Choosing a Display Panel Location

Place the display panel in an area that meets the

following location criteria:

• Mounted on an inside wall of the cabin, away from

direct sunlight

• Sets slightly higher than mid-height of the cabin

• Located in an area of freely circulating air

• Placed a maximum distance of 15 (4.6 m) from the

air conditioner

8

r

5 Eikon Bezel Cutout Dimensions

1.9 in. (48 mm)

q

3.8 in. (97 mm)

w

2.2 in. (56 mm)

e

2.8 in. (71 mm)

r

6.3 Installing an Optional Sensor

1. Mount the optional sensor according to the

installation instructions included with the sensor.

2. Plug the sensor cable into the appropriate sensor

jack on the upper side of the control board. Refer to

“Wiring Diagrams” on page 6 for details on the

sensor jack locations.

EN

Page 9

Elite Control Operation

6.4 Mounting the Display Panel

PRESS SWT

MA DISPLAY CA DISPLAY

DC

HP LP

RES

SEL

LPF EMBLE

CW EMBLE

JP3

JP1 JP2

JP5

JP4

AUX HEAT

GATE

TRM-1

COMPL2FANL2PUMP

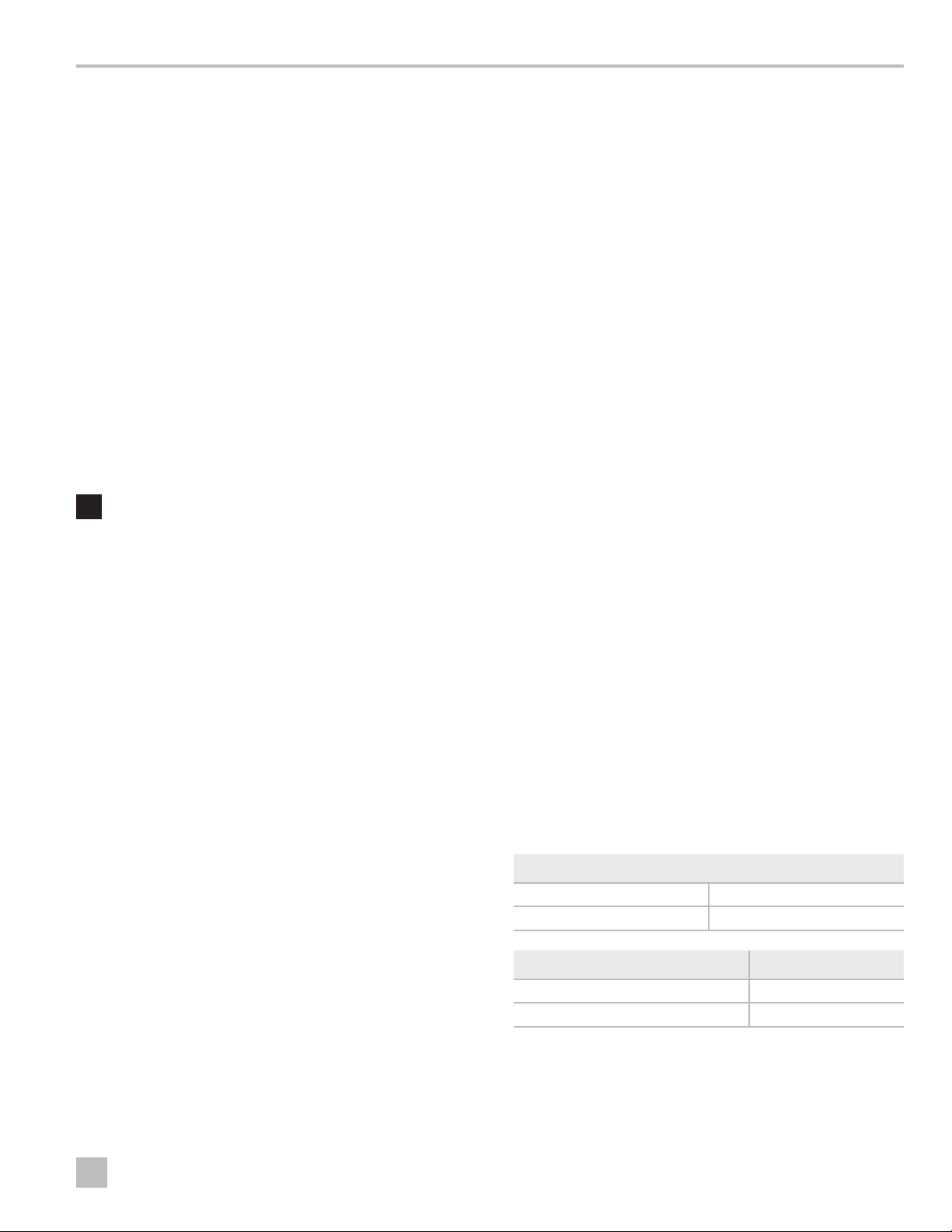

6 Plugging in the Display Cable

1. Plug the display cable 8-pin connector into the

upper-right jack on the circuit board.

2. Insert the other end of the display cable into the

display jack on the back of the display panel.

INSIDE H20INH20

J2 J3

J1

PSNB

JP6

VSNB

JP8

COMP

VALVEL1FAN

PUMP

L1L2

L2

L1

L1

P4 P5 P6

6.5 Testing the Display

NOTICE: For DX units only: do not turn the circuit

breaker or power supplied to the unit OFF and then

immediately turn it back ON. Allow at least five minutes

for the refrigerant pressure to equalize. Failure to obey

this notice could result in damage to the air conditioning

unit.

1. Open the seawater-intake ball valve (seacock).

OAT

OUT

L1

2. Turn the display OFF. Wait a minimum of five minutes.

3. Turn the air conditioner circuit breaker ON.

If the seawater pump is on a separate circuit

I

breaker, be sure to turn it ON.

4. Turn the display ON.

5. Press the Fan button.

6. Verify that the fan is running and that a steady airflow

is coming out of the supply-air grille.

7. Select a temperature set point lower than the current

cabin temperature.

8. Verify that a steady, solid stream of water is coming

out from the overboard discharge.

q

e

r

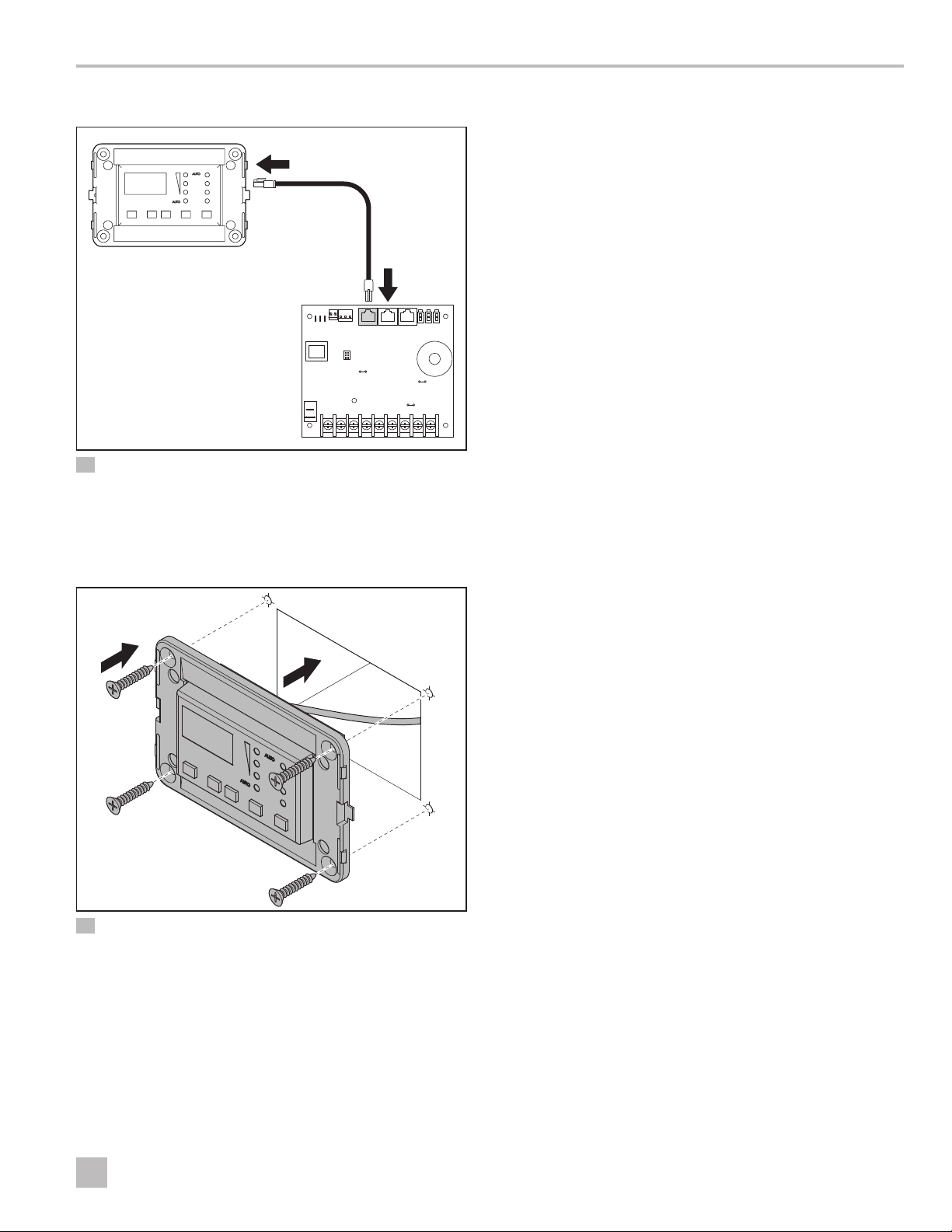

7 Securing the Display

Cutout

q

Display Panel

w

3. Use the four screws provided to secure the display

panel to the bulkhead. Do not use a screw gun or

overtighten the screws.

4. Snap the bezel onto the display panel frame.

w

e

r

Bezel

Screw

9. Verify that a steady airflow is continues to flow out of

the supply-air grille.

If the unit is not functioning as expected, refer to

I

“Troubleshooting” on page 25.

7 Operation

NOTICE: If the unit is cool-only, change parameter P-33

to CL, then select AUTO mode. Do not set the unit to

AUTOMATIC mode before changing parameter P-33 to

CL. Cool-only units do not heat unless equipped with

auxiliary heating. Failure to obey this notice will cause

the unit to cool in both modes. Refer to “Selecting a

Parameter” on page 16.

When used with optional auxiliary electric heater,

I

the fan remains ON for four minutes aer the heater

cycles OFF, even if the fan is set to cycled operation.

The images in this section show the Elite Control

I

display, unless otherwise indicated.

This section describes the cycle, programming, and

functions for the Elite Control.

EN

9

Page 10

Operation Elite Control

7.1 Understanding the Heating and Cooling Cycles

The heating and cooling cycles operate differently

depending on the system installed. This section

describes the possible cycles.

7.1.1 Normal Heating or Cooling Cycle

In AUTOMATIC mode, heating and cooling are supplied

as required to meet the cabin temperature set point.

• The system starts a cooling cycle once the cabin

temperature exceeds the temperature set point by

2°F (1°C) and starts a heating cycle once the cabin

temperature falls below the temperature set point by

2°F (1°C). The system continues the cycle until the

cabin temperature equals the set point.

• During a cycle, the cabin temperature must drop

below the set point by at least 4°F (2°C) before the

system switches from cooling to heating or exceed

the set point by at least 4°F (2°C) before the system

switches from heating to cooling. This behavior

prevents small temperature overshoots from causing

the system to switch between heating and cooling

when it is not necessary.

COOL mode supplies cooling only and HEAT mode

supplies heating only.

• The cabin temperature for either mode is maintained

within 2°F (1°C) of the set point by default.

• When the heating or cooling set point is satisfied,

the compressor cycles OFF and the fan returns to low

speed.

To view the current water temperature, press and hold

Power and Down. Refer to “Using the Control Display

Panel” on page 13. The fan remains on low speed

until the adequate water temperature is available.

To provide heat when the required water

I

temperature is not available, install the optional

auxiliary electric heater and program parameter

P-13. Refer to “Programming the Control” on page

14.

7.1.3 Air and Water Temperature

Differential (CW Systems Only)

The electric heater and the chilled-water heat can affect

the CW system.

The optional auxiliary electric heater overlaps with the

chilled-water heat by 22 °F (12° C). The heater turns on

when required and remains on until the chilled-water

temperature exceeds the ambient air temperature by

22 °F (12° C) or until the room temperature is satisfied.

During very cold conditions, the auxiliary electric heat

overlaps the chilled-water heat to supplement heating.

Water Temperature Differential

in °F

Default is 15 °F (-9°C)

22°F (-6°C) Open Off

15°F (-9°C) Open On

7 to 15 °F (-14 to 9 °C) Hysteresis On

7°F (-14°C) Close On

7 to 0 °F (-14 to -18 °C) Close On

0°F (-18°C) Close Off

Valve

Auxiliary

Heater

In Manual Fan Mode, the fan speed remains constant.

7.1.2 Chilled-Water System Operation

(CW Systems Only)

In CW systems, the water valve does not open unless the

water temperature is adequate to heat or cool the cabin.

The adequate heating or cooling water temperature is

defined by the water temperature differential setting in

the control parameters. Refer to “Selecting a Parameter”

on page 16.

10

0 to -7 °F (-18 to -22°C) Close Off

-7°F (-22°C) Close Off

-7 to -15 °F (-22 to -26°C) Hysteresis Off

-15°F (-26°C) Open Off

EN

Page 11

Elite Control Operation

7.1.4 Reversing-Valve Operation (DX

Systems Only)

COOL mode or HEAT mode is determined by the

position of the reversing valve. The reversing valve is

programmed to automatically toggle in these situations:

• When the system is running and an opposite cycle is

needed to maintain the temperature, the reversing

valve will toggle to the opposite position to initiate

the opposite cycle and reduce the starting surge of

the compressor.

• When a cooling or heating cycle is initiated aer the

system has been OFF for less than five minutes.

• When a cycle is interrupted by changing the display

mode to OFF or changing the set point from the

display panel.

To reduce reversing-valve noise, unnecessary valve

toggling is limited by default. Program the minimum

compressor staging delay (parameter P-3) to five

minutes or greater, to eliminate valve toggling. Refer to

“Programming the Control” on page 14.

When the system is powered up, a power-on-reset

I

always initiates a valve toggle.

and by periodic HEAT mode cycles with the fan turned off.

The de-icing cycle algorithm initiates periodic

compressor shutdowns every 10 minutes if the inside

temperature is at or below 69 °F (20 °C). The lower the

temperature, the longer the compressor shutdown will

last. In addition, the de-icing cycle algorithm will perform

brief reverse cycle runs (with the fan purposely turned

off) if the cooling cycle runs for 40 minutes without any

cooling progress or if the cooling cycle runs for more

than 60 minutes, regardless of cooling progress.

The parameter setting for the de-icing feature

depends on whether you are using the

optional inside air temperature sensor or the

display built-in temperature sensor. Installation of an

optional inside air temperature sensor (located in the

return air path) greatly increases the effectiveness of the

de-icing feature, and this option should be considered

whenever the display sensor cannot read the room

temperature accurately.

For additional details on parameter settings and

navigation options, refer to “Selecting a Parameter” on

page 16 and “Navigation Tree” on page 24.

7.2 Choosing the Control Operation

7.1.5 De-icing Cycle (DX Systems Only)

DX systems have a de-icing cycle option to prevent ice

buildup on the evaporator coil during extended periods

of cooling operation. Installation variables, such as

grille sizes, length of ducting, insulation, and ambient

temperatures, determine the runtime required to achieve

the set point.

Factors that substantially increase the runtime include

operating the system with hatches and doors open and

programming an unrealistic set point (e.g. 65 °F/18 °C).

Such situations can cause the evaporator to form ice on

warm humid days.

De-icing is accomplished by closely monitoring the room

air temperature in 10-minute intervals during a cooling

cycle. Depending on the parameter value and the change

in room temperature during these monitoring intervals,

the control performs various actions to prevent ice from

forming or to melt ice that has already formed. This is

accomplished by short compressor shutdown periods

combined with a one-speed increase in the fan speed,

The four Mode indicators represent the different modes

of the control: COOL, DEHUMIDIFICATION, HEAT, and

AUXILIARY HEAT. Refer to “Using the Control Display

Panel” on page 13.

8 Choosing the Control Operation

1. Press and release the Mode button to select a

mode. Refer to “Available Modes and Options for

Operation” on page 12.

EN

11

Page 12

Operation Elite Control

– Display LEDs illuminate to indicate the selected

mode.

– To indicate an OFF state, all the display LEDs turn off.

– When the display is making a call for heating,

– The display locks into the last mode selected aer

five seconds of inactivity, then displays the room

temperature. The selected mode LED remains lit.

– Aer 3 seconds of inactivity, the display shows the

room temperature and enters the IDLE state.

2. Press the Power button to wake up the control from

the OFF state.

Available Modes and Options for Operation

Icon Description/Mode Function

The AUTOMATIC mode LED illuminates, together with the HEAT or COOL mode LED, when the

AUTOMATIC

AUTO

AUTOMATIC with

Auxiliary Heat

COOL

HEAT

DEHUMIDIFICATION

system is in AUTOMATIC mode, switching to cooling or heating as required to satisfy the temperature

set-point. When AUTOMATIC mode is selected, the system provides both heating and cooling, as

required.

The AUTOMATIC mode LED flashes when the optional auxiliary electric heater is in operation.

• The control’s display will indicate AAH.

• The HEAT mode or COOL mode LED also illuminates to indicate whether the unit is cooling or

heating.

• In CW systems, these LEDs indicate the water-valve operating status (open or closed). No watervalve status is indicated when the system is in manual HEAT or COOL modes.

The COOL mode LED illuminates when the COOL mode is selected or when the unit is in an

AUTOMATIC mode cooling cycle. Only the cooling system operates. If the ambient temperature drops

below the set point, the system will not automatically switch to the HEAT mode.

The HEAT mode LED illuminates when the HEAT mode is selected or when the unit is in an

AUTOMATIC mode heating cycle. Only the heating system operates. If the ambient temperature rises

above the set point, the system will not automatically switch to the COOL mode. When the unit is

heating with auxiliary heat, the HEAT mode LED will flash to differentiate from reverse cycle heating.

The DEHUMIDIFICATION mode LED illuminates when the DEHUMIDIFICATION mode is selected.

This mode controls humidity during periods when the vessel is unoccupied and prevents the cabin

temperature from dropping below the minimum default temperature setting.

During humidity control:

• The fan circulates air for 30 minutes.

• Air temperature is sampled and recorded.

• Aer 30 minutes, a cooling cycle starts and continues until the temperature is lowered 2°F (1°C) or

until the cooling cycle runs a maximum of one hour.

• Four hours aer the temperature is satisfied or the cooling cycle times out, the cycle repeats.

For temperature control:

• Aer the 30-minute fan circulation, if the sampled temperature is at or above the factory default

setting 50°F (10°C), a cooling cycle begins and runs for humidity control.

• If the temperature is below 50°F (10°C), a heating cycle begins. The heating cycle continues until

the temperature reaches 50°F (10°C) or until the heating cycle runs a maximum of one hour.

• Four hours aer the temperature is satisfied or the cooling/heating cycle times out, the cycle

repeats, each time determining whether cooling or heating is required.

cooling, auxiliary heat, or humidity, the appropriate

Mode indicator illuminates (and flashes for auxiliary

heat).

12

ON

For DX systems only: the DEHUMIDIFICATION mode heat cycle will not run when the ambient

I

temperature is below 40°F (4°C). This protects the condenser coil from freezing. Systems

configured with electric heat will run the DEHUMIDIFICATION mode heat cycle regardless of

the cabin temperature.

All control outputs are on and the display indicates the current state of operation. The display shows

the cabin temperature. All parameters operate as set.

EN

Page 13

Elite Control Operation

Available Fan Modes and Options for Operation

Press and release the Fan button to select a fan mode.

Refer to “Available Modes and Options for Operation”

– Display LEDs illuminate to indicate the selected

mode.

on page 12.

Indicator Description/Mode Function

The automatic fan mode balances the most efficient temperature control with a slower, quieter fan

speed. This mode selects the fan speed automatically based on the temperature differential.

To select automatic fan mode, press and release the Fan button until the AUTO LED below the Manual

Fan indicator illuminates on the display.

• The auto fan speeds are automatic based on default and programmed values. Program menu

parameter settings P-1, P-2, and P-32 determine the maximum, minimum, and middle fan speed

AUTO Automatic Fan

Manual Fan

Fan-Only

CYN / CON

Cycled / Continuous

Fan

settings.

• Fan speed decreases as the temperature set-point is approached in COOL mode and operates at

low speed when the set point is reached.

• The automatic fan speed operation can be reversed for HEAT mode when parameter P-12 is set to

rEF. Refer to “Programming the Control” on page 14.

Refer to “Selecting a Parameter” on page 16. Once high and low fan speed limits are set, the

I

unit automatically readjusts the remaining fan speeds in both automatic and manual fan modes.

The manual fan LED illuminates to indicate the current fan speed. There are three manual fan speeds

available. The number of bars illuminate (1=low, 2=medium, and 3=high) on the display when

selected.

• Press and release the Fan button to advance from automatic to manual fan operation.

• Press and release the Fan button to cycle through the manual fan speeds, from low to high.

• Press and release the Fan button to return to automatic fan operation.

Use fan-only to operate the fan for air circulation when no cooling or heating is desired.

• From the OFF mode, press and release the Fan button to select a desired fan speed.

Turning the control ON reverts the fan to the AUTOMATIC mode or the last selected manual fan

I

setting.

The fan can be set to run continuously whenever the system is turned ON, or it can be set to cycle ON

and OFF in conjunction with the cooling or heating cycles.

• Press and hold the Fan button for five seconds.

– CYC displays when the operational setting is set to cycled. When used with an optional

auxiliary electric heater, the fan remains on for 4 minutes aer the heater cycles off.

– CON displays when the operational setting is set to continuous.

7.3 Using the Control Display Panel

The following table details the button combinations to

use to achieve different functions on the control.

Button Combinations Button Names Function

Fan, Up, & Down

& &

EN

Lock and unlock the keypad:

Press simultaneously to toggle the keypad lock on or off. The display shows LC

when the keypad is locked, or UL when the keypad is unlocked.

For soware revisions B28 and newer, view some indicators even if the keypad

is locked:

• (CW only) To view the chilled-water-inlet temperature, simultaneously press

the Power & Up buttons

• (DX only) To view the pump sentry water temperature, simultaneously press

the Power & Up buttons (P-8 must be on)

• (DX only) To view the sea water low-limit temperature, simultaneously press

the Power & Down buttons

13

Page 14

Operation Elite Control

Button Combinations Button Names Function

&

&

&

&

&

, ,

& ,

Up & Down

Power & Down

Power & Up

Mode & Up

Up & Down

AC Power set to Off &

then Mode, Power, or

Down

Power & Mode

Display the outdoor temperature: Press simultaneously and hold.

The display shows the outdoor temperature reading while this combination is

held.

(CW only)

Display the chilled-water-inlet temperature: Press simultaneously and hold.

(DX only)

Display the pump sentry water temperature: Press simultaneously and hold.

Enter the programming menu:

• With the control in OFF mode, press the following buttons in this order:

Mode, Up, Down, and Mode. P1 appears on the display. The display will

alternate between the parameter number and the current setting.

• Navigate using the Mode and Fan buttons and adjust a parameter setting

using the Up and Down buttons.

• Press the Power button once to save changes and return to OFF mode.

Set new default parameters:

While in PROGRAM mode, press simultaneously and hold for three seconds.

Disconnect the AC power, then press the specified button immediately aer

reconnecting the AC power and while all LEDs are illuminated during power-on

reset for the following information.

• View the fault history log: press the MODE button.

• Exit the fault history log: press the POWER or MODE button once, and wait

30 seconds.

• Clear the fault history log: press simultaneously the POWER and DOWN

buttons while viewing the fault history log.

• Display the compressor run-time hour meter: press the DOWN button. This

meter displays hours of compressor usage, with a maximum capture time of

65,536 hours.

• Enter the self-test program: press the POWER button. Use the self-test

program to diagnose problems and test the air conditioning system.

Restore factory default settings:

• Turn off the air conditioning unit.

• Press simultaneously and hold the POWER and MODE buttons.

• Turn the air conditioning unit on, and then release the buttons when the

display reads IP.

7.4 Programming the Control

If your AC has a Shaded-Pole (SP) fan motor

I

instead of a Split-Capacitor (SC) High-Velocity

(HV) fan motor, you must change the parameter

P-14 setting to shaded-pole (SP) before operating

the equipment. SP units are recognizable by an

overhanging blower motor. Only reprogram the

fan motor type parameter if you do not have an HV

blower.

14

For CW Only: Standard air handlers come

I

equipped with chilled-water bypass valves.

However, for no-valve air handlers, the fan must be

set to cycle on demand (CYC).

For DX Only: If your air conditioning unit is cool-

I

only (if it does not have a reversing valve), you

must change the parameter P-33 setting from heat

pump (HP) to cool only (CL). Refer to “Selecting a

Parameter” on page 16.

– You must change the parameter before setting the

Automatic mode for a cool-only unit.

EN

Page 15

Elite Control Operation

– Once this parameter is set, the only allowable

modes are OFF, COOL, AUXILIARY HEAT, and

DEHUMIDIFICATION.

– If the AUTOMATIC mode is selected and the

thermostat calls for heat, the compressor will

run. Since there is no reversing valve, the air

conditioning unit will supply cool air when

heating is desired. Cool-only units do not heat

unless equipped with auxiliary heating.

Parameter settings are used to program and fine-tune

the system for the most efficient operation within an

installation and to adjust operating parameters for your

particular needs. Aer new values are entered and

memorized, the factory defaults are overwritten and the

new parameters become the default values.

Should the Elite lose power, the operating parameters

are retained. When power is restored, the control

resumes operating as last programmed.

The control has factory default values stored in

permanent memory (memorized factory default settings)

that can be recalled if you have any programming

difficulties. You can restore the original factory default

parameters manually. Refer to “Selecting a Parameter”

on page 16 for a summary of the parameters, the

permitted values, and original factory default settings.

7.4.1 Entering Programming Mode

1. While the control is in the OFF mode, press the

following buttons in this order: Mode, Up, Down,

and Mode to enter the programming menu. P-1

appears on the display. The display will alternate

between the parameter number and the current

setting.

2. Use the Mode and Fan buttons to navigate to

different parameters (P-1, P-2, P-3, etc.).

3. Press the Up and Down buttons to adjust a

parameter setting.

4. Press the Power button once to save any changes

and to return to OFF mode. If no button is pressed for

50 seconds, the system will exit the Program mode

and return to OFF mode automatically.

EN

15

Page 16

Operation Elite Control

7.4.2 Selecting a Parameter

The following table describes the parameters available

for the Elite Control.

Parameter Name DX CW Factory Default Parameter Range

x x 95 51–95

P-1 High Fan Limit

Select a higher number to increase the fan speed, a lower number to decrease the fan speed.

The 35-95 parameter range setting is applicable to soware revision #B24 and newer.

I

P-2 Low Fan Limit

P-3

P-4

P-5 Failsafe Level

P-6 Low Voltage Monitor

Compressor Staging

Time Delay

Inside Air Temperature

Sensor Calibration

x x 50 30–50

Select a higher number to increase the fan speed, a lower number to decrease the fan speed.

x 15 5–135 seconds

Use for installations where more than one system operates from the same power source. Different

staging delays allow compressors to start at different times when the power is interrupted. Stage the

units at least five seconds apart.

x x Ambient Temperature Ambient Temperature ±10°F (6°C)

Calibrate the sensor to display the correct room temperature reading.

The setting increments are in °F even when the control is set to display °C.

0 = Minimal Protection

x 3

1Part of the functionality of this setting is only applicable to soware revision #C40 and newer.

I

2The setting is applicable to soware revision #C39 and older.

Refer to “Fail Safe Levels” on page 23.

x OFF OFF, 95 VAC/195 VAC

Set the built-in voltmeter circuit that monitors the AC input voltage prior to each cooling or heating

cycle when set to 95 VAC or 195 VAC.

• For 100–120 VAC input power, set to OFF or 95.

• For 208–240 VAC input power, set to OFF or 195.

The setting is applicable to soware revision #A15 and newer.

1 = Continuous No Display

2 = Continuous With Display

3 = Four Failures, Reset Required

1

2

2

I

16

EN

Page 17

Elite Control Operation

Parameter Name DX CW Factory Default Parameter Range

OFF

1 = ON with 5°F (3°C) Display Sensor Differential

2 = ON with 7°F (4°C) Display Sensor Differential

OFF

ON = Select 100°F to 150°F

(38°C and 66°C)

P-7 De-icing Cycle

P-8 Optional Pump Sentry

x OFF

Select the parameter setting for the de-icing feature depending on whether you are using the

display built-in temperature sensor or the optional inside air temperature sensor.

• If using an optional inside air temperature sensor., set this parameter to 1 to turn the de-icing feature

ON, or to OFF to disable.

• If using the display built-in temperature sensor, choose one of the two selectable behavior modes:

– 1: assumes the display built-in temperature sensor may be reading the room temperature as

much as 5°F (3°C) greater than the actual evaporator temperature (standard).

– 2: for more extreme installations - assumes the display built-in temperature sensor may be

reading the room temperature as much as 7°F (4°C) greater than the actual evaporator

temperature.

• The setting of 2 should only be used if a setting of 1 does not prevent evaporator ice from forming.

The following applies to soware revision #A13 and older.

I

De-icing is accomplished by switching the reversing valve to HEAT mode while the system

is cooling. The valve remains energized for the programmed cycle time. The cycle is

programmable to OFF or to a period of one, two,or three minutes.

The following applies to soware revision #A15 and newer.

I

De-icing is accomplished by closely monitoring the room air temperature in 10-minute intervals

during a cooling cycle. Depending on the parameter value and the change in room temperature

during these monitoring intervals, the control performs various actions to prevent ice from

forming or to melt ice that has already formed. These actions include short compressor shutdown

periods combined with a one-speed increase in fan speed and by periodic HEAT mode cycles

with the fan turned off.

x OFF

Set this parameter setting when the optional pump sentry water sensor is installed to monitor the

condenser coil temperature and to shut down the pump and compressor when the coil temperature

rises above the programmed value. This sensor is plugged into the H2O OUT sensor jack on the

control board.

P-9

P-10

P-11

P-12

Display Brightness

Control

Fahrenheit or Celsius

Selection

Cycle Pump with

Compressor

Reverse Automatic Fan

Speeds During Heating

Program a temperature between 100°F and 150°F (38°C and 66°C), depending on seawater

temperature and the system type. Refer to the sensor installation instructions for detail. The setting

increments are in °F even when the control is set to display °C.

x x 4 (Dimmest)–18 (Brightest)

Set this parameter setting between 4 and 18.

A dark cabin requires a setting of 4. A very bright cabin requires a setting of 12–18.

F = Fahrenheit Displayed

x x F

Select °C for Celsius. (Celsius readings are displayed in tenths, for example 22.2°). The default setting is °F.

x CYC

Select cycled or continuous pump operation:

• CYC: increases the pump life and conserves electricity by cycling ON and OFF with the compressor.

• Con: programs the pump to operate continuously whenever the system is on.

x x rEF

Reverse the automatic fan speeds during HEAT mode to improve heat output in cooler climates.

• When set to rEF, the fan speeds up as the set point is approached. The fan switches to low speed

when the set point is satisfied and the water valve or compressor cycles OFF.

• When set to nOr, the fan operates the same as during cooling, which represents normal fan operation.

C = Celsius Displayed

A = Automatic Selection Based on Voltage

50 Hz = Celsius

60 Hz = Fahrenheit

CYC = Cycle with Compressor

Con = Continuous Pump

nOr = Normal Fan Operation

rEF = Reversed Fan in HEAT Mode

EN

17

Page 18

Operation Elite Control

Parameter Name DX CW Factory Default Parameter Range

nOr = Disable

A-H = Auxiliary Electric Heat

SC = Split Capacitor Fan Motor

SP = Shaded Pole Fan Motor

rST = Reset Defaults

nOr = Normal

OPn = Valve Forced Open

nOr = Normal Operation

P-13 Auxiliary Heat Enable

P-14 Fan Motor Selection

P-15

P-16

P-17

Restore Factory Default

Settings

Hydronic Water Valve

Forced Open

Water Temperature

Differential

x x nOr

Enable the operation of an optional auxiliary electric heater that if installed, can heat an individual cabin

when the chiller system is in cooling mode. Refer to “Wiring Diagrams” on page 6.

The following is applicable to soware revision #A13 and older.

I

When this parameter is programmed for auxiliary electric heat, only the electric-heat relay located

toward the middle of the circuit board is energized during a heating cycle.

The following is applicable to soware revision #A15 - #C30.

I

When programmed for auxiliary electric heat, both the electric-heater relay and the valve relay

are energized. This change supports newer circuit board revisions without the electric-heat

relay. Please consult with Dometic Customer Service or with an authorized service technician for

assistance.

– For CW systems: Circuit boards that do not have electric-heat relays require a display with

soware revision A15 or newer to properly energize the compressor relay. Also, when using

this configuration, the electric heater L-1 connection must be connected to the COMP L-1

terminal on the AH-Passport I/O or U-board.

– For DX systems: Circuit boards that do not have electric-heat relays require a display with

soware revision A15 or newer to properly energize the valve relay. Also, since the valve-relay

output only supports a maximum of 15 amps at 115VAC or 10 amps at 230 VAC (PPIO circuit

boards revision F and newer) of resistive load, when installing an optional electric heater that

exceeds this load, it is necessary to install an additional contactor that is rated to handle the

full load of the electric heater.”

x x SC

Set to SC for AC switch high-velocity blowers. Set to SP if your unit has a Shaded Pole fan motor. Refer

to “Programming the Control” on page 14.

x x nOr

To reset all programming parameters, set this parameter to rST. This restores all programmable

parameters to the factory default values.

x nOr

Open the water valve to bleed air from the system.

• OPn: forces the valve open for four hours while the control is turned OFF. If the control is turned ON

or if AC power is interrupted during this four-hour period, the valve override is canceled.

• nOr: returns the valve to normal operation.

x 15°F (8°C) 5°F to 25°F (3° C to 14°C)

Set the temperature differential between the ambient air temperature and the hydronic water

temperature that controls the water valve. For example, selecting 10 °F (-12 °C) opens the valve when

the water temperature is 10 °F (-12 °C ) less than the ambient temperature in the cooling mode and 10

°F (-12 °C ) greater than the ambient temperature in the heating mode.

Careful selection of the temperature differential can fully utilize the ship’s heating and cooling resources.

For example, while in cooling mode and using a 10° F (-12 °C ) value, the valve will open to allow some

cooling while the hydronic system is coming down to temperature. Refer to “Air and Water Temperature

Differential (CW Systems Only)” on page 10 for a graphical explanation of this parameter.

18

EN

Page 19

Elite Control Operation

Parameter Name DX CW Factory Default Parameter Range

10–250

Displays the elapsed time (in hours x10) since the timer

was started or reset.

P-18

Air Filter Cleaning/

Replacement Timer

Setting

x x 0

Establish a reminder to clean or replace the air filter. FIL flashes briefly on the LED display every

10 seconds until it is cleared. The FIL reminder can only be cleared and the timer reset via the

programmable parameter P-19.

• The parameter entered represents that number times 10 hours. Select the number of operating

hours until the filter reminder appears.

• Parameter choices are between 10 (100 hours) and 250 (2500 hours).

• Press the Down button to reset the value to 0, restart the timer, and clear the reminder.

This setting is applicable to soware revision #A15 and newer.

I

Dometic recommends checking the air filter at least every 500 hours of operation.

I

P-19

P-20 CAN Bus Unit ID

P-21 CAN Bus Group ID

Filter Cleaning/

Replacement Timer

Value & Reset

x x 0

Display the current elapsed time (in hours x 10) since the timer was started or reset. When this parameter

value reaches the value set in parameter P-18, FIL flashes on the display every 10 seconds until cleared.

Press the Down button to reset the value to 0, restart the timer, and clear the reminder.

This setting is applicable to soware revision #A15 and newer.

Displays the elapsed time

(in hours x10) since the timer was started or reset.

I

x x

Enables all units with a CAN Bus adapter installed to be networked together and communicate with

each other or the ship’s CAN Bus system (with additional translator equipment in some cases).

• The Elite must be plugged into networked Passport I/O and U-boards (this parameter does not

display if the Elite is plugged into a standard board). Each control on the same CAN bus network

must be assigned a unique Unit ID (0 - 255).

• Enter the unit’s CAN Bus Unit ID number.

This setting is applicable to soware revision #A16 and newer.

dIS Unit ID = 59

(aer enabling and

power cycling)

0–255

I

x x

Enables all units with a CAN Bus adapter installed to be grouped together in a network system and

communicate with the ship’s CAN Bus system (with additional translator equipment in some cases).

• The Elite must be plugged into networked Passport I/O and U-boards (this parameter does not

display if the Elite is plugged into a standard board). Each control on the same CAN bus network

must be assigned a unique Unit ID (0 - 255)

• Enter the unit’s CAN Bus Group ID number.

This setting is applicable to soware revision #A16 and newer.

58 (aer enabling

and power cycling)

0–255

I

P-22 Voltage Calibration

EN

x x AC Voltage Adjust to match the accurate voltage reading.

Displays a live reading of the voltage being read by the circuit board. Use the Up and Down buttons

to calibrate for a more accurate voltage level when calculating low voltage for parameter P-6. Use a

reliable voltmeter during adjustment.

This setting is applicable to soware revision #A15 and newer.

I

19

Page 20

Operation Elite Control

Parameter Name DX CW Factory Default Parameter Range

1 = 1°F (.6°C) Differential

2 = 2°F (1°C) Differential

P-23

Set Point Temperature

Differential

x x 2

Set the temperature differential in Fahrenheit for all modes of operation: AUTOMATIC, COOL, HEAT, or

AUXILIARY HEAT. Refer to “Choosing the Control Operation” on page 11.

• 1: maintains the room temperature ±1°F (0.6°C) from the desired set point.

• 2: maintains the room temperature ±2°F (1°C) from the desired set point.

This setting is applicable to soware revision #B23 and newer.

I

x x 50°F (10°C) 40°F to 75°F (4°C to 24°C)

Set the minimum room temperature (in Fahrenheit) for which DEHUMIDIFICATION mode initiates a

cooling cycle to remove moisture from the air. If the room temperature is below this parameter setting,

DEHUMIDIFICATION mode runs a heating cycle. Refer to “Choosing the Control Operation” on page

11.

This setting is applicable to soware revision #B23 and newer.

P-24

Dehumidification Mode

Minimum Temperature

I

x x 2°F (1°C) 1°F to 3°F (0.6°C to 2°C)

Set the incremental differential (with cumulative steps) between the ambient temperature and the set

point temperature at which the fan speed will increment to the next speed.

P-25

Auto Fan Speed

Temperature Differential

A 1°F (0.6°C) hysteresis in the auto fan speed differential prevents the speed from changing if

I

the room temperature changes. In addition, programming parameters P-12 and P-23 both have

an effect on the operation of the auto fan speed.

This setting is applicable to soware revision #B24 and newer.

I

P-26

P-27

Supply Air High

Temperature Limit

Seawater Low-Limit

Adjustment

x x OFF

Set the maximum supply air-discharge temperature allowed.

• Enabling this parameter has no effect unless parameter P-13 is enabled and set to A-H.

• Use of this parameter requires that the OAT sensor be placed in the supply air stream immediately

downstream of the blower discharge.

• HEAT mode shuts down if the temperature of this sensor exceeds the setting. HEAT mode is

restored when a 10°F (6°C ) hysteresis is satisfied or when power is cycled to the control and the

OAT sensor temperature is less than the setting but still within the hysteresis. SAH is displayed when

this fault occurs.

• Display the discharge temperature by pressing the Up and Down buttons simultaneously (same as

viewing the outside air temperature).

This setting is applicable to soware revision #B24 and newer.

OFF

95°F to 140°F in 5° increments

(35°C to 60°C in 2.8° increments)

I

x 40°F (4.4 °C) 35 °F to 50 °F (2°C to 10°C)

If the optional seawater low-limit adjustment sensor is connected to the control board H2O Out 2-pin

plug, set the system to switch from reverse-cycle heat to auxiliary electric heat (if an auxiliary electric

heater is installed and enabled).

• When the seawater temperature drops below 40°F (4°C) (default) and the reverse-cycle heat

has operated more than five minutes. Once the seawater rises 3°F above the seawater low-limit

adjustment sensor temperature set point, the system returns to reverse-cycle heating.

• If an auxiliary electric heater is not installed, the system will shut down and flash LSF when the

seawater drops below 40 °F (4.4 °C). Once the seawater rises 3 °F above the seawater low limit

temperature, the system automatically goes back into reverse-cycle heating and stops flashing LSF.

This setting is applicable to soware revision #C39 and newer.

I

20

EN

Page 21

Elite Control Operation

Parameter Name DX CW Factory Default Parameter Range

P-28

Relative Humidity

Enable

x x OFF 50–80

Enable the optional room temperature/relative humidity combination sensor. This allows the system to

dehumidify using auxiliary electric heat (if an auxiliary electric heater is installed and enabled) when the

cabin humidity rises above the selected relative humidity (RH).

• For DX applications: Relative humidity enabled. If the optional room temperature/relative humidity

combination sensor is connected to the control board and senses that the humidity has increased,

the compressor run time will extend by operating to 1°F lower than the set point to remove the

humidity. If an auxiliary electric heater is installed, it will cycle ON and OFF to maintain the set point

while the compressor stays on longer to dehumidify.

There could be a period of overlap when the compressor and the auxiliary electric heater are on

I

at the same time. This cycle continues until the cabin’s relative humidity is less than less than the

humidity set point.

• For CW applications: Relative humidity enabled. If the optional room temperature/relative humidity

combination sensor is connected to the control board, this feature allows the system to dehumidify

with electric heat (if an auxiliary electric heater is installed and enabled) when the cabin humidity

rises above the humidity set point. The auxiliary electric heater will cycle ON and OFF to maintain

the set point while the bypass valve opens to allow cold loop water to enter the air handler coil to

dehumidify. This operation continues until the cabin’s relative humidity is less than the humidity set

point. If an auxiliary electric heater is not installed, the ON time of the bypass valve will extend by

operating to 1°F lower than the set point. This cycle continues until the cabin’s relative humidity is

less than the humidity set point. The range of adjustment for the relative humidity is 50% to 80% RH.

This setting is applicable to soware revision #C39 and newer only.

I

P-29

P-30

P-31 Reserved

P-32 Medium Fan Speed

High-Pressure Switch

Test

Low-Pressure Switch

Test

x x DIS

Allow a test on the high-pressure circuit to identify an overcharged system or loss of water flow.

• The unit will operate in COOL mode at high fan speed, and display nOr (closed circuit) if the highpressure switch circuit is OK. If the high-pressure switch circuit has a fault, is over-charged, or has a

loss of water flow, the system will display OPn (open circuit).

• Press the MODE button to enter the low-pressure switch test, and press the FAN button to exit the

test mode.

This setting is applicable to soware revision #C39 and newer only.

nOr = closed circuit (OK)

OPn = open circuit (fault/overcharged/low water flow)

I

x x DIS

Allow a test on the low-pressure circuit to identify a fault or a low charge. This test can also be used to

charge a system.

• The unit will operate in COOL mode at high fan speed, and display nOr (closed circuit) if the lowpressure switch circuit is OK. If the low-pressure switch circuit has a fault or the system is low on

charge, the system will display OPn (open circuit).

• Press the MODE button to enter the low-pressure switch test, and press the FAN button to exit the

test mode.

This setting is applicable to soware revision #C39 and newer only.

nOr = closed circuit (OK)

OPn = open circuit (fault/undercharged)

I

x x 75 33 to 95

Adjust the speed assigned to the medium fan setting. Set a higher number to increase the fan speed or

a lower number to slow the fan speed.

This setting is applicable to soware revision #C39 and newer only.

I

EN

21

Page 22

Operation Elite Control

Parameter Name DX CW Factory Default Parameter Range

HP = heat pump mode

CL = cool or (optional) electric heat mode

P-33 Cool-Only Mode

x HP

Select heat pump or cool-only operation.

• Selecting HP operates the unit in the default heat pump mode, which allows for cooling, reverse

cycle heating, or (optional) auxiliary electric heat.

• Selecting CL operates the unit in COOL or (optional) AUXILIARY HEAT modes. AUXILIARY HEAT

mode is available only if the unit is equipped with an auxiliary electric heater.

Selecting CL initiates a five-minute compressor delay whenever the compressor shuts down on

I

the set point, a fault, or a power outage. The delay begins immediately aer compressor shuts

down. The display will show a flashing pixel in the bottom right corner every second during the

five minute countdown period. If the five-minute delay period has passed before the compressor

is called to operate, the compressor will come on with no delay.

This setting is applicable to soware revision #C39 and newer only.

I

7.4.3 Exiting programming mode

To exit the programming menu manually, press the

Power button to return to OFF mode. Alternatively, the

display automatically exits the programming menu aer

50 seconds of inactivity.

7.4.4 Identifying the Soware Version

The control’s soware version (such as “39”) appears

in the display for three seconds prior to the manual or

automatic exit from the programming mode. The control

enters OFF mode aer exit.

7.4.5 Identifying Programming Fault Codes

To protect the unit, certain fault conditions trigger a lockout

that shuts down the control. The control will not restart until

the fault is repaired. The type of lockout associated with

the fault depends on the type of fault detected (refer to the

Fault and Status Codes table) in combination with the level

of protection (refer to the Fail Safe Levels table) that was

programmed in the P-5 parameter (refer to ”Selecting a

Parameter” on page 16).

Fault and Status Codes

Code Description DX CW

High Pressure Switch Fault: indicates

HPF

high refrigerant pressure. This fault is not

applicable in HEAT mode.

Low Pressure Switch Fault: indicates low

refrigerant pressure. This fault has a three-

LPF

minute shutdown delay (for display firmware

#41 and newer).

Low Pump Flow Fault: indicates high-water

PLF

temperature in the condensing coil or low

pump flow.

Inside Sensor: indicates the

ASF

display built-in temperature sensor is

damaged or not connected.

Indicates the air filter replacement timer has

FIL

expired.

SAH Indicates a high supply air temperature limit. x x

Indicates a locked or unlocked display

LC/UL

mode, although some buttons do function.

Refer to “Using the Control Display Panel”

on page 13.

LSF Indicates a seawater low limit. x

Low Voltage Fault: indicates low voltage.

This fault offers extra protection for the

LAC

compressor and components within the

system during low-voltage (brownout)

conditions.

x

x

x

x x

x x

x x

x

22

EN

Page 23

Elite Control Operation

Fail Safe Levels

Lvl Description DX Only

Fail Safe Level 0: Temporary failsafe, limited to

five-minutes (only in display firmware #C40 and

newer). Provides minimal failsafe protection

and is not recommended.

• The system will automatically switch back

to Level 3 aer five minutes (for display

firmware #C40 and newer. Any older

0

display firmware will not revert to full

detection).

• Only the ASF fault is detected and displayed.

• The control shuts down and will not restart

until the fault is repaired.

• Once repaired, the control restarts aer a

two-minute delay.

Fail Safe Level 1 (only for display firmware #C39

and older): includes the failsafe actions of the

previous level and detects all other faults, but

they are not displayed.

1

• The system shuts down for two minutes or

until the fault is cleared, whichever is longer.

• The system restarts when the fault is cleared.

Fail Safe Level 2 (only in display firmware #C39

and older): includes the failsafe actions of the

previous levels and displays all other faults.

2

• The system shuts down for two minutes or

until the fault is cleared, whichever is longer.

• The system restarts when the fault is cleared.

Fail Safe Level 3: includes the failsafe actions of

previous levels and the system will lockout aer

four consecutive HPF, LPF or PLF faults. In

addition, the lockout can be cleared.

3

• The system shuts down for two minutes or

until the fault is cleared, whichever is longer.

• To clear the lockout, enter OFF mode.

Then, return to ON mode.

x

EN

23

Page 24

Operation Elite Control

7.5 Navigation Tree

This section shows the menu navigation for the Elite

Control.

DISPLAY ICONS

Fan Fan Modes

Mode Operating Modes

Mode+Down Fault Log

Mode+Up Programming Menu

Fan+Up Seawater Temp.

Up+Down+Mode Relative Humidity

(DX) Fan+Down Compressor

Run-Time Meter

OPERATING MODES

Cool Mode

Heat Mode

Dehumidification Mode

Aux Heat Mode

Automatic Mode

FAULT HELP

Air Sensor Fault

High Pressure Fault

Low Pressure Fault

Low AC Fault

Pump Sentry Fault

FAN MODES

Fan Mode

Manual Fan Mode

Fan-Only Mode

Cycled/Continuous Fan Mode

FAULT CODES

HPF High Pressure Fault

LPF Low Pressure Fault

PLF Pump Sentry Fault

ASF Inside Sensor Failure

FIL Clean/Replace Filter

SAH High Supply Air Temp

SAH High Supply Air Temp

LC/UL Lock/Unlock Keypad

LSF Sea Water Low Limit

LAC Low AC Voltage

DX PROGRAMMABLE PARAMETERS

P-1 High Fan Limit

P-2 Low Fan Limit

P-3 Compressor Staging Time Delay

P-4 Inside Air Temperature Sensor Calibration

P-5 Failsafe Level

P-6 Low Voltage Monitor

P-7 De-Icing Cycle

P-8 Optional Pump Sentry

P-9 Display Brightness Control

P-10 Fahrenheit or Celsius Selection

P-11 Cycle Pump with Compressor

P-12 Reverse Automatic Fan Speeds During Heating

P-13 Auxiliary Heat Enable

P-14 Fan Motor Selection

P-15 Restore Factory Default Settings

P-16 Reserved

P-17 Reserved

P-18 Air Filter Cleaning/Replacement Timer Setting

P-19 Filter Cleaning/Replacement Timer Value & Reset

P-20 CAN Bus Unit ID

P-21 CAN Bus Group ID

P-22 Voltage Calibration

P-23 Set Point Temperature Differential

P-24 Dehumidification Mode Minimum Temperature

P-25 Auto Fan Speed Temperature Differential

P-26 Supply Air High Temperature Limit

P-27 Seawater Low Limit Adjustment

P-28 Relative Humidity Enable

P-29 High-Pressure Switch Test

P-30 Low-Pressure Switch Test

P-31 Reserved

P-32 Medium Fan Speed

P-33 Cool-Only Mode

CW PROGRAMMABLE PARAMETERS

P-1 High Fan Limit

P-2 Low Fan Limit

P-3 Reserved

P-4 Inside Air Temperature Sensor Calibration

P-5 Reserved

P-6 Reserved

P-7 Reserved

P-8 Reserved

P-9 Display Brightness Control

P-10 Fahrenheit or Celsius Selection

P-11 Reserved

P-12 Reverse Automatic Fan Speeds During Heating

P-13 Auxiliary Heat Enable

P-14 Fan Motor Selection

P-15 Restore Factory Default Settings

P-16 Hydronic Water Valve Forced Open

P-17 Water Temperature Differential

P-18 Air Filter Cleaning/Replacement Timer Setting

P-19 Filter Cleaning/Replacement Timer Value & Reset

P-20 CAN Bus Unit ID

P-21 CAN Bus Group ID

P-22 Voltage Calibration

P-23 Set Point Temperature Differential

P-24 Dehumidification Mode Minimum Temperature

P-25 Auto Fan Speed Temperature Differential

P-26 Supply Air High Temperature Limit

P-27 Reserved

P-28 Relative Humidity Enable

P-29 High-Pressure Switch Test

P-30 Low-Pressure Switch Test

P-31 Reserved

P-32 Medium Fan Speed

P-33 Reserved

24

EN

Page 25

Elite Control Troubleshooting

8 Troubleshooting

The following table describes some common

occurrences that are not a result of defective

workmanship or materials.

Problem Possible Causes Recommended Solution

The system does

not power up.

The air conditioning unit circuit breaker is off.

The display is not turned on.

The terminal strip is miswired.

Turn on the air conditioning unit circuit breaker at the ship’s panel.

Turn on the display.

Check the wiring diagram and correct if necessary.

The system runs

continuously.

There is a lack of

airflow.

The fan coil is iced.

The input-line voltage is insufficient. 7

An electrical component has failed.

The unit is not able to reach the set point.

The seawater temperature is too high for

cooling or too low for heating.

The optional inside air temperature sensor is

not located properly.

The de-icing feature is not enabled.

The airflow is blocked or restricted.

The fan speed is set to manual low.

The fan coil may be iced.

The humidity level is set too high.

The supply air is short-cycling.

The airflow is blocked or restricted

The fan runs too slow.

The system runs continuously.

• Check the power source (shore/generator) for proper voltage.

• Check the wiring and terminals for proper sizes and connections.

• Verify with a voltmeter that the power at the unit is the same as the

power source.

A technician should inspect the display, cable, and circuit board. Look for

a red light on the circuit board.

Close all the port holes and hatches. Adjust the set point so it is not too

low for cooling or too high for heating.

Seawater temperature will directly affect the air conditioning unit’s

efficiency. This air conditioning unit can effectively cool your boat in water

temperatures up to 90°F (32°C) and heat (if reverse-cycle option is

installed) in water as low as 40°F (4°C).

• Verify the display location with the criteria found in the installation

section of this manual.

• Install an optional inside air temperature sensor if necessary. If an

optional inside air temperature sensor is already installed in the air

stream, ensure it does not touch anything warm (like the condenser

coil).

Enable de-icing in the parameters. If ice still forms immediately, revisit the

above possible causes.

Ice on a fan coil can be removed quickly by running the unit in HEAT

I

mode.

• Remove any obstructions in the return-air stream.

• Clean the return-air filter and grille.

• Check for crushed or restricted ducting. Ducting must be as straight,

smooth, and taut as possible.

• If the fan speed is set to manual low, raise the speed to a higher setting

or set to automatic mode.

• Or, increase the minimum low speed in the program parameters.

Refer to “The fan coil is iced.” in this table.

Close the hatches and doors.

• Redirect the supply air so that is not blowing in or near the return-air

stream.

• Seal any air leaks on the duct.

Refer to “There is a lack of airflow.”in this table.

Set the fan speed to automatic mode or increase the manual fan speed.

Or, increase the minimum low speed in the program parameters.

Close hatches and doors, raise set point, turn on de-icing.

EN

25

Page 26

Troubleshooting Elite Control

Problem Possible Causes Recommended Solution

The condenser

coil is iced while in

HEAT mode.

The fan does

not run or runs

continuously.

The unit does not

heat.

The unit does not

cool.

The unit switches

to heat while in

COOL mode.

The seawater temperature is below 40°F

(4°C).

The digital control is set for either fan cycling

with compressor or for continuous fan

operation.

The circuit board on the unit is defective.

Typically, the compressor and pump are still

running.

The unit does not have a heating cycle.

The display is set to cool-only or auxiliary

electric heat.

The reversing valve is stuck.

The seawater temperature is too low.

There is a loss of refrigerant gas.

(For CW systems only)

The chilled-water loop is inadequately heated,

the chiller system is not in the proper mode

of operation, or the auxiliary electric heater is

disabled.

The display is set to heat-only.

The seawater temperature is too high.

There is a loss of refrigerant gas.

(For CW systems only)

The chilled-water loop is inadequately cooled

or the chiller system is not in the proper mode

of operation.

The de-icing feature is enabled due to the coil

possibly icing up during long run times.

• Shut down the system to prevent damage to the condenser.

• Allow the coil to defrost.

Change the fan operation to continuous fan operation or fan cycling with

compressor.

When configured for auxiliary electric heat, the fan will stay on for

I

four minutes aer a heat cycle ends even if the fan is set to cycled

operation.

Call for service to replace the board.

A shorted relay or triac may cause the fan to never shut off or never

I

turn on. If the fan never shuts off, the fan may be set to ‘continuous’

on the display.

Most units have a reverse cycle to create heat, but some units may not

have this function.

Change the parameters on the display or press the Mode button to

activate heating or automatic. The auxiliary electric heat will not function

if the display is set to auxiliary electric heat and the unit does not have an

auxiliary electric heater added.

• Lightly press on the valve with a rubber mallet while the unit is in HEAT

mode.

• Call a service technician if that does not correct the problem.

Seawater temperature directly affects the unit’s efficiency. For the unit to

heat (if the reverse-cycle option is available), water temperatures must be

40 °F (4 °C) or higher.

• Check the air conditioning unit for a refrigerant oil leak.

• Call for service.

• Be sure the chiller is in HEAT mode.

• If the air handler system is equipped with water-temperature sensors,

check the water temperature at the digital control.

• If the water temperature is not at least 15 °F warmer for HEAT mode,

the water valve will not open.

• If the air handler system is equipped with an auxiliary electric heater,

ensure that the auxiliary electric heat is enabled.

Change the parameters on the display or press the Mode button to

activate cool or automatic mode.

Seawater temperature will directly affect the air conditioning unit’s

efficiency. This air conditioning unit can effectively cool your boat in water

temperatures up to 90 °F (32 °C). The unit may still work at higher water

temperatures, but not as efficiently.

• Check the air conditioning unit for a refrigerant oil leak.

• Call for service.

• Be sure the chiller is in COOL mode.

• If the air handler system is equipped with water-temperature sensors,

check the water temperature at the digital control.

• If the water temperature is not at least 15 °F cooler for COOL mode,

the water valve will not open.

Reprogram the de-icing cycle under the parameter settings.

26

EN

Page 27

Elite Control Troubleshooting

Problem Possible Causes Recommended Solution

The pump does

not shut off.

The pump does

not run.

The compressor

does not shut off.

The compressor

does not run.

A low-pressure fault

is present.

The circuit board is shorted.

The pump parameter on the display is set for

the pump to run continuously.

A high-pressure fault may be present.

A relay on the circuit board has shorted

closed.

A relay on the circuit board has shorted open.