MS-24 U

Original Instruction Manual

Originalbedienungsanleitung

Important:

Read this instruction manual carefully before putting the brush cutter/string trimmer into operation and strictly observe the safety regulations! Preserve

instruction manual carefully!

Wichtlg:

Bitte lesen Sie dieses Anweisungshandbuch sorgfältig durch, bevor Sie die Motorsense / den Rasentrimmer in Betrieb nehmen, und beachten Sie die

Sicherheitsvorschriften strikt!

Bewahren Sie das Anweisungshandbuch sorgfältig auf.

2

Thank you very much for purchasing the DOLMAR brush cutter/string trimmer.

We are pleased to recommend to you the DOLMAR brush cutter/string

trimmer which is the result of a long development program and many years of

knowledge and experience.

Please read this booklet which refers in detail to the various points that will

demonstrate its outstanding performance. This will assist you to obtain the best

possible result from your DOLMAR brush cutter/string trimmer.

Table of Contents Page

Symbols .........................................................................2

Safety instructions .........................................................3

Technical data................................................................7

Designation of parts.......................................................8

Assembly of engine and shaft .......................................9

Mounting of handle ......................................................10

Mounting of protector...................................................11

Mounting of cutter blade or nylon cutting head............12

Fuels/Refuelling ..........................................................13

Correct handling of machine........................................14

Points in operation and how to stop ............................15

Resharpening the cutting tool ......................................16

Servicing instructions...................................................18

Storage ........................................................................20

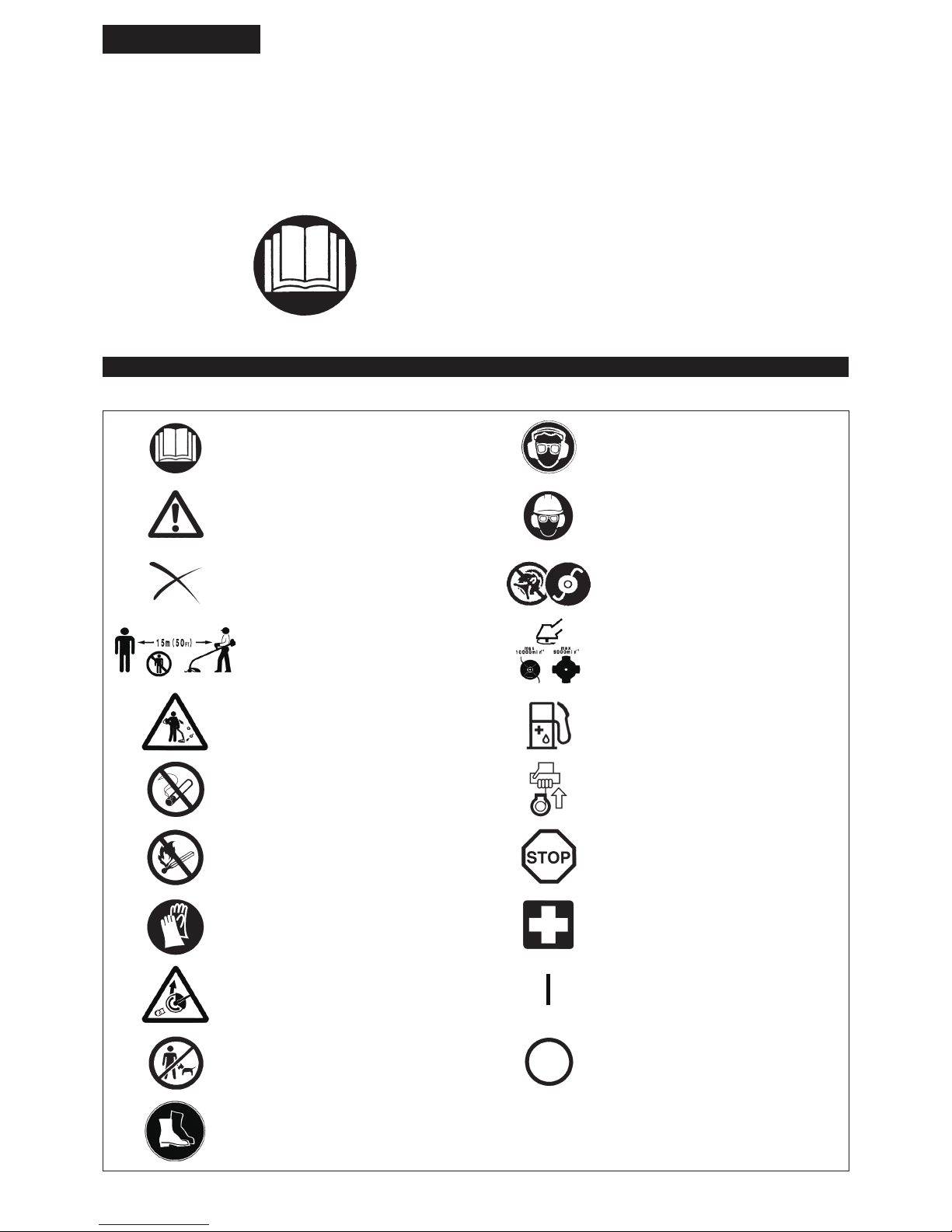

You will note the following symbols when reading the instructions manual.

SYMBOLS

English

(Original instructions)

Read instruction Manual

Wear eye and ear protection

(for string trimmer only)

Take Particular care and Attention

Wear protective helmet, eye and ear

protection (for brush cutter only)

Forbidden

Do not use metal blades

(for string trimmer only)

Keep distance Top permissible tool speed

Flying object hazard Fuel and oil mixture

No Smoking Engine-Manual start

No open ame Emergency stop

Protective gloves must be worn First Aid

Kickback

Beware of blade thrust

ON/START

Keep the area of operation clear of all

persons and pets

OFF/STOP

Wear sturdy boots with non-slip

soles. Steel toed safety boots are

recommended.

3

General Instructions

To ensure correct operation, user has to read this instruction manual to make –

himself familiar with the handling of the brush cutter/string trimmer. Users

insufciently informed will risk danger to themselves as well as others due to

improper handling.

It is recommended only to lend the brush cutter/string trimmer to people who –

have proven to be experienced with brush cutter/string trimmers.

Always hand over the instruction manual.

First users should ask the dealer for basic instructions to familiarize oneself –

with the handling of an engine powered cutter.

Children and young persons aged under 18 years must not be allowed to –

operate the brush cutter/string trimmer. Persons over the age of 16 years

may however use the device for the purpose of being trained only whilst

under supervision of a qualied trainer.

Use brush cutter/string trimmers with the utmost care and attention. –

Operate the brush cutter/string trimmer only if you are in good physical –

condition.

Perform all work calmly and carefully. The user has to accept liability for

others.

Never use the brush cutter/string trimmer after consumption of alcohol or –

drugs, or if feeling tired or ill.

National regulation can restrict the use of the machine. –

WARNING: This power tool produces an electromagnetic eld during

operation.

This eld may under some circumstances interfere with active or

passive medical implants. To reduce the risk of serious or fatal

injury, we recommend persons with medical implants to consult

their physician and the medical implant manufacturer before

operating this machine.

Intended use of the machine

The brush cutter/string trimmer is only intended for cutter grass, weeds, –

bushes, undergrowth it should not be used for any other purpose such as

Edging or hedge cutting as this may cause injury.

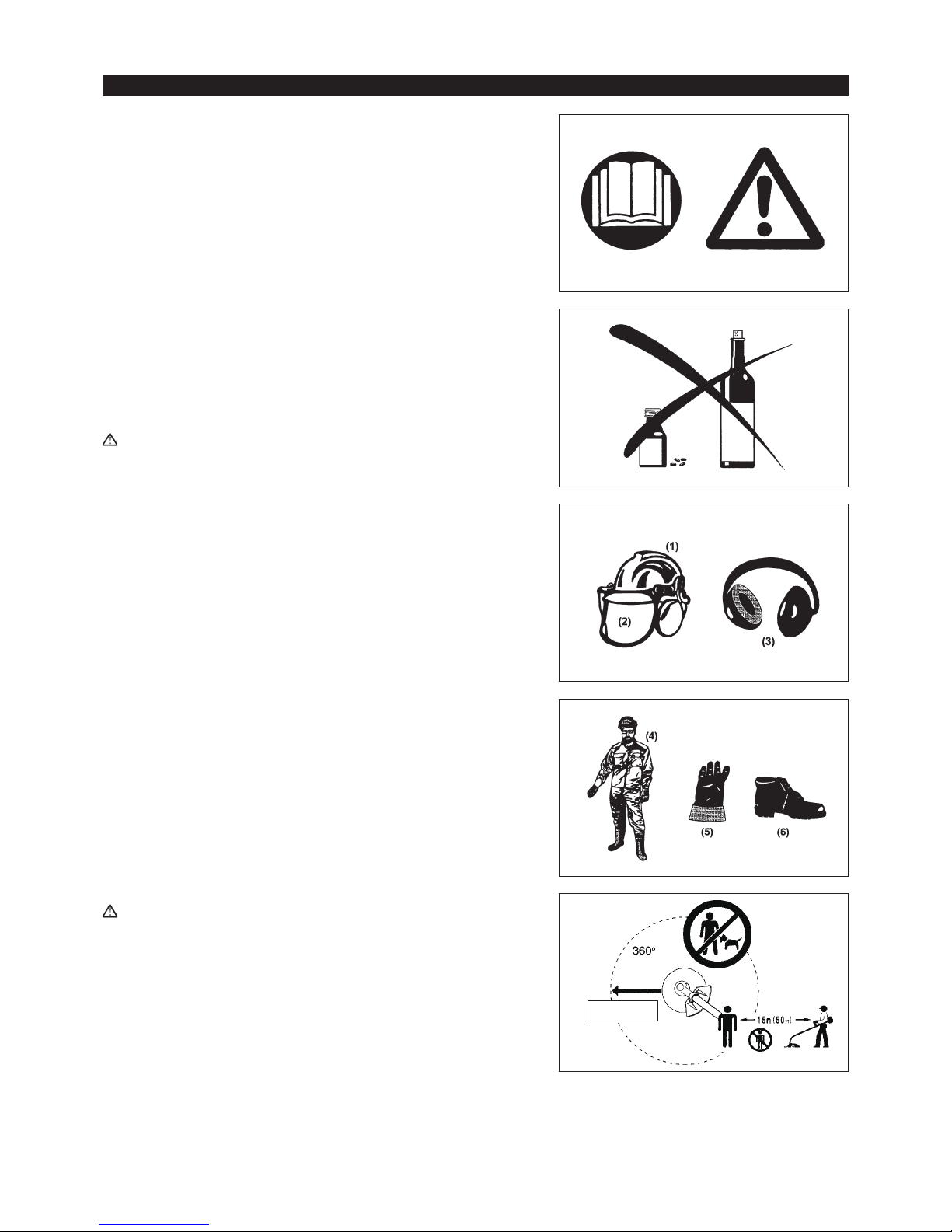

Personal protective equipment

The clothing worn should be functional and appropriate, i.e. it should be tight- –

tting but not cause hindrance. Do not wear either jewelry or clothing which

could become entangled with bushes or shrubs.

In order to avoid either head, eye, hand or foot injuries as well as to protect –

your hearing the following protective equipment and protective clothing must

be used during operation of the brush cutter/string trimmer.

Always wear a helmet where there is a risk of falling objects. The protective –

helmet (1) is to be checked at regular intervals for damage and is to be

replaced at the latest after 5 years. Use only approved protective helmets.

The visor (2) of the helmet (or alternatively goggles) protects the face from –

ying debris and stones. During operation of the brush cutter/string trimmer

always wear goggles, or a visor to prevent eye injuries.

Wear adequate noise protection equipment to avoid hearing impairment (ear –

muffs (3), ear plugs etc.).

The work overalls (4) protect against ying stones and debris. We strongly –

recommend that the user wears work overalls.

Special gloves (5) made of thick leather are part of the prescribed equipment –

and must always be worn during operation of the brush cutter/string trimmer.

When using the brush cutter/string trimmer, always wear sturdy shoes (6) –

with a non-slip sole. This protects against injuries and ensures a good footing.

Residual risks

Even when the power tool is used as prescribed it is not possible to eliminate all

residual risk factors. The following hazards may arise in connection with the

power tool’s construction and design:

1. Damage to lungs if an effective dust mask is not worn.

2. Damage to hearing if effective hearing protection is not worn.

3. Damages to health resulting from vibration emission if the power tool is being

used over longer period of time or not adequately managed and properly

maintained.

Starting up the brush cutter

Please make sure that there are no children or other people within a working –

range of 15 meters (50 ft), also pay attention to any animals in the working

vicinity.

Before use always check that the brush cutter/string trimmer is safe for –

operation:

Check the security of the cutting tool, the control lever for easy action and

check for proper functioning of the control lever lock.

Rotation of the cutting tool during idling speed is not allowed. Check with your –

dealer for adjustment if in doubt. Check for clean and dry handles and test

the function of the start/stop switch.

15 Meters

Diagrammatic gure

SAFETY INSTRUCTIONS

4

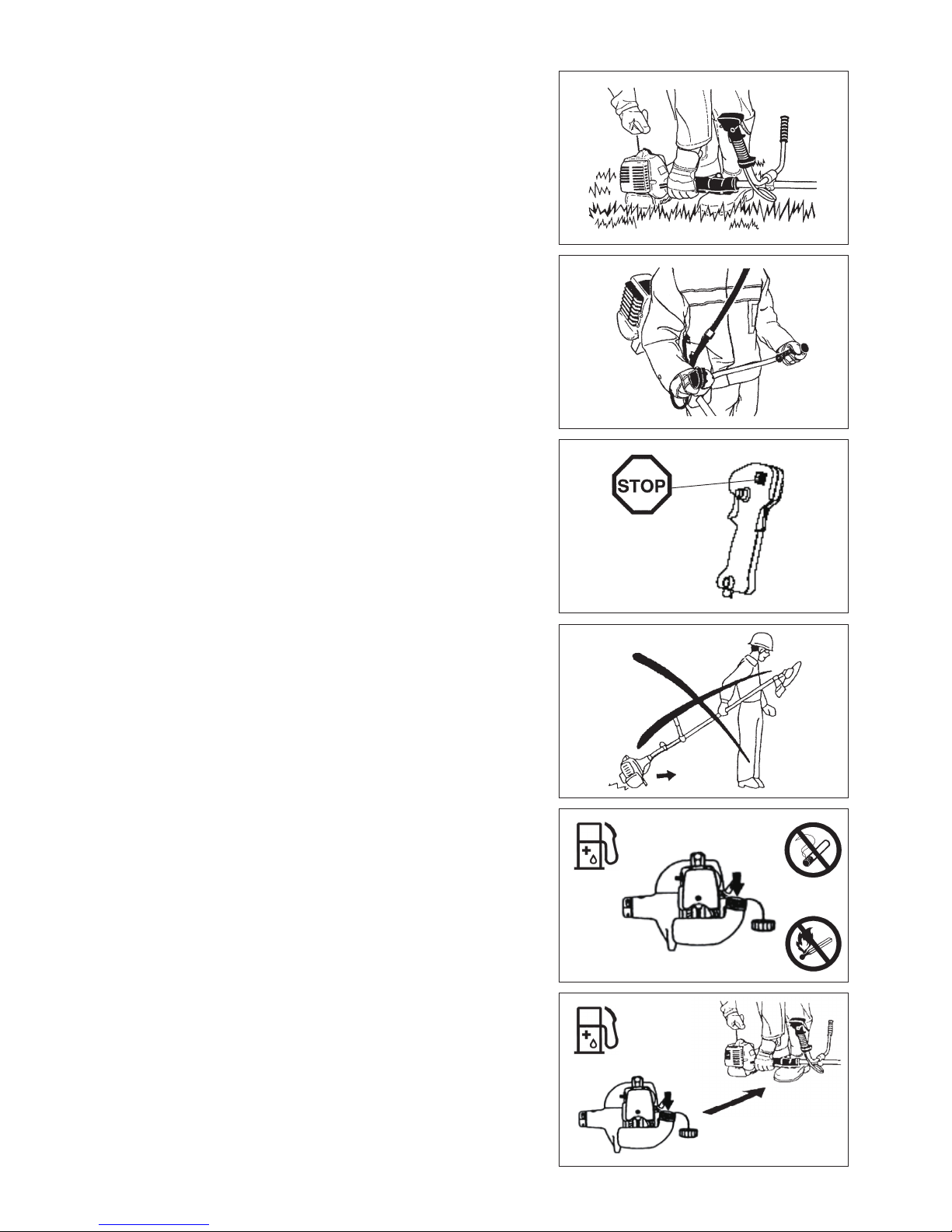

Start the brush cutter/string trimmer only in accordance with the instructions.

Do not use any other methods for starting the engine! –

Use the brush cutter/string trimmer and the tools only for such applications as –

specied.

Only start the brush cutter/string trimmer engine, after the entire assembly –

is done. Operation of the device is only permitted after all the appropriate

accessories are attached!

Before starting make sure that the cutting tool has no contact with hard –

objects such as branches, stones etc. as the cutting tool will revolve when

starting.

The engine is to be switched off immediately in case of any engine problems. –

Should the cutting tool hit stones or other hard objects, immediately switch off –

the engine and inspect the cutting tool.

Inspect the cutting tool at short regular intervals for damage (detection of –

hairline cracks by means of tapping-noise test).

Operate the brush cutter/string trimmer only with the shoulder strap attached –

which is to be suitably adjusted before putting the brush cutter/string trimmer

into operation. It is essential to adjust the shoulder strap according to the

user’s size to prevent fatigue occurring during use. Never hold the cutter with

one hand during use.

During operation always hold the brush cutter/string trimmer with both hands. –

Always ensure a safe footing.

Operate the brush cutter/string trimmer in such a manner as to avoid –

inhalation of the exhaust gases. Never run the engine in enclosed rooms (risk

of gas poisoning). Carbon monoxide is an odorless gas.

Switch off the engine when resting and when leaving the brush cutter/string –

trimmer unattended, and place it in a safe location to prevent danger to

others or damage to the machine.

Never put the hot brush cutter/string trimmer onto dry grass or onto any –

combustible materials.

The cutting tool has to be equipped with it’s appropriate guard. –

Never run the cutter without this guard!

All protective installations and guards supplied with the machine must be –

used during operation.

Never operate the engine with faulty exhaust mufer. –

Shut off the engine during transport. –

When transporting the equipment, always attach the cover to the cutting blade. –

Ensure safe position of the brush cutter/string trimmer during car –

transportation to avoid fuel leakage.

When transporting the brush cutter/string trimmer, ensure that the fuel tank is –

completely empty.

When unloading the brush cutter/string trimmer from the truck, never drop the –

Engine to the ground or this may severely damage the fuel tank.

Except in case of emergency, never drop or cast the brush cutter/string –

trimmer to the ground or this may severely damage the brush cutter/string

trimmer.

Remember to lift the entire equipment from the ground when moving the –

equipment. Dragging the fuel tank is highly dangerous and will cause damage

and leakage of fuel, possibly causing re.

If the equipment gets heavy impact or fall, check the condition before –

continuing work. Check the fuel system for fuel leakage and the controls

and safety devices for malfunction. If there is any damage or doubt, ask our

authorized service center for the inspection and repair.

Refuelling

Shut off the engine during refuelling, keep away from open ames and do not –

smoke.

Avoid skin contact with mineral oil products. Do not inhale fuel vapor. Always –

wear protective gloves during refuelling. Change and clean protective clothing

at regular intervals.

Take care not to spill either fuel or oil in order to prevent soil contamination –

(environmental protection). Clean the brush cutter/string trimmer immediately

after fuel has been spilt.

Avoid any fuel contact with your clothing. Change your clothing instantly if –

fuel has been spilt on it (to prevent clothing catching re).

Inspect the fuel cap at regular intervals making sure that it can be securely –

fastened and does not leak.

Carefully tighten the fuel tank cap. Change location to start the engine (at –

least 3 meters away from the place of refuelling).

Never refuel in closed rooms. Fuel vapors accumulate at ground lever (risk of –

explosions).

Only transport and store fuel in approved containers. Make sure the fuel –

stored is not accessible to children.

• Resting

• Transport

• Refuelling

• Maintenance

• Tool Replacement

3 meters

5

Method of operation

Only use the – brush cutter/string trimmer in good light and visibility. During the

winter season beware of slippery or wet areas, ice and snow (risk of slipping).

Always ensure a safe footing.

Never cut above waist height. –

Never stand on a ladder and run the – brush cutter/string trimmer.

Never climb up into trees to perform cutting operation with the – brush cutter/

string trimmer.

Never work on unstable surfaces. –

Remove sand, stones, nails etc. found within the working range. –

Foreign particles may damage the cutting tool and can cause dangerous

kick-backs.

Before commencing cutting, the cutting tool must have reached full working –

speed.

Take a rest to prevent loss of control caused by fatigue. We recommend to –

take a 10 to 20-minute rest every hour.

If grass or branches get caught between the cutting tool and guard, always –

stop the engine before cleaning. Otherwise unintentional blade rotation may

cause serious injury.

Caution:

Kickback

Diagrammatic

gure

Diagrammatic

gure

Kickback (blade thrust)

When operating the brush cutter, uncontrolled kickback may occur. –

This is particularly the case when attempting to cut within a blade segment –

between 12 and 2 o’clock.

Never apply the brush cutter within a segment between 12 and 2 o’clock. –

Never apply this segment of the brush cutter blade to solids, such as bushes –

and trees, etc., having a diameter in excess of 3 cm or the brush cutter will be

deected at great force with the risk of injuries.

Kickback prevention

To avoid kickbacks, observe the following:

Operation within a blade segment between 12 and 2 o’clock presents positive –

hazards, especially when using metal cutting tools.

Cutting operations within a blade segment between 11 and 12 o’clock, and –

between 2 and 5 o’clock, must only be performed by trained and experienced

operators, and then only at their own risk.

Easy cutting with almost no kickback is possible within a blade segment

between 8 and 11 o’clock.

Maintenance instructions

Have your equipment serviced by our authorized service center, always using –

only genuine replacement parts. Incorrect repair and poor maintenance can

shorten the life of the equipment and increase the risk of accidents.

The condition of the cutter, in particular of the cutting tool of the protective –

devices and also of the shoulder strap must be checked before commencing

work.

Particular attention is to be paid to the cutting blades which must be correctly

sharpened.

Turn off the engine and remove spark plug connector when replacing or –

sharpening cutting tools, and also when cleaning the cutter or cutting tool.

Cutting Tools

Employ only the correct cutting tool for the job in hand.

MS-24 U with cutter blade (Star Blade (4 teeth)) or Nylon cutting head.

Never use other blades including metal multi-piece pivoting chains and ail

blades. Otherwise serious injury may result.

For cutting thick materials, such as weed, high grass, bushes, shrubs,

underwood, thicket etc. (max. 2 cm dia. thickness). Perform this cutting work by

swinging the brush cutter evenly in half-circles from right to left (similar to using

a scythe).

6

Never straighten or weld damaged cutting tools.

Operate the – brush cutter/string trimmer with as little noise and contamination

as possible. In particular check the correct setting of the carburetor.

Clean the – brush cutter/string trimmer at regular intervals and check that all

screws and nuts are well tightened.

Never service or store the brush cutter/string trimmer in the vicinity of naked –

ames.

Always store the brush cutter/string trimmer in locked rooms and with an –

emptied fuel tank.

When cleaning, servicing and storing the equipment, always attach the cover –

to the cutting blade.

Observe the relevant accident prevention instructions issued by the relevant trade associations and by the insurance companies.

Do not perform any modications on the brush cutter/string trimmer as this will endanger your safety.

The performance of maintenance or repair work by the user is limited to those activities as described in the instruction manual. All other work is

to be done by an Authorized Service Agent. Use only genuine spare parts and accessories released and supplied by DOLMAR.

Use of non-approved accessories and tools means increased risk of accidents. DOLMAR will not accept any liability for accidents or damage

caused by the use of non-approved cutting tools and xing devices of cutting tools, or accessories.

Vibration

People with poor circulation who are exposed to excessive vibration may –

experience injury to blood vessels or the nervous system. Vibration may

cause the following symptoms to occur in the ngers, hands or wrists: “Falling

asleep” (numbness), tingling, pain, stabbing sensation, alteration of skin color

or of the skin. If any of these symptoms occur, see a physician!

To reduce the risk of “white nger disease”, keep your hands warm during –

operation and well maintain the equipment and accessories.

First Aid

In case of accident make sure that a rst-aid box is available in the vicinity of

the cutting operations. Immediately replace any item taken from the rst aid box.

When asking for help, please give the following

information:

Place of accident –

What happened –

Number of injured persons –

Kind of injuries –

Your name –

For European countries only

EC Declaration of Conformity

The undersigned, Tamiro Kishima and Rainer Bergfeld, as authorized by Dolmar GmbH, declare that the DOLMAR machine (s) :

Designation of Machine: Brush Cutter/String Trimmer

Model No./ Type: MS-24 U

Specications: see “TECHNICAL DATA” table

are of series production and

Conforms to the following European Directives:

2000/14/EC, 2006/42/EC

And are manufactured in accordance with the following standards or standardized documents:

EN ISO 11806-1, EN ISO 14982

The technical documentation is on le at:

Dolmar GmbH,

Jenfelder Straße 38, Abteilung FZ,

D-22045 Hamburg

The conformity assessment procedure required by Directive 2000/14/EC was in Accordance with annex VI.

Max. sound power values: 108.93 dB (A)

Max. guaranteed sound power values: 114 dB (A)

28. 12. 2011

Tamiro Kishima

Managing Director

Rainer Bergfeld

Managing Director

7

TECHNICAL DATA MS-24 U

Model MS-24 U

Engine model 1E34F

Engine displacement 24.5 cm³

Maximum engine performance 0.73 kW max.

Engine speed at recommended max.

9,700/min max. (Blade)

8,200/min max. (String-head)

Cutting Width:

230 mm (Blade)

430 mm (String-head)

Idling speed 3,000/min ± 100/min

Clutch engagement speed 4,100/min ± 300/min

Gear ratio 14/19

Fuel

Mixed gas

Gasoline: Two-stroke Engine Oil = 50:1

Volume (fuel tank) 0.5 L

Vibration (tested according to ISO 22867): Max. a

h

= 4.599 m/s2 K = 1.5 m/s

2

Noise (tested according to ISO 22868):

Max. sound pressure values (operator position): LpA: 96.70 dB (A); KpA = 2.5 dB (A)

Max. sound power values: L

wA

: 108.93 dB(A); KwA = 2.5 dB (A)

Noise (tested according to 2000/14/EC, amended by 2005/88/EC):

Max. guaranteed sound power values

L

wA

: 114 dB (A)

Mass (without plastic guard and cutting blade) 4.5 kg

8

DESIGNATION OF PARTS

(7)

(3)

(19)

(1)

(21)

(6)

(23)

(2)

(20)

(22)

(5)

(16)

(13)

(14)

(15)

(17)

(14)

(15)

(13)

(11)

(4)

(9)

(12)

(7)

(8)

(10)

(16)

(18)

(10)

(7)

(4)

(9)

(11)

GB DESIGNATION OF PARTS

1 Fuel Tank

2 Rewind Starter

3 Air Cleaner

4 I-O Switch (on/off)

5 Spark Plug

6 Exhaust Mufer

7 Clutch Case

8 Waist Pad

9 Hanger

10 Handle

11 Control Lever

12 Control Cable

13 Shaft

14 Protector (Cutting tool guard)

15 Gear Case

16 Handle Holder

17 Cutter Blade

18 Nylon Cutting Head

19 Fuel Filler Cap

20 Starter Knob

21 Primer Pump

22 Choke Lever

23 Exhaust Pipe

9

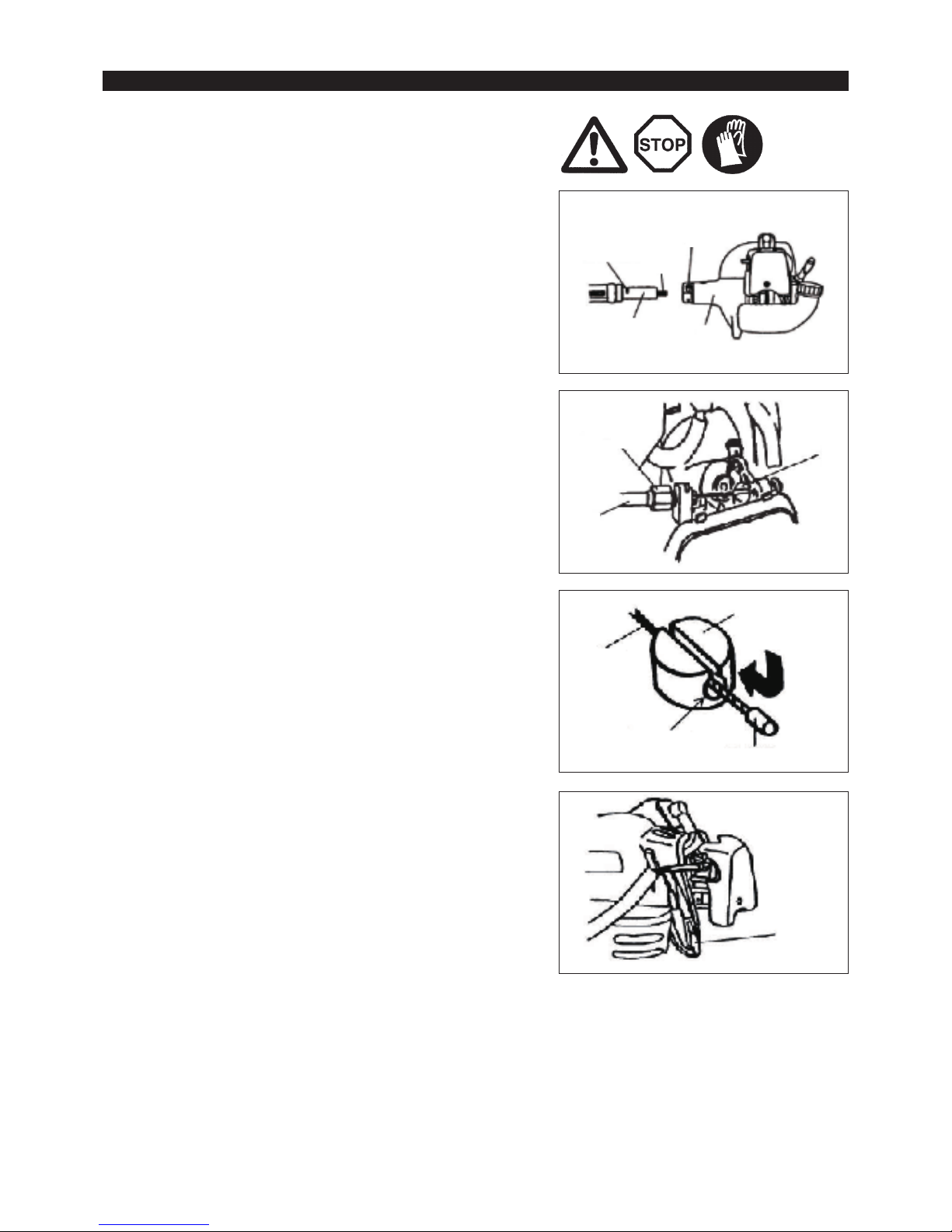

CAUTION: Before doing any work on the string trimmer, always switch off the

motor and pull the spark plug connector off the spark plug.

Always wear protective gloves.

CAUTION: Start the string trimmer only after having assembled it completely.

Loosen the two bolts (1) and insert the main pipe (2) into the case clutch (3). –

Insert it up to the arrow-mark position. (Refer to the sketch on the right.) –

If it is difcult to insert, turn the spline (4) a little and re-insert.

Tighten the two bolts (1) uniformly on the right and left by Allen wrench –

supplied.

How to mount the control cable

Remove the air cleaner cover. –

Put the control cable (5) into the adjusting cable (6). Shift the swivel (7) and –

put the cable into the swivel. At this time, be careful that the round hole in the

swivel is oriented toward the tting at the inner wire end.

Release the swivel and make sure that the inner wire tting is placed in the –

hole.

Mount the air cleaner cover. –

Connection of the switch cord

Connect the switch cords to the two cords from the engine by inserting one –

into the other.

Fix the cord connector by clamp. –

ASSEMBLY OF ENGINE AND SHAFT

(1)

(6)

(7)

Swivel

End tting

Connector

Control cable

Round hole

(5)

(4)

(3)

(2)

Arrow-mark

10

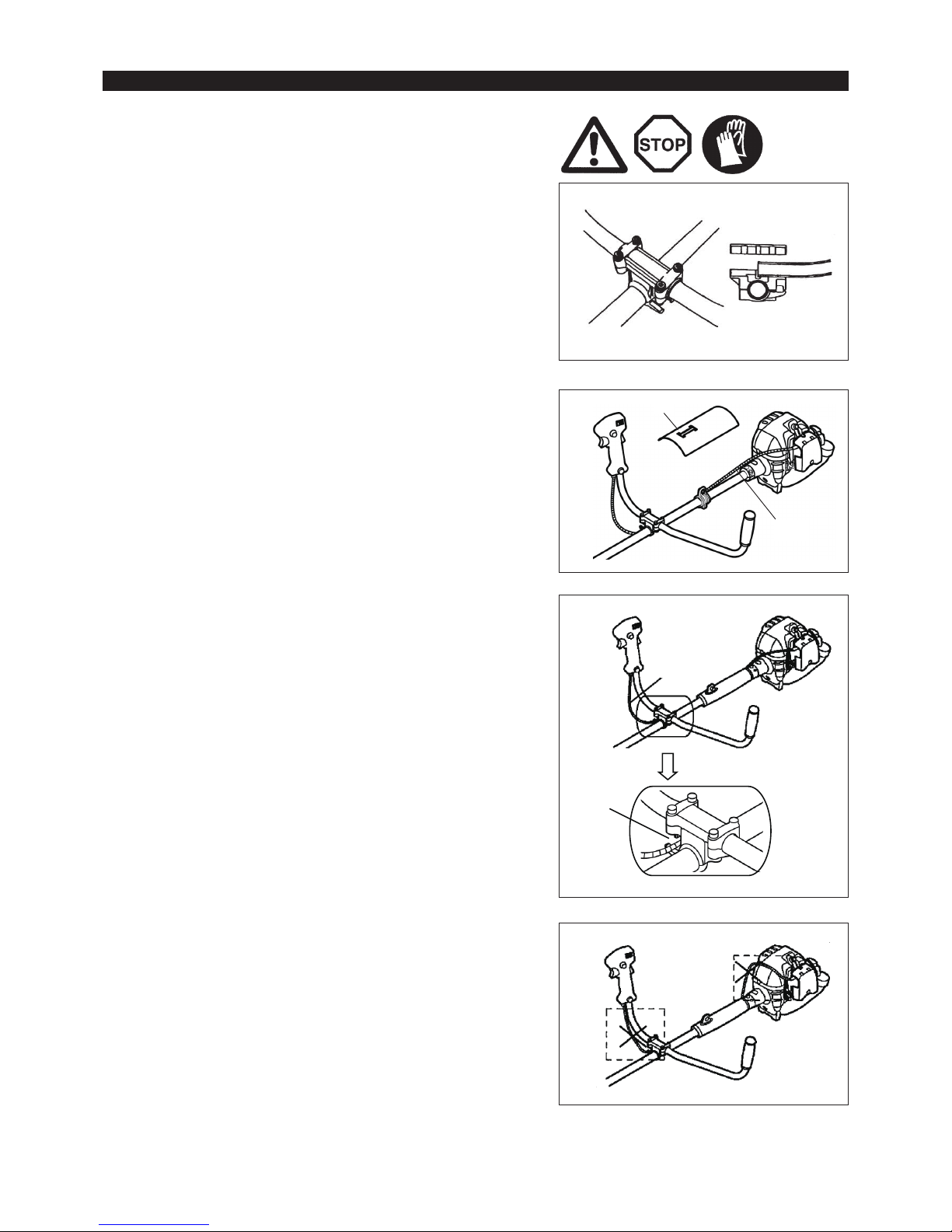

CAUTION: Before doing any work on the brush cutter, always stop the engine

and pull the spark plug connector off the spark plug.

Always wear protective gloves!

CAUTION: Start the brush cutter only after having assembled it completely.

For machines with U Handle models

Place the handle-xing metal so that the handle with the control lever will be –

positioned on the right (the right-hand grip side) as viewed from the engine

side, and the other handle on the left side.

Fit the groove of the handle-xing material to the handle end. Fix provisionally –

the attached metal by hexagon socket bolt supplied.

Adjust the handle to an easy-to-operate position, and tighten securely the –

four hexagon socket bolts uniformly on the right and left by Allen wrench.

MOUNTING OF HANDLE

Throttle cable of control lever assembly instructions

Step one: Surround the throttle cable (1) which comes from carburetor along –

the engine cylinder cover in accordance with the direction which is away from

the operator, and wrap it by waist pad (2) along the opposite side of the pipe

operator.

Step two: Insert the throttle cable (1) of control lever into the clamping slot (3) –

of lower splint of handle holder.

CAUTION: After waist pad is packed, the redundant throttle cable close to the

engine side can not be curved which can cause phenomenon of too

high idle speed and the blade can not stop, see right photo.

(2)

L

R

(1)

(1)

(3)

11

To meet the applicable safety provisions, only the tool/protector combinations as

indicated in the table must be used.

Be sure to use genuine DOLMAR cutter blades or nylon

cutting head.

The cutter blade must be well polished, free of cracks or breakage. If the –

cutter blade hits against a stone during operation, stop the engine and check

the blade immediately.

Polish or replace the cutter blade every three hours of operation. –

If the nylon cutting head hits against a stone during operation, stop the –

engine and check the nylon cutting head immediately.

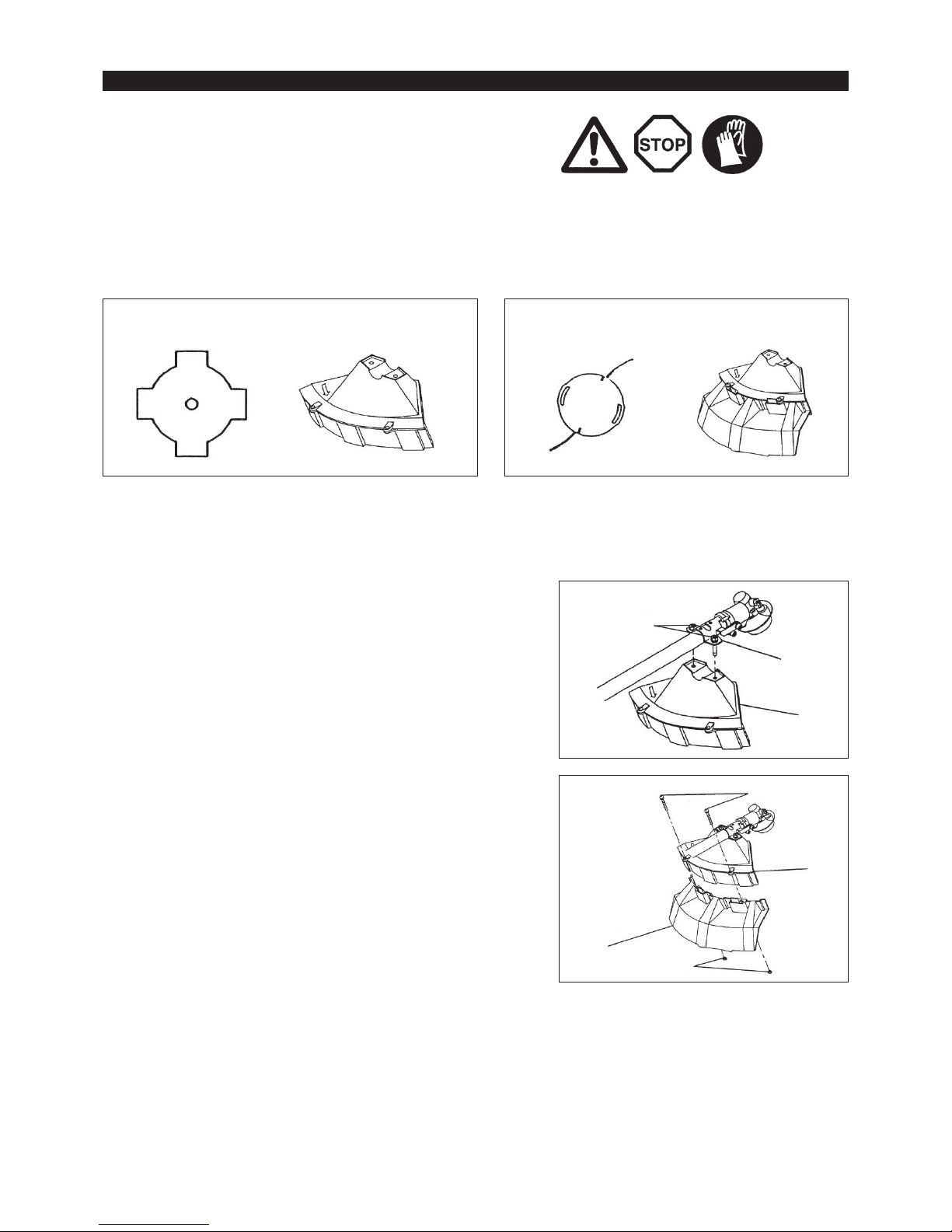

Star Blade

Nylon cutting headProtector for metal blades Protector for cord cutter

MOUNTING OF PROTECTOR

CAUTION: The appropriate protector must always be installed, for your own

safety and in order to comply with accident-prevention regulations.

Operation of the equipment without the guard being in place is not

permitted.

(1)

(3)

(2)

(1)

(4)

(6)

(5)

When using the string head, t the protector (6) into the protector (1), and –

tighten them with two nuts (5) and two screws (4).

Fix the protector (1) to the clamp (3) with two bolts M6 x 30 (2). –

12

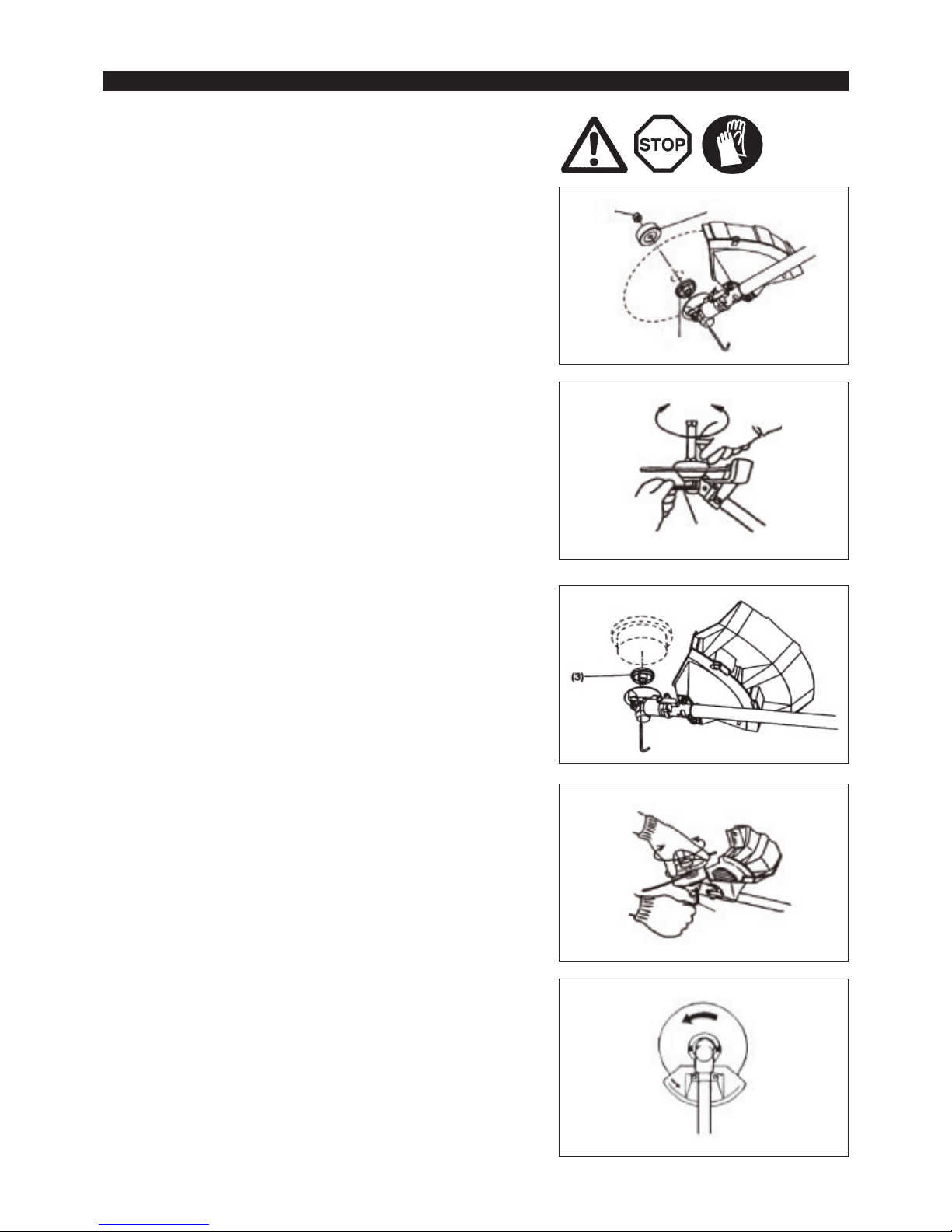

Turn the machine upside down, and you can replace the cutter blade or the

nylon cutting head easily.

Insert the hex wrench through the hole in the gear case and rotate the –

receiver washer (3) until it is locked with the hex wrench.

Loosen the nut (1) (left-hand thread) with the socket wrench and remove the –

nut (1), and clamp washer (2).

Rotation

Hex wrench

MOUNTING OF CUTTER BLADE OR NYLON CUTTING HEAD

With the hex wrench still in place.

Mount the cutter blade onto the shaft so that the guide of the receiver washer –

(3) ts in the arbor hole in the cutter blade. Install the clamp washer (2) and

secure the cutter blade with the nut (1).

[Tightening torque: 13 - 23 N-m]

NOTE: Always wear gloves when handling the cutter blade.

NOTE: The cutter blade-fastening nut (with spring washer) is a consumable

part. If there appears any wear or deformation on the spring washer,

replace the nut.

NOTE: The clamp washer (2), and nut (1) are not necessary for mounting the

nylon cutting head. The nylon head should go on top of the receiver

washer (3).

Make sure that the blade is the left way up. –

Screw the nylon cutting head onto the shaft. –

Loosen

Loosen

Tighten

(2)

(1)

(3)

Tighten

Hex wrench