Page 1

100sx - SERVICE 1

SERIAL NUMBER

SERVICE

SERIAL NUMBER

Record serial numbers and date of purchase in spaces provide d.

Date of Manufacture:

Date of Purchase:

Plow Serial Number

Engine Serial Number:

Page 2

2 100sx - SERVICE

SUPPORT PROCEDURE

SUPPORT PROCEDURE

Notify your dealer immediately of any malfunction or failure of

Ditch Witch equipment.

Always give model, serial number, and approximate date of

equipment purchase. This information should be recorded and

placed on file by owner at time of purchase.

Return damaged parts to dealer for inspection and warranty

consideration.

Order genuine Ditch Witch replacement or repair parts from your

authorized Ditch Witch dealer. Use of another manufacturer's

parts may void warranty.

RESOURCES

Publications

Contact your Ditch Witch dealer for publications and videos

covering safety, operation, service, and repair of your equipment.

Ditch Witch Training

For information about on-site, individualized training, contact yo ur

Ditch Witch dealer.

Page 3

100sx - FOREWORD 3

FOREWORD

This manual is an important part of your equipment. It provid es

safety information and operation instructions to help you use and

maintain your Ditch Witch equipment.

Read this manual before using your equipment. Keep it with the

equipment at all times for future reference. If you sell your

equipment, be sure to give this manual to the new owner.

If you need a replacement copy, contact your Ditch Witch dealer.

If you need assistance in locating a dealer, visit our website at

www.ditchwitch.com or write to the following address:

The Charles Machine Works, Inc.

Attn: Marketing Department

PO Box 66

Perry, OK 73077-0066

USA

The descriptions and specifications in this manual ar e su bjec t to

change. The Charles Machine Works, Inc. reserves the right to

improve equipment. Some product improvements may have

taken place after this manual was published. For the latest

information on Ditch Witch equipment, see your Ditch Witch

dealer.

Thank you for buying and using Ditch Witch equipment.

Page 4

4 100sx - FOREWORD

Operator's Manual

100sx

Issue No.4.1/OP-2/07

Part Number 054-406

Copyright 1998, 1999, 2007

by The Charles Machine Works, Inc.,

Perry, Oklahoma

, Ditch Witch, CMW, AutoCrowd,

Modularmatic, Jet Trac, Roto Witch, Subsite, Fluid Miser, PermaSoil, Power Pipe, Super Witch, Super Witch II, Pierce Airrow, The

Underground, and The Underground Authority Worldwide are

registered trademarks of The Charles Machine Works, Inc.

Page 5

100sx - CONTENTS 5

CONTENTS

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Serial Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Support Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Underground Hazards . . . . . . . . . . . . . . . . . . . . . . . .14

Emergency Procedures . . . . . . . . . . . . . . . . . . . . . . .15

Jobsite Classifications. . . . . . . . . . . . . . . . . . . . . . . . . 18

Safety Alert Classifications . . . . . . . . . . . . . . . . . . . . .22

Safety Alerts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Page 6

6 100sx - CONTENTS

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Inspect Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Attach and Remove Blade . . . . . . . . . . . . . . . . . . . . . 25

Plow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

TRANSPORTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Haul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Unload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Engine Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Wheel Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Tires and Lugnuts . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Air Filter Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Belt Tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Page 7

100sx - OVERVIEW 7

OVERVIEW

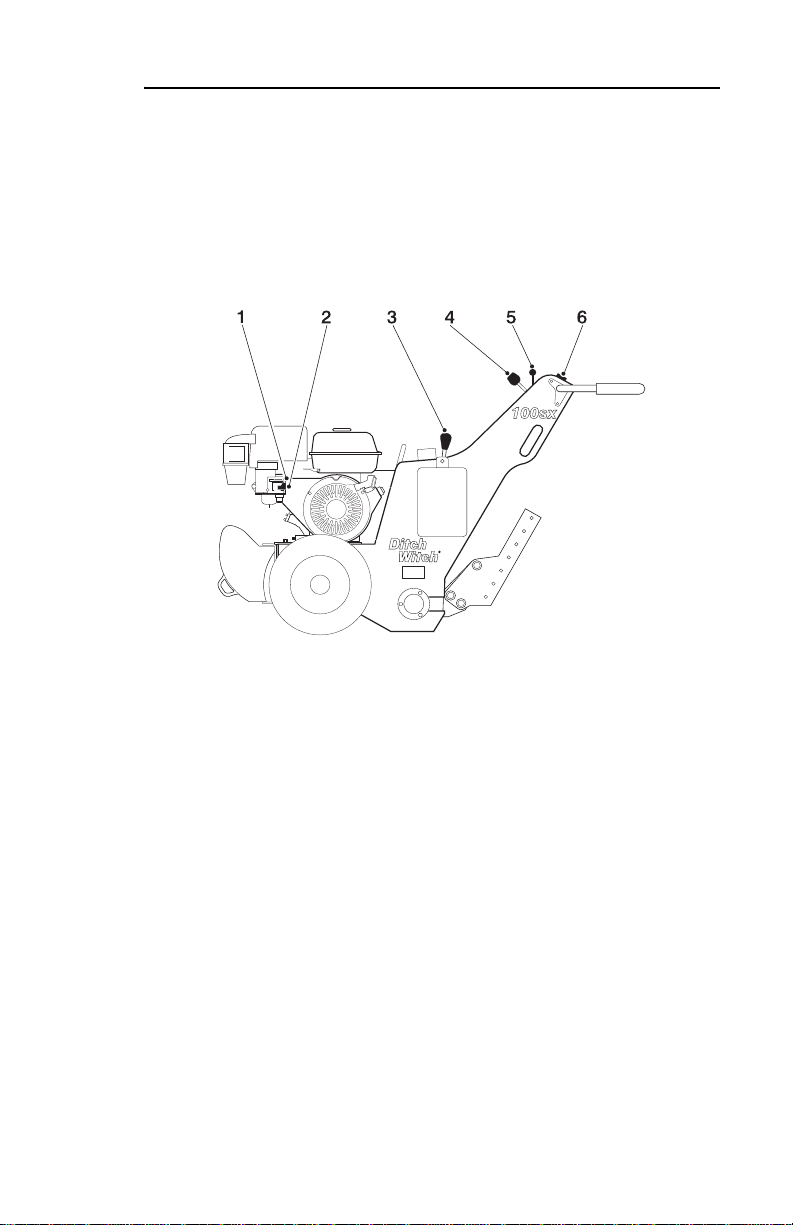

The 100SX is a self-propelled, walk-along vibratory plow. The

100SX is powered by a 10 hp (8.2 kw) Honda engine and is

designed to operate in a variety of soil conditions with either a pull

or feed blade.

om0384h.eps

1. Control panel/operator position

2. Engine

3. Weight assembly

4. Blade mount bracket

Page 8

8 100sx - OVERVIEW

Page 9

100sx - CONTROLS 9

OVERVIEW

CONTROLS

OVERVIEW

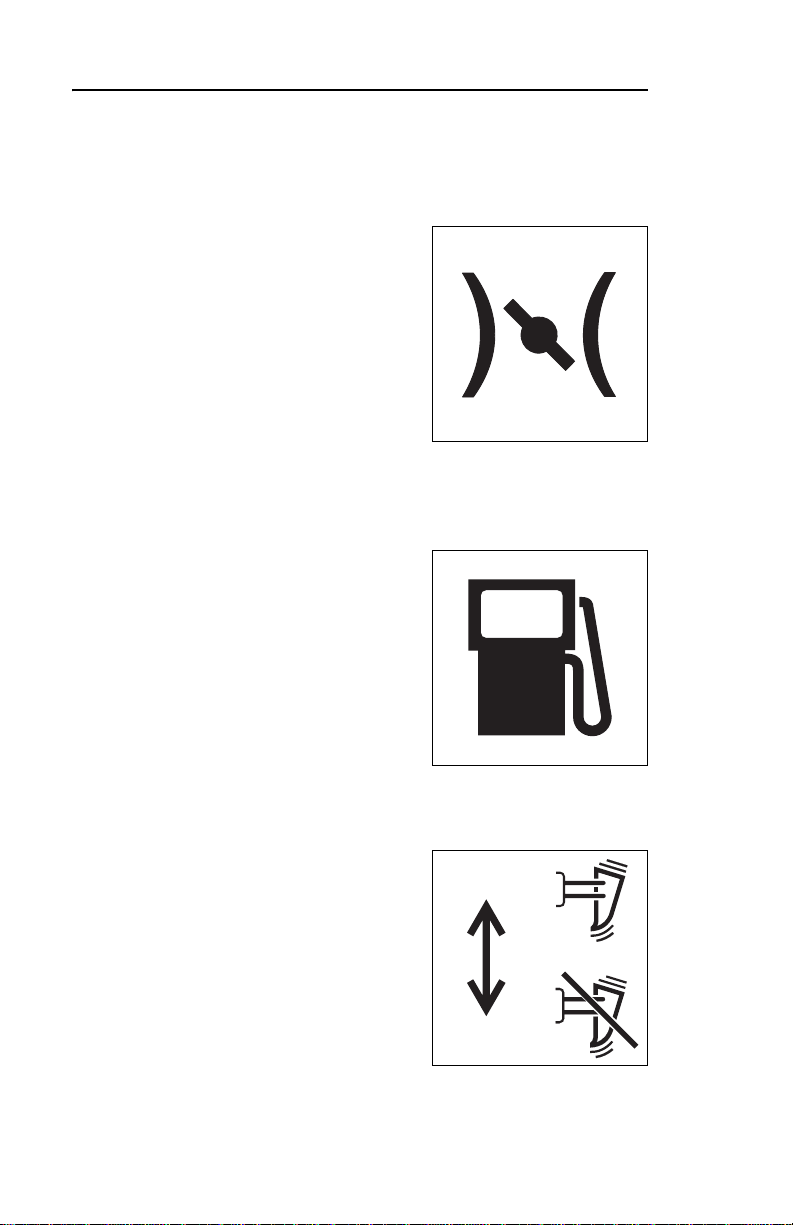

om0374h.eps

1. Choke

2. Fuel shutoff valve

3. Plow control

4. Speed/direction control

5. Throttle lever

6. Key switch

Page 10

10 100sx - CONTROLS

CONTROL DESCRIPTIONS

CONTROL DESCRIPTIONS

Choke

This control assists in starting cold

engine.

• Push lever forward before

starting.

• Pull lever back after engine is

running.

Fuel Shutoff Valve

Controls fuel flow to engine.

• Open to run machine.

• Close when machine is not

running.

Plow Control

This lever engages and disengages

plow vibrator drive.

• Push forward to engage plow

vibrator.

• Pull backward to disengage

plow vibrator.

Page 11

100sx - CONTROLS 11

CONTROL DESCRIPTIONS

Speed/Direction Control

This lever controls the speed and

direction of the ground drive.

• To travel forward, move lever to

forward position.

• To travel in reverse, move lever

to reverse position. Control

automatically returns to neutral

position if released in reverse

position.

• To go faster in either direction, move control farther from

neutral.

• Move control to neutral position to stop movement.

Throttle Lever

This lever controls engine and

vibrator speed when plow is

engaged.

• Move lever forward to increase

speed.

• Move lever backward to

decrease speed.

Page 12

12 100sx - CONTROLS

CONTROL DESCRIPTIONS

Key Switch

This switch enables engine start.

• Ensure plow control is

disengaged.

• Move speed/direction control to

neutral position.

• Insert key and turn to on position

to enable rope start.

• Turn key to off position to stop engine.

Page 13

100sx - SAFETY 13

CONTROL DESCRIPTIONS

SAFETY

Follow these guidelines before operating any jobsite equipment:

• Complete proper training and read operator’s manual before

using equipment.

• Contact One-Call (811) and any utility companies. Have all

underground lines and cables located and marked before

operating equipment. If you damage a utility, contact utility

company.

• Classify jobsite based on its hazards and use correct

equipment, safety equipment, and work methods for jobsite.

• Mark jobsite clearly and keep spectators away.

• Wear personal protective equipment.

• Review jobsite hazards, safety and emergency procedures,

and individual responsibilities with all personnel before work

begins. Safety videos are available from your Ditch Witch

dealer.

• Replace missing or damaged safety shields and safety signs.

• Use equipment carefully. Stop operation and investigate

anything that does not look or feel right.

• Do not operate unit where flammable gas is present.

• Contact your Ditch Witch dealer if you have any question

about operation, maintenance, or equipment use.

Page 14

14 100sx - SAFETY

UNDERGROUND HAZARDS

UNDERGROUND HAZARDS

Striking underground hazards can cause explosion, electrocution,

fire, and exposure to hazardous materials.

Hazards include:

• Electric cables

• Natural gas lines

• Fiber optic lines

• Water lines

• Sewer lines

• Pipes carrying other chemicals, liquids, or gase s

• Storage tanks

Page 15

100sx - SAFETY 15

EMERGENCY PROCEDURES

EMERGENCY PROCEDURES

If an Electric Line is Damaged

1. DO NOT MOVE. Stay where you are and do not touch any

equipment.

2. Warn others that an electric line has been hit and that they

should stay away.

3. Have someone contact electric company.

4. Do not return to area until given permission by electric

company.

If a Gas Line is Damaged

1. Immediately shut off engine and remove any ignition sources.

2. LEAVE AREA as quickly as possible.

3. Warn others that a gas line h as been hit an d that they should

leave the area.

4. Contact emergency personnel.

5. Contact gas company.

6. Do not return to area until given permission by gas company.

If a Fiber Optic Cable is Damaged

Do not look into cut ends of fiber optic or unidentified cable.

Vision damage can occur.

Page 16

16 100sx - SAFETY

SAFETY ALERT CLASSIFICATIONS

SAFETY ALERT CLASSIFICATIONS

These classifications and the icons defined on the following

pages work together to alert you to situations which could be

harmful to you, jobsite bystanders or your equipment. When you

see these words and icons in the book or on the machine,

carefully read and follow all instructions. YOUR SAFETY IS AT

STAKE.

Watch for the three safety alert levels: DANGER, WARNING and

CAUTION. Learn what each level means.

indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

Watch for two other words: NOTICE and IMPORTANT.

NOTICE can keep you from doing something that might damage

the machine or someone's property. It can also to alert against

unsafe practices.

IMPORTANT can help you do a better job or make your job

easier in some way.

Page 17

100sx - SAFETY 17

SAFETY ALERTS

SAFETY ALERTS

Electric shock. Contacting electric

lines will cause death or serious injury. Know

location of lines and stay away.

Deadly gases. Lack of oxygen or

presence of gas will cause sickness or death.

Provide ventilation.

Jobsite hazards

could cause death or serious injury .

Use correct equipment and work

methods. Use and maintain proper

safety equipment.

Crushing weight

could cause death or serious injury .

Use proper procedures and

equipment or stay away.

Moving parts could

cut off hand or foot. Stay away.

Page 18

18 100sx - SAFETY

SAFETY ALERTS

Runaway possible. Machine could

run over you or others. Learn how to use all

controls. Start and operate only from operator’s

position.

Improper control function could

cause death or serious injury. If control does not

work as described in instructions, stop machine

and have it serviced.

Incorrect procedures could result

in death, injury, or property damage. Learn to use

equipment correctly.

NOTICES:

• Unless otherwise instructed, all service should be performed

with engine shut off.

• Refer to engine manufacturer's manual for engine

maintenance instructions.

Page 19

100sx - SAFETY 19

SAFETY ALERTS

Hot parts may cause burns. Do not

touch until cool.

Exposure to high noise levels may

cause hearing loss. Wear hearing protection.

Page 20

20 100sx - SAFETY

Page 21

100sx - OPERATION 21

INSPECT MACHINE

OPERATION

INSPECT MACHINE

Check the following before each day's work. Refer to

LUBRICATION and MAINTENANCE for additional information.

• General appearance.

• Condition of plow blade, drive belts, and air filter.

• Fuel lines and fittings for signs of leakage, wear, or other

damage.

• Tire pressure. Use reliable tire pressure gauge.

• Engine oil level. Keep oil level at highest line on filler cap/

dipstick.

• Fuel level. Fill tank at end of day to reduce condensation.

• Signs are in place and readable.

• Guards and shields are in place.

• Nuts and bolts are tight. Tighten as specified in torque table s

in Parts Manual.

Page 22

22 100sx - OPERATION

START-UP

START-UP

Deadly gases. Lack of oxygen or

presence of gas will cause sickness or death.

Provide ventilation.

Incorrect procedures could result

in death, injury, or property damage. Learn to use

equipment correctly.

IMPORTANT: Read engine manufacturer's starting and

operating instructions. Follow directions for new engine break-in.

1. Disengage plow control by moving lever back.

2. Open fuel shutoff valve.

3. Check that speed/direction control (orange) is in neutral

position.

4. Move throttle to half open.

5. Close choke to start cold engine.

6. Insert key into switch and turn to on position.

Page 23

100sx - OPERATION 23

SHUTDOWN

7. Pull briskly on starter-rope handle at left side of machine.

If engine does not start after three pulls on rope start, turn key

switch to off position and check for fuel blockage or ignition

system problems.

8. Check controls for correct operation.

9. After engine has warmed up, return choke to open position.

Improper control function could

cause death or serious injury. If control does not

work as described in instructions, stop machine

and have it serviced.

EMERGENCY SHUTDOWN: Turn key switch to off position.

SHUTDOWN

1. Move speed/direction contr o l to neutral position.

2. Disengage plow drive by moving plow control lever back.

3. Turn key switch to off position and remove key.

4. Close fuel shutoff valve.

Page 24

24 100sx - OPERATION

DRIVE

DRIVE

Incorrect procedures could result

in death, injury, or property damage. Learn to use

equipment correctly.

NOTICE: Drive slowly and cautiously at all times.

Jobsite hazards

could cause death or serious injury.

Use correct equipment and work

methods. Use and maintain proper

safety equipment.

1. Start with speed/direction control in neutral position.

2. Run engine with throttle at low idle.

3. Slowly engage speed/direction control.

4. Adjust drive speed with speed/direction control.

5. To stop, move speed/direction control to neutral position.

Page 25

100sx - OPERATION 25

ATTACH AND REMOVE BLADE

ATTACH AND REMOVE BLADE

1. Shut off engine, close fuel shutoff valve, and tip machine forward onto weight assembly.

2. Use two blade pins to position blade mounts onto vibrator

arm.

3. When attaching blade mount to vibrator arm, pin top hole

first. Pivot blade mount to align lower vibrator arm hole with

one of lower blade mount holes. Outer hole gives more

vertical angle for normal plowing. Hole nearer plow gives

steeper blade angle for difficult soil conditions.

4. The plow blade can be adjusted up or down in blade mount.

Always install blade pin in lowest hole possible.

5. To remove blade, remove pins holding blade mount to

vibrator arm.

Page 26

26 100sx - OPERATION

PLOW

PLOW

Incorrect procedures could resu lt

in death, injury, or property damage. Learn to use

equipment correctly.

NOTICE: Keep hands on handlebars while

operating plow.

1. Drive to starting point.

2. Follow blade attachment procedure.

3. Feed cable in cable chute or insert material in pulling grip.

4. Open fuel shutoff valve.

5. Tilt machine back onto blade.

6. Start engine and run at high idle.

7. Engage plow control.

8. Lower plow blade to desired depth by pushing down on

handlebars until skid-plate touches ground.

9. Slowly move speed/direction control forward to begin

plowing.

10. To turn, push down on handlebars to break traction and pivot

machine. Concentrate weight on handlebar to outside of turn.

11. When finished plowing, return speed/direction control to

neutral position, lift handlebars to clear blade from ground,

disengage plow control, and and move throttle to low idle.

12. Follow shutdown procedure.

13. Remove cable from cable chute and follow blade removal

procedure.

Page 27

100sx - TRANSPORTATION 27

LIFT

TRANSPORTATION

Crushing weight

could cause death or serious injury.

Use proper procedures and

equipment or stay away.

LIFT

Points

Lifting points are identified by lifting

decals. Lifting at any other point is

unsafe and can damage machinery.

Procedure

Before lifting, check SPECIFICATIONS. Use a crane capable of

supporting the equipment’s size and weight.

om0385h.eps

Page 28

28 100sx - TRANSPORTATION

HAUL

HAUL

Machine can be hauled by trailer, van, or pickup truck. Before

hauling check the following:

• Check that loading ramps will support weight. See

SPECIFICATIONS.

• Check that adequate tiedowns are available.

Jobsite hazards

could cause death or serious injury.

Use correct equipment and work

methods. Use and maintain proper

safety equipment.

NOTICES:

• Park, unload, and load trailer on level part of jobsite.

• To prevent tipping, connect trailer to tow vehicle before

loading or unloading.

Page 29

100sx - TRANSPORTATION 29

LOAD

LOAD

1. Follow blade removal procedure.

2. Start machine following instructions in OPERATION.

3. Move throttle to half open.

EMERGENCY SHUTDOWN: Turn ignition switch to off position.

4. Align machine with ramps or trailer, boom first.

5. Guide machine onto trailer.

6. When tie-down position is reached, move speed/direction

control to neutral position.

7. Chain through loop on weight assembly and tightly attach

chain tie-down points on bed of trailer or vehicle.

For machines with serial numbers below 4R0376, chain

across weight assembly.

8. Move speed/direction contr o l to reve r se po sit i on .

9. Reverse machine to tighten front chain.

10. Follow shutdown procedure in OPERATION.

11. Place chain through slots below control console, attach chain

to tie-down points on bed of trailer or vehicle and tighten

chain with binder.

Page 30

30 100sx - TRANSPORTATION

UNLOAD

UNLOAD

1. Remove tiedowns from machine.

2. Start machine following instructions in OPERATION.

3. Use speed/direction control to slowly back machine o ff tr ailer

or down ramps.

Page 31

100sx - LUBRICATION 31

UNLOAD

LUBRICATION

Proper lubrication and maintenance protects Ditch Witch

equipment from damage and failure. In extreme conditions,

lubricate more frequently.

Use only recommended lubricants. Fill to capacities listed in

SPECIFICATIONS section.

Recommended Lubricants

GEO Gasoline engine oil (see oil temper ature chart for ap propriate SA E weight) mee ting API

MPG Multipurpose grease

THF Tractor hydraulic fluid, similar to Phillips 66 HG, Mobilfluid 423, Chevron Trac tor

CL Chain lubricant

engine service classification SD

Hydraulic Fluid, Texaco TDH Oil, or equivalent

Incorrect procedures could result

in death, injury, or property damage. Learn to use

equipment correctly.

sf1027

NOTICES:

• Unless otherwise instructed, all service should be performed

with engine off.

• Refer to engine manufacturer’s manual for engine

maintenance instructions.

Page 32

32 100sx - LUBRICATION

OVERVIEW

OVERVIEW

om0372h.eps

Interval Task Ref. Lubricant

10 hours Check hydraulic oil 3 THF

Check engine oil 4 GEO

25 hours Lube chain 6 CL

50 hours Change engine oil 4,5 GEO

150 hours Change hydraulic oil and filter 1,2,3 THF

Lube wheel bearings 7 MPG

Page 33

100sx - LUBRICATION 33

HYDRAULIC OIL

HYDRAULIC OIL

Check

Check hydraulic oil at filler/breather

cap every 10 hours. Oil level should

be at bottom of strainer screen

when cool. Add THF if needed.

Change

Change hydraulic oil and filter every

150 hours. Drain oil at plug (2)

located behind the plow mount.

Replace drain plug.

Change hydraulic oil filter (1)

located above drain plug.

Fill to bottom of strainer screen with

THF.

CHAIN

Lube chain every 25 hours with CL.

Access chain through hole in front of engine.

Page 34

34 100sx - LUBRICATION

ENGINE OIL

ENGINE OIL

Check

Check engine oil at filler cap/

dipstick. Oil should be at level

indicated on dipstick. Add GEO if

needed. Consult "Engine Oil

Temperature Chart" for oil

specifications.

Change

Change engine oil every 50 hours.

To drain oil remove drain plug at

front of engine.

Replace drain plug, fill with GEO,

and replace filler cap/dipstick.

Engine Oil Temperature Chart

Page 35

100sx - 35

WHEEL BEARINGS

WHEEL BEARINGS

Lube zerk every 150 hours with

MPG.

Page 36

36 100sx -

WHEEL BEARINGS

Page 37

100sx - MAINTENANCE 37

WHEEL BEARINGS

MAINTENANCE

Proper lubrication and maintenance protects Ditch Witch

equipment from damage and failure. In extreme conditions,

lubricate more frequently.

Incorrect procedures could result

in death, injury, or property damage. Learn to use

equipment correctly.

NOTICES:

• Unless otherwise instructed, all service should be performed

with engine shut off.

• Refer to engine manufacturer’s manual for engine

maintenance instructions.

Page 38

38 100sx - MAINTENANCE

OVERVIEW

OVERVIEW

om0373h.eps

Interval Task Ref.

10 hours Check tires and lugnuts 5,4

25 hours Clean foam air filter element 2

100 hours Change paper air filter element 1

As needed Clean feed chute on plow blade

Adjust belt tension 3

Page 39

100sx - MAINTENANCE 39

TIRES AND LUGNUTS

TIRES AND LUGNUTS

Check tires every 10 hours for proper inflation. Use an accurate

pressure gauge. Maintain air pressure at 15 psi (10.3 kPa).

Tighten lugnuts to 32 ft•lb (43.2 N•m).

For machines with serial numbers below 4R0376, tighten castle

nut firmly, then align castle nut slot with pin hole and insert cotter

pin. If wheel will not turn without binding, loosen nut to next slot

that aligns with hole. Reinstall cotter pin.

AIR FILTER ELEMENTS

Wash foam element (2) ever y 25 hours

in high flashpoint solvent.

NOTICE: Do not use gasoline or low

flashpoint solvent for cleaning. They

are flammable and are explosive under

certain conditions.

Change paper element (1) every 100 hours.

Page 40

40 100sx - MAINTENANCE

BELT TENSION

BELT TENSION

As needed, adjust belt tension by loosening four engine moun ting

bolts. Move engine forward to increase belt tension or backward

to reduce tension.

Page 41

100sx - SPECIFICATIONS 41

BELT TENSION

SPECIFICATIONS

om0376h.eps

DIMENSIONS U.S. METRIC

H1 Operating height 41 in 104 cm

A3’ Angle of departure without blade 50° 50°

L1 Maximum length without reel carrier 70 in 178 cm

L2 Maximum length with reel carrier 86.5 in 220 cm

W1 Plow vehicle width 35 in 89 cm

A’ Maximum depth 13 in 33 cm

A Maximum cover depth 12 in 30 cm

GENERAL

Ditch Witch Model 100SX, self-propelled, non-riding, hydrostatic, two-wheel

drive, vibratory plow. Pull and feed blades available. Ground drive is through

rubber tires.

Page 42

42 100sx - SPECIFICATIONS

BELT TENSION

OPERATION U.S. METRIC

Maximimum crowd speed forward 92 fpm 28 m/min

Maximum crowd speed reverse 92 fpm 28 m/min

Vehicle clearance circle 70 in 178 cm

Plow blade sizes

Pull blades (cover depth x mole diameter) 6-12 x .75 in 152-305 x

19 mm

Feed blades (tube diameter x cover depth (bend

radius)

Operating weight 720 lb 327 kg

Operator orientation: facing front of vehicle

Vibration

ENGINE

Honda GX340 gasoline engine

Cooling medium: air

Number of cylinders: one

Displacement

Bore 3.22 in 82 mm

Stroke 2.52 in 64 mm

Engine manufacturer’s gross power rating @ 3600

rpm

*Maximum governed speed as installed (no load) 3400 rpm 3400 rpm

Flywheel power @ 3400 rpm (full load) 10.2 hp 7.5 kW

Fuel consumption @ 3600 rpm 0.89 gph 3.4 L/h

**Maximum tilt angle 20° 20°

*All warranty is void if engine is run above maximum governed speed as

installed (no load)

.375 x 6-12

(1) in

47.9 ft/s

20.6 in

2

3

9 x 152-305

(25) mm

14.6 m/s

337 cm

11 hp 8.2 kW

2

3

**Exceeding these operating angles will cause engine damage. This DOES

NOT imply machine is stable to maximum angle of safe engine operation.

Page 43

100sx - SPECIFICATIONS 43

BELT TENSION

POWER TRAIN U.S. METRIC

Transmission: Hydrostatic, infinitely variable forward and reverse, 3:1 chain drive from

motor to axle

Tires: 18 x 1 1-8, 3-ply

Drive line system: belts and sheaves

Vibratory mechanism: eccentric shaft

HYDRAULIC SYSTEM

Ground drive pump capacity @ 3600 rpm, relief

2.2 gpm 8.3 L/min

valve setting @ 2,000 psi

Ground drive pump displacement/revolution

Ground drive motor displacement/revolution

.223 in

9.6 in

3

3

.556 cm

157 cm

3

3

Directional control valve type: open center

Delivery capacity 10 gpm 37.8 L/min

System relief valve setting 2500 psi 17 237 kPa

FLUID CAPACITIES

Fuel tank 1.7 gal 6.5 L

Engine oil 2.3 pt 1.1 L

Hydraulic system 3.5 gal 13.2 L

NOISE LEVELS

Operator 92 dBA sound pressure per ISO 6394

Exterior 101 dBA sound power per ISO 6393

VIBRATION LEVELS

Vibration at the operator’s hand during normal operation is x m/s

2

Specifications are general and subject to change without notice. If exact

measurements are required, equipment should be weighed and measured. Due to

selected options, delivered equipment may not necessarily match that shown.

Page 44

44 100sx - SPECIFICATIONS

Page 45

100sx - WARRANTY 45

WARRANTY

Ditch Witch Equipment and Replacement Parts

North American*

Limited Warranty Policy

Major Component Limited Warranty

Major components are warranted for a period of 1000 hours of use or one year,

whichever occurs first, beginning on date of delivery of any such new product. The

Major Component Limited Warranty covers only Major Components listed under

Major Component Limited Warranty that are manufactured and distributed by The

Charles Machine Works, Inc. (“CMW”). Replacement parts and other serial

numbered products (“Products”) that are not listed under Major Component

Limited Warranty, and non-major components are covered under Product Limited

Warranty.

Major Components are defined as:

•Frames.

• Differentials and parts contained within.

• Mechanical transmissions.

• Drive gearboxes and parts contained within.

• Hydraulic, hydrostatic, and fluid pumps, motors and components that control or

protect pumps and motors.

• Auxiliary hydraulic control valves and electrical components used for controlling

hydraulic components.

• Hydraulic cylinders and components excluding repair kits.

• Batteries, alternators, instruments, gauges, and protection components for

electrical systems.

• Pierce Airrow bodies, strikers, and tailpieces.

Free replacement parts and labor will be provided at any authorized dealership for

any part of Major Component which has a defect in material or workmanship

within warranty period. Defects will be determined by an inspection of major

component or part by CMW or its authorized dealer. The product containing a

major component or part must be presented to CMW or its authorized dealer for

inspection within 30 days of the date major component or part fails. CMW will

provide the location of its inspection facilities or its nearest authorized dealer upon

inquiry. CMW reserves the right to supply remanufactured replacement parts as it

deems appropriate.

* Equipment owners in countries other than U.S., Canada, Mexico, and Puerto

Rico should refer to Ditch Witch International Warranty Policy.

Page 46

46 100sx - WARRANTY

Product Limited Warranty

Products are warranted for 90 days from date of delivery of any new product. Free

replacement parts and labor will be provided at any authorized dealership for any

product which has a defect in material or workmanship within warranty period.

Replacement parts are warranted for 90 days from date of delivery of any such

replacement part. Any part of a product subject to ground contact is warranted

only for defects in material or workmanship and only for the period of operational

life of such part, which period shall not in any event exceed 90 days. Defects will

be determined by an inspection of the product or part by CMW or its authorized

dealer. The product or part must be presented to CMW or its authorized dealer for

inspection within 30 days of the date of failure. CMW will provide the location of its

inspection facilities or its nearest authorized dealer upon inquiry. CMW reserves

the right to supply remanufactured replacement parts as it deems appropriate.

Page 47

100sx - WARRANTY 47

Exclusions

from Major Component and Product Limited Warranty

Specifically excluded from Major Component and Product Limited Warranty are:

• Transportation charges related to repair, replacement, or inspection of

products, major components, or parts.

• Parts subject to ground contact (including but not limited to drill pipe, downhole

tools, digging chain, teeth and sprockets).

• All incidental or consequential damages.

• All defects, damages, or injuries caused by misuse, abuse, improper

installation, alteration, neglect, or uses other than those for which products

were intended.

• All defects, damages, or injuries caused by improper training, operation, or

servicing of products in a manner inconsistent with manufacturer’s

recommendations.

• All engines and engine accessories (these are covered by original

manufacturer’s warranty).

• Parts which may be subject to another manufacturer’s warranty (such warranty

will be available to purchaser).

• All implied warranties not expressly stated herein, including any warranty of

fitness for a particular purpose and merchantability.

IF THE PRODUCTS ARE PURCHASED FOR COMMERCIAL PURPOSES AS

DEFINED BY THE UNIFORM COMMERCIAL CODE, THEN THERE ARE NO

WARRANTIES WHICH EXTEND BEYOND THE FACE HEREOF AND THERE

ARE NO IMPLIED WARRANTIES OF ANY KIND WHICH EXTEND TO A

COMMERCIAL BUYER. ALL OTHER PROVISIONS OF THIS LIMITED

WARRANTY APPLY INCLUDING THE DUTIES IMPOSED.

Ditch Witch products have been tested to deliver acceptable performance in most

conditions. This does not imply they will deliver acceptable performance in all

conditions. Therefore, to assure suitability, products should be operated under

anticipated working conditions prior to purchase.

This limited warranty applies to the owner of the product. Some states do not

allow exclusion or limitation of incidental or consequential damages, so above

limitation of exclusion may not apply. Further, some states do not allow exclusion

of or limitation of how long an implied warranty lasts, so the above limitation may

not apply. This limited warranty gives owner specific legal rights and the owner

may also have other rights which vary from state to state.

Page 48

48 100sx - WARRANTY

For information regarding this limited warranty, contact CMW’s Product Support

department, P.O. Box 66, Perry, OK 73077-0066, or contact your local Ditch Witch

dealer.

First version: 1/91; Latest revision: 4/99

Page 49

Page 50

Loading...

Loading...