Page 1

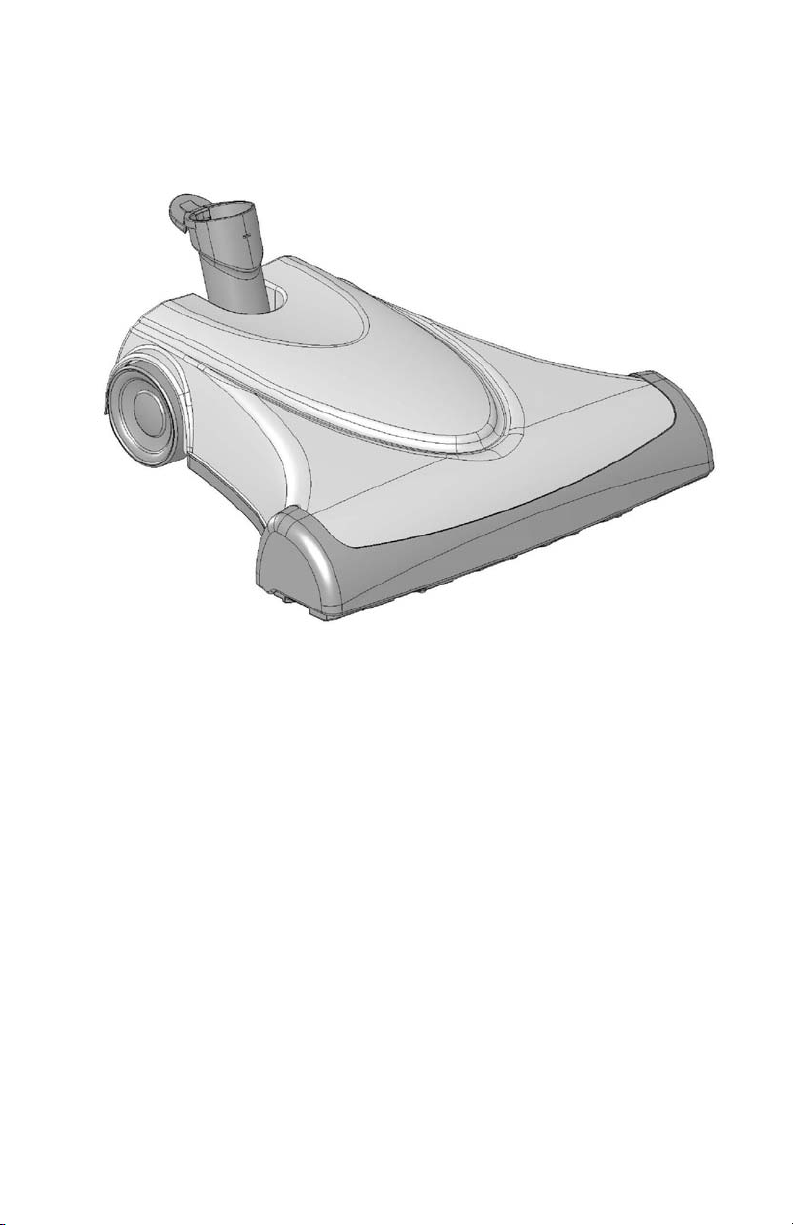

Turbine Powerhead

Operating Instructions

This Turbine Powerhead has been engineered for higher performance, quieter

operation and superior cleaning ability. It has been carefully designed and

manufactured for long life, reliable performance and convenient cleaning. It

requires no electricity because it runs off the airflow of your central vacuum

system. The Turbine Powerhead moves easily and does not require downward

pressure for thorough cleaning.

Please read and save these Operating Instructions.

SAFETY PRECAUTIONS

As with any tool with moving parts, caution must be exercised while using this

Turbine Powerhead.

1. Keep hair, hands and feet away from rotating brush while the Turbine

Powerhead is running.

2. Remember that Turbine Powerheads operate whenever they are connected

to a running vacuum. If children are present, make sure to turn vacuum

system off when leaving Powerhead unit unattended.

3. Do not attempt to service or unclog Turbine Powerhead while unit is running.

Page 1

p/n 8429 1/06

Page 2

Use & Care of Your Turbine Powerhead

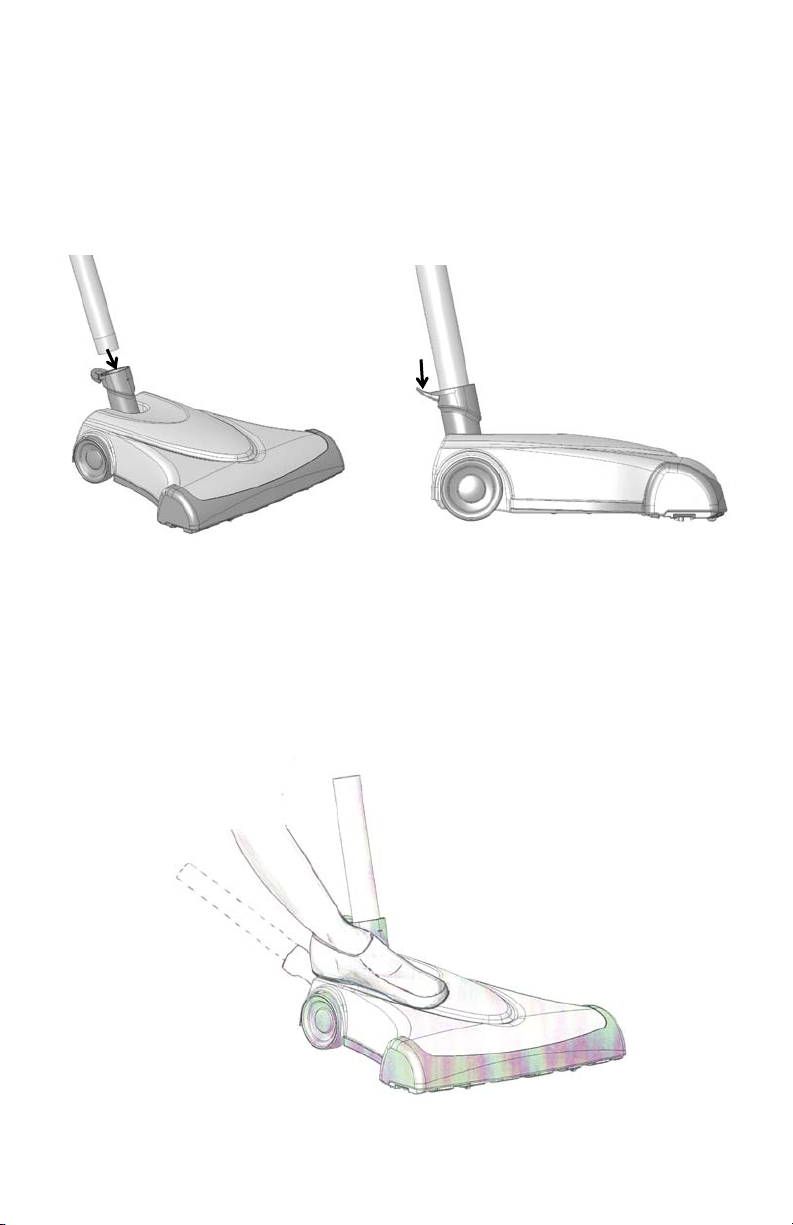

(A) ATTACHING THE TURBINE POWERHEAD

To attach your metal wand, simply insert wand into Powerhead neck until it fits

snugly. The built-in, locking mechanism will prevent the wand from coming

loose. To detach wand, depress wand release tab on back of neck with foot or

hand and twist wand free.

Inserting the Wand

Push

here to

Release

Wand

The wand can be locked in an upright position by pushing it forward until the

lock is engaged. This locked position is convenient for storage and lifting the

Powerhead. To release wand from the vertical locked position, gently place foot

on Powerhead, grasp wand and pull back.

Page 2

Page 3

Use & Care of Your Turbine Powerhead

(B) OPERATING PROCEDURES

Your Turbine Powerhead runs off the airflow of your vacuum system. It has no

on/off switch. Whenever it is attached to an operating vacuum system, it will be

running. No adjustments to the powerhead are necessary for different types of

carpeting.

To ensure maximum efficiency of the Turbine Powerhead, make sure that any

filters, bags and cleaning hoses in your vacuum system are clean and free of

blockage.

Avoid picking up water or spilled liquid with your Turbine Powerhead. The

vacuum system is designed for dry pick up only.

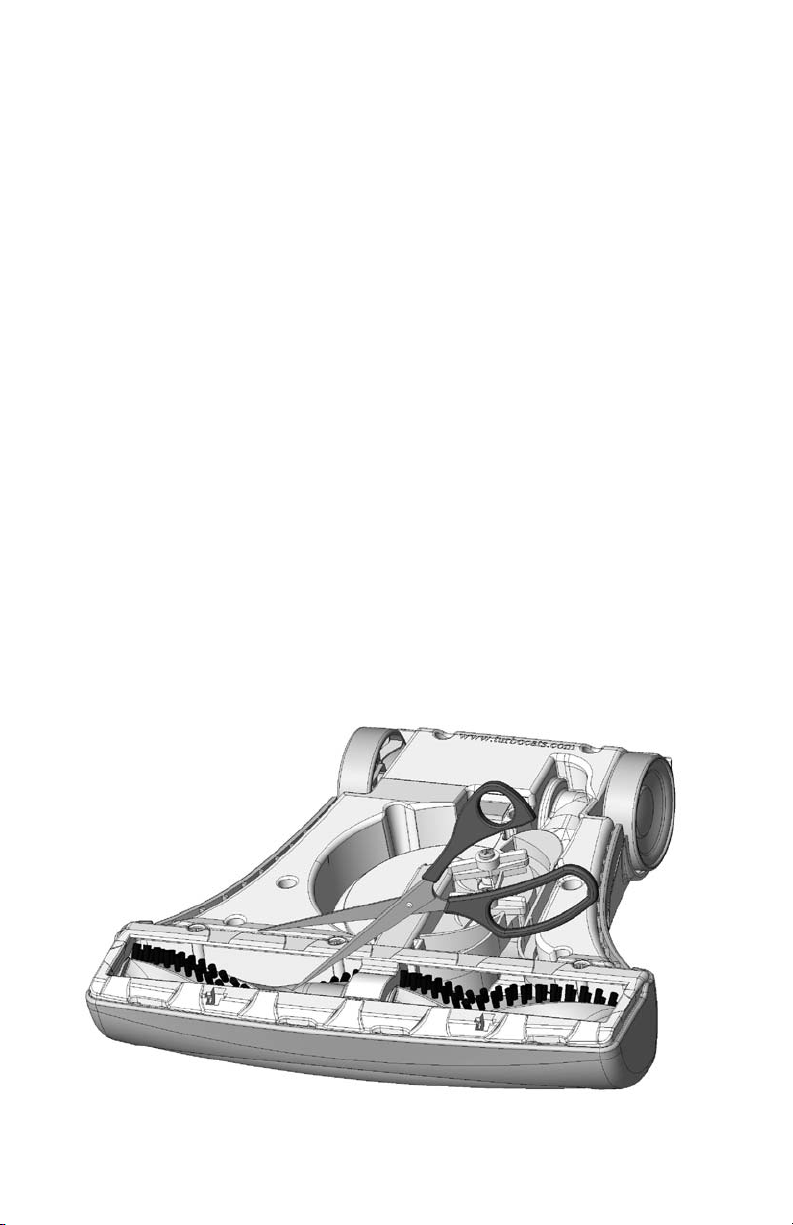

(C) CLEANING ROLLER BRUSH

Turn off vacuum system and disconnect Powerhead. Threads, string, carpet

fiber, fuzz and similar items may become wound around the beater brush.

These should be removed by unwinding them by hand or carefully cutting with

scissors. Keeping the beater brush clean will maintain efficiency.

Page 3

Page 4

Use & Care of Your Turbine Powerhead

(D) REMOVING CLOGS

Follow these steps if the turbine becomes obstructed:

1. Turn off vacuum system and disconnect the Powerhead.

2. Remove the clear belt cover by turning the Powerhead over and rotating the

two latches until they align with the openings in the belt cover. Remove the

belt cover.

3. Remove debris from the intake or turbine. Rotate brush to ensure the

system is clear. Ensure the orange seal on the belt cover and mating

surfaces are clean before reinstalling the belt cover.

4. To reinstall the belt cover, simply insert the front of the belt cover under the

baseplate edge and lower into its original position.

5. Secure the belt cover in place by turning the two latches to the locked

position.

Turn latches

to remove

Belt Cover

Remove

Belt Cover

Like This

Page 4

Remove

clog

here.

Baseplate

Edge

Page 5

Use & Care of Your Turbine Powerhead

(E) REPLACING THE DRIVE BELT

It is recommended that the drive belt be replaced by a Qualified Service

Technician.

1. Turn off vacuum system and disconnect powerhead.

2. Remove belt cover as described on page 4.

3. Remove the 3 screws securing the baseplate.

4. Remove the baseplate.

5. IMPORTANT: Please note correct brush and belt orientation. They must be

reinstalled correctly for proper function.

6. Lift the brush, belt and support assembly out of the housing.

7. Remove the old belt.

8. Place the new belt over one end, onto the brush roller, between the two

center flanges.

9. Loop belt around shaft. Twist belt as shown.

10. Slide the brush/belt assembly back into the housing recesses so the

supports seat properly into the housing. The assembly is designed to fit

only one way into housing. NOTE: The brush will rotate in the wrong

direction if the belt is twisted incorrectly.

11. Replace belt cover.

Baseplate

Shaft

Lift Rollerbrush

and Belt straight

up to remove

Position Belt

between these

two Flanges

Proper Belt

Orientation

Page 5

Page 6

TROUBLESHOOTING THE TURBINE POWERHEAD

CAUTION: Moving parts—disconnect from vacuum system before servicing unit.

Use the chart below to troubleshoot common problems you may experience with

your turbine powerhead. If you cannot solve the problem using the solutions

below, please contact your distributor or dealer for service.

Check for clog at air intake.

Clean central vac power unit guard

Turbine

Runs

Slow

z

z

Brush

Bounces

in Use

Brush

Hard to

Push

screen/filter.

Check for clog in hose.

Check for clog in tube line

Ensure belt orientation is correct.

Change direction you are vacuuming.

z

z

z

z

OTHER REPAIRS

For repairs or service beyond those described in this manual, please contact

your servicing distributor or dealer. Visit www.turbocats.com for servicing dealer

contact information.

LIMITED WARRANTY

H-P PRODUCTS, INC. warrants that the turbine powerhead when used for household

purposes, pursuant to Seller’s instructions, will be free from defects in materials and

workmanship for a period of three(3) years from the date of the initial consumer

purchase. H-P PRODUCTS, INC. warrants that the turbine powerhead, when used in a

commercial application pursuant to Seller’s instructions, will be free from defects in

materials and workmanship for a period of ninety (90) days from the date of the initial

consumer purchase. This warranty is limited to the replacement of defective parts and

any costs of shipping shall be incurred by the purchaser. THIS WARRANTY IS

EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS, IMPLIED, OR

STATUTORY, AND H-P PRODUCTS, INC. SPECIFICALLY DISCLAIMS

RESPONSIBILITY FOR CONSEQUENTIAL AND INCIDENTAL DAMAGES, AND

LIMITS THE IMPLIED WARRANTY OF MERCHANTABILITY TO THE PERIOD OF

EFFECTIVENESS OF THIS EXPRESS WARRANTY.

H-P PRODUCTS, INC.

Louisville, Ohio 44641

U.S.A.

(330) 875-5556

Page 6

Page 7

REPLACEMENT PARTS

# Description Part #

1 Lower Housing 8412*

2 Wheel Assembly (2) 8425*

3 Turbine Assembly 8558

4 Belt Cover 8413

5 Base Plate 8414*

6 Compression Spring 8557

7 Washer, Spring 5974

8 Washer, Neck 5971

9 Neck Assembly 8423

10 Spring, Neck Lock 7218

11 Top Housing 8411*

12 Seal, Small 7223

13 Roller Brush Assembly 8457

# Description Part #

14 T-Latch (2) 7226

15 Belt 8439

16 Screw, Housing (12) 7228

17 Screw, T-Latch (2) 7230

18 Bearing, Idler Assembly 8556

19 Bushing, Wheel (2) 7231

20 Shaft Support Assembly, Left 8428

21 Shaft Support, Right, with

washer

22 Ballast (2) 7238

23 Foam Pad (4) 7239

24 Shaft, Roller Wheel (2) 8416

25 Roller Wheel (2) 8417

26 Bearing Isolator (2) 8427

27 Retaining Ring (2) 8458

28 Seal, Belt Guard, Large 7224

* Please specify color when ordering.

8561

Page 7

p/n 8429

Loading...

Loading...