Page 1

DW802, DW802G

Heavy Duty Small Angle Grinder

Petites meuleuses angulaires de service intensif

Esmeriladoras angulares pequenas para trabajo pesado

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO

ANTES DE USAR EL PRODUCTO.

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DEWALT • www.dewalt.com

Page 2

English

SAVE THESE INSTRUCTIONS

WARNING! Read and understand all instructions including that provided with attachment and accessories.

Failure to follow all instructions listed below may result in electric

shock, fire and/or serious personal injury.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS

OR ANY D

EWALT TOOL, CALL US TOLL FREE AT:

1-800-4-DEWALT (1-800-433-9258)

General Safety Instructions

WORK AREA

• Keep your work area clean and well lit. Cluttered benches

and dark areas invite accidents.

• Do not operate power tools in explosive atmospheres, such

as in the presence of flammable liquids, gases, or dust.

Power tools create sparks which may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while operating a power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

• Grounded tools must be plugged into an outlet properly

installed and grounded in accordance with all codes and

ordinances. Never remove the grounding prong or modify

the plug in any way. Do not use any adapter plugs. Check

with a qualified electrician if you are in doubt as to whether

the outlet is properly grounded. If the tools should electrically

malfunction or break down, grounding provides a low resistance path to carry electricity away from the user. Applicable

only to Class I (grounded) tools.

• Double insulated tools are equipped with a polarized plug

(one blade is wider than the other.) This plug will fit in a

polarized outlet only one way. If the plug does not fit fully

in the outlet, reverse the plug. If it still does not fit, contact

a qualified electrician to install a polarized outlet. Do not

change the plug in any way. Double insulation eliminates

the need for the three wire grounded power cord and grounded

power supply system. Applicable only to Class II (double

insulated) tools.

• Avoid body contact with grounded surfaces such as pipes,

radiators, ranges, and refrigerators. There is an increased

risk of electric shock if your body is grounded.

• Don’t expose power tools to rain or wet conditions. Water

entering a power tool will increase the risk of electric shock.

• Do not abuse the cord. Never use the cord to carry the tools

or pull the plug from an outlet. Keep cord away from heat,

oil, sharp edges or moving parts. Replace damaged cords

immediately. Damaged cords increase the risk of electric shock.

• When operating a power tool outside, use an outdoor extension cord marked “W-A” or “W.” These cords are rated for

outdoor use and reduce the risk of electric shock.

Minimum Gage for Cord Sets

Volts Total Length of Cord in Feet

120V 0-25 26-50 51-100 101-150

240V 0-50 51-100 101-200 201-300

Ampere Rating

More Not more AWG

Than Than

6 - 10 18 16 14 12

PERSONAL SAFETY

• Stay alert, watch what you are doing and use common

sense when operating a power tool. Do not use tool while

tired or under the influence of drugs, alcohol, or medication.

A moment of inattention while operating power tools may result

in serious personal injury.

Page 3

English

1

• Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewelry, or long hair

can be caught in moving parts. Air vents often cover moving

parts and should also be avoided.

• Avoid accidental starting. Be sure switch is off before

plugging in. Carrying tools with your finger on the switch or

plugging in tools that have the switch on invites accidents.

• Remove adjusting keys or wrenches before turning the

tool on. A wrench or a key that is left attached to a rotating part

of the tool may result in personal injury.

• Do not overreach. Keep proper footing and balance at all

times. Proper footing and balance enables better control of the

tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust

mask, non-skid safety shoes, hard hat, or hearing protection

must be used for appropriate conditions.

TOOL USE AND CARE

• Use clamps or other practical way to secure and support

the workpiece to a stable platform. Holding the work by hand

or against your body is unstable and may lead to loss of control.

• Do not force tool. Use the correct tool for your application.

The correct tool will do the job better and safer at the rate for

which it is designed.

• Do not use tool if switch does not turn it on or off. Any tool

that cannot be controlled with the switch is dangerous and

must be repaired.

• Disconnect the plug from the power source before making

any adjustments, changing accessories, or storing the

tool. Such preventative safety measures reduce the risk of

starting the tool accidentally.

• Store idle tools out of reach of children and other untrained

persons. Tools are dangerous in the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp and

clean. Properly maintained tools, with sharp cutting edges are

less likely to bind and are easier to control.

• Check for misalignment or binding of moving parts, breakage of parts, and any other condition that may affect the

tools operation. If damaged, have the tool serviced before

using. Many accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the manufacturer for your model. Accessories that may be suitable for

one tool, may become hazardous when used on another tool.

SERVICE

• Tool service must be performed only by qualified repair

personnel. Service or maintenance performed by unqualified

personnel could result in a risk of injury.

• When servicing a tool, use only identical replacement

parts. Follow instructions in the Maintenance section of

this manual. Use of unauthorized parts or failure to follow

maintenance instructions may create a risk of electric shock or

injury.

Additional Specific Safety Instructions

for Grinders

• Always use proper guard with grinding wheel. A guard protects operator from broken wheel fragments and wheel contact.

• Accessories must be rated for at least the speed recommended on the tool warning label. Wheels and other acces-

sories running over rated speed can fly apart and cause injury.

Accessory ratings must be above listed minimum wheel speed

as shown on tool nameplate.

• Hold tool by insulated gripping surfaces when performing

an operation where the cutting tool may contact hidden

Page 4

English

2

wiring or its own cord. Contact with a “live” wire will make

exposed metal parts of the tool “live” and shock the operator.

• Do not use Type 11 (flaring cup) wheels on this tool. Using

inappropriate accessories can result in injury.

• Before using, inspect recommended accessory for cracks

or flaws. If such a crack or flaw is evident, discard the

accessory. The accessory should also be inspected whenever you think the tool may have been dropped. Flaws may

cause wheel breakage.

• When starting the tool with a new or replacement wheel, or

a new or replacement wire brush installed, hold the tool in

a well protected area and let it run for one minute. If the

wheel has an undetected crack or flaw, it should burst in less

than one minute. If the wire brush has loose wires, they will be

detected. Never start the tool with a person in line with the

wheel. This includes the operator.

• Avoid bouncing the wheel or giving it rough treatment. If

this occurs, stop the tool and inspect the wheel for cracks or

flaws.

• Direct sparks away from operator, bystanders or flamma-

ble materials. Sparks may be produced while using a sander

or grinder. Sparks may cause burns or start fires.

• Always use side handle. Tighten the handle securely. The

side handle should always be used to maintain control of the

tool at all times.

• Do not operate this tool for long periods of time. Vibration

caused by the operating action of this tool may cause permanent

injury to fingers, hands, and arms. Use gloves to provide extra

cushion, take frequent rest periods, and limit daily time of use.

• Clean out your tool often, especially after heavy use. Dust

and grit containing metal particles often accumulate on interior

surfaces and could create an electric shock hazard.

• The label on your tool may include the following symbols:

V..................volts A ............amperes

Hz................hertz W ..........watts

min ..............minutes ..........alternating current

............direct current

n

o ..........no load speed

................

Class II ..........safety alert symbol

....................Construction

..........

earthing terminal

…/min..........revolutions or

reciprocation per minute

CAUTION: Use extra care when working into a corner because

a sudden, sharp movement of the grinder may be experienced

when the wheel or other accessory contacts a secondary surface

or a surface edge.

CAUTION: Wear appropriate personal hearing protection

during use. Under some conditions and duration of use, noise

from this product may contribute to hearing loss.

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chemicals known to cause cancer, birth defects, or other reproductive

harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to

filter out microscopic particles.

Page 5

English

3

ASSEMBLY AND ADJUSTMENTS

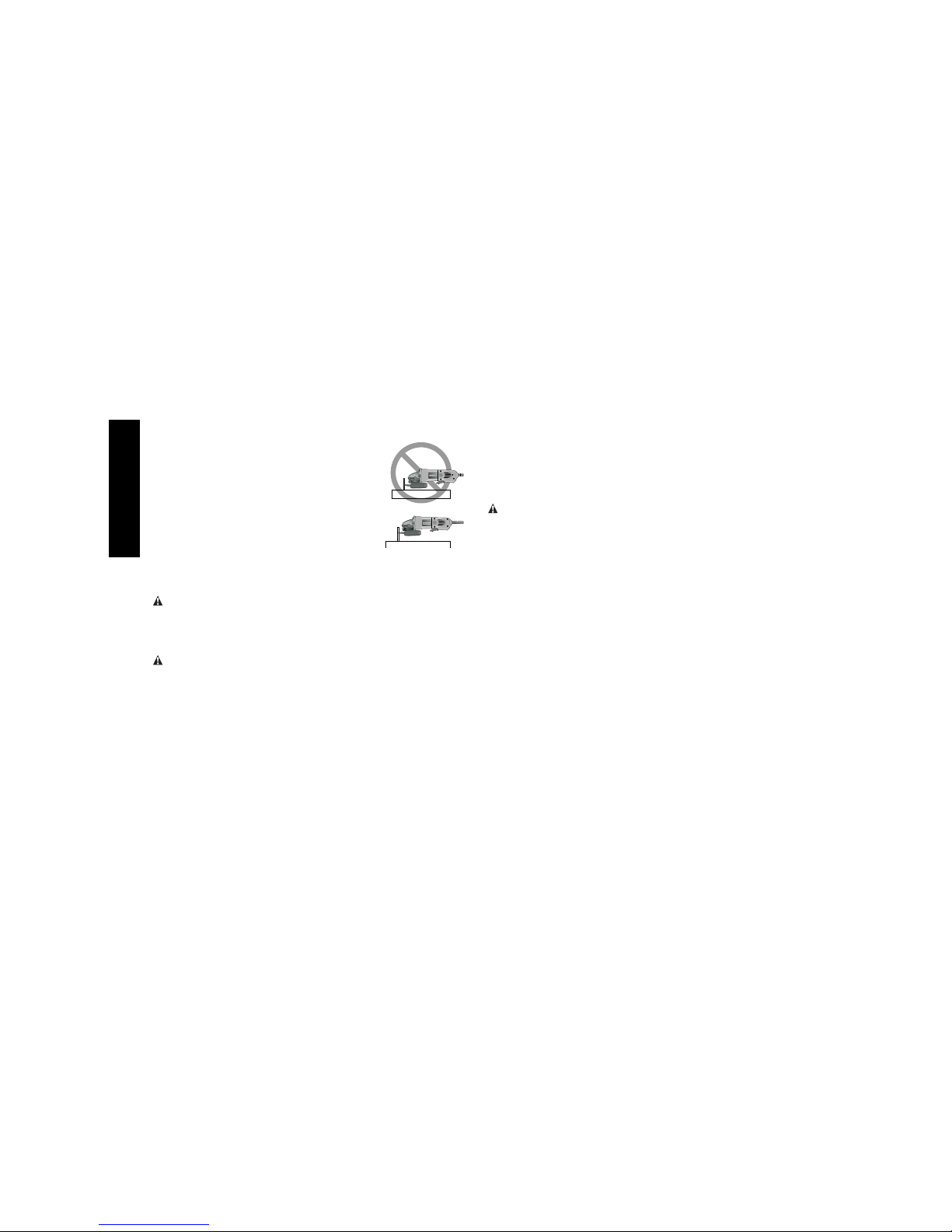

ATTACHING SIDE HANDLE

The side handle can be fitted to either side of the gear case in the

threaded holes, as shown. Before using the tool, check that the

handle is tightened securely. Use a wrench to firmly tighten the

side handle.

Accessories

It is important to choose the correct guards, backing pads and

flanges to use with grinder accessories. See pages 4-5 for information on choosing the correct accessories.

CAUTION: Accessories must be rated for at least the speed

recommended on the tool warning label. Wheels and other accessories running over rated accessory speed may fly apart and

cause injury. Threaded accessories must have a 5/8"-11 hub.

Every unthreaded accessory must have a 7/8" arbor hole. If it

does not, it may have been designed for a circular saw. Use only

the accessories shown on pages 4-5 of this manual. Accessory

ratings must be above listed minimum wheel speed as shown on

tool nameplate.

E

• Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction

activities. Wear protective clothing and wash exposed areas

with soap and water. Allowing dust to get into your mouth, eyes,

or lay on the skin may promote absorption of harmful chemicals.

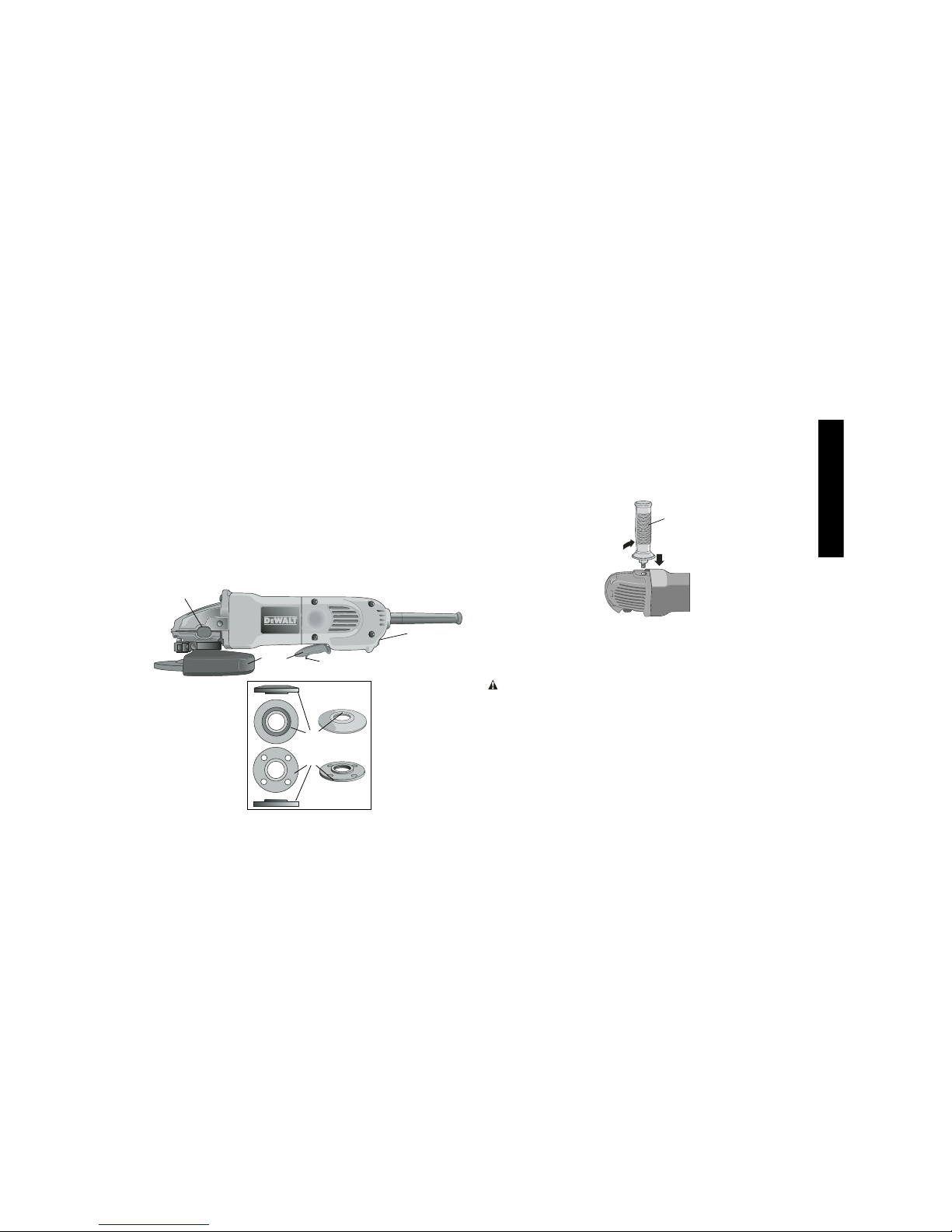

COMPONENTS

A. Paddle Switch F. Lock-On Button

B. Lock-Off Lever G. Unthreaded Backing Flange

C. Spindle Lock Button H. Threaded Clamp Nut

D. Spindle (not shown) I. Guard

E. Side Handle

(shown on the right)

H

A

B

C

F

G

I

Page 6

English

4

Type 27 guard

4 1/2" Grinding Wheels

unthreaded

backing flange

threaded clamp nut

Type 27 hubbed wheel

Type 27 guard

Type 27 depressed

center wheel

Wire Wheels

3" wire cup

brush

4" wire wheel

Type 27 guard

Type 27 guard

Page 7

English

5

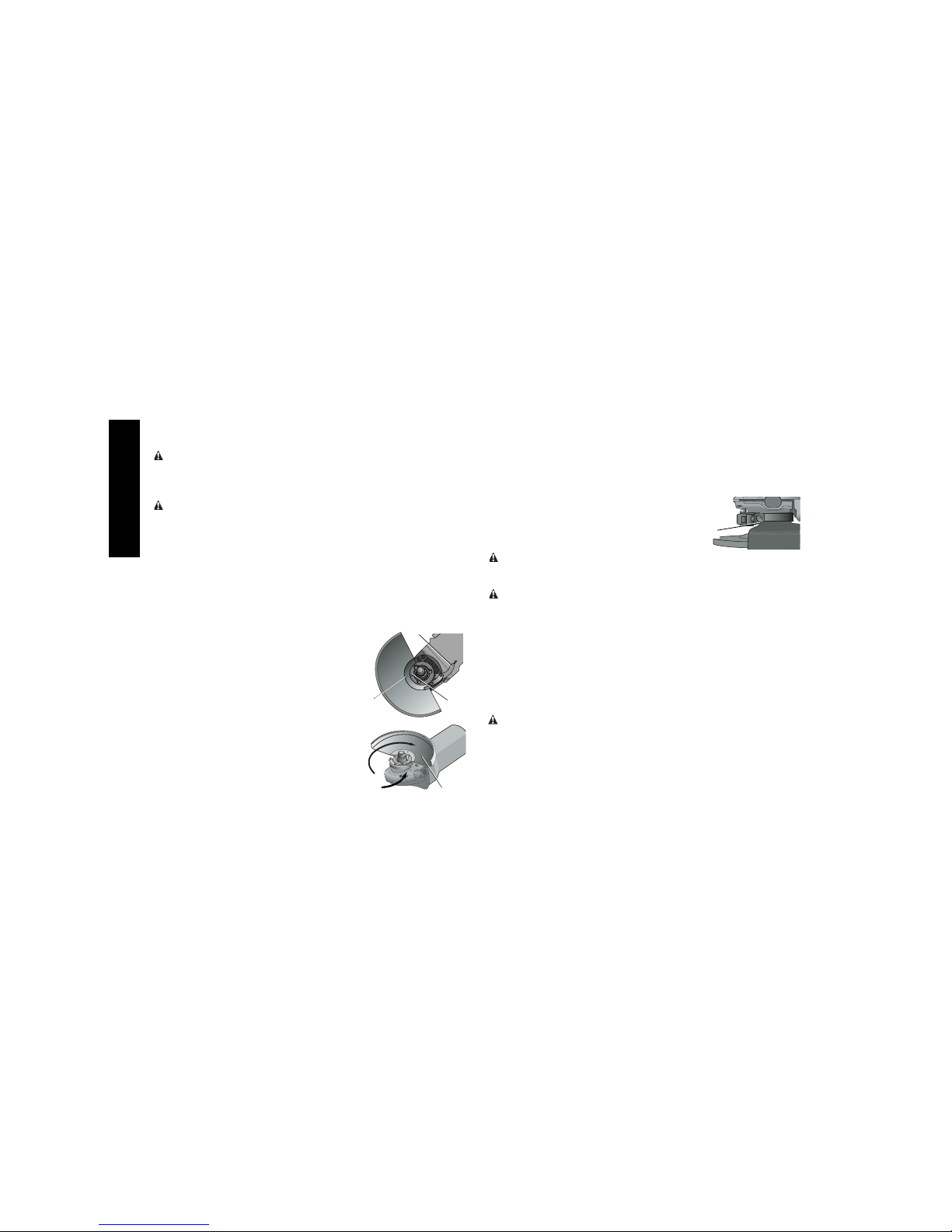

4 1/2" Sanding Flap Discs

hubbed sanding

flap disc

unthreaded backing

flange

non-hubbed sanding

flap disc

threaded clamp nut

rubber backing pad

sanding disc

threaded clamp nut

Sanding Discs

4 1/2" Cutting Wheels

Type 1 guard

backing flange

abrasive cutting wheel

clamp nut

Type 1 guard

backing flange

diamond cutting wheel

clamp nut

Type 27 guard

Type 27 guard

Page 8

English

6

Mounting Guard

MOUNTING AND REMOVING GUARD

CAUTION: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or accessories. Before reconnecting the tool, depress and release the

paddle switch to ensure that the tool is off.

CAUTION: Guards must be used with all grinding wheels,

sanding flap discs, wire brushes, and wire wheels. The tool

may be used without a guard only when sanding with conventional

sanding discs. D

E

WALT model DW802 is provided with a guard

intended for use with depressed center wheels (Type 27) and

hubbed grinding wheels (Type 27). The same guard is designed for

use with sanding flap discs (Type 27 and 29) and wire cup brushes. Grinding and cutting with wheels other than Type 27 and 29

require different accessory guards not included with tool. Mounting

instructions for these accessory guards are included in the accessory package.

1. Open the guard latch (J), and align the

arrow on the guard (K) with the arrow

on the hub (L). This will align the lugs

on the guard with the slots on the gear

case cover.

2. Push the guard down until the guard

lugs engage and rotate freely in the

groove on the gear case hub.

3. With the guard latch open, rotate the

guard (I) into the desired working position. The guard body should be positioned between the spindle and the

operator to provide maximum operator protection.

4. Close the guard latch to secure the guard on the gear case. You

should not be able to rotate the guard by hand when the latch is

closed. Do not operate the grinder with a loose guard or the

clamp lever in open position.

5. To remove the guard, open the guard latch, rotate the guard so

that the arrows are aligned and pull up on the guard.

NOTE: The guard is pre-adjusted to the

diameter of the gear case hub at the factory.

If, after a period of time, the guard becomes

loose, tighten the adjusting screw (M) with

clamp lever in the closed position.

CAUTION: Do not tighten the adjusting screw with the clamp

lever in open position. Undetectable damage to the guard or the

mounting hub may result.

CAUTION: If guard cannot be tightened by adjusting clamp, do

not use tool and take the tool and guard to a service center to repair

or replace the guard.

NOTE: Edge grinding and cutting can be performed with type 27

wheels designed and specified for this purpose; 1/4" thick wheels

are designed for surface grinding while 1/8" wheels are designed

for edge grinding.

OPERATION

Switch

CAUTION: Before connecting the tool to a power source

depress and release the paddle switch (A) once without depressing

the lock-on button (F) to ensure that the switch is off. Depress and

release the paddle switch as described above after any interruption

in power supply to the tool, such as the activation of a ground fault

interrupter, throwing of a circuit breaker, accidental unplugging, or

power failure. If the paddle switch is locked on, the tool will start

unexpectedly when it is reconnected.

M

I

J

L

K

Page 9

English

7

while the tool is operating because damage to the tool will result. To

engage the lock, depress the spindle lock button and rotate the

spindle until you are unable to rotate the spindle further.

Mounting and Using Depressed

Center Grinding Wheels and

Sanding Flap Discs

MOUNTING AND REMOVING HUBBED WHEELS

CAUTION: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or accessories. Before reconnecting the tool, depress and release the

paddle switch to ensure that the tool is off.

Hubbed wheels install directly on the 5/8"-11 threaded spindle.

1. Thread the wheel on the spindle by hand.

2. Depress the spindle lock button and use a wrench to tighten the

hub of the wheel.

3. Reverse the above procedure to remove the wheel.

CAUTION: Failure to properly seat the wheel before turning the

tool on may result in damage to the tool or the wheel.

MOUNTING NON-HUBBED WHEELS

CAUTION: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or accessories. Before reconnecting the tool, depress and release the

paddle switch to ensure that the tool is off.

Depressed center Type 27 grinding wheels

must be used with included flanges. See

page 5 of this manual for more information.

1. Install the unthreaded backing flange (G)

on spindle (D) with the raised section (pilot)

against the wheel.

CAUTION: Hold the side handle and body of the tool firmly to

maintain control of the tool at start up and during use and until the

wheel or accessory stops rotating. Make sure the wheel has come

to a complete stop before laying the tool down.

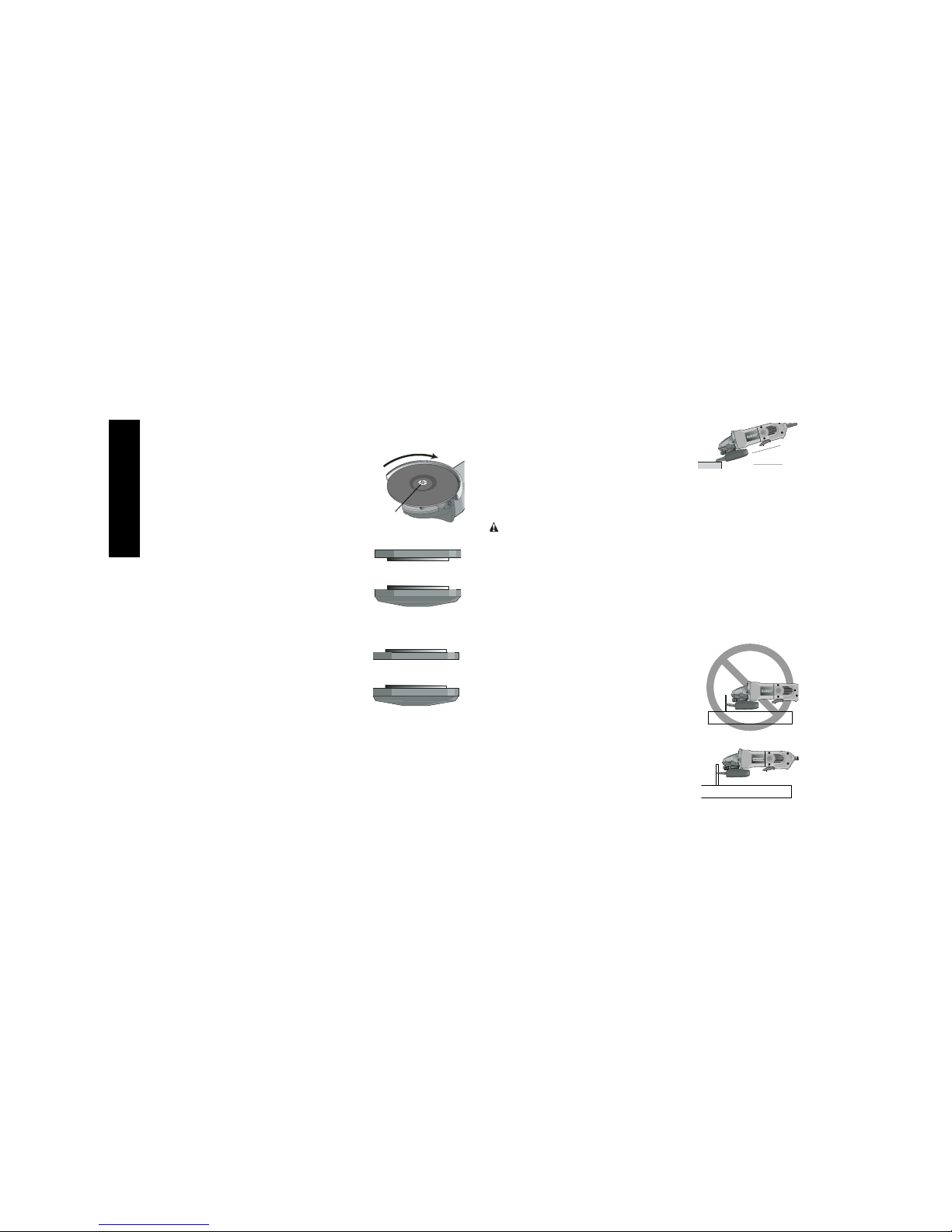

PADDLE SWITCH

To turn the tool on, push the lock-off

lever (B) toward the back of the tool,

then depress the paddle switch (A).

The tool will run while the switch is

depressed. Turn the tool off by

releasing the paddle switch.

WARNING: Do not disable the lock-off lever. If the lock-off lever

is disabled, the tool may start unexpectedly when it is laid down.

LOCK-ON BUTTON

The lock-on button offers increased comfort

in extended use applications. To lock the tool

on, push the lock-off lever (B) toward the

back of the tool then depress the paddle

switch (A). With the tool running, depress the

lock-on button (F). The tool will continue to

run after the paddle switch is released. To

unlock the tool, depress and release the paddle switch. This will cause the tool to stop.

CAUTION: Allow the tool to reach full speed before touching

tool to the work surface. Lift the tool from the work surface before

turning the tool off.

SPINDLE LOCK

The spindle lock pin is provided to prevent the spindle from rotating

when installing or removing wheels. Operate the spindle lock pin

only when the tool is turned off, unplugged from the power supply,

and has come to a complete stop. Do not engage the spindle lock

7

A

B

B

F

G

D

Page 10

English

8

2. Place wheel against the backing flange, centering the wheel on

the raised section (pilot) of the backing flange.

3. While depressing the spindle lock button, thread the clamp nut (H) on spindle. If the wheel you are installing is

more than 1/8" thick, place the threaded

clamp nut on the spindle so that the

raised section (pilot) fits into the center

of the wheel. If the wheel you are

installing is 1/8" thick or less, place the

threaded clamp nut on the spindle so

that the raised section (pilot) is not

against the wheel.

4. While depressing the spindle lock button, tighten the clamp nut with a wrench.

5. To remove the wheel, depress the spindle lock button and loosen the threaded

clamp nut with a wrench.

NOTE: If the wheel spins after the clamp nut

is tightened, check the orientation of the

threaded clamp nut. If a thin wheel is

installed with the pilot on the clamp nut

against the wheel, it will spin because the

height of the pilot prevents the clamp nut

from holding the wheel.

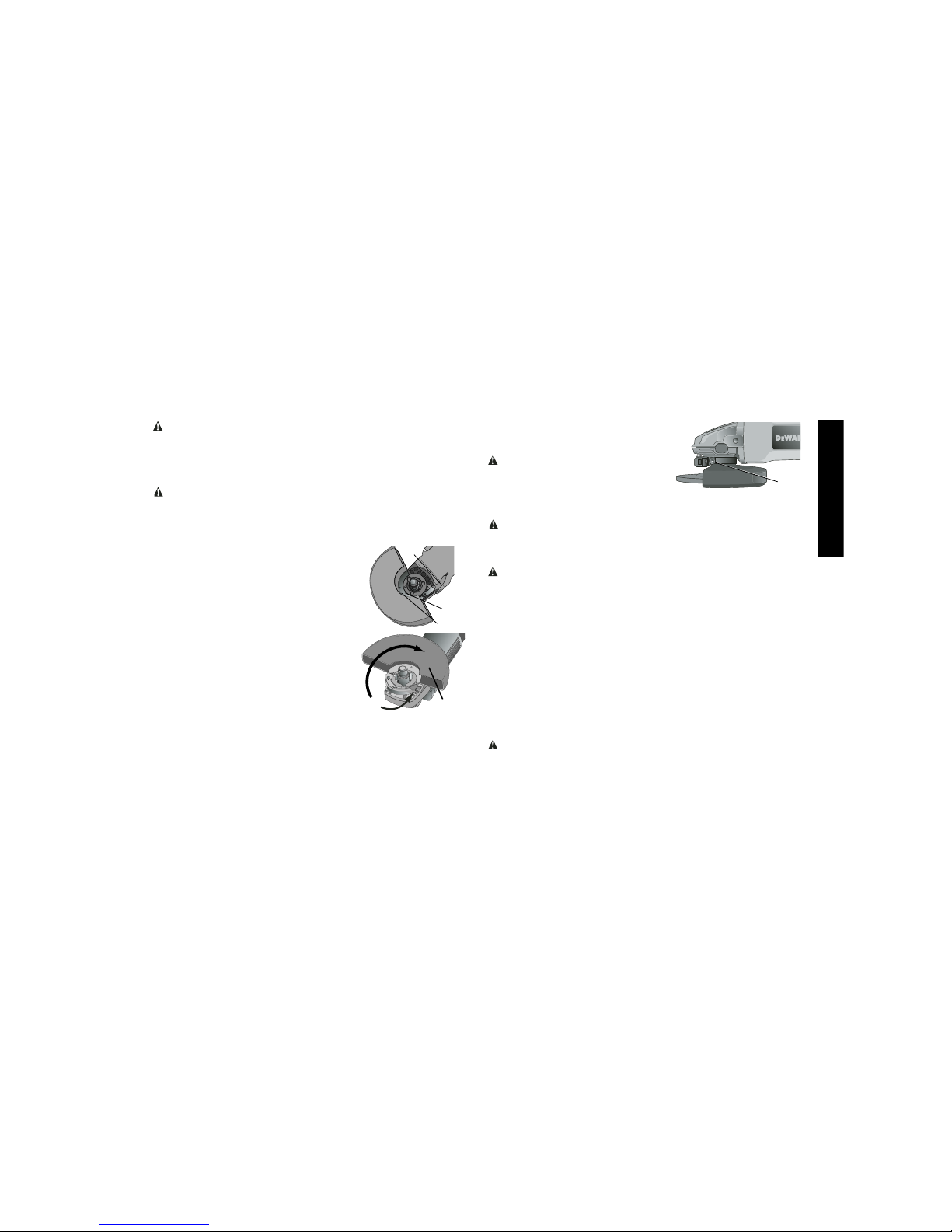

SURFACE GRINDING WITH GRINDING WHEELS

1. Allow the tool to reach full speed before touching the tool to the

work surface.

2. Apply minimum pressure to the work surface, allowing the tool

to operate at high speed. Grinding rate is greatest when the tool

operates at high speed.

3. Maintain a 20˚ to 30˚ angle between the

tool and work surface.

4. Continuously move the tool in a forward

and back motion to avoid creating gouges

in the work surface.

5. Remove the tool from work surface before turning tool off. Allow

the tool to stop rotating before laying it down.

EDGE GRINDING WITH GRINDING WHEELS

CAUTION: Wheels used for cutting and edge grinding may break

if they bend or twist while the tool is being used to do cut-off work or

deep grinding. To reduce the risk of serious injury, limit the use of

these wheels with a standard Type 27 guard to shallow cutting and

notching (less than 1/2" in depth). The open side of the guard must

be positioned away from the operator. For deeper cutting with a

Type 1 cut-off wheel, use a closed, Type 1 guard. See the chart on

pages 4-5 for more information. Type 1 guards are available at extra

cost from your local dealer or authorized service center.

1. Allow the tool to reach full speed before

touching the tool to the work surface.

2. Apply minimum pressure to the work

surface, allowing the tool to operate at

high speed. Grinding rate is greatest

when the tool operates at high speed.

3. Position yourself so that the openunderside of the wheel is facing away

from you.

4. Once a cut is begun and a notch is

established in the workpiece, do not

change the angle of the cut. Changing

the angle will cause the wheel to bend

and may cause wheel breakage. Edge

1/4" WHEELS

1/8" WHEELS

H

20˚-30˚

Backing Flange

Clamp Nut

Backing Flange

Clamp Nut

Page 11

English

9

1. Place or appropriately thread backing

pad (N) on the spindle.

2. Place the sanding disc (O) on the backing pad (N).

3. While depressing spindle lock, thread

clamp nut (P) on spindle, piloting the

raised hub on the clamp nut into the

center of sanding disc and backing pad.

4. Tighten the clamp nut by hand. Then

depress the spindle lock button while

turning the sanding disc until the sanding disc and clamp nut are snug.

5. To remove the wheel, grasp and turn the backing pad and

sanding pad while depressing the spindle lock button.

USING SANDING BACKING PADS

Choose the proper grit sandpaper for your application. Sandpaper

is available in various grits. Coarse grits yield faster material

removal rates and a rougher finish. Finer grits yield slower material removal and a smoother finish.

Begin with coarse grit discs for fast, rough material removal.

Move to a medium grit paper and finish with a fine grit disc for

optimal finish.

Coarse 16 - 30 grit

Medium 36 - 80 grit

Fine Finishing 100 - 120 grit

Very Fine Finishing 150 - 180 grit

1. Allow the tool to reach full speed before touching tool to the work

surface.

2. Apply minimum pressure to work surface, allowing the tool to

operate at high speed. Sanding rate is greatest when the tool

operates at high speed.

grinding wheels are not designed to withstand side pressures

caused by bending.

5. Remove the tool from the work surface before turning the tool

off. Allow the tool to stop rotating before laying it down.

WARNING: Do not use edge grinding/cutting wheels for surface

grinding applications because these wheels are not designed for

side pressures encountered with surface grinding. Wheel breakage

and injury may result

.

SURFACE FINISHING WITH SANDING FLAP DISCS

1. Allow the tool to reach full speed before touching the tool to the

work surface.

2. Apply minimum pressure to work surface, allowing the tool to

operate at high speed. Sanding rate is greatest when the tool

operates at high speed.

3. Maintain a 5˚ to 10˚ angle between

the tool and work surface.

4. Continuously move the tool in a

forward and back motion to avoid

creating gouges in the work surface.

5. Remove the tool from work surface before turning tool off. Allow

the tool to stop rotating before laying it down.

MOUNTING SANDING BACKING PADS

CAUTION: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or accessories. Before reconnecting the tool, depress and release the

paddle switch to ensure that the tool is off.

CAUTION: Proper guard must be reinstalled for grinding

wheel, sanding flap disc, wire brush or wire wheel applications

after sanding applications are complete.

P

N

O

5˚-10˚

Page 12

English

10

3. Maintain a 5˚ to 15˚ angle between the

tool and work surface. The sanding

disc should contact approximately

one inch of work surface.

4. Move the tool constantly in a straight

line to prevent burning and swirling of work surface. Allowing the

tool to rest on the work surface without moving, or moving the

tool in a circular motion causes burning and swirling marks on

the work surface.

5. Remove the tool from work surface before turning tool off. Allow

the tool to stop rotating before laying it down.

Mounting and Using Wire Brushes

and Wire Wheels

Wire cup brushes or wire wheels screw directly on the grinder spindle without the use of flanges. Use only wire brushes or wheels provided with a 5/8"-11 threaded hub. A Type 27 guard is required

when using wire brushes and wheels.

CAUTION: Wear work gloves when handling wire brushes

and wheels. They can become sharp.

CAUTION: Wheel or brush must not touch guard when mounted

or while in use. Undetectable damage could occur to the accessory,

causing wires to fragment from accessory wheel or cup.

MOUNTING WIRE CUP BRUSHES AND WIRE WHEELS

CAUTION: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or accessories. Before reconnecting the tool, depress and release the

paddle switch to ensure that the tool is off.

1. Thread the wheel on the spindle by hand.

2. Depress spindle lock button and use a wrench on the hub of the

wire wheel or brush to tighten the wheel.

3. To remove the wheel, reverse the above procedure.

CAUTION: Failure to properly seat the wheel hub before turning

the tool on may result in damage to tool or wheel.

USING WIRE CUP BRUSHES AND WIRE WHEELS

Wire wheels and brushes can be used for removing rust, scale and

paint, and for smoothing irregular surfaces.

1. Allow the tool to reach full speed before

touching the tool to the work surface.

2. Apply minimum pressure to work surface,

allowing the tool to operate at high speed.

Material removal rate is greatest when the

tool operates at high speed.

3. Maintain a 5˚ to 10˚ angle between the tool

and work surface for wire cup brushes.

4. Maintain contact between the edge of the wheel

and the work surface with wire wheels.

5. Continuously move the tool in a forward and

back motion to avoid creating gouges in the work

surface. Allowing the tool to rest on the work surface without

moving, or moving the tool in a circular motion causes burning

and swirling marks on the work surface.

6. Remove the tool from the work surface before turning the tool

off. Allow the tool to stop rotating before setting it down.

CAUTION: Use extra care when working over an edge, as a

sudden sharp movement of grinder may be experienced.

Mounting and Using Cutting

(Type 1) Wheels

Cutting wheels include diamond wheels and abrasive discs.

Abrasive cutting wheels for metal and concrete use are available.

Diamond blades for concrete cutting can also be used.

5˚-15˚

5˚-10˚

Page 13

English

11

loose, tighten the adjusting screw (M)

with the clamp lever in the closed

position.

CAUTION: Do not tighten adjust-

ing screw with clamp lever in open

position. Undetectable damage to

guard or mounting hub may result.

MOUNTING CUTTING WHEELS

CAUTION: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or accessories. Before reconnecting the tool, depress and release the

paddle switch to ensure that the tool is off.

CAUTION: Matching diameter threaded backing flange and

clamp nut (included with tool) must be used for cutting wheels.

1. Place the unthreaded backing flange on spindle with the raised

section (pilot) facing up. The raised section (pilot) on the backing

flange will be against the wheel when the wheel is installed.

2. Place the wheel on the backing flange, centering the wheel on

the raised section (pilot).

3. Install the threaded clamp nut with the raised section (pilot)

facing away from the wheel.

4. Depress the spindle lock button and tighten clamp nut with

a wrench.

5. To remove the wheel, grasp and turn while depressing the

spindle lock button.

USING CUTTING WHEELS

WARNING: Do not use edge grinding/cutting wheels for surface

grinding applications because these wheels are not designed for

side pressures encountered with surface grinding. Wheel breakage

and injury may result.

1. Allow tool to reach full speed before touching tool to work

surface.

WARNING: A closed, 2-sided cutting wheel guard is not included

with this tool but is required when using cutting wheels. Failure to

use proper flange and guard can result in injury resulting from wheel

breakage and wheel contact. See page 7 for more information.

MOUNTING CLOSED (TYPE 1) GUARD

CAUTION: Turn off and unplug the tool before making any

adjustments or removing or installing attachments or accessories. Before reconnecting the tool, depress and release the

paddle switch to ensure that the tool is off.

1. Open the guard latch (J), and align the

arrow on the guard (K) with the arrow

on the hub (L). This will align the lugs

with slots on the gear case cover.

Position the guard facing backward.

2. Push the guard down until the guard lug

engages and rotates freely in the

groove on the gear case hub.

3. Rotate guard (I) into desired working

position. The guard body should be

positioned between the spindle and the

operator to provide maximum operator

protection.

4. Close the guard latch to secure the

guard on the gear case cover. You

should be unable to rotate the guard by hand when the latch is

in closed position. Do not operate grinder with a loose guard or

clamp lever in open position.

5. To remove the guard, open the guard latch, rotate the guard so

that the arrows are aligned and pull up on the guard.

NOTE: The guard is pre-adjusted to the diameter of the gear case

hub at the factory. If, after a period of time, the guard becomes

M

J

L

K

I

Page 14

English

12

2. Apply minimum pressure to work surface, allowing tool to

operate at high speed. Cutting rate is

greatest when the tool operates at high

speed.

3. Once a cut is begun and a notch is estab-

lished in the workpiece, do not change the

angle of the cut. Changing the angle will

cause the wheel to bend and may cause

wheel breakage.

4. Remove the tool from work surface before

turning tool off. Allow the tool to stop rotating

before setting it down.

MAINTENANCE

Cleaning

WARNING: Blow dust and grit out of the motor housing regularly

using clean, dry compressed air. Dust and grit containing metal

particles often accumulate on interior surfaces and could create an

electrical shock hazard if not frequently cleaned out. ALWAYS

WEAR SAFETY GLASSES.

CAUTION: Never use solvents or other harsh chemicals

for cleaning the non-metallic parts of the tool. Use a clean, dry

cloth only.

Lubrication

DEWALT tools are properly lubricated at the factory and are ready

for use.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustment (including brush inspection and replacement)

should be performed by a D

EWALT factory service center, a

D

EWALT authorized service center or other qualified service per-

sonnel. Always use identical replacement parts.

Purchasing Accessories

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

need assistance in locating any accessory for your tool, please

contact D

EWALT Industrial Tool Co., 701 East Joppa Road,

Baltimore, MD 21286, call 1-800-4-D

EWALT (1-800-433-9258) or

visit our website www.dewalt.com.

CAUTION: The use of any other accessory not recommended

for use with this tool could be hazardous.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for three years from the date of purchase.

This warranty does not cover part failure due to normal wear or tool

abuse. For further detail of warranty coverage and warranty repair

information, visit www.dewalt.com or call 1-800-4-D

EWALT (1-800-

433-9258). This warranty does not apply to accessories or damage

caused where repairs have been made or attempted by others.

This warranty gives you specific legal rights and you may have

other rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT tools are covered by our:

1 YEAR FREE SERVICE

D

EWALT will maintain the tool and replace worn parts caused by

normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALT Power Tool, Laser, or Nailer for any reason, you can

return it within 90 days from the date of purchase with a receipt for

a full refund – no questions asked.

Page 15

English

13

LATIN AMERICA: This warranty does not apply to products sold in

Latin America. For products sold in Latin America, see country specific warranty information contained either in the packaging, call the

local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning labels

become illegible or are missing, call 1-800-4-D

EWALT for a free

replacement.

Page 16

Français

14

CONSERVER CES DIRECTIVES

AVERTISSEMENT! S’assurer de lire et de bien comprendre

toutes les directives, y compris celles fournies avec les

pièces et accessoires. Le non-respect des directives présentées

ci-dessous pourrait causer un choc électrique, un incendie et/ou

des blessures graves.

POUR TOUTE QUESTION OU REMARQUE AU SUJET DE CET

OUTIL OU DE TOUT AUTRE OUTIL D

EWALT, COMPOSER LE

NUMÉRO SANS FRAIS :

1 800 4-DEWALT (1 800 433-9258)

Directives de sécurité d’ordre général

AIRE DE TRAVAIL

• L’aire de travail doit être propre et bien éclairée. Les établis

encombrés et le manque de lumière peuvent entraîner des

accidents.

• Ne pas faire fonctionner des outils électriques dans des

atmosphères explosives, comme en présence de liquides,

de gaz et de poussières inflammables. Les outils électriques

produisent des étincelles qui peuvent enflammer la poussière

ou les vapeurs.

• Tenir les spectateurs, les enfants et les visiteurs à l’écart

lorsqu’on utilise l’outil. Les distractions peuvent entraîner

une perte de maîtrise.

RÈGLES DE SÉCURITÉ RELATIVES À L’ÉLECTRICITÉ

• Les outils mis à la terre doivent être branchés dans une

prise correctement installée et mise à la terre tel que

l’indiquent les codes et règlements en vigueur. Ne jamais

retirer la broche de mise à la terre ou modifier la prise en

aucune façon. Ne pas utiliser de fiche d’adaptation.

Consulter un électricien qualifié s’il y a un doute en ce qui

concerne la mise à la terre de la prise. En cas de mauvais

fonctionnement ou de bris des outils, la mise à la terre offre un

chemin de faible résistance afin d’empêcher l’électrocution de

l’utilisateur. S’applique uniquement aux outils de classe I

(mis à la terre).

• Les outils à double isolation sont pourvus d’une fiche

polarisée (une lame est plus large que l’autre). Cette fiche

ne peut être branchée dans une prise polarisée que dans

un seul sens. Si la fiche ne peut être branchée dans la

prise, inverser la fiche. Si on n’arrive toujours pas à la

brancher, communiquer avec un électricien qualifié afin

qu’il installe une prise polarisée. Ne pas modifier la fiche.

La double isolation évite de recourir à une rallonge d’alimentation trifilaire et à un bloc d’alimentation mis à la terre.

S’applique uniquement aux outils de classe II (à double

isolation).

• Éviter tout contact corporel avec des surfaces mises à la

terre, comme des tuyaux, des radiateurs, des cuisinières

et des réfrigérateurs. Le risque de choc électrique augmente

si le corps est mis à la terre.

• Ne pas exposer les outils électriques à la pluie ni à l’eau.

Si de l’eau pénètre dans un outil électrique, le risque d’électrocution augmente.

• Manipuler le cordon avec soin. Ne jamais s’en servir pour

transporter l’outil ou pour tirer la fiche hors de la prise. Tenir

le cordon à l’écart de la chaleur, de l’huile, des arêtes vives

ou des pièces mobiles. Remplacer immédiatement les cordons endommagés car ils augmentent le risque d’électrocution.

• Lorsqu’on utilise un outil électrique à l’extérieur, il faut

employer une rallongeportant l’inscription “W-A” ou “W.”

Ces rallonges sont conçues pour l’utilisation à l’extérieur et

réduisent le risque d’électrocution.

Page 17

Français

15

Calibre minimal des cordons de rallonge

Tension Longueur totale du cordon en mètres

120 V De 0 à 7 De 7 à 15 De 15 à 30 De 30 à 45

240 V De 0 à 7 De 7 à 15 De 15 à 39 De 30 à 45

Intensité (A)

Au Au Calibre moyen de fil

moins plus

6 - 10 18 16 14 12

SÉCURITÉ PERSONNELLE

• Demeurer alerte, prêter attention à ce que l’on fait et faire

preuve de bons sens lorsqu’on utilise un outil électrique.

Ne pas utiliser un outil lorsqu’on ressent de lafatigue ou

après avoir consommé des drogues, de l’alcool ou

desmédicaments. Un moment d’inattention durant l’utilisation

d’outils électriques peut entraîner de graves blessures.

• Porter des vêtements appropriés. Ne pas porter de

vêtements amples ni de bijoux. Attacher les cheveux longs.

Tenir les cheveux, les vêtements et les gants à l’écart des

pièces mobiles. Les vêtements amples, les bijoux et les

cheveux longs peuvent être happés par des pièces mobiles. Il

faut également se tenir à l’écart des évents qui recouvrent

souvent les pièces mobiles.

• Éviter le démarrage accidentel. S’assurer que l’interrupteur

est en position d’arrêt avant de brancher l’outil.Le fait de

transporter un outil en appuyant sur la gâchette ou de le

brancher lorsque l’interrupteur se trouve en position de marche

peut causer des accidents.

• Déposer les clés de réglage ou de serrage avant de mettre

l’outil sous tension. Si une clé demeure fixée à une pièce

rotative de l’outil, des blessures peuvent survenir.

• Ne pas tendre le bras trop loin. Il faut demeurer en équilibre

en tout temps. Un bon équilibre permet une meilleure maîtrise

de l’outil dans les situations inattendues.

• Utiliser du matériel de sécurité. Toujours porter des

lunettes de protection. Il faut utiliser, au besoin, un masque

anti-poussières, des chaussures de sécurité antidérapantes, un

casque de sécurité ou des protecteurs d’oreilles.

UTILISATION DES OUTILS ET PRÉCAUTIONS

• Utiliser des pinces ou un autre moyen pratique de fixer et de

soutenir la pièce à travailler sur une plateforme stable. Le fait

de tenir la pièce avec la main ou de l’appuyer contre le corps ne

permet pas de la stabiliser et cela risque de causer une perte de

maîtrise.

• Ne pas forcer l’outil. Utiliser celui qui convient au travail à

effectuer. L’outil adéquat permet de faire le travail de façon plus

convenable et sûre lorsqu’il est employé suivant l’utilisation pour

laquelle il a été conçu.

• Ne pas utiliser l’outil si l’interrupteur ne permet pas de le

mettre sous ou hors tension. Tout outil impossible à

commander au moyen de l’interrupteur est dangereux et doit

être réparé.

• Débrancher la fiche de la source d’alimentation avant

d’effectuer des réglages, de changer d’accessoire ou de

ranger l’outil. De telles mesures préventives réduisent le risque

de le mettre en marche accidentellement.

• Ranger les outils hors de la portée des enfants et des autres

personnes non qualifiées. Les outils sont dangereux entre les

mains d’utilisateurs non qualifiés.

• Veiller à entretenir correctement les outils. Affûter et

nettoyer les accessoires de coupe. Des outils bien

entretenus, et dont les arêtes sont coupantes, sont moins

susceptibles de se coincer et sont plus faciles à manier.

• Vérifier la présence de pièces mobiles mal alignées ou

coincées, de pièces brisées ou de toute autre condition

pouvant nuire au fonctionnement de l’outil. Si l’outil est

Page 18

Français

16

endommagé, il faut le faire réparer avant de l’utiliser. De

nombreux accidents sont causés par des outils mal entretenus.

• Utiliser seulement des accessoires recommandés par le

fabricant du modèle. Des accessoires convenant à un outil

peuvent être dangereux lorsqu’on les installe sur un autre outil.

RÉPARATION

• Seules des personnes qualifiées peuvent réparer les outils. Une réparation ou un entretien effectué par une personne

non qualifiée risque d’entraîner des blessures.

• Il faut utiliser uniquement des pièces de rechange identiques pour réparer un outil. Suivre les directives figurant

dans la section Entretien du présent manuel. L’emploi de

pièces inadéquates ou le non-respect des directives d’entretien

peut provoquer un choc électrique ou des blessures.

Consignes de sécurité particulières

relatives aux meuleuses

• Utiliser toujours le protecteur convenant à la meule. Il pro-

tège l’utilisateur contre les projections de fragments en cas de

bris et empêche tout contact avec la meule.

• Les accessoires doivent être conçus au moins pour le

régime recommandé sur l’étiquette d’avertissement de

l’outil. Les meules et autres accessoires tournant à un régime

supérieur à la vitesse nominale peuvent se désintégrer et

causer des blessures. Le régime nominal des accessoires doit

être supérieur à la vitesse minimale de la meule, telle

qu’indiquée sur la plaque signalétique de l’outil.

• Tenir l’outil par les surfaces de saisie isolées pour les

travaux où l’outil de coupe risque de toucher à des fils

dissimulés ou au cordon d’alimentation. Tout contact avec un

fil “sous tension” provoquera “l’électrisation“ des parties

métalliques exposées et l’électrocution de l’utilisateur.

• Ne pas utiliser des meules de type 11 (meules boisseaux

coniques) sur cet outil. L’utilisation d’accessoires non

appropriés pourrait causer des blessures.

• Avant d’utiliser les accessoires recommandés, s’assurer

qu’ils ne présentent aucune fissure ou défectuosité. Si une

fissure ou défectuosité est évidente, mettre l’accessoire au

rebut. Il faut également vérifier l’accessoire si l’on

soupçonne que l’outil a subi une chute. Un accessoire

défectueux pourrait entraîner le bris de la meule.

• Lorsqu’on démarre l’outil après y avoir installé une meule

ou une brosse métallique, neuve ou de rechange, tenir

l’outil dans un endroit bien protégé et le faire fonctionner

pendant une minute. Si la meule comporte une fissure ou une

défectuosité non détectée, elle devrait se désintégrer en moins

d’une minute. S’il y a des fils lâches dans la brosse métallique,

ils seront détectés. Ne jamais mettre l’outil en marche lorsqu’une

personne est placée dans l’axe de la meule. Cette mesure

s’applique également à l’utilisateur.

• Éviter de faire rebondir la meule ou de l’utiliser de façon

abusive. Si cela se produit, arrêter l’outil et vérifier s’il y a

présence de fissure ou de défectuosité.

• Orienter les étincelles dans la direction opposée à

l’utilisateur et aux autres personnes présentes ou de tout

matériau inflammable. L’utilisation d’une meuleuse ou d’une

ponceuse peut produire des étincelles qui risquent de causer des

brûlures ou des incendies.

• Utiliser toujours la poignée latérale et la serrer solidement.

Il faut toujours se servir de la poignée latérale pour maîtriser

l’outil en tout temps.

• Ne pas utiliser cet outil pendant des périodes prolongées.

Les vibrations causées par l’action de fonctionnement de l’outil

peuvent blesser en permanence les doigts, les mains et les

Page 19

Français

17

bras. Porter des gants pour amortir les vibrations, faire des

pauses fréquentes et limiter le temps d’utilisation quotidien de

l’outil.

• Nettoyer l’outil fréquemment, plus particulièrement s’il est

soumis à une utilisation intensive. De la poussière contenant

des particules métalliques s’accumule souvent sur les surfaces

intérieures et pourrait provoquer un choc électrique.

• L’étiquette apposée sur l’outil peut comprendre les symboles

suivants :

V ..............volts

A ..............ampères

Hz ............hertz

W ............watts

min ..........minutes

............courant alternatif

........courant direct

n

o ............régime sans charge

............

fabrication de classe II

............symbole d’alerte relative à la sécurité

............

borne de mise à la terre

…/min ......mouvement alternatif ou tours par minute

MISE EN GARDE : Le meulage à l’intérieur d’un angle peut

créer un soudain mouvement brusque de l’outil si la meule ou un

autre accessoire touche à une surface secondaire ou à toute autre

surface. Il faut donc être très vigilant.

MISE EN GARDE : Porter des protecteurs d’oreilles

appropriés durant l’utilisation. Selon les conditions et la durée

d’utilisation, le bruit émis par cet outil peut causer une perte auditive.

AVERTISSEMENT : Certaines poussières créées par le

ponçage, le sciage, le meulage et le forage mécanique ainsi que

d’autres activités de construction contiennent des produits

chimiques susceptibles de causer le cancer, des anomalies

congénitales ou d’autres anomalies liées à la reproduction. Parmi

ces produits chimiques, citons notamment :

• le plomb des peintures au plomb;

• la silice cristalline provenant des briques, du béton et autres

matériaux de maçonnerie;

• l’arsenic et le chrome provenant du bois traité (arséniate de

cuivre et de chrome).

Le risque associé à ces expositions varie selon la fréquence de ces

types de travaux. Pour réduire l’exposition aux produits chimiques :

travailler dans un local bien ventilé et utiliser du matériel de sécurité

approuvé, comme les masques anti-poussières spécialement

conçus pour filtrer les particules microscopiques.

• Éviter le contact prolongé avec la poussière provenant du

ponçage, du sciage, du meulage et du forage mécanique

ainsi que d’autres activités de construction. Porter des

vêtements de protection et laver les parties exposées au

savon et à l’eau. La poussière qui pourrait pénétrer dans la

bouche et les yeux ou se déposer sur la peau peut favoriser

l’absorption de produits chimiques nocifs.

Page 20

Français

18

ASSEMBLAGE ET RÉGLAGES

FIXATION DE LA POIGNÉE LATÉRALE

La poignée latérale peut être fixée dans les orifices filetés situés sur

un côté ou l’autre du carter d’engrenage, comme le montre

l’illustration. Avant d’utiliser l’outil, s’assurer que la poignée est bien

serrée. Utiliser une clé pour la serrer fermement.

Accessoires

Il est important de choisir les écrans protecteurs, plateaux portedisque et brides qui conviennent aux accessoires de meulage. Voir

les pages 19 et 20 pour obtenir plus de renseignements quant aux

accessoires appropriés.

MISE EN GARDE : Les accessoires doivent être conçus au moins

pour le régime recommandé sur l’étiquette d’avertissement de l’outil.

Les meules et autres accessoires tournant à un régime supérieur à la

vitesse nominale des accessoires peuvent se désintégrer et causer

des blessures. Les accessoires filetés doivent être montés sur un

moyeu de 5/8 po-11. Tous les accessoires non-filetés doivent avoir un

orifice d’arbre de 7/8 po. Si ce n’est pas le cas, il est possible qu’ils

aient été conçus pour une scie circulaire. Utiliser uniquement les

accessoires illustrés aux pages 19 et 20 du présent manuel. Le

régime nominal des accessoires doit être supérieur à la vitesse

minimale de la meule, telle qu’indiquée sur la plaque signalétique de

l’outil.

E

COMPOSANTES

A. Interrupteur à palette F. Bouton de verrouillage

B. Levier de déverrouillage G. Bride de support non-filetée

C. Bouton de verrouillage H. Écrou de la bride filetée

de la broche I. Protecteur

D. Broche (non illustrée)

E. Poignée latérale

(illustrée à droite)

H

A

B

C

F

G

I

Page 21

Français

19

Protecteur de

type 27

Meules de 4 1/2 po

Bride de support

non filetée

Écrou de bride filetée

Meule à moyeu

de type 27

Protecteur de

type 27

Meule à moyeu

déporté de type 27

Brosses métalliques circulaires

Brosse forme

coupelle de 3 po

Meule métallique

de 4 po

Protecteur de

type 27

Protecteur de

type 27

Page 22

Français

20

Disques de ponçage

de 4 1/2 po

Disque de

ponçage à moyeu

Bride de support non

filetée

Disque de ponçage

sans moyeu

Écrou de bride filetée

Plateau porte-disque

en caoutchouc

Disque de ponçage

Écrou de bride filetée

Disques de

ponçage

Meules à tronçonner de 4 1/2 po

Protecteur de type 1

Bride de support

Meules abrasives à

tronçonner

Écrou de bride

Protecteur de type 1

Bride de support

Meules à diamant à

tronçonner

Écrou de bride

Protecteur de type 27

Protecteur de type 27

Page 23

Français

21

Installation du protecteur

INSTALLATION ET DÉPOSE DU PROTECTEUR

MISE EN GARDE : Mettre l’outil hors tension et le débrancher

avant d’y apporter des réglages, de retirer ou d’installer des

accessoires. Avant de brancher l’outil à nouveau, appuyer sur

l’interrupteur à palette, puis le relâcher pour s’assurer que

l’outil est bien hors tension.

MISE EN GARDE : Le protecteur doit être utilisé avec les

meules, les disques de ponçage, les brosses métalliques ou les

brosses métalliques circulaires. Il est possible d’utiliser l’outil sans

le protecteur pour le ponçage avec des disques ordinaires. Le

modèle DW802 de D

E

WALT comprend un protecteur que l’on doit

utiliser pour les travaux exigeant une meule à moyeu déporté (de

type 27) ou une meule montée sur moyeu (de type 27). Ce même

protecteur est conçu pour être utilisé avec les disques de ponçage

(de type 27 et 29) et les brosses forme coupelle. Un protecteur de

modèle différent et non compris avec l’outil est requis pour le

meulage ou le tronçonnage à l’aide de meules autres que celles de

type 27 et 29. Les directives d’installation sont comprises dans

l’emballage de ces protecteurs et accessoires.

1. Ouvrir le verrou du protecteur (J) et

aligner la flèche du protecteur (K) avec

celle du moyeu (L). Ceci permettra

d’aligner les pattes du protecteur avec

les fentes sur le couvercle du carter

d’engrenage.

2. Abaisser le protecteur jusqu’à ce que

les pattes s’enclenchent et tournent

librement dans la rainure sur le moyeu

du carter d’engrenage.

3. Alors que le verrou du protecteur est

ouvert, tourner le protecteur (I) jusqu’à

ce qu’il soit à la position désirée. Le

corps du protecteur doit être placé

entre la broche et l’utilisateur de sorte

que ce dernier soit bien protégé.

4. Fermer le verrou du protecteur pour le fixer sur le carter

d’engrenage. Lorsque le verrou est bien fermé, il ne sera pas

possible de faire tourner le protecteur manuellement. Ne pas

utiliser la meuleuse si le protecteur n’est pas bien serré ou si le

levier de la bride est en position ouverte.

5. Pour retirer le protecteur, ouvrir le verrou, tourner le protecteur de

sorte que les flèches soient alignées et tirer le protecteur vers le

haut.

NOTA : Le protecteur est réglé en usine

selon le diamètre du moyeu du carter

d’engrenage. Si le protecteur se desserre

après un certain temps, serrer la vis de

réglage (M) alors que le levier de la bride est

en position fermée.

MISE EN GARDE : Ne pas serrer la vis de réglage si le levier de

la bride est en position ouverte. Ceci risquerait de causer des

dommages invisibles au protecteur ou au moyeu.

MISE EN GARDE : S'il est impossible de serrer le protecteur en

réglant la bride, ne pas utiliser d'outil; apporter l'outil et le protecteur à

un centre de service afin d'y faire réparer ou remplacer le protecteur.

NOTA : Le tronçonnage et le découpage peuvent être effectués

avec des meules de type 27 conçues spécifiquement pour ce genre

de travail; le meulage de surface s’effectue à l’aide de meules de 1/4

po alors que le tronçonnage s’effectue à l’aide de meules de 1/8 po.

M

I

J

L

K

Page 24

Français

22

BOUTON DE VERROUILLAGE

Le bouton de verrouillage offre un plus

grand confort quand le travail demande plus

de temps. Pour verrouiller l’outil, ramener le

levier de déverrouillage (B) vers l’arrière,

puis enfoncer l’interrupteur à palette (A).

Lorsque l’outil est en marche, enfoncer le

bouton de verrouillage (F). L’outil continuera

de fonctionner une fois que l’interrupteur

sera relâché. Pour déverrouiller l’outil, appuyer sur l’interrupteur et

le relâcher. L’outil s’arrêtera.

MISE EN GARDE : Laisser l’outil atteindre le régime maximal

avant qu’il ne touche à la surface de travail. Il faut lever l’outil de la

surface de travail avant de le mettrehors tension.

VERROUILLAGE DE LA BROCHE

La tige de verrouillage de la broche sert à éviter que la broche ne

tourne pendant l’installation ou le retrait des meules. Actionner la

tige de verrouillage de la broche seulement quand l’outil est hors

tension, qu’il est débranché de la source d’alimentation et qu’il a

complètement cessé de tourner. Ne pas enclencher le verrou de la

broche quand l’outil est en marche car ceci l’endommagerait. Pour

enclencher le verrou, enfoncer le bouton de verrouillage de la

broche et la tourner jusqu’à ce qu’elle ne puisse tourner davantage.

Installation et utilisation de meules à

moyeu déporté et de disques de ponçage.

INSTALLATION ET DÉPOSE DES ROUES À MOYEU

MISE EN GARDE : Mettre l’outil hors tension et le débrancher

avant de procéder au réglage, à la dépose ou à l’installation des

pièces et accessoires. Avant de brancher l’outil à nouveau,

appuyer sur l’interrupteur à palette et le relâcher pour s’assurer

que l’outil est hors tension.

FONCTIONNEMENT

Interrupteur

MISE EN GARDE : Avant de brancher l’outil à une source

d’alimentation, appuyer une fois sur l’interrupteur à palette (A) et le

relâcher sans enfoncer le bouton de verrouillage (F) pour s’assurer

que l’outil est hors tension. Après toute interruption de l’alimentation

de l’outil provoquée par le déclenchement du disjoncteur de fuite à

la terre ou d’un autre disjoncteur, le débranchement par

inadvertance ou la perte de courant, appuyer sur l’interrupteur à

palette et le relâcher tel qu’indiqué précédemment. L’outil démarrera

automatiquement au moment du branchement si l’interrupteur est

en position de marche.

MISE EN GARDE : Saisir la poignée latérale et le corps de l’outil

fermement pour maîtriser l’outil au démarrage, pendant l’utilisation

et jusqu’à ce que la meule ou l’accessoire utilisé ait cessé de

tourner. S’assurer que le mouvement de la meule ait cessé

complètement avant de déposer l’outil.

INTERRUPTEUR À PALETTE

Pour mettre l’outil en marche,

ramener le levier de déverrouillage

(B) vers l’arrière, puis enfoncer

l’interrupteur à palette (A). L’outil

fonctionnera pendant que

l’interrupteur est enfoncé. Pour

arrêter l’outil, relâcher l’interrupteur.

AVERTISSEMENT:Ne pas démonter le levier de déverrouillage.

L’outil pourrait se mettre en marche soudainement en le déposant

si le levier de déverrouillage était démonté.

22

A

B

B

F

Page 25

Français

23

Les meules montées sur moyeu s’installent directement sur une

broche filetée de 5/8 po-11.

1. Visser manuellement la meule sur la broche.

2. Enfoncer le bouton de verrouillage de la broche et utiliser une clé

pour serrer le moyeu de la meule.

3. Effectuer la procédure inverse pour retirer la meule.

MISE EN GARDE : Afin de ne pas endommager la meule ou

l’outil, s’assurer que la meule est bien en place avant de mettre l’outil

sous tension.

INSTALLATION DE MEULES SANS MOYEU

MISE EN GARDE : Mettre l’outil hors tension et le débrancher

avant de procéder au réglage, à la dépose ou à l’installation des

pièces et accessoires. Avant de brancher l’outil à nouveau,

appuyer sur l’interrupteur à palette et le relâcher pour s’assurer

que l’outil est hors tension.

Utiliser les brides fournies pour l’utilisation des

meules de type 27 à moyeu déporté. Voir la

page 21 du présent manuel pour obtenir plus

de précisions.

1. Installer la bride de support non-filetée (G)

sur la broche (D) en plaçant la section

surélevée (guide) contre la meule.

2. Placer la meule contre la bride de support et centrer la meule sur

la section surélevée (guide) de la bride de support.

3. Tout en appuyant sur le bouton de

verrouillage de la broche, visser l’écrou

de la bride (H) sur la broche. Si la meule

utilisée est d’une épaisseur supérieure à

1/8 po, placer l’écrou de la bride filetée

sur la broche de sorte que la section

surélevée (guide) s’ajuste dans le

centre de la meule. Si la meule utilisée

est d’une épaisseur de 1/8 po ou moins,

placer l’écrou de la bride filetée sur la

broche de sorte que la section

surélevée (guide) ne repose pas contre

la meule.

4. Tout en appuyant sur le bouton de

verrouillage de la broche, visser l’écrou

de la bride au moyen d’une clé.

5. Pour retirer la meule, appuyer sur le

bouton de verrouillage de la broche et

desserrer l’écrou de la bride filetée au

moyen d’une clé.

NOTA : Si la meule tourne une fois que

l’écrou de la bride est serré, vérifier

l’orientation de l’écrou de la bride filetée. Si une meule mince est

installée et que le guide de l’écrou de la bride est placé contre la

meule, celle-ci pourra tourner car la hauteur du guide ne permettra

pas à l’écrou de la retenir.

MEULAGE DE SURFACE AU MOYEN DE MEULES

1. Laisser l’outil atteindre le régime maximal avant qu’il ne touche

à la surface de travail.

2. Exercer peu de pression sur la surface de travail de sorte que

l’outil puisse fonctionner à régime élevé. La vitesse de meulage

est supérieure quand l’outil fonctionne à régime élevé.

3. Conserver un angle de 20˚ à 30˚ entre

l’outil et la surface de travail.

4. Pour ne pas creuser la surface de travail

par endroits, déplacer l’outil en un

mouvement continu de va-et-vient.

MEULES DE 1/4 PO

MEULES DE 1/8 PO

H

20˚-30˚

Bride de support

Écrou de bride

Bride de support

Écrou de bride

G

D

Page 26

Français

24

tronçonner ne sont pas conçues pour résister aux pressions

latérales créées par la torsion.

5. Soulever l’outil de la surface de travail avant de le mettre hors

tension. Attendre que l’outil ne soit plus en rotation avant de le

déposer.

AVERTISSEMENT : Ne pas utiliser de meules à tronçonner ou à

découper pour les travaux de meulage de surface. Ces meules ne

sont pas conçues pour les travaux de meulage où une pression

latérale est exercée. La meule risquerait de se briser et de causer

des blessures

.

FINITION DE SURFACE AU MOYEN DE DISQUES DE

PONÇAGE

1. Laisser l’outil atteindre le régime maximal avant qu’il ne touche

à la surface de travail.

2. Exercer peu de pression sur la surface de travail de sorte que

l’outil puisse fonctionner à régime élevé. La vitesse de ponçage

est supérieure quand l’outil fonctionne à régime élevé.

3. Conserver un angle de 5˚ à 10˚ entre

l’outil et la surface de travail.

4. Pour ne pas creuser la surface de

travail par endroits, déplacer l’outil en

un mouvement continu de va-et-vient.

5. Soulever l’outil de la surface de travail avant de le mettre hors

tension. Attendre que l’outil ne soit plus en rotation avant de le

déposer.

INSTALLATION DES PLATEAUX PORTE-DISQUE

MISE EN GARDE : Mettre l’outil hors tension et le débrancher

avant de procéder au réglage, à la dépose ou à l’installation des

pièces et accessoires. Avant de brancher l’outil à nouveau,

appuyer sur l’interrupteur à palette et le relâcher pour s’assurer

que l’outil est hors tension.

5. Soulever l’outil de la surface de travail avant de le mettre hors

tension. Attendre que l’outil ne soit plus en rotation avant de le

déposer.

TRONÇONNAGE AU MOYEN DE MEULES

MISE EN GARDE : Les meules utilisées pour le découpage ou

le tronçonnage peuvent s’effriter ou se briser si elles se tordent ou

se déforment pendant leur utilisation pour le découpage ou le

meulage en profondeur. Afin de réduire les risques de blessures,

n’utiliser ces meules qu’avec le protecteur standard de type 27

pour légers travaux de découpage ou d’entaillage (de moins de 1/2

po de profondeur). Le côté ouvert du protecteur doit être placé à

l’opposé de l’utilisateur. Pour les travaux de découpage plus profond

au moyen d’une meule à tronçonner de type 1, utiliser un protecteur

fermé de type 1. Voir le tableau des pages 19 et 20 pour obtenir plus

de précisions. Les protecteurs de type 1 sont offerts, moyennant un

coût supplémentaire, chez votre détaillant ou centre de service

autorisé local.

1. Laisser l’outil atteindre le régime maximal

avant qu’il ne touche à la surface de

travail.

2. Exercer peu de pression sur la surface

de travail de sorte que l’outil puisse

fonctionner à régime élevé. La vitesse

de meulage est supérieure quand l’outil

fonctionne à régime élevé.

3. L’utilisateur doit se placer à l’opposé de

la partieouverte inférieure de la meule.

4. Ne pas modifier l’angle de coupe une fois

que l’ébauche du tronçon ou de l’entaille

est effectué sur la pièce. La meule risque

de se déformer et de s’effriter si l’on

modifie l’angle de coupe. Les meules à

5˚-10˚

Page 27

Français

25

MISE EN GARDE : Après avoir terminé le ponçage, il faut

replacer le protecteur approprié sur l’outil avant d’effectuer des

travaux de meulage avec une meule, un disque de ponçage ou une

brosse métallique.

1. Placer le plateau porte-disque (N) et le visser adéquatement sur

la broche.

2. Placer le disque de ponçage (O) sur le

plateau porte-disque (N).

3. En appuyant sur le verrou de la broche,

visser l’écrou de la bride (P) sur la broche,

en guidant le moyeu surélevé sur l’écrou

de la bride au centre du disque de

ponçage et du plateau porte-disque.

4. Serrer manuellement l’écrou de la

bride. Appuyer ensuite sur le bouton de

verrouillage de la broche tout en

tournant le disque de ponçage jusqu’à

que le disque et l’écrou de la bride soient bien ajustés.

5. Pour retirer la meule, saisir et faire tourner le plateau portedisque et le patin de ponçage tout en appuyant sur le bouton

de verrouillage de la broche.

UTILISATION DES PLATEAUX PORTE-DISQUE

Utiliser un papier de verre dont la grosseur des grains convient au

travail à effectuer. Le papier de verre est offert en différentes

grosseurs de grain. Les papiers de verre à gros grains effectuent le

travail plus rapidement et le fini est plus rugueux. Les papiers de

verre à grains fins effectuent le travail moins rapidement et le fini est

plus lisse.Commencer par un papier de verre à gros grains pour

enlever de la matière rapidement et grossièrement. Utiliser ensuite

un papier à grains moyens et terminer par un papier à grains fins

pour obtenir un fini plus lisse.

Grossier 16 à 30 grains

Moyen 36 à 80 grains

Finition - fins 100 à 120 grains

Finition lisse - très fins 150 à 180 grains

1. Laisser l’outil atteindre le régime maximal avant qu’il ne touche

à la surface de travail.

2. Exercer peu de pression sur la surface de travail de sorte que

l’outil puisse fonctionner à régime élevé. La vitesse de ponçage

est supérieure quand l’outil fonctionne à régime élevé.

3. Conserver un angle de 5˚ à 15˚ entre

l’outil et la surface de travail. Le disque

de ponçage doit être en contact avec

environ un pouce de la surface de

travail.

4. Déplacer constamment l’outil en ligne droite pour éviter de brûler

et de creuser la surface de travail. Une meuleuse stationnaire sur

la surface de travail ou que l’on déplace en effectuant des

mouvements circulaires peut brûler la surface ou laisser des

marques d’ondulation.

5. Soulever l’outil de la surface de travail avant de le mettre hors

tension. Attendre que l’outil ne soit plus en rotation avant de le

déposer.

Installation et utilisation de brosses

et de meules métalliques

Les brosses forme coupelle ou les brosses métalliques circulaires

se vissent directement sur la broche de la meuleuse sans utiliser

de brides. Utiliser seulement les brosses ou les meules métalliques

montées sur moyeu fileté de 5/8 po-11. Un protecteur de type 27

est nécessaire lorsqu’on utilise des brosses et des meules

métalliques.

5˚-15˚

P

N

O

Page 28

Français

26

3. Pour les brosses métalliques forme

coupelle, conserver un angle de 5˚ à 10˚

entre l’outil et la surface de travail.

4. Maintenir le contact entre le bord de la

meule métallique et la surface de travail.

5. Pour ne pas creuser la surface de travail

par endroits, déplacer l’outil en un mouvement

continu de va-et-vient. Une meuleuse

stationnaire sur la surface de travail ou que l’on

déplace en effectuant des mouvements

circulaires peut brûler la surface ou laisser des

marques d’ondulation.

6. Soulever l’outil de la surface de travail avant de le mettre hors

tension. Attendre que l’outil ne soit plus en rotation avant de le

déposer.

MISE EN GARDE : Être très vigilant en travaillant près d’une

bordure car la meuleuse peut produire un mouvement brusque

soudain.

Installation et utilisation de meules à

tronçonner (de type 1)

Les meules à tronçonner comprennent les meules à diamant et les

disques abrasifs. Des meules abrasives pour couper le métal et le

béton sont disponibles. Des lames à diamant pour couper le béton

peuvent également être utilisées.

AVERTISSEMENT : Un protecteur fermé pour meule à tronçon-

ner à deux faces, non compris avec l’outil, est nécessaire pour

l’utilisation de meules à tronçonner. L’utilisation d’une bride ou d’un

protecteur inapproprié peut occasionner des blessures s’il y a contact avec la meule ou si celle-ci est endommagée. Voir la page 21

du présent manuel pour obtenir plus de précisions.

MISE EN GARDE : Porter des gants de travail pour manipuler les

brosses et les meules métalliques car elles peuvent devenir

coupantes.

MISE EN GARDE : La meule ou la brosse ne doit pas toucher au

protecteur une fois installée ou pendant l’utilisation. L’accessoire

pourrait présenter des dommages non apparents qui

fragmenteraient les fils métalliques de la meule ou de la coupelle.

INSTALLATION DE BROSSES FORME COUPELLE ET

MEULES MÉTALLIQUES

MISE EN GARDE : Mettre l’outil hors tension et le débrancher

avant de procéder au réglage, à la dépose ou à l’installation des

pièces et accessoires. Avant de brancher l’outil à nouveau,

appuyer sur l’interrupteur à palette et le relâcher pour s’assurer

que l’outil est hors tension.

1. Visser manuellement la meule sur la broche.

2. Enfoncer le bouton de verrouillage de la broche et utiliser une clé

pour serrer la meule ou la brosse métallique sur le moyeu.

3. Effectuer la procédure inverse pour retirer la meule.

MISE EN GARDE : Afin de ne pas endommager la meule ou

l’outil, s’assurer que la meule est bien en place avant de mettre l’outil

sous tension.

UTILISATION DE BROSSES FORME COUPELLE ET DE

BROSSES MÉTALLIQUES CIRCULAIRES

Les brosses métalliques circulaires et les brosses forme coupelle

servent à enlever la poussière, les écaillures et la peinture ainsi qu’à

aplanir les irrégularités de surface.

1. Laisser l’outil atteindre le régime maximal avant qu’il ne touche

à la surface de travail.

2. Exercer peu de pression sur la surface de travail de sorte que l’outil

puisse fonctionner à régime élevé. La matière s’enlève plus

rapidement quand l’outil fonctionne à régime élevé.

5˚-10˚

Page 29

Français

2727

INSTALLATION DU PROTECTEUR FERMÉ (DE TYPE 1)

MISE EN GARDE : Mettre l’outil hors tension et le

débrancher avant de procéder au réglage, à la dépose ou à

l’installation des pièces et accessoires. Avant de brancher

l’outil à nouveau, appuyer sur l’interrupteur à palette et le

relâcher pour s’assurer que l’outil est hors tension.

1. Ouvrir le verrou du protecteur (J) et

aligner la flèche du protecteur (K) avec

celle du moyeu (L). Ceci permettra

d’aligner les pattes avec les fentes sur

le couvercle du carter d’engrenage.

Mettre le protecteur en place en l’orientant vers l’arrière.

2. Abaisser le protecteur jusqu’à ce que

les pattes s’enclenchent et tournent

librement dans la rainure sur le moyeu

du carter d’engrenage.

3. Tourner le protecteur (I) à la position de

travail désirée. Le corps du protecteur doit

être placé entre la broche et l’utilisateur de

sorte que ce dernier soit bien protégé.

4. Fermer le verrou du protecteur pour le fixer sur le carter d’en-

grenage. Lorsque le verrou est bien fermé, il ne sera pas possible de faire tourner le protecteur manuellement. Ne pas utiliser

la meuleuse si le protecteur n’est pas bien serré ou si le levier

de la bride est ouvert.

5. Pour retirer le protecteur, ouvrir le verrou, tourner le protecteur

de sorte que les flèches soient alignées et tirer le protecteur vers

le haut.

NOTA : Le protecteur est réglé en usine selon le diamètre du

moyeu du carter d’engrenage. Si le protecteur se desserre après

un certain temps, serrer la vis de

réglage (M) alors que le levier de la

bride est en position fermée.

MISE EN GARDE : Ne pas serrer la

vis de réglage si le levier de la bride

est en position ouverte. Ceci risquerait

d’endommager le protecteur ou le

moyeu.

INSTALLATION DE MEULES À TRONÇONNER

MISE EN GARDE : Mettre l’outil hors tension et le débrancher

avant de procéder au réglage, à la dépose ou à l’installation des

pièces et accessoires. Avant de brancher l’outil à nouveau,

appuyer sur l’interrupteur à palette et le relâcher pour s’assurer

que l’outil est hors tension.

MISE EN GARDE : Une bride de support filetée et un écrou de

bride de même diamètre (compris avec l’outil) doivent être utilisés

avec les meules à tronçonner.

1. Installer la bride de support non filetée sur la broche en plaçant

la section surélevée (guide) face vers le haut. La section

surélevée (guide) sur la bride de support doit être appuyée

contre la meule lorsque celle-ci est installée.

2. Placer la meule sur la bride de support et centrer la meule sur la

section surélevée (guide).

3. Installer l’écrou de la bride filetée en orientant la section

surélevée (guide) à l’opposé de la meule.

4. Tout en appuyant sur le bouton de verrouillage de la broche,

visser l’écrou de la bride au moyen d’une clé.

5. Pour retirer la meule, la saisir et la tourner tout en appuyant sur

le bouton de verrouillage de la broche.

J

L

K

I

M

Page 30

Français

28

UTILISATION DE MEULES À TRONÇONNER

AVERTISSEMENT : Ne pas utiliser de meules à tronçonner ou à

découper pour les travaux de meulage de surface. Ces meules ne

sont pas conçues pour les travaux de meulage de surface où une

pression latérale est exercée. La meule risquerait de se briser et de

causer des blessures

1. Laisser l’outil atteindre le régime maximal

avant qu’il ne touche à la surface de travail.

2. Exercer peu de pression sur la surface de

travail de sorte que l’outil puisse fonctionner

à régime élevé. La vitesse de tronçonnage

est supérieure quand l’outil fonctionne à

régime élevé.

3. Ne pas modifier l’angle de coupe une fois

que l’ébauche du tronçon ou de l’entaille est

effectué sur la pièce. La meule risque de se

déformer et de s’effriter si l’on modifie l’angle de coupe.

4. Soulever l’outil de la surface de travail avant de le mettre hors

tension. Attendre que l’outil ne soit plus en rotation avant de le

déposer.

ENTRETIEN

Nettoyage

AVERTISSEMENT : Il est nécessaire d’éliminer régulièrement la