Page 1

If you have questions or comments, contact us.

Pour toute question ou tout commentaire, nous contacter.

Si tiene dudas o comentarios, contáctenos.

1-800-4-DEWALT • www.dewalt.com

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW723

Miter Saw Stand

Support de scie à onglets

Base para ingleteadora

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA

DE GARANTÍA. ADVERTENCIA: LÉASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

Page 2

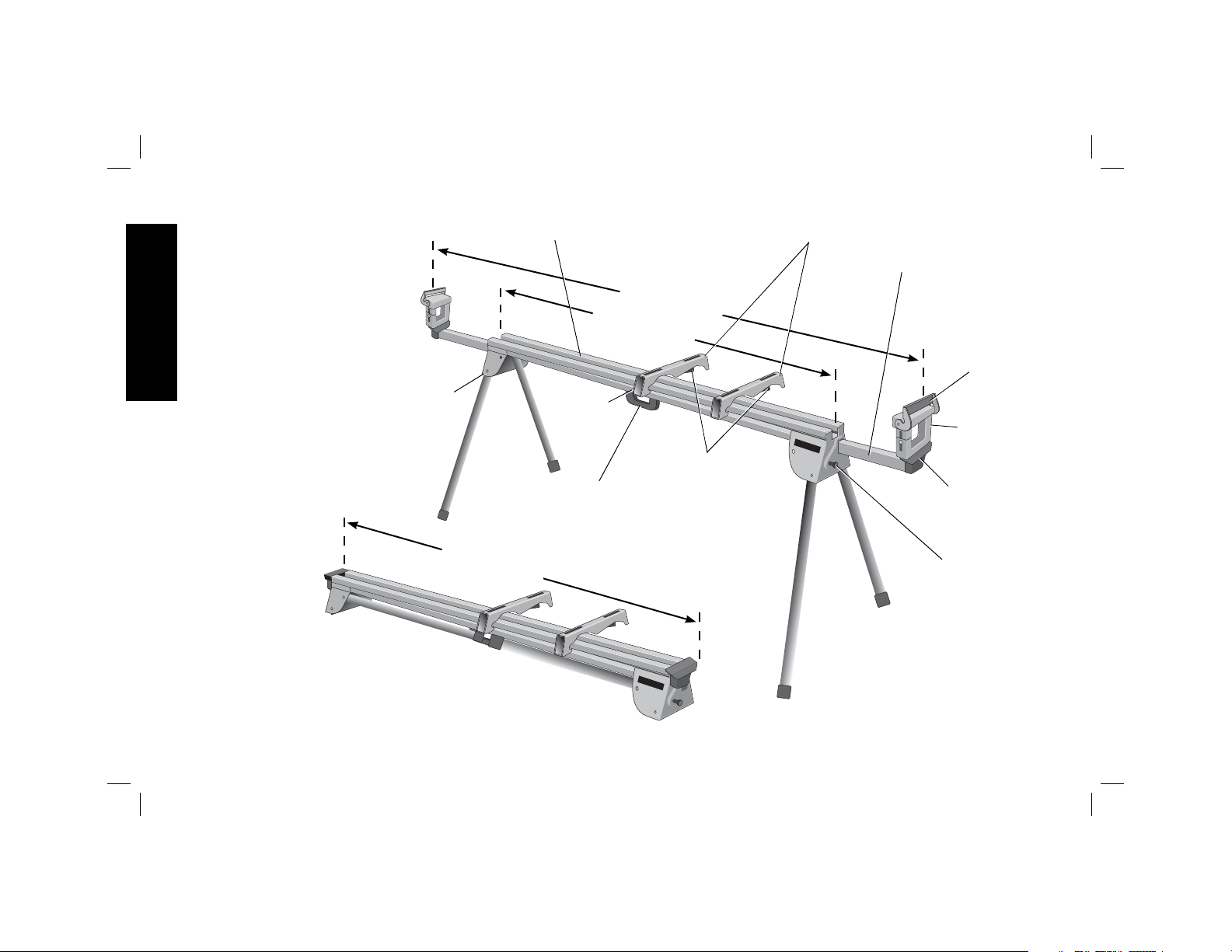

DW723 Miter Saw Stand

English

RELEASE BUTTON

BEAM SAW MOUNTING BRACKETS

EXTENSION ARM

12'-6" (3810 mm)

5'-6" (1480 mm)

LOCKING

LOCATOR

CLIP

RELEASE LEVERS

LENGTH

STOP

WORKPIECE

SUPPORT

5'-6" (1480 mm)

CARRY HANDLE

2

EXTENSION

ARM END CAP

EXTENSION

ARM LOCK

KNOB

Page 3

Defi nitions: Safety Guidelines

The definitions below describe the level of severity

for each signal word. Please read the manual and pay

attention to these symbols.

DANGER: Indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

CAUTION: Used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided, may

result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR

ANY D

E

(1-800-433-9258)

WALT TOOL, CALL US TOLL FREE AT: 1-800-4-DEWALT

Miter Saw Stand with Folding Legs

DW723

This stand is designed for use with most miter saws. If you have

any problem with alignment or mounting, call 1-800-4-D

(1-800-433-9258).

WARNING: For your own safety, read the miter saw

instruction manual before using any accessory. Failure

to heed these warnings may result in personal injury and

serious damage to the miter saw and the accessory. When

servicing this tool, use only identical replacement parts.

EWALT

Tools Required

1. Socket or wrench set

2. Drill with 3/8" (9.5 mm) drill bit (Not required for D

Saws)

3. Phillips #2 screwdriver

EWALT Miter

General Safety Instructions for Miter

Saw Accessories

WARNING: To reduce the risk of personal injury:

• ALWAYS use eye protection. All users and bystanders must

wear eye protection that conforms to ANSI Z87.1.

• DO NOT exceed the weight this stand can hold. The main center

beam of the miter saw stand is designed to support 500 lbs.

(227 kg.) safely in a work environment. It is unsafe to climb, sit or

stand on the stand.

• Follow the mounting instructions carefully. Fasten the tool to the

saw mounting brackets securely as instructed.

• DO NOT modify or use stand for operations for which it is

unintended.

• DO NOT use the stand on uneven surfaces. The stand is

designed to be used on a flat, stable surface.

PREPARATION

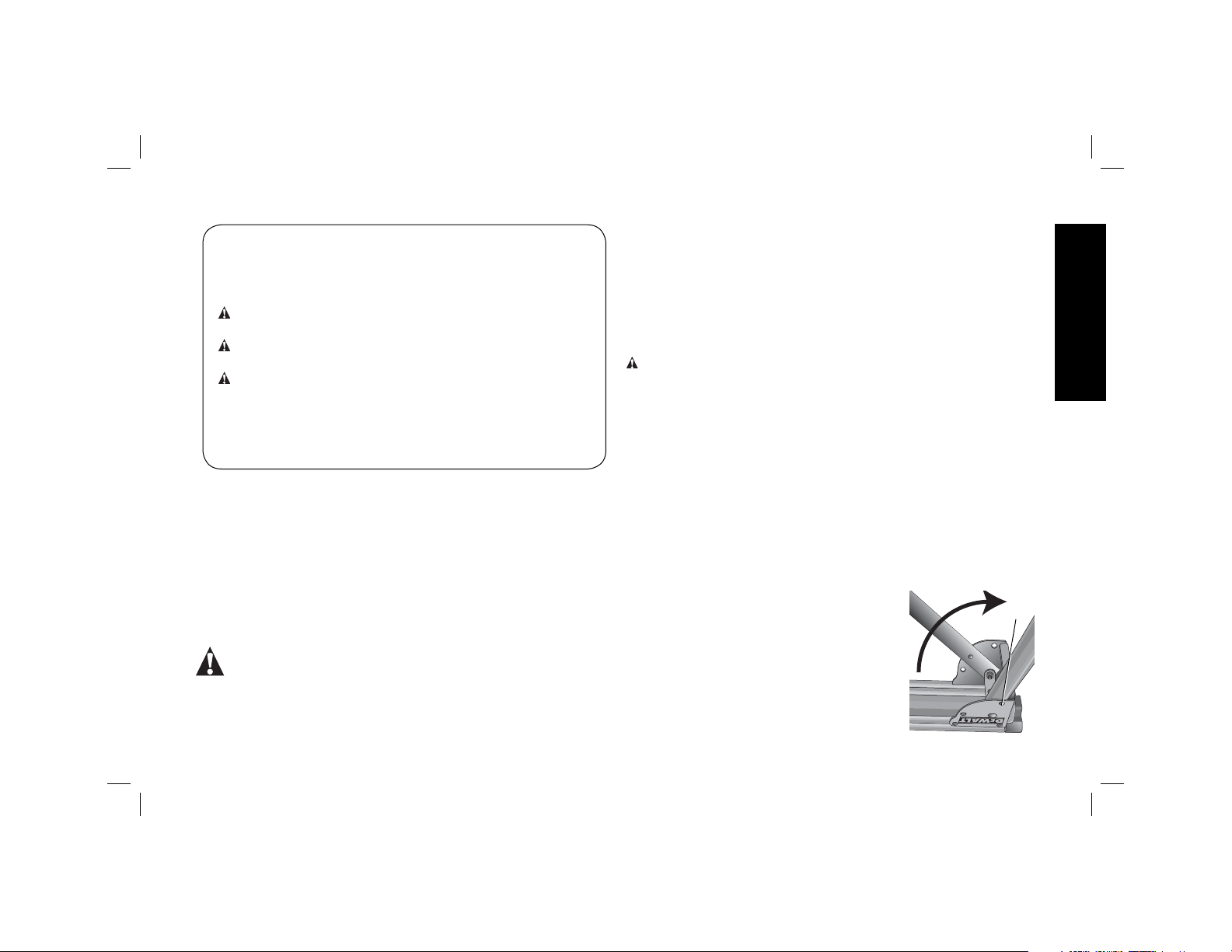

Lay the miter saw stand on the floor with the

folded legs on top. Push the locking pin and

pull each leg up until the locking pin (A)

clicks into its detent. Lift the stand by the

center beam and place it in an upright

position. The stand should be stable and

should not rock. Check the legs to be sure

that the locking pins have engaged and the

legs are firmly held in place.

A

English

1

Page 4

ASSEMBLY

Work Stop/Support

a. The work stop/support has a clamp

(B) to capture the beam and keep

it from being knocked off the beam

by your material. The knob may be

English

locked by turning clockwise and

the work stop/support is free to be

repositioned when the knob is

turned counterclockwise. Do not

overtighten, firm pressure on the

knob will hold the stop in place.

b. Adjust the height of the work stop/support by loosening the

knobs on both sides (C) and raise or lower the top surface to

align with a straight edge or level to the saw table. Tighten the

bolts.

D

F

C

D

c. The work stop/support (D) can also be installed in the end cap

(E) at the end of the extension arms.

d. The length stop (F) may be rotated up to serve as a length stop

or hold the end of long work pieces.

Adjustable Length Extension Arm

To lengthen the support surface, turn the beam

lock knob counter clockwise to release the

extendable support arm. Pull the extendable

extension arm out to the desired length. Turn

the knob clockwise to lock.

B

Miter Saw Mounting

WARNING: To reduce the risk of injury, turn unit off,

disconnect machine from power source before assembling the

E

miter saw to the miter saw stand. An accidental start-up can cause

injury.

WARNING: Stability Hazard. You must use the plywood mounting

method detailed in step 13 when mounting a miter saw not

manufactured by D

WARNING: To reduce the risk of personal injury, be sure the

miter saw is fully anchored on the stand.

WARNING: For your own safety, read and understand the miter

saw instruction manual before using. Failure to heed these warnings

may result in personal injury and serious damage to the miter saw

and the accessory.

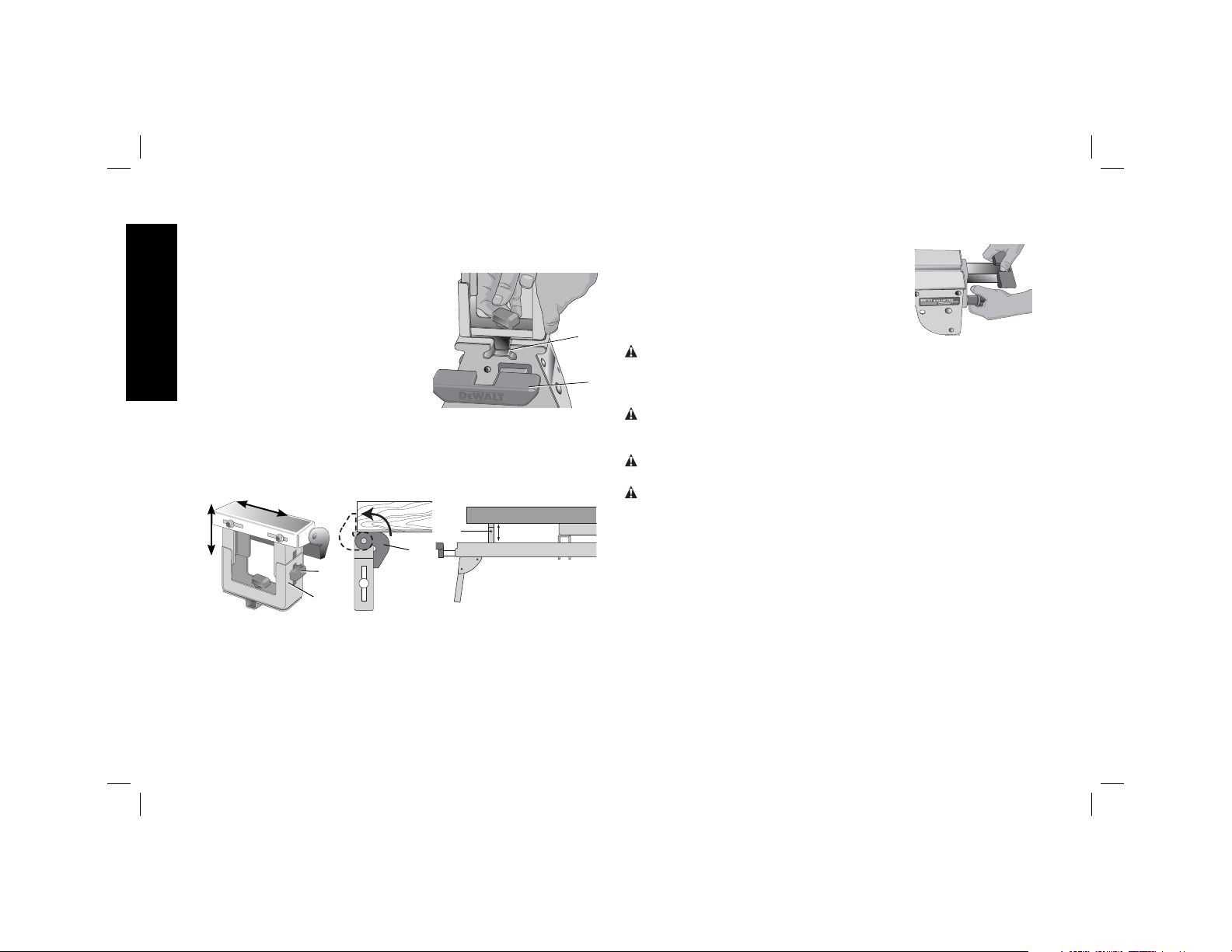

1. Place saw in operational position with blade facing you. Align

with label on the mounting bracket showing front.

2. Place a spacer, such as a 2 x 4, under one side of the miter saw

to hold the saw’s mounting feet above the work surface.

3. Hold a mounting bracket under the saw and feed a carriage bolt

(hardware bag) up through the bracket and the foot of the saw.

NOTE: See DW723 Mounting Procedure Chart for the correct

mounting hardware procedures for D

all instructions properly, otherwise the miter saw's table rotation

will be obstructed.

EWALT to this miter saw stand.

EWALT miter saws. Follow

2

Page 5

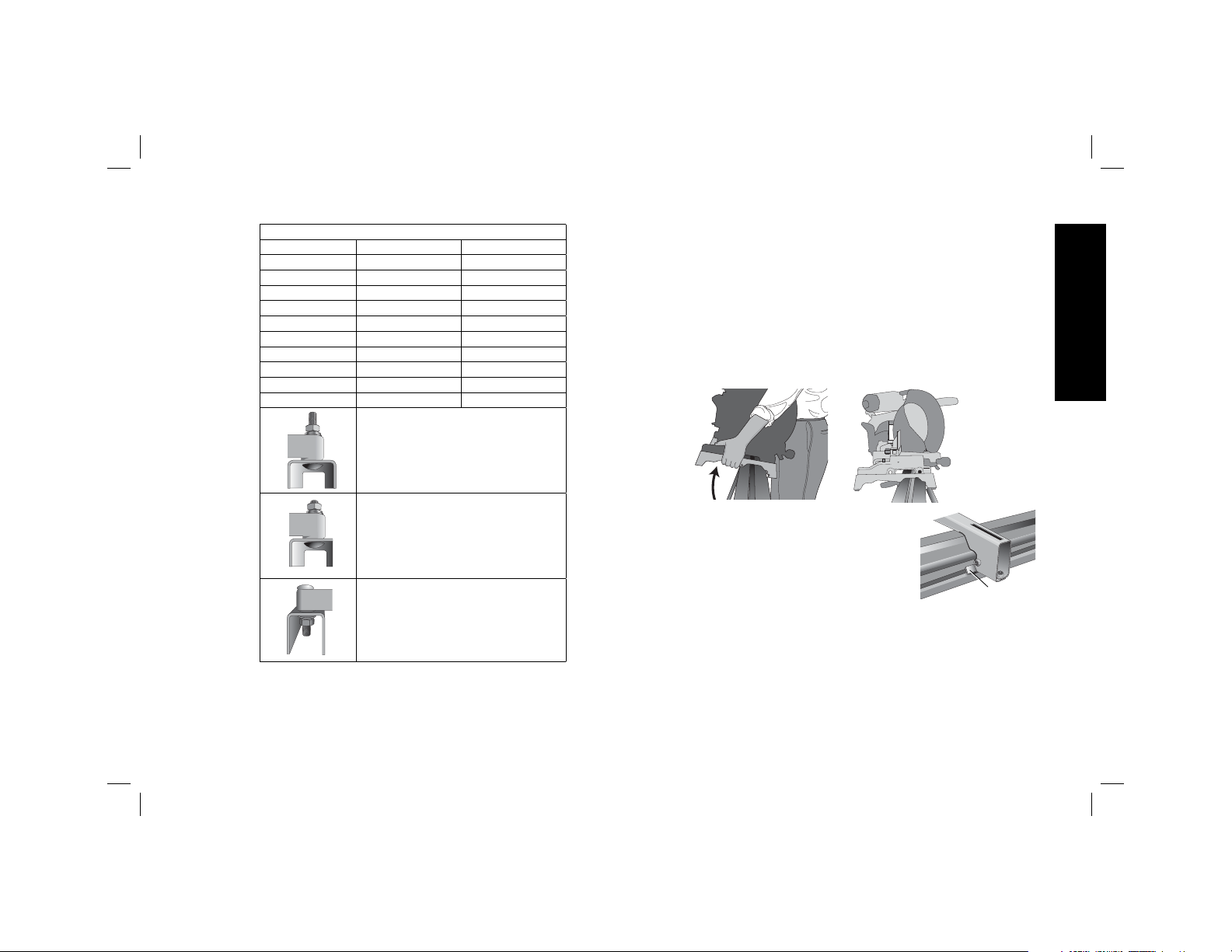

DW723 MOUNTING PROCEDURE CHART

Left Side Right Side

DW703 1 1

DW705 1 1

DW706 1 1

DW708 1 2

DW712 1 2

DW713 1 1

DW715 1 1

DW716 1 1

DW717 2 1

DW718 3 2

1 = Long screw, Head on bottom

2 = Short screw, Head on bottom

3 = Long screw, Head on top

4. Once the carriage bolt (hardware bag) is installed per Mounting

Procedure Chart, assemble a flat washer; lock washer and nut

onto the bolt. Tighten the bolts finger tight.

5. Repeat procedure on the other end of the bracket.

6. Move the 2 x 4 to the other side of the saw to hold the other end

of the saw up in order to access the saw base.

7. Feed carriage bolts through the other bracket and the base of

the saw as before. Ensure both brackets are parallel to each

other.

8. To place the saw onto the stand, grasp and lift saw by mounting

bracket assembly by the release levers. These levers do not

lock the saw laterally in place but merely serve as a means of

mounting the saw to the beam.

9. Approach the beam with saw/bracket

assembly tilting toward your body slightly.

Engage the concave front lip of the mounting

bracket with rounded edge of beam. One of

the brackets must engage the locator clip

(G) to prohibit lateral movement of the saw

during use.

10. When front edge of the beam and locking locator clip are

engaged, a slight downward pivot will allow secure engagement

of the rear levers to back of beam. Rock the saw gently on the

brackets to verify locking in position.

11. Adjust the saw position as necessary to have the blade

perpendicular to the beam when in the 0 degree miter position.

12. Tighten the four nuts holding the saw to the brackets securely.

G

English

3

Page 6

WARNING: For your own safety, read and understand the miter

saw instruction manual before using. Failure to heed these warnings

may result in personal injury and serious damage to the miter saw

and the accessory.

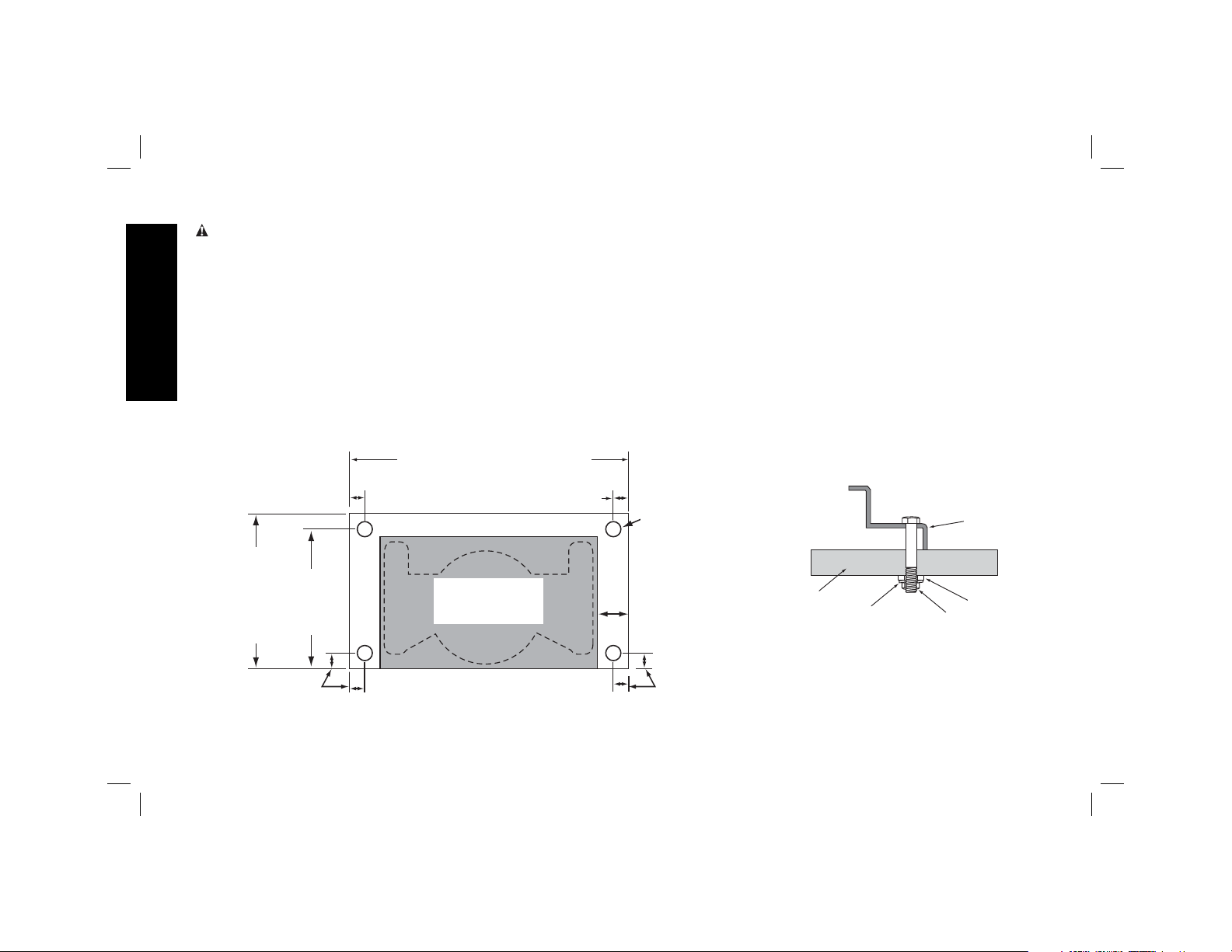

13. The miter saw MUST be positioned so all four corners can be

bolted squarely to the mounting brackets. If this is not possible,

please call D

English

(1-800-433-9258) for technical assistance.

EWALT Customer Support at 1-800-4-DEWALT

NOTE: If the saw mounting holes do not line up with the slots in

the mounting brackets, mount the saw to a piece of 3/4" (19 mm)

plywood. The plywood must be a minimum of 4" (101.6 mm) wider

than the miter saw base being mounted and a minimum depth of

WIDTH OF SAW + 4" (101.6 mm)

16" (406.4 mm). Plywood must be at least as deep as the saw

base being mounted. Place the mounting brackets on the stand and

mount the plywood board to the mounting brackets exactly as shown

in figure. Drill 3/8" (9.4 mm) holes 1" (2.5 mm) from each end to

secure plywood to mounting brackets. Other hardware (not supplied)

may be necessary under these circumstances. NOTE: All purchased

hardware must be a minimum of Grade 2. Hardware should be

1-1/4" (31,8 mm) longer than the saw base you are assembling.

NOTE: If the saw mounting holes do not line up with the slots in

the mounting brackets and the method of utilizing plywood does not

accommodate your saw, please call 1-800-4-D

EWALT (1-800-433-

9258) for additional hardware to install your miter saw.

MINIMUM OF

16" (406.4 mm)

MUST BE AT

LEAST AS

DEEP AS THE

SAW BEING

MOUNTING

1" (2.5 mm)

15"

((381 mm)

BOTH

SIDES

1" (2.5 mm)

1" (2.5 mm)

MOUNT MITER

SAW IN SHADED

AREA

3/8" (9.5 mm)

DIAMETER

HOLES, ALL

4 CORNERS

2" (50.8 mm)

BOTH SIDES

4

MINIMUM

1" (2.5 mm)

3/4" (19 mm)

PLYWOOD

LOCK

WASHER

SAW

BASE

FLAT

WASHER

NUT

Page 7

Locking Locator Clip

The locking locator clip (G) keeps the saw from sliding left or right

during cutting operations. To move the clip, remove saw/bracket

assembly, loosen the screw in the center of the clip, slide it to the

desired position and tighten the screw. You can then remount the

saw/bracket in the new location.

Removing the Saw

Once the miter saw is fastened to the brackets, it can be removed by

grasping the release levers, pulling up slightly to clear the beam and

can be set down on the rubber feet for transportation or cleaning.

Carry Handle

A handle has been supplied to safely transport

the Miter Saw Stand to and from the work site.

WARNING: To reduce the risk of personal

injury, DO NOT attempt to store the stand –

with or without the saw attached – in a vertical

position. Loss of control may result.

Accessories

WARNING: Since accessories, other than those offered by

D

EWALT, have not been tested with this product, use of such

accessories with this tool could be hazardous. To reduce the risk of

injury, do not create unstable conditions and use only with D

miter saws.

EWALT

Recommended accessories for use with your tool are available at

extra cost from your local dealer or authorized service center. If you

need assistance in locating any accessory, please contact D

Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286,

call 1-800-4-D

dewalt.com.

EWALT (1-800-433-9258) or visit our website www.

EWALT

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance

and adjustments should be performed by a D

center, a D

service personnel. Always use identical replacement parts.

EWALT authorized service center or other qualified

EWALT factory service

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty

materials or workmanship for three years from the date of purchase.

This warranty does not cover part failure due to normal wear or

tool abuse. For further detail of warranty coverage and warranty

repair information, visit www.dewalt.com or call 1-800-4-D

(1-800-433-9258). This warranty does not apply to accessories or

damage caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and you may

have other rights which vary in certain states or provinces.

In addition to the warranty, D

EWALT will maintain the tool and replace worn parts caused by

D

normal use, for free, any time during the first year after purchase.

EWALT tools are covered by our:

1 YEAR FREE SERVICE

EWALT

English

5

Page 8

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your

D

EWALT Power Tool, Laser, or Nailer for any reason, you can return

it within 90 days from the date of purchase with a receipt for a full

refund – no questions asked.

LATIN AMERICA: This warranty does not apply to products sold

in Latin America. For products sold in Latin America, see country

specific warranty information contained either in the packaging, call

English

the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT: If your warning

labels become illegible or are missing, call 1-800-4-D

(1-800-433-9258) for a free replacement.

EWALT

6

Page 9

BRAS

EXTENSIBLE

BOUTON DE

DÉGAGEMENT

1480 mm (5 pieds-6 po)

LA FERRURE À

L’AGRAFE DE

FIXATION DU

POSITIONNEUR

DW723 Support de scie à onglets

LONGERON

BUTÉE RÉGLABLE

3810 mm (12 pieds-6 po)

1480 mm (5 pieds-6 po)

POIGNÉE DE

TRANSPORT

FERRURES

POSITIONNEUR

LEVIERS DE

DÉGAGEMENT

AGRAFE DE

FIXATION DU

BUTÉE/SUPPORT

AU CAPUCHON

D’EXTRÉMITÉ

SUPPORT DE

LA PIÈCE

BUTÉE

RÉGLABLE

Défi nitions : lignes directrices

en matière de sécurité.

Les définitions ci-dessous décrivent le niveau de danger

pour chaque mot-indicateur employé. Veuillez lire le

mode d’emploi et porter une attention particulière à ces

symboles.

DANGER : indique une situation dangereuse

imminente qui, si elle n’est pas évitée, causera la mort

ou des blessures graves.

AVERTISSEMENT : indique une situation

potentiellement dangereuse qui, si elle n’est pas évitée,

pourrait causer la mort ou des blessures graves.

ATTENTION : indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée, peut causer des

blessures mineures ou modérées.

ATTENTION : utilisé sans le symbole d’alerte de sécurité,

indique une situation potentiellement dangereuse qui, si

elle n’est pas évitée, peut se solder par des dommages

à la propriété.

EN CAS DE QUESTIONS OU DE COMMENTAIRES SUR CET

E

OUTIL OU SUR TOUT AUTRE OUTIL D

NOUS SANS FRAIS AU NUMÉRO SUIVANT : 1 (800) 4-D

WALT, APPELEZ-

E

WALT

(1 (800) 433-9258)

Support de scie à onglets avec pattes

pliantes DW723

Ce support est destiné à être utilisé avec la plupart des modèles

de scie à onglets. Si on éprouve des difficultés au niveau de son

alignement ou de son montage, composer le 1-800-4-D

(1 800 433-9258).

EWALT

Français

7

Page 10

AVERTISSEMENT : Pour votre sécurité, lire le manuel

de l’utilisateur de la scie à onglet avant l’utilisation de

tout accessoire. Tout manquement à ces avertissements

augmente les risques de dommages corporels, et les

risques de sérieusement endommager la scie à onglet et

ses accessoires. Lors de l’entretien de cet appareil, utiliser

seulement des pièces de rechange identiques.

Outils nécessaires :

1. Jeu de douilles ou clés

2. Perceuse munie d’une mèche de 9,5 mm (3/8 po) (inutile avec

les scies à onglet D

3. Tournevis Phillips nº2

EWALT)

Consignes de sécurité générales

relatives aux accessoires de scie à

onglet

Pour réduire tout risque de dommages corporels :

Français

• Porter SYSTÉMATIQUEMENT une protection oculaire. Tout

utilisateur ou individu présent doit porter une protection oculaire

homologuée ANSI Z87.1.

• NE PAS excéder le poids maximum recommandé pour ce

support. Le longeron central principal du support de scie à onglet

a été conçu pour supporter en toute sécurité 227 kg (500 lb).

• Respecter attentivement les directives d’assemblage. Fixer

solidement l’outil aux supports de fixation comme indiqué.

• NE PAS modifier ou utiliser le socle pour des fonctions auxquelles

il n’est pas conçu.

• NE PAS utiliser le socle sur une surface inégale. Il est conçu pour

une utilisation sur une surface plane et stable.

PRÉPARATION

Poser le support sur le plancher en orientant

les pattes vers le haut. Enfoncer la goupille

de sécurité et tirer chaque patte vers le haut

jusqu’à ce que la goupille (A) s’enclenche

dans la détente. Retourner le support, en le

tenant par le longeron central, afin de le

mettre debout. Le support doit être stable et

ne pas osciller. S’assurer que les goupilles

de sécurité des pattes sont bien enclenchées

et que ces dernières sont solidement fixées.

ASSEMBLAGE

Ensemble butée/support de la pièce

a. Le dispositif butée/support de la

pièce est équipé d’une fixation (B)

pour l’arrimer au longeron et

l’empêcher d’être rejeté hors du

longeron par le matériau. La

molette peut être verrouillée en

tournant vers la droite, et le

dispositif butée/support de la pièce

peut être repositionné librement

en tournant la molette vers la gauche. Ne pas trop serrer, une

pression ferme sur la molette suffira pour maintenir le dispositif

en place.

b. Régler la hauteur de l’ensemble butée/support en desserrant

les boulons (C) situés des deux côtés et en soulevant (ou en

abaissant) la surface supérieure de manière à l’aligner avec un

guide de bord droit ou à le mettre de niveau avec le plateau.

Resserrer les boulons.

c. On peut aussi fixer l’ensemble butée/support (D) au capuchon

d’extrémité (E) situé au bout des bras extensibles.

8

A

B

E

Page 11

D

F

C

D

d. On peut tourner la butée réglable (F) vers le haut en vue de

s’en servir comme butée ou pour retenir l’extrémité de longues

pièces.

Bras extensible réglable

Pour allonger la surface du support, tourner

le bouton de verrouillage du longeron vers la

gauche afin de dégager le bras extensible.

Tirer sur le bras jusqu’à la longueur voulue,

puis tourner le bouton vers la droite pour le

verrouiller.

Installation de la scie à onglet

AVERTISSEMENT : Pour réduire tout risque de dommages

corporels, arrêter et débrancher la scie à onglet du secteur avant

de la monter sur le support de scie à onglet. Tout démarrage

accidentel comporte des risques de dommages corporels.

AVERTISSEMENT : Risques potentiels. Pour installer une scie

à onglet non fabriquée par D

onglet, suivre la méthode d’installation sur contreplaqué détaillée

à l’étape 13.

AVERTISSEMENT : Pour réduire tout risque de dommages

corporels, s’assurer que la scie à onglet est fermement arrimée

au support.

EWALT sur ce support de scie à

AVERTISSEMENT : Pour votre sécurité, lire et comprendre le

manuel de l’utilisateur de la scie à onglet avant toute utilisation.

Tout manquement à ces avertissements augmente les risques de

dommages corporels, et les risques de sérieusement endommager

la scie à onglet et ses accessoires.

1. Installez la scie en position opérationnelle avec la lame face à

vous. Alignez-la sur l’étiquette de la ferrure affichant « avant ».

2. Placez une barre d’écartement, comme un colombage, sous

l’un des côtés de la scie à onglet pour surélever les pieds de

montage de la scie au-dessus de la surface de travail.

3. Maintenez une ferrure sous la scie et insérez un boulon de

carrosserie (sac pour quincaillerie) au travers de la ferrure et du

pied de scie.

REMARQUE : Veuillez consulter le tableau de procédure

d’installation DW723 pour connaître la procédure correcte

d’installation de la quincaillerie d’installation pour scies à onglet

D

EWALT. Suivez soigneusement toutes les directives, pour

éviter que la rotation de la table de scie à onglet soit gênée.

TABLEAU DE PROCÉDURE D'INSTALLATION DW723

Côté gauche Côté droit

DW703 1 1

DW705 1 1

DW706 1 1

DW708 1 2

DW712 1 2

DW713 1 1

DW715 1 1

DW716 1 1

DW717 2 1

DW718 3 2

Français

9

Page 12

1 = vis longue, tête dessous

2 = vis courte, tête dessous

3 = vis longue, tête dessus

4. Une fois le boulon de carrosserie (sac pour quincaillerie) installé

Français

conformément au tableau de procédure d’installation, installez

une rondelle plate, puis verrouillez la rondelle et l’écrou sur le

boulon. Resserrez à fond manuellement les boulons.

5. Répétez la procédure à l’autre bout de la ferrure.

6. Déplacez le colombage de l’autre côté de la scie pour le soutenir

et avoir accès à la base de la scie.

7. Insérez les boulons au travers de l’autre ferrure et de la base de

la scie comme indiqué ci-dessus. Assurez-vous que les ferrures

sont bien parallèles.

8. Pour installer la scie sur le support, attrapez et soulevez la scie

par les leviers de dégagement du dispositif de ferrure. Ces

leviers ne servent pas à verrouiller la scie en place latéralement,

mais seulement à installer la scie sur le longeron.

9. Approchez-vous du longeron avec le

dispositif scie/ferrure légèrement incliné

vers votre corps. Engagez la lèvre avant

concave des ferrures sur le rebord arrondi

du longeron. L’une des ferrures doit

s’enclencher dans l’agrafe de positionnement

(G) pour éviter tout mouvement latéral de la scie pendant son

utilisation.

10. Lorsque le bord avant du longeron et l’agrafe de positionnement

sont verrouillés, un léger pivotement vers le bas permettra

d’engager les leviers postérieurs à l’arrière du longeron. Essayez

de remuer légèrement la scie sur les ferrures pour vérifier qu’elle

est bien verrouillée en place.

11. Ajustez la position de la scie comme nécessaire de façon à ce

que la lame soit perpendiculaire au longeron en position de zéro

degré d’onglet.

12. Resserrez les quatre écrous arrimant la scie aux ferrures.

AVERTISSEMENT : Pour votre sécurité, lire et comprendre le

manuel de l’utilisateur de la scie à onglet avant toute utilisation.

Tout manquement à ces avertissements augmente les risques de

dommages corporels, et les risques de sérieusement endommager

la scie à onglet et ses accessoires.

10

G

Page 13

13. La scie à onglet DOIT être positionnée de façon à ce que ses

quatre coins soient boulonnés directement aux ferrures. Dans

le cas contraire, veuillez contacter le service à la clientèle

D

EWALT au 1-800-4-DEWALT (1-800-433-9258) pour recevoir

l’assistance technique nécessaire.

REMARQUE : Si les trous de montage de la scie ne s’alignent

pas sur les fentes des ferrures, montez la scie sur un morceau de

contreplaqué de 19 mm (3/4 po). Le contreplaqué doit dépasser

d’au moins 101,6 mm (4 po) de la base de la scie à onglet et avoir

une profondeur minimale de 406,4 mm (16 po). Le contreplaqué doit

être au moins aussi large que la base de la scie installée. Placez

les ferrures sur le support et montez le panneau de contreplaqué

LARGEUR DE SCIE + 101,6 mm (4 po)

406,4 mm

(16 po)

MINIMUM

DOIT ÊTRE

AUSSI LARGE

QUE LA BASE

DE LA SCIE

INSTALLÉE

381 mm

(15 po)

DE

CHAQUE

CÔTÉ

2,5 mm (1 po)

MONTAGE DE LA SCIE

DE BÂTI DANS LE

SECTEUR OMBRAGÉ

2,5 mm (1 po)

aux ferrures exactement comme illustré. Percez des trous de

9,4 mm (3/8 po) à 2,5 mm (1 po) de chaque bout pour arrimer

le contreplaqué aux ferrures. Vous pouvez avoir besoin dans ces

circonstances de matériel supplémentaire (non fourni avec l’outil).

REMARQUE : Toute quincaillerie utilisée doit être d’un grade 2

minimum. Elle doit dépasser d’au moins 31,8 mm (1-1/4 po) de la

base de la scie installée. REMARQUE : Si les trous de montage

de la scie ne s’alignent pas avec les fentes des ferrures, et que la

méthode utilisant le contreplaqué ne peut être utilisée avec votre

scie, veuillez contacter le 1-800-4-D

EWALT (1-800-433-9258) pour

obtenir la quincaillerie additionnelle nécessaire pour installer votre

scie à onglet.

DIAMÈTRE

DE TROUS :

9,5 mm (3/8 po),

DANS LES

4 COINS

CONTREPLAQUÉ

DE 19 mm (3/4 po)

MINIMUM DE

50,8 mm (2 po) DE

CHAQUE CÔTÉ

RONDELLE

DE

BLOCAGE

BASE DE

SCIE

RONDELLE

PLATE

ÉCROU

Français

2,5 mm (1 po)

2,5 mm (1 po)

11

Page 14

Agrafe de fi xation du positionneur

L’agrafe de fixation du positionneur (G) empêche la scie de glisser

vers la gauche ou vers la droite durant la coupe. Pour déplacer

l’agrafe, retirer la scie et ses ferrures, desserrer la vis située au

centre de l’agrafe et faire glisser celle-ci jusqu’à la position voulue;

resserrer la vis. Réinstaller la scie (avec les ferrures) à la nouvelle

position.

Dégagement de la scie

Lorsque la scie à onglets est fixée au support au moyen des ferrures,

on peut la dégager en la saisissant par les leviers de dégagement et

en la soulevant légèrement de manière à la libérer du longeron. Une

fois la scie retirée, on peut la déposer sur les pattes en caoutchouc

pour la transporter ou la nettoyer.

Poignée de transport

Le support de scie à onglets est doté d’une

poignée permettant de le transporter en toute

sécurité.

Français

AVERTISSEMENT : pour réduire le risque

de blessure, NE PAS essayer de ranger le

socle (avec ou sans la scie) en position verticale. Une telle pratique

risque de se solder par une perte d’équilibre de l’accessoire.

Accessoires

AVERTISSEMENT : Comme les accessoires autres que ceux

offerts par D

utilisation avec cet appareil pourrait comporter un danger. Pour

réduire tout risque de dommages corporels, éviter toute condition

précaire et utiliser seulement des scies à onglet D

Les accessoires recommandés pour votre outil peuvent être achetés

auprès du distributeur local ou d’un centre de réparation agréé. Si vous

EWALT n’ont pas été testés avec ce produit, leur

EWALT.

avez besoin d’assistance pour trouver un accessoire pour votre outil,

veuillez contacter D

Baltimore, MD 21286, États-Unis, composer le 1(800) 4-D

(1-800-433-9258) ou visiter notre site Web à www.dewalt.com.

EWALT Industrial Tool Co., 701 East Joppa Road,

EWALT

Réparations

Pour assurer la SÉCURITÉ et la FIABILITÉ du produit, les

réparations, l’entretien et les réglages doivent être réalisés par un

centre de réparation en usine D

autorisé D

Toujours utiliser des pièces de rechange identiques.

EWALT ou par un personnel de réparation professionnel.

EWALT, un centre de réparation

Garantie limitée trois ans

DEWALT réparera gratuitement tous les problèmes dus à des

défauts de matériau ou de fabrication pendant trois ans à compter

de la date d’achat. Cette garantie ne couvre pas des défaillances de

pièce dues à une usure normale ou à une mauvaise utilisation de

l’outil. Pour plus de détails relatifs à la couverture de la garantie et

aux réparations sous garantie, visiter le site Web www.dewalt.com

ou composer le 1-800-4-D

ne s’applique pas aux accessoires ni aux dommages causés par

des réparations réalisées ou tentées par des tiers. Cette garantie

vous accorde des droits légaux spécifiques et il est possible que

vous ayez d’autres droits qui varient d’un État ou d’une province à

l’autre.

En plus de la garantie, les outils D

SERVICE D’ENTRETIEN GRATUIT DE 1 AN

D

EWALT entretiendra l’outil et remplacera les pièces usées par une

utilisation normale et ce, gratuitement, à tout instant pendant la

première année à compter de la date d’achat.

EWALT (1-800-433-9258). Cette garantie

EWALT sont couverts par notre :

12

Page 15

GARANTIE DE REMBOURSEMENT DE 90 JOURS

Si vous n’êtes pas entièrement satisfait des performances de votre

outil électrique, laser ou de votre marteau-cloueur D

EWALT pour

quelque raison que ce soit, vous pouvez le retourner accompagné

d’un reçu dans les 90 jours suivant la date d’achat et nous vous

rembourserons entièrement - sans poser de questions.

AMÉRIQUE LATINE : cette garantie ne s’applique pas aux produits

vendus en Amérique latine. Pour ceux-ci, veuillez consulter les

informations relatives à la garantie spécifique présente dans

l’emballage, appeler l’entreprise locale ou consulter le site Web pour

les informations relatives à cette garantie.

REMPLACEMENT GRATUIT DES ÉTIQUETTES

D’AVERTISSEMENT : si les étiquettes d’avertissement deviennent

illisibles ou sont manquantes, composer le 1-800-4-D

EWALT

(1-800-433-9258) pour en obtenir le remplacement gratuit.

Français

13

Page 16

DW723 Base para ingleteadora

VIGA

BRAZO DE

EXTENSIÓN

BOTONES

DE

LIBERACIÓN

ASA PARA

1480 mm (5 pies-6 pulg.)

PINZA

DEL

LOCALIZADOR

DEL SEGURO

Español

TRANSPORTE

SOPORTES

DE MONTAJE

PARA LA

SIERRA

3810 mm (12 pies-6 pulg.)

1480 mm (5 pies-6 pulg.)

PALANCAS

DE

LIBERACIÓN

TAPA DEL

BRAZO DE

PERILLA DE

SEGURIDAD

DEL BRAZO DE

EXTENSIÓN

EXTENSIÓN

TOPE

LONGITUDINAL

APOYO

PARA LA

PIEZA DE

TRABAJO

Defi niciones: Normas de

seguridad

Las siguientes definiciones describen el nivel de gravedad

de cada palabra de señal. Lea el manual y preste atención

a estos símbolos.

PELIGRO: Indica una situación de peligro inminente que,

si no se evita, provocará la muerte o lesiones graves.

ADVERTENCIA: Indica una situación de peligro potencial

que, si no se evita, podría provocar la muerte o lesiones

graves.

ATENCIÓN: Indica una situación de peligro potencial

que, si no se evita, posiblemente provocaría lesiones

leves o moderadas.

ATENCIÓN: Utilizado sin el símbolo de alerta de seguridad

indica una situació n de peligro potencial que, si no se

evita, puede provocar dañ os en la propiedad.

SI TIENE ALGUNA DUDA O ALGÚN COMENTARIO SOBRE

ÉSTA U OTRA HERRAMIENTA D

NÚMERO GRATUITO: 1-800-4-D

EWALT, LLÁMENOS AL

EWALT (1-800-433-9258)

Base para ingleteadora DW723

Esta base está diseñada para usarse con la mayoría de las

ingleteadoras. Si tiene algún problema con la alineación o el

montaje, llame al 1-800-4-D

ADVERTENCIA : Para su seguridad, lea el manual

de instrucciones de la ingleteadora antes de utilizar

cualquier accesorio. De no seguir estas advertencias

podrían producirse lesiones corporales y graves daños a

la ingleteadora y al accesorio. Cuando realice el

mantenimiento de esta herramienta, utilice únicamente

repuestos originales.

14

EWALT.

Page 17

Herramientas requeridas

1. Toma o juego de llaves

2. Taladro con una broca de 9,5 mm (3/8 pulg.) (No es necesario

con las ingleteadoras de D

3. Destornillador Phillips #2

EWALT)

Instrucciones de seguridad generales

para accesorios de la ingleteadora

Para reducir el riesgo de lesión personal:

• SIEMPRE use protección ocular. Todos los usuarios y

transeúntes deben de usar protección ocular conforme a ANSI

Z87.1.

• NO exceda el peso que el pie puede aguantar. La viga central

principal de la ingleteadora ha sido diseñada para aguantar

227 kg (500 lbs.) sin peligro alguno.

• Siga cuidadosamente todas las instrucciones de montaje. Sujete

bien la herramienta a los soportes de montaje de la sierra, según

lo indicado.

• NO modifique la base ni la utilice para otras tareas que no sean

aquéllas para la que fue diseñada.

• NO utilice la base sobre superficies desniveladas. La base fue

diseñada para utilizarse sobre una superficie plana y estable.

PREPARACIÓN

Coloque la base para ingleteadora en el piso

con las patas plegadas hacia arriba. Empuje

el perno de seguridad y tire de cada pata

hasta que el perno (A) se trabe en el hueco

correspondiente. Levante la base tomándola

de la viga central y colóquela en la posición

normal. La base deberá quedar estable y no

A

deberá balancearse. Revise que los pernos de seguridad de las

patas se hayan trabado y que éstas estén firmemente sujetas en su

sitio.

ENSAMBLAJE

Tope/soporte para piezas

a. El tope/soporte tiene un dispositivo

de sujeción (B) que captura la

viga e impide que su material lo

tire de la viga. Puede sujetar el

pomo girándolo en el sentido de

las agujas del reloj y podrá liberar

el tope/soporte para volver a

colocarlo girando el pomo en el

sentido contrario de las agujas del

reloj. No lo apriete demasiado. Si

presiona el pomo firmemente, podrá guardarlo en su lugar.

b. Ajuste la altura del tope/soporte para piezas aflojando los

tornillos que están a ambos lados (C) y suba o baje la superficie

superior para alinearla con una regla o un nivel con la mesa de

la sierra. Apriete los tornillos.

D

F

C

D

c. El tope/soporte (D) puede instalarse también en la tapa del

extremo (E) de los brazos de extensión.

B

E

Español

15

Page 18

d. El tope longitudinal (F) puede girarse para servir como tope , o

para sujetar los extremos de piezas muy largas.

Brazo de extensión de longitud ajustable

Para alargar la superficie de apoyo, gire la

perilla de seguridad de la viga en sentido

contrario a las manecillas del reloj para liberar

el brazo de soporte extensible. Tire del brazo

de soporte extensible hasta la longitud que

desee. Gire la perilla en el sentido de las

manecillas del reloj para asegurar.

Instalación de la ingleteadora

ADVERTENCIA: Para reducir el riesgo de lesión, apague la

unidad, desconecte la máquina de la fuente de corriente antes

de ensamblar la ingleteadora al pie de la ingleteadora. Puede

lastimarse si la unidad se prende accidentalmente.

ADVERTENCIA: Peligro de estabilidad. Debe de usar el método

de instalación de contrachapado explicado en detalle en la etapa

13 al instalar una ingleteadora que no ha sido fabricada por

D

EWALT a este pie de ingleteadora.

ADVERTENCIA: Para reducir el riesgo de lesión, asegúrese que

la ingleteadora ha sido completamente anclada al pie.

ADVERTENCIA: Para su seguridad, lea y comprenda el manual

de instrucciones de la ingleteadora antes de utilizarla. El no respetar

estas advertencias puede resultar en lesiones corporales y daños

serios a la ingleteadora y al accesorio.

1. Coloque la sierra en la posición de funcionamiento con la hoja

Español

orientada hacia usted. Alinéela con la etiqueta sobre el soporte

de montaje hacia el frente.

2. Coloque un espaciador, como un 2 x 4, debajo de un lado de la

ingleteadora para sujetar el pie del soporte de la sierra sobre la

superficie de trabajo.

3. Sujete un soporte de montaje debajo de la sierra e introduzca

un tallo de tornillo (bolsa de ferretería) a través del soporte y el

pie de la sierra.

NOTA: Consulte la tabla del procedimiento de montaje del

DW723 para obtener los pasos correctos para montar la

ferretería de las ingleteadoras de D

instrucciones correctamente para no obstruir la rotación de la

mesa de la ingleteadora.

DW723 TABLA DEL PROCEDIMIENTO DE MONTAJE

Lado izquierdo Lado derecho

DW703 1 1

DW705 1 1

DW706 1 1

DW708 1 2

DW712 1 2

DW713 1 1

DW715 1 1

DW716 1 1

DW717 2 1

DW718 3 2

1 = Tornillo largo, cabeza hacia abajo

2 = Tornillo corto, cabeza hacia abajo

EWALT. Siga todas las

16

Page 19

3 = Tornillo largo, cabeza hacia arriba

4. Una vez que el tallo de tornillo (bolsa de ferretería) ha

sido instalado según la tabla del procedimiento de montaje,

ensamble una arandela plana, una arandela de bloqueo y una

tuerca sobre el perno. Apriete los pernos con sus dedos.

5. Repita estos pasos para el otro lado del soporte.

6. Desplace el 2X4 al otro lado de la sierra para sujetar el otro lado

de la sierra hacia arriba para acceder a la base de la sierra.

7. Introduzca los tallos de tornillos a través del otro soporte y la

base de la sierra como previamente. Asegúrese que los dos

soportes se ubiquen en posición paralela.

8. Para colocar la sierra sobre el pie, agarre y levante la sierra

del ensamblaje del soporte de montaje al lado de las palancas

de liberación. Estas palancas no fijan la sierra lateralmente en

su lugar, sino que ofrecen una manera de montar la sierra a la

viga.

9. Acerque la viga al ensamblaje de la sierra/

pie inclinándola ligeramente hacia usted.

Active el borde delantero cóncavo del

soporte de montaje con el borde redondeado

de la viga. Uno de los soportes debe de

activar la pinza de seguridad del localizador

G

(G) para impedir el movimiento lateral de la sierra cuando utilice

la sierra.

10. Cuando el borde delantero de la viga y la pinza de seguridad del

localizador han sido activados, un giro ligeramente hacia abajo

permite de activar las palancas traseras con la parte trasera

de la viga. Mece la sierra con cuidado sobre los soportes para

asegurarse que ha sido fijada correctamente.

11. Ajuste la posición de la sierra según sea necesario para que

la hoja se encuentre perpendicular a la viga cuando esté en la

posición de inglete de 0 grados.

12. Apriete las cuatro tuercas sujetando la sierra firmemente sobre

los soportes.

ADVERTENCIA: Para su seguridad, lea y comprenda el manual

de instrucciones de la ingleteadora antes de utilizarla. El no respetar

estas advertencias puede resultar en lesiones corporales y daños

serios a la ingleteadora y al accesorio.

13. La ingleteadora DEBE de ser colocada de manera que las

cuatro esquinas puedan ser atornilladas directamente a los

soportes de montaje. Si no es posible, llame al servicio al cliente

de D

EWALT al 1-800-4-DEWALT (1-800-433-9258) para obtener

ayuda técnica.

NOTA: Si los agujeros de montaje de la sierra no se pueden alinear

con las ranuras en los soportes de montaje, coloque la sierra sobre

un pedazo de contrachapado de 19 mm (3/4 pulg.). El contrachapado

debe de tener un ancho de por lo menos 101,6 mm (4 pulg.) más

que la base de la ingleteadora montada y una profundidad de por

Español

17

Page 20

lo menos 406,4 mm (16 pulg.) El contrachapado debe de tener

por lo menos una profundidad que equivalga a la base de la sierra

instalada. Coloque los soportes de montaje sobre el pie e instale

el contrachapado a los soportes de montaje, exactamente como

aparece en la figura. Taladree agujeros de 9,4 mm (3/8 pulg.), a

2,5 mm (1 pulg.) de cada extremidad para fijar el contrachapado a

los soportes de montaje. Bajo estas circunstancias, puede necesitar

más ferretería (no incluida). NOTA: Toda la ferretería comprada

debe de tener un grado mínimo de 2. La ferretería debería de

tener un largo de 31,8 mm (1-1/4 pulg.) más que la base de la

sierra ensamblada. NOTA: Si los agujeros de montaje de la sierra

no se alinean con las ranuras de los soportes de montaje y el

método de utilización de contrachapado no acomoda su sierra,

llame al 1-800-4-D

EWALT (1-800-433-9258) para obtener ferretería

adicional para instalar su ingleteadora.

Pinza de seguridad del localizador

La pinza de seguridad del localizador (G) impide que la sierra se

deslice a izquierda o derecha durante las operaciones de corte.

Para mover la pinza, retire el montaje de sierra/soportes, afloje

el tornillos del centro de la pinza, deslícela hacia la posición que

desee y apriete el tornillos. Ahora podrá colocar el montaje de sierra/

soportes en la nueva posición.

MÍNIMO DE

406,4 mm

(16 pulg.) LA

PROFUNDIDAD

DEBE DE SER

POR LO MENOS

IGUAL A LA

SIERRA

MONTADA

Español

2,5 mm (1 pulg.)

381 mm

(15 pulg.)

LOS DOS

LADOS

ANCHURA DE LA SIERRA

+ 101,6 mm (4 pulg.)

2,5 mm (1 pulg.)

SIERRA DEL INGLETE

DEL MONTAJE EN

ÁREA SOMBREADA

2,5 mm (1 pulg.)

AGUJEROS

CON UN

DIÁMETRO

DE 9,5 mm

(3/8 pulg.) EN

LAS CUATRO

ESQUINAS

MÍNIMO DE

50,8 mm (2 pulg.)

LOS DOS LADOS

2,5 mm (1 pulg.)

18

CONTRACHAPADO

DE 19 mm

(3/4 pulg.)

DE BLOQUEO

ARANDELA

BASE

DE LA

SIERRA

ARANDELA

PLANA

TUERCA

Page 21

Para quitar la sierra

Una vez que se fijó la ingleteadora a los soportes, puede desmontarse

sujetando las palancas de liberación, tirando hacia arriba con

suavidad para librar la viga y pueda así colocarse sobre las patas

de goma para transportarla o para limpiarla.

Asa para transporte

Se proporciona un asa para transportar con

seguridad la base para la ingleteadora al sitio de

trabajo.

ADVERTENCIA: Para reducir el riesgo de

lesiones personales, NO intente guardar la

base (con o sin la sierra montada) en posición

vertical. Puede causar la pérdida de control.

Accesorios

ADVERTENCIA: Como otros accesorios fuera de los ofrecidos

EWALT no han sido probados con este producto, el uso de

por D

tales accesorios con esta herramienta podría ser peligroso. Para

reducir el riesgo de lesiones, no cree condiciones inestables y

utilícelos únicamente con ingleteadoras de D

EWALT.

Los accesorios que se recomiendan para la herramienta están

disponibles para la compra en su distribuidor local o en el centro de

mantenimiento autorizado. Si necesita ayuda para localizar algún

accesorio para su herramienta, comuníquese con D

EWALT Industrial

Tool Co., 701 East Joppa Road, Baltimore, MD 21286, llame

al 1-800-4-D

EWALT (1-800-433-9258) o visite nuestro sitio Web

www.dewalt.com.

Reparaciones

Para garantizar la SEGURIDAD y la CONFIABILIDAD, deberán

hacerse reparaciones, mantenimiento y ajustes de esta herramienta

en los centros autorizados de servicio D

autorizadas. Estas organizaciones prestan servicio a las herramientas

EWALT y emplean siempre refacciones legitimas DEWALT.

D

EWALT u otras organizaciones

PARA REPARACIÓN Y SERVICIO DE SUS HERRAMIENTAS

ELÉCTRICAS, FAVOR DE DIRIGIRSE AL

CENTRO DE SERVICIO MÁS CERCANO

CULIACAN, SIN

Blvd.Emiliano Zapata 5400-1 Poniente

Col. San Rafael (667) 717 89 99

GUADALAJARA, JAL

Av. La Paz #1779 - Col. Americana Sector Juárez (33) 3825 6978

MEXICO, D.F.

Eje Central Lázaro Cárdenas No. 18

Local D, Col. Obrera (55) 5588 9377

MERIDA, YUC

Calle 63 #459-A - Col. Centro (999) 928 5038

MONTERREY, N.L.

Av. Francisco I. Madero 831 Poniente - Col. Centro (818) 375 23 13

PUEBLA, PUE

17 Norte #205 - Col. Centro (222) 246 3714

QUERETARO, QRO

Av. San Roque 274 - Col. San Gregorio (442) 2 17 63 14

SAN LUIS POTOSI, SLP

Av. Universidad 1525 - Col. San Luis (444) 814 2383

TORREON, COAH

Blvd. Independencia, 96 Pte. - Col. Centro (871) 716 5265

VERACRUZ, VER

Prolongación Díaz Mirón #4280 - Col. Remes (229) 921 7016

VILLAHERMOSA, TAB

Constitución 516-A - Col. Centro (993) 312 5111

PARA OTRAS LOCALIDADES:

Si se encuentra en México, por favor llame al (55) 5326 7100

Si se encuentra en U.S., por favor llame al

1-800-433-9258 (1-800 4-DEWALT)

19

Español

Page 22

Póliza de Garantía

IDENTIFICACIÓN DEL PRODUCTO:

Sello o firma del Distribuidor.

Nombre del producto: __________ Mod./Cat.: _____________

Marca: _____________________ Núm. de serie:__________

(Datos para ser llenados por el distribuidor)

Fecha de compra y/o entrega del producto: __________________

Nombre y domicilio del distribuidor donde se adquirió el producto:

_____________________________________________________

Este producto está garantizado por un año a partir de la fecha de

entrega, contra cualquier defecto en su funcionamiento, así como

en materiales y mano de obra empleados para su fabricación.

Nuestra garantía incluye la reparación o reposición del producto

y/o componentes sin cargo alguno para el cliente, incluyendo mano

de obra, así como los gastos de transportación razonablemente

erogados derivados del cumplimiento de este certificado.

Para hacer efectiva esta garantía deberá presentar su herramienta

y esta póliza sellada por el establecimiento comercial donde se

adquirió el producto, de no contar con ésta, bastará la factura de

compra.

EXCEPCIONES.

Esta garantía no será válida en los siguientes casos:

• Cuando el producto se hubiese utilizado en condiciones

distintas a las normales;

• Cuando el producto no hubiese sido operado de acuerdo con

el instructivo de uso que se acompaña;

Español

• Cuando el producto hubiese sido alterado o reparado por

personas distintas a las enlistadas al final de este certificado.

Anexo encontrará una relación de sucursales de servicio de fábrica,

centros de servicio autorizados y franquiciados en la República

Mexicana, donde podrá hacer efectiva su garantía y adquirir partes,

refacciones y accesorios originales.

Garantía limitada de tres años

DEWALT reparará sin cargo cualquier defecto ocasionado por

materiales defectuosos o mano de obra, durante tres años a partir de

la fecha de compra. Esta garantía no cubre fallas en las piezas que

resulten del desgaste normal de la herramienta o de su utilización

inadecuada. Para obtener información detallada sobre la cobertura

de la garantía y sobre reparaciones, visite nuestra página Web www.

dewalt.com o llame al 1-800-4-D

garantía no se extiende a los accesorios o a los daños causados

por terceros al intentar realizar reparaciones. Esta garantía le

concede derechos legales específicos; usted goza también de otros

derechos que varían según el estado o provincia.

Además de la garantía, las herramientas D

por nuestro:

SERVICIO GRATUITO DE 1 AÑO

EWALT realizará el mantenimiento de la herramienta y reemplazará

D

las piezas gastadas tras el uso normal, sin costo alguno, en cualquier

momento durante el primer año después de la compra.

GARANTÍA DE REEMBOLSO DE DINERO DE 90 DÍAS

Si por alguna razón no estuviera plenamente satisfecho con el

rendimiento de la herramienta eléctrica, el láser o la clavadora

EWALT, puede devolver el producto dentro de los 90 días

D

siguientes a la fecha de compra acompañado del recibo de compra.

De esta manera, se le reintegrará el importe total del producto sin

formularle pregunta alguna.

EWALT (1-800-433-9258). Esta

EWALT están cubiertas

20

Page 23

AMÉRICA LATINA: Esta garantía no se aplica a los productos que

se venden en América Latina. Para los productos que se venden

en América Latina, debe consultar la información de la garantía

específica del país que viene en el empaque, llamar a la compañía

local o visitar el sitio Web a fin de obtener esa información.

REEMPLAZO GRATUITO DE LAS ETIQUETAS DE ADVERTENCIA:

si sus etiquetas de advertencia se tornan ilegibles o faltan, llame al

1-800-4-D

EWALT (1-800-433-9258) para que se las reemplacen

gratuitamente.

SOLAMENTE PARA PROPÓSITO DE MÉXICO:

IMPORTADO POR: D

BOSQUES DE CIDROS, ACCESO RADIATAS NO.42

3A. SECCIÓN DE BOSQUES DE LAS LOMAS

DELEGACIÓN CUAJIMALPA,

05120, MÉXICO, D.F.

TEL. (52) 555-326-7100

R.F.C.: BDE810626-1W7

Para servicio y ventas consulte

“HERRAMIENTAS ELECTRICAS”

en la sección amarilla.

EWALT S.A. DE C.V.

Español

21

Page 24

DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 (MAY10) Part No. N081238 DW723

Copyright © 2001, 2004, 2005, 2008, 2010 D

The following are trademarks for one or more D

EWALT power tools: the yellow and black color scheme; the “D” shaped air intake grill; the

EWALT

array of pyramids on the handgrip; the kit box configuration; and the array of lozenge-shaped humps on the surface of the tool.

Loading...

Loading...