Page 1

IF YOU SHOULD EXPERIENCE A PROBLEM WITH YOUR DEWALT PURCHASE,

CALL 1-800-4 DEWALT

IN MOST CASES, A DEWALT REPRESENTATIVE CAN RESOLVE YOUR

PROBLEM OVER THE PHONE.

IF YOU HAVE A SUGGESTION OR COMMENT, GIVE US A CALL.

YOUR FEEDBACK IS VITAL TO THE SUCCESS OF DEWALT'S QUALITY

IMPROVEMENT PROGRAM.

Questions? See us on the World Wide Web at www.dewalt.com

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

INSTRUCTIVO DE OPERACION, CENTROS DE SERVICIO Y POLIZA

DE GARANT{A. ADVERTENCIA: LI2ASE ESTE INSTRUCTIVO ANTES

DE USAR EL PRODUCTO.

DW718 (120 Volt), DW718 (230 Volt) 12" Double Bevel Sliding Compound Miter Saw

®

DW718 (120 Volt), DW718 (230 Volt) Scie coulissante a onglet mixte 305 mm (12 po)

DW718 (120 Voltios), DW718 (230 Voltios) Sierra ingletadora compuesta deslizante de

doble bisel de 305 mm (12")

Page 2

TABLE OF CONTENTS

DOUBLE INSULATION/POLARIZED PLUG INSTRUCTIONS ..................................... 2

SAFETY INSTRUCTIONS FOR ALL TOOLS ..................................................... 2

ADDITIONAL SAFETY RULES ....................................................................... 3

ELECTRICAL CONNECTION ......................................................................... 4

ACCESSORIES .............................................................................................................. 4

BLADE DESCRIPTIONS ................................................................................................ 5

UNPACKING YOUR SAW ............................................................................. 5

SPECIFICATIONS .......................................................................................................... 5

FAMILIARIZATION ...................................................................................... 6

BENCH MOUNTING ..................................................................................... 6

CHANGING OR INSTALLING A NEW SAW BLADE .................................................... 6

REMOVING THE BLADE ............................................................................................... 6

INSTALLING THE BLADE .............................................................................. 7

TRANSPORTING THE SAW .......................................................................... 7

ADJUSTMENTS ......................................................................................... 7

MITER SCALE ADJUSTMENT ................................................................... 8

MITER POINTER ADJUSTMENT ................................................................ 8

BEVEL SQUARE TO TABLE ..................................................................................... 8

BEVEL POINTER ........................................................................................................ 8

BEVEL STOP .............................................................................................................. 8

FENCE ADJUSTMENT ............................................................................. 8

AUTOMATIC ELECTRIC BRAKE .............................................................................. 8

GUARD ACTUATION AND VISIBILITY ........................................................ 9

KERF PLATE ADJUSTMENT .................................................................................... 9

BRUSHES .................................................................................................. 9

CONTROLS .................................................................................................................... 9

OPERATION ............................................................................................... 9

SWITCH ..................................................................................................................... 9

CUTTING WITH YOUR SAW ................................................................................... 9

CROSSCUTS ............................................................................................................ 10

BEVEL CUTS ............................................................................................................ 10

QUALITY OF CUT .................................................................................................... 10

BODY AND HAND POSITION ................................................................................. 10

CLAMPING THE WORKPIECE .............................................................................. 11

SUPPORT FOR LONG PIECES ............................................................................. 11

CUTTING PICTURE FRAMES, SHADOW BOXES

AND OTHER FOUR-SIDED PROJECTS ............................................................... 11

CUTTING TRIM MOLDING AND OTHER FRAMES ............................................. 11

CUTTING COMPOUND MITERS ........................................................................... 11

CUTTING BASE MOLDINGS ................................................................................. 12

CUTTING CROWN MOLDING ............................................................................... 12

SPECIAL CUTS ............................................................................................................ 13

REMOVING AND REPLACING THE BELT ................................................................. 14

MAINTENANCE ............................................................................................................ 14

SERVICE INFORMATION ............................................................................................ 14

WARRANTY ................................................................................................................. 14

TROUBLESHOOTING GUIDE ..................................................................................... 15

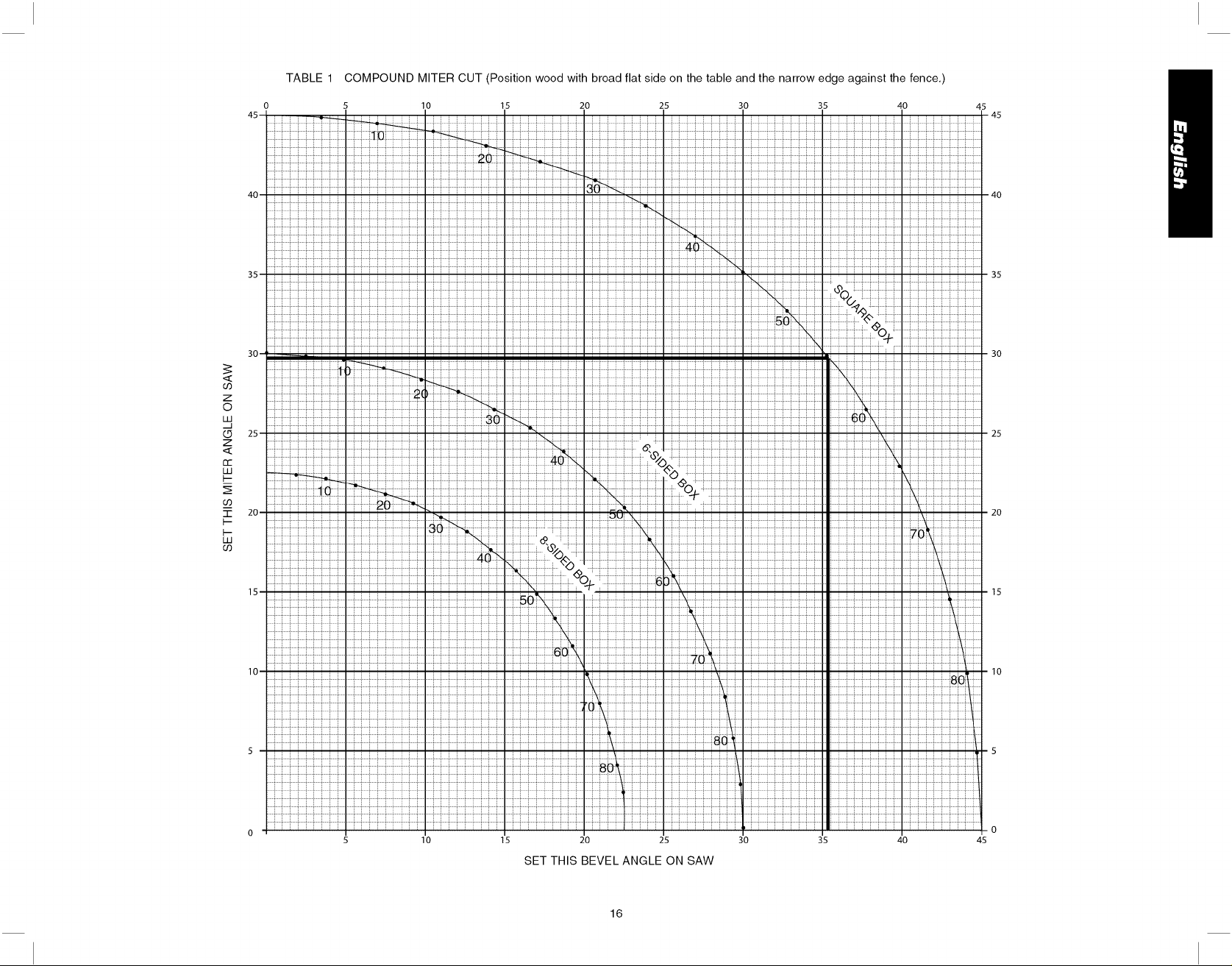

TABLE 1: COMPOUND MITER CUT ........................................................................... 16

RAIL GUIDE ADJUSTMENT ...................................................................................... 9

MITER LOCK ADJUSTMENT .................................................................................... 9

Page 3

Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read

the manual and pay attention to these symbols.

i_,DANGER: Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

AWARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

_&CAUTION: Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

CAUTION: Used without the safety alert symbol indicates a potentially hazardous

situation which, if not avoided, may result in property damage.

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT

TOOL, CALL US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-9258)

Important Safety Instructions

A ARNING: Read all instructions before operating product. Failure to follow all

instructions fisted below may result in electric shock, fire and/or serious injury.

READ ALL INSTRUCTIONS

Double Insulation

Double insulated tools are constructed throughout with two separate layers of electrical

insulation or one double thickness of insulation between you and the tool's electrical sys-

tem. Tools built with this insulation system are not intended to be grounded. As a result,

your tool is equipped with a two prong plug which permits you to use extension cords

without concern for maintaining a ground connection.

NOTE: Double insulation does not take the place of normal safety precautions when oper-

ating this tool. The insulation system is for added protection against injury resulting from a

possible electrical insulation failure within the tool.

ACAUTION: WHEN SERVICING USE ONLY IDENTICAL REPLACEMENT PARTS.

Repair or replace damaged cords.

Polarized Plugs

Polarized plugs (one blade is wider than the other) are used on equipment to reduce the

risk of electric shock. When provided, this plug will fit in the polarized outlet only one way.

If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit, contact a

qualified electrician to install the proper outlet. Do not change the plug in any way.

Safety Instructions For All Tools

• KEEP GUARD IN PLACE and in working order.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that

keys and adjusting wrenches are removed from spindle before turning tool on. Tools,

scrap pieces, and other debris can be thrown at high speed, causing injury.

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

• DO NOT USE THE MACHINE IN A DANGEROUS ENVIRONMENT. The use of power

tools in damp or wet locations or in rain can cause shock or electrocution. Keep your

work area well-lit to avoid tripping or placing arms, hands, and fingers in danger.

• KEEP CHILDRENAWAY. All visitors shouldbe keptata safe distance from workarea.

Your shop is a potentially dangerous environment.

• MAKE WORKSHOP CHILDPROOF with padlocks, master switches, or by removing

starter keys. The unauthorized start-up of a machine by a child or visitor may result in

injury.

• DON'T FORCE TOOL. It will do the job better and be safer at the rate for which it was

designed.

• USE RIGHT TOOL. Don't force tool or attachment to do a job for which it was not

designed. Using the incorrect tool or attachment may result in personal injury.

• WEAR PROPER APPAREL. No loose clothing, gloves, neckties, rings, bracelets, or

other jewelry to get caught in moving parts. Non-slip footwear is recommended. Wear

protective hair covering to contain long hair. Air vents may cover moving parts and

should also be avoided.

• ALWAYS USE SAFETY GLASSES. Everyday eyeglasses are NOT safety glasses.

Also use face or dust mask if cutting operation is dusty. ALWAYS WEAR CERTIFIED

SAFETY EQUIPMENT:

• ANSI Z87.1 eye protection (CAN/CSA Z94.3)

• ANSI $12.6 (S3.19) hearing protection

• NIOSH/OSHA/MSHA respiratory protection

• SECURE THE WORKPIECE. Use clamps or a vise to hold the workpiece on the

table and against the fence or when your hand will be dangerously close to the blade

(within 6"). It is safer than using your hand and it frees both hands to operate tooL

• DON'T OVERREACH. Keep proper footing and balance at all times. Loss of balance

may cause personal injury.

• MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing accessories. Poorly

maintained tools and machines can further damage the tool or machine and/or cause

injury.

• TURN THE MACHINE "OFF'; AND DISCONNECT THE MACHINE FROM THE

POWER SOURCE before installing or removing accessories, before adjusting or

changing set-up& when making repairs or changing locations. An accidental start-up

can cause injury. Do not touch the plug's metal prongs when unplugging or plugging in

the cord.

• REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure that the switch is

in the "OFF" position before plugging in the power cord.

• USE PROPER EXTENSION CORD. Make sure your extension cord is in good

condition. If your product is equipped with a cordset, use only 3-wire extension

cords that have 3-prong grounding-type plugs and 3-pole receptacles that accept

the tool's plug. When using an extension cord, be sure to use one heavy enough

to carry the current your product will draw. An undersized cord will cause a drop in

line voltage resulting in loss of power and overheating. The following table shows

the correct size to use depending on cord length and nameplate ampere rating. If in

doubt, use the next heavier gage. The smaller the gage number, the heavier the cord.

Volts

120V

240V

Ampere Rating

More Not more

Than Than

O- 6

6- 10

10 - 12

12 - 16

• CHECK for DAMAGED PARTS. Before further use of the tool, a guard or other part

that is damaged should be carefully checked to determine that it will operate properly

and perform its intended function--check for alignment of moving parts, binding of

Minimum Gauge for Cord Sets

Total Length of Cord in Feet

0-25 26-50 51-100 101-150

0-50 51-100 101-200 201-300

AWG

18 16 16 14

18 16 14 12

16 16 14 12

14 12 Not Recommended

Page 4

movingparts,breakageofparts,mountingandanyotherconditionsthatmayaffect

itsoperation.Aguardorotherpartthatis damagedshouldbeproperlyrepairedor

replaced.Donotusetoolffswitchdoesnotturnitonandoff.

• USE RECOMMENDED ACCESSORIES. Use only accessories that are recommended

by the manufacturer for your model Accessories that may be suitable for one tool

may be hazardous when used on another tooL Consult the instruction manual for

recommended accessories. The use of improper accessories may cause risk of injury

to persons.

• NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the

cutting tool is unintentionally contacted.

• NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don't leave

tool until it comes to a complete stop. Serious injury can result.

• DO NOT OPERATE ELECTRIC TOOLS NEAR FLAMMABLE LIQUIDS OR IN

GASEOUS OR EXPLOSIVE ATMOSPHERES. Motors in these tools may spark and

ignite fumes.

• STAY ALERT, WATCH WHAT YOU ARE DOING, AND USE COMMON SENSE. DO

NOT USE THE MACHINE WHEN YOU ARE TIRED OR UNDER THE INFLUENCE

OF DRUGS or ALCOHOL. A moment of inattention while operating power tools may

result in injury.

Additional Safety Rules For Miter Saws

WARNING: Do not allow familiarity (gained from frequent use of your saw) to replace

safety rules. Always remember that a careless fraction of a second is sufficient to inflict

severe injury.

• DO NOT OPERATE THIS MACHINE until it is completely assembled and installed

according to the instructions. A machine incorrectly assembled can cause serious

injury.

• OBTAIN ADVICE from your supervisor, instructor, or another qualified person ff you

are not thoroughly familiar with the operation of this machine. Knowledge is safety.

• STABILITY. Make sure the miter saw is placed on a secure supporting surface and

does not slip or move during use. If the mobility kit is installed, raise the moveable

caster(s) so saw is in its stationary position.

• FOLLOW ALL WIRING CODES and recommended electrical connections to prevent

shock or electrocution. Protect electric supply line with at least a 15 ampere time-delay

fuse or a circuit breaker."

• MAKE CERTAIN the blade rotates in the correct direction. The teeth on the blade

should point in the direction of rotation as marked on the saw.

• TIGHTEN ALL CLAMP HANDLES, knobs and levers prior to operation. Loose clamps

can cause parts or the workpiece to be thrown at high speeds.

• BE SURE aft blade and clamp washers are clean, recessed sides of collars are against

blade and arbor screw is tightened securely. Loose or improper blade clamping may

result in damage to the saw and possible personal injury.

• ALWAYS USE A SHARP BLADE. Check the blade to see if it runs true and is free

from vibration. A dull or a vibrating blade can cause damage to the machine and/or

serious injury."

• DO NOT OPERATE ON ANYTHING OTHER THAN THE DESIGNATED VOLTAGE

for the saw. Overheating, damage to the tool and personal injury may occur.

• DO NOT WEDGE ANYTHING AGAINST THE FAN to hold the motor shaft. Damage

to tool and possible personal injury may occur.

• DO NOT force cutting action. Stalling or partial stalling of motor can cause damage. To

the machine or blade and/or serious injury.

• ALLOW THE MOTOR TO COME TO FULL SPEED prior to starting cut. Starting the

cut too soon may cause damage to the machine or blade and/or serious injury."

• NEVER CUT FERROUS METALS (Those with any iron or steel content) or masonry.

Either of these can cause the carbide tips to fly off the blade at high speeds causing

serious injury.

• DO NOT USE ABRASIVE WHEELS. The excessive heat and abrasive particles

generated by them may damage the saw and cause personal injury.

• NEVER have any part of your body in line with the path of the saw blade. Personal

injury will occur.

• NEVER apply blade lubricant to a running blade. Applying lubricant could cause your

hand to move into the blade resulting in serious injury.

• DO NOT place either hand in the blade area when the saw is connected to the power

source. Inadvertent blade activation may result in serious injury.

• DO NOT PERFORM FREE-HAND OPERATIONS (workpiece not supported by table

and fence). Hold the work firmly against the fence and table. Free-hand operations on

a miter saw could cause the workpiece to be thrown at high speeds, causing serious

injury.

• NEVER REACH AROUND or behind the saw blade. A blade can cause serious

injury.

• DO NOT reach underneath the saw unless it is unplugged and turned off. Contact with

saw blade may cause personal injury.

• SECURE THE MACHINE TO A STABLE SUPPORTING SURFACE. Vibration can

possibly cause the machine to slide, walk, or tip over, causing serious injury.

• USE ONLY CROSSCUT SAW BLADES recommended for miter saws. For best

results, use only zero-degree or negative hook angles when using carbide-tipped

blades. Do not use blades with deep gullets. These can deflect and contact the guard,

and can cause damage to the machine and/or serious injury.

• USE ONLY BLADES OF THE CORRECT SIZE AND TYPE specified for this tool to

prevent damage to the machine and/or serious injury.

• INSPECT BLADE FOR CRACKS or other damage prior to operation. A cracked or

damaged blade can come apart and pieces can be thrown at high speeds, causing

serious injury. Replace cracked or damaged blades immediately.

• CLEAN THE BLADE AND BLADE FLANGES prior to operation. Cleaning the blade

and flanges allows you to check for any damage to the blade or flanges. A cracked or

damaged blade or flange can come apart and pieces can be thrown at high speeds,

causing serious injury.

• DO NOT use lubricants or cleaners (particularly spray or aerosol) in the vicinity of the

plastic guard. The polycarbonate material used in the guard is subject to attack by

certain chemicals.

• AL WAYS USE THE KERF PLA TE AND REPLACE THIS PLATE WHEN DAMAGED.

Small chip accumulation under the saw may interfere with the saw blade or may cause

instability of workpiece when cutting.

• USE ONLY BLADE FLANGES specified for this tool to prevent damage to the machine

and/or serious injury.

• CLEAN THE MOTOR AIR SLOTS of chips and sawdust. Clogged motor air slots can

cause the machine to overheat, damaging the machine and possibly causing a short

which could cause serious injury.

• KEEP ARMS, HANDS, AND FINGERS away from the blade to prevent severe cuts.

Clamp all workpieces that would cause your hand to be within 6" of the saw blade.

• NEVER LOCK THE SWITCH IN THE "ON" position. Severe personal injury may

result.

Page 5

• TURN OFF THE MACHINE and allow the blade to come to a complete stop before

raising the arm and prior to cleaning the blade area, removing debris in the path of the

blade, before servicing or adjusting tool A moving blade can cause serious injury.

• PROPERLY SUPPORT LONG OR WIDE WORKPIECES. Loss of control of the

workpiece can cause injury.

• NEVER cross arms in front of blade while using tool Always make a dry run

(unpowered) before making a finish cut so that you can check the path of the blade or

severe personal injury may result.

• ADDITIONAL INFORMATION regarding the safe and proper operation of power

tools (i.e. a safety video) is available from the Power Tool Institute, 1300 Sumner

Avenue, Cleveland, OH 44115-2851 (www.powertoolinstitute.com). Information is also

available from the National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-

3201. Please refer to the American National Standards Institute ANSI 01.1 Safety

Requirements for Woodworking Machines and the U.S. Department of Labor OSHA

1910.213 Regulations.

J&CAUTION: Do not connect unit to electrical power source until complete instructions are

read and understood.

_ WARNING: Always wear proper personal hearing protection that conforms to

ANSI $12.6 ($3.19) during use. Under some conditions and duration of use, noise from

this product may contribute to hearing loss.

WARNING: NEVER MAKE ANY CUT UNLESS THE MATERIAL IS SECURED ON

THE TABLE AND AGAINST THE FENCE.

_ WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contains chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work.

To reduce your exposure to these chemicals: work in a well ventilated area, and work

with approved safety equipment, such as those dust masks that are specially designed to

filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding,

drilling, and other construction activities. Wear protective clothing and wash

exposed areas with soap and water. Allowing dust to get into your mouth, eyes,

or lay on the skin may promote absorption of harmful chemicals.

WARNING: Use of this tool can generate and/or disburse dust, which may cause

serious and permanent respiratory or other injury. Always use NIOSH/OSHA approved

respiratory protection appropriate for the dust exposure. Direct particles away from face

and body.

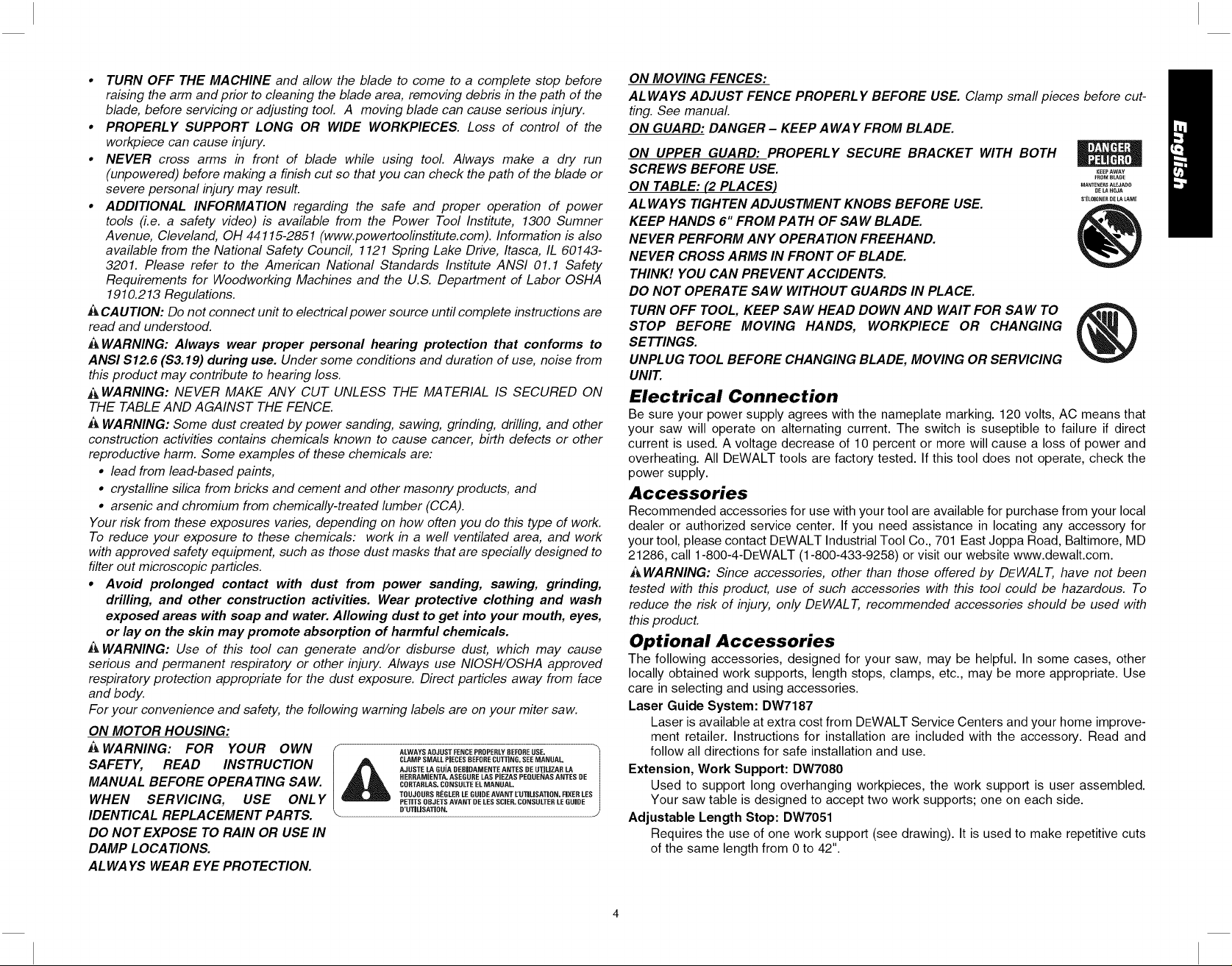

For your convenience and safety, the following warning labels are on your miter saw.

ON MOTOR HOUSING:

A WARNING: FOR YOUR OWN

SAFETY, READ INSTRUCTION

MANUAL BEFORE OPERA TING SAW.

WHEN SERVICING, USE ONLY

IDENTICAL REPLACEMENT PARTS.

I_ ALWAYS ADJUSTFENCE PROPERLYBEFOREUSE.

CLAMP SMALL PIECES BEFORECUTTING. SEE MANUAL

AJUSTE LA GUiA DEBiDAMENTE ANTES DE UTiLiZAR LA

HERRAMiENTA. ASEGURE LAS PJEZAS PEQUENAS ANTES DE

CORTARLAS. CONSULTE ELMANUAL.

TOUJOURS REGLERLE GUIDE AVANT EUTILiSATION. FIXER LES

PETiTS OBJETS AVANT DE LESSCiER. CONSULTER LE GUIDE

O'UTJLiSATiON. /

DO NOT EXPOSE TO RAIN OR USE IN

DAMP LOCATIONS.

ALWAYS WEAR EYE PROTECTION.

ON MOVING FENCES:

AL WAYS ADJUST FENCE PROPERLY BEFORE USE. Clamp small pieces before cut-

ting. See manual

ON GUARD: DANGER - KEEP A WAY FROM BLADE.

ON UPPER GUARD: PROPERLY SECURE BRACKET WITH BOTH

SCREWS BEFORE USE.

ON TABLE: (2 PLACES)

AL WAYS TIGHTEN ADJUSTMENT KNOBS BEFORE USE.

_EEPAWAY

FROMBL_OE

MANTENE_SALEJADO

OE_AHOJA

S'ELOIUNERDELALA_qE

KEEP HANDS 6" FROM PATH OF SAW BLADE.

NEVER PERFORM ANY OPERA TION FREEHAND.

NEVER CROSS ARMS IN FRONT OF BLADE.

THINK! YOU CAN PREVENT ACCIDENTS.

DO NOT OPERATE SAW WITHOUT GUARDS IN PLACE.

TURN OFF TOOL, KEEP SAW HEAD DOWN AND WAIT FOR SAW TO

STOP BEFORE MOVING HANDS, WORKPIECE OR CHANGING

SETTINGS.

UNPLUG TOOL BEFORE CHANGING BLADE, MOVING OR SERVICING

UNIT.

Electrical Connection

Be sure your power supply agrees with the nameplate marking. 120 volts, AC means that

your saw will operate on alternating current. The switch is suseptible to failure if direct

current is used. A voltage decrease of 10 percent or more will cause a loss of power and

overheating. All DEWALT tools are factory tested. If this tool does not operate, check the

power supply.

Accessories

Recommended accessories for use with your tool are available for purchase from your local

dealer or authorized service center. If you need assistance in locating any accessory for

your tool, please contact DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD

21286, call 1-800-4-DEWALT (1-800-433-9258) or visit our website www.dewalt.com.

_&WARNING: Since accessories, other than those offered by DEWAL T, have not been

tested with this product, use of such accessories with this tool could be hazardous. To

reduce the risk of injury, only DEWAL T, recommended accessories should be used with

this product.

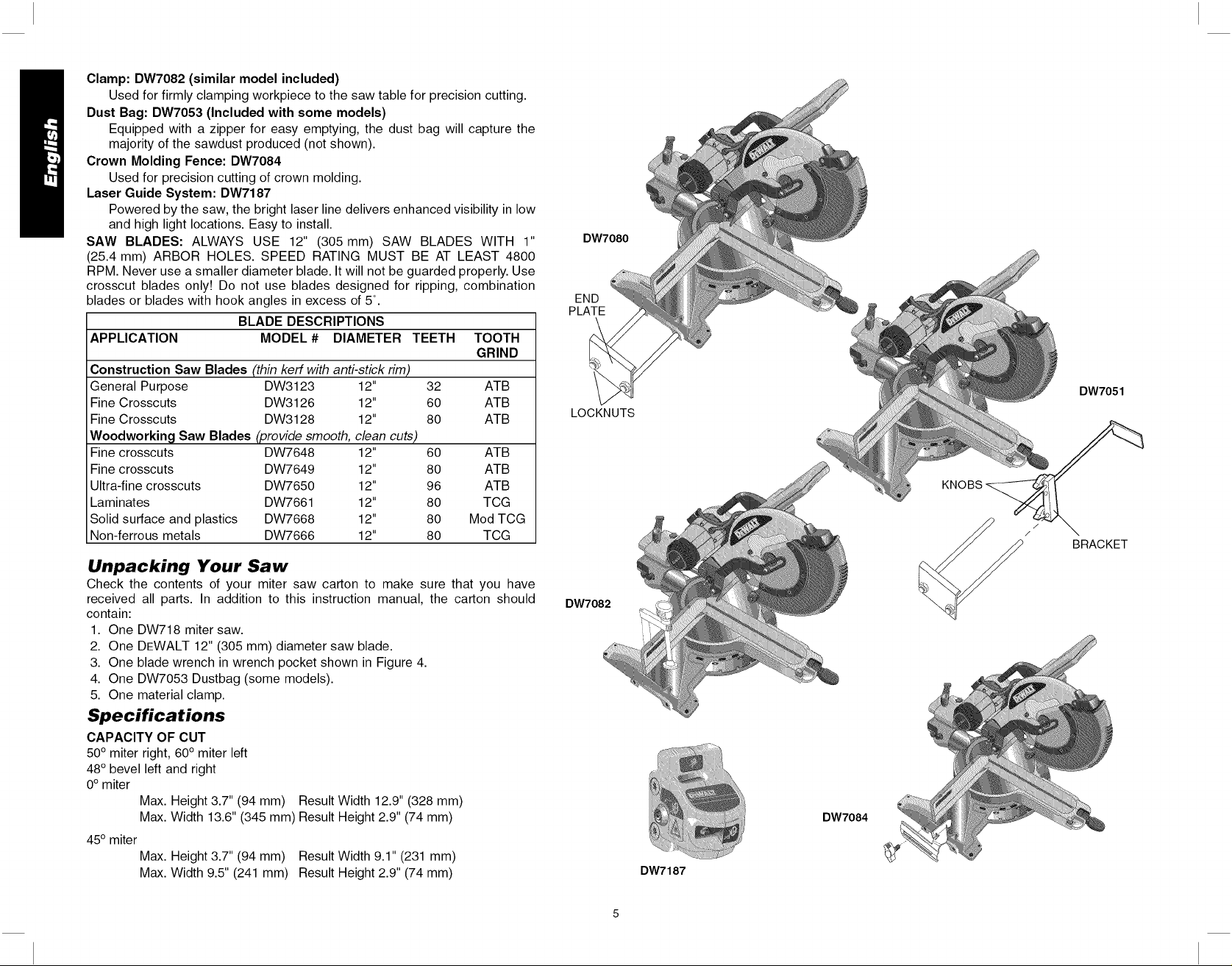

Optional Accessories

The following accessories, designed for your saw, may be helpful. In some cases, other

locally obtained work supports, length stops, clamps, etc., may be more appropriate. Use

care in selecting and using accessories.

Laser Guide System: DW7187

Laser is available at extra cost from DEWALT Service Centers and your home improve-

ment retailer. Instructions for installation are included with the accessory. Read and

follow all directions for safe installation and use.

Extension, Work Support: DW7080

Used to support long overhanging workpieces, the work support is user assembled.

Your saw table is designed to accept two work supports; one on each side.

Adjustable Length Stop: DW7051

Requires the use of one work support (see drawing). It is used to make repetitive cuts

of the same length from 0 to 42".

Page 6

Clamp:DW7082(similarmodelincluded)

Usedforfirmlyclampingworkpiecetothesawtableforprecisioncutting.

DustBag:DW7053(Includedwithsomemodels)

Equippedwithazipperforeasyemptying,thedustbagwillcapturethe

majorityofthesawdustproduced(notshown).

CrownMoldingFence:DW7084

Usedforprecisioncuttingofcrownmolding.

LaserGuideSystem:DW7187

Poweredbythesaw,thebrightlaserlinedeliversenhancedvisibilityinlow

andhighlightlocations.Easytoinstall.

SAWBLADES:ALWAYSUSE12"(305mm)SAWBLADESWITH1"

(25.4mm)ARBORHOLES.SPEEDRATINGMUSTBEATLEAST4800

RPM.Neveruseasmallerdiameterblade.Itwillnotbeguardedproperly.Use

crosscutbladesonly!Donotusebladesdesignedforripping,combination

bladesorbladeswithhookanglesinexcessof5°.

BLADEDESCRIPTIONS

APPLICATION MODEL# DIAMETERTEETH TOOTH

GRIND

ConstructionSawBlades (thin kerf with anti-stick rim)

General Purpose DW3123 12" 32 ATB

Fine Crosscuts DW3126 12" 60 ATB

Fine Crosscuts DW3128 12" 80 ATB

Woodworkinq Saw Blades (provide smooth, clean cuts)

Fine crosscuts DW7648 12" 60 ATB

Fine crosscuts DW7649 12" 80 ATB

Ultra-fine crosscuts DW7650 12" 96 ATB

Laminates DW7661 12" 80 TCG

Solid surface and plastics DW7668 12" 80 Mod TCG

Non-ferrous metals DW7666 12" 80 TCG

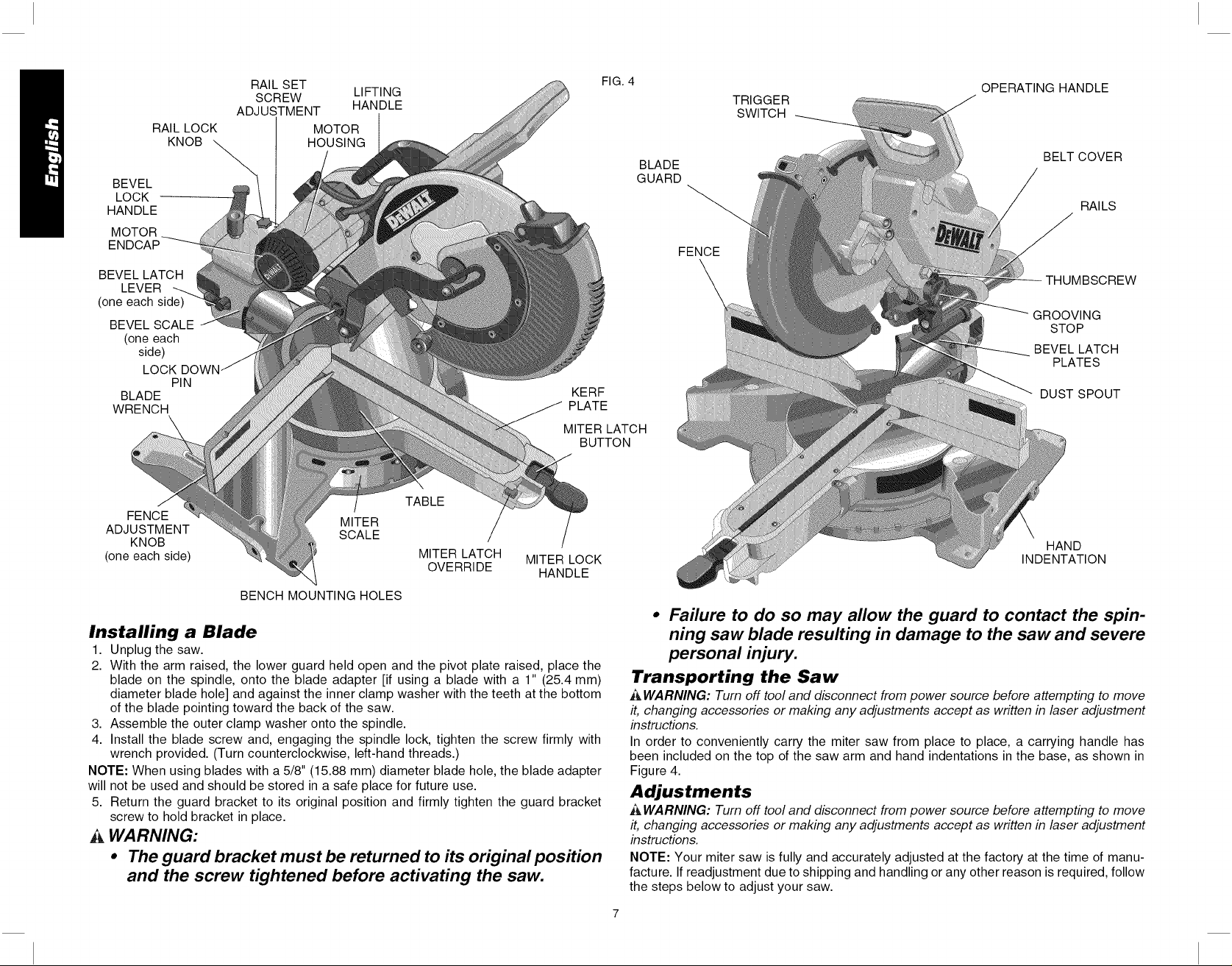

Unpacking Your Saw

Check the contents of your miter saw carton to make sure that you have

received all parts. In addition to this instruction manual, the carton should

contain:

1. One DW718 miter saw.

2. One DEWALT 12" (305 mm) diameter saw blade.

3. One blade wrench in wrench pocket shown in Figure 4.

4. One DW7053 Dustbag (some models).

5. One material clamp.

Specifications

CAPACITY OF CUT

50° miter right, 60° miter left

48° bevel left and right

0° miter

Max. Height 3.7" (94 mm) Result Width 12.9" (328 mm)

Max. Width 13.6" (345 mm) Result Height 2.9" (74 mm)

45° miter

Max. Height 3.7" (94 mm) Result Width 9.1" (231 mm)

Max. Width 9.5" (241 mm) Result Height 2.9" (74 mm)

DW7080

END

PLATE

DW7051

LOCKNUTS

BRACKET

DW7082

DW7084

DW7187

Page 7

45° bevel - Left

Max. Height 2.4" (61 mm) Result Width 12.9" (328 mm)

Max. Width 13.6" (345 mm) Result Height 1.9" (48 mm)

45° bevel - Right

Max. Height 1.7" (43 mm) Result Width 12.9" (328 mm)

Max. Width 13.6" (345 mm) Result Height 1.1" (28 mm)

Your saw is capable of cutting baseboard moldings 0.8" (20 mm) thick by 6.5" (165 mm)

tall on a 45° right or left miter.

NOTE: Your saw is capable of cutting the following once a special setup procedure is fol-

lowed (see Special Cuts).

0° miter height 1.5 width 16.1

45° miter height 1.5 width 11.7

DRIVE

120 Volt Motor

1600 Watts In 15 Amp Motor

3600 RPM Cut Helical Gears

Multi-V Belt Roller Bearings

Automatic Electric Brake Carbide Blade

Familia riza tion

Your miter saw is fully assembled in the carton. Open the

box and lift the saw out by the convenient carrying handle, FIG. 1

as shown in Figure 1.

Place the saw on a smooth, flat surface such as a work-

bench or strong table.

Examine the two figures on page 7 to become familiar with

the saw and its various parts. The section on adjustments

will refer to these terms and you must know what and

where the parts are.

Press down lightly on the operating handle and pull out the lock FIG. 2

down pin. Gently release the downward pressure and hold the arm

allowing it to rise to its full height. Use the lock down pin when car-

rying the saw from one place to another. Always use the carrying

handle to transport the saw or the hand indentations shown in

Figure. 2.

Bench Mounting-

Holes are provided in all 4 feet to facilitate bench mounting, as

shown in Figure 4. (Two different sized holes are provided to

accommodate different sizes of screws. Use either hole, it is not

necessary to use both.) Always mount your saw firmly to a stable

surface to prevent movement. To enhance the tool's portability, it

can be mounted to a piece of 1/2" (12.7 mm) or thicker plywood

which can then be clamped to your work support or moved to other job sites and rec-

lamped.

NOTE: If you elect to mount your saw to a piece of plywood, make sure that the mounting

screws don't protrude from the bottom of the wood. The plywood must sit flush on the work

support. When clamping the saw to any work surface, clamp only on the clamping bosses

where the mounting screw holes are located. Clamping at any other point will surely inter-

fere with the proper operation of the saw.

,&CAUTION: To prevent binding and inaccuracy, be sure the mounting surface is not

warped or otherwise uneven, ff the saw rocks on the surface place a thin piece of material

under one saw foot until the saw sits firmly on the mounting surface.

IMPORTANT SAFETY INSTRUCTIONS

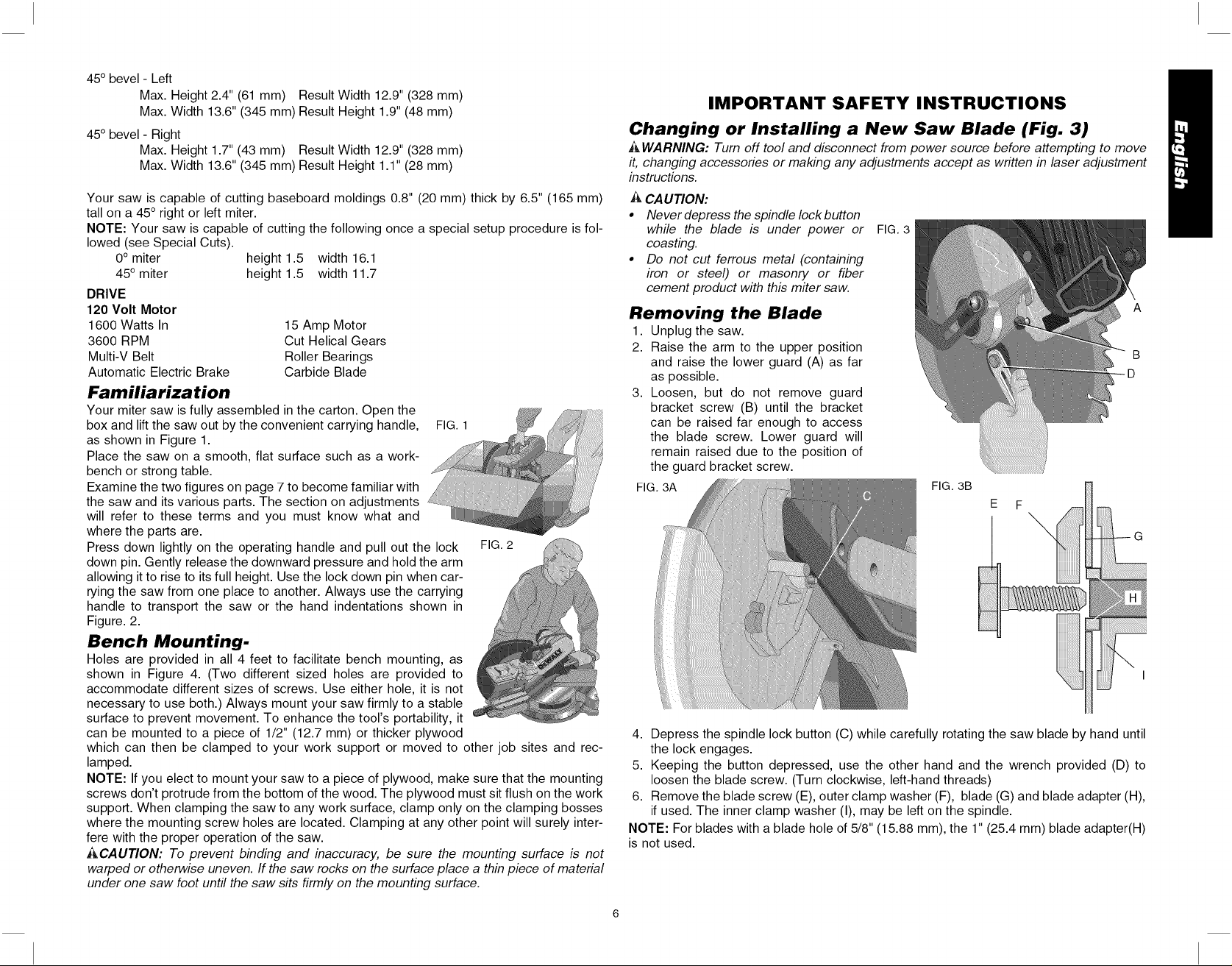

Changing or Installing a New Saw Blade (Fig. 3)

h&WARNING: Turn off tool and disconnect from power source before attempting to move

it, changing accessories or making any adjustments accept as written in laser adjustment

instructions.

CAUTION:

• Never depress the spindle lock button

while the blade is under power or

coasting.

• Do not cut ferrous metal (containing

iron or steel) or masonry or fiber

cement product with this miter saw.

FIG. 3

Removing the Blade

1. Unplug the saw.

2. Raise the arm to the upper position

and raise the lower guard (A) as far

as possible.

3. Loosen, but do not remove guard

bracket screw (B) until the bracket

can be raised far enough to access

the blade screw. Lower guard will

remain raised due to the position of

the guard bracket screw.

FIG. 3A FIG. 3B

E F

4. Depress the spindle lock button (C) while carefully rotating the saw blade by hand until

the lock engages.

5. Keeping the button depressed, use the other hand and the wrench provided (D) to

loosen the blade screw. (Turn clockwise, left-hand threads)

6. Remove the blade screw (E), outer clamp washer (F), blade (G) and blade adapter (H),

if used. The inner clamp washer (I), may be left on the spindle.

NOTE: For blades with a blade hole of 5/8" (15.88 mm), the 1" (25.4 mm) blade adapter(H)

is not used.

D

B

G

Page 8

BEVEL

LOCK

HANDLE

RAILLOCK

KNOB

RAIL SET

SCREW

ADJUSTMENT

HOUSING

LIFTING

HANDLE

MOTOR

MOTOR

BEVEL LATCH

LEVER

(one each side)

BEVEL SCALE

(one each

side)

LOCK

BLADE

PIN

WRENCH

FENCE

ADJUSTMENT

KNOB

(one each side)

TABLE

MITER

SCALE

MITER LATCH MITER LOCK

OVERRIDE HANDLE

BENCH MOUNTING HOLES

KERF

PLATE

MITER LATCH

BUTTON

Installing a Blade

1. Unplug the saw.

2. With the arm raised, the lower guard held open and the pivot plate raised, place the

blade on the spindle, onto the blade adapter [if using a blade with a 1" (25.4 mm)

diameter blade hole] and against the inner clamp washer with the teeth at the bottom

of the blade pointing toward the back of the saw.

3. Assemble the outer clamp washer onto the spindle.

4. Install the blade screw and, engaging the spindle lock, tighten the screw firmly with

wrench provided. (Turn counterclockwise, left-hand threads.)

NOTE: When using blades with a 5/8" (15.88 mm) diameter blade hole, the blade adapter

will not be used and should be stored in a safe place for future use.

5. Return the guard bracket to its original position and firmly tighten the guard bracket

screw to hold bracket in place.

WARNING:

• The guard bracket must be returned to its original position

and the screw tightened before activating the saw.

FIG. 4

TRIGGER

SWITCH

BLADE

OPERATING HANDLE

BELT COVER

GUARD

FENCE

THUMBSCREW

GROOVING

STOP

BEVEL LATCH

PLATES

DUST SPOUT

HAND

INDENTATION

• Failure to do so may allow the guard to contact the spin-

ning saw blade resulting in damage to the saw and severe

personal injury.

Transporting the Saw

A WARNING: Turn off tool and disconnect from power source before attempting to move

it, changing accessories or making any adjustments accept as written in laser adjustment

instructions.

In order to conveniently carry the miter saw from place to place, a carrying handle has

been included on the top of the saw arm and hand indentations in the base, as shown in

Figure 4.

Adjustments

A WARNING: Turn off tool and disconnect from power source before attempting to move

it, changing accessories or making any adjustments accept as written in laser adjustment

instructions.

NOTE: Your miter saw is fully and accurately adjusted at the factory at the time of manu-

facture. If readjustment due to shipping and handling or any other reason is required, follow

the steps below to adjust your saw.

RAILS

Page 9

Oncemade,theseadjustmentsshouldremainaccurate.

Takealittletimenowtofollowthesedirectionscarefullyto

maintaintheaccuracyofwhichyoursawiscapable.

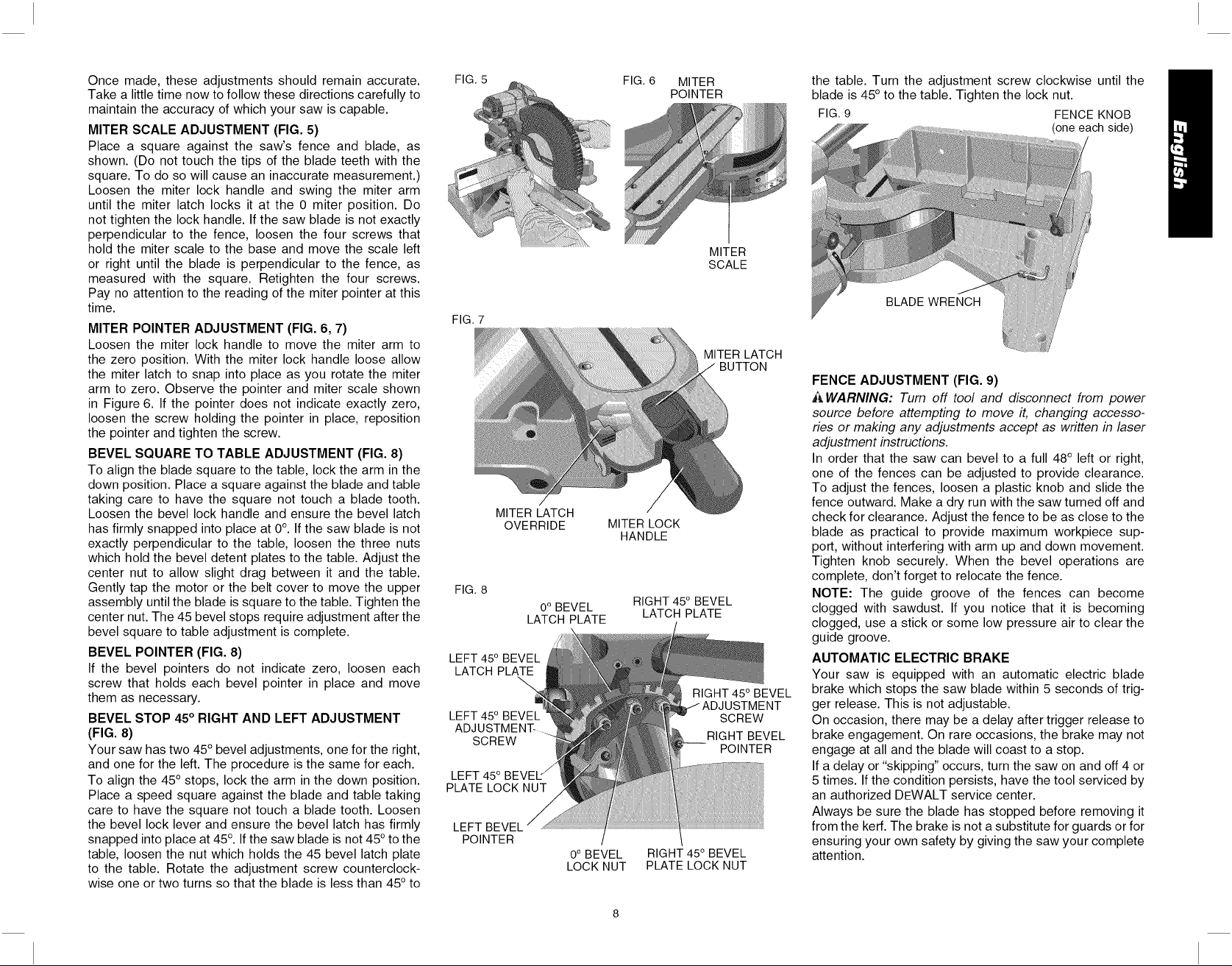

MITERSCALEADJUSTMENT (FIG. 5)

Place a square against the saw's fence and blade, as

shown. (Do not touch the tips of the blade teeth with the

square. To do so will cause an inaccurate measurement.)

Loosen the miter lock handle and swing the miter arm

until the miter latch locks it at the 0 miter position. Do

not tighten the lock handle. If the saw blade is not exactly

perpendicular to the fence, loosen the four screws that

hold the miter scale to the base and move the scale left

or right until the blade is perpendicular to the fence, as

measured with the square. Retighten the four screws.

Pay no attention to the reading of the miter pointer at this

time.

MITER POINTER ADJUSTMENT (FIG. 6, 7)

Loosen the miter lock handle to move the miter arm to

the zero position. With the miter lock handle loose allow

the miter latch to snap into place as you rotate the miter

arm to zero. Observe the pointer and miter scale shown

in Figure 6. If the pointer does not indicate exactly zero,

loosen the screw holding the pointer in place, reposition

the pointer and tighten the screw.

BEVEL SQUARE TO TABLE ADJUSTMENT (FIG. 8)

To align the blade square to the table, lock the arm in the

down position. Place a square against the blade and table

taking care to have the square not touch a blade tooth.

Loosen the bevel lock handle and ensure the bevel latch

has firmly snapped into place at 0°. If the saw blade is not

exactly perpendicular to the table, loosen the three nuts

which hold the bevel detent plates to the table. Adjust the

center nut to allow slight drag between it and the table.

Gently tap the motor or the belt cover to move the upper

assembly until the blade is square to the table. Tighten the

center nut. The 45 bevel stops require adjustment after the

bevel square to table adjustment is complete.

BEVEL POINTER (FIG. 8)

If the bevel pointers do not indicate zero, loosen each

screw that holds each bevel pointer in place and move

them as necessary.

BEVEL STOP 45° RIGHT AND LEFT ADJUSTMENT

(FIG. 8)

Your saw has two 45°bevel adjustments, one for the right,

and one for the left. The procedure is the same for each.

To align the 45° stops, lock the arm in the down position.

Place a speed square against the blade and table taking

care to have the square not touch a blade tooth. Loosen

the bevel lock lever and ensure the bevel latch has firmly

snapped into place at 45°. If the saw blade is not 45° to the

table, loosen the nut which holds the 45 bevel latch plate

to the table. Rotate the adjustment screw counterclock-

wise one or two turns so that the blade is less than 45° to

FIG. 5

FIG. 7

MITER LATCH

OVERRIDE

FIG. 8

LATCH PLATE

LEFT 45o BEVEL

LATCH PLATE

LEFT 450

ADJUSTMENT-

SCREW

LEFT 450 BEVEL "/

PLATE LOCK NUT

LEFT BEVEL

POINTER

0° BEVEL

0° BEVEL

LOCK NUT

FIG. 6 MITER

MITER LOCK

HANDLE

RIGHT 450 BEVEL

LATCH PLATE

RIGHT 450 BEVEL

PLATE LOCK NUT

POINTER

MITER

SCALE

MITER LATCH

BUTTON

RIGHT 450 BEVEL

SCREW

RIGHT BEVEL

POINTER

the table. Turn the adjustment screw clockwise until the

blade is 45° to the table. Tighten the lock nut.

FIG.9 FENCE KNOB

(one each side)

BLADE WRENCH

FENCE ADJUSTMENT (FIG. 9)

i_ WARNING: Turn off tool and disconnect from power

source before attempting to move it, changing accesso-

ries or making any adjustments accept as written in laser

adjustment instructions.

In order that the saw can bevel to a full 48° left or right,

one of the fences can be adjusted to provide clearance.

To adjust the fences, loosen a plastic knob and slide the

fence outward. Make a dry run with the saw turned off and

check for clearance. Adjust the fence to be as close to the

blade as practical to provide maximum workpiece sup-

port, without interfering with arm up and down movement.

Tighten knob securely. When the bevel operations are

complete, don't forget to relocate the fence.

NOTE: The guide groove of the fences can become

clogged with sawdust. If you notice that it is becoming

clogged, use a stick or some low pressure air to clear the

guide groove.

AUTOMATIC ELECTRIC BRAKE

Your saw is equipped with an automatic electric blade

brake which stops the saw blade within 5 seconds of trig-

ger release. This is not adjustable.

On occasion, there may be a delay after trigger release to

brake engagement. On rare occasions, the brake may not

engage at all and the blade will coast to a stop.

If a delay or "skipping" occurs, turn the saw on and off 4 or

5times. If the condition persists, have the tool serviced by

an authorized DEWALT service center.

Always be sure the blade has stopped before removing it

from the ken<.The brake is not a substitute for guards or for

ensuring your own safety by giving the saw your complete

attention.

Page 10

GUARD ACTUATION AND VISIBILITY

The blade guard on your saw has been designed to auto-

matically raise when the arm is brought down and to lower

over the blade when the arm is raised.

The guard can be raised by hand when installing or

removing saw blades or for inspection of the saw. NEVER

RAISE THE BLADE GUARD MANUALLY UNLESS THE

SAW IS TURNED OFF.

NOTE: Certain special cuts of large material will require

that you manually raise the guard. See page 13.

The front section of the guard is Iouvered for visibility

while cutting. Although the louvers dramatically reduce

flying debris, they are openings in the guard and safety

glasses should be worn at all times when viewing

through the louvers.

KERF PLATE ADJUSTMENT

To adjust the kerf plates, loosen the screws holding the

kerr plates in place. Adjust so that the kerr plates are

as close as possible without interfering with the blade's

movement.

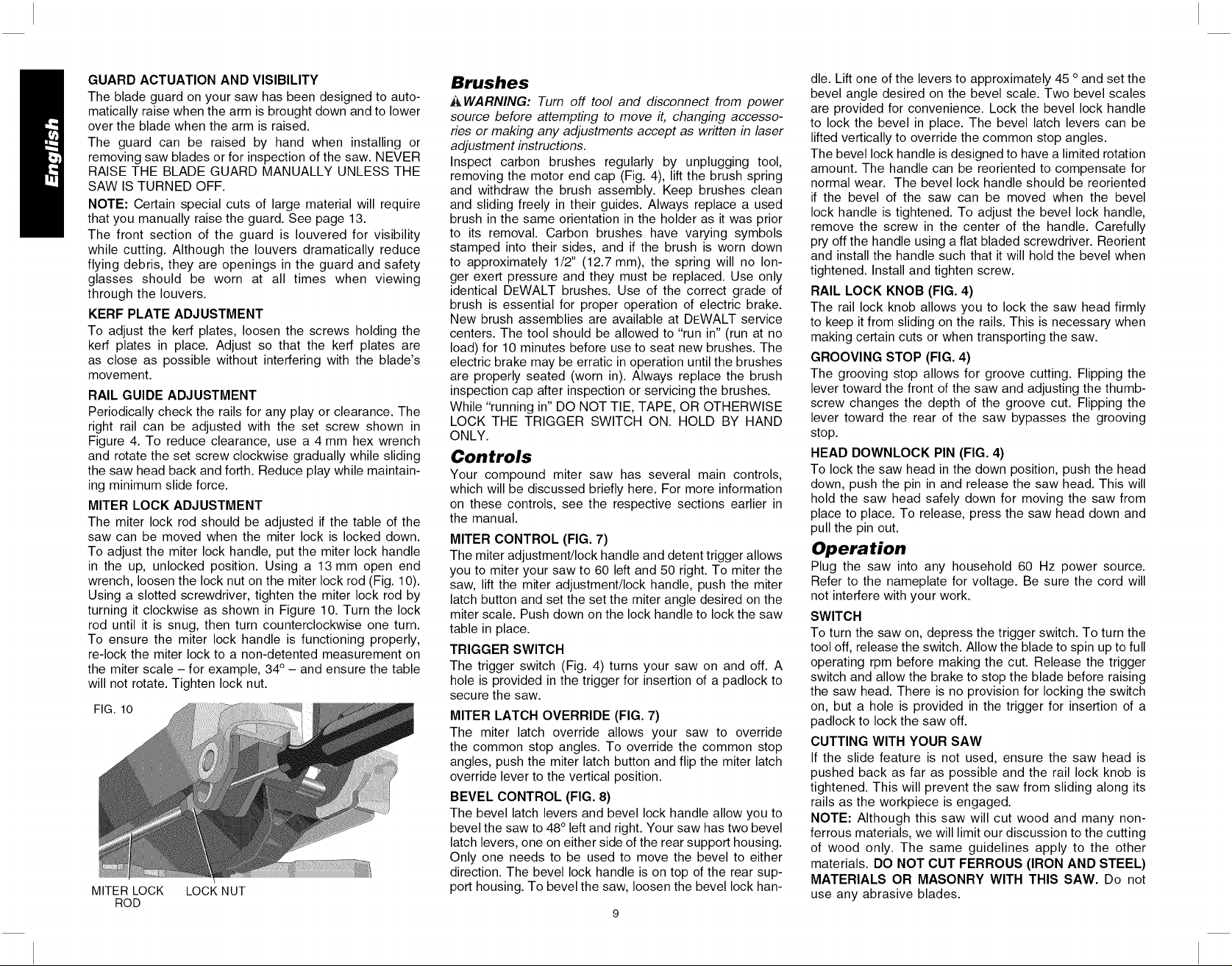

RAIL GUIDE ADJUSTMENT

Periodically check the rails for any play or clearance. The

right rail can be adjusted with the set screw shown in

Figure 4. To reduce clearance, use a 4 mm hex wrench

and rotate the set screw clockwise gradually while sliding

the saw head back and forth. Reduce play while maintain-

ing minimum slide force.

MITER LOCK ADJUSTMENT

The miter lock rod should be adjusted if the table of the

saw can be moved when the miter lock is locked down.

To adjust the miter lock handle, put the miter lock handle

in the up, unlocked position. Using a 13 mm open end

wrench, loosen the lock nut on the miter lock rod (Fig. 10).

Using a slotted screwdriver, tighten the miter lock rod by

turning it clockwise as shown in Figure 10. Turn the lock

rod until it is snug, then turn counterclockwise one turn.

To ensure the miter lock handle is functioning properly,

re-lock the miter lock to a non-detented measurement on

the miter scale - for example, 34° - and ensure the table

will not rotate. Tighten lock nut.

FIG, 10

MITER LOCK LOCK NUT

ROD

Brushes

A WARNING: Turn off tool and disconnect from power

source before attempting to move it, changing accesso-

ries or making any adjustments accept as written in laser

adjustment instructions.

Inspect carbon brushes regularly by unplugging tool,

removing the motor end cap (Fig. 4), lift the brush spring

and withdraw the brush assembly. Keep brushes clean

and sliding freely in their guides. Always replace a used

brush in the same orientation in the holder as it was prior

to its removal. Carbon brushes have varying symbols

stamped into their sides, and if the brush is worn down

to approximately 1/2" (12.7 mm), the spring will no lon-

ger exert pressure and they must be replaced. Use only

identical DEWALT brushes. Use of the correct grade of

brush is essential for proper operation of electric brake.

New brush assemblies are available at DEWALT service

centers. The tool should be allowed to "run in" (run at no

load) for 10 minutes before use to seat new brushes. The

electric brake may be erratic in operation until the brushes

are properly seated (worn in). Always replace the brush

inspection cap after inspection or servicing the brushes.

While "running in" DO NOT TIE, TAPE, OR OTHERWISE

LOCK THE TRIGGER SWITCH ON. HOLD BY HAND

ONLY.

Controls

Your compound miter saw has several main controls,

which will be discussed briefly here. For more information

on these controls, see the respective sections earlier in

the manual.

MITER CONTROL (FIG. 7)

The miter adjustment/lock handle and detent trigger allows

you to miter your saw to 60 left and 50 right. To miter the

saw, lift the miter adjustment/lock handle, push the miter

latch button and set the set the miter angle desired on the

miter scale. Push down on the lock handle to lock the saw

table in place.

TRIGGER SWITCH

The trigger switch (Fig. 4) turns your saw on and off. A

hole is provided in the trigger for insertion of a padlock to

secure the saw.

MITER LATCH OVERRIDE (FIG. 7)

The miter latch override allows your saw to override

the common stop angles. To override the common stop

angles, push the miter latch button and flip the miter latch

override lever to the vertical position.

BEVEL CONTROL (FIG. 8)

The bevel latch levers and bevel lock handle allow you to

bevel the saw to 48° left and right. Your saw has two bevel

latch levers, one on either side of the rear support housing.

Only one needs to be used to move the bevel to either

direction. The bevel lock handle is on top of the rear sup-

port housing. To bevel the saw, loosen the bevel lock han-

die. Lift one of the levers to approximately 45 oand set the

bevel angle desired on the bevel scale. Two bevel scales

are provided for convenience. Lock the bevel lock handle

to lock the bevel in place. The bevel latch levers can be

lifted vertically to override the common stop angles.

The bevel lock handle is designed to have a limited rotation

amount. The handle can be reoriented to compensate for

normal wear. The bevel lock handle should be reoriented

if the bevel of the saw can be moved when the bevel

lock handle is tightened. To adjust the bevel lock handle,

remove the screw in the center of the handle. Carefully

pry off the handle using a flat bladed screwdriver. Reorient

and install the handle such that it will hold the bevel when

tightened. Install and tighten screw.

RAIL LOCK KNOB (FIG. 4)

The rail lock knob allows you to lock the saw head firmly

to keep it from sliding on the rails. This is necessary when

making certain cuts or when transporting the saw.

GROOVING STOP (FIG. 4)

The grooving stop allows for groove cutting. Flipping the

lever toward the front of the saw and adjusting the thumb-

screw changes the depth of the groove cut. Flipping the

lever toward the rear of the saw bypasses the grooving

stop.

HEAD DOWNLOCK PIN (FIG. 4)

To lock the saw head in the down position, push the head

down, push the pin in and release the saw head. This will

hold the saw head safely down for moving the saw from

place to place. To release, press the saw head down and

pull the pin out.

Operation

Plug the saw into any household 60 Hz power source.

Refer to the nameplate for voltage. Be sure the cord will

not interfere with your work.

SWITCH

To turn the saw on, depress the trigger switch. To turn the

tool off, release the switch. Allow the blade to spin up to full

operating rpm before making the cut. Release the trigger

switch and allow the brake to stop the blade before raising

the saw head. There is no provision for locking the switch

on, but a hole is provided in the trigger for insertion of a

padlock to lock the saw off.

CUTTING WITH YOUR SAW

If the slide feature is not used, ensure the saw head is

pushed back as far as possible and the rail lock knob is

tightened. This will prevent the saw from sliding along its

rails as the workpiece is engaged.

NOTE: Although this saw will cut wood and many non-

ferrous materials, we will limit our discussion to the cutting

of wood only. The same guidelines apply to the other

materials. DO NOT CUT FERROUS (IRON AND STEEL)

MATERIALS OR MASONRY WITH THIS SAW. Do not

use any abrasive blades.

Page 11

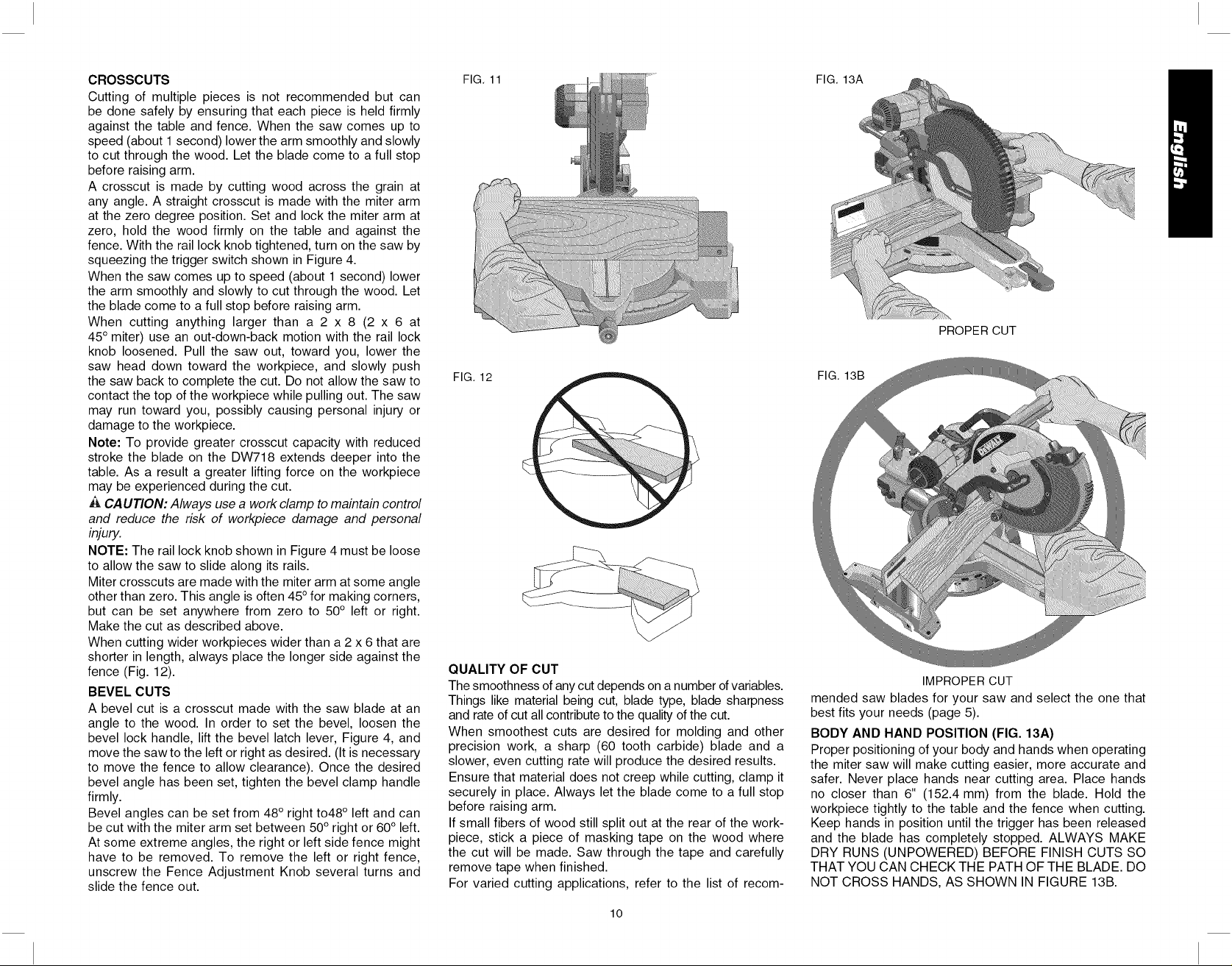

CROSSCUTS

Cuttingof multiplepiecesis notrecommendedbutcan

bedonesafelybyensuringthateachpieceisheldfirmly

againstthetableandfence.Whenthesawcomesupto

speed(about1second)lowerthearmsmoothlyandslowly

tocutthroughthewood.Letthebladecometoafullstop

beforeraisingarm.

Acrosscutismadebycuttingwoodacrossthegrainat

anyangle.Astraightcrosscutismadewiththemiterarm

atthezerodegreeposition.Setandlockthemiterarmat

zero,holdthewoodfirmlyonthetableandagainstthe

fence.Withtheraillockknobtightened,turnonthesawby

squeezingthetriggerswitchshowninFigure4.

Whenthesawcomesuptospeed(about1second)lower

thearmsmoothlyandslowlytocutthroughthewood.Let

thebladecometoafullstopbeforeraisingarm.

Whencuttinganythinglargerthana2 x 8 (2 x 6 at

45°miter)useanout-down-backmotionwiththeraillock

knobloosened.Pullthesawout,towardyou,lowerthe

sawheaddowntowardtheworkpiece,andslowlypush

thesawbacktocompletethecut.Donotallowthesawto

contactthetopoftheworkpiecewhilepullingout.Thesaw

mayruntowardyou,possiblycausingpersonalinjuryor

damagetotheworkpiece.

Note:Toprovidegreatercrosscutcapacitywithreduced

strokethebladeontheDW718extendsdeeperintothe

table.Asaresultagreaterliftingforceontheworkpiece

maybeexperiencedduringthecut.

CAUTION: Always use a work clamp to maintain control

and reduce the risk of workpiece damage and personal

injury.

NOTE: The rail lock knob shown in Figure 4 must be loose

to allow the saw to slide along its rails.

Miter crosscuts are made with the miter arm at some angle

other than zero. This angle is often 45° for making corners,

but can be set anywhere from zero to 50° left or right.

Make the cut as described above.

When cutting wider workpieces wider than a 2 x 6 that are

shorter in length, always place the longer side against the

fence (Fig. 12).

BEVEL CUTS

A bevel cut is a crosscut made with the saw blade at an

angle to the wood. In order to set the bevel, loosen the

bevel lock handle, lift the bevel latch lever, Figure 4, and

move the sawto the left or right as desired. (It is necessary

to move the fence to allow clearance). Once the desired

bevel angle has been set, tighten the bevel clamp handle

firmly.

Bevel angles can be set from 48° right to48 ° left and can

be cut with the miter arm set between 50° right or 60° left.

At some extreme angles, the right or left side fence might

have to be removed. To remove the left or right fence,

unscrew the Fence Adjustment Knob several turns and

slide the fence out.

FIG. 11

FIG. 12

QUALITY OF CUT

The smoothness of any cut depends on a number of variables.

Things like material being cut, blade type, blade sharpness

and rate of cut all contribute to the quality of the cut.

When smoothest cuts are desired for molding and other

precision work, a sharp (60 tooth carbide) blade and a

slower, even cutting rate will produce the desired results.

Ensure that material does not creep while cutting, clamp it

securely in place. Always let the blade come to a full stop

before raising arm.

If small fibers of wood still split out at the rear of the work-

piece, stick a piece of masking tape on the wood where

the cut will be made. Saw through the tape and carefully

remove tape when finished.

For varied cutting applications, refer to the list of recom-

FIG. 13A

PROPER CUT

FIG. 13B

IMPROPER CUT

mended saw blades for your saw and select the one that

best fits your needs (page 5).

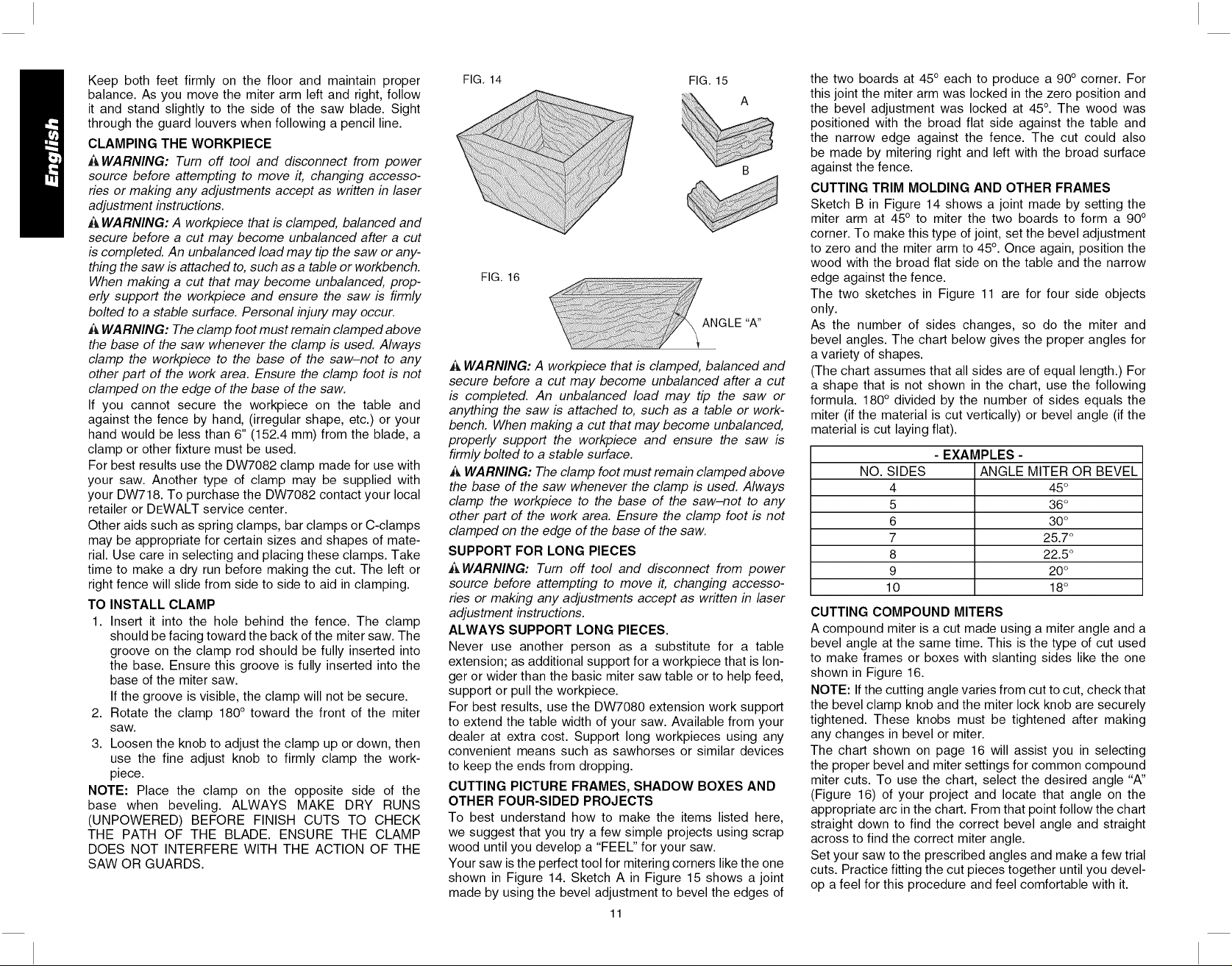

BODY AND HAND POSITION (FIG. 13A)

Proper positioning of your body and hands when operating

the miter saw will make cutting easier, more accurate and

safer. Never place hands near cutting area. Place hands

no closer than 6" (152.4 mm) from the blade. Hold the

workpiece tightly to the table and the fence when cutting.

Keep hands in position until the trigger has been released

and the blade has completely stopped. ALWAYS MAKE

DRY RUNS (UNPOWERED) BEFORE FINISH CUTS SO

THAT YOU CAN CHECK THE PATH OF THE BLADE. DO

NOT CROSS HANDS, AS SHOWN IN FIGURE 13B.

lO

Page 12

Keep both feet firmly on the floor and maintain proper

balance. As you move the miter arm left and right, follow

it and stand slightly to the side of the saw blade. Sight

through the guard louvers when following a pencil line.

CLAMPING THE WORKPIECE

i_,WARNING: Turn off tool and disconnect from power

source before attempting to move it, changing accesso-

ries or making any adjustments accept as written in laser

adjustment instructions.

WARNING: A workpiece that is clamped, balanced and

secure before a cut may become unbalanced after a cut

is completed. An unbalanced load may tip the saw or any-

thing the saw is attached to, such as a table or workbench.

When making a cut that may become unbalanced, prop-

erly support the workpiece and ensure the saw is firmly

bolted to a stable surface. Personal injury may occur.

i_ WARNING: The clamp foot must remain clamped above

the base of the saw whenever the clamp is used. Always

clamp the workpiece to the base of the saw-not to any

other part of the work area. Ensure the clamp foot is not

clamped on the edge of the base of the saw.

If you cannot secure the workpiece on the table and

against the fence by hand, (irregular shape, etc.) or your

hand would be less than 6" (152.4 mm) from the blade, a

clamp or other fixture must be used.

For best results use the DW7082 clamp made for use with

your saw. Another type of clamp may be supplied with

your DW718. To purchase the DW7082 contact your local

retailer or DEWALT service center.

Other aids such as spring clamps, bar clamps or C-clamps

may be appropriate for certain sizes and shapes of mate-

rial. Use care in selecting and placing these clamps. Take

time to make a dry run before making the cut. The left or

right fence will slide from side to side to aid in clamping.

TO INSTALL CLAMP

1. Insert it into the hole behind the fence. The clamp

should be facing toward the back of the miter saw. The

groove on the clamp rod should be fully inserted into

the base. Ensure this groove is fully inserted into the

base of the miter saw.

If the groove is visible, the clamp will not be secure.

2. Rotate the clamp 180° toward the front of the miter

saw.

3. Loosen the knob to adjust the clamp up or down, then

use the fine adjust knob to firmly clamp the work-

piece.

NOTE: Place the clamp on the opposite side of the

base when beveling. ALWAYS MAKE DRY RUNS

(UNPOWERED) BEFORE FINISH CUTS TO CHECK

THE PATH OF THE BLADE. ENSURE THE CLAMP

DOES NOT INTERFERE WITH THE ACTION OF THE

SAW OR GUARDS.

FIG. 14

FIG. 16

FIG. 15

_ WARNING: A workpiece that is clamped, balanced and

secure before a cut may become unbalanced after a cut

is completed. An unbalanced load may tip the saw or

anything the saw is attached to, such as a table or work-

bench. When making a cut that may become unbalanced,

properly support the workpiece and ensure the saw is

firmly bolted to a stable surface.

_ WARNING: The clamp foot must remain clamped above

the base of the saw whenever the clamp is used. Always

clamp the workpiece to the base of the saw-not to any

other part of the work area. Ensure the clamp foot is not

clamped on the edge of the base of the saw.

SUPPORT FOR LONG PIECES

i_ WARNING: Turn off tool and disconnect from power

source before attempting to move it, changing accesso-

ries or making any adjustments accept as written in laser

adjustment instructions.

ALWAYS SUPPORT LONG PIECES.

Never use another person as a substitute for a table

extension; as additional support for a workpiece that is lon-

ger or wider than the basic miter saw table or to help feed,

support or pull the workpiece.

For best results, use the DW7080 extension work support

to extend the table width of your saw. Available from your

dealer at extra cost. Support long workpieces using any

convenient means such as sawhorses or similar devices

to keep the ends from dropping.

CUTTING PICTURE FRAMES, SHADOW BOXES AND

OTHER FOUR-SIDED PROJECTS

To best understand how to make the items listed here,

we suggest that you try a few simple projects using scrap

wood until you develop a "FEEL" for your saw.

Your saw is the perfect tool for mitering corners like the one

shown in Figure 14. Sketch A in Figure 15 shows a joint

made by using the bevel adjustment to bevel the edges of

11

the two boards at 45° each to produce a 90° corner. For

this joint the miter arm was locked in the zero position and

the bevel adjustment was locked at 45°. The wood was

positioned with the broad flat side against the table and

the narrow edge against the fence. The cut could also

be made by mitering right and left with the broad surface

against the fence.

CUTTING TRIM MOLDING AND OTHER FRAMES

Sketch B in Figure 14 shows a joint made by setting the

miter arm at 45° to miter the two boards to form a 90 °

corner. To make this type of joint, set the bevel adjustment

to zero and the miter arm to 45°. Once again, position the

wood with the broad flat side on the table and the narrow

edge against the fence.

The two sketches in Figure 11 are for four side objects

only.

As the number of sides changes, so do the miter and

bevel angles. The chart below gives the proper angles for

a variety of shapes.

(The chart assumes that all sides are of equal length.) For

a shape that is not shown in the chart, use the following

formula. 180° divided by the number of sides equals the

miter (if the material is cut vertically) or bevel angle (if the

material is cut laying flat).

- EXAMPLES -

NO. SIDES ANGLE MITER OR BEVEL

4 45°

5 36°

6 30°

7 25.7 °

8 22.5 °

9 20°

10 18°

CUTTING COMPOUND MITERS

A compound miter is a cut made using a miter angle and a

bevel angle at the same time. This is the type of cut used

to make frames or boxes with slanting sides like the one

shown in Figure 16.

NOTE: Ifthe cutting angle varies from cut to cut, check that

the bevel clamp knob and the miter lock knob are securely

tightened. These knobs must be tightened after making

any changes in bevel or miter.

The chart shown on page 16 will assist you in selecting

the proper bevel and miter settings for common compound

miter cuts. To use the chart, select the desired angle "A"

(Figure 16) of your project and locate that angle on the

appropriate arc in the chart. From that point follow the chart

straight down to find the correct bevel angle and straight

across to find the correct miter angle.

Set your saw to the prescribed angles and make a few trial

cuts. Practice fitting the cut pieces together until you devel-

op a feel for this procedure and feel comfortable with it.

Page 13

Example:Tomakea4sidedboxwith26°exteriorangles

(AngleA,Figure15),usetheupperrightarc.Find26°

onthearcscale.Followthehorizontalintersectingline

toeithersidetogetmiteranglesettingonsaw(42°).

Likewise,followtheverticalintersectinglinetothetopor

bottomtogetthebevelanglesettingonthesaw(18°).

Alwaystrycutsonafewscrappiecesofwoodtoverify

settingsonsaw.

CUTTINGBASEMOLDING

ALWAYSMAKEA DRYRUNWITHOUTPOWER

BEFOREMAKINGANYCUTS.

Straight90°cuts:

Positionthewoodagainstthefenceandholdit in

placeasshowninFigure11.Turnonthesaw,allow

thebladeto reachfullspeedandlowerthearm

smoothlythroughthecut.

CUTTINGBASEMOLDINGUPTO6.5"(165ram)HIGH

VERTICALLYAGAINSTTHEFENCE

PositionmaterialasshowninFigure11.

Allcutsmadewiththebackofthemoldingagainstthe

fenceandbottomofthemoldingagainstthebase.

INSIDECORNER:

Leftside

1.Miterleft45°

2. Saveleftsideofcut

Rightside

1.MiterRight45°

2. Saverightsideofcut

OUTSIDECORNER:

Leftside

1.Miterrightat45°

2. Saveleftsideofcut

Rightside

1.Miterleftat45°

2. Saverightsideofcut

Materialupto 6.5"(159mm)canbecutasdescribed

above.

CUTTINGCROWNMOLDING

Yourmitersawisbettersuitedtothetaskofcutting

crownmoldingthananytoolmade.Inordertofitproperly,

crownmoldingmustbecompoundmiteredwithextreme

accuracy.

Thetwoflatsurfacesonagivenpieceofcrownmolding

areatanglesthat,whenaddedtogether,equalexactly

90°.Most,butnotall,crownmoldinghasatoprearangle

(thesectionthatfitsflatagainsttheceiling)of52°anda

bottomrearangle(thepartthatfitsflatagainstthewall)

of38°.

Yourmitersawhasspecialpre-setmiterlatchpointsat

31.62°leftandrightforcuttingcrownmoldingattheproper

angleandbevelstoppawlsat33.85°leftandright.There

isalsoamarkontheBevelscaleat33.85°.

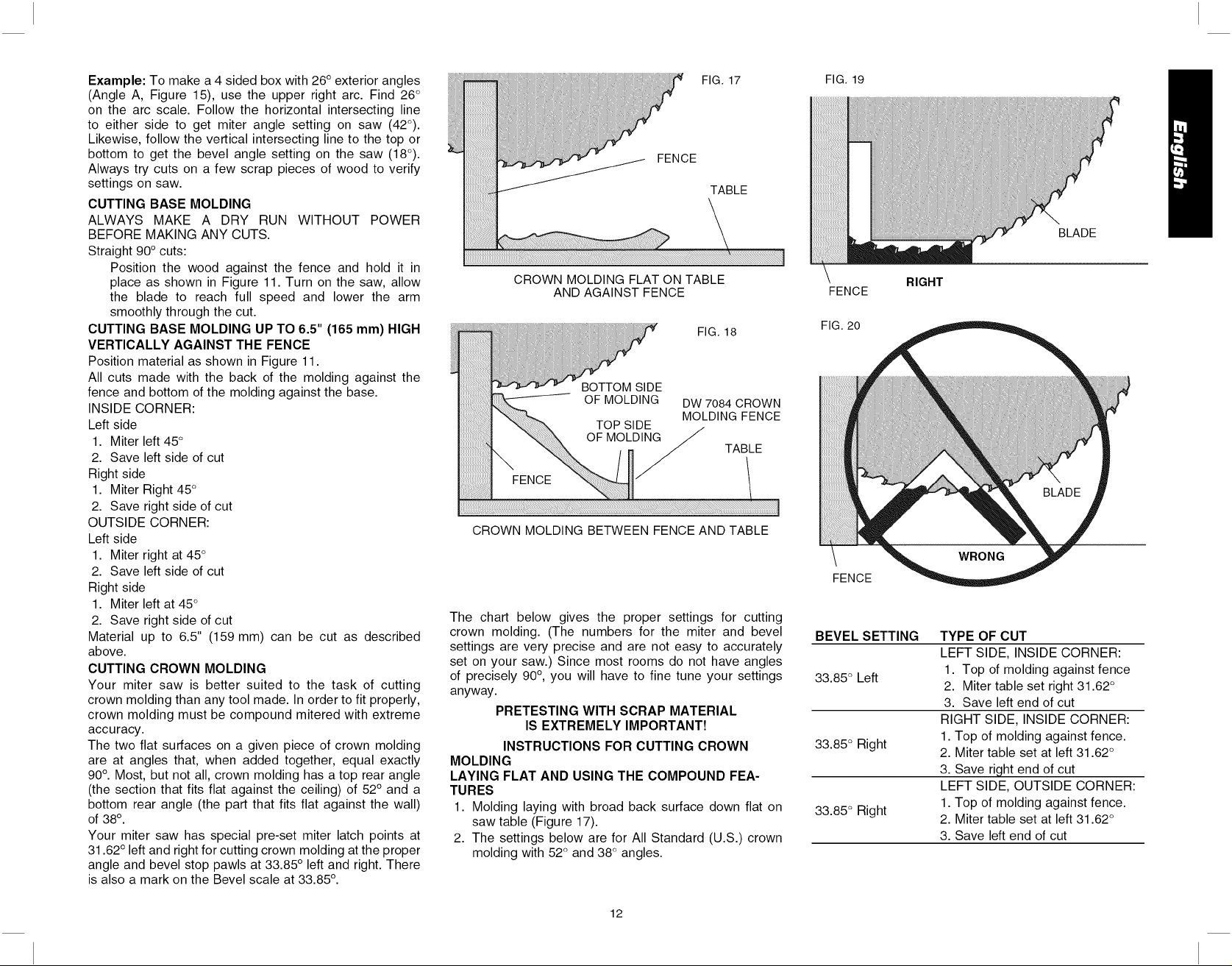

FIG. 17

FENCE

TABLE

CROWN MOLDING FLAT ON TABLE

AND AGAINST FENCE

FIG. 18

BOTTOM SIDE

OF MOLDING

CROWN MOLDING BETWEEN FENCE AND TABLE

The chart below gives the proper settings for cutting

crown molding. (The numbers for the miter and bevel

settings are very precise and are not easy to accurately

set on your saw.) Since most rooms do not have angles

of precisely 90°, you will have to fine tune your settings

anyway.

PRETESTING WITH SCRAP MATERIAL

IS EXTREMELY IMPORTANT!

INSTRUCTIONS FOR CUTTING CROWN

MOLDING

LAYING FLAT AND USING THE COMPOUND FEA-

TURES

1. Molding laying with broad back surface down flat on

saw table (Figure 17).

2. The settings below are for All Standard (U.S.) crown

molding with 52° and 38 ° angles.

DW 7O84 CROWN

MOLDING FENCE

TABLE

FIG. 19

FENCE

FIG. 20

FENCE

BEVEL SETTING

33.85 ° Left

33.85 ° Right

33.85 ° Right

BLADE

RIGHT

TYPE OF CUT

LEFT SIDE, INSIDE CORNER:

1. Top of molding against fence

2. Miter table set right 31.62 °

3. Save left end of cut

RIGHT SIDE, INSIDE CORNER:

1. Top of molding against fence.

2. Miter table set at left 31.62 °

3. Save right end of cut

LEFT SIDE, OUTSIDE CORNER:

1. Top of molding against fence.

2. Miter table set at left 31.62 °

3. Save left end of cut

12

Page 14

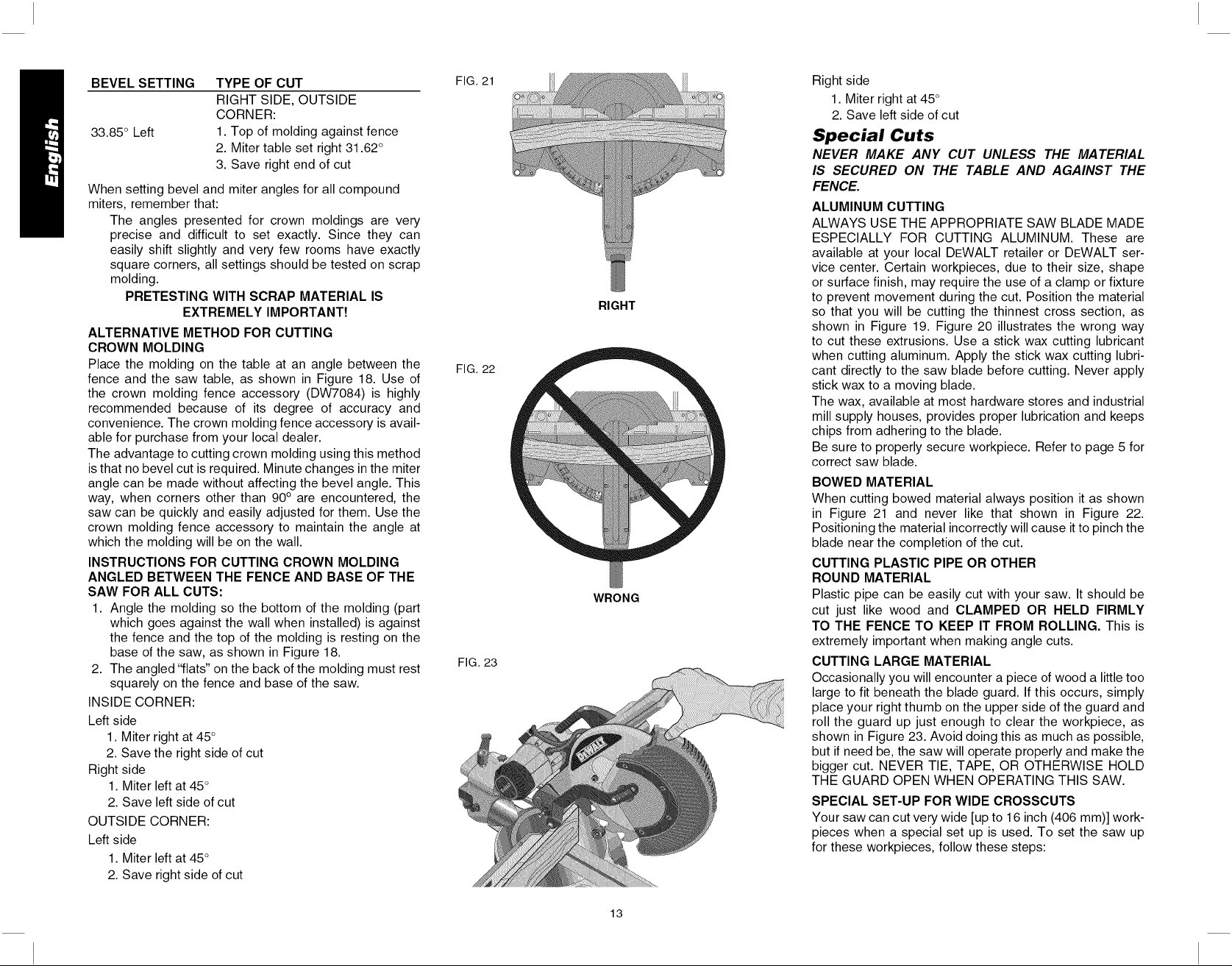

BEVEL SETTING FIG.21

TYPE OF CUT

RIGHT SIDE, OUTSIDE

CORNER:

33.85 ° Left

1. Top of molding against fence

2. Miter table set right 31.62 °

3. Save right end of cut

When setting bevel and miter angles for all compound

miters, remember that:

The angles presented for crown moldings are very

precise and difficult to set exactly. Since they can

easily shift slightly and very few rooms have exactly

square corners, all settings should be tested on scrap

molding.

PRETESTING WITH SCRAP MATERIAL IS

EXTREMELY IMPORTANT!

ALTERNATIVE METHOD FOR CUTTING

CROWN MOLDING

Place the molding on the table at an angle between the

FIG. 22

fence and the saw table, as shown in Figure 18. Use of

the crown molding fence accessory (DW7084) is highly

recommended because of its degree of accuracy and

convenience. The crown molding fence accessory is avail-

able for purchase from your local dealer.

The advantage to cutting crown molding using this method

isthat no bevel cut is required. Minute changes inthe miter

angle can be made without affecting the bevel angle. This

way, when corners other than 90° are encountered, the

saw can be quickly and easily adjusted for them. Use the

crown molding fence accessory to maintain the angle at

which the molding will be on the wall.

INSTRUCTIONS FOR CUTTING CROWN MOLDING

ANGLED BETWEEN THE FENCE AND BASE OF THE

SAW FOR ALL CUTS:

1. Angle the molding so the bottom of the molding (part

which goes against the wall when installed) is against

the fence and the top of the molding is resting on the

base of the saw, as shown in Figure 18.

2. The angled fflats" on the back of the molding must rest

FIG. 23

squarely on the fence and base of the saw.

INSIDE CORNER:

Left side

1. Miter right at 45°

2. Save the right side of cut

Right side

1. Miter left at 45°

2. Save left side of cut

OUTSIDE CORNER:

Left side

1. Miter left at 45°

2. Save right side of cut

RIGHT

WRONG

Right side

1. Miter right at 45°

2. Save left side of cut

Special Cuts

NEVER MAKE ANY CUT UNLESS THE MATERIAL

IS SECURED ON THE TABLE AND AGAINST THE

FENCE.

ALUMINUM CUTTING

ALWAYS USE THE APPROPRIATE SAW BLADE MADE

ESPECIALLY FOR CUTTING ALUMINUM. These are

available at your local DEWALT retailer or DEWALT ser-

vice center. Certain workpieces, due to their size, shape

or surface finish, may require the use of a clamp or fixture

to prevent movement during the cut. Position the material

so that you will be cutting the thinnest cross section, as

shown in Figure 19. Figure 20 illustrates the wrong way

to cut these extrusions. Use a stick wax cutting lubricant

when cutting aluminum. Apply the stick wax cutting lubri-

cant directly to the saw blade before cutting. Never apply

stick wax to a moving blade.

The wax, available at most hardware stores and industrial

mill supply houses, provides proper lubrication and keeps

chips from adhering to the blade.

Be sure to properly secure workpiece. Refer to page 5 for

correct saw blade.

BOWED MATERIAL

When cutting bowed material always position it as shown

in Figure 21 and never like that shown in Figure 22.

Positioning the material incorrectly will cause it to pinch the

blade near the completion of the cut.

CUTTING PLASTIC PIPE OR OTHER

ROUND MATERIAL

Plastic pipe can be easily cut with your saw. It should be

cut just like wood and CLAMPED OR HELD FIRMLY

TO THE FENCE TO KEEP IT FROM ROLLING. This is

extremely important when making angle cuts.

CUTTING LARGE MATERIAL

Occasionally you will encounter a piece of wood a little too

large to fit beneath the blade guard. If this occurs, simply

place your right thumb on the upper side of the guard and

roll the guard up just enough to clear the workpiece, as

shown in Figure 23. Avoid doing this as much as possible,

but if need be, the saw will operate properly and make the

bigger cut. NEVER TIE, TAPE, OR OTHERWISE HOLD

THE GUARD OPEN WHEN OPERATING THIS SAW.

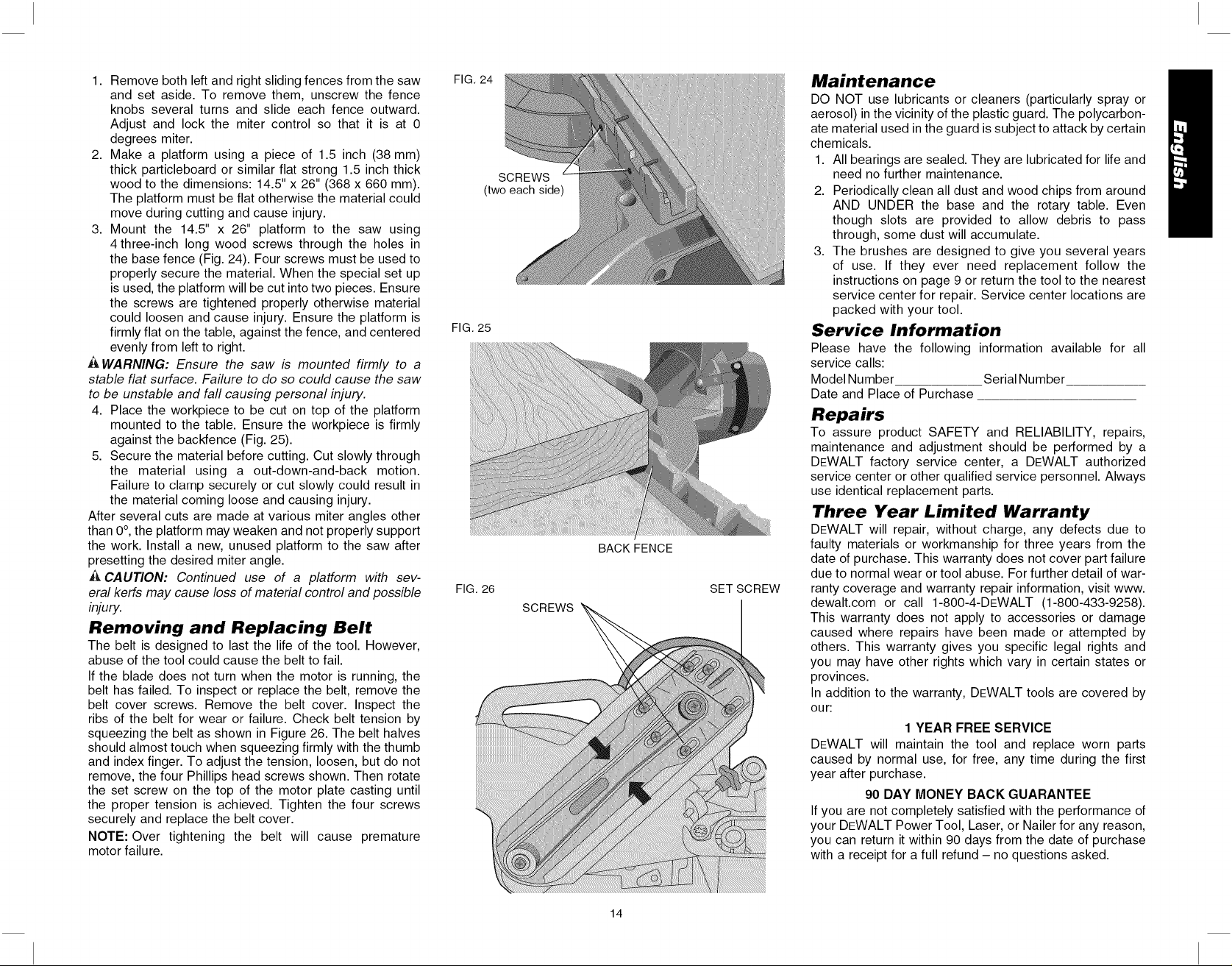

SPECIAL SET-UP FOR WIDE CROSSCUTS

Your saw can cut very wide [up to 16 inch (406 mm)] work-

pieces when a special set up is used. To set the saw up

for these workpieces, follow these steps:

13

Page 15

1.Removebothleftandrightslidingfencesfromthesaw

andsetaside.Toremovethem,unscrewthefence

knobsseveralturnsandslideeachfenceoutward.

Adjustandlockthemitercontrolsothatit is at0

degreesmiter.

2. Makea platformusinga pieceof 1.5inch(38mm)

thickparticleboardorsimilarflatstrong1.5inchthick

woodtothedimensions:14.5"x26"(368x660mm).

Theplatformmustbeflatotherwisethematerialcould

moveduringcuttingandcauseinjury.

3. Mountthe 14.5"x 26"platformto thesawusing

4three-inchlongwoodscrewsthroughtheholesin

thebasefence(Fig.24).Fourscrewsmustbeusedto

properlysecurethematerial.Whenthespecialsetup

isused,theplatformwillbecutintotwopieces.Ensure

thescrewsaretightenedproperlyotherwisematerial

couldloosenandcauseinjury.Ensuretheplatformis

firmlyflatonthetable,againstthefence,andcentered

evenlyfromlefttoright.

WARNING: Ensure the saw is mounted firmly to a

stable flat surface. Failure to do so could cause the saw

to be unstable and fall causing personal injury.

4. Place the workpiece to be cut on top of the platform

mounted to the table. Ensure the workpiece is firmly

against the backfence (Fig. 25).

5. Secure the material before cutting. Cut slowly through

the material using a out-down-and-back motion.

Failure to clamp securely or cut slowly could result in

the material coming loose and causing injury.

After several cuts are made at various miter angles other

than 0 °,the platform may weaken and not properly support

the work. Install a new, unused platform to the saw after

presetting the desired miter angle.

A CAUTION: Continued use of a platform with sev-

eral kerfs may cause loss of material control and possible

injury.

Removing and Replacing Belt

The belt is designed to last the life of the tool. However,

abuse of the tool could cause the belt to fail.

If the blade does not turn when the motor is running, the

belt has failed. To inspect or replace the belt, remove the

belt cover screws. Remove the belt cover. Inspect the

ribs of the belt for wear or failure. Check belt tension by

squeezing the belt as shown in Figure 26. The belt halves

should almost touch when squeezing firmly with the thumb

and index finger. To adjust the tension, loosen, but do not

remove, the four Phillips head screws shown. Then rotate

the set screw on the top of the motor plate casting until

the proper tension is achieved. Tighten the four screws

securely and replace the belt cover.

NOTE: Over tightening the belt will cause premature

motor failure.

FIG. 24

(two each side)

FIG. 25

FIG. 26

SCREWS

SCREWS

BACK FENCE

SET SCREW

Maintenance

DO NOT use lubricants or cleaners (particularly spray or

aerosol) in the vicinity of the plastic guard. The polycarbon-

ate material used in the guard is subject to attack by certain

chemicals.

1. All bearings are sealed. They are lubricated for life and

need no further maintenance.

2. Periodically clean all dust and wood chips from around

AND UNDER the base and the rotary table. Even

though slots are provided to allow debris to pass

through, some dust will accumulate.

3. The brushes are designed to give you several years

of use. If they ever need replacement follow the

instructions on page 9 or return the tool to the nearest

service center for repair. Service center locations are

packed with your tool.

Service Information

Please have the following information available for all

service calls:

Model Number Serial Number

Date and Place of Purchase

Repairs

To assure product SAFETY and RELIABILITY, repairs,

maintenance and adjustment should be performed by a

DEWALT factory service center, a DEWALT authorized

service center or other qualified service personnel. Always

use identical replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to

faulty materials or workmanship for three years from the

date of purchase. This warranty does not cover part failure

due to normal wear ortool abuse. For further detail of war-

ranty coverage and warranty repair information, visit www.

dewalt.com or call 1-800-4-DEWALT (1-800-433-9258).

This warranty does not apply to accessories or damage

caused where repairs have been made or attempted by

others. This warranty gives you specific legal rights and

you may have other rights which vary in certain states or

provinces.

In addition to the warranty, DEWALT tools are covered by

our:

1 YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts

caused by normal use, for free, any time during the first

year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of

your DEWALT Power Tool, Laser, or Nailer for any reason,

you can return it within 90 days from the date of purchase

with a receipt for a full refund - no questions asked.

14

Page 16

RECONDITIONEDPRODUCT:Reconditionedproductis

coveredunderthe1YearFreeServiceWarranty.The90

DayMoneyBackGuaranteeandtheThreeYearLimited

Warrantydonotapplytoreconditionedproduct.

FREEWARNINGLABELREPLACEMENT:If your

warninglabelsbecomeillegibleor aremissing,call

1-800-4-DEWALTforafreereplacement.

Patent Notification

Manufactured under one or more of the following U.S.

patents:

6,823,765 6,101,914 5,907,987 5,375,495

6,810,780 6,035,754 5,862,734 5,285,708

6,520,059, 6,032,563 5,582,089 5,199,343

Other patents may be pending.

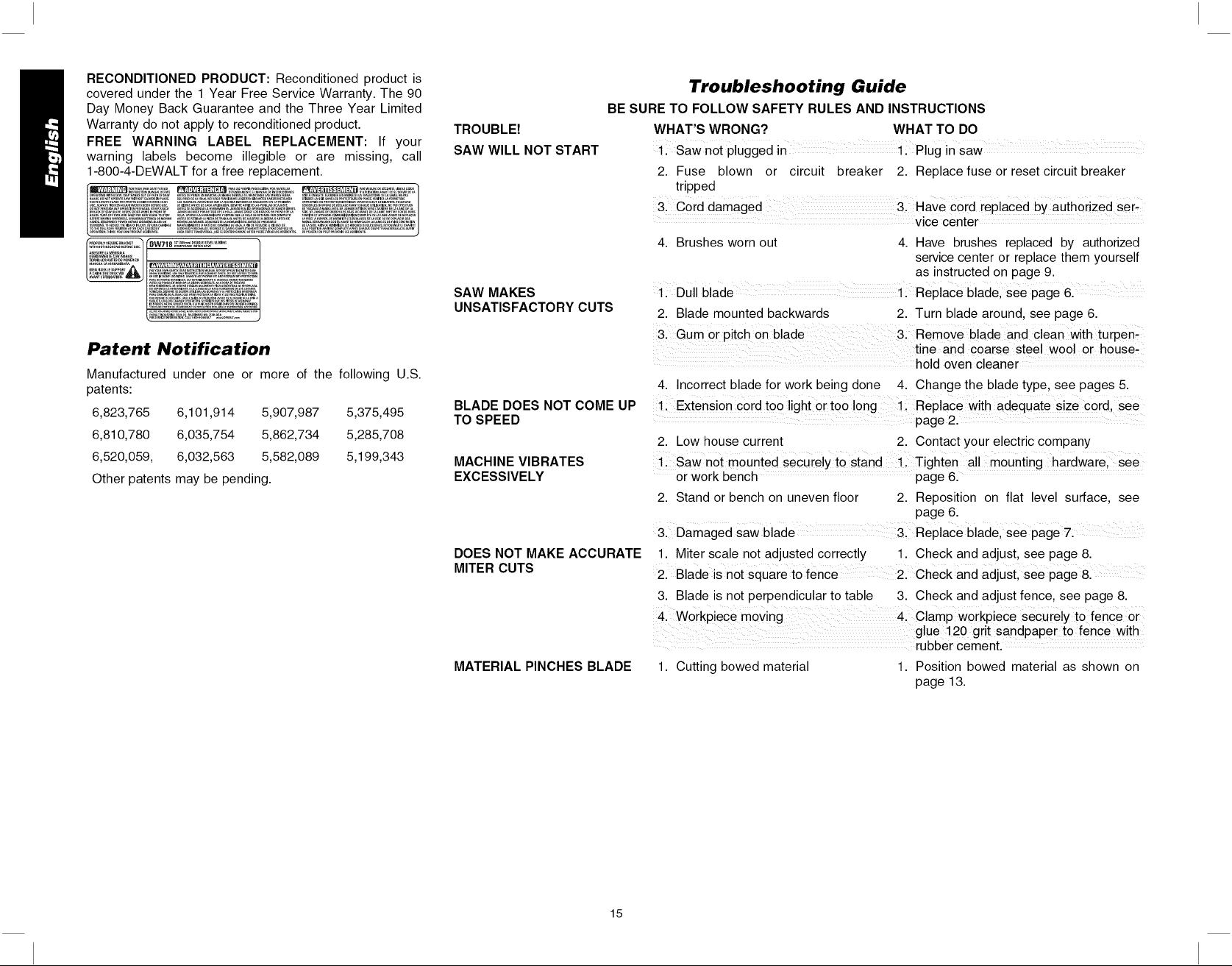

BE SURE TO FOLLOW SAFETY RULES AND INSTRUCTIONS

TROUBLE!

SAW WILL NOT START

SAW MAKES

UNSATISFACTORY CUTS

BLADE DOES NOT COME UP

TO SPEED

MACHINE VIBRATES

EXCESSIVELY

DOES NOT MAKE ACCURATE

MITER CUTS

MATERIAL PINCHES BLADE

Troubleshooting Guide

WHAT'S WRONG? WHAT TO DO

ii Saw notpiugged in li Plug insaw

2. Fuse blown or circuit breaker 2. Replace fuse or reset circuit breaker

tripped

31 Cord damaged 31 Have coid replaced bY authorized ser_

vice center

4. Brushes worn out 4. Have brushes replaced by authorized

service center or replace them yourself

as instructed on page 9.

Dull blade ii Repiace blade' see page 61

2. Blade mounted backwards 2. Turn blade around, see page 6.

3. Gum or pitch on blade 3: Remove blade and clean with turpen-

tine and coarse steel wool or house,

........................ hold oven cleaner

4. Incorrect blade for work being done 4. Change the blade type, see pages 5.

Extensi0n Cord too light or to0 long 11 Replace with adequate size cor d, see

page 2.

2. Low house current 2. Contact your electric company

llSaw not mounted securely to stand 11 Tighten all mounting hardware, see

or work bench page 6.

2. Stand or bench on uneven floor 2. Reposition on flat level surface, see

page 6.

3. Damaged saw blade & Replace blade' see page 7:

1. Miter scale not adjusted correctly 1. Check and adjust, see page 8.

2. Blade is not square to fence 21 Check and adjust, see page&

3. Blade is not perpendicular to table 3. Check and adjust fence, see page 8.

4. woikpiece moving 4. ClamP workpiece securely to fence or

glue 120 grit sandpaper to fence with

rubber cement.

1. Cutting bowed material 1. Position bowed material as shown on

page 13.

15

Page 17

TABLE 1 COMPOUND MITER CUT (Position wood with broad flat side on the table and the narrow edge against the fence,)

45-

40-

35-

30-1

: _---1Tll i : :

<

Z

o

W

.d

25-

Z

<

re

UJ

10 30 35 4015 20 25

45

- 45

- 40

35

30

25

: ::ii iiiiiiiiiiiii[iiiiii

20-

"-r

20

UJ

_iiiiiiiiiiiiiiiiiiiiii_, iii

15-

10-

5 -

5o

8_

10

15 20 25

SET THIS BEVEL ANGLE ON SAW

16

iiiiiiiii iiiiiiii

30 35 40 45

15

10

Page 18

TABLE DES MA TI_'RES

INSTRUCTIONS RELATIVES ,_ LA DOUBLE ISOLATION ET

,_ LA FICHE POLARISC:E ............................................................................................ 18

REGLES DE S¢:CURIT¢: POUR TOUS LES OUTILS ................................................ 18

RI_GLES DE S¢:CURIT¢: SUPPLC:MENTAIRES ......................................................... 19

CONNEXION €:LECTRIQUE ........................................................................ 21