Page 1

5.1 Maintenance schedule

cardiagn.com

5.2 Maintenance diagram

5.3 Maintenance work carried out

Maintenance

5

© 2005

Page 2

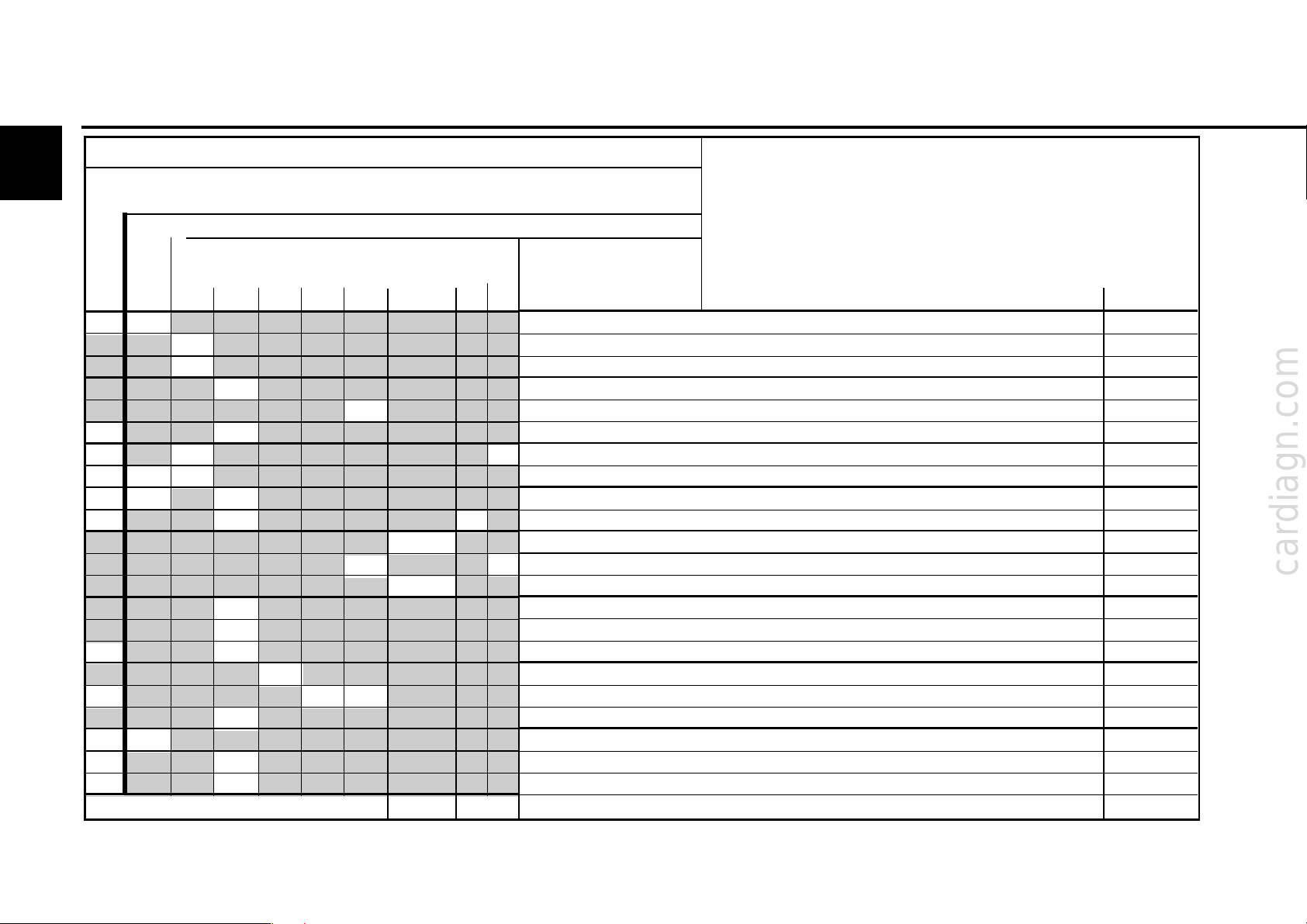

Maintenance 5.1 Maintenance schedule

cardiagn.com

5

check= z set= clean=L renew=

⇓ check 2x daily before or during the 1st trial run, during the running-in phase or

when commissioning new and overhauled engines.

⇓ every 10 oh or daily

in operating hours (oh) every year(s)

E10 E20 E30 E40 E45 E50 E60 E70

500 1,000 1,5003,0006 ,00 0 12,000 1 2

zz

z

z

zz

zzz

zz

zz L

zz

zz

zz

zz

zz

1)

L

z

L

z

z

z

Activity

Lube oil level, if necessary re-fill 6.1.2

Lube oil (oil change intervals depending on engine application and oil quality), see TR 0199-99-3002

Oil filter cartridge 6.1.3

Fuel filter cartridge 6.2.1

Electronic injector check via EMR3

Fuel filter insert1) (fuel pre-filter) 4.2

Coolant (additive concentration) 4.3.1/2/3

Coolant level –

Intake air filter

Charge air cooler (drain lube oil/condensation)

EGR(option)* Check non-return valve (option)

EGR(option) Check cap and adjustment mechanism for clearance, renew if necessary .

CoolerEGR (option)

Check function of heating flange

Battery and cable connections 6.7.1

Engine monitoring, warning system 3.3

Valve clearance 6.6.1

V-belt/tension pulley (renew when wear limit reached) 6.5.1/6.5.3

Crankcase pressure bleed valve (option)

Engine tightness (visual inspection for leaks). –

Engine mounting (renew in case of damage) 9.2

Fastenings, hose connections / clamps –

General overhaul

(if available, maintenance as per maintenance display)

Industrial engines

The engine maintenance times given are maximum permissible job

times. Depending on the usage circumstances, shorter maintenance

times may be necessary. Observe the instruction manual of the

equipment manufacturer.

# Maintenance only to be carried out by authorised service personnel

Section

6.1.1/ 6.1.2

#

6.4.3 /6.4.4

#

#

#

EGR* exhaust gas recirculation (system); If the warning system (light/siren) is activated, the fuel pre-filter must be emptied immediately.

1)

The intervals can be reduced, depending on the degree of soiling of the fuel used.

© 2005

Page 3

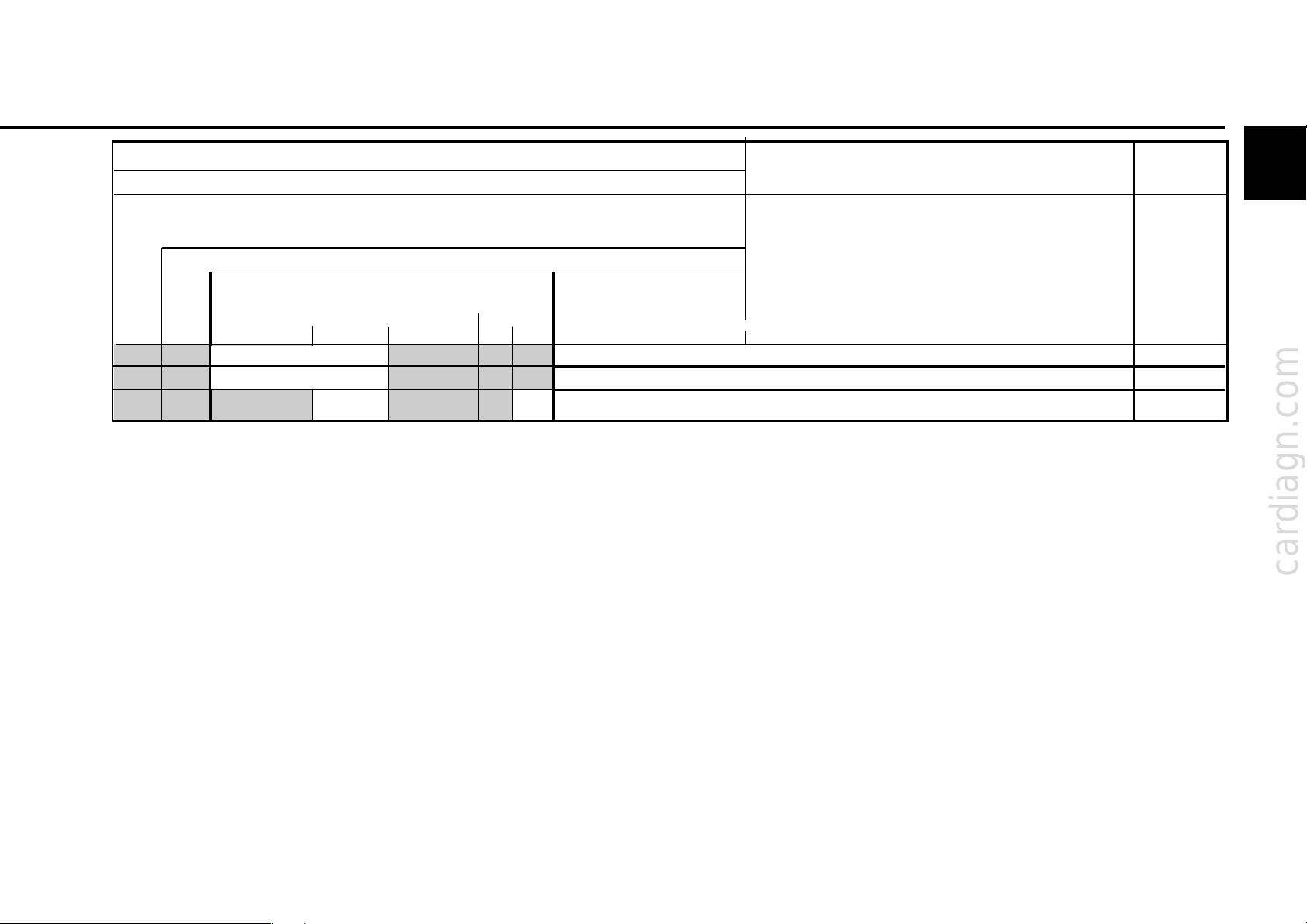

5.1 Maintenance schedule Maintenance

cardiagn.com

check= z set= clean= L renew=

max. permissible job times in operating hours (oh) every

check 2x daily before or during the 1st trial run, during the running-in phase or

⇓

when commissioning new and overhauled engines.

⇓

every 10 oh or daily

in operating hours (oh) every

E10 E30 E40 E70

500 6.000 12.000 1 2

z L

z L

L

Charge air cooler (drain lube oil/condensation)

Charge air cooler inlet surface (clean if necessary) #

Crankcase pressure bleed valve (option)

Activity

Enhancements or modifications for engines with

EPA acceptance

The engine maintenance times given are maximum

permissible job times. Depending on the usage

circumstances, shorter maintenance times may be

necessary. Observe the instruction manual of the

equipment manufacturer. # Maintenance only to be

carried out by authorised service personnel

Section

#

#

5

© 2005

Page 4

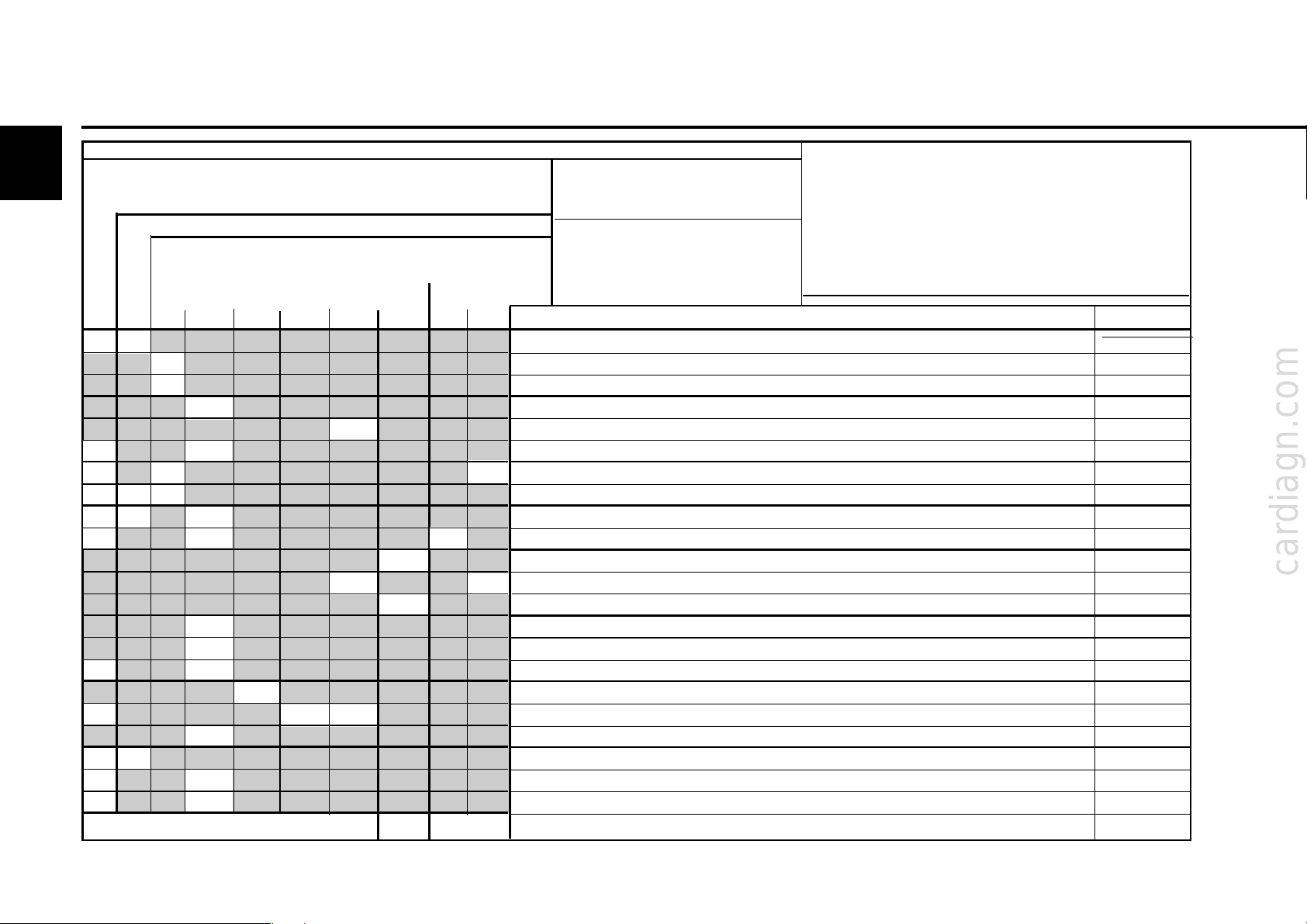

Maintenance 5.1 Maintenance schedule

cardiagn.com

5

check= z set= clean= L renew=

⇓ check 2x daily before or during the 1st trial run, during the running in phase or when commissioning new and overhauled engines.

⇓ every 200 km or daily

OPERATIONAL PERFORMANCE IN (km)year(s)

E10 E20 E30 E4 0 E4 5 E5 0 E60 E70

5,000

1 0.000

2 0.000

3 0.000

120..000

240.000

1

zz

z

z

zz

zz z

zz

zz L

zz

zz

zz

zz

zz

EGR* Exhaust gas recirculation (system); If the warning system (light/siren) is activated, the fuel pre-filter must be emptied immediately.

1)

The intervals can be reduced, depending on the degree of soiling of the fuel used.

1)

L

z

L

z

z

z

2

General overhaul

Service Yearly op. Average

group performance

km

I <30 000 20

II >30 to 100 000 40

II I >100 000 60

Activity

Lube oil level, if necessary re-fill 6.1.2

Lube oil (oil change intervals depending on engine application and oil quality), see TR 0199-99-3002

Oil filter cartridge 6.1.3

Fuel filter cartridge 6.2.1

Electronic injector check via EMR3

Fuel filter insert1) (fuel pre-filter) 4.2

Coolant (additive concentration) 4.3.1/2/3

Coolant level –

Intake air filter

Charge air cooler (drain lube oil/condensation)

EGR(option)* Check non-return valve (option)

EGR(option) Check cap and adjustment mechanism for clearance, renew if necessary .

CoolerEGR (option)

Check function of heating flange

Battery and cable connections 6.7.1

Engine monitoring, warning system & 3.3

Valve clearance 6.6.1

V-belt/tension pulley (renew when wear limit reached) 6.5.1/6.5.3

Crankcase pressure bleed valve (option)

Engine tightness (visual inspection for leaks). –

Engine mounting (renew in case of damage) 9.2

Fastenings, hose connections / clamps –

(if available, maintenance as per maintenance display)

Drive

speed

approx.km/h

Service group I <30 000km 20

The engine maintenance times given are maximum permissible

job times. Depending on the usage circumstances, shorter

maintenance times may be necessary. Observe the instruction

manual of the equipment manufacturer.

to be carried out by authorised service personnel

Vehicle engines

approx.km/h

#

Maintenance only

Section

6.1.1/ 6.1.2

#

6.4.3 /6.4.4

#

#

#

Page 5

5.1 Maintenance schedule Maintenance

cardiagn.com

check= zset= clean= L renew=

⇓ check 2x daily before or during the 1st trial run, during the runningin phase or when commissioning new and overhauled engines.

⇓ every 200 km or daily

OPERATIONAL PERFORMANCE IN (km)year(s)

E10 E20 E30 E40 E40 E50 E60 E70

20,000

40, 000

50, 000

240,000

480,000

1

zz

z

z

zz

zz z

zz

zz L

zz

zz

zz

zz

zz

1)

L

z

L

z

z

z

Activity

2

Lube oil level, if necessary re-fill 6.1.2

L

ube oil (oil change intervals depending on engine application and oil quality), see TR 0199-99-3002

Oil filter cartridge 6.1.3

Fuel filter cartridge 6.2.1

Electronic injector check via EMR3

Fuel filter insert1) (fuel pre-filter) 4.2

Coolant (additive concentration) 4.3.1/2/3

Coolant level –

Intake air filter

Charge air cooler (drain lube oil/condensation)

EGR(option)* Check non-return valve (option)

EGR(option) Check cap and adjustment mechanism for clearance, renew if necessary .

CoolerEGR (option)

Check function of heating flange

Battery and cable connections 6.7.1

Engine monitoring, warning system & 3.3

Valve clearance 6.6.1

V-belt/tension pulley (renew when wear limit reached) 6.5.1/6.5.3

Crankcase pressure bleed valve (option)

Engine tightness (visual inspection for leaks). –

Engine mounting (renew in case of damage) 9.2

Fastenings, hose connections / clamps –

General overhaul

Service Yearly op. Average

group performance

km

I <30 000 20

II >30 to 100 000 40

II I >100 000 60

(if available, maintenance as per maintenance display)

Drive

speed

approx.km/h

Vehicle engines

Service group Il 100 000km 40approx.km/h

The engine maintenance times given are maximum permissible

job times. Depending on the usage circumstances, shorter

maintenance times may be necessary. Observe the instruction

manual of the equipment manufacturer. # Maintenance only to be

carried out by authorised service personnel

Section

6.1.1/ 6.1.2

#

6.4.3 /6.4.4

#

#

#

5

EGR* Exhaust gas recirculation (system); If the warning system (light/siren) is activated, the fuel pre-filter must be emptied immediately.

1)

The intervals can be reduced, depending on the degree of soiling of the fuel used.

Page 6

Maintenance

cardiagn.com

5.1 Maintenance schedule

5

check= zset= clean= L renew=

check 2x daily before or during the 1st trial run, during the running-in phase

⇓

or when commissioning new and overhauled engines

⇓ every 200 km or daily

OPERATIONAL PERFORMANCE IN (km) every

Service group III year(s)

E10 E20 E30 E40 E45 E50 E60 E70

30.000

60.000

zz

z

zz

zz z

zz

zz L

zz

zz

zz

zz

zz

EGR* Exhaust gas recirculation (system); If the warning system (light/siren) is activated, the fuel pre-filter must be emptied immediately.

1)

The intervals can be reduced, depending on the degree of soiling of the fuel used.

© 2005

1)

z

z

z

90.000

120.000

360.000

1000. 000

1

z

L

z

L

Activity

2

Lube oil level, if necessary re-fill 6.1.2

L

ube oil (oil change intervals depending on engine application and oil quality), see TR 0199-99-3002

Oil filter cartridge 6.1.3

Fuel filter cartridge 6.2.1

Electronic injector check via EMR3

Fuel filter insert1) (fuel pre-filter) 4.2

Coolant (additive concentration) 4.3.1/2/3

Coolant level –

Intake air filter

Charge air cooler (drain lube oil/condensation)

EGR(option)* Check non-return valve (option)

EGR(option) Check cap and adjustment mechanism for clearance, renew if necessary .

CoolerEGR (option)

Check function of heating flange

Battery and cable connections 6.7.1

Engine monitoring, warning system & 3.3

Valve clearance 6.6.1

V-belt/tension pulley (renew when wear limit reached) 6.5.1

Crankcase pressure bleed valve (option)

Engine tightness (visual inspection for leaks). –

Engine mounting (renew in case of damage) 9. 2

Fastenings, hose connections / clamps –

General overhaul

ServiceYearly op. Average

group performance

km

I <30 000 20

II >30 to 100 000 40

II I >100 000 60

(if available, maintenance as per maintenance display)

Drive

speed

approx.km/h

V ehicle engines

Service group Ill >100 000 km 60approx.km/h

The engine maintenance times given are maximum

permissible job times. Depending on the usage circumstances,

shorter maintenance times may be necessary. Observe the

instruction manual of the equipment manufacturer.

# Maintenance only to be carried out by authorised service personnel

Section

6.1.1/ 6.1.2

#

6.4.3/6.4.4

#

#

#

Page 7

Maintenance 5.1 Maintenance schedule

cardiagn.com

5.1.1 Standard maintenance schedule

Intervals Deutz maintenance and Activity Execution by:

at/after service schedules

50 oh E 10 after commissioning and E 50-E 70 authorised specialists

daily E 20 daily inspection round the user / authorised specialists

500 oh E 30 inspection authorised specialists

1000 oh E 40 intermediate overhaul authorised specialists

1500 oh E 45 extended intermediate overhaul authorised specialists

3 000 oh E 60 partial overhaul authorised specialists

6000 oh E 60 partial overhaul authorised specialists

10 000 oh (2012) E 70 overhaul authorised specialists

13 000 oh (2013) E 70 overhaul authorised specialists

5

*) approximate value, depends on the type of engine application and/or regular engine maintenance.

Please contact your responsible DEUTZ Service partner.

© 2005

Page 8

5

cardiagn.com

5.2 Maintenance diagram Maintenance

The maintenance diagram shown on this

page is supplied with every engine in selfadhesive form. It should be stuck onto a well

visible location on the engine or equipment.

Check that this is the case!

If not, request a replacement from your engine

or equipment supplier!

The maintenance schedule is decisive for

standard maintenance, see 5.1.

All maintenance work should

only be carried out when the

engine is not running.

© 2005

Page 9

5.3 Maintenance work carried out Maintenance

cardiagn.com

Op. hrs.

50-150

125

375

625

875

1125

1375

1625

1875

*

Date

Signature / stamp Op. hrs. D at e

250

500

750

1000

1250

1500

1750

2000

Signature / stamp

5

2115

2375

* after commissioning new and overhauled engines

The maintenance work carried out methodically can be recorded in the table and confirmed.

2250

2500

2750

© 2005

Page 10

Maintenance 5.3 Maintenance work carried out

cardiagn.com

5

Op. hrs.

2875

3125

3375

3625

3875

4125

4375

4625

4875

Da te Signature / stamp

Op. hrs. Signature / stamp

3000

3250

3500

3750

4000

4250

4500

4750

5000

Date

5125

5375

5625

The maintenance work carried out methodically can be recorded in the table and confirmed.

© 2005

5250

5500

5750

Page 11

5.3 Maintenance work carried out Maintenance

cardiagn.com

Op. hrs.

5875

6125

6375

6625

6875

7125

7375

7625

7825

Date

Signature / stamp Op. hrs. D at e

6000

6250

6500

6750

7000

7250

7500

7750

8000

Signature / stamp

5

8125

8375

8625

The maintenance work carried out methodically can be recorded in the table and confirmed.

8250

8500

8750

© 2005

Page 12

Maintenance 5.3 Maintenance work carried out

cardiagn.com

5

Op. hrs.

8875

9125

9375

9625

9875

10125

10375

10625

10875

Da te Signature / stamp

Op. hrs. Signature / stamp

9000

9250

9500

9750

10000

10250

10500

10750

10000

Date

10125

10375

10625

The maintenance work carried out methodically can be recorded in the table and confirmed.

© 2005

10250

10500

10750

Loading...

Loading...