Page 1

Care and maintenance work

cardiagn.com

6.1Lubrication system

6.2Fuel system

6.3Cooling system

6.4 Combustion air filter

6.5 Belt drive

6.6Setting work

6.7 Add-on parts

6

© 2005

Page 2

Care and maintenance work 6.1Lubrication system

cardiagn.com

6

6.1.1 Oil change intervals

z The oil change times depend on the engine

application and the quality of the lube oil.

z If the oil change times are not reached

within a year, the oil change should be

carried out at least 1x yearly.

z The following conditions apply for the table

–Sulphur content max. 0.5 % of weight for

diesel fuel.

–Constant ambient temperature ³ -10 °C

(+14 °F)

z For fuels

– with sulphur content > 0.5 to 1%

or

– Constant ambient temperatures < -10 °C

(+14 °F)

or

– with bio-diesel fuels according to DIN

51606- FAME the oil change times

should be halved.

z If the lube oil change intervals are planned

in terms of operating hours, the lube oil

change intervals for installed engines

6.1.1.1 apply.

z For fuels with a sulphur content higher

than 1% ask your responsible

service representative.

Carry out oil changes on warm engine when the

engine is not running (lube oil temperature < 80 °C).

© 2005

Page 3

6.1 Lubrication system Care and maintenance work

cardiagn.com

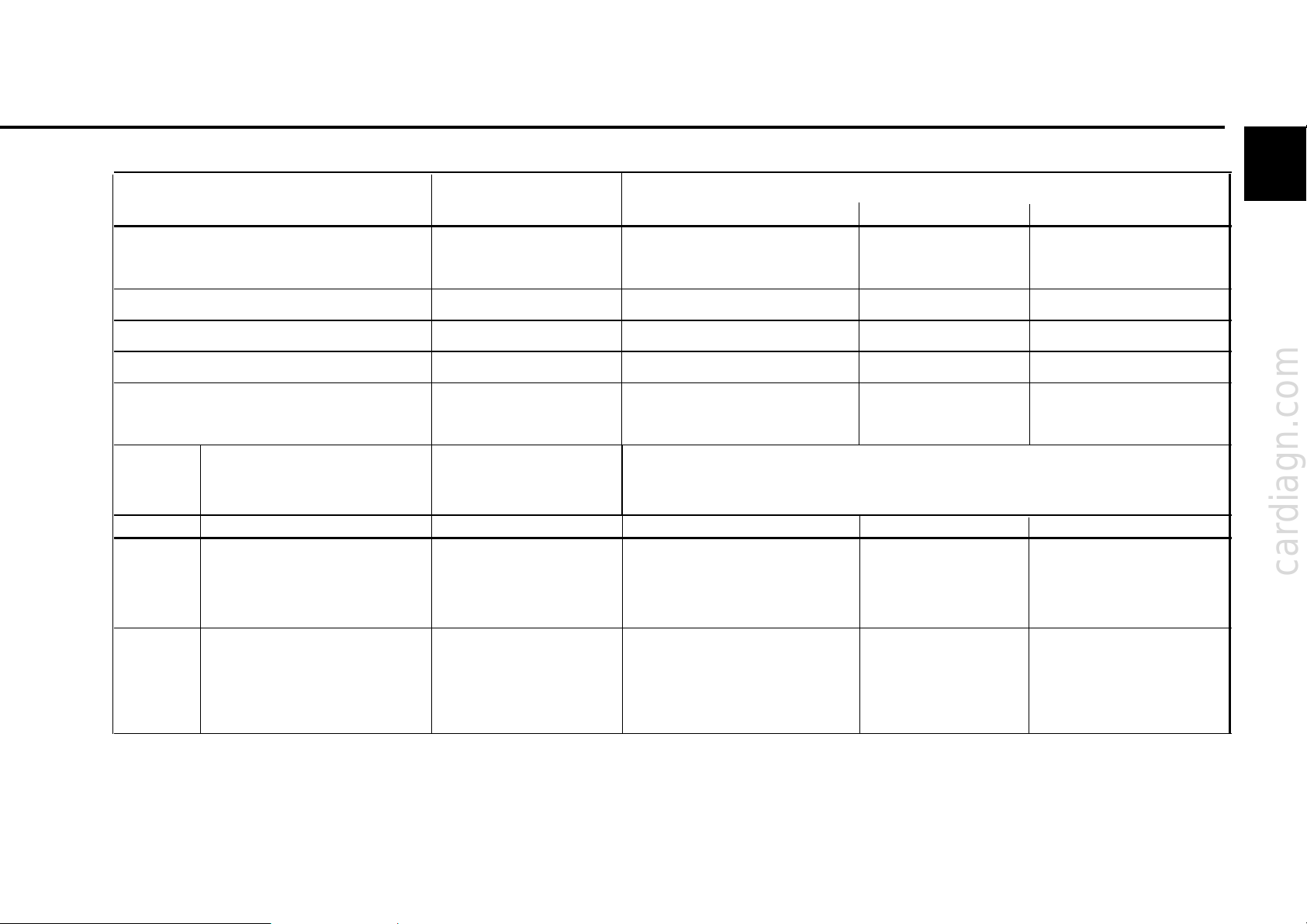

6.1.1.1 Lube oil change intervals for installed engines

Lube oil quality

Deutz lube oil quality class DQ C I- 02 DQ C II -0 5 DQ C III-05 DQC iV-05

ACEA specification E2-96 E3-96/E5-02/E07-04 E4-99/E6-04 E4-99/E6-04

see 6 .1.1.3 only fully synthetic

API specification CF /C F -4 CG- 4/C H-4/ CI- 4 - worldwide specification - DHD-1 - special DEUTZ release list - - see chap. 4.1.2.1 Standard lubricant code designation EO... EO...C - for building machines and building vehicles EO...A, EO...B

Engine Engine version Lube oil change intervals in oh

series

6

TCD All engines with:

2012 Crankcase ventilation:

L04/06 4V open - 500 500 500

closed - - 500 500

2013 Crankcase ventilation:

L04/06 4V open - 500 50 0 500

closed - - 50 0 5 00

© 2005

Page 4

Care and maintenance work 6.1 Lubrication system

cardiagn.com

6

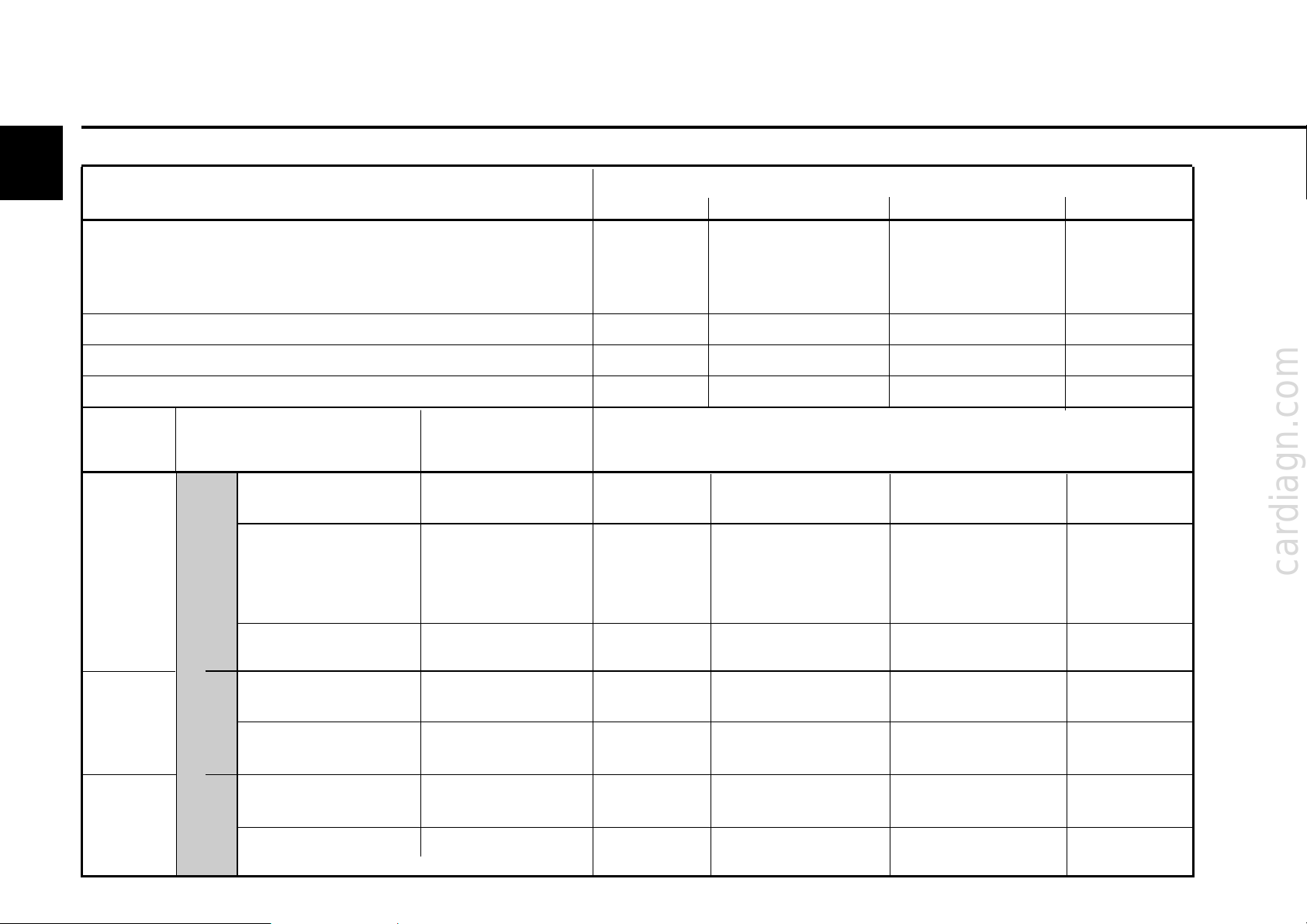

6.1.1. 2 Lube oil change intervals for vehicle engines

Lube oil quality

Deutz lube oil quality class DQ C I- 02 DQ C II -0 5 DQC III-05 DQC iV-05

ACEA specification E2-96 E3-96/E5-02/E07-04 E4-99/E6-04 E4-99/E6-04

see 6.1 .1.3 only fully

synthetic

API specification CF /C F -4 CG- 4/C H-4/ CI- 4 - worldwide specification - DHD-1 - special DEUTZ release list - - see chap. 4.1.2.1 -

Application

Building site

vehicles /

city buses/ Coach bus clo se d - 30 000 50 000 50 000

City TCD 2013 L04 4V clo se d - 25 000 45 000 45 000

transport TCD 2013 L06 4V close d - 30 000 50 000 50 000

Local transport 40 TCD 2013 L04 4V close d - 40 000 60 000 60 000

average driving speed km/h

Long distance

transport

© 2005

Engine version Crankcase

TCD 2012/2013 L04/ 06 4V ventilation Lube oil change intervals in km

TCD

2012 4V open - 20 000 20 000 20 000

clo se d - - 20 000 20 000

TCD 2013 L06 4V

25 Inter city bus cl os e d - 20 000 30 000 30 000

City busbus cl o se d - 15 000 20 000 20 000

TCD

2012 4V open - 30 000 30 000 30 000

clo se d - - 30 000 30 000

TCD 2013 L06 4V close d - 50 000 75 000 75 000

TCD

2012 4V open - 40 000 40 000 40 000

60 clo se d - - 40 000 40 000

TCD 2013 L04 4V close d - 60 000 80 000 80 000

TCD 2013 L06 4V closed - 75 000 100 000 100 000

Page 5

6.1 Lubrication system Care and maintenance work

cardiagn.com

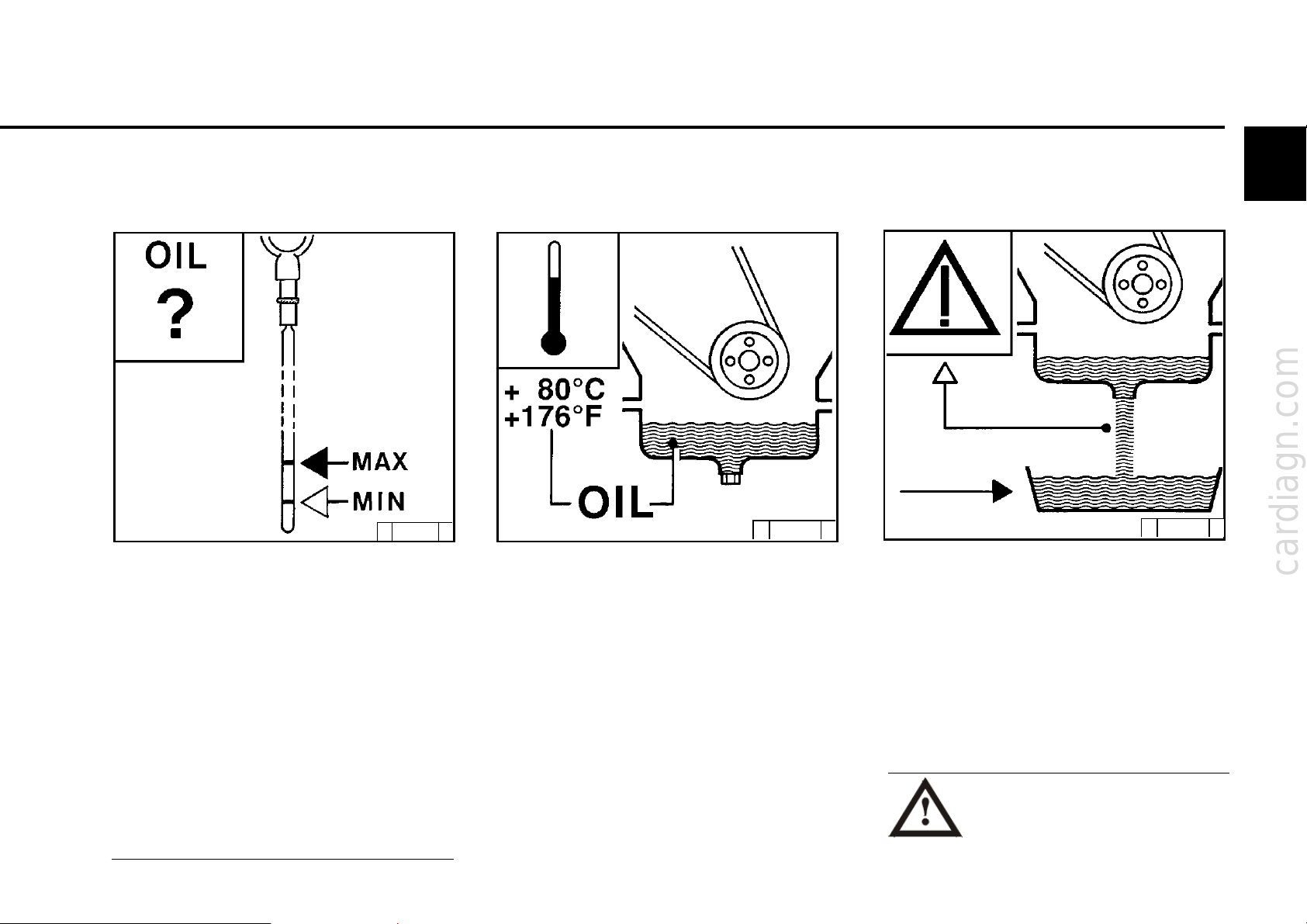

6.1.2 Checking oil level / changing

engine oil

6.1.2.1Checking oil level

© 25 729 0

z Position the engine or vehicle so as to be level.

z – Engine warm:

Switch off the engine, wait for 5 minutes and

check oil level.

z – Engine cold:

Check oil level.

z Extract oil dipstick.

z Wipe with a fibre-free, clean cloth.

z Insert until it stops and extract again.

z Check oil level and re-fill to „MAX“ if necessary.

– If the oil level lies just above the „MIN“-

line marking, re-filling is necessary.

The oil level may not fall short of the „MIN“ line

marking.

6.1.2.2 Changing engine oil

© 26 022 0

z Warm up engine.

z Position the engine or vehicle so as to be level.

– Lube oil temperature approx. 80 °C.

z Switch off engine.

© 26 023 0

z Position oil drip cup under the engine.

z Unscrew oil drain screw.

z Drain off oil.

z Screw in oil drain screw with new sealing ring

and tighten. (For tightening torque

see 9.2).

z Pour in lube oil.

– For quality / viscosity data see 4.1.

– For filling quantities, see 9.1.

z Check oil level, see 6.1.2.1.

Caution when draining

hot oil: danger of scalding!

Collect the used oil, do not allow to

seep into floor!

Dispose of according to instructions!

6

© 2005

Page 6

6

cardiagn.com

Care and maintenance work 6.1 Lubrication system

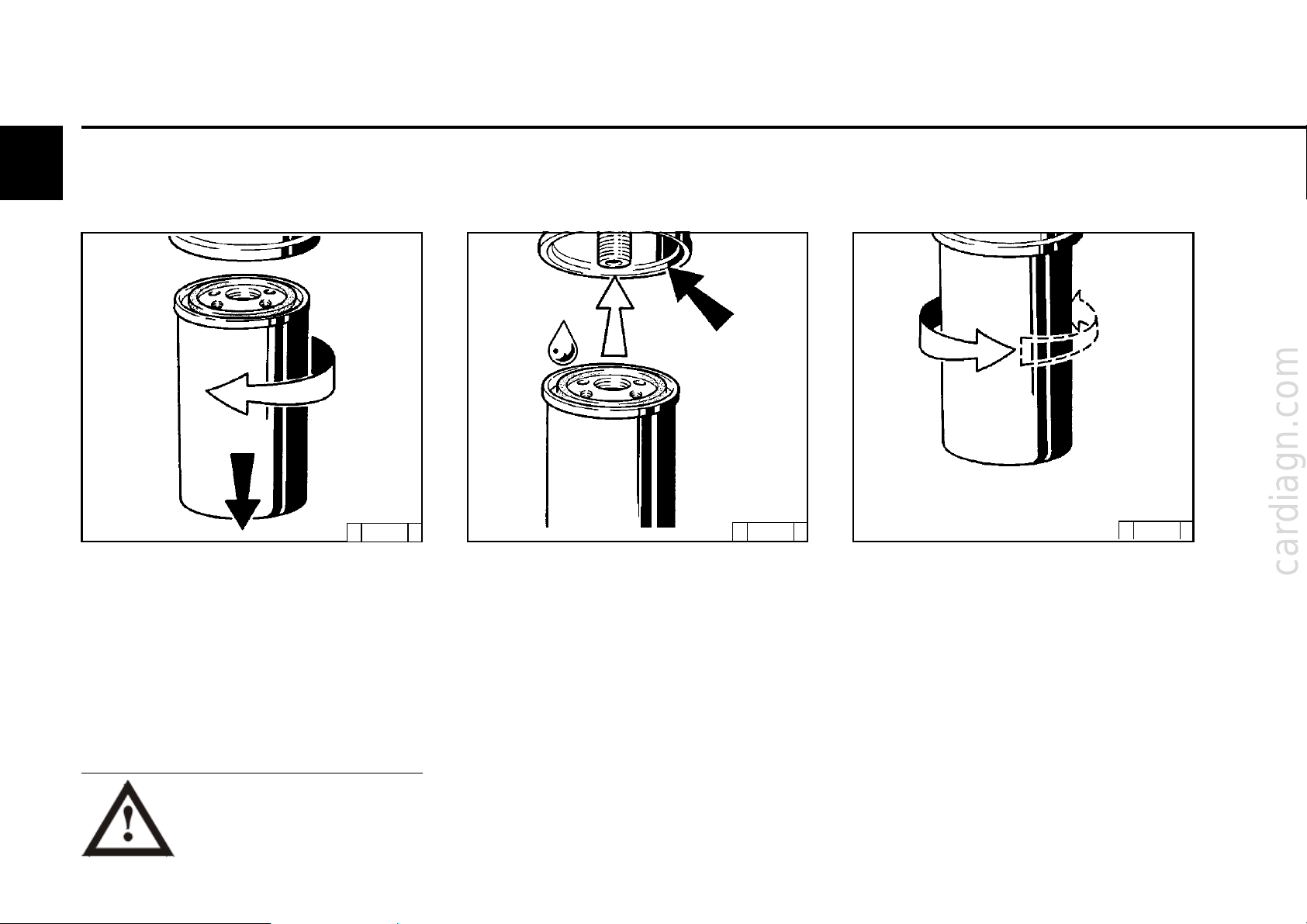

6.1.3 Changing oil filter insert

z When anti-rotation lock is installed:

Loosen clamping screws and remove tightening clamps from below.

z Loosen lube oil filter cartridge with stan-

dard tool and unscrew.

z Collect any oil which may run out.

Careful with hot oil:

danger of scalding!

© 2005

© 25 880 0

© 25 881 0

z Clean the sealing surface of the filter sup-

port for any possible dirt.

z Lightly oil the rubber seal of the new lube

oil cartridge.

z Screw on the cartridge by hand until the

seal makes contact.

© 25 88 2 0

z Tighten lube oil filter cartridge three quarters

of a turn (approx. 10 Nm).

z If there is an anti-rotation lock:

Position the tightening clamps and tighten

with clamping screws.

z Check oil level, see 6.1.2.

z Check oil pressure, see 3.3.1.

z Check the seal of the lube oil filter cartridge

for tightness.

Page 7

6.1 Lubrication system Care and maintenance work

cardiagn.com

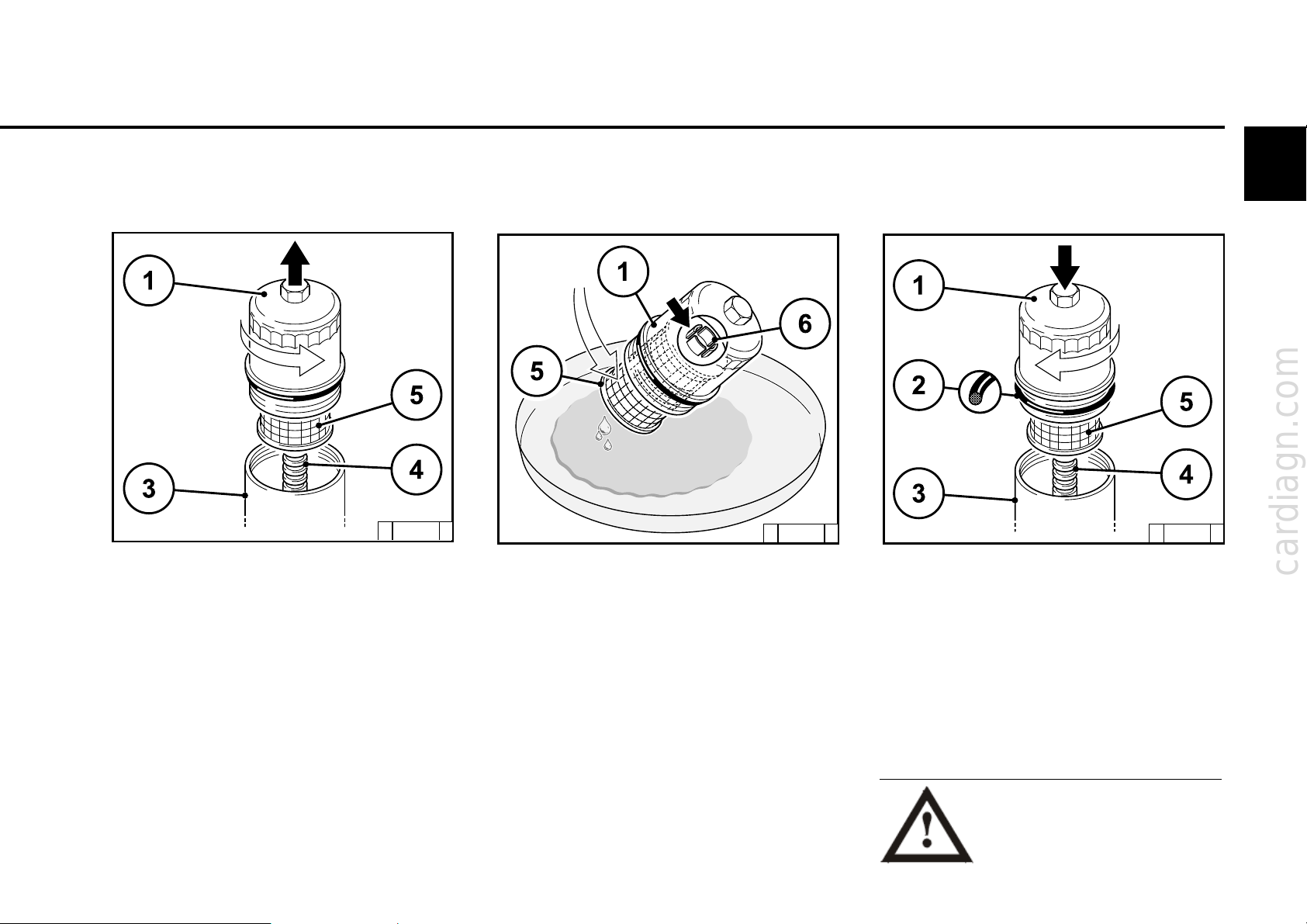

6.1.4 Cleaning / changing oil filter

(cup)

6

z Switch off engine.

z Loosen lube oil filter cover 1 with two or three

turns and wait for 30 seconds.

z Unscrew lube oil filter cover 1 with paper filter

cartridge 5 in anti-clockwise direction.

z Carefully loosen paper filter cartridge 5 from

the guide 4, which is inserted in the housing 3,

from above.

© 30 0 74 1

© 43 937 0 © 300 74 0

z Collect any lube oil which may run out.

z Crease the paper filter cartridge 5 in the

collection vessel slightly at the side until the

cartridge is released from the clip 6.

z Clean the sealing surface of the filter support

and the lube oil filter cover 1 as well as the guide

4 of any dirt there may be

z Change the round sealing ring 2 and lightly oil.

z Press new paper filter cartridge 5 into the clip

6 and insert carefully in the guide 4 together.

z Screw the lube oil filter cover 1 tight in clock-

wise direction (25 Nm).

z Start the engine.

z Check lube oil filter assembly for leaks.

z Check engine oil level and top up if necessary.

Careful with hot oil:

Danger of scalding

Dispose of used oil in an

environmentally friendly way.

© 2005

Page 8

Care and maintenance work 6.2 Fuel system

cardiagn.com

6

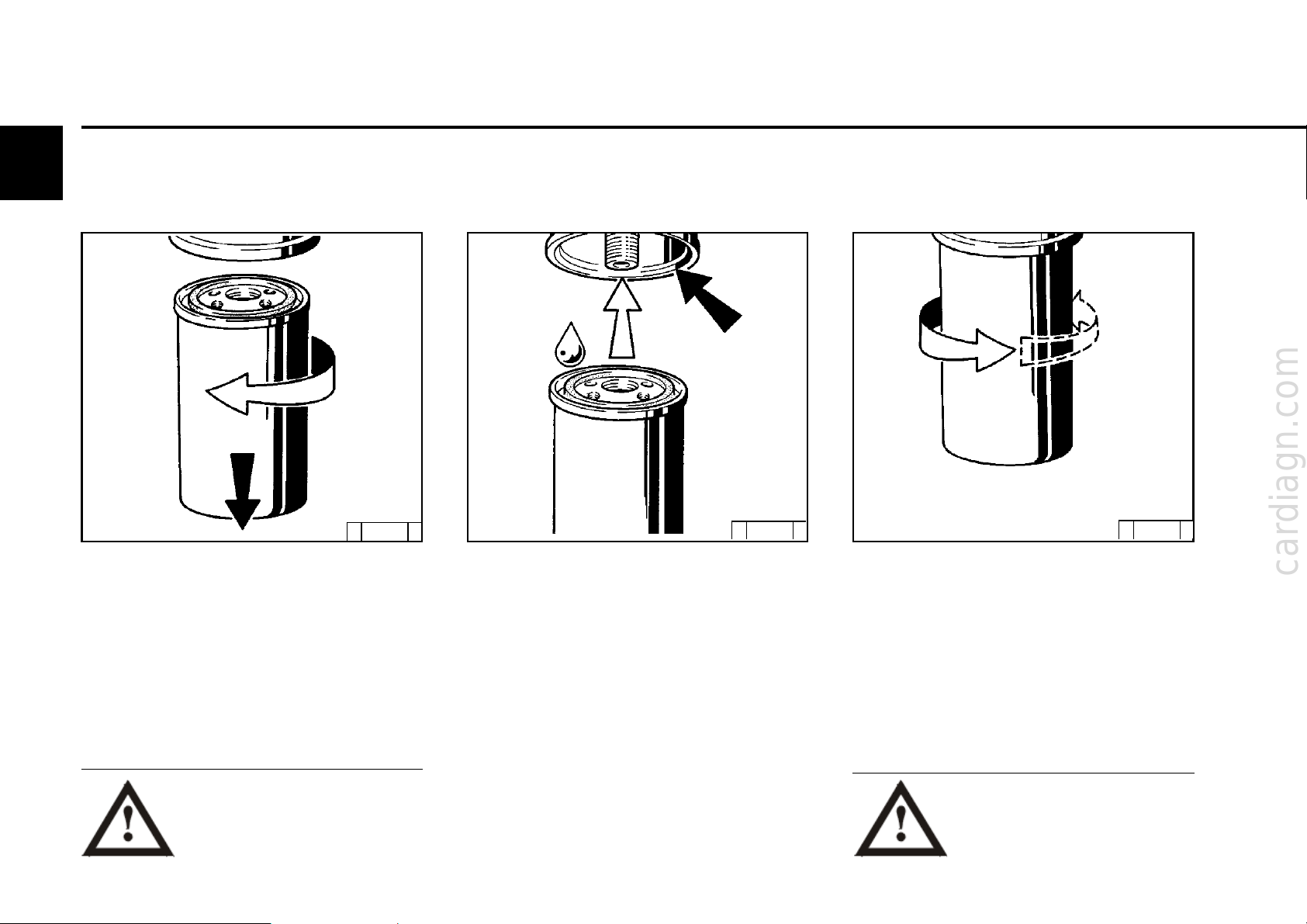

6.2.1 Changing fuel filter

© 25 880 0

z Close fuel stopcock.

z Loosen fuel filter cartridge with standard tool

and unscrew.

z Collect any fuel which may run out.

z Clean the sealing surface of the filter support

for any dirt there may be.

z Lightly oil the rubber seal of the new DEUTZ

original fuel filter cartridge or wet with diesel

fuel.

© 25 881 0

z Screw on the cartridge by hand until the seal

makes contact.

z Tighten the fuel filter cartridge with one more

half turn.

z Open fuel stopcock.

z Check for tightness.

© 25 882 0

Only work on the fuel system

when the engine is switched off.

Wait at least 30 seconds. No open

fire! Do not smoke!

© 2005

Pay attention to cleanliness as the

fuel system (Rail) is very sensitive!!!

It is necessary to bleed the fuel

system.

Page 9

6.2 Fuel system Care and maintenance work

cardiagn.com

6.2.2 Cleaning / changing fuel filter

(cup)

© 300 74 0

z Switch off engine

z Loosen fuel filter cover 1 and unscrew in anti-

clockwise direction.

z Carefully loosen paper filter cartridge 3 from

the guide 4 from above.

z Collect any fuel which may run out.

z Change paper filter cartridge 3.

z Clean the sealing surface of the filter support

and the fuel filter cover 1 as well as the guide4

of any dirt there may be.

6

z Change the rubber seal 2 and lightly oil.

z Carefully place new paper filter cartridge 3 in

the guide 4.

z Tighten the fuel filter cover 1 in clockwise

direction (25 Nm).

z Start engine.

z Check fuel filter attachment for tightness.

Only work on the fuel system

when the engine is switched off

(at least 30 seconds).

No open fire! Do not smoke!

Dispose of used fuel in an

environmentally friendly

manner.

© 2005

Page 10

Care and maintenance work 6.2 Fuel system

cardiagn.com

6

6.2.3 Changing / bleeding

fuel pre-filter , filter insert

© 43 848 1

Filter change:

z Close fuel stopcock (for high tanks).

z Position fuel collecting vessel beneath fuel pre-filter.

z Loosen drain cock (7) and drain water + fuel

completely .

z Unscrew filter cartridge (5) together with

water collecting vessel (8) in anti-clockwise

direction and remove.

z Loosen water collecting vessel (8) from old

filter cartridge (5) in anti-clockwise direction

and remove.

z Empty remaining fuel into the fuel collecting

vessel and clean water collectingvessel (8).

z Screw water collecting vessel (8) onto the

new filter cartridge (5) in clockwise direction.

© 2005

z Clean any dirt from the sealing surface of the

new filter cartridge (5) and the reverse side

of the filter head

z Wet the sealing surfaces of the filter cartridge

(5) slightly with fuel and screw back onto the

filter head in clockwise direction (17-18 Nm)

z Open the fuel stopcock and bleed the system

(see „Bleeding fuel system“).

z Dispose of collected fuel and old filter cartridge

(5) properly.

Bleeding fuel system:

z Unlock the bayonet plug of the fuel hand

pump (3) by pressing and turning

anti-clockwise at the same time. The pump

plunger is now pushed out through the spring.

Turn the shutdown lever of the ther-

mostat valve (4) by approx. 45° in

clockwise direction until it is felt to

engage.

z Pump until a very strong resistance is felt and

pumping becomes very slow.

z Now pump a few more times.

(The return line must be filled).

z Turn the shutdown lever of the thermostat

valve (4) by approx. 45° in anti-clockwise

direction until it is felt to engage.

z Lock the bayonet plug of the fuel hand pump

(3) by pressing and turning clockwise at the

same time.

1 Fuel supply to pump

2 Fuel return from control block FCU

Fuel Control Unit)

(

3 Fuel hand pump with bayonet plugfor

locking and unlocking

4 Thermostat valve with shutdown lever

5 Filter cartridge

6 Connection facility for electrical

water level sensor

7 Drain cock

8 Water collecting vessel (bowl)

9 Fuel inlet from fuel tank

10 Fuel return to fuel tank

Only work on the fuel system

when the engine is switched off.

No open fire! Do not smoke!

Dispose of used fuel in an

environmentally friendly manner.

Page 11

6.3 Cooling system Care and maintenance work

cardiagn.com

6.3.1 Cleaning intervals

z The cooling system soiling depends on the

type of engine application.

z The risk of soiling is increased by oil and fuel

residues on the engine. Therefore pay particular

attention to tightness when operating under

high dust exposure.

z Increased soiling occurs, for example, during:

- Building site application from high dust content

of air.

- Harvesting application from high proportion of

chaff and chopped straw , for example, in the

area of the work machine.

z Due to the various application conditions, the

cleaning intervals must be defined according

to each case. Therefore, the cleaning intervals

given in the table below can be used as

guidelines.

Checking or cleaning intervals

Guideline oh

2000 Ships, electronic units in

1000 Vehicles on paved

500 Tractors, fork lift trucks, drivable

250 Vehicles on building sites and

125 Agricultural machinery, tractors

Engine application

enclosed spaces, pumps.

roads

electronic units.

unpaved roads, building

machines, compressors, mining

equipment.

with harvesting application.

6

© 2005

Page 12

Care and maintenance work 6.3 Cooling system

cardiagn.com

6

6.3.2 Cleaning cooling system

©39 0010

Cleaning with compressed air

- Blast out the engine wih compressed air. Do not

damage any components.

- Rinse out the loosened dirt with a water jet.

© 39 002 0

Cleaning with cold cleaner

- Spray the engine with standard cold cleaner

and leave to work for approx. 10 minutes.

- Spray the engine clean with an acute water jet

(do not spray the water jet directly at sensitive

engine parts, e.g. generator, cabling, electronic

components, fan drive).

© 38 999 0

© 2005

Page 13

6.3 Cooling system Care and maintenance work

cardiagn.com

6.3.3 Emptying / filling / bleeding

cooling system

6

Emptying cooling system:

z Position collecting dish underneath locking

screw 5 and coolant supply 4.

z Remove locking screw 5 on the crankcase

and pull off hose on 4.

z Loosen bleed screw 2.

z Drain off coolant.

z Re-tighten locking screw 5 and hose on 4 and

bleed screw 2.

z If locking screw 3 is not accessible,

emptying may be carried out on the engine

oil cooler (coolant channel).

Filling / bleeding cooling system:

z Open cooler cover.

z Loosen bleed screw item 2.

z Pour in coolant until the maximum mark or the filling

limit (system heating valve must be open, if

present).

z Tighten bleed screw item 2 + locking screw

item 5.

zClose cooler cover.

zStart engine and warm up until the thermostat opens.

zSwitch off engine.

zCheck the coolant level with the engine cold and

re-fill if necessary.

zClose cooler cover item 1.

Bleeding

zThe cooling system, which was built according

to our installation guides, is bled automatically

after filling.

© 39 851 0

Caution when draining hot coolant:

danger of scalding! Collect coolant

when draining off.

Dispose of according to

instructions!

© 2005

Page 14

Care and maintenance work 6.4Combustion air filter

cardiagn.com

6

6.4.1 Cleaning intervals

z The soiling of the combustion air filter

depends on the dust content of the air and

the selected filter size. If a high dust

exposure is to be expected, a cyclone

separator can be connected to the

combustion air filter.

z The cleaning intervals cannot be generally

defined. They must be defined depending

on each case.

z If dry air filters are used, cleaning should only

be carried out according to the maintenance

display or maintenance switch.

z Filter maintenance is required when on the:

- Maintenance display

the red service field 1 is fully

visible when the engine is not running.

- Maintenance switch

the yellow warning light comes on when

the engine is running.

© 25 885 1

z After completion of the maintenance work

push the reset button on the maintenance

display. The maintenance display is ready

for operation again.

© 2005

Page 15

6.4 Combustion air filter Care and maintenance work

cardiagn.com

6.4.2 Emptying cyclone preseparator

© 25 886 0

z Loosen wing nut 1 and lift housing cover 2.

z Remove the dust container 3 from the base of

the cyclone 4 and empty . Clean foliage, straw

and the like from the cylone base.

z Place the dust container 3 on the base 4 and

tighten the housing cover 2 with wing nut 1.

6

Never fill the dust container with oil, replace

damaged containers!

© 2005

Page 16

Care and maintenance work 6.4 Combustion air filter

cardiagn.com

6

6.4.3 Dry air filter

Dust discharge valve

© 25 888 2

z Empty the dust discharge valve 1 by squeezing

the discharge slot in the direction of the arrow.

z Clean the discharge slot occasionally.

z Remove any stuck on dust residues by

squeezing the upper area of the valve.

Filter cartridge

© 25 889 1

z Open clamping bracket 1.

z Remove filter hood 2 and pull out filter cartridge 3.

z Clean filter cartridge, renew after a year at the latest.

z Clean filter cartridge 3.

- Blast out from the inside out with dry

compressed air (max. 5 bar), or

- beat out (only in extreme cases). Do not

damage the cartridge, or

- Wash according to manufacturer’s

specifications.

z Check filter cartridge for damage to the filter

paper (shine light through) and check seals.

Exchange if necessary.

z Renew the safety cartridge 4 after 5 filter

maintenances, after 2 years at the latest

(never clean!).

To do this:

- Loosen the hexagonal nut 5 and pull out

the cartridge 4.

- Insert new cartridge, re-mount hexagonal

nut and tighten.

z Insert filter cartridge 3, close hood 2 and

secure clamping bracket 1.

Never clean filter cartridge with

petrol or hot liquids!

© 2005

Page 17

6.5 Belt drive Care and Maintenance work

cardiagn.com

6.5.1 Changing V-belt

V -rib belt

© 39 004 0

z Push tension pulley in the direction of the arrow

until V-rib belt is free.

z First remove the V-rib belt from the smallest

pulley .

z Put on new V-rib belt

z Loosen tension pulley in the opposite direction

of the arrow until the V-rib belt is taut

Whilst doing this, check that the V-rib belt is

positioned correctly in your guide.

6.5 . 2 Changing V-belt

V-rib belt

© 39 005 0

z Push tension pulley in the direction of the arrow

until V-rib belt is free.

z First remove the V-rib belt from the smallest pulley.

z Put on new V-rib belt

z Loosen tension pulley in the opposite direction

of the arrow until the V-rib belt is taut Whilst

doing this, check that the V-rib belt is

positioned correctly in your guide.

6.5 .3Checking V-rib belt

wear limit

© 43 851 0

z The wear limit of the V-rib belt is checked as

follows:

z Check the distance between the projection

of the moving tension arm and the contact

with the fixed tensioner housing.

z If „ a“ i s le ss t han 3 mm the V-rib belt should be

changed.

6

Only check/tighten/change Vbelts when the engine is not

running. If necessary, re-mount

V-belt guard.

© 2005

Page 18

6

cardiagn.com

Care and maintenance work 6.6 Setting work

6.6.1 Checking valve clearance,

setting if necessary

z Loosen bleed valve and swing aside.

z Remove cylinder head cover.

z Before setting the valve clearance allow the

engine to cool down for at least 30 minutes: Oil

temperature below 80 °C.

z Place the turning device over the fastening

screws of the belt pulley.

z Turn over engine until the valve overlap is

achieved, cylinder no. 1

z Crankshaft setting as per setting diagram, see

6.6.1.1.

Note: Valve overlap means:

Exhaust valve is not yet closed. Inlet valve

begins to open. For valve setting diagram see

6.6.1.1, the table on the right.

© 2005

© 38 995 0

© 38 996 0

Setting instructions:

IN= inlet valve

EX = exhaust valve

z Perform test and setting work on every cylinder.

z Re-mount cylinder head cover (if necessary

with new gasket).

z Swing the bleed valve into position and fasten

Example: BF4M 2013

Valve clearance setting

1. Work step 1. Set cylinder to overlap, set cylinder 4.

2. Work step 3. Set cylinder to overlap, set cylinder 2.

3. Work step 4. Set cylinder to overlap, set cylinder 1.

4. Work step 2. Set cylinder to overlap, set cylinder 3.

Page 19

6.6 Setting work Care and maintenance work

cardiagn.com

6.6.1.1 Valve clearance setting diagram

Setting the valves: (black identification

z Perform valve clearance setting on appropria-

te cylinder with valve clearance setting device

part no. 8190.

Loosen all lock nuts 2 of the rocker arm

assembly to be set. Turn setting screw 1 back

with the valve clearance setting device one

turn in anti-clockwise direction.

On the valve to be set, turn setting screw 1 in

clockwise direction so as to be free of clearance.

That means, there must not be any clearance

between the rocker arm and valve and no

pressure may be applied to the valve.

z Set needle of measuring plate to [i| , not

twisting the knurled handle any more.

z Hold the measuring plate exactly in this position

and turn the setting screw 1 in anti-clockwise

direction with the knurled handle until the

needle is on the „in“ or „ex“ marking.

z Hold the knurled handle exactly in this position and

tighten lock nut 2 with a torque wrench (20 Nm).

z Üput on seal (poss. new seal).

z Visual inspection of screws and rubber ele-

ments, renew if necessary.

z Put on valve mechanism cover and tighten

screws according to tightening specification:

9 Nm (see 9.2).

)

6

© 38 997 0

© 2005

Page 20

Care and maintenance work 6.6 Setting work

cardiagn.com

6

6.6.2 Checking control piston

clearance at engine brake,

setting if necessary

© 43 935 0

z After the valve clearance has been set.

- Control unit for engine brake is already

mounted.

z Set the clearance on the control unit as follows.

z Turn engine until reaching the valve overlap

is reached, cylinder no. 1

z Set control piston clearance on every exhaust

valve.

z Proceed as for valve clearance.

Note

Valve overlap means:

Exhaust valve is not yet closed. Inlet valve begins

to open, see valve setting diagram.

© 2005

© 43 936 0

z Set control piston clearance if necessary, by:

- Loosening the lock nut 2.

- Mount the control piston clearance X on

setting screw 1 (see 6.6.1) with setting device

in EX and set as follows:

Fix the magnet

Turn th e set ting devic e without clearance

until the control piston contacts with the valve

bridge, set scale to „0“.

Then turn back angle degree 432° (by

hand or torque wrench):

EX = exhaust valve 432° for M8 thread

(corresponds to 1.5 mm clearance)

- Tighten lock nut 4.

z Perform test and setting work on every

cylinder.

z Replace cylinder head cover (if necessary

with new gasket).

z Swing the bleed valve into position and

fasten.

IN = Inlet valve

EX = Exhaust valve

1 Setting screw

2 Lock nut

3 Solenoid valve (electronic control)

4 Control board

Page 21

6

cardiagn.com

© 2005

Page 22

Care and maintenance work 6.7 Add-on parts

cardiagn.com

6

6.7.1.1Testing battery and cable

connections

© 25 895 0

z Keep the battery clean and dry.

z Loosen soiled connection terminals.

z Clean the battery poles (+ and -) and terminals,

and grease with an acid-free and acid-resistant

grease.

z Ensure that the terminal connections contact

well when assembling. Tighten the clamping

screws by hand.

6.7.1.2 Checking the acid level

© 24 232 3 © 25 896 0

z Remove sealing cap 1.

z If checking inserts 2 are available:

The liquid level should reach to their bottom.

z Without checking inserts:

The liquid level should reach 10-15 mm above

the upper edge of the plate.

z If necessary, re-fill with distilled water.

z Screw sealing cap back on.

6.7.1.3 Checking acid density

z Measure the acid density of individual cells

with a standard acid testing device.

The measured values (see table overleaf)

indicate the charge status of the battery. The

acid temperature when measuring should be

20 °C if possible.

© 2005

Page 23

6.7 Add-on parts Care and maintenance work

cardiagn.com

Acid density

in [kg/ l]

in [°Bé (Baumé degree)*] Charg e leve l

6

Normal

1,28

1,20

1,12

* The data for acid density in °Bé

(Baumé degree) is out of date and rarely

still in use.

Tropics

1,23

1,12

1,08

The gases released by the battery

are explosive! Avoid sparks and

open fire in the vicinity of the

battery! Do not allow acid to get on

skin or clothes!

Wear protective glasses!

Do not place any tools on the

battery!

Normal

32

24

16

Tropics

27

16

11

well charged

half charged, re-charge

discharged, charge immediately

© 2005

Page 24

Care and maintenance work 6.7 Add-on parts

cardiagn.com

6

6.7.2 Three-phase current

generator

Notes on three-phase current system:

z Do not interrupt the connections between the

battery, generator and governor when the

engine is running.

z If, however, an engine must be started and

operated without battery, the connection

governor / generator is to be separated before

starting.

z Do not swap battery connections.

z Replace defective charging warning light

immediately .

z When cleaning engine: Do not spray water/

steam jet directly at generator!

lWarm up the engine so that the water residues

evaporate.

z Under no circumstances may the voltage of a

three-phase current system be tested by

tapping against the earth cable.

6.7.3 Transportation suspension

z Only use the correct suspension equipment

for engine transportation. Suspension

equipment must be adjustable for the engine

centre of gravity.

© 38 9943 0© 38 994 0

z Fastening devices cannot be fixed safely over

the centre of gravity.

z Fastening devices can slip, engine capsizes.

z Short fastening devices cause bending

moments in the suspension. This can damage

the suspension.

z When carrying out electrical welding work,

clamp the earth terminal of the welding device

directly to the part to be clamped.

© 2005

Only use correct suspension

equipment!

Engine can fall.

Danger to life!

Loading...

Loading...