Page 1

Detcon, Inc.

TP-424C Hydrogen Sulfide Sensor

Operator’s Installation & Instruction Manual

March 18, 2014 • Document #2324 • Version 2.2

Page 2

Table of Contents

3.0 Description

3.1 Principle of Operation

3.2 Constant Temperature Control

3.3 One Man Remote Calibration

3.4 Application and Interference Data

3.5 Specifications

3.6 Installation

3.7 Start Up

3.8 Calibration

3.9 Calibration Frequency

3.10 Heater Voltage Adjustment

3.11 Fault Supervision

3.12 Trouble-shooting

3.13 Parts List

3.14 Warranty

3.15 Service Policy

Detcon Model TP-424C Hydrogen Sulfide Sensor PG.2

Page 3

3.0 DESCRIPTION

Construction of

Semiconductor Sensor

Sensor

Film

Heater

Film

Silicon

Microchip

Detcon Model TP-424C, hydrogen sulfide sensors are designed to detect and monitor H2S in air over the

range of 0-100 ppm. The sensor assembly consists of a solid state semi-conductor sensor in a stainless steel

ousing, a plug-in control transmitter circuit, a base connector board and an explosion proof enclosure. The

h

sensor assembly is suitable for use in Class I; Div. 1; Groups B, C, D electrically classified areas.

Sensor Technology

The sensor technology is a patented solid state metal oxide semiconductor. The sensor consists of two thin

films; a temperature sensitive heater film, and an hydrogen sulfide sensitive sensor film. Both films are

deposited on a silicon microchip by vacuum deposition. The heater film elevates the operating temperature

of the sensor film to a level where a good sensitivity and response to hydrogen sulfide is achieved. The sensor

film is a proprietary metal oxide that shows a dynamic response to hydrogen sulfide gas. Range of sensitivity

is from part per billion to % by volume. The rugged sensor is capable of maintaining its operating characteristics for periods of up to 7-10 years in most industrial environments and as such, is supported by a 10-year

conditional warranty.

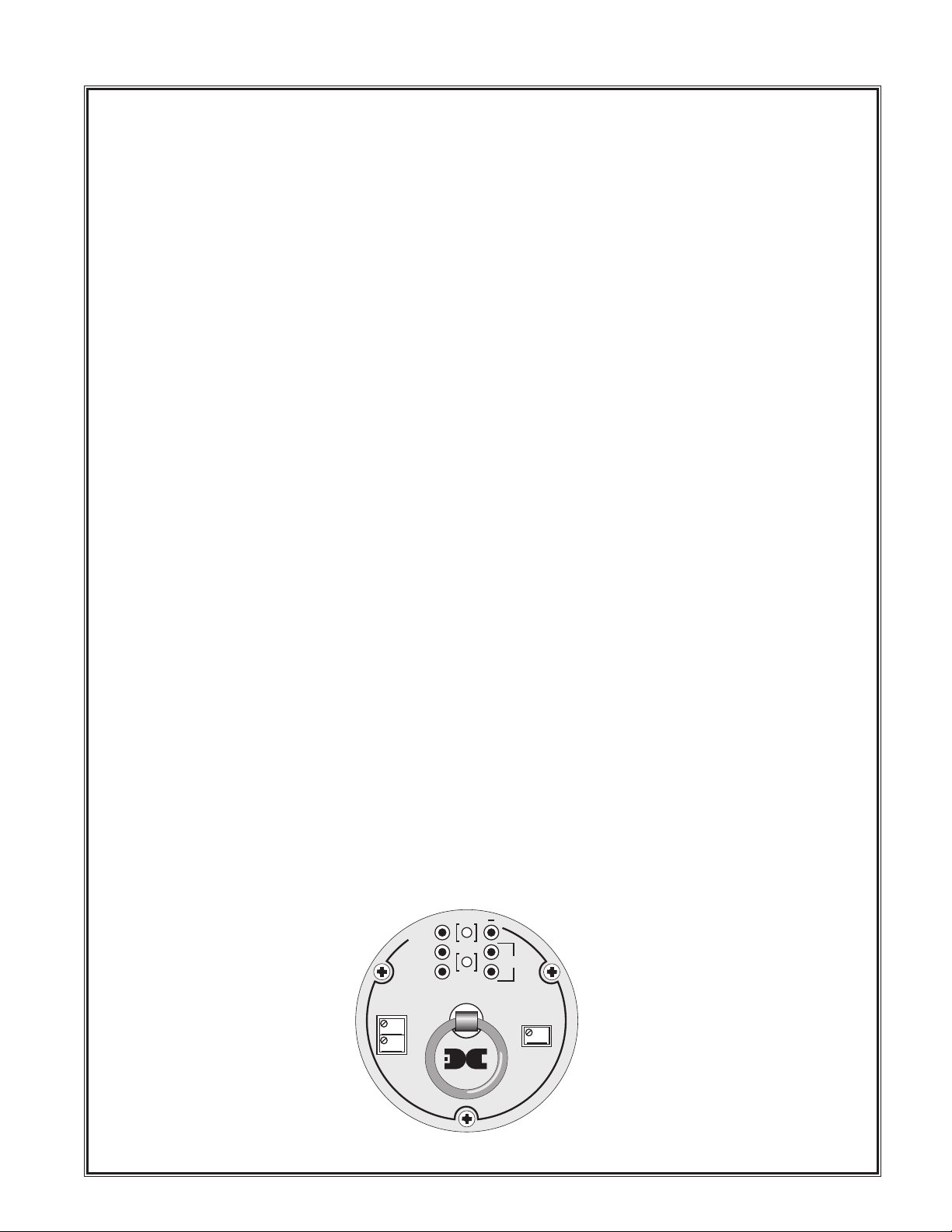

Plug in Control Transmitter Circuit

The control transmitter is a remote mounted electronic circuit designed and packaged as a plug-in module.

The transmitter assembly consists of several circuit functions: input power conditioning, sensor heater control, sensor signal conditioning, sensor fault supervision, and fault LEDs. A metallic face plate with pull

ring identifies test points and calibration adjustments. The plug-in module design supports easy field level

maintenance and repair. The mating plug is gold plated for maximum resistance to corrosion.

Detcon Model TP-424C Hydrogen Sulfide Sensor PG.3

Page 4

Base Connector Board

T

P-424C

C

OARSE

+

P

PM H2S

4

-

2

0 mADC

T

E

X

A

S

H

O

U

S

T

O

N

TEMP

HEATER

detcon inc.

SPAN

FINE

SIGNAL

CURRENT

VOLT

SIG

FLT

H

TR

FLT

BLUE

YELLOW

MA

24VDC

To Controller

Ter m i n a ls

BLACK

WHITE

Sensor

–

+

4-20MA

The base connector board is mounted in the explosion proof enclosure and includes: the mating connector

for the control transmitter, reverse input and secondary transient suppression, input filter, and lugless terminals for all field wiring.

Explosion Proof Enclosure

The explosion proof enclosure is constructed of cast metal with an epoxy finish. The enclosure is fitted

with a threaded cover. Electrical classification is Class I; Div. 1, Groups B, C, D

Detcon Model TP-424C Hydrogen Sulfide Sensor PG.4

Page 5

3.1 PRINCIPLE OF OPERATION

P

RE-AMP

(

SPAN)

C

ONSTANT

TEMPERATURE

C

ONTROL

S

IGNAL

CONDITIONING

X

MTR

POWER

S

UPPLY

MOS

S

ENSOR

R

TD

HEATER

I/O CIRCUIT

PROTECTION

S

IGNAL OUT

POWER IN

In operation TP-424C sensors are installed in industrial areas where hydrogen sulfide gas leaks are most likely to occur. Method of detection is by diffusion adsorption. As hydrogen sulfide gas diffuses through the sin-

ered porous filter and contacts the surface of the heated sensor element, the metal oxide sensor film decreas-

t

es in electrical resistance non-linearly proportional to the concentration of gas. This change in resistance is

conditioned by a control transmitter circuit which, in turn, provides a linear 4-20 mA DC signal corresponding to the range 0-100 ppm. As the gas leak subsides and the area clears, the sensor film returns to its original

resistance range. In application, sensor operation is a continuous reading detection/monitoring method.

3.2 CONSTANT TEMPERATURE CONTROL

A unique feature of the TP-424C solid state sensor is the RTD type heater film. The heater film serves two

important functions. First, it elevates the operating temperature of the sensor film to a level where most

efficient response and clearing characteristics are achieved. And second, it allows control circuits to control

surface temperature of the sensor film regardless of ambient temperature conditions. This constant temperature method improves long term stability and overall accuracy, as well as improves sensor performance in

cold weather applications.

3.3 ONE MAN REMOTE CALIBRATION

Sensor assembly design incorporates a modular plug-in remote control transmitter which accommodates

all calibration adjustments: span (coarse and fine) and heater voltage. A metallic face plate protects against

damage and allows easy access to test points and trimming potentiometers. With the use of a digital voltmeter, the design supports one man remote calibration.

3.4 APPLICATION & INTERFERENCE DATA

Model TP-424C sensors are designed to detect and monitor hydrogen sulfide gas in ambient air in the

range of 0-100 parts per million. Minimum sensitivity and scale resolution is 1 ppm. Sensor specifications

reflect an operating temperature range of -40° F. to +175° F. While the sensor is capable of operating outside these temperatures, performance specifications are verified within the limit.

Sensor Placement/Mounting

Sensor location should be reviewed by facility engineering and safety personnel. Area leak sources and

perimeter monitoring are typically used to determine number and location of sensors. Hydrogen sulfide gas

is slightly heavier than air (approximately 1.18); therefore, the sensors are generally located 2 - 4 feet above

grade. The sensors should always be mounted in accessible locations to facilitate periodic maintenance.

Interference Data

Methane 25,000 = 0

Ethane 5,000 = 0

Hexane 5,000 = 0

Propane 5,000 = 0

Butane 5,000 = 0

Carbon Monoxide 800 = 0

Carbon Dioxide 5,000 = 0

Carbon Disulfide 14 = 0

Methanol 500 = 3

Isopropanol 500 = 1

Detcon Model TP-424C Hydrogen Sulfide Sensor PG.5

Page 6

Ammonia 500 = 0

Diesel Fuel 5000= 0

Demethyl Sulfide 4.4 = 0

thylene 200 = 0

E

Freon 12 1000 = 0

Hydrogen 1000 = 8

Methyl Mercaptan 5 = 8

Sulfur Dioxide 300 = 0

Toluene 32 = 0

Ethanol 500 = 2

3.5 SPECIFICATIONS

Method of Detection

Solid state metal oxide. Diffusion/adsorption

Electrical Classification

Class I; Div 1, Groups B, C, D

Response Time

50% <45 seconds, 80% <90 seconds

Clearing Time

50% <45 seconds, 80% <90 seconds

Repeatability

± 2ppm or ±10% of Reading (Greater Of)

Range of Sensitivity

PPB to % by volume

Operating Temperature

-40° to +175° F

Accuracy

± 2ppm or ±10% of Reading (Greater Of)

Sensor Life

10 year conditional warranty

Field Wiring

3 conductor; max 10 ohms single conductor resistance

Input Power

22.5-28 VDC

Power Consumption

57 mA normal operation (1.37 watts @ 24 VDC); 81 mA max. (2 watts @ 24 VDC)

3.6 INSTALLATION

NOTE: The Detcon MOS sensor can be damaged to the point of not functioning if the power is turned off in

the presence of high levels of humidity for periods exceeding 8 hours. Always protect the sensor with the

Detcon sealing cap and fresh dessicant packet while the sensr is off power. This will avoid permanent sensor damage and help preserve the span calibration.

Optimum performance of ambient air/gas sensor devices is directly relative to proper application installation and adherence to recommended maintenance schedules including periodic recalibration.

Field Wiring Table

Detcon Model TP-424C solid state H2S sensor assemblies require three conductor connection between

power supplies and electronic controllers. Wiring designators are + (DC), – (DC) , and mA (sensor signal).

Maximum single conductor resistance between sensor and controller is 10 ohms. Maximum wire size for

termination in the sensor assembly terminal board is 14 gauge.

AWG Meters Feet

20 240 800

18 360 1200

Detcon Model TP-424C Hydrogen Sulfide Sensor PG.6

Page 7

16 600 2000

EYS

Seal

Fitting

Drain

“T”

Plug any unused ports.

14 900 3000

Note 1:

This wiring table is based on stranded tinned copper wire and is designed to serve as a reference only.

Note 2: Shielded cable may be required in installations where cable trays or conduit runs include high voltage lines or other sources of induced interference.

Note 3: The supply of power must be from an isolating source with over-current protection as follows:

AWG

Over-current Protection AWG Over-current Protection

22 3A 16 10A

20 5A 14 20A

18 7A 12 25A

Sensor Location

Selection of physical sensor location is critical to the overall safe performance of the product. Four factors

play an important role in selection of sensor locations:

(1) Density of the gas to be detected

(2) Most probable leak sources within the industrial process

(3) Ventilation or prevailing wind conditions

(4) Personnel exposure

Density - Placement of sensors relative to the density of the target gas is such that sensors for the detection

of heavier than air gases should be located within 2-4 feet of grade as these heavy gases will tend to settle

in low lying areas. For gases lighter than air, sensor placement should be 4-8 feet above grade in open

areas or in pitched areas of enclosed spaces. Give consideration to easy access by maintenance personnel

as well as the consequences of close proximity to contaminants that may foul the sensor prematurely.

Leak Sources - Most probable leak sources within an industrial process include flanges, valves, and tubing

connections of the sealed type where seals may either fail or wear. Other leak sources are best determined

by facility engineers with experience in similar processes.

Ventilation - Normal ventilation or prevailing wind conditions can dictate efficient location of gas sensors

in a manner where the migration of gas clouds is quickly detected.

Personnel Exposure - The migration of gas clouds should not be allowed to approach concentrated personnel areas such as control rooms, maintenance or warehouse buildings.

A more general and applicable thought toward selecting sensor location is combining leak source and

perimeter protection in the best possible configuration.

Note: In all installations, the sensor element in stainless steel housing points down relative to grade (see

figure #2). Improper sensor orientation will result in false reading and permanent sensor damage.

Fig. #2

Detcon Model TP-424C Hydrogen Sulfide Sensor PG.7

Page 8

Local Electrical Codes

4 3/4"

3/4" NPT

1/4" Dia.

Mounting Holes

7"

6 1/8"

5 1/2"

3/4" NPT

Rainshield/

Splashguard

2"

2 1/8"

BLUE

YELLOW

MA

24VDC

To Controller

Ter m i n a ls

BLACK

WHITE

Sensor

–

+

4-20MA

Sensor and transmitter assemblies should be installed in accordance with all local electrical codes. Use

ppropriate conduit seals. Drains & breathers are recommended. The sensor assemblies are designed to

a

meet NEC and CSA requirements for Class I; Div. 1, Groups B, C,D environments.

Note: An appropriate conduit seal must be located within 18" of the sensor assembly. Crouse Hinds type

EYS2 or EYD2 or equal are suitable for this purpose.

Installation Procedure

a) Remove the junction box cover and un-plug the control transmitter

b) Securely mount the sensor junction box in accordance with recommended practice. See dimensional

drawing (Fig. 3).

c) Observing correct polarity, terminate 3 conductor field wiring to the sensor base connector board (see

figure #4).

d) Replace the plug-in transmitter module and junction box cover.

Detcon Model TP-424C Hydrogen Sulfide Sensor PG.8

Page 9

Remote Mounting Applications

1234

WHT

BLK

YEL

BLU

Remote Transmitter

TP-424C-RT

Remote Sensor

TP-424C-RS

W

HT

BLK

YEL

B

LU

Plug unused port

with 3/4 NPT plug.

Measure Heater V oltage

From White (1) to Black (2)

Target voltage is 5.25v ±.05 v

Some sensor mounting applications require that the gas sensor head be remotely mounted away from the

ensor transmitter. This is usually true in instances where the gas sensor head must be mounted in a loca-

s

tion that is difficult to access. Such a location creates problems for maintenance and calibration activities.

Detcon provides the TP-424C sensor in a remote-mount configuration in which the sensor (Model TP-424CRS) and the transmitter (Model TP-424C-RT) are provided in their own condulet housing and are interfaced together with a three conductor cable. Reference the figure below for wiring diagram.

Remote Mounting Configuration - Heater Voltage Adjustment

When a sensor is remote mounted, consideration must be given to the lengths of cable used and how it

affects the sensor heater voltage. Differing lengths of cables will have varying amounts of resistance which will

shift the sensor heater voltage. Because of this, the heater voltage will need to be adjusted after initial power

up. Replacement of the sensor will also require readjusting the heater voltage. See section 3.7.2 for instructions.

3.7 START UP

Upon completion of all mechanical mounting and termination of all field wiring, apply system power and

observe the following normal conditions:

a) Transmitter “Fault” LEDs (Heater Fault and Signal Fault) are off.

b) Detcon controller (if applicable) “Fault” LED is off.

c) A temporary upscale reading will occur as the sensor heats up. This upscale reading will clear to "0"

ppm within 5-10 minutes of turn-on, assuming there is no gas in the area of the sensor.

Important Note:

A desiccant cap is attached to the sensor housing during storage and shipping. This prevents H20 from contacting the sensor film while it is off power, and thus helps to avoid damage and retain the stability of the

factory span calibration. Remove the desiccant cap 5~10 minutes after applying power to the sensor, then

install the weatherproof splashguard accessory supplied with your sensor.

Store the desiccant caps in a sealed container (i.e., zip-lock bag) for future use. It is advised (but not mandatory) to use the desiccant caps during long periods without power (more than 1 day).

Detcon Model TP-424C Hydrogen Sulfide Sensor PG.9

Page 10

3.7.1 Initial Operational Tests

TP-424C

COARSE

+

PPM H

2

S

4

-

20 mADC

T

E

X

A

S

H

O

U

S

T

O

N

TEMP

HEATER

detcon inc.

SPAN

FINE

SIGNAL

CURRENT

VOLT

SIG

FLT

HTR

FLT

After a warm up period of approximately 60 minutes, the sensor should be checked to verify proper operation and sensitivity to H2S gas.

Caution: Initial test and operational procedures require that the sensor junction box cover be removed

and, therefore, negate the electrical classification. De-classify the area before proceeding.

Required Materials

Digital volt/ohm meter

Jeweler’s type screwdriver

Test gas: H2S in Air in the range 25 to 50 ppm. (H2S in nitrogen mixes are not acceptable.)

Detcon P/N 6038 Threaded Calibration Adapter

Detcon P/N 985-241100-321 In-Line Humidifying Tube

a) Remove the junction box cover.

b) Measure the voltage between heater test points (see figure #5). A nominal reading of 5.25 VDC ± 0.1

VDC is acceptable.

c) Measure the voltage between the signal test points: a zero gas reading of 39-40 mv DC is acceptable.

d) Apply 200-500cc/min flow (200cc/min is the recommended flow) of a test gas in the range 25-50 ppm

H2S in Air, using the humidifying tube between the calibration gas cylinder and the H2S sensor.

Observe that the signal voltage increases to a level of 56 mv DC or higher.

e) Remove the test gas and observe that the signal voltage decreases to 39-40 mv DC.

Initial operational tests are complete. Detcon hydrogen sulfide sensors are pre-calibrated prior to shipment

and will, in most cases, not require significant adjustment on start up. However, Detcon recommends that

a complete calibration test and adjustment be performed 16 to 24 hours after power-up. Refer to calibration

instructions in later text.

3.7.2 Remote Mount Heater Voltage Setup

If the sensor has been installed using the remote mounting configuration as described in section 3.6, the sensor heater voltage must be adjusted after initial power up. Replacement of the sensor will also require readjusting the heater voltage. Follow the steps below to set the sensor heater voltage.

Material Requirements

* Digital volt/ohm meter.

a) Declassify the area around the sensor.

b) Remove the junction box cover from the remote sensor enclosure.

c) Using the digital volt/ohm meter, measure the bridge voltage at the remote sensor connector board from

the “White” terminal to the “Black” terminal as shown in figure on page 9. Target voltage is 5.25 volts.

d) At the transmitter, adjust the “TEMP” potentiometer (see figure #5) to achieve a reading of VDC at the

remote sensor connector board as described in item “c” above.

e) Replace the junction box cover on the remote sensor enclosure.

Heater voltage adjustment is complete.

Fig. #5

Detcon Model TP-424C Hydrogen Sulfide Sensor PG.10

Page 11

3.8 CALIBRATION

Note 1: Detcon solid state MOS hydrogen sulfide sensors give erroneous readings in oxygen depleted environments. Calibration gas mixtures of H2S in air are required. (Do not use span gas cylinders with nitro-

en and H2S mixtures.)

g

Material Requirements

Detcon P/N 6038 Threaded Calibration Adapter

Span Gas: 25 ppm H2S in air at a controlled flow rate between 200 and 500 cc/min.

Detcon P/N 985-241100-321 In-Line Humidifying Tube

NOTE: Span gas bottles contain 0% humidify and this ultra-low condition will cause inaccurate read-

ings when used to calibrate a sensor. To prevent this error, Detcon prescribes the use of a 24” flexible

In-Line Humidifying Tube, which adds the relative humidity to the span gas. The humidifying tube is

not necessary when using a gas generating calibration device that consists of pumped ambient air and

an H2S generating source.

NOTE: Span gas mixtures in the range 20 to 100 ppm are acceptable but 25 ppm is recommended to

provide the best signal linearity. Span gas mixtures less than 20 ppm are not recommended as these

will reduce the accuracy of signal linearity and are known to lose H2S concentration over time, espe-

cially at higher temperatures.

Caution: Calibration procedures require that the sensor junction box cover be removed and, therefore,

negate the electrical classification. De-classify the area before proceeding.

1) Declassify the area around the sensor.

2) Remove the junction box cover.

3) Measure the voltage between heater test points (see figure #5). A nominal reading of 5.25 ±0.15VDC

should be observed; minimum 4.8 VDC; maximum 5.5 VDC. See section 3.10 “Heater Voltage

Adjustment” for additional information.

4) Measure the voltage between signal test points. A zero gas reading of 39 to 40 mV DC is expected in

clean air.

5) Remove the rain shield or splashguard and attach the threaded calibration adapter.

6) At a flow rate of between 200 cc/min to 500 cc/min (200cc/min is the recommended flow), use the

span gas humidifier and apply a humidified gas standard of 25 or 50 ppm. Wait 3-5 minutes for signal

stability.

7) Using the span potentiometers (coarse and fine), adjust the signal to a reading equal to the level as

reflected in the calibration table below.

8) Remove the gas standard and calibration adapter. Observe that the signal decreases to 39-40 mvdc

within 2-3 minutes.

Calibration Table

Each 1 ppm increase in H2S gas will increase the signal by 1.6 millivolts from a baseline of 40 millivolts.

Below are a sample of gas concentrations and the correct signal output they will provide.

PPM mV DC

0 39-40

10 56

25 80

30 88

40 104

50 120

60 136

70 152

80 168

90 184

100 200

Detcon Model TP-424C Hydrogen Sulfide Sensor PG.11

Page 12

3.9 CALIBRATION FREQUENCY

In most applications, monthly to quarterly calibration intervals will assure reliable detection. However,

ndustrial environments differ. Upon initial installation and commissioning, close frequency tests should

i

be performed weekly to monthly. Less frequent test schedules should be implemented based on analysis of

tests prior to adjustment.

3.10 HEATER VOLTAGE ADJUSTMENT

Each sensor is pre-calibrated and tested prior to shipment. The heater voltage set point is marked on the

bottom of the stainless steel sensor housing. This temperature is referenced to 72° F ambient. Slight variations in heater voltage will occur in higher or lower ambient temperatures. Typical variation from 72°F reference point is + or – 3% of original value between 32°F - 100°F. For a sensor set for 5.25 VDC at 72°F, the

heater voltage change at 100°F would typically be –.15 VDC; and at 32°F would typically be + .15 VDC.

The general effect of the heater function is such that a lower voltage will cause a slower, but more stable

long-term repeatability to gas, while a higher voltage will cause a slightly quicker response but a less stable

long-term repeatability. If it should become necessary to elevate the heater voltage to maintain response

and clearing characteristics, do not exceed 5.75 volts in 72°F temperature point. Note that any adjustment

to the heater voltage will require that the sensor be recalibrated with H2S gas after 24 hours of stabilization

time.

The heater voltage is adjusted via the “TEMP” potentiometer and is measured at the two test points

labeled “VOLT”.

Optional Heater Power Adjustment Instructions

A new feature included with the latest revision of the TP-424C allows for a more accurate adjustment to be

made to the sensor heater circuit. This feature is based on power rather than voltage. Setting the sensor

heater voltage, as measured at the “VOLT” test points, is an acceptable method. However, the new power

feature is an option that allows the user to calculate and implement a more precise method of temperature

control to the sensor over longer periods of service. After several years of service the sensor heater film

may degrade and require more precise power level adjustment.

The main objective of the sensor heater circuit is to elevate the temperature of the solid state sensor element to between 500 and 527°F. This temperature provides the best combination of speed and stability for

detecting H2S gas. Because the sensor heater resistance increases with age, the power being applied to the

sensor decreases even if the heater voltage remains constant. This decrease in power also reduces the sensor temperature. Thus, a constant power being applied to the sensor will render better performance than a

constant voltage.

The desired power setting which is measured in milliwatts, will vary depending on ambient temperatures.

If the ambient temperature is 72° F, the desired power setting should be 235 mW, ±10mW. On hotter days

when the ambient temperature is 100°F, the optimal power setting should be 225mW, ±10mW. A cold day

with an ambient temperature of 32°F, would call for a power setting of 250mW, ±10mW.

To set the sensor heater for power rather than voltage, follow the instructions below.

Note 1: Power (P) is the result of multiplying the heater voltage “VOLT” (V) by the heater current “CURRENT” (I). P = V x I

Note 2: Because the heater current is routed through a 1 ohm resistor located between the test points

labeled “CURRENT”, it is not necessary to set your volt/ohm meter to measure current to obtain the proper reading. Your meter should be set to measure millivolts and the reading is simply interpreted as heater

current in milliamps.

1 - Measure the heater voltage at the test points labeled “VOLT”. (example = 5.25V @ 72°F)

2 - Next, measure the heater current at the test points labeled “CURRENT”. (example .045 A)

Thus, 5.25 (volts) x .045 (amps) = .236 (watts or 236 milliwatts). This falls within 10mW of the target power

Detcon Model TP-424C Hydrogen Sulfide Sensor PG.12

Page 13

setting of 235 mW and is acceptable. If the value was too low you would increase the voltage by turning

the potentiometer labeled “TEMP” clockwise, and then recalculate with the new voltage and current readings. If the value was too high, you would decrease the voltage and repeat the process as necessary to reach

he desired power setting.

t

3.11 FAULT SUPERVISION

Model TP-424C sensors incorporate fault circuitry which monitors both the heater loop and sensing film

loop of the H2S sensor element. Should one or both of these circuits become electrically “open” a fault condition will occur which will result in the illumination of the corresponding fault LED located on the transmitter face plate (Heater Fault and Signal Fault) as well as the 4-20 mA signal dropping to 0 mA. When

used with Detcon Model 10 or Model 12 controls, this drop in the mA signal will result in a fault condition

on the affected control module.

3.12 TROUBLE SHOOTING

Caution: Trouble shooting procedures require that the sensor junction box cover be removed and, therefore, negate the electrical classification. De-classify the area before proceeding.

Tools Required

Digital volt/ohm meter, Jeweler’s type screwdriver

Note: As described in section 3.11, fault supervision circuitry monitors the heater and signal loop of the

sensor element. If the mA output has dropped to 0 mA and the Heater Fault and/or Signal Fault LED is

illuminated, the sensor element has become electrically open and should be returned for repair/replacement.

Open Heater

Verify resistance between black and white wires using ohm-meter with the sensor unplugged and at room

temperature.

Heater Film Check: normal reading range should be 65-95 ohms

Open Sensor

Verify resistance between blue and yellow wires using ohm-meter with the sensor unplugged and at room temperature. Sensor Film’s normal reading range should be 5-100 k-ohms. For sensors with an “X” in the serial

number, the normal reading range should be 75 k-ohms to 100 meg-ohms. Failure would be open circuit.

If you are unsure if the sensor film has an open circuit due to the limits of your measurement equipment,

then apply 5.25 VDC to the heater film and apply 25 ppm H2S/Air test gas while measuring the sensor f ilm

resistance with an ohm-meter. The sensor film is not “open circuit” if the resistance quickly falls to <100 kohms while on the test gas.

Low or Slow response to Cal Gas

1. Check Heater Voltage Setting (should be 5.25 V).

2. Use humidifier with DI Water.

3. Check validity of span gas with a pull tube.

4. Check for obstructions through s/s sinter element (including being wet).

5. Check sensor lot # and report to Detcon.

Poor calibration Repeatability

1. Check Heater Voltage Setting (should be 5.25 V).

2. Use humidifier with Distilled Water.

3. Check validity of span gas with a pull tube.

4. Check for obstructions through s/s sinter element (including being wet).

5. Check sensor lot # and report to Detcon.

6. Check area for presence of reducing gases such as Cl2 and ozone.

Detcon Model TP-424C Hydrogen Sulfide Sensor PG.13

Page 14

Unstable output/Sudden spiking

H2S Sensor in SS Housing

Cal ib ra tio n A da pte r

Rain Shield

Tra nsm it te r As se mb ly

Base Connector Board

Enclosure

Enclosure Cover

#6 x .125" Nylon Washer (X2)

6-32 X 3/8 Screw (X2)

#6 Star Washer (X2)

#6 Flat Washer (X2)

Condensation

Prevention Packet

(replace annually)

Unstable power supply, Inadequate grounding, Inadequate RFI protection.

1. Verify Power source.

. Contact Detcon to optimize shielding and grounding.

2

3. Add RFI protection accessory.

4. Check area for after gas releases, such as cleaning chemical vapors.

Nuisance Alarms

1. Check condulet for accumulated water and abnormal corrosion.

2. If Nuisance alarms happening at night suspect condensation in condulet .

3. Add/Replace Detcon Condensation Prevention Packet P/N

960-202200-000

Transmitter not responding

1. Verify condulet has no accumulated water or abnormal corrosion.

2. Verify required DC power is applied to correct terminals.

3. Swap with a known-good transmitter to determine if transmitter is faulty.

Bad 4-20 mA output

1. Check that wiring is connected to correct terminal outputs.

2. Swap with a known-good transmitter to determine if transmitter is faulty.

3.13 Spare Parts

600-500000-000 Sensor rain shield

600-610000-000 Sensor splash guard

943-000006-038 Threaded Calibration Adapter

399-800000-000 H2S sensor in stainless steel housing

924-015400-100 TP-424C Plug-in control circuit

500-005065-007 Connector board

960-202200-000 Condensation prevention packet (replace annually).

985-241100-321 In-Line Humidifying Tube

943-020000-000 Span Gas Kit: Includes cal adapter, In-Line Humidifying Tube, 200 ml/m span

gas regulator, and carrying case. Does not include span gas.

942-010112-010 Span gas bottle containing 58 liters 10ppm H2S in air (operating range dependent).

942-010112-020 Span gas bottle containing 58 liters 20ppm H2S in air (operating range dependent).

942-010112-025 Span gas bottle containing 58 liters 25ppm H2S in air (operating range dependent).

942-010112-050 Span gas bottle containing 58 liters 50ppm H2S in air (operating range dependent).

943-090005-502 200 ml/m regulator for span gas bottle

960-398800-000 H2S/MOS DRICAP w/desiccant (10 pack)

Detcon Model TP-424C Hydrogen Sulfide Sensor PG.14

Page 15

3.14 WARRANTY

Detcon, Inc., as manufacturer, warrants each hydrogen sulfide sensor element (P/N 399-800000-000), for a ten

year period under the conditions described as follows: The warranty period begins on the date of shipment to

the original purchaser, and follows the schedule below. The sensor element is warranted to be free from

defects in material and workmanship. Should any sensor fail to perform in accordance with published specif ications within the warranty period, return the defective part to Detcon, Inc., 3200 A-1 Research Forest Dr.,

The Woodlands, Texas 77381, for necessary repairs or replacement.

NOTE: The warranty will not be honored if evidence shows that the sensor cell was damaged by moisture

exposure due to improper handling and protection during periods of removed power or storage. The sensor

cell must be protected during periods of removed power or storage by use of a Dust Cap (P/N 600-003307-

000) and a Desiccant Packet (P/N 960-240010-000).

First year No Charge

2nd-5th years $25.00 handling charge

6th year $60.00 handling charge

7th year $96.00 handling charge

8th year $120.00 handling charge

9th year $150.00 handling charge

10th year $176.00 handling charge

Warranty voided $200.00 charge

Non-warranty $295.00 charge

Terms & Conditions

* The original serial number must be legible on each sensor element base.

* Shipping point is FOB the Detcon factory.

* Net payment is due within 30 days of invoice.

* Detcon, Inc. reserves the right to refund the original purchase price in lieu of sensor replacement.

3.15 SERVICE POLICY

Detcon, Inc., as manufacturer, warrants under intended normal use each new TP-424C sensor signal transmitter to be free from defects in material and workmanship for a period of two years from the date of shipment to the original purchaser. Detcon, Inc., further provides for a five year fixed fee service policy wherein any failed transmitter shall be repaired or replaced as is deemed necessary by Detcon, Inc., for a fixed fee

of $35.00. The fixed fee service policy shall effect any factory repair for the period following the two year

warranty and shall end five years after expiration of the warranty. All warranties and service policies are

FOB the Detcon facility located in The Woodlands, Texas.

3.16 Revision Log

Date Version Changes Made Approval

2/1/10 2.0 Previously Issued BM

8/16/10 2.1 Updated procedure for testing “open circuit” BM

3/18/14 2.2 Add dessicant cap notes BM

Shipping Address: 4055 Technology Forest Blvd, Suite 100, The Woodlands Texas 77381

Mailing Address: P.O. Box 8067, The Woodlands Texas 77387-8067

Phone: 888.367.4286, 281.367.4100 • Fax: 281.292.2860 • www.detcon.com • sales@detcon.com

Detcon Model TP-424C Hydrogen Sulfide Sensor PG.15

Loading...

Loading...