Detcon Quick Start Guide

Model FP-524D

Combustible Gas Sensor (0-100% LEL)

If equipment is used in a manner not specified by Detcon, the protection provided by

the equipment may be impaired. Applying power with devices hooked up incorrectly

CAUTION

General Installation Notes

Install the sensor only in areas with classifications matching the approval label, and in compliance with local

electrical codes.

Follow all warnings listed on the label.

Mount the FP-524D vertically, with sensor facing down. Locate the sensor with due consideration for the

properties of the gas to be detected, likely sources, ventilation, personnel exposure, and maintenance access.

Ensure that the housing bottom and plug-in sensor are installed during operation. The housing bottom should be

threaded tightly to the sensor housing.

Field Wiring Mounting Installation

may cause damage to the equipment.

After mounting the FP-524D vertically with the sensor pointing straight down, mount the explosion-proof enclosure or

junction box on a wall or pole. When mounting on a pole, secure the junction box to a suitable mounting plate and

attach the mounting plate to the pole using U-bolts.

NOTE

Do not use Teflon tape or any other type of pipe thread material on the ¾-in. threads unless the

unit is mounted in a severe or harsh environment. Metal-on-metal contact must be maintained to

provide a solid electrical ground path. If Teflon tape is used, the sensor must be externally

grounded using a ground strap.

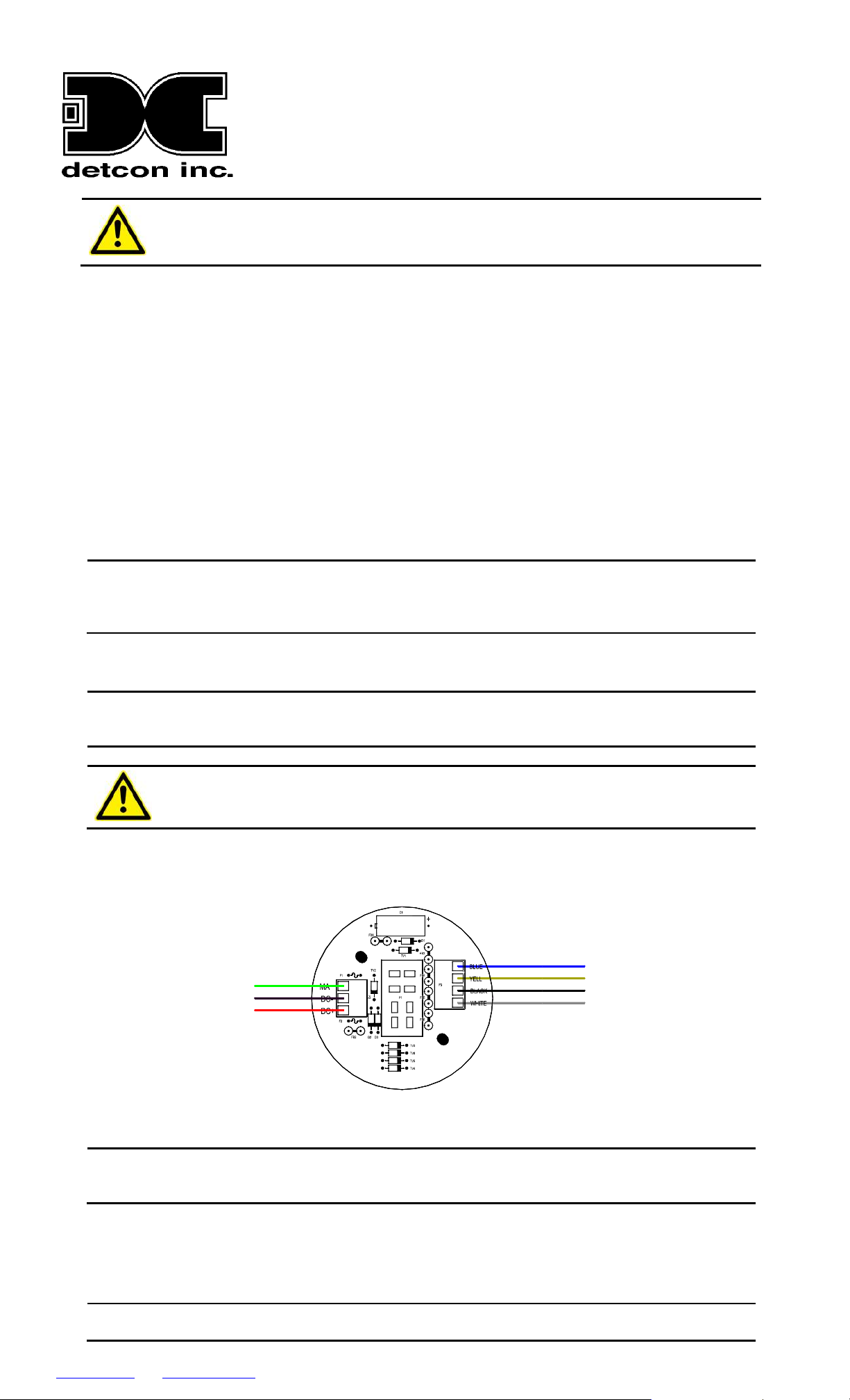

Sensor Connector PCB

NOTE

NOTE

1. Remove the junction box cover and unplug the Transmitter Module.

2. Observing correct polarity, terminate the three-conductor 4-20mA field wiring (DC+, DC-, and MA) to the sensor

assembly wiring in accordance with the detail shown in Figure 1.

Shielded cable is required for installations where cable trays or conduit runs include high

voltage lines or other possible sources of induced interference. Separate conduit runs are highly

recommended in these cases.

The supply of power should be from an isolated source with over-current protection.

Do not apply System power to the sensor until all wiring is properly terminated.

CAUTION

Blue

Yellow

Black

White

Wiring to

LEL Sensor

NOTE

mA

Ground

Power

Customer

Wiring

Figure 1 FP-524D Sensor Connector PCB

A 6-32 or 8-32 threaded exterior ground point is provided on most junction boxes for an external

ground. If the Sensor Assembly is not mechanically grounded, an external ground strap must be

used to ensure that the sensor is electrically grounded.

3. Trim and cap all exposed wire leads if they are not permanently landed in the terminal board.

4. Plug the Transmitter Module into the connector PCB and replace the junction box cover.

Remote Mounting Installation

NOTE

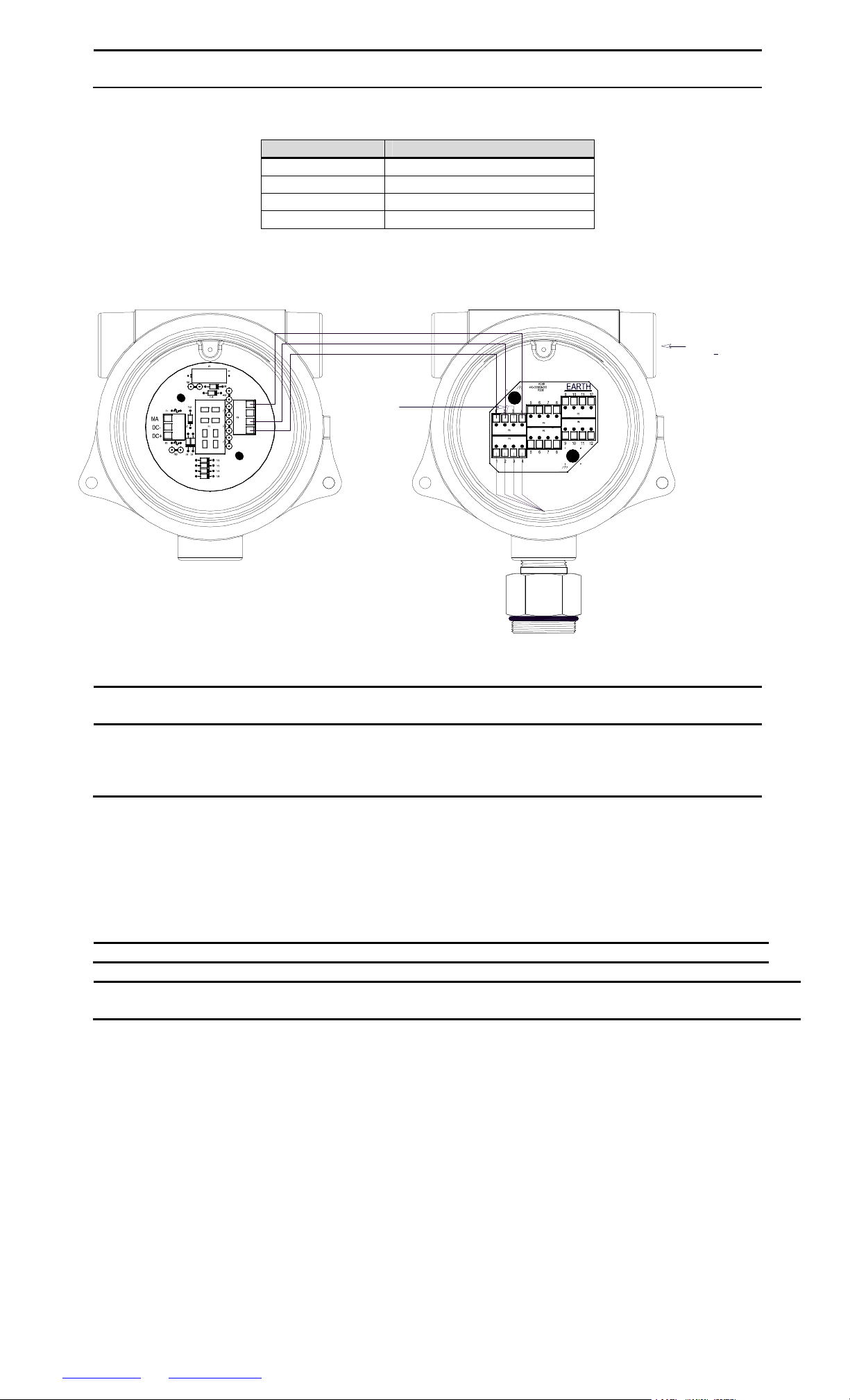

If using the FP-524D remote-mount configuration (sensor model FP-524D-RS and transmitter

model FP524D-RT), follow the specifications for maximum separation in Table 1 and refer to the

www.detcon.com service@detcon.com 713.559.9200 FP-524D Quick Start Guide April 23, 2014 • Document #4462 • Revision 1.1

wiring diagram in Figure 2. There is a limit 0.5-ohm maximum resistance drop per wire over the

separation distance.

Table 1 FP-524D Remote Sensor Maximum Separation

AWG Maximum Separation (feet)

20 50

18 75

16 125

14 175

Remote Transmitter

FP-524D-RT

Blue

Black

White

Remote Sensor

FP-524D-RS

Blue

Black

Install

Jumper

Figure 2 FP-524D Remote Sensor Wiring Diagram

White

Yellow

White

Black

Blue

Plug unused port

3

with

" NPT plug

4

Measure Bridge Voltage

From White (1) to Blue (4)

Target Voltage is 2.7V

NOTE

A jumper is required on the remote sensor connector board. Failure to install this jumper will

cause a sensor fault condition.

NOTE

For remote-mounted sensors, different lengths of cables will have varying amounts of resistance,

which will shift the sensor bridge voltage. Therefore, the bridge voltage must be adjusted after

initial power up. This adjustment is only required after initial installation and will not be

necessary thereafter (except in case of replacement of the plug-in sensor).

Initial Start Up

1. Upon completion of all mechanical mounting and termination of all field wiring, apply system power in the range

of 12-28VDC (24VDC typical) and observe the following normal conditions:

a. FP-524D display reads “0” and no fault messages are flashing.

b. A temporary upscale reading may occur as the sensor heats up. This upscale reading will decrease to 0%

within 1-2 minutes of power-up, assuming there is no gas in the area of the sensor.

NOTE

2. After a warm up period of 1 hour, check the sensor to verify sensitivity to combustible gas.

NOTE

a. Attach the calibration adapter to the threaded sensor housing.

b. Apply the test gas at a controlled flow rate of 200–500 cc/min (200 cc/min is the recommended flow).

c. Allow 1-2 minutes for the reading to stabilize.

d. Observe that the display increases to a level near that of the applied calibration gas value during the 1-2

minutes.

e. Remove test gas and observe that the display decreases to zero.

3. Initial operational tests are complete. Detcon FP-524D combustible gas sensors are factory-calibrated prior to

shipment and should not require significant adjustment at start-up. However, it is recommended that a complete

calibration test and adjustment is performed 16 to 24 hours after power-up.

The 4-20mA signal is held constant at 4mA for the first 2 minutes after power-up.

Do not use calibration gases in nitrogen background gas mixtures. This will cause significant reading

inaccuracies.

www.detcon.com service@detcon.com 713.559.9200 FP-524D Quick Start Guide April 23, 2014 • Document #4462 • Revision 1.1

Loading...

Loading...