Denon DVD-800 Service Manual

Hi-Fi Personal Component System

SERVICE MANUAL

For U.S.A., Canada,

Europe & Asia models

ON/STANDBY

MODEL

DVD VIDEO PLAYER

PCM AUDIO TECHNOLOGY / DVD VIDEO PLAYER

DVD-800

REMOTE SENSOR

DVD-800

STANDBY

OPEN/CLOSE

RANDOM

REPEAT

MODE

REPEAT

STILL/PAUSE STOP

PLAY

A-B

SLOW/SEARCHSKIP

TOP MENU

PLAY MODE

REPEAT MODE

A-B REPEAT

V.S.S.

SET UP CLEAR

STILL/PAUSESTOP

SLOW/SEARCH

SKIP

ENTER

SUBTITLE AUDIO ANGLE

123

456

789

REMOTE CONTROL UNIT

RC-550

OPEN/CLOSEPOWER

PLAY

MENU

RETURNDISPLAY

10

0

Some illustrations using in this service manual are slightly different from the actual set.

14-14, AKASAKA 4-CHOME, MINATO-KU, TOKYO 107-8011 JAPAN

Telephone: 03 (3584) 8111

X0122 1174 NC 0109

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to

chassis resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side

of the power cord is less than 460 kohms, the unit is defective.

SPECIFICATIONS

Power requirements:

Power supply: AC 120 V, 60 Hz (For U.S.A. and Canada models)

Power consumption: 14 W

Dimensions: 434 (W) × 247 (D) × 82 (H)

Mass: 2.6 kg

Signal system: NTSC (For U.S.A and Canada models)

Operating temperature range: +5 to +35 °C

Operating humidity range: 5-90 % RH (no condensation)

Discs played

(1) DVD-Video disc

(2) Compact disc (CD-DA, Video CD)

(3) CD-R/CD-RW (CD-DA, Video CD formatted discs)

Video output

Output level: 1 Vp-p (75Ω)

Output terminal: Pin jack (1 system) (For U.S.A., Canada and Asia models)

Output connector: Pin jack 1 system/AV 1 (For Europe model)

S video output

Y output level: 1 Vp-p (75 Ω)

C output level: NTSC: 0.286 Vp-p (75 Ω)

Output terminal: S terminal (1 system) (For U.S.A., Canada and Asia models)

Output connector: S terminal (1 system)/AV 1

Component video output (For U.S.A., Canada and Asia models)

Y output level: 1 Vp-p (75 Ω)

CB output level: 0.7 Vp-p (75 Ω)

R output level: 0.7 Vp-p (75 Ω)

C

Output terminal: Pin jack

Audio output

Output level: 2 Vrms (1 kHz, 0 dB/For U.S.A., Canada mocels: 10 kΩ load impedance)

Output terminal:

Mixed output (L/R): Pin jack (1 system)

Subwoofer output: Pin jack (1 system)

Output connector (For Europe model):

Number of connectors (For Europe model):

2ch: 1 system

Subwoofer output (0.1ch): 1 system

Audio signal output characteristics

(1) Frequency response:

DVD (linear audio): 4 Hz-22 kHz (48 kHz sampling)

CD audio: 4 Hz-20 kHz

(2) S/N ratio:

CD audio: 115 dB

(3) Dynamic range:

DVD (linear audio): 102 dB

CD audio: 98 dB

(4) Total harmonic distortion:

CD audio: 0.0025 %

Digital audio output

Optical digital output: Optical terminal

Pickup

Wave length (For U.S.A., Canada and Asia models): 658 nm/790 nm

Laser power (For U.S.A., Canada and Asia models): CLASS

Bolgelenged (For Europe model): 658 nm/790 nm

Laser-styrke (For Europe model): Ingenfarlig strålning sendes ut KLASS 2/KLASS 1

Power consumption in standby mode: approx. 2.5 W (For U.S.A. and Canada models)

AC 220-240 V, 50 Hz (For Europe model)

AC 110-240 V, 50/60 Hz (For Asia model)

(including protrusions parts)

PAL625/50, PAL525/60, NTSC (For Europe, Asia models)

PAL: 0.300 Vp-p (75 Ω) (For Europe, Asia models)

(Y: green, PB : blue, PR: red)

Pin jack/AV 1

4 Hz-44 kHz (96 kHz sampling)

a/CLASS

approx. 4 W (For Europe model)

approx. 3.5 W (For Asia model)

2

1 SAFETY PRECAUTIONS

1.1. GENERAL GUIDELINES

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

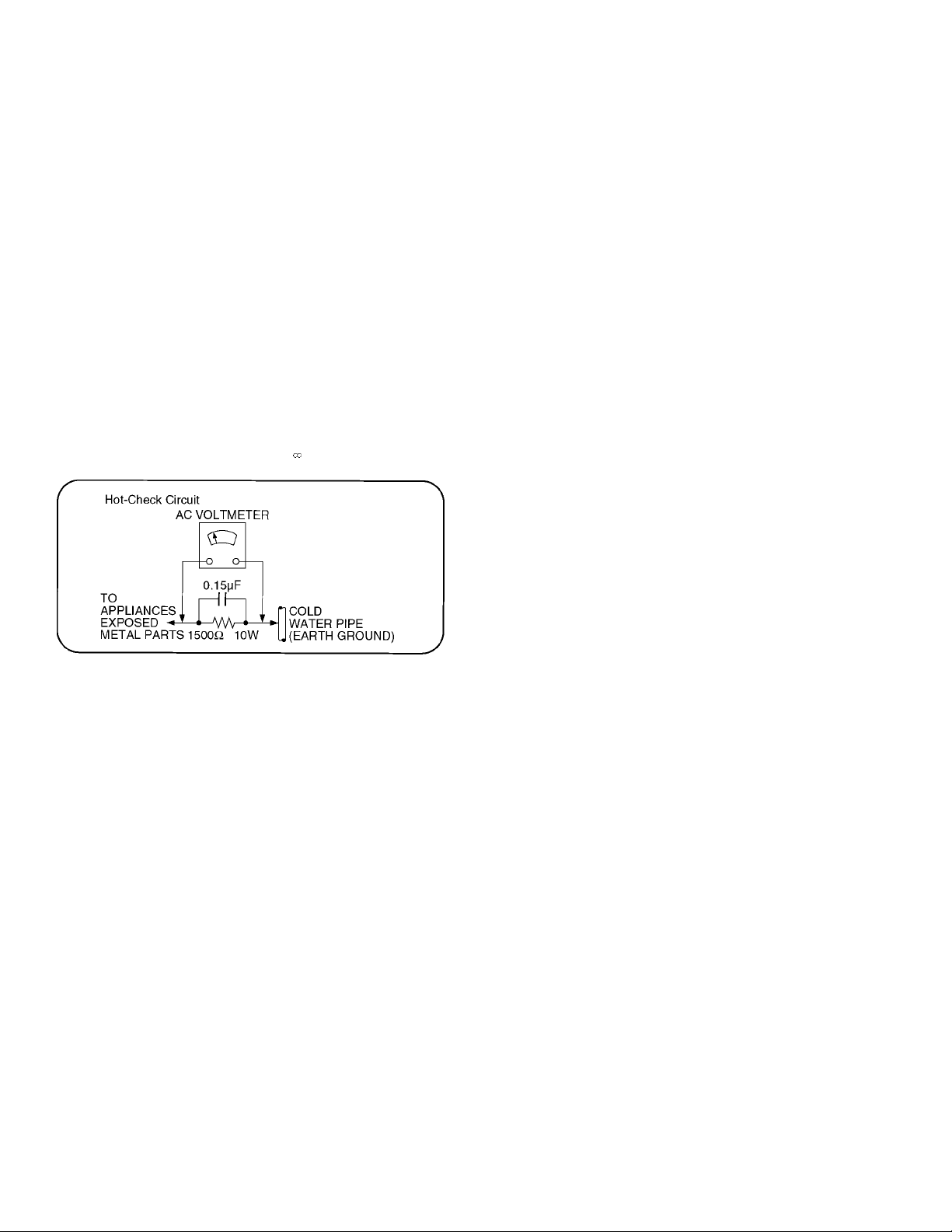

1.1.1. LEAKAGE CURRENT COLD

CHECK

1. Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the equipment such as screwheads, connectors,

control shafts, etc. When the exposed metallic part has a

return path to the chassis, the reading should be between

1M! and 5.2M!.

When the exposed metal does not have a return path to

the chassis, the reading must be

Figure 1

.

1.1.2. LEAKAGE CURRENT HOT CHECK

(See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2. Connect a 1.5k!, 10 watts resistor, in parallel with a 0.15µF

capacitors, between each exposed metallic part on the set

and a good earth ground such as a water pipe, as shown in

Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the

above measurements.

6. The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current mu3st not exceed 1/2 milliamp. In case a

measurement is outside of the limits specified, there is a

possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the

customer.

2 PREVENTION OF ELECTRO STATIC DISCHARGE (ESD)

TO ELECTROSTATICALLY SENSITIVE (ES) DEVICES

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as alminum

foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, alminum foil or comparable

conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

3

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise hamless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

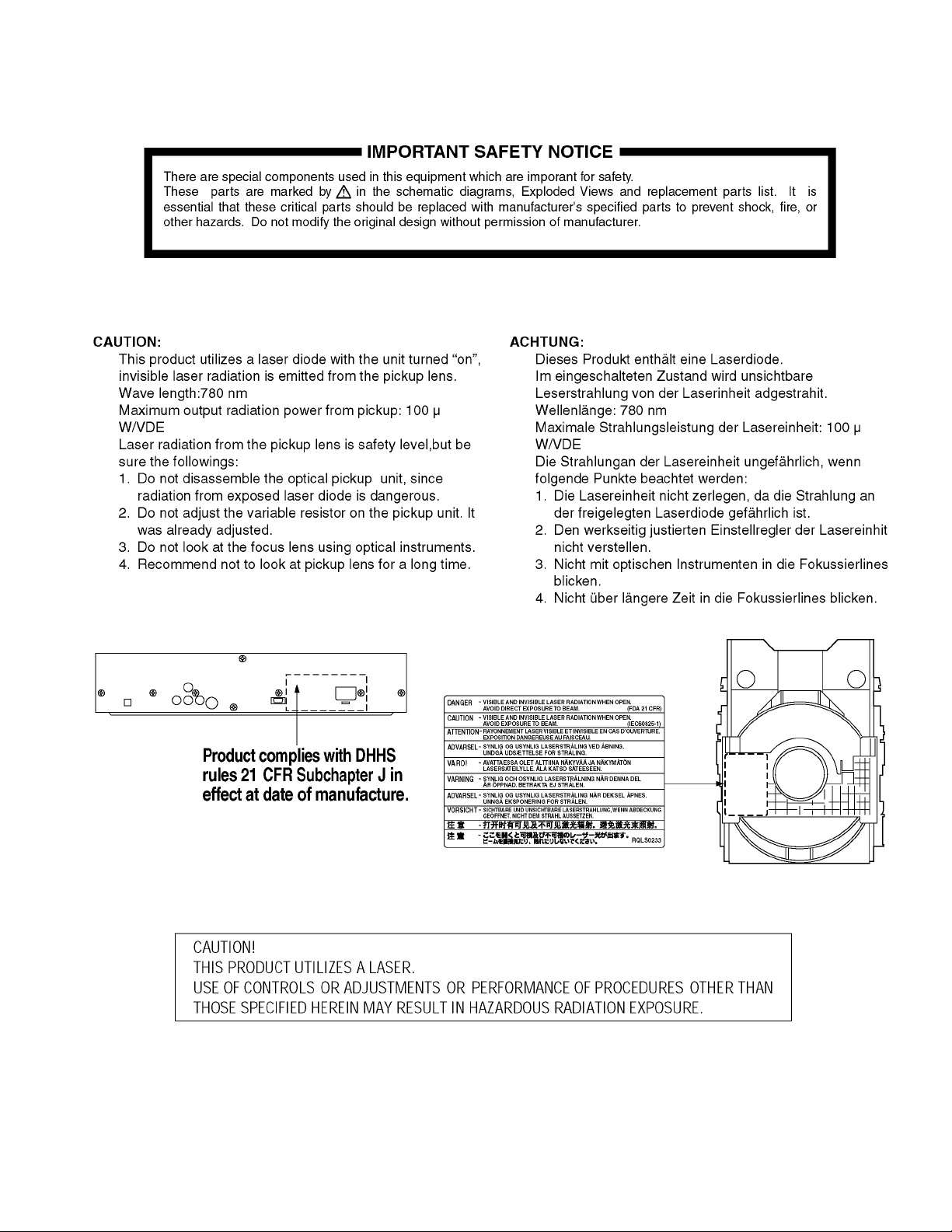

3 Precaution of Laser Diode

130KOJ

4

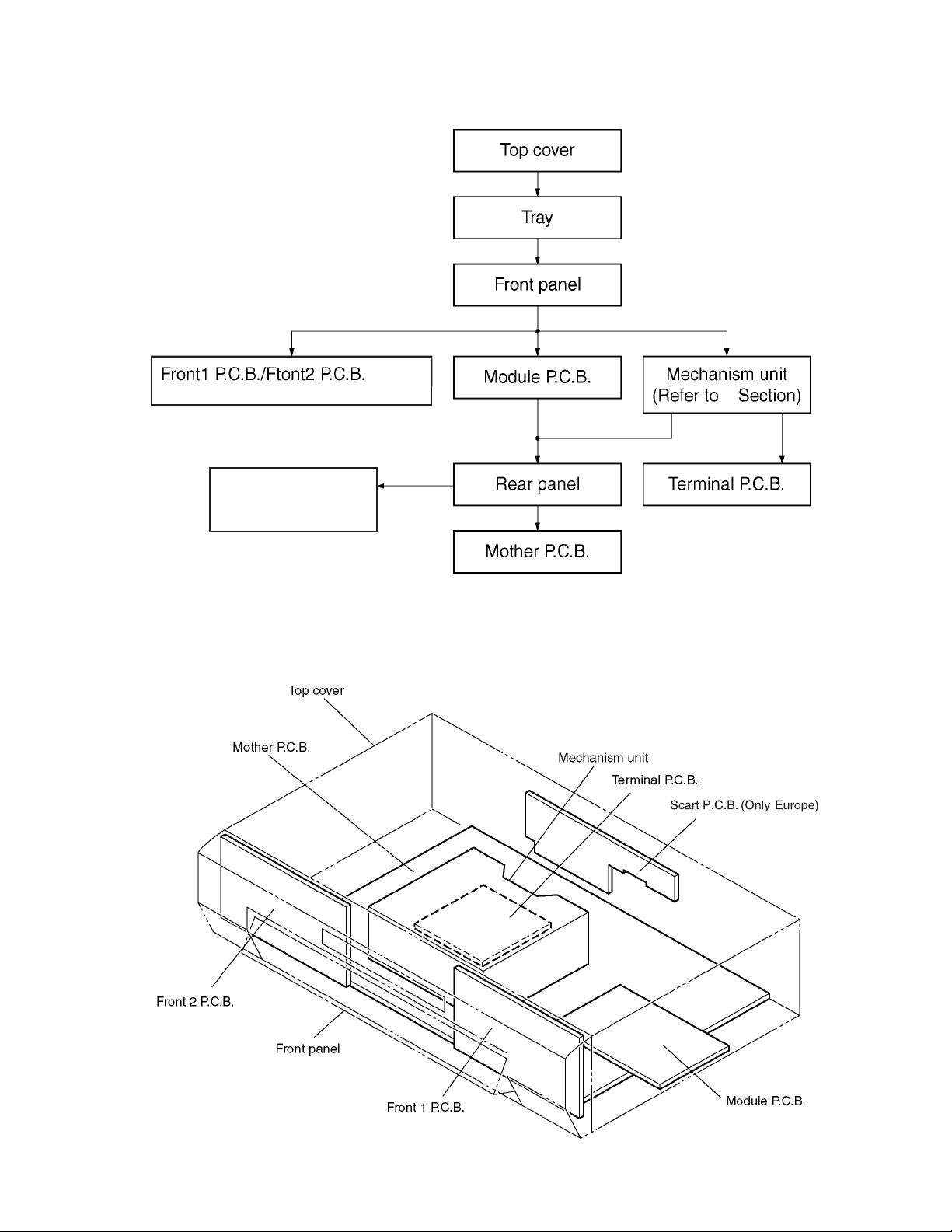

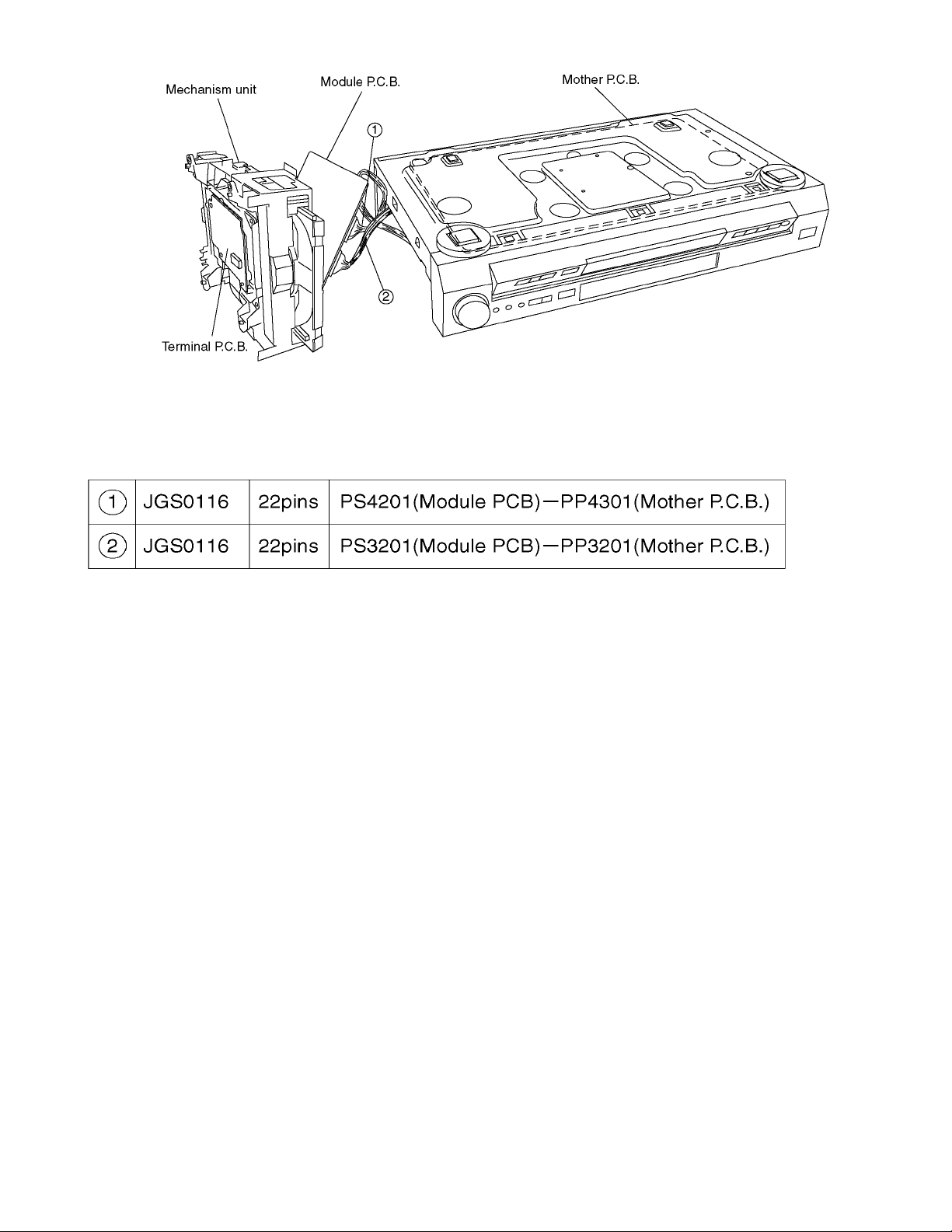

4 DisassemblingtheCasingandCheckingP.C.B.s

4.1. DissasemblyProcedure

8

Scart P.C.B.

(Only Europe)

4.2. Caseing Parts and P.C.B. Positions

5

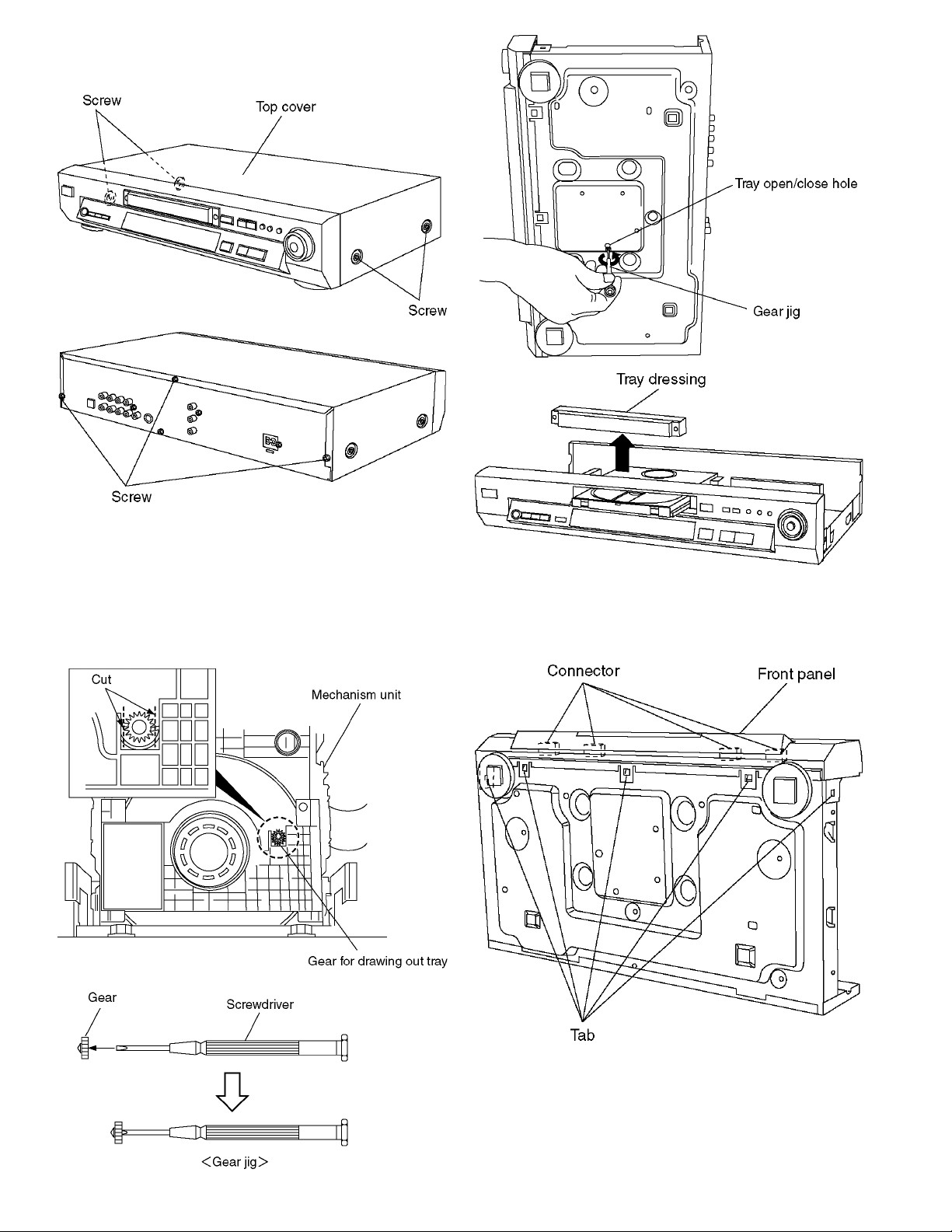

4.3. TopCover

1. Unscrew the screws.

4.4. Tray

1. Pull the tray out of the mechanism unit. Remove the gear

and install it onto a screwdriver to make a gear jig.

2. Insert the gear jig into the tray open/close hole.

3. Turn the gear jig counterclockwise to open the tray.

4. Remove the tray dressing from the tray section.

4.5. FrontPanel

1. Release the tabs.

2. Remove the connectors.

6

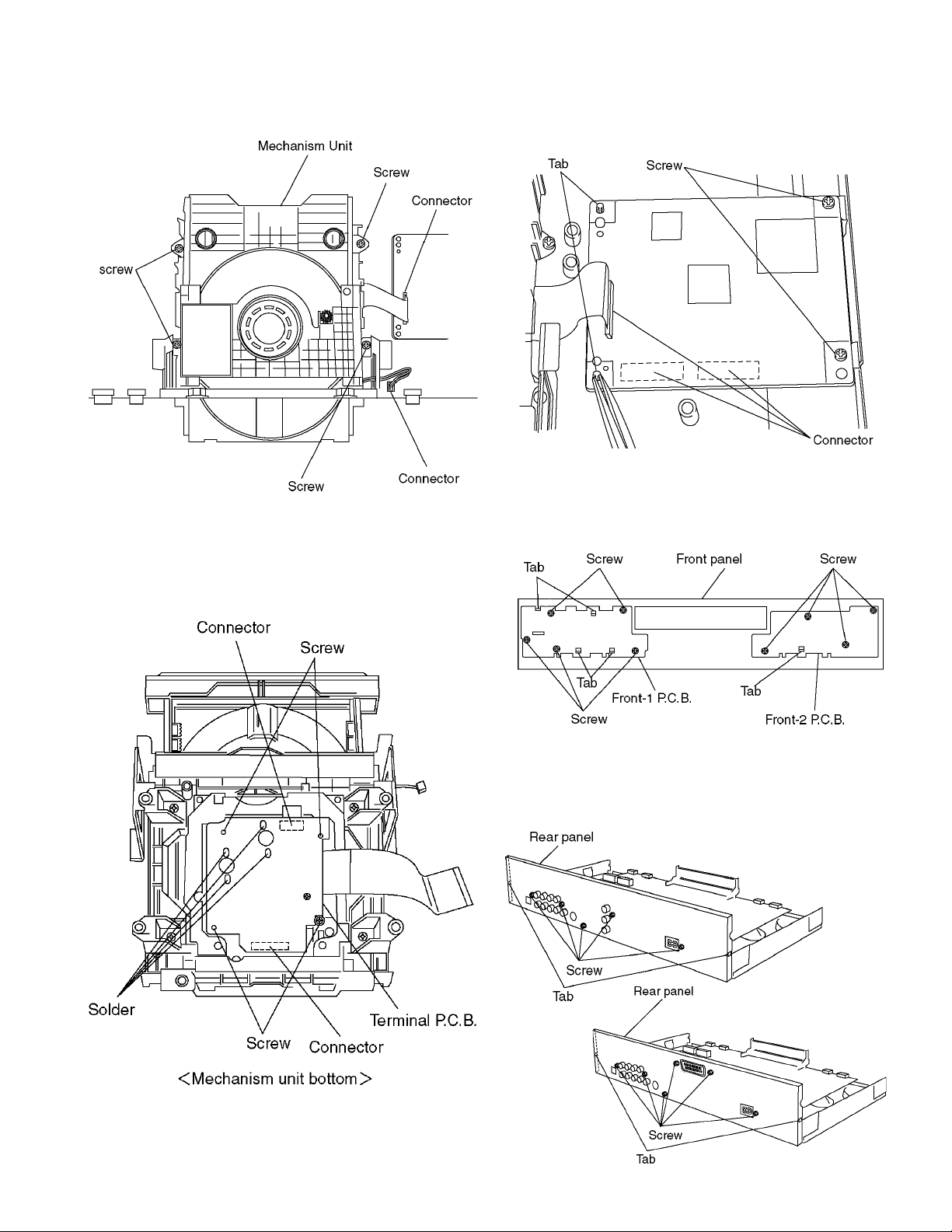

4.6. MechanismUnit

4.8. ModuleP.C.B.

1. Unscrew the screws.

2. Remove the connectors.

3. Pull out the mechanism unit vertically.

4.7. TerminalP.C.B.

1. Unscrew the screws.

2. Remove the connectors.

3. Press each tab with the nipper to pull out the module PCB

vertically.

4.9. Front-1P.C.B.,Front-2P.C.B.

1. Unscrew the screws.

2. Release the tabs.

1. Unscrew the screws.

2. Remove the solders.

3. Remove the connectors.

4.10. Rearpanel

1. Unscrew the screws

2. Release the tabs.

(Only Europe)

7

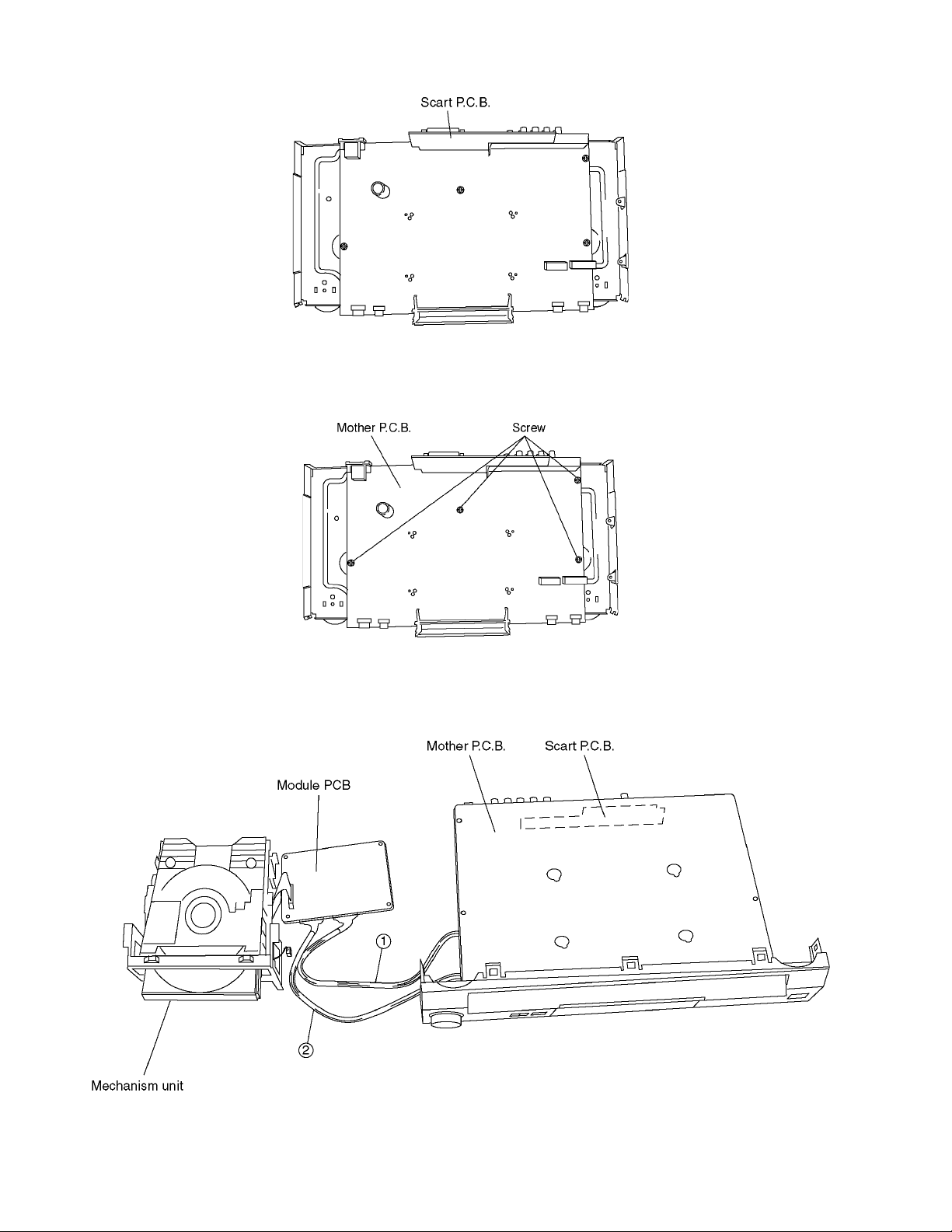

4.11. ScartP.C.B.

1. Remove the connector.

4.12. MotherP.C.B.

1. Unscrew the screws.

4.13. ServicingPosition

4.13.1. ServicingpositionoftheModuleP.C.B.

8

4.13.2. Servicing position of the Terminal P.C.B.

4.13.3. List of the Extention Cables

9

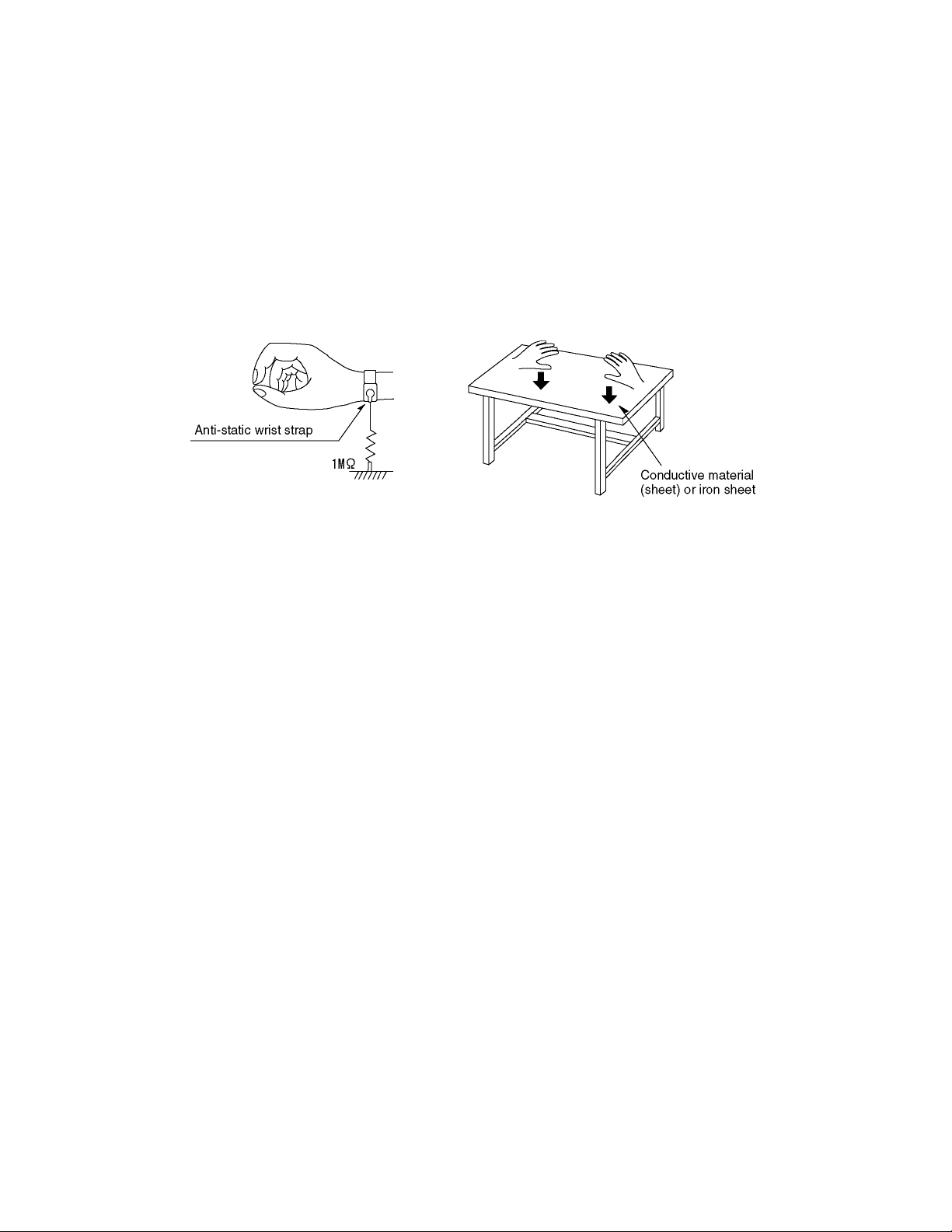

5 PREVENTIONOFSTATICELECTRICITYDISCHARGE

The laser diode in the traverse unit (optical pickup) may brake down due to static electricity of clothes or human body. Use due

caution to electrostatic breakdown when servicing and handling the laser diode.

5.1. Groundingforelectrostaticbreakdownprevention

Some devices such as the DVD player use the optical pickup (laser diode) and the optical pickup will be damaged by static

electricity in the working environment. Proceed servicing works under the working environment where grounding works is

completed.

5.1.1. Worktablegrounding

1. Put a conductive material (sheet) or iron sheet on the area where the optical pickup is placed, and ground the sheet.

5.1.2. Humanbodygrounding

1. Use the anti-static wrist strap to discharge the static electricity form your body.

5.1.3. Handlingofopticalpickup

1. To keep the good quality of the optical pickup maintenance parts during transportation and before installation, the both ends of

the laser diode are short-circuited. After replacing the parts with new ones, remove the short circuit according to the correct

procedure. (See this Technical Guide.)

2. Do not use a tester to check the laser diode for the optical pickup. Failure to do so will damage the laser diode due to the power

supply in the tester.

5.2. HandlingPrecautionsforTraverseUnit(OpticalPickup)

1. Do not give a considerable shock to the traverse unit (optical pickup) as it has an extremely high-precise structure.

2. When replacing the optical pickup, install the flexible cable and cut its short land with a nipper. See the optical pickup

replacement procedure in this Technical Guide. Before replacing the traverse unit, remove the short pin for preventing static

electricity and install a new unit. Connect the connector as short times as possible.

3. The flexible cable may be cut off if an excessive force is applied to it. Use caution when handling the cable.

4. The half-fixed resistor for laser power adjustment cannot be adjusted. Do not turn the resistor.

10

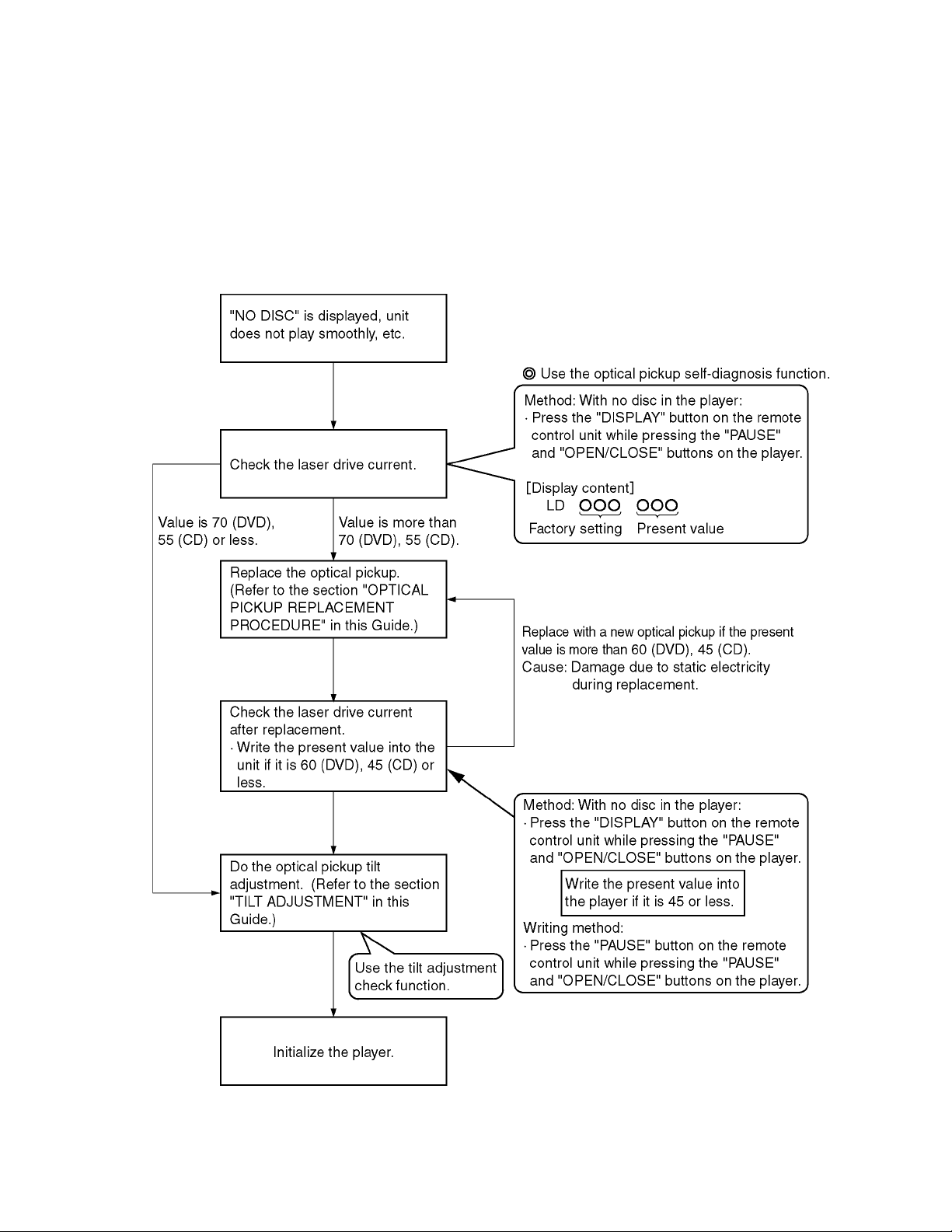

6 OPTICALPICKUPSELF-DIAGNOSISAND

REPLACEMENT PROCEDURE

6.1. Self-diagnosis

The optical pickup self-diagnosis function and tilt adjustment check function have been included in this unit. When repairing, use

the following procedure for effective Self-diagnosis and tilt adjustment.Be sure to use the self-diagnosis function before replacing

the optical pickup when "NO DISC" is displayed. As a guideline, you should replace the optical pickup when the value of the laser

drive current is more than 55.

Note:

Press the power button to turn on the power, and check the value within three minutes before the unit warms up. (Otherwise,

the result will be incorrect.)

11

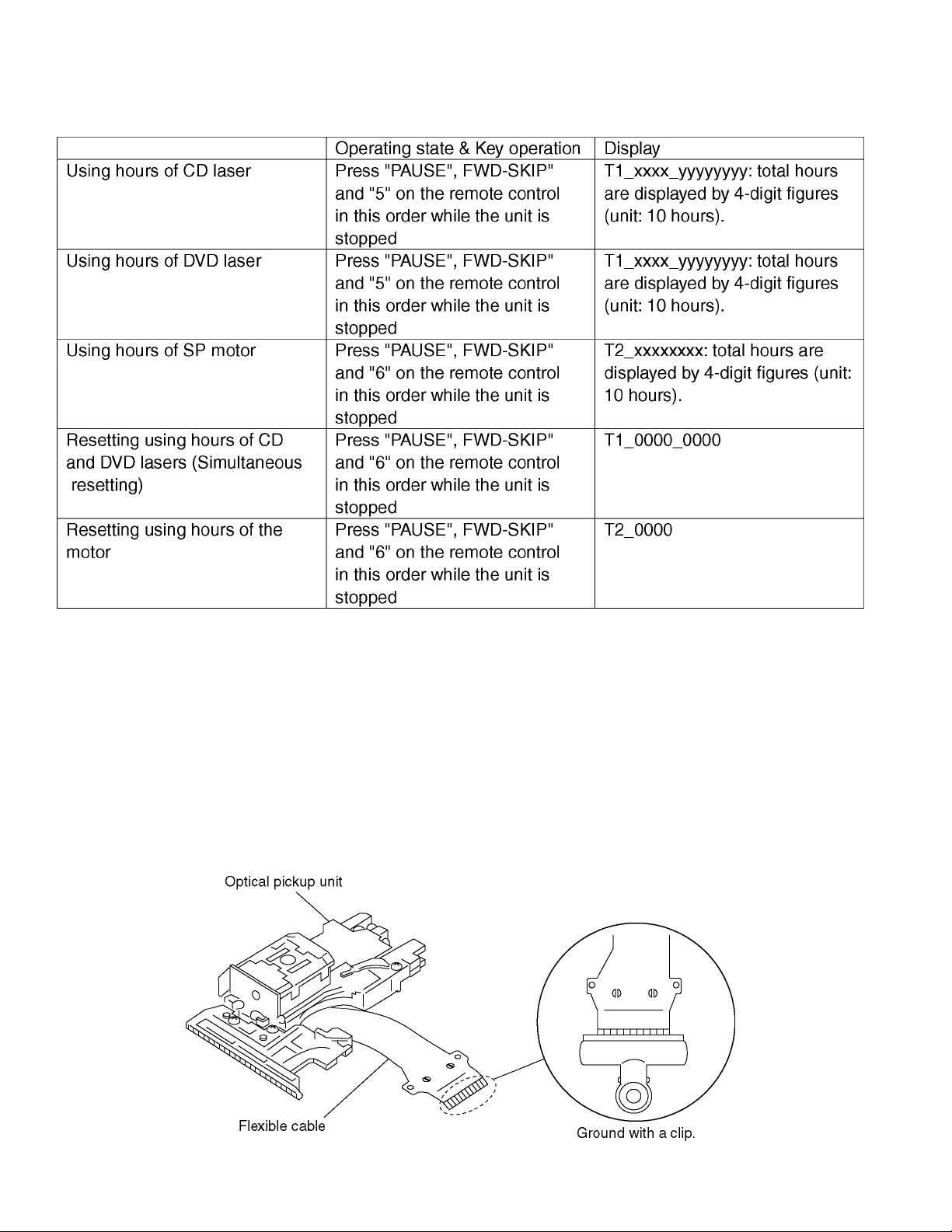

6.2. CautionstoBeUsedBeforeReplacingtheOpticalPickupUnitand

Spindle Motor Assembly

Before replacing the optical pickup unit and spindle motor assembly, check the total using hours for each of them. The checking

method is as follows:

Cautions to be taken when replacing the optical pickup

The optical pickup may break down due to the static

electricity of human body. Take proper protection measures

against static electricity before repairing the parts around

the optical pickup. (See the page describing the

PREVENTION OF STATIC ELECTRICITY DISCHARGE.)

1. Do not touch the areas around the laser diode and

actuator.

2. Do not judge the laser diode with a tester. (The tester

will be damaged easily.)

3. It is recommended to use a destaticized soldering iron

for short-circuiting or removing the laser diode.

(Recommended soldering iron) HAKKO ESD Product

4. Solder the land of the flexible cable in the optical pickup.

Note:

"""" · """"When using a soldering iron which is not

destaticized, short-circuit the terminal face of the

flexible case with a clip. After that, short-circuit

the land.

"""" · """"After the repairing work is completed, remove the

solder according to the correct procedure shown

in this Technical Guide.

12

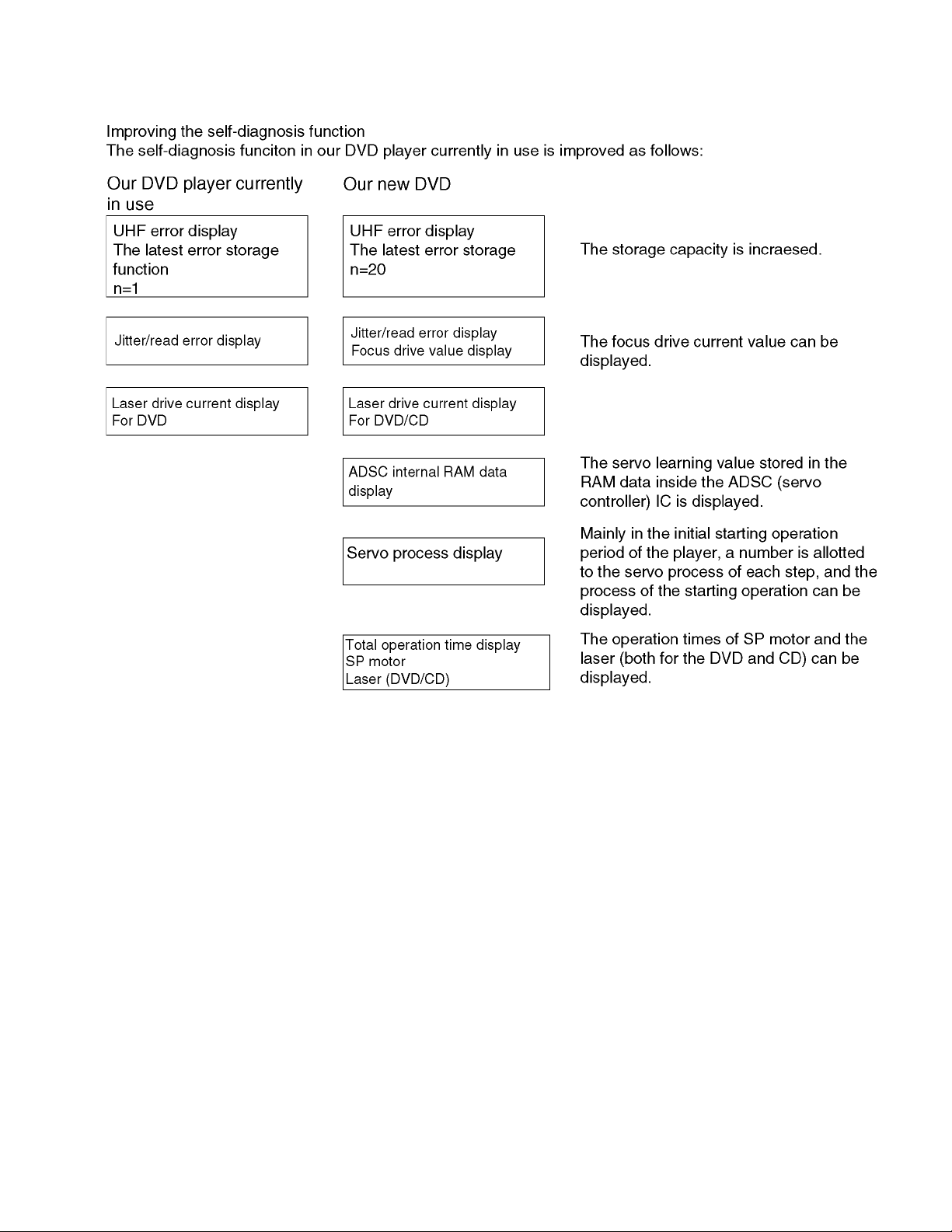

7 SELF-DIAGNOSISFUNCTIONANDSERVICEMODES

7.1. Self-diagnosisFunctionandServiceModes

13

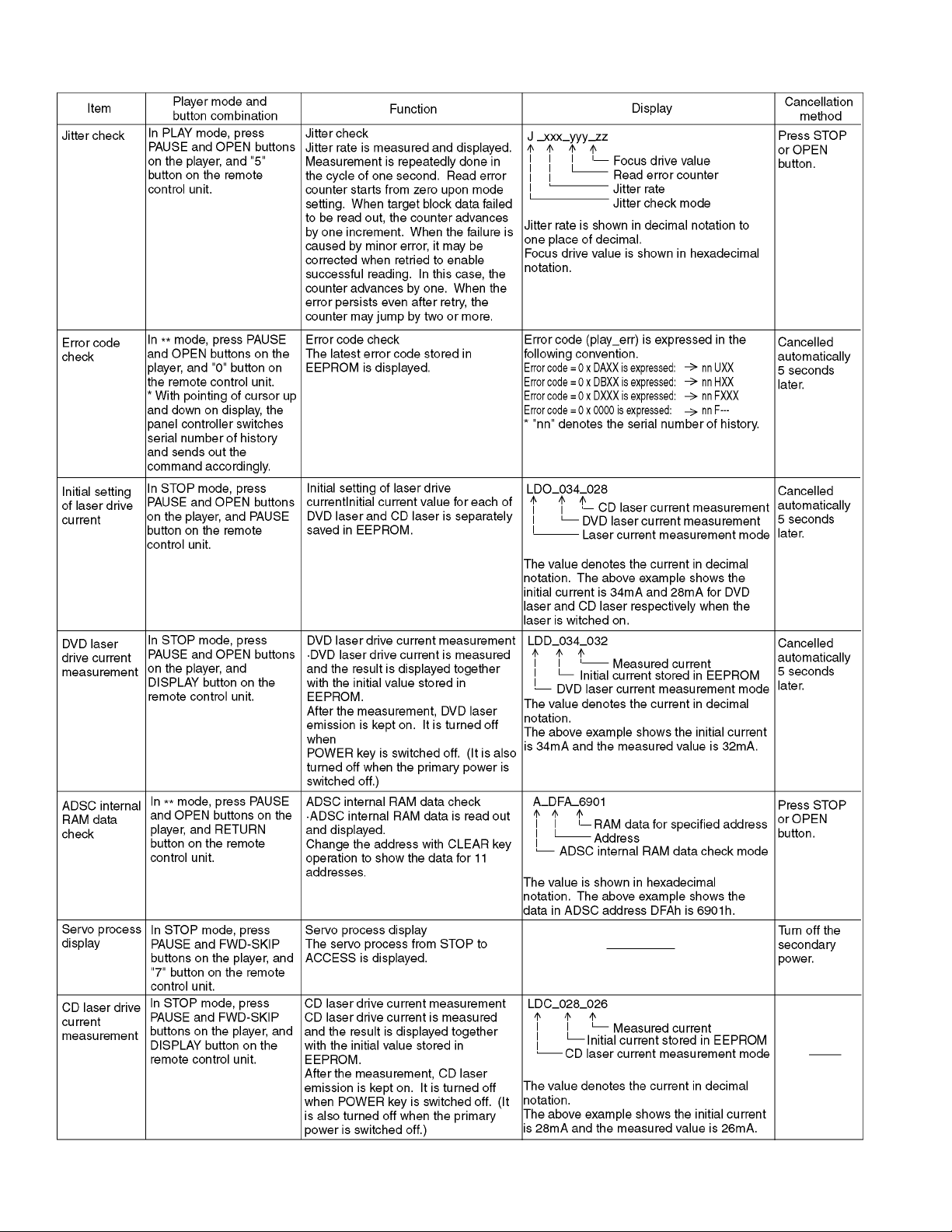

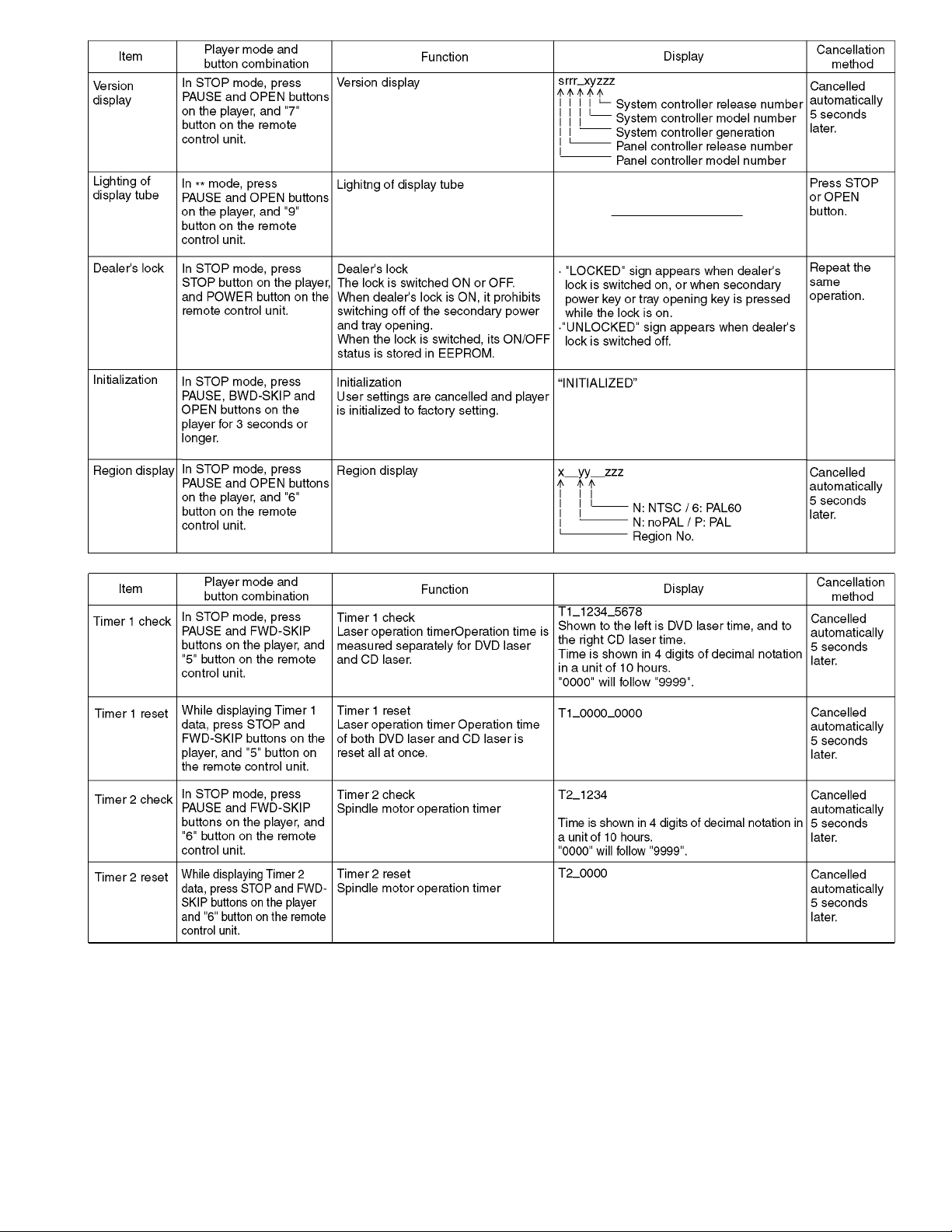

7.2. Servicemodetable

Pressing various button combinations on the player and remote control unit can activate the service modes.

14

15

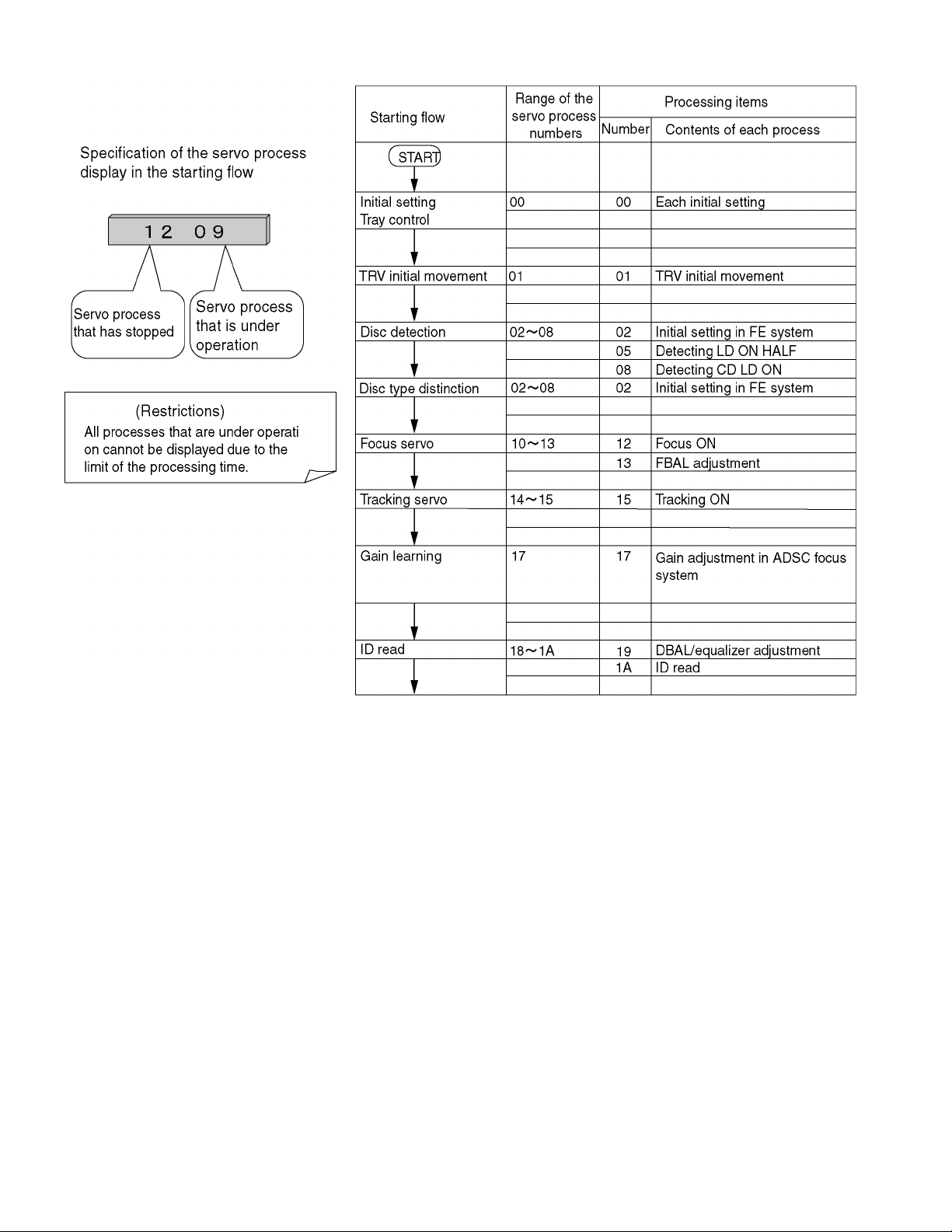

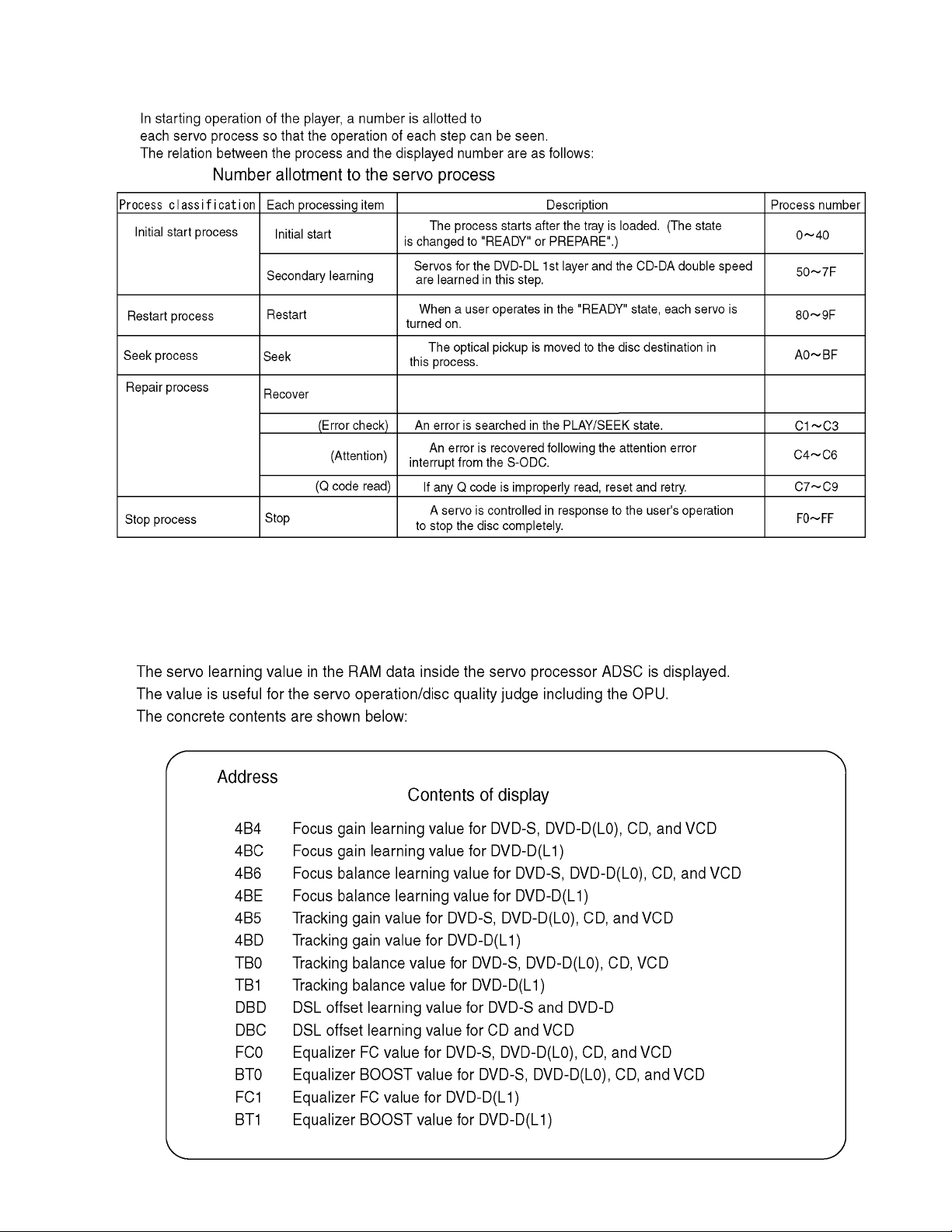

7.3. ServoProcessFlow

16

7.4. ServoProcessDisplayMode

7.5. ADSCInternalRamDataDisplay

17

7.6. Salesdemonstrationlockfunction

This function prevents discs from being lost when the unit is used for sales demonstrations by disabling the disc eject function.

"LOCKED" is displayed on the unit, and ordinary operation is disabled.

7.6.1. Setting

The sales demonstration lock is set by simultaneously pressing STOP button on the player and POWER button on the remote

control unit.

7.6.2. Cancellation

The lock can be cancelled by the same procedure as used in setting. ("UNLOCKED" is displayed on cancellation. Disconnecting

the power cable from power outlet does not cancel the lock.)

7.7. ServicePrecautions

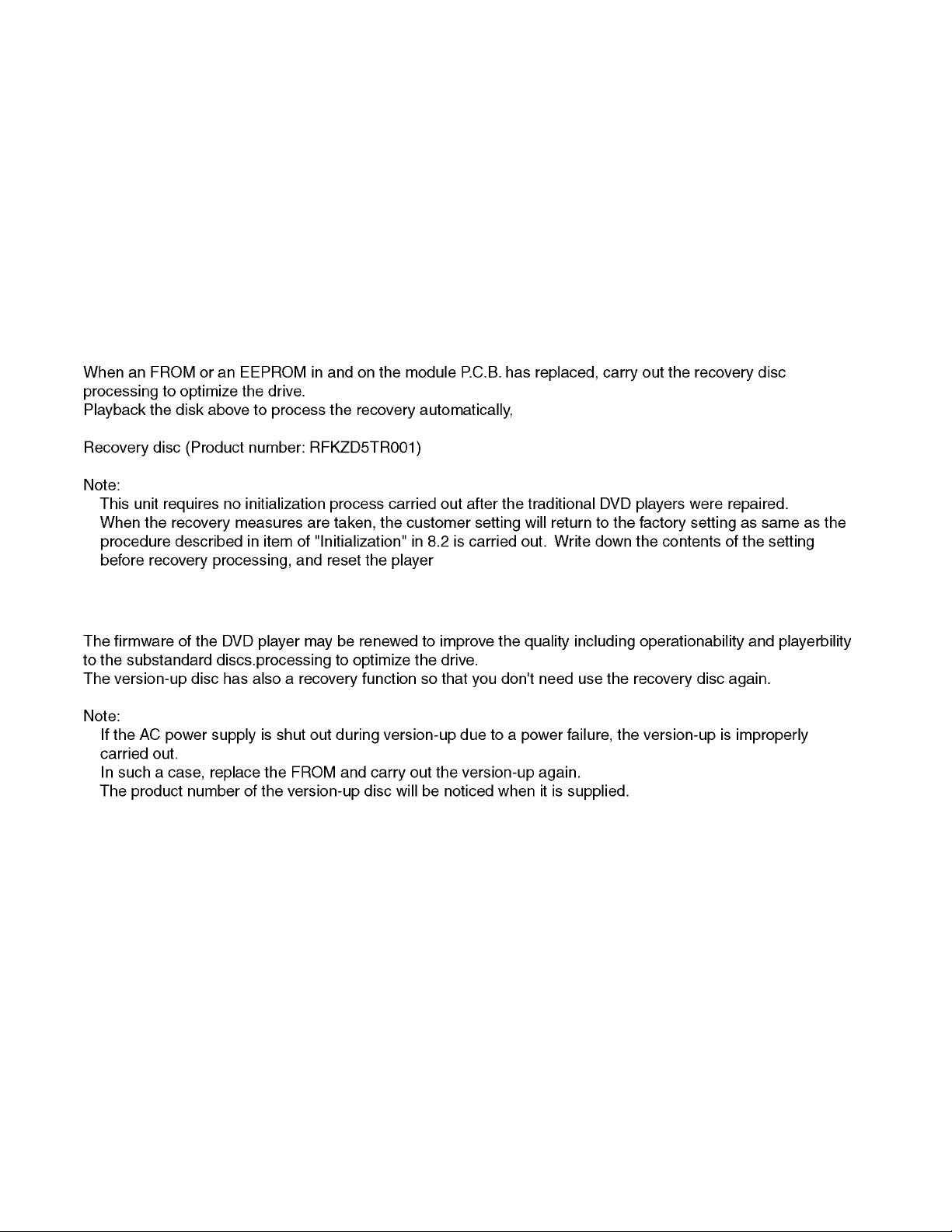

7.7.1. Recoveryafterthedvdplayerisrepaired

7.7.2. Firmwareversion-upoftheDVDplayer

7.8. HandlingAfterCompletingRepairs

Use the following procedure after completing repairs.

7.8.1. Method

Confirm that the power is turned on:

1. Press the "OPEN/CLOSE" button to close the tray.

2. Press the "POWER" button to turn off the power.

3. Disconnect the power plug from the outlet.

7.8.2. Precautions

Do not disconnect the power plug from the outlet with the tray still open, then close the tray manually.

18

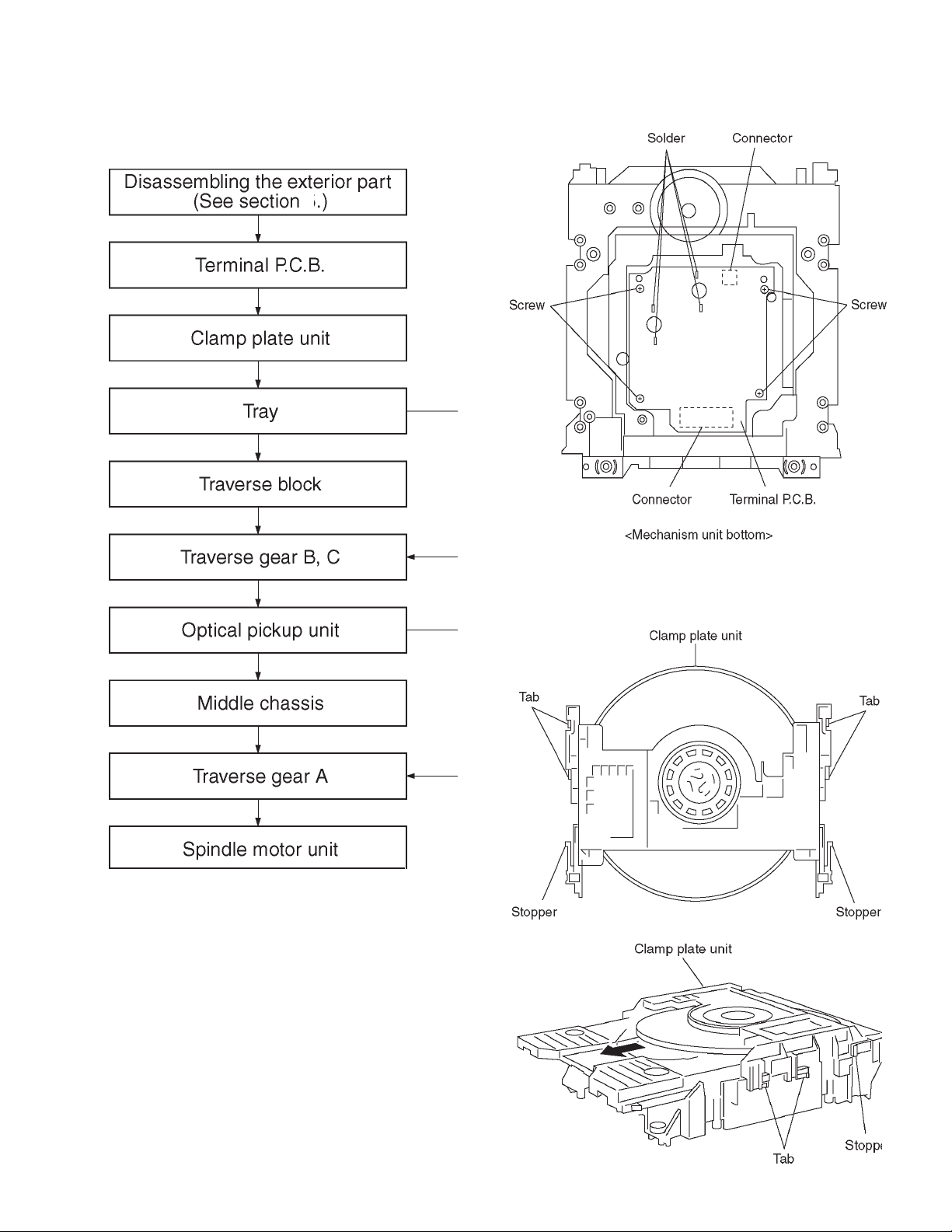

8

ASSEMBLING AND DISASSEMBLING

THE MACHANISM UNIT

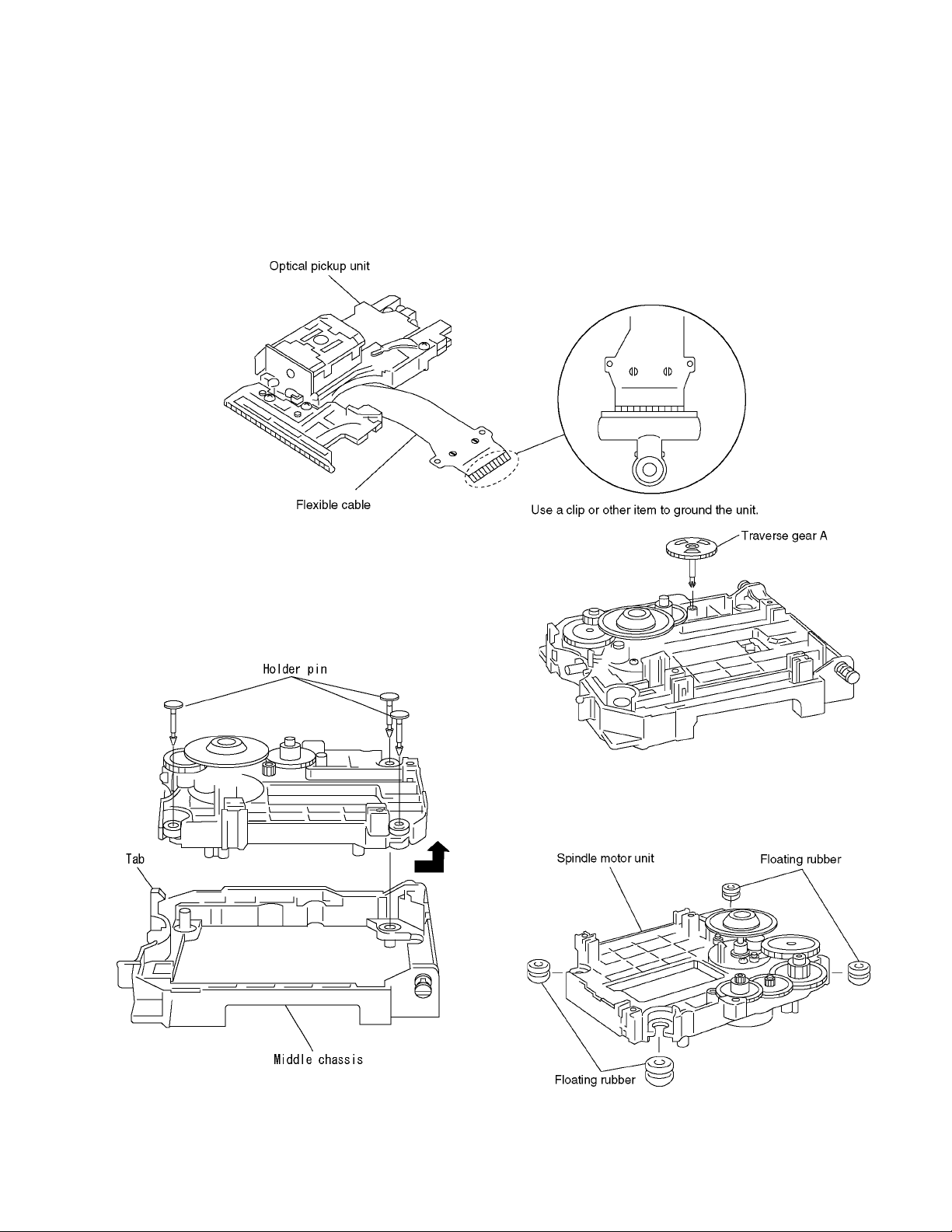

8.1. Disassaembly

Procedure

4

8.3. Clamp Plate Unit

1. Spread the stopper with hand to slide the tabs and remove

the clamp plate unit.

8.2. Terminal P.C.B.

1. Unscrew the screws.

2. Remove the solders.

3. Remove the connectors.

19

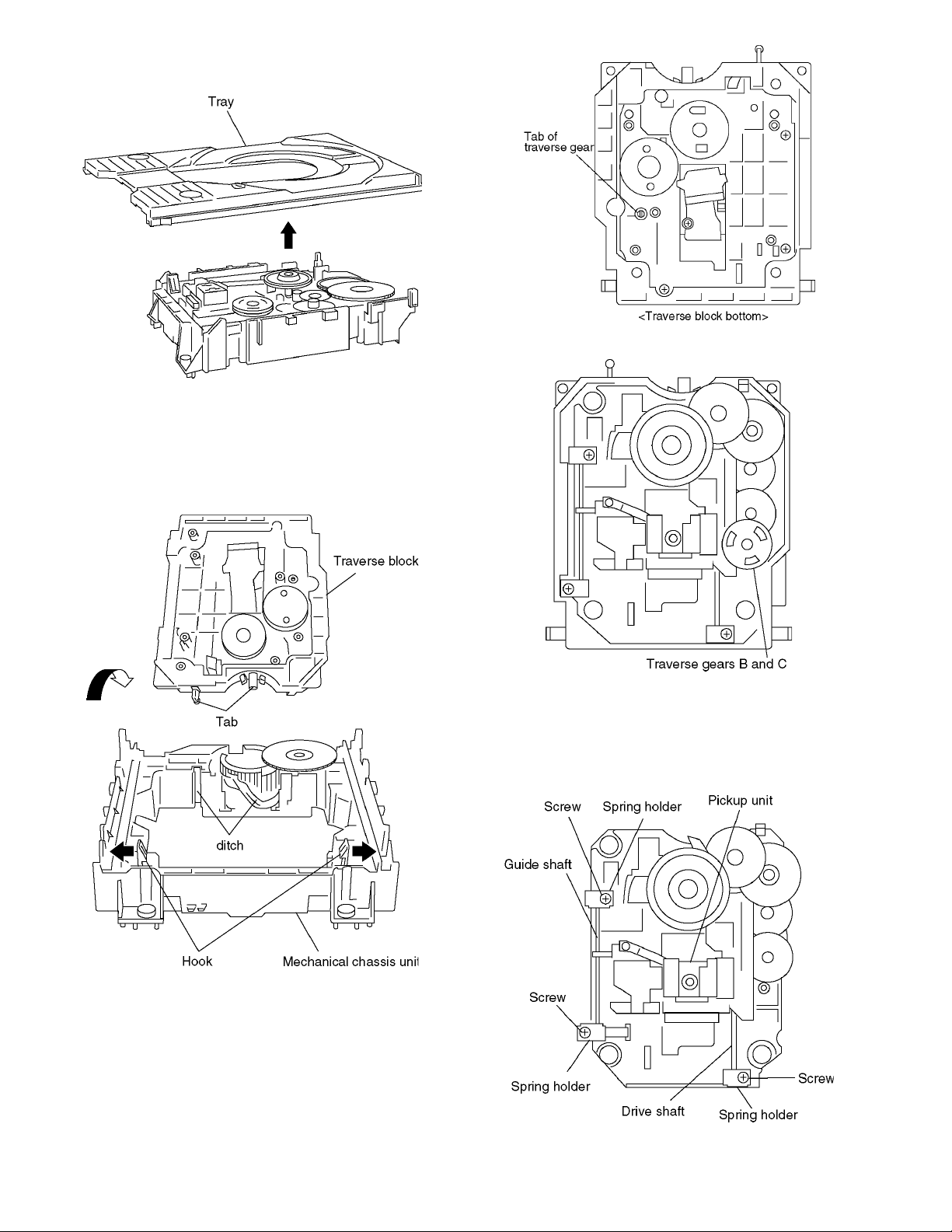

8.4. Tray

1. Lift the tray.

8.5. Traverse Block

1. Lift the traverse block while spreading the hook of the

mechanical chassis unit.

2. Disengage the tabs from the holes of the mechanical

chassis unit.

8.6. Traverse Gear

1. Disengage the tabs from the traverse gear.

2. Remove the traverse gears B and C.

8.7. Optical Pickup Unit

1. Unscrew the screws.

2. Remove the spring holders and the springs.

3. Pull out the drive shaft and guide shaft.

20

8.7.1. Precautions in optical pickup

replacement

The optical pickup can be damaged by static electricity

from you body. Be sure to take static electricity

countermeasures when working around the optical pickup.

(Refer to the related page in this Manual about the

countermeasures.)

1. Do not touch laser diode, actuator and their peripheries.

2. Do not use tester to check laser diode. (Laser diode can be

damaged easily.)

3. The use of soldering iron with anti-static feature is

recommended when providing short-circuit to laser diode or

when removing it.

4. Solder the land on flexible cable of optical pickup unit.

Caution

"""" ·"""" When using the soldering iron without anti-static

feature, short-circuit the flexible cable terminal with a

clip before short-circuiting the land.

"""" ·""""After intended repair is finished, remove the solder

for short-circuit of laser diode in a correct way

following the procedures described in this Manual.

8.8. Disassembling the Middle

Chassis

1. Remove the holder pins.

2. Remove the tab.

3. It lifts while pulling it in the direction of the arrow.

8.10. Disassembling the Spindle

Motor Unit

1. Remove the floating rubbers.

8.9. Disassemblingthe Traverse

Gear A

1. Remove the traverse gear A.

21

9

ADJUSTMENT PROCEDURES

9.1. Service Tools and Equipment

Application Name Number

Tilt adjustment DVD test disc DVDT-S01

Hex wrench

Inspection Extensioncable(moduleP.C.B.tomotherP.C.B.)

Others Screw lock RZZ0L01

Grease RFKXGAK152

Oil RFKXGA1280, JZS0648

Confirmation CD test disc Any othercommercially

VCD test disc Any othercommercially

availabledisc

available disc

9.2. Important points in adjustment

9.2.1. Important points in optical adjustment

·

Before starting optical adjustment, be sure to take anti-static measures.

·

Optical pickup tilt adjustment is needed after replacement of the following components.

1. Optical pickup unit

2. Spindle motor unit

3. Optical pickup peripheral parts (such as rail)

Notes

Adjustment is generally unnecessary after replacing other parts of the traverse unit. However, make adjustment if there is a

noticeable degradation in picture quality. Optical adjustments cannot be made inside the optical pickup. Adjustment is generally

unnecessary after replacing the traverse unit.

9.2.2. Important points in electrical adjustment

·

Follow the adjustment procedures described in this Manual.

9.3. Storing and Handling Test Discs

·

Surface precision is vital for DVD test discs. Be sure to store and handle them carefully.

1. Do not place discs directly onto the workbench, etc., after use.

2. Handle discs carefully in order to maintain their flatness. Place them into their case after use and store them vertically. Store

discs in a cool place where they are not exposed to direct sunlight or air from air conditioners.

3. Accurate adjustment will not be possible if the disc is warped when placed on a surface made of glass, etc. If this happens, use

a new test disc to make optical adjustments.

4. If adjustment is done using a warped disc, the adjustment will be incorrect and some discs will not be playable.

22

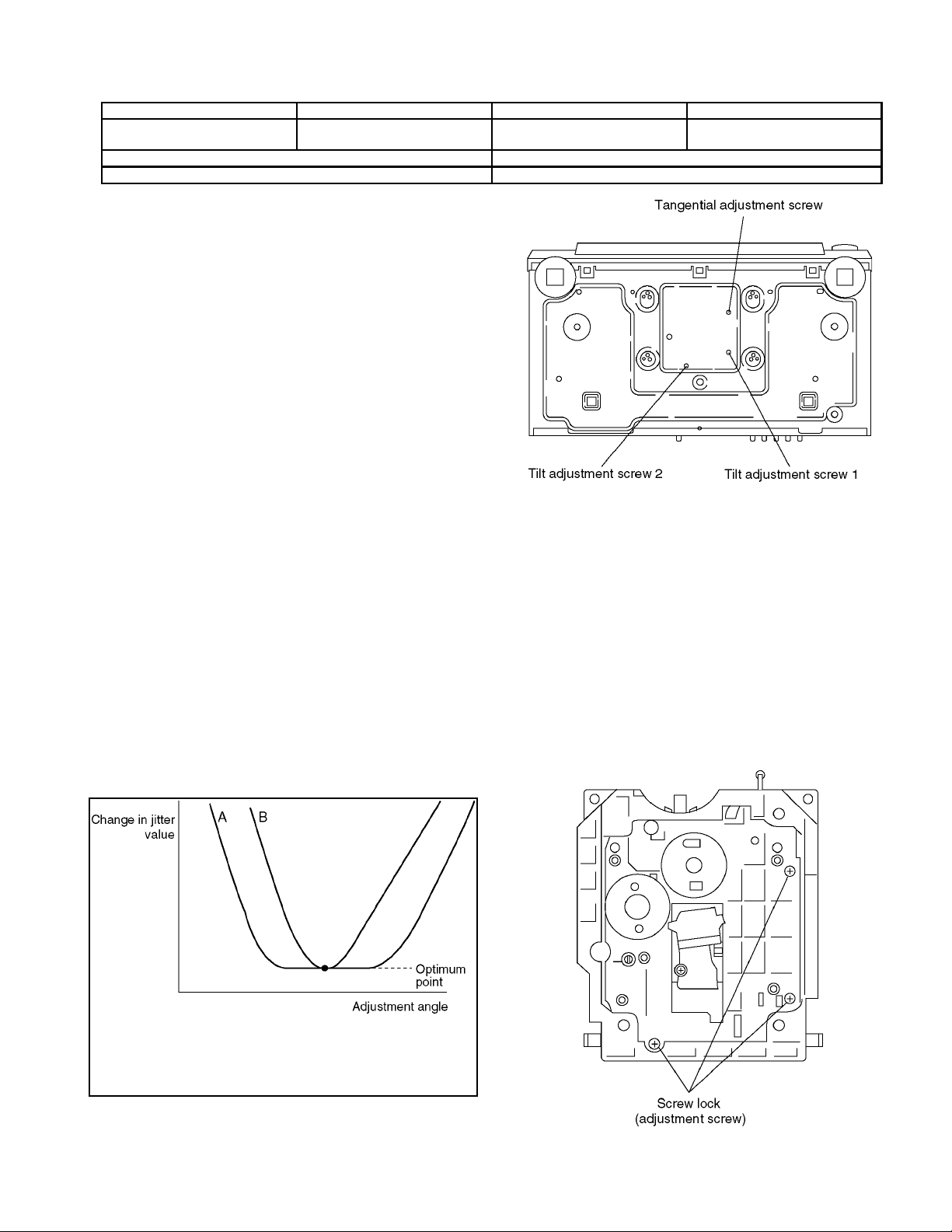

9.4. Opticaladjustment

9.4.1. Opticalpickuptiltadjustment

Measurement point Adjustment point Mode Disc

Tangential adjustment screw

Tilt adjustment screw

Measuring equipment Adjustment value

None (Main unit display for servicing is used.) Adjust to the minimum jitter value.

9.4.1.1. Adjustmentprocedure

1. While pressing PAUSE and OPEN/CLOSE buttons on the

main unit, press "5" on the remote control unit.

2. Confirm that "J_xxx_yyy_zz" is shown on the front display.

For your information:

"yyy" and "zz" shown to the right have nothing to do with

the jitter value. "yyy" is the error counter, while "zz" is

the focus drive value.

Note:

Jitter value appears on the front display.

3. Play test disc T01 (inner periphery).

4. Adjust tangential adjustment screw so that the jitter value is

minimized.

5. Play test disc T43 (outer periphery).

6. Adjust tilt adjustment screw 1 so that the jitter value is

minimized.

7. Play test disc T43 (outer periphery).

8. Adjust tilt adjustment screw 2 so that the jitter value is

minimized.

9. Repeat adjusting tilt adjustment screws 1 and 2 alternately

until the jitter value is minimized.

9.4.1.2. Importantpoints

1. Make tangential adjustment first, and then make tilt

adjustment.

2. Repeat adjusting two or three times to find the optimum

point.

3. Finish the procedure with tilt adjustment.

T01 (inner periph ery) play

T43 (outer periphery) play

9.4.1.3. Checkafteradjustment

Play test disc or any other disc to make sure there is no picture

degradation in the inner, middle and outer peripheries, and no

audio skipping. After adjustment is finished, lock each

adjustment screw in position using screw lock.

9.4.1.4. Procedureforscrewlock

1. After adjustment, remove top cover, tray, clamper base and

traverse unit in this sequence.

2. Lay the traverse unit upside down, and fix adjustment screw

with screw lock.

3. After fixing, reassemble traverse unit, clamper base, tray

and top cover.

DVDT-S01

Jitter value depends on the model:

1. If the jitter value changes like B, the optimum point is easy to

find.

2. If the jitter value changes like A, set the optimum point near the

middle.

23

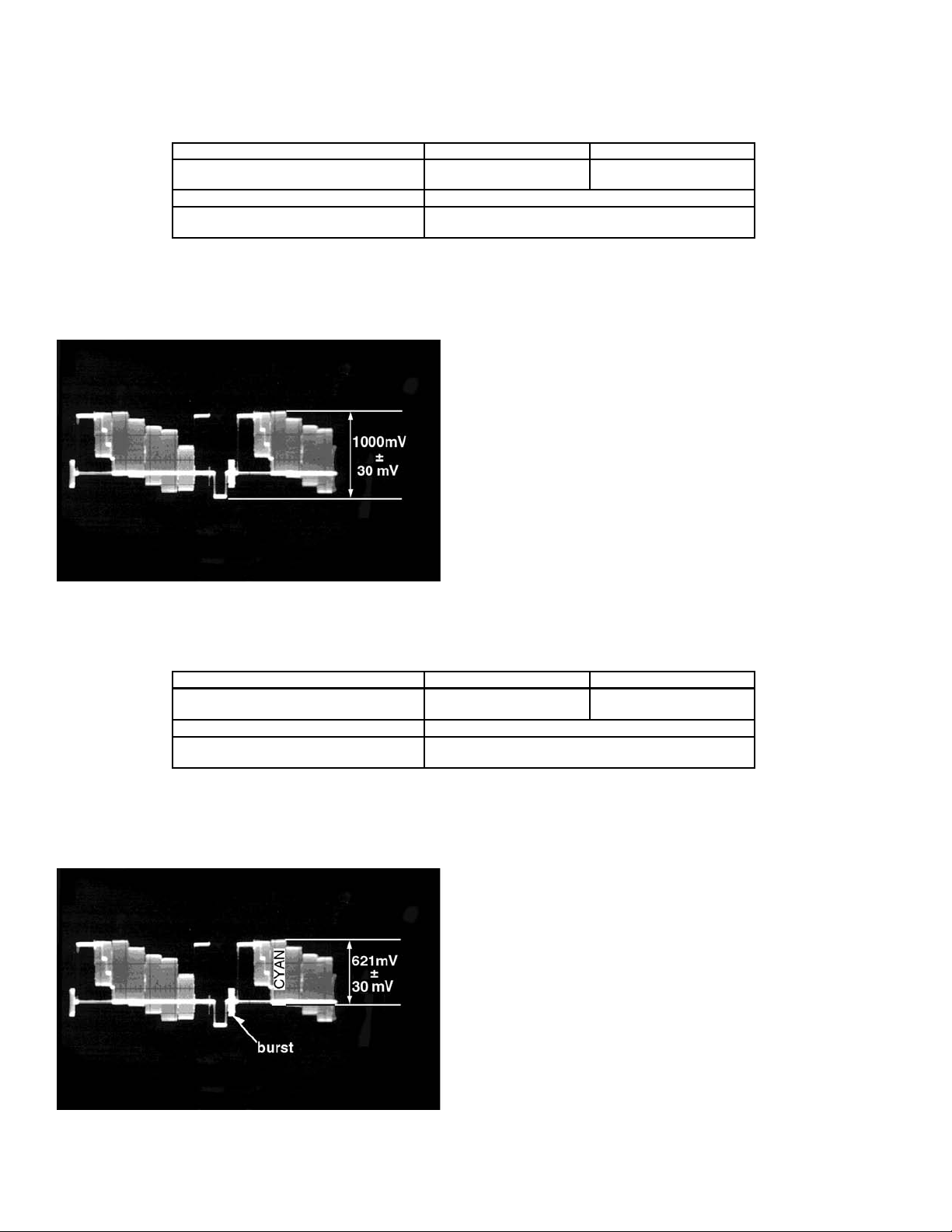

10 ElectricalConfirmation

10.1. VideoOutput(LuminanceSignal)Confirmation

Do this confirmation after replacing a P.C.B.

Measurement point Mode Disc

Video output terminal Color bar 75%

Measuring equipment, tools Confirmation value

Screwdriver, Oscilloscope

200mV/div, 10µsec/div

Purpose: To maintain video signal output compatibility.

1. Connect the oscilloscope to the video output terminal and terminate at 75 ohms.

2. Confirm that the luminance signal (Y+S) level is 1000 mVp-p±30 mV.

PLAY (Title 12):DVDT-S01 DVDT-S01

1000mVp-p±30mV

10.2. VideoOutput(ChrominanceSignal)Confirmation

Do this confirmation after replacing a P.C.B.

Measurement point Mode Disc

Video output terminal Color bar 75%

Measuring equipment, tools Confirmation value

Screwdriver,Oscilloscope

200mV/div, 10µsec/div

Purpose: To maintain video signal output compatibility.

1. Connect the oscilloscope to the video output terminal and terminate at 75 ohms.

2. Confirm that the chrominance signal (C) level is 621 mVp-p±30 mV.

PLAY (Title 12):DVDT-S01 DVDT-S01

621mVp-p±30mV

24

Loading...

Loading...