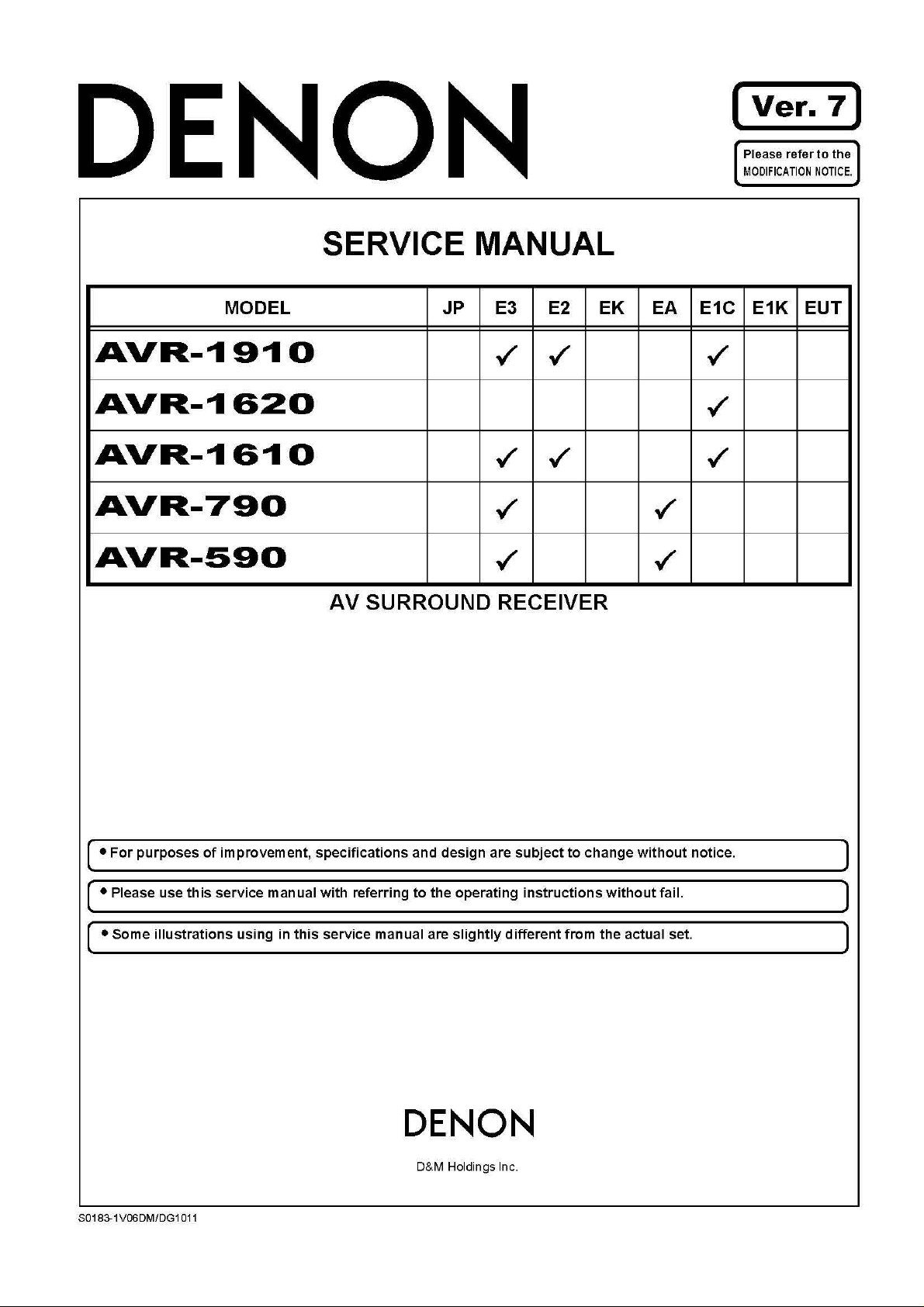

Page 1

Page 2

Please heed the points listed below during servicing and inspection.

SAFETY PRECAUTIONS

The following check should be performed for the continued protection of the customer and service technician.

LEAKAGE CURRENT CHECK

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the unit is defective.

CAUTION

CAUTION

◎Heed the cautions!

Spots requiring particular attention when servicing, such

as the cabinet, parts, chassis, etc., have cautions indicated

on labels or seals. Be sure to heed these cautions and the

cautions indicated in the handling instructions.

◎Caution concerning electric shock!

(1) An AC voltage is impressed on this set, so touching in-

ternal metal parts when the set is energized could

cause electric shock. Take care to avoid electric shock,

by for example using an isolating transformer and

gloves when servicing while the set is energized, unplugging the power cord when replacing parts, etc.

(2)There are high voltage parts inside. Handle with extra

care when the set is energized.

◎Caution concerning disassembly and

assembly!

Though great care is taken when manufacturing parts from

sheet metal, there may in some rare cases be burrs on the

edges of parts which could cause injury if fingers are

moved across them. Use gloves to protect your hands.

◎Only use designated parts!

The set's parts have specific safety properties (fire resistance, voltage resistance, etc.). For replacement parts, be

sure to use parts which have the same properties. In particular, for the important safety parts that are marked z on

wiring diagrams and parts lists, be sure to use the designated parts.

◎Be sure to mount parts and arrange

the wires as they were originally!

For safety reasons, some parts use tape, tubes or other insulating materials, and some parts are mounted away from

the surface of printed circuit boards. Care is also taken with

the positions of the wires inside and clamps are used to

keep wires away from heating and high voltage parts, so

be sure to set everything back as it was originally.

◎Inspect for safety after servicing!

Check that all screws, parts and wires removed or disconnected for servicing have been put back in their original positions, inspect that no parts around the area that has been

serviced have been negatively affected, conduct an insulation check on the external metal connectors and between

the blades of the power plug, and otherwise check that

safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and turn the power switch on. Using a 500V insulation resistance tester, check that the insulation resistance between the terminals of the power

plug and the externally exposed metal parts (antenna terminal, headphones terminal, microphone terminal, input

terminal, etc.) is 1MΩ or greater. If it is less, the set must

be inspected and repaired.

Concerning important safety

parts

Many of the electric and structural parts used in the set

have special safety properties. In most cases these properties are difficult to distinguish by sight, and using replacement parts with higher ratings (rated power and

withstand voltage) does not necessarily guarantee that

safety performance will be preserved. Parts with safety

properties are indicated as shown below on the wiring diagrams and parts lists is this service manual. Be sure to replace them with parts with the designated part number.

(1) Schematic diagrams ... Indicated by the z mark.

(2) Parts lists ... Indicated by the z mark.

Using parts other than the designated

parts could result in electric shock, fires or

other dangerous situations.

AVR-1910/1620/1610/790/590

2

Page 3

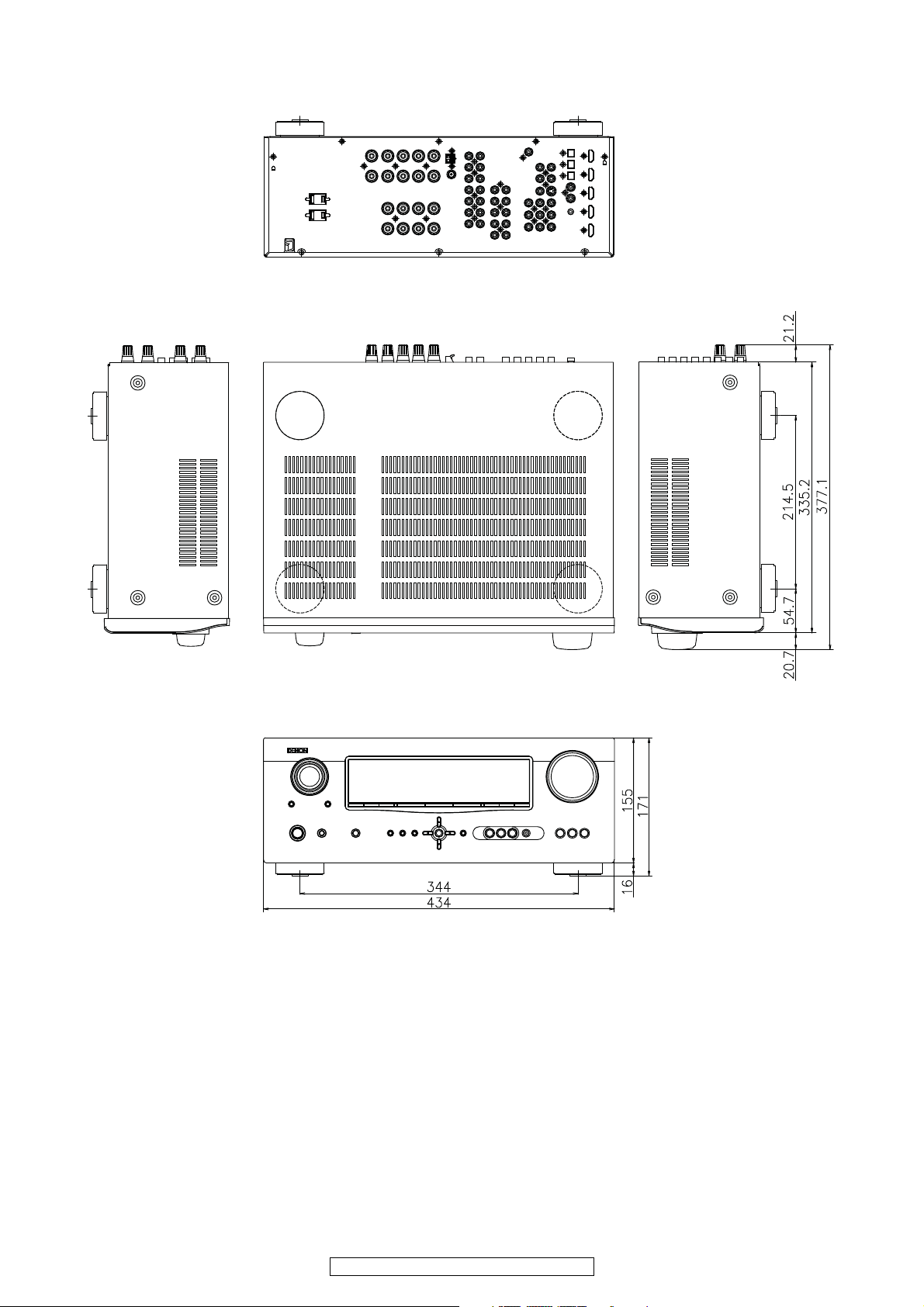

DIMENSION

AVR-1910 model

3

AVR-1910/1620/1610/790/590

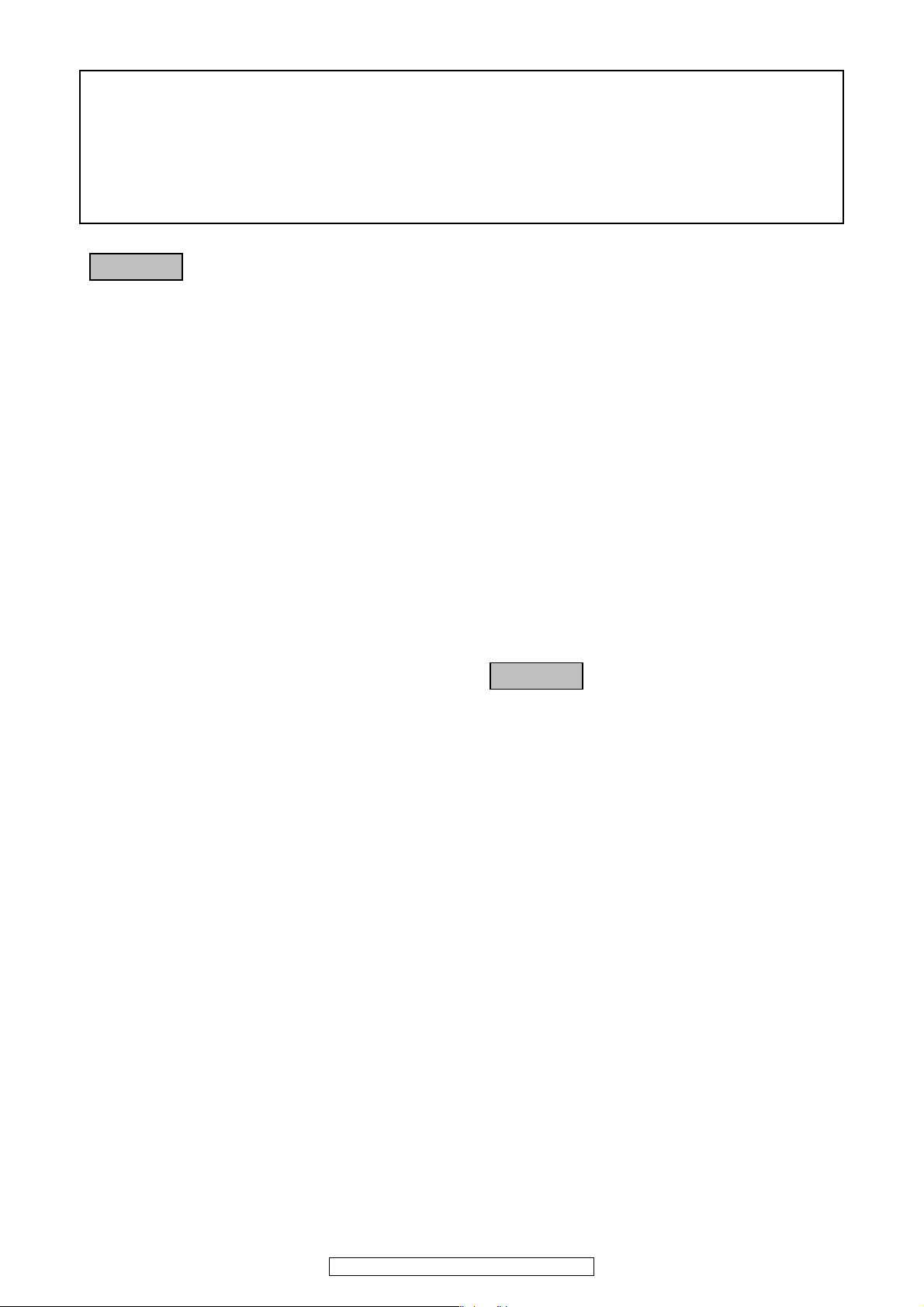

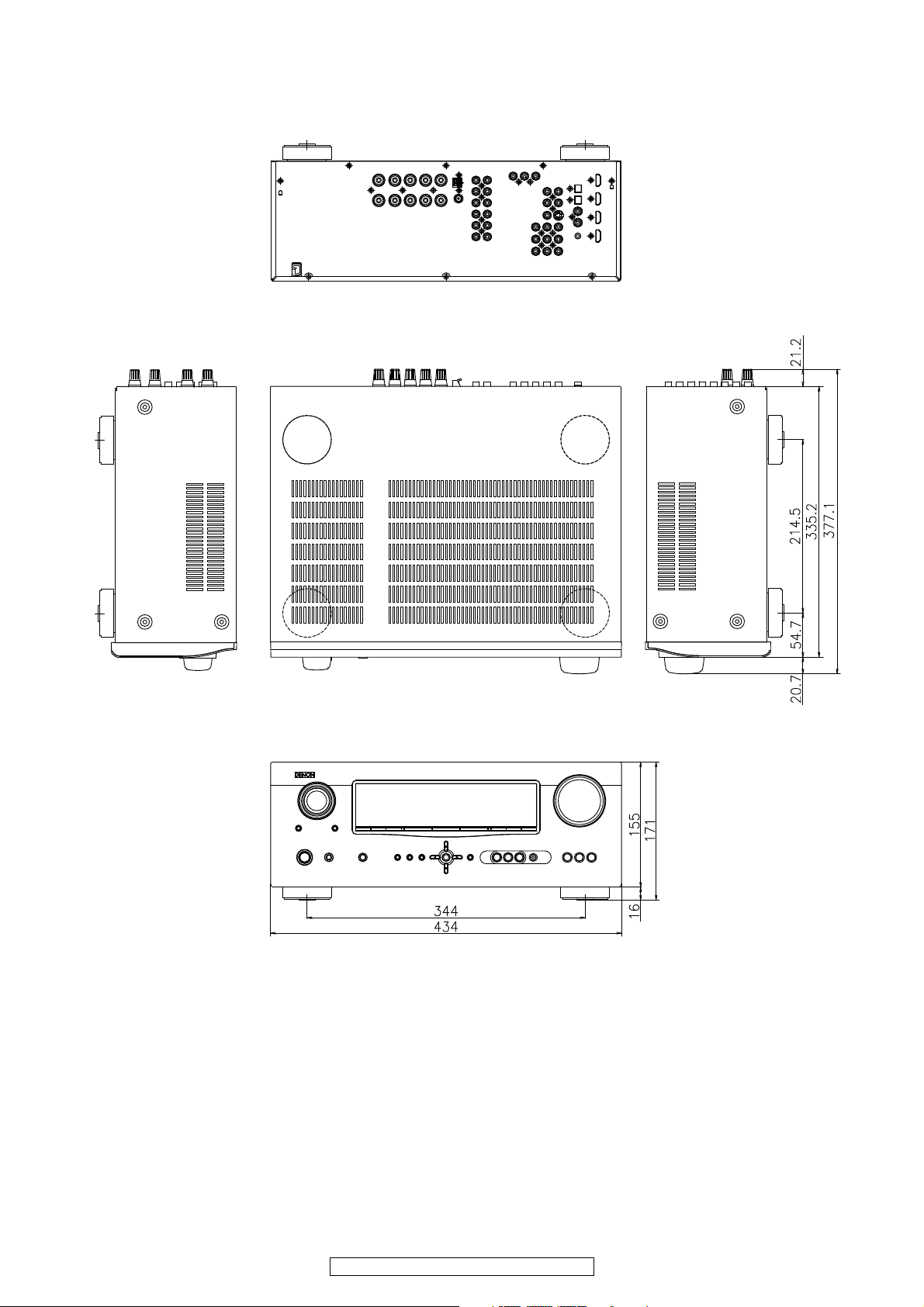

Page 4

AVR-1610/1620 model

4

AVR-1910/1620/1610/790/590

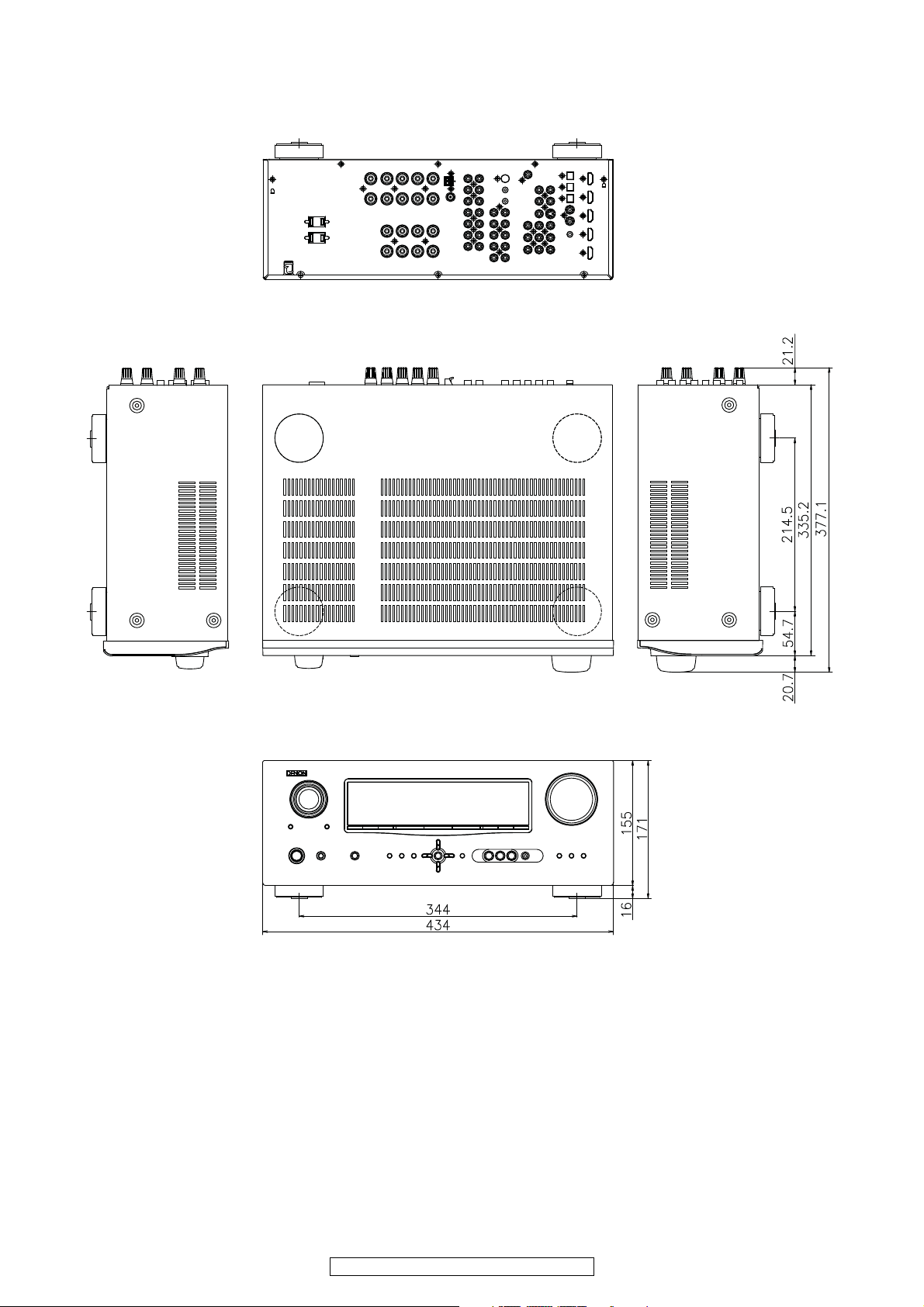

Page 5

AVR-790 model

5

AVR-1910/1620/1610/790/590

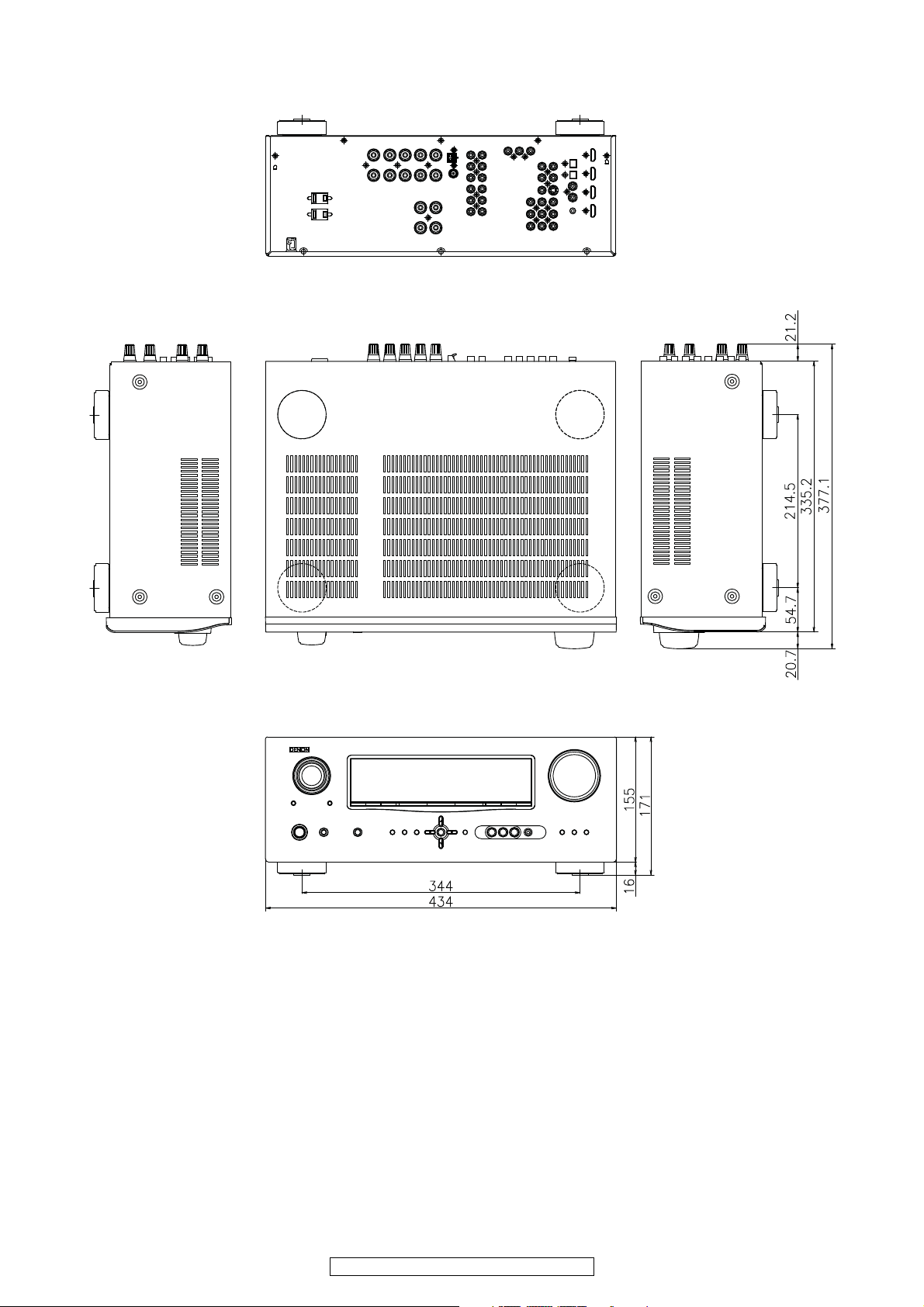

Page 6

AVR-590 model

6

AVR-1910/1620/1610/790/590

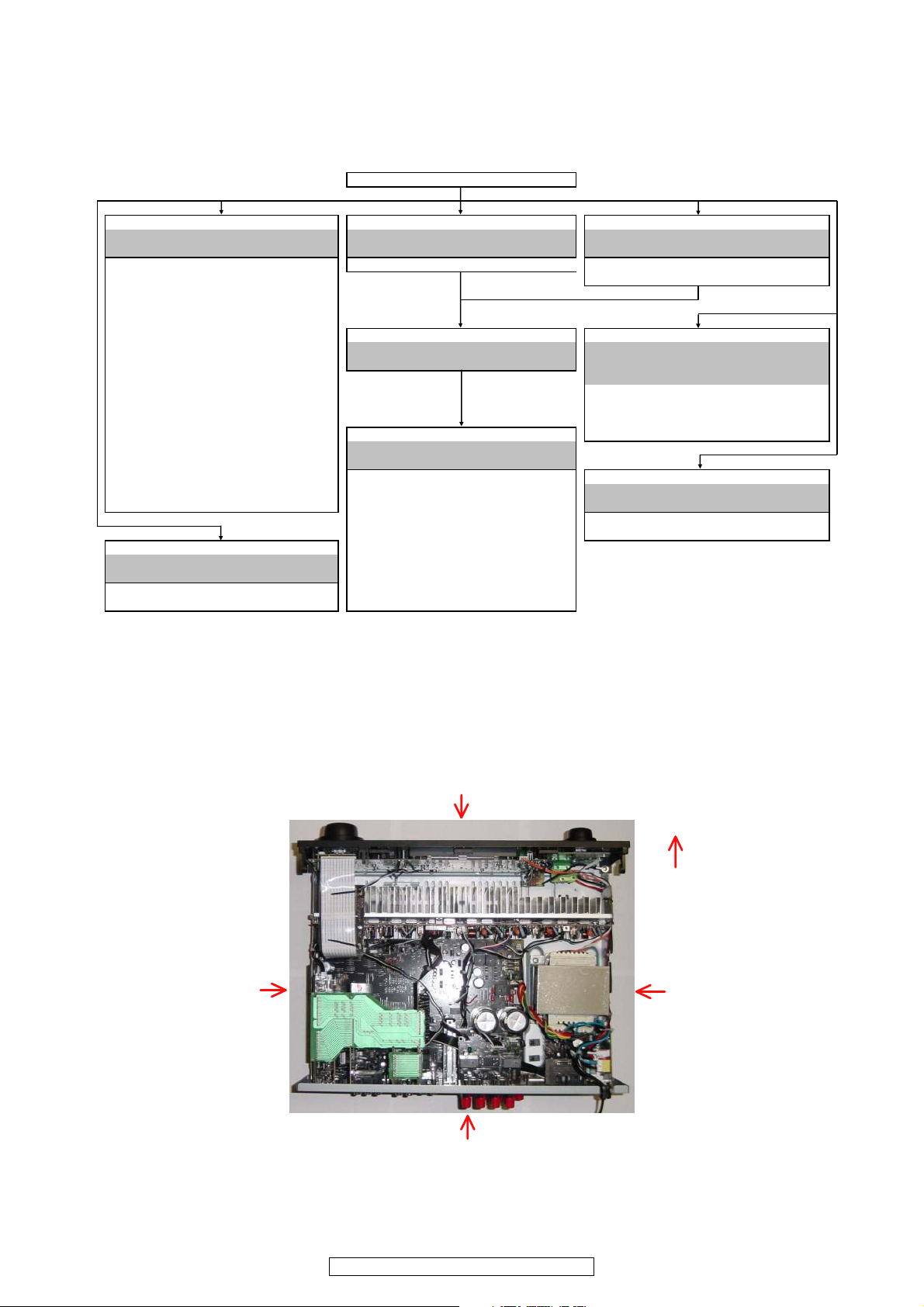

Page 7

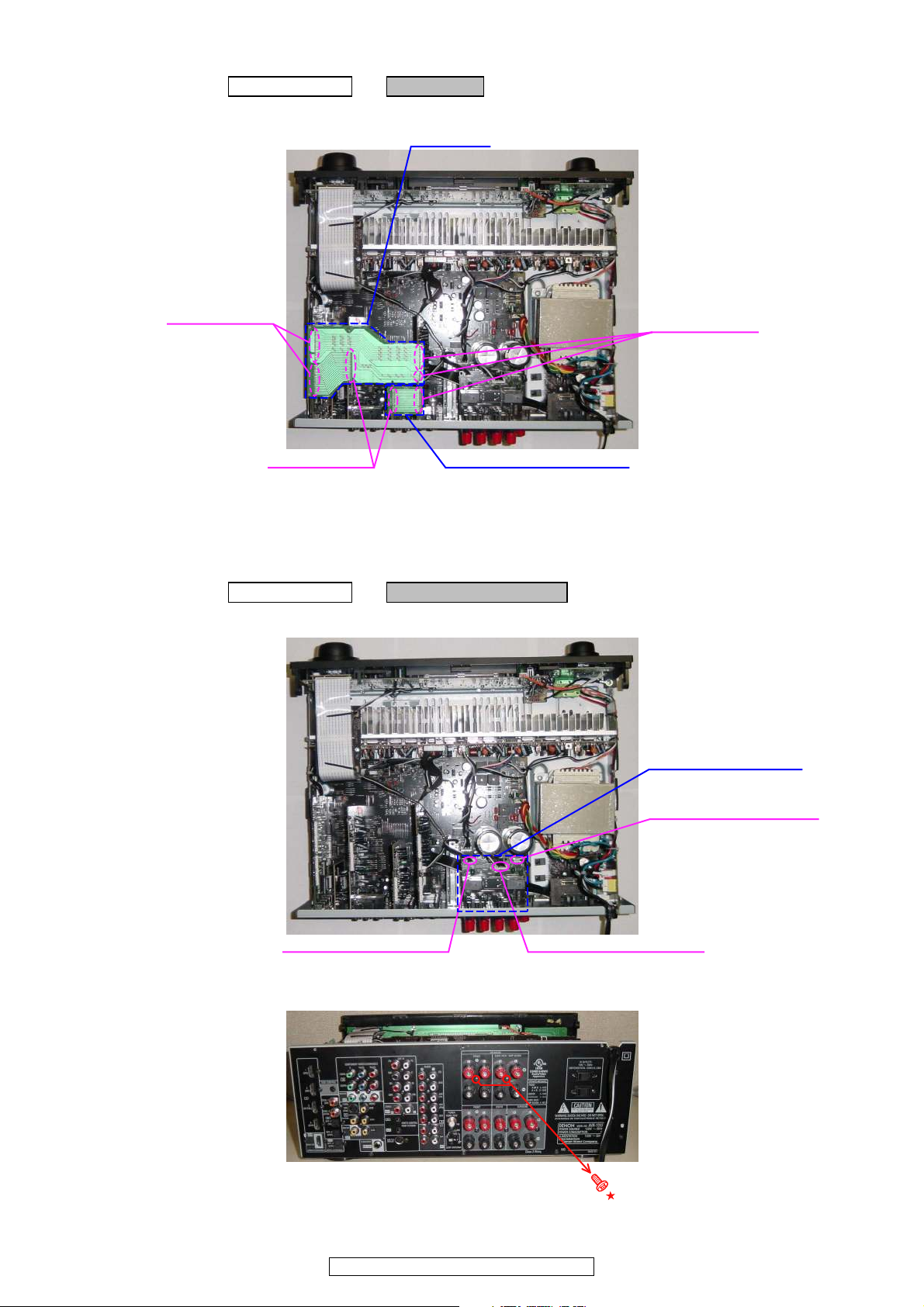

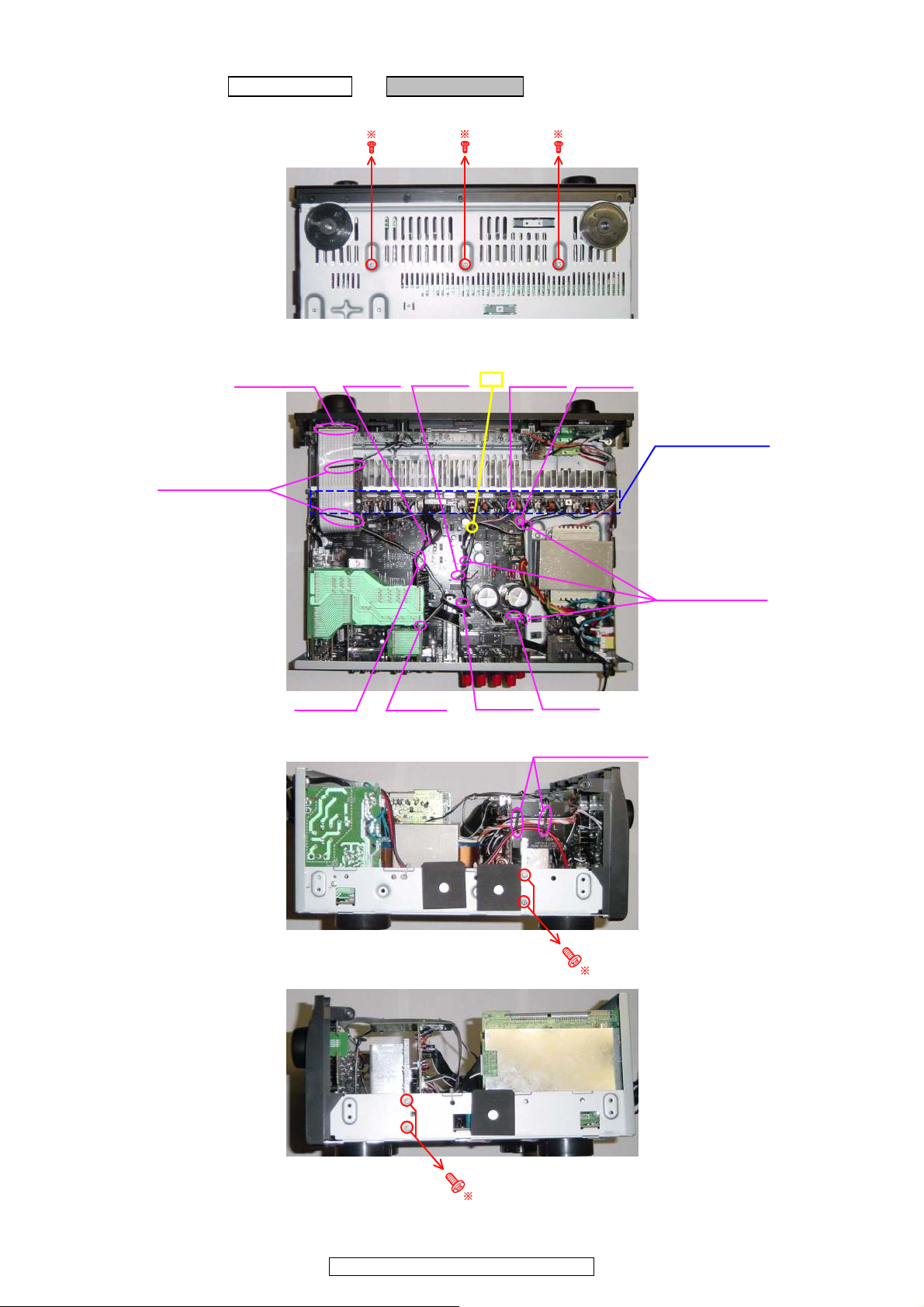

WIRE ARRANGEMENT

Back Panel side

Front Panel side

If wire bundles are untied or moved to perform adjustment or parts replacement etc., be sure to rearrange them neatly as

they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise

generation.

Wire arrangement viewed from the top

7

AVR-1910/1620/1610/790/590

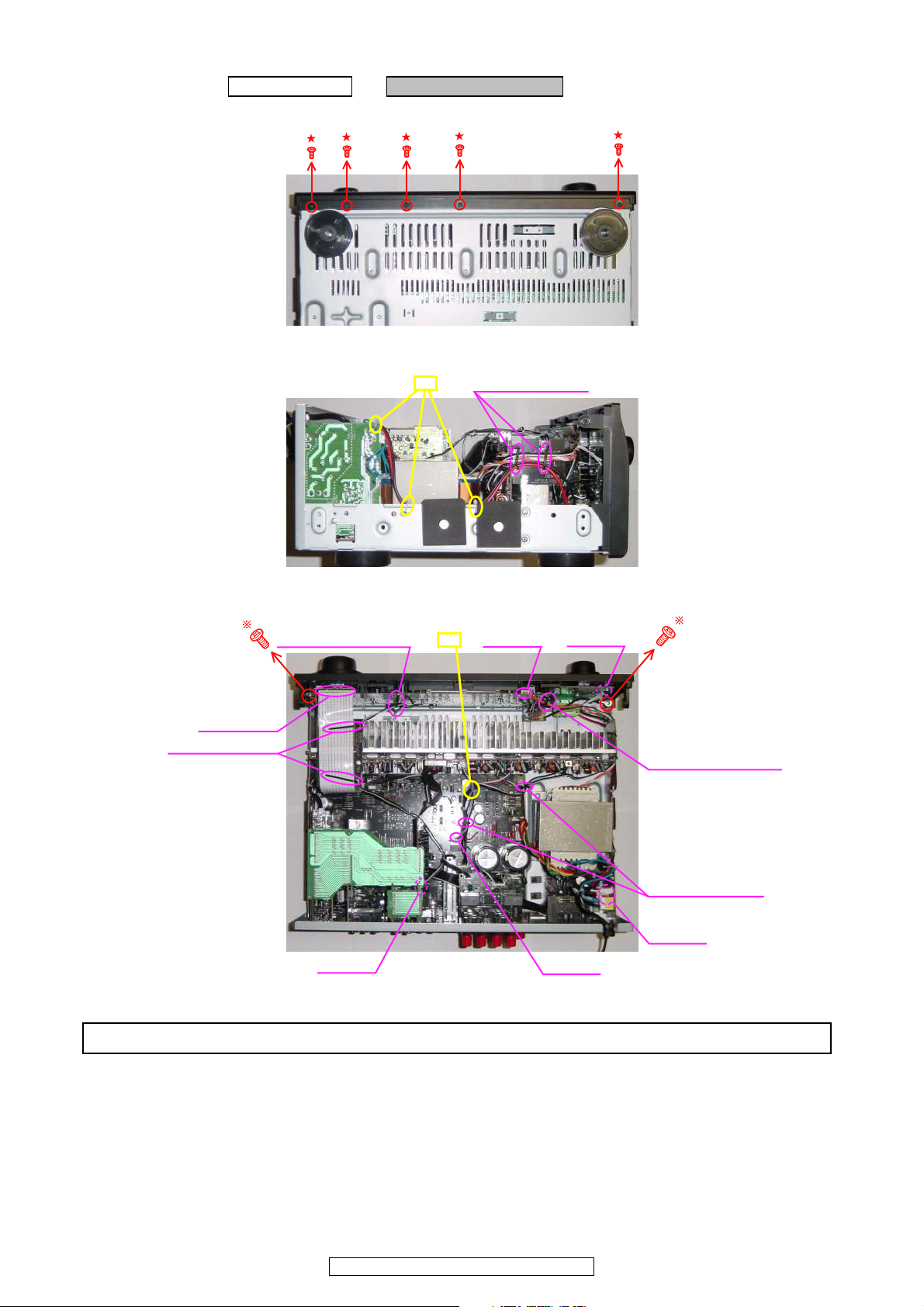

Page 8

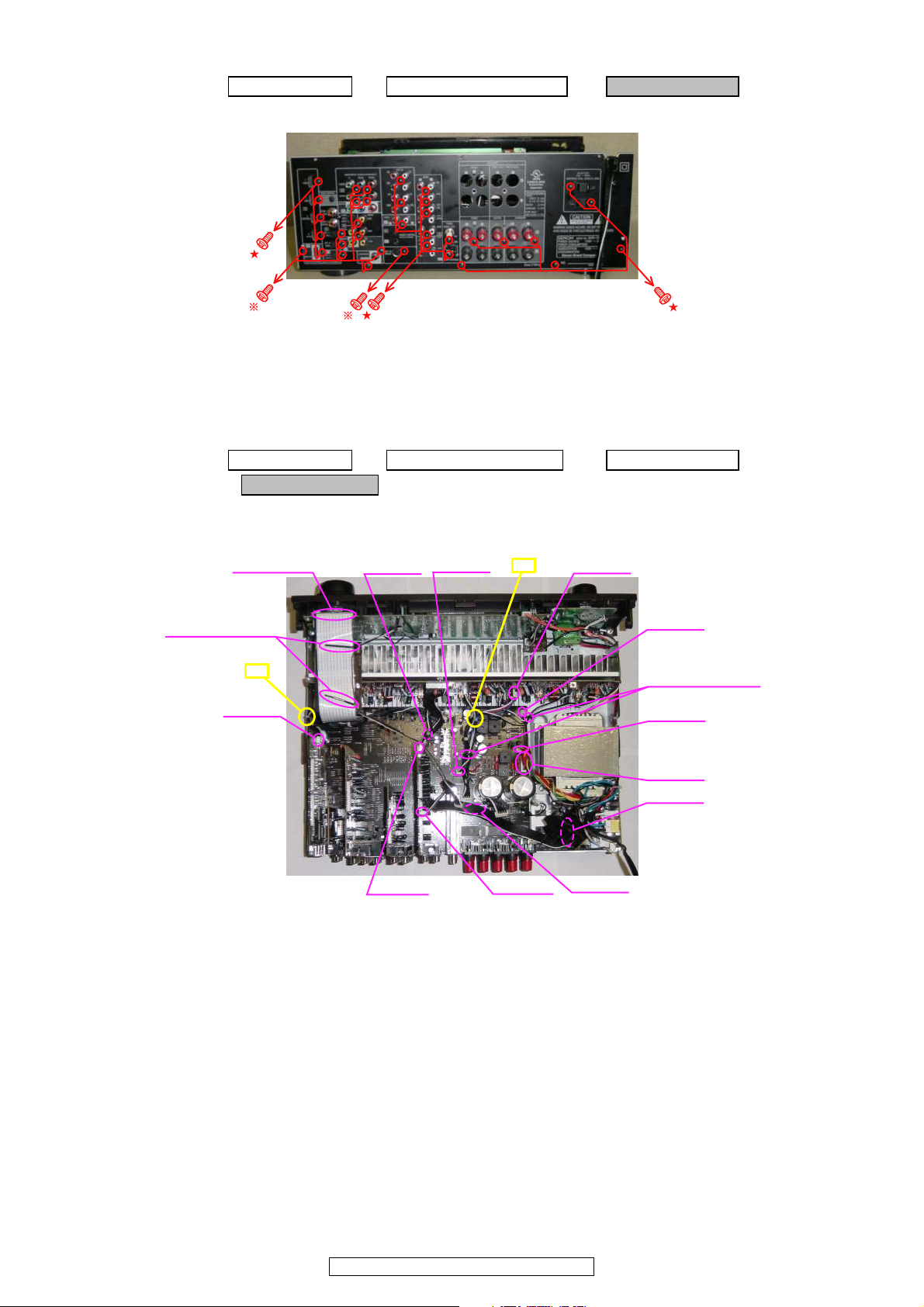

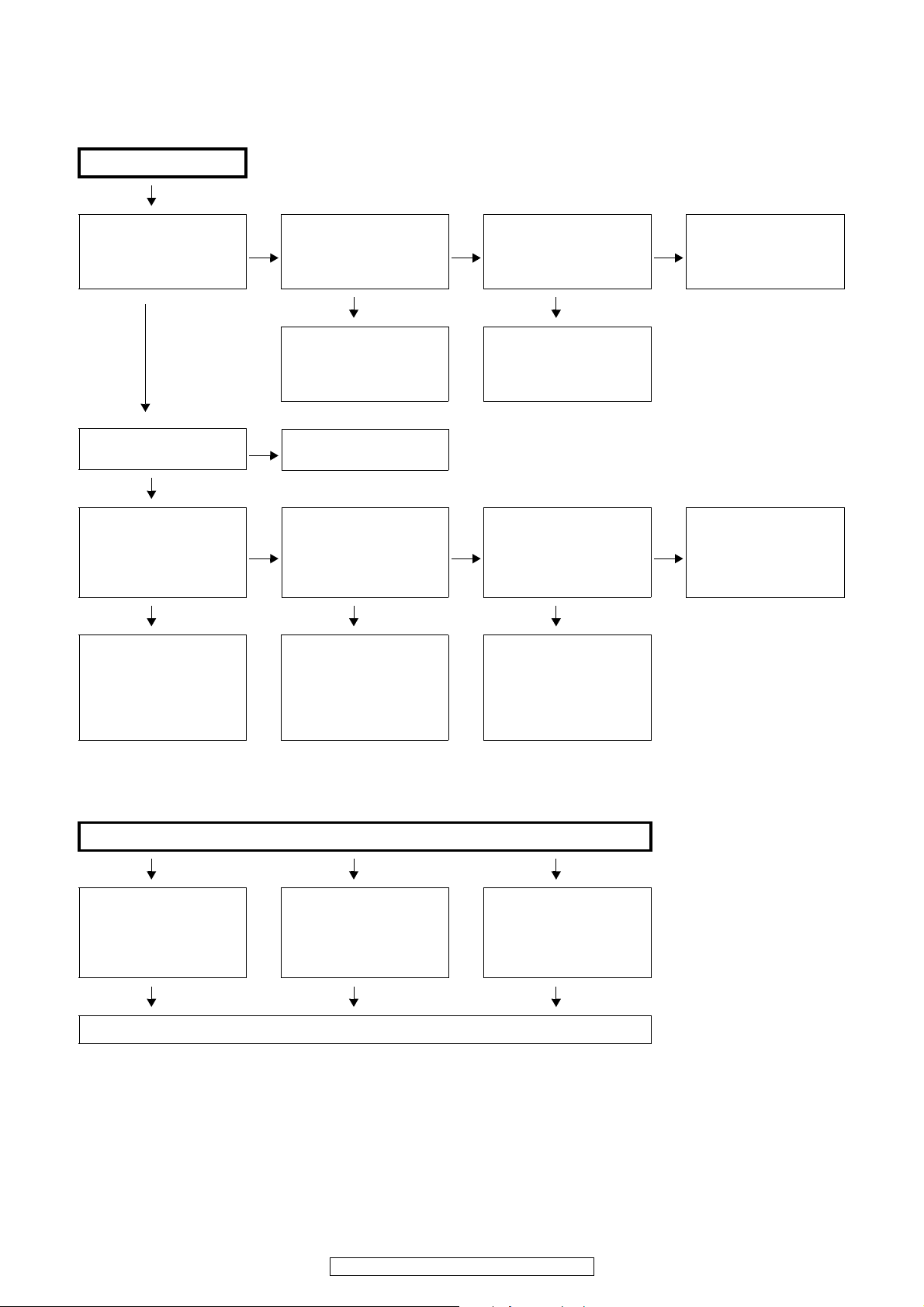

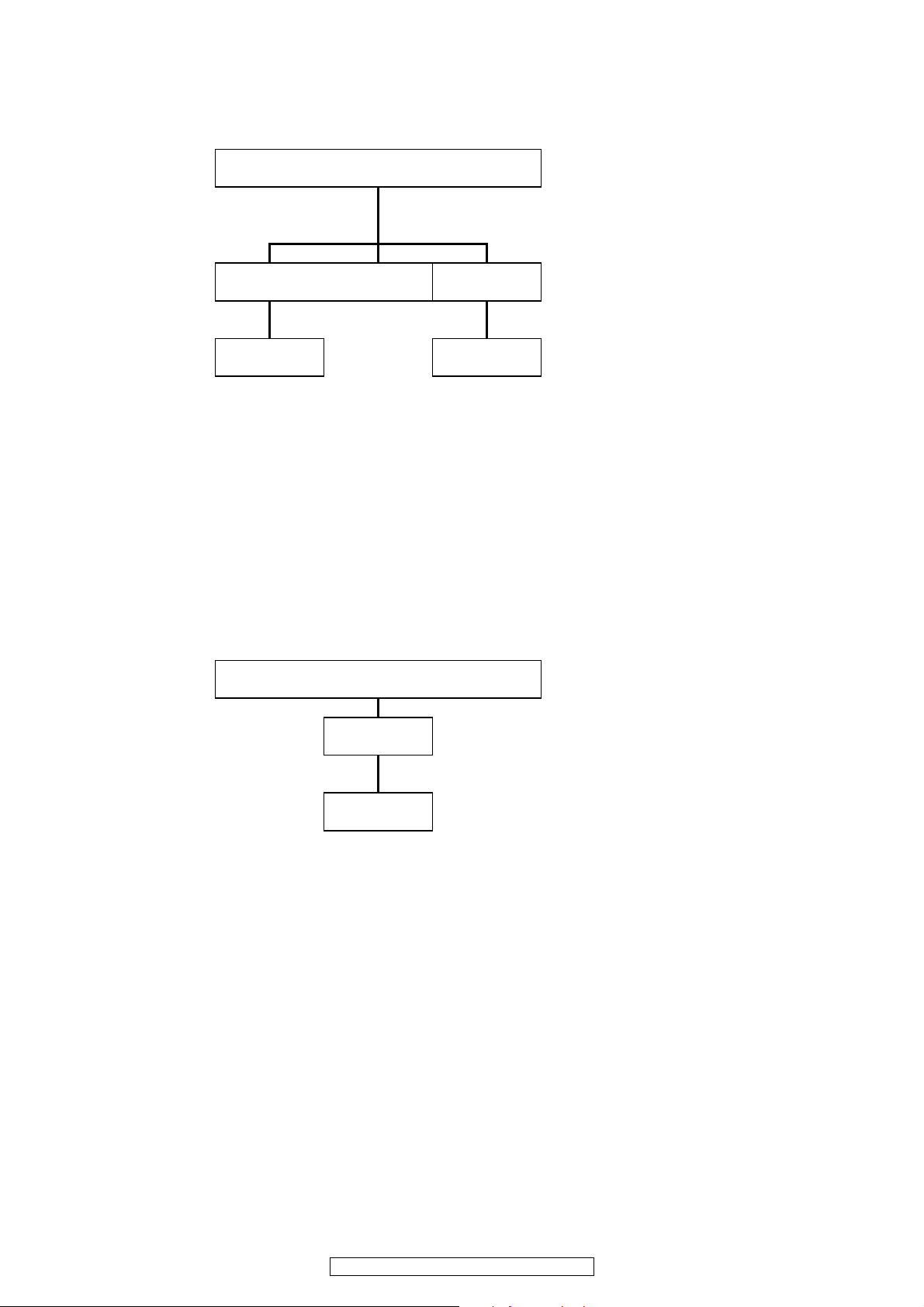

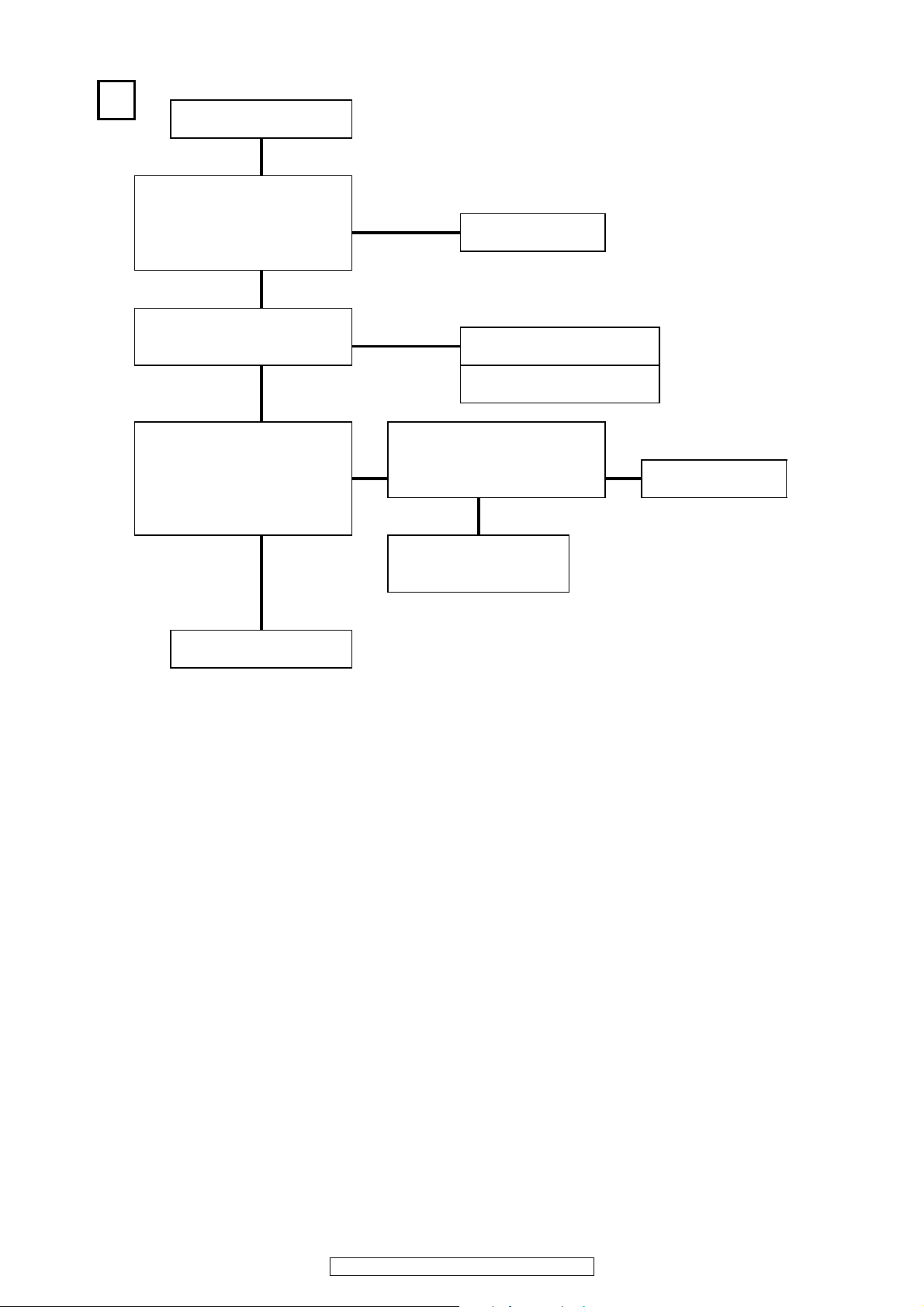

DISASSEMBLY

CABINET TOP

PANEL FRONT ASSY PCB CNT1 PCB SPEAKER ASSY

Refer to "DISASSEMBLY 1.PANEL FRONT ASSY" Refer to "DISASSEMBL 2.PCB CNT1" Refer to "DISASSEMBLY 3.PCB SPEAKER ASSY"

and "EXPLODED VIEW" and "EXPLODED VIEW" and "EXPLODED VIEW"

PCB POWER SW ASSY PCB CNT1 (Ref. No. of EXPLODED VIEW : 71) PCB SPEAKER ASSY

(Ref. No. of EXPLODED VIEW : 9) (Ref. No. of EXPLODED VIEW : 63)

PCB FUNC ASSY

(Ref. No. of EXPLODED VIEW : 10)

PCB FRONT ASSY

(Ref. No. of EXPLODED VIEW : 11)

CHASSIS BACK PCB POWER/POWER SUPPLY ASSY

PCB ENCORDER

Refer to "DISASSEMBLY 4.CHASSIS BACK" Refer to "DISASSEMBLY

(Ref. No. of EXPLODED VIEW : 13) and "EXPLODED VIEW" 6.PCB POWER/POWER SUPPLY ASSY"

PCB HEAD PHONE ASSY

and "EXPLODED VIEW"

(Ref. No. of EXPLODED VIEW : 14) PCB POWER SUPPLY ASSY

PCB V-AUX ASSY (Ref. No. of EXPLODED VIEW : 56)

(Ref. No. of EXPLODED VIEW : 21) PCB POWER ASSY

PCB MIC ASSY

PCB MAIN ASS

Y

(Ref. No. of EXPLODED VIEW : 57)

(Ref. No. of EXPLODED VIEW : 22)

Refer to "DISASSEMBLY 5.PCB MAIN ASSY"

PCB CNT ENCORDER and "EXPLODED VIEW"

(Ref. No. of EXPLODED VIEW : 61) PCB MAIN ASSY

TRANS MAIN

PCB SW (Ref. No. of EXPLODED VIEW : 50)

Referto"DISASSEMBLY8.TRANSMAIN"

(Ref. No. of EXPLODED VIEW : 78) PCB INPUT ASSY and "EXPLODED VIEW"

(Ref. No. of EXPLODED VIEW : 51) TRANS MAIN

PCB VIDEO ASSY (Ref. No. of EXPLODED VIEW : 46)

PCB AMP ASSY (Ref. No. of EXPLODED VIEW : 53)

Refer to "DISASSEMBLY 7.PCB AMP ASSY"

PCB DIGITAL ASSY

and "EXPLODED VIEW" (Ref. No. of EXPLODED VIEW : 54)

PCB AMP ASSY PCB HDMI ASSY

(Ref. No. of EXPLODED VIEW : 33) (Ref. No. of EXPLODED VIEW : 55)

The viewpoint of each photograph

(Photografy direction)

[View from above]

Front side

Direction of photograph: B

Direction of photograph: D

Direction of photograph: C

Direction of photograph: A

• Disassemble in order of the arrow of the figure of following flow.

• In the case of the re-assembling, assemble it in order of the reverse of the following flow.

• In the case of the re-assembling, observe "attention of assembling" it.

About the photos used for descriptions in the “DISASSEMBLY” section.

• The direction from which the photographs used herein were photographed is indicated at "Direction of photograph: ***" at

the left of the respective photographs.

• Refer to the table below for a description of the direction in which the photos were taken.

• Photographs for which no direction is indicated were taken from above the product.

• The photograph is AVR-1910.

8

AVR-1910/1620/1610/790/590

Page 9

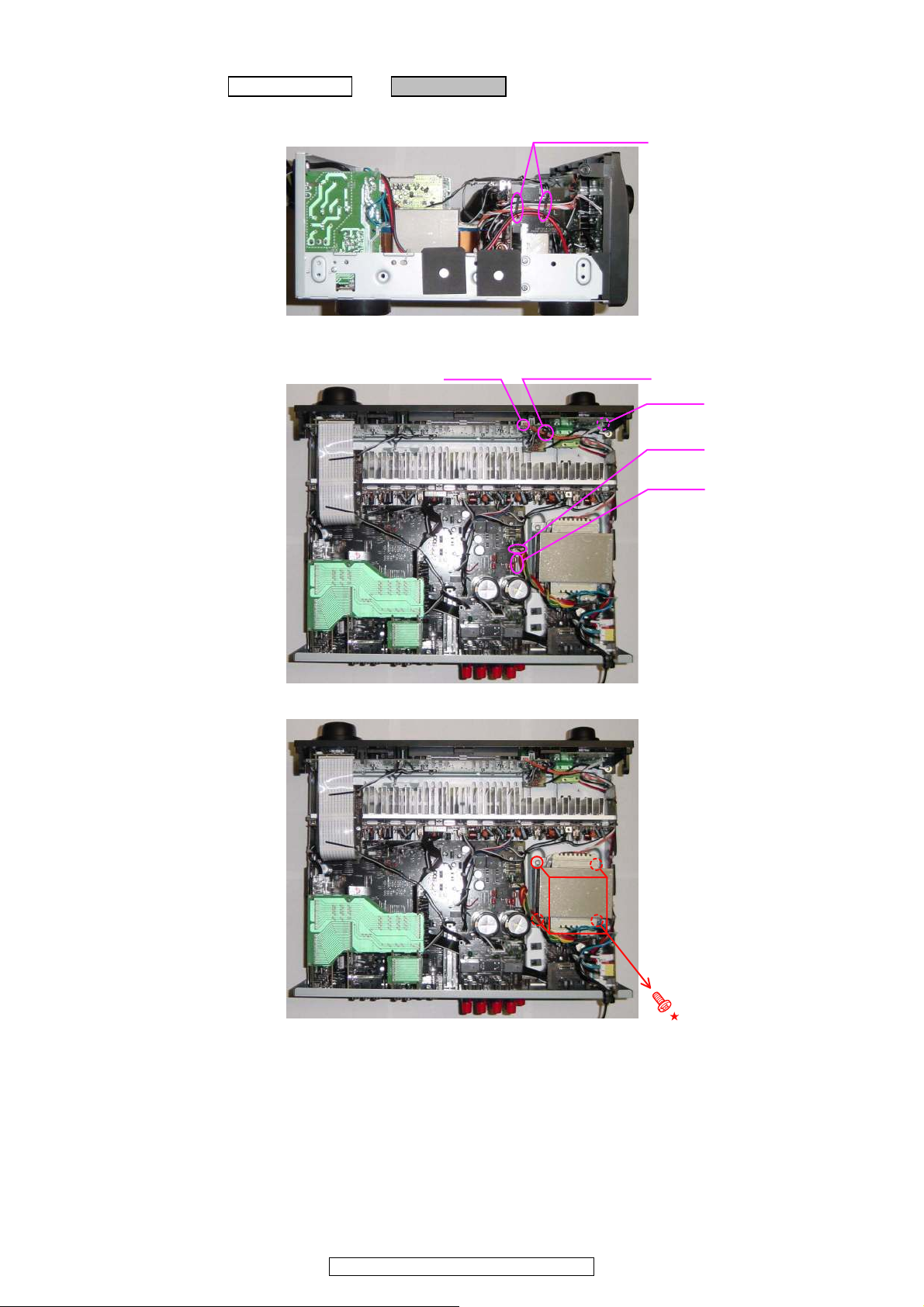

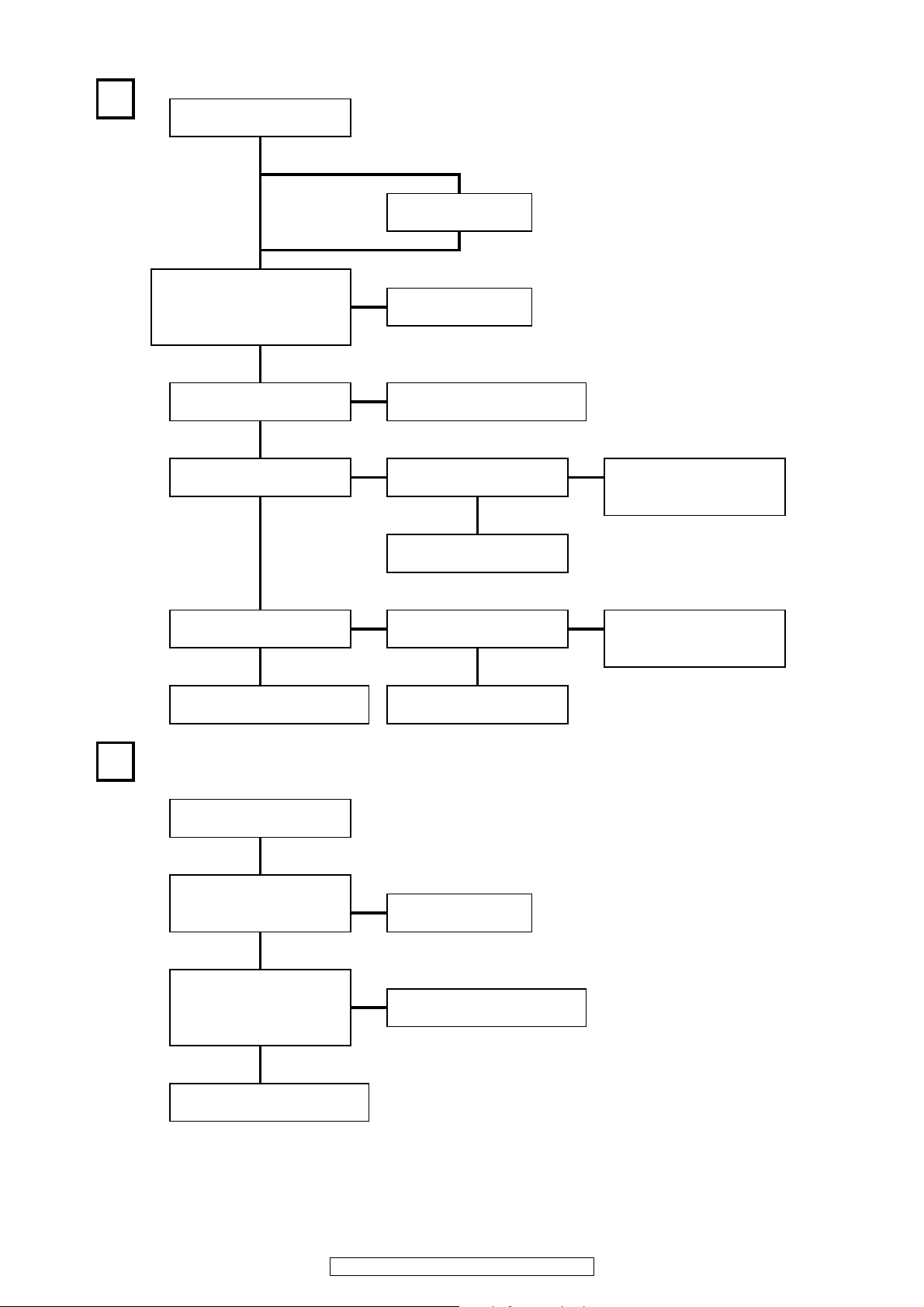

1. PANEL FRONT ASSY

Proceeding : CABINET TOP →PANEL FRONT ASSY

View from bottom

Direction of photograph: D

Style pin : Loose

cut

Cord holder : Loose

Cord holder : Loose

Style pin : Loose

CP1501

CP1300

Style pin : Loose

CP1001

CP1705

FFC Cable

CP1307

cut

Please refer to "EXPLODED VIEW" for the disassembly method of each P.W.B included in PANEL FRONT ASSY.

(1) Remove the screws.

(2) Cut the wire clamp band, and loose the style pin.

(3) Cut the wire clamp band, then loose the style pin and Cord holder. Disconnect the connector wire and FFC Cable.

AVR-1910/1620/1610/790/590

9

Page 10

2. PCB CNT1

Proceeding : CABINET TOP →PCB CNT1

PCB CNT1

PCB CNT (1910/790 model)

Board to board

Board to board

Board to board

Proceeding : CABINET TOP →PCB SPEAKER ASSY

CP1001 (1910/790 model)

CN1309 (1910/790 model)

CP1002 (1910/790 model)

※CP1003 (1610/1620/590/ model), CP1004 (1610/1620/590/ model)

PCB SPEAKER ASSY

Direction of photograph: A

(1) Disconnect the connector board.

3. PCB SPEAKER ASSY

(1) Disconnect the connector wires.

(2) Remove the screws.

10

AVR-1910/1620/1610/790/590

Page 11

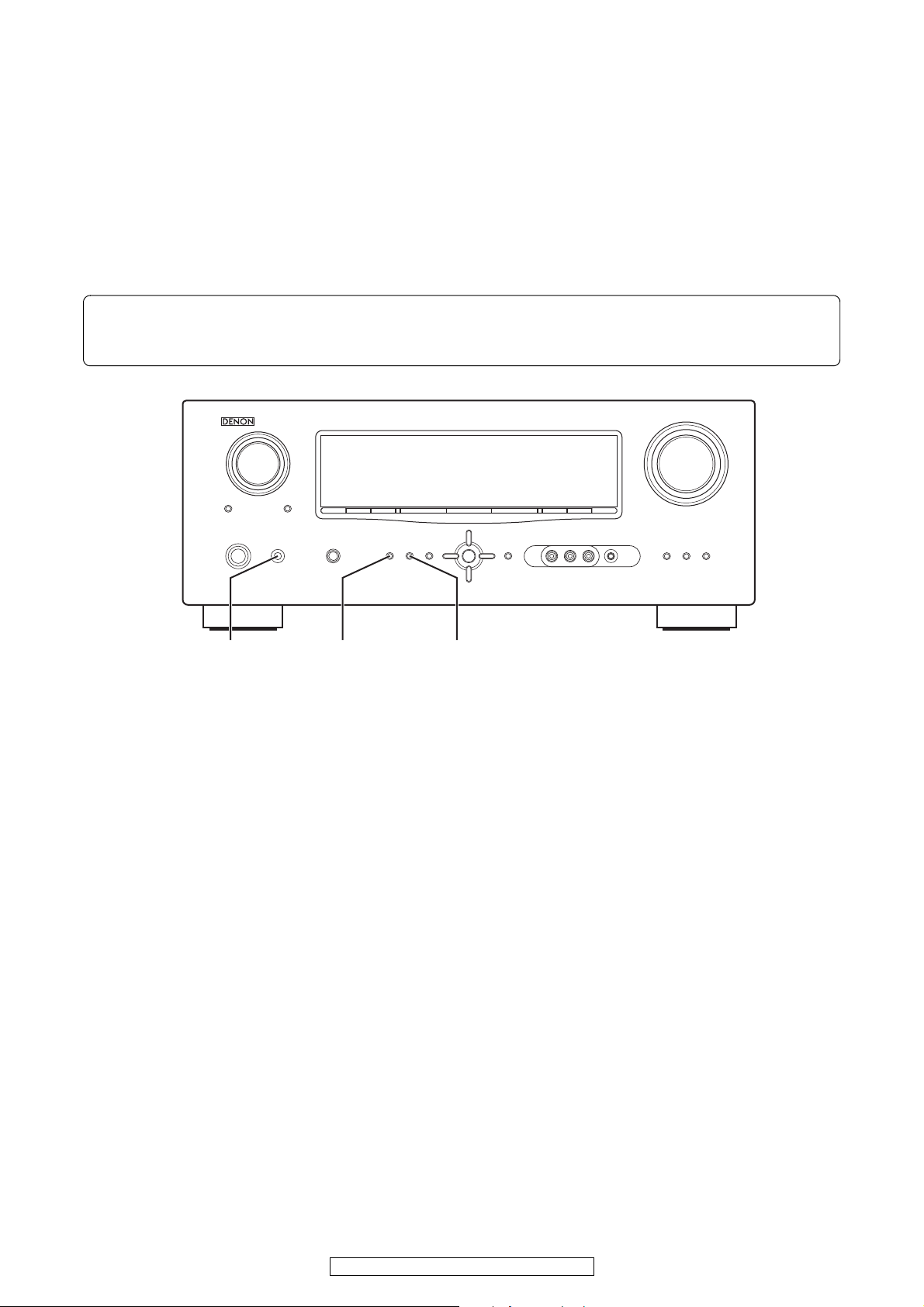

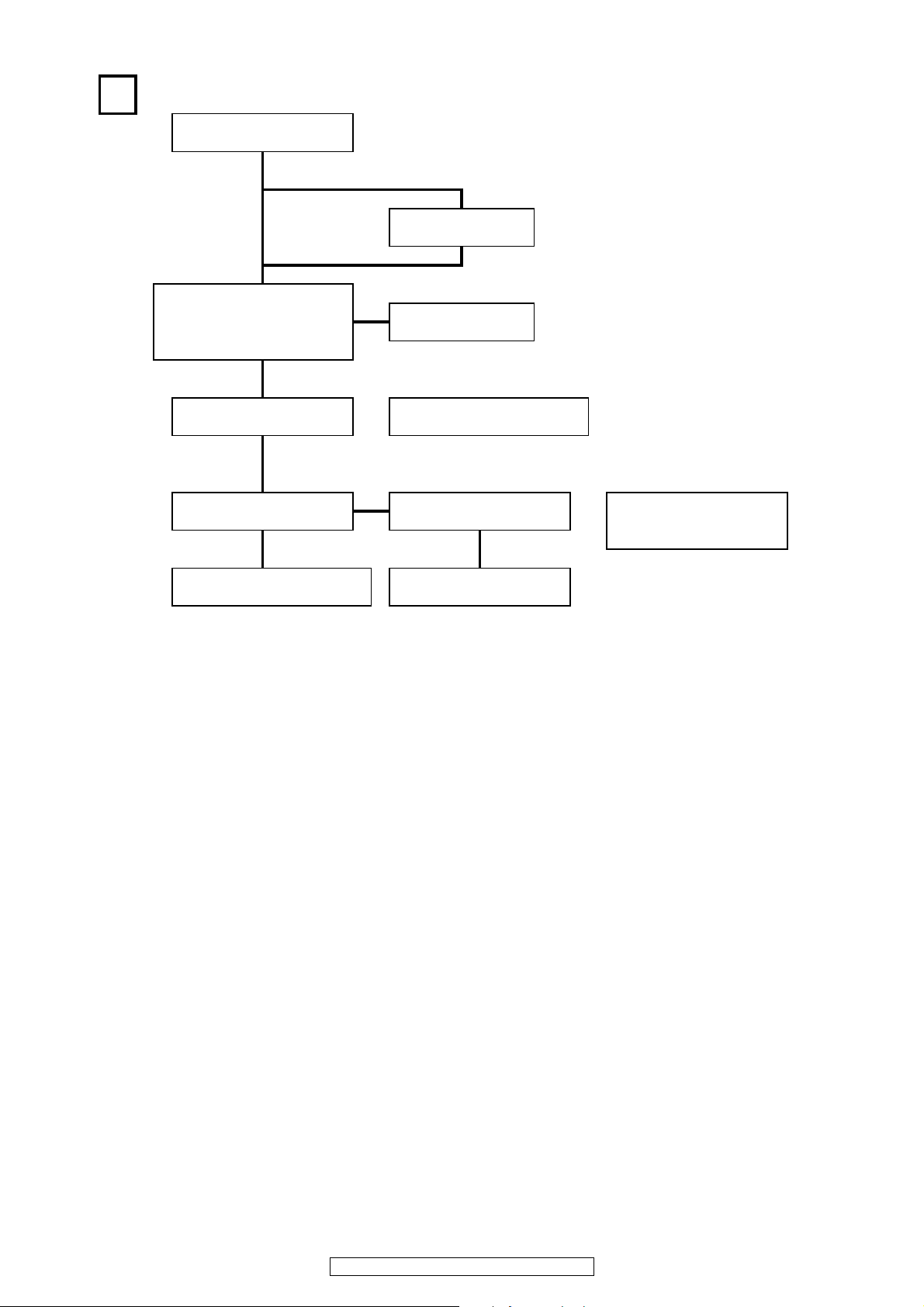

4. CHASSIS BACK

Proceeding : CABINET TOP →PCB SPEAKER ASSY →CHASSIS BACK

Direction of photograph: A

Proceeding : CABINET TOP →PCB SPEAKER ASSY →CHASSIS BACK

→PCB MAIN ASSY

CP1700

CP1002

CP1004

CP1001

CP1003

Style pin : Loose

CP1001

CP1005

CP1501

CP1200

CP1000

CP1003

FFC Cable

Style pin : Loose

cut

cut

(1) Remove the screws.

5. PCB MAIN ASSY

(1) Cut the wire clamp band, then loose the style pin and Cord holder. Disconnect the connector wire and FFC Cable.

11

AVR-1910/1620/1610/790/590

Page 12

(1) Disconnect the connector board.

Board to board

Board to board

Board to board

PCB DIGITAL ASSY

PCB MAIN ASSY

PCB VIDEO ASSY

PCB EXT. ASSY (1910/790 model) PCB INPUT ASSY

PCB HDMI ASSY

(2) Remove the screws.

AVR-1910/1620/1610/790/590

12

Page 13

6. PCB POWER/POWER SUPPLY ASSY

Proceeding : CABINET TOP →PCB POWER/POWER SUPPLY ASSY

cut

cut

CP1705

CP1706

CP1704

CP1700

Style pin : Loose

PCB POWER ASSY

PCB POWER SUPPLY ASSY

ً

(1) Cut the wire clamp band, then loose the style pin and Cord holder. Disconnect the connector wire.

(2) Remove the screws.

AVR-1910/1620/1610/790/590

13

Page 14

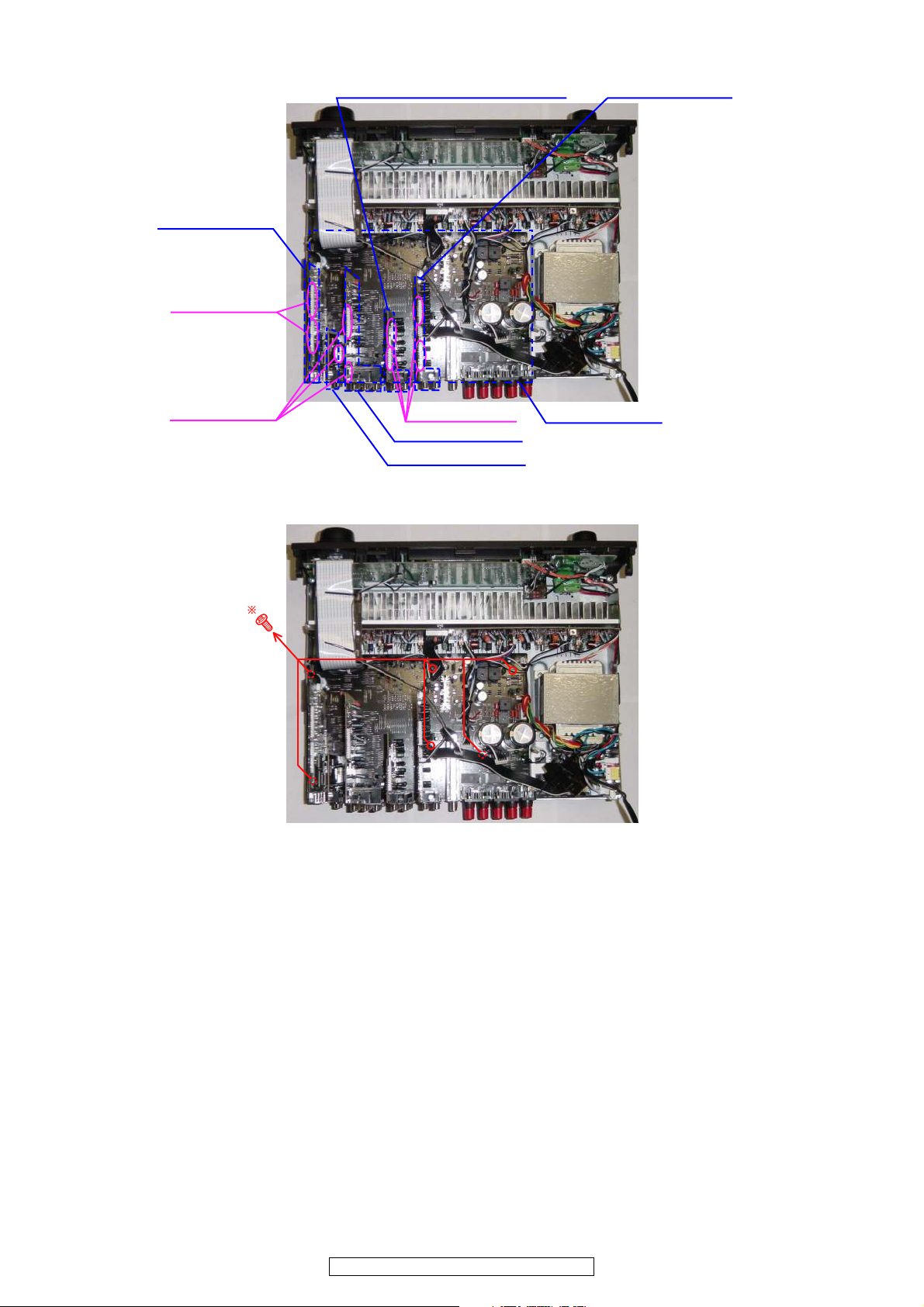

7. PCB AMP ASSY

Proceeding : CABINET TOP →PCB AMP ASSY

View from bottom

FFC Cable

CP1200

CP1003

Style pin : Loose

Style pin : Loose

CP1005

CP1001

CP1001

CP1000

CP1309

CP1501

cut

PCB AMP ASSY

Direction of photograph: D

Style pin : Loose

Direction of photograph: C

(1) Remove the screws.

(2) Cut the wire clamp band, then loose the style pin and Cord holder. Disconnect the connector wire.

(3) Loose the style pin, then remove the screws.

AVR-1910/1620/1610/790/590

14

Page 15

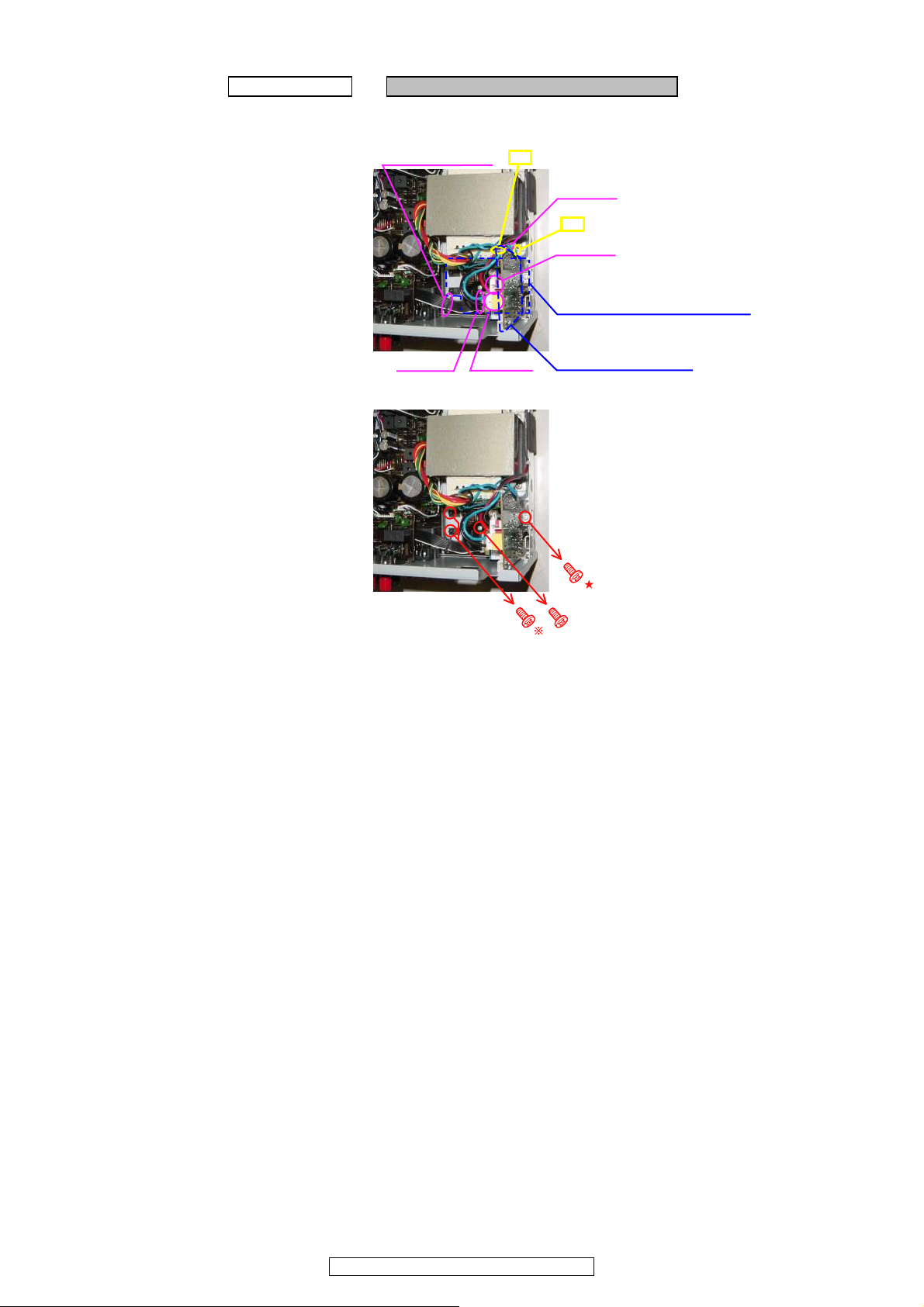

8. TRANS MAIN

Proceeding : CABINET TOP → TRANS MAIN

Direction of photograph: D

Style pin : Loose

CP1002

CP1004

CP1307

CP1300

Cord holder : Loose

(1) Loose the style pin.

(2) Loose the Cord holder, then disconnect the connector wire.

(3) Remove the screws.

AVR-1910/1620/1610/790/590

15

Page 16

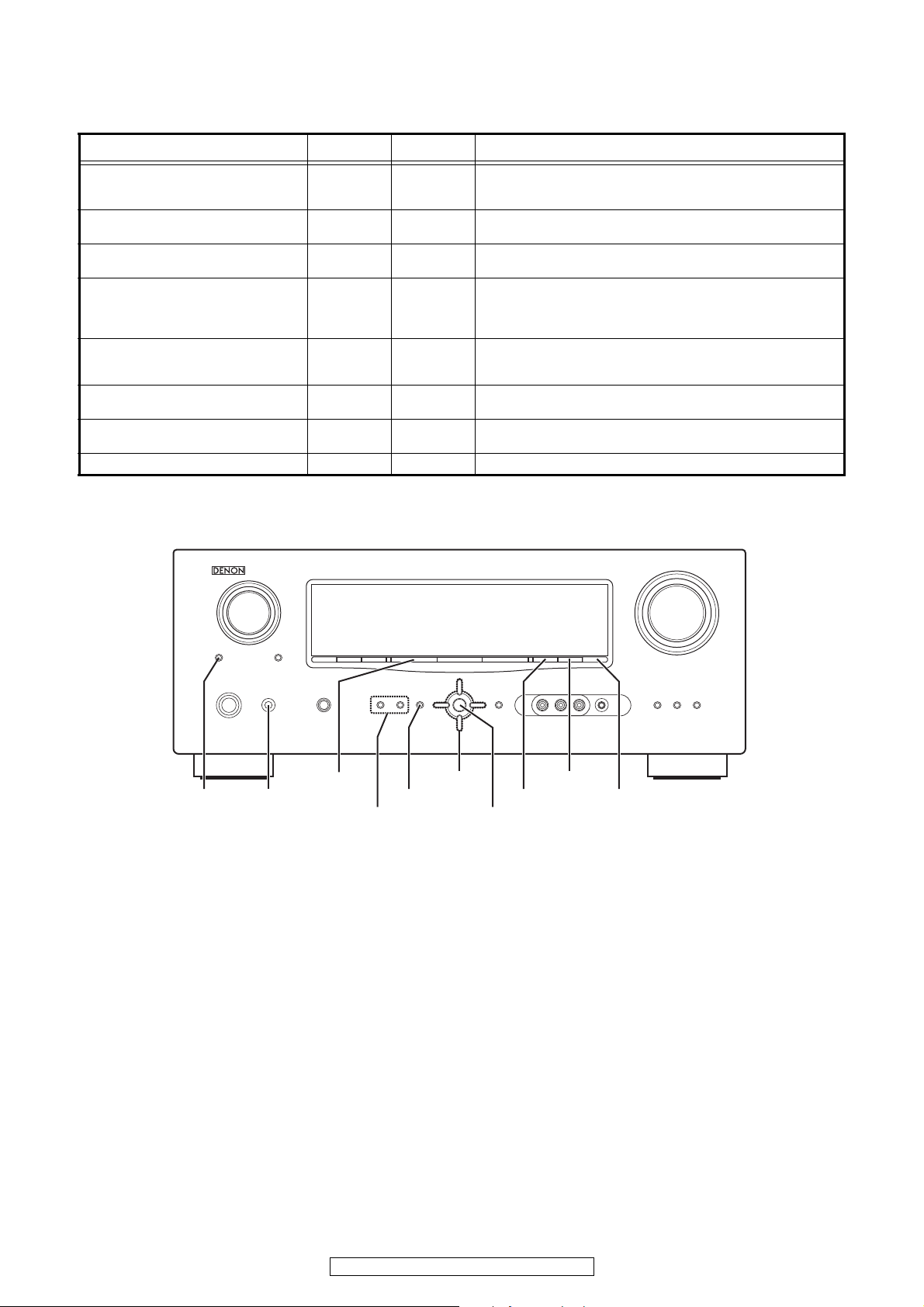

CAUTION IN SERVICING

Note:・If step 3 does not work, start over from step 1.

・ All user settings will be lost and this factory setting will be recovered when this initialization mode.

So make sure to m+emorize your setting for restoring after the initialization.

SURROUND

MODE 0

SURROUND

MODE 1

ON/OFF

Initializing AV SURROUND RECEIVER

AV SURROUND RECEIVER initialization should be performed when the µcom, peripheral parts of µcom, and Digital P.W.B.

are replaced.

1. Switch off the unit.

2. With the "SURROUND MODE 0" and "SURROUND MODE 1" buttons pressed, press the "ON/OFF" button to turn the

power on.

3. Check that the entire display is flashing with an interval of about 1 second, and release your fingers from the 2 buttons and

the microprocessor will be initialized.

JIG to use for servicing

When you repair the printing board, you can use the following JIG (Extension cable kit). Please order to Denon Official Service

Distributor in your region if necessary.

00D SPK- 561 EXTENSION UNIT KIT : 1 Set

00D SPK- 562 9120 CONN. JOINT KIT : 1 Set

When you update the firmware, you can use the following

JIG (RS232C to internal connector conversion adapter with 8P cable kit ). Please order to Denon Official Service Distributor

in your region if necessary.

00DSPK-581 WRITING UNIT : 1 Set

AVR-1910/1620/1610/790/590

16

Page 17

SPECIAL MODE g

0

0

DIMMER

STATUSMULTEQ

ENTER

MENU

SURROUND

0 MODE 1

ON/OFF

CURSOR

SOURCE

RESTORER

Special mode setting button

※Press the ON/OFF button to turn on while pressing both buttons A and B at the same time.

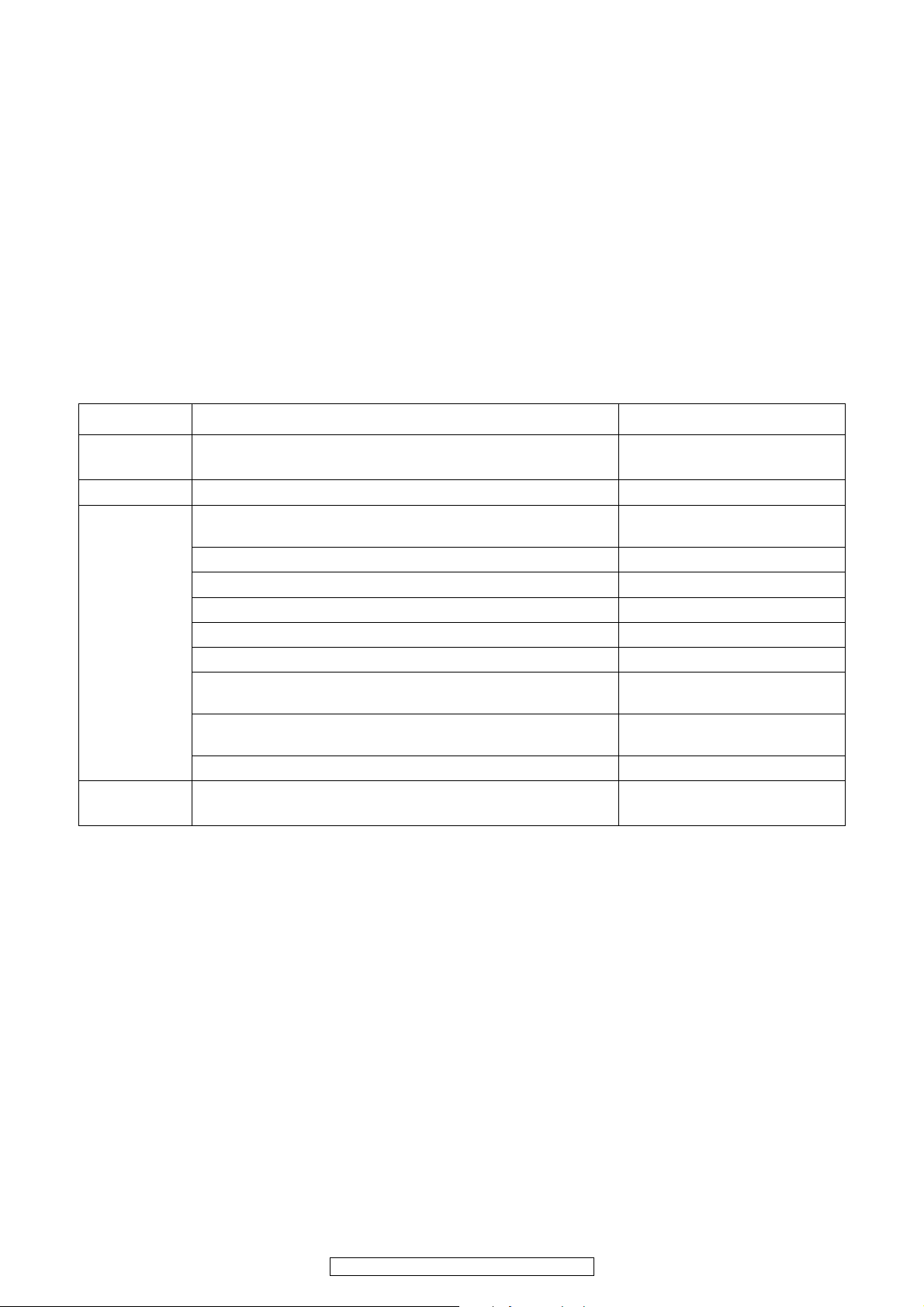

Mode Button A Button B Contents

µcom/DSP Version display mode

Errors checking mode

(Displaying the protection history)

Initialization mode

Mode for switching tuner frequency step

Mode for preventing remote control

acceptance

Panel lock mode

Panel lock mode

(Remove Master volume)

Cancellation of panel lock mode MENU RESTORER Panel lock mode is cancelled.

STATUS DIMMER

STATUS MULT EQ

SURROUND

MODE0

SOURCE

CURSOR 0 RESTORER

SURROUND

MODE0

SURROUND

MODE1

SURROUND

MODE1

-

(non)

RESTORER

RESTORER Operations using main unit panel buttons are rejected.

Serial No. and firmware versions such as Main, Sub, DSP are

displayed in the FL manager. Errors are displayed when they

occur. (Refer to 18 page.)

Displaying the protection history

(Refer to 19 page.)

Backup data initialization is carried out.

(Refer to 16 page.)

---E2 model only--Select with the SOURCE 01 button.

Change tuner frequency step to AM9k/FM50kHz STEP or AM:10k/

FM:200kHz.

Operations using remote control are rejected.

(Mode cancellation: Turn off power and execute the same button

operations as when performing setup.)

Operations using main unit panel buttons or master volume are

rejected.

AVR-1910/1620/1610/790/590

17

Page 18

1. µcom/DSP Version display mode

1.1. Operation specifications

µcom/DSP version display mode:

When started up, the version information is displayed.

Starting up:

With the "DIMMER" and "STATUS" buttons pressed, press the "ON/OFF" button to turn the power on.

Now, press the "STATUS" button to the display the 2nd item information on the FL Display.

1.2. Display Order

Destination information →Main-µcom version information →Sub-µcom version information → DSP version information

→ APLD version information

1.3. Error display g

See the following table for each "Error information" display and its contents (status).

Display order is ①②③④.

Condition State Display

①Sub-µcom

NG

②DIR NG

③DSP NG

Both SUB/DSP

④

OK

No response from Sub-µcom

No response from DIR

When DSP boot, executing DSP reset makes no change to DSP FLAG0

port "H".

No change to DSP FLAG0 port "H" before issuing DSP command.

When DSP data read, executing WRITE="L" makes no change to ACK="H".

When DSP data read, executing REQ="L" makes no change to ACK="L".

When DSP data write, executing WRITE="H" makes no change to ACK="H".

When DSP data write, executing REQ="L" makes no change to ACK="L".

When DSP special code boot, executing DSP reset makes no change to

DSP FLAG0 port "H".

No change to DSP FLAG0 port "H" before issuing DSP special read com-

mand.

No change to DSP FLAG0 port "H" before DSP version read.

"□SUB□ □ERROR□01□□"

"□DIR□ □ERROR□01□□"

"□DSP□□ERROR□01□ □"

"□DSP□□ERROR□02□ □"

"□DSP□□ERROR□03□ □"

"□DSP□□ERROR□04□ □"

"□DSP□□ERROR□05□ □"

"□DSP□□ERROR□06□ □"

"□DSP□□ERROR□11□ □"

"□DSP□□ERROR□12□ □"

"□DSP□□ERROR□13□ □"

(No error display, version display

only)

18

AVR-1910/1620/1610/790/590

Page 19

2. Errors checking mode (Displaying the protection history)

2.1. Operation specifications

Error mode (Displaying the protection history):

When started up, the error information is displayed.

Starting up:

●All model commonness

With the "STATUS" and "MULTEQ" buttons pressed, press the "ON/OFF" button to turn the power on. The error (protection

history display) mode is set.

Now, press the "STATUS" button to turn on the FL display.

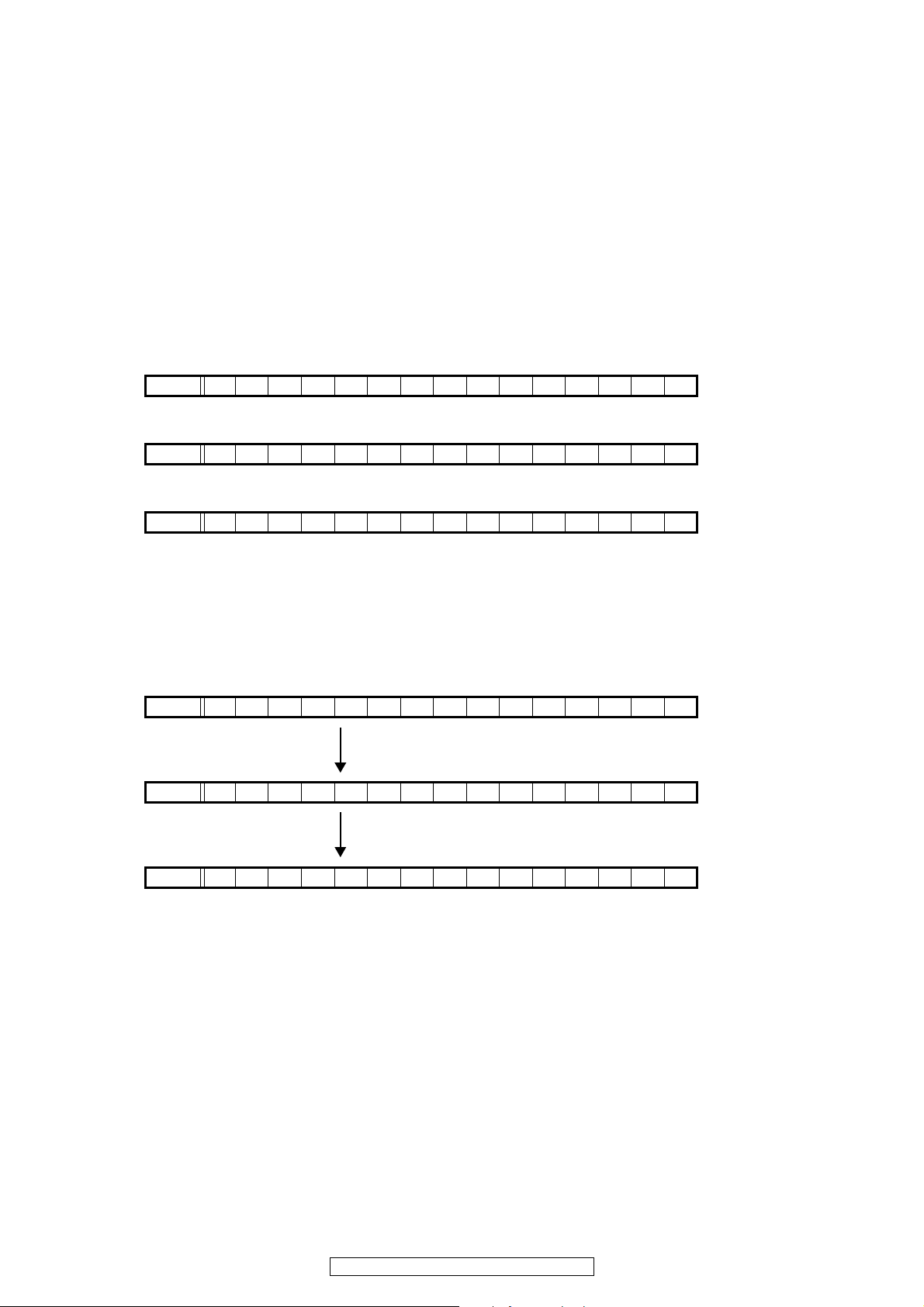

2.2. About the display on the FL display

When the "STATUS" button is pressed after setting the error (protection history display) mode, a history like the one shown

below is displayed, depending on the conditions.

(1) Normally (when there has been no protection incident)

FLD N O P R O T E C T

(2) For ASO/DC (when the last protection incident was ASO or DC protection)

FLD P R T : A S O / D C

(3) For THERMAL (when the last protection incident was THERMALprotection)

FLD P R T : T H E R M A L

When the "STATUS" button is pressed again after the above protection history is displayed, the normal display reappears.

2.3. Clearing the protection history

There are two ways to clear the protection history, as described below.

(1) Start up the error (protection display) mode, display the error, then press and hold in the "ENTER" button for 3 seconds.

FLD : T H E R M A L T H E

Press and hold in the "ENTER" button for 3 seconds

FLD P R T : C L E A R

The above is displayed and the protection history is cleared.

FLD

(2) Initialize.

※If you want to save a backup, use the method in 3.(1) above.

NO PROT E C T

Warning indication by the POWER LED

If the power is turned off when a protection incident has been detected, the POWER LED (red) flashes as a warning according to the conditions in which the protection incident occurred.

(1) ASO/DC PROTECTION : Flashes in cycles of 0.5 seconds (0.25 seconds lit, 0.25 seconds off)

(2) THERMAL PROTECTION : Flashes in cycles of 2 seconds (1 second lit, 1 second off)

19

AVR-1910/1620/1610/790/590

Page 20

ADJUSTMENT

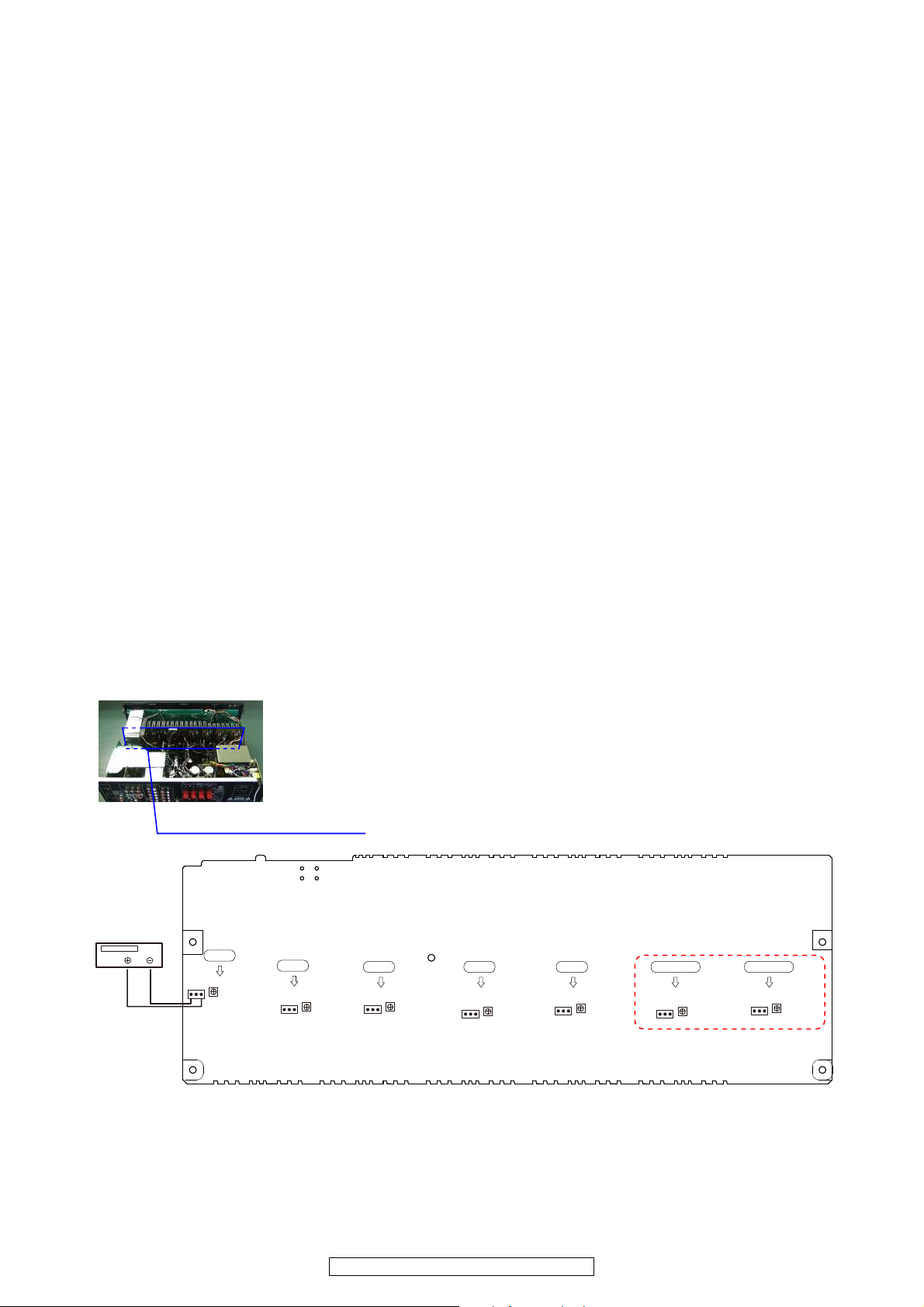

5CH AMP UNIT (1610/1620/590 model)

7CH AMP UNIT (1910/790 model)

7CH AMP UNIT (1910/790 model)

DC Voltmeter

F Lch

S Lch

C ch

S Rch

F Rch

S Back Lch

S Back Rch

T1201FL

T1201SL

V1201FL

V1201SL

T1201C

V1201C

T1201SR

V1201SR

T1201FR

V1201FR

T1201SBL

V1201SBL

T1201SBR

V1201SBR

Audio Section

Idling Current

Required measurement equipment: DC Voltmeter

1. Preparation

(1) Avoid direct blow from an air conditioner or an electric fan, and adjust the unit at normal room temperature

15 °C ~ 30 °C (59 °F ~ 86 °F).

(2) Presetting

• POWER (Power source switch) OFF

• SPEAKER (Speaker terminal) No load

(Do not connect speaker, dummy resistor, etc.)

2. Adjustment

(1) Remove top cover and set VR1201 FL, FR, C, SL, SR, SBL, SBR on 7CH AMP UNIT at fully counterclockwise (c)

position(1910/790 model).

(1’) Remove top cover and set VR1201 FL, FR, C, SL, SR on 5CH AMP UNIT at fully counterclockwise (c) position(1610/

1620/590 model).

(2) Connect DC Voltmeter to test points (FRONT-Lch: TP1201, FRONT-Rch: TP1205, CENTER ch: TP1203, SUR-

ROUND-Lch: TP1202, SURROUND-Rch: TP1204, SURROUND-BACK Lch: TP1207(1910/790 model), SURROUNDBACK Rch: TP1206 (1910/790 model)).

(3) Connect power cord to AC Line, and turn power switch "ON".

(4) Presetting.

MASTER VOLUME : "---" counterclockwise (c min.)

SPEAKER (Speaker terminal) : No load

(Do not connect speaker, dummy resistor, etc.)

MODE : 7CH STEREO (5CH STEREO)

FUNCTION : CD

(5) Within 2 minutes after the power on, turn VR1201 clockwise (x) to adjust the TEST POINT voltage to 1.5 mV ± 0.5 mV

DC.

(6) After 10 minutes from the preset above, turn VR1201 to set the voltage to 2.0 mV ± 0.5 mV DC.

(7) Adjust the Variable Resistors of other channels in the same way.

20

AVR-1910/1620/1610/790/590

Page 21

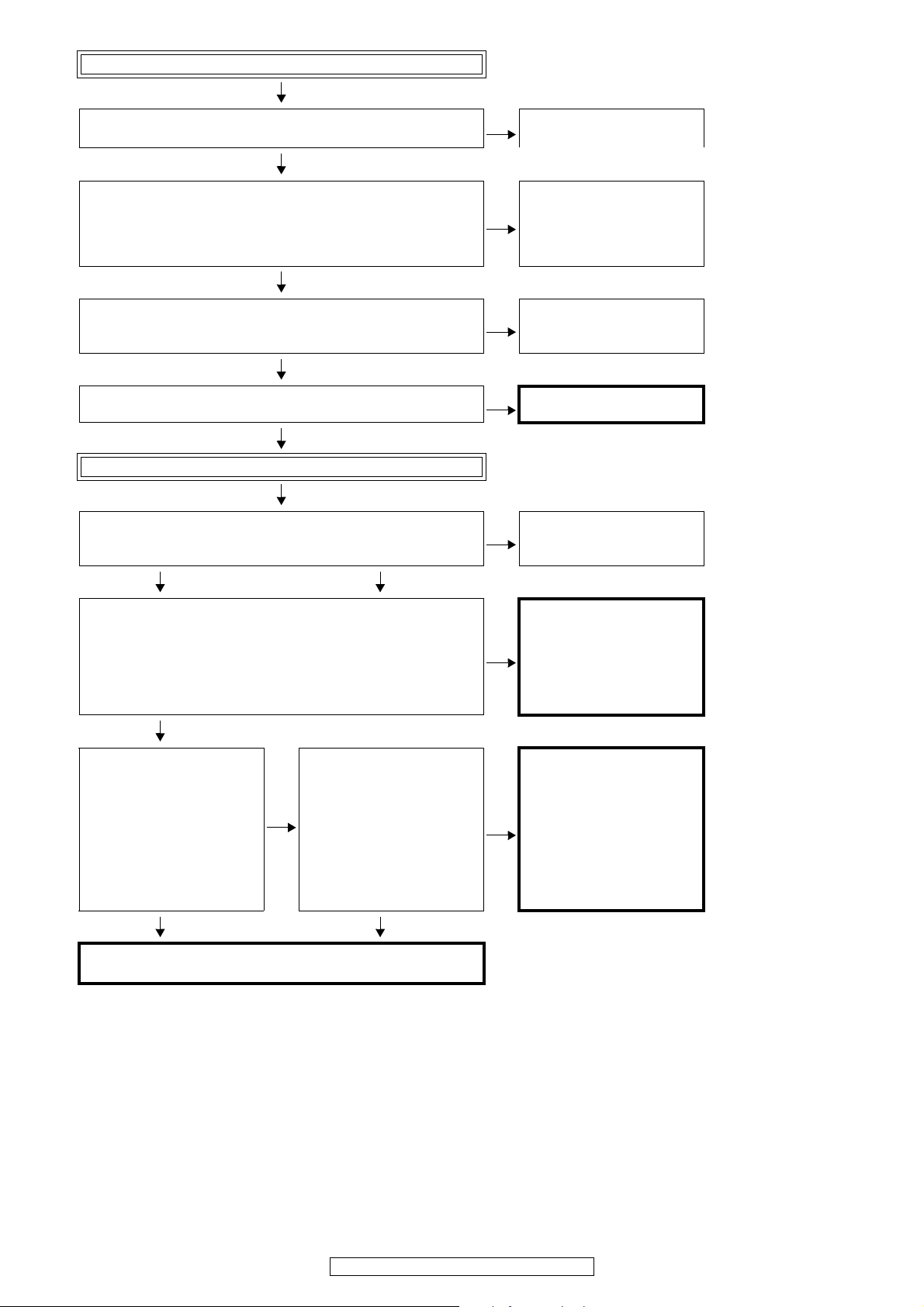

TROUBLE SHOOTING

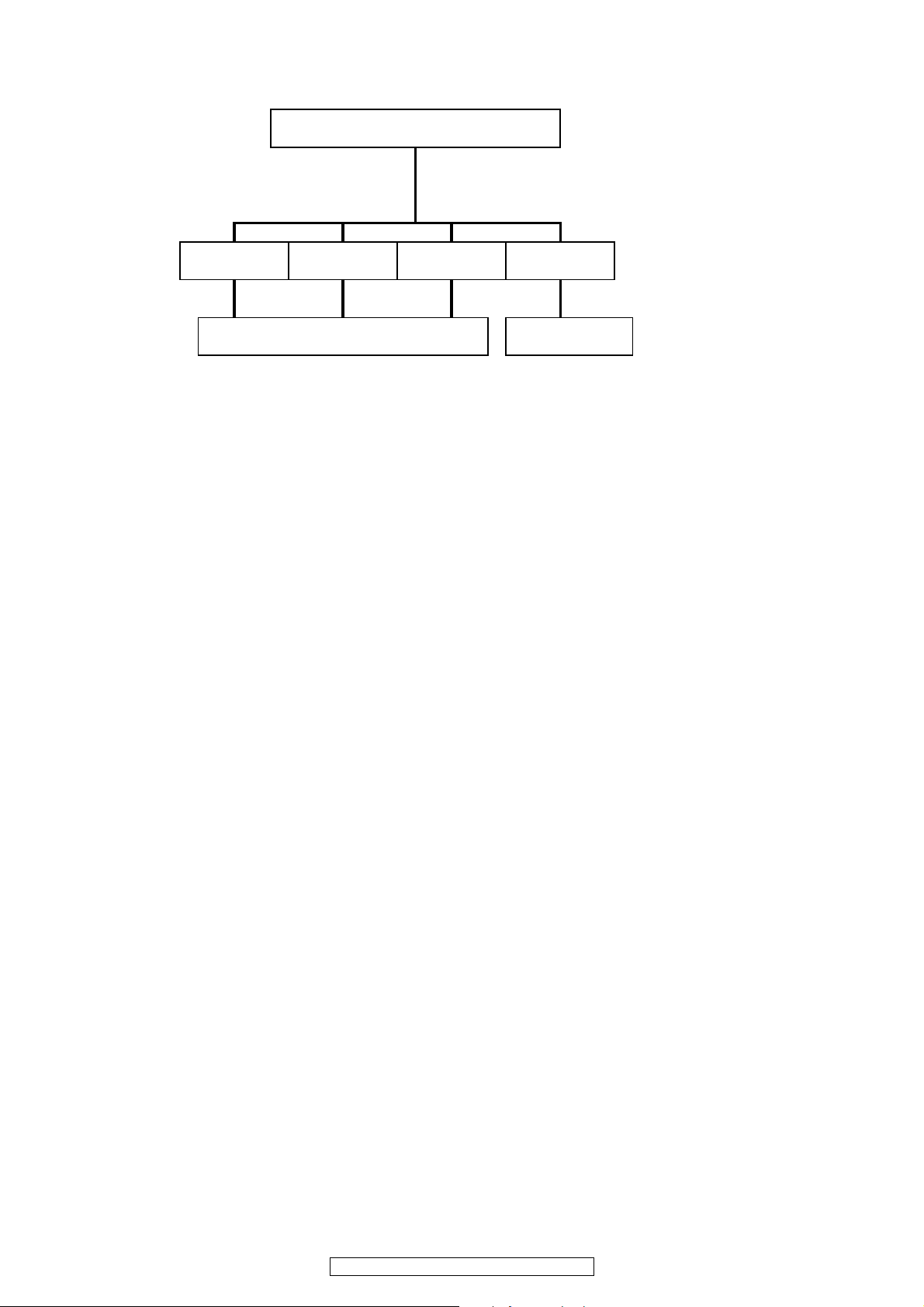

1. POWER

1.1. Power not turn on

Power not turn on

YES

Is the ON/STANDBY indicator on the front panel flashing

red?

YES

Is the fuse blown?

YES

Does the power turn on when

the POWER switch is turned

off then back on?

YES YES YES

Check the primary circuitry

parts including the POWER

switch (for poor contacts,

etc.), and replace any defective parts.

Are there any incomplete

connections in the connec-

NO

tors connecting between the

various circuit boards?

YES YES

Connect the connectors

properly.

NO

NO

Refer to Fuse is blown

Is a DC 5V voltage being

supplied from the POWER

B’D (CN1701 pin 4) to the

microprocessor?

Check the microprocessor

periphery circuitry and

replace any defective parts.

Is there a short circuit

NO

between the speaker terminals and the ground?

Check for damage in the

power amplifier circuitry parts

and replace any defective

parts.

Is a DC 5V voltage output

when the cord supplying the

NO

power from the SUPPLY B’D

to the microprocessor

(CP1700) is unplugged?

Check the circuitry and parts

from CP1700 on the SUPPLY B’D to the microprocessor for damage and shortcircuits, and replace any

defective parts.

Correct the short circuit

NO

between the speaker and

the ground.

Check the parts from

IC1703 to the primary cir-

NO

cuitry and replace any

defective parts.

1.2. Fuse is blown

YES YES YES

Check for leaks or short circuits in the primary side

parts, and replace any defective parts.

YES YES YES

Fuse is blown

Check for short circuits in the

rectifier diodes and circuitry

of the secondary side rectifying circuits, and replace any

defective parts.

After repairing, also replace the fuse.

Check for short circuits in the

power stabilizer unit's regulator output terminal and the

ground, and replace any

defective parts.

21

AVR-1910/1620/1610/790/590

Page 22

2. Analog video

※

※

MONITOR OUT (CVBS/COMPONENT) output NG

When checking operation, select

VCR for the function.

DVR MONITOR OUT(CVBS) Output NG

C

Input

CVBS/S

B

Input

COMPONENT

Input

CVBS/S

When checking operation, select

VCR for the CVBS/S and select

DVD for the COMPONENT.

A

2.1. MONITOR OUT (CVBS/COMPONENT) output NG

DVR MONITOR OUT (CVBS) output NG

AVR-1910/1620/1610/790/590

22

Page 23

Input S

Input CVBS

OK

OK

Check V±5V,4094_PWR(+5V)

OK

Check input selector and

surrounding circuitry soldering.

Output V:

IC1901 24pin

Input V:

Check output of input selector.

To troubleshooting 1.1

Power not turn on.

+5V:

CN1018 3pin

Check connection of

iPod Doc.

Check input of VIDEO buffer.

Check surrounding circuitry

soldering of OSD IC.

Check input of OSD IC.

Input V:

IC1905 17pin

IC1901 12pin

OK

NG

Check input selector and

surrounding circuitry soldering.

Input

COMPONENT

V±5V

NG

OK

A

Input

CVBS or S

-5V:

CN1018 4pin

4094_PWR(+5V):

-5V:

CN1018 4pin

To troubleshooting 1.1

Power not turn on.

NG

CN1018 3pin

+5V:

B

Check output of input selector. NG

Output V:

IC1906 3pin

Check output of VIDEO buffer.

IC1905 13pin

NG

Check cable between main unit

and monitor or check monitor.

OK

CN1018 1pin

Check output of VIDEO buffer

(IC19000A) and surrounding

circuitry soldering.

Check output of VIDEO buffer

(IC1904B) and surrounding

circuitry soldering.

NG

OK

NG

NGCheck output of OSD IC.

Output V:

OK

Check cable between main unit

and monitor or check monitor.

IC1907 24pin

IC1907 22pin

IC1907 20pin

Output Y:

Output Cb:

Output Cr:

Check surrounding circuitry

soldering of VIDEO buffer.

AVR-1910/1620/1610/790/590

23

Page 24

Input S

Input CVBS

-5V:

OK

Check surrounding circuitry

soldering of VIDEO buffer.

OK

Check output of VIDEO buffer

(IC1904B) and surrounding

circuitry soldering.

Output V:

IC1901 33pin

Input V:

IC1901 3pin

OK OK

Check input selector and

surrounding circuitry soldering.

Output V:

IC1906 3pin

Check output of VIDEO buffer. NG Check input of VIDEO buffer. NG

Check output of input selector. NG

C

Input

CVBS/S

CN1018 3pin

4094_PWR(+5V):

+5V:

Check connection of

iPod Doc.

To troubleshooting 1.1

Power not turn on.

CN1018 4pin

NG

Check V±5V,4094_PWR(+5V)

CN1018 1pin

Check cable between main unit

and monitor or check monitor.

24

AVR-1910/1620/1610/790/590

Page 25

2.2. HDMI OUT Output NG (AVR-1910/790 model)

※

HDMI OUT output NG

Input

CVBS

Input

S

When checking operation, select

DVD for the function.

(COMPONENT1 input)

Input

COMPONENT

Input

HDMI

To troubleshooting

HDMI/DVI.

D

25

AVR-1910/1620/1610/790/590

Page 26

OK

※

D

+5V:

CN1018 3pin

Check connector base

soldering of CNT 1 B'D and

incomplete connection of B'D.

To troubleshooting HDMI/DVI.

Unless specified, HDMI B'D part.

OK

Input Cb:

Input Cr:

CN1102 7pin

CN1102 9pin

Input

CVBS/S/OMPONENT

OK

HDMI B'D

Check input of video decoder signal.

To troubleshooting 1.1 Power not

turn on.

Check output of CVBS VIDEO buffer

(IC1900A) of VIDEO B'D and

COMPONENT input selector (IC1907

24,22,20pin).

NG NG

To A or B

Input V:

Input Y:

CN1102 3pin

CN1102 5pin

+1.8V:

L3 and L4

OK

CN1018 4pin

-5V:

CN1018 1pin

4094_PWR(+5V):

NG

To troubleshooting 1.1

Power not turn on.

OK

NG

Check of power supply voltage .

+3.3V:

Emitter side of Q24 and L2

Check surrounding circuitry

soldering of IC19, IC29 and IC35.

Check of power supply voltage

(VIDEO B'D).

26

AVR-1910/1620/1610/790/590

Page 27

3. HDMI/DVI

3.1. No picture or sound is output

No picture or sound is output

Check the HDMI/DVI cable

connection

Is the HDMI/DVI cable properly

connected?

Are you using an HDMI/DVI

selector, repeater or a device

for improving picture quality?

Are you using a certified HDMI

cable (one with the HDMI

stamp)?

Are you using an HDMI/DVI

cable less than 5 meters in

length?

YES

YES

YES

NO

YES

There may be a problem with

NO

the HDMI/DVI cable. Check the

connection.

Disconnect everything and

YES

connect only the HDMI/DVI

cable to check.

Use a certified HDMI cable

NO

(one with the HDMI stamp).

Replace the HDMI/DVI cable

with one that is less than 5

NO

meters in length (2 meters

recommended) to check.

YES

Are the picture and sound

output when another HDMI/DVI

cable is used?

NO

Checking the DVD player

YES

Is the DVD player's HDMI

output setting correct?

YES

When using a DENON DVD player, is the fluorescent display tube's

"HDMI" indicator lit?

If using a non-DENON DVD player, proceed to "YES".

YES

Are the picture and sound

NO

Is sound output from the set's speaker terminals when the TV's power is

turned off or the connection cable between the TV and the set is

disconnected?

output when the DVD player's

resolution is changed?

NO

The HDMI/DVI cable is

YES

defective.

Check the HDMI output setting,

YES

referring to the DVD player's

operating instructions.

Set the DVD player's output

YES

resolution to a resolution with

which the TV is compatible.

The DVD player may not be

compatible with HDCP

YES

repeaters. Ask the DVD

player's manufacturer.

NO

Are the picture and sound

output when a different DVD

player is used?

NO

27

AVR-1910/1620/1610/790/590

YES

The DVD player is defective.

Page 28

Check the TV

Is the TV HDCP-compatible?

YES

Is the TV compatible with resolutions of 1080P?

YES

Is the TV's input set to HDMI?

YES

Use an HDCP-compatible TV.

NO

PC TVs cannot be used.

If the TV is not compatible with

resolutions of 1080P, no picture

NO

will be output, even if the DVD

player's resolution is set to

1080P.

Check the TV's input setting,

NO

referring to the TV's operating

instructions.

Are the picture and sound output when a different TV is used?

YES

Check the set (AVR-4310CI)

Is the set's input set to HDMI?

YES YES

The set does not recognize the TV.

Is the TV information properly displayed on the "Monitor info." display

menu?

Is IC5 pin 3 "H" (3V-5V)? With the TV connected, check the voltage of

the IC on the side on which the TV is connected.

YES

The DVD player does not

recognize the connection

When using a DENON DVD

player, is the fluorescent

display tube's "HDMI" indicator

lit?

If using a non-DENON DVD

player, proceed to "NO".

with the set.

Is the HDMI connector (JACK1/

NO

JACK2/JACK3/JACK4) pin 19

"H" (5V)? With the DVD player

connected, check the voltage

of the HDMI connector for the

input on the side on which the

DVD player is connected.

NO

The TV is defective.

Check the set's input setting,

NO

referring to the set's operating

instructions.

The pattern and circuit from

the HDMI connector (JACK5)

to the IC (IC5) is defective, or

NO

the HDMI output circuitry is

defective.

(IC5/IC31 and surrounding

circuitry)

The pattern and circuit from

the HDMI connector (JACK1/

NO

JACK2/JACK3/JACK4) to the

IC1045 is defective.

YES YES

The HDMI output circuitry is defective.

(IC1/IC31/IC5 and surrounding circuitry)

28

AVR-1910/1620/1610/790/590

Page 29

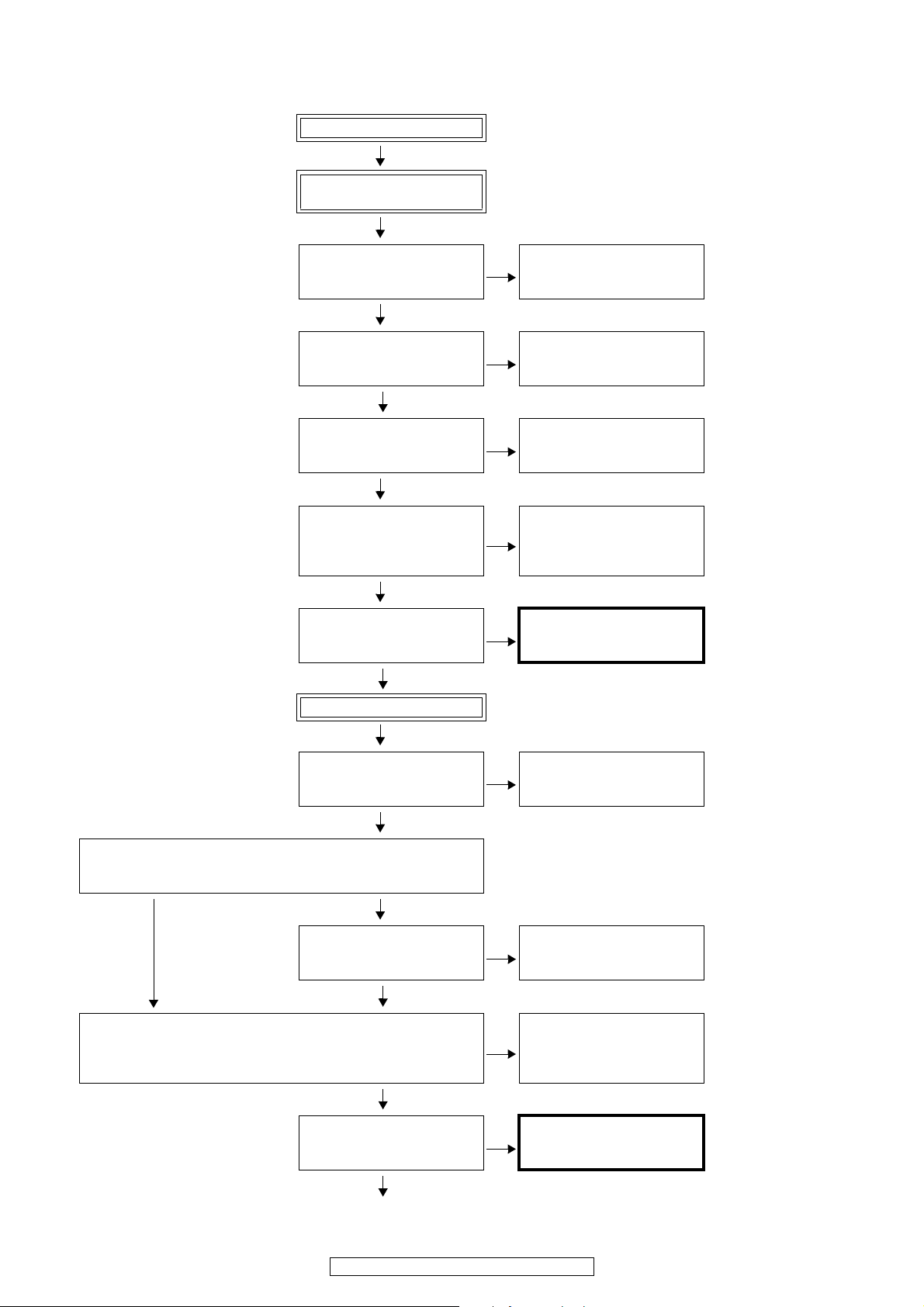

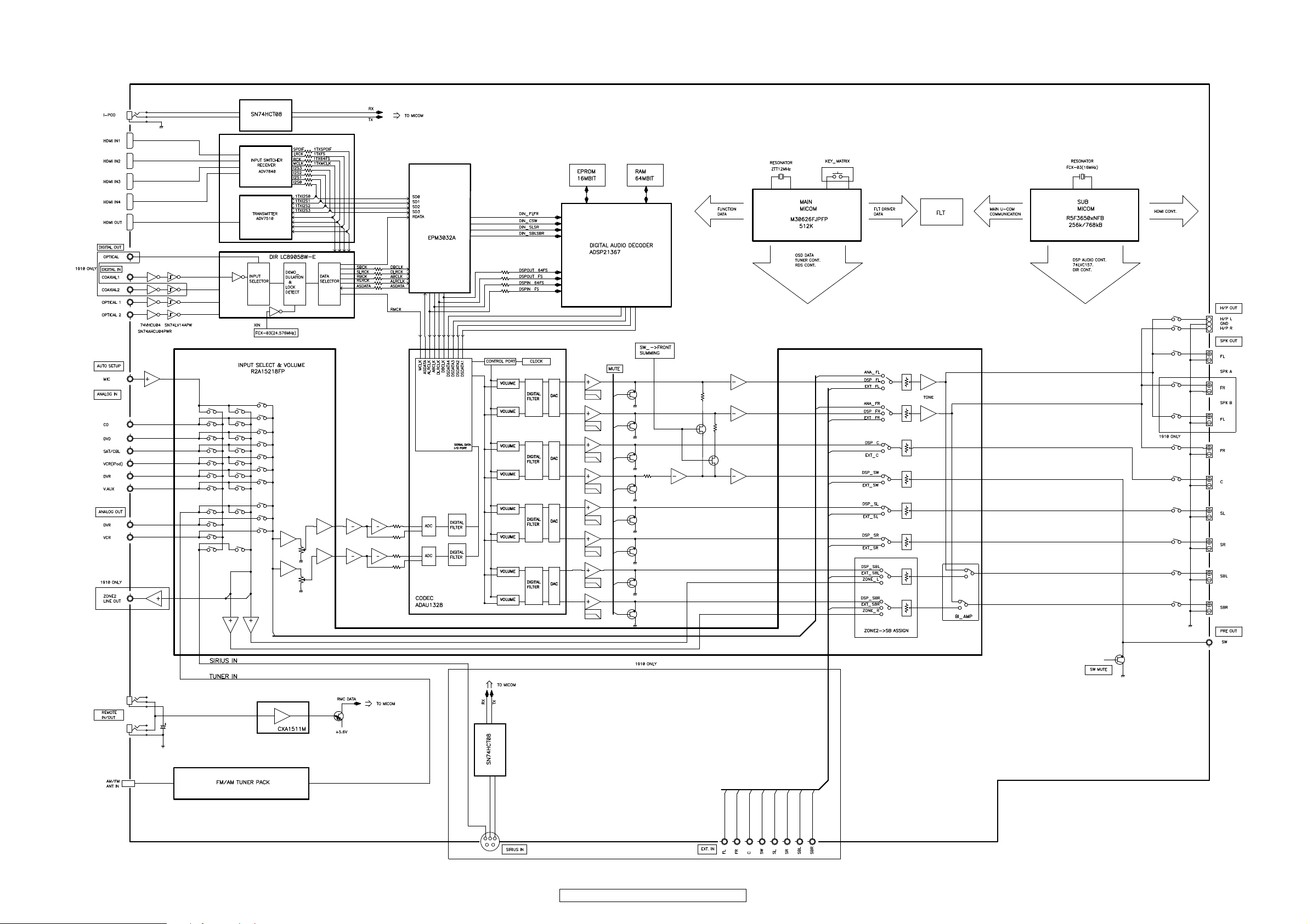

BLOCK DIAGRAM

AUDIO BLOCK DIAGRAM

29

AVR-1910/1620/1610/790/590

Page 30

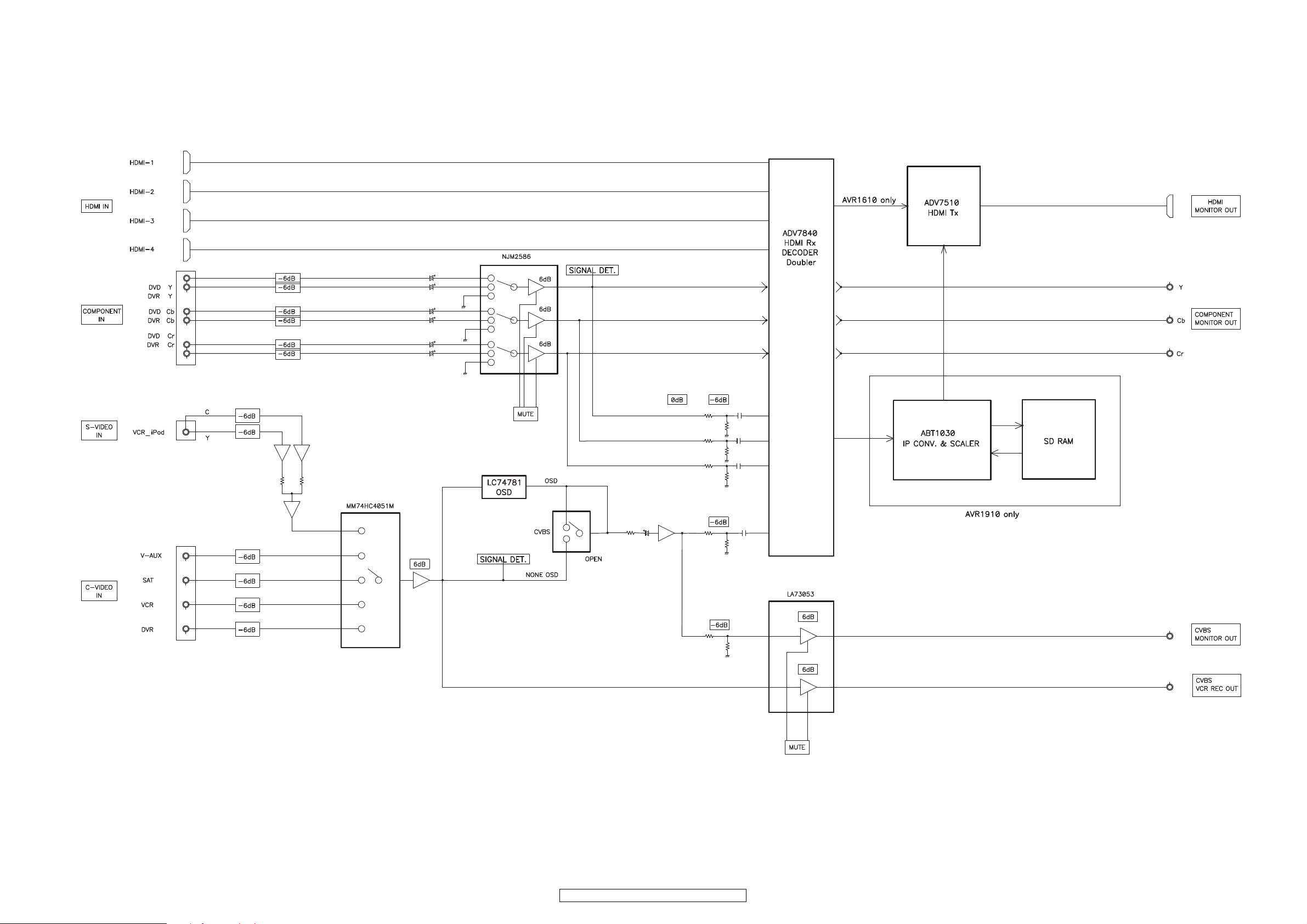

VIDEO BLOCK DIAGRAM

30

AVR-1910/1620/1610/790/590

Page 31

VCC DIAGRAM

S4(VIDEO)

S1(AMP +B)

S5(-VKK)

S6(FILAMENT)

MAIN TRANS

S3(DSP.HDMI)

S2(+12V,-12V)

AVR1910 ONLY

SUB TRANS

AC CORD

AC OUTLET

AVR1910 ONLY

31

AVR-1910/1620/1610/790/590

Page 32

LEVEL DIAGRAMS

F$

F$

F$

&52

F$

010%.+%2/#:5+)0#..'8'.8TOU

%QPHKIޓ&1.$;.+/+6.'8'.8TOU#..EJF$(5

F$

57/(41/59EJ

%QPHKIޓ&1.$;.+/+6.'8'.#..EJF$(5

8

FRONT LEVEL DIAGRAM

4#(2

LEVEL DIAGRAM

FRONT ch

#0#.1)

#66

*2176

.+0'+0

#8410.;

':6+0

F$

F$

ޓF$

O8

F$

F$

㧗

㧗

.+0'+0':6+0#845GTKGU

#8410.;

61

5WTTQWPF$CEM

<10'/1&'

㧗㧙

㧗

)#+0

#&,

#&

#

F$(5&+)+0

2%/QT&&%QPHKI

F$(5#&+0

F$(5&+)+0

ޓ&&%QPHKI

&#

F$(5

8TOU

F$(5

F$(5

F$(5

F$(5

㧙

(41/59EJ

F$

㧙

°

/76'

㧗

㧙

㧙

F$

㧙

#

F$(5

F$(5

F$(5

#&+0

O8TOU

F$(5

52'#-'4

4'%176

F$

52176

8TOUǡ

F$

F$

4'%176

ޓF$

*2176

O8TOU

F$

F$

176

F$

F$

F$(5

F$(5

F$

F$

32

AVR-1910/1620/1610/790/590

Page 33

CENTER LEVEL DIAGRAM

F$

F$

F$

010%.+%2/#:5+)0#..'8'.8TOU

%QPHKIޓ&1.$;.+/+6.'8'.#..EJF$(5

F$

%QPHKIޓ&1.$;.+/+6.'8'.#..EJF$(5

&52

LEVEL DIAGRAM

CENTER ch

4#(2

#8410.;

':6+0

F$

F$

O8

ޓF$

F$

F$

㧗

':6+0#845GTKGU

㧗

㧗

#&

㧙

#

F$(5&+)+0

2%/QT&&%QPHKI

F$(5#&+0

F$(5&+)+0

ޓ&&%QPHKI

F$(5

8TOU

&#

F$(5

F$(5

F$(5

F$(5

㧗

F$

㧙

°

/76'

)#+0

#&,

52'#-'4

F$

52176

8TOUǡ

F$

F$

ޓF$

F$

F$

176

F$

F$

F$(5

F$

F$

33

AVR-1910/1620/1610/790/590

Page 34

SUB WOOFER LEVEL DIAGRAM

F$

2.&

&52

010%.+%2/#:5+)0#..'8'.8TOU

%QPHKIޓ&1.$;.+/+6.'8'.#..EJF$(5

F$

%QPHKIޓ&1.$;.+/+6.'8'.ޓ#..EJF$(5

8

57/VQ(4106EJ

LEVEL DIAGRAM

SUBWOOFER ch

4#(2

#8410.;

':6+0

F$

F$

ޓF$

O8

F$

F$

F$

㧗

':6+0#845GTKGU

㧗

#&

#

㧙

F$(5

8TOU

F$(52%/+0

F$(5#&+0

F$(5&+)+0

ޓ&&%QPHKI

&#

#

F$(5

F$(5

F$(5

F$(5

F$(5

㧙

)#+0

㧗

F$

㧙

㧙㧙㧙

F$

°

/76'

F$

57/VQ(4106EJ%QPHKI

#&,

F$

F$

F$

24'176

O8TOU

ޓF$

24'176

O8TOU

F$

F$

F$

24'176/76'

F$

F$(5

F$

34

AVR-1910/1620/1610/790/590

Page 35

SURROUND LEVEL DIAGRAM

F$

F$

F$

010%.+%2/#:5+)0#..'8'.8TOU

%QPHKIޓ&1.$;.+/+6.'8'.8TOU#..EJF$(5

F$

%QPHKIޓ&1.$;.+/+6.'8'.8TOU#..EJF$(5

&52

LEVEL DIAGRAM

SURROUND ch

4#(2

':6+0

#8410.;

㧗

F$

F$

㧗

㧗

#&

㧙

#

F$(5

8TOU

&#

F$(5

㧗

㧙

°

/76'

)#+0

#&,

52'#-'4

F$

52176

8TOUǡ

F$

F$

176

O8

':6+0#845GTKGU

ޓF$

F$

F$

F$

F$

F$(5

F$(5&+)+0

2%/QT&&%QPHKI

F$(5#&+0

F$(5&+)+0

ޓ&&%QPHKI

F$(5

F$(5

F$(5

F$

35

AVR-1910/1620/1610/790/590

ޓF$

F$

F$

F$

F$

Page 36

SURROUND BACK LEVEL DIAGRAM (1910/790 model)

F$

F$

F$

010%.+%2/#:5+)0#..'8'.8TOU

%QPHKIޓ&1.$;.+/+6.'8'.8TOU#..EJF$(5

F$

%QPHKIޓ&1.$;.+/+6.'8'.8TOU#..EJF$(5

F$

&52

LEVEL DIAGRAM

SURR.BACK ch

4#(2

#8410.;

':6+0

O8

F$

F$

':6+0#845GTKGU

ޓF$

F$

F$

F$

㧗

㧗

#&

㧙

㧗

#

F$(5#&+0

F$(5&+)+0

&&':%QPHKI

F$(5&+)+0

&&':%QPHKI

&#

F$(5

8TOU

F$(5

F$(5

F$(5

F$(5

F$(5

㧗

F$

㧙

°

/76'

)#+0

#&,

52'#-'4

176

F$

52176

8TOUǡ

52176°

8TOUǡ

F$

F$

ޓF$

F$

F$

F$

F$

F$

36

AVR-1910/1620/1610/790/590

Page 37

SURROUND BACK LEVEL DIAGRAM (1610/1620/590 model)

F$

010%.+%2/#:5+)0#..'8'. 8TOU

%QPHKIޓ&1.$;.+/+6.'8'.8TOU#..EJF$(5

F$

%QPHKIޓ&1.$;.+/+6.'8'.8TOU#..EJF$(5

F$

&52

LEVEL DIAGRAM

SURR.BACK ch

4#(2

24'176

O8

F$

F$

ޓF$

F$

F$

F$

':6+0

㧗

#&

㧙

#

F$(5#&+0

F$(5&+)+0

&&':%QPHKI

F$(5&+)+0

&&':%QPHKI

&#

F$(5

8TOU

F$(5

F$(5

F$(5

F$(5

F$(5

㧗

F$

㧙

°

/76'

)#+0

#&,

F$

52176°

8TOUǡ

F$

ޓF$

24'176

O8TOU

24'176°

O8TOU

F$

F$

F$

F$

F$

37

AVR-1910/1620/1610/790/590

Page 38

CLOCK FLOW & WAVE FORM IN DIGITAL BLOCK

Wave form

1

CH1: D-DATA

2

CH1: DATA

CH2: fs

CH3: 64fs

3

CH1: DATA

INPUT

㽲

(V.AUX) 1RIDATAD)44()12(ATADR

LC89058W-E

XR)2(1-LAIXAOC 0

(4)RX2 CRLS)34()32(KCRLSK

XR)5(1-LACITPO 3

XR)6(2-LACITPO 4 IDsf652)73()61(KCMRR

(7)RX5 IDsf46)43()71(KCBRR

XR)8(3-LACITPO 6

(1)RXOUT TBCK(45)

DIR/DIT

IC14

㽳

)42(NIDS2-LAIXAOC

RLRCK(20) (42)fsDIR

TMCK(44)

TLRCK(46)

TDATA(47)

GND

CBS)33()22(KCBS K

(F3)HRMCK

HRMCK(19)

(B1)HR64fs/DCLK

HR64fs/DCLK(20)

IC1

HDMI Rx

ADV7840

(A2)HRfs/DR0

(K3)HRSD0/DL0

HRfs/DR0(21)

HRSD0/DL0(22)

(J4)HRSD3/DR2

(D5)HRSD1/DR1

(J3)HRSD2/DL1

HRSD2/DL1(25)

HRSD3/DR2(27)

HRSD1/DR1(23)

IC102

AUDIO PLD

EPM3032ATC

(B2)HRSPDIF/DL2

CH2: fs

CH3: 64fs

CH4: 256fs

ADC/DAC

IC13

ADAU1328

ABCLK(21)

ALRCK(22)

ASDATA(20)

DSDDATA4(11)

DSDDATA3(14)

DSDDATA2(15)

DSDDATA1(16)

DBCLK(17)

DLRCK(18)

38

AVR-1910/1620/1610/790/590

㽴

sf652CAD)53()2(IKLCM

DAC_FL/FR(133)

DAC_C/SW(134)

DAC_SL/SR(135)

(6)DSPIN64fs

(146)

IC204

DSP

ADSP-21367

DAC_SBL/SBR(136)

(8)DSPINfs

(144)

(10)DSPINSB

(132)

(2)DSPINS

(131)

(12)DSPINC

(130)

(13)DSPINF

(125)

(3)DSPOUTfs

(143)

(5)DSPOUT64fs

(137)

Page 39

SEMICONDUCTORS

1 2 3 4 5 6 7 8 9101112131415161718192021222324252627282930

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

515253545556575859606162636465666768697071727374757677787980

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

1

00

P0_0/AN0_0/D0

P0_1/AN0_1/D1

P0_2/AN0_2/D2

P0_3/AN0_3/D3

P0_4/AN0_4/D4

P0_5/AN0_5/D5

P0_6/AN0_6/D6

P0_7/AN0_7/D7

8D/0_1P

9D/1_1P

01D/2_1P

11D/3_1P

21D/4_1P

VREF

AVSS

1CCV

NIX

TUOX

SSV

RESET

SSVNC

P8_7/XCIN

TUOCX/6_8P

ETYB

)-/0D/(0A/0_2NA/0_2P

)0D/1D/(1A/1_2NA/1_2P

)1D/2D/(2A/2_2NA/2_2P

)2D/3D/(3A/3_2NA/3_2P

)3D/4D/(4A/4_2NA/4_2P

)4D/5D/(5A/5_2NA/5_2P

)5D/6D/(6A/6_2NA/6_2P

)6D/7D/(7A/7_2NA/7_2P

P3_0/A8(/-/D7)

9A/1_3P

01A/2_3

P

11A/3_3P

21A/4_3P

31A/5_3P

41A/6_3P

51A/7_3P

61A/0_4P

71A/1_4P

81A/2_4P

91A/3_4P

P7_4/TA2OUT/W

TUO3AT/6_7P

P5_6/ALE

P7_7/TA3IN

P5_5/HOLD

P5_4/HLDA

P5_3/BCLK

P5_2/RD

2CCV

VSS

P5_7/RDY/CLKOUT

P4_5/CS1

P4_6/CS2

P4_7/CS3

AVCC

P6_3/TXD0/SDA0

P6_5/CLK1

P6_6/RXD1/SCL1

P6_7/TXD1/SDA1

P6_1/CLK0

P6_2/RXD0/SCL0

P10_0/AN0

P10_1/AN1

P10_2/AN2

P10_3/AN3

P9_3/DA0/TB3IN

P9_4/DA1/TB4IN

4KLC/0XENA/5_9P

P9_6/ANEX1/SOUT4

P9_1/TB1IN/SIN3

P9_2/TB2IN/SOUT3

P8_0/TA4OUT/U

P6_0/CTS0/RTS0

P6_4/CTS1/RTS1/CTS0/CLKS1

V/TUO1AT/2KLC/2_7P

P8_2/INT0

NI5BT/NI0AT/2LCS/2DXR/1_7P

)1(

P8_3/INT1

IMN/5_8P

P9_7/ADTRG/SIN4

P4_4/CS0

P5_0/WRL/WR

P5_1/WRH/BHE

3KLC/NI0BT/0_9P

P7_0/TXD2/SDA2/TA0OUT

)1(

P8_4/INT2/ZP

P8_1/TA4IN/U

V/NI1AT/2STR/2STC/3_7P

P7_5/TA2IN/W

P1_5/D13/INT3

P1_6/D14/INT4

P1_7/D15/INT5

P10_7/AN7/KI3

P10_6/AN6/KI2

P10_5/AN5/KI1

P10_4/AN4/KI0

M16C/62 Group

(

M16C/62P, M16C/62PT

)

NOTES:

1. P7_0 and P7_1 are N channel open-drain output pins.

Only major semiconductors are shown, general semiconductors etc. are omitted to list.

The semiconductor which described a detailed drawing in a schematic diagram are omitted to list.

1. IC’s

M30626FJPFP (IC1005)

39

AVR-1910/1620/1610/790/590

Page 40

M30626FJPFP Block Diagram

Output (timer A): 5

Input (timer B): 6

Internal peripheral functions

Watchdog timer

(15 bits)

DMAC

(2 channels)

D-A converter

(8 bits X 2 channels)

Memory

ROM

(1)

RAM

(2)

A-D converter

(10 bits X 8 channels

Expandable up to 26 channels)

UART or

clock synchronous serial I/O

(8 bits X3 channels)

System clock

generation circuit

XIN-XOUT

XCIN-XCOUT

PLL frequency synthesizer

Ring oscillator

M16C/60 series16-bit CPU core

Port P0

8

Port P18Port P2

8 8 8 8

Port P6

8

8

R0LR0H

R1H R1L

R2

R3

A0

A1

FB

SB

ISP

USP

INTB

CRC arithmetic circuit (CCITT )

(Polynomial : X

16+X12+X5

+1)

Multiplier

7

8

8

01PtroP

9PtroP

5_8PtroP

8PtroP

7PtroP

NOTES :

1. ROM size depends on microcomputer type.

2. RAM size depends on microcomputer type.

3. Ports P11 to P14 exist only in 128-pin version.

4. Use M16C/62PT on VCC1= VCC2.

Port P5

Port P4Port P3

Clock synchronous serial I/O

(8 bits X2 channels)

PC

FLG

Timer (16-bit)

Three-phase motor

control circuit

8 8 82

Port P11

Port P12

Port P14

Port P13

(3)

<VCC2 ports>

(4)

<VCC1 ports>

(4)

>strop1CCV<

)4(

<VCC2 ports>

(4)

<VCC1 ports>

(4)

(3) (3)

(3)

M30626FJPFP Terminal Functio

PIN

PIN PIN NAME I/O Type DET

No.

1 P96/

(SOUT4)

2 P95/

NC O C - - - - Z - O/L O/L O/L UART

MICDET I - Lv - - Eu Z - - O/L O/L Mic insert detect

n

Lv

Op

Cnv

(in)Op(ex)

PURE DCEC

Res

STBY

STBY

STOP

P. O F F

STOP

Function

(CLK4)

3 P94 H/PDET I - Lv - - Eu Z - - O/L O/L Headphone insert detect

4 P93 FL_DATA O C - - - Z - O/L O/L O/L FLD control

5 P92/

SOUT3

6 P91/SIN3 SOMIm I - Lv 5/3 - - Z - - I O/L Interface between Main CPU and

7 P90/CLK3 CLKMO O C - 5/3 - - Z - - O/L O/L Interface between Main CPU and

8BYTEBYTE I---------- GND

9 CNVCS CNVSS I - - - - Ed Z - - I I Firmware update control

10 P87 FL_RST O C - - - Z - O/L O/L O/L FL display control

MOSI O C - 5/3 - - Z - - O/L O/L Interface between Main CPU and

11 P86 REDLED O C - - - - Z - O/H O/H O/L H : ON Power indicator (red led) control

12 RESET RESET I - Lv - - Eu L - - I I RESET pulse input

13XOUTXOUT O---------- Oscillator connect

14VSS VSS ---- ------ GND

15XIN XIN I---------- Oscillator connect

16VCC VCC ----------- POWER 5V

17P85/NMINMI I---------- Connect to +5V

18 P84/INT2 PROTECTION

19 P83/INT1 LED1 (TBD) O C - - - - Z - O/L O/L O/L H : ON LED control

20 P82/INT0 GRNLED O C - - - - Z - O/L O/L O/L H : ON Power indicator (green led)

21 P81 BLUE LED O C - - - - Z - O/L O/L O/L H : ON HD_AUDIO indicator (blue led)

E

↓&

- - Eu Z - - I I Fall Edge & L PROTECTION Detect

L

I-

Sub CPU

Sub CPU

Sub CPU

control

control

AVR-1910/1620/1610/790/590

40

Page 41

Lv

PIN

PIN PIN NAME I/O Type DET

No.

22 P80 DYN_GRN_LEDO C - - - - Z - O/L O/L O/L H : ON DYNAMIC EQ indicator

23 P77 DYN_RED_LED O C - - - - Z - O/L O/L O/L H : ON DYNAMIC EQ indicator (red led)

24 P76 ISELA I - - - - Eu Z - - O/L O/L SOURCE encoder operation

25 P75 ISELB O C - - - - Z - O/L O/L O/L SOURCE encoder operation

26 P74 VSELA O C - - - - Z - O/L O/L O/L VOLUME encoder operation

27 P73 VSELB I - - - - Eu Z - - O/L O/L VOLUME encoder operation

28 P72/CLK2 LED2 (TBD) O C - - - - Z - O/L O/L O/L H : ON LED control

29 P71/RXD2 SIRIUS RXD O C - - - - Z - O/L O/L O/L UART SIRIUS control

30 P70/TXD2 SIRIUS TXD O N - - - - Z O/L - O/L O/L UART SIRIUS control

31 P67/TXD1 MO232CI O C - - - - Z - - O/L O/L UART Interface between Main CPU and

32 P66/RXD1 MI232CO I - - - - Ed Z - - O/L O/L UART Interface between Main CPU and

33 P65/CLK1 NC O C - - - Ed Z - - O/L O/L PullDown

34 P64/ NC O C - - - Ed Z - - O/L O/L PullDown

35 P63/TXD0 MOIPI O C - - - - Z - - O/L O/L UART iPod dock control

36 P62/RXD0 MIIPO I - - - - Ed Z - - O/L O/L UART iPod dock control

37 P61/

(CLK0)

38 P60 NC O C - - - Ed Z - - O/L O/L PullDown

39 P57 SCPUPOWER O C - - - - Z - O/H O/L O/L H : SCPUPOWER ON Sub CPU power control

40 P56 FL_CE1 O C - - - Z - O/L O/L O/L FLD control

41 P55/EPM FRASH EMP/

42 P54 NC O C - - - Ed Z - - O/L O/L PullDown

43 P53 VOLCLK O C - - - - Z - O/L O/L O/L Volume control

44 P52 VOLDATA O C - - - - Z - O/L O/L O/L Volume control

45 P51 FRONT

46 P50/CE FRASH CE O C - - - - Z - - O/L O/L Firmware upddate control

47 P47 RDSDOUT I - - - - Eu Z - - O/L O/L TUNER control

48 P46 TURDSCLK

49 P45 TURDSDATA

50 P44 RDSCE O C - - - - Z - O/L O/L O/L TUNER control

51 P43 RDSRST O C - - - - Z - O/L O/L O/L TUNER control

52 P42 THERMAL

53 P41 FRONT A RLY O C - - - - Z - O/L O/L O/L H : Front A Sp ON FRONT A speaker relay control

54 P40 FRONT B RLY O C - - - - Z - O/L O/L O/L H : Front B Sp ON FRONT B speaker relay control

55 P37 STEREO I - Lv - - Ed Z - - O/L O/L STEREO broadcast detect

56 P36 TUSTB O C - - - - Z - O/L O/L O/L TUNER control

57 P35 NC O C - - - Ed Z - O/L O/L O/L

58 P34 TUNED I - Lv - - Eu Z - O/L O/L O/L TUNED det.

59 P33 TUNER MUTE O C - - - - Z - O/L O/H O/L H : MUTE TUNER mute control

60 P32 SIRIUS MUTE O C - - - - Z - O/L O/H O/L H : MUTE SIRIUS mute control

61 P31 MULTI MUTE O C - - - - Z - O/L O/H O/L H : MUTE MULTI ZONE mute control

62VCC VCC ----------63 P30 SW MUTE O C - - - - Z - O/L O/H O/L H : MUTE SW mute control

64VSS VSS ----------65 P27 MULTI POWER O C - - - - Z - O/L O/L O/L H : ON MULTI power control

66 P26 SUB UPDATE O C - - - - Z - O/L O/L O/L Sub-CPU F/W update control

67 P25 SIRIUS RESET O C - - - - Z - - O/L O/L SIRIUS control

68 P24 POWER O C - - - Ed Z - O/H O/L O/L H:POWER ON Main relay control

69 P23 PRE POWER O C - - - - Z - O/L O/L O/L H : ON Pre-power components powert

70 P22 CENTER RLY O C - - - Ed Z - O/L O/L O/L H : Center Sp ON Center speaker relay control

71 P21 SURROUND

NC O C - - - - Z - O/L O/L O/L H : ON

O C - - - - Z - O/L O/L O/L Firmware update / FL display

FL_CLK

O C - - - - Z - O/L O/L O/L H : Front H Sp ON

HEIGHT RLY

(TBD)

O C - - - - Z - O/L O/L O/L TUNER control

(CKTU)

O C - - - - Z - O/L O/L O/L TUNER control

(D ATATU )

I - - - - Ed Z - - O/L O/L L : PROTECTION Thermal protection detect

O C - - - - Z - O/L O/L O/L H : Surround Sp ON Surround speaker relay control

RLY

Cnv

Op

(in)Op(ex)

PURE DCEC

Res

STBY

STBY

STOP

P. O F F

STOP

Function

(green led) control

control

detect

detect

detect

detect

external i/o port

external i/o port

control

control

41

AVR-1910/1620/1610/790/590

Page 42

Lv

PIN

PIN PIN NAME I/O Type DET

No.

72 P20 SURRUOND

BACK RLY

73 P17/INT5 REMOCOM I -

74 P16/INT4 REQSOMIm I -

75 P15/INT3 POWER DOWN I -

76 P14 RSTSUB O C - - - - Z - - O/L O/L Interface between Main CPU and

77 P13 LIMITDET I - Lv - - Eu Z - - O/L O/L L : DETECTIVE Max current det

78 P12 LIMIT O C - - - - Z - O/L O/L O/L H : ON Current limit control

79 P11 H/P RLY O C - - - - Z - O/L O/L O/L

80 P10 SBL MUTE O C - - - - Z - O/L O/H O/L H : MUTE Surround back channel mute

81 P07 IPDET I - Lv - - Eu Z - - O/L O/L H:DETECTIVE iPod dock connection det

82 P06 NC O C - - - - Z O/L O/L O/L O/L

83 P05 NC O C - - - - Z O/L O/L O/L O/L

84 P04 SYNCDET_M I - Lv - - - Z - - O/L O/L OSD control

85 P03 CVBS MUTE O C - - - - Z O/L O/L O/L O/L CVBS mute control

86 P02 OSD STR O C - - - - Z O/L O/L O/L O/L L : MUTE OSD control

87 P01 OSD_CLK O C - - - - Z O/L O/L O/L O/L L : MUTE OSD control

88 P00 OSD_DT O C - - - - Z O/L O/L O/L O/L L : MUTE OSD control

89 P107/AN7/

KI3

90 P106/AN6/

KI2

91 P105/AN5/

KI1

92 P104/

(AN4)/(KI0)

P103/(AN3)

93

P102/(AN2)

94

95

P101/(AN1)

96AVSSAVSS -----------97 P100/AN0 SET_OPTION I - Lv - - - Z - - I O/L Lv Area setting

98 VREF VREF - - - - - - - ----99AVCCAVCC ------------

100 P97/(SIN4) NC O C - - - - Z O/L O/L O/L O/L

KEY1 I - Lv - - Eu Z - - I O/L Front panel key operation det

KEY2 I - Lv - - Eu Z - - I O/L Front panel key operation det

KEY3 I - Lv - - Eu Z - - I O/L Front panel key operation det

ACKSUB O C - 5/3 - - Z - - O/L O/L Interface between Main CPU and

NC O C - - - Ed Z - - O/L O/L PullDown

NC O C - - - Ed Z - - O/L O/L PullDown

NC O C - - - Ed Z - - O/L O/L PullDown

O C - - - - Z - O/L O/L O/L H : SurBack Sp ON Surround-back speaker relay

↑&

E

E

↓& H-

↓&

E

Op

Cnv

(in)Op(ex)

- - Ed Z - - I I Rise Edge & H Remote signal detect

H

- - Z - - I O/L Interface between Main CPU and

- - Eu Z - - I I Fall Edge & L Power off detect

H

PURE DCEC

Res

STBY

STBY

STOP

P. O F F

STOP

H : Headphone ON

control

Sub CPU

external i/o port

Headphone relay control

control

Sub CPU

Function

42

AVR-1910/1620/1610/790/590

Page 43

R5F3650ENFB (IC28)

123456789

101112131415161718192021222324

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51525354555657585960616263646566676869707172737475

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

1

00

P0_0/AN0_0/D0

P0_1/AN0_1/D1

P0_2/AN0_2/D2

P0_3/AN0_3/D3

P0_4/AN0_4/D4

P0_5/AN0_5/D5

P0_6/AN0_6/D6

P0_7/AN0_7/D7

P1_0/CTS6/RTS6/D8

P1_1/CLK6/D9

P1_2/RXD6/SCL6/D10

VREF

AVSS

AVCC

P10_0/AN0

P10_1/AN1

P10_2/AN2

P10_3/AN3

P9_5/ANEX0/CLK4

P9_6/ANEX1/SOUT4

P9_7/ADTRG/SIN4

P10_7/AN7/KI3

P10_6/AN6/KI2

P10_5/AN5/KI1

P10_4/AN4/KI0

M16C/65 Group

PLQP0100KB-A

(100P6Q-A)

(top view)

P1_3/TXD6/SDA6/D11

P1_4/D12

P3_1/A9

P3_2/A10

P3_3/A11

P3_4/A12

P3_5/A13

P3_6/A14

P3_7/A15

P4_0/A16

P4_1/A17

VCC2

VSS

P4_2/A18

P4_3/A19

P5_6/ALE

P5_5/HOLD

P5_4/HLDA

P5_3/BCLK

P5_2/RD

P5_7/RDY/CLKOUT

P6_3/TXD0/SDA0

P6_5/CLK1

P6_6/RXD1/SCL1

P6_7/TXD1/SDA1

P6_1/CLK0

P6_2/RXD0/SCL0

P6_0/RTCOUT/CTS0/RTS0

P6_4/CTS1/RTS1/CTS0/CLKS1

P5_0/WRL/WR

P5_1/WRH/BHE

P7_2/CLK2/TA1OUT/ V

P7_1/RXD2/SCL2/SCLMM/TA0IN/TB5IN

(1)

P7_0/TXD2/SDA2/SDAMM/TA0OUT

(1)

VCC1

XIN

XOUT

VSS

RESET

CNVSS

P8_7/XCIN

P8_6/XCOUT

BYTE

P7_4/TA2OUT/W

P9_3/DA0/TB3IN/PWM0

P9_4/DA1/TB4IN/PWM1

P9_1/TB1IN/PMC1/SIN3

P9_2/TB2IN/PMC0/SOUT3

P8_2/INT0

P8_3/INT1

P8_5/NMI/SD/CEC

(1)

P9_0/TB0IN/CLK3

P8_4/INT2/ZP

P7_5/TA2IN/W

P7_3/CTS2/RTS2/TA1IN/V

P7_6/TA3OUT/TXD5/SDA5

P7_7/TA3IN/CLK5

P8_0/TA4OUT/U/RXD5/SCL5

P8_1/TA4IN/U/CTS5/RTS5

P4_5/CLK7/CS1

P4_4/CTS7/RTS7/CS0

P3_0/A8 [A8/D7]

P2_0/AN2_0/A0, [A0/D0], A0

P2_1/AN2_1/A1, [A1/D1], [A1/D0]

P2_2/AN2_2/A2, [A2/D2], [A2/D1]

P2_3/AN2_3/A3, [A3/D3], [A3/D2]

P2_4/INT6/AN2_4/A4, [A4/D4], [A4/D3]

P2_5/INT7/AN2_5/A5, [A5/D5], [A5/D4]

P2_6/AN2_6/A6, [A6/D6], [A6/D5]

P2_7/AN2_7/A7, [A7/D7], [A7/D6]

(3)

P1_5/INT3/IDV/D13

P1_6/INT4/IDW/D14

P1_7/INT5/IDU/D15

P4_6/PWM0/RXD7/SCL7/CS2

P4_7/PWM1/TXD7/SDA7/CS3

VCC2 ports

VCC1 ports

Notes:

1. N-channel open drain output.

2. Check the position of Pin 1 by referring to appendix 1, Package Dimensions.

3. Pin names in brackets [ ] represent a single functional signal. They should not be considered as two separate functional signals.

AVR-1910/1620/1610/790/590

43

Page 44

R5F3650ENFB Terminal Function

Clock synchronous serial I/O

(8 bits x 2 channels)

DMAC

(4 channels)

Internal peripheral functions

System clock generator

XIN-XOUT

XCIN-XCOUT

PLL frequency synthesizer

On-chip oscillator (125 kHz)

High-speed on-chip oscillator

Notes :

1. ROM size depends on MCU type.

2. RAM size depends on MCU type.

Port P0

8

Port P2

8 8 4 8

Port P5

Port P4Port P3

UART or

clock synchronous serial I/O

(3 channels)

UART

(1 channel)

VCC1 ports

M16C/60 series CPU core

R0LR0H

R1H R1L

R2

R3

A0

A1

FB

SB

ISP

USP

INTB

FLG

Memory

ROM

(1)

RAM

(2)

Multiplier

PC

CRC arithmetic circuit

(CCITT or CRC-16)

8 7 4

Port P7

Port P8Port P9Port P10

8

Port P6

8

Outputs (timer A): 5

Inputs (timer B) : 6

Timer (16-bit)

VCC1 ports

Real time clock

PWM function (8 bits X 2)

Remote control signal receiver

(2 circuits)

Watchdog timer

(15 bits

X 1)

A/D converter

(10 bits X 26 channels)

D/A converter

(8 bits X 2 channels)

Multi-master I2C bus interface

(1 channel)

CEC function

Voltage detection circuit

Power-on reset

On-chip debugger

R5F3650ENFB Terminal Function

Pin PIN PIN NAME I/O Type Det

1P94 NC O C - - - Z O/L O/L Z

2 P93 DIR CE O C - - - Z O/L O/L Z DIR(LC89058W-VF4A) control

3 P92/SOUT3 DIR DIN O C - - - Z O/L O/L Z DIR(LC89058W-VF4A) control

4 P91/SIN3 DIR DOUT I - Lv - Eu Z - - Z DIR(LC89058W-VF4A) control

5 P90/CLK3 DIR CLK O C - - - Z O/L O/L Z DIR(LC89058W-VF4A) control

6 BYTE BYTE - - - - - - - - - GND

7 CNVCS CNVSS - - - - Ed47k - - - - Firmware update control

8 P87 NC O C - - Eu Z O/H O/H Z

9 P86 NC O C - - Ed Z O/L O/L Z

10 RESET SUBRESET

11XOUT X1 O- - ------Oscillator connect

12VSS VSS -- - ------GND

13XIN X2 I- - ------Oscillator connect

14VCC VCC -- - - -- --+3.3V

15 P85/NMI/

(CEC)

16 P84/INT2 CEC_IN I -

17 P83/INT1 ACK SIMO I -

18 P82/INT0 SUB BDOWN

19 P81 IP RST O C - - - Z O/H O/H Z IP CONV.(ABT1030) control

20 P80/(RXD5) NC O C - - Ed Z O/L O/L Z (1910/790 model)

I - Lv - Eu L - - Z RESET pulse input

NMI/(CEC_IN) I - - - - - - - - Connect to +3.3V

I-

Op

(in)

E

↓&

E

↓&

↓&

E

- Eu Z - - Z CEC control

L

- Ed Z - - Z Interface between Main CPU and Sub CPU

L

L

Op(ex) Res

PURE DCEC

STBY

P. O F

F

Eu Z - - Z Power off detect

Function

44

AVR-1910/1620/1610/790/590

Page 45

Op

Pin PIN PIN NAME I/O Type Det

20 P80/(RXD5) PLDCE/TDO O C - - Ed Z O/L O/L Z PLD(EPM240T100C5N) firmware update control

21 P77/(CLK5) SI CODECO I - Lv - - Z O/L O/L Z CODEC(ADAU1328) control

22 P76/(TXD5) CPUMUTE/TMS/M_D O C - - Eu Z O/L - O/L PLD(EPM240T100C5N) control

23 P75 APLDSEL/TDI O C - - - Z O/L O/L Z PLD(EPM240T100C5N) control

24 P74 MTCK O C - - - Z O/L O/L Z PLD(EPM240T100C5N) control

25 P73/(CTS2) ANALOG VIDEO

POWER

26 P72/(CLK2) DIGITAL (D/A) POWER O C - - - Z Z - Z Digital components power control

27 P71/RXD2/

SCLMM

27 P71/RXD2/

SCLMM

28 P70/TXD2/

SDAMM

28 P70/TXD2/

SDAMM

29 P67/TXD1 TXD O C - - Eu Z - - Z Interface between Main CPU and external i/o port

30 P66/RXD1 RXD I - Lv - Eu Z - - Z Interface between Main CPU and external i/o port

31 P65/(CLK1) SW SUM O C - - Ed Z - O/L Z Subwoofer signal control

32 P64/(CTS1) SYNCDET I - Lv - - Z - - Z Sync signal detect

33 P63/TXD0 SOMI O C - - - Z - - Z Interface between Main CPU and Sub CPU

34 P62/RXD0 SIMO I - - - Ed Z - - Z Interface between Main CPU and Sub CPU

35 P61/CLK0 CLK SIMO I - - - Ed Z - - Z Interface between Main CPU and Sub CPU

36 P60/(CTS0) REQ SOMI O C - - Ed Z - - Z Interface between Main CPU and Sub CPU

37 P57 NC O C - - - Z O/H - Z

38 P56 HPD2 O C - - - Z O/L - Z HDMI control (hot plug detect)

39 P55/EPM EPM O C - - Ed Z - - Z Firmware update control

40 P54 CEC_OUT O C - - - Z O/L - Z CEC control

41 P53 MONI DIS O C - - Z O/L O/L Z Copponent monitor out control

42 P52 DVR INH O C - - - Z O/L O/L Z Video recout control

43 P51 NC O C - - - Z O/L O/L Z

44 P50/CE CE O C - - Eu Z O/L - Z Firmware update control

45 P47/(TXD7)/

SDA7

46 P46/(RXD7)/

SCL7

47 P45/(CLK7) HPD1 O C - - Ed Z O/L - Z HDMI control (hot plug detect)

48 P44 NC O C - - - Z Z - Z

49 P43 NC O C - - - Z Z - Z

50 P42 NC O C - - Ed Z O/L O/L Z

51 P41 CEC PWR O C - - Ed Z O/L O/L Z CEC components power control

52 P40 NC O C - - Z O/L O/L Z

53 P37 HDMIR_RST O C - - Eu Z O/H - Z HDMI receiver (ADV7840) control

54 P36 1TX RST O C - - Eu Z O/H - Z HDMI transmitter (ADV7510) control

55 P35 NC O C - - Ed Z O/L O/L Z

56 P34 NC I - Lv - Eu Z - - Z

57 P33 NC O C - - - Z Z - Z

58 P32 SO CODECI O C - - - Z O/L O/L Z CODEC (ADAU1328) control

59 P31 CLK CODEC O C - - - Z O/L O/L Z CODEC (ADAU1328) control

60VCC VCC -- - ------+3.3V

61 P30 CE CODEC O C - - - Z O/L O/L Z CODEC (ADAU1328) control

62VSS VSS -- - ------GND

63 P27 CODEC RST O C - - - Z O/H O/H Z CODEC (ADAU1328) control

64 P26 DIG VIDEO POWER O C - - - Z O/L O/L Z Digital video components power control

65 P25/INT7 NC I - Lv - - Z - - Z

66 P24/INT6 1TX INT I - Lv - . Z - - Z HDMI control

67 P23 NC

68 P22 VEXP STB O C - - - Z O/L O/L Z Extended i/o components (BU4094BCFV) control

69 P21 VEXP OE O C - - Ed Z O/L O/L Z Extended i/o components (BU4094BCFV) control

70 P20 VEXP CLK O C - - - Z O/L O/L Z Extended i/o components (BU4094BCFV) control

HSCL(400k) I/O N - - Eu Z O/L O/L O/L Interface between IP CONV(ABT1030)/

HSCL(400k) I/O N - - Eu Z O/L O/L O/L Interface between HDMI_RECEIVER(ADV7840)

HSDA(400k) I/O N - - Eu Z O/L O/L O/L Interface between IP CONV(ABT1030)/

HSDA(400k) I/O N - - Eu Z O/L O/L O/L Interface between HDMI_RECEIVER(ADV7840)

COMP SW1 I/O C - - Eu Z O/L - O/L Component selector control

COMP SW2 I/O C - - Eu Z O/L - O/L Component selector control

O C - - - Z O/L O/L Z Video components power control

(in)

Op(ex) Res

PURE DCEC

STBY

P. O F

F

(1610/1620/590 model)

HDMI_RECEIVER(ADV7840)

/HDMI TRANSMITTER1 (ADV7510)

(1910/790 model)

/HDMI TRANSMITTER1 (ADV7510)

(1610/1620/590 model)

HDMI_RECEIVER(ADV7840)

/HDMI TRANSMITTER1 (ADV7510)

(1910/790 model)

/HDMI TRANSMITTER1 (ADV7510)

(1610/1620/590 model)

Function

45

AVR-1910/1620/1610/790/590

Page 46

Op

Pin PIN PIN NAME I/O Type Det

71 P17/INT5 ADVINT1 I -

72 P16/INT4 ADVINT2 I -

73 P15/INT3 ADVINT3 I -

74 P14 OSD SEL O C - - Eu Z - - Z OSD control

75 P13/TXD6 DSP MOSI O C - - Eu Z O/L O/L Z DSP(ADSP-21367-333) control

76 P12/RXD6 DSP MISO I - - - Eu Z - - Z DSP(ADSP-21367-333) control

77 P11/CLK6 DSPICLK O C - - Eu Z O/L O/L Z DSP(ADSP-21367-333) control

78 P10 Z1VSIG.DET I - Lv - Eu Z - - Z Video signal detect

79 P07 PLD WRITE

80 P06 PLDCE/TDO O C - - Ed Z O/L O/L Z PLD(EPM240T100C5N) firmware update control

80 P06 NC O C - - Ed Z O/L O/L Z (1610/1620/590 model)

81 P05 HPD3 O C - - - Z O/L - Z HDMI control (hot plug detect)

82 P04 HPD4 O C - - - Z O/L - Z HDMI control (hot plug detect)

83 P03 DIR INT I - Lv - Eu Z - - Z DIR(LC89058W-VF4A) control

84 P02 NC O C - - - Z Z - Z

85 P01 NC O C - - - Z Z - Z

86 P00 DIR RST1 O C - - - Z O/L O/L O/L DIR(LC89058W-VF4A) control

87 P107/(AN7) DSP RST O C - - - Z O/L O/L Z DSP(ADSP-21367-333) control

88 P106/(AN6) NC O C - - - Z O/L O/L Z

89 P105/(AN5) DSP ROMRST O C - - Ed Z O/L O/L Z Memory for DSP control

90 P104/(AN4) COMPS DET I - Lv - Eu Z - - Z Component video signal detect

91 P103/(AN3) DSP FLAG0 I - Lv - Ed Z - - Z DSP(ADSP-21367-333)control

92 P102/(AN2) DSPICS O C - Eu Z O/L O/L Z DSP(ADSP-21367-333) control

93 P101/(AN1) DSP FLAG1 I - Lv - Ed Z - - Z DSP(ADSP-21367-333) control

94AVSS AVSS -- - ------GND

95 P100/(AN0) NC O C - - - Z O/L O/L Z

96 VREF VREF - - - - - - - - - +3.3V

97 AVCC AVCC - - - - - - - - - +3.3V

98 P97/(SIN4) NC O C - - Eu Z O/L O/L Z

99

P96/(SOUT4)

100 P95/(CLK4) VEXP DIN O C - - - Z O/L O/L Z Extended i/o components (BU4094BCFV) control

NC O C - - Eu Z O/L O/L Z

O C - - - Z O/L O/L Z PLD(EPM240T100C5N) firmware update control

E

↓&

E

↓&

E

↓&

L

L

L

Op(ex) Res

(in)

- - Z - - Z HDMI receiver(ADV7840) control

- - Z - - Z HDMI receiver(ADV7840) control

- - Z - - Z HDMI receiver(ADV7840) control

PURE DCEC

STBY

P. O F

F

(1910/790 model 9

Function

46

AVR-1910/1620/1610/790/590

Page 47

ADSP-21367 (IC10)

1

208 157

156

105

10453

52

TOP VIEW

(PINS DOW N)

PIN 1 INDICATOR

Pin No. Signal Pin No. Signal Pin No. Signal Pin No. Signal

1 VDD 53 VDD 105 VDD 157 VDD

2 DATA28 54 GND 106 GND 158 VDD

3 DATA27 55 IOVDD 107 IOVDD 159 GND

4 GND 56 ADDR0 108 SDCAS

160 VDD

5 IOVDD 57 ADDR2 109 SDRAS

161 VDD

6 DATA26 58 ADDR1 110 SDCKE 162 VDD

7 DATA25 59 ADDR4 111 SDWE

163 TDI

8 DATA24 60 ADDR3 112 WR

164 TRST

9 DATA23 61 ADDR5 113 SDA10 165 TCK

10 GND 62 GND 114 GND 166 GND

11 VDD 63 VDD 115 IOVDD 167 VDD

12 DATA22 64 GND 116 SDCLK0 168 TMS

13 DATA21 65 IOVDD 117 GND 169 CLK_CFG0

14 DATA20 66 ADDR6 118 VDD 170 BOOTCFG0

15 IOVDD 67 ADDR7 119 RD

171 CLK_CFG1

16 GND 68 ADDR8 120 ACK 172 EMU

17 DATA19 69 ADDR9 121 FLAG3 173 BOOTCFG1

18 DATA18 70 ADDR10 122 FLAG2 174 TDO

19 VDD 71 GND 123 FLAG1 175 DAI4

20 GND 72 VDD 124 FLAG0 176 DAI2

21 DATA17 73 GND 125 DAI20 177 DAI3

22 VDD 74 IOVDD 126 GND 178 DAI1

23 GND 75 ADDR11 127 VDD 179 IOVDD

24 VDD 76 ADDR12 128 GND 180 GND

25 GND 77 ADDR13 129 IOVDD 181 VDD

26 DATA16 78 GND 130 DAI19 182 GND

27 DATA15 79 VDD 131 DAI18 183 DPI14

28 DATA14 80 AVSS 132 DAI17 184 DPI13

29 DATA13 81 AVDD 133 DAI16 185 DPI12

30 DATA12 82 GND 134 DAI15 186 DPI11

31 IOVDD 83 CLKIN 135 DAI14 187 DPI10

32 GND 84 XTAL2 136 DAI13 188 DPI9

33 VDD 85 IOVDD 137 DAI12 189 DPI8

34 GND 86 GND 138 VDD 190 DPI7

35 DATA11 87 VDD 139 IOVDD 191 IOVDD

36 DATA10 88 ADDR14 140 GND 192 GND

37 DATA9 89 GND 141 VDD 193 VDD

38 DATA8 90 IOVDD 142 GND 194 GND

39 DATA7 91 ADDR15 143 DAI11 195 DPI6

40 DATA6 92 ADDR16 144 DAI10 196 DPI5

41 IOVDD 93 ADDR17 145 DAI8 197 DPI4

42 GND 94 ADDR18 146 DAI9 198 DPI3

43 VDD 95 GND 147 DAI6 199 DPI1

44 DATA4 96 IOVDD 148 DAI7 200 DPI2

45 DATA5 97 ADDR19 149 DAI5 201 CLK OUT

46 DATA2 98 ADDR20 150 IOVDD 202 RESET

47 DATA3 99 ADDR21 151 GND 203 IOVDD

48 DATA0 100 ADDR23 152 VDD 204 GND

49 DATA1 101 ADDR22 153 GND 205 DATA30

50 IOVDD 102 MS1

154 VDD 206 DATA31

51 GND 103 MS0

155 GND 207 DATA29

52 VDD 1 04 VDD 156 VDD 2 08 VDD

ADSP-21367 Terminal Function

AVR-1910/1620/1610/790/590

47

Page 48

ADV7510 (IC5)

ADV7510

TOP VIEW

(Not to Scale)

1

GND

DDCSDA

DDCSCL

GND

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26272829303132333435363738394041424344454647484950

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

100

9998979695949392919089888786858483828180797877

76

PIN 1

INDICATOR

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

AVAV

DD

AVAV

DD

AVAV

DD

PV

DD

PV

DD

PV

DD

DV

DD

DV

DD

DVDDDV

DD

D18

D22

D21

D20

D19

D35

D29

D28

D27

D26

D25

D24

D23

D34

D33

D32

D31

D30

SCL

SDA

NC

D17

D10

D11

D12

D13

D14

D15

D16

D9

D7

D8

D0D1D2

D3D4D5

D6

CLK

DE

HSYNC

VSYNC

DSD0

DSD5

DSD4

DSD3

DSD2

DSD1

DSD_CLK

SPDIF

MCLK

I2S0

I2S3

I2S2

I2S1

SCLK

LRCLK

BGV

DD

R_EXT

HPD

TXC-

TXC+

TX0-

TX1-

TX2-

TX2+

TX1+

TX0+

PD

INT

DV

DD

_3V

CEC_IN

CEC_CLK

DV

DD

Audio

Data

Capture

Video

Data

Capture

I2C

Slave

4:2:2

4:4:4

&

Color

Space

Converter

Registers

&

Config.

Logic

HDCP &

EDID

Micro-

controller

HDCP

Keys

HDCP

Encryption

I2C

Master

TMDS

Outputs

D[35:0]

DE

CLK

HPD

INT

SCL

SDA

MCLK

SCLK

I

2

S[3:0]

LRCLK

S/PDIF

DDCSDA

DDCSCL

Tx1

Tx0

Tx2

TxC

CEC

Audio

Data

Capture

Video

Data

Capture

I2C

Slave

4:2:2

4:4:4

&

Color

Space

Converter

Registers

&

Config.

Logic

HDCP &

EDID

Micro-

controller

HDCP

Keys

HDCP

Encryption

I2C

Master

TMDS

Outputs

D[35:0]

DE

CLK

HPD

INT

SCL

SDA

MCLK

SCLK

I

2

S[3:0]

LRCLK

S/PDIF

DDCSDA

DDCSCL

Tx1

Tx0

Tx2

TxC

CEC Controller/

Buffer

ADV7510

VSYNC

HSYNC

DSD[5:0]

DSD_CLK

ADV7510 Block Diagram

AVR-1910/1620/1610/790/590

48

Page 49

R2A15218FP (IC1504)

1

30

31

50

80

81

100

51

AGND

SWC

AGND

SLC

AGND

SBLC

INLB/RECL2

INRB/RECR2

INR11/RECR5

INL10/RECL4

RECR3

INL11/RECL5

FLIN1

RECL3

CIN1

FRIN1

SLIN1

SWIN1

AVEE

MUTE

FLIN2

FRIN2

SLIN2

SRIN2

CIN2

SWIN2

SBLIN2

SBRIN2

AVCC

TREL

BASSL1

BASSL2

FLOUT

CC

FLC

FROUT

AGND

FRC

ADCR

SBLIN1

SRIN1

SBRIN1

SBL OUT

ADCL

SBR OUT

SLOUT

SBRC

SROUT

SWOUT

SRC

COUT

INL5

INL1

INR1

INL2

INR2

INL3

INR3

INL4

INR4

INR5

INL6

INR6

INL7

INR7

INL8

INR8

INLA/RECL1

INRA/RECR1

INL9

INR9

SUBR

SUBL

DGND

INR10/RECR4

DATA

CLOCK

BASSR1

BASSR2

TRER

N.C.

AGND

N.C.

AGND

N.C.

N.C.

N.C.

N.C.

SBRCIN

SBLCIN

N.C.

N.C.

AGND

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

N.C.

MAI N

SUB

REC

ATT

0/-6/-12/-18dB

Bass/ Treb

le

-14~+14dB

(2dB step)

+42~-95dB,

- (0.5dBstep)

+42~-95dB,

- (0.5dBstep)

+42~-95dB,

- (0.5dBstep)

+42~-95dB,

- (0.5dBstep)

+42~-95dB,

- (0.5dBstep)

+42~-95dB,

- (0.5dBstep)

Tone

+42~0dB

(0.5dBstep)

Tone

Bass/ Treble

-14~+14dB

(2dB step)

0~-95dB,

-

(0.5dBstep)

+42~0dB

(0.5dBstep)

0~-95dB,

-

(0.5dBstep)

MCU

I/F

AVEE

AVCC

Bypass

Tone

Tone+MIX

Bypass

Tone

Tone+MIX

CMIX

SWMIX

MAI N

SUB

MAI N

SUB

81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99

100

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50 49 48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33 32 31

R2A15218FP Block Diagram

49

AVR-1910/1620/1610/790/590

Page 50

R2A15218FP Terminl Function

PIN No.

Name

Function

49 DATA

Input pin of c ontrol data

50 CLOCK Input pin of c ontrol clock

Output pin of FL/ FR/C/SW/SL/ SR/SBL/ SBR channel

FRIN2, FLIN2,

SRN2,SLIN2,

SWIN2,CIN2 ,

SBRIN2,S BLIN2

43,42,

41,40,

39,38,

37,36

Input pin of L/R /C/SW/ SL/ SR/SBL /SBR channel (Multi IN 1/2)

Output pin for L/R chann el RE C Output

Frequency characteristic setting pin of L/R chann el tone control (Treble)

28,34

TREL, TRE R

26,27,

32,33

23,21,

17,15,

11,9,

5,3

FROUT,FLO UT,

COUT,SWOUT,

SROUT, SLO UT,

SBROUT,S BL OUT

BA SSL1,BA SSL2

BA SSR1,BASSR2

FLIN1, F RIN1,

CIN1,SWIN1 ,

SLIN1,S RIN1,

SBLIN1,S BRI N1

93,94,

95,96,

97,98,

99,100

Frequency characteristic setting pin of L/R chann el tone control (Bass)

24,20,

18,14,

12,8,

6,2

FRC,FLC,

CC,SWC,

SRC,SLC,

SBRC,SBL C

Connects capacitor fo r reducing click no ise of

L/R /C/SW/ SL/SR/SBL/ SBR channel vol ume

INL1, INL2, I N L3,

INL4, INL5, INL6,

INL7, INL8, INL9

Input pin of L/R channel ( I nput Selector)

59,61,63,

65,67,69,

71,73,79

INR1,INR2, I NR3,

INR4,INR5,I NR6,

INR7,INR8,I NR9

58,60,62,

64,66,68,

70,72,78

54,55 ADCL, ADCR

Output pin for L/R chann el ADC

90,91

4,7,10,16,

19,22,56

AGN D

Analog groun d of intern al circuit

30

AVCC

Positive powe r supply to int ernal cir cuit

48 DGN D

Digital ground of intern al circuit

52

AVEE

Negative pow er supply to internal cir cuit

46,47 SUBL,SU BR

Output pin for L/R chann el SUB Outpu t

RECR3,RECL3

51

MUTE

Outside Mute Con trol PIN

75,76,

81,82,

83,84,

85,86

INRA/RECR1,INLA/RECL1,

INRB/REC R2,INLB/ RECL2,

INR10/RECR4,I NL10/RECL4,

INR11/RECR5,I NL11/RECL5

Input pin of L/R channel ( I nput Selector)/

Output pin for L/R chann el RE C Output

N.C.

1,13,25,29,31,

35,53,

57,74,77,80,

87,88,89,92

No Connected PIN

44,45 SBRCIN,SBL CIN

Input pin for S BL/ SBR channel Volum e

AVR-1910/1620/1610/790/590

50

Page 51

W9864G2GH (IC8)

W9864G2GH Block Diagram

51

AVR-1910/1620/1610/790/590

Page 52

W9864G2GH-6 Pim Description

52

AVR-1910/1620/1610/790/590

Page 53

K4S641632K (IC30 : for AVR-1910)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

54Pin TSOP (II)

(400mil x 875mil)

(0.8 mm Pin pitch)

PIN FUNCTION DESCRIPTION

Pin Name Input Function

CLK System clock Active on the positive going edge to sample all inputs.

CS

Chip select

Disables or enables device operation by masking or enabling all inputs except

CLK, CKE and DQM

CKE Clock enable

Masks system clock to freeze operation from the next clock cycle.

CKE should be enabled at least one cycle prior to new command.