Page 1

e

SERVICE MANUAL

MODEL JP E3 E2 EK EA E1 E1K E1C

Ver. 4

Please refer to the

MODIFICATION NOTICE.

AVR-1312

MODEL JP E3 E2 EK EA E1 E1K E1C

DHT-1312XP

5.1CH HOME THEATER SYSTEM

P P P P

AV SURROUND RECEIVER

s

P P

• For purposes of improvement, specications and design are subject to change without notice.

Please use this service manual with referring to the operating instructions without fail.

•

Some illustrations using in this service manual are slightly different from the actual set.

•

e

D&M Holdings Inc.

S0396-0V04DM/DG1111

START::|qzT7t3cIXfGvpSN6RPbAWw==|i4QKmwTsguF5/wkPVABzlM4GcWQGNoMv02uNeNz1Wog=|RtRIz5LbaS+BXuKmvA5tJg==|::END

Copyright 2011 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

Page 2

CONTENTS

SAFETY PRECAUTIONS ..........................................................3

NOTE FOR SCHEMATIC DIAGRAM .........................................4

TECHNICAL SPECIFICATIONS ................................................5

DIMENSION ...............................................................................5

CAUTIONS IN SERVICING .......................................................6

Initializing AV SURROUND RECEIVER ....................................6

Service Jig ................................................................................6

DISASSEMBLY ..........................................................................7

1. FRONT PANEL ASSY ...........................................................8

2. HDMI UNIT ............................................................................9

3. INPUT UNIT ........................................................................10

4. RADIATOR ASSY ................................................................11

5. POWER UNIT......................................................................12

6. POWER TRANS ..................................................................12

SPECIAL MODE ......................................................................13

Special mode setting button ....................................................13

1. µcom/DSP Version display mode ........................................14

WHEN THE MICROPROCESSOR IS REPLACED

WITH A NEW ONE ...................................................................15

PROCEDURE FOR UPGRADING

THE VERSION OF THE FIRMWARE ......................................15

1. Preparations ........................................................................15

2. UPDATE FIRMWARE ..........................................................16

3. Notice: .................................................................................27

Conrming the rmware’s number after upgraded ..................27

ADJUSTMENT .........................................................................28

Audio Section ..........................................................................28

SURROUND MODES AND PARAMETERS ............................29

TROUBLE SHOOTING ............................................................33

1. POWER ...............................................................................33

2. Analog video ........................................................................34

3. HDMI/DVI ............................................................................35

4. AUDIO .................................................................................40

CLOCK FLOW & WAVE FORM IN DIGITAL BLOCK .............42

BLOCK DIAGRAM ...................................................................43

LAEVEL DIAGRAM .................................................................47

PRINTED WIRING BOARDS ...................................................49

FRONT (COMPONENT SIDE) ................................................49

POWER (COMPONENT SIDE)...............................................49

HEADPHONE (COMPONENT SIDE) .....................................49

PORTABLE IN (COMPONENT SIDE) .....................................49

REGULATOR (COMPONENT SIDE) ......................................49

VOLUME (COMPONENT SIDE) .............................................49

VOLUME (FOIL SIDE) ............................................................50

REGULATOR (FOIL SIDE)......................................................50

FRONT (FOIL SIDE) ...............................................................50

PORTABLE IN (FOIL SIDE) ....................................................50

HEADPHONE (FOIL SIDE) .....................................................50

POWER (FOIL SIDE) ..............................................................50

MAIN (COMPONENT SIDE) ...................................................51

INPUT (COMPONENT SIDE) .................................................52

INPUT (FOIL SIDE) .................................................................53

HDMI (COMPONENT SIDE) ...................................................54

HDMI (FOIL SIDE) ..................................................................54

SCHEMATIC DIAGRAMS (1/7) ...............................................55

FRONT UNIT ...........................................................................55

POWER UNIT .........................................................................55

HEADPHONE UNIT ................................................................55

PORTABLE UNIT ....................................................................55

PORTABLE UNIT(AVR-1312 ONLY) .......................................55

PORTABLE UNIT(AVR-1312 ONLY) .......................................55

iPOD/USB UNIT(AVR-1612 ONLY) .........................................55

SCHEMATIC DIAGRAMS (2/7) ...............................................56

FRONT PART ..........................................................................56

SCHEMATIC DIAGRAMS (3/7) ...............................................57

INPUT & VOLUME UNIT .........................................................57

SCHEMATIC DIAGRAMS (4/7) ...............................................58

VIDEO UNIT ............................................................................58

SCHEMATIC DIAGRAMS (5/7) ...............................................59

DSP UNIT ................................................................................59

SCHEMATIC DIAGRAMS (6/7) ...............................................60

MCU UNIT ...............................................................................60

SCHEMATIC DIAGRAMS (7/7) ...............................................61

MAIN UNIT ..............................................................................61

WIRING DIAGRAM ..................................................................62

EXPLODED VIEW ....................................................................63

PARTS LIST OF EXPLODED VIEW ........................................64

PACKING VIEW (for AVR-1312) .............................................67

PARTS LIST OF PACKING & ACCESSORIES

(for AVR-1312) .........................................................................68

PACKING VIEW (for DHT-1312XP) ........................................69

PARTS LIST OF PACKING & ACCESSORIES

(for DHT-1312XP) ...................................................................69

SEMICONDUCTORS ...............................................................70

1. IC's ......................................................................................70

2. FL DISPLAY.........................................................................88

PARTS LIST OF P.W.B. UNIT ..................................................90

FRONT P.W.B. UNIT ASS'Y ....................................................90

MAIN P.W.B. UNIT ASS'Y .......................................................93

INPUT P.W.B. UNIT ASS'Y ......................................................97

HDMI P.W.B. UNIT ASS'Y .....................................................101

SPEAKER SYSTEM PACK ...................................................103

TECHNICAL SPECIFICATIONS ............................................103

DIMENSION ...........................................................................103

SC-C1312 EXPLODED VIEW ................................................104

SC-C1312 PARTS LIST OF EXPLODED VIEW ....................104

SC-F1312 EXPLODED VIEW ................................................105

SC-F1312(F) PARTS LIST OF EXPLODED VIEW ................105

SC-F1312(R) PARTS LIST OF EXPLODED VIEW ...............105

DSW-1312 EXPLODED VIEW ...............................................106

DSW-1312 PARTS LIST OF EXPLODED VIEW ...................106

SYS-1312 PACKING VIEW ....................................................107

SYS-1312 PARTS LIST OF PACKING VIEW ........................108

SCHEMATIC DIAGRAMS (1/1) .............................................110

2

Page 3

SAFETY PRECAUTIONS

The following items should be checked for continued protection of the customer and the service technician.

LEAKAGE CURRENT CHECK

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the set is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, when the set's power is in each state (on,

off and standby mode), if applicable.

CAUTION

Please heed the following cautions and instructions during servicing and

inspection.

◎Heed the cautions!

Cautions which are delicate in particular for servicing

are labeled on the cabinets, the parts and the chassis,

etc. Be sure to heed these cautions and the cautions

described in the handling instructions.

◎Cautions concerning electric shock!

(1) An AC voltage is impressed on this set, so if

you touch internal metal parts when the set is

energized, you may get an electric shock. Avoid

getting an electric shock, by using an isolating

transformer and wearing gloves when servicing

while the set is energized, or by unplugging the

power cord when replacing parts, for example.

(2) There are high voltage parts inside. Handle with

extra care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Through great care is taken when parts were

manufactured from sheet metal, there may be burrs

on the edges of parts. The burrs could cause injury if

ngers are moved across them in some rare cases.

Wear gloves to protect your hands.

◎Use only designated parts!

The set's parts have specic safety properties (re

resistance, voltage resistance, etc.). Be sure to use

parts which have the same properties for replacement.

The burrs have the same properties. In particular, for

the important safety parts that are indicated by the z

mark on schematic diagrams and parts lists, be sure to

use the designated parts.

◎ Be sure to mount parts and arrange the wires

as they were originally placed!

For safety seasons, some parts use tapes, tubes or

other insulating materials, and some parts are mounted

away from the surface of printed circuit boards.

Care is also taken with the positions of the wires by

arranging them and using clamps to keep them away

from heating and high voltage parts, so be sure to set

everything back as it was originally placed.

◎Make a safety check after servicing!

Check that all screws, parts and wires removed or

disconnected when servicing have been put back in

their original positions, check that no serviced parts

have deteriorate the area around. Then make an

insulation check on the external metal connectors and

between the blades of the power plug, and otherwise

check that safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet,

disconnect the antenna, plugs, etc., and on the power.

Using a 500V insulation resistance tester, check that

the insulation resistance value between the inplug and

the externally exposed metal parts (antenna terminal,

headphones terminal, input terminal, etc.) is 1MΩ or

greater. If it is less, the set must be inspected and

repaired.

CAUTION

Concerning important safety

parts

Many of the electric and the structural parts used in

the set have special safety properties. In most cases

these properties are difcult to distinguish by sight, and

the use of replacement parts with higher ratings (rated

power and withstand voltage) does not necessarily

guarantee that safety performance will be preserved.

Parts with safety properties are indicated as shown

below on the wiring diagrams and the parts list in this

service manual. Be sure to replace them with the parts

which have the designated part number.

(1) Schematic diagrams .......Indicated by the z mark.

(2) Parts lists .......Indicated by the z mark.

The use of parts other than the

designated parts could cause electric

shocks, res or other dangerous

situations.

3

Page 4

NOTE FOR SCHEMATIC DIAGRAM

NOTE FOR PARTS LIST

WARNING:

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

CAUTION:

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis resistance check. If

the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the set

is defective.

WARNING:

DO NOT return the set to the customer unless the problem is identied and remedied.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

ALL CAPACITANCE VALUES ARE EXPRESSED IN MICRO FARAD, UNLESS OTHERWISE INDICATED. P INDICATES MICRO-MICRO

FARAD. EACH VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL INPUT CONDITION. CIRCUIT AND PARTS ARE SUBJECT

TO CHANGE WITHOUT PRIOR NOTICE.

NOTE FOR PARTS LIST

1.

Parts indicated by "nsp" on this table cannot be supplied.

2.

When ordering a part, make a clear distinction between "1" and "I" (i) to avoid mis-supplying.

3.

A part ordered without specifying its part number can not be supplied.

4.

Part indicated by "★" mark is not illustrated in the exploded view.

5.

General-purpose Carbon Film Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

6.

General-purpose Carbon Chip Resistors are not included are not included in the P.W.Board parts list.

(Refer to the Schematic Diagram for those parts.)

WARNING:

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

4

Page 5

TECHNICAL SPECIFICATIONS

nAudio Section

• Poweramplier

Rated output :

Front :

75 W + 75 W (8 Ω, 20 Hz – 20 kHz with 0.08 % T.H.D.)

110 W + 110 W (6 Ω, 1 kHz with 0.7 % T.H.D.)

Center :

75 W (8 Ω, 20 Hz – 20 kHz with 0.08 % T.H.D.)

110 W (6 Ω, 1 kHz with 0.7 % T.H.D.)

Surround :

75 W + 75 W (8 Ω, 20 Hz – 20 kHz with 0.08 % T.H.D.)

110 W + 110 W (6 Ω, 1 kHz with 0.7 % T.H.D.)

Output connectors : 6 – 16 Ω

• Analog

Input sensitivity/Input impedance : 200 mV/47 kΩ

Frequency response: 10 Hz – 100 kHz — 0, –3 dB (DIRECT mode)

S/N : 98 dB (IHF–A weighted, DIRECT mode)

nTuner section

[FM](Note: μV at 75 Ω, 0 dBf = 1 x 10

Receiving Range (for E3) :

[FM] 87.5 MHz – 107.9 MHz [AM]520 kHz – 1710 kHz

Receiving Range (for E2, EA, E1C) :

[FM] 57.5 MHz – 108.0 MHz [AM]522 kHz – 1611 kHz

Usable Sensitivity :

[FM]1.2 μV (12.8 dBf) [AM]18 μV

–15

W)

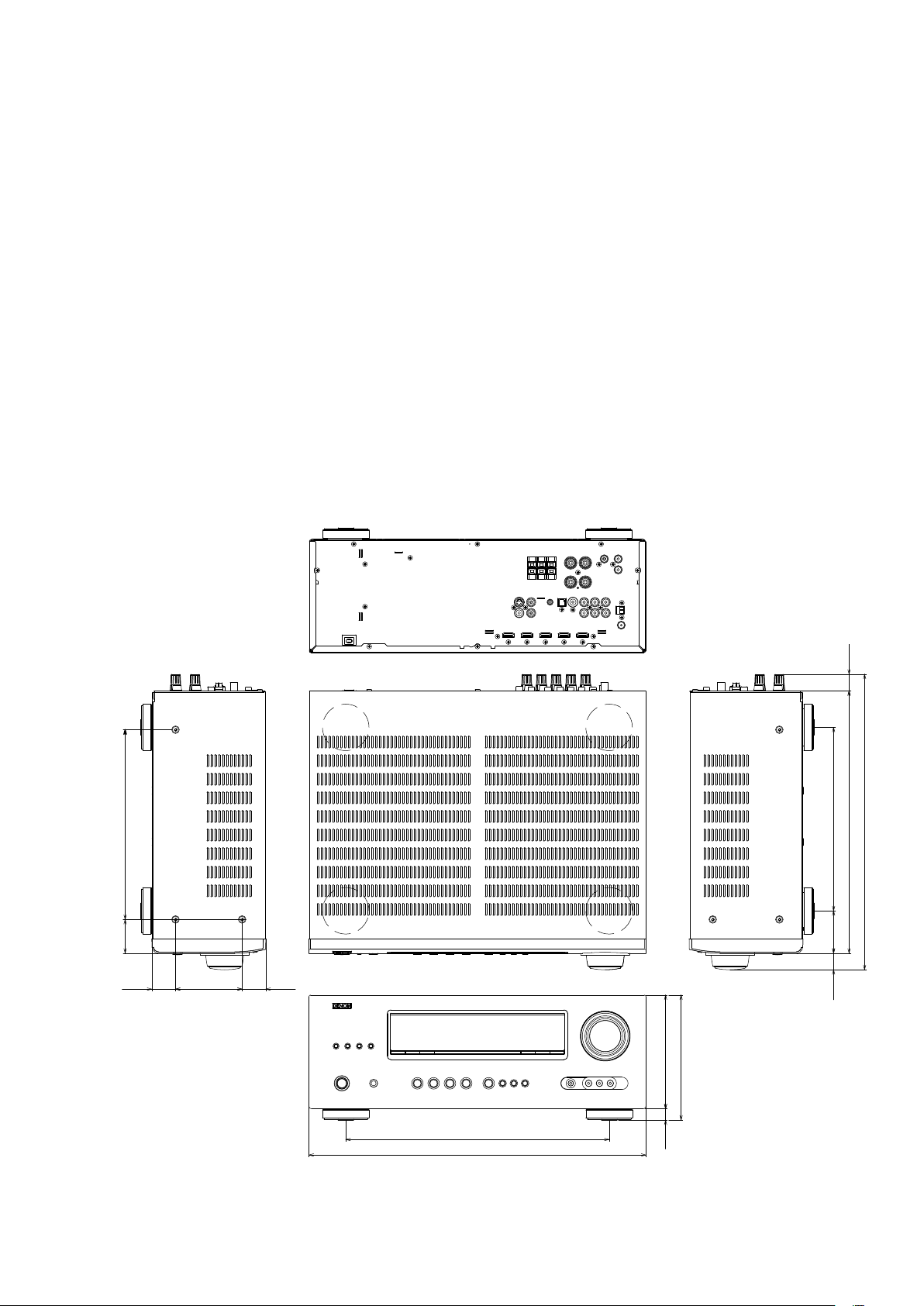

DIMENSION

50 dB Quieting Sensitivity :

[FM]MONO 2.8 μV (20.2 dBf)

S/N (IHF-A) :

[FM]MONO 70 dB

STEREO 67 dB

Total harmonic Distortion (at 1 kHz) :

[FM]MONO 0.7 %

STEREO 1.0 %

nGeneral

Power supply (for E3) : AC 120 V, 60 Hz

(for E2, EA) : AC 230 V, 50 Hz / 60Hz

(for E1C) : AC 220 V, 50 Hz

Power consumption :

330 W

0.5 W (Standby)

Maximum external dimensions :

435 (W) x 162 (H) x 382 (D) mm

Weight : 9.2 kg

nRemote Control Unit (RC-1158)

Batteries : R03/AAA Type (two batteries)

Maximum external dimensions : 50 (W) x 211 (H) x 22 (D) mm

Weight : 110 g (including batteries)

245.0

43.5

30.5

86.0

30.5

162.0

236.8

54.7

21.5

22.0

338.5

382.0

340.0

435.0

15.0 147.0

5

Page 6

CAUTIONS IN SERVICING

Initializing AV SURROUND RECEIVER

AV SURROUND RECEIVER initialization should be performed when the μcom, peripheral parts of μcom, and Digital

P.W.B. were replaced.

1. Turn off the power pressing ON/STANDBY button.

2. Press ON/STANDBY button while simultaneously while pressing DOCK CONTROL 8 and DOCK CONTROL

buttons.

3. Check that the entire display is ashing at intervals of about 1 second, and then release the 2 buttons.

The microprocessor will be initialized.

Note: • If step 3 fails, start over from step 1.

• All user settings will be lost and the factory setting will be recovered after the set is initialized.

So make sure to note down your setting beforehand for restoring after the initialization.

9

ON/STANDBY

DOCK CONTROL 9

DOCK CONTROL 8

Service Jig

When you update the rmware, you can use the following

JIG (RS232C to internal connector conversion adapter).

Please order it from Denon Ofcial Service Distributor in your region if necessary.

8U-210100S : WRITING KIT : 1 Set

606050028012P : 7P FFC(1.0) L-240 : 1 Set

(Refer to "PROCEDURE FOR UPGRADING THE VERSION OF THE FIRMWARE".)

6

Page 7

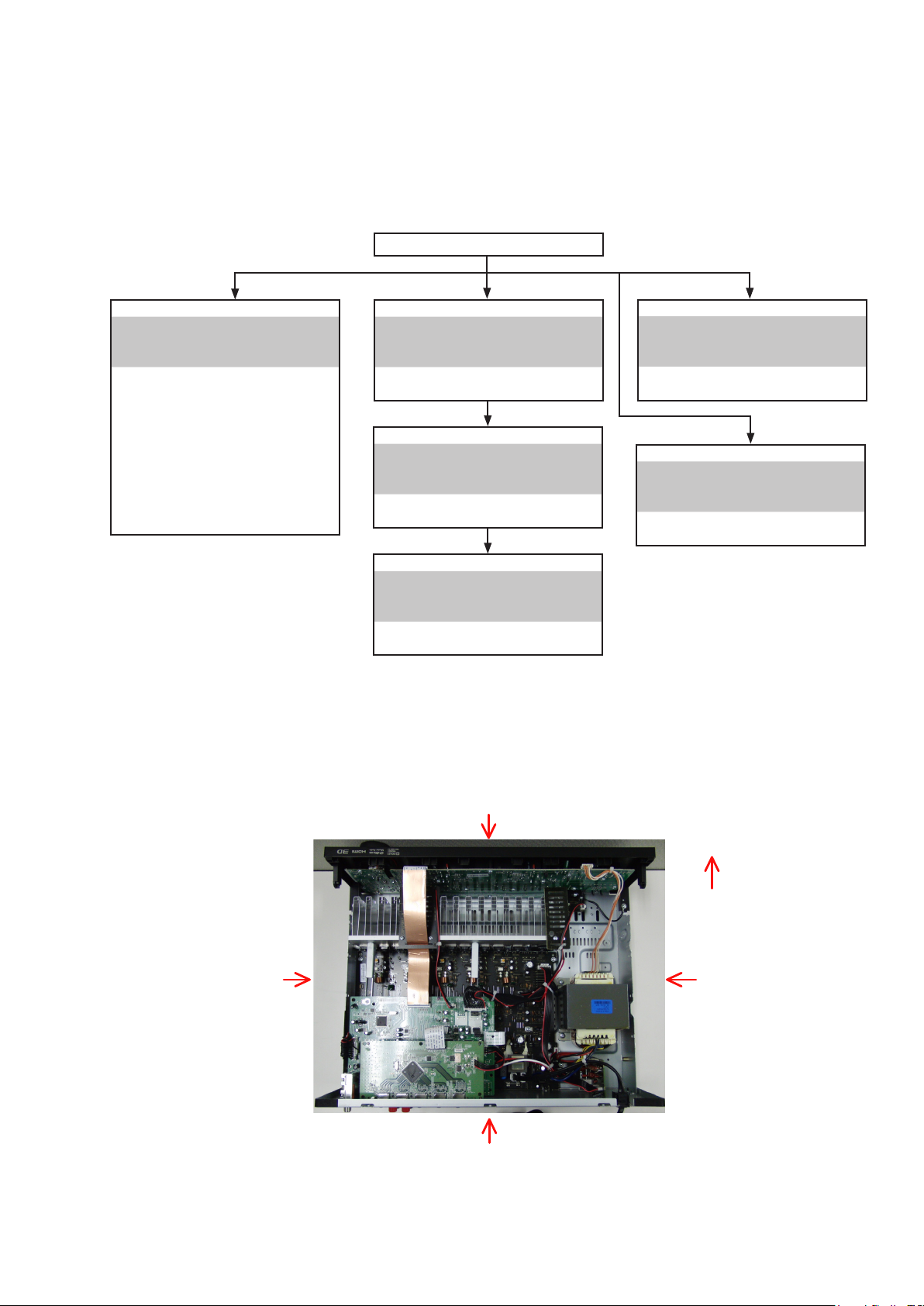

DISASSEMBLY

• Disassemble in order of the arrow in the following gure.

• In the case of the re-assembling, assemble it in order of the reverse of the following ow.

• In the case of the re-assembling, observe "attention of assembling".

• If wire bundles are untied or moved to perform adjustment or replace parts etc., be sure to rearrange them neatly as

they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

TOP COVER

FRONT PANEL ASSY

Refer to "DISASSEMBLY

1. FRONT PANEL ASSY"

and "EXPLODED VIEW"

PORTABLE IN UNIT

(Ref. No. of EXPLODED VIEW : C1)

VOLUME UNIT

(Ref. No. of EXPLODED VIEW : C2)

FRONT UNIT

(Ref. No. of EXPLODED VIEW : C3)

HEADPHONE UNIT

(Ref. No. of EXPLODED VIEW : C4)

POWER UNIT

(Ref. No. of EXPLODED VIEW : C5)

HDMI UNIT

Refer to "DISASSEMBLY

2. HDMI UNIT"

and "EXPLODED VIEW"

HDMI UNIT

(Ref. No. of EXPLODED VIEW : C11)

INPUT UNIT

Refer to "DISASSEMBLY

3. INPUT UNIT"

and "EXPLODED VIEW"

INPUT UNIT

(Ref. No. of EXPLODED VIEW : C10)

RADIATOR ASSY

Refer to "DISASSEMBLY

4. RADIATOR ASSY"

and "EXPLODED VIEW"

MAIN UNIT

(Ref. No. of EXPLODED VIEW : C6)

REGULATOT UNIT

(Ref. No. of EXPLODED VIEW : C7)

POWER TRANS

(Ref. No. of EXPLODED VIEW : C14)

POWER UNIT

Refer to "DISASSEMBLY

5. POWER UNIT"

and "EXPLODED VIEW"

POWER TRANS

Refer to "DISASSEMBLY

6. POWER TRANS "

and "EXPLODED VIEW"

About the photos used for "descriptions of the DISASSEMBLY" section

• The shooting direction of each photograph used herein is indicated on the left side of the respective photograph as

"Shooting direction: ***".

• Refer to the diagram below about the shooting direction of each photograph.

• Photographs with no shooting direction indicated were taken from the top of the set.

The viewpoint of each photograph

(Shooting direction)

[View from the top]

Shooting direction : B

Front side

Shooting direction: C

Shooting direction: D

Shooting direction: A

7

Page 8

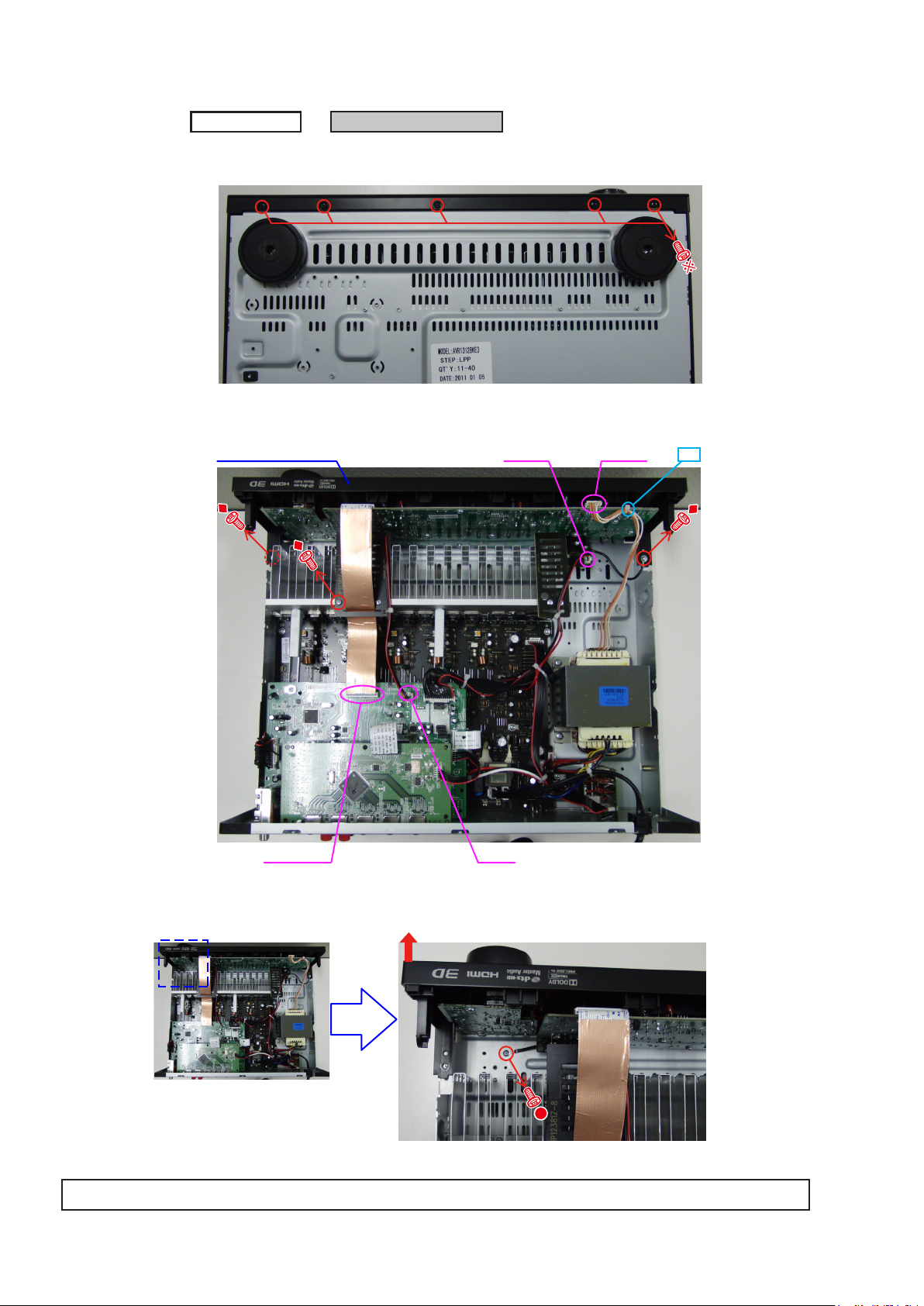

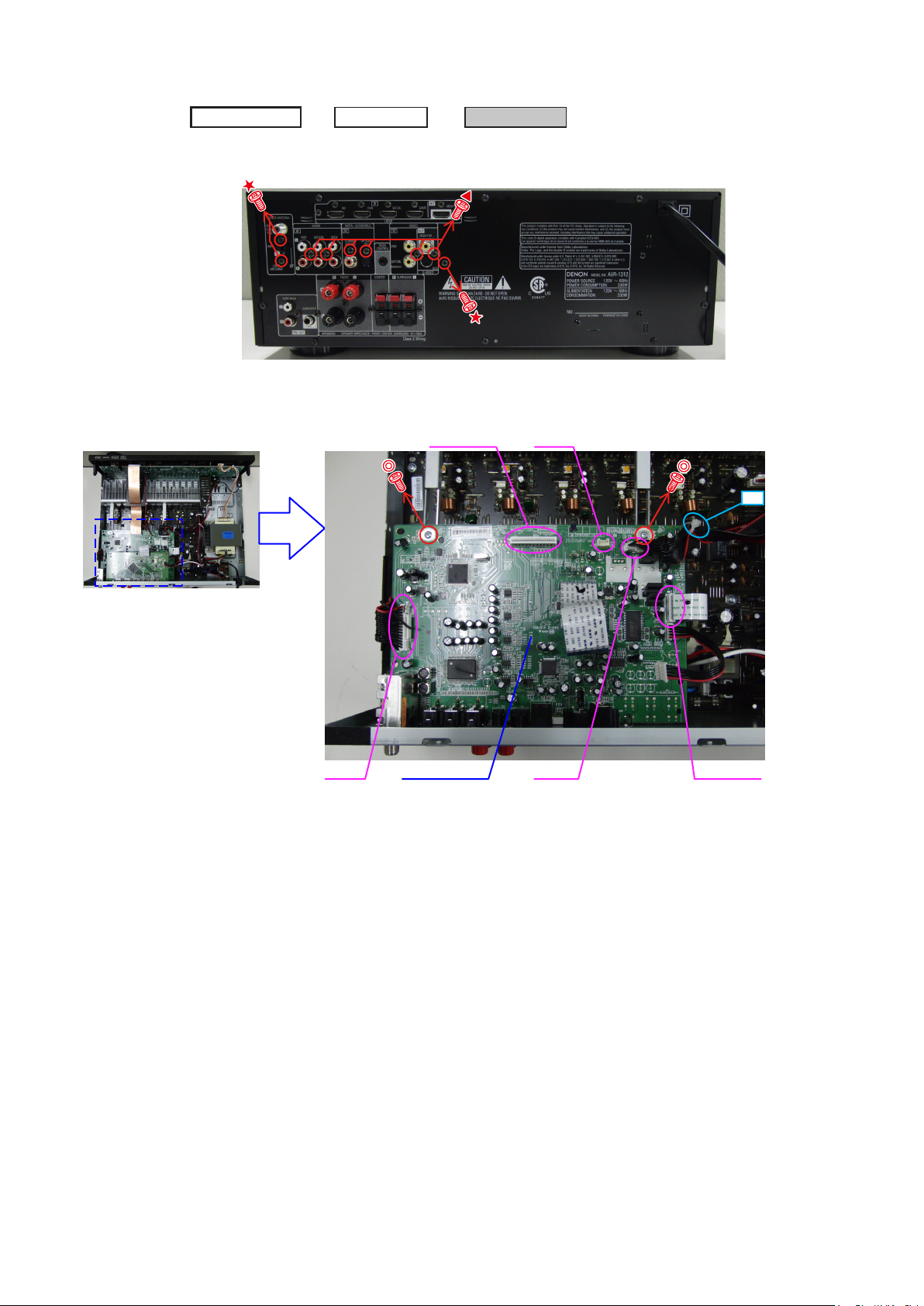

1. FRONT PANEL ASSY

Proceeding :

(1) Remove the screws.

View from the bottom

(2) Cut the wire clamp band, then disconnect the connector wires and FFC cable. Remove the screws.

TOP COVER

FRONT PANEL ASSY

FRONT PANEL ASSY

→

CN603

CN610

cut

CN71FFC cable

(3) Remove the screws.

Please refer to "EXPLODED VIEW" for the disassembly method of each P.W.B included in FRONT PANEL ASSY.

8

Page 9

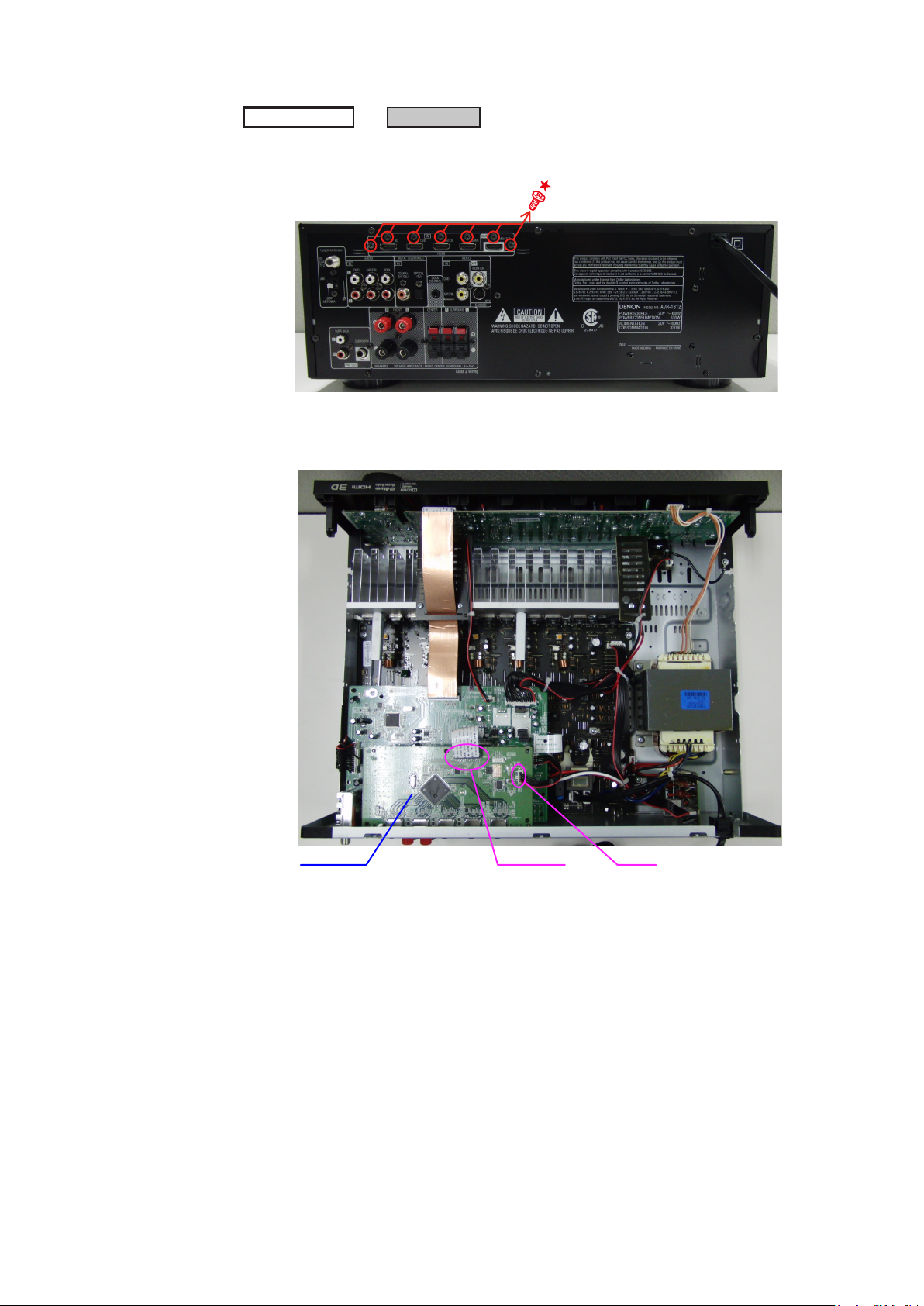

2. HDMI UNIT

Proceeding :

(1) Remove the screws.

Shooting direction: A

(2) Disconnect the connector wire and FFC cable.

TOP COVER

HDMI UNIT

→

HDMI UNIT

CN12FFC cable

9

Page 10

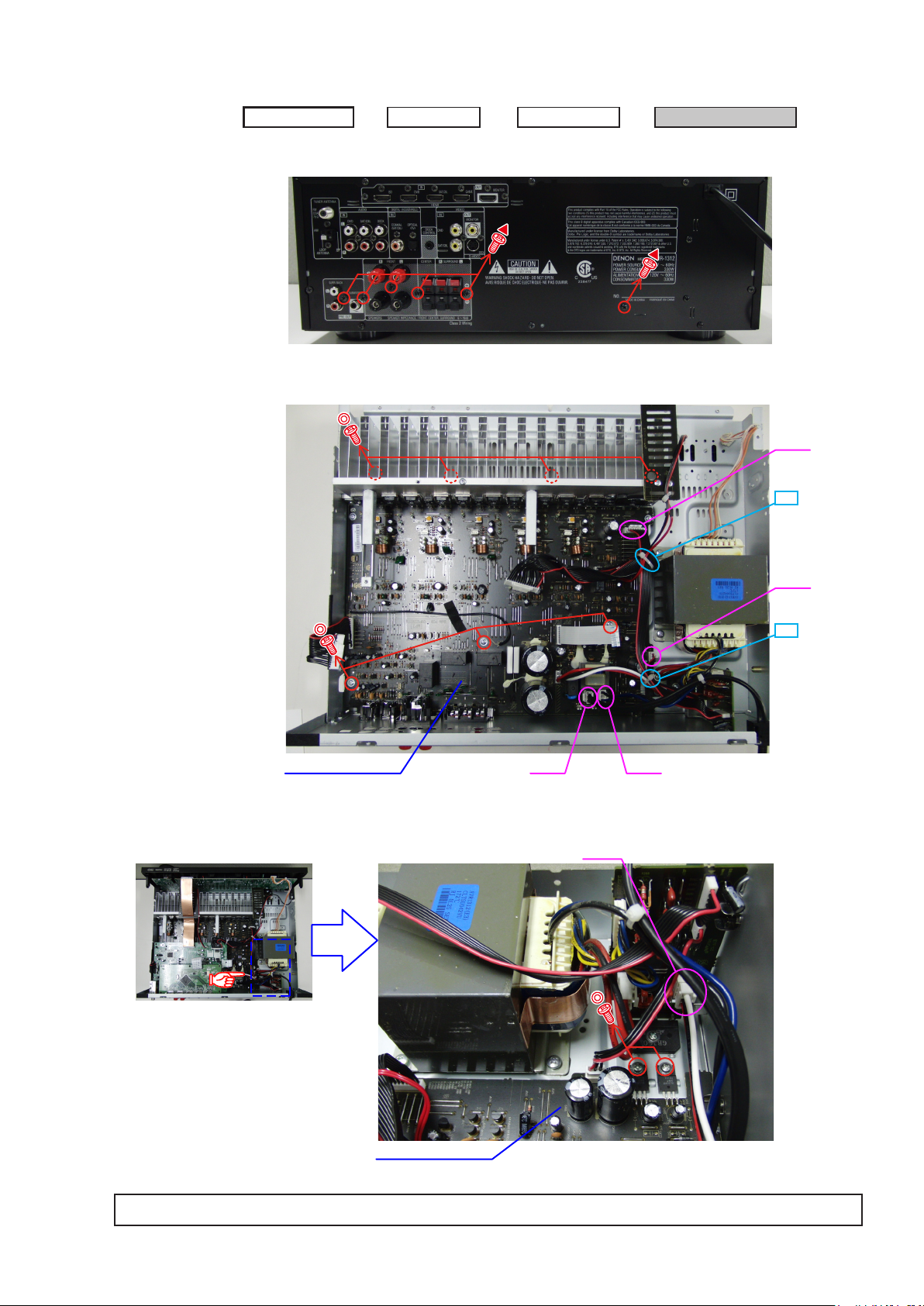

3. INPUT UNIT

Proceeding :

(1) Remove the screws.

Shooting direction: A

(2) Disconnect the connector wires and FFC cables, then remove the screws.

TOP COVER

HDMI UNIT

→

INPUT UNIT

→

FFC cable

CN71

cut

CN42

INPUT UNIT

FFC cableCN43

10

Page 11

4. RADIATOR ASSY

Proceeding :

(1) Remove the screws.

Shooting direction: A

(2) Disconnect the connector wires, then remove the screws.

TOP COVER

HDMI UNIT

→

→

INPUT UNIT

RADIATOR ASSY

→

CN46

cut

CN45

cut

RADIATOR ASSY

(3) Disconnect the connector wire, then remove the screws. Remove the RADIATOR ASSY from the main unit.

CN47 CN48

CN41

Shooting direction: C

RADIATOR ASSY

Please refer to "EXPLODED VIEW" for the disassembly method of each P.W.B included in RADIATOR ASSY.

11

Page 12

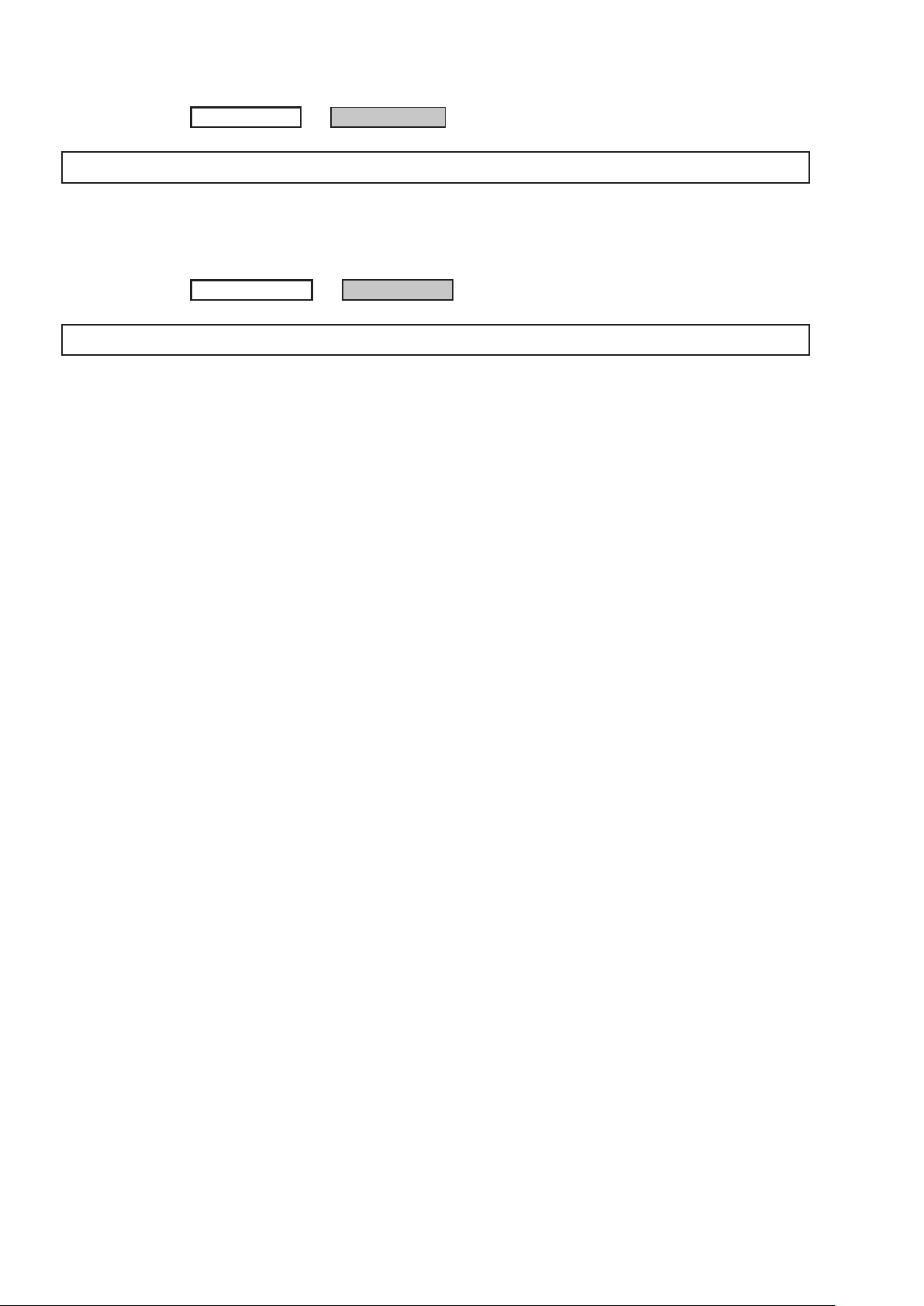

5. POWER UNIT

Proceeding :

Please refer to "EXPLODED VIEW" for the disassembly method of POWER UNIT.

TOP COVER

POWER UNIT

→

6. POWER TRANS

Proceeding :

Please refer to "EXPLODED VIEW" for the disassembly method of POWER TRANS.

CABINET TOP

TRANS MAIN

→

12

Page 13

SPECIAL MODE

Special mode setting button

Press the ON/STANDBY button to turn on the power while pressing both the button A and the button B at the same

b

time.

Mode Button A Button B Contents

Firmware versions such as Main or DSP are displayed in the

µcom/DSP Version display mode STATUS DIMMER

Initialization mode

Mode for switching tuner frequency

step

Mode for preventing remote control

acceptance

When power is turned on, pressing both buttons A and B at the same time for 3 seconds or more.

b

Mode Button A Button B Contents

Select the video signal format STATUS DIMMER

DOCK

CONTROL

RESTORER SOURCE

8

DIMMER PRESET CH +

DOCK

CONTROL

FL display. Errors are displayed or when they occur.

(Refer to page 14 .)

Backup data initialization is carried out. (Refer to page 6 .)

9

---E2 model only---

Change tuner frequency step to AM9k/FM50kHz STEP or

AM:10k/FM:200kHz.

Operations using the remote control are rejected.

"REMOTE LOCK:ON" is displayed in FL display.

f

(Mode the cancellation: Turn off the power and execute the

same button operations as when performing setup.)

Select with the "+", "-" and iPod play button change video

format NTSC or PAL

ON/STANDBY

DIMMERSOURCE f

RESTORER

DOCK CONTROL 8

STATUS

DOCK CONTROL 9

13

Page 14

1. µcom/DSP Version display mode

1.1. Operationspecications

µcom/DSP version display mode:

When the set is started up in this mode, the version information is displayed.

Starting up:

Press the "ON/STANDBY" button to turn on the power while pressing the "RETURN" and "STATUS" buttons.

Now, press the "STATUS" button to the display the 2nd item information on the FL Display.

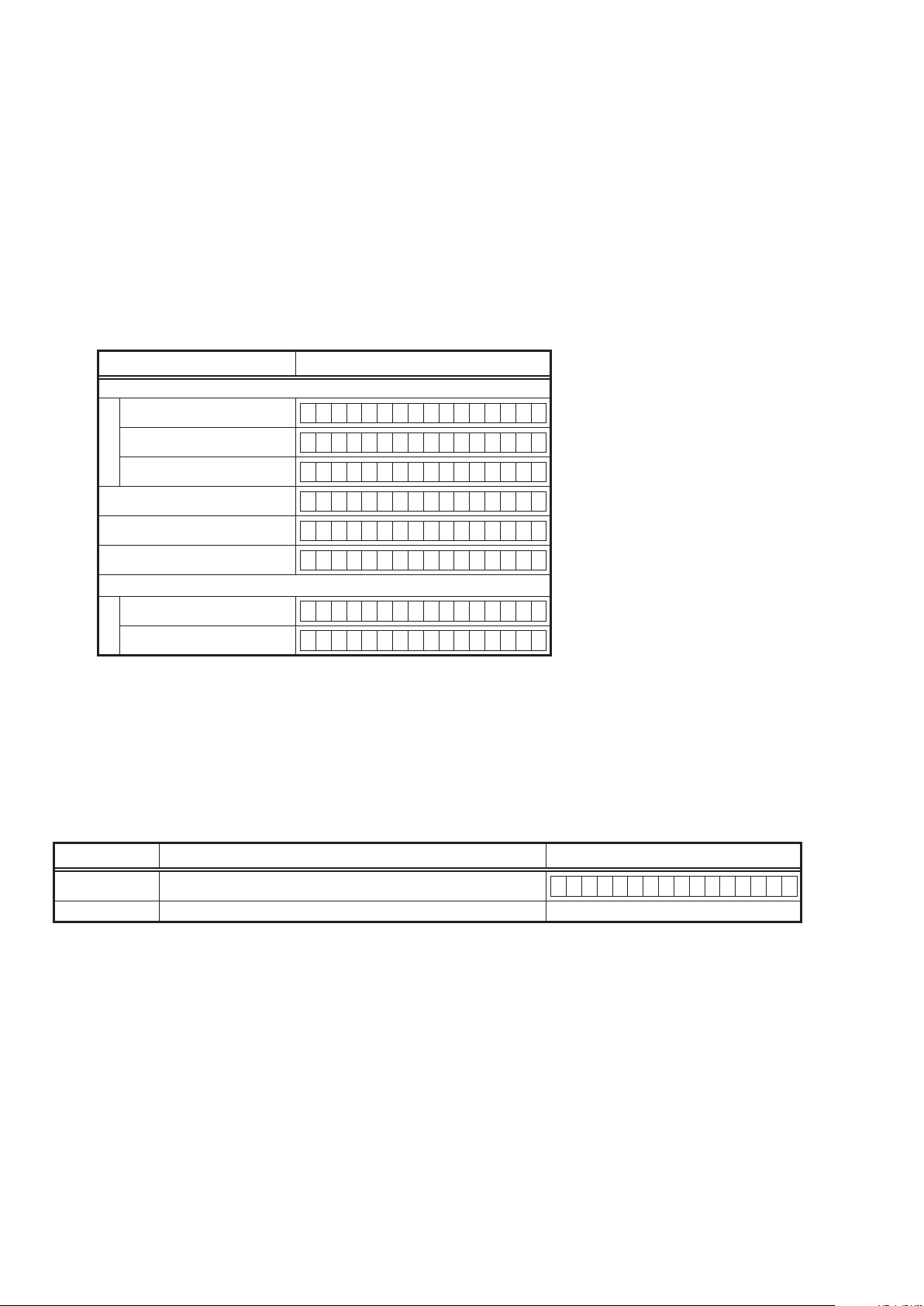

1.2. Display Order

Model destination information → w Main-µcom version → e DSP version → r OSD version

q

→ t iPod Dock version (Connecting iPod Dock)

Display State

Model destination information

q

AVR-1312 E3 model

A V R 1 3 1 2 E 3

AVR-1312 E2 model

AVR-1312 E1C model

Main-µcom version

w

DSP version

e

OSD version

r

iPod Dock version (Connecting iPod Dock)

t

(ASD-1R/11R)

(ASD-3/51)

A V R 1 3 1 2 E 2

A V R 1 3 1 2 E 1 C

M a i n : * * . * *

D S P . * . * . *

O S D : * * . * *

D o c k V e r : * * . * *

D o c k : I * * * * * * * *

Cleared of mode:

Press the "ON/STANDBY" button to turn the power off.

1.3. Error display

See the following table for each "Error information" display and its contents (status).

Condition - State

DSP NG When DSP boot, executing DSP reset makes to becomes error.

DSP OK (No error display, version display only)

D S P E R R O R 0 1

14

Page 15

WHEN THE MICROPROCESSOR IS REPLACED WITH A NEW ONE

When the U-PRO (Microprocessor) or the Flash ROM is replaced, conrm the following.

PWB Name Ref. No. Description

INPUT IC91 T5CN5 B SOFTWARE: Main

INPUT IC82 ST25VF080B-50-4C-S2AF B SOFTWARE: DSP ROM

After

replaced

Remark

After replacing

A : Mask ROM (With software). No need for write-in of software to the microprocessor.

B : Flash ROM (With software). Usually, no need for write-in of software. But, when the software was updated, you should

write the new software on the microprocessor or ash ROM. Please check the software version.

C : Empty Flash ROM (Without software). You should write the software on the microprocessor or ash ROM.

Refer to "Update procedure" or "writing procedure", when you write the software.

PROCEDURE FOR UPGRADING THE VERSION OF THE FIRMWARE

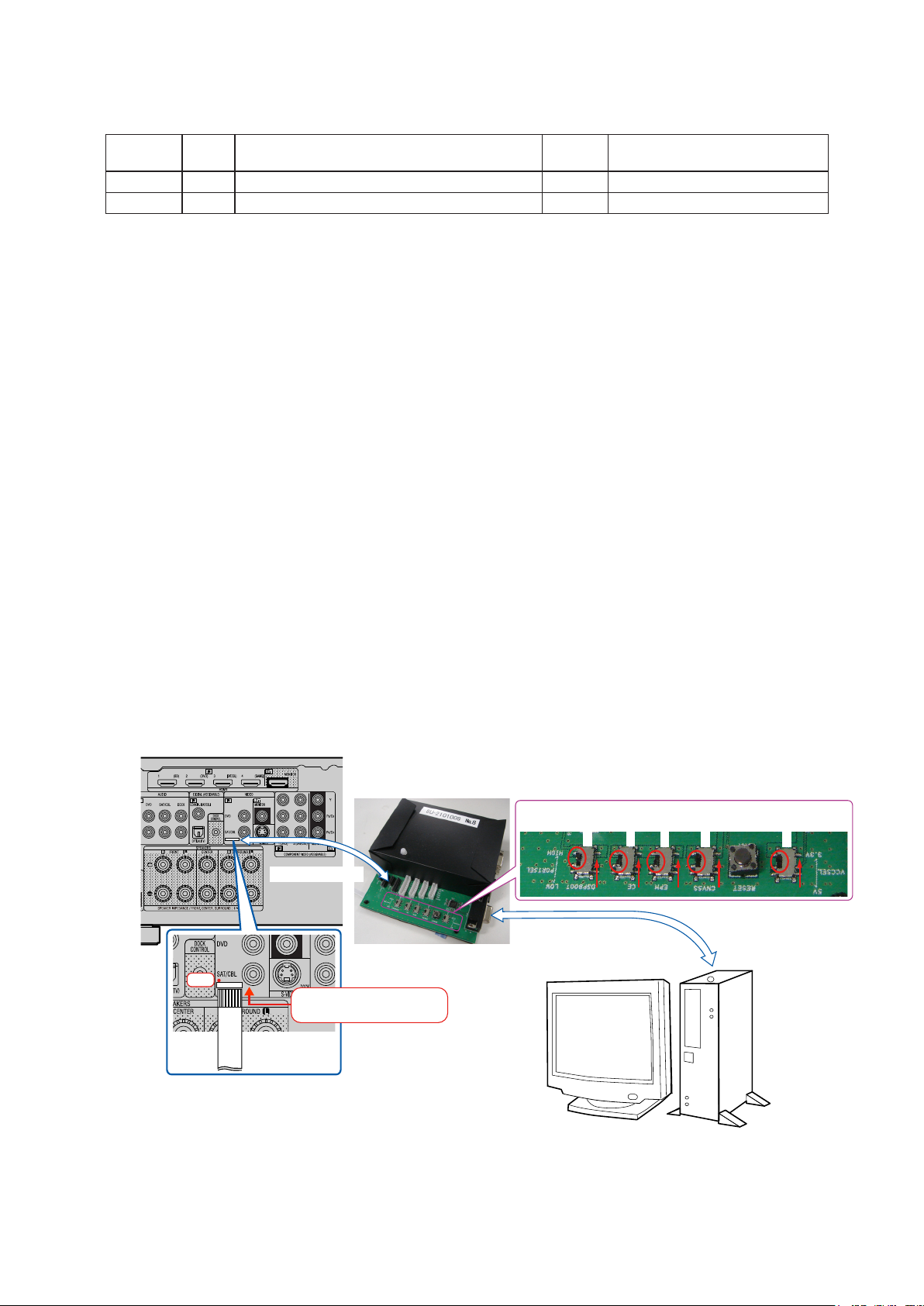

1. Preparations

1.1. Before starting the operation

(1) Personal Computer (Installed “BootTool_M330(Writing program).exe”).

(2) RS-232 cable (9P (Male), Straight).

(3) 8U-210100S Writing Kit.

(4) 606050028012P / 7P FFC(1.0) L=240.

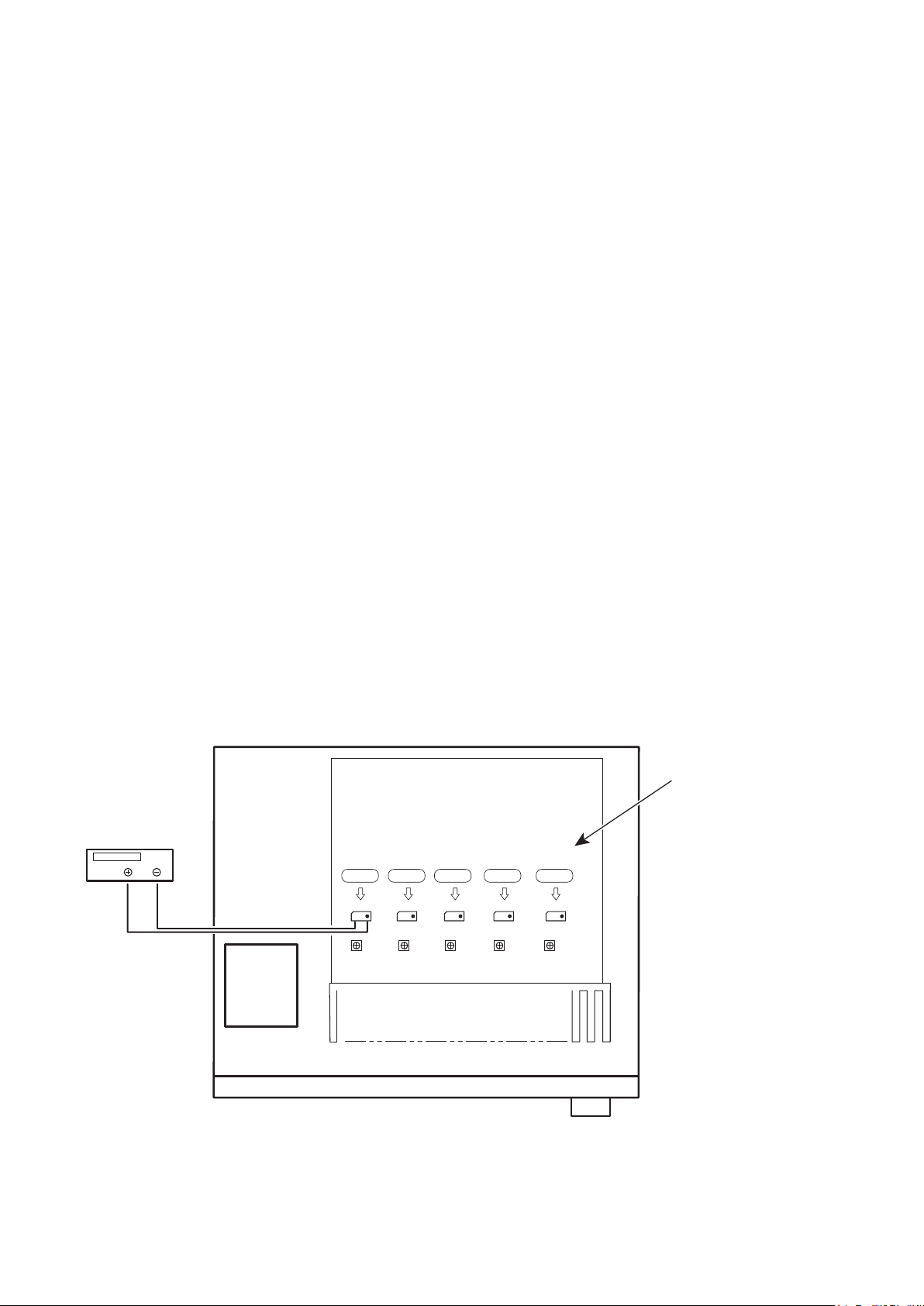

1.2. Connection of the AV receiver

(1) Conrm the power on/off switch of the AV receiver is turning off.

(2) Connect the update terminal of AV receiver with the “Writing Kit”.

(Refer to gure below for the connection of the 7P FFC cable.)

(3) Connect the RS-232C cable from PC with the “Writing Kit”.

7P FFC Cable

Writing Kit

1 pin

This side is contacts of

7P FFC Cable.

7P FFC Cable

S706-709 : HIGE

S709

S708

RS-232C Cable

S707

S706

S702 : 3.3V

S702

PC

15

Page 16

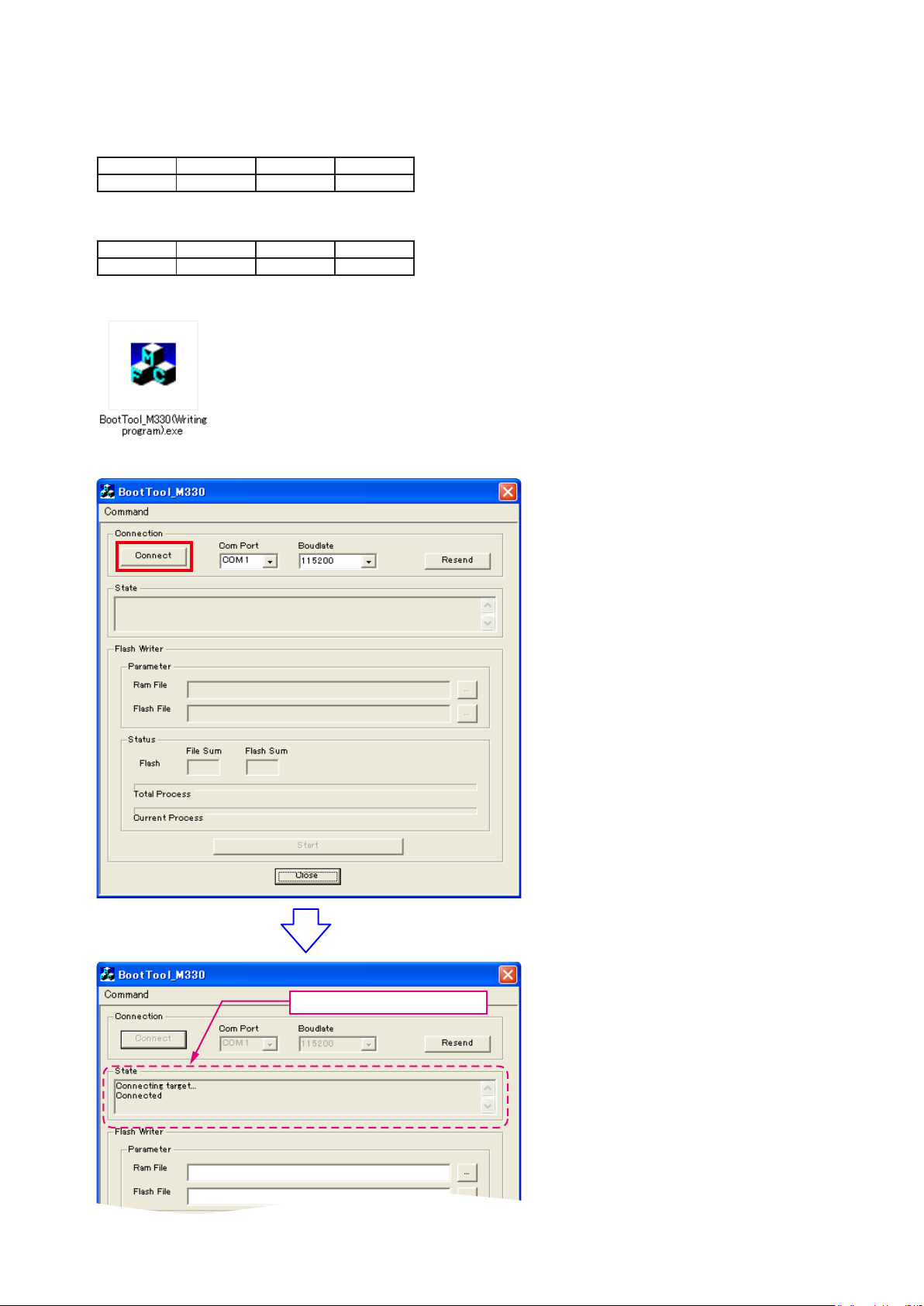

2. UPDATE FIRMWARE

(1) Connect the update terminal of AV receiver with the “Writing Kit”.

(2) Set the switch of “Writing Kit" (Refer to the table below).

DSPBOOT CE EPM CNVSS

H H H H

(3) Press the "ON/STANDBY" button to turn the power on of AV receiver.

(4) Set the switch of “Writing Kit" (Refer to the table below).

DSPBOOT CE EPM CNVSS

H H L H

(5) Press the "RESET" switch of “Writing Kit".

(6) Run the “BootTool_M330(Writing program).exe” on desktop of PC.

(7)-1 Click the “Connect” button.

"Connected" is displayed, it is OK.

16

Page 17

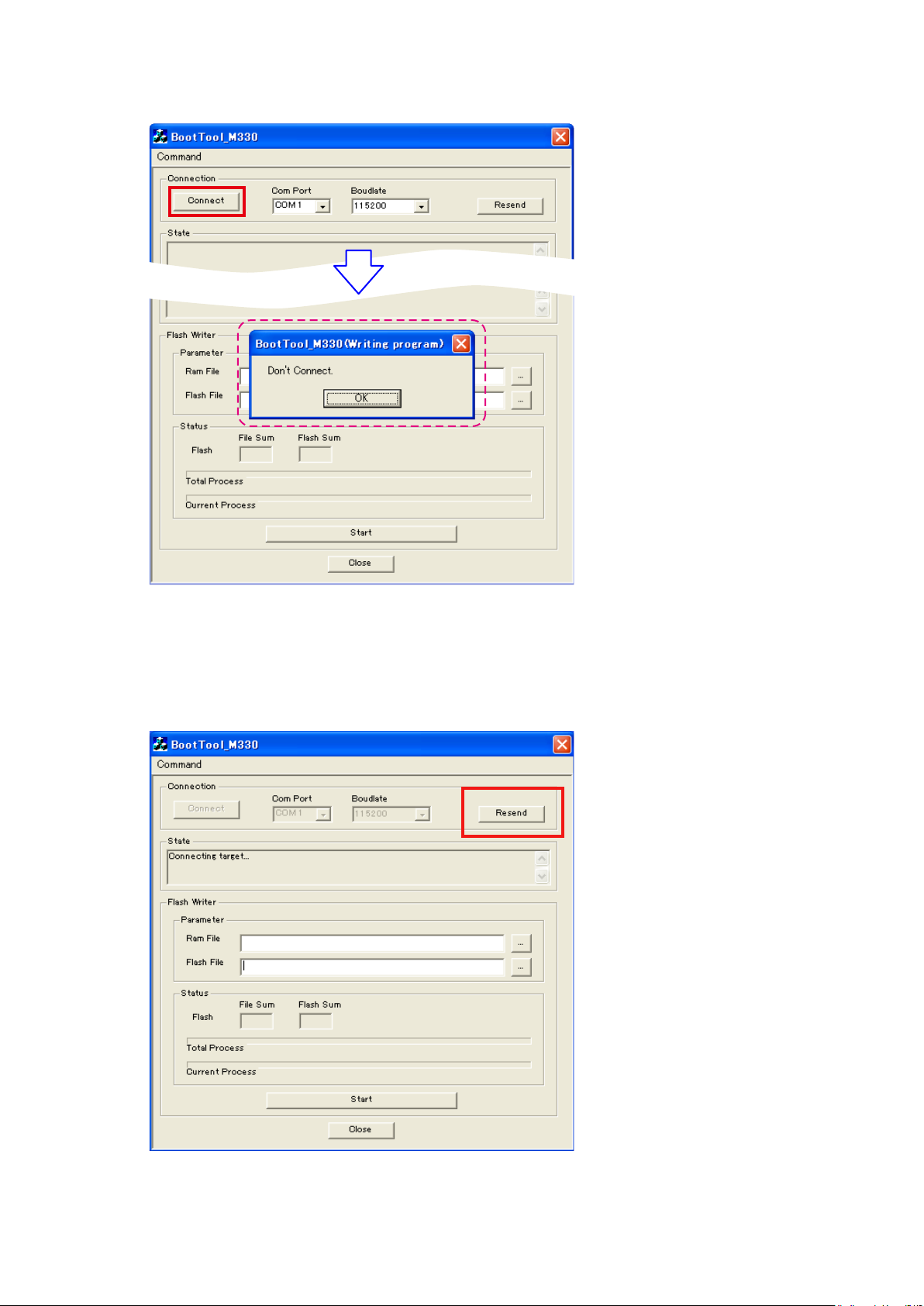

[ If you can't get a "Connected" message. ]

(7-a) Click the “Connect” button. If connection is not good, then you can see the “Don't Connect” message.

Please conrm the following

(i) Check the connection of the AV receiver and PC. (Refer to "1.2. Connection of the AV receiver" )

(ii) Check the selection of the RS-232C port number of PC.

(ii) Refer to "3. Notice: ". (page 27 )

(7-b) If Ram/Flash le selection screen is active, after you Click "Resend" button.

Connection is good, go to next step.

17

Page 18

SP SF1

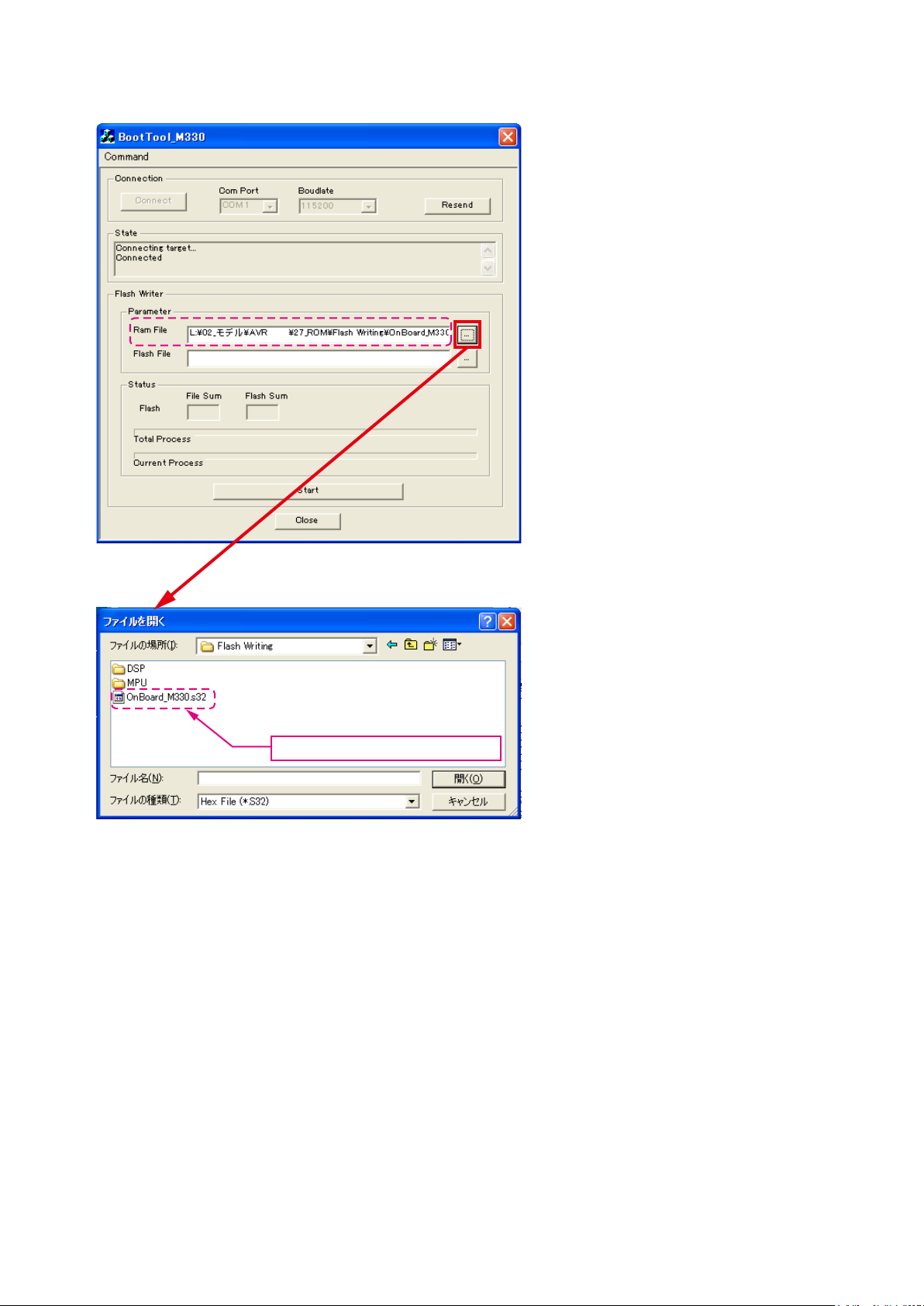

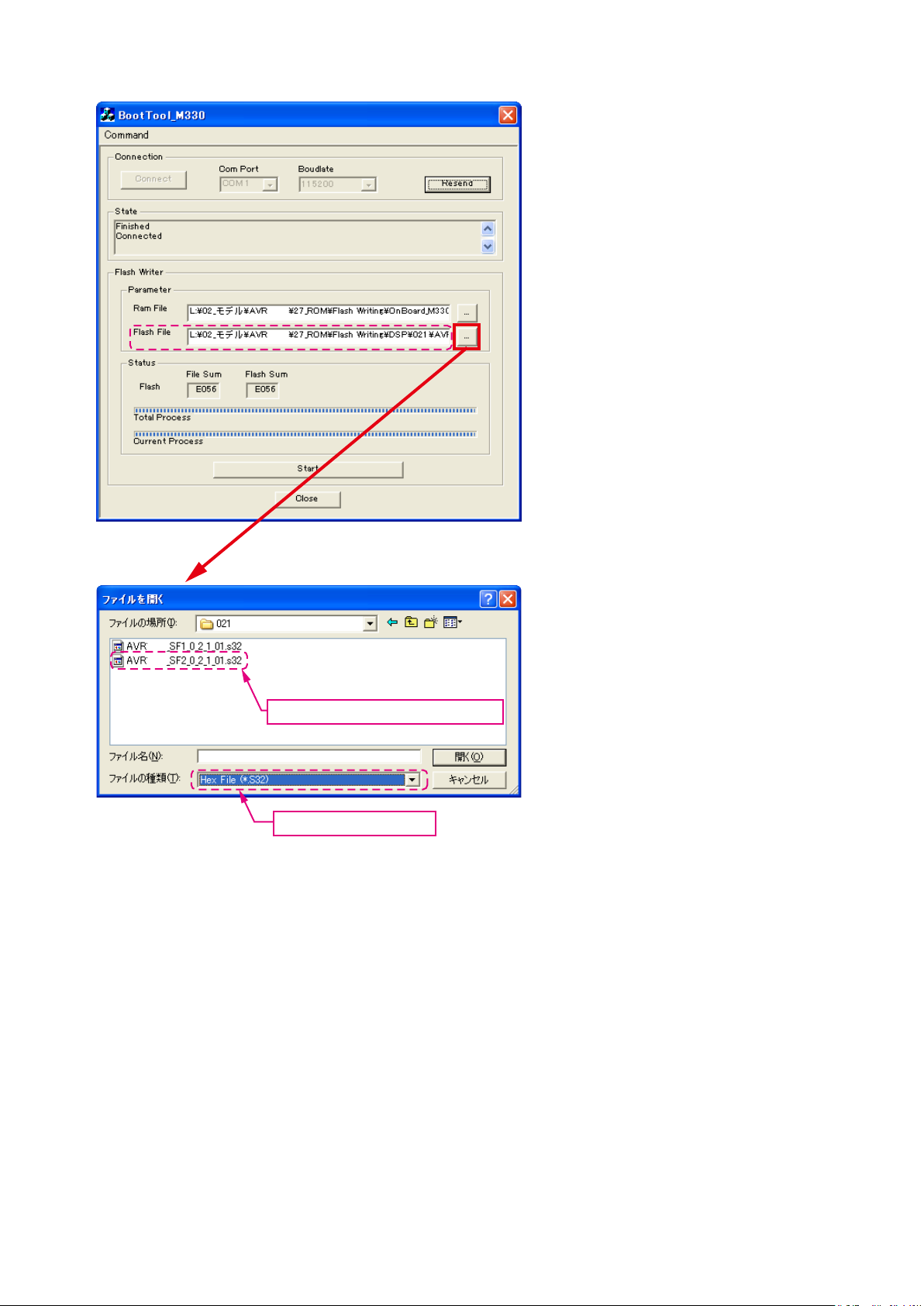

(8) Choose Ram File(OnBoard_M330.s32).

XXXX

Choose Ram File(OnBoard_M330.s32).

18

Page 19

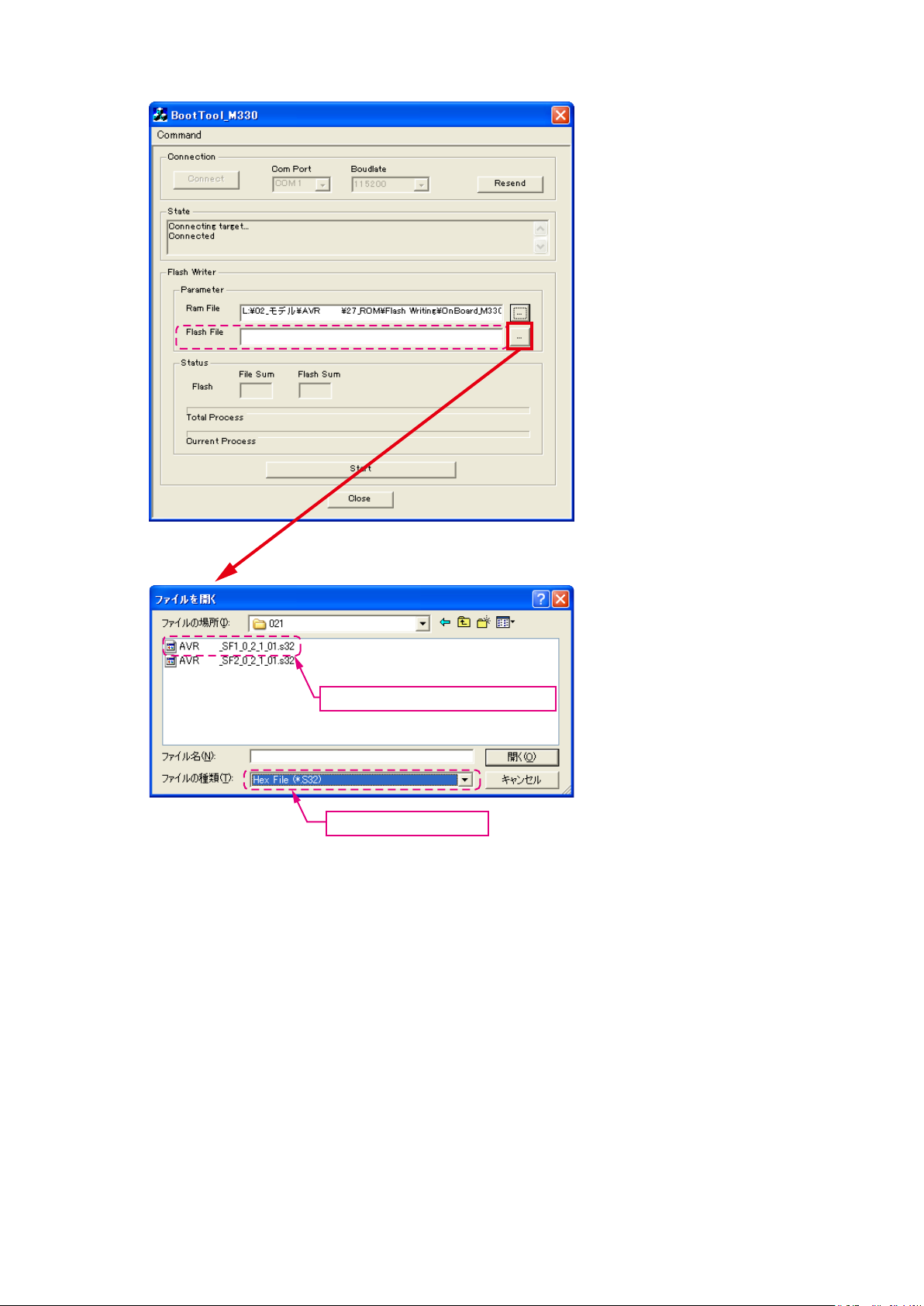

(9) Choose Flash File(DSP : SF1).

XXXX

XXXX

XXXX

Choose "AVRXXXX_SF1_*_*_*_01.s32".

Choose "Hex File (*.S32)".

19

Page 20

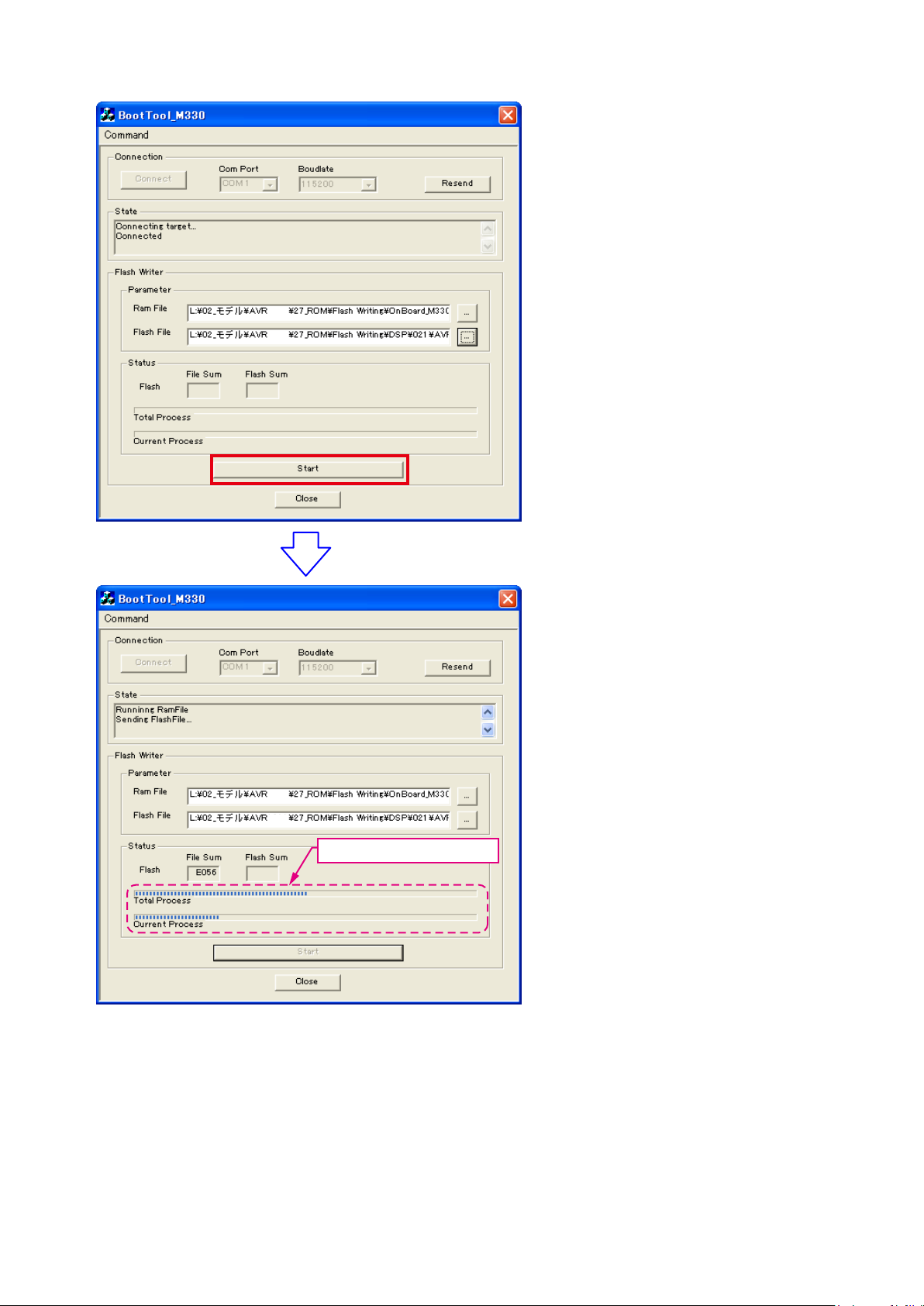

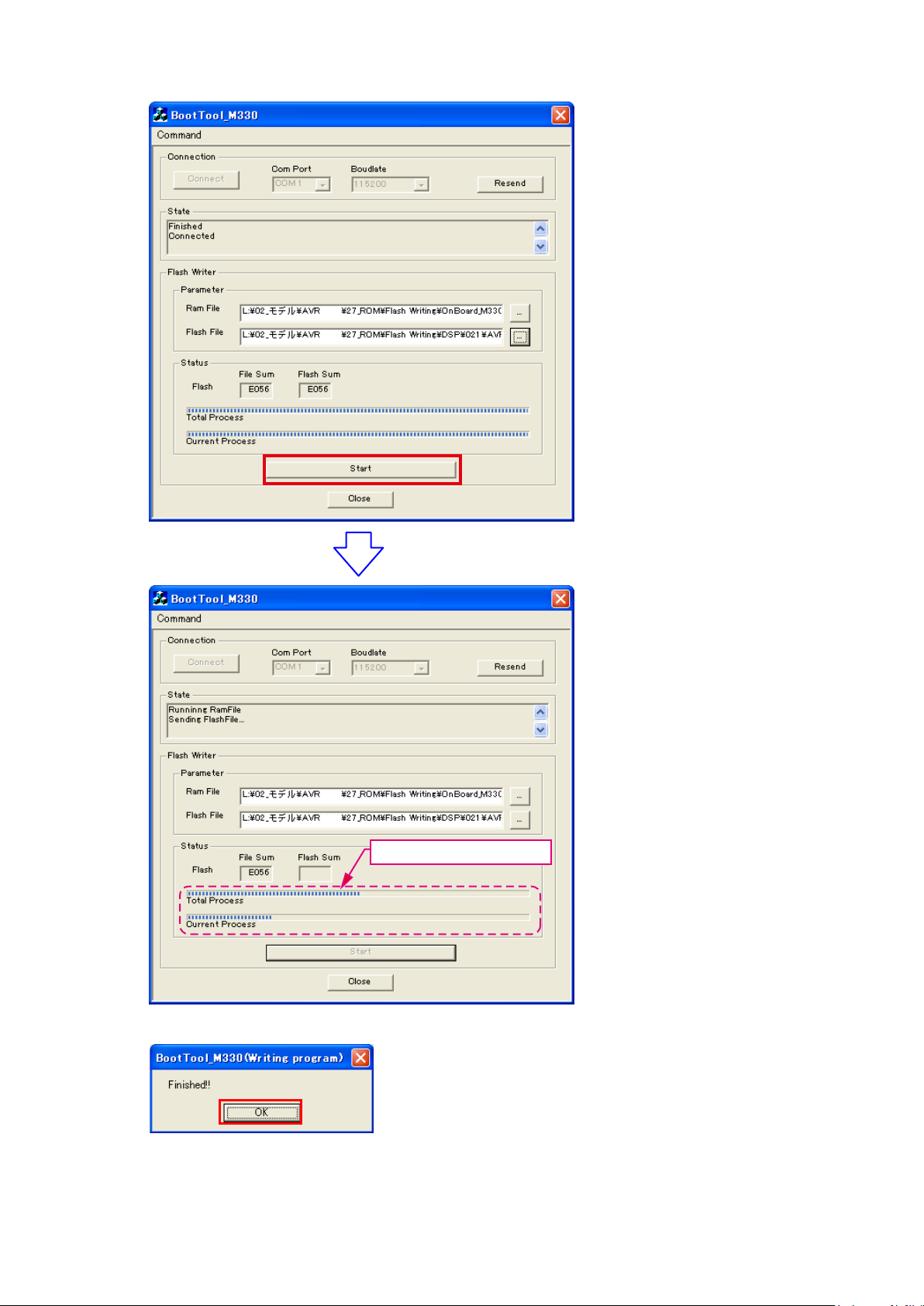

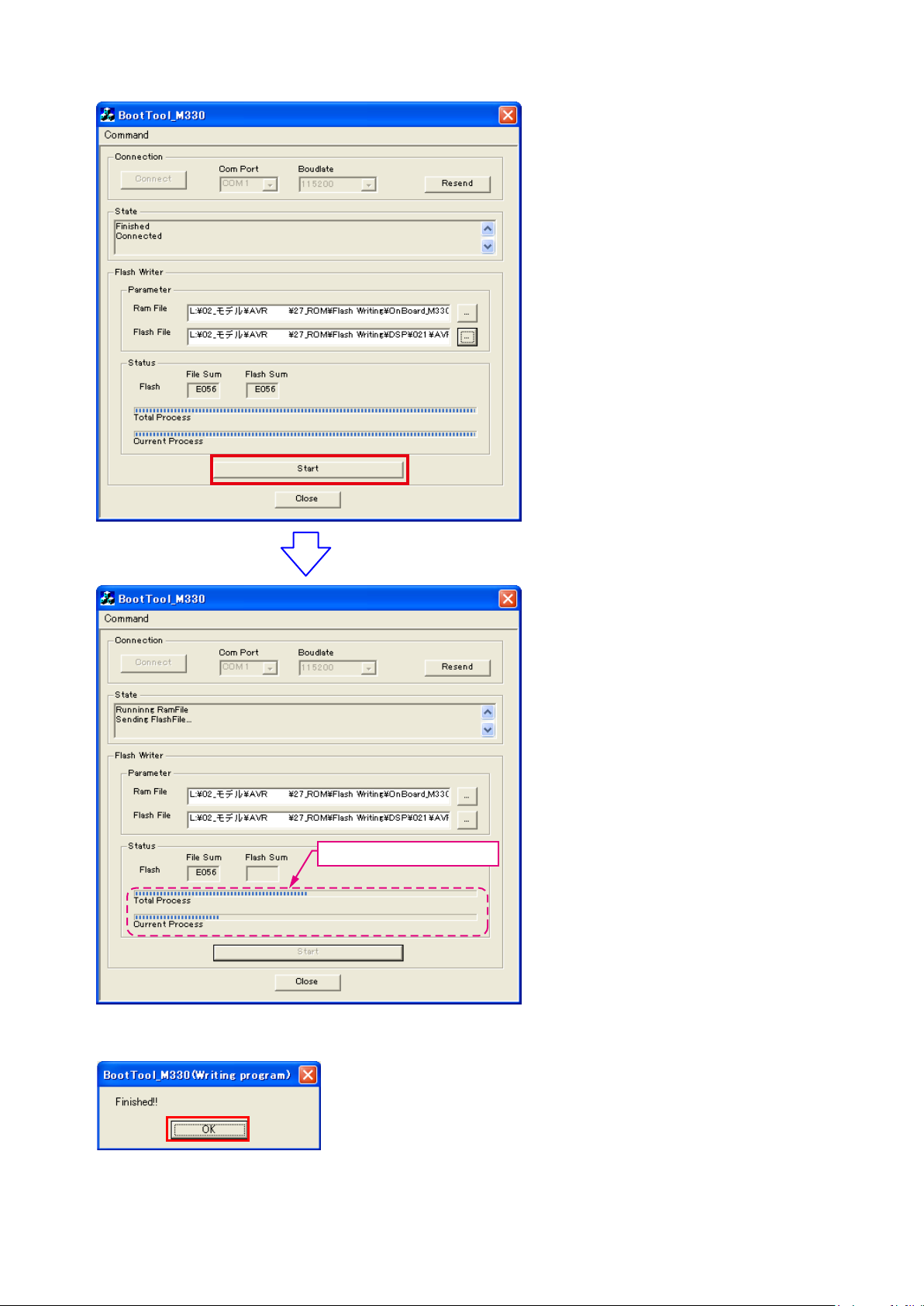

(10) Click the “Start” button.

XXXX

XXXX

XXXX

XXXX

The Setup Status bar appears.

20

Page 21

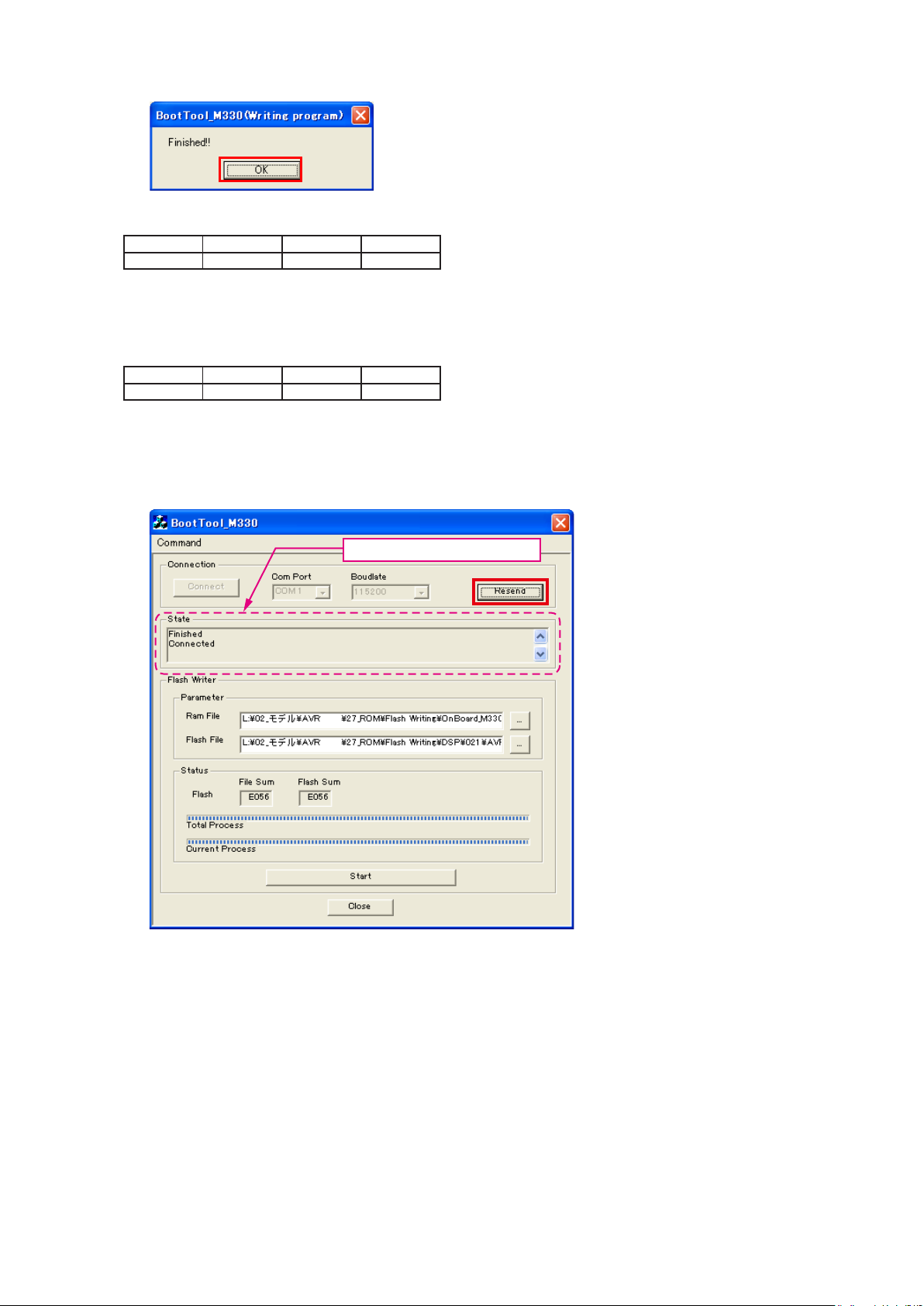

(11) "Finished!!" is displayed. Click the "OK"” button.

(12) Set the switch of “Writing Kit" (Refer to the table below).

DSPBOOT CE EPM CNVSS

H H H H

(13) Press the "RESET" switch of “Writing Kit".

(14) AV receiver is power on and starts update of DSP1.

(15) "Write Comleted" is displayed in the FL tube.

(16) Set the switch of “Writing Kit" (Refer to the table below).

DSPBOOT CE EPM CNVSS

H H L H

(17) Press the "RESET" switch of “Writing Kit".

DSP SF2

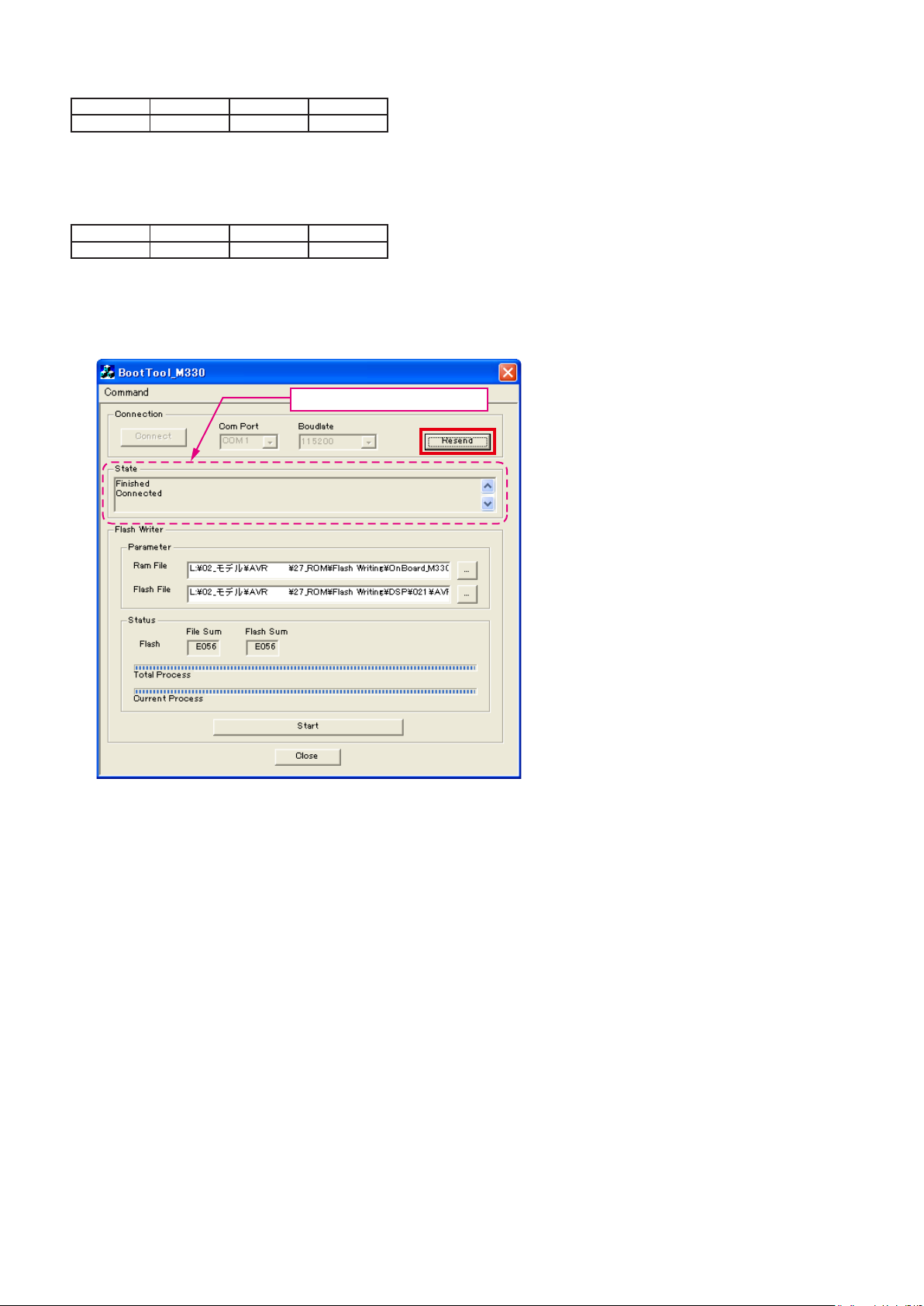

(18) Click the “Resend” button.

"Connected" is displayed, it is OK.

XXXX

XXXX

21

Page 22

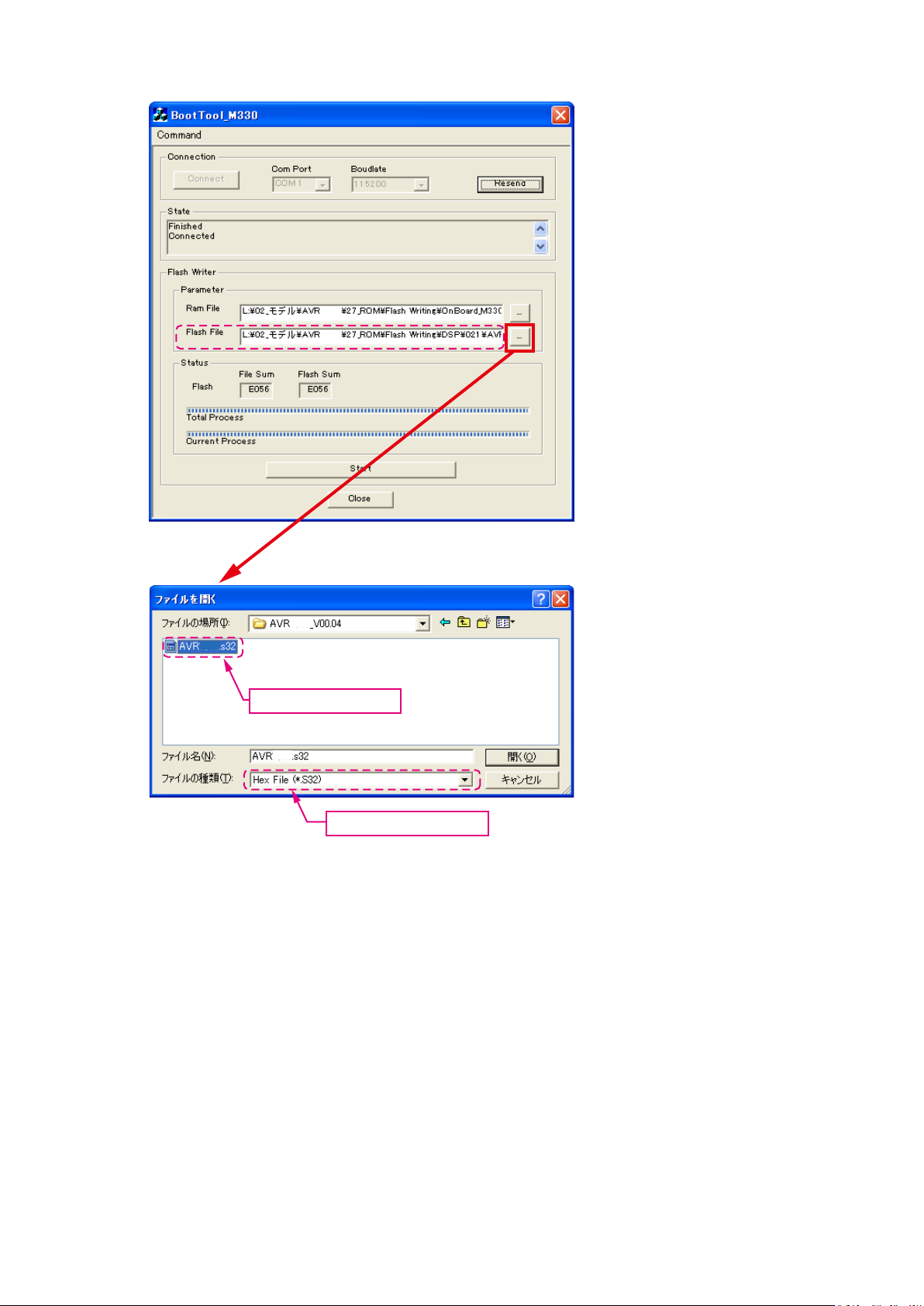

(19) Choose Flash File(DSP : SF2).

XXXX

XXXX

XXXX

XXXX

Choose "AVRXXXX_SF2_*_*_*_01.s32".

Choose "Hex File (*.S32)".

22

Page 23

(20) Click the “Start” button.

XXXX

XXXX

XXXX

XXXX

The Setup Status bar appears.

(21) "Finished!!" is displayed. Click the "OK" button.

23

Page 24

(22) Set the switch of “Writing Kit" (Refer to the table below).

DSPBOOT CE EPM CNVSS

H H H H

(23) Press the "RESET" switch of “Writing Kit".

(24) AV receiver is power on and starts update of DSP2.

(25) "Write Comleted" is displayed in the FL tube.

(26) Set the switch of “Writing Kit" (Refer to the table below).

DSPBOOT CE EPM CNVSS

H H L H

(27) Press the "RESET" switch of “Writing Kit".

MAIN

(28) Click the “Resend” button.

"Connected" is displayed, it is OK.

XXXX

XXXX

24

Page 25

(29) Choose Flash File(MAIN).

XXXX

XXXX

XXXX

XXXX

Choose "AVRXXXX.s32".

XXXX

Choose "Hex File (*.S32)".

25

Page 26

(30) Click the “Start” button.

XXXX

XXXX

XXXX

XXXX

The Setup Status bar appears.

(31) "Finished!!" is displayed. Click the "OK" button.

26

Page 27

(32) Set the switch of “Writing Kit" (Refer to the table below).

DSPBOOT CE EPM CNVSS

H H H H

(33) Press the "RESET" switch of “Writing Kit".

(34) Initializing.

1. Turn off the power using ON/STANDBY button.

2. Press ON/STANDBY button while simultaneously pressing DOCK CONTROL 8 and DOCK CONTROL

buttons.

3. Check that the entire display is ashing with an interval of about 1 second, and release your ngers from the 2

buttons and the microprocessor will be initialized.

Note: • If step 3 does not work, start over from step 1.

• All user settings will be lost and this factory setting will be recovered when this initialization mode.

So make sure to memorize your setting for restoring after the initialization.

3. Notice:

Please keep the following notice for rmware update.

(a) Keep the PC environment

(b) Avoid the communication cable from the electrical noise source.

(e.g. telephone cable, AC line, a uorescent light)

(c) Don’t remove cable during update.

(d) Don’t turn off the power during update.

(e) Don’t run other PC application during update.

(f) Stop the resident program on PC (Virus checker and System check utilitu, etc)

(g) Stop the screen saver on PC.

(h) Stop the power save ability on PC.

(i) In case of laptop PC, Use the AC adaptor.

9

Conrmingthermware’snumberafterupgraded

After completion of the updating operation, the new version number can conrmed by starting up the AVR-1312 according

to the following procedure.

With the following operation, the AVR-1312 can be set to the Flash ROM Version-Number Conrmation mode.

Turn on power switch while simultaneously pressing "DIMMER" and "STATUS" buttons on the front panel. Every time the

"STATUS" button is pressed, version number of the Model, Main, DSP, … are indicated on the front panel section. (Refer

to "1.2. Display other" (page 14 ))

27

Page 28

ADJUSTMENT

Audio Section

Adjusting Idling Current

Required measurement equipment: DC Voltmeter

1. Preparation

(1) Avoid direct blow from an air conditioner or an electric fan and humidity should be moderate, and place the set at

normal usage environment.

Temperature should be at 15 °C ~ 30 °C.

(2) Presetting

• POWER (Power source switch) OFF

• SPEAKER (Speaker terminal) No load

(Do not connect speaker, dummy resistor, etc.)

2. Adjustment

(1) Removed the top cover and set VR41(FL),VR45(FR),VR42(C),VR44(SL),VR43(SR), on Main Amp. Unit at fully

counterclockwise position.

(2) Connect DC Voltmeter to test points (Front-Lch:CN51,Front-Rch:CN55,CENTERch:CN53,

Surround-Lch:CN52,Surround-Rch:CN54).

(3) Connect the power cord to AC Line, and set the power switch to "ON".

(4) Presetting.

MASTER VOLUME : "---" counterclockwise (c min.)

SPEAKER (Speaker terminal) : No load

(Do not connect speaker, dummy resistor, etc.)

FUNCTION : DVD

(5) Within 2 minutes after the power on, turn VR41 clockwise (x) to adjust the TEST POINT voltage at

1.5 mV ± 0.5 mV DC.

(6) After 10 minutes from the preset above, turn VR41 to set the voltage to 2.0 mV ± 0.5 mV DC.

(7) Adjust the Variable Resisters of each channel (VR42-VR45) in the same way.

DC Voltmeter

S Lch

F Lch

CN51

VR41 VR44 VR42 VR43 VR45

CN52

C ch

CN53

S Rch

CN54

F Rch

CN55

MAIN UNIT ASS'Y

28

Page 29

SURROUND MODES AND PARAMETERS

S S

D. Comp z3 DRC z4 LFE z5

z2

Channel output Audio Adjust

S S

D S S S

z1

z2

S D

S D D D D S S

S D D D D S S

S D D D D S S

S D D D D S S

S D D D D S S

S D D D D S

S D D D D S S

S D D D D S S S

DOLBY PRO LOGIC g S D D D S S S

S D D D D S S

DTS NEO:6

DOLBY DIGITAL

DTS 96/24

DTS SURROUND

DOLBY TrueHD

DOLBY DIGITAL Plus

DTS Express

DTS-HD

z1 A signal for each channel contained in an input signal is output as audio.

z2 Only when “SW Mode” is set to “LFE+Main” (“Bass Setting”), sound is output from the subwoofer.

z3 This item can be selected when a Dolby Digital or DTS signal is played.

z4 This item can be selected when a Dolby TrueHD signal is played.

VIRTUAL

MULTI CH STEREO

S D

S D S S S

S D D D D S

S D D D

Front L/R Center Surround L/R Surround Back L/R Subwoofer Mode

Surround mode)

STEREO

MULTI CH IN

DOLBY PRO LOGIC gx S D D D D S S S

DIRECT (2channel)

Symbols in the table

S This indicates the audio output channels or surround parameters that can be set.

D This indicates the audio output channels. The output channels depend on the settings of “Speaker Config.”.

DIRECT (Multi-channel)

29

z5 This item can be selected when a Dolby Digital or DTS signal or DVD-Audio is played.

Page 30

RESTORER z7

Tone

NEO:6 Music mode only

PRO LOGIC g/gx Music mode only

Panorama Dimension Center Width Center Image

Audio Adjust

S S

S S

z2

S

SB CH OUT Subwoofer

AFDM z6

Surround mode

DIRECT (2 channel)

S S S

DIRECT (Multi-channel)

STEREO

MULTI CH IN

DOLBY PRO LOGIC gx S S S S S S

DOLBY PRO LOGIC g S S S S S S

S S S S

S S S

DOLBY DIGITAL

DOLBY DIGITAL Plus

DTS NEO:6

S S S

S S

DOLBY TrueHD

S S S

S S S

S S

S S S

DTS SURROUND

DTS 96/24

DTS-HD

DTS Express

S S S

z2 Only when “SW Mode” is set to “LFE+Main” (“Bass Setting”), sound is output from the subwoofer.

z6 This item can be selected when a Dolby Digital or DTS or DVD-Audio signal is played.

z7 This item can be set when the input signal is analog, PCM 48 kHz or 44.1 kHz.

MULTI CH STEREO

VIRTUAL

30

Page 31

DOLBY

DIGITAL

DOLBY

DIGITAL

DOLBY

DIGITAL

DOLBY

DIGITAL EX

(2ch)

(4/3ch)

(5.1/5/4ch)

Flag)

(With no

DOLBY

(With Flag)

DIGITAL EX

DOLBY

DIGITAL Plus

DOLBY

TrueHD

DTS 96/24

DTS

(5.1ch)

Input signal types and formats

MTRX

DTS ES

DSCRT

DTS ES

DTS

High

DTS-HD

(With Flag)

(With Flag)

EXPRESS

Audio

Resolution

S F F F

F

F

S S F

F

F

F

Audio

Master

DTS-HD

(2ch)

LINEAR PCM

PCM DTS-HD DTS DOLBY DOLBY DIGITAL

(multi ch)

LINEAR PCM

S S S

z S S S

DTS EXPRESS

DTS + NEO:6

DTS NEO:6 CINEMA

S S S

DTS NEO:6 MUSIC

DOLBY TrueHD

DOLBY SURROUND

ANALOG

z F D

z F D

Surround mode NOTE

DTS-HD MSTR

DTS-HD HI RES

DTS ES DSCRT6.1

DTS ES MTRX6.1

DTS SURROUND

DTS 96/24FDTS + PLgx CINEMA z S S S S

DTS + PLgx MUSIC z S S S S

Symbols in the table

F This indicates the default surround mode.

D This indicates the surround mode that is fixed when “AFDM” is set to “ON”.

S This indicates the selectable surround mode.

DTS SURROUND

z S S S S

DOLBY DIGITAL+

DOLBY DIGITAL EX

DOLBY DIGITAL

DOLBY (D) +PLgx CINEMA z F D S S S

S S S

z If “Speaker Config.“ – “Surround Back“ (“Speaker Config.”) is set to “None”, this surround mode cannot be selected.

DOLBY (D) +PLgx MUSIC z S S S S

DOLBY PRO LOGIC gx CINEMA z S S S

DOLBY PRO LOGIC gx MUSIC z S S S

DOLBY PRO LOGIC gx GAME z S S S

DOLBY PRO LOGIC g CINEMA S S S

DOLBY PRO LOGIC g MUSIC S S S

DOLBY PRO LOGIC g GAME S S S

DOLBY PRO LOGIC

31

Page 32

DOLBY

DIGITAL

DOLBY

DIGITAL

DOLBY

DIGITAL

DOLBY

DIGITAL EX

DOLBY

DIGITAL EX

DOLBY

DOLBY

DTS 96/24

DTS

(2ch)

(4/3ch)

(5.1/5/4ch)

Flag)

(With no

(With Flag)

DIGITAL Plus

TrueHD

(5.1ch)

Input signal types and formats

MTRX

DTS ES

(With Flag)

DSCRT

DTS ES

(With Flag)

DTS

EXPRESS

High

DTS-HD

Resolution

Audio

Master

DTS-HD

(2ch)

LINEAR PCM

PCM DTS-HD DTS DOLBY DOLBY DIGITAL

(multi ch)

LINEAR PCM

ANALOG

Audio

F

F D (7.1)

F S F S S S S S S S S S S S S S S

S S S S S S S S S S S S

S S S S S S S S S S S S

S S S S S S S S S S S S S S S S S

z If “Speaker Config.“ – “Surround Back“ (“Speaker Config.) is set to “None”, this surround mode cannot be selected.

Surround mode NOTE

MULTI CH IN

MULTI CH IN + PLgx CINEMA z S

MULTI CH IN

MULTI CH IN + PLgx MUSIC z S

MULTI CH IN 7.1

DIRECT

MULTI CH STEREO

DIRECT

DSP SIMULATION

VIRTUAL

STEREO

STEREO

32

Page 33

TROUBLE SHOOTING

1. POWER

1.1. Power not turn on

Power not turn on.

Is the ON/STANDBY

indicator on the front panel

ashing red?

YES

Are there any incomplete

connections in the

connectors connecting

between the various circuit

boards?

Is there a short circuit

NO

between the speaker

terminals and the ground?

Correct the short

YES

circuit between the

speaker and ground.

NO

Is the fuse blown?

NO

Does the power turn on

when the POWER switch is

turned off then back on?

YES YES YES

Check the primary circuitry

parts including the POWER

switch(for poor contacts,

etc.), and replace any

defective parts.

YES

Connect the connectors

property.

YES

Refer to "1.2. Fuse is blown".

Is a DC 5V voltage being

NO NO

supplied from the MAIN B'd

to the microprocessors?

Check the microprocessor

periphery circuitry and

replace any defective parts.

NO

Check for damage in the

power amplier circuitry

parts and replace any

defective parts.

Is a DC5V voltage output

when the cord supplying the

power from the MAIN B'd to

the microprocessor(BN43)

is unplugged?

Check the circuitry and parts

from BN43 on the MAIN

B'd to the microprocessor

for damage and short-

circuits,and replace any

defective parts.

Check the parts from

NO

IC45 to the primary

circuitry and replace

any defective parts.

1.2. Fuse is blown

Check for leaks or short

circuits in the primary side

parts and replace any

defective parts.

Fuse is blown

Check for short circuits in the

rectier diodes and circuitry of

the secondary side rectifying

circuits and replace any

defective parts.

After repairing, also replace the fuse.

33

Check for short circuits in

the power stabilizer unit's

regulator output terminal and

the ground and replace any

defective parts.

Page 34

2. Analog video

MONITOR OUT(CVBS) Output NG

Check ±5V

+5V : C755

-5V : C754

YES

Check output

Output V : IC71-1pin

YES YES

Check cable between main unit and

monitor or Check monitor.

VIDEO test point

BK61

BK61

JK72

C772

R763

R764

JK73

C766

1.PROTECTION

2.FRONT_R

3.C_SUR_RLY

4.C_SUR_RLY

5.HP_RLY

6.P_DOWN

7.SB_MUTE

8.SUB_MUTE

9.PWR_RLY

10.LIMIT_DET

11.LIMIT

12.NC

13.NC

C785

C789

C787

C783

C778

C781

C782

R782

R781

R783

R780

R779

R778

C797

C795

C793

C796

IC73

C799

BN12

IC83

C791

C792

RN83

R785

1.+5VH

R784

C790

2.+5VH

3.DGND

RN84

4.DGND

5.+1V8

C730

C731

BD63

C629

O

I

G

7905

IC74

R940

IC68

7805

CN9A

LY

J1

C720

5

C74

C747

IC60

CN43

C958

C959

7805

ET71

C957

C771

C718

C780

C779

C755

1.VGND

2.+5VH

C860

C859

BD62

0

6

C9

3.+5VH

4.DGND

5.DGND

C765

C768

C757

IC71

A

R768

7

R766

R760

R76

R771

RN85

RN86

R866

R851

R823

R867

R853

R854

R861

R852

RN88 RN87

IC69

C726

IC70

C961

6.+5VD

7.+5VD

8.DGND

9.DGND

11.PRE_GND

10.-12V

IC72

C769

C770

R765

C759

C756

C754

SCLK

R846

C843

IC81

R855

RN89

RN90

CN8A

C749

C751

AUX_CV

1.VGND

3.VGND

2.

IC

15.MCUGND

13.+12V

12.PRE_GND

14.MCU+5V

INPUT (COMPONENT SIDE)

C764

C763

R845

R847

R844

RN80

IC82

C728

R609

R613

C724

C725

CN71

MP_CUP12375Z

ICT

ADJ1

JK71

C811

RXP2

C824

C822

C826

C825

C827C882

SDOUT

C806

C804

R808

R809

R812

R813

LRCK

CLK

LRCK

DATA0

R842

C839

X801

R839

R838

R837

R819

RN82

X-OUT

1

RN8

R860

857

R856

R859

C842

R

R858

R881

R826

R827

R825

R824

D605

R736

R612

946

R

R945

C722

D606

R944

R942

R943

1.HDMIOSD_MI

C723

R737

ADJ2

RP

NO

The power supply circuitry is

defective.

Check input

NO NO

(When the DVD function)

Vin5 : IC71-3pin

Check pattern from JK71 to IC71 and

check cable between AMP and player or

check player .

Check set value of IC.

SW1 : IC71-14pin : 3.3V : OK

SW2 : IC71-10pin : 3.3V : OK

NO

CPU(IC91) aw.

SW3 : IC71-4pin : 3.3V : OK

SW4 : IC71-6pin : 3.3V : OK

YES

The IC71 and surrounding

circuitry is defective.

8

5

6

R

15

R6

RN93

1312E1C

R659

C611

C612

C610

C613

L601

JK62

7

0

608

R6

R

R638

8

6

C635

1

620

R6

R61

C

C634

R639

L602

R640

C633

R651

R643

R642

C643

C648

C642

C644

C645

C921

IC94

CN93

CN92

R937

R956

C902

R955

C908

C907

R905

C906

02

3

R9

R90

C905

7

C909

R928

R926

R92

C918

IC96

Q901

C954

R917

R916

R901

R954

IC92

R910

10K

10K

TU61

INT

RESET

CE

SDIO

SCLK

VCC

R-OUT

L-OUT

C607

CN42

ET01

1.FL

2.AGND

3.SL

4.AGND

5.CT

6.AGND

7.SR

8.AGND

9.FR

10.AGND

11.SW

C649

12.AGND

13.SBR

14.AGND

15.SBL

C919

IC93

IC95

C904

906

R

904

R

Q903

C926C927

ET91

Detail A

C955

03

9

D

R908

R953

C956

C928

C779

SW1 SW2

R765

CN91

1

2

R922

R923

R9

JK91

C816

BD83

C814

IC84

24.576MHz

IC85

C836

R828

5.DGND

2.HDMIOSD_MO

6.HDMIOSD_HOLD

3.HDMIOSD_CS

4.HDMIOSD_CLK

23.MCUGND

JK81

JK82

C830

C975

8

43

5

R935

C924

C923

757

C7

R7

R

C742

R936

IC67

C815

C737

C813

05

R8

41

C7

754

R

C658

C660

R670

C656

R671

R676

R672

R677

R673

C657

C659

C810

C808

C676

C674

C672

R686

R687

R692

R688

R693

R689

C673

C675

C693

C691

C689

R702

R708

R703

R709

R704

R820

R705

C690

C692

J3

C707

C709

C705

R718

R724

R719

R720

829

R725

R830

R

R721

C706

3

2

R79

R79

R959

DGND

7.DGND

8.HDMI_SDA

10.HDMI_SCL

12.INT1_RX

9.DGND

16.DGND

14.INT_TX

15.HDMI_RST

21.HDMI_LRCLK

17.HDMI_SDAA0

19.HDMI_SDAA2

18.HDMI_SDAA1

13.INT2_RX

11.

23.HDMI_MCLK

20.HDMI_SDAA3

22.HDMI_SCLK

D94

BD92

BD93

BD91

BD95

B

11.KEY1

8.VOL-

13.STBY _LEDG

9.KEY3

10.KEY2

18.VFD_DATA

21.MCU+3V3

12.STBY _LDER

15.VFD_RST

20.MCU+3V3

14.REMOTE_IN

19.PWR_RLY

17.VFD_CLK

16.VFD_CE

22.MCUGND

C974

C829

0

9

R7

R791

35

C7

R745

C736

R746

IC66

R748

R678

94

679

R7

C661

R

IC62

C662

R681

R680

C665

R795

R694

796

R695

C678

R

IC63

C679

7

9

R697

R7

R696

R710

98

711

R7

R

C694

IC64

8

C695

9

C6

R713

R799 C682

R712

R726

7

0

2

R7

R80

C710

IC65

R652

C711

C708

9

R738

R72

R728

Pb

A30C5/C5

J2

CN1A

1.+12V

3.VAUX_L

2.-12V

5.VAUX_R

5.MCU+5V

6.3D_LEDB

7.N.C

7.VOL+

4.AGND

6.HP_DET

0

4

3

2

2

25

6

619

627R6

R622

C619

R

C62

R626

R621

C

R623

C628R624

R

R617

C6

C617

C732

C618

C663

C664

IC61

C638

C640

C636

C680

C681

C641

C639

C637

C696

C650

C646

C717

C697

R735

C712

C713

Q608

Q609

0

33

32

3

9

9

R

R

R931

R9

R929

R920

IC91

RN91

C913

N92

R

C916

C915

C914

R912

1

91

C

5

4

1

R91

X901

R913

C917

R9

10MHz

1312E3

1312E2/EA

R916

10K

10K

R917

X

1.-12V

BARCODE LABEL

4K7

CN2A

2._MIC_DET

3.MIC_SIGNAL

4.AGND

34

C860

IC71

R766

R760

RN85

C755

+5V

Output V SW3Input V SW4

R767

C757

R771

R768

C756

C759

C754

-5V

SCLK

R846

R844

Page 35

3. HDMI/DVI

3.1. No picture or sound is output

No picture or sound is output.

Check HDMI/DVI cable connection.

(1) Is the HDMI/DVI cable properly connected?

YES

(2) Are you using an HDMI/DVI selector, repeater or a device for

improving picture quality?

NO

(3) Are you using a certied HDMI cable (with the HDMI stamp)?

YES

(3) Are you using an HDMI/DVI cable less than 5 meters in length?

YES

(4) Are the picture and sound output when another HDMI/DVI cable

is used?

NO

d

NO

There may be the a problem with the HDMI/

DVI cable. Check connection.

YES

Disconnect everything and connect only the

HDMI/DVI cable to check

NO

Use a certied HDMI cable (with the HDMI

stamp).

Replace the HDMI/DVI cable with one that

NO

is less than 5 meters in length (2 meters

recommended) to check.

YES

The HDMI/DVI cable is defective.

Check BD/DVD player.

(5) Is the BD/DVD player's HDMI output setting correct?

YES

(6) When you use a DENON BD/DVD player's, is the uorescent

display tube's "HDMI" indicator lit? If you use a non-DENON BD/

DVD player's, proceed to

NO

(8) Is sound output from the set's speaker terminals when the TV's

power is turned off or the connection cable between the TV and

the set is disconnected?

"YES".

YES

(7)

Are the picture and sound output

when the BD/DVD player's

resolution is changed?

NO

NO

(9) Are the picture and sound

output when a different BD/

DVD player is used?

NO

NO

Check the HDMI output setting, referring to

the BD/DVD player's operating instructions.

YES

Set the BD/DVD player output resolution to

a resolution with which the TV is compatible.

YES

The BD/DVD player may not be compatible

with HDCP repeaters. Ask the BD/DVD

player's manufacturer.

YES

The BD/DVD player is defective.

35

Page 36

Check TV

(10) Is the TV HDCP-compatible?

YES

(11) Is the TV compatible with resolutions of 1080P?

YES

(12) Is the TV's input set to HDMI?

YES

(13) Are the picture and sound output when a different TV is used?

YES

Check set (AVR-1312)

Is a contact part of HDMI connector normal? (Refer to 37 page (*1).)

YES

NO

Use an HDCP-compatible TV. PC TVs

cannot be used.

If the TV is not compatible with resolutions

NO

of 1080P, no picture will be output, even

if the BD/DVD player's resolution is set to

1080P.

NO

Check the TV's input setting, referring to the

TV's operating instructions.

NO

The TV is defective.

NO

The HDMI connector is defective.

Replace the new HDMI connector.

(14) Is the set's input set to HDMI?

YES

The set does not recognize the TV.

(15) Is test point (HPD_O) set to the "H"(3V-5V)?

With the TV connected, Check voltage of the IC on the side on

which the TV is connected.

Is communication waveform conrmed in Test point (DDC_CLK/

DDC_DATA)?

Is terminate the TMDS signal

D145/D146/D147/D148/D149/D150?

YES

(16)

When using a DENON

BD/DVD player, is the FL

display's "HDMI" indicator lit?

If using a non-DENON BD/

DVD player, proceed to "NO".

is

3.3V

conrmed in

The BD/DVD player does not recognize the

connection with the set.

(17)

Is HDMI connector Test point (HPD) set to the

"H"(3V-5V)?

NO NO

With the BD/DVD player connected, Check

voltage of the HDMI connector for the input on the

side on which the BD/DVD player is connected.

Is communication waveform conrmed in Test

point (DDC_CLK/DDC_DATA)?

Is terminate the TMDS signal

each HDMI connector?

HDMI IN1 : D133 : 140

HDMI IN2 : D123 : 130

HDMI IN3 : D113 : 120

HDMI IN4 : D103 : 110

D143/D144/

is

NO

Check the set's input setting, referring to the

set's operating instructions.

The pattern and circuit from the HDMI

NO

connector (JK15) to the IC11 is defective, or

HDMI output circuitry is defective (IC11 and

surrounding circuitry).

Replace the IC11.

The pattern and circuit

from the HDMI connector

(JK11/JK12/JK13/JK14)

to the IC11 are defective.

3.3V

conrmed

of

Replace the IC11.

YES

Check operation of IC11.

(Video input 480P from BD/DVD players / Connect the TV.)

Replace the IC11.

YES

36

Page 37

(18) Check power supply.

Are 1.8V or 3.3V supplied to IC11 (each power supply pin)?

YES

(19) Check xtal oscillator.

Is there 28.6363MHz oscillation of X101?

YES

NO

The power supply circuitry is defective.

NO

The X101 or IC11 is defective.

Replace the new parts.

(20) Check RESET.

Is RESET waveform conrmed at IC11 (97pin)? (If reference

waveform, proceed to "YES".)

YES

(21) Check control signal(I2C).

Is waveform conrmed at Test point (SDA/SCL). (If not continued

to " L", proceed to "YES".)

YES

HDMI output circuitry is defective (IC11 and surrounding circuitry).

Replace the IC11.

(*1) Abnormal sample of HDMI connector : The internal terminal has bent.

NO

The RESET pattern or IC11 is defective.

Replace the new parts.

NO

The SDATA/SCL line pattern is defective.

37

Page 38

3.2. HDMI test point and waveforms

D

D

D

D

D

D

D

C

D

R108

DD

BK11

L114

+5V_O

1.+5V

2.+5V

3.GND

4.GND

5.+1V8H

CN12

T104

(GND)

JK15

C162

C161

A

L113

150

D149

D

IC13

D146

D145

48

1

D143

D144

D147

D

C153

C152

C157

C156

59

C158

C160

L301

R301

C304

C303

C302

L109

C165

C170

C168

T105

(+8V)

CN11

1.SCK

2.GND

4.VCC

3.MISO

6.MOSI

5./CS

C1

C155

C154

C179

8

16

R

IC16

301

C

4

C33

T103

(POK)

C174 C173

C169

L110

98

7.GND

R1

R200

R196

R199

JK11

D152

HPD_O

R183

D153

D110

DDC_CLK_O

R124

D109

R148

DDC_DATA_O

D108

R147

C182

R180

145

R

R146

R181

R179

41

C181

1

D

D142

R170

R169

C178

(EAOUT)

T102

R167

(AGND)

T101

R103

C167

C185

C166

C164

IC15

C163

CN8B

MI

MO

CS CLK

D105

D106

D107

D

SDA

INT1

R109

C102

B

HPD_3

D115

A

A

R175

R176

DDC_CLK_3

A

+5V_3

R193

R107

3

1

D114

D1

R108

R192

IC11

B

A

B

C

A

R177

3.CS

2.MO

1.MI

R110

Q103

Q104

JK13

R186

D111 R111

D112 R172

30

D129

D1

28

D1

DDC_DATA_3

B

B

B

A

B

5

3

RN11

1

R

R136

R157

7

9

33

1

R

R134

R132

R1

4.CLK

9.GND

6.HOLD

10.SCL

13.INT2

5.GND

8.SDA

12.INT1

11.GND

7.GND

R105

Q101

Q102

JK12

R187

HPD_4

+5V_4

119

D

D120

R104

C101

D104

D103

DDC_CLK_4

R195

R101

R102

R194

D101 R106

R164

R162

C180

RESET

SCL

INT_TX

D0

INT2

D116

D118

D117

DDC_DATA_4

: 1.8V

A

: 3.3V

B

71

1

R

D102

B

C332

A

A

122

C137

R123

R

A

R178

IC14

MCLK

SCLK

LRCLK

D1

D2 D3

R114

C103

R115

Q105

JK14

HPD_2

D125

D126

D124

D127

A

A

B

B

A

R142

A

RN12

Q106

R185

73

1

+5V_2

R

R116

9

36

D13

D135

D140

D1

2

12

D121

D

B

137

R191

D138

R112

DDC_DATA_2

R113

R190

C333

X101

C146

5

C14

28.636 36 MHz

BAR CODE LABEL

C331

D

D123

DDC_CLK_2

A

R143

R144

R141

MP

CUP12376Z_A(MP)

IC ICT

18.SDATA1

17.SDATA0

14.INT_TX

21.LRCLK

15.RESET

16.GND

19.SDATA2

20.SDATA3

22.SCLK

23.MCLK

ADJ1

D134

D133

ADJ2

HPD_1

DDC_CLK_1

Pb

A30C5/C5

D131

RP

+5V_1

DDC_DATA_1

121

R174

R

D132

R184

R117

R188

BK12

R120

R118

R119

C104

Q107

Q108

189

R

DIPPING

Detail A

+5V

+5V_O

TMDS D2+

BK11

TMDS D0+

TMDS D2-

L114

C162

C161

L113

IC13

C160

D150

C152

JK15

D149

C153

D148

C154

TMDS D1+ TMDS CK+

TMDS D1- TMDS CK-

TMDS D0-

D146

D147

C156

C155

DDC_CLK_0

D145

D144

D143

C157

C158

C159

HPD_0

HPD_O

DC_CLK_O

R124

DDC_DATA_0

D152

R183

D153

R148

R147

R146

D142

DC_DATA_O

C182

R180

R145

R181

R179

C181

D141

D110

HDMI (COMPONENT SIDE)

B

Detail

TMDS D2+

Q105

JK14

Q106

D140

D139

TMDS D1+ TMDS CK+

TMDS D0+

TMDS D2-

D135

D136

D137

D138

TMDS D1- TMDS CK-

TMDS D0-

DDC_CLK_1

D134

D133

DDC_CLK_1

+5V

+5V_1

DDC_DATA_1

D131

D132

HPD_1

R184

R188

R121

R174

HPD_1

DDC_DATA_1

BK12

R117

R189

R118

Q107

Q108

R120

R119

C104

C

Detail

Check that silk A/B described in the terminal is numerical

value of a red frame.

R192

IC11

AB: 1.8V

B

: 3.3V

A

A

A

B

B

A

B

A

C137

R123

R122

A

A

A

R175

R157

DD

B

B

A

B

R142

A

B

A

B

R135

RN11 RN12

R136

A

B

A

R143

R144

Detail

D

SDA SCL RESET

A

CN8B

MCLK

SCLK

LRCLK

R141

MI

CS

CLK

SDA

INT1

MO

SCL

INT2

RESET

INT_TX

D0

D1 D2

D3

38

Page 39

DDC_CLK/DDC_DATA/TMDS : Check items (15),(17)

0.9V

DDC_CLK

TMDS SIGNAL

2.48V

DVDD/XTAL/RESET/SCL : Check items (18),(19),(20)

P-ON

DDC_DATA

HDMI_SDA/SCL(I2C) : Check item (21)

HDMI_SDA

HDMI_SCL

39

Page 40

4. AUDIO

4.1. AUDIO CHECK

AUDIO OUTPUT : NG

CHECK1

CHECK2

CHECK3

CHECK4

CHECK5

Check other factors.

INPUT SURROND MODE SOURCE

ANALOG 2CH DIRECT ANALOG

OK

INPUT SURROND MODE SOURCE

COAX or OPT --- Legacy(PCM or DolbyDigital or dts…)

OK

INPUT SURROND MODE SOURCE

ANALOG 2CH 7ch STEREO ANALOG

OK

INPUT SURROND MODE SOURCE

HDMI --- Legacy(PCM2ch or DolbyDigital or dts…)

OK

INPUT SURROND MODE SOURCE

HDMI ---

OK (Digital Audio BOLCK is OK)

NG

Check ANALOG AUDIO BLOCK.

NG

Check Digital AUDIO BLOCK.

NG

Check via AD.

NG

Check HDMI BLOCK.

HD AUDIO

(PCM MULTI or DolbyTrueHD or dtsHD MA)

NG

HDMI IN

OPT

IN

COAX

IN

②

③

Connect Setting SOURCE

CHECK6

HDMI OUT→other AVR HDMI IN TV MODE

Check Digital AUDIO BLOCK.

HDMI

TRANSCEIVER

DSP

OK

⑤

④

DIR + CODEC

HD AUDIO

(PCM MULTI or DolbyTrueHD or dtsHD MA)

NG

Check HDMI BLOCK.

HDMI OUT

HDMI UNIT

FUNCTION

SELECTOR

+

VOLUME

Analog IN

①

INPUT UNIT

MAIN UNIT

40

Page 41

4.2. Power AMP (MAIN UNIT)

No sound is output.

The protector operates.

YES

Is the power transistor open or short-

circuited?

2SB1560/2SD2390

NO

Is the emitter resistance of the power

transistor open?

0.47Ω

NO

Is the base resistance of the power

transistor open?

4.7Ω

NO

Is the trimmer potentiometer between the

base of the power transistor open?

1kΩ

NO

Are the zener diode and diode which

are connected with the base of a power

transistor short-circuited?

MTZJ3.3B

1SS133

NO

YES

Replace the power transistor.

YES

Replace the emitter resistance.

YES

Replace the base resistance.

YES

Replace the trimmer potentiometers.

YES

Replace the zener diode and the diode.

YES

Is other transistor trouble?

NO

Is other resistance trouble?

Turn on the power, check that voltage of the section is normal and that idling electric current is

owing.

Replace the transistor.

YES

Replace the resistance.

41

Page 42

CLOCK FLOW & WAVE FORM IN DIGITAL BLOCK

C813

BD83

C810

Wave form

1

CH1: RXP2

2

CH1: SDOUT

Coaxial1

Optical1

IC11

ADV7623BSTZ

(88)AP1_OUT

(87)AP0_OUT

(89)AP2_OUT

(90)AP3_OUT

(91)AP4_OUT

(94)AP5_OUT

(95)SCLK_OUT

(96)MCLK_OUT

IC84

CS42528

(DIR+CODEC)

DAI1_DATA0,DSD0(27)

DAI1_DATA1,DSD1(26)

DAI1_DATA2,DSD2(24)

DAI1_DATA3,DSD3(23)

q

(47)RXP2/GPO2

(49)RXP0

RMCK(55)

SAI_CLK(61)

SAI_LRCK(60)

SAI_SDOUT(54)

(32)DAI2_LRCK

(33)DAI2_SCLK

(34)DAI2_DATA,DSD5

DAO_MCLK(40)

DAI1_LRCK,DSD4(30)

DAI1_SCLK,DSD-CLK(29)

IC81

CS497024CVZ

(AUDIO DSP)

w

CH2: LRCLK

(47)DAO1_D3

(48)DAO1_D2,HS2

(49)DAO1_DATA1,HS1

(51)DAO1_DATA0,HS0

(52)DAO1_SCLK

(54)DAO1_LRCLK

(59)OMCK

(3)CX_LRCK

(2)CX_SCLK

(1)CX_SDIN1

(64)CX_SDIN2

(63)CX_SDIN3

(62)CX_SDIN4

(16)XTAL_OUT

CH3: CLK

e

Test point

BK61

3

CH1: DATA0

C785

C789

1.PROTECTION

2.FRONT_R

3.C_SUR_RLY

4.C_SUR_RLY

5.HP_RLY

6.P_DOWN

7.SB_MUTE

8.SUB_MUTE

9.PWR_RLY

10.LIMIT_DET

11.LIMIT

12.NC

13.NC

C787

C783

C781

R782

R781

R783

R780

R779

R778

C797

C799

1.+5VH

2.+5VH

3.DGND

4.DGND

5.+1V8

LY

C747

C958

C795

C793

C796

IC73

BN12

R785

R784

C790

RN84

C730

C731

BD63

C629

O

I

G

IC74

R940

IC68

CN9A

J1

C720

5

C74

CN43

ET71

C957

C959

CH2: LRCK

CH3: SCK

CH4: X-OUT

BK61

JK72

C772

R763

R764

C764

JK73

C765

C768

C780

C778

C779

C782

C791

RN83

7805

C757

IC71

C755

R768

7

R766

R760

R771

R76

IC83

C792

C860

RN85

RN86

R866

R851

R823

R867

R853

R854

R861

R852

7905

IC60

7805

RN88 RN87

R855

C859

C771

IC69

C726

C718

IC70

3.VGND

BD62

0

6

C961

C9

1.VGND

6.+5VD

7.+5VD

3.+5VH

2.+5VH

8.DGND

9.DGND

4.DGND

5.DGND

11.PRE_GND

10.-12V

12.PRE_GND

C763

C766

IC72

C769

C770

R765

C825

C759

C806

R845

R847

LRCK

C756

C754

DATA0

SCLK

R842

R846

R844

RN80

C843

IC81

C842

RN89

RN90

IC82

C728

CN8A

C749

D605

R609

R613

R612

C724

C751

C725

D606

CN71

AUX_CV

1.VGND

2.

MP_CUP12375Z

IC

ICT

ADJ1

15.MCUGND

13.+12V

14.MCU+5V

C826

SDOUT

C804

R808

R809

LRCK

CLK

C839

A

X801

R839

R838

R837

RN82

X-OUT

1

RN8

R860

857

R856

R859

R

R858

R881

R824

R736

946

R

R945

C722

R943

C723

R737

ADJ2

RP

CN91

1

2

R922

R923

R9

JK91

JK71

R935

C924

C811

C816

BD83

C814

RXP2

C824

C822

C827C882

R812

R813

IC84

24.576MHz

R819

R820

IC85

R826

R827

R825

C836

829

R830

R

R828

R944

R942

1.HDMIOSD_MI

5.DGND

2.HDMIOSD_MO

6.HDMIOSD_HOLD

3.HDMIOSD_CS

7.DGND

8.HDMI_SDA

4.HDMIOSD_CLK

9.DGND

23.MCUGND

21.MCU+3V3

22.MCUGND

JK81

JK82

C830

C975

8

43

5

C923

757

C7

R7

R

C742

R936

IC67

C815

C737

C813

05

R8

41

C7

754

R

C658

C660

R670

C656

R671

R676

R672

R677

R673

C657

C659

C662

C810

R681

R680

C808

DGND

10.HDMI_SCL

12.INT1_RX

11.

BD91

18.VFD_DATA

20.MCU+3V3

19.PWR_RLY

R695

C676

C674

C672

R686

R687

R692

R688

R693

R689

C673

C675

C679

R697

R696

711

R

C693

C691

C689

R702

R708

R703

R709

R704

R705

C690

C692

C695

R713

R712

J3

R726

7

2

R7

C710

C707

C709

R718

C705

R719

R724

R720

R725

R721

C706

C708

R738

3

2

R79

R79

R959

16.DGND

14.INT_TX

21.HDMI_LRCLK

17.HDMI_SDAA0

19.HDMI_SDAA2

18.HDMI_SDAA1

13.INT2_RX

15.HDMI_RST

22.HDMI_SCLK

23.HDMI_MCLK

20.HDMI_SDAA3

D94

BD92

BD93

BD95

B

11.KEY1

8.VOL-

7.VOL+

9.KEY3

6.HP_DET

10.KEY2

13.ST BY_LEDG

15.VFD_RST

12.ST BY_LDER

14.REMOTE_IN

17.VFD_CLK

16.VFD_CE

C974

C829

0

9

R7

R791

35

C7

25

627R6

R626

C

R623

R745

R746

C736

R748

R678

94

679

R7

R

C661

R795

C665

R694

796

C678

R

7

9

R7

R710

98

R7

C694

R799 C68 2

0

R80

C711

9

R72

R728

Pb

A30C5/C5

J2

CN1A

1.+12V

3.VAUX_L

2.-12V

5.VAUX_R

4.AGND

C628R624

C617

IC66

C732

C618

C663

IC62

C664

IC61

C636

IC63

C680

C681

C637

C696

C717

IC64

C697

R735

8

9

C6

C712

IC65

C713

Q608

Q609

R652

N92

R

C914

C915

R912

X901

10MHz

1312E2/EA

R916

R917

CN2A

BAR CODE LABEL

1.-12V

5.MCU+5V

6.3D_LEDB

7.N.C

2._MIC_DET

3.MIC_SIGNAL

4.AGND

8

6

0

4

3

1

15

2

2

620

6

619

R6

R61

R6

R622

C619

C

R

R621

C62

R

R617

C6

C643

C638

C640

C641

C639

C650

C646

CN93

0

33

32

3

9

9

R

R

R931

R9

R929

R920

IC91

RN91

C913

C916

1

91

C

5

4

1

RN93

R91

R913

C917

R9

1312E3

1312E1C

10K

10K

10K

X

10K

4K7

8

5

6

R

R659

C611

C612

C610

C613

L601

JK62

7

0

608

R6

R

R638

C635

C634

R639

L602

R640

C633

R651

R643

R642

C648

C644

C642

C649

C645

C921

IC94

IC93

CN92

R937

R956

C902

R955

C908

C907

R905

C906

02

3

R9

R90

C905

7

C909

R926

R92

R928

C918

IC96

Q901

C954

R917

R916

R901

R954

IC92

R910

TU61

INT

RESET

CE

SDIO

SCLK

VCC

R-OUT

L-OUT

C607

CN42

ET01

1.FL

2.AGND

3.SL

4.AGND

5.CT

6.AGND

7.SR

8.AGND

9.FR

10.AGND

11.SW

12.AGND

13.SBR

14.AGND

15.SBL

C919

IC95

C904

906

R

904

R

C955

03

9

D

R908

R953

C956

Q903

C928

C926C927

ET91

Detail A

C770

9

754

SCLK

R846

R844

R845

RN80

R847

C825

C806

LRCK

DATA0

R842

R837

R838

RN82

C826

SDOUT

C804

R839

LRCK

CLK

C839

C824C882

R808

R809

R812

X801

X-OUT

C822

C827

R813

C814

RXP2

IC84

24.576MHz

R819

R805

C808

R820

INPUT (COMPONENT SIDE)

42

Page 43

BLOCK DIAGRAM

43

Page 44

44

Page 45

DOCK

45

Page 46

46

Page 47

LAEVEL DIAGRAM

47

Page 48

48

Page 49

PRINTED WIRING BOARDS

181716151413121110987654321

FRONT (COMPONENT SIDE)

CN604

NC

NC

FL_AC

FL_AC

GND

VDISP

NC

D6001

Pb

A30C5/C5

C6104

D6002

R6008

C6105

OUT

SW601 SW607 SW602 SW613

TUNER

SHIFT

GRN_LED

MCU+5

D_GND

J6007

J6006

J6005

J6008

RED_L

ED

J6009

POWER_KEY

PRESET CH-

CN610

GND

GND

C6005

R6030

R6031

VDISP

J6001

F6001

T100mAL/250V

PRESET CH+

VOLUME (COMPONENT SIDE)

C6017

R6004

C6001

FL_

FL_AC

AC

R6096

R6007

C6006

C6002

R6003

R6002

R6001

D6005

Q6001

C6004

D6004

D6003

C6003

RC601

C6035

C6007

BK601

C6010

VDD

GND

F2

VDDH

VFL

TSB

CP

DA

TSA

OSC

/RESET

/CS

Q6005

FL601

C6008

C6018

Q18G

18G

D6006

D6007

F1

17G

Q17G

CMD1A572

SW608

SOURCEDOWN