20

Dear Customer,

Thank you and congratulations on your purchase of our appliance.

All our products are the result of highly accurate planning and meticulous technical testing.

We have prepared this manual to help you make the most of your deep-cleaner and to fully

appreciate its superb quality.

We are certain that, if you follow our suggestions, this appliance will give you maximum

satisfaction and many years of service.

This appliance uses steam power to help you take the hard work of day-to-day household

cleaning.

By using steam power, you will contribute to reduce pollution derived from the dispersion of

chemical household detergents into the environment.

It has been designed to obtain greater hygiene of all hard surfaces and upholstery.

ENGLISH

Accessories provided

(depending on the model)

Vacuuming accessories

30. Multipurpose brush

31. Dry vacuum frame

32. Round dusting brush

33. Multi-purpose attachment

34. Crevice tool

35. Radiator brush attachment

36. Carpet/floor brush

37. Parquet attachment

38. Turbo brush

Tools and accessories-extraction

steam

39. Floor cloth Clips

40. Steam frame

41. Floor cloth

42. Large triangular nozzle

43. Small triangular nozzle

44. “T” nozzle

45. Squeegee insert

46. Bristle-tipped insert

47. Squeegee

48. “T” nozzle with brush-tipped steam insert

49. Steam accessory connector

50. Triangular brush

51. Crevice tool

52. In-line brush

53. Brush

Description

1. Cover

2. Removable liquid/solid tank

3. Air flow conveyer

4. Liquid filter

5. Tank cover

6. Tank removal handle

7. Air filter

8. Float

9. Handle

10. Front cover trigger

11. Rear cover

12. Boiler cap

13. Monotube inlet port

14. Outlet cover

15. On/off button

16. On/off boiler button

17. Power indicator

18. Boiler on indicator

19. Steam ready light

20. Water out indicator

21. Steam adjustment knob

(only for some models)

22. Pressure gauge

23. Suction button ON/OFF

24. Suction adjustment button

25. Steam output button

26. Monotube plug-in

27. Bayonet coupling

28. Full flexible hose

29. Rigid extension tubes

GB 2-04-2002 8:01 Pagina 20

21

1. Important

1) Read the instruction booklet carefully.

2) When in use, the appliance contains pressurized steam: incorrect use could be

dangerous. The appliance is only for domestic uses as shown in the booklet. The

manufacturer disclaims all responsibility for damage caused by incorrect use of the

appliance.

3) Always unplug the appliance before refilling the boiler or carrying out any

maintenance or cleaning work on the machine.

4) Before using, check that the mains voltage corresponds to the voltage specified on

the rating plate of the appliance.

5) Plug the appliance into power outlets of 10A current rating and provided with good

earthing.

6) Do not aim the steam jet at electrical sockets, pressurized elements as you

may damage them and get an electric shock.

7) Do not aim the steam jet at the appliance itself.

8) Do not unplug by pulling the electrical lead or the appliance.

9) To avoid damage to the insulation, do not run the appliance over the electrical

supply lead.

10) Make sure the cap is firmly screwed on and remove any water residue from

the cavity before you switch on the boiler.

11) Do not plug in the boiler without water in it. To add water, unplug the

appliance and wait for about 15 minutes to avoid steam release from the cap.

Place the cloth over the cap and unscrew slowly allowing residual steam to

escape gradually.

12) DO NOT UNSCREW THE BOILER CAP WHEN UNDER PRESSURE.

13) Unplug all electrically operated objects or appliances (stove, fridge, oven

hood, etc.) from their power points before steam cleaning. Before plugging in

again, ensure they are completely dry as any remaining water could cause

electrical discharges.

14) Avoid steam contact with the skin – the high temperature can cause serious burns.

Never aim the steam jet at persons or animals, or use on objects unable to

withstand high temperatures.

15) Do not touch the plug with wet hands.

16) When in use, hold the appliance only by the handle: the machine contains a boiler

so its surface heats up during normal use. Persons with a pathological insensitivity

to heat must exercise particular care when using this appliance.

17) Always keep the appliance level while in operation.

18) Do not put detergents or other cleaning agents in the tank. Use only water.

19) Do not wash the appliance with trichloroethylene or other solvents. Use only

water with ordinary liquid detergent.

20) Do not shut the power cord in doors or rub against sharp corners. Keep away from

hot surfaces.

21) Do not use the appliance to pick up inflammable liquids.

22) Avoid vacuuming hard or sharp objects that could damage the appliance.

23) Before switching on ensure that the right filters are correctly set .

GB 2-04-2002 8:01 Pagina 21

22

24) Do not use the appliance without the polyurethane filter fitted over the float holder.

25) Water is always necessary if the appliance is going to be used for dry vacuuming.

26) Be especially careful when using the appliance on stairs

27) Keep away from children or persons unfit to use it.

28) Do not use the appliance if it seems defective. Return it to the place of purchase or

contact an authorized Technical Service Centre.

29) If the overheating safety control is activated, the iron and controls will cease to

function. The appliance can only be re-set by an authorized Technical Service Centre.

30) Do not expose the appliance to atmospheric agents (rain, frost, sun, etc.)

31) The noises produced when the boiler heats up or cools down are due to the normal

dilation of the stainless steel with which it is made.

32) For all repairs apply only to the place of purchase or to an authorized Technical

Service Centre, this is to maintain the effectiveness of your appliance and the validity of the guarantee. For the same reason, use only original parts.

33) Always have the power cord replaced at an Authorized Service Centre only.

KEEP THESE INSTRUCTIONS

The manufacturer reserves the right to modify the appliance and/or accessories without

prior notice.

This appliance is manufactured to comply with the current legislation on electrical safety

and electromagnetic compatibility.

A) If your appliance comes fitted with a plug, it will incorpora-

te a 13 Amp fuse. If it does not fit your socket, the plug

should be cut off from the mains lead, and an appropriate

plug fitted, as below.

WARNING: Very carefully dispose of the cut off plug after removing the fuse: do not insert in a 13 Amp socket

elsewhere in the house as this could cause a shock hazard.

With alternative plugs not incorporating a fuse, the circuit must be protected by a 15 Amp fuse.

If the plug is a moulded-on type, the fuse cover must be refitted when changing the fuse using a 13 Amp Asta approved fuse to BS 1362. In the event of losing the fuse cover, the plug must NOT be used until a replacement fuse

cover can be obtained from your nearest electrical dealer.

The colour of the correct replacement fuse cover is that as

marked on the base of the plug.

B) If your appliance is not fitted with a plug, please follow

the instructions provided below:

WARNING - THIS APPLIANCE MUST BE EARTHED

IMPORTANT

The wires in the mains lead are coloured in accordance with

the following code:

Green and yellow: Earth

Blue: Neutral

Brown: Live

As the colours of the wires in the mains lead may not correspond with the coloured markings identifying the terminals in

your plug, proceed as follows:

The green and yellow wire must be connected to the terminal

in the plug marked with the letter E or the earth symbol

or coloured green or green and yellow.

The blue wire must be connected to the terminal marked with

the letter N or coloured black.

The brown wire must be connected to the terminal marked

with the letter L or coloured red.

N

E

L

ELECTRICAL CONNECTION (UK ONLY)

GB 2-04-2002 8:01 Pagina 22

23

2. Setting up the appliance

for dry/wet vacuuming

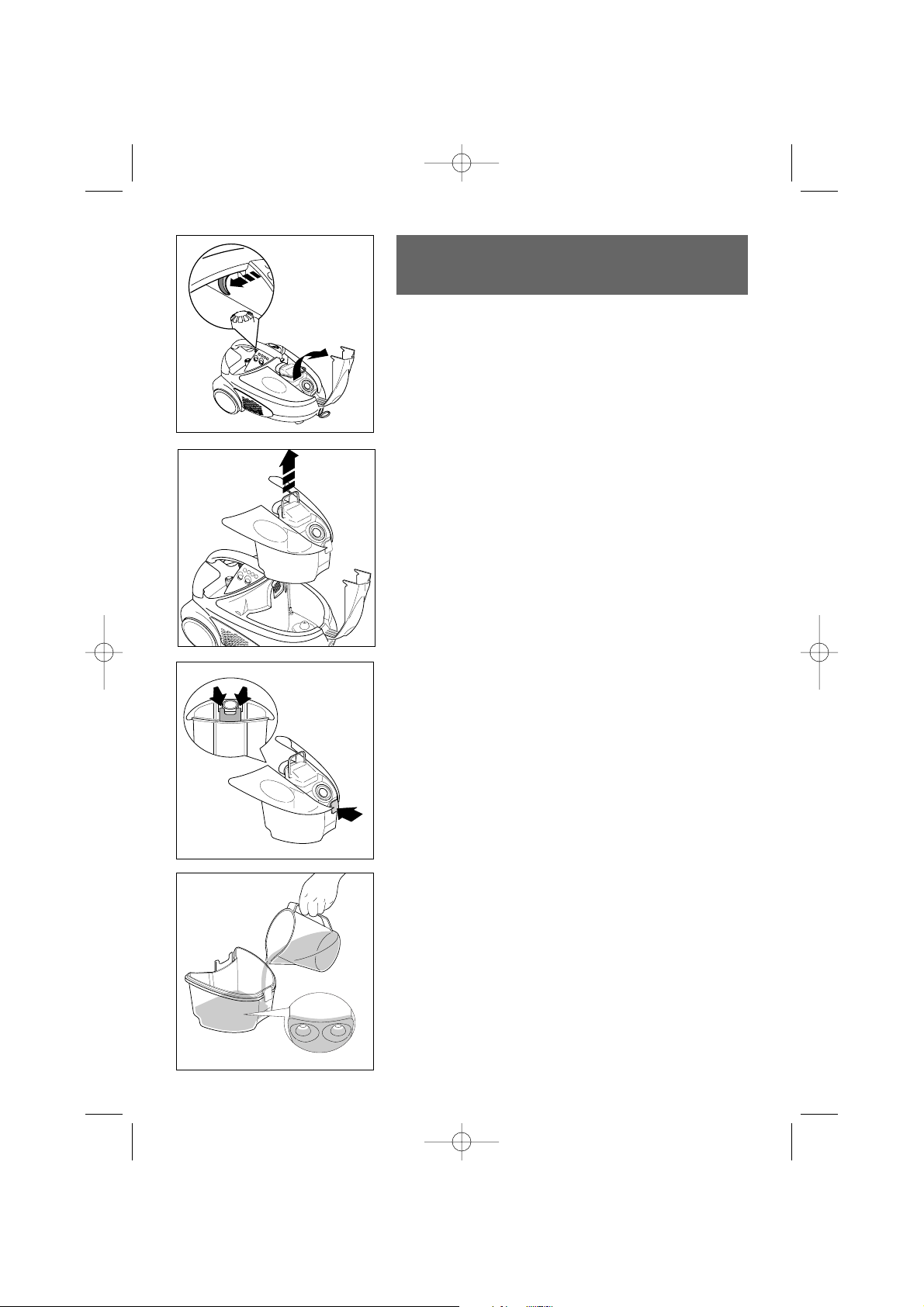

Open the front cover (1) by pulling trigger (10) placed

under the handle of the appliance.

Remove the water tank by pulling the trigger and at the

same time lifting the tank by the handle (6).

By means of the hooks, remove the tank cover with float system.

To extract the cover correctly, position the thumbs inside

the central cavity in contact with the two projecting edges of

the tank.

Press on the two projecting edges to facilitate release of the

cover tooth from the slot.

Use the handle to facilitate extraction of the cover from the

front lock.

Press on the bottom of the front locking device to free the

tooth from the slot.

You can also act on the top of the hook to facilitate the operation. Lift the cover and empty the tank.

Remove the air flow conveyer (3) and pour water into the

tank until the two projections on the base of the tank are covered (about 800 cc)

Re-insert the air flow conveyer, to its original position. Replace the tank cover pressing down firmly to ensure the cover is locked in position. Hold down the trigger (10) and replace the tank to its final position. Close the cover.

N.B.: No water is necessary if the appliance is going

to be used for wet vacuuming.

1

2

GB 2-04-2002 8:01 Pagina 23

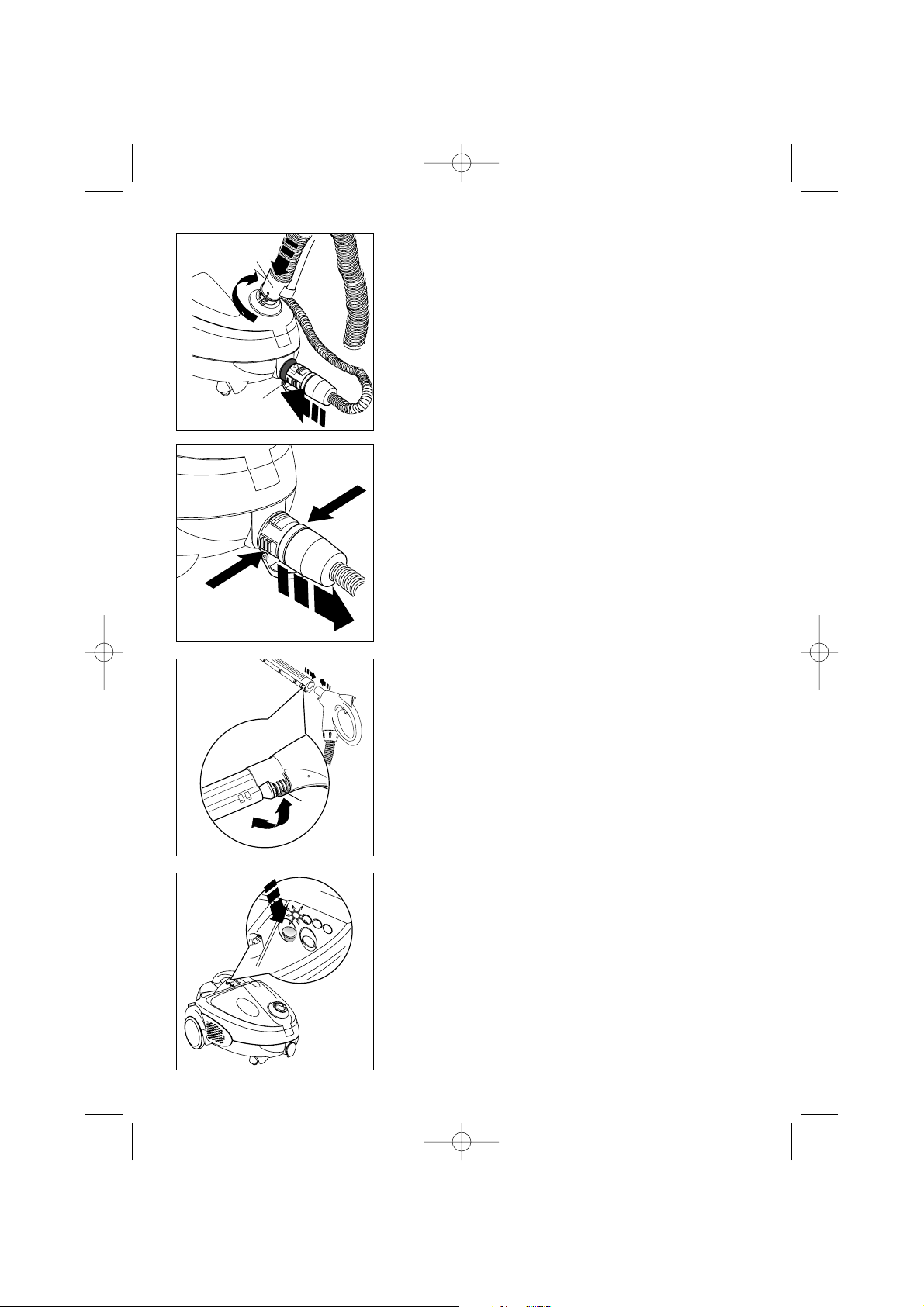

Fit the appliance with flexible hose (28). Insert bayonet

coupling (27) into the hole on front cover (1), pressing it

in firmly and rotating clockwise until it stops.

Open safety hatch (14) and plug in connector (26) into

socket (13) on the bottom of the machine, making sure

the reference arrow is pointing upward. Push in firmly

until securely locked in place.

To disconnect, push on the two side locking tabs and

pull.

Insert extension tube (29) onto the flexible hose

handgrip making sure the handgrip coupling is perfectly

connected with the extension tube coupling. Push firmly

all the way in, then lock into position by rotating the

locking ring (A).

Try to pull the extension tube out to make sure the

connection is perfectly secure.

To add the second extension tube or the brush nozzle,

proceed as described above.

Connect the power cord to the mains, press on/off button

(15) and indicator light (17) will come on. Now your

appliance is ready to start.

24

A

27

26

GB 2-04-2002 8:01 Pagina 24

To activate vacuuming, press Suction button ON/OFF

(23) on the handgrip of the flexible hose. The appliance

will be reach maximum vacuuming power in a few

seconds. To disactivate suction, press Suction button

ON/OFF (23) once more.

To decrease or increase suction power, press button (24)

keeping it depressed until the desired suction power has

been reached.

N.B.: Do not press button (16) to power the boiler

when the appliance is used for vacuuming only.

Important notice: during wet vacuuming, when tank

(2) is full, a special device will shut suction off and the

motor will rev up. At this point, switch off the

appliance by pressing button (15), disconnect it from

the mains, and empty out the wet/dry tank. The

above device will be activated also when filters (7)

and (4) are exhausted – in this case, remove them

and clean them (see chap. 4)

The suction shut-off device may be triggered off also

by any violent impact or shock to the machine. In this

case, switch the motor off and wait a few seconds

before starting the machine once again.

25

GB 2-04-2002 8:01 Pagina 25

26

Vacuuming accessories

(depending on the model)

Multipurpose brush (30)

With this brush attachment you can pick up liquids as

well as dry-vacuum.

When using as a dry-vacuum, you can get better result if

you add brush frame (31).

Before you add the frame, make sure the brush bristles

are withdrawn and check that the pedal is in the position

shown in the picture.

Fit the frame onto the brush taking care to insert the four

connection points into their slots.

Round dusting brush (32)

The attachment swivels to facilitate cleaning operations.

Suitable for removing dust from upholstery, furniture, books,

drapes, picture frames, and clothes.

Multi-purpose attachment (33)

For cleaning sofas, upholstery, car interiors, curtains etc.

When vacuuming drapes, decrease suction power if

necessary by adjusting regulating button (24) on the

handgrip.

Crevice tool (34)

Useful to vacuum crumbs, dust and other small debris. Ideal

for all those hard-to-reach places

GB 2-04-2002 8:01 Pagina 26

Radiator brush attachment (35)

Ideal for vacuuming between the elements of central heating radiators.

Fit onto the crevice tool.

Carpet/floor brush (36)

Effectively vacuums up dust from both hard floors and

carpets or rugs. For hard floors, the brush lever should be

set to the ( ).

For carpets or rugs, the lever should be set to the opposite

side ( ).

Parquet Attachment (37)

Ideal for vacuuming wood floors. Fit the accessory onto the

floor/carpet brush as shown.

27

Position of selector switch

for long pile rugs and carpets

Position of selector switch

for short pile rugs and carpets

Turbo-brush (38)

Fit the turbo brush accessory in place of

the carpet and floor brush supplied.

When the cleaner is turned on, the passage

of air activates the rotating brush.

Avoid touching the underneath of the turbo

brush when the cleaner is in operation.

Always turn the motor off before cleaning

the roller. Avoid passing the brush over the

fringe as this could be damaged by the

movement of the roller. Avoid frequent use

of the turbo brush on particularly delicate

rugs or carpets as over time the fabric

could be damaged.

GB 2-04-2002 8:01 Pagina 27

28

3. Setting up the appliance

for steam cleaning

Steam extraction cleaner

Remove rear cover (11), unscrew boiler cap (12) and fill

the chamber with water without adding any detergent

(the particular shape of the cap seat allows filling without

the use of a funnel). Remove any water residue from the

cap cavity, secure cap and rear cover.

Fit the machine with flexible hose (28), extension tubes

(29) and brush nozzle (30) following the assembly

instructions for the tubes, hose, and brush container in

chapter 2.

Connect the plug of the power cord to the mains, press

on/off button (15) and boiler power button (16). At this

point, indicator lights (17 – power) and (18 boiler on) and

will come on . When the steam-ready light (19) comes

on, your cleaner is ready for use.

For steam output, keep button (25) under the handgrip

of the flexible hose pressed and release when you want

to stop steam output. Start suction by pressing the

ON/OFF button (23), in this way the appliance will wash

and vacuum at the same time. In case of stubborn

stains, first steam and then vacuum the area (See

section on “Extraction cleaning technique”, p. 30.)

N.B.: When the appliance is used for the first time, it

may give off a particular smell for a few minutes due

to heating and the consequent drying of the

sealants used in assembling the boiler.

GB 2-04-2002 8:01 Pagina 28

When the water in the boiler is about to run out, the

water out indicator light (20) will come on. Fill the tank as

follows:

Switch off the appliance by pressing button (15) and the

boiler by pressing button (16). Disconnect from the

mains. Wait for 10-15 minutes until the appliance has

cooled down, then place a cloth over cap (12) and

unscrew slowly allowing residual steam to escape

gradually. Proceed to fill the chamber again as described

above.

Important notice! Never unscrew cap with the boiler

under pressure and never operate it without water.

29

Steam adjustment knob (21)

(only for some models)

Use to adjust steam output.

Keep the knob on the maximum steam output setting

when switching on the appliance.

Pressure gauge (22)

(only for some models)

Allows you check the pressure in the boiler.

Depending on the model, the manometer has a

graduated 0-6 bar scale or coloured segments:

- The normal operating pressure of the appliance is

around 3 - 4 bars (green segment).

- If the pressure remains above 5 bars or around 0

(red or yellow segment), contact an authorised

Service Centre.

GB 2-04-2002 8:01 Pagina 29

Extraction cleaning technique

For extraction cleaning, proceed as follows:

- Spray the steam jet onto the surface to be treated by

pressing spray trigger (25) while simultaneously

vacuuming using ON/OFF button (23).

- Go over the area to be treated several times using dry

vacuum only, after depressing the pedal to withdraw

the bristles: The treated surfaces will be almost fully

dry and dirt will have been effectively removed.

N.B.: Regulate suction power at its maximum output.

Steam cleaning without suction

To use the appliance as a steam cleaner, proceed as

described above without activating the vacuuming

system – do not press suction button (24).

Tools and accessoriesextraction steam

(depending on the model)

Multipurpose brush (30)

To use the brush for steam extraction cleaning hard

flooring, rotate the pedal to extend the bristles. This way,

the combined action of steam + brush will give you more

effective cleaning power.

Caution! Not recommended for fired clay tiles,

waxed floors and parquets.

Frame (40), cloth (41) and clips (39)

For Steam cleaning without suction, fit brush with frame

(40).

After fitting the frame to the brush, secure floor cloth (40)

by means of its clips (39)

N.B.: this type of cleaning is particularly effective on tiled

floors.

30

GB 2-04-2002 8:01 Pagina 30

Triangular brush (50)

Recommended for cleaning roller blinds and vertical

surfaces. Can be fitted with the cloth by using the spring

clips.

Triangular nozzles (42 e 43)

Fit directly onto the extension tube or the handgrip

making sure the coupling is perfectly connected with the

extension tube or the handgrip coupling. Push firmly all

the way in, then lock into position by rotating the

locking ring.

Large triangular nozzle

The large triangular nozzle is indicated for washing and

wet vacuuming on carpeting, carpets and rugs.

Small triangular nozzle

The small triangular nozzle is indicated for washing and

wet vacuuming on upholstery, sofas, furniture, and

vertical fabric coverings.

Important: To avoid damage to delicate colours and fabrics, test colourfastness on a small inconspicuous area

of the carpet or upholstery to be cleaned.

“T” nozzle (44)

This attachment can be used together with the squeegee

or the brush-tipped insert. After fitting the desired insert,

fit the “T” nozzle onto the extension tube or directly onto

the handgrip. Secure with the locking ring provided.

Squeegee insert (45)

Ideal for cleaning small glass surfaces and panes.

Bristle-tipped insert (46)

Ideal for fabrics (drapes, clothes, upholstery, etc.).

31

GB 2-04-2002 8:01 Pagina 31

Squeegee (47)

The squeegee attachment is a very practical tool for

cleaning windows and large glass surfaces. Fit directly

onto the extension tube or the handgrip making sure the

coupling is perfectly connected with the extension tube

or the handgrip coupling. Push firmly all the way in, then

lock into position by rotating the locking ring.

Spray steam onto the surface to be cleaned. To dry it,

skew the squeegee to let it perfectly adhere to the

surface to dry.

Important notice: at low temperatures, it is advisable to

warm window panes with a weak jet of steam to avoid

breakages and cracks due to the sudden change in

temperature.

“T” nozzle with brush-tipped steam insert (48)

Fit directly onto the extension tube or the handgrip

making sure the coupling is perfectly connected with the

extension tube or the handgrip coupling. Push firmly all

the way in, then lock into position by rotating the

locking ring. Tile grouting, radiators, bathroom fixtures

and all other nooks and crannies will be easily dealt with

by using the crevice tool together with the bush-tipped

steam insert. To vacuum and dry the surface more effectively, remove the brush.

Steam accessory connector (49)

It allows you to use more specific attachments for steam

cleaning and can be fitted directly onto the flexible hose

handgrip or the extension tube.

Crevice tool (51) +brushes (round and in-line) (52)

The crevice tool can be fitted with one the brush inserts

provided. The brushed are colour-coded, so that each

can be used for the same task without mixing them (e.g.,

red for oven cleaning, yellow for bathroom fixtures, etc.).

The in-line brush insert is particularly indicated for

cleaning tile grouting.

Important: After fitting the desired accessory onto the

machine, proceed with cleaning operations as indicated

in your instruction manual

32

GB 2-04-2002 8:01 Pagina 32

33

4. Care and maintenance of

the appliance

Caution: Always disconnect the appliance from

mains outlet before performing any cleaning or

maintenance operation.

After the appliance has been used for extraction

cleaning or wet vacuuming, the tools and accessories on

the machine should be rinsed to ensure maximum

hygiene before storing. Clean nozzle, tubes and hose by

vacuuming up a few litres of clean water.

Always empty out the dirty-water tank after use.

If the appliance must be stored away for long periods,

remove all water from the boiler.

After having emptied out the wet/dry tank, remove the

liquid filter, rinse it under running water and dry

thoroughly

The filter must be stored dry to prolong its life.

Exhaust air is filtered by a high-efficiency filter (A) that

captures and retains particles with a size of over 3

microns. When dirty, the filter must be replaced.

Filters B and C can be washed when dirty, carefully

dried and reinserted.

It is important to maintain the filters efficiency unimpaired

as they guarantee the optimal functioning of the

machine.

Spare filters are available at your Authorized Service

Centre.

Periodically check to see that the floater is moving freely

in its casing, and that wet filter (4) and air filter (7) are in

place and correctly positioned in their seats.

GB 2-04-2002 8:01 Pagina 33

C

B

A

5. Warranty

For repairs and spare parts (including accessories, filters

or attachments) contact your dealer or an authorised

Service Centre.

The warranty runs for 12 months from the date of

purchase and includes replacement of any faulty parts

and labour involved.

Use only original spare parts and attachments.

This is to maintain the effectiveness of your appliance

and the validity of the warranty.

The manufacturer reserves the right to modify the

appliance and/or accessories without prior notice.

34

GB 2-04-2002 8:01 Pagina 34

35

Technical characteristics

Voltage / frequency 230 V / 50 Hz

Engine, absorbed power rated output max

1000 Watt 1200W

Boiler, absorbed power 1400 Watt

Boiler capacity 1,5 Litres (2 Litres, in some models)

Operating pressure rated output max

3.5 bar 3.8 bar

350 Kpa 380 Kpa

Commands on machine ON/OFF BUTTON

ON/OFF BOILER BUTTON

Indicator lights Power on indicator

Boiler power indicator

Steam ready light

Water finished light

Safety low-voltage Suction activation

commands on handgrip Suction power variation

Steam delivery

Liquid suction safety Float

Inlet filtration Water filter with 1.3 lt of water

Stainless steel 304 mesh micro-filter

Polyurethane pre-filter

Engine inlet polyurethane filter

Outlet filtration (exhaust air) HEPA filter

Engine-cooling air filter Polyurethane filter

Total levels of filtration 8 stages

Removable collection tank capacity rated output max

2.3 litres 2.7 litres

Cable winding manual

Power supply cable 3x1 length: 6 m

Approval IMQ

Weight in operation (without tubes) 12 kg (approx.)

Dimensions length L = 550

depth P = 370

GB 2-04-2002 8:01 Pagina 35

Loading...

Loading...