Page 1

Dell Precision 5750

Service Manual

Regulatory Model: P92F

Regulatory Type: P92F001

May 2020

Rev. A00

Page 2

Notes, cautions, and warnings

NOTE: A NOTE indicates important information that helps you make better use of your product.

CAUTION: A CAUTION indicates either potential damage to hardware or loss of data and tells you how to avoid the

problem.

WARNING: A WARNING indicates a potential for property damage, personal injury, or death.

© 2020 Dell Inc. or its subsidiaries. All rights reserved. Dell, EMC, and other trademarks are trademarks of Dell Inc. or its subsidiaries. Other

trademarks may be trademarks of their respective owners.

Page 3

Contents

1 Working on your computer............................................................................................................ 5

Safety instructions................................................................................................................................................................ 5

Working inside your computer....................................................................................................................................... 5

After working inside your computer.............................................................................................................................. 7

2 Technology and components......................................................................................................... 8

USB features..........................................................................................................................................................................8

USB Type-C........................................................................................................................................................................... 9

HDMI 1.4a...............................................................................................................................................................................11

Power On and LED behavior with Fingerprint reader..................................................................................................... 12

3 Disassembly and reassembly........................................................................................................ 14

Base cover.............................................................................................................................................................................14

Removing the base cover..............................................................................................................................................14

Installing the base cover................................................................................................................................................16

Battery................................................................................................................................................................................... 17

Removing the battery.................................................................................................................................................... 17

Installing the battery...................................................................................................................................................... 18

Memory modules..................................................................................................................................................................19

Removing the memory modules...................................................................................................................................19

Installing the memory modules.....................................................................................................................................20

Solid-state drive in SSD1 slot............................................................................................................................................. 22

Removing the M.2 2230 solid-state drive from the SSD1 slot................................................................................ 22

Installing the M.2 2230 solid-state drive in the SSD1 slot........................................................................................ 22

Removing the M.2 2280 solid-state drive from the SSD1 slot................................................................................ 23

Installing the M.2 2280 solid-state drive in the SSD1 slot........................................................................................ 24

Solid-state drive in SSD2 slot............................................................................................................................................ 25

Removing the M.2 2230 solid-state drive from the SSD2 slot............................................................................... 25

Installing the M.2 2230 solid-state drive in the SSD2 slot....................................................................................... 26

Removing the M.2 2280 solid-state drive from the SSD2 slot................................................................................27

Installing the M.2 2280 solid-state drive in the SSD2 slot....................................................................................... 28

Fans.......................................................................................................................................................................................29

Removing the fan 1........................................................................................................................................................29

Installing the right fan................................................................................................................................................... 30

Removing the fan 2........................................................................................................................................................31

Installing the left fan......................................................................................................................................................32

Heat sink...............................................................................................................................................................................33

Removing the heat sink (for computers shipped with integrated graphics card)................................................ 33

Installing the heat sink (for computers shipped with integrated graphics card)...................................................34

Removing the heat sink................................................................................................................................................ 35

Installing the heat sink...................................................................................................................................................36

I/O board.............................................................................................................................................................................. 37

Removing the I/O board............................................................................................................................................... 37

Installing the I/O board................................................................................................................................................. 38

Contents 3

Page 4

Display assembly..................................................................................................................................................................39

Removing the display assembly................................................................................................................................... 39

Installing the display assembly...................................................................................................................................... 41

System board....................................................................................................................................................................... 44

Removing the system board........................................................................................................................................ 44

Installing the system board...........................................................................................................................................47

Antenna................................................................................................................................................................................ 50

Removing the antennas................................................................................................................................................50

Installing the antennas................................................................................................................................................... 51

Palm-rest and keyboard assembly.................................................................................................................................... 53

Removing the palm-rest and keyboard assembly......................................................................................................53

Installing the palm-rest and keyboard assembly........................................................................................................54

4 Troubleshooting......................................................................................................................... 56

SupportAssist diagnostics.................................................................................................................................................. 56

System diagnostic lights.....................................................................................................................................................56

System board built-in self-test (M-BIST)........................................................................................................................ 57

Recovering the operating system..................................................................................................................................... 57

Flashing the BIOS................................................................................................................................................................58

Flashing BIOS (USB key)....................................................................................................................................................58

Backup media and recovery options.................................................................................................................................58

WiFi power cycle................................................................................................................................................................. 58

Flea power release.............................................................................................................................................................. 59

5 Getting help.............................................................................................................................. 60

Contacting Dell.................................................................................................................................................................... 60

4

Contents

Page 5

Working on your computer

Safety instructions

Use the following safety guidelines to protect your computer from potential damage and to ensure your personal safety. Unless otherwise

noted, each procedure included in this document assumes that you have read the safety information that shipped with your computer.

NOTE: Before working inside your computer, read the safety information that is shipped with your computer. For more

safety best practices, see the Regulatory Compliance home page at www.dell.com/regulatory_compliance.

NOTE: Disconnect your computer from all power sources before opening the computer cover or panels. After you finish

working inside the computer, replace all covers, panels, and screws before connecting your computer to an electrical

outlet.

CAUTION: To avoid damaging the computer, ensure that the work surface is flat, dry and clean.

CAUTION: To avoid damaging the components and cards, handle them by their edges, and avoid touching the pins and

the contacts.

CAUTION: You should only perform troubleshooting and repairs as authorized or directed by the Dell technical

assistance team. Damage due to servicing that is not authorized by Dell is not covered by your warranty. See the safety

instructions that is shipped with the product or at www.dell.com/regulatory_compliance.

1

CAUTION: Before touching anything inside your computer, ground yourself by touching an unpainted metal surface,

such as the metal at the back of the computer. While you work, periodically touch an unpainted metal surface to

dissipate static electricity which could harm internal components.

CAUTION: When you disconnect a cable, pull it by its connector or its pull tab, not the cable itself. Some cables have

connectors with locking tabs or thumb-screws that you must disengage before disconnecting the cable. When

disconnecting cables, keep them evenly-aligned to avoid bending the connector pins. When connecting cables, ensure

that the ports and the connectors are correctly oriented and aligned.

CAUTION: Press and eject any installed card from the media-card reader.

NOTE: The color of your computer and certain components may appear differently than shown in this document.

Working inside your computer

Before working inside your computer

About this task

NOTE: The images in this document may differ from your computer depending on the configuration you ordered.

Steps

1. Save and close all open files and exit all open applications.

2. Shut down your computer. Click Start > Power > Shut down.

If you are using a different operating system, see the documentation of your operating system for shut-down

NOTE:

instructions.

3. Disconnect your computer and all attached devices from their electrical outlets.

Working on your computer 5

Page 6

4. Disconnect all attached network devices and peripherals, such as keyboard, mouse, and monitor from your computer.

CAUTION: To disconnect a network cable, first unplug the cable from your computer and then unplug the cable from

the network device.

5. Remove any media card and optical disc from your computer, if applicable.

Electrostatic discharge—ESD protection

ESD is a major concern when you handle electronic components, especially sensitive components such as expansion cards, processors,

memory DIMMs, and system boards. Very slight charges can damage circuits in ways that may not be obvious, such as intermittent

problems or a shortened product life span. As the industry pushes for lower power requirements and increased density, ESD protection is

an increasing concern.

Due to the increased density of semiconductors used in recent Dell products, the sensitivity to static damage is now higher than in

previous Dell products. For this reason, some previously approved methods of handling parts are no longer applicable.

Two recognized types of ESD damage are catastrophic and intermittent failures.

• Catastrophic – Catastrophic failures represent approximately 20 percent of ESD-related failures. The damage causes an immediate

and complete loss of device functionality. An example of catastrophic failure is a memory DIMM that has received a static shock and

immediately generates a "No POST/No Video" symptom with a beep code emitted for missing or nonfunctional memory.

• Intermittent – Intermittent failures represent approximately 80 percent of ESD-related failures. The high rate of intermittent failures

means that most of the time when damage occurs, it is not immediately recognizable. The DIMM receives a static shock, but the

tracing is merely weakened and does not immediately produce outward symptoms related to the damage. The weakened trace may

take weeks or months to melt, and in the meantime may cause degradation of memory integrity, intermittent memory errors, etc.

The more difficult type of damage to recognize and troubleshoot is the intermittent (also called latent or "walking wounded") failure.

Perform the following steps to prevent ESD damage:

• Use a wired ESD wrist strap that is properly grounded. The use of wireless anti-static straps is no longer allowed; they do not provide

adequate protection. Touching the chassis before handling parts does not ensure adequate ESD protection on parts with increased

sensitivity to ESD damage.

• Handle all static-sensitive components in a static-safe area. If possible, use anti-static floor pads and workbench pads.

• When unpacking a static-sensitive component from its shipping carton, do not remove the component from the anti-static packing

material until you are ready to install the component. Before unwrapping the anti-static packaging, ensure that you discharge static

electricity from your body.

• Before transporting a static-sensitive component, place it in an anti-static container or packaging.

ESD field service kit

The unmonitored Field Service kit is the most commonly used service kit. Each Field Service kit includes three main components: antistatic mat, wrist strap, and bonding wire.

Components of an ESD field service kit

The components of an ESD field service kit are:

• Anti-Static Mat – The anti-static mat is dissipative and parts can be placed on it during service procedures. When using an antistatic mat, your wrist strap should be snug and the bonding wire should be connected to the mat and to any bare metal on the system

being worked on. Once deployed properly, service parts can be removed from the ESD bag and placed directly on the mat. ESDsensitive items are safe in your hand, on the ESD mat, in the system, or inside a bag.

• Wrist Strap and Bonding Wire – The wrist strap and bonding wire can be either directly connected between your wrist and bare

metal on the hardware if the ESD mat is not required, or connected to the anti-static mat to protect hardware that is temporarily

placed on the mat. The physical connection of the wrist strap and bonding wire between your skin, the ESD mat, and the hardware is

known as bonding. Use only Field Service kits with a wrist strap, mat, and bonding wire. Never use wireless wrist straps. Always be

aware that the internal wires of a wrist strap are prone to damage from normal wear and tear, and must be checked regularly with a

wrist strap tester in order to avoid accidental ESD hardware damage. It is recommended to test the wrist strap and bonding wire at

least once per week.

• ESD Wrist Strap Tester – The wires inside of an ESD strap are prone to damage over time. When using an unmonitored kit, it is a

best practice to regularly test the strap prior to each service call, and at a minimum, test once per week. A wrist strap tester is the

best method for doing this test. If you do not have your own wrist strap tester, check with your regional office to find out if they have

one. To perform the test, plug the wrist-strap's bonding-wire into the tester while it is strapped to your wrist and push the button to

test. A green LED is lit if the test is successful; a red LED is lit and an alarm sounds if the test fails.

• Insulator Elements – It is critical to keep ESD sensitive devices, such as plastic heat sink casings, away from internal parts that are

insulators and often highly charged.

6

Working on your computer

Page 7

• Working Environment – Before deploying the ESD Field Service kit, assess the situation at the customer location. For example,

deploying the kit for a server environment is different than for a desktop or portable environment. Servers are typically installed in a

rack within a data center; desktops or portables are typically placed on office desks or cubicles. Always look for a large open flat work

area that is free of clutter and large enough to deploy the ESD kit with additional space to accommodate the type of system that is

being repaired. The workspace should also be free of insulators that can cause an ESD event. On the work area, insulators such as

Styrofoam and other plastics should always be moved at least 12 inches or 30 centimeters away from sensitive parts before physically

handling any hardware components

• ESD Packaging – All ESD-sensitive devices must be shipped and received in static-safe packaging. Metal, static-shielded bags are

preferred. However, you should always return the damaged part using the same ESD bag and packaging that the new part arrived in.

The ESD bag should be folded over and taped shut and all the same foam packing material should be used in the original box that the

new part arrived in. ESD-sensitive devices should be removed from packaging only at an ESD-protected work surface, and parts

should never be placed on top of the ESD bag because only the inside of the bag is shielded. Always place parts in your hand, on the

ESD mat, in the system, or inside an anti-static bag.

• Transporting Sensitive Components – When transporting ESD sensitive components such as replacement parts or parts to be

returned to Dell, it is critical to place these parts in anti-static bags for safe transport.

ESD protection summary

It is recommended that all field service technicians use the traditional wired ESD grounding wrist strap and protective anti-static mat at all

times when servicing Dell products. In addition, it is critical that technicians keep sensitive parts separate from all insulator parts while

performing service and that they use anti-static bags for transporting sensitive components.

Transporting sensitive components

When transporting ESD sensitive components such as replacement parts or parts to be returned to Dell, it is critical to place these parts in

anti-static bags for safe transport.

Lifting equipment

Adhere to the following guidelines when lifting heavy weight equipment:

CAUTION: Do not lift greater than 50 pounds. Always obtain additional resources or use a mechanical lifting device.

1. Get a firm balanced footing. Keep your feet apart for a stable base, and point your toes out.

2. Tighten stomach muscles. Abdominal muscles support your spine when you lift, offsetting the force of the load.

3. Lift with your legs, not your back.

4. Keep the load close. The closer it is to your spine, the less force it exerts on your back.

5. Keep your back upright, whether lifting or setting down the load. Do not add the weight of your body to the load. Avoid twisting your

body and back.

6. Follow the same techniques in reverse to set the load down.

After working inside your computer

About this task

CAUTION: Leaving stray or loose screws inside your computer may severely damage your computer.

Steps

1. Replace all screws and ensure that no stray screws remain inside your computer.

2. Connect any external devices, peripherals, or cables you removed before working on your computer.

3. Replace any media cards, discs, or any other parts that you removed before working on your computer.

4. Connect your computer and all attached devices to their electrical outlets.

5. Turn on your computer.

Working on your computer

7

Page 8

Technology and components

This chapter details the technology and components available in the system.

USB features

Universal Serial Bus, or USB, was introduced in 1996. It dramatically simplified the connection between host computers and peripheral

devices like mice, keyboards, external drivers, and printers.

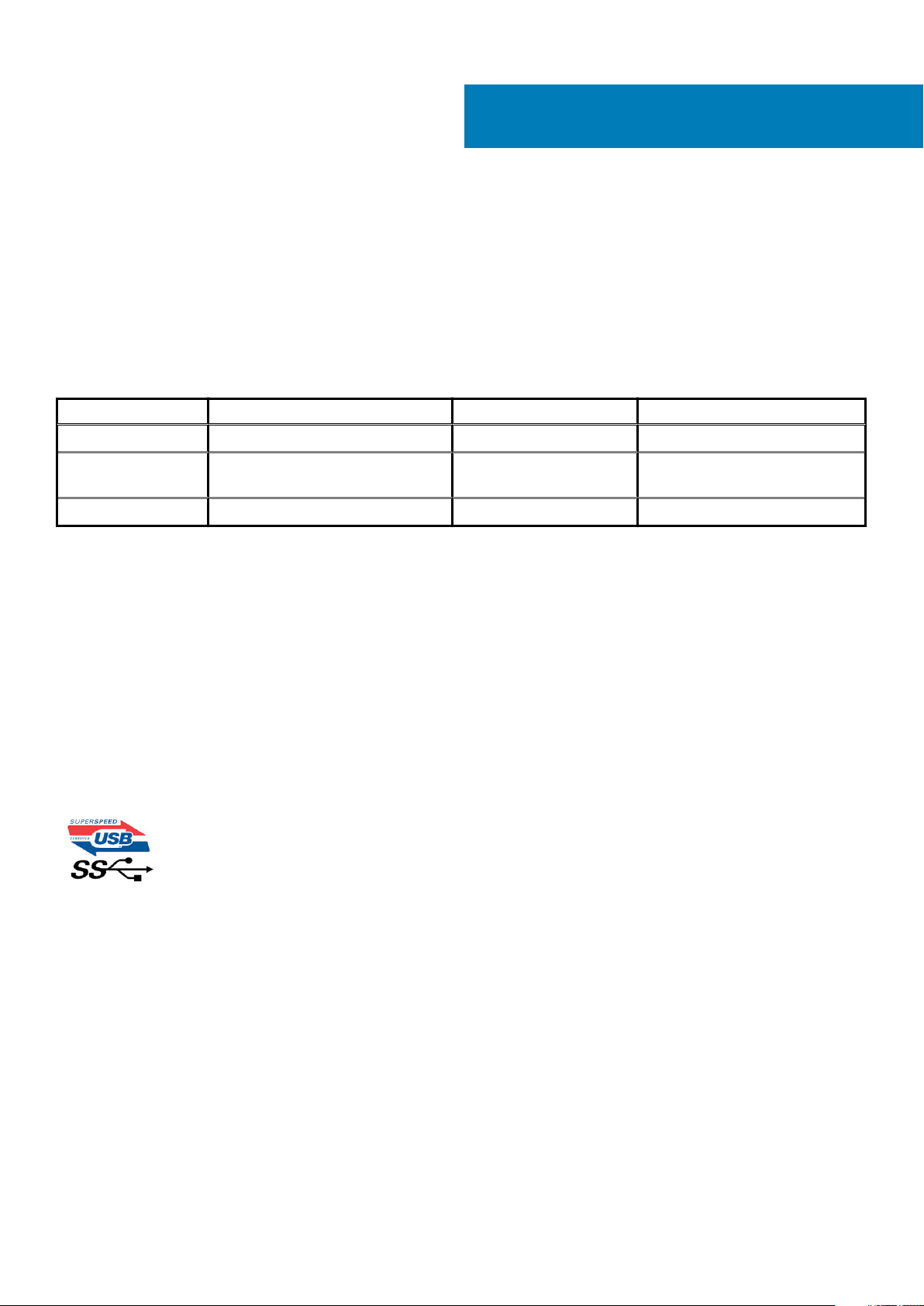

Table 1. USB evolution

Type Data Transfer Rate Category Introduction Year

USB 2.0 480 Mbps High Speed 2000

2

USB 3.0/USB 3.1 Gen 1

Port

USB 3.1 Gen 2 10 Gbps SuperSpeed 2013

5 Gbps SuperSpeed 2010

USB 3.0/USB 3.1 Gen 1 (SuperSpeed USB)

For years, the USB 2.0 has been firmly entrenched as the de facto interface standard in the PC world with about 6 billion devices sold, and

yet the need for more speed grows by ever faster computing hardware and ever greater bandwidth demands. The USB 3.0/USB 3.1 Gen 1

finally has the answer to the consumers' demands with a theoretically 10 times faster than its predecessor. In a nutshell, USB 3.1 Gen 1

features are as follows:

• Higher transfer rates (up to 5 Gbps)

• Increased maximum bus power and increased device current draw to better accommodate power-hungry devices

• New power management features

• Full-duplex data transfers and support for new transfer types

• Backward USB 2.0 compatibility

• New connectors and cable

The topics below cover some of the most commonly asked questions regarding USB 3.0/USB 3.1 Gen 1.

Speed

Currently, there are 3 speed modes defined by the latest USB 3.0/USB 3.1 Gen 1 specification. They are Super-Speed, Hi-Speed and FullSpeed. The new SuperSpeed mode has a transfer rate of 4.8 Gbps. While the specification retains Hi-Speed, and Full-Speed USB mode,

commonly known as USB 2.0 and 1.1 respectively, the slower modes still operate at 480 Mbps and 12 Mbps respectively and are kept to

maintain backward compatibility.

USB 3.0/USB 3.1 Gen 1 achieves the much higher performance by the technical changes below:

• An additional physical bus that is added in parallel with the existing USB 2.0 bus (refer to the picture below).

• USB 2.0 previously had four wires (power, ground, and a pair for differential data); USB 3.0/USB 3.1 Gen 1 adds four more for two

pairs of differential signals (receive and transmit) for a combined total of eight connections in the connectors and cabling.

• USB 3.0/USB 3.1 Gen 1 utilizes the bidirectional data interface, rather than USB 2.0's half-duplex arrangement. This gives a 10-fold

increase in theoretical bandwidth.

8 Technology and components

Page 9

With today's ever increasing demands placed on data transfers with high-definition video content, terabyte storage devices, high

megapixel count digital cameras etc., USB 2.0 may not be fast enough. Furthermore, no USB 2.0 connection could ever come close to the

480Mbps theoretical maximum throughput, making data transfer at around 320 Mbps (40 MB/s) — the actual real-world maximum.

Similarly, USB 3.0/USB 3.1 Gen 1 connections will never achieve 4.8Gbps. We will likely see a real-world maximum rate of 400MB/s with

overheads. At this speed, USB 3.0/USB 3.1 Gen 1 is a 10x improvement over USB 2.0.

Applications

USB 3.0/USB 3.1 Gen 1 opens up the laneways and provides more headroom for devices to deliver a better overall experience. Where USB

video was barely tolerable previously (both from a maximum resolution, latency, and video compression perspective), it's easy to imagine

that with 5-10 times the bandwidth available, USB video solutions should work that much better. Single-link DVI requires almost 2Gbps

throughput. Where 480Mbps was limiting, 5Gbps is more than promising. With its promised 4.8Gbps speed, the standard will find its way

into some products that previously weren't USB territory, like external RAID storage systems.

Listed below are some of the available SuperSpeed USB 3.0/USB 3.1 Gen 1 products:

• External Desktop USB 3.0/USB 3.1 Gen 1 Hard Drives

• Portable USB 3.0/USB 3.1 Gen 1 Hard Drives

• USB 3.0/USB 3.1 Gen 1 Drive Docks & Adapters

• USB 3.0/USB 3.1 Gen 1 Flash Drives & Readers

• USB 3.0/USB 3.1 Gen 1 Solid-state Drives

• USB 3.0/USB 3.1 Gen 1 RAIDs

• Optical Media Drives

• Multimedia Devices

• Networking

• USB 3.0/USB 3.1 Gen 1 Adapter Cards & Hubs

Compatibility

The good news is that USB 3.0/USB 3.1 Gen 1 has been carefully planned from the start to peacefully co-exist with USB 2.0. First of all,

while USB 3.0/USB 3.1 Gen 1 specifies new physical connections and thus new cables to take advantage of the higher speed capability of

the new protocol, the connector itself remains the same rectangular shape with the four USB 2.0 contacts in the exact same location as

before. Five new connections to carry receive and transmitted data independently are present on USB 3.0/USB 3.1 Gen 1 cables and only

come into contact when connected to a proper SuperSpeed USB connection.

USB Type-C

USB Type-C is a new, tiny physical connector. The connector itself can support various exciting new USB standards like USB 3.1 and USB

power delivery (USB PD).

Technology and components

9

Page 10

Alternate Mode

USB Type-C is a new connector standard that is very small. It is about a third the size of an old USB Type-A plug. This is a single

connector standard that every device should be able to use. USB Type-C ports can support a variety of different protocols using

“alternate modes,” which allows you to have adapters that can output HDMI, VGA, DisplayPort, or other types of connections from that

single USB port

USB Power Delivery

The USB PD specification is also closely intertwined with USB Type-C. Currently, smartphones, tablets, and other mobile devices often

use a USB connection to charge. A USB 2.0 connection provides up to 2.5 watts of power — that'll charge your phone, but that's about

it. A laptop might require up to 60 watts, for example. The USB Power Delivery specification ups this power delivery to 100 watts. It's bidirectional, so a device can either send or receive power. And this power can be transferred at the same time the device is transmitting

data across the connection.

This could spell the end of all those proprietary laptop charging cables, with everything charging via a standard USB connection. You could

charge your laptop from one of those portable battery packs you charge your smartphones and other portable devices from today. You

could plug your laptop into an external display connected to a power cable, and that external display would charge your laptop as you used

it as an external display — all via the one little USB Type-C connection. To use this, the device and the cable have to support USB Power

Delivery. Just having a USB Type-C connection doesn't necessarily mean they do.

USB Type-C and USB 3.1

USB 3.1 is a new USB standard. USB 3's theoretical bandwidth is 5 Gbps, while USB 3.1's is 10 Gbps. That's double the bandwidth, as fast

as a first-generation Thunderbolt connector. USB Type-C isn't the same thing as USB 3.1. USB Type-C is just a connector shape, and the

underlying technology could just be USB 2 or USB 3.0. In fact, Nokia's N1 Android tablet uses a USB Type-C connector, but underneath

it's all USB 2.0 — not even USB 3.0. However, these technologies are closely related.

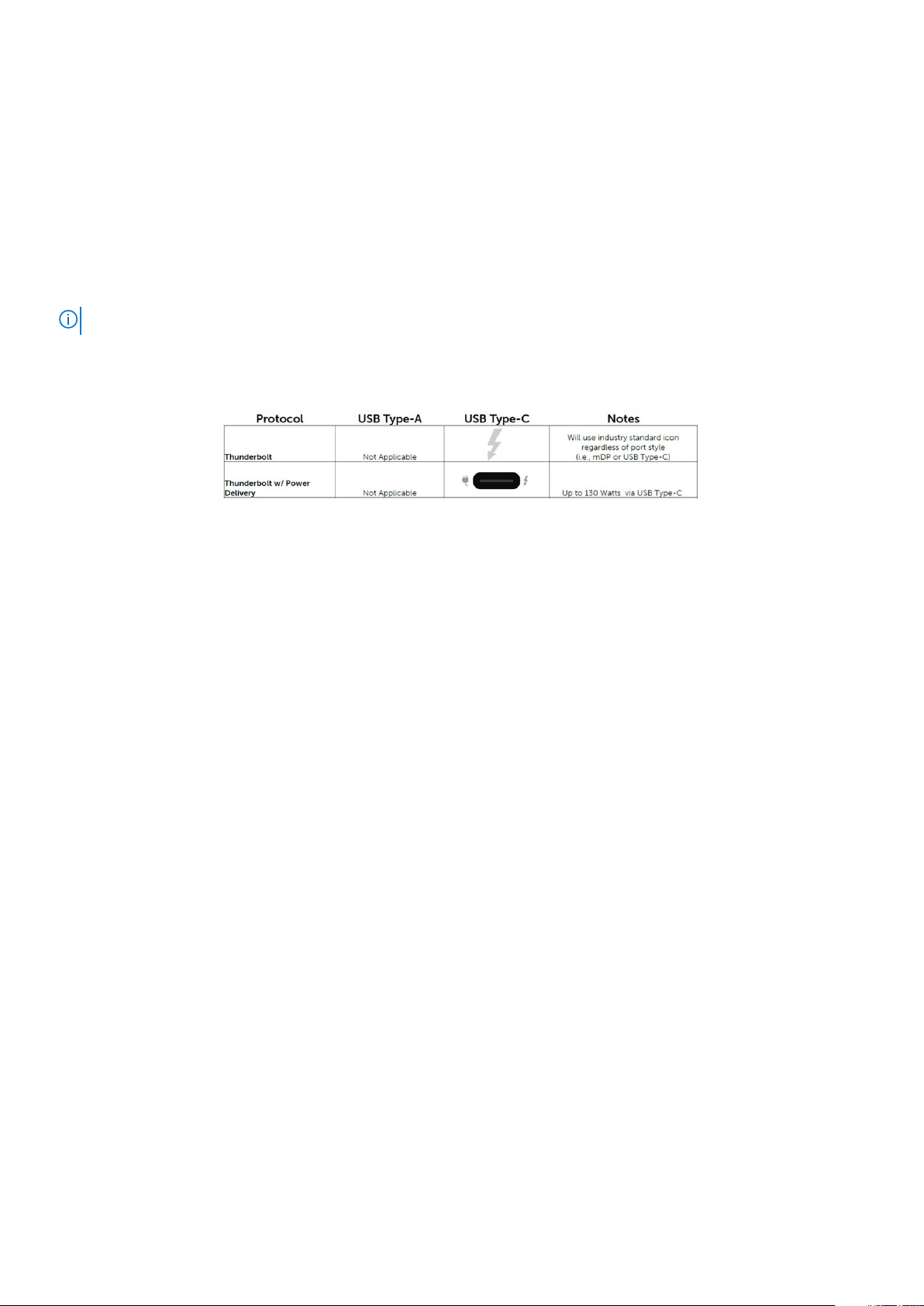

Thunderbolt over USB Type-C

Thunderbolt is a hardware interface that combines data, video, audio, and power in a single connection. Thunderbolt combines PCI

Express (PCIe) and DisplayPort (DP) into one serial signal, and additionally provides DC power, all in one cable. Thunderbolt 1 and

Thunderbolt 2 use the same connector as miniDP (DisplayPort) to connect to peripherals, while Thunderbolt 3 uses a USB Type-C

connector.

Figure 1. Thunderbolt 1 and Thunderbolt 3

1. Thunderbolt 1 and Thunderbolt 2 (using a miniDP connector)

2. Thunderbolt 3 (using a USB Type-C connector)

Thunderbolt 3 over USB Type-C

Thunderbolt 3 brings Thunderbolt to USB Type-C at speeds up to 40 Gbps, creating one compact port that does it all - delivering the

fastest, most versatile connection to any dock, display or data device like an external hard drive. Thunderbolt 3 uses a USB Type-C

connector/port to connect to supported peripherals.

1. Thunderbolt 3 uses USB Type-C connector and cables - It is compact and reversible

2. Thunderbolt 3 supports speed up to 40 Gbps

10

Technology and components

Page 11

3. DisplayPort 1.4 – compatible with existing DisplayPort monitors, devices and cables

4. USB Power Delivery - Up to 130W on supported computers

Key Features of Thunderbolt 3 over USB Type-C

1. Thunderbolt, USB, DisplayPort and power on USB Type-C on a single cable (features vary between different products)

2. USB Type-C connector and cables which are compact and reversible

3. Supports Thunderbolt Networking (*varies between different products)

4. Supports up to 4K displays

5. Up to 40 Gbps

NOTE: Data transfer speed may vary between different devices.

Thunderbolt Icons

Figure 2. Thunderbolt Iconography Variations

HDMI 1.4a

This topic explains the HDMI 1.4a and its features along with the advantages.

HDMI (High-Definition Multimedia Interface) is an industry-supported, uncompressed, all-digital audio/video interface. HDMI provides an

interface between any compatible digital audio/video source, such as a DVD player, or A/V receiver and a compatible digital audio and/or

video monitor, such as a digital TV (DTV). The primary advantage is cable reduction and content protection provisions. HDMI supports

standard, enhanced, or high-definition video, plus multichannel digital audio on a single cable.

HDMI 1.4a Features

• HDMI Ethernet Channel - Adds high-speed networking to an HDMI link, allowing users to take full advantage of their IP-enabled

devices without a separate Ethernet cable.

• Audio Return Channel - Allows an HDMI-connected TV with a built-in tuner to send audio data "upstream" to a surround audio

system, eliminating the need for a separate audio cable.

• 3D - Defines input/output protocols for major 3D video formats, paving the way for true 3D gaming and 3D home theater applications.

• Content Type - Real-time signaling of content types between display and source devices, enabling a TV to optimize picture settings

based on content type.

• Additional Color Spaces - Adds support for additional color models used in digital photography and computer graphics.

• 4K Support - Enables video resolutions far beyond 1080p, supporting next-generation displays that will rival the Digital Cinema

systems used in many commercial movie theaters.

• HDMI Micro Connector - A new, smaller connector for phones and other portable devices, supporting video resolutions up to 1080p.

• Automotive Connection System - New cables and connectors for automotive video systems, designed to meet the unique

demands of the motoring environment while delivering true HD quality.

Advantages of HDMI

• Quality HDMI transfers uncompressed digital audio and video for the highest, crispest image quality.

• Low-cost HDMI provides the quality and functionality of a digital interface while also supporting uncompressed video formats in a

simple, cost-effective manner.

• Audio HDMI supports multiple audio formats from standard stereo to multichannel surround sound.

• HDMI combines video and multichannel audio into a single cable, eliminating the cost, complexity, and confusion of multiple cables

currently used in A/V systems.

Technology and components

11

Page 12

• HDMI supports communication between the video source (such as a DVD player) and the DTV, enabling new functionality.

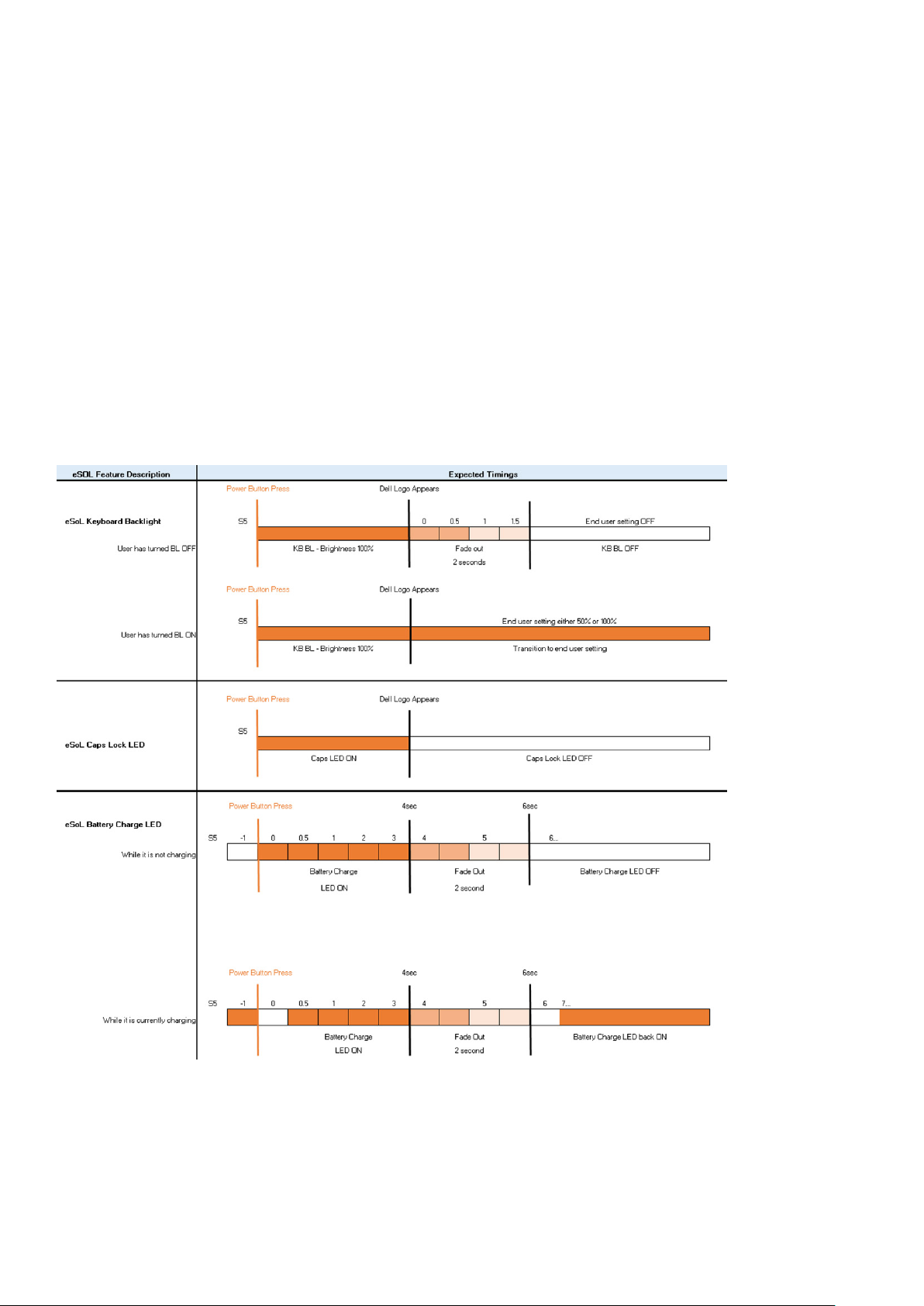

Power On and LED behavior with Fingerprint reader

Power On and LED behavior with Fingerprint reader

• Pressing the power button for a duration between 50 msec to 2 sec turns on the device.

• Power button does not register additional presses until the SOL (Sign-Of-Life) has been provided to the user.

• System LED's illuminates upon pressing the power button.

• All the available LED's (Keyboard backlit/ Keyboard caps lock LED/ Battery Charge LED) illuminates and displays specified behavior.

• The auditory tone is Off by default. It can be enabled in the BIOS setup.

• Safeguards do not time out if the device gets hung during the logon process.

• Dell logo: Turns on within 2 secs after pressing the power button.

• Full boot: Within 22 secs after pressing the power button.

• Below is the example timelines:

Power button with fingerprint reader has no LED and leverages the available LED's in the system to provide indication of the system

status

• Power Adapter LED:

○ The LED on Power adapter connector illuminates white when power is supplied from electrical outlet.

• Battery Indicator LED:

12

Technology and components

Page 13

○ If the computer is connected to an electrical outlet, the battery light operates as follows:

1. Solid white -the battery is charging. When the charge is complete the LED turns off.

○ If the computer is running on a battery, the battery light operates as follows:

1. Off -the battery is adequately charged (or the computer is turned off).

2. Solid amber -the battery charge is critically low. A low battery state is approximately 30 minutes or less of battery life

remaining.

• Camera LED

○ White LED activates when camera is on.

• Mic Mute LED:

○ When activated (muted), the mic mute LED on the F4 Key should illuminate WHITE.

• RJ45 LEDs:

○

Table 2. LED on either side of RJ45 port

Link speed indicator (LHS) Activity indicator (RHS)

Green Amber

Technology and components 13

Page 14

Disassembly and reassembly

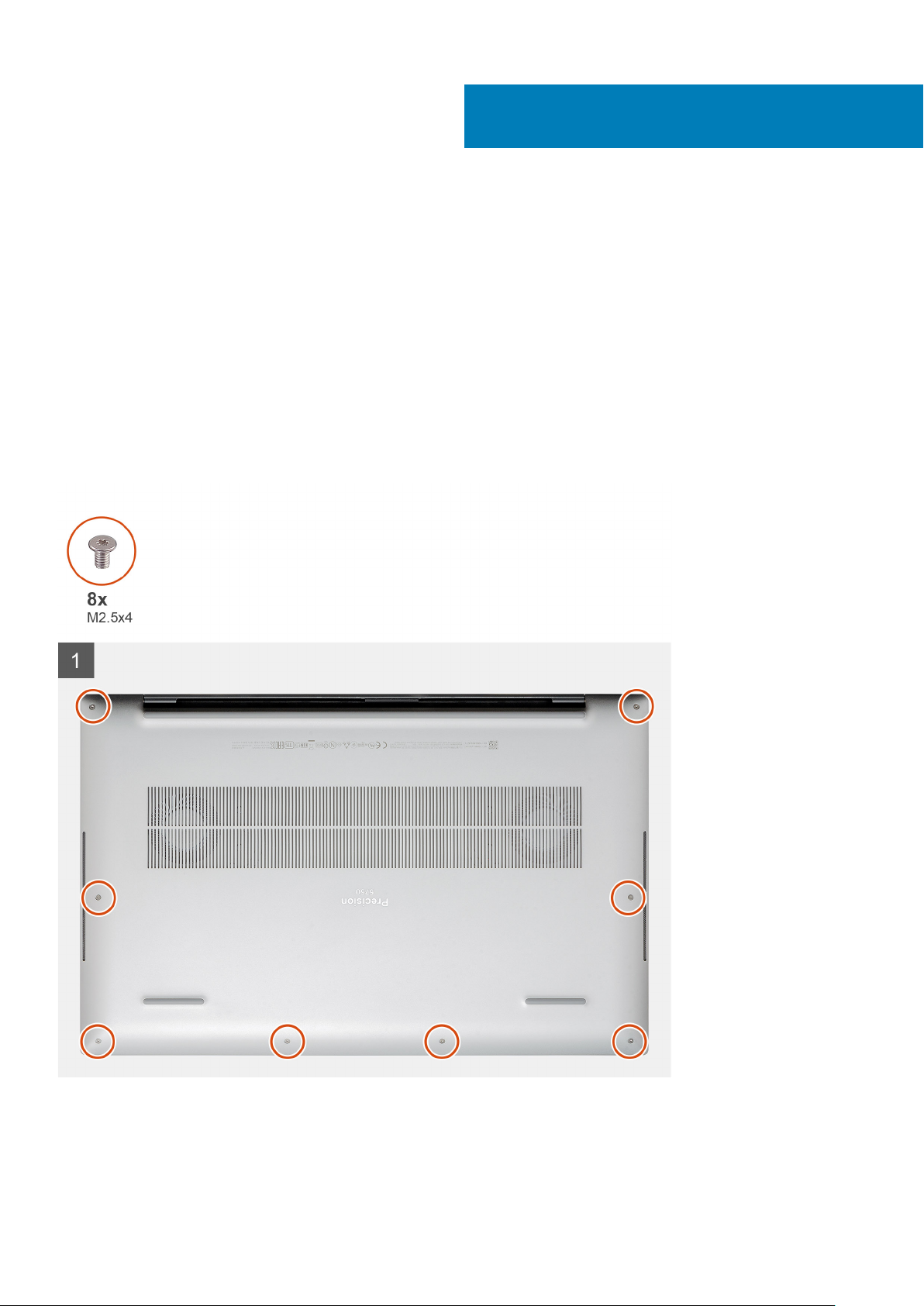

Base cover

Removing the base cover

Prerequisites

1. Follow the procedure in Before working inside your computer.

About this task

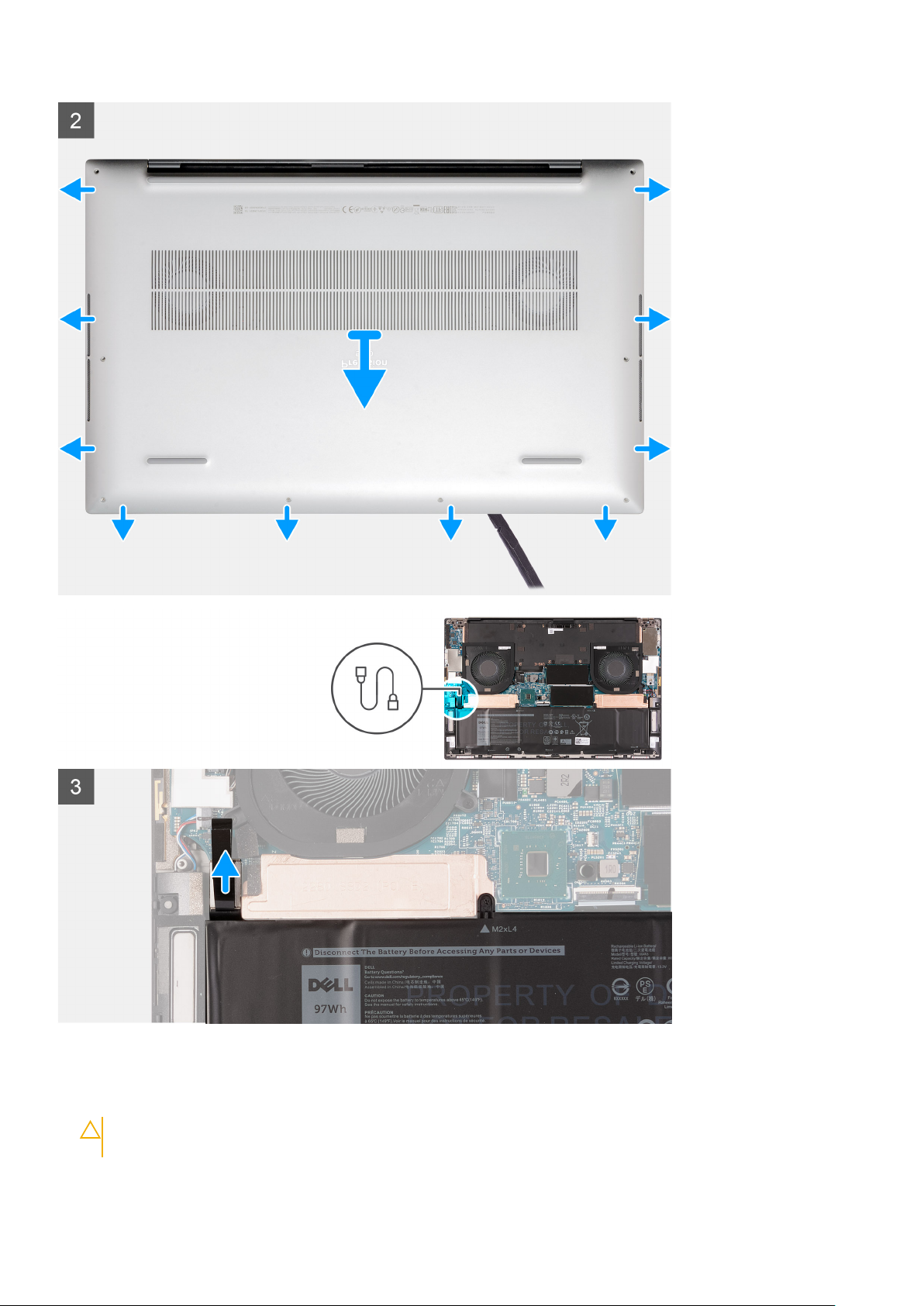

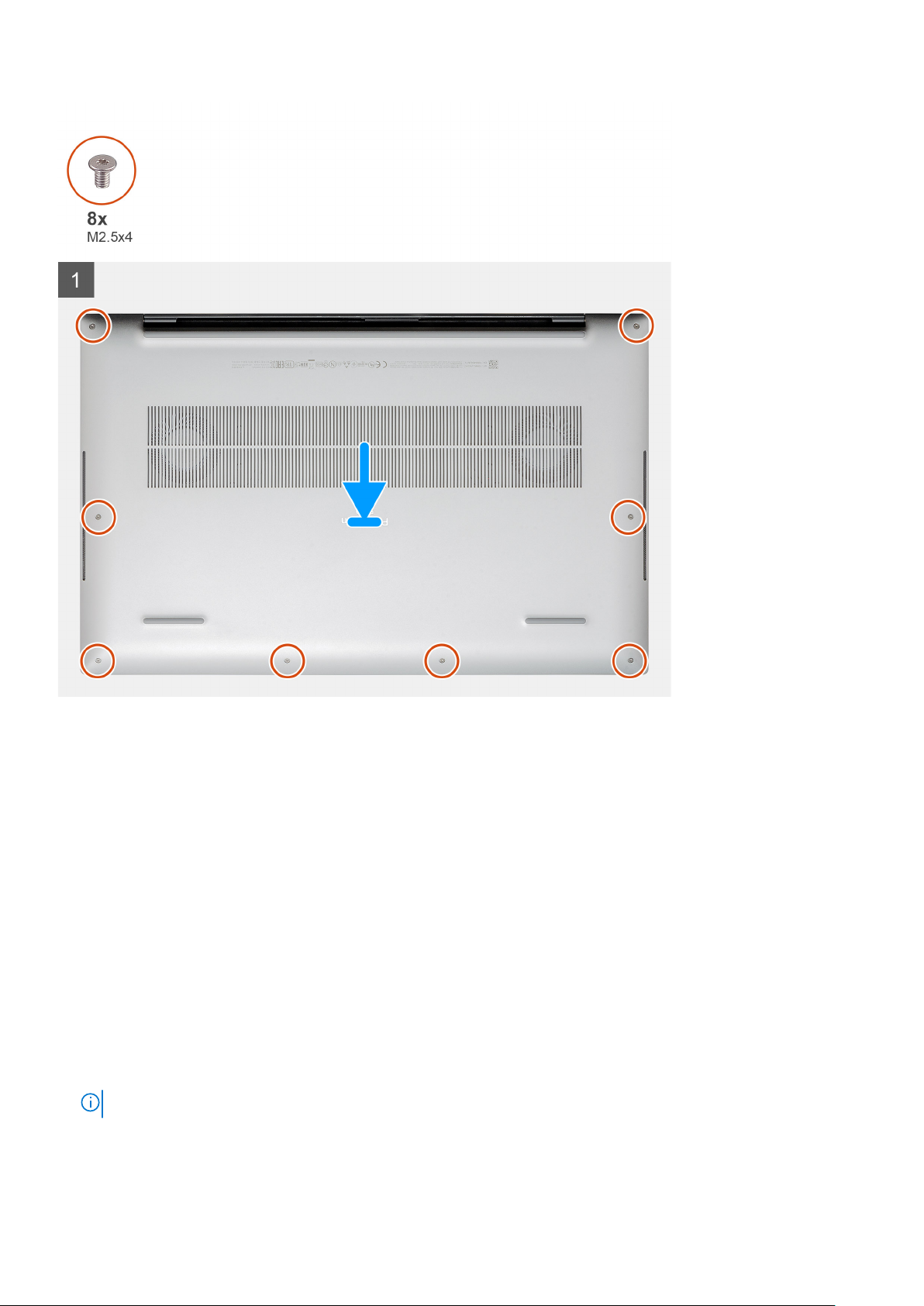

The following images indicate the location of the base cover and provide a visual representation of the removal procedure.

3

14 Disassembly and reassembly

Page 15

Steps

1. Remove the eight screws (M2.5x4) that secure the base cover to the palm-rest and keyboard assembly.

2. Using a plastic scribe, pry the base cover from the palm-rest and keyboard assembly.

CAUTION:

base cover.

Do not pull on or pry the base cover at the side where the hinges are located; doing so may damage the

Disassembly and reassembly 15

Page 16

NOTE: The pins at the bottom of the base cover for grounding the audio board is fragile. Place the base cover on a

clean surface to avoid damage to the pins.

NOTE: The following steps are applicable only if you want to further remove any other component from your

computer.

NOTE: Disconnecting the battery cable or removing the battery, resets the BIOS settings on your computer.

3. Disconnect the battery cable from the system board.

Installing the base cover

Prerequisites

About this task

The following images indicate the location of the base cover and provide a visual representation of the installation procedure.

16 Disassembly and reassembly

Page 17

Steps

1. Connect the battery cable to the system board, if applicable.

2. Align the screw holes on the base cover with the screw holes on the palm-rest and keyboard assembly, and then snap the base cover

into place.

3. Replace the eight screws (M2.5x4) that secure the base cover to the palm-rest and keyboard assembly.

Next steps

1. Follow the procedure in After working inside your computer.

Battery

Removing the battery

Prerequisites

1. Follow the procedure in Before working inside your computer.

2. Remove the base cover.

NOTE: Removing the battery clears the CMOS and resets the BIOS settings on your computer.

About this task

The following image indicates the location of the battery and provides a visual representation of the removal procedure.

Disassembly and reassembly

17

Page 18

Steps

1. Disconnect the battery cable from the system board, if it was not disconnected earlier.

2. Remove the seven screws (M2x4) that secure the solid-state drive thermal bracket and the battery to the palm-rest and keyboard

assembly.

NOTE:

The two screws (M2x4) that secure the top of the battery also secure the solid-state drive thermal brackets

to the system board.

3. Lift the battery off the palm-rest and keyboard assembly.

Installing the battery

Prerequisites

About this task

The following image indicates the location of the battery and provides a visual representation of the installation procedure.

18

Disassembly and reassembly

Page 19

Steps

1. Align the screw hole on each solid-state drive thermal bracket with the respective screw hole on the palm-rest and keyboard

assembly.

2. Align the screw holes on the battery with the screw holes on the solid-state thermal brackets and the palm-rest and keyboard

assembly.

NOTE:

The two screws (M2x4) that secure the top of the battery also secure the solid-state drive thermal brackets

to the system board. Ensure that the solid-state drive thermal bracket is installed between the battery and the

system board.

3. Replace the two screws (M2x4) that secure the top of the battery and the solid-state drive thermal brackets to the palm-rest and

keyboard assembly.

4. Replace the five screws (M2x4) that secure the bottom of the battery to the palm-rest and keyboard assembly.

5. Connect the battery cable to the system board.

Next steps

1. Install the base cover.

2. Follow the procedure in After working inside your computer.

Memory modules

Removing the memory modules

Prerequisites

1. Follow the procedure in Before working inside your computer.

2. Remove the base cover.

About this task

The following image indicates the location of the memory modules and provides a visual representation of the removal procedure.

Disassembly and reassembly

19

Page 20

Steps

1. Lift the flap that covers the memory module.

2. Use your fingertips to carefully spread apart the securing-clips on each end of the memory-module slot until the memory module pops

up.

3. Slide and remove the memory module from the memory-module slot.

NOTE: Repeat step 1 and step 2 if there is another memory module to remove.

Installing the memory modules

Prerequisites

About this task

The following image indicates the location of the memory modules and provides a visual representation of the installation procedure.

20

Disassembly and reassembly

Page 21

Steps

1. Lift the flap that covers the memory-module slot.

2. Align the notch on the memory module with the tab on the memory-module slot.

3. Slide the memory module firmly at an angle, into the memory-module slot.

4. Press the memory module down until it clicks into place.

NOTE: If you do not hear the click, remove the memory module and reinstall it.

NOTE: Repeat step 1 to step 4 if there is another memory module to install.

Next steps

1. Install the base cover.

2. Follow the procedure in After working inside your computer.

Disassembly and reassembly

21

Page 22

Solid-state drive in SSD1 slot

Removing the M.2 2230 solid-state drive from the SSD1 slot

Prerequisites

1. Follow the procedure in Before working inside your computer.

2. Remove the base cover.

3. Remove the battery.

About this task

NOTE: This procedure applies only to computers shipped with an M.2 2230 solid-state drive installed in the SSD1 slot.

NOTE: Depending on the configuration ordered, your computer may support an M.2 2230 solid-state drive or an M.2

2280 solid-state drive in the SSD1 slot.

The following image indicates the location of the M.2 2230 solid-state drive that is installed in the SSD1 slot and provides a visual

representation of the removal procedure.

Steps

1. Remove the screw (M2x4) that secures the solid-state drive thermal bracket and the solid-state drive to the system board.

2. Lift the thermal plate off the system board.

3. Slide and lift the solid-state drive off the SSD1 slot.

Installing the M.2 2230 solid-state drive in the SSD1 slot

Prerequisites

If you are replacing a component, remove the existing component before performing the installation procedure.

22

Disassembly and reassembly

Page 23

About this task

NOTE: This procedure applies only to computers shipped with an M.2 2230 solid-state drive installed in SSD1 slot.

NOTE: Depending on the configuration ordered, your computer may support an M.2 2230 solid-state drive or an M.2

2280 solid-state drive in the SSD1 slot.

NOTE: Install the solid-state drive mounting bracket, if it is not installed.

The following image indicates the location of the M.2 2230 solid-state drive that is installed in the SSD1 slot and provides a visual

representation of the installation procedure.

Steps

1. Align the notch on the solid-state drive with the tab on the SSD1 slot.

2. Slide the solid-state drive into the SSD1 slot.

3. Using the guide post, place the solid-state thermal bracket over the solid-state drive.

4. Align the screw hole on the solid-state thermal bracket with the screw hole on the system board.

5. Replace the screw (M2x4) that secures the solid-state thermal bracket and the solid-state drive to the system board.

Next steps

1. Install the base cover.

2. Install the battery

3. Follow the procedure in After working inside your computer.

Removing the M.2 2280 solid-state drive from the SSD1 slot

Prerequisites

1. Follow the procedure in Before working inside your computer.

2. Remove the base cover.

3. Remove the battery.

Disassembly and reassembly

23

Page 24

About this task

NOTE: This procedure applies only to computers shipped with an M.2 2280 solid-state drive installed in the SSD1 slot.

NOTE: Depending on the configuration ordered, your computer may support an M.2 2230 solid-state drive or an M.2

2280 solid-state drive in the SSD1 slot.

The following image indicates the location of the M.2 2280 solid-state drive that is installed in SSD1 slot and provides a visual

representation of the removal procedure.

Steps

1. Remove the screw (M2x4) that secures the solid-state drive thermal bracket and the solid-state drive to the system board.

2. Lift the thermal plate off the system board.

3. Slide and lift the solid-state drive off the SSD1 slot.

Installing the M.2 2280 solid-state drive in the SSD1 slot

Prerequisites

If you are replacing a component, remove the existing component before performing the installation procedure.

About this task

NOTE: This procedure applies only to computers shipped with an M.2 2280 solid-state drive installed in the SSD1 slot.

NOTE: Depending on the configuration ordered, your computer may support an M.2 2230 solid-state drive or an M.2

2280 solid-state drive in the SSD1 slot.

NOTE: Install the solid-state drive mounting bracket, if it is not installed.

The following image indicates the location of the M.2 2280 solid-state drive that is installed in SSD1 slot and provides a visual

representation of the installation procedure.

24

Disassembly and reassembly

Page 25

Steps

1. Align the notch on the solid-state drive with the tab on the SSD1 slot.

2. Slide the solid-state drive into the SSD1 slot.

3. Using the guide post, place the solid-state drive thermal bracket over the solid-state drive.

4. Align the screw hole on the solid-state drive thermal bracket with the screw hole on the system board.

5. Replace the screw (M2x4) that secures the solid-state drive thermal bracket and the solid-state drive to the system board.

Next steps

1. Install the base cover.

2. Install the battery

3. Follow the procedure in After working inside your computer.

Solid-state drive in SSD2 slot

Removing the M.2 2230 solid-state drive from the SSD2 slot

Prerequisites

1. Follow the procedure in Before working inside your computer.

2. Remove the base cover.

3. Remove the battery.

About this task

NOTE: This procedure applies only to computers shipped with an M.2 2230 solid-state drive installed in the SSD2 slot.

NOTE: Depending on the configuration ordered, your computer may support an M.2 2230 solid-state drive or an M.2

2280 solid-state drive in SSD2 slot.

Disassembly and reassembly 25

Page 26

The following image indicates the location of the M.2 2230 solid-state drive that is installed in the SSD2 slot and provides a visual

representation of the removal procedure.

Steps

1. Remove the screw (M2x4) that secures the solid-state drive to the palm-rest and keyboard assembly.

2. Slide and lift the solid-state drive off the SSD2 slot on the system board.

Installing the M.2 2230 solid-state drive in the SSD2 slot

Prerequisites

If you are replacing a component, remove the existing component before performing the installation procedure.

About this task

NOTE: This procedure applies only to computers shipped with an M.2 2230 solid-state drive installed in the SSD2 slot.

NOTE: Depending on the configuration ordered, your computer may support an M.2 2230 solid-state drive or an M.2

2280 solid-state drive in the SSD2 slot.

NOTE: Install the solid-state drive mounting bracket, if it is not installed.

The following image indicates the location of the M.2 2230 solid-state drive that is installed in the SSD2 slot and provides a visual

representation of the installation procedure.

26

Disassembly and reassembly

Page 27

Steps

1. Slide the solid-state drive mounting bracket into the slot on the palm-rest and keyboard assembly, if it is not installed.

2. Align the notches on the solid-state drive with the tabs in the SSD2 slot on the system board.

3. Slide the solid-state drive into the SSD2 slot on the system board.

4. Replace the screw (M2x4) that secures the solid-state drive to the palm-rest and keyboard assembly.

Next steps

1. Install the battery

2. Install the base cover.

3. Follow the procedure in After working inside your computer.

Removing the M.2 2280 solid-state drive from the SSD2 slot

Prerequisites

1. Follow the procedure in Before working inside your computer.

2. Remove the base cover.

3. Remove the battery.

About this task

NOTE: This procedure applies only to computers shipped with an M.2 2280 solid-state drive installed in the SSD2 slot.

The following image indicates the location of the M.2 2280 solid-state drive that is installed in the SSD2 slot and provides a visual

representation of the removal procedure.

Disassembly and reassembly

27

Page 28

Steps

1. Remove the screw (M2x4) that secures the solid-state drive thermal bracket and the solid-state drive to the system board.

2. Lift the thermal plate off the system board.

3. Slide and lift the solid-state drive off the SSD2 slot.

Installing the M.2 2280 solid-state drive in the SSD2 slot

Prerequisites

If you are replacing a component, remove the existing component before performing the installation procedure.

About this task

NOTE: This procedure applies only to computers shipped with an M.2 2280 solid-state drive installed in the SSD2 slot.

NOTE: Install the solid-state drive mounting bracket, if it is not installed.

The following image indicates the location of the M.2 2280 solid-state drive that is installed in the SSD2 slot and provides a visual

representation of the installation procedure.

28

Disassembly and reassembly

Page 29

Steps

1. Align the notch on the solid-state drive with the tab on the SSD2 slot.

2. Slide the solid-state drive into the SSD2 slot.

3. Using the guide post, place the solid-state drive thermal bracket over the solid-state drive.

4. Align the screw hole on the solid-state drive thermal bracket with the screw hole on the system board.

5. Replace the screw (M2x4) that secures the solid-state drive thermal bracket and the solid-state drive to the system board.

6. Adhere the tape that secures the solid-state drive thermal bracket to the system board.

Next steps

1. Install the battery

2. Install the base cover.

3. Follow the procedure in After working inside your computer.

Fans

Removing the fan 1

Prerequisites

1. Follow the procedure in Before working inside your computer.

2. Remove the base cover.

About this task

The following image indicates the location of the right fan 1 and provides a visual representation of the removal procedure.

Fan depicted is for systems with discrete graphics, UMA fan may appear different but installs in the same

NOTE:

manner.

Disassembly and reassembly 29

Page 30

Steps

1. Remove the two screws (M2x4) and the single screw (M1.6x4) that secure the right fan (FAN1) to the system board and palm-rest

and keyboard assembly.

2. Disconnect the right fan cable from the system board.

3. Lift the right fan (FAN1) off the palm-rest and keyboard assembly.

Installing the right fan

Prerequisites

About this task

The following images indicate the location of the fan 1 and provides a visual representation of the installation procedure.

30

Disassembly and reassembly

Page 31

Steps

1. Connect the right fan (Fan 1) cable to the system board.

2. Align the screw holes on the fan 1 with the screw holes on the system board and palm-rest and keyboard assembly.

3. Replace the two screws (M2x4) and the single screw (M1.6x4) that secure the right fan (Fan 1) to the system board and palm-rest

and keyboard assembly.

Next steps

1. Install the base cover.

2. Follow the procedure in After working inside your computer.

Removing the fan 2

Prerequisites

1. Follow the procedure in Before working inside your computer.

2. Remove the base cover.

About this task

The following image indicates the location of the fan 2 and provides a visual representation of the removal procedure.

Disassembly and reassembly

31

Page 32

Steps

1. Remove the two screws (M2x4) and the single screw (M1.6x4) that secure the left fane (Fan 2) to the system board and palm-rest

and keyboard assembly.

2. Disconnect the fan cable from the system board.

3. Lift the left fan (Fan 2) off the palm-rest and keyboard assembly.

Installing the left fan

Prerequisites

About this task

The following image indicates the location of the fan 2 and provides a visual representation of the installation procedure.

32

Disassembly and reassembly

Page 33

Steps

1. Align the screw holes on the left fan (Fan 2) with the screw holes on the system board and palm-rest and keyboard assembly.

2. Replace the two screws (M2x4) and the single screw (M1.6x4) that secure the left fan (Fan 2) to the system board and palm-rest and

keyboard assembly.

3. Connect the left fan (Fan 2) cable to the system board.

Next steps

1. Install the base cover.

2. Follow the procedure in After working inside your computer.

Heat sink

Removing the heat sink (for computers shipped with integrated graphics card)

Prerequisites

1. Follow the procedure in Before working inside your computer.

CAUTION:

your skin can reduce the heat transfer capability of the thermal grease.

For maximum cooling of the processor, do not touch the heat transfer areas on the heat sink. The oils in

NOTE: The heat sink may become hot during normal operation. Allow sufficient time for the heat sink to cool before

you touch it.

2. Remove the base cover.

About this task

The following image indicates the location of the heat sink and provides a visual representation of the removal procedure.

Disassembly and reassembly

33

Page 34

Steps

1. In reverse sequential order (as indicated by the numbers on the heat sink), remove the four screws (M2x6.5) that secure the heat sink

to the system board.

2. Lift the heat sink off the system board.

Installing the heat sink (for computers shipped with integrated graphics card)

Prerequisites

CAUTION: Incorrect alignment of the heat sink can damage the system board and the processor.

NOTE: If either the system board or the heat sink is replaced, use the thermal pad or thermal paste provided in the kit to

ensure that there is thermal conductivity.

About this task

The following image indicates the location of the heat sink and provides a visual representation of the installation procedure.

34

Disassembly and reassembly

Page 35

Steps

1. Align the screw holes on the heat sink with the screw holes on the system board.

2. In sequential order (as indicated by the numbers on the heat sink), replace the four screws (M2x6.5) that secure the heat sink to the

system board.

Next steps

1. Install the base cover.

2. Follow the procedure in After working inside your computer.

Removing the heat sink

Prerequisites

1. Follow the procedure in Before working inside your computer.

CAUTION:

your skin can reduce the heat transfer capability of the thermal grease.

NOTE: The heat sink may become hot during normal operation. Allow sufficient time for the heat sink to cool before

you touch it.

2. Remove the base cover.

3. Remove the battery.

About this task

The following image indicates the location of the heat sink and provides a visual representation of the removal procedure.

For maximum cooling of the processor, do not touch the heat transfer areas on the heat sink. The oils in

Disassembly and reassembly

35

Page 36

Steps

1. In reverse sequential order (as indicated by the numbers on the heat sink), remove the screws that secure the heat sink to the system

board.

• Heat sink for system boards with integrated graphics card: four screws (M2.5x6)

• Heat sink for system boards with discrete graphics card: six screws (M2.5x6)

2. Lift the heat sink off the system board.

Installing the heat sink

Prerequisites

CAUTION: Incorrect alignment of the heat sink can damage the system board and the processor.

NOTE: If either the system board or the heat sink is replaced, use the thermal pad or thermal paste provided in the kit to

ensure that there is thermal conductivity.

About this task

The following image indicates the location of the heat sink and provides a visual representation of the installation procedure.

36

Disassembly and reassembly

Page 37

Steps

1. Align the screw holes on the heat sink with the screw holes on the system board.

2. In sequential order (as indicated by the numbers on the heat sink), replace the screws that secure the heat sink to the system board.

• Heat sink for system boards with integrated graphics card: four screws (M2.5x6)

• Heat sink for system boards with discrete graphics card: six screws (M2.5x6)

Next steps

1. Install the battery

2. Install the base cover.

3. Follow the procedure in After working inside your computer.

I/O board

Removing the I/O board

Prerequisites

1. Follow the procedure in Before working inside your computer.

2. Remove the base cover.

3. Remove the battery.

About this task

The following image indicates the location of the I/O board and provides a visual representation of the removal procedure.

Disassembly and reassembly

37

Page 38

Steps

1. Disconnect the I/O-board cable from the system board and the I/O board.

2. Lift the I/O-board cable off the system board.

3. Remove the three screws (M2x4) that secures the I/O board to the palm-rest and keyboard assembly.

4. Lift the I/O board off the palm-rest and keyboard assembly.

Installing the I/O board

Prerequisites

About this task

The following image indicates the location of the I/O board and provides a visual representation of the installation procedure.

38

Disassembly and reassembly

Page 39

Steps

1. Align the screw hole on the I/O board with the screw hole on the palm-rest and keyboard assembly.

2. Replace the three screws (M2x4) that secure the I/O board to the palm-rest and keyboard assembly.

3. Connect the I/O-board cable to the connectors on the system board and the I/O board.

Next steps

1. Install the battery.

2. Install the base cover.

3. Follow the procedure in After working inside your computer.

Display assembly

Removing the display assembly

Prerequisites

1. Follow the procedure in Before working inside your computer.

2. Remove the base cover.

About this task

The following images indicate the location of the display cable and the display hinges and provide a visual representation of the removal

procedure.

Disassembly and reassembly

39

Page 40

40 Disassembly and reassembly

Page 41

Steps

1. Remove the two screws (M2x4) that secure the display-cable bracket to the system board.

2. Lift the display-assembly cable bracket off the system board.

3. Push the camera connector and the display connector away from the system board to disconnect them from the system board.

4. Remove the three screws (M2.5x5) that secure the left display hinge to the palm-rest and keyboard assembly.

5. Remove the three screws (M2.5x5) that secure the right display hinge to the palm-rest and keyboard assembly.

6. Lift the left and the right hinges from the palm-rest and keyboard assembly.

7. Slide the palm-rest and keyboard assembly from the display assembly.

8. After performing all the above steps, you are left with the display assembly.

Installing the display assembly

Prerequisites

About this task

The following images indicate the location of the display cable and the display hinges and provide a visual representation of the installation

procedure.

Disassembly and reassembly

41

Page 42

42 Disassembly and reassembly

Page 43

Steps

1. Slide the palm-rest and keyboard assembly under the display hinges.

2. Align the screw holes on the palm-rest assembly with the screw holes on the right and the left display hinges.

3. Replace the three screws (M2.5x5) that secure the left display hinge to the system board and the palm-rest and keyboard assembly.

4. Replace the three screws (M2.5x5) that secure the right display hinge to the system board and the palm-rest and keyboard assembly.

5. Connect the display cable and the camera cable to the display-assembly cable.

6. Align the screw holes on the display-assembly cable bracket with the screw holes on the system board.

7. Replace the two screws (M2x4) that secure the display-assembly cable bracket to the palm-rest and keyboard assembly.

NOTE: Apply gentle torque when tightening the two screws (M2x4) to avoid damaging the screw threads.

Next steps

1. Install the base cover.

2. Follow the procedure in After working inside your computer.

Disassembly and reassembly

43

Page 44

System board

Removing the system board

Prerequisites

1. Follow the procedure in Before working inside your computer.

NOTE: The Service Tag of your computer is stored in the system board. Enter the Service Tag in the BIOS setup

program after you replace the system board.

NOTE: Replacing the system board removes any changes that you have made to the BIOS using the BIOS setup

program. Make the appropriate changes again after you replace the system board.

NOTE: Before disconnecting the cables from the system board, note the location of the connectors so that you can

reconnect the cables correctly after you replace the system board.

2. Remove the base cover.

3. Remove the battery.

4. Remove the memory modules.

5. Remove the M.2 2230 solid-state drive or the M.2 2280 solid-state drive from the SSD1 slot.

6. Remove the M.2 2230 solid-state drive or the M.2 2280 solid-state drive from the SSD2 slot.

7. Remove the heat sink.

NOTE:

The system board can be removed or installed together with the heat sink attached. This simplifies the

procedure and avoids breaking the thermal bond between the system board and the heat sink.

8. Remove the right fan.

9. Remove the left fan.

10. Remove the I/O board.

11. Remove the display assembly.

About this task

The following image indicates the location of the connectors on your system board.

Figure 3. System-board connectors

1.

Power-button connector 2. Left fan connector

3. Left antenna cable (applicable only to computers shipped with

active antenna)

5. Keyboard cable 6. Right speaker cable

4. Left speaker cable

44 Disassembly and reassembly

Page 45

7. Antenna cables 8. Right antenna cable (applicable only to computers shipped with

active antenna)

9. Right fan cable 10. Display cable

The following images indicate the location of the system board and provide a visual representation of the removal procedure.

Disassembly and reassembly 45

Page 46

Steps

1. Remove the two screws (M2x4) that secure the display-assembly cable bracket to the system board.

2. Lift the display-assembly cable bracket off the system board.

3. Disconnect the camera cable and the display cable from the system board.

4. Remove the two screws (M2x4) that secure the USB Type-C port bracket to the palm-rest and keyboard assembly.

5. Peel off the Mylar tape that secures the woofer cable and the speaker cable to the system board.

6. Open the latch and disconnect the power-button cable from the system board.

7. Open the latch and disconnect the woofer cable from the system board.

8. Disconnect the speaker cable from the system board.

9. Disconnect the keyboard cable from the system board.

10. Remove the two screws (M2x4) that secure the USB Type-C port bracket to the palm-rest and keyboard assembly.

11. Peel off the mylar that secures the woofer cable and the speaker cable to the system board.

12. Remove the screw (M2x4) that secures the wireless-card bracket to the system board.

13. Open the latch and disconnect the woofer cable from the system board.

14. Disconnect the antenna cables from the wireless card.

15. Disconnect the speaker cable from the system board.

16. Remove the three screws (M2x4) that secure the system board to the palm-rest and keyboard assembly.

17. Lift the system board off the palm-rest and keyboard assembly.

46

Disassembly and reassembly

Page 47

Installing the system board

Prerequisites

NOTE: The Service Tag of your computer is stored in the system board. Enter the Service Tag in the BIOS setup

program after you replace the system board.

NOTE: Replacing the system board removes any changes that you have made to the BIOS using the BIOS setup

program. Make the appropriate changes again after you replace the system board.

About this task

The following image indicates the location of the connectors on your system board.

Figure 4. System-board connectors

Power-button connector 2. Left fan connector

1.

3. Left antenna cable (applicable only to computers shipped with

active antenna)

5. Keyboard cable 6. Right speaker cable

7. Antenna cables 8. Right antenna cable (applicable only to computers shipped with

9. Right fan cable 10. Display cable

The following images indicate the location of the system board and provide a visual representation of the installation procedure.

4. Left speaker cable

active antenna)

Disassembly and reassembly

47

Page 48

48 Disassembly and reassembly

Page 49

Steps

1. Align the screw holes on the system board with the screw holes on the palm-rest and keyboard assembly.

2. Replace the three screws (M2x4) that secure the system board to the palm-rest and keyboard assembly.

3. Connect the woofer cable to the system board and close the latch to secure the woofer cable to the system board.

4. Connect the antenna cables to the wireless card.

The following table provides the antenna-cable color scheme for the wireless card that is supported by your computer.

Table 3. Antenna-cable color scheme

Connectors on the wireless card Antenna-cable color

Main (white triangle) White

Auxiliary (black triangle) Black

5. Connect the speaker cable to the system board and close the latch to secure the speaker cable to the system board.

6. Replace the two screws (M2x4) that secure the USB Type-C port bracket to the palm-rest and keyboard assembly.

7. Adhere the Mylar tape that secures the woofer connector and the speaker connector to the system board.

8. Replace the screw (M2x4) that secures the wireless-card bracket to the system board.

9. Connect the power-button cable to the system board and close the latch to secure the power-button cable to the system board.

10. Connect the woofer cable to the system board and close the latch to secure the woofer cable to the system board.

11. Connect the speaker cable to the system board and close the latch to secure the speaker cable to the system board.

12. Replace the two screws (M2x4) that secure the USB Type-C port bracket to the palm-rest and keyboard assembly.

13. Adhere the Mylar tape that secures the woofer connector and the speaker connector to the system board.

14. Connect the display cable and the camera cable to the display-assembly cable.

15. Align the screw holes on the display-assembly cable bracket with the screw holes on the system board.

16. Replace the two screws (M2x4) that secure the display-assembly cable holder to the palm-rest and keyboard assembly.

NOTE: Apply gentle torque when tightening the two screws (M2x4) to avoid damaging the screw threads.

Disassembly and reassembly 49

Page 50

Next steps

1. Install the display assembly.

2. Install the I/O board.

3. Install the right fan.

4. Install the left fan.

5. Install the heat sink.

6. Install the M.2 2230 solid-state drive or the M.2 2280 solid-state drive in the SSD2 slot.

7. Install the M.2 2230 solid-state drive or the M.2 2280 solid-state drive in the SSD1 slot.

8. Install the memory modules.

9. Install the battery.

10. Install the base cover.

11. Follow the procedure in After working inside your computer.

Antenna

Removing the antennas

Prerequisites

1. Follow the procedure in Before working inside your computer.

NOTE:

The Service Tag of your computer is stored in the system board. Enter the Service Tag in the BIOS setup

program after you replace the system board.

NOTE: Replacing the system board removes any changes that you have made to the BIOS using the BIOS setup

program. Make the appropriate changes again after you replace the system board.

NOTE: Before disconnecting the cables from the system board, note the location of the connectors so that you can

reconnect the cables correctly after you replace the system board.

2. Remove the base cover.

3. Remove the battery.

4. Remove the memory modules.

5. Remove the M.2 2230 solid-state drive or the M.2 2280 solid-state drive from the SSD1 slot.

6. Remove the M.2 2230 solid-state drive or the M.2 2280 solid-state drive from the SSD2 slot.

7. Remove the heat sink.

NOTE:

The system board can be removed or installed together with the heat sink attached. This simplifies the

procedure and avoids breaking the thermal bond between the system board and the heat sink.

8. Remove the fan 1.

9. Remove the fan 2.

10. Remove the I/O board.

11. Remove the display assembly.

12. Remove the system board.

About this task

The following image indicates the location of the antennas and provides a visual representation of the removal procedure.

50

Disassembly and reassembly

Page 51

Steps

1. Remove the four screws (M2x2) that secure the right antenna to the palm-rest and keyboard assembly.

2. Remove the four screws (M2x2) that secure the left antenna to the palm-rest and keyboard assembly.

3. Note the routing of the antenna cables along the routing guides on the palm-rest and keyboard assembly.

4. Peel off the tapes that secure the antenna cable to the palm-rest and keyboard assembly.

5. Remove the antenna cable from the routing guides on the palm-rest and keyboard assembly.

6. Lift the left and the right antenna, along with its cables, off the palm-rest and keyboard assembly.

Installing the antennas

Prerequisites

About this task

The following image indicates the location of the antennas and provides a visual representation of the installation procedure.

Disassembly and reassembly

51

Page 52

Steps

1. Place the antennas into the slots on the palm-rest and keyboard assembly.

2. Route the antenna cable through the routing guides on the palm-rest and keyboard assembly.

3. Adhere the tapes that secure the antenna cable to the palm-rest and keyboard assembly.

4. Align the screw holes on the right antenna with the screw holes on the palm-rest and keyboard assembly.

5. Replace the four screws (M2x2) that secure the right antenna to the palm-rest and keyboard assembly.

6. Align the screw holes on the left antenna with the screw holes on the palm-rest and keyboard assembly.

7. Replace the four screws (M2x2) that secure the left antenna to the palm-rest and keyboard assembly.

Next steps

1. Install the system board.

2. Install the display assembly.

3. Install the I/O board.

4. Install the fan 2.

5. Install the fan 1.

6. Install the heat sink.

The system board can be removed or installed together with the heat sink attached. This simplifies the

NOTE:

procedure and avoids breaking the thermal bond between the system board and the heat sink.

7. Install the M.2 2230 solid-state drive or the M.2 2280 solid-state drive from the SSD2 slot.

52

Disassembly and reassembly

Page 53

8. Install the M.2 2230 solid-state drive or the M.2 2280 solid-state drive from the SSD1 slot.

9. Install the memory modules.

10. Install the battery.

11. Install the base cover.

12. Follow the procedure in After working inside your computer.

Palm-rest and keyboard assembly

Removing the palm-rest and keyboard assembly

Prerequisites

1. Follow the procedure in Before working inside your computer.

NOTE: The Service Tag of your computer is stored in the system board. Enter the Service Tag in the BIOS setup

program after you replace the system board.

NOTE: Replacing the system board removes any changes that you have made to the BIOS using the BIOS setup

program. Make the appropriate changes again after you replace the system board.

NOTE: Before disconnecting the cables from the system board, note the location of the connectors so that you can

reconnect the cables correctly after you replace the system board.

2. Remove the base cover.

3. Remove the battery.

4. Remove the memory modules.

5. Remove the M.2 2230 solid-state drive or the M.2 2280 solid-state drive from the SSD1 slot.

6. Remove the M.2 2230 solid-state drive or the M.2 2280 solid-state drive from the SSD2 slot.

7. Remove the heat sink.

NOTE:

The system board can be removed or installed together with the heat sink attached. This simplifies the

procedure and avoids breaking the thermal bond between the system board and the heat sink.

8. Remove the fan 1.

9. Remove the fan 2.

10. Remove the I/O board.

11. Remove the display assembly.

12. Remove the system board.

13. Remove the antenna.

About this task

The following image indicates the palm-rest and keyboard assembly and provides a visual representation of the removal procedure.

Disassembly and reassembly

53

Page 54

After performing the steps in the pre-requisites, you are left with the palm-rest and keyboard assembly.

Installing the palm-rest and keyboard assembly

Prerequisites