Page 1

EMC CLARiiON

2-Gigabit Disk-Array Enclosure (DAE2)

FC and ATA Models

HARDWARE REFERENCE

P/N 014003048

REV A05

EMC Corporation

Corporate Headquarters

Hopkinton, MA 01748

1

-508-435-1000

www.EMC.com

:

-9103

Page 2

Copyright © 2002-2004 EMC Corporation. All rights reserved.

Published January, 2004

EMC believes the information in this publication is accurate as of its publication date. The

information is subject to change without notice.

THE INFORMATION IN THIS PUBLICATION IS PROVIDED "AS IS." EMC CORPORATION

MAKES NO REPRESENTATIONS OR WARRANTIES OF ANY KIND WITH RESPECT TO THE

INFORMATION IN THIS PUBLICATION, AND SPECIFICALLY DISCLAIMS IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Use, copying, and distribution of any EMC software described in this publication requires an

applicable software license.

Trademark Information

EMC2, EMC, CLARiiON, Navisphere, and PowerPath are registered trademarks and Access Logix, EMC ControlCenter, FLARE, MirrorView,

SAN Copy, and SnapView are trademarks of EMC Corporation.

All other trademarks used herein are the property of their respective owners.

ii

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 3

Regulatory Notices Product Type(s) KAE, KLE

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

Testing was done with shielded cables. Therefore, in order to comply with the FCC regulations, you must use shielded

cables with your installation. Changes or modifications to this unit not expressly approved by the party responsible

for compliance could void the user's authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his own expense.

This Class A digital apparatus complies with Canadian ICES-003

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada

Manufacturer’s Declaration of Conformity - CE mark

This equipment has been tested and found to comply with the requirements of European Community Council

Directives 89/336/EEC, 73/23/EEC, and 98/68/EEC relating to electromagnetic compatibility and product safety

respectively.

This product complies with EN55022, CISPR22 and AS/NZS 3548 Class A.

This is a Class A product. In a domestic environment this product may cause radio interference in which case the user

may be required to take adequate measures.

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

iii

Page 4

iv

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 5

Contents

Preface............................................................................................................................. ix

Warnings and Cautions......................................................................................... xiii

Chapter 1 About DAE2 Disk Enclosures

Introduction...................................................................................... 1-2

Midplane.................................................................................... 1-6

Front Bezel................................................................................. 1-6

Link Control Cards (LCCs)............................................................. 1-7

Disk Modules.................................................................................... 1-8

Disk Drives ................................................................................ 1-8

Drive Carrier ............................................................................. 1-8

Power Supply/System Cooling Modules .................................... 1-9

Chapter 2 Installing a DAE2

Requirements.................................................................................... 2-2

Site Requirements..................................................................... 2-2

Cabling Requirements.............................................................. 2-2

Installing a Disk Enclosure in a Cabinet....................................... 2-3

Warnings and Recommendations .......................................... 2-3

Setting Up an Installed Disk Enclosure........................................ 2-4

Powerup and Initialization........................................................... 2-12

Binding Disk Modules into RAID Groups................................. 2-13

Disk Configuration Rules and Recommendations ............ 2-13

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

v

Page 6

Contents

Chapter 3 Servicing a DAE2

Monitoring Disk Enclosure Status ................................................ 3-2

Handling FRUs ................................................................................ 3-6

Power Issues and FRUs ........................................................... 3-6

Avoiding Electrostatic Discharge (ESD) Damage................ 3-6

Emergency Procedures (Without an ESD Kit)...................... 3-7

Precautions When Removing, Installing, or Storing FRUs 3-8

Replacing or Adding a Disk Module............................................ 3-9

Unlocking and Removing the Front Bezel.......................... 3-10

Removing a Disk Filler Module ........................................... 3-11

Removing a Disk Module...................................................... 3-11

Installing a Disk or Filler Module ........................................ 3-12

Installing and Locking the Front Bezel................................ 3-14

Replacing an LCC Module ........................................................... 3-15

Removing an LCC .................................................................. 3-15

Installing an LCC.................................................................... 3-16

Replacing a Power Supply/System Cooling Module .............. 3-20

Appendix A Technical Specifications

Enclosure Specifications ............................................................... A-2

Ac Power Requirements......................................................... A-2

Size and Weight ....................................................................... A-3

Drive Type ................................................................................ A-3

LCC FC-AL Interface .............................................................. A-3

Standards Certification and Compliance............................. A-4

Fibre Channel Related Standards.......................................... A-4

Operating Limits ............................................................................ A-5

Environmental Recovery........................................................ A-5

Shipping and Storage Requirements.................................... A-6

Appendix B Customer Support

Overview of Detecting and Resolving Problems ...................... B-2

Troubleshooting the Problem ....................................................... B-3

Before Calling the Customer Support Center ............................ B-4

Documenting the Problem ........................................................... B-5

Reporting a New Problem ............................................................ B-6

Sending Problem Documentation ............................................... B-7

Index................................................................................................................................ i-1

vi

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 7

Figures

Figure

1-1 DAE2 .............................................................................................................. 1-2

1-2 DAE2 Front LED Display ............................................................................ 1-4

1-3 Disk Enclosure Rear View ........................................................................... 1-5

1-4 Disk Enclosure Rear Displays ..................................................................... 1-5

1-5 Disk Enclosure Front Bezel ......................................................................... 1-6

1-6 LCC Connectors and LEDs ......................................................................... 1-7

1-7 Disk Modules ................................................................................................ 1-8

1-8 Power/Cooling Module .............................................................................. 1-9

2-1 Setting the Enclosure Address (EA) .......................................................... 2-5

2-2 Plugging in the ac Line Cord ...................................................................... 2-6

2-3 Connecting DAE2 Power Cords ................................................................. 2-7

2-4 Connecting a Disk Enclosure to Another FC Device .............................. 2-8

2-5 Cabling Disk Enclosures Together — Two Fibre Channel Loops ......... 2-9

2-6 Cabling DAE2s Together — Four Fibre Channel Loops ...................... 2-10

2-7 Cabling Disk Enclosures Together —

Segregated Loop Configuration ............................................................... 2-11

3-1 Front Disk Enclosure and Disk Module Status Lights

(Bezel Removed) ........................................................................................... 3-2

3-2 Enclosure Address and Loop ID Indicators ............................................. 3-4

3-3 Power/Cooling Module Status Indicators ............................................... 3-4

3-4 LCC Status LEDs .......................................................................................... 3-5

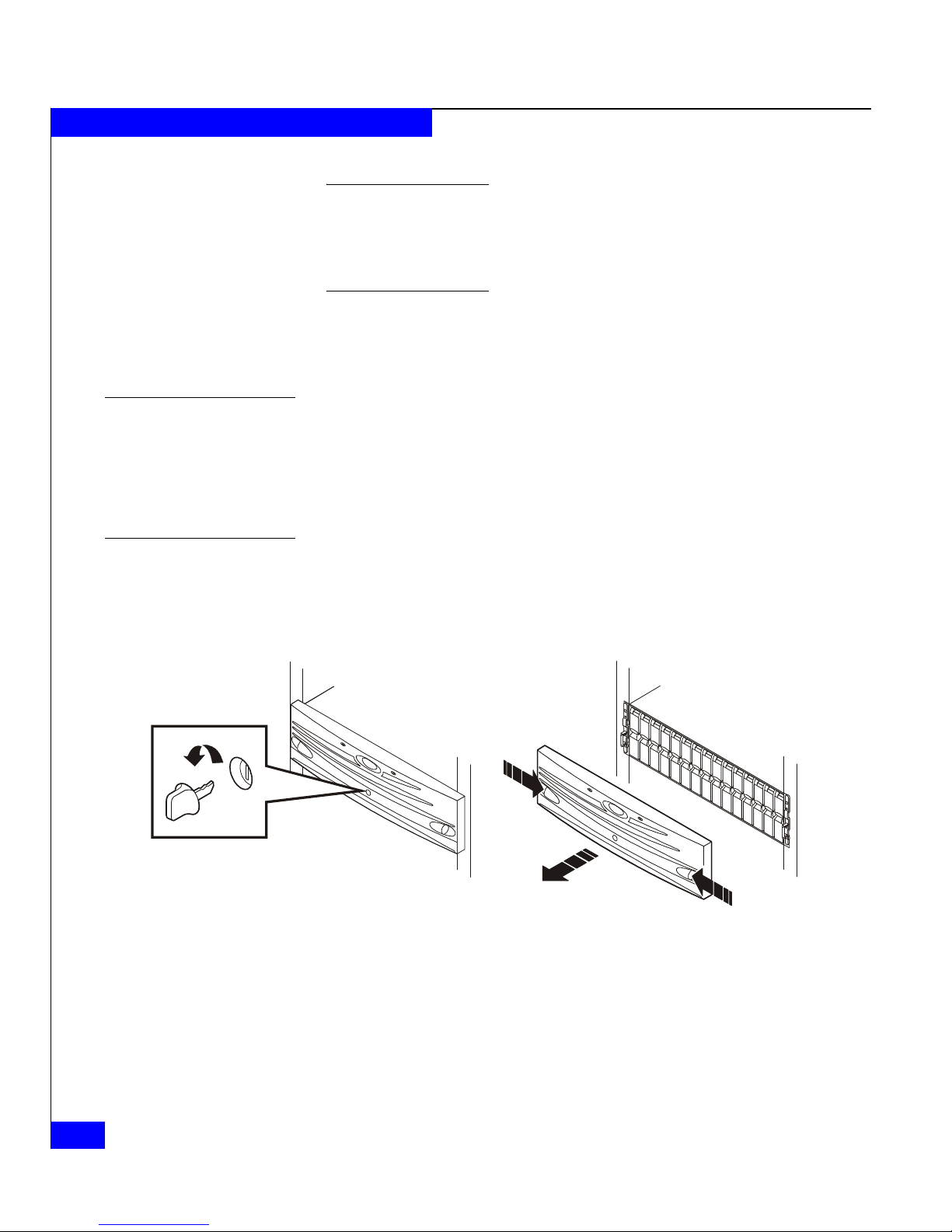

3-5 Unlocking and Removing the Front Bezel .............................................. 3-10

3-6 Removing a Disk Filler Module (FC Disk Carrier Shown) ................... 3-11

3-7 Removing a Disk Module (FC Disk Carrier Shown) ............................. 3-12

3-8 Installing a Disk or Filler Module (FC Disk Carrier Shown) ............... 3-13

3-9 Installing and Locking the Front Bezel .................................................... 3-14

3-10 Removing a Copper Cable from an LCC ................................................ 3-15

3-11 Removing an LCC ...................................................................................... 3-16

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

vii

Page 8

Figures

3-12 Installing an LCC ........................................................................................ 3-17

3-13 Reconnecting a Copper Cable to an LCC ................................................ 3-18

3-14 Connecting Disk Enclosures Together with Copper Cable .................. 3-19

3-15 Unplugging the ac Power Cord ................................................................ 3-20

3-16 Removing a Power/Cooling Module ...................................................... 3-21

3-17 Installing a Power/Cooling Module ........................................................ 3-21

3-18 Plugging in the Power Cord ...................................................................... 3-22

B-1 Problem Detection and Resolution Process .............................................. B-2

viii

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 9

Preface

This manual is your primary source of information about EMC

2-gigabit disk-array enclosure (DAE2) hardware. It covers DAE2

models that use Fibre Channel disks, and DAE2-ATA models that

include Advanced Technology Attachment drives.

The DAE2 is often called a disk enclosure.

Audience This guide is part of the DAE2 documentation set, and is intended for

use by system administrators and others responsible for the

installation, setup, and maintenance of the product.

Readers of this guide are expected to be familiar with the following

topics:

◆ Storage-system operation

◆ Basic computer hardware safety and maintenance procedures.

Organization The information in this guide is organized as follows:

Chapter 1, About DAE2 Disk Enclosures, provides a descriptive

overview of the disk enclosure.

Chapter 2, Installing a DAE2, describes how to set up and power up

the enclosure(s) in your cabinet.

Chapter 3, Servicing a DAE2, provides instructions and procedures for

recognizing and replacing failed components.

Appendix A, Technical Specifications, lists operating limits, shipping

and storage requirements, and technical specifications.

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

ix

Page 10

Preface

Related

Documentation

Cabinet Setup Guide for the 40U Cabinet (P/N 014003099)

Site Preparation and Unpacking Guide for the 40U Cabinet

(P/N 014003100)

EMC Rails and Enclosures Installation Guide for 19-Inch NEMA Cabinets

(P/N 014003082)

EMC 2-Gigabit Disk Enclosure (DAE2) Setup Guide (P/N 014003104)

EMC Navisphere Manager Revision 6.X Administrator’s Guide

(P/N 069001161)

EMC CLARiiON CX300, CX500, and CX700 Storage Systems

Configuration Planning Guide (P/N 300-001-273)

EMC Storage System CX400-Series and CX600-Series Configuration

Planning Guide (P/N 014003113)

EMC Fibre Channel Storage System CX200-Series

Configuration Planning

Guide (P/N 014003115)

EMC Navisphere Version 6.X Security Administrator’s Guide

(P/N 069001124)

EMC Installation Roadmap for CX-Series and FC-Series Storage Systems

(P/N 069001166)

Conventions Used in

This Guide

!

EMC Storage Systems CX-Series Disk and FLARE OE Matrix

(P/N 014003111)

Navisphere® is a member of the EMC ControlCenter™ family of products.

EMC uses the following conventions for notes, cautions, warnings,

and danger notices.

A note presents information that is important, but not hazard-related.

CAUTION

A caution contains information essential to avoid data loss or

damage to the system or equipment. The caution may apply to

hardware or software.

x

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 11

Preface

WARNING

A warning contains information essential to avoid a hazard that can

cause severe personal injury, death, or substantial property damage

if you ignore the warning.

DANGER

A danger notice contains information essential to avoid a hazard

that will cause severe personal injury, death, or substantial property

damage if you ignore the message.

Typographical Conventions

This manual uses the following format conventions:

This

typeface

Indicates text (including punctuation) that you type

verbatim, all commands, pathnames, filenames,

and directory names. It indicates the name of a

dialog box, field in a dialog box, menu, menu

option, or button.

This typeface Represents variables for which you supply the

values; for example, the name of a directory or file,

your username or password, and explicit

arguments to commands.

This

typeface

x > y

Represents a system response (such as a message or

prompt), a file or program listing.

Represents a menu path. For example, Operations

> Poll All Storage Systems tells you to select Poll

All Storage Systems on the Operations menu.

[ ]

|

Encloses optional entries.

Separates alternative parameter values; for

example:

LUN-name | LUN-number means you can use either

the LUN-name or the LUN-number.

Finding Current

Information

The most up-to-date information about the DAE2 is posted on the

EMC Powerlink website. We recommend that you download the

latest information before you install or service your DAE2. If you

purchased this product from an EMC reseller and you cannot access

Powerlink, the latest product information should be available from

your reseller.

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

xi

Page 12

Preface

To access EMC Powerlink, use the following link:

http://powerlink.emc.com

After you log in, select Support > Document Library and find the

following:

◆ The FLARE™ software release notes

◆ The latest version of this reference.

◆ EMC Installation Roadmap for CX-Series and FC-Series Storage

Systems, which provides a checklist of the tasks that you must

complete to install your storage system in a storage area network

(SAN) or direct attach configuration.

Where to Get Help For questions about technical support and service, contact your

service provider.

If you have an EMC service contract, contact EMC Customer Service

at:

United States: (800) 782-4362 (SVC-4EMC)

Canada: (800) 543-4782 (543-4SVC)

Worldwide: (800) 497-7901

Follow the voice menu prompts to open a service call, then select

CLARiiON Product Support.

Sales and Customer

Service Contacts

For the list of EMC sales locations, please access the EMC home page

at:

http://www.emc.com/contact/

For additional information on the EMC products and services

available to customers and partners, refer to the EMC Powerlink Web

site at:

http://powerlink.emc.com

Your Comments Your suggestions will help us continue to improve the accuracy,

organization, and overall quality of the user publications. Please send

a message to techpub_comments@emc.com with your opinions of

this guide.

xii

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 13

The following warnings and cautions pertain throughout this guide.

WARNING Trained service personnel only.

Ground circuit continuity is vital for safe operation of the machine.

Never operate the machine with grounding conductors disconnected.

Remember to reconnect any grounding conductors removed for or

during any installation procedure.

ATTENTION Resérvé au personnel autorisé.

Un circuit de terre continu est essentiel en vue du fonctionnement

sécuritaire de l'apareil. Ne jamais mettre l'appareil en marche lorsque

le conducteur de mise a la terre est débranché.

Warnings and

Cautions

WARNUNG Nur für Fachpersonal.

STROMSTREUVERLUST: Gerät muss geerdet werden, bevor es am

Stromnetz angeschlossen wird.

!

CAUTION

Service personnel are advised to exercise great care at all times

when working on the unit. Remember to:

◆ Remove rings, watches, or other jewelry and neckties before

you begin any procedures.

◆ Use caution near any moving part and any part that may start

unexpectedly such as fans, motors, solenoids, and so on.

◆ Always use the correct tools for the job.

◆ Always use the correct replacement parts.

◆ Keep all paperwork, including incident reports, up to date,

complete, and accurate.

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

xiii

Page 14

Warnings and Cautions

Static Precautions EMC incorporates state-of-the-art technology in its designs, including

the use of LSI and VLSI components. These chips are very susceptible

to damage caused by static discharge and need to be handled

accordingly.

!

Replacing a Lithium Battery

CAUTION

Before handling printed-circuit boards or other parts containing

LSI and/or VLSI components, observe the following precautions:

◆ Store all printed-circuit boards in antistatic bags.

◆ Use a ground strap whenever you handle a printed-circuit

board.

◆ Unless specifically designed for nondisruptive replacement,

never plug or unplug printed-circuit boards with the power on.

Severe component damage may result

Some EMC products include lithium batteries that only trained

personnel should change or replace.

WARNING

Danger of explosion if battery is incorrectly replaced. Replace only

with the same or equivalent type recommended by the equipment

manufacturer. Discard used batteries according to manufacturer's

instructions.

xiv

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 15

Invisible Body Tag

1

About DAE2 Disk

Enclosures

Topics in this chapter include

◆ Introduction........................................................................................1-2

◆ Link Control Cards (LCCs)...............................................................1-7

◆ Disk Modules......................................................................................1-8

◆ Power Supply/System Cooling Modules ......................................1-9

About DAE2 Disk Enclosures

1-1

Page 16

About DAE2 Disk Enclosures

Introduction

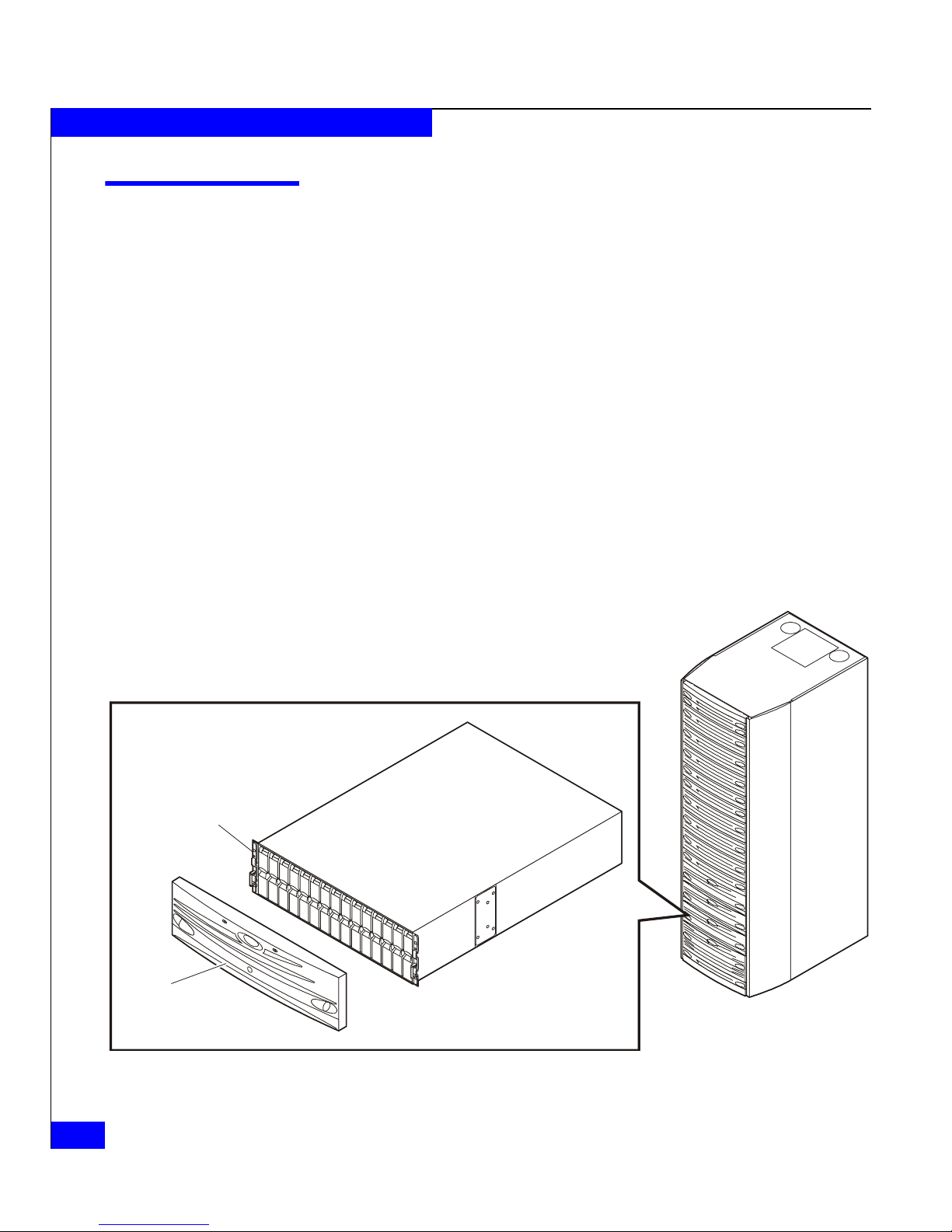

The DAE2 (2-gigabit disk-array enclosure) is a highly available,

high-performance, high-capacity storage system that uses a Fibre

Channel Arbitrated Loop (FC-AL) as its interconnect interface. An

enclosure connects to another DAE2 or a processor such as a CX700,

CX500, or CX300, and is managed by storage-system software in

RAID (Redundant Array of Independent Disk) configurations. The

enclosure is only 3U (5.25 inches) high, but can include 15 hard disk

drive/carrier modules. Its modular, scalable design allows for

additional disk storage as your needs increase. The examples and

illustrations in this manual show the rackmounted DAE2 in a

standard 40U EMC cabinet.

EMC produces two types of DAE2. The standard version includes

high-performance Fibre Channel disk drives and FC-AL link control

cards to manage them. The DAE2-ATA (Advanced Technology

Attachment) version uses economical, high-capacity ATA disk drives

and FC-to-ATA link control cards to manage the disks and provide an

interface between the FC-AL and the drives.

Disk

Drive

(0 - 14)

Front

Bezel

Figure 1-1 DAE2

1-2

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Rackmount

Cabinet

EMC2164

Page 17

About DAE2 Disk Enclosures

Any DAE2 can support up to fifteen 3.5-inch disk modules. Simple

serial cabling provides easy scalability. You can interconnect DAE2s

to Fibre Channel loops (sometimes called busses) to form a large disk

storage system; the number and size of loops depends on the

capabilities of your storage processor. Highly available

configurations require at least one pair of physically independent

loops (A and B sides of Loop 0, sharing the same dual-port disks).

Other configurations use two, three, or four loops. You can place the

disk enclosures in the same cabinet, or in one or more separate

cabinets. High-availability features are standard.

The DAE2 includes the following components:

◆ A sheet-metal enclosure with a midplane and front bezel

◆ Two link control cards (LCCs)

◆ As many as 15 disk modules

◆ Two power supply/system cooling modules

The power supply and system cooling components of the power/cooling

modules function independently of each other, but the assemblies are

packaged together into a single field-replaceable unit (FRU).

Any unoccupied disk module slot has a filler module to maintain air

flow.

The LCCs, disk modules, power supply/system cooling modules,

and filler modules are field-replaceable units (FRUs), which you can

add or replace without tools while the array is powered up.

Standard DAE2 disk modules are FC-AL compliant and support

dual-port FC-AL interconnects through the two LCCs and their

cabling. ATA disk modules include dual-port ATA interconnects; the

FC-to-ATA link control cards provide the bridge between Fibre

Channel and ATA signals.

You can integrate and connect FC and ATA enclosures within a storage

system, but you cannot mix ATA and fibre components within a DAE2.

Standard link control cards will not recognize ATA disk drives, and ATA link

control cards will not recognize Fibre Channel disks.

The system can continue running with one operating power supply

and a single functional LCC. At least three of the four system cooling

blowers must be running correctly for continuous operation.

Figures 1-2 through 1-4 show the disk enclosure components. Details

on each component accompany the figures. Where the enclosure

Introduction

1-3

Page 18

About DAE2 Disk Enclosures

(

)

provides slots for two identical components, the components are

called component-name A or component-name B, as shown in the

illustrations.

For increased clarity, the following figures depict the disk enclosure outside

of the rack cabinet. Your disk enclosure may be installed in a rackmount

cabinet as shown in Figure 1-1.

As shown in Figure 1-2, the front LED display contains two status

lights for each disk module, and two disk enclosure status lights. The

enclosure status lights are visible with the front bezel installed.

Fault LED

(Amber)

Disk Activity

LED

Green

Figure 1-2 DAE2 Front LED Display

Fault LED

(Amber)

Figure 1-3 shows the DAE2 components visible from the rear of the

enclosure. Each highly-available DAE2 includes two link control

cards and two power supply/system cooling (power/cooling)

modules.

Power LED

(Green)

EMC2166

1-4

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 19

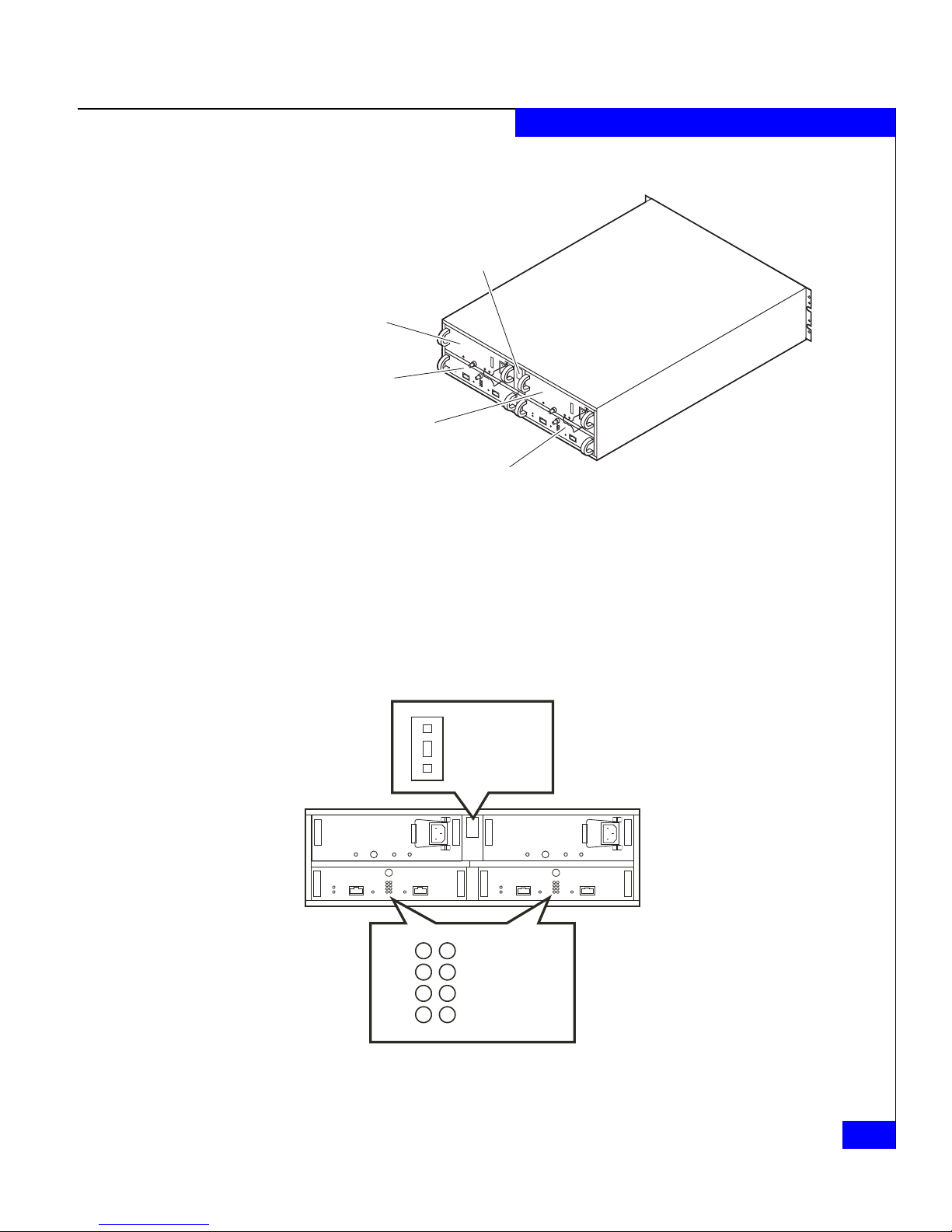

Enclosure

Address

Switch

Power/Cooling

Module B

Link Control

Card B (LCC B)

Power/Cooling

Module A

Link Control

Card A (LCC A)

Figure 1-3 Disk Enclosure Rear View

As shown in Figure 1-3 and Figure 1-4, an enclosure address (EA)

switch/indicator is located between the power supplies at the rear of

the disk enclosure. (The EA is sometimes referred to as an enclosure

ID.) Each link control card (LCC) includes a loop (bus) identification

indicator. The storage processor initializes loop ID when the

operating system loads.

About DAE2 Disk Enclosures

EMC2770

_

Enclosure

0

Address

+

0

1

2

3

Figure 1-4 Disk Enclosure Rear Displays

4

5

6

7

Loop ID

EMC2771

Introduction

1-5

Page 20

About DAE2 Disk Enclosures

The enclosure address is set on the switch at installation. Disk module IDs are

numbered left to right (looking at the front of the unit) and are contiguous

throughout an array: enclosure 0 contains modules 0-14; enclosure 1 contains

modules 15-29; enclosure 2 includes 30-44, and so on through eight

enclosures.

The enclosure EA switch and loop indicator are described in the

installation procedure in Chapter 2. The status lights are described in

the Monitoring Disk Enclosure Status section of Chapter 3.

Midplane

Front Bezel

A midplane between the disk modules and the LCC and

power/cooling modules distributes power and signals to all

components in the enclosure. LCCs, power/cooling modules, and

disk drives — the enclosure’s field-replaceable units (FRUs) — plug

directly into the midplane.

The front bezel, shown in Figure 1-5, has a locking latch and an

electromagnetic interference (EMI) shield. You must remove the bezel

to remove and install drive modules. EMI compliance requires a

properly installed front bezel.

Figure 1-5 Disk Enclosure Front Bezel

1-6

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

EMC2173

Page 21

Link Control Cards (LCCs)

(

)

(

)

An LCC supports and controls one Fibre Channel loop and monitors

the DAE2.

Fault

LED

(Amber)

Power

LED

(Green)

About DAE2 Disk Enclosures

Loop

ID LEDsLatch

Expansion

Connector

Figure 1-6 LCC Connectors and LEDs

Expansion

Link Active

LED

Green

The LCCs in a DAE2 are connected to other Fibre Channel devices

(processor enclosures, DAE2s, and so on) using twin-axial copper

cables. The cabling is not explicitly configured as a loop (with a long

return from the last disk enclosure to the server), but instead, as a set

of full-duplex, point-to-point connections with the last disk enclosure

in the chain closing the loop on its LCC.

The LCC independently receives and electrically terminates the

incoming FC-AL signal. The LCC passes the input signal to the disk

drives in the enclosure; it then sends the output signal, via cables, to

the next DAE2 in the loop. ATA link control cards provide the same

Fibre Channel input and output, but convert those signals to and

from the ATA protocol used by their disk drives.

Each LCC independently monitors the environmental status of the

entire enclosure, using a microcomputer-controlled FRU

(field-replaceable unit) monitor program. The monitor communicates

status to the server, which polls DAE2 status. LCC firmware also

controls the LCC port bypass circuits and the disk-module status

lights.

Primary

Link Active

LED

Green

Primary

Connector

EMC2165

LCCs do not communicate with or control each other.

Each LCC has four status lights. These status lights are described in

Monitoring Disk Enclosure Status in Chapter 3.

Link Control Cards (LCCs)

1-7

Page 22

About DAE2 Disk Enclosures

Disk Modules

A latch on the LCC locks it into place to ensure proper connection to

the midplane. You can add or replace an LCC while the disk

enclosure is powered up.

Each disk module consists of one disk drive in a carrier. You can add

or remove a disk module while the DAE2 is powered up, but should

exercise special care when removing modules while they are in use.

Drive modules are extremely sensitive electronic components. Refer to the

instructions on Handling FRUs and Replacing or Adding a Disk Module in

Chapter 3 whenever you handle a disk module.

Fibre Channel disk modules will not work in an ATA enclosure, and

vice versa. You can visually distinguish between module types by

their different latch and handle mechanisms. ATA drive modules also

include a small printed-circuit adapter board in the back (connector

side) of the carrier. Figure 1-7 shows the DAE2 disk modules.

Fibre Channel Disk Module

Carrier

Latch

Handle

Figure 1-7 Disk Modules

Disk Drives

Drive Carrier

ATA Disk

Disk

Drive

EMC1758

Latch

Handle

Carrier

Adapter

Board

Disk Drive

EMC2654

DAE2 disk drives conform to either FC-AL or ATA 6 specifications,

and either 1-Gbit and 2-Gbit Fibre Channel or 1.5-Gbit ATA interface

standards. The disk module slots in the enclosure accommodate

1-inch (2.54 cm) by 3.5-inch (8.75 cm) disk drives.

The disk drive carriers are metal and plastic assemblies that provide

smooth, reliable contact with the enclosure slot guides and midplane

connectors. Each carrier has a handle with a latch and spring clips.

1-8

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 23

The latch holds the disk module in place to ensure proper connection

with the midplane. Disk drive Activity/Fault LEDs are integrated

into the carrier.

Power Supply/System Cooling Modules

The power supply/system cooling (power/cooling) modules are

located above the LCCs. The units integrate independent power

supply and dual-blower cooling assemblies into a single module.

Each power supply is an auto-ranging, power-factor-corrected,

multi-output, off-line converter with its own line cord and on/off

switch. Each supply supports a fully configured DAE2 and shares

load currents with the other supply. The drives and LCC have

individual soft-start switches that protect the disk drives and LCCs if

you install them while the disk enclosure is powered up. A FRU

(disk, LCC, or power/cooling module) with power-related faults will

not adversely affect the operation of any other FRU.

About DAE2 Disk Enclosures

The enclosure cooling system includes two dual-blower modules. If

one blower fails, the others will speed up to compensate. If two

blowers in a system (both in one power/cooling module, or one in

each module) fail, the DAE2 will go off line within two minutes.

Each power/cooling module has three visible status lights. The

rightmost LED indicates power to the supply; the LED adjacent to it

indicates a power supply fault. The leftmost LED indicates a failure

in one of the integrated blowers within that module that cool the disk

enclosure. The status lights are shown in Figure 1-8 and described in

Monitoring Disk Enclosure Status in Chapter 3.

Blower Fault

LED

(Amber)

Figure 1-8 Power/Cooling Module

Latch

Power Fault

LED (Amber)

ac

Connector

Power

LED

(Green)

EMC2714

A latch on the power/cooling module locks it into place to ensure

proper connection to the midplane. You can add or remove one

power/cooling module in a DAE2 while the system is powered up.

Power Supply/System Cooling Modules

1-9

Page 24

About DAE2 Disk Enclosures

1-10

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 25

Invisible Body Tag

2

Installing a DAE2

This chapter describes the DAE2 installation requirements and

procedures. Major topics are

◆ Requirements......................................................................................2-2

◆ Installing a Disk Enclosure in a Cabinet.........................................2-3

◆ Setting Up an Installed Disk Enclosure ..........................................2-4

◆ Powerup and Initialization............................................................. 2-12

◆ Binding Disk Modules into RAID Groups ...................................2-13

Installing a DAE2

2-1

Page 26

Installing a DAE2

Requirements

This section explains site and cabling requirements.

Site Requirements

Power To determine a DAE2’s worst case power requirements, use the

Cooling The temperature at the front bezel inlet must meet the ambient

For proper operation, the installation site must conform to certain

environmental specifications. These are detailed below and in

Appendix A.

power rating on the enclosure label. This rating is the maximum

power required for a fully loaded enclosure. The amount of internally

regulated power that a maximum configuration requires from the

power supplies and cooling system determines the values for input

current, power (VA), and dissipation per disk enclosure. Typical

values will be less depending on the number, manufacturer, and type

(FC or ATA) of disk drives. These values represent the sum of the

values shared by the line cords of two power supplies in the same

enclosure. Power cords and supplies share the power load evenly. If

one of the two power supplies fails, the remaining supply and cord

support the full load. You must use a rackmount cabinet with ac

power distribution, and have main branch ac distribution that can

handle these values for the number of disk enclosures that you will

interconnect.

temperature specification described in Appendix A. The site must

have air conditioning that can maintain the specified ambient

temperature range. The air conditioning must be able to handle the

BTU requirements of the DAE2 disk enclosures.

Cabling

Requirements

2-2

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

The DAE2 supports copper cable for a Fibre Channel connection to

another Fibre Channel device (for example, a storage processor or

another DAE2).

Any copper cables you use must meet the appropriate standards for

2-Gbit FC-AL. Such cables are fully shielded, twin-axial, full-duplex

cables with High Speed Serial Data Connector (HSSDC) connectors.

Distances greater than 1 meter require equalized cables; unequalized

one-meter cables are adequate. The DAE2 does not support cables

shorter than 1 meter or longer than 10 meters.

Page 27

EMC supports and can provide 1-, 5-, and 10-meter cables. The 5- and

10-meter cables are equalized.

Interconnections between disk enclosures should maintain LCC

consistency; that is, one Fibre Channel (FC) loop should interconnect

all and only the LCC As, and the other Fibre Channel loop should

interconnect all and only LCC Bs.

Connect all cables at both ends, or remove unused cables completely

from the host or LCC ports. An unused (dangling) cable may cause

excess noise on the loop.

Installing a Disk Enclosure in a Cabinet

Each disk enclosure mounts on two L-shaped rails that connect to the

cabinet’s vertical channels.

◆ The Cabinet Setup Guide for the 40U Cabinet ships with standard

EMC cabinets, and explains how to unpack and install the 40U

cabinet itself.

Installing a DAE2

Warnings and

Recommendations

◆ The EMC Rails and Enclosures Installation Guide for 19-Inch NEMA

Cabinets ships on your hardware documentation CD. It explains

how to install universal mounting rails in the cabinet, and how to

install the enclosure on those rails.

The cabinet in which you will install the disk enclosure(s) must have

a full earth ground to provide reliable grounding. Also, the cabinet

should have its own switchable power distribution. We suggest that

you use a cabinet that has dual power distribution units, one on each

side.

WARNING

The enclosure is heavy and should be installed into a rack by two

people. To avoid personal injury and/or damage to the equipment, do

not attempt to lift and install the enclosure into a rack without a

mechanical lift and/or help from another person.

L’armoire étant lourde, sa mise en place sur une rampe nécessite deux

personnes. Afin de ne pas vous blesser et/ou endommager le matériel,

n’essayez pas de soulever et d’installer l’armoire sur une rampe sans

avoir recours à un relevage mécanique et/ou à l’aide d’une autre

personne.

Installing a Disk Enclosure in a Cabinet

2-3

Page 28

Installing a DAE2

Das Gehäuse ist schwer und sollte nur von zwei Personen in einem

Rack installiert werden. Zur Vermeidung von körperlichen

Verletzungen und/oder der Beschädigung des Gerätes, bitte das

Gehäuse nicht ohne die Hilfe einer zweiten Person anheben und

einbauen.

Il contenitore è pesante e dev'essere installato nel rack da due

persone. Per evitare danni personali e/o all’apparecchiatura, non

tentare di sollevare ed installare in un rack il contenitore senza un

sollevatore meccanico e/o l’aiuto di un’altra persona.

Debido a su considerable peso, la instalación del compartimento en

el bastidor deben realizarla siempre dos personas. Para evitar daños

personales o en el equipo, el compartimento no debe levantarse ni

instalarse en el bastidor sin la ayuda de un elevador mecánico o de

otra persona.

We recommend that you use cabinet anti-tip devices, especially if you

are installing or removing a disk enclosure in the upper half of the

cabinet when the lower half is empty.

Setting Up an Installed Disk Enclosure

Each disk enclosure in a Fibre Channel loop must have a unique

enclosure address (also called an EA, or enclosure ID) that identifies

the enclosure and determines disk module IDs. In many cases, the

factory sets the enclosure address before shipment to coincide with

the rest of the system; you will need to reset the switch if you

installed the enclosure into your rack independently. The enclosure

address ranges from 0 through 7. You set the EA with the enclosure

address switch, which has one push button for incrementing the

address and another for decrementing it. To set the EA, use a tool

such as a pen, paper clip, or small screwdriver.

The enclosure address is set on the EA switch at installation. Disk module IDs

are numbered left to right (facing the unit) and are contiguous throughout an

array: enclosure 0 contains modules 0-14; enclosure 1 contains modules 15-29;

enclosure 2 includes 30-44, and so on through eight enclosures.

2-4

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 29

Installing a DAE2

!

CAUTION

Each drive reads its FC-AL physical address only at powerup or

when the drive is reset. To avoid losing data, you must set the

enclosure address when power is off; you cannot change the EA

while power is on.

1. Set the enclosure address to the desired value, as shown in

Figure 2-1.

_

Enclosure

0

Address

Switch

+

Figure 2-1 Setting the Enclosure Address (EA)

EMC2769

2. If the power/cooling module on the DAE2 includes a power

switch, turn it to the off position before you plug an ac line cord

from the cabinet’s power distribution unit into each

power/cooling module, as shown in Figure 2-2.

Make certain you secure the power cord with the strain reliefs at each

connector. The strain reliefs prevent the power cord from pulling out of

the connections.

Setting Up an Installed Disk Enclosure

2-5

Page 30

Installing a DAE2

ac

Connector

Retention

Bail

EMC2778

Figure 2-2 Plugging in the ac Line Cord

Highly available, write-caching configurations require that you

connect the first disk enclosure (EA 0, loop 0) to a Standby Power

Supply (SPS) for enclosure power. If you do connect a DAE2 to an

SPS (if, for example, the DAE2 is the first disk enclosure in a

CX700-Series or CX600-Series configuration), be sure that you

maintain power/loop integrity; always connect power/cooling

module A to SPS A, and module B to SPS B.

Figure 2-3 shows the power cord connections for a typical

CX700-Series or CX600-Series configuration.

Do not configure an ATA model DAE2 as EA 0, loop 0. ATA enclosures do not

support the boot and SPS requirements of the first disk array in a storage

system.

An integrated disk-and-processor enclosure, such as a CX500, CX400, CX300,

or CX200-Series DPE2, is always the first disk enclosure on the first loop (0,0).

You should not connect the first DAE2 in a DPE2 configuration to an SPS.

2-6

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 31

DAE2

DAE2

Installing a DAE2

Circuit

Breaker

Power

Supply B

SPS B

Power Switch

SPS B

Figure 2-3 Connecting DAE2 Power Cords

3. Repeat steps 1 and 2 for each disk enclosure in the cabinet, as

necessary.

DAE2

DAE2

Power Switch

SPS A

Power

Connector

DAE2

Power

Supply A

SPS A

EMC2780

Setting Up an Installed Disk Enclosure

2-7

Page 32

Installing a DAE2

4. Attach the copper cable from the external device (storage

processor or another DAE2) to the PRI connector as shown in

Figure 2-4. If you are continuing the loop to another DAE2, attach

a cable from the EXP connector to the PRI connector in the next

DAE2.

PRI

Connector

To other FC device

Figure 2-4 Connecting a Disk Enclosure to Another FC Device

5. If you are installing multiple disk enclosures, cable them as

shown in Figure 2-5 or Figure 2-7.

The configuration example in Figure 2-5 shows a CLARiiON

CX500 disk processor enclosure (DPE2) below seven DAE2

disk-array enclosures. The eight devices support two completely

redundant loops. Note that the external device connects to the

Primary disk enclosure connectors, and subsequent enclosures

connect in an Expansion-to-Primary chain.

EA 0, loop 0 must be a Fibre Channel DPE2 or DAE2. ATA enclosures do not

support the boot and SPS requirements of the first disk array in a storage

system.

EMC2772

®

2-8

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 33

LCC B LCC A

EA3/Loop 1

Installing a DAE2

Loop 0

Loop 0

Loop 1

Loop 1

Loop 1

EA3/Loop 0

EA2/Loop 1

EA2/Loop 0

EA1/Loop 1

EA1/Loop 0

Loop 1

Loop 0

Loop 1

Loop 0

Loop 1

EXP EXPPRI PRI

Loop 0 Loop 0

Loop 1

BE 0

Figure 2-5 Cabling Disk Enclosures Together — Two Fibre Channel Loops

BE 1

EA0/Loop 1

EA0/Loop 0

BE 0

Loop 1

BE 1

Setting Up an Installed Disk Enclosure

EMC2720

2-9

Page 34

Installing a DAE2

Loop 3

Figure 2-6 shows a more complicated configuration with eight

DAE2s and four redundant Fibre Channel loops.

EA1/Loop 3

Loop 2

Loop 1

Loop 0

LCC ALCC B

EA1/Loop 2

EA1/Loop 1

Loop 1

EA1/Loop 0

Loop 0

EA0/Loop 3

Loop 3

Loop 2

Loop 3

EA0/Loop 2

Loop 2

EA0/Loop 1

Loop 1

EA0/Loop 0

Loop 0

Loop 0

SP B

SP A

SPS B SPS A

Figure 2-6 Cabling DAE2s Together — Four Fibre Channel Loops

All DAE2 configurations follow the same primary-to-expansion

connection principles. For example, Figure 2-7 shows two

segregated loops connecting contiguous disk enclosures across

two cabinets.

Loop 3

Loop 2

Loop 1

EMC2709

2-10

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 35

DAE2 EA7/Loop 0

Installing a DAE2

LCC ALCC B

Loop 0

Loop 0

Loop 0

Loop 0

Loop 0

Loop 0

Loop 0

Loop 0

DAE2 EA6/Loop 0

DAE2 EA5/Loop 0

DAE2 EA4/Loop 0

DAE2 EA3/Loop 0

DAE2 EA2/Loop 0

DAE2 EA1/Loop 0

DAE2 EA0/Loop 0

Loop 0

Loop 0

Loop 0

Loop 0

Loop 0

Loop 0

Loop 0

Loop 1

Loop 1

Loop 1

Loop 1

Loop 1

Loop 1

LCC B

DAE2 EA7/Loop 1

DAE2 EA6/Loop 1

DAE2 EA5/Loop 1

DAE2 EA4/Loop 1

DAE2 EA3/Loop 1

DAE2 EA2/Loop 1

DAE2 EA1/Loop 1

LCC A

Loop 1

Loop 1

Loop 1

Loop 1

Loop 1

Loop 1

1-Meter

Cable

SP A

SPS B

5- or 10-Meter Cable

SP B

Figure 2-7 Cabling Disk Enclosures Together — Segregated Loop Configuration

6. For proper cooling and normal operation, make sure all the disk

Loop 0

Loop 1

DAE2 EA0/Loop 1

Loop 1

SPS A

EMC1989

module slots in each disk enclosure contain either disk or filler

modules.

Setting Up an Installed Disk Enclosure

2-11

Page 36

Installing a DAE2

7. Set any SPS switches, and then the main circuit breaker switches,

Powerup and Initialization

The only power switches that control most DAE2s are those on the

SPS and the cabinet circuit breakers, which are normally on. If a DAE2

power/cooling module includes a power switch, it is usually on as

well. As a result, a DAE2 is always active.

When you initially apply ac power to a disk enclosure, the disk drive

modules power up according to their specifications, and spin up in a

specified sequence dictated by enclosure and loop IDs. The slot

spin-up delays range from 0 to 84 seconds. The same delays are used

when you insert a drive module while the system is powered up.

Do not power up a disk enclosure without at least one LCC installed.

You can configure a driveless disk enclosure within a Fibre Channel loop.

High availability with write-caching requires disks in slots 0-4 in the first

DPE2 or DAE2 connected to a storage processor (Enclosure Address 0,

loop 0).

to the on position. The disk enclosures in the cabinet power up.

The LCC hardware monitor (FRU monitor) resets and begins its

control loop. The port bypass circuits enter the states indicated by

their associated drives. The monitor continues to run in this local

mode until it receives commands that dictate otherwise. In local

mode, the monitor maintains the port bypass circuits in the same

states as the drive command signals. When a drive fault occurs, the

corresponding drive fault light turns on. Firmware commands can

take control of the port bypass circuits and the drive status lights.

!

CAUTION

Each drive reads its FC-AL physical address only at powerup or

when the drive is reset. To avoid potential data loss, you must set

the enclosure address when you install the disk enclosure and

power is off; you cannot change the EA while power is on.

2-12

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 37

Binding Disk Modules into RAID Groups

After cabling the disk enclosure, use EMC Navisphere® Manager

software to bind the disks into RAID groups. Refer to the EMC

Navisphere Manager Revision 6.X Administrator’s Guide and your

storage processor configuration and planning guide for detailed

information.

Disk Configuration Rules and Recommendations

The following rules and recommendations apply to all CX-Series

systems.

◆ You cannot use disks 000 through 004 (enclosure 0, loop 0, disks

0-4) as a hot spare in a CX-Series system.

◆ On CX-Series systems, the hardware reserves several gigabytes

on each of disks 000 through 004 for the cache vault and internal

tables. To conserve disk space, you should avoid binding any

other disk into a RAID Group that includes any of these disks.

Any disk you include in a RAID Group with a cache disk 000-004

is bound to match the lower unreserved capacity, resulting in lost

storage of several gigabytes per disk.

◆ Each disk in the RAID Group should have the same capacity. All

disks in a Group are bound to match the smallest capacity disk,

and you could waste disk space. The first five drives (000-004)

should always be the same size.

◆ You cannot mix ATA (Advanced Technology Attachment) and

Fibre Channel disk drives within a RAID Group.

◆ Hot spares for Fibre Channel drives must be Fibre Channel

drives; ATA drives require ATA hot spares.

◆ If a storage system will use disks of different speeds (for example,

10K and 15K rpm), then EMC recommends that you use disks of

the same speed throughout each 15-disk enclosure. For any

enclosure, the hardware allows one speed change within an

enclosure, so you may use disks of differing speeds. Place the

higher speed drives in the first (leftmost) drive slot(s).

◆ You should always use disks of the same speed and capacity in

any RAID Group.

◆ Do not use ATA drives to store boot images of an operating

system. You must boot host operating systems from a Fibre

Channel drive.

Installing a DAE2

Binding Disk Modules into RAID Groups

2-13

Page 38

Installing a DAE2

2-14

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 39

Invisible Body Tag nvisible

3

Servicing a DAE2

This chapter describes how to monitor disk enclosure status, handle

FRUs, and replace or add a Field Replaceable Unit (FRU). Topics are

◆ Monitoring Disk Enclosure Status...................................................3-2

◆ Handling FRUs...................................................................................3-6

◆ Replacing or Adding a Disk Module ..............................................3-9

◆ Replacing an LCC Module .............................................................3-15

◆ Replacing a Power Supply/System Cooling Module................. 3-20

For more information about upgrading your DAE2, contact your service

provider.

Servicing a DAE2

3-1

Page 40

Servicing a DAE2

(

)

Monitoring Disk Enclosure Status

Status lights on the DAE2 and its FRUs indicate error conditions.

These lights are visible outside the disk enclosure. Some lights are

visible from the front, and the others from the back. Figures 3-1

through 3-4 and Tables 3-1 through 3-3 describe the status lights.

Fault LED

(Amber)

Disk Activity

LED

Green

Figure 3-1 Front Disk Enclosure and Disk Module Status Lights (Bezel Removed)

Fault LED

(Amber)

Power LED

(Green)

EMC2166

Table 3-1 describes the LEDs visible from the front of the DAE2.

3-2

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 41

Servicing a DAE2

Table 3-1 Status Lights Visible from the Front of the Disk Enclosure

Light Quantity Color Meaning

Disk Enclosure Power 1 Green Power to enclosure is on.

Disk Enclosure Fault 1 Amber On when any fault condition exists; if the fault is not obvious

from a disk module light, look at the back of the disk enclosure.

Disk Active 1 per disk module Green Off when the slot is empty or contains a filler module.

Also off when the disk is powered down by command; for

example, the result of a temperature fault.

Flashing

(mostly off)

spinning; this is a normal part of the spin

when the FC drive is powered up but not

-

up sequence,

occurring during the spin-up delay of a slot.

Flashing

(at a constant rate)

FC drive: when the drive is spinning up or spinning down

normally.

ATA drive: when the module has received power but the disk

has not started spinning

On when the drive has power but is not handling any I/O activity

(the ready state). ATA modules also show the Disk Active LED

on while the disk spins up or down normally.

Flashing

(mostly on

) when the drive is spinning and handling I/O

activity.

Flashing (constant fast rate) when an ATA LCC has forced

ownership of the drive.

Disk Fault 1 per disk module Amber On when the disk module is faulty, or as an indication to remove

the drive.

Figure 3-2 shows the enclosure address and loop ID indicators,

visible from the back of the enclosure.

Monitoring Disk Enclosure Status

3-3

Page 42

Servicing a DAE2

_

0

+

Enclosure

Address

0

1

2

3

Figure 3-2 Enclosure Address and Loop ID Indicators

4

5

6

7

Loop ID

EMC2771

Table 3-2 describes the ID indicators.

Table 3-2 Enclosure and Loop ID Indicators

Light Quantity Color Meaning

Enclosure Address 1 Green Displayed number indicates Enclosure Address

Loop ID 8 Green Displayed number indicates Loop ID

Figure 3-3 shows the status LEDs for the power supply/system

cooling (power/cooling) modules.

Figure 3-3 Power/Cooling Module Status Indicators

3-4

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Blower Fault

LED

(Amber)

Latch

Power Fault

LED (Amber)

ac

Connector

Power

LED

(Green)

EMC2714

Page 43

Figure 3-4 shows the status LEDs for the link control cards.

(

)

(

)

Fault

LED

(Amber)

Power

LED

(Green)

Loop

ID LEDs

Servicing a DAE2

Expansion

Link Active

LED

Green

Figure 3-4 LCC Status LEDs

Primary

Link Active

LED

Green

EMC2221

Table 3-3 describes the status LEDs visible from the rear of the disk

enclosure.

Table 3-3 Status Lights Visible from the Rear of the Disk Enclosure

Light Quantity Color Meaning

LCC Power 1 per LCC Green On when the LCC is powered up.

LCC Fault 1 per LCC Amber On when either the LCC or a Fibre Channel connection is faulty.

Also on during Power On Self Test (POST).

Primary Link Active 1 per LCC Green On when Primary connection is active.

Expansion Link Active 1 per LCC Green On when Expansion connection is active.

Power Supply Active 1 per supply Green On when the power supply is operating.

Power Supply Fault* 1 per supply Amber On when the power supply is faulty or is not receiving ac line voltage.

Flashing when either a multiple blower or ambient overtemperature

condition have shut off dc power to the system.

Blower Fault* 1 per cooling module Amber On when a single blower in the power supply is faulty.

* The DAE2 will continue running with a single power supply and three of its four blowers. Removing a power/cooling module constitutes a

multiple blower fault condition, and will power down the enclosure unless you replace a blower within two minutes.

If the disk enclosure Fault light is on, examine the other status lights

to determine which FRU(s) is faulty. If a fault light on a FRU remains

on, you should replace that FRU as soon as possible.

Monitoring Disk Enclosure Status

3-5

Page 44

Servicing a DAE2

Handling FRUs

When a redundant FRU fails, high availability will be compromised until you

replace the faulty FRU.

This section describes the precautions that you must take and the

general procedures you must follow when removing, installing, and

storing FRUs.

Power Issues and

FRUs

Avoiding

Electrostatic

Discharge (ESD)

Damage

The DAE2 is designed to always be powered up and hot repairable.

Its front bezel should be attached and each of its compartments

should contain a FRU or filler panel to ensure EMI compliance and

proper air flow over the FRUs.

While the disk enclosure is powered up, you can service or replace

any FRU, although removing an active LCC will affect operating

system access to the disks it controls. You should not remove a faulty

FRU until you have a replacement available.

Since you can replace or add any FRU without sliding the disk

enclosure out of the cabinet, you do not have to use cabinet anti-tip

devices when you upgrade or service a DAE2.

If you need to power down a DAE2, simply unplug the unit. You do

not need to shut down main ac lines to the disk enclosure unless you

need to power down all the cabinet contents connected to that line.

When you replace or install FRUs, you can inadvertently damage the

sensitive electronic circuits in the equipment by simply touching

them. Electrostatic charge that has accumulated on your body

discharges through the circuits. If the air in the work area is very dry,

running a humidifier in the work area will help decrease the risk of

ESD damage. You must follow the procedures below to prevent

damage to the equipment.

3-6

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Read and understand the following instructions:

◆ Provide enough room to work on the equipment. Clear the work

site of any unnecessary materials or materials that naturally build

up electrostatic charge, such as foam packaging, foam cups,

cellophane wrappers, and similar items.

Page 45

Servicing a DAE2

◆ Do not remove replacement or upgrade FRUs from their antistatic

packaging until you are ready to install them.

◆ Gather together the ESD kit and all other materials you will need

before you service a disk enclosure. Once servicing begins, you

should avoid moving away from the work site; otherwise, you

may build up an electrostatic charge.

◆ An ESD wristband is supplied with your disk enclosure. To use it,

attach the clip of the ESD wristband (strap) to any bare

(unpainted) metal on the disk enclosure; then put the wristband

around your wrist with the metal button against your skin.

◆ Use the ESD kit when handling any FRU. If an emergency arises

and the ESD kit is not available, follow the procedures in the

Emergency Procedures (Without an ESD Kit) section.

Emergency

Procedures (Without

an ESD Kit)

In an emergency when an ESD kit is not available, use the following

procedures to reduce the possibility of an electrostatic discharge by

ensuring that your body and the subassembly are at the same

electrostatic potential.

These procedures are not a substitute for the use of an ESD kit.

Follow them only in the event of an emergency.

◆ Before touching any FRU, touch a bare (unpainted) metal surface

of the cabinet or enclosure.

◆ Before removing any FRU from its antistatic bag, place one hand

firmly on a bare metal surface of the enclosure, and at the same

time, pick up the FRU while it is still sealed in the antistatic bag.

Once you have done this, do not move around the room or touch

other furnishings, personnel, or surfaces until you have installed

the FRU.

◆ When you remove a FRU from the antistatic bag, avoid touching

any electronic components and circuits on it.

◆ If you must move around the room or touch other surfaces before

installing a FRU, first place the FRU back in the antistatic bag.

When you are ready again to install the FRU, repeat these

procedures.

Handling FRUs

3-7

Page 46

Servicing a DAE2

Precautions When

Removing,

Installing, or Storing

FRUs

Use the precautions listed below when you remove, handle, or store

FRUs:

◆ Do not remove a faulty FRU until you have a replacement

available.

◆ Handle a FRU only when using an ESD wristband. Attach the clip

of the ESD wristband to the ESD bracket or bare metal on the

enclosure, and put the wristband around your wrist with the

metal button against your skin.

◆ Handle FRUs gently. A sudden jar, drop, or vibration can

permanently damage a FRU and may not be immediately

evident. Never place a FRU on a hard surface such as an

unpadded cart, floor, or desktop, or stacked on top of another

FRU.

◆ Never use excessive force to remove or install a FRU.

◆ Store a FRU in the antistatic bag and specially designed shipping

container in which you received it. Use that container if you need

to return the FRU for repair.

◆ Store FRUs within the temperature and humidity limits specified

in Appendix A.

◆ Place the cables where no one can step on them or roll equipment

over them.

3-8

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 47

Replacing or Adding a Disk Module

Servicing a DAE2

!

CAUTION

Disk modules are extremely sensitive electronic components.

Always handle a disk module gently, and observe the following

guidelines:

◆ Always replace a disk drive with another of the same model; do

not mix Fibre Channel and ATA components in the same

enclosure. Refer to Figure 1-7 on page 1-8 for a visual

comparison of FC and ATA disk carriers.

◆ Follow the instructions in the preceding section Avoiding

Electrostatic Discharge (ESD) Damage on page 3-6.

◆ Always wear a properly-attached ESD wristband when

removing or replacing a disk module.

◆ When removing a disk module, pull the module partially out of

the slot, then wait 30 seconds for the drive to spin down before

removing it.

◆ Place modules on a soft, antistatic surface, such as an

industry-standard antistatic foam pad or the container used to

ship the module. Never place a disk module directly on a hard

surface.

◆ Never hit modules, stack modules, or allow them to tip over or

fall.

◆ Avoid touching any exposed electronic components and circuits

on the disk module.

◆ Do not remove a faulty disk module until you have a

replacement module (with the same part number) or a filler

module available. The part number (PN005xxxxxx) appears on

the top or bottom of the module. A replacement or add-on disk

module should have the same format (bytes per sector) and the

same capacity (size and speed) as the other modules in the

enclosure.

You must remove the disk enclosure’s front bezel to gain access to the

disk modules. The bezel is required for EMI compliance when the

enclosure is powered up. Remove it only to replace or add a disk

module.

Replacing or Adding a Disk Module

3-9

Page 48

Servicing a DAE2

Unlocking and Removing the Front Bezel

Follow these steps to remove the front bezel and gain access to the

disk modules. Refer to Figure 3-5.

1. Insert the key that shipped with your enclosure into the bezel

lock, and turn it to release the lock.

2. Press the two latch buttons on the bezel surface toward each other

to release the bezel from the cabinet.

3. Pull the bezel off the cabinet and put it on a clean, static-free

surface.

3-10

EMC2173

Figure 3-5 Unlocking and Removing the Front Bezel

If you are adding a new disk module, continue to the disk filler

module removal procedure that follows. If you are replacing a faulty

disk module, proceed to the disk module removal procedure.

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 49

Removing a Disk Filler Module

Locate the slot where you want to install the disk module, and

remove the filler module, as shown in Figure 3-6.

Servicing a DAE2

Figure 3-6 Removing a Disk Filler Module (FC Disk Carrier Shown)

Removing a Disk Module

!

EMC2210

Skip to the disk installation procedure (Page 3-12) to install the

add-on disk in the slot you just emptied.

CAUTION

If a disk module has been bound into a LUN, do not move it to

another slot unless you do not care about the data on the LUN. Each

module contains LUN-identifying information written when it was

bound. Moving it to another slot can make information on the

original LUN inaccessible.

Generally, you should not remove a disk module unless its amber

fault light is on. See Table 3-1.

1. Attach an ESD wristband to your wrist and the enclosure (see the

precautions on Page 3-7).

Replacing or Adding a Disk Module

3-11

Page 50

Servicing a DAE2

2. If the active light is on steadily, pull the latch, and slowly pull the

module about 1 in (3 cm) from its slot. Wait 30 seconds for the

disk to stop spinning. Then remove the module and place it on a

padded, static-free surface.

If the active light is off or mostly off you do not need to wait for

the disk to stop spinning. Pull the latch and slowly pull the

module from its slot, as shown in Figure 3-7. Place it on a padded,

static-free surface.

Figure 3-7 Removing a Disk Module (FC Disk Carrier Shown)

Continue to the next section to install the replacement disk module.

Installing a Disk or Filler Module

Always replace a disk drive with another of the same model; do not mix Fibre

Channel and ATA components in the same enclosure. Refer to Figure 1-7 on

page 1-8 for a visual comparison of FC and ATA disk carriers.

1. Make sure an ESD wristband is attached to your wrist and the

enclosure (see the precautions on Page 3-7).

2. Align the module with the guides in the slot.

3. Gently push the module completely into the slot, and then engage

the latch. See Figure 3-8.

EMC2174

3-12

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 51

EMC2211

Figure 3-8 Installing a Disk or Filler Module (FC Disk Carrier Shown)

The disk module’s Active light flashes to reflect the disk’s spin-up

sequence.

Servicing a DAE2

4. Remove and store the ESD wristband and continue to the next

section to install the front bezel.

Replacing or Adding a Disk Module

3-13

Page 52

Servicing a DAE2

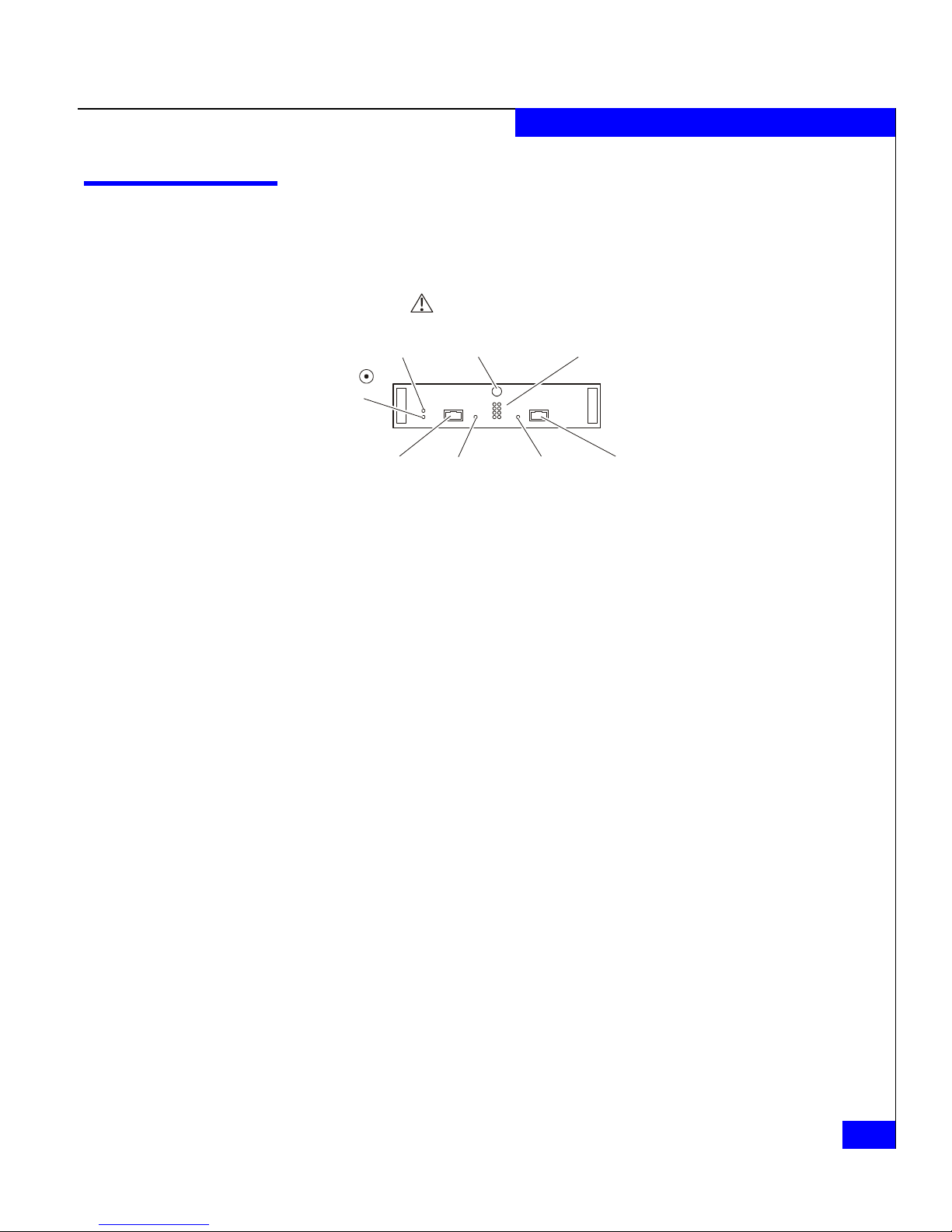

Installing and Locking the Front Bezel

Refer to Figure 3-9 as you do the following:

1. Align the bezel with the disk enclosure.

2. Gently push the bezel into place on the cabinet until it latches.

3. Secure the bezel by turning the key in the lock.

Figure 3-9 Installing and Locking the Front Bezel

EMC2222

3-14

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 53

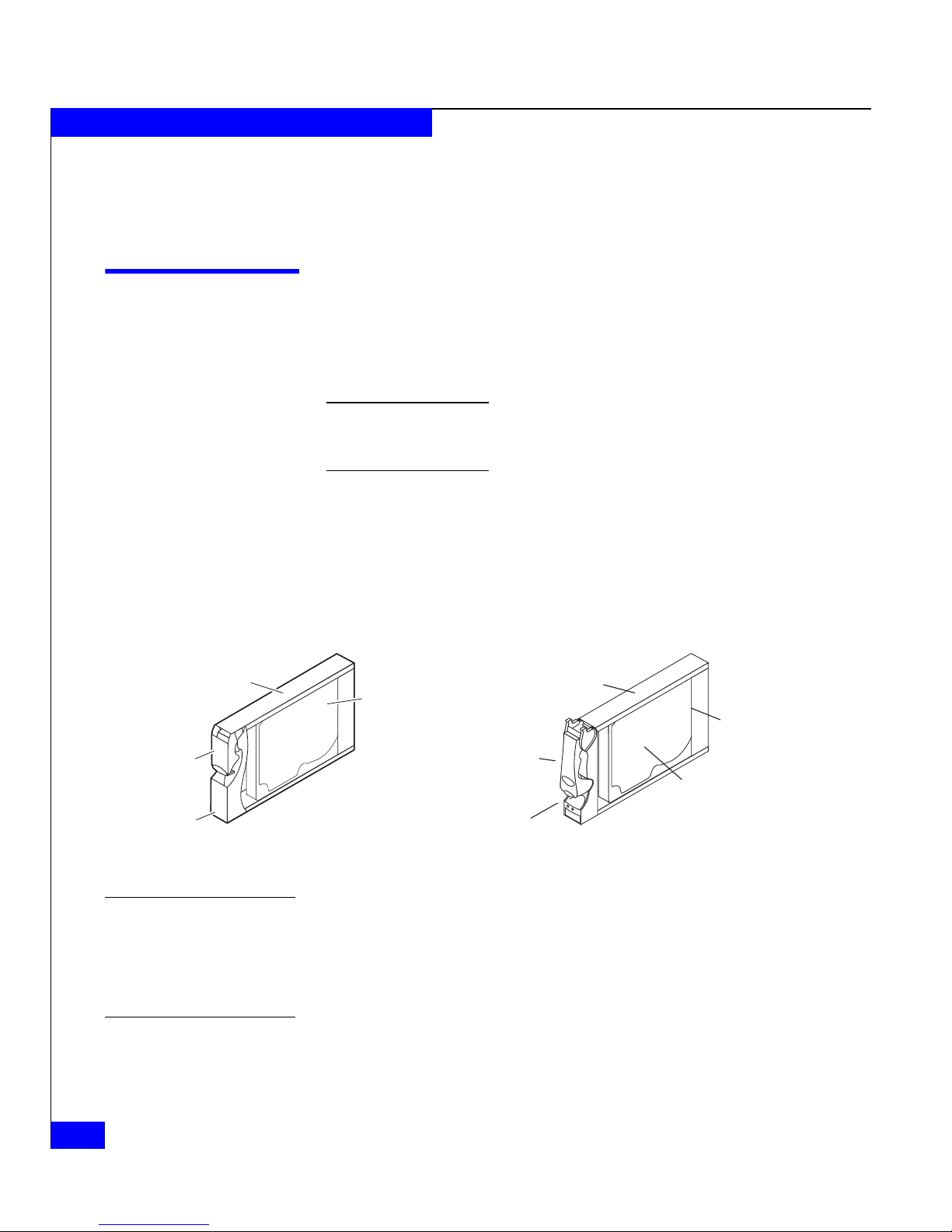

Replacing an LCC Module

Servicing a DAE2

Removing an LCC

!

CAUTION

Handle an LCC gently and use an ESD wristband. Do not remove a

faulty LCC until you have a replacement module available.

A DAE2 must have at least one LCC installed while it is powered up. Do not

remove both LCCs while the disk enclosure is powered up.

Always replace an LCC with another of the same model; do not mix Fibre

Channel and ATA components in the same enclosure. (An "ATA Ctlr" label on

the module bulkhead identifies the ATA LCC.)

1. Gently press the connector latches to release them as you remove

the copper cables connected to the LCC, as shown in Figure 3-10.

Note where the cable(s) connect to the LCC; you will need to reconnect

them to the replacement LCC.

To other FC device

Figure 3-10 Removing a Copper Cable from an LCC

PRI

Connector

EMC2782

Replacing an LCC Module

3-15

Page 54

Servicing a DAE2

2. Turn the latch counterclockwise to release the module, and then

remove the LCC from its slot, as shown in Figure 3-11.

Figure 3-11 Removing an LCC

Installing an LCC

Latch

EMC2774

Continue to the next section to install the replacement LCC.

1. Gently insert the LCC as shown in Figure 3-12. Be sure the module

is completely seated in the DAE2 midplane.

3-16

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 55

Servicing a DAE2

Latch

Figure 3-12 Installing an LCC

The LCC Power light turns on.

2. Turn the latch clockwise to secure the module.

The DAE2 LCC latch holds the module in an established position. It does

not pull or otherwise help to seat the LCC.

3. Reattach the copper cables to the same connector from which you

removed them, as shown in Figure 3-13.

EMC2776

Replacing an LCC Module

3-17

Page 56

Servicing a DAE2

PRI

Connector

To other FC device

EMC2772

Figure 3-13 Reconnecting a Copper Cable to an LCC

4. Remove and store the ESD wristband.

The configuration example in Figure 3-14 shows a CLARiiON® CX300 disk

processor enclosure (DPE2) below three DAE2 disk-array enclosures. Note

that the external device connects to the Primary disk enclosure connectors,

and subsequent enclosures connect in an Expansion-to-Primary chain.

3-18

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 57

LCC B LCC A

EA3/Loop 0

Servicing a DAE2

EA2/Loop 0

Loop 0 Loop 0

EA1/Loop 0

EXP EXPPRI PRI

Loop 0 Loop 0

EA0/Loop 0

BE 0

BE 0

Figure 3-14 Connecting Disk Enclosures Together with Copper Cable

Loop 0Loop 0

EMC2743

Replacing an LCC Module

3-19

Page 58

Servicing a DAE2

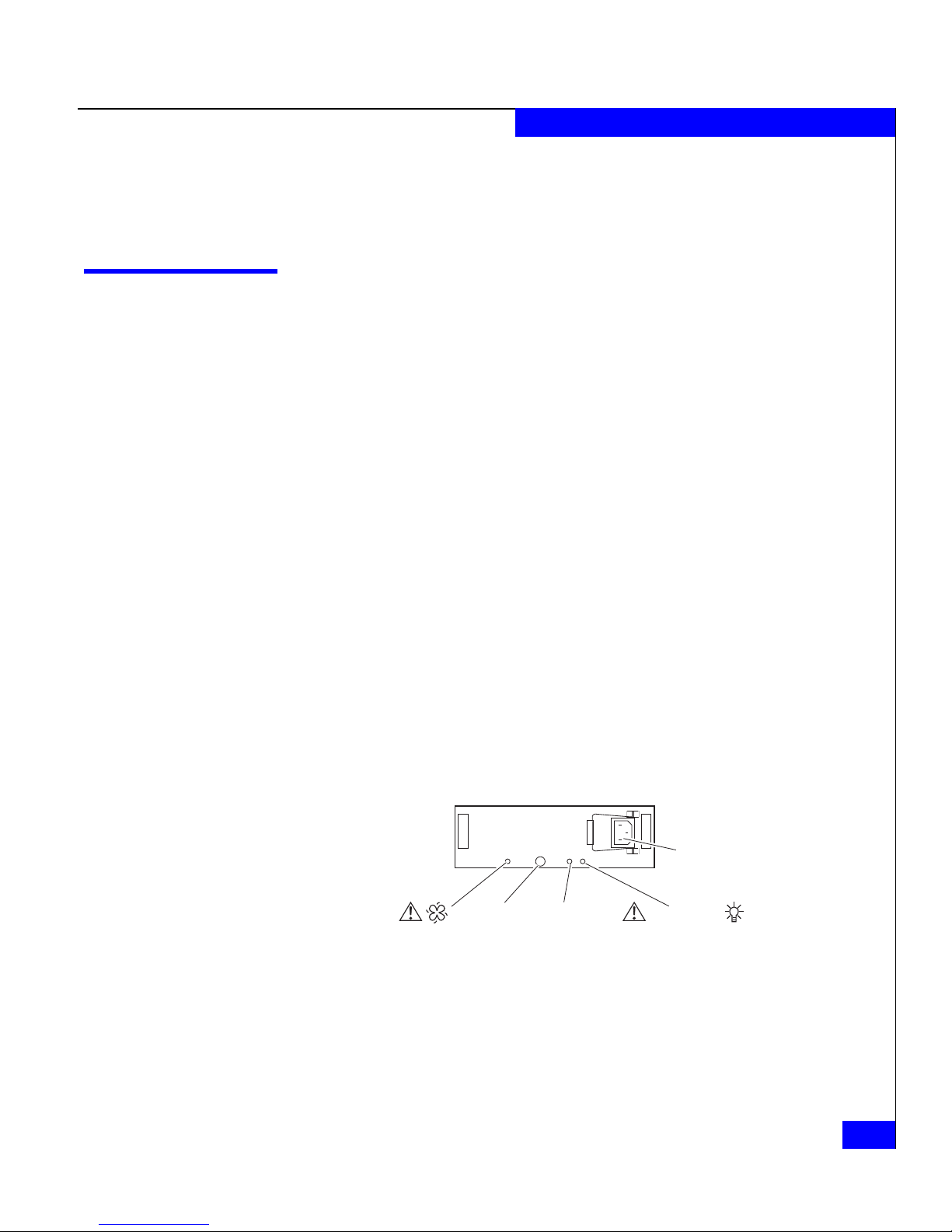

Replacing a Power Supply/System Cooling Module

!

CAUTION

Handle a power supply/system cooling (power/cooling) module

gently and use an ESD wristband. Do not remove a power/cooling

module until you have a replacement module available.

Access to the disks in your enclosure will time out and the disks

will spin down two minutes after a power/cooling module is

removed from the enclosure. While the system can continue

operating on a single power supply, the loss of a module’s two

blowers will cause a time-out unless you replace the module within

two minutes.

When replacing a power/cooling module, make certain the green

LED on one module has been steadily on for at least 5 seconds

before removing power from the second module.

Turn any power/cooling module switch to the off position before

unplugging the power cord from the module.

Follow these steps to replace a power/cooling module.

1. Turn off the power/cooling module (if a switch is present) and

unplug its ac line cord as shown in Figure 3-15.

3-20

ac

Connector

Retention

Bail

EMC2775

Figure 3-15 Unplugging the ac Power Cord

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 59

Servicing a DAE2

2. Turn the latch counterclockwise to release the module, and then

remove the power/cooling module as shown in Figure 3-16.

To protect a running system from overheating, the enclosure will time

out unless you replace the power/cooling module within two minutes.

Latch

Figure 3-16 Removing a Power/Cooling Module

3. Gently insert the new power/cooling module into the enclosure,

as shown in Figure 3-17. Be sure the module is completely seated.

Latch

EMC2773

Figure 3-17 Installing a Power/Cooling Module

EMC2777

Replacing a Power Supply/System Cooling Module

3-21

Page 60

Servicing a DAE2

4. Turn the latch clockwise to secure the module.

The latch holds the power/cooling module in an established position. It

does not pull or otherwise help to seat the module.

5. Make sure any power switch on the replacement module is off

before you plug the ac power cord into the new supply as shown

in Figure 3-18. Turn a power switch to the on position after you

plug in the ac power cord.

ac

Connector

Figure 3-18 Plugging in the Power Cord

Make certain you secure the power cord with the retention bails at each

connector. The bails prevent the power cord from pulling out of the

connections.

Retention

Bail

EMC2778

3-22

2-Gigabit Disk-Array Enclosure (DAE2) Hardware Reference

Page 61

Invisible Body Tag

A

Technical

Specifications

Body Tag

This appendix describes the disk-array enclosure technical

specifications, operating limits, and shipping and storage

requirements. Major topics are

◆ Enclosure Specifications...................................................................A-2

◆ Operating Limits...............................................................................A-5

Technical Specifications

A-1

Page 62

Technical Specifications

Enclosure Specifications

Technical enclosure specifications include power requirements, size,

drive, interface, and standards information.

Ac Power

Requirements

Requirement DAE2 (Fibre Channel) DAE2-ATA

ac line voltage 100 to 240 V ac + 10%, single phase, 47 to 63 Hz

ac line current 4.0 A at 100 V ac, 1.6 A at 200 V ac 3.0 A at 100 Vac, 1.4 A at 200 V ac

The input current, power (VA), and dissipation per DAE2 are based

on the requirements that a maximum DAE2 configuration places on