Page 1

Gas-fired boilers

DTG 230

EN

User Guide

300011506-001-D

Page 2

.

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.1 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2.1 Manufacturer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.2 Installer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2.3 User's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2 Safety instructions and recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.1 Main parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3.2 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.2.1 B3 control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.2.2 DIEMATIC-m3 control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.2.3 K3 control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4 Utilisation de l’appareil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

4.1 Commissioning the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.2 Changing the settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.2.1 B3 control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.2.2 DIEMATIC-m3 control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4.2.3 K3 control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4.3 Switching off the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4.3.1 Precautions to take if there is a danger of frost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4.3.2 Precautions to take in the event of prolonged shutdown (one year or more). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4.1 Commissioning the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

5 Checking and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

6.1 Data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

6.2 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6.2.1 B3 control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6.2.2 DIEMATIC-m3 control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6.2.3 K3 control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

6.3 Incidents and solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

7 Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

8 Energy savings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

2

DTG 230 09/03/2011 - 300011506-001-D

Page 3

1Introduction

1.1 Symbols used

1. Introduction

Caution danger

Risk of injury and damage to equipment. Attention must be

paid to the warnings on safety of persons and equipment.

Specific information

Information must be kept in mind to maintain comfort.

1.2 General

Congratulations on your choice of a high quality product. We

strongly advise you to read the following instructions in order to

guarantee the optimal operation of your appliance. We are sure

that it will be entirely to your satisfaction and will meet with all

of your expectations.

1.2.1 Manufacturer's liability

` The liability of De Dietrich Thermique SAS as the manufacturer may not

be invoked in the following cases:

- Failure to abide by the instructions on using the appliance,

- Faulty or insufficient maintenance of the appliance,

- Failure to abide by the instructions on installing the appliance

Reference

Z

Refer to another manual or other pages in this instruction

manual.

DHW: Domestic hot water

` Keep these instructions in a safe place close to the appliance.

` In the interest of customers, De Dietrich Thermique SAS are

continuously endeavouring to make improvements in product quality.

All the specifications stated in this document are therefore subject to

change without notice.

1.2.2 Installer's liability

The installer is responsible for the installation and inital start up of the

appliance. The installer must respect the following instructions:

` Read and follow the instructions given in the manuals provided

with the appliance,

` Carry out installation in compliance with the prevailing

legislation and standards,

` Perform the initial start up and carry out any checks necessary

1.2.3 User's liability

To ensure the optimum operation of your appliance, we strongly

recommend that you abide by the following instructions :

` Read and follow the instructions given in the manuals provided

with the appliance.

Get your fitter to explain your installation to you.

When handing over the installation to the user, the installer will draw

the user's particular attention to the following points:

- The safety of the installation,

- The functioning of the installation and the boiler,

- Periodic maintenance to be done.

` Call on qualified professionals to:

- Carry out installation in compliance with the prevailing legislation

and standards

- Perform the initial start up

- Carry out work on the appliance and the installation

- Have the required checks and services done

09/03/2011 - 300011506-001-D DTG 230

3

Page 4

2. Safety instructions and recommendations

2 Safety instructions and recommendations

2.1 Safety instructions

Fire hazard

Do not stock products of an inflammable nature close to

the appliance.

If you smell gas, do not use a naked flame, do not smoke,

do not operate electrical contacts or switches (doorbell,

lights, motor, lift, etc.).

1.Shut off the gas supply

2.Open the windows

3.Extinguish all flames

4.Evacuate the premises

5.Contact a qualified professional

6.Inform the gas supplier

Risk of intoxication

Do not obstruct the air inlets in the room (even partially).

If you smell flue gases

1.Switch the appliance off

2.Open the windows

3.Evacuate the premises

4.Contact a qualified professional

Risk of being burnt

Avoid direct contact with the flame viewport.

Depending on the settings of the appliance:

- The temperature of the flue gas conduits may exceed 60°C

- The temperature of the radiators may reach 95°C

- The temperature of the domestic hot water may reach 65°C

Risk of damage

Do not stock chloride or fluoride compounds close to the

appliance.

Install the appliance in frost-free premises.

Do not neglect to service the appliance: Contact a qualified

professional or take out a maintenance contract for the annual

servicing of the appliance.

2.2 Recommendations

Only qualified professionals are authorised to work on the

appliance and the instalation.

Before any work, switch off the mains supply to the

appliance.

Check regularly that the installation contains water and is

pressurised.

Keep the appliance accessible at all times.

Avoid draining the installation.

The appliance should be on Summer or Antrifreeze mode rather than

switched off to guarantee the following functions:

- Frost protection

- Protection against corrosion on domestic hot water tanks fitted

with a titanium anode

4

DTG 230 09/03/2011 - 300011506-001-D

Page 5

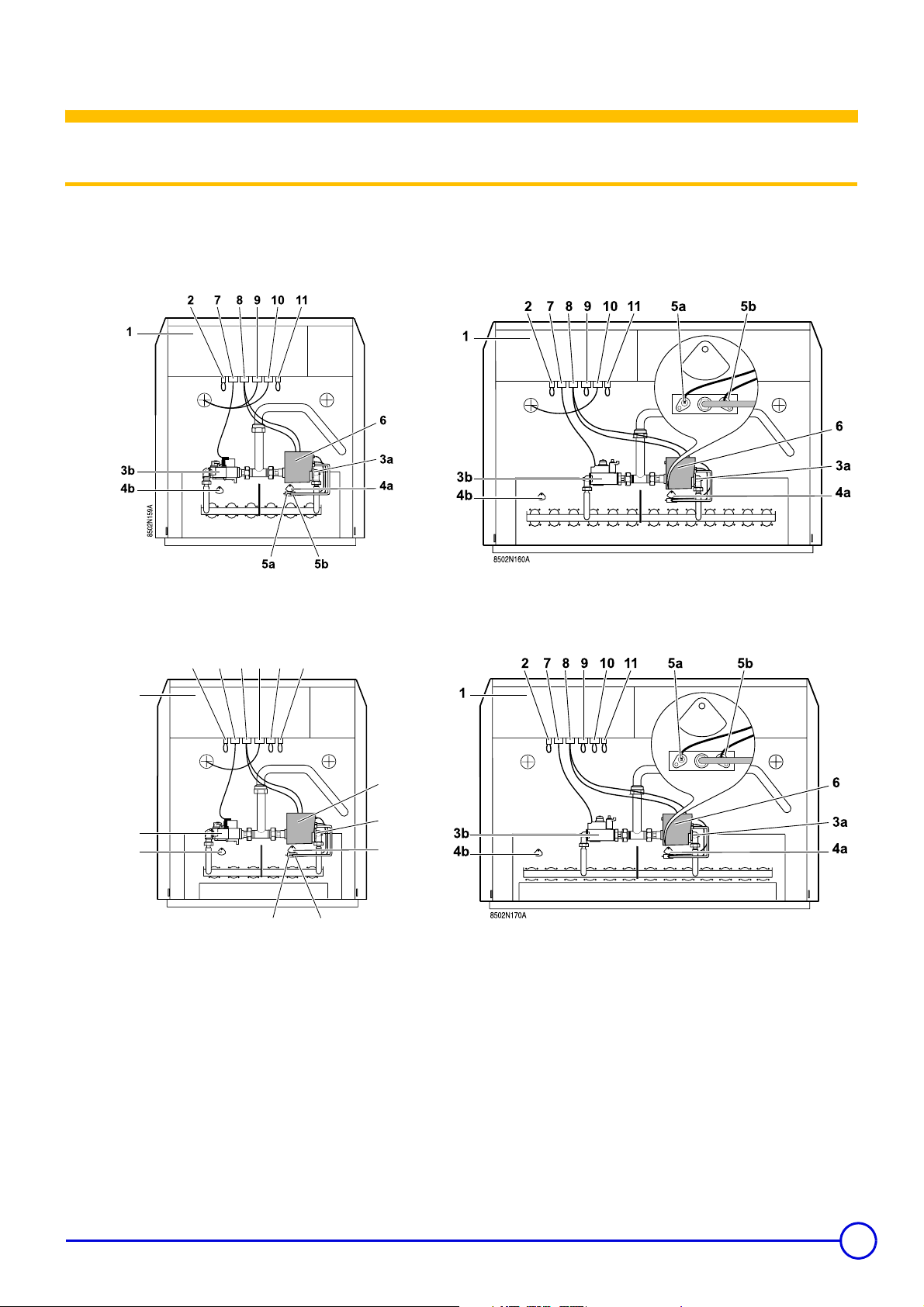

3 Description

3.1 Main parts

The models presented are marketed in the various countries according to the countries' specific sales programme.

DTG 230 Eco.NOx

6 to 13 sections 14 sections

3. Description

DTG 230 S

7 to 13 sections 14 sections

7 8 9 10 11

2

1

6

3b

4b

8502N169A

5a 5b

1. Control panel

2. Factory fitted bridge

Connection for gas pressure switch (Option - Package GC191)

Natural gas: 12.5 mbar

Propane: 20 mbar

3. a: Gas valve - Stage1

b: Gas valve - Stage2

4. a: Flame inspection window - Stage1

b: Flame inspection window - Stage2

5. a: Ignition electrode

b: Ionization probe

6. Safety box

7. Valve connector - Stage2

8. Safety control box and valve connector - Stage1

3a

4a

9. Downdraught thermostat

6-9 sections: Supplied

10-14 sections: Option (Factory fitted bridge) - Package GC22

Belgium + Russia: The downdraught thermostat is

compusory for all models of boiler and must be fitted

systematically.

10. DTG 230 Eco.NOx: Flue damper

DTG 230 S: Not used (Factory fitted bridge)

11. Factory fitted bridge

- Connection for cyclical tightness controller (Option - Package

CY41)

or

- Connection for safety valve (Option - Package GC191)

09/03/2011 - 300011506-001-D DTG 230

5

Page 6

3. Description

3.2 Control panel

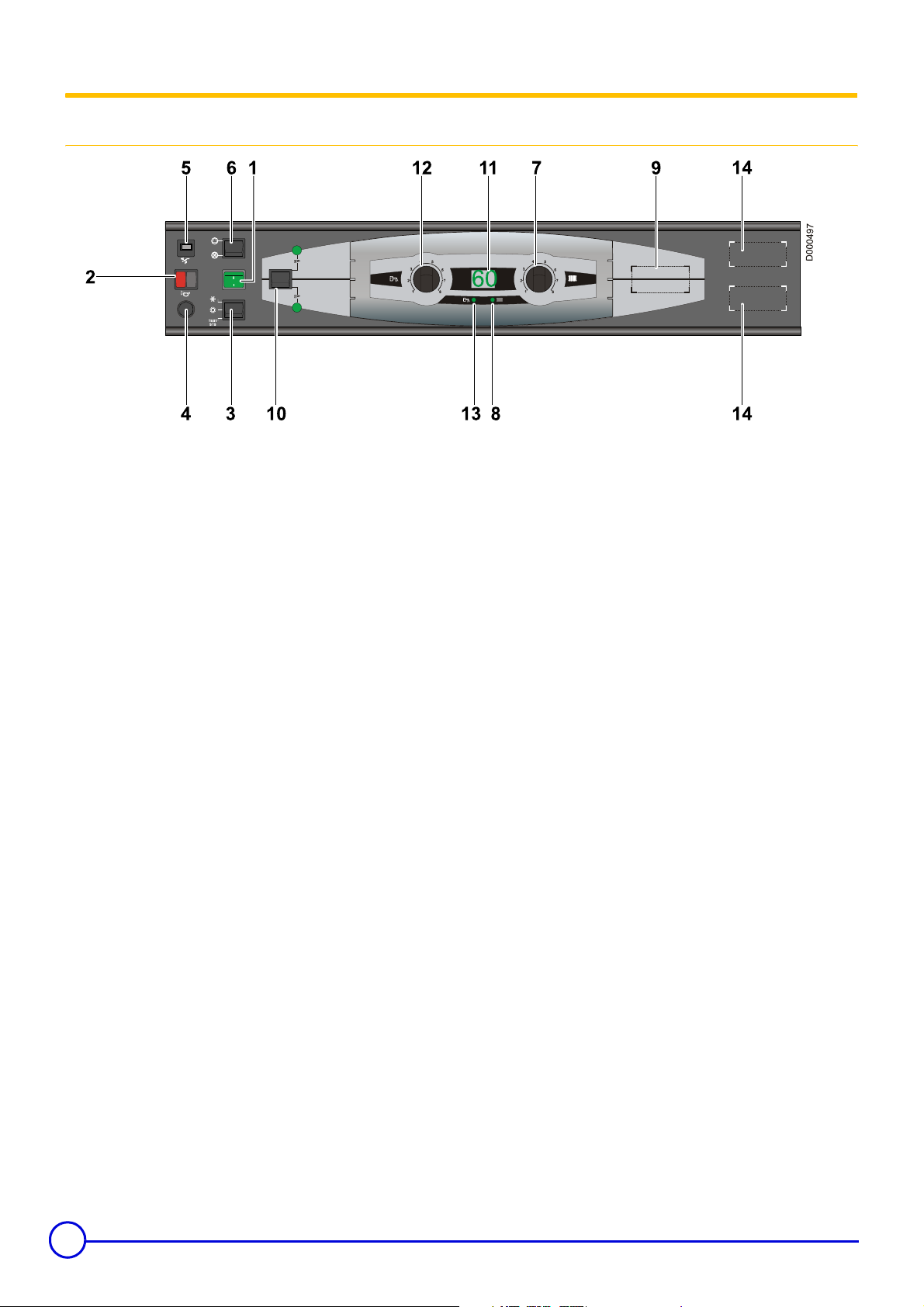

3.2.1 B3 control panel

1. General ON (1) / OFF (0) switch

2. Burner alarm indicator + Reset button

This light comes on when the safety control box is in safety

lockout (out of order).

3. Switch TEST-STB/

: Heating and domestic hot water are in operation

.

: Only domestic hot water is in operation

%

Position TEST-STB: Temporary action to test the safety

thermostat

4. Safety thermostat with manual reset

Set at 110° C

5. Timed circuit breaker (4 A)

6. Pump shutdown switch

7. Electronic thermostat (30 to 90 °C)

8. Heating on light

9. Location for flue gas thermometer (optional)

10. Switch for selecting the number of burner stages

(2-stage boilers)

11. Digital display

-Light 8 lit: Boiler temperature display

-Light

13

lit: Domestic hot water display

./%

When preparing domestic hot water

12. Electronic thermostat (10 to 80 °C)

13. Domestic hot water on light

14. Location for hour run meter (Option)

6

DTG 230 09/03/2011 - 300011506-001-D

Page 7

3.2.2 DIEMATIC-m3 control panel

Electromechanical components

3. Description

1. General ON (1) / OFF (0) switch

2. Burner alarm indicator + Reset button

This light comes on when the safety control box is in safety

lockout (out of order).

3. Switch AUTO/

/TEST-STB

!

AUTO: Automatic control

: Manual control

!

TEST-STB: Temporary action to test the safety thermostat

4. Safety thermostat with manual reset

Set at 110° C

5. Timed circuit breaker (4 A)

Display

3 4 5 6

2

024681012141618202224

1

1 Text and numerical display

2 Graphic display bar for the programme in circuit A, B or C

Light area: Reduced temperature heating period or tank load

3

disabled

Dark area: Comfort temperature heating period or tank load

4

enabled

5 Flashing cursor showing the current time

Number display (current time, adjusted values, parameters,

6

etc.)

7 Number of the boiler for which the parameters are displayed

The arrows flash when setting values can be modified using

8

the + and - keys

9 Circuit operation symbols

Opening the 3-way valve

>

Closing the 3-way valve

=

SUNDAY

6. Pump shutdown switch

7. Boiler thermostat (30 to 90 °C)

8. Boiler thermometer

9. Switch for selecting the number of burner stages

(2-stage boilers)

10. Connector USB

14. Boiler heat curve

15. Flap

16. Display

7

8

A

BC

91011

Arrows indicating the chosen time programme (P1, P2, P3 or

10

P4) for the circuit displayed, A, B, C, or the activation of the

manual summer mode

Symbols indicating that the following inputs/outputs are

11

active

DHW load pump on

Summer mode (Automatic / Manual)

#

Burner on

D

` Operation with modulating burner

Not used

` Operation with 2-stage burner

D Burner on with 1 stage

Burner on with 2 stages

Y

Displayed circuit pump on

:

A B C Name of the circuit displayed

09/03/2011 - 300011506-001-D DTG 230

7

Page 8

3. Description

3.2.3 K3 control panel

1. General ON (1) / OFF (0) switch

2. Burner alarm indicator + Reset button

This light comes on when the safety control box is in safety

lockout (out of order).

3. Switch AUTO/

AUTO: This position enables automatic operation of the

installation in accordance with DIEMATIC-m 3 regulation

controls.

: The boiler no longer takes orders from the DIEMATIC-m 3

!

regulation into account. The boiler is regulated by the boiler

thermostat(s).

TEST-STB: Temporary action to test the safety thermostat

/TEST-STB

!

4. Safety thermostat with manual reset

Set at 110° C

5. Timed circuit breaker (4 A)

6. Pump shutdown switch

7. Boiler thermostat (30 to 90 °C)

8. Boiler thermometer

9. Switch for selecting the number of burner stages

(2-stage boilers)

10. Connector USB

8

DTG 230 09/03/2011 - 300011506-001-D

Page 9

4 Operating the appliance

4.1 Commissioning the boiler

4. Operating the appliance

Initial commissioning must be done by a qualified

professional.

1. Check the water pressure in the installation. Top up with more

water if necessary.

2. Open the gas valve.

3. Make the settings on the control panel:

` B3 control panel:

- Turn the switch

- Turn the pump shutdown switch to

- Set the boiler thermostat to the desired setting.

- When preparing domestic hot water: Set the DHW thermostat to

the desired setting. Setting 6 (approx 60) recommended.

` DIEMATIC-m3 control panel:

- Turn the

- Turn the pump shutdown switch to

- Set the boiler thermostat to maximum (between 7½ and 9).

TEST-STB/./% to ..

AUTO / ! / TEST STB

9

switch to

9

AUTO

.

4.2 Changing the settings

` K3 control panel (Secondary boiler in cascade with a

DIEMATIC-m3 boiler):

-Set switch

4. Turn the burner switch to 2 (2 stage version)

5. Check that the safety thermostat has not triggered. Remove the

safety thermostat hood and press the reset button with a

screwdriver.

6. Set the On/Off switch to 1.

Only for control panel DIEMATIC-m3:

When the boiler is switched on, the tank exchanger is purged

for one minute if a tank is connected and its temperature is

lower than 25°C.

If disgassing has already taken place, press the MODE key to

suspend disgassing.

Only for control panel DIEMATIC-m3:

On commissioning, it is necessary to select the desired

language with the + and - keys and confirm with the MODE key.

AUTO

/ ! /

TEST STB

to the

AUTO

position.

4.2.1 B3 control panel

Heating temperature setting: Set the boiler thermostat to the

desired setting.

Setting the domestic hot water temperature: Set the DHW

thermostat to the desired setting.

09/03/2011 - 300011506-001-D DTG 230

9

Page 10

4. Operating the appliance

4.2.2 DIEMATIC-m3 control panel

Keys accessible when the flap is closed Keys accessible when the flap is open

Adjustment keys

MODE Various operating modes can be selected by successively

pressing key MODE:

` AUTOMATIQUE

` DAY 7/7: Forced operation at permanent Day temperature

` DAY (Until midnight): Forced operation at temporary Day

temperature

` NIGHT 7/7: Forced operation at permanent Night

temperature

` NIGHT (Until midnight): Forced operation at temporary

Night temperature

` DAYS ANTIFREEZ: Antifreeze mode for the number of

days set

` ANTIFREEZ 7/7: Permanent antifreeze mode

Restart key for a DHW calorifier load

` AUTOMATIQUE

` DHW: Restarts DHW load until midnight

` DHW 7/7: DHW load is forced permanently

After a few seconds, the display disappears but the mode is

activated.

Display key for the various counters (number of burner start-ups,

+

number of burner operating hours, etc.)

Adjustment keys

%O

$P

STANDARD

S

J

I

*

#

K

M

Enter (per 1/2 hour) the comfort temperature period or

tank load enabled (dark area).

Enter (per 1/2 hour) the reduced temperature period or

tank load disabled (light area).

Simultaneously pressing the 2 keys,

, resets all of the time programmes.

$P

Return key

Page scrolling

Line scrolling

Scroll of boilers connected

Manual "Summer" shutdown key. The heating is

switched off and DHW production is ensured.

Fitter settings access key

DO NOT USE

%O

and

Set temperatures Day (Heating / DHW / Pool)

2%

Set temperatures Night (Heating / DHW)

2$

Access key to the secondary boilers (Control panel K3) in a

cascade

*

If using only one boiler, this key is inactive.

Setting the gradients for circuits A, B and C

(

Setting the parallel offsets DECAL.// DEP.A, DECAL.// DEP.B or

DECAL.// DEP.C for the heating curves on circuits A, B or C.

)

If the Day setting for one of the circuits, A, B or C, is above 30°C,

you no longer have access parallel offset on this circuit.

Adjustment keys

+/-

4.2.3 K3 control panel

Heating temperature setting: Set the boiler thermostat to the

desired setting.

Make all other settings on the master boiler fitted with a DIEMATIC-

m3 control panel

Press the

*

key.

10

DTG 230 09/03/2011 - 300011506-001-D

Page 11

4.3 Switching off the boiler

4. Operating the appliance

Set the On/Off switch to 0.

DIEMATIC-m3 control panel

The panel must always be supplied with 230V voltage:

- to ensure the anti-grip of the heating pump,

- to ensure Titan Active System® operation when a titanium anode

is protecting the DHW tank.

Use the mode:

- summer to shut down the heating.

- antifreeze to shut down the boiler if you are to be absent.

4.3.1 Precautions to take if there is a danger of frost

Heating circuit:

Use a correctly dosed antifreeze to prevent the heating water

freezing. If this cannot be done, drain the system completely. In all

cases, consult the fitter.

Domestic hot water circuit:

Drain the domestic water tank and pipes.

4.3.2 Precautions to take in the event of prolonged shutdown (one year or more)

- Close the gas valve

- The boiler and the chimney must be swept carefully.

- Close the door of the boiler to prevent the internal circulation of air.

09/03/2011 - 300011506-001-D DTG 230

11

Page 12

5. Checking and maintenance

5 Checking and maintenance

Make the following checks at least 1 time a year:

- Checking the ignition burner

- Safety devices

- Water level

- Checking burner safety

- Checking the safety thermostat

- Checking the downdraught thermostat

6 Troubleshooting

6.1 Data plate

Before informing the fitter of a fault, make a note of the following

information:

Type of gas used

Boiler type

Manufacturing date

Year (01 = 2001, 02 = 2002, ...)

Week

Serial no. of the appliance

This information can be found on the rating plate stuck to the

front plate of the boiler.

Carry out the following maintenance at least 1 time a year:

- Cleaning main burner and ignition burner

- Cleaning of the heating body

- Cleaning painted surfaces

XX-XX

12

DTG 230 09/03/2011 - 300011506-001-D

Page 13

6.2 Error messages

6.2.1 B3 control panel

Message Faults Probable causes Action

AL 50 Boiler sensor

AL 52 Domestic hot water sensor The sensor is cut

AL td

Titanium anode

AL tc

The sensor circuit has been broken or

short circuited.

The titanium anode is in open circuit or

the tank is empty.

A short circuit has occurred on the

titanium anode or connection

reversed.

6.2.2 DIEMATIC-m3 control panel

Message Probable causes Action

SHOW REM. CTRL

REVISION Boiler service required. Advise the installer.

DISGAS

AUX1.SENS.FAIL

AUX2.SENS.FAIL

UNIV.SENS.FAIL

DHW 2 S. FAIL

BOILER S.FAIL.

OUTSI. S.FAIL.

DHW S. FAILURE

OUTL S.A FAIL.

OUTL S.B FAIL.

OUTL S.C FAIL.

ROOM S.A FAIL.

ROOM S.B FAIL.

ROOM S.C FAIL.

SMOKE S. FAIL.

SWIM.P.A S.FAIL

SWIM.P.B. S.FAIL

SWIM.P.C. S.FAIL

SOLAR S. FAIL

ST.TANK S.FAIL

The message SHOW REM.CTRL indicates the

presence of an override on a remote control.

When connecting voltage, if the hot water tank

temperature is below 25 ºC, the boiler carries out a

domestic water exchanger purge cycle.

The sensor circuit has been broken or short

circuited.

The sensor circuit has been broken or short

circuited.

The sensor circuit has been broken or short

circuited.

The sensor circuit has been broken or short

circuited.

The sensor circuit has been broken or short

circuited.

The sensor circuit has been broken or short

circuited.

The sensor circuit has been broken or short

circuited.

The sensor circuit has been broken or short

circuited.

The sensor circuit has been broken or short

circuited.

The sensor circuit has been broken or short

circuited.

To cancel the overrides on all remote controls, press the AUTO key for 5

seconds.

Wait 1 minute.

Advise the installer.

If the boiler sensor fails, the burner is controlled by the boiler thermostat and

the heating and DHW circuits operate normally.

Advise the installer.

The boiler setting is equal to BOILER MAX. but can be limited by the boiler

thermostat to a lower value.

- The valve setting is no longer ensured but monitoring the maximum

temperature of the circuit after the valve is ensured.

- Valves may be manually operated.

- Reheating the domestic hot water remains ensured.

Advise the installer.

To ensure domestic hot water production, set the switch AUTO/

STB to

!

Advise the installer.

The circuit concerned goes from automatic to manual mode: The pump

operates.

Advise the installer.

The circuit concerned operates without any influence from the room sensor.

Advise the installer.

This failure has no impact on the operating modes.

Advise the installer.

Pool reheating is independent of its temperature.

Advise the installer.

Reheating domestic hot water using the solar panel is no longer ensured.

Advise the installer.

The hot water storage tank reheating operation is no longer assured.

Advise the installer.

The installation is stopped.

Advise the installer.

The installation continues to operate but domestic hot

water heating is no longer covered.

Advise the installer.

Production of domestic hot water is stopped. This may be

reactivated for 24 hours by disconnecting and

reconnecting the power supply to the boiler.

Advise the installer.

.

5. Checking and maintenance

/TEST-

!

09/03/2011 - 300011506-001-D DTG 230

13

Page 14

5. Checking and maintenance

Message Probable causes Action

Domestic hot water production is shut down and can be restarted using key

TA-S SHORT-CIR The Titan Active System® is short-circuited.

TA-S DISCONNEC The Titan Active System® is on an open circuit.

TA-S FAILURE Internal problem.

The last ten failures are memorised in the paragraph #DEF.

HISTORY

. The tank is no longer protected.

Advise the installer.

Domestic hot water production is shut down and can be restarted using key

. The tank is no longer protected.

Advise the installer.

Switch off the current.

Advise the installer.

6.2.3 K3 control panel

No error messages displayed. See DIEMATIC-m3 control panel

display.

6.3 Incidents and solutions

The burner is not working:

- Check the boiler thermostat settings.

- Shutdown by the safety thermostat due to accidental overheating

Check that the safety thermostat has not triggered. To restart the

boiler, reset the safety thermostat. Remove the safety thermostat

hood and press the reset button with a screwdriver. Carry out the

start-up operations again. Call your fitter.

- Check the circuit breaker

- The safety control box is malfunctioning (Fault indicator light

illuminated)

Press the resetting button of the burner. Call your fitter.

The burner is operating but the radiators are cold:

- Bleed the radiators.

- Top up the primary circuit with water.

If it is often necessary to top up the installation with water, contact

your fitter.

- Check that the heating pump is operating correctly.

- Check the position of the 3 position switch.

B3 control panel: TEST-STB/

DIEMATIC-m3 control panel: AUTO/

K3 control panel: AUTO/

- Check the boiler thermostat settings.

/TEST STB on AUTO

!

./%

on ..

/TEST STB on AUTO.

!

14

DTG 230 09/03/2011 - 300011506-001-D

Page 15

7 Technical characteristics

7. Technical characteristics

DTG 230-... Eco.NOx / S

Useful output

Smoke temperature

Minimum output temperature°C 303030303030303030

Maximum output temperature°C 909090909090909090

Maximum operating pressurebar666666666

Electrical connection V/Hz 230/50 230/50 230/50 230/50 230/50 230/50 230/50 230/50 230/50

Electrical power

(1) (3)

Gas connection inch R1R1R1R1R1R1R1R1R1

Heating connection inch R1 1/2 R1 1/2 R1 1/2 R1 1/2 R1 1/2 R1 1/2 R1 1/2 R1 1/2 R1 1/2

Internal diameter flue gas nozzle mm 150 160/180 180 180 200 200 200 220/225 220/225

Water content l 25 29 32.6 36.2 39.8 43.4 47 50.6 54.2

Net weight (without water) kg 203 230 257 283 305 334 357 386 408

(1) At nominal output (Stage2)

(2) Boiler temperature: 80 °C

(3) Electrical power of the boiler only with no accessories

Only in France:

(4)

Stage1 kW 27 27 36 36 45 45 54 54 54

Stage2 kW 45 54 63

(1) (2)

B3

DIEMATIC-m3K3W

°C 135 135 135 135 135 135 135 135 135

A useful output lower than 70 kW makes it possible to install

the boiler in a mini-boiler room.

(5) Only Eco.NOx version

(5)

6

20

21

19

7 8 9 10 11 12 13 14

20

21

19

20

21

19

69.9

20

21

19

(4)

/72

81 90 99 108 117

20

21

19

20

21

19

20

21

19

20

21

19

20

21

19

Conditions of use:

- Max. safety temperature: 110 °C

- Max. operating pressure: 6 bar

- Thermostat adjustable from 30 to 90°C

- Safety thermostat: 110 °C

8 Energy savings

Here are a few tips for saving energy:

- Install reflector panels behind the radiators.

- Do not cover the radiators. Do not hang curtains in front of the

radiators.

- Insulate pipes to prevent thermal losses and condensation.

- Do not obstruct aeration grates (even partially). They help to

reduce humidity in the home. The more humid a home, the more

heating it consumes.

- Turn heating off when airing a room (5 minutes a day is sufficient)

Avoid deregulating the thermostat. Switch the On/Off switch to Off.

- Do not shut down heating completely if you are absent. Lower the

thermostat by 3-4°C.

- Use the sun's heat as much as possible.

- Take showers rather than baths. Use a water-saving shower head.

09/03/2011 - 300011506-001-D DTG 230

15

Page 16

7. Technical characteristics

Warranty

You have just purchased one of our appliances and we thank you

for the trust you have placed in our products. Please note that your

appliance will provide good service for a longer period of time if it is

regularly checked and maintained. Your fitter and our customer

support network are at your disposal at all times.

Warranty terms

Starting from the purchase date shown on the original fitter's

invoice, your appliance has a contractual guarantee against any

manufacturing defect.

The length of the guarantee is mentioned in the price catalogue.

The manufacturer is not liable for any improper use of the appliance

or failure to maintain or install the unit correctly (the user shall take

care to ensure that the system is installed by a qualified fitter). In

particular, the manufacturer shall not be held responsible for any

damage, loss or injury caused by installations which do not comply

with the following:

- applicable local laws and regulations

- specific requirements relating to the installation, such as national

and/or local regulations

- the manufacturer's instructions, in particular those relating to the

regular maintenance of the unit

- the rules of the profession

The warranty is limited to the exchange or repair of such parts as

have been recognised to be faulty by our technical department and

does not cover labour, travel and carriage costs. The warranty shall

not apply to the replacement or repair of parts damaged by normal

wear and tear, negligence, repairs by unqualified parties, faulty or

insufficient monitoring and maintenance, faulty power supply or the

use of unsuitable fuel. Sub-assemblies such as motors, pumps,

electric valves etc. are guaranteed only if they have never been

dismantled.

Italy

The duration of our warranty is shown on the certificate delivered

with the appliance.

Our liability as manufacturer may not be invoked in respect of

incorrect use of the appliance, incorrect or insufficient maintenance

thereof, or incorrect installation of the appliance (you must

therefore ensure that installation and maintenance operations are

carried out respectively by a qualified professional and by an after

sales service company).

The legislation laid down by European Directive 99/44/EEC,

transposed by Legislative Decree No. 24 of 2 February 2002

published in O.J. No. 57 of 8 March 2002, continues to apply.

Russia

The foregoing provisions in no way affect the rights of the

consumer, which are guaranteed by the legislation of the Russian

Federation as regards hidden defects.

The terms and conditions of warranty and the terms and conditions

of application of the warranty are indicated on the warranty form.

The warranty shall not apply as regards the replacement or repair

of wearing parts under normal use. Such parts include

thermocouples, injection nozzles, flame control and ignition

systems, fuses and gaskets.

Turkey

Due to the laws and regulations the product life for this product is

10 years. During that time the producer and/or the distributor has

to provide after sales services and spare parts.

Other countries

The above provisions do not restrict the benefit of the legal laws

regarding hidden defects applicable in the buyer's country.

France

The preceding dispositions are not exclusive of benefits for the

purchaser of the legal guarantee as stated in Civil Code articles

1641 to 1648.

Poland

Warranty conditions are included in the warranty card.

Switzerland

The application of the warranty is subject to the terms and

conditions of sale, delivery and warranty of the company marketing

our products.

Belgium

The preceding dispositions about the contractual guarantee are not

exclusive of profit if the need arises for the purchaser in Belgium of

the applicable legal dispositions on hidden defects.

16

DTG 230 09/03/2011 - 300011506-001-D

Page 17

7. Technical characteristics

09/03/2011 - 300011506-001-D DTG 230

17

Page 18

Page 19

Page 20

FR

DE DIETRICH THERMIQUE S.A.S.

www.dedietrich-thermique.fr

Direction des Ventes France

57, rue de la Gare

F- 67580 MERTZWILLER

+33 (0)3 88 80 27 00

+33 (0)3 88 80 27 99

DE

BE

CN

DE DIETRICH REMEHA GmbH

www.dedietrich-remeha.de

Rheiner Strasse 151

D- 48282 EMSDETTEN

+49 (0)25 72 / 23-5

+49 (0)25 72 / 23-102

info@dedietrich.de

VAN MARCKE

www.vanmarcke.be

Weggevoerdenlaan 5

B- 8500 KORTRIJK

+32 (0)56/23 75 11

DE DIETRICH

www.dedietrich-heating.com

Room 512, Tower A, Kelun Building

12A Guanghua Rd, Chaoyang District

C-100020 BEIJING

+86 (0)106.581.4017

+86 (0)106.581.4018

+86 (0)106.581.7056

+86 (0)106.581.4019

contactBJ@dedietrich.com.cn

LU

RU

AT

NEUBERG S.A.

www.dedietrich-heating.com

39 rue Jacques Stas

L- 2010 LUXEMBOURG

+352 (0)2 401 401

DE DIETRICH

www.dedietrich-otoplenie.ru

129090 г. Москва

ул. Гиляровс кого, д. 8

офис 52

+7 495 988-43-04

+7 495 988-43-04

dedietrich@nnt.ru

ÖAG AG

www.oeag.at

Schemmerlstrasse 66-70

A-1110 WIEN

+43 (0)50406 - 61624

+43 (0)50406 - 61569

dedietrich@oeag.at

CH

WALTER MEIER (Klima Schweiz) AG

www.waltermeier.com

Bahnstrasse 24

CH-8603 SCHWERZENBACH

+41 (0) 44 806 44 24

Serviceline +41 (0)8 00 846 846

+41 (0) 44 806 44 25

ch.klima@waltermeier.com

WALTER MEIER (Climat Suisse) SA

www.waltermeier.com

Z.I. de la Veyre B, St-Légier

CH-1800 VEVEY 1

+41 (0) 21 943 02 22

Serviceline +41 (0)8 00 846 846

+41 (0) 21 943 02 33

ch.climat@waltermeier.com

© Copyright

All technical and technological information contained in these technical instructions, as well as any

drawings and technical descriptions supplied, remain our property and shall not be multiplied

without our prior consent in writing.

Subject to alterations.

09/03/2011

AD001NU-AC

DE DIETRICH THERMIQUE

57, rue de la Gare F- 67580 MERTZWILLER - BP 30

Loading...

Loading...