Page 1

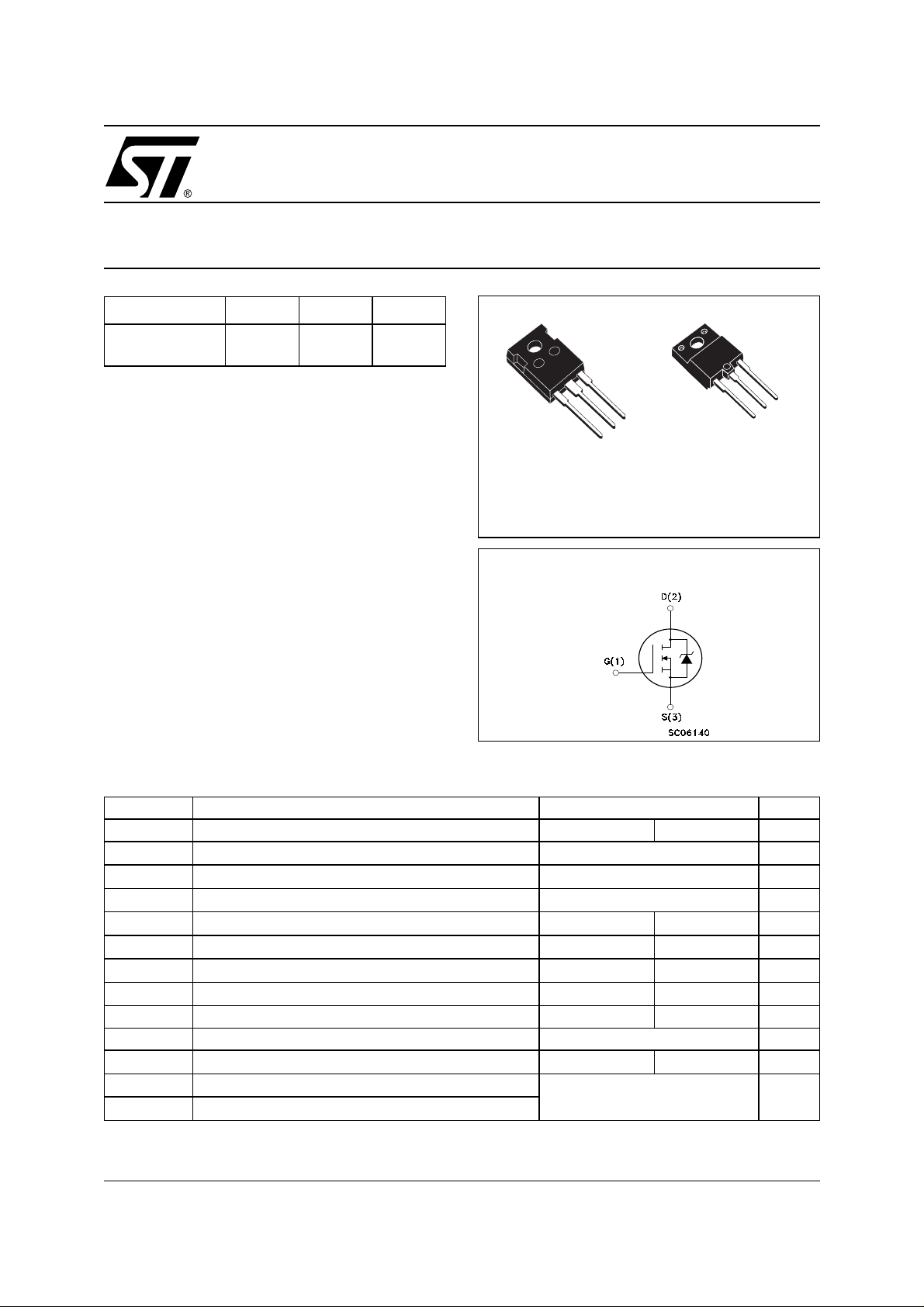

STW10NC60

STH10NC60FI

N-CHANNEL 600V - 0.6Ω - 10A - TO-247/ISOWATT218

PowerMesh™II MOSFET

TYPE V

STW10NC60

STH10NC60 FI

■ TYPICAL R

■ EXTREMELY HI GH dv /d t CAPABILITY

■ 100% AVALANCHE TESTED

■ NEW HIGH VOLTAGE BENCHMARK

■ GATE CHARGE MINIMIZED

DS

DSS

600 V

600 V

(on) = 0.6 Ω

R

DS(on)

< 0.75 Ω

< 0.75 Ω

I

D

10 A

10 A (*)

DESCRIPTION

The PowerMESH

generation of MESH OVERLAY

™II is the evolution of the first

™. The layout re-

finements introduced greatly improve the Ron*area

figure of merit while keeping the device at the lea ding edge for what concerns swithing speed, gate

charge and ruggedness.

APPLICATIONS

■ HIGH CURRENT, HIGH SPEED SWITCHING

■ SWITH MODE POWER SUPPLIES (SMPS)

■ DC-AC CONVERTERS FOR WELDING

EQUIPMENT AND UNINTERRUPTIBLE

POWER SUPPLIES AND MOTOR DRIVER

2

1

TO-247

3

2

1

ISOWATT218

INTERNAL SCHEMATIC DIAGRAM

3

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

STW10NC60 STH10NC60FI

(1)

j

Drain-source Voltage (VGS = 0)

Drain-gate Voltage (RGS = 20 kΩ)

600 V

600 V

Gate- source Voltage ±30 V

Drain Current (continuous) at TC = 25°C

Drain Current (continuous) at TC = 100°C

10 10 (*) A

6.3 6.3 (*) A

Drain Current (pulsed) 40 40 (*) A

Total Dissipation at TC = 25°C

160 60 W

Derating Factor 1.28 0.48 W/°C

Insulation Withstand Voltage (DC) - 2500 V

Storage Temperature

Max. Operating Junction Temperature

(1)ISD ≤10A, di/dt ≤100A/µs, VDD ≤ V

(*) Limited only by Maximum Temperature Allowed

– 55 to 150 °C

, Tj ≤ T

(BR)DSS

JMAX

V

DS

V

DGR

V

GS

I

D

I

D

I

DM

P

TOT

dv/dt Peak Diode Recovery voltage slope 3.5 V/ns

V

ISO

T

stg

T

(•)Pu l se width limite d by safe operati ng area

.

1/9February 2002

Page 2

STW10NC60 / STH10NC60FI

THERMA L D ATA

TO-247 ISOWATT218

Rthj-case Thermal Resistance Junction-case Max 0.78 2.08 °C/W

Rthj-amb Thermal Resistance Junction-ambient Max 30 °C/W

T

AVALANCHE CHARACTERISTICS

Symbol Parameter Max Value Unit

I

AR

E

AS

ELECTRICAL CHARACTERISTICS (TCASE = 25 °C UNLESS OTHERWISE SPECIFIED)

OFF

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

(BR)DSS

I

DSS

I

GSS

Maximum Lead Temperature For Soldering Purpose 300 °C

l

Avalanche Current, Repetitive or Not-Repetitive

(pulse width limited by T

max)

j

Single Pulse Avalanche Energy

(starting T

= 25 °C, ID = IAR, VDD = 50 V)

j

Drain-source

Breakdown Voltage

Zero Gate Voltage

Drain Current (V

GS

= 0)

Gate-body Leakage

Current (V

DS

= 0)

10 A

820 mJ

ID = 250 µA, VGS = 0 600

V

= Max Rating

DS

V

= Max Rating, TC = 125 °C

DS

V

= ±30V ±100 nA

GS

1µA

50 µA

V

ON

(1)

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

V

GS(th)

R

DS(on)

Gate Threshold Voltage

Static Drain-source On

= VGS, ID = 250µA

DS

VGS = 10V, ID = 4.5 A

234V

0.6 0.75 Ω

Resistance

DYNAMIC

Symbol Parameter Test Conditions Min. Typ. Max. Unit

(1) Forward Transconductance VDS =20 V , ID=4.5A 9 S

g

fs

C

iss

C

oss

C

rss

Input Capacitance

Output Capacitance 205 pF

Reverse Transfer

Capacitance

V

= 25V, f = 1 MHz, VGS = 0

DS

1420 pF

35 pF

2/9

Page 3

STW10NC60 / STH10NC60FI

ELECTRICAL CHARACTERISTICS (CONTINUED)

SWITCHING ON

Symbol Parameter Test Conditions Min. Typ. Max. Unit

t

d(on)

Turn-on Delay Time VDD = 300V, ID = 4.5 A

RG=4.7Ω VGS = 10V

t

r

Q

g

Q

gs

Q

gd

Rise Time 16 ns

Total Gate Charge

Gate-Source Charge 4.5 nC

Gate-Drain Charge 31 nC

(see test circuit, Figure 3)

V

= 480V, ID = 9.0 A,

DD

V

= 10V

GS

SWITCHING OFF

Symbol Parameter Test Conditions Min. Typ. Max. Unit

t

d(off)

Turn-off Delay Time

t

f

Fall Time

VDD = 300 V, ID = 4.5 A

R

= 4.7Ω VGS = 10 V

G

(Resistive Load see, Figure 3)

t

r(Voff)

t

f

t

c

Fall Time

Cross-over Time

Off-voltage Rise Time

= 480V, ID = 9.0 A,

V

DD

RG= 4.7Ω, V

GS

= 10V

(Inductive Load see, Figure 5)

SOURCE DRAIN DIODE

Symbol Parameter Test Conditions Min. Typ. Max. Unit

I

SD

I

SDM

V

(1)

SD

t

rr

Q

rr

I

RRM

Note: 1. Pulsed: Puls e duration = 300 µs, duty cycle 1 .5 %.

2. Pulse width limited by safe operating area.

Source-drain Current 10 A

(2)

Source-drain Current (pulsed) 40 A

Forward On Voltage

Reverse Recovery Time

Reverse Recovery Charge 4.7 µC

ISD = 9 A, VGS = 0

I

= 9 A, di/dt = 100A/µs,

SD

VDD = 100V, Tj = 150°C

(see test circuit, Figure 5)

Reverse Recovery Current 15.5 A

20 ns

55 77 nC

64

32

19

13

32

1.6 V

600 ns

ns

ns

ns

ns

ns

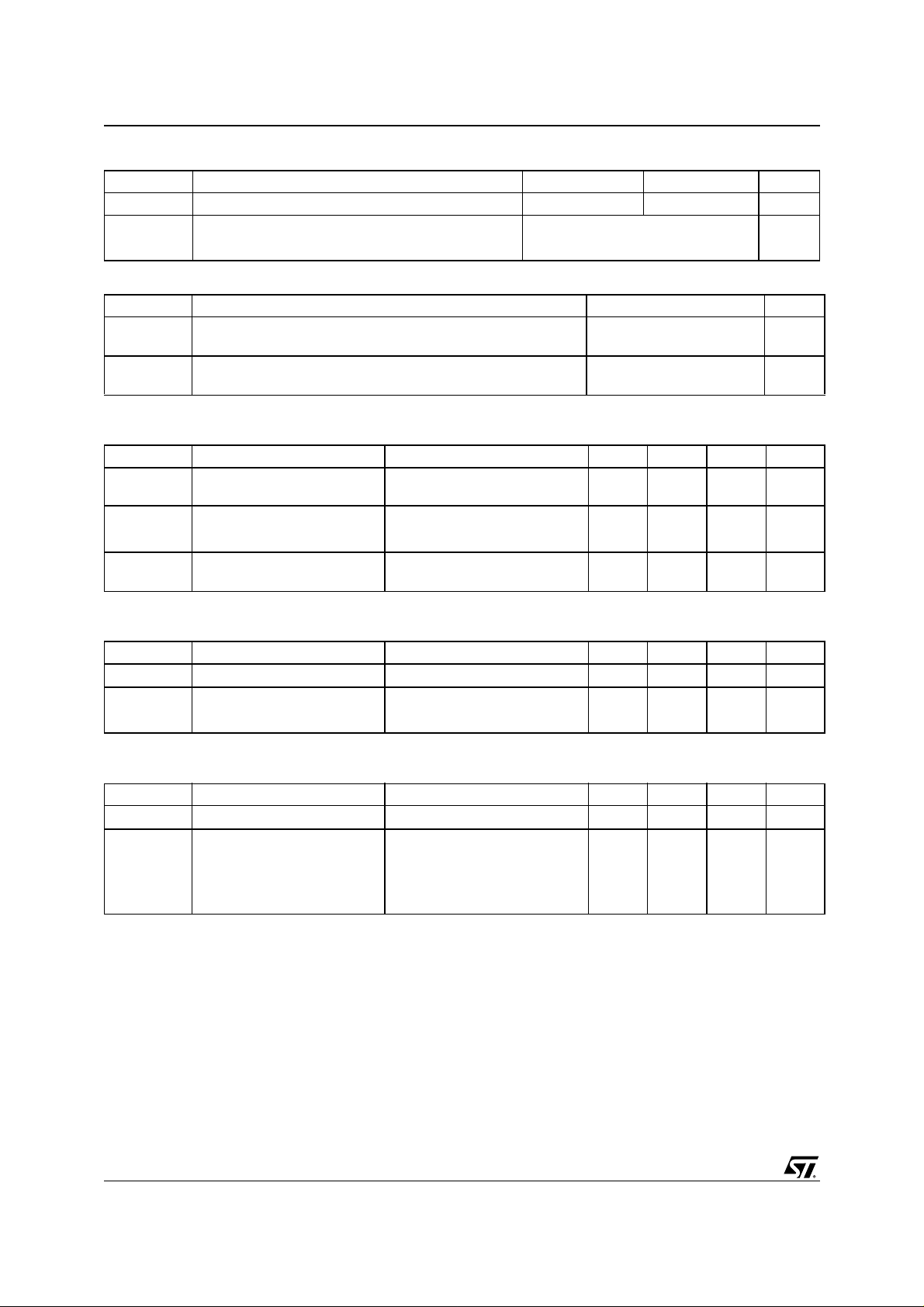

Safe Operating Area for ISOWATT218Safe Operating Area for TO-247

3/9

Page 4

STW10NC60 / STH10NC60FI

Thermal Impedance for ISOWATT218Thermal Impedance for TO-247

Output Characteristics Transfer Characteristics

Transco nductance

4/9

Static Drain-source On Resistance

Page 5

STW10NC60 / STH10NC60FI

Gate Charge vs Gate-source Voltage

Normalized Gate Thereshold Voltage vs Temp. Normalized On Resistance vs Temperature

Capacitance Variations

Source-drain Diode Forward Characteristics

5/9

Page 6

STW10NC60 / STH10NC60FI

Fig. 2: Unclamped Inductive WaveformFig. 1: Unclamped Inductive Load Test Circuit

Fig. 3: Switching Times Test Circuit For

Resistive Load

Fig. 5: Test Circuit For Inductive Load Switching

And Diode Recovery Times

Fig. 4: Gate Charge test Circuit

6/9

Page 7

TO-247 MECHANICAL DATA

STW10NC60 / STH10NC60FI

DIM.

A 4.85 5.15 0.19 0.20

D 2.20 2.60 0.08 0.10

E 0.40 0.80 0.015 0.03

F 1 1.40 0.04 0.05

F1 3 0.11

F2 2 0.07

F3 2 2.40 0.07 0.09

F4 3 3.40 0.11 0.13

G 10.90 0.43

H 15.45 15.75 0.60 0.62

L 19.85 20.15 0.78 0.79

L1 3.70 4.30 0.14 0.17

L2 18.50 0.72

L3 14.20 14.80 0.56 0.58

L4 34.60 1.36

L5 5.50 0.21

M 2 3 0.07 0.11

V

V2

Dia 3.55 3.65 0.14 0.143

MIN. TYP MAX. MIN. TYP. MAX.

mm. inch

5º5º

60º 60º

7/9

Page 8

STW10NC60 / STH10NC60FI

ISOWATT218 MECHANICAL DATA

DIM.

A 5.35 5.65 0.211 0.222

C 3.30 3.80 0.130 0.150

D 2.90 3.10 0.114 0.122

D1 1.88 2.08 0.074 0.082

E 0.75 0.95 0.030 0.037

F 1.05 1.25 0.041 0.049

F2 1.50 1.70 0.059 0.067

F3 1.90 2.10 0.075 0.083

G 10.80 11.20 0.425 0.441

H 15.80 16.20 0.622 0.638

L 9 0.354

L1 20.80 21.20 0.819 0.835

L2 19.10 19.90 0.752 0.783

L3 22.80 23.60 0.898 0.929

L4 40.50 42.50 1.594 1.673

L5 4.85 5.25 0.191 0.207

L6 20.25 20.75 0.797 0.817

N 2.1 2.3 0.083 0.091

R 4.6 0.181

DIA 3.5 3.7 0.138 0.146

MIN. TYP. MAX. MIN. TYP. MAX.

mm inch

8/9

- Weight : 4.9 g (typ.)

- Maximum Torque (applied to mounting flange) Recommended: 0.8 Nm; Maximum: 1 Nm

- The side of the dissipator must be flat within 80 µm

P025C/A

Page 9

STW10NC60 / STH10NC60FI

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such informa tion n or for an y infring ement of patent s or other rig hts of third part ies which may resu lt from its use . No l i cen se i s

granted by implication or otherwise under any patent or patent rights of STMicroelectronics. Specification mentioned in this publication are

subject to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products

are not authorized for use as critical compo nents in life support devices or systems without express written approval of STMicroelectronics.

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta - Morocco -

The ST logo is a trademark of STMicroelectronics

© 2001 STMicroelectronics – Printed in Italy – All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

9/9

Loading...

Loading...