Page 1

MT9044

T1/E1/OC3 System Synchronizer

Advance Information

Features

• Supports AT&T TR62411 and Bellcore

GR-1244-CORE Stratum 3, Stratum 4

Enhanced and Stratum 4 timing for DS1

interfaces

• Supports ITU-T G.812 Type IV clocks for 1,544

kbit/s interfaces and 2,048 kbit/s interfaces

• Supports ETSI ETS 300 011, TBR 4, TBR 12

and TBR 13 timing for E1 interfaces

• Selectable 1.544MHz, 2.048MHz or 8kHz input

reference signals

• Provides C1.5, C2, C3, C4, C6, C8, C16, and

C19 (STS-3/OC3 clock divided by 8) output

clock signals

• Provides 5 different styles of 8 KHz framing

pulses

• Holdover frequency accuracy of 0.05 PPM

• Holdover indication

• Attenuates wander from 1.9Hz

• Provides Time Interval Error (TIE) correction

• Accepts reference inputs from two independent

sources

• JTAG Boundary Scan

Applications

• Synchronization and timing control for

multitrunk T1,E1 and STS-3/OC3 systems

• ST-BUS clock and frame pulse sources

DS5058 ISSUE 3 September 1999

Ordering Information

MT9044AP 44 Pin PLCC

MT9044AL 44 Pin MQFP

-40 to +85 °C

Description

The MT9044 T1/E1/OC3 System Synchronizer

contains a digital phase-locked loop (DPLL), which

provides timing and synchronization signals for

multitrunk T1 and E1 primary rate transmission links

and STS-3/0C3 links.

The MT9044 generates ST-BUS clock and framing

signals that are phase locked to either a 2.048MHz,

1.544MHz, or 8kHz input reference.

The MT9044 is compliant with AT&T TR62411 and

Bellcore GR-1244-CORE Stratum 3, Stratum 4

Enhanced, and Stratum 4; and ETSI ETS 300 011. It

will meet the jitter/wander tolerance, jitter/wander

transfer, intrinsic jitter/wander, frequency accuracy,

capture range, phase change slope, holdover

frequency and MTIE requirements for these

specifications.

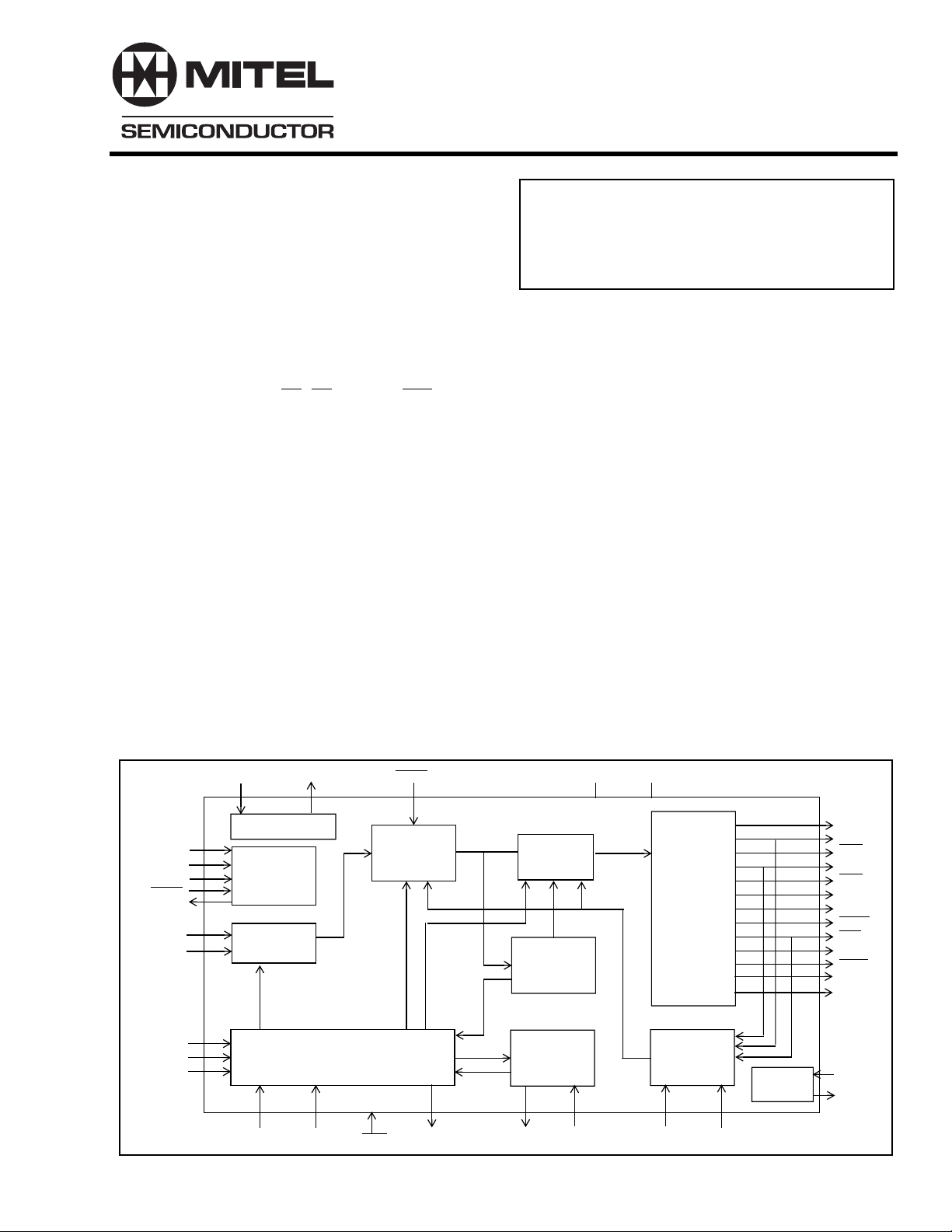

TCK

TDI

TMS

TRST

TDO

PRI

SEC

RSEL

LOS1

LOS2

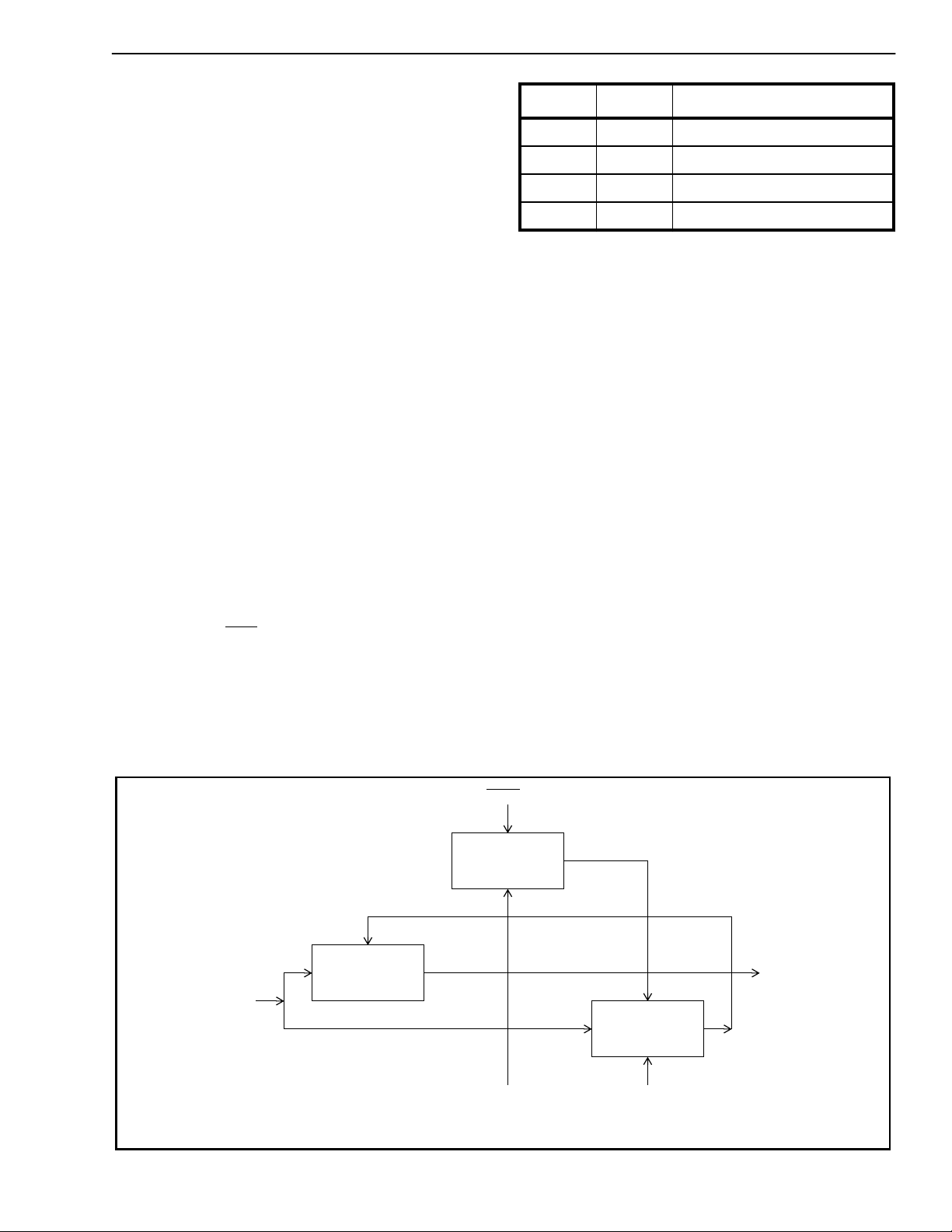

Corrector

TIE

Corrector

Enable

RST

TCLR

TIE

Circuit

State

Select

HOLDOVER

Virtual

Reference

Impairment

Monitor

Guard Time

Circuit

OSCoOSCi

Master Clock

IEEE

1149.1a

Selected

Reference

Select

MUX

Reference

Select

Automatic/Manual

Control State Machine

MS1 MS2 GTo GTi FS1 FS2

Reference

DPLL

State

Select

Input

VDD VSS

Output

Interface

Circuit

Feedback

Frequency

Select

MUX

Figure 1 - Functional Block Diagram

APLL

C19o

C1.5o

C3o

C2o

C4o

C6o

C8o

C16o

F0o

F8o

F16o

RSP

TSP

ACKi

ACKo

1

Page 2

MT9044 Advance Information

TDI

RST

FS1

343536

FS2

33

32

31

30

29

28

27

26

25

24

23

TEST

RSEL

MS1

MS2

TDO

LOS1

LOS2

GTo

VSS

GTi

HOLDOVER

VDD

OSCo

OSCi

VSS

F16o

RSP

F0o

TSP

F8o

C1.5o

AVDD

SEC

PRI

TRST

TCLR

43

7

8

9

10

11

12

13

14

15

16

17

18 19 20 21 22 23 24

MT9044

VSS

TCK

1

2564344

TDI

TMS

RST

25 26 27 28

FS1

404142

FS2

39

38

37

36

35

34

33

32

31

30

29

TEST

RSEL

MS1

MS2

TDO

LOS1

LOS2

GTo

VSS

GTi

HOLDOVER

VDD

OSCo

OSCi

VSS

F16o

RSP

F0o

TSP

F8o

C1.5o

AVDD

SEC

PRI

TRST

TCLR

42 41

1

2

3

4

5

6

7

8

9

10

11

12 13 14 15 16 17 18

MT9044AL

VSS

TCLK

39

404344 3738

TMS

19 20 21 22

C3o

C2o

C4o

C19o

ACKi

VSS

C4o

C2o

C6o

C8o

VDD

C16o

ACKo

C3o

ACKi

C19o

VSS

C8o

C6o

VDD

C16o

ACKo

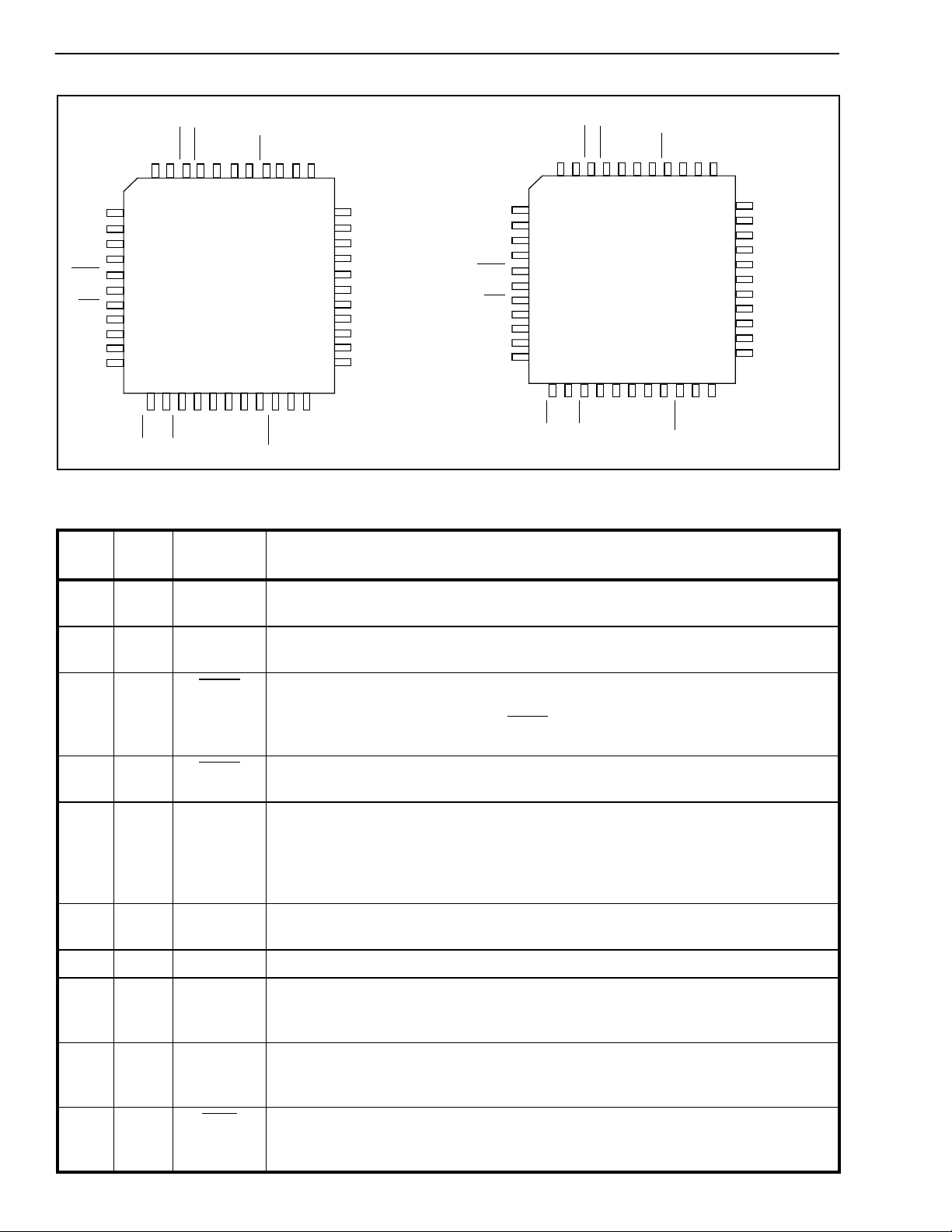

Figure 2 - Pin Connections

Pin Description

Pin #

PLCC

1,10,

23,31

Pin #

MQFP

39,4,17

Name Description

V

SS

Ground. 0 Volts.

,25

2 40 TCK Test Clock (TTL Input): Provides the clock to the JTAG test logic. This pin is

internally pulled up to VDD.

341TCLR TIE Circuit Reset (TTL Input): A logic low at this input resets the Time Interval

Error (TIE) correction circuit resulting in a re-alignment of input phase with output

phase as shown in Figure 19. The TCLR pin should be held low for a minimum of

300ns. This pin is internally pulled down to VSS.

442TRST Test Reset (TTL Input): Asynchronously initializes the JTAG TAP controller by

putting it in the Test-Logic-Reset state. This pin is internally pulled down to VSS.

543 SEC Secondary Reference (TTL Input). This is one of two (PRI & SEC) input

reference sources (falling edge) used for synchronization. One of three possible

frequencies (8kHz, 1.544MHzMHz, or 2.048MHz) may be used. The selection of

the input reference is based upon the MS1, MS2, LOS1, LOS2, RSEL, and GTi

control inputs (Automatic or Manual). This pin is internally pulled up to VDD.

6 44 PRI Primary Reference (TTL Input). See pin description for SEC. This pin is

internally pulled up to VDD.

7,28 1,22 V

DD

Positive Supply Voltage. +5VDC nominal.

8 2 OSCo Oscillator Master Cloc k (CMOS Output). For crystal operation, a 20MHz crystal

is connected from this pin to OSCi, see Figure 10. For clock oscillator operation,

this pin is left unconnected, see Figure 9.

9 3 OSCi Oscillator Master Clock (CMOS Input). For crystal operation, a 20MHz crystal is

connected from this pin to OSCo, see Figure 10. F or clock oscillator oper ation, this

pin is connected to a clock source, see Figure 9.

11 5 F16o Frame Pulse ST-BUS 8.192 Mb/s (CMOS Output). This is an 8kHz 61ns active

low framing pulse, which marks the beginning of an ST-BUS frame. This is typically

used for ST-BUS operation at 8.192 Mb/s. See Figure 20.

2

Page 3

Advance Information MT9044

Pin Description (continued)

Pin #

PLCC

12 6 RSP Receive Sync Pulse (CMOS Output). This is an 8kHz 488ns active high framing

13 7 F0o Frame Pulse ST-BUS 2.048Mb/s (CMOS Output). This is an 8kHz 244ns active

14 8 TSP T ransmit Sync Pulse (CMOS Output). This is an 8kHz 488ns activ e high fr aming

15 9 F8o Frame Pulse (CMOS Output). This is an 8kHz 122ns active high framing pulse,

16 10 C1.5o Clock 1.544MHz (CMOS Output). This output is used in T1 applications.

17 11 AVdd Analog Vdd. +5VDC nominal.

18 12 C3o Clock 3.088MHz (CMOS Output). This output is used in T1 applications.

19 13 C2o Clock 2.048MHz (CMOS Output). This output is used for ST-BUS operation at

20 14 C4o Clock 4.096MHz (CMOS Output). This output is used for ST-BUS operation at

Pin #

MQFP

Name Description

pulse, which marks the end of an ST-BUS frame. This is typically used for

connection to the Siemens MUNICH-32 device. See Figure 21.

low framing pulse, which marks the beginning of an ST-BUS frame. This is typically

used for ST-BUS operation at 2.048Mb/s and 4.096Mb/s. See Figure 20.

pulse, which marks the beginning of an ST-BUS frame. This is typically used for

connection to the Siemens MUNICH-32 device. See Figure 21.

which marks the beginning of a frame. See Figure 20.

2.048Mb/s.

2.048Mb/s and 4.096Mb/s.

21 15 C19o Clock 19.44MHz (CMOS Output). This output is used in OC3/STS3 applications.

22 16 ACKi Analog PLL Clock Input (CMOS Input). This input clock is a reference for an

internal analog PLL. This pin is internally pulled down to VSS.

24 18 ACKo Analog PLL Clock Output (CMOS Output). This output clock is generated by

the internal analog PLL.

25 19 C8o Clock 8.192MHz (CMOS Output). This output is used for ST-BUS operation at

8.192Mb/s.

26 20 C16o Clock 16.384MHz (CMOS Output). This output is used for ST-BUS operation with

a 16.384MHz clock.

27 21 C6o Clock 6.312 Mhz (CMOS Output). This output is used for DS2 applications.

29 23 HOLDOVER Holdover (CMOS Output). This output goes to a logic high whenever the digital

PLL goes into holdover mode.

30 24 GTi Guard Time (Schmitt Input). This input is used by the MT9044 state machine in

both Manual and Automatic modes. The signal at this pin aff ects the state changes

between Primary Holdover Mode and Primary Normal Mode, and Primary

Holdover Mode and Secondary Normal Mode. The logic level at this input is gated

in by the rising edge of F8o. See Tables 4 and 5.

32 26 GTo Guard Time (CMOS Output). The LOS1 input is gated by the rising edge of F8o,

buffered and output on GTo. This pin is typically used to driv e the GTi input through

an RC circuit.

33 27 LOS2 Secondary Reference Loss (TTL Input). This input is normally connected to the

loss of signal (LOS) output signal of a Line Interface Unit (LIU). When high, the

SEC reference signal is lost or invalid. LOS2, along with the LOS1 and GTi inputs

control the MT9044 state machine when operating in Automatic Control. The logic

level at this input is gated in by the rising edge of F8o. This pin is internally pulled

down to VSS.

3

Page 4

MT9044 Advance Information

Pin Description (continued)

Pin #

PLCC

34 28 LOS1 Primary Reference Loss (TTL Input). Typically, external equipment applies a

35 29 TDO Test Serial Data Out (TTL Output). JTAG serial data is output on this pin on the

36 30 MS2 Mode/Control Select 2 (TTL Input). This input, in conjunction with MS1,

37 31 MS1 Mode/Control Select 1 (TTL Input). The logic level at this input is gated in by the

38 32 RSEL Reference Source Select (TTL Input). In Manual Control, a logic low selects the

39 33 TEST Test (TTL Input). This input is normally tied low. When pulled high, it enables

Pin #

MQFP

Name Description

logic high to this input when the PRI reference signal is lost or invalid. The logic

level at this input is gated in b y the rising edge of F8o . See LOS2 description. This

pin is internally pulled down to VSS.

falling edge of TCK. This pin is held in high impedance state when JTAG scan is

not enable.

determines the device’s mode (Automatic or Manual) and state (Normal, Holdover

or Freerun) of operation. The logic level at this input is gated in by the rising edge

of F8o. See Table 3.

rising edge of F8o. See pin description for MS2. This pin is internally pulled down

to VSS.

PRI (primary) reference source as the input reference signal and a logic high

selects the SEC (secondary) input. In Automatic Control, this pin must be at logic

low. The logic level at this input is gated in by the rising edge of F8o. See Table 2.

This pin is internally pulled down to VSS.

internal test modes. This pin is internally pulled down to VSS.

40 34 FS2 Frequency Select 2 (TTL Input). This input, in conjunction with FS1, selects

which of three possible frequencies (8kHz, 1.544MHz, or 2.048MHz) may be input

to the PRI and SEC inputs. See Table 1.

41 35 FS1 Frequency Select 1 (TTL Input). See pin description for FS2.

42 36 TDI Test Serial Data In (TTL Input). JTAG serial test instructions and data are shifted

in on this pin. This pin is internally pulled up to VDD.

43 37 RST Reset (Schmitt Input). A logic low at this input resets the MT9044. To ensure

proper operation, the device must be reset after changes to the method of control,

reference signal frequency changes and power-up. The RST pin should be held

low for a minimum of 300ns. While the RST pin is low, all frame and clock outputs

are at logic high. Following a reset, the input reference source and output clocks

and frame pulses are phase aligned as shown in Figure 19.

44 38 TMS Test Mode Select (TTL Input). JTAG signal that controls the state transitions of

the TAP controller. This pin is internally pulled up to VDD.

4

Page 5

Advance Information MT9044

Functional Description

The MT9044 is a Multitrunk System Synchronizer,

providing timing (clock) and synchronization (frame)

signals to interface circuits for T1 and E1 Primary

Rate Digital Transmission links.

Figure 1 shows the functional block diagram which is

described in the following sections.

Reference Select MUX Circuit

The MT9044 accepts two simultaneous reference

input signals and operates on their falling edges.

Either the primary reference (PRI) signal or the

secondary reference (SEC) signal can be selected

as input to the TIE Corrector Circuit. The selection is

based on the Control, Mode and Reference

Selection of the device. See Tables 1, 4 and 5.

Frequency Select MUX Circuit

The MT9044 operates with one of three possible

input reference frequencies (8kHz, 1.544MHz or

2.048MHz). The frequency select inputs (FS1 and

FS2) determine which of the three frequencies may

be used at the reference inputs (PRI and SEC). Both

inputs must have the same frequency applied to

them. A reset (RST) must be performed after every

frequency select input change. Operation with FS1

and FS2 both at logic low is reserved and must not

be used. See Table 1.

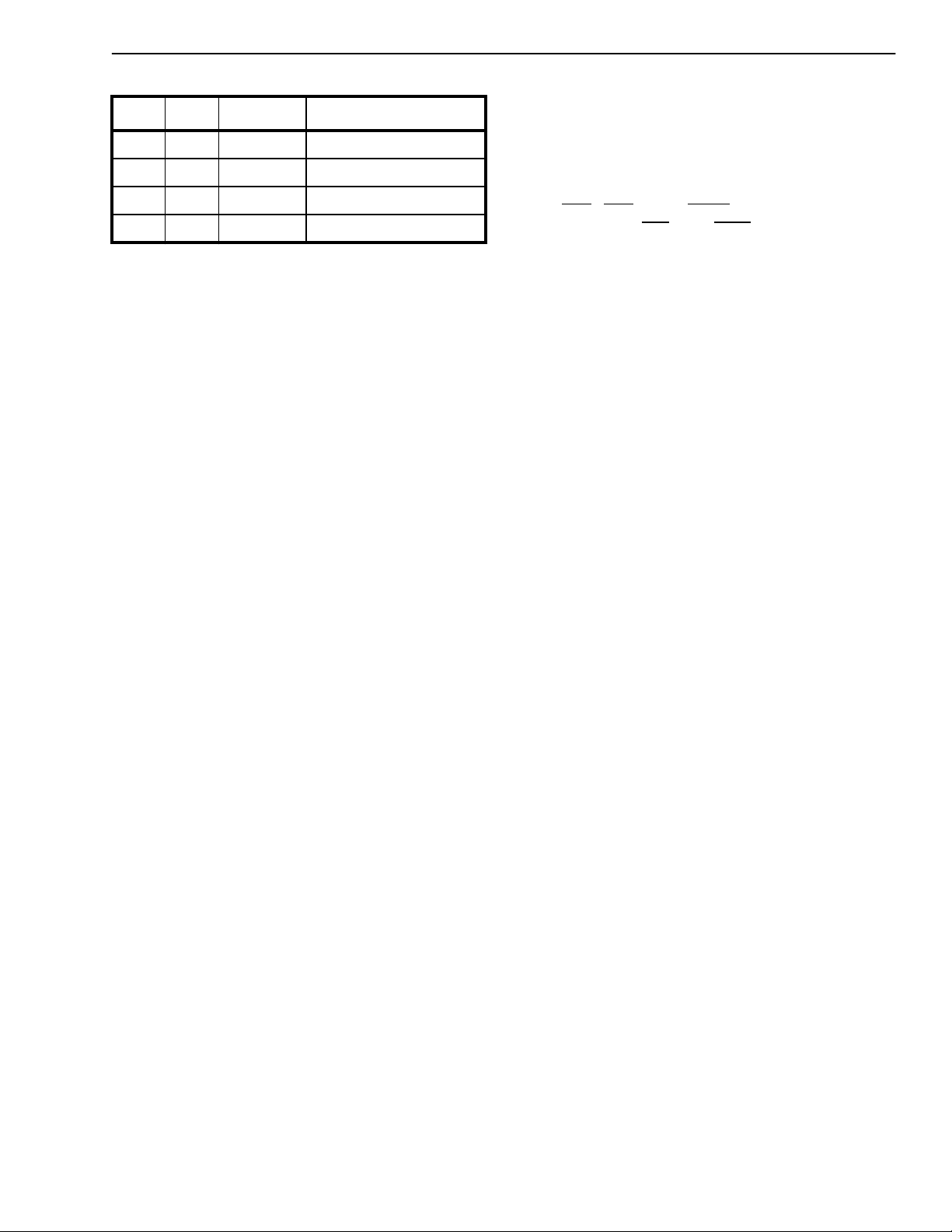

FS2 FS1 Input Frequency

0 0 Reserved

0 1 8kHz

1 0 1.544MHz

1 1 2.048MHz

Table 1 - Input Frequency Selection

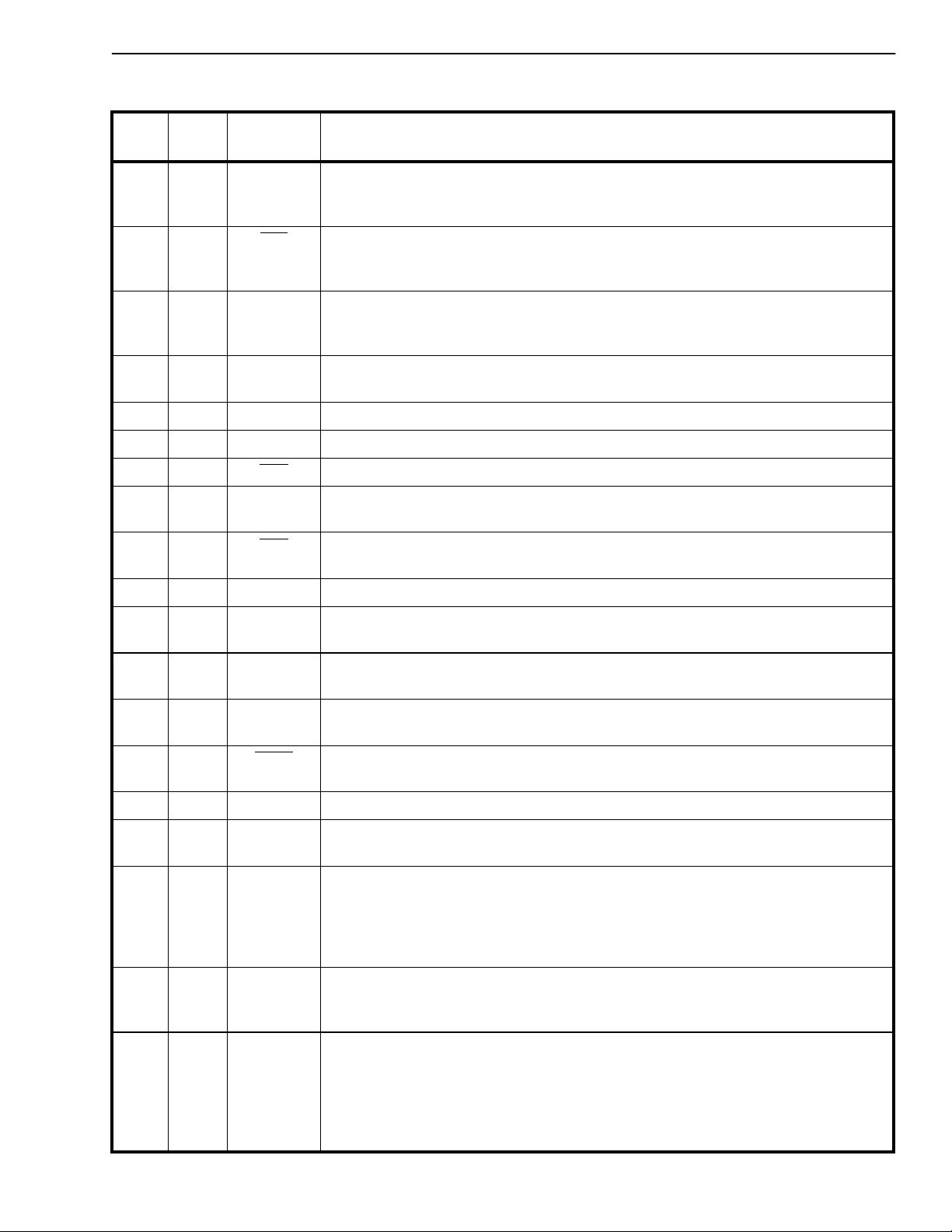

Time Interval Error (TIE) Corrector Circuit

The TIE corrector circuit, when enabled, prevents a

step change in phase on the input reference signals

(PRI or SEC) from causing a step change in phase at

the input of the DPLL block of Figure 1.

During reference input rearrangement, such as

during a switch from the primary reference (PRI) to

the secondary reference (SEC), a step change in

phase on the output signals will occur. A phase step

at the input of the DPLL will lead to unacceptable

phase changes in the output signal.

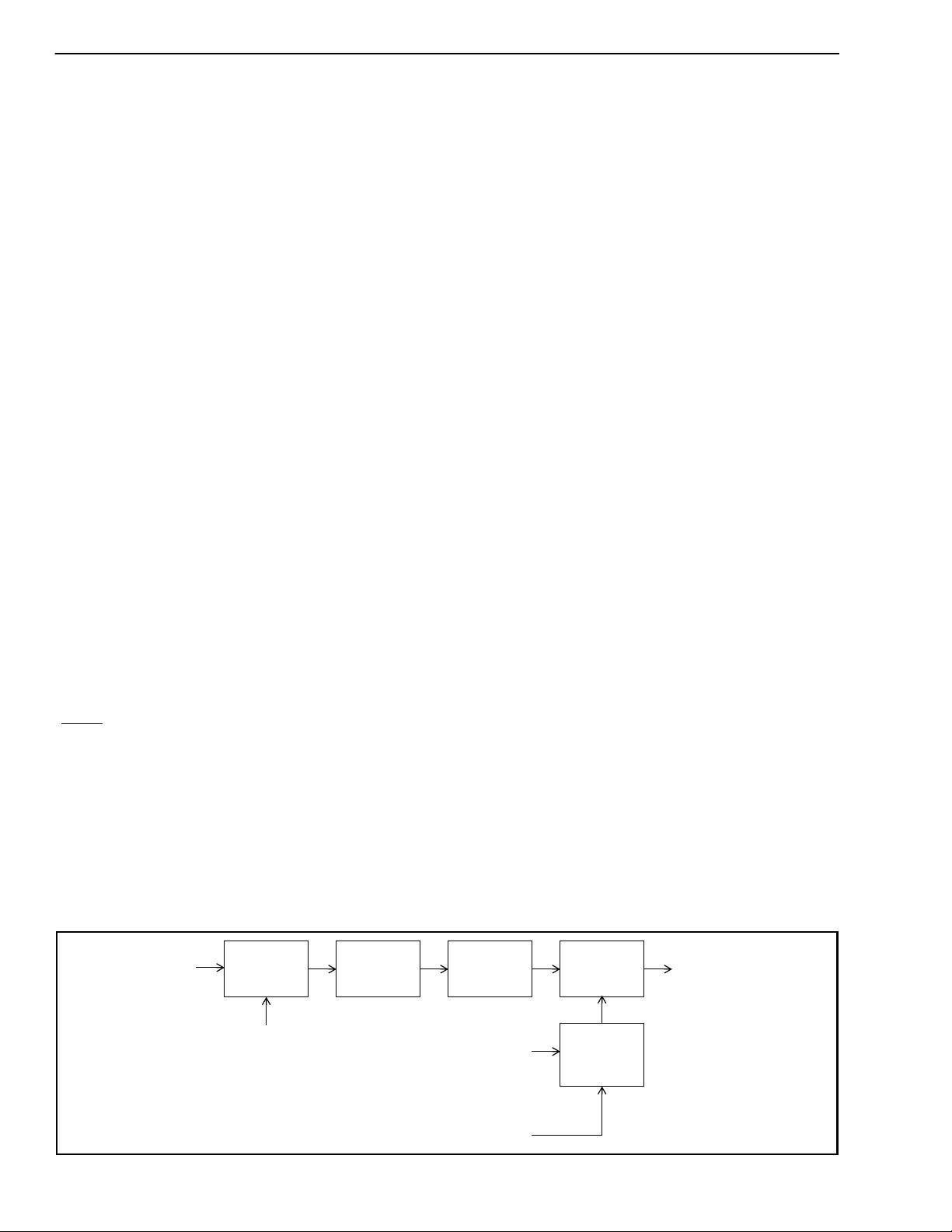

As shown in Figure 3, the TIE Corrector Circuit

receives one of the two reference (PRI or SEC)

signals, passes the signal through a programmable

delay line, and uses this delayed signal as an

internal virtual reference, which is input to the DPLL.

Therefore, the virtual reference is a delayed version

of the selected reference.

During a switch, from one reference to the other, the

State Machine first changes the mode of the device

PRI or SEC

from

Reference

Select Mux

Programmable

Delay Circuit

TCLR

Resets Delay

Control

Circuit

TIE Corrector

Enable

from

State Machine

Control Signal

Delay Value

Compare

Circuit

Feedback

Signal from

Frequency

Select MUX

Figure 3 - TIE Corrector Circuit

Virtual

Reference

to DPLL

5

Page 6

MT9044 Advance Information

from Normal to Holdover. In Holdover Mode, the

DPLL no longer uses the virtual reference signal, but

generates an accurate clock signal using storage

techniques. The Compare Circuit then measures the

phase delay between the current phase (feedback

signal) and the phase of the new reference signal.

This delay value is passed to the Programmable

Delay Circuit (See Figure 3). The new virtual

reference signal is now at the same phase position

as the previous reference signal would have been if

the reference switch had not taken place. The State

Machine then returns the device to Normal Mode.

The DPLL now uses the new virtual reference signal,

and since no phase step took place at the input of

the DPLL, no phase step occurs at the output of the

DPLL. In other words, reference switching will not

create a phase change at the input of the DPLL, or at

the output of the DPLL.

Since internal delay circuitry maintains the alignment

between the old virtual reference and the new virtual

reference, a phase error may exist between the

selected input reference signal and the output signal

of the DPLL. This phase error is a function of the

difference in phase between the two input reference

signals during reference rearrangements. Each time

a reference switch is made, the delay between input

signal and output signal will change. The value of

this delay is the accumulation of the error measured

during each reference switch.

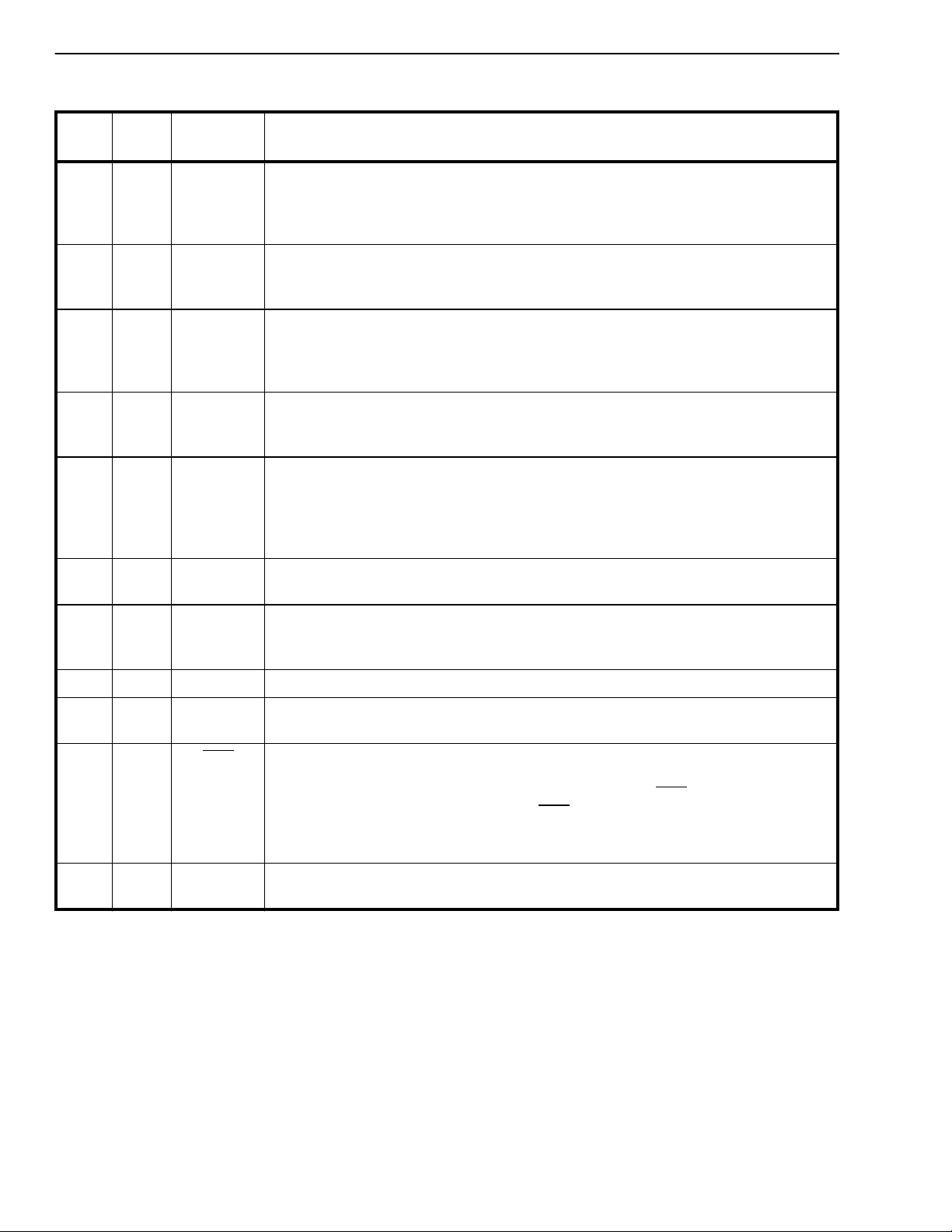

Digital Phase Lock Loop (DPLL)

As shown in Figure 4, the DPLL of the MT9044

consists of a Phase Detector, Limiter, Loop Filter,

Digitally Controlled Oscillator, and a Control Circuit.

Phase Detector - the Phase Detector compares the

virtual reference signal from the TIE Corrector circuit

with the feedback signal from the Frequency Select

MUX circuit, and provides an error signal

corresponding to the phase difference between the

two. This error signal is passed to the Limiter circuit.

The Frequency Select MUX allows the proper

feedback signal to be externally selected (e.g., 8kHz,

1.544MHz or 2.048MHz).

Limiter - the Limiter receives the error signal from

the Phase Detector and ensures that the DPLL

responds to all input transient conditions with a

maximum output phase slope of 5ns per 125us. This

is well within the maximum phase slope of 7.6ns per

125us or 81ns per 1.326ms specified by AT&T

TR62411, and Bellcore GR-1244-CORE.

Loop Filter - the Loop Filter is similar to a first order

low pass filter with a 1.9 Hz cutoff frequency for all

three reference frequency selections (8kHz,

1.544MHz or 2.048MHz). This filter ensures that the

jitter transfer requirements in ETS 300 011 and AT&T

TR62411 are met.

The programmable delay circuit can be zeroed by

applying a logic low pulse to the TIE Circuit Reset

(TCLR) pin. A minimum reset pulse width is 300ns.

This results in a phase alignment between the input

reference signal and the output signal as shown in

Figure 20. The speed of the phase alignment

correction is limited to 5ns per 125us, and

convergence is in the direction of least phase travel.

The state diagrams of Figure 7 and 8 indicate the

state changes that activate the TIE Corrector Circuit.

Virtual Reference from

TIE Corrector

Phase

Detector

Feedback Signal from

Frequency Select MUX

Limiter Loop Filter

Figure 4 - DPLL Block Diagram

Control Circuit - the Control Circuit uses status and

control information from the State Machine and the

Input Impairment Circuit to set the mode of the

DPLL. The three possible modes are Normal,

Holdover and Freer un.

Digitally Controlled Oscillator (DCO) - the DCO

receives the limited and filtered signal from the Loop

FIlter, and based on its value, generates a

corresponding digital output signal. The

synchronization method of the DCO is dependent on

the state of the MT9044.

State Select from

Input Impairment

Monitor

State Select from

State Machine

Digitally

Controlled

Oscillator

Control

Circuit

DPLL Reference to

Output Interface Circuit

6

Page 7

Advance Information MT9044

In Normal Mode, the DCO provides an output signal

which is frequency and phase locked to the selected

input reference signal.

In Holdover Mode, the DCO is free running at a

frequency equal to the last (less 30ms to 60ms)

frequency the DCO was generating while in Normal

Mode.

T1 Divider

12MHz

Tapped

Delay

Line

C1.5o

C3o

In Freerun Mode, the DCO is free running with an

accuracy equal to the accuracy of the OSCi 20MHz

source.

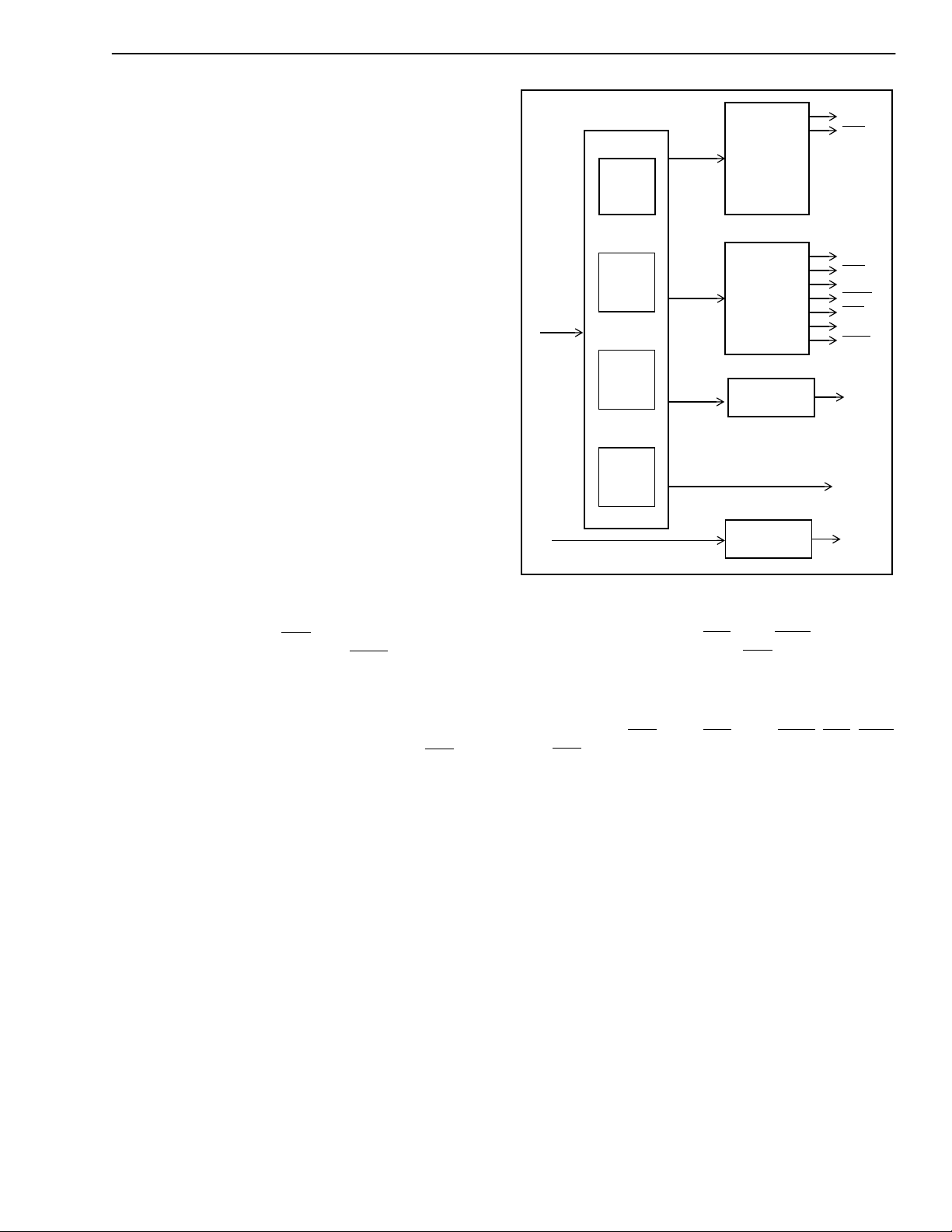

Output Interface Circuit

The output of the DCO (DPLL) is used by the Output

Interface Circuit to provide the output signals shown

in Figure 5. The Output Interface Circuit uses four

Tapped Delay Lines followed by a T1 Divider Circuit ,

an E1 Divider Circuit, a DS2 Divider Circuit and an

analog PLL to generate the required output signals.

Four tapped delay lines are used to generate a

16.384MHz, 12.352MHz, 12.624MHz and 19.44 MHz

signals.

The E1 Divider Circuit uses the 16.384MHz signal to

generate four clock outputs and three frame pulse

outputs. The C8o, C4o and C2o clocks are

generated by simply dividing the C16o clock by two,

four and eight respectively. These outputs have a

nominal 50% duty cycle.

The T1 Divider Circuit uses the 12.384MHz signal to

generate two clock outputs. C1.5o and C3o are

generated by dividing the internal C12 clock by four

and eight respectively. These outputs have a

nominal 50% duty cycle.

The DS2 Divider Circuit uses the 12.624 MHz signal

to generate the clock output C6o. This output has a

nominal 50% duty cycle.

C2o

C4o

C8o

C16o

F0o

F8o

F16o

C6o

C19o

ACKo

From

DPLL

ACKi

Tapped

Delay

Line

Tapped

Delay

Line

Tapped

Delay

Line

16MHz

12MHz

19MHz

E1 Divider

DS2 Divider

Analog PLL

Figure 5 - Output Interface Circuit Block

Diagram

The frame pulse outputs (F0o, F8o, F16o, TSP, RSP)

are generated directly from the C16 clock.

The T1 and E1 signals are generated from a

common DPLL signal. Consequently, the clock

outputs C1.5o, C3o, C2o, C4o, C8o, C16o, F0o, F16o

and C6o are locked to one another for all operating

states, and are also locked to the selected input

reference in Normal Mode. See Figures 20 and 21.

All frame pulse and clock outputs hav e limited driving

capability, and should be buffered when driving high

capacitance (e.g. 30pF) loads.

Analog Phase Lock Loop (APLL)

The analog PLL is intended to be used to achieve a

50% duty cycle output clock. Connecting C19o to

ACKi will generate a phase locked 19.44 MHz ACKo

output with a nominal 50% duty cycle. The analog

PLL has an intrinsic jitter of less than 0.01 U.I. In

order to achieve this low jitter level a separate pin is

provided to power (AVdd) the analog PLL.

7

Page 8

MT9044 Advance Information

Input Impairment Monitor

This circuit monitors the input signal to the DPLL and

automatically enables the Holdover Mode

(Auto-Holdover) when the frequency of the incoming

signal is outside the auto-holdover capture range

(See AC Electrical Characteristics - Performance).

This includes a complete loss of incoming signal, or

a large frequency shift in the incoming signal. When

the incoming signal returns to normal, the DPLL is

returned to Normal Mode with the output signal

locked to the input signal. The holdover output

signal is based on the incoming signal 30ms

minimum to 60ms prior to entering the Holdover

Mode. The amount of phase drift while in holdover is

negligible because the Holdover Mode is very

accurate (e.g. ±0.05ppm). The the Auto-Holdover

circuit does not use TIE correction. Consequently,

the phase delay between the input and output after

switching back to Normal Mode is preserved (is the

same as just prior to the switch to Auto-Holdover).

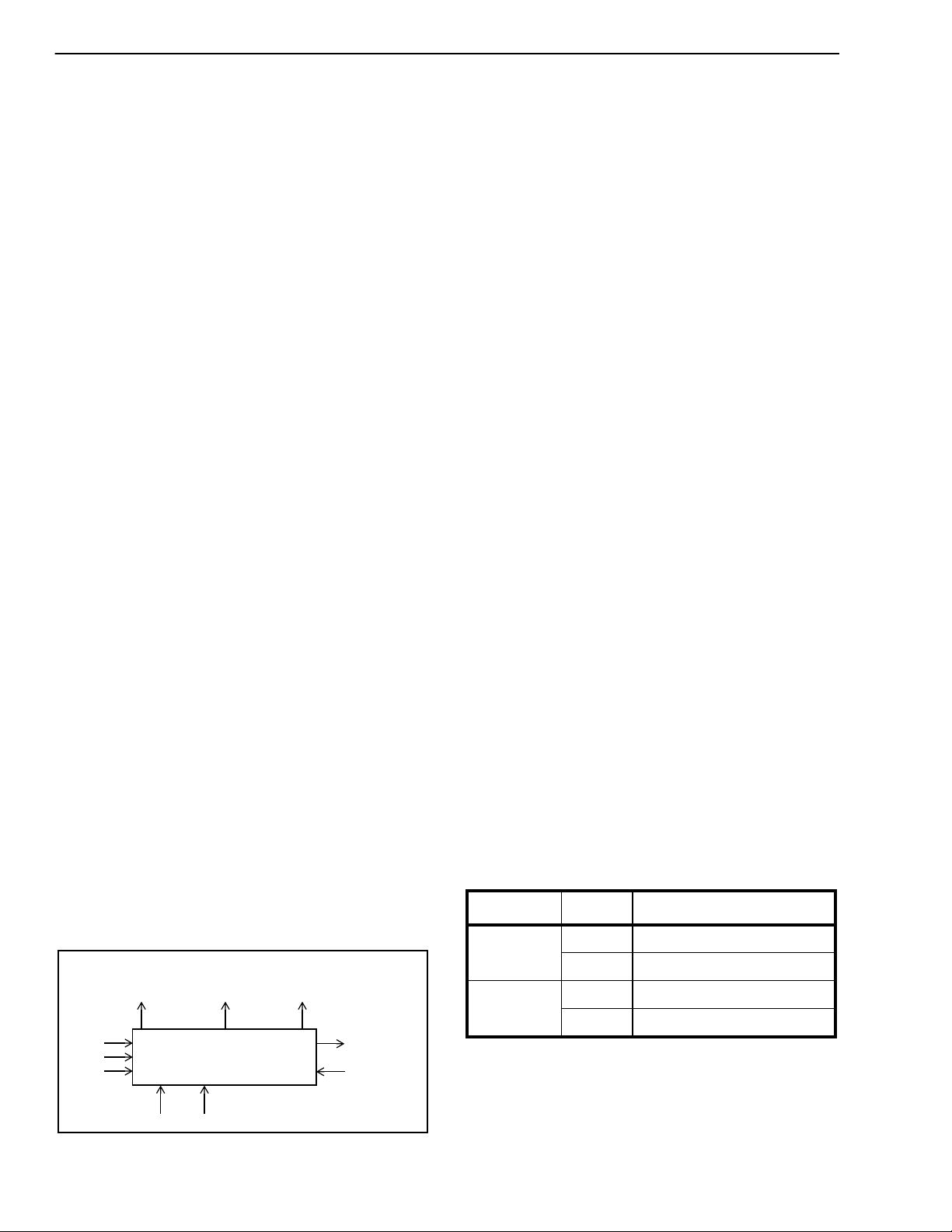

Automatic/Manual Control State Machine

Guard Time Circuit

The GTi pin is used by the Automatic/Manual Control

State Machine in the MT9044 under either Manual or

Automatic control. The logic level at the GTi pin

performs two functions, it enables and disables the

TIE Corrector Circuit (Manual and Automatic), and it

selects which mode change takes place (Automatic

only). See the Applications - Guard Time section.

For both Manual and Automatic control, when

switching from Primary Holdover to Primary Normal,

the TIE Corrector Circuit is enabled when GTi=1, and

disabled when GTi=0.

Under Automatic control and in Primary Normal

Mode, two state changes are possible (not counting

Auto-Holdover). These are state changes to Primary

Holdover or to Secondary Normal. The logic level at

the GTi pin determines which state change occurs.

When GTi=0, the state change is to Primary

Holdover. When GTi=1, the state change is to

Secondary Normal.

The Automatic/Manual Control State Machine allows

the MT9044 to be controlled automatically (i.e.

LOS1, LOS2 and GTi signals) or controlled manually

(i.e. MS1, MS2, GTi and RSEL signals). With

manual control a single mode of operation (i.e.

Normal, Holdover and Freerun) is selected. Under

automatic control the state of the LOS1, LOS2 and

GTi signals determines the sequence of modes that

the MT9044 will follow.

As shown in Figure 1, this state machine controls the

Reference Select MUX, the TIE Corrector Circuit, the

DPLL and the Guard Time Circuit. Control is based

on the logic levels at the control inputs LOS1, LOS2,

RSEL, MS1, MS2 and GTi of the Guard Time Circuit

(See Figure 6).

All state machine changes occur synchronously on

the rising edge of F8o. See the Controls and Modes

of Operation section for full details on Automatic

Control and Manual Control.

To

Reference

Select MUX

To TIE

Corrector

Enable

To DPLL

State

Select

Master Clock

The MT9044 can use either a clock or crystal as the

master timing source. For recommended master

timing circuits, see the Applications - Master Clock

section.

Control and Modes of Operation

The MT9044 can operate either in Manual or

Automatic Control. Each control method has three

possible modes of operation, Normal, Holdover and

Freerun.

As shown in Table 3, Mode/Control Select pins MS2

and MS1 select the mode and method of control.

Control RSEL Input Reference

MANUAL 0 PRI

1 SEC

AUTO 0 State Machine Control

RSEL

LOS1

LOS2

Automatic/Manual Control

State Machine

MS1

MS2

Figure 6 - Automatic/Manual Control State

Machine Block Diagram

8

To and From

Guard Time

Circuit

1 Reserved

Table 2 - Input Reference Selection

Page 9

Advance Information MT9044

Normal Mode

MS2 MS1 Control Mode

0 0 MANUAL NORMAL

0 1 MANUAL HOLDOVER

1 0 MANUAL FREERUN

1 1 AUTO State Machine Control

Table 3 - Operating Modes and States

Manual Control

Normal Mode is typically used when a slave clock

source, synchronized to the network is required.

In Normal Mode, the MT9044 provides timing (C1.5o,

C2o, C3o, C4o, C8o, C16o, and C19) and frame

synchronization (F0o, F8o, F16o, RSP, TSP) signals,

which are synchronized to one of two reference

inputs (PRI or SEC). The input reference signal may

have a nominal frequency of 8kHz, 1.544MHz or

2.048MHz.

Manual Control should be used when either very

simple MT9044 control is required, or when complex

control is required which is not accommodated by

Automatic Control. For example, very simple control

could include operation in a system which only

requires Normal Mode with reference switching

using only a single input stimulus (RSEL). Very

simple control would require no external circuitry.

Complex control could include a system which

requires state changes between Normal, Holdover

and Freerun Modes based on numerous input

stimuli. Complex control would require external

circuitry, typically a microcontroller.

Under Manual Control, one of the three modes is

selected by mode/control select pins MS2 and MS1.

The active reference input (PRI or SEC) is selected

by the RSEL pin as shown in Table 2. Refer to Table

4 and Figure 7 for details of the state change

sequences.

Automatic Control

Automatic Control should be used when simple

MT9044 control is required, which is more complex

than the very simple control provide by Manual

Control with no external circuitry, but not as complex

as Manual Control with a microcontroller. For

example, simple control could include operation in a

system which can be accommodated by the

Automatic Control State Diagram shown in Figure 8.

Automatic Control is also selected by mode/control

pins MS2 and MS1. However, the mode and active

reference source is selected automatically by the

internal Automatic State Machine (See Figure 6).

The mode and reference changes are based on the

logic levels on the LOS1, LOS2 and GTi control pins.

Refer to Table 5 and Figure 8 for details of the state

change sequences.

From a reset condition, the MT9044 will take up to 25

seconds for the output signal to be phase locked to

the selected reference.

The selection of input references is control

dependent as shown in State Tables 4 and 5. The

reference frequencies are selected by the frequency

control pins FS2 and FS1 as shown in Table 1.

Holdover Mode

Holdover Mode is typically used for short durations

(e.g. 2 seconds) while network synchronization is

temporarily disrupted.

In Holdover Mode, the MT9044 provides timing and

synchronization signals, which are not locked to an

external reference signal, but are based on storage

techniques. The storage value is determined while

the device is in Normal Mode and locked to an

external reference signal.

When in Normal Mode, and locked to the input

reference signal, a numerical value corresponding to

the MT9044 output frequency is stored alternately in

two memory locations every 30ms. When the device

is switched into Holdover Mode, the value in memory

from between 30ms and 60ms is used to set the

output frequency of the device.

The frequency accuracy of Holdover Mode is

±0.05ppm, which translates to a worst case 35 frame

(125us) slips in 24 hours. This meets the Bellcore

GR-1244-CORE Stratum 3 requirement of ±0.37ppm

(255 frame slips per 24 hours).

Two factors affect the accuracy of Holdover Mode.

One is drift on the Master Clock while in Holdover

Mode, drift on the Master Clock directly affects the

Holdover Mode accuracy. Note that the absolute

Master Clock (OSCi) accuracy does not affect

Holdover accuracy, only the change in OSCi

accuracy while in Holdover. For example, a ±32ppm

9

Page 10

MT9044 Advance Information

master clock may have a temperature coefficient of

±0.1ppm per degree C. So a 10 degree change in

temperature, while the MT9044 is in Holdover Mode

may result in an additional offset (over the

±0.05ppm) in frequency accuracy of ±1ppm, which

is much greater than the ±0.05ppm of the MT9044.

The other factor affecting accuracy is large jitter on

the reference input prior (30ms to 60ms) to the

mode switch. For instance, jitter of 7.5UI at 700Hz

may reduce the Holdover Mode accuracy from

0.05ppm to 0.10ppm.

Freerun Mode

Freerun Mode is typically used when a master clock

source is required, or immediately following system

power-up before network synchronization is

achieved.

In Freerun Mode, the MT9044 provides timing and

synchronization signals which are based on the

master clock frequency (OSCi) only, and are not

synchronized to the reference signals (PRI and

SEC).

The accuracy of the output clock is equal to the

accuracy of the master clock (OSCi). So if a ±32ppm

output clock is required, the master clock must also

be ±32ppm. See Applications - Crystal and Clock

Oscillator sections.

10

Page 11

Advance Information MT9044

Description State

Input Controls Freerun

Normal

(PRI)

Normal

(SEC)

Holdover

(PRI)

Holdover

(SEC)

MS2 MS1 RSEL GTi S0 S1 S2 S1H S2H

0 0 0 0 S1 - S1 MTIE S1 S1 MTIE

0 0 0 1 S1 - S1 MTIE S1 MTIE S1 MTIE

0 0 1 X S2 S2 MTIE - S2 MTIE S2 MTIE

0 1 0 X / S1H / - /

0 1 1 X / S2H S2H / 10 X X - S0 S0 S0 S0

Legend:

- No Change

/ Not Valid

MTIE State change occurs with TIE Corrector Circuit

Refer to Manual Control State Diagram for state changes to and from Auto-Holdover State

Table 4 - Manual Control State Table

S1

Normal

Primary

(000)

(GTi=0)

(GTi=1)

NOTES:

(XXX) MS2 MS1 RSEL

{A} Invalid Reference Signal

Movement to Normal State from any

state requires a valid input signal

{A} {A}

S1A

Auto-Holdover

Primary

(000)

S1H

Holdover

Primary

(010)

Phase Re-Alignment

Phase Continuity Maintained (without TIE Corrector Circuit)

Phase Continuity Maintained (with TIE Corrector Circuit)

S0

Freerun

(10X)

S2A

Auto-Holdover

Secondary

(001)

S2H

Holdover

Secondary

(011)

S2

Normal

Secondary

(001)

Figure 7 - Manual Control State Diagram

11

Page 12

MT9044 Advance Information

Description State

Input Controls Freerun

Normal

(PRI)

Normal

(SEC)

Holdover

(PRI)

Holdover

(SEC)

LOS2 LOS1 GTi RST S0 S1 S2 S1H S2H

1 1 X 0 to 1 - S0 S0 S0 S0

X 0 0 1 S1 - S1 MTIE S1 S1 MTIE

X 0 1 1 S1 - S1 MTIE S1 MTIE S1 MTIE

0 1 0 1 S1 S1H - - S2 MTIE

0 1 1 1 S2 S2 MTIE - S2 MTIE S2 MTIE

1 1 X 1 - S1H S2H - -

Legend:

- No Change

MTIE State change occurs with TIE Corrector Circuit

Refer to Automatic Control State Diagram for state changes to and from Auto-Holdover State

Table 5 - Automatic Control (MS1=MS2=1, RSEL=0) State Table

(11X) RST=1

Reset

(X0X)

(11X)

S0

Freerun

(01X)

(X0X)

S1

Normal

Primary

(X00)

(X01)

NOTES:

(XXX) LOS2 LOS1 GTi

{A} Invalid Reference Signal

Movement to Normal State from any

state requires a valid input signal

(X0X)

{A}

(010 or 11X)

(010 or 11X)

(X0X)

S1A

Auto-Holdover

Primary

S1H

Holdover

Primary

Phase Re-Alignment

Phase Continuity Maintained (without TIE Corrector Circuit)

Phase Continuity Maintained (with TIE Corrector Circuit)

(X0X)

(X0X)

(011)

(011)

(11X)

(01X)

S2A

Auto-Holdover

Secondary

S2H

Holdover

Secondary

(01X)

{A}

(01X)

S2

Normal

Secondary

(11X)

(01X)

12

Figure 8 - Automatic Control State Diagram

Page 13

Advance Information MT9044

MT9044 Measures of Performance

The following are some synchronizer performance

indicators and their corresponding definitions.

Intrinsic Jitter

Intrinsic jitter is the jitter produced by the

synchronizing circuit and is measured at its output.

It is measured by applying a reference signal with no

jitter to the input of the device, and measuring its

output jitter. Intrinsic jitter may also be measured

when the device is in a non-synchronizing mode,

such as free running or holdover, by measuring the

output jitter of the device. Intrinsic jitter is usually

measured with various bandlimiting filters depending

on the applicable standards.

Jitter Tolerance

Jitter tolerance is a measure of the ability of a PLL to

operate properly (i.e., remain in lock and or regain

lock in the presence of large jitter magnitudes at

various jitter frequencies) when jitter is applied to its

reference. The applied jitter magnitude and jitter

frequency depends on the applicable standards.

same signal, these transfer values apply to all

outputs.

It should be noted that 1UI at 1.544MHz is 644ns,

which is not equal to 1UI at 2.048MHz, which is

488ns. Consequently, a transfer value using

different input and output frequencies must be

calculated in common units (e.g. seconds) as shown

in the following example.

What is the T1 and E1 output jitter when the T1 input

jitter is 20UI (T1 UI Units) and the T1 to T1 jitter

attenuation is 18dB?

A–

------ -

OutputT1 InputT 1

OutputT 120

OutputE1 OutputT 1

OutputE1 OutputT 1

Using the above method, the jitter attenuation can be

calculated for all combinations of inputs and outputs

based on the three jitter transfer functions provided.

×10 2.5UI T 1()==

20

×10=

18–

-------- 20

1UIT1()

----------------------

×=

1UIE 1()

-------------------

644ns()

488ns()

3.3UI T1()=×=

Jitter Transfer

Jitter transfer or jitter attenuation refers to the

magnitude of jitter at the output of a device for a

given amount of jitter at the input of the device . Input

jitter is applied at various amplitudes and

frequencies, and output jitter is measured with

various filters depending on the applicable

standards.

For the MT9044, two internal elements determine

the jitter attenuation. This includes the internal

1.9Hz low pass loop filter and the phase slope

limiter. The phase slope limiter limits the output

phase slope to 5ns/125us. Therefore, if the input

signal exceeds this rate, such as for very large

amplitude low frequency input jitter, the maximum

output phase slope will be limited (i.e. attenuated) to

5ns/125us.

The MT9044 has thirteen outputs with three possible

input frequencies for a total of 39 possible jitter

transfer functions. However, the data sheet section

on AC Electrical Characteristics - Jitter Transfer

specifies transfer values for only three cases, 8kHz

to 8kHz, 1.544MHz to 1.544MHz and 2.048MHz to

2.048MHz. Since all outputs are derived from the

Note that the resulting jitter transfer functions for all

combinations of inputs (8kHz, 1.544MHz, 2.048MHz)

and outputs (8kHz, 1.544MHz, 2.048MHz,

4.096MHz, 8.192MHz, 16.384MHz) for a given input

signal (jitter frequency and jitter amplitude) are the

same.

Since intrinsic jitter is always present, jitter

attenuation will appear to be lower for small input

jitter signals than for large ones. Consequently,

accurate jitter transfer function measurements are

usually made with large input jitter signals (e.g. 75%

of the specified maximum jitter tolerance).

Frequency Accuracy

Frequency accuracy is defined as the absolute

tolerance of an output clock signal when it is not

locked to an external reference, but is operating in a

free running mode. For the MT9044, the Freerun

accuracy is equal to the Master Clock (OSCi)

accuracy.

Holdover Accuracy

Holdover accuracy is defined as the absolute

tolerance of an output clock signal, when it is not

13

Page 14

MT9044 Advance Information

locked to an external reference signal, but is

operating using storage techniques. For the

MT9044, the storage value is determined while the

device is in Normal Mode and locked to an external

reference signal.

The absolute Master Clock (OSCi) accuracy of the

MT9044 does not affect Holdover accuracy, but the

change in OSCi accuracy while in Holdover Mode

does.

Capture Range

Also referred to as pull-in range. This is the input

frequency range over which the synchronizer must

be able to pull into synchronization. The MT9044

capture range is equal to ±230ppm minus the

accuracy of the master clock (OSCi). For example, a

±32ppm master clock results in a capture range of

±198ppm.

Lock Range

This is the input frequency range over which the

synchronizer must be able to maintain

synchronization. The lock range is equal to the

capture range for the MT9044.

end of a particular obser vation period. Usually, the

given timing signal and the ideal timing signal are of

the same frequency. Phase continuity applies to the

output of the synchronizer after a signal disturbance

due to a reference switch or a mode change. The

observation period is usually the time from the

disturbance, to just after the synchronizer has settled

to a steady state.

In the case of the MT9044, the output signal phase

continuity is maintained to within ±5ns at the

instance (over one frame) of all reference switches

and all mode changes. The total phase shift,

depending on the switch or type of mode change,

may accumulate up to ±200ns over many frames.

The rate of change of the ±200ns phase shift is

limited to a maximum phase slope of approximately

5ns/125us. This meets the maximum phase slope

requirement of Bellcore GR-1244-CORE (81ns/

1.326ms).

Phase Lock Time

This is the time it takes the synchronizer to phase

lock to the input signal. Phase lock occurs when the

input signal and output signal are not changing in

phase with respect to each other (not including jitter).

Phase Slope

Phase slope is measured in seconds per second and

is the rate at which a given signal changes phase

with respect to an ideal signal. The given signal is

typically the output signal. The ideal signal is of

constant frequency and is nominally equal to the

value of the final output signal or final input signal.

Time Interval Error (TIE)

TIE is the time delay between a given timing signal

and an ideal timing signal.

Maximum Time Interval Error (MTIE)

MTIE is the maximum peak to peak delay between a

given timing signal and an ideal timing signal within a

particular obser vation period.

MTIE S() TIEmax t() TIEmin t()–=

Lock time is very difficult to determine because it is

affected by many factors which include:

i) initial input to output phase difference

ii) initial input to output frequency difference

iii) synchronizer loop filter

iv) synchronizer limiter

Although a short lock time is desirable, it is not

always possible to achieve due to other synchronizer

requirements. For instance, better jitter transfer

performance is achieved with a lower frequency loop

filter which increases lock time. And better (smaller)

phase slope performance (limiter) results in longer

lock times. The MT9044 loop filter and limiter were

optimized to meet the AT&T TR62411 jitter transfer

and phase slope requirements. Consequently,

phase lock time, which is not a standards

requirement, may be longer than in other

applications. See AC Electrical Characteristics Performance for maximum phase lock time.

Phase Continuity

Phase continuity is the phase difference between a

given timing signal and an ideal timing signal at the

14

Page 15

Advance Information MT9044

MT9044 and Network Specifications

The MT9044 fully meets all applicable PLL

requirements (intrinsic jitter/wander, jitter/wander

tolerance, jitter/wander transfer, frequency accuracy,

frequency holdover accuracy, capture range, phase

change slope and MTIE during reference

rearrangement) for the following specifications.

1. Bellcore GR-1244-CORE June 1995 for

Stratum 3, Stratum 4 Enhanced and Stratum 4

2. AT&T TR62411 (DS1) December 1990 for

Stratum 3, Stratum 4 Enhanced and Stratum 4

3. ANSI T1.101 (DS1) February 1994 for

Stratum 3, Stratum 4 Enhanced and Stratum 4

4. ETSI 300 011 (E1) April 1992 for

Single Access and Multi Access

5. TBR 4 November 1995

6. TBR 12 December 1993

7. TBR 13 January 1996

8. ITU-T I.431 March 1993

9. ITU-T G.812 June 1998 for type IV clocks for

1,544 kbit/s interfaces and 2,048 kbit/s interfaces

Applications

This section contains MT9044 application specific

details for clock and crystal operation, guard time

usage, reset operation, power supply decoupling,

Manual Control operation and Automatic Control

operation.

Master Clock

The MT9044 can use either a clock or crystal as the

master timing source.

In Freerun Mode, the frequency tolerance at the

clock outputs is identical to the frequency tolerance

of the source at the OSCi pin. For applications not

requiring an accurate Freerun Mode, tolerance of the

master timing source may be ±100ppm. For

applications requiring an accurate Freerun Mode,

such as Bellcore GR-1244-CORE, the tolerance of

the master timing source must Be no greater than

±32ppm.

Another consideration in determining the accuracy of

the master timing source is the desired capture

range. The sum of the accuracy of the master timing

source and the capture range of the MT9044 will

always equal ±230ppm. For example, if the master

timing source is ±100ppm, then the capture range

will be ±130ppm.

Clock Oscillator - when selecting a Clock Oscillator,

numerous parameters must be considered. This

includes absolute frequency, frequency change over

temperature, output rise and fall times, output levels

and duty cycle. See AC Electrical Characteristics.

MT9044

OSCi

OSCo

No Connection

+5V

+5V

20MHz OUT

GND 0.1uF

Figure 9 - Clock Oscillator Circuit

For applications requiring ±32ppm clock accuracy,

the following clock oscillator module may be used.

CTS CXO-65-HG-5-C-20.0MHz

Frequency: 20MHz

Tolerance: 25ppm 0C to 70C

15

Page 16

MT9044 Advance Information

Rise & Fall Time: 8ns (0.5V 4.5V 50pF)

Duty Cycle: 45% to 55%

The output clock should be connected directly (not

AC coupled) to the OSCi input of the MT9044, and

the OSCo output should be left open as shown in

Figure 9.

Crystal Oscillator - Alternatively, a Crystal

Oscillator may be used. A complete oscillator circuit

made up of a crystal, resistor and capacitors is

shown in Figure 10.

MT9044

OSCi

56pF

20MHz

100Ω

39pF

3-50pF

1uH

1MΩ

OSCo

1uH inductor: may improve stability and is optional

Figure 10 - Crystal Oscillator Circuit

e.g., CTS R1027-2BB-20.0MHZ

(±20ppm absolute,±6ppm 0C to 50C, 32pF, 25Ω)

Guard Time Adjustment

Excessive switching of the timing reference (from

PRI to SEC) in the MT9044 can be minimized by first

entering Holdover Mode for a predetermined

maximum time (i.e., guard time). If the degraded

signal returns to normal before the expiry of the

guard time (e.g. 2.5 seconds), then the MT9044 is

returned to its Normal Mode (with no reference

switch taking place). Otherwise, the reference input

may be changed from Primary to Secondary.

MT9044

GTo

R

150kΩ

GTi

R

1kΩ

+

C

10uF

P

The accuracy of a crystal oscillator depends on the

crystal tolerance as well as the load capacitance

tolerance. Typically, for a 20MHz crystal specified

with a 32pF load capacitance, each 1pF change in

load capacitance contributes approximately 9ppm to

the frequency deviation. Consequently, capacitor

tolerances, and stray capacitances have a major

effect on the accuracy of the oscillator frequency.

The trimmer capacitor shown in Figure 10 may be

used to compensate for capacitive effects. If

accuracy is not a concern, then the trimmer may be

removed, the 39pF capacitor may be increased to

56pF, and a wider tolerance crystal may be

substituted.

The crystal should be a fundamental mode type - not

an overtone. The fundamental mode crystal permits

a simpler oscillator circuit with no additional filter

components and is less likely to generate spurious

responses. The crystal specification is as follows.

Frequency: 20MHz

Tolerance: As required

Oscillation Mode: Fundamental

Resonance Mode: Parallel

Load Capacitance: 32pF

Maximum Series Resistance: 35

Approximate Drive Level: 1mW

Ω

Figure 11 - Symmetrical Guard Time Circuit

A simple way to control the guard time (using

Automatic Control) is with an RC circuit as shown in

Figure 11. Resistor RP is for protection only and

limits the current flowing into the GTi pin during

power down conditions. The guard time can be

calculated as follows.

V

DD

guard

guard

time

time

RC

RC 0.6×≈

--------------------------------- -

ln×=

V

–

DDVSIH

example

guard

•V

is the logic high going threshold level for the

SIH

GTi Schmitt Trigger input, see DC Electr ical

Characteristics

time

150k 10u× 0.6 0.9s=×≈

In cases where fast toggling might be expected of

the LOS1 input, then an unsymmetrical Guard Time

Circuit is recommended. This ensures that reference

switching doesn’t occur until the full guard time value

has expired. An unsymmetrical Guard Time Circuit

is shown in Figure 12.

16

Page 17

Advance Information MT9044

MT9044

GTo

+

C

10uF

GTi

R

C

150kΩ

R

D

1kΩ

R

1kΩ

P

Figure 12 - Unsymmetrical Guard Time

Circuit

Figure 13 shows a typical timing example of an

unsymmetrical Guard Time Circuit with the MT9044

in Automatic Control.

TIE Correction (using GTi)

When Primary Holdover Mode is entered for short

time periods, TIE correction should not be enabled.

This will prevent unwanted accumulated phase

change between the input and output. This is mainly

applicable to Manual Control, since Automatic

Control together with the Guard Time Circuit

inherently operate in this manner.

For instance, 10 Normal to Holdover to Normal mode

change sequences occur, and in each case Holdover

was entered for 2s. Each mode change sequence

could account for a phase change as large as 350ns.

Thus, the accumulated phase change could be as

large as 3.5us, and, the overall MTIE could be as

large as 3.5us.

Phase

hold

Phase

state

Phase

10

• 0.05ppm is the accuracy of Holdover Mode

• 50ns is the maximum phase continuity of the

MT9044 from Normal Mode to Holdover Mode

• 200ns is the maximum phase continuity of the

MT9044 from Holdover Mode to Normal Mode (with

or without TIE Corrector Circuit)

0.05ppm 2s× 100ns==

50ns 200ns 250ns=+=

10 250ns 100ns+()× 3.5us==

When 10 Normal to Holdover to Normal mode

change sequences occur without MTIE enabled, and

in each case holdover was entered for 2s, each

mode change sequence could still account for a

phase change as large as 350ns. However, there

would be no accumulated phase change, since the

input to output phase is re-aligned after every

Holdover to Normal state change. The overall MTIE

would only be 350ns.

SEC

SIGNAL

STATUS

LOS2

PRI

SIGNAL

STATUS

LOS1

GTo

GTi

MT9044

STATE

NOTES:

1. TD represents the time delay from when the reference goes

bad to when the MT9044 is provided with a LOS indication.

GOOD

V

SIH

PRI

NORMAL

BAD

T

D

PRI

HOLDOVER

GOOD

NORMAL

GOOD

PRI

Figure 13 - Automatic Control, Unsymmetrical Guard Time Circuit Timing Example

T

D

PRI

HOLDOVER

BAD

SEC

NORMAL

GOOD

PRI

NORMAL

17

Page 18

MT9044 Advance Information

Reset Circuit

A simple power up reset circuit with about a 50us

reset low time is shown in Figure 14. Resistor RP is

for protection only and limits current into the RST pin

during power down conditions. The reset low time is

not critical but should be greater than 300ns.

MT9044

+5V

R

10kΩ

RST

R

P

1kΩ

C

10nF

Figure 14 - Power-Up Reset Circuit

To Line 1

To

TX Line

XFMR

To

RX Line

XFMR

To Line 2

To

TX Line

XFMR

To

RX Line

XFMR

MT9074

TTIP

TRING

RTIP

RRING

MT9074

TTIP

TRING

RTIP

RRING

DSTo

DSTi

F0i

C4i

E1.5o

LOS

DSTo

DSTi

F0i

C4i

E1.5o

LOS

Dual T1 Reference Sources with MT9044 in

Automatic Control

For systems requiring simple state machine control,

the application circuit shown in Figure 15 using

Automatic Control may be used.

In this circuit, the MT9044 is operating Automatically,

using a Guard Time Circuit, and the LOS1 and LOS2

inputs to determine all mode changes. Since the

Guard Time Circuit is set to about 1s, all line

interruptions (LOS1=1) less than 1s will cause the

MT9044 to go from Primary Normal Mode to

Holdover Mode and not switch references. For line

interruptions greater than 1s, the MT9044 will switch

Modes from Holdover to Secondary Normal,

provided that the secondary signal is valid (LOS2=0).

After receiving a good primary signal (LOS1=0), the

MT9044 will switch back to Primary Normal Mode

For complete Automatic Control state machine

details, refer to Table 5 for the State Table, and

Figure 8 for the State Diagram.

MT9044

F0o

C4o

FS1

FS2

GTo

GTi

OSCi

+ 5V

+ 5V

150kΩ

1kΩ

1kΩ

+

10uF

CLOCK

Out

20MHz ±32ppm

+ 5V

1kΩ

PRI

SEC

LOS1

LOS2

MS1

MS2

RSEL

TRST

RST

10kΩ

10nF

18

MT8985

STo0

STi0

STo1

STi1

F0i

C4i

Figure 15 - Dual T1 Reference Sources with MT9044 in 1.544MHz Automatic Control

Page 19

Advance Information MT9044

To Line 1

To

TX Line

XFMR

To

RX Line

XFMR

To Line 2

To

TX Line

XFMR

To

RX Line

XFMR

MT9075

TTIP

TRING

RTIP

RRING

MT9075

TTIP

TRING

RTIP

RRING

DSTo

DSTi

F0i

C4i

RxFP

LOS

DSTo

DSTi

F0i

C4i

RxFP

LOS

MT9044

PRI

SEC

LOS1

LOS2

MS1

MS2

RSEL

TRST

RST

F0o

C4o

C1.5o

FS1

FS2

GTi

OSCi

+ 5V

CLOCK

Out

20MHz ±32ppm

External Stimulus

MT8985

STo0

STi0

STo1

STi1

F0i

C4i

Figure 16 - Dual E1 Reference Sources with MT9044 in 8kHz Manual Control

Dual E1 Reference Sources with MT9044 in

Manual Control

For systems requiring complex state machine

control, the application circuit shown in Figure 16

using Manual Control may be used.

In this circuit, the MT9044 is operating Manually

and is using a controller for all mode changes. The

controller sets the MT9044 modes (Normal, Holdover

or Freerun) by controlling the MT9044 mode/control

select pins (MS2 and MS1). The input (Primary or

Secondary) is selected with the reference select pin

(RSEL). TIE correction from Primary Holdover Mode

to Primary Normal Mode is enabled and disabled

with the guard time input pin (GTi). The input to

output phase alignment is re-aligned with the TIE

CONTROLLER

circuit reset pin (TCLR), and a complete device reset

is done with the RST pin.

The controller uses two stimulus inputs (LOS)

directly from the MT9075 E1 interfaces, as well as an

external stimulus input. The external input may

come from a device that monitors the status registers

of the E1 interfaces, and outputs a logic one in the

event of an unacceptable status condition.

For complete Manual Control state machine details,

refer to Table 4 for the State Table, and Figure 7 for

the State Diagram.

19

Page 20

MT9044 Advance Information

To E1 Line

To

TX Line

XFMR

To

RX Line

XFMR

To OC3 Line

To

TX Line

XFMR

To

RX Line

XFMR

MT9075

TTIP

TRING

RTIP

RRING

MT90840

PDo0-7

PPFTo

PDi0-7

PCKR

PPFRi

DSTo

DSTi

F0i

C4i

RxFP

LOS

STo0-7

STi0-7

F0i

C4b

PCKT

1kΩ

10kΩ

10nF

MT9044

PRI

LOS1

LOS2

MS1

MS2

RSEL

TCLR

RST

+ 5V

F0o

C4o

C1.5o

FS1

FS2

OSCi

C19o

ACKi

ACKo

GTi

+ 5V

CLOCK

Out

20MHz ±32ppm

MT90820

STo0

STi0

STo1-8

STi1-8

F0i

C4i

Figure 17 - Single Source - E1 to STS-3 with 8kHz Reference

Single Reference Source E1 to STS-3 with 8 kHz

Reference

The device may operate in freerun mode or with a

single reference source. The 8 kHz output from the

MT9075 is sourced from the clock extracted from the

E1 trunk. It becomes the reference for the PLL which

then generates ST-BUS signals F0o, C4o and C2o to

form the system backplane clock. The MT90840

connects to the system backplane, as well as to an

OC3 link via an STS-3 Framer and optical link. The

19.44 Mhz clock required by the MT90840 is

generated by the MT9044. In the event that the E1

link is broken, the LOS output of the MT9075 goes

high placing the MT9044 in freerun mode.

20

Page 21

Advance Information MT9044

Absolute Maximum Ratings* - Voltages are with respect to ground (V

) unless otherwise stated.

SS

Parameter Symbol Min Max Units

1 Supply voltage V

2 Voltage on any pin V

3 Current on any pin I

4 Storage temperature T

5 PLCC package power dissipation P

6 MQFP package power dissipation P

* Exceeding these values may cause permanent damage. Functional operation under these conditions is not implied.

DD

PIN

PIN

ST

PD

PD

Recommended Operating Conditions* - * Voltages are with respect to ground (V

-0.3 7.0 V

-0.3 VDD+0.3 V

20 mA

-55 125 °C

900 mW

900 mW

) unless otherwise stated.

SS

Characteristics Sym Min Max Units

1 Supply voltage V

2 Operating temperature T

DD

A

DC Electrical Characteristics* - * Voltages are with respect to ground (V

4.5 5.5 V

-40 85 C

) unless otherwise stated.

SS

Characteristics Sym Min Max Units Conditions/Notes

1 Supply current with: OSCi = 0V I

2 OSCi = Clock I

3 TTL high-level input voltage V

4 TTL low-level input voltage V

5 CMOS high-level input voltage V

6 CMOS low-level input voltage V

7 Schmitt high-level input voltage V

8 Schmitt low-level input voltage V

9 Schmitt hysteresis voltage V

10 Input leakage current I

11 High-level output voltage V

12 Low-level output voltage V

* Supply voltage and operating temperature are as per Recommended Operating Conditions.

DDS

DD

IH

IL

CIH

CIL

SIH

SIL

HYS

IL

OH

OL

2.0 V

0.7V

DD

2.3 V GTi, RST

0.4 V GTi, RST

-10 +10 uAVI=VDD or 0V

0.8V

DD

10 mA Outputs unloaded

90 mA Outputs unloaded

0.8 V

0.3V

DD

0.8 V GTi, RST

0.2V

DD

V OSCi

V OSCi

VIOH=4mA

VIOL=4mA

21

Page 22

MT9044 Advance Information

AC Electrical Characteristics - Performance

Characteristics Sym Min Max Units Conditions/Notes†

1 Freerun Mode accuracy with OSCi at: ±±0ppm -0 +0 ppm 5-8

2 ±32ppm -32 +32 ppm 5-8

3 ±100ppm -100 +100 ppm 5-8

4 Holdover Mode accuracy with OSCi at: ±0ppm -0.05 +0.05 ppm 1,2,4,6-8,40

5 ±32ppm -0.05 +0.05 ppm 1,2,4,6-8,40

6 ±100ppm -0.05 +0.05 ppm 1,2,4,6-8,40

7 Capture range with OSCi at: ±0ppm -230 +230 ppm 1-3,6-8

8 ±32ppm -198 +198 ppm 1-3,6-8

9 ±100ppm -130 +130 ppm 1-3,6-8

10 Phase lock time 30 s 1-3,6-14

11 Output phase continuity with: reference switch 200 ns 1-3,6-14

12 mode switch to Normal 200 ns 1-2,4-14

13 mode switch to Freerun 200 ns 1-,4,6-14

14 mode switch to Holdover 50 ns 1-3,6-14

15 MTIE (maximum time interval error) 600 ns 1-14,27

16 Output phase slope 45 us/s 1-14,27

17 Reference input for Auto-Holdover with: 8kHz -18k +18k ppm 1-3,6,9-11

18 1.544MHz -36k +36k ppm 1-3,7,9-11

19 2.048MHz -36k +36k ppm 1-3,8-11

† See "Notes" following AC Electrical Characteristics tables.

AC Electrical Characteristics - Timing P arameter Measurement Voltage Levels* - Voltages are

with respect to ground (VSS) unless otherwise stated.

Characteristics Sym Schmitt TTL CMOS Units

1 Threshold Voltage V

2 Rise and Fall Threshold Voltage High V

3 Rise and Fall Threshold Voltage Low V

* Supply voltage and operating temperature are as per Recommended Operating Conditions.

* Timing for input and output signals is based on the worst case result of the combination of TTL and CMOS thresholds.

* See Figure 18.

T

HM

LM

1.5 1.5 0.5V

2.3 2.0 0.7V

0.8 0.8 0.3V

DD

DD

DD

V

V

V

ALL SIGNALS

22

Timing Reference Points

t

IRF, tORF

t

IRF, tORF

Figure 18 - Timing Parameter Measurement Voltage Levels

V

HM

V

T

V

LM

Page 23

Advance Information MT9044

AC Electrical Characteristics - Input/Output Timing

Characteristics Sym Min Max Units

1 Reference input pulse width high or low t

2 Reference input rise or fall time t

3 8kHz reference input to F8o delay t

4 1.544MHz reference input to F8o delay t

5 2.048MHz reference input to F8o delay t

6 F8o to F0o delay t

7 F16o setup to C16o falling t

8 F16o hold from C16o rising t

9 F8o to C1.5o delay t

10 F8o to C6o delay t

11 F8o to C3o delay t

12 F8o to C2o delay t

13 F8o to C4o delay t

14 F8o to C8o delay t

15 F8o to C16o delay t

16 F8o to TSP delay t

17 F8o to RSP delay t

18 F8o to C19o delay t

19 C1.5o pulse width high or low t

20 C3o pulse width high or low t

21 C6o pulse width high or low t

22 C2o pulse width high or low t

23 C4o pulse width high or low t

24 C8o pulse width high or low t

25 C16o pulse width high or low t

26 TSP pulse width high t

27 RSP pulse width high t

28 C19o pulse width high or low t

29 F0o pulse width low t

30 F8o pulse width high t

31 F16o pulse width low t

32 Output clock and frame pulse rise or fall time t

33 Input Controls Setup Time t

34 Input Controls Hold Time t

† See "Notes" following AC Electrical Characteristics tables.

RW

IRF

R8D

R15D

R2D

F0D

F16S

F16H

C15D

C6D

C3D

C2D

C4D

C8D

C16D

TSPD

RSPD

C19D

C15W

C3W

C6W

C2W

C4W

C8W

C16WL

TSPW

RSPW

C19W

F0WL

F8WH

F16WL

ORF

S

H

100 ns

10 ns

-21 6 ns

337 363 ns

222 238 ns

110 134 ns

11 35 ns

020ns

-51 -37 ns

-3 11 ns

-51 -37 ns

-13 2 ns

-13 2 ns

-13 2 ns

-13 2 ns

-10 10 ns

-10 10 ns

052ns

309 339 ns

149 175 ns

72 86 ns

230 258 ns

111 133 ns

52 70 ns

24 35 ns

478 494 ns

474 491 ns

16 36 ns

230 258 ns

111 133 ns

52 70 ns

9ns

100 ns

100 ns

23

Page 24

MT9044 Advance Information

t

PRI/SEC

8kHz

PRI/SEC

1.544MHz

PRI/SEC

2.048MHz

t

R15D

t

R2D

t

t

t

RW

RW

RW

R8D

V

T

V

T

V

T

NOTES:

F8o

1. Input to output delay values

are valid after a TRST or RST

with no further state changes

F8o

F0o

F16o

C16o

C8o

C4o

Figure 19 - Input to Output Timing (Normal Mode)

t

F0WL

t

F16WL

t

t

C16WL

t

C8W

t

C4W

t

C8W

t

C4W

F16S

t

t

t

C16D

C8D

C4D

t

F8WH

t

F0D

t

F16H

V

T

V

T

V

T

V

T

V

T

V

T

V

T

24

C2o

C6o

C3o

C1.5o

C19o

t

C19W

t

C2W

t

C6W

t

C3W

t

C6W

t

C19W

t

C15W

Figure 20 - Output Timing 1

t

C3W

t

C2D

t

C6D

t

C3D

t

C15D

t

C19D

V

T

V

T

V

T

V

T

V

T

Page 25

Advance Information MT9044

F8o

C2o

RSP

TSP

F8o

MS1,2

LOS1,2

RSEL, GTi

t

TSPW

Figure - 21 Output Timing 2

t

S

t

H

t

RSPD

t

TSPD

t

RSPW

V

T

V

T

V

T

V

T

V

T

V

T

Figure 22 - Input Controls Setup and Hold Timing

AC Electrical Characteristics - Intrinsic Jitter Unfiltered

Characteristics Sym Min Max Units Conditions/Notes†

1 Intrinsic jitter at F8o (8kHz) 0.0002 UIpp 1-14,21-24,28

2 Intrinsic jitter at F0o (8kHz) 0.0002 UIpp 1-14,21-24,28

3 Intrinsic jitter at F16o (8kHz) 0.0002 UIpp 1-14,21-24,28

4 Intrinsic jitter at C1.5o (1.544MHz) 0.030 UIpp 1-14,21-24,29

5 Intrinsic jitter at C2o (2.048MHz) 0.040 UIpp 1-14,21-24,30

6 Intrinsic jitter at C3o (3.088MHz) 0.060 UIpp 1-14,21-24,31

7 Intrinsic jitter at C6o (6.312MHz) 0.120 UIpp 1-14,21-24,31

8 Intrinsic jitter at C4o (4.096MHz) 0.080 UIpp 1-14,21-24,32

9 Intrinsic jitter at C8o (8.192MHz) 0.160 UIpp 1-14,21-24,33

10 Intrinsic jitter at C16o (16.384MHz) 0.320 UIpp 1-14,21-24,34

11 Intrinsic jitter at TSP (8kHz) 0.0002 UIpp 1-14,21-24,28

12 Intrinsic jitter at RSP (8kHz) 0.0002 UIpp 1-14,21-24,28

13 Intrinsic jitter at C19o (19.44MHz) 0.10 UIpp 1-14,21-24,41

† See "Notes" following AC Electrical Characteristics tables.

25

Page 26

MT9044 Advance Information

AC Electrical Characteristics - C1.5o (1.544MHz) Intrinsic Jitter Filtered

Characteristics Sym Min Max Units Conditions/Notes†

1 Intrinsic jitter (4Hz to 100kHz filter) 0.015 UIpp 1-14,21-24,29

2 Intrinsic jitter (10Hz to 40kHz filter) 0.010 UIpp 1-14,21-24,29

3 Intrinsic jitter (8kHz to 40kHz filter) 0.010 UIpp 1-14,21-24,29

4 Intrinsic jitter (10Hz to 8kHz filter) 0.005 UIpp 1-14,21-24,29

† See "Notes" following AC Electrical Characteristics tables.

AC Electrical Characteristics - C2o (2.048MHz) Intrinsic Jitter Filtered

Characteristics Sym Min Max Units Conditions/Notes†

1 Intrinsic jitter (4Hz to 100kHz filter) 0.015 UIpp 1-14,21-24,30

2 Intrinsic jitter (10Hz to 40kHz filter) 0.010 UIpp 1-14,21-24,30

3 Intrinsic jitter (8kHz to 40kHz filter) 0.010 UIpp 1-14,21-24,30

4 Intrinsic jitter (10Hz to 8kHz filter) 0.005 UIpp 1-14,21-24,30

† See "Notes" following AC Electrical Characteristics tables

AC Electrical Characteristics - 8kHz Input to 8kHz Output Jitter Transfer

Characteristics Sym Min Max Units Conditions/Notes†

1 Jitter attenuation for 1Hz@0.01UIpp input 0 6 dB 1-3,6,9-14,21-22,24,28,35

2 Jitter attenuation for 1Hz@0.54UIpp input 6 16 dB 1-3,6,9-14,21-22,24,28,35

3 Jitter attenuation for 10Hz@0.10UIpp input 12 22 dB 1-3,6,9-14,21-22,24,28,35

4 Jitter attenuation for 60Hz@0.10UIpp input 28 38 dB 1-3,6,9-14,21-22,24,28,35

5 Jitter attenuation for 300Hz@0.10UIpp input 42 dB 1-3,6,9-14,21-22,24,28,35

6 Jitter attenuation for 3600Hz@0.005UIpp input 45 dB 1-3,6,9-14,21-22,24,28,35

† See "Notes" following AC Electrical Characteristics tables.

AC Electrical Characteristics - 1.544MHz Input to 1.544MHz Output Jitter Transfer

Characteristics Sym Min Max Units Conditions/Notes†

1 Jitter attenuation for 1Hz@20UIpp input 0 6 dB 1-3,7,9-14,21-22,24,29,35

2 Jitter attenuation for 1Hz@104UIpp input 6 16 dB 1-3,7,9-14,21-22,24,29,35

3 Jitter attenuation for 10Hz@20UIpp input 12 22 dB 1-3,7,9-14,21-22,24,29,35

4 Jitter attenuation for 60Hz@20UIpp input 28 38 dB 1-3,7,9-14,21-22,24,29,35

5 Jitter attenuation for 300Hz@20UIpp input 42 dB 1-3,7,9-14,21-22,24,29,35

6 Jitter attenuation for 10kHz@0.3UIpp input 45 dB 1-3,7,9-14,21-22,24,29,35

7 Jitter attenuation for 100kHz@0.3UIpp input 45 dB 1-3,7,9-14,21-22,24,29,35

† See "Notes" following AC Electrical Characteristics tables.

26

Page 27

Advance Information MT9044

AC Electrical Characteristics - 2.048MHz Input to 2.048 MHz Output Jitter Transfer

Characteristics Sym Min Max Units Conditions/Notes†

1 Jitter at output for 1Hz@3.00UIpp input 2.9 UIpp 1-3,8,9-14,21-22,24,30,35

2 with 40Hz to 100kHz filter 0.09 UIpp 1-3,8,9-14,21-22,24,30,36

3 Jitter at output for 3Hz@2.33UIpp input 1.3 UIpp 1-3,8,9-14,21-22,24,30,35

4 with 40Hz to 100kHz filter 0.10 UIpp 1-3,8,9-14,21-22,24,30,36

5 Jitter at output for 5Hz@2.07UIpp input 0.80 UIpp 1-3,8,9-14,21-22,24,30,35

6 with 40Hz to 100kHz filter 0.10 UIpp 1-3,8,9-14,21-22,24,30,36

7 Jitter at output for 10Hz@1.76UIpp input 0.40 UIpp 1-3,8,9-14,21-22,24,30,35

8 with 40Hz to 100kHz filter 0.10 UIpp 1-3,8,9-14,21-22,24,30,36

9 Jitter at output for 100Hz@1.50UIpp input 0.06 UIpp 1-3,8,9-14,21-22,24,30,35

10 with 40Hz to 100kHz filter 0.05 UIpp 1-3,8,9-14,21-22,24,30,36

11 Jitter at output for 2400Hz@1.50UIpp input 0.04 UIpp 1-3,8,9-14,21-22,24,30,35

12 with 40Hz to 100kHz filter 0.03 UIpp 1-3,8,9-14,21-22,24,30,36

13 Jitter at output for 100kHz@0.20UIpp input 0.04 UIpp 1-3,8,9-14,21-22,24,30,35

14 with 40Hz to 100kHz filter 0.02 UIpp 1-3,8,9-14,21-22,24,30,36

† See "Notes" following AC Electrical Characteristics tables.

AC Electrical Characteristics - 8kHz Input Jitter Tolerance

Characteristics Sym Min Max Units Conditions/Notes†

1 Jitter tolerance for 1Hz input 0.80 UIpp 1-3,6,9-14,21-22,24-26,28

2 Jitter tolerance for 5Hz input 0.70 UIpp 1-3,6,9-14,21-22,24-26,28

3 Jitter tolerance for 20Hz input 0.60 UIpp 1-3,6,9-14,21-22,24-26,28

4 Jitter tolerance for 300Hz input 0.20 UIpp 1-3,6,9-14,21-22,24-26,28

5 Jitter tolerance for 400Hz input 0.15 UIpp 1-3,6,9-14,21-22,24-26,28

6 Jitter tolerance for 700Hz input 0.08 UIpp 1-3,6,9-14,21-22,24-26,28

7 Jitter tolerance for 2400Hz input 0.02 UIpp 1-3,6,9-14,21-22,24-26,28

8 Jitter tolerance for 3600Hz input 0.01 UIpp 1-3,6,9-14,21-22,24-26,28

† See "Notes" following AC Electrical Characteristics tables.

27

Page 28

MT9044 Advance Information

AC Electrical Characteristics - 1.544MHz Input Jitter Tolerance

Characteristics Sym Min Max Units Conditions/Notes†

1 Jitter tolerance for 1Hz input 150 UIpp 1-3,7,9-14,21-22,24-26,29

2 Jitter tolerance for 5Hz input 140 UIpp 1-3,7,9-14,21-22,24-26,29

3 Jitter tolerance for 20Hz input 130 UIpp 1-3,7,9-14,21-22,24-26,29

4 Jitter tolerance for 300Hz input 35 UIpp 1-3,7,9-14,21-22,24-26,29

5 Jitter tolerance for 400Hz input 25 UIpp 1-3,7,9-14,21-22,24-26,29

6 Jitter tolerance for 700Hz input 15 UIpp 1-3,7,9-14,21-22,24-26,29

7 Jitter tolerance for 2400Hz input 4 UIpp 1-3,7,9-14,21-22,24-26,29

8 Jitter tolerance for 10kHz input 1 UIpp 1-3,7,9-14,21-22,24-26,29

9 Jitter tolerance for 100kHz input 0.5 UIpp 1-3,7,9-14,21-22,24-26,29

† See "Notes" following AC Electrical Characteristics tables.

AC Electrical Characteristics - 2.048MHz Input Jitter Tolerance

Characteristics Sym Min Max Units Conditions/Notes†

1 Jitter tolerance for 1Hz input 150 UIpp 1-3,8,9-14,21-22,24-26,30

2 Jitter tolerance for 5Hz input 140 UIpp 1-3,8,9-14,21-22,24-26,30

3 Jitter tolerance for 20Hz input 130 UIpp 1-3,8,9-14,21-22,24-26,30

4 Jitter tolerance for 300Hz input 50 UIpp 1-3,8,9-14,21-22,24-26,30

5 Jitter tolerance for 400Hz input 40 UIpp 1-3,8,9-14,21-22,24-26,30

6 Jitter tolerance for 700Hz input 20 UIpp 1-3,8,9-14,21-22,24-26,30

7 Jitter tolerance for 2400Hz input 5 UIpp 1-3,8,9-14,21-22,24-26,30

8 Jitter tolerance for 10kHz input 1 UIpp 1-3,8,9-14,21-22,24-26,30

9 Jitter tolerance for 100kHz input 1 UIpp 1-3,8,9-14,21-22,24-26,30

† See "Notes" following AC Electrical Characteristics tables.

AC Electrical Characteristics - OSCi 20MHz Master Clock Input

Characteristics Sym Min Max Units Conditions/Notes†

1 Frequency accuracy

(20 MHz nominal)

2 -32 +32 ppm 16,19

-0 +0 ppm 15,18

3 -100 +100 ppm 17,20

4 Duty cycle 40 60 %

5 Rise time 10 ns

6 Fall time 10 ns

† See "Notes" following AC Electrical Characteristics tables.

28

Page 29

Advance Information MT9044

† Notes:

Voltages are with respect to ground (VSS) unless otherwise stated.

Supply voltage and operating temperature are as per Recommended Operating Conditions.

Timing parameters are as per AC Electrical Characteristics - Timing Parameter Measurement Voltage Levels

1. PRI reference input selected.

2. SEC reference input selected.

3. Normal Mode selected.

4. Holdover Mode selected.

5. Freerun Mode selected.

6. 8kHz Frequency Mode selected.

7. 1.544MHz Frequency Mode selected.

8. 2.048MHz Frequency Mode selected.

9. Master clock input OSCi at 20MHz ±0ppm.

10. Master clock input OSCi at 20MHz ±32ppm.

11. Master clock input OSCi at 20MHz ±100ppm.

12. Selected reference input at ±0ppm.

13. Selected reference input at ±32ppm.

14. Selected reference input at ±100ppm.

15. For Freerun Mode of ±0ppm.

16. For Freerun Mode of ±32ppm.

17. For Freerun Mode of ±100ppm.

18. For capture range of ±230ppm.

19. For capture range of ±198ppm.

20. For capture range of ±130ppm.

21. 25pF capacitive load.

22. OSCi Master Clock jitter is less than 2nspp, or 0.04UIpp where1UIpp=1/20MHz.