Page 1

Operator’s Manual

Page 2

Page 3

Copyright Information:

CG Triumvirate is a trademark of Agfa Corporation.

CG Times based upon Times New Roman under license from the Monotype Corporation.

Windows is a registered trademark of the Microsoft Corporation.

All other brand and product names are trademarks, service marks, registered trademarks, or registered

service marks of their respective companies.

Firmware (Software) Agreement:

The enclosed Firmware (Software) resident in the Printer is owned by Licensor or its suppliers and is licensed

for used only on a single printer in the user’s Trade or Business. The User agrees not to, and not to

authorize or permit any other person or party to, duplicate or copy the Firmware or the

information contained in the non-volatile or programmable memory. The firmware (Software) is

protected by applicable copyright laws and Licensor retains all rights not expressly granted. In no event will

Licensor or its suppliers be liable for any damages or loss, including direct, incidental, economic, special, or

consequential damages, arising out of the use or inability to use the Firmware (Software).

Information in this document is subject to change without notice and does not represent a commitment on the

part of Datamax-O’Neil Corporation. No part of this manual may be reproduced or transmitted in any form or

by any means, for any purpose other than the purchaser's personal use, without the expressed written

permission of Datamax-O’Neil Corporation.

All rights reserved. Printed in the United States of America.

© Copyright 2009 by Datamax-O’Neil Corporation

Part Number: 88-2348-01

Revision: A

Important Safety Instructions:

This printer has been carefully designed to provide many years of safe, reliable performance. As with all types

of electrical equipment, however, there are a few basic precautions you should take to avoid hurting yourself

or damaging the device:

• Carefully read the installation and operating instructions provided with your printer.

• Read and follow all warning instruction labels on the printer.

• Place the printer on a flat, firm, solid surface.

• To protect your printer from overheating, make sure all openings on the printer are not blocked.

• Do not place the printer on or near a heat source.

• Do not use your printer near water, or spill liquid into it.

• Be certain that your power source matches the rating listed on your printer. If you are unsure, check

with your dealer or with your local power company.

• Do not place the power cord where it will be walked on. If the power cord becomes damaged or frayed

replace it immediately.

• Do not insert anything into the ventilation slots or openings on the printer.

• Only qualified, trained service technicians should attempt to repair your printer.

Page 4

Agency Compliance and Approvals:

C US

Listed

FCC: This device complies with FCC CFR 47 Part 15 Class A.

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part

UL60950-1, First Edition, Information Technology Equipment

CSA C22.2 No. 60950-1-03, First Edition

IEC 60950-1 :2001, First Edition

As an Energy Star Partner, the manufacturer has determined that this product meets the

Energy Star guidelines for energy efficiency.

The manufacturer declares under sole responsibility that this product conforms to the

following standards or other normative documents:

EMC: EN 55022 (1998) Class A

EN 50024 (1998)

Safety: This product complies with the requirements of IEC 60950-1:2001, First Edition

Gost-R

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy, and if not installed and used in accordance with the instructions in this manual, it may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at his own expense.

Page 5

s

t

n

e

t

n

o

C

C

C

G

e

G

e

G

e

P

r

i

P

r

i

P

r

i

n

o

n

o

t

t

i

n

g

t

t

1.1 Introduction................................................................... 1

1.2

n

n

n

2.1 Introduction................................................................... 3

2.2 Connecting the Printer..................................................... 3

2.3 Adjusting the Media Sensor .............................................. 5

2.4 Loading Media ................................................................ 8

2.5 Loading Ribbon............................................................... 10

S

t

i

n

g

t

i

n

g

About this Printer............................................................ 1

t

e

r

S

t

e

r

S

t

e

r

S

2.2.1 Power Connection .................................................. 3

2.2.2

2.2.3 Interface Cables..................................................... 4

2.3.1 AMS Adjustment .................................................... 6

2.4.1 Loading Media for Optional Peel Configuration ............ 9

e

t

e

t

t

a

r

t

e

S

S

t

t

e

e

e

d

a

r

t

e

d

a

r

t

e

d

t

u

p

t

u

p

t

u

p

Interface Connection .............................................. 4

n

n

t

t

s

s

P

r

i

n

t

e

r

O

p

e

r

a

t

i

o

n

a

i

t

i

o

n

t

i

o

n

n

d

A

d

j

u

s

t

m

e

n

t

s

a

n

d

A

d

j

u

s

t

a

n

d

A

d

n

g

i

n

g

i

n

g

m

j

u

s

t

m

e

n

t

s

e

n

t

s

P

r

i

n

t

e

r

O

p

e

r

P

r

i

n

t

e

r

O

3.1 Introduction ................................................................... 11

3.2 Lights ........................................................................... 11

3.3 Buttons ......................................................................... 12

3.4 Printer Configuration Tools ............................................... 13

3.5 Printer Configuration Utility (DMXConfig)............................ 14

3.6 Windows Driver .............................................................. 16

3.7 Media Calibration ............................................................ 18

3.8 Internal Labels ............................................................... 21

3.8.1 Database Configuration Label................................... 21

3.8.2

3.8.3 Hex Dump Label .................................................... 22

M

a

i

n

t

e

n

n

u

n

b

b

t

b

a

e

n

t

e

n

l

e

s

l

e

s

l

e

s

M

a

i

M

a

i

4.0 Introduction ................................................................... 23

4.1 Cleaning the Printhead .................................................... 24

4.2 Media Width Adjustment .................................................. 26

4.3 Fine Printhead Adjustment ............................................... 27

4.4 Printhead Replacement .................................................... 28

4.5 Downloading Firmware and Fonts...................................... 29

T

r

o

u

T

r

o

u

T

r

o

a

p

e

r

a

Test Label ............................................................. 21

n

c

e

h

h

h

n

n

o

o

o

c

e

c

e

o

t

o

t

o

t

a

a

5.0 Introduction................................................................... 30

5.1 Troubleshooting Tips....................................................... 30

i

Page 6

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

G

G

G

p

p

p

p

p

p

p

p

l

p

p

p

p

l

p

p

p

o

o

l

o

p

p

p

p

p

p

p

p

p

p

p

p

p

p

s

s

s

p

e

e

e

e

e

e

e

e

e

n

d

i

c

e

s

e

n

d

d

d

d

d

d

d

d

d

d

d

d

d

r

r

r

n

i

i

i

i

y

y

i

d

i

x

A

i

x

A

i

x

A

x

B

i

x

B

i

x

B

x

C

i

x

C

i

x

C

x

D

i

x

D

i

x

D

y

e

n

n

e

n

n

n

e

n

n

n

e

n

n

n

e

n

s

a

s

a

s

a

c

c

e

s

e

s

-

S

p

e

c

i

f

i

c

a

t

i

o

n

s

-

S

p

e

c

i

f

i

c

a

-

S

p

e

c

-

I

n

t

e

I

I

E

E

W

W

W

n

r

t

e

r

n

t

e

r

t

h

e

r

t

h

e

r

t

h

e

a

r

r

a

r

r

a

r

r

-

-

-

E

-

-

-

-

-

t

i

f

i

c

a

t

n

a

l

M

n

a

l

M

n

a

l

M

n

e

t

S

n

e

t

a

a

a

n

n

n

n

S

e

t

S

t

y

t

y

t

y

r

i

o

n

s

i

o

n

s

e

n

u

e

n

u

e

n

u

e

t

u

p

e

t

u

p

e

t

u

p

ii

Page 7

d

e

t

r

a

t

S

g

n

i

t

t

e

G

G

G

1

1

1

1

.

1

1

.

1

1

.

1

The E-Class Mark II (hereafter referred to as ‘the printer’) are user-friendly devices that blend quality and

durability into an affordable package. The printer, available in direct and optional thermal transfer

configurations, uses a unique front panel design to simplify operation, while it’s RS232 serial, USB, parallel,

and optional LAN interfaces allow easy connection to your host system.

This manual provides all the information necessary to operate the

printer.

To print labels or tags simply refer to the instructions included with

the software you have chosen to create the labels. A Windows

printer driver can be found on our website (www.datamax-oneil.com)

or on the included Accessories CD-ROM.

If you wish to write a custom program, a copy of the Class Series

Programmer’s Manual (part number 88-2341-01) can be found on

this CD-Rom or our website.

1

.

2

1

.

2

1

.

2

I

n

t

r

o

d

u

c

t

i

I

n

t

r

o

b

d

t

r

o

d

o

u

t

o

u

t

o

u

t

I

n

A

b

A

b

A

u

u

t

t

o

c

t

i

o

c

t

i

o

h

i

s

h

i

s

t

h

i

s

e

e

n

n

n

P

P

P

t

t

r

i

n

t

e

r

i

n

t

e

r

i

n

t

e

t

t

r

r

r

i

i

n

n

g

g

S

S

t

t

a

a

r

r

t

t

e

e

d

d

After removing the printer from the packaging material, check the

contents. The following items should be included:

Printer

Power supply

Accessories CD-ROM

Any special or additionally ordered items

Additional Requirements

The following items are necessary for generating labels from your

printer. Contact your customer support or sales representative for

advice on which media and software may best be suited for your

application.

Serial, USB or Parallel cable

Ethernet cable for optional LAN connectivity

Applicable Media

It is a good idea to save all packaging materials in the event that shipping the printer is ever

required.

Chapter 1 – Getting Started 1

Page 8

2 Chapter 1 – Getting Started

Page 9

p

u

t

e

S

r

e

t

n

i

r

P

r

P

P

2

2

2

2

.

1

2

.

1

2

.

1

This section explains how to connect your printer, load media (and ribbon, if equipped for thermal transfer),

and print a configuration label.

2

.

2

2

.

2

2

.

2

2.2.1 Power Connection

The printer is powered by an external auto-ranging power supply, which connects between the printer and

wall outlet as shown below.

Before connecting, ensure that the range of the printer’s power supply is compatible with your electrical

service (see Appendix A - Specifications for details).

I

n

t

r

o

d

u

c

e

e

d

d

e

c

c

u

u

c

t

c

t

c

t

t

i

n

t

i

n

t

i

n

I

n

t

r

I

C

n

o

o

o

t

n

n

n

o

r

o

n

n

n

C

C

Before connecting the AC Power Cord or interface cables to the printer, ensure the Power On/Off

Switch is in the ‘Off’ position.

r

i

o

i

o

i

o

g

g

g

n

n

i

i

n

t

t

t

n

n

h

e

h

e

h

e

e

t

e

t

P

r

i

n

P

t

r

i

n

t

r

i

n

P

r

r

e

r

e

r

t

e

r

S

S

e

e

t

t

u

u

p

p

Chapter 2 – Printer Setup 3

Power

Connection

Page 10

2.2.2 Interface Connection

The printer can be connected to the host via a USB, serial, or parallel cable.

An optional Wired or Wireless LAN interface is also available. For information on using this interface, refer to

Appendix C.

Serial

Connection

Parallel

Connection

To Host

USB

Connection

LAN Connection

(optional)

2.2.3 Interface Cables

Choose a connection method that will best serve your purpose:

To connect the printer to the host’s serial (RS-232C) interface use an acceptable cable

configuration, as shown below (contact your reseller for ordering information).

Part # 32-2483-01

To connect the printer to the host’s parallel interface use a Centronics

Note that the printer has a versatile communications feature: When connected to more than one interface, the

printer will automatically connect to the first port (serial, parallel, or USB) from which valid data is received.

After this connection has been made, the printer’s power must be cycled ‘Off’ and ‘On’ to change the interface

connection.

To connect the printer to the host’s USB interface use a standard USB cable.

4 Chapter 2 – Printer Setup

Part # 32-2301-01

parallel cable.

Page 11

2

.

3

A

d

j

u

s

t

i

n

g

t

h

e

M

e

d

i

a

S

e

2

.

3

A

d

j

u

s

t

i

n

g

t

h

e

M

e

d

i

2

.

3

A

d

j

u

s

t

i

n

g

t

h

e

M

The printer is available with a Fixed-Position Media Sensor or an Adjustable Media Sensor. To identify the type

of sensor in your printer, proceed as follows:

1. Open the cover.

2. Push down the Printhead Latch and raise the Printhead Carrier Assembly.

The Fixed-Position Media Sensor, shown below, is immoveable. If your printer has this sensor, proceed to

‘Loading Media’ (Section 2.4).

Printhead

Carrier Assembly

Printhead Latch

e

d

a

i

a

n

S

e

n

S

e

n

s

s

s

o

o

o

r

r

r

Fixed-Position Media Sensor

The Adjustable Media Sensor (AMS), shown below, may need to be positioned as described in section 2.3.1.

Printhead

Carrier Assembly

Printhead Latch

Adjustable Media Sensor

Chapter 2 – Printer Setup 5

Page 12

2.3.1 AMS Adjustment

For the proper detection of media and the label top of form (TOF), the table below indicates suggested AMS

positions for various media types.

Adjustable Media Sensor Position

Media Type Suggested Sensor Placement TOF Sensing Used

Continuous* Near the center of the media Continuous

Die-cut Near the center of the label Gap

Notched Near the center of the notch Gap

Reflective Near the center of the black mark Reflective

*The printer must be configured to use continuous media, see Section 3.4.

To properly position the AMS, you will need to know where the TOF mark is located on your media. (For more

information on media, see Appendix A - Specifications.)

Depending of your media type, take a measurement from the left-justified media edge across to the center of

the TOF mark as suggested in the table above. The following example illustrates the measurement of notched

media.

Reflective marks are placed on the underside of the media.

Measurement

Media

Movement

Notch

Left-Justified

6 Chapter 2 – Printer Setup

Page 13

To simplify the adjustment, the AMS uses Reference Letter designators that correspond to the following TOF

mark distances:

Reference

Distance of the TOF Mark from the Media Edge

Letter

(inches) (millimeters)

A .180 4.6

B .500 12.7

C .750 19.1

D 1.00 25.4

E 1.25 31.8

F 1.50 38.1

G 1.75 44.5

H 2.00 50.8

I 2.25 57.2

J 2.50 63.5

K 2.75 69.9

L 3.00 76.2

Position the Adjustable Media Sensor as follows:

1. Based on the measurement made earlier, choose the Reference Letter that best corresponds to the

location of your TOF mark.

Reference Letters

Setting Window

Top Slide

Bottom Slide

Setting Window

Reference Letters

2. Use a finger to move the Bottom Slide until your selected Reference Letter appears in the Setting Window

of the slide.

3. Use a finger to move the Top Slide until your selected Reference Letter appears in the Setting Window of

the slide.

The Top and Bottom Slides must be positioned over the same Reference Letter for proper media

sensor function.

4. Proceed to ‘Loading Media’ (Section 2.4).

Chapter 2 – Printer Setup 7

Page 14

2

.

4

L

o

a

d

i

n

g

M

e

d

i

a

2

.

4

L

o

a

d

i

n

g

M

2

.

4

L

o

a

d

i

n

Load media into the printer as follows:

With the Cover open and the

1.

Printhead Carrier Assembly raised,

remove the Media Hub and insert it

through the Roll Media (with the

labels spilling forward).

Place the Media Hub Flange (with its

2.

smooth side toward the media) onto

the Media Hub.

Place the Media Hub, flange, and

3.

media onto the Standoffs in the

printer.

Route the media through the printer,

4.

as shown.

g

M

e

e

d

d

i

a

i

a

Roll

Media

Printhead

Carrier

Media Hub Flange

(smooth side toward media)

Media

Hub

Printhead

Latch

Standoff

5. Slide the Media Guide and Media Hub Flange to the edge of the media.

6. Close the Printhead Carrier Assembly and press down until it locks into place.

7. Close the cover and press the

(If the printer does not correctly sense the top of each label, as denoted by the FAULT Light, it may be

necessary to perform the Calibration Procedure, Section 3.7.).

The printer is factory set to use 4-inch media (and ribbon, if thermal transfer equipped). When using

a different media width, refer to Chapter 4 for additional printer adjustments.

8 Chapter 2 – Printer Setup

F2

button several times to position the media and ensure proper tracking.

Page 15

2.4.1 Loading Media for Optional Peel Configuration

1. Open the cover.

2. Push the Printhead Latch down and raise the Printhead Carrier Assembly.

3. Place a roll of media (labels facing up) on the Media Hub and insert them into the printer. Slide the Media

4. Pull the Peel Lever forward to the ‘Open’ position.

5. Remove 6 (152 mm) of labels from the backing. Route the Media Backing over the Platen and Peel Bar

When using the Peel Mechanism do not exceed print speeds of 4 inches per second.

Hub Flange with its smooth side towards media onto the Media Hub.

and behind the Peel Roller and Fascia as shown below.

6. Push the Peel Lever back to the ‘Closed’ position.

7. Close the Printhead Carrier Assembly and press down until it locks into place.

8. Close the cover and press the

The labels will separate automatically as it is fed through the printer. (If the printer does not correctly

sense the top of each label, as denoted by the FAULT Light, it may be necessary to perform the Calibration

Procedure, Section 3.7.)

F2

button several times to advance the media and ensure proper tracking.

Chapter 2 – Printer Setup 9

Page 16

2

.

5

L

o

a

d

i

n

g

R

i

b

b

o

n

2

.

5

L

o

a

d

i

n

g

R

i

b

2

.

5

L

o

a

d

i

n

g

Ribbon is required with thermal transfer media. If your printer is equipped with the thermal transfer option

and if you will be using thermal transfer media, load ribbon as follows:

1. Open the cover.

2. Remove both Ribbon

Hubs.

3. Slide a roll of Ribbon onto

one of the Ribbon Hubs

and an Empty Core onto

the other hub.

4. Push the Printhead Latch

down and raise the

Printhead Carrier

Assembly.

b

R

i

b

b

o

o

n

n

Push in and lift

to remove the Hubs

Slide a Ribbon onto a Hub and

an Empty Core onto a Hub

Empty Core

Printhead

Carrier

Ribbon

Printhead

Latch

5. Place the Ribbon Hubs back into the printer and route the ribbon through the Printhead Carrier Assembly

as shown below, then close the Printhead Carrier.

Ensure the inked side of the ribbon faces the media and NOT the printhead.

7. The ‘Media Type’ setting within the printer’s setup must be set to ‘Thermal Transfer’ to print using a

ribbon. See Section 3.4.

10 Chapter 2 – Printer Setup

Page 17

r

e

t

n

i

r

P

r

P

P

3

3

3

3

.

1

I

n

t

r

o

d

u

c

3

.

1

I

n

t

r

3

.

1

The Front Panel consists of three indicator lights

and three function buttons. The functions of these

lights and controls are listed in the following

sections.

o

I

n

t

r

o

d

d

u

u

c

c

t

t

t

r

i

o

i

o

i

o

i

i

n

n

n

n

n

t

t

e

e

r

r

O

O

O

p

p

p

e

e

e

r

r

r

a

a

a

t

t

t

i

i

i

o

o

o

n

n

n

3

.

2

3

.

2

3

.

2

L

i

g

h

t

s

L

i

g

L

i

g

All three lights will be on during power-up initialization and a warm reset.

h

h

t

s

t

s

(Normal power-up)

Normal Mode

Power

Fault

Paused

Indicates the printer is on

Indicates a top of form or mechanical

error has occurred

Solid On:

‘Paused’ stat e

Blinking:

receiving data from the host

Indicates the printer is in the

Indicates the printer is

Chapter 3 – Printer Operation 11

Page 18

3

3

3

.

3

B

u

t

t

o

n

s

.

3

B

u

t

B

u

t

t

t

.

3

o

o

n

n

s

s

The three buttons, F1, F2, and

F3

perform different functions based on the printer’s operational mode.

Ready Mode Functions

These functions can be performed at any time when the printer is at idle.

Function Button(s) Description

Pause

Feed / Clear Fault

Cancel

Soft Reset

Print Test Label

Print Configuration Label

Print Ethernet Label

Quick Calibration

Empty Calibration

F1

F2

F3

Press and Hold

F1

Press and Hold

Press and Hold

F3

F1

+

F2

F1

+

F3

F2

+

+ F2 +

F2

F2

F1

+

F3

Pauses and un-pauses the printer

Feeds one label or clears fault condition

Cancels the current batch of labels. Press the

Pause button to print the next batch of labels in

Produces Database Configuration and Test Label

Prints the printers Ethernet configuration

Performs a “Quick Calibration”, see section 3.7.1

Performs a “Empty Calibration”, see section 3.7.2

the printers buffer.

Resets the printer

Prints the Test Label

Delayed Power-up Functions

Turn on the printer, when the three lights turn on press and hold the button sequence. Continue to hold the

button(s) until the three lights turn off.

Function Button(s) Description

Hex Dump

Level 1 Reset

Level 2 Reset

Press and Hold

F2

Press and Hold

Press and Hold

F1

F3

F1

+

+ F2 +

F3

Enters Hex Dump Mode, see section 3.8.3

Resets the printer to a saved configuration file.

Resets the printer to the default factory settings.

12 Chapter 3 – Printer Operation

Page 19

3

.

4

P

r

i

n

t

e

r

C

o

n

f

i

g

u

r

a

t

i

o

n

T

o

o

l

s

3

.

4

P

r

i

n

t

e

r

C

o

n

f

i

g

u

r

a

t

i

o

n

T

3

.

4

P

r

i

n

t

e

r

C

o

n

f

i

g

u

r

a

t

i

o

The printer contains many user adjustable parameters. These parameters are configurable using a few

methods. The table below lists the most popular ways of configuring the printer and the pros and cons of

each. Choose the method that best addresses your application.

Method Description Pros Cons For More Info

DMXConfig (located on the

Accessories CD-ROM) is a Windows

based configuration utility that

DMXConfig

Program*

allows the user to make changes to

the existing printer setup via a

direct connection to the host

computer’s serial, USB, or parallel

connection.

n

o

T

o

l

s

o

o

l

s

Easy to use, gives

the user the most

control of the

printer.

Software must be

installed on a

Windows based host

computer.

See

Section 3.5

Internal Web

Pages*

Windows

Driver

Internal Menu

System

Internal web pages are simple HTML

pages that can be accessed with

any web browser via the optional

Ethernet port.

The Windows printer driver (located

on the Accessories CD-ROM).

Internal menu system that uses the

printers front panel buttons to

navigate to desired printer settings.

Since the printer is not equipped

with a display, feedback is printed

directly on the label stock.

Easy to use. Printer

can be configured

from any host

connected to the

network regardless

of physical location

or host operating

system.

No additional

software required.

Many applications

require use of

driver for printing

rd

from 3

applications. This

can be an all in one

solution for some

users that do not

require advanced

setups.

No host or software

required.

party

Printer must be

equipped with an

Ethernet option.

Depending on the

complexity of the

network, initial

connection may not

be possible until

network parameters

are set via another

method.

Requires installation

of a driver on a

Windows based host.

Only basics

parameters can be

configured.

Complicated

procedure.

Requires loading of

label and ribbon (if

equipped).

See

Appendix C.3

See

Section 3.6

See

Appendix B

DPL

Programming

Commands

* Recommended methods

DPL Programming Language

commands can be built into custom

label formats or sent individually to

the printer.

Chapter 3 – Printer Operation 13

DPL commands can

be built directly into

label formats which

can configure the

printer on the fly.

DPL programming

knowledge needed.

See the

Class Series

Programmer’s

Manual

Page 20

3

.

5

P

r

i

n

t

e

r

C

o

n

f

i

g

u

r

a

t

i

o

n

U

t

i

3

.

5

P

r

i

n

t

e

r

C

o

n

f

i

g

u

r

a

t

i

o

3

.

5

P

r

i

n

t

e

r

C

o

n

f

i

g

u

r

DMXConfig (located on the Accessories CD-ROM) is a windows based configuration utility that allows the

user to make changes to the existing printer setup via a direct connection to the host computer’s serial,

USB, or parallel connection.

DMXConfig Features:

Allows Real-Time Control/Query of Printer Configuration

Define and Save Optimal Configurations for Applications

Saved Configurations can be Shared with other Printers and Sent via Email

Download Files, Formats and Fonts

Query Memory Modules

Be sure to use the DMXConfig utility located on the Accessories CD-Rom that is included with your

A new feature of DMXConfig allows the use of Datamax-O’Neil Windows Driver for bi-directional

communications and configuration. Before this feature can be used, a small setting change must be made to

the printer driver’s properties.

Right-click on the printer driver icon and select “Properties”. Click on the “Advanced” Tab and select "Print

directly to the printer", then Click “OK”.

printer. Older versions might not operate correctly with some printers. For the latest version please

visit our web site at www.datamax-oneil.com.

a

n

t

i

o

n

l

U

t

i

U

t

i

(

D

M

X

C

o

n

f

i

g

)

i

t

y

(

D

M

X

C

o

l

i

t

y

(

D

l

i

t

y

M

X

C

o

n

n

f

i

g

)

f

i

g

)

14 Chapter 3 – Printer Operation

Page 21

Once you have installed the DMXConfig utility:

1. Connect the host to the printer with a

serial or parallel cable.

2. Turn on the printer.

3. Launch the DMXConfig utility.

4. Query the printer by using the ‘Query

Printer’ toolbar button (top-left). This

will connect to the printer and get the

current printer settings.

5. At this point you may browse the tabs

and make any changes necessary to the

printer configuration. Once complete,

send the new settings to the printer

using the ‘Configure Printer’ toolbar

button. The example below illustrates

changing the Media Type setting to

“Thermal Transfer.

6. Select the ‘Media Settings’ tab, in the

‘Media Type’ drop-down box select

‘Thermal Transfer’.

7. Send the settings to the printer using

the ‘Configure Printer’ toolbar button.

The printer is now configured to ‘Thermal

Transfer’. You may close the DMXConfig

utility and begin printing using ribbon.

Other parameters can be changed using this

procedure as well.

Chapter 3 – Printer Operation 15

Page 22

3

.

6

W

i

n

d

o

w

s

D

r

i

v

e

r

3

.

6

W

i

n

d

o

w

s

D

3

.

6

W

i

n

d

o

w

The Windows driver is located on the Accessories CD-Rom included with your printer. For the latest version

please visit our web site at www.datamax-oneil.com.

Installing the Windows Driver:

Place the Accessories CD-Rom included with your printer

into your computers CD-Rom drive.

Once the CD-Rom starts, select "Install Windows Driver"

from the main menu and follow the instructions on the

screen to install.

When prompted, select your printer from the list, (i.e.

Datamax E-4xxx). Continue to follow the on-screen

instructions to install the driver.

s

r

D

r

i

v

e

r

i

v

e

r

16 Chapter 3 – Printer Operation

Page 23

Important Notes:

The Windows driver functions the same as any other Windows printer. A built in help file is available for

complete information on all settings, however there are some important settings that should be observed

for trouble free printing.

Page Setup Tab: Stock

It is important that the Stock setting matches the

size of the label you are using. If you cannot find

a match for your label click 'New' and enter the

dimensions of your label.

Options Tab: Print Speed & Printhead Temperature

These two settings will have the greatest effect on

print quality. Some label stocks will require more

heat and slower print speeds to generate a quality

image.

The Windows application software used to create the label format will likely have a "Page Setup" screen.

This will also need to match the size of the label you are using.

Chapter 3 – Printer Operation 17

Page 24

3

.

7

M

e

d

i

a

C

a

l

i

b

r

a

t

i

o

n

3

3

.

7

M

e

d

i

a

C

a

l

i

b

r

.

7

M

e

d

i

a

C

a

a

l

i

b

r

a

t

i

o

n

t

i

o

n

3.7.1 Quick Calibration

Quick Calibration should be performed as part of the media loading routine to fine-tune the sensing

parameters.

(1) This calibration is not necessary when using continuous stock.

Calibrate the printer as follows:

1. Ensure that the printer is ON and in an idle state (i.e., not off-line) with media loaded, the media sensor

2. Press and hold the

(2) Media containing large gaps may require a change in the PAPER OUT DISTANCE before proceeding.

adjusted, and the sensor type selected.

F2

button until one label has been output then release. Wait for the printer to process

the data. There are two possible outcomes:

Upon completion, one of the following lights will flash five times to denote the result of the auto

calibration attempt:

POWER light = Successful calibration.

FAULT light = Unsuccessful calibration, try again. If the calibration continues to fail proceed to Section

3.7.3.

3.7.2 Empty Calibration

Empty Calibration calibrates the printer’s media sensor to detect an ‘Out of Stock’ condition. Calibrate the

printer as follows:

1. Ensure that the printer is ON and in an idle state with media removed.

F2

2. Press and hold the

F1

buttons for a few seconds.

+

18 Chapter 3 – Printer Operation

Page 25

3.7.3 Standard Calibration

The Standard Calibration can be performed using the DMXConfig Utility, (see section 3.5 for more information

on DMXConfig) or using the front panel buttons (see Appendix B for more information).

Once you have installed the DMXConfig utility and the printer is properly loaded with media:

1. Connect the host to the printer with a serial

or parallel cable.

2. Turn on the printer.

3. Launch the DMXConfig utility.

4. Query the printer by using the ‘Query Printer’

toolbar button (top-left). This will connect to

the printer and get the current printer

settings.

5. Select the “Sensor Calibration” Tab and then

click the “Media Calibration Wizard” button.

When prompted click “OK” to start the

calibration wizard.

6. The Calibration Wizard will now prompt you to

‘Load Stock’. Be sure the media is properly

loaded in the printer. Close the printhead and

click “OK”.

Chapter 3 – Printer Operation 19

Page 26

7. The Calibration Wizard will now prompt you to

‘Load Backing’. Peel off a few labels and

position the backing material in the media

sensor. Close the printhead and click “OK”.

8. The Calibration Wizard will now prompt you to

‘Remove Stock’. Remove all media and

backing from the printer. Close the printhead

and click “OK”.

9. The Calibration Wizard will now respond with

‘Passed Calibration’, click “OK” Re-install the

media in the printer. Close the printhead and

press the

Each press of the

one label.

If the printer was unsuccessful in calibrating.

Retry the procedure beginning at Step 5.

F2

button to test the calibration.

F2

button labels should feed

20 Chapter 3 – Printer Operation

Page 27

3

.

8

I

n

t

e

r

n

a

l

L

a

b

e

l

s

3

.

8

I

n

t

e

r

n

a

l

L

a

3

.

8

I

n

t

e

r

n

a

The following section details the printer’s resident labels.

b

l

L

a

b

e

e

l

s

l

s

3.8.1 Database Configuration Label

The Database Configuration Label provides valuable printer

information including the firmware version, memory allocations,

enabled options, and label-counter data.

To print the Database Configuration Label, proceed as follows:

With the printer on, loaded with media (at least 4 inches wide)

and ribbon (if printing with thermal transfer media), press the

F2

F3

buttons simultaneously.

+

3.8.2 Test Label

The Test Label is used to evaluate the current printer setup for print quality,

label tracking, and print positioning.

To print the Test Label, proceed as follows:

With the printer loaded with media (at least 4 inches wide), and ribbon (if

printing with thermal transfer media), simultaneously press the

F2

buttons.

F1

+

Faulty Test Label:

Instead of consistent patterns,

streaks in the direction of print

indicate a dirty or faulty printhead.

See section 4.3 for cleaning

instructions.

Chapter 3 – Printer Operation 21

Page 28

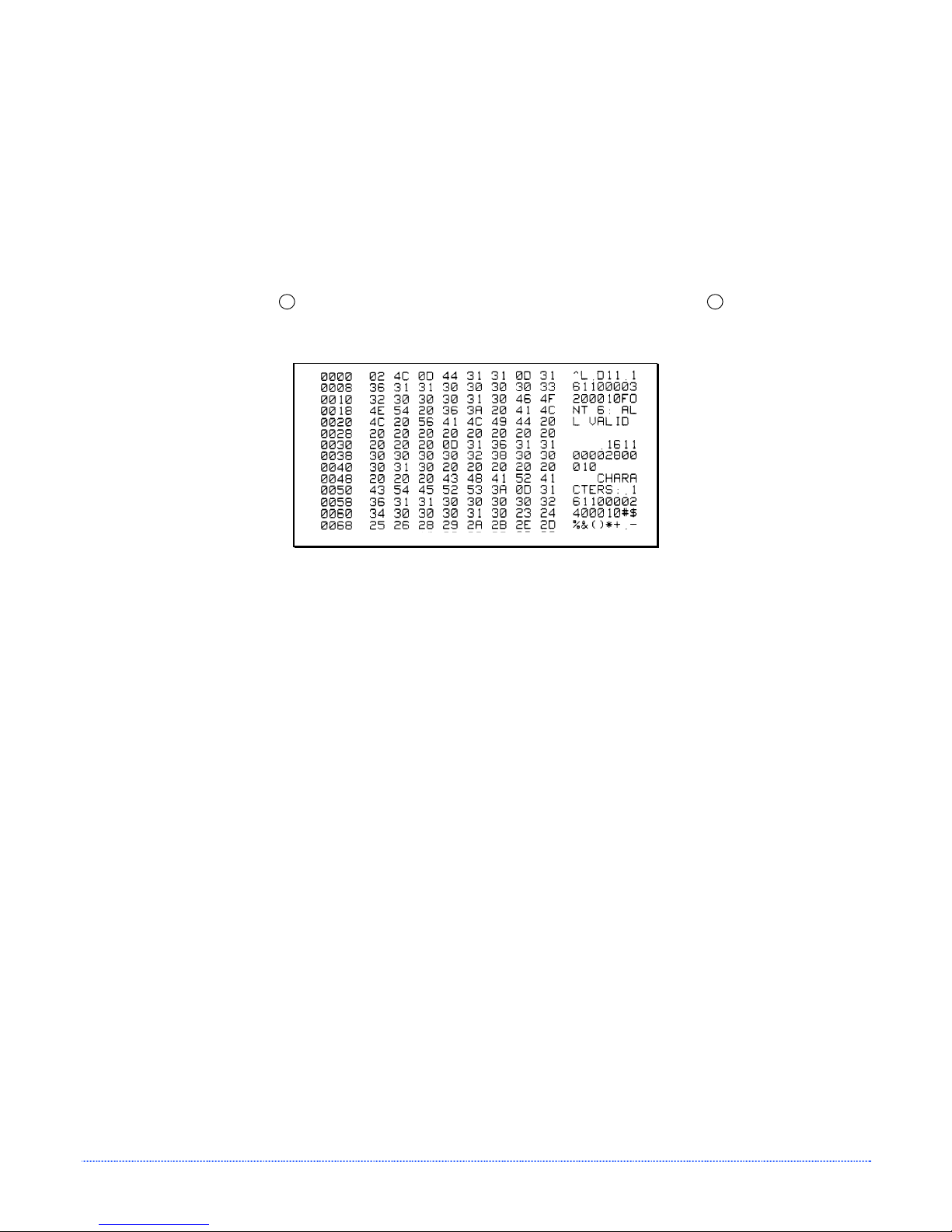

3.8.3 Hex Dump Label

The Hex Dump Label is a useful tool in the diagnosis of problems including communications handshaking and

DPL syntax errors. To generate a Hex Dump Label the printer enters into Hex Dump Mode. In this mode, all

data sent to the printer will be immediately output in hexadecimal code, along with the printable ASCII

equivalents. To decode this information, the Class Series Programmer’s Manual is an essential reference. As a

final note, many software programs use bit mapping to construct the label, making diagnosis of this data

difficult. Contact Datamax-O’Neil Technical Support with any questions.

To enter Hex Dump Mode and print a Hex Dump Label, proceed as follows:

With the printer off, loaded with media (at least 4 inches wide) and ribbon (if printing with thermal transfer

media), press and hold the

PAUSED Light turns off. Now, all data received by the printer will be output in hexadecimal code, as shown

below.

F2

button while turning the printer on. Continue holding the F2 button until the

To exit the Hex Dump Mode, turn the printer off.

22 Chapter 3 – Printer Operation

Page 29

d

n

a

e

c

n

a

n

e

t

n

i

M

M

M

4

4

4

4

.

0

I

n

t

r

o

d

u

4

.

0

I

n

t

4

.

0

This section details the cleaning, adjusting, and troubleshooting tips for the printer. The following table

outlines the recommended maintenance schedule for the various printer parts.

r

I

n

t

r

c

o

d

u

c

o

d

u

c

Area Method Interval

a

a

a

t

i

o

n

t

i

o

n

t

i

o

n

i

i

A

A

A

n

n

d

d

d

t

t

j

j

j

e

e

u

u

u

n

n

s

s

s

a

a

t

t

t

m

m

m

n

n

c

c

e

e

e

e

e

n

n

n

t

t

a

a

t

s

s

s

n

n

d

d

Printhead

Platen Roller

Peel-Off Roller

Media Path Solvent* After every roll of media.

Peel/Tear Bar Solvent* As needed

Media Sensor Blown air or brush Monthly

Exterior Mild detergent or desktop cleaner. As needed

Interior Brush or vacuum cleaner As needed.

* It is recommended that a solvent containing isopropyl alcohol be used.

Isopropyl alcohol is a flammable solvent; always take the proper precautions when using this

substance.

Turn off the printer before cleaning the printhead.

Use solvent* on a cotton swab to clean the

printhead from end to end.

Turn the power off. Rotate the platen roller and

clean it thoroughly with solvent* and a cotton

swab.

Rotate the peel-off roller and clean it thoroughly

with solvent* and a cotton swab.

After every roll of media.

After every roll of media.

After every roll of media.

Chapter 4 – Maintenance and Adjustments 23

Page 30

4

.

1

C

l

e

a

n

i

n

g

t

h

e

P

r

i

n

t

h

e

a

d

4

.

1

C

l

e

a

n

i

n

g

t

h

e

P

r

i

n

t

4

.

1

C

l

e

a

n

i

n

g

t

h

e

P

Never use a sharp, hard, or abrasive object on the printhead.

If print quality declines (symptoms can include unreadable bar codes or streaks through text and graphics),

the typical cause is debris buildup on the printhead which, left unattended, can lead to premature dot failure.

Depending upon the supplies and printing parameters used, different cleaning methods are recommended.

h

r

i

n

t

h

e

e

a

a

d

d

Proper cleaning is critical. To maintain peak performance of the

printer, Datamax-O’Neil offers a complete line of cleaning

products including pens, cards, films and swabs. Visit our

website at http://www.datamaxcorp.com/clean/ to learn more.

Cotton Swab Procedure (for users of direct thermal media, or thermal transfer media with wax

ribbon):

1. Turn OFF the Power Switch and unplug the printer. Raise the cover, then raise the Printhead Assembly

2. Remove media and ribbon. Using a Cotton Swab moistened (not soaked) with isopropyl alcohol,

and wait briefly for the printhead to cool.

thoroughly clean the printhead.

Streaks can indicate a dirty or faulty printhead.

24 Chapter 4 – Maintenance Adjustments

Page 31

Cleaning Card Procedure (for users of direct thermal media, or thermal transfer media with wax/resin

ribbon combinations; also for unsuccessful Cotton Swab cleaning attempts):

1. Raise the cover, then raise the Printhead Assembly and wait briefly for the printhead to cool.

2. Remove media and ribbon then place a Cleaning Card under the printhead. (Part number 70-2013-01 for

4-inch cards).

3. Close and latch the printhead. Turn the Media Width Thumbwheel counterclockwise as far as possible.

4. Close the cover then press

5. After the cleaning card has been run through the printer, reinstall media (and ribbon, if needed). Plug in

and turn ON the printer. Run a few sample labels and examine them. If streaking is still present, use the

Cleaning Film Procedure, below; otherwise, this completes cleaning.

F2

button to initiate cleaning.

Cleaning Film Procedure (for users of thermal transfer media and resin ribbon, when printing with a

Heat Value of 22 or higher, or when other methods prove unsuccessful):

1. Raise the cover, then raise the Printhead Assembly and wait briefly for the printhead to cool.

2. Remove media and ribbon then place a sheet of Cleaning Film under the printhead. (Part number 70-

2087-01 for 4-inch film).

3. Close and latch the printhead. Turn the Media Width Thumbwheel counterclockwise as far as possible.

4. Close the cover then press

5. After the cleaning film has been run through the printer, turn OFF the Power Switch and unplug the

printer. Open the cover then raise the Printhead Assembly and wait briefly for the printhead to cool.

Using a cotton swab moistened (not soaked) with isopropyl alcohol, clean the printhead then allow it to

dry.

6. Reinstall media (and ribbon, if needed). Plug in and turn ON the printer. Run a few sample labels and

examine them. If streaking is still present the printhead may need to be replaced; see Section 4.5.

F2

button to initiate cleaning.

Chapter 4 – Maintenance and Adjustments 25

Page 32

4

.

2

M

e

d

i

a

W

i

d

t

h

A

d

j

u

s

t

m

e

n

t

4

.

2

M

e

d

i

a

W

i

d

t

h

A

d

j

u

s

t

4

.

2

M

e

d

i

a

W

i

d

t

h

A

d

A Thumbwheel on the side of the Printhead Carrier Assembly allows the printhead to be adjusted for various

sizes of media. When adjusting for narrow media move the Thumbwheel to the left (clockwise); conversely,

when adjusting for wide media move it to the right (counterclockwise).

The numbers on the Thumbwheel are for reference only and do not correspond to specific media

widths.

m

j

u

s

t

m

e

e

n

n

t

t

To perform a media width adjustment, proceed as follows:

F2

1. Load media into the printer. Print a label (press the

2. If the printing appears too light on the right-hand side of the label (see example below), then move the

Thumbwheel counterclockwise. Print another label and examine it; make additional adjustments as

necessary.

If the printing is light on

the right side of a label,

make a counterclockwise

adjustment with the

Thumbwheel.

If the media begins tracking too far to the right while printing, the Thumbwheel should be adjusted to

the clockwise.

F1

buttons simultaneously) and examine it.

+

Direction

of Media

Movement

26 Chapter 4 – Maintenance Adjustments

Page 33

4

.

3

F

i

n

e

P

r

i

n

t

h

e

a

d

A

d

j

u

s

t

m

e

n

t

4

.

3

F

i

n

e

P

r

i

n

t

h

e

a

d

A

d

j

u

s

t

4

.

3

F

i

n

e

P

r

i

n

t

h

e

a

d

A

d

The Fine Printhead Adjustment Set Screw, located on top of the printhead carrier assembly, is used for

adjusting print quality. This adjustment is set at the factory and should not need further adjustment;

however, with the different types and thickness of media some re-adjustment may be necessary if print

quality suffers.

If thermal transfer equipped, it is not necessary to remove the Ribbon Handler Assembly; an access

To adjust the printhead, turn the Set Screw until optimum print quality is obtained (some trial and error may

be necessary). Do not over tighten the Set Screw.

hole through the assembly is provided.

m

j

u

s

t

m

e

e

n

n

t

t

Chapter 4 – Maintenance and Adjustments 27

Page 34

4

.

4

P

r

i

n

t

h

e

a

d

R

e

p

l

a

c

e

m

e

n

4

.

4

P

r

i

n

t

h

e

a

d

R

e

p

l

a

c

e

4

.

4

P

r

i

n

t

h

e

a

d

R

e

p

l

Always follow proper Electro Static Discharge procedures when replacing the printhead.

Remove the printhead as follows:

1. Turn off the printer.

2. Loosen the Printhead Screw until the

3. Press the Printhead Latch then raise the

4. Remove the printhead cable from the back of

If thermal transfer equipped, it is not necessary to remove the Ribbon Handler Assembly; an access

hole is provided.

printhead is freed.

carrier assembly.

the printhead.

a

c

e

m

m

e

e

n

n

t

t

t

Replace the printhead as follows:

1. Connect the printhead cable to the new printhead.

2. Position the printhead in the printhead carrier assembly, ensure that the printhead cable is not pinched,

and then tighten the Printhead Screw.

3. Clean the Printhead (see Section 4.1) and allow it to dry before use.

28 Chapter 4 – Maintenance Adjustments

Page 35

4

.

5

D

o

w

n

l

o

a

d

i

n

g

F

i

r

m

w

a

r

e

a

n

d

F

4

.

5

D

o

w

n

l

o

a

d

i

n

g

F

i

r

m

w

a

r

e

a

4

.

5

D

o

w

n

l

o

a

d

i

n

g

F

i

r

m

w

a

r

The operating programs and fonts for the printer are stored in Flash memory on the Main PCB. When program

updates and/or new features are added, they can be downloaded to the printer as follows:

1. Identify the new version for your model of printer from the Datamax-O’Neil FTP site at ftp.datamax-

oneil.com and download it onto your computer’s hard drive or a floppy disk.

2. Ensure that the printer is connected to the host and that the power is ‘On.’ Using the DOS copy command

enter:

Other programs (e.g., hyper-terminal and certain Windows Driver programs) may also be used to

3. The PAUSED Light will flash during the download.

4. Following a successful download, the PAUSED Light will illuminate then the printer will perform a ‘cold

If the printer fails to boot-up after an unsuccessful download, turn ‘Off’ the power. Simultaneously press and

hold the

download this file.

reset.’ The previous printer setup will not be affected unless substantial firmware data structure changes

have occurred. Print a Database Configuration Label to verify your new firmware version.

Following an unsuccessful download, the FAULT Light will illuminate then the printer will perform a

‘warm reset’ (both the POWER and PAUSED Light will be on during power-up initialization). The original

firmware will remain operational. If the printer fails to reset, toggle the power ‘Off’ and ‘On.’

Try re-sending the file to the printer. If the failure continues, check the following possible causes:

An invalid or corrupted file is being downloaded - Ensure the file being downloaded is correct and

applicable for your printer model.

Possible communications error - Check the cable connection between the host and printer and

ensure that a quality, shielded cable is used.

Possible Flash memory problem - Call for service.

F1

+

copy filename.zg lpt1/b

F3

buttons while powering ‘On’ the printer. Now, try downloading the file to the printer again.

e

n

a

n

d

d

o

F

o

F

o

n

n

n

t

s

s

t

t

s

Chapter 4 – Maintenance and Adjustments 29

Page 36

g

n

i

t

o

o

h

s

e

l

b

u

o

r

T

T

T

5

5

5

5

.

0

I

n

t

r

o

d

u

c

5

.

0

I

n

t

r

5

.

0

Occasionally, situations arise that require troubleshooting. Possible problem situations and potential solutions

are listed in this section. While not every situation is addressed, you may find some of these tips helpful. After

the correction action is taken press the FEED button to clear the alarm. Contact a qualified service technician

for problems that persist or are not covered in this section.

5

.

1

5

5

The following section lists the symptoms and the associated page numbers of the topics covered in the

troubleshooting section.

Unacceptable print quality:

The printer does not print or prints several labels at once:

The ribbon does not advance (the paper advances, but ribbon does not):

T

.

1

T

.

1

o

I

n

t

r

o

r

o

u

b

r

o

u

T

Dirty printhead: Clean the printhead (see Section 4.1).

The temperature setting may be incorrect for the media being used: Use the software program or

A mismatched incorrect ribbon/media combination is being used: Check the types being used.

Faulty printhead: Replace it (see Section 4.4) or call for service.

The labels are incorrectly loaded: See the loading instructions on the inside cover of the printer or

The media is not calibrated: Calibrate it (see Section 3.7).

If equipped, the Adjustable Media Sensor may need to be repositioned (see Section 2.3.1).

The media sensor or sensor circuitry may be defective: Call for service.

The ribbon may be installed incorrectly: Ensure that the ribbon’s inked side faces the paper. With

A mismatched ribbon/paper combination is resulting in an insufficient amount of friction between

b

r

o

u

b

DPL commands adjust the Heat Setting and Print Speed.

Section 2.4.

most ribbons this can be verified by rubbing paper against the ribbon; the ink should smudge the

paper. Or, if using label stock, the sticky side of a label will pull off the ink.

paper and ribbon: Ensure that the correct type of ribbon is being used with the media.

d

d

t

u

c

t

u

c

t

l

e

s

h

l

e

s

h

l

e

s

h

i

i

i

o

o

r

r

o

o

o

o

o

o

n

n

o

n

t

o

o

i

n

t

i

n

t

i

n

g

g

g

u

u

T

i

T

i

T

b

b

p

p

i

p

s

s

s

e

l

e

l

s

s

h

h

o

o

o

o

t

t

i

i

n

n

g

g

30 Chapter 5 – Troubleshooting

Page 37

Skips every other label (print quality is good, but every other label is skipped):

The label is formatted too close to the top edge of the label: Leave white space equal to 8-dot

rows (about .02 inch [.5mm]) at the top of the label.

The media is not calibrated: Calibrate it (see Section 3.7).

If equipped, the Adjustable Media Sensor may need to be repositioned (see Section 2.3.1).

The media sensor or media sensor circuitry may be defective: Call for service.

Unable to print in rotation 4:

The characters are formatted outside the dimensions of the label: Check that the row/column

values provide enough room for the height of the image being printed.

Prints light on the right side of the label:

The media width adjustment is set for a narrower media width than is actually being used: Adjust

for the media width (see Section 4.2).

The printhead is not properly aligned: Call for service.

The printhead carrier assembly is not latched down: Latch it.

Printer fails to power on:

The AC wall outlet may be faulty: Try another outlet.

A fuse may be blown: Call for service.

The power supply may be faulty: Replace it.

A defective power switch may exist on the printer: Call for service.

Label advances 1-2 inches before a fault indication:

The ribbon may be incorrectly installed. Ensure that the ribbon’s inked side faces the paper. With

most ribbons this can be verified by rubbing paper against the ribbon; the ink should smudge the

paper. Or, if using label stock, the sticky side of a label will pull off the ink.

A mismatched ribbon/paper combination is resulting in an insufficient amount of friction between

paper and ribbon: Ensure that the correct type of ribbon is being used with the media.

Label advances 16 inches before a fault indication:

Labels move excessively from side to side during printing:

The media may not be properly loaded: Reload it (see Section 2.4). When loading media ensure

that the media hub and media guide are against the media and that gaps or marks in the labels

are in line with the media sensor.

If equipped, the Adjustable Media Sensor may need to be repositioned (see Section 2.3.1).

The media sensor or media sensor circuitry may be defective: Call for service.

The media may not be properly loaded: Reload it (see Section 2.4). When loading media ensure

that the media hub and media guide are against the media and that gaps or marks in the labels

are in line with the media sensor.

The media width adjustment may not be properly set: Readjust for the label width (see Section

4.2).

Chapter 5 – Troubleshooting 31

Page 38

i

f

i

c

e

p

S

p

S

p

S

A

A

A

Mechanical

Width 8.77 inches (22.3 cm)

Depth 10.0 inches (25.4 cm)

Height 7.05 inches (17.9 cm)

Weight 5.2 pounds (2.4 kg)

e

e

c

c

i

i

f

f

i

i

c

c

c

a

a

a

t

t

t

i

i

i

o

o

o

n

n

n

s

s

s

Operating Temperature

AC Input Voltage

Printing

Print Method Direct Thermal; Thermal Transfer (optional)

Print Speed

Resolution

Tear Bar Tear up

DRAM Memory 16MB

FLASH Memory 4MB

40 to 95 F (4 to 35 C)

Power Supply

105 VAC to 250 VAC / 50-60 Hz

E-4205e: 1 - 5 IPS (25.4 - 127 mm/s)

E-4304e: 1 - 4 IPS (25.4 - 101.6 mm/s)

E-4205e: 203 DPI (8 dots/mm)

E-4304e: 300 DPI (11.8 dots/mm)

32 Appendix A – Specifications

Page 39

Media / Ribbon

Media Types Roll-Fed, Die-Cut, Continuous, Fan-Fold

Max. Media Width 4.3 inches (109 mm)

Min. Media Width 0.75 inches (19 mm)

Max. Print Width

Print Length Range

Media Thickness Range

Media Supply Roll Capacity 5 inches (127.0 mm) O.D. on a 1 inch (25.4 mm) core

Ribbon Width Range 1.0 - 4.3 inches (25 - 110 mm)

E-4205e: 4.25 inches (108 mm)

E-4304e: 4.12 inches (106 mm)

.375 – 100 inches (9.5-2540 mm); min length of 1 .25 inches

(31.8mm) with optional Cutter.

.0025 - .01 inches (.064 - .254 mm); up to .007 inches (.117 mm)

with optional Cutter;

Ribbon Roll Capacity

Matched to media: approx. 361 feet (110 m) long with a 1.5 inch (38

mm) O.D. on a .5 inch core

Communications

Interface USB, RS-232 (DB-9), and Centronics Parallel

Baud Speed 600 to 38,400 bits per second (BPS)

Handshaking Xon/Xoff, CTS, DTR

Parity Even, Odd, or None

Stop Bits 1 or 2

Data Bits 7 or 8

Fonts

9 Bit Map Fonts; rotated 0, 90, 180, and 270 degrees.

Embedded Bar Codes

32 embedded barcodes, (see the programmers manual for a detailed listing).

Appendix A – Specifications 33

Page 40

A

Approved Media

To achieve optimum print quality and maximum printhead life, Datamax-O’Neil specifies the use of DatamaxO’Neil brand media and ribbons. These supplies are specially formulated for use in our printers; use of other

supplies may affect the print quality, performance, and life of the printer or its components. For a current list

of approved media and ribbons for use in direct thermal and thermal transfer applications, please contact a

Media Representative at (407) 523-5650.

I

G

F

H

J

E

D

C

Description Max

B

[1]

Min

[1]

A Label width 4.09 1.00

B Backing width 4.30 1.00

C Gap between labels .25 .10

D Label length 24

E Total thickness .010

[3]

.375

[6]

.0025

[4]

F Notch opening width .50 .20

Distance from the edge of the media to

the media sensor aperture (left justified)

G

.175

.125

with the Adjustable Media Sensor option 2.94 .125

H Reflective mark width

I Distance between reflective marks 24

J Reflective mark length .25 .10

[1]

Units of measure are in inches.

[2]

The reflective (black) mark must be carbon based, placed on the backside of the

stock, and the reflectance shall be less than 10% at wavelengths of 950 and 640

nm.

[3]

The label length may vary up to 99 inches with printable area not exceeding the

maximum label length.

[4]

This distance is inclusive of the minimum gap between labels. Min length of 1.25

inches (31.8mm) with optional Cutter installed.

[5]

This distance is inclusive of the minimum reflective mark.

[6]

.007 inches (.117 mm) w/Standard Cutter, .005 inches (.127 mm) w/LD Cutter

[2]

4.10 .50

[3]

.375

[5]

34 Appendix A – Specifications

Page 41

Appendix A – Specifications 35

Page 42

u

n

n

n

n

c

c

c

e

e

t

i

t

i

t

i

e

o

n

o

n

o

n

n

n

s

s

s

u

u

I

I

I

B

B

B

B

.

1

B

u

t

t

o

n

s

B

.

1

B

u

t

P

P

B

P

r

r

u

r

t

t

t

i

n

i

n

i

n

B

.

1

The three buttons (PAUSE, FEED and CANCEL) perform different functions based on the printer’s operational

mode. The printer operates in one of the three following modes:

Normal: Normal printer functions. See Section 3.3.

Printer Setup: Allows changes to the printer’s operational settings. See Section B.2.

Calibration: Allows the ‘calibration’ of the media being used for the correct sensing of the top of form. See

B

.

2

B

.

2

B

.

2

o

n

s

o

n

s

Section B.4.

t

e

r

S

e

e

r

S

e

r

S

t

e

t

e

n

n

t

u

p

t

u

p

t

u

p

t

t

M

M

M

e

e

o

d

o

d

o

d

r

r

e

e

e

-

-

n

n

B

B

-

B

u

u

u

a

a

t

t

o

t

t

o

t

t

o

l

n

n

n

l

F

F

F

M

M

u

u

u

M

l

a

n

r

e

t

n

In ‘Printer Setup’ mode, the buttons control the operational settings of such items as media type,

communications, and options as detailed below.

It is recommended that the Printer Setup Mode not be entered while in Peel Mode or with the optional

Present Sensor enabled. Depending on label size, this can cause unpredictable results.

Printer and cutter faults are disabled during the Printer Setup Mode, but can still occur while printing

“test” labels.

If at any time you wish to discard your changes and revert

power to the printer.

F1

If you wish to restore Factory Defaults Press and Hold

+ F2 +

back to the previous values, simply turn off

F3

36 Appendix B – Internal Menu

Page 43

To change Printer Setup, proceed as follows:

F1

(Press and hold during power-up until the Paused Light turns off)

Printer Setup Mode

Prints the ‘Printer Setup Menu List’, see section B.2.1

F1

Press and

F2

(

Release

Press and hold to advance to the desired menu

F2

(

item by counting the number of Fault Light flashes

Prints the ‘Test Label’ for “test”

F3

Saves the current values

F3

F1

+

and resumes

Feeds one la bel for “test”

)

Normal Mode

)

Printer Setup Procedure

Increments item’s value

F1

Press and

F2

(

Release

Press and

F2

(

Hold

F3

Decrements item’s value

Accepts the current

F3

F1

+

values for “test”

When adjusting CONT FORM LENGTH, LABEL WIDTH, or ALIGN LENGTH, momentarily pressing F1 or

F2

will change the value by 1; and, holding either button down until the Fault light flashes will change

the value by ten for each flash.

(Current Item and Value is printed)

Selects the next menu item

)

“Direct Select” menu item

)

(e.g., 9 Faul t L i ght flashes = Baud Rate,

menu item #9; see Section B.2.2)

Appendix B – Internal Menu 37

Page 44

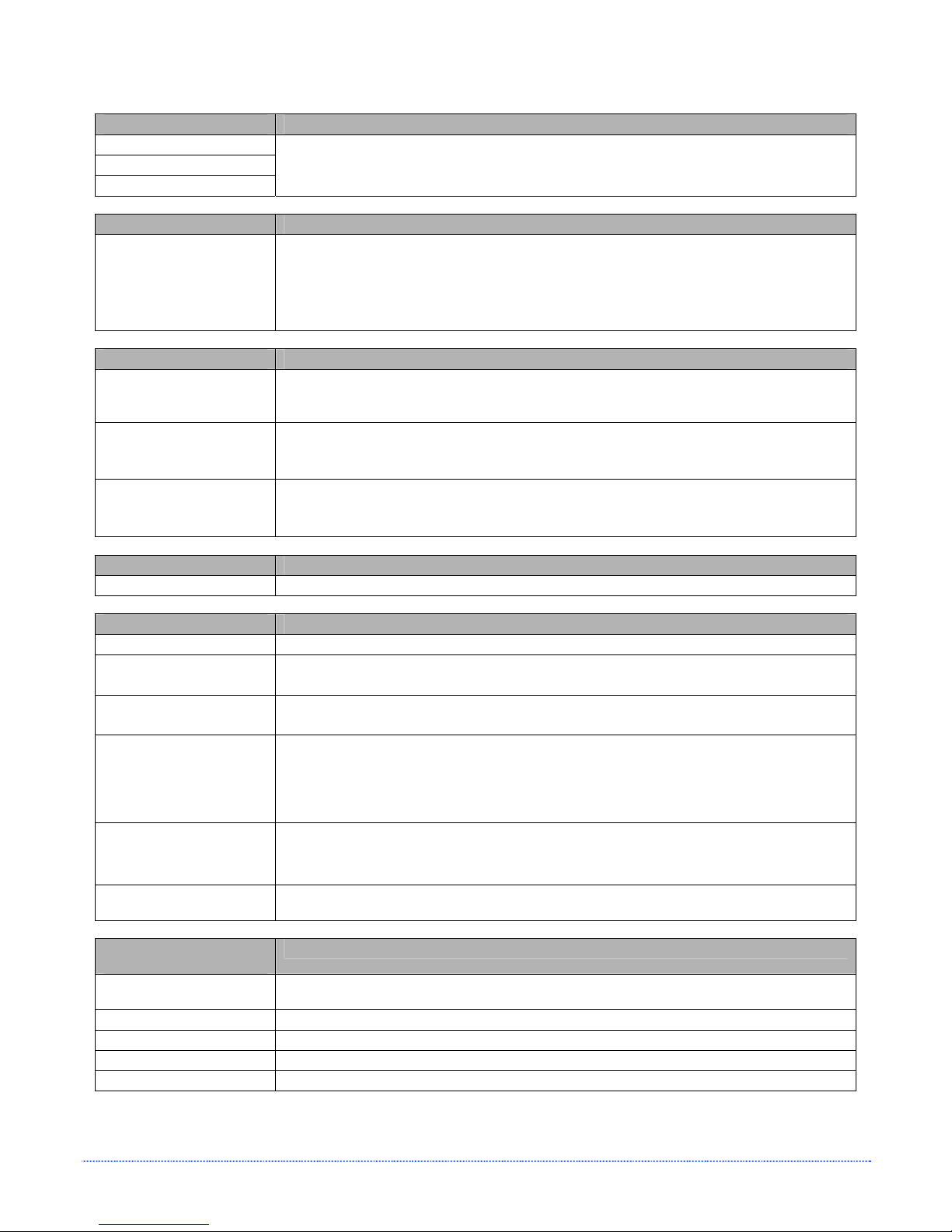

B.2.1 Printer Setup Menu List

The Printer Setup Menu List label, shown below, contains the printer’s current values for each menu item that

can be modified via the front panel (See Section B.2.2 for detailed item descriptions.)

The Menu Item Numbers correspond to the item’s position in the Menu List for selection when pressing the

button during the Printer Setup Procedure. For example to “Direct Select” the BAUD RATE Menu Item press

and hold the

etc.

F2

button for 9 flashes of the FAULT Light or for the LABEL LENGTH item hold F2 for 12 flashes,

Menu Item

Numbers

Values

Menu

Items

1) DIRECT THERMAL = MEDIA TYPE

2) GAP = SENSOR TYPE

3) AUTO = PRESENT SENSOR

4) AUTO = CUTTER

5) IMPERIAL =UNITS OF MEASURE

6) 0 = ROW ADJUST

7) 0 = COLUMN ADJUST

8) 0 = PRESENT ADJUST

9) 9600 BPS = BAUD RATE bps

10) 8 = DATA BITS.

11) STANDARD CODES = CONTROL CODES

12) 100 = LABE LENGTH .01 in

13) 426 = LABEL WIDTH .01 in

14) 511 = SCALEABLE FONT CACHE 1KB

15) 1024 = INTERNAL MODULE

16) AUTO = PRESENT DISTANCE

17) NO = LABEL ALIGNMENT

18) 1 = ALIGNMENT LENGTH .01 in

19) DPL = INPIT MODE

20) STANDARD = DPL EMULATION

21) 10 = HEAT

22) M ULTIPLE LABEL = IMAGING MODE

23) STANDARD = FAULT HANDLING

24) ENABLED = HEAT COMMAND

25) ENABLED = SPEED COMMANDS

F2

When using narrow media, the ‘Menu Items’ column may be truncated.

38 Appendix B – Internal Menu

Page 45

B.2.2 Menu Items and Values

The table below details the Printer Setup Menu List items with a brief description of the item’s function, and

the possible values.

* = Default Setting

1) MEDIA TYPE

Sets printing for direct thermal

(no ribbon) or thermal transfer

(ribbon) media.

Possible Values:

* DIRECT THERMAL

THERMAL TRANSFER

4) CUTTER

Enables/Disables the optional

Media Cutter feature.

Possible Values:

* AUTO

NO

YES

7) COLUMN ADJUST

Shifts the horizontal start of

print position (in xxx dots).

Possible Values:

Range: 0 – 255; nominal =

*128

(0 = close to edge; 255 =

farthest from edge)

10) DATA BITS

Sets the serial data word length

(Must match the host setting).

Possible Values:

* 8

7

2) SENSOR TYPE

Selects the sensor type used to

detect the media’s Top Of Form

(TOF) mark.

Possible Values:

* EDGE: gap / notch TOF marks

REFL (Reflective): black marks

CONT (Continuous): no TOF

marks

5) UNITS OF MEASURE

Sets the printer to interpret

measurements as metric or

imperial values.

Possible Values:

* Imperial

Metric

8) PRESENT ADJUST

Specifies an additional amount to

feed the label after printing.

Possible Values:

Range: 0 – 255; nominal = *128

(0 = close to edge; 255 = farthest

from edge)

11) CONTROL CODES

Allows code selection listed in

Programmer’s manual.

Possible Values:

* (STD) Standard Codes

(ALT) Alternate Codes