Page 1

Data sheet

Hot gas bypass regulator

Type KVC

KVC hot gas bypass regulator are used to adapt

compressor capacity to actual evaporator load by

supplying a replacement capacity in form of

hot / cool gas.

It is installed in a bypass line between the high and

low pressure sides of the refrigeration system and

is designed for direct gas injection into the suction

line.

Features • Accurate, adjustable pressure regulation

• Wide capacity and operating range

• Pulsation damping design

• Stainless steel bellows

© Danfoss | DCS (rm) | 2020.10

• Compact angle design for easy installation

• ”Hermetic” brazed construction

• Available with are or ODF solder connections

• May be used in the following EX range: Category

3 (Zone 2)

DKRCC.PD.HE0.A7.22 | 1

Page 2

Data sheet | Hot gas bypass regulator, type KVC

Approvals

Technical data

Metric conversions:

1 psi = 0.07 bar

5

⁄9 (t

°F - 32) = t

1

1 TR = 3.5 kW

°C

2

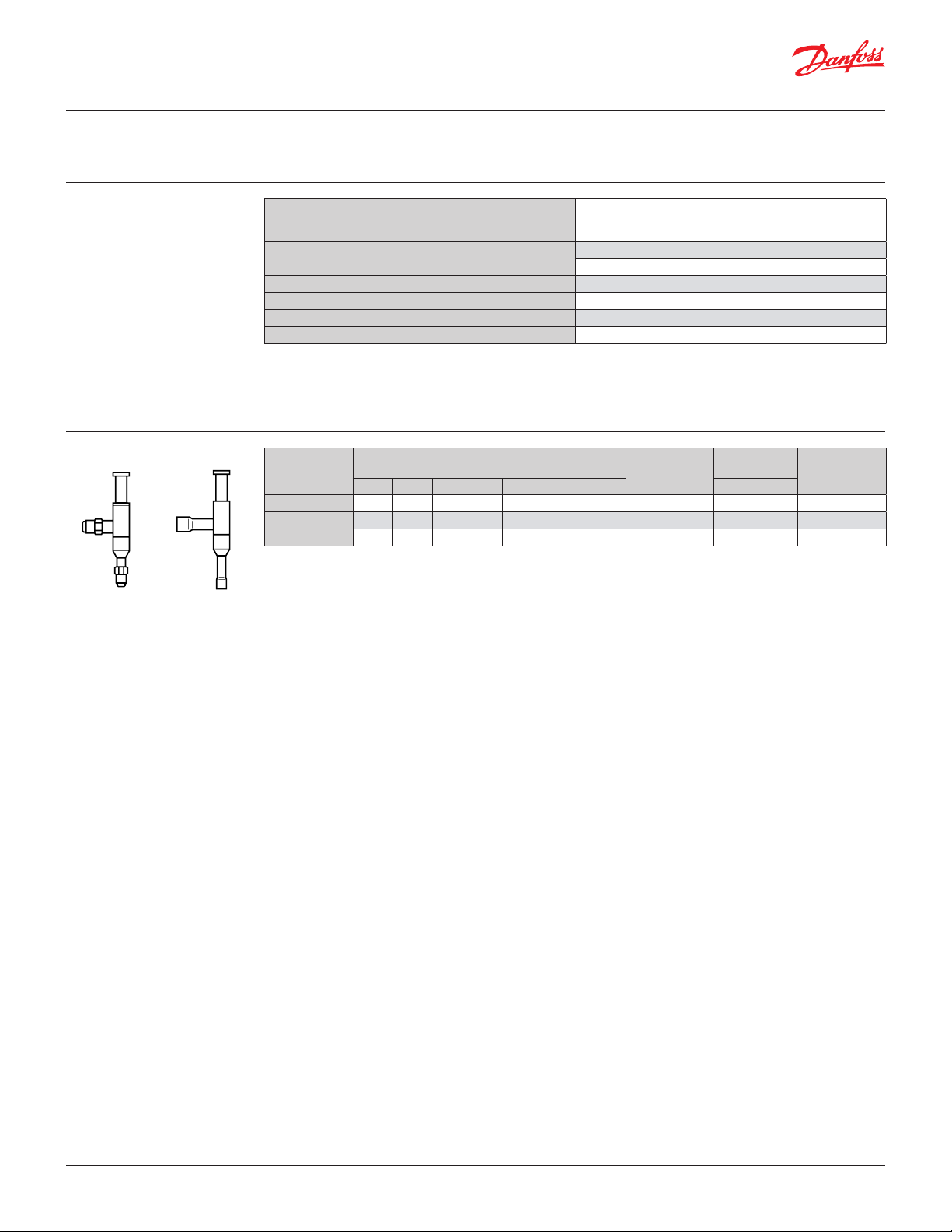

Ordering

UL LISTED, le SA7200

EAC

Refrigerants

Regulating range

Maximum working pressure MWP = 406 psig

Maximum test pressure Pe = 450 psig

Medium temperature range -49 – 266 °F

Maximum P-band 29 psi

This product is approved for R290, R454A, R454C,

R455A, R600, R600a, R1234ze(E), R1234yf, R1270

by ignition source assessment in accordance with

standard EN ISO80079-36. Flare connections are

R22, R134a, R290, R404A, R407A, R407C, R407F, R407H, R448A,

R449A, R449B, R450A, R452A, R454A, R454C, R455A, R507A, R513A,

R515B, R516A, R600, R600a, R1234ze(E), R1234yf, R1270

Pe = 3.00 – 87.00 psig

Factory setting = 29 psig

For complete list of approved refrigerants, visit

www.products.danfoss.com and search for

individual code numbers, where refrigerants are

listed as part of technical data.

only approved for A1 and A2L refrigerants.

Rated capacity 1)

= 77 °F

l

[TR]

Type

KVC 12 2.14 1.36 2.02 2.31

KVC 15 4.17 2.65 3.93 4.50

KVC 22 5.35 3.41 5.04 5.78 – –

1

) Rated capacity is based on:

Suction gas temperature ts = 14 °F

Condensing temperature t

Oset ∆p = 10 psi

2

) KVC are delivered without are nuts. Separate are nuts can be supplied:

1⁄2 in code no 011L1103

5⁄8 in code no 011L1167

R22 R134a R404A/R507 R407C [in] [in]

Flare

connection 2)

1

⁄2 034L0141

5

⁄8 034L0142

Code no.

Solder

connection

1

⁄2 034L0143

5

⁄8 034L0147

7

⁄8 034L0144

Code no.

Note:

The connection dimensions chosen must not be

too small, as gas velocities in excess of 130 ft / s at

the inlet of the regulator can result in ow noise.

If the temperature in the discharge gas line is too

high according to the compressor specications, it

is recommanded to install a liquid injection valve in

a bypass from the liquid line to the suction line.

© Danfoss | DCS (rm) | 2020.10

DKRCC.PD.HE0.A7.22 | 2

Page 3

Data sheet | Hot gas bypass regulator, type KVC

Replacement capacity

Metric conversions:

1 psi = 0.07 bar

5

⁄9 (t

°F - 32) = t

1

1 TR = 3.5 kW

1 in = 25.4 mm

°C

2

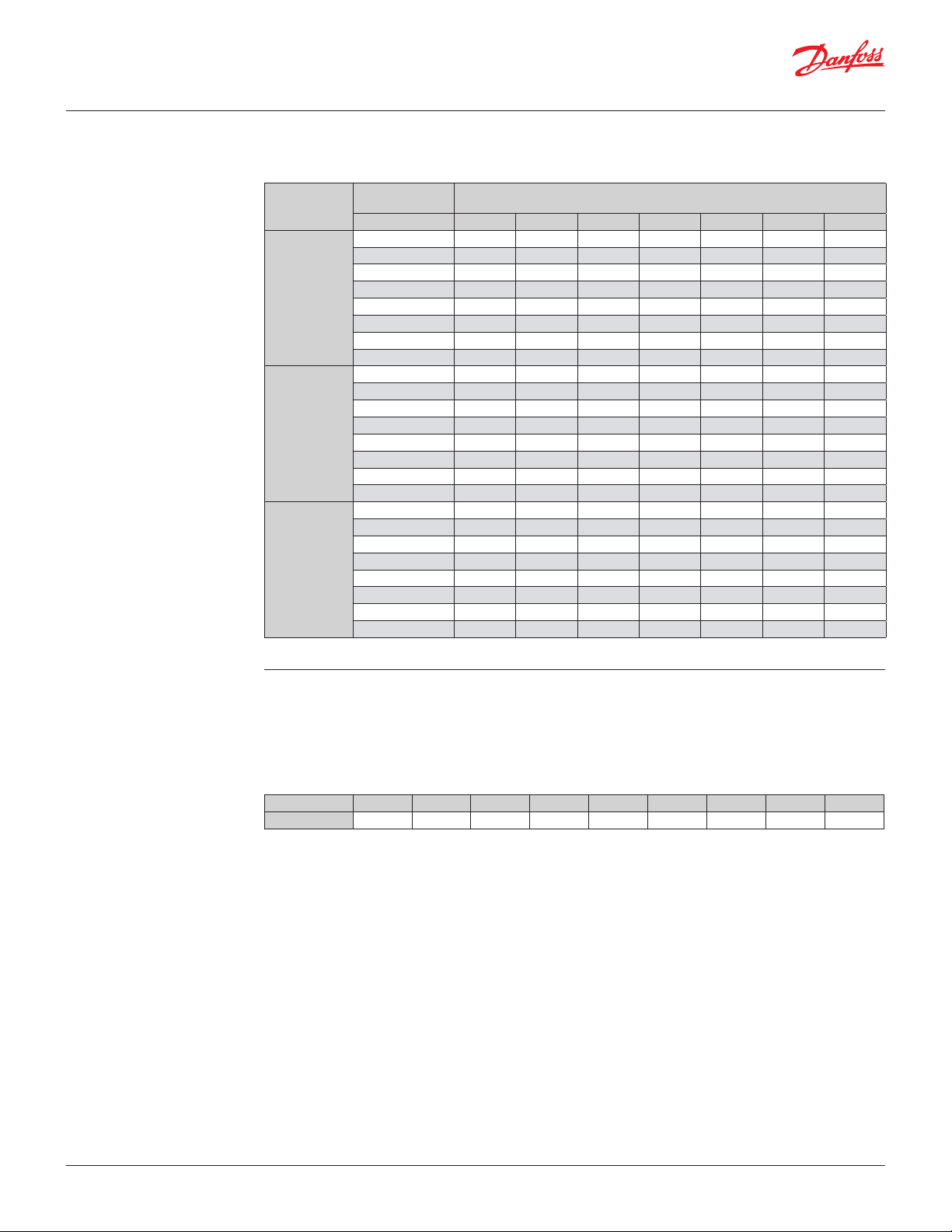

Maximum regulator capacity Qe 1)

Type

KVC 12

KVC 15

KVC 22

1

) The capacities are based on: Condensing temperature tl = 77 °F

Oset ∆p

[psi] -50 -40 -25 -10 10 30 50

1.5 – 0.68 0.70 0.71 0.73 0.75 0.77

2.0 – 0.93 0.95 0.97 1.00 1.03 1.05

3.0 – 1.33 1.36 1.39 1.43 1.47 1.51

5.0 – 1.75 1.79 1.83 1.88 1.93 1.98

7.5 – 1.93 1.97 2.01 2.07 2.12 2.18

10.0 – 2.00 2.04 2.08 2.14 2.20 2.26

15.0 – 2.19 2.24 2.28 2.35 2.41 2.48

20.0 – 2.62 2.67 2.72 2.80 2.87 2.94

1.5 – 1.01 1.03 1.06 1.09 1.12 1.15

2.0 – 1.20 1.23 1.25 1.29 1.32 1.35

3.0 – 1.73 1.77 1.80 1.85 1.90 1.95

5.0 – 2.64 2.69 2.75 2.83 2.90 2.98

7.5 – 3.39 3.46 3.54 3.63 3.73 3.83

10.0 – 3.90 3.98 4.06 4.17 4.28 4.39

15.0 – 4.76 4.66 4.75 4.88 5.01 5.14

20.0 – 5.05 5.16 5.27 5.42 5.57 5.72

1.5 – 1.09 1.12 1.14 1.17 1.21 1.24

2.0 – 1.38 1.41 1.44 1.48 1.52 1.56

3.0 – 1.89 1.93 1.97 2.02 2.07 2.12

5.0 – 2.88 2.94 3.00 3.08 3.16 3.24

7.5 – 4.02 4.11 4.19 4.31 4.43 4.54

10.0 – 4.98 5.09 5.20 5.35 5.50 5.64

15.0 – 6.35 6.49 6.63 6.82 7.01 7.20

20.0 – 7.10 7.25 7.40 7.60 7.79 7.99

Regulator capacity Q

1

) [TR] suction gas temperature ts after

e

pressure / temperature reduction [°F]

R22

Correction factors for condensing temperature tl.

When liquid temperature tl is other than 77 °F,

adjust the table capacities by multiplying them

by the appropriate correction factor found in the

following table.

Correction factors for condensing temperature t

tl [°F] 50 59 68 77 86 95 104 113 122

R22 0.9 0.93 0.96 1.00 1.05 1.1 1.13 1.18 1.24

System capacity × correction factor = table capacity

l

© Danfoss | DCS (rm) | 2020.10

DKRCC.PD.HE0.A7.22 | 3

Page 4

Data sheet | Hot gas bypass regulator, type KVC

Replacement capacity

(continued)

Metric conversions:

1 psi = 0.07 bar

5

⁄9 (t

°F - 32) = t

1

1 TR = 3.5 kW

1 in = 25.4 mm

°C

2

Maximum regulator capacity Qe 1)

Type

KVC 12

KVC 15

KVC 22

1

) The capacities are based on: Condensing temperature tl = 77 °F

Oset ∆p

[psi] -50 -40 -25 -10 10 30 50

1.5 – – 0.41 0.43 0.46 0.48 0.50

2.0 – – 0.58 0.60 0.62 0.66 0.70

3.0 – – 0.83 0.86 0.91 0.95 1.00

5.0 – – 1.09 1.14 1.20 1.25 1.31

7.5 – – 1.20 1.25 1.31 1.37 1.44

10.0 – – 1.25 1.30 1.36 1.42 1.49

15.0 – – 1.36 1.42 1.49 1.56 1.63

20.0 – – 1.62 1.69 1.78 1.86 1.94

1.5 – – 0.62 0.65 0.68 0.72 0.76

2.0 – – 0.74 0.78 0.82 0.86 0.90

3.0 – – 1.08 1.13 1.18 1.24 1.28

5.0 – – 1.64 1.72 1.79 1.87 1.96

7.5 – – 2.12 2.21 2.30 2.41 2.51

10.0 – – 2.45 2.54 2.65 2.77 2.88

15.0 – – 2.87 2.96 3.11 3.25 3.40

20.0 – – 3.13 3.26 3.44 3.61 3.79

1.5 – – 0.67 0.70 0.73 0.78 0.82

2.0 – – 0.86 0.90 0.94 0.97 1.02

3.0 – – 1.18 1.22 1.28 1.33 1.39

5.0 – – 1.80 1.86 1.96 2.04 2.12

7.5 – – 2.52 2.62 2.74 2.87 2.99

10.0 – – 3.13 3.25 3.41 3.55 3.71

15.0 – – 4.00 4.15 4.34 4.54 4.74

20.0 – – 4.43 4.61 4.82 5.05 5.28

Regulator capacity Q

1

) [TR] suction gas temperature ts after

e

pressure / temperature reduction [°F]

R134 a

Correction factors for condensing temperature tl.

When liquid temperature tl is other than 77 °F,

adjust the table capacities by multiplying them

by the appropriate correction factor found in the

following table.

Correction factors for condensing temperature t

tl [°F] 50 59 68 77 86 95 104 113 122

R134a 0.88 0.92 0.96 1.00 1.05 1.1 1.16 1.23 1.31

System capacity × correction factor = table capacity

l

© Danfoss | DCS (rm) | 2020.10

DKRCC.PD.HE0.A7.22 | 4

Page 5

Data sheet | Hot gas bypass regulator, type KVC

Replacement capacity

(continued)

Metric conversions:

1 psi = 0.07 bar

5

⁄9 (t

°F - 32) = t

1

1 TR = 3.5 kW

1 in = 25.4 mm

°C

2

Maximum regulator capacity Qe 1)

Type

KVC 12

KVC 15

KVC 22

1

) The capacities are based on: Condensing temperature tl = 77 °F

Oset ∆p

[psi] -50 -40 -25 -10 10 30 50

1.5 0.57 0.58 0.62 0.64 0.67 0.70 0.74

2.0 0.79 0.81 0.85 0.88 0.92 0.97 1.01

3.0 1.16 1.19 1.23 1.28 1.34 1.40 1.46

5.0 1.54 1.58 1.64 1.69 1.77 1.85 1.93

7.5 1.68 1.73 1.79 1.86 1.96 2.05 2.13

10.0 1.74 1.78 1.85 1.93 2.02 2.11 2.21

15.0 1.89 1.94 2.01 2.10 2.20 2.31 2.41

20.0 2.27 2.33 2.42 2.51 2.62 2.74 2.85

1.5 0.86 0.89 0.92 0.96 1.01 1.06 1.10

2.0 1.05 1.07 1.11 1.16 1.21 1.27 1.32

3.0 1.51 1.55 1.61 1.66 1.74 1.82 1.90

5.0 2.29 2.34 2.44 2.53 2.65 2.77 2.89

7.5 2.94 3.01 3.14 3.26 3.42 3.58 3.74

10.0 3.38 3.47 3.61 3.75 3.93 4.11 4.30

15.0 3.95 4.06 4.22 4.39 4.61 4.82 5.04

20.0 4.36 4.48 4.66 4.85 5.09 5.34 5.58

1.5 0.92 0.96 0.99 1.02 1.08 1.12 1.18

2.0 1.19 1.22 1.27 1.31 1.38 1.44 1.51

3.0 1.71 1.75 1.83 1.89 1.98 2.08 2.17

5.0 2.63 2.71 2.81 2.92 3.06 3.20 3.34

7.5 3.58 3.67 3.82 3.96 4.17 4.35 4.54

10.0 4.33 4.46 4.63 4.81 5.04 5.28 5.51

15.0 5.49 5.64 5.86 6.08 6.39 6.69 6.99

20.0 6.31 6.49 6.74 7.01 7.35 7.70 8.04

Regulator capacity Q

1

) [TR] suction gas temperature ts after

e

pressure / temperature reduction [°F]

R404A/R507

Correction factors for condensing temperature tl.

When liquid temperature tl is other than 77 °F,

adjust the table capacities by multiplying them

by the appropriate correction factor found in the

following table.

Correction factors for condensing temperature t

tl [°F] 50 59 68 77 86 95 104 113 122

R404A/R507 0.84 0.89 0.94 1.00 1.07 1.06 1.26 1.4 1.57

System capacity × correction factor = table capacity

l

© Danfoss | DCS (rm) | 2020.10

DKRCC.PD.HE0.A7.22 | 5

Page 6

Data sheet | Hot gas bypass regulator, type KVC

Replacement capacity

(continued)

Metric conversions:

1 psi = 0.07 bar

5

⁄9 (t

°F - 32) = t

1

1 TR = 3.5 kW

1 in = 25.4 mm

°C

2

Maximum regulator capacity Qe 1)

Type

KVC 12

KVC 15

KVC 22

1

) The capacities are based on: Condensing temperature tl = 77 °F

Oset ∆p

[psi] -50 -40 -25 -10 10 30 50

1.5 – 0.73 0.76 0.77 0.79 0.81 0.83

2.0 – 1.00 1.03 1.05 1.08 1.11 1.13

3.0 – 1.44 1.47 1.50 1.54 1.59 1.63

5.0 – 1.89 1.93 1.98 2.03 2.08 2.14

7.5 – 2.08 2.13 2.17 2.24 2.29 2.35

10.0 – 2.16 2.20 2.25 2.31 2.38 2.44

15.0 – 2.37 2.42 2.46 2.54 2.60 2.68

20.0 – 2.83 2.88 2.94 3.02 3.10 3.18

1.5 – 1.09 1.11 1.14 1.18 1.21 1.24

2.0 – 1.30 1.33 1.35 1.39 1.43 1.46

3.0 – 1.87 1.91 1.94 2.00 2.05 2.11

5.0 – 2.85 2.91 2.97 3.06 3.13 3.22

7.5 – 3.66 3.74 3.82 3.92 4.03 4.14

10.0 – 4.21 4.30 4.38 4.50 4.62 4.74

15.0 – 4.92 5.03 5.13 5.27 5.41 5.55

20.0 – 5.45 5.57 5.69 5.85 6.02 6.18

1.5 – 1.18 1.21 1.23 1.26 1.31 1.34

2.0 – 1.49 1.52 1.56 1.60 1.64 1.68

3.0 – 2.04 2.08 2.13 2.18 2.24 2.29

5.0 – 3.11 3.18 3.24 3.33 3.41 3.50

7.5 – 4.34 4.44 4.53 4.65 4.78 4.90

10.0 – 5.38 5.50 5.62 5.78 5.94 6.09

15.0 – 6.86 7.01 7.16 7.37 7.57 7.78

20.0 – 7.67 7.83 7.99 8.21 8.41 8.63

Regulator capacity Q

1

) [TR] suction gas temperature ts after

e

pressure / temperature reduction [°F]

R407C

Correction factors for condensing temperature tl.

When liquid temperature tl is other than 77 °F,

adjust the table capacities by multiplying them

by the appropriate correction factor found in the

following table.

Correction factors for condensing temperature t

tl [°F] 50 59 68 77 86 95 104 113 122

R407C 0.88 0.91 0.95 1.00 1.05 1.11 1.18 1.26 1.35

System capacity × correction factor = table capacity

l

© Danfoss | DCS (rm) | 2020.10

DKRCC.PD.HE0.A7.22 | 6

Page 7

Data sheet | Hot gas bypass regulator, type KVC

Sizing

Metric conversions:

1 psi = 0.07 bar

5

⁄9 (t

°F - 32) = t

1

1 TR = 3.5 kW

1 in = 25.4 mm

°C

2

Valve selection

Example

For optimum performance, it is important to select

a KVC valve according to system conditions and

application.

The following data must be used when sizing a KVC

valve:

Note:

When selecting the appropriate valve, it may be

necessary to convert the actual capacity using a

correction factor for condensing temperature.

This is due to dierences between the table rated

conditions and the design conditions.

The following example illustrates how this is done.

Step 1:

Determine the correction factor for the

condensing temperature tl.

• Refrigerant: HCFC, HFC and HC

• Suction temperature at maximum

compressor / evaporator load ts in [°F] / [psig]

• Minimum suction temperature ts in [°F] / [psig]

• Compressor capacity in [TR]

• Evaporating load in [TR]

• Condensing temperature tl in [°F]

• Connection type: are or solder

• Connection size [in]

Conditions:

• Refrigerant type: R134a

• Suction temperature at maximum

compressor / evaporator load ts: 0 °F ~ 7 psi.

• Minimum suction temperature ts: 10 °F ~ 12 psi.

• Compressor capacity at 10 °F: 4.4 TR

• Evaporating load at 10 °F: 2.85 TR

• Condensing temperature tl: 95 °F

• Connection type: solder

• Connection size: 5⁄8 in

From the correction factors table (see below)

a condensing temperature of 95 °F, R134a

corresponds to a factor of 1.1.

Correction factors for condensing temperature t

tl [°F] 50 59 68 77 86 95 104 113 122

R 134a 0.88 0.92 0.96 1.00 1.05 1.1 1.16 1.23 1.31

R22 0.9 0.93 0.96 1.00 1.05 1.1 1.13 1.18 1.24

R404A/R507 0.84 0.89 0.94 1.00 1.07 1.16 1.26 1.4 1.57

R407C 0.88 0.91 0.95 1.00 1.05 1.11 1.18 1.26 1.35

l

Step 2:

The required replacement capacity is dened as

the (compressor capacity – the evaporator load)

divided by the correction factor is equal:

(4.4-2.85) / 1.1 = 1,41 TR

Step 3:

Now select the appropriate capacity table

and choose the column for minimum suction

temperature ts = 10 °F.

KVC 15 delivers 1.79 TR at an oset of 5 psi.

Based on the required connection size of

5

⁄8 in ODF, the KVC 15 is the proper selection for this

example.

Using the corrected replacement capacity, select

a valve that provides an equivalent or greater

capacity than required.

From the correction factors table (see below) a

condensing temperature of

95 °F, R134a corresponds to a factor of 1.1.

Step 4:

KVC 15, 5⁄8 in ODF

Code no 034L0147.

© Danfoss | DCS (rm) | 2020.10

DKRCC.PD.HE0.A7.22 | 7

Page 8

Data sheet | Hot gas bypass regulator, type KVC

Design / Function KVC

Hot gas bypass regulator type KVC opens on a fall in

pressure on the outlet side, i.e. when the pressure in

the evaporator reaches the set value.

Type KVC regulates on outlet pressure (suction

pressure) only. Pressure variations on the inlet side

of the regulator do not aect the degree of opening

as the valve is equipped with equalization bellows (6).

The bellows has an eective area corresponding to

that of the valve seat neutralizing any aect to the

setting.

1. Protective cap

2. Gasket

3. Setting screw

4. Main spring

5. Valve body

6. Equalization bellows

7. Valve plate

8. Valve seat

9. Damping device

P-band and Oset

Capacity

The regulator is also equipped with a damping

device (9) providing protection against pulsations

which can normally arise in a refrigeration system.

The damping device helps to ensure long life

for the regulator without impairing regulation

accuracy.

Danfoss

34L182.11

© Danfoss | DCS (rm) | 2020.10

Oset

P-band

Proportional band:

The proportional band or P-band is dened as the

amount of pressure required to move the valve

plate from closed to full open position.

If the setting is 80 psig and the p-band is 29 psi,

the pressure at which the valve gives maximum

capacity will be 51 psig.

Setting

[bar]

Oset:

The oset is dened as the permissible pressure

variation in suction line pressure (temperature).

It is calculated as the dierence between the

required working pressure and the minimum

allowable pressure.

The oset is always a part of the P-band.

Example with R 404A:

A suction temperature ahead of the compressor

of 25 °F ~ 61 psig is required, and the temperature

must not drop below 14 °F ~ 48 psig.

The oset will then be 13 psi.

DKRCC.PD.HE0.A7.22 | 8

Page 9

Danf

already on order pro

All trademarks in this material are property of the respec

Dimensions and weights KVC

Type

Connection

Flare

Solder

ODF

NV

NV

1

H

2

H

1

B

2

1

C

solder

øD

[in] [in] [in] [in] [in] [in] [in] [in] [in] [lbs]

KVC 12

Metric conversions

1 in = 25.4 mm

1 lb = 0.454 kg

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

KVC 15

KVC 22 –

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

1

⁄2

5

⁄8

1

⁄2

5

⁄8

7

8

/

3

⁄4

15

⁄16

15

⁄16 7.047 3.898 2.520 0.394 1.181 0.88

15

⁄16 7.047 3.898 2.520 0.472 1.181 0.88

– – 7.047 3.898 2.520 0.669 1.181 0.88

Net

weight

© Danfoss | DCS (rm) | 2020.10

DKRCC.PD.HE0.A7.22 | 9

Loading...

Loading...