Page 1

REFRIGERATION AND

AIR CONDITIONING

Pulse Motor

Expansion Valves

Type KV

TECHNICAL LEAFLET

Page 2

Technical leaflet Pulse Motor Expansion Valves, Type KV

Contents

Page

Introduction .....................................................................................................................................................................................3

Features ..............................................................................................................................................................................................3

Explanation of Action ...................................................................................................................................................................4

Operation Principles .................................................................................................................................................................. 4-5

Common Refrigerant Valve and Coil Specifications...........................................................................................................6

Application Examples ...................................................................................................................................................................7

Selection Method .......................................................................................................................................................................8-9

Capacity R410A ............................................................................................................................................................................10

Applications .......................................................................................................................................................................... 11

CO

2

Dimensions ....................................................................................................................................................................................12

2 USCO.PD.V1.A1.22 / 521U0082 © Danfoss Inc (USCO / mks), 1-2008

Page 3

Technical leaflet Pulse Motor Expansion Valves, Type KV

4800

Pulse

Flow

Max

4800

Pulse

Flow

Max

4800

Pulse

Flow

Max

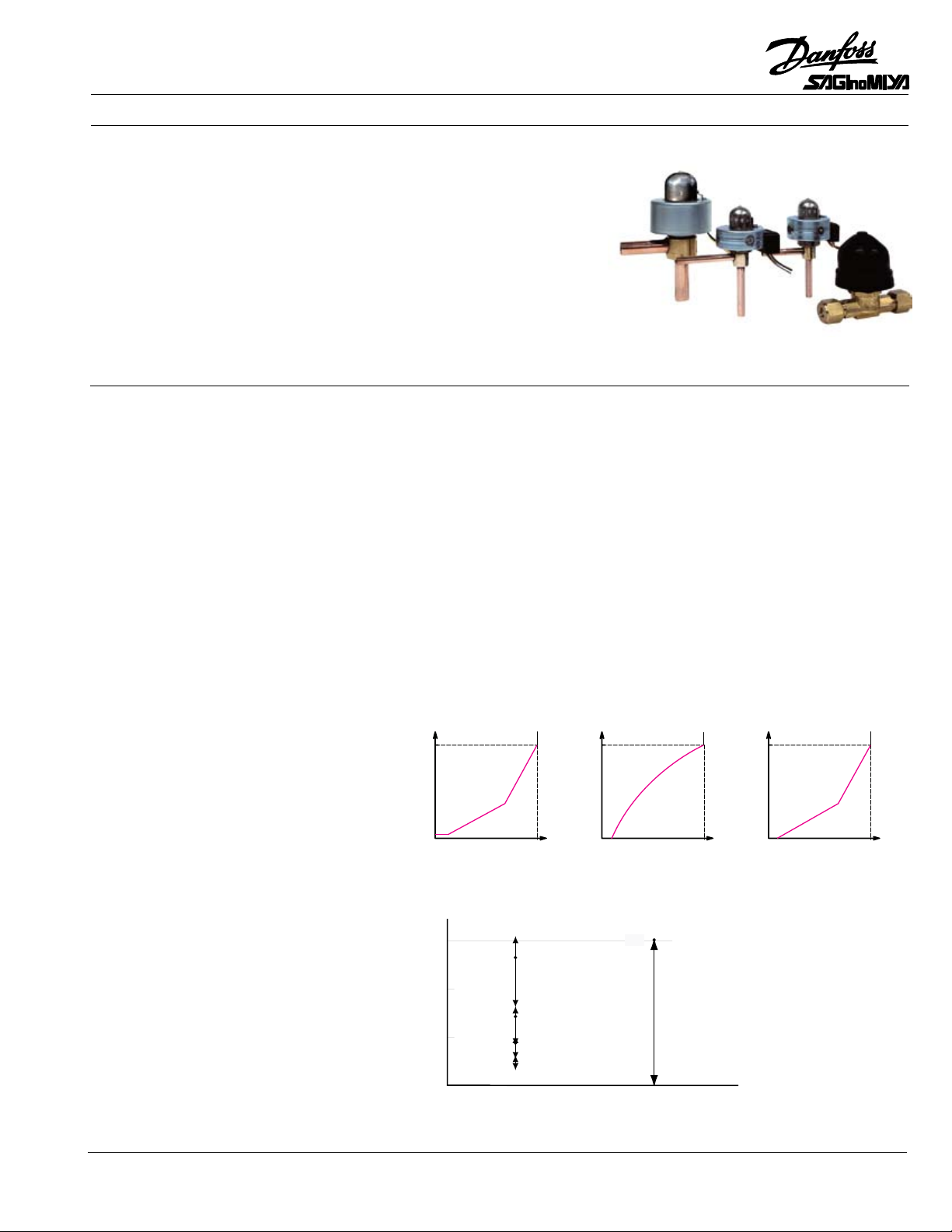

a b c

VPX-3415BPC

2.62

PKV-18BS

Capacity (U.S.R.T)

0

3

VPX-3408BPC

1.40

VPX-3405BPC

0.87

VPX-3403BPC

0.52

Our mechanical

expansion valves

Our pulse motor

expansion valves

(capacity ..... R407C)

3.0

Introduction As environmental consciousness is being raised

and global warming concerns are bringing ever

more stringent regulations, the demand is

quickly growing for energy-saving cooling and

heating devices in household and commercial

applications, including cold storage warehouses

and, rapid freezing devices.

The KV series of stepper motor expansion valves

have been solidly respected in Japanese markets

since 1982. Danfoss Saginomiya offers KV series

pulse motor expansion valves for numerous

applications. KV reliability has been extensively

field proven.

Features

Wide selection for refrigeration and air •

conditioning applications

Compatible with various refrigerants: •

R-410A, R-407C, R-134a, R-404A, R-22

Stepper motor drive provides high-precision •

flow control

A range of full closing valve types is available •

that generally require no solenoid valve

Compact and lightweight design•

Power-saving design requires no energy for •

stopping.

Ideally suited for microcomputer control•

Unipolar drive system (for bipolar drive, please •

contact us)

Bi-flow design for heat pump applications•

UKV, SKV, VKV, AKV: UL recognized•

High resolution: 480 steps from fully closed •

to fully open

KV valves have excellent flow characteristics, including high resolution at low load. •

In KV valves that have an inflected flow characteristic as shown in (a) and (c), the flow per pulse

has one rate for low flow and a higher rate for greater flow. With these valves, fine control can be

accomplished with a low load (low flow). Full closing KV valves having a flow characteristic (b), (c)

are available with inflected flow characteristic or continuous flow characteristic, the latter having

very nearly the same change in flow rate per pulse.

© Danfoss Inc (USCO / mks), 1-2008 USCO.PD.V1.A1.22 / 521U0082 3

As can be seen in the diagram above, pulse motor expansion valves have a much greater range than

mechanical valves.

Long valve lift range results in a wider range of controllable capacity•

Page 4

Technical leaflet Pulse Motor Expansion Valves, Type KV

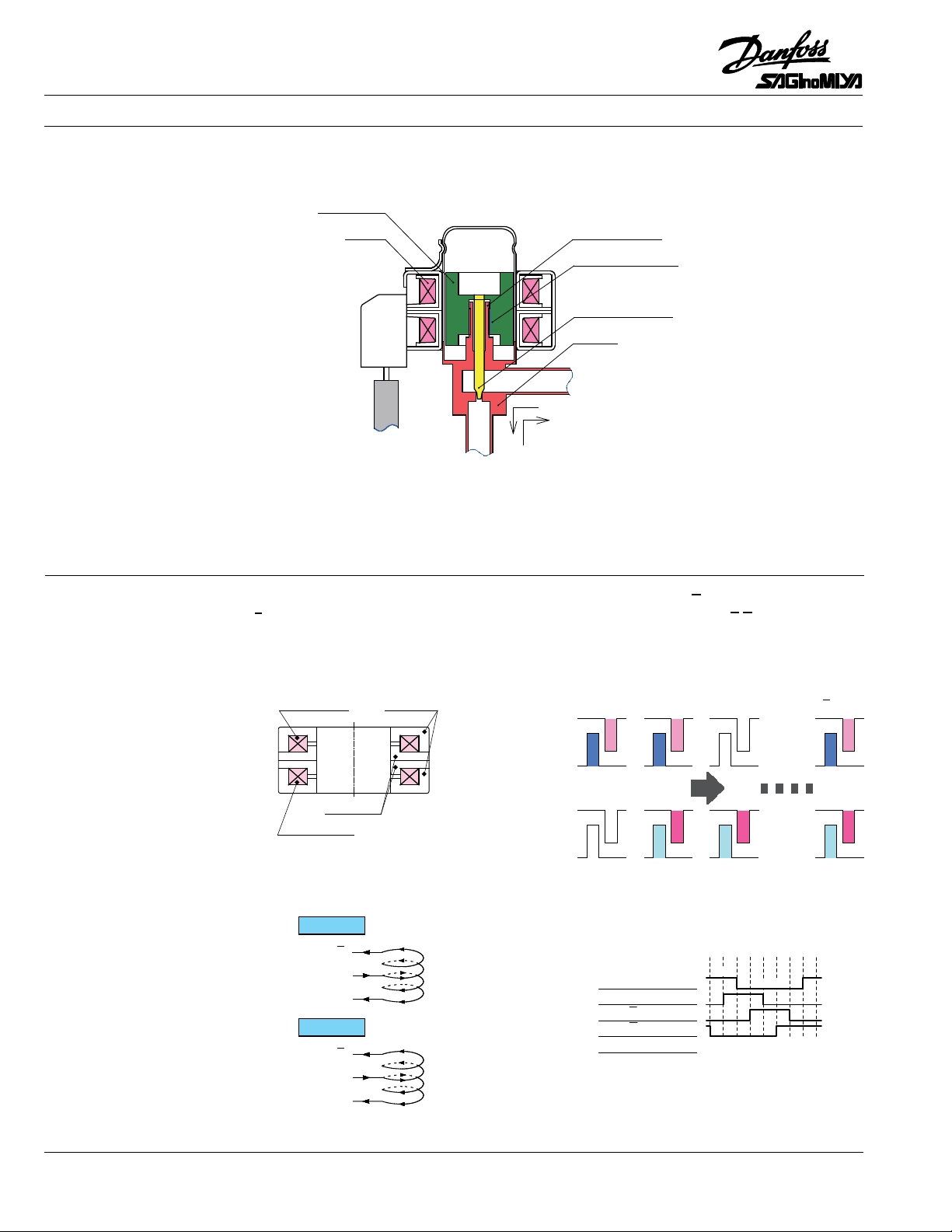

Sectional diagram of KV series

B

A

Magnet

Coil Male screw

Female screw

Needle valve

Body

Fluid direction

Lower coil

Stator

Upper coil

Housing

SS

NN

COM

COM

A

A

B

B

A Phase A,B Phase A,B PhaseB Phase

Upper coil

Lower coil

S

N

S

N

N

S

N

S

S

N

S

N

Fig.1-1

Fig.1-2

Fig.1-3

Connector No.

ON

OFF

1

A Phase

2

B Phase

A Phase

B Phase

3

4

5 COM.(+)

Fig.1-4 Excitation sequence

(1-2 phase excitation)

Valve operation Valve opens

Valve is closed

Explanation of Action

In operation of the KV valve, the magnet-needle valve assembly is rotated by the stepper motor

(principle described in next paragraph) and by means of a screw structure has linear motion, opening

and closing to regulate refrigerant flow. This simple structure results in compact products.

Operation Principle I

Figs.1-1 and 1-2 show a vertical cross section of the coils (upper coil (A and A) and lower coil (B and

B). Each coil comprises a clockwise winding A, B and a counterclockwise winding A, B. Each coil has 3

terminals. Fig.1-3 shows the arangement of the stators that surround the armature. The polarities of the

magnetic poles change depending on the direction of current flow.

4 USCO.PD.V1.A1.22 / 521U0082 © Danfoss Inc (USCO / mks), 1-2008

Page 5

Technical leaflet Pulse Motor Expansion Valves, Type KV

Fig.2-1

A Phase

Upper tooth

Lower tooth

B Phase

Upper tooth

Lower tooth

N

N N

S

N

S

S

A Phase

S

N

N

S

S

S

S

N

N

AB Phase

N

N

S

S

S

S

N

N

AB Phase

S

S

N

N

N

N

S

S

N

N

S

S

AB Phase

N

N

S

S

S

N

N

S

N

S

N

N

N

S

S

B Phase

S

S

S

N

N

AB Phase

N

N

S

S

S

S

N

N

S

N

S

N

S

N

N

A Phase

S

N

N

S

S

S

N

N

B Phase

S

Fig.2-2

Operation Principle II

This section explains the rotation of the permanent magnet rotor. The rotor has 24 poles, but the

following explanation is simplified by dealing with only 4 of the poles.

Fig.2-1 shows a vertical cross section through the stator. It shows the positional relation of the stator

magnetic poles with the horizontal sectional diagram in Fig.2-2. In Fig.2-1, j shows the upper teeth of

phase A, k shows the lower teeth of phase A, l shows the upper teeth of phase B, and m shows the

lower teeth of phase B.

Assume that a current flows to phase A as a pulse. The polarities in Fig. (I) are generated in the stator to

stabilize the rotor with an arrow facing upward. When feeding a current to phase AB by sending a pulse,

the polarities are as shown in Fig. (II) causing the rotor to turn 22.5 degrees. When a subsequent current

pulse is sent to phase B, the polarities are as shown in Fig. (III) causing the rotor to turn a further 22.5

degrees. By feeding pulses sequentially, one cycle is composed of 8 pulses, and the rotor rotates 180

grees in this figure. (A KV valve, remember, actually has 24 poles, so that the rotor rotates one sixth as far

as in our example, or 30 degrees with every cycle. )

© Danfoss Inc (USCO / mks), 1-2008 USCO.PD.V1.A1.22 / 521U0082 5

Page 6

Technical leaflet Pulse Motor Expansion Valves, Type KV

0.31 OD 0.31 OD

0 to 3.5 {0 to 507}

0.28

0.23

0.18

2.4 {348} or less

1.0 {145} or less

VKV–25D

0 to 2.5 {0 to 362}

1.5 {217} or less

0.37 OD

0.50 OD

0.63 OD 0.63 OD

0 to 2.5 {0 to 362} 0.7 {101} or less

2.2 {319} or less

2.8 {406} or less

1.5 {217} or less

2.2 {319} or less

3/8"

0 to 2.3 {0 to 333}

0 to 2.8 {0 to 406}

0.5

0.8

0.3

PKV-24BS

0.09

0 to 2.2 {0 to 319} 0.7

1/2"(Flare)

5.0 {17.5} 3.9 {13.7} 3.5 {12.3} 5.1 {18.0}

PKV-14BS 0.06 1.5 {5.2} 1.1 {4.0} 1.0 {3.6} 1.5 {5.3} 1.7 {6.1}

2.9 {10.3}PKV-18BS 0.07 2.3 {8.1} 2.1 {7.3} 3.0 {10.6} 3.4 {12.1}

5.9 {20.6}

5.3 {18.5} 4.1 {14.5} 3.7 {13.1} 5.4 {19.0} 6.2 {21.8}

PKV-30BS

0.12

7.9 {27.8} 6.2 {21.7} 5.6 {19.6} 8.1 {28.5} 9.3 {32.7}

Catalog No.

Port

Size

(

inch)

Capacity

(U.S.R.T.) {kW}

Connection (Solder)

(inch)

Operating Pressure

Differential, B to A

(MPa) {psi}

Wt.

(kg)

R22 R134a R407C R410A B side A side

0.31 OD 0.31 OD

0.25 OD 0.25 OD

0.31 OD 0.31 OD

0 to 3.5 {0 to 507}

0 to 3.5 {0 to 507}

Valve shut press.

on, A to B

flow directionflow direction

(MPa) {psi}

R404A

2.5 {362} or less

2.4 {348} or less

Capacity: Based on CT=38°C

[100˚F]

, ET=5°C

[41˚F]

, SC=0°C

[0˚K]

and SH=0°C

[0˚K]

(Flare)

3/8"

(Flare)

*1

*1 Refer to the following fig. *2 Weight includes a coil.

*1*1 *2

2.3 {8.2} 1.8 {6.4} 2.4 {8.5} 2.8 {9.7}SKV–16D 1.7 {5.8}0.06

SKV–18D 2.9 {10.3} 2.3 {8.1} 3.0 {10.6} 3.4 {12.1}2.1 {7.3}0.07

2.9 {10.3} 2.3 {8.1} 2.1 {7.3} 3.0 {10.6} 3.4 {12.1}UKV–18D 0.07

VKV–20D 2.5 {8.7}3.5 {12.4} 2.7 {9.7} 3.6 {12.7} 4.1 {14.5}0.08

0.09

VKV–30D 7.0 {24.7} 5.5 {19.3} 5.0 {17.4} 7.2 {25.4} 8.3 {29.1}0.12

5.6 {19.6} 4.4 {15.3} 3.9 {13.8} 5.7 {20.1} 6.5 {23.0}UKV–25D 0.09

7.6 {26.8} 6.0 {20.9} 5.4 {18.9} 7.8 {27.5} 9.0 {31.5}UKV–30D 0.12

VKV–32D 5.8 {20.3}8.2 {28.8} 6.4 {22.5} 8.4 {29.6} 9.6 {33.9}0.125

AKV–55D 27.9 {98.1}16.7 {58.8}0.22 23.7 {83.4} 18.5 {65.2} 24.4 {85.6}

0.38A / Phase

AKV

0.26A / Phase

Current (at 20˚C[68˚F])

12V DC

±10%

Rated voltage

UKV,SKV,VKV,PKV

Type

32 ± 3 Ω

(at 20˚C[68˚F])

46 ± 3 Ω

(at 20˚C[68˚F])

Direct current resistance

IP66

Enclosure

Class E MoldedInsulation class

115˚C[239˚F] or less by rated voltage,

temperature - resistance method.

Max. coil temperature

B Side

Conn.

A Side

Conn.

*1

B to A flow direction

A to B flow direction

Common Refrigerant Models

Specifications

Motor and Drive Specifications

Valve Specifications

Maximum working pressure: 609 psi (4.2 MPa)

Ambient temperature: -22 to 140oF (-30 to 60oC)

Type PKV: -58 to 140

o

Fluid Temperature: -22 to 248

F (-30 to 12oC)

o

F (-50 to 60oC)

Type AKV: -22 to 266oF (-30 to 130oC)

Type PKV: -58 to 140oF (-50 to 60oC)

Ambient humidity 95% RH or less

Modulation: Permanent magnet type direct operating stepper motor

Excitation method: 1-2 phase

Excitation speed: 31.3 pps +10%

Operating range: 0 to 480 pulses

Intialization: Phase A COM (+)

Coil Specifications

6 USCO.PD.V1.A1.22 / 521U0082 © Danfoss Inc (USCO / mks), 1-2008

Page 7

Technical leaflet Pulse Motor Expansion Valves, Type KV

Comp.

Remote Controller

Main PC Board

Anti Freeze Heater

Pulse Motor Expansion Valve

KV series

4-Way

Reversing Valve

Type STF

Pressure Sensor

Type XSK

High Pressure Controls

Type HNS

Aircoil Temperature

Sensor

Type TEK

Inlet Temperature Sensor

Type TEK

Outlet Temperature Sensor

Type TEK

Flow Switch

Type FQS

Comp.

Cooling

Indoor Unit

Outdoor Unit

Controller

Accumulator

Pressure Sensor

Type NSK

4-way reversing

valve

Type STF

Pulse Motor Expansion Valve

KV series

Application Examples Multi-type heat pump unit

Chiller unit

© Danfoss Inc (USCO / mks), 1-2008 USCO.PD.V1.A1.22 / 521U0082 7

Page 8

Technical leaflet Pulse Motor Expansion Valves, Type KV

Selection Method

If the operating conditions of the unit are known, a KV valve can be selected easily according to the

capacity – valve opening graph given on the next page.

Let’s select an optimum pulse motor expansion valve for the operating conditions shown at the bottom of

this page.

1) Calculate the required maximum refrigerating capacity of the unit (normally, the capacity just after

starting).

Enter the R-407C correction factor table in the row for evaporating temperature (-22˚F) and condensing

temperature (72˚F) , and in the column for the subcool temperature (54˚F) , and at their intersection

find the correction factor (1.39). Then calculate the required maximum capacity (19.1kW) of the unit by

dividing the refrigerating capacity (26.5kW) by the correction factor.

2) Calculate the required minimum refrigerating capacity of the unit (normally, the capacity just after

stopping operation).

Enter the table in the row for the evaporating temperature (-58˚F) and condensing temperature

(104˚F) , and in the column for the subcool temperature (72˚F) , and at their intersection find the

correction factor (1.47). Then calculate the required minimum capacity (10.6kW) of the unit by dividing the

refrigerating capacity (15.6kW) by the correction factor.

3) Selection of pulse motor expansion valves

Pulse motor expansion valves PKV-30BS and PKV-24BS can have refrigerating capacity larger than the

required maximum capacity of the unit at maximum opening 480 pulses. When comparing the valve

opening width between the maximum load and the minimum load with each other, it is 80 pulses in

PKV-30BS and 200 pulses in PKV-24BS. Select PKV-24BS in this case because the valve opening width

between the maximum load and minimum load is wider (high resolution).

Aimed refrigerating temperature: - 40oF

Kind of refrigerant used: R407C

Operating

conditions of unit

Condensing temp

(CT)

Sub cool (SC) 54

Evaporating temp

(ET)

Required capacity

Just after starting operation Just after terminating operation

o

F 104oF

104

o

F 72oF

o

F -58oF

-22

26.5kW

(with the maximum load)

15.6kW

8 USCO.PD.V1.A1.22 / 521U0082 © Danfoss Inc (USCO / mks), 1-2008

Page 9

PKV -14BS

PKV -18BS

PKV -24BS

PKV -30BS

0.0

5.0

[1.42]

10.0

[2.84]

15.0

[4.27]

20.0

[5.69]

25.0

[7.11]

30.0

[8.53]

kW

[U.S.R.T]

0 50 100 150 250 300 350 4 00 450200

R407C Correction factor table

Superheat=9

˚F

Sub cool[

˚F]

[˚F] [˚F]

0 18 36 54 72 90 108

-58

0.88 1.04 1.20 1.35 1.51 1.66 1.81

0.90 1.05 1.20 1.35 1.49 1.63 1.77

0.92 1.06 1.20 1.33 1.47 1.60 1.73

0.93 1.06 1.19 1.31 1.44 1.57 1.69

0.93 1.05 1.17 1.29 1.41 1.52 1.64

-40

0.92 1.08 1.24 1.39 1.55 1.70 1.85

0.94 1.09 1.24 1.38 1.53 1.67 1.81

0.95 1.09 1.23 1.37 1.50 1.63 1.76

0.96 1.09 1.22 1.34 1.47 1.59 1.71

0.96 1.08 1.20 1.31 1.43 1.54 1.66

-22

0.95 1.11 1.27 1.43 1.58 1.73 1.88

0.97 1.12 1.27 1.41 1.55 1.69 1.83

0.98 1.12 1.25 1.39 1.52 1.65 1.78

0.98 1.11 1.24 1.36 1.48 1.60 1.73

0.97 1.09 1.21 1.32 1.44 1.55

-

-13

0.97 1.13 1.28 1.44 1.59 1.74 1.89

0.98 1.13 1.28 1.42 1.56 1.70 1.84

0.99 1.13 1.26 1.39 1.53 1.66 1.79

0.99 1.12 1.24 1.36 1.48 1.61

-

0.98 1.09 1.21 1.32 1.44 1.55

-

-4

122

0.98 1.14 1.29 1.45 1.60 1.74 1.89

113

0.99 1.14 1.28 1.43 1.56 1.70 1.84

104

1.00 1.13 1.27 1.40 1.53 1.66

-

95

0.99 1.12 1.24 1.36 1.48 1.60

-

86

122

113

104

95

86

122

113

104

95

86

122

113

104

95

86

122

113

104

95

86

0.98 1.09 1.21 1.32 1.43

- -

Pulse

[PKV]

19.1

10.6

Refrigerant : R407C

Evaporating temp : 5˚F

Condensing temp : 104˚F

Sub cool : 0˚F

Superheat : 9˚F

Capacity – valve opening graph

Evaporating

temp.

Condensing

temp.

Technical leaflet Pulse Motor Expansion Valves, Type KV

Selection Method, continued

© Danfoss Inc (USCO / mks), 1-2008 USCO.PD.V1.A1.22 / 521U0082 9

Page 10

Technical leaflet Pulse Motor Expansion Valves, Type KV

[˚F] [˚F]

0 18 36 54 72 90 108

-76

122

0.87 1.06 1.23 1.40 1.57 1.73 1.89

113

0.91 1.08 1.24 1.40 1.56 1.71 1.86

104

0.94 1.09 1.24 1.39 1.54 1.68 1.82

0.95 1.10 1.24 1.37 1.51 1.64 1.77

86

95

122

113

104

95

86

122

113

104

86

95

122

113

104

95

86

122

113

104

95

86

122

113

104

95

86

122

113

104

95

86

122

113

104

95

86

122

113

104

95

86

122

113

104

86

95

122

113

104

95

86

0.96 1.09 1.22 1.35 1.48 1.60 1.72

-58

0.91 1.09 1.27 1.44 1.60 1.77 1.93

0.94 1.11 1.27 1.43 1.59 1.74 1.89

0.97 1.12 1.27 1.42 1.56 1.70 1.84

0.98 1.12 1.26 1.40 1.53 1.66 1.79

0.98 1.11 1.24 1.37 1.49 1.62 1.74

-40

0.93 1.12 1.29 1.46 1.63 1.79 1.95

0.97 1.14 1.30 1.45 1.61 1

.76 1.91

0.99 1.14 1.29 1.44 1.58 1.72 1.86

1.00 1.14 1.28 1.41 1.54 1.67 1.80

1.00 1.13 1.25 1.38 1.50 1.62 1.74

-22

0.96 1.14 1.31 1.48 1.64 1.80 1.96

0.98 1.15 1.31 1.46 1.61 1.76 1.91

1.00 1.15 1.30 1.44 1.58 1.72 1.85

1.00 1.14 1.28 1.41 1.54 1.67 1.79

1.00 1.12 1.25 1.37 1.49 1.61 -

-13

0.96 1.14 1.31 1.48 1.64 1.80 1.95

0.99 1.15 1.31 1.46 1.61 1.76 1.90

1.00 1.15 1.29 1.44 1.57 1.71 1.84

1.00 1.14 1.27 1.40 1.53 1.65 -

0.99 1.12 1.24 1.36 1.48 1.59 -

-4

0.96 1.14 1.31 1.48 1.64 1.79 1.95

0.99 1

.15 1.31 1.46 1.60 1.75 1.89

1.00 1.15 1.29 1.43 1.56 1.70 -

1.00 1.13 1.26 1.39 1.51 1.64 -

0.98 1.10 1.22 1.34 1.46 - -

5

0.96 1.14 1.31 1.47 1.63 1.78 1.93

0.98 1.14 1.30 1.45 1.59 1.73 -

0.99 1.14 1.28 1.41 1.55 1.68 -

0.98 1.12 1.24 1.37 1.49 - -

0.97 1.09 1.20 1.32 1.43 - -

0.96 1.14 1.30 1.46 1.61 1.77 -

0.98 1.13 1.28 1.43 1.57 1.71 -

0.98 1.12 1.26 1.39 1.52 - -

0.97 1.10 1.22 1.34 1.46 - -

0.94 1.06 1.17 1.28 - - -

0.95 1.12 1.29 1.44 1.59 1.74 -

0.96 1.12 1.26 1.41 1.55 - -

0.96 1.10 1.23 1.36 1.49 - -

0.94 1.07 1.19 1.31 - - -

0.92 1.03 1.13 1.24 - - -

32

23

0.94 1.11 1.27 1.42 1.57 - -

0.95 1.10 1.24 1.38 1.51 - -

0.94 1.07 1.20 1.32 - - -

0.91 1.03 1.15 1.26 - - -

0.88 0.98 1.09 - - - -

41

0.92 1.08 1.24 1.38 1.53 - -

0.92 1.07 1.20 1.34 - - -

0.91 1.03 1.16 1.28 - - -

0.87 0.99 1.10 - - - -

0.83 0.93 1.02 - - - -

0.0

10.0

(2.84)

20.0

(5.69)

30.0

(8.53)

[kW]

([U.S.R.T])

0 50 100 150 200 250 300 350 400 450

[Pulse]

SKV-16D46

SKV-18D49

VKV-20D32

VKV-25D34

VKV-30D36

VKV-32D38

Refrigerant : R410A

Evaporating temp. : -13˚F

Condensing temp. : 104˚F

Sub cool : 0˚F

Superheat : 9˚F

R410A Correction factor table

Superheat=9˚F

Sub cool[˚F]

Evaporating

temp.

Condensing

temp.

14

Capacity - R410A

10 USCO.PD.V1.A1.22 / 521U0082 © Danfoss Inc (USCO / mks), 1-2008

Page 11

Technical leaflet Pulse Motor Expansion Valves, Type KV

0.18

Catalog No.

Port

Size

(

inch)

Capacity

kW {U.S.R.T.}

Connection (Solder)

(inch)

Operating Pressure

Differential, B to A

psi {MPa}

Wt.

(kg)

R744 B side A side

0.25 OD 0.25 OD 0 to 1450 {0 to 10}

Valve shut press.

on, A to B

flow directionflow direction

(MPa) {psi}

Capacity: Based on inlet temp.=100°F

[38˚C]

, ET=41°F

[5˚F],

inlet pressure=

1378psi[

9.5MPa

] andSH=0°K[0°C]

*1

*1*1 *2

5.95{1.69}UKV–J14D 0.06

UKV-J

0.26A / Phase

Current (at 68˚F[20˚C])

12V DC

±10%

Rated voltage

Type

46 ± 3 Ω

(at 68˚F[20˚C])

Direct current resistance

IP66

Enclosure

Class E MoldedInsulation class

239˚F[115˚C] or less by rated voltage,

temperature - resistance method.

Max. coil temperature

B Side

Conn.

A Side

Conn.

*1

*1 Refer to the following fig. *2 Weight includes a coil.

B to A flow direction

A to B flow direction

Hot water storage unit side

Relief valve

Type VSV/WSV

Pressure

reducing valve

Type CRV

Hydrothermal

exchanger

Air heat

exchanger

Tank

Comp.

Defrost

Solenoid valve

Pressure control

Type CCB

Type HPV

Motorized

control valve

Type UKV-J

Heat pump unit side

Mixing

valve

Water

Supply

Hot Water

Supply

Pump

Hot water

irrigation

Water

irrigation

CO

Application

2

Specifications

Maximum working pressure: 2175 psi (15 MPa)

Ambient temperature: -22 to 158oF (-30 to 70oC)

Fluid temperature: -22 to 148oF (-30 to 70oC)

Ambient humidity 95% RH or less

Motor and Drive Specifications

Valve Specifications

Coil Specifications

Application Examples

CO2 Hot Water Supply Unit

Modulation: Permanent magnet type direct operating stepper motor

Excitation method: 1-2 phase

Excitation speed: 31.3 pps +10%

Operating range: 0 to 480 pulses

Intialization: Phase A COM (+)

© Danfoss Inc (USCO / mks), 1-2008 USCO.PD.V1.A1.22 / 521U0082 11

Page 12

Technical leaflet Pulse Motor Expansion Valves, Type KV

1.50[38]

1.89

[ 48]

[ 7.94±0.1 t=0.8]

0.31±0.004 t=0.031

1.39±0.08[49±2]

4.06±0.12[103±2]

7.94±0.1 t=0.8

2.44±0.08[62±2]

Conn.

Conn.

A Side

B Side

0.31±0.004

t=0.031

[ 15.88±0.15 t=1.2]

Conn.

[( 67)]( 2.64)

(2.58)[(65.5)]

(2.54)[(64.5)]

(5.91)[(150)]

Conn.

A side

B side

[ 15.88±0.15 t=1.2]

0.63±0.006 t=0.047

0.63±0.006 t=0.047

1.46 [37]

1.89

Conn.

2.52±0.08[64±2]

1.93±0.08[49±2]

4.41±0.12[112±3]

Conn.

B side

A side

[ 48]

[ 7.94±0.1 t=0.8]

0.31±0.004

t=0.031

[ 7.94±0.1 t=0.8]

0.31±0.004

t=0.031

1.46[37]

1.89

Conn.

2.60±0.08[66±2]

2.52±0.08[64±2]

5.12±0.12[130±3]

Conn.

[ 12.7±0.15 t=0.8]

[ 9.52±0.15 t=0.8]

[ 48]

A side

B side

0.5±0.006 t=0.031

0.37±0.006 t=0.031

Inlet

Flow direction

Outlet

1.18[30]

0.71[85]

( 2.17)[( 55)]

(3.62)[(92)]

19.69[500]

5/8 - 18UNF 5/8 - 18UNF

Inlet

Flow direction

M14×1

Outlet

1.42 [ 36]

( 2.17)[( 55)]

(4.13)[(105)]

19.69[500]

3.82[97]

5/8 - 18UNF 3/4 - 16UNF

0.250±0.039

t=0.047

1.54 [39]

1.85±0.079

[47±2]

Conn.

Conn.

B side

A side

1.97±0.079[50±2]

(3.90)[(99)]

[6.35±0.1 t=1.2]

[6.35±0.1 t=1.2]

1.28[32.5]

0.250±0.039 t=0.047

Catalog No.

A

B

UKV–18D

0.250±0.039 t=0.028

[ 6.35±0.1 t=0.7]

UKV–30D

UKV–25D

[ 7.94±0.1 t=0.8]

0.313±0.039 t=0.031

1.97±0.079[50±2]

(3.88)[(98.6)]

1.85±0.079

[47±2]

A

B

(1.85)[(47)]

Conn.

Conn.

Catalog No.

A

B

UKV–18D

0.250±0.039 t=0.028

[ 6.35±0.1 t=0.7]

UKV–30D

UKV–25D

(1.69)[(43)]

(1.26)[(32)]

B side

A side

[ 7.94±0.1 t=0.8]

0.313±0.039 t=0.031

Dimensions

Unit: inch[mm]

Type VKV-20D to 30D

Type UKV

Type UKV-J

Type VKV-32D

Type SKV

Type AKV

Type PKV-14BS to 24BS

Type PKV-30BS

Danfoss, Refrigeration & Air-Conditioning Division, 7941 Corporate Drive, Baltimore, MD 21236 Tel. 410-931-8250, Fax 410-931-8256, www.danfoss.us

12 USCO.PD.V1.A1.22 / 521U0082 © Danfoss Inc (USCO / mks), 1-2008

Loading...

Loading...