Page 1

Operating Guide

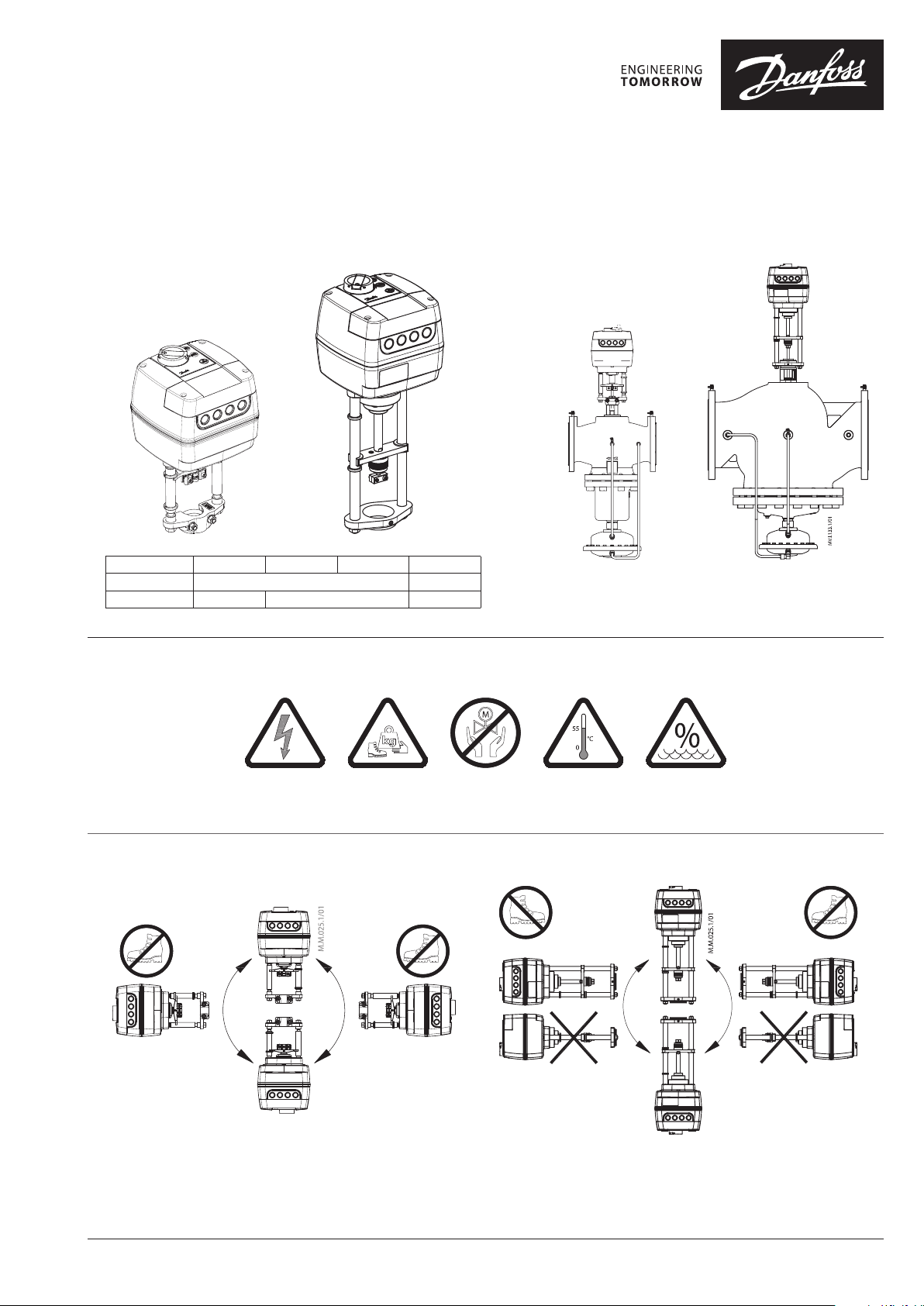

Actuator t ype

AM E 655 -1

AME 658 SD-1

AME 658 SU-1

AM E 68 5-1

AME 655-1/658 SD-1/658 SU-1 & AME 685-1

Ste m Trav el 32 mm 32 mm

Travel Speed 2 or 6 s/mm 4 or 6 s/mm 3 or 6 s/mm

MAINTENANCE

FREE

AME 655-1/658 SD-1/658 SU-1

(AB-Q M 5” & 6” / 5” & 6” HF)

5-95 % RH

no condensing

AME 685-1

(AB -Q M 8”-10 ”)

AME 685-1AME 655-1/658 SD-1/658 SU-1

AQ323736153498en-000103 | 1© Danfoss | 2021.03

Page 2

AME 655-1/658 SD-1/658 SU-1 & AME 685-1

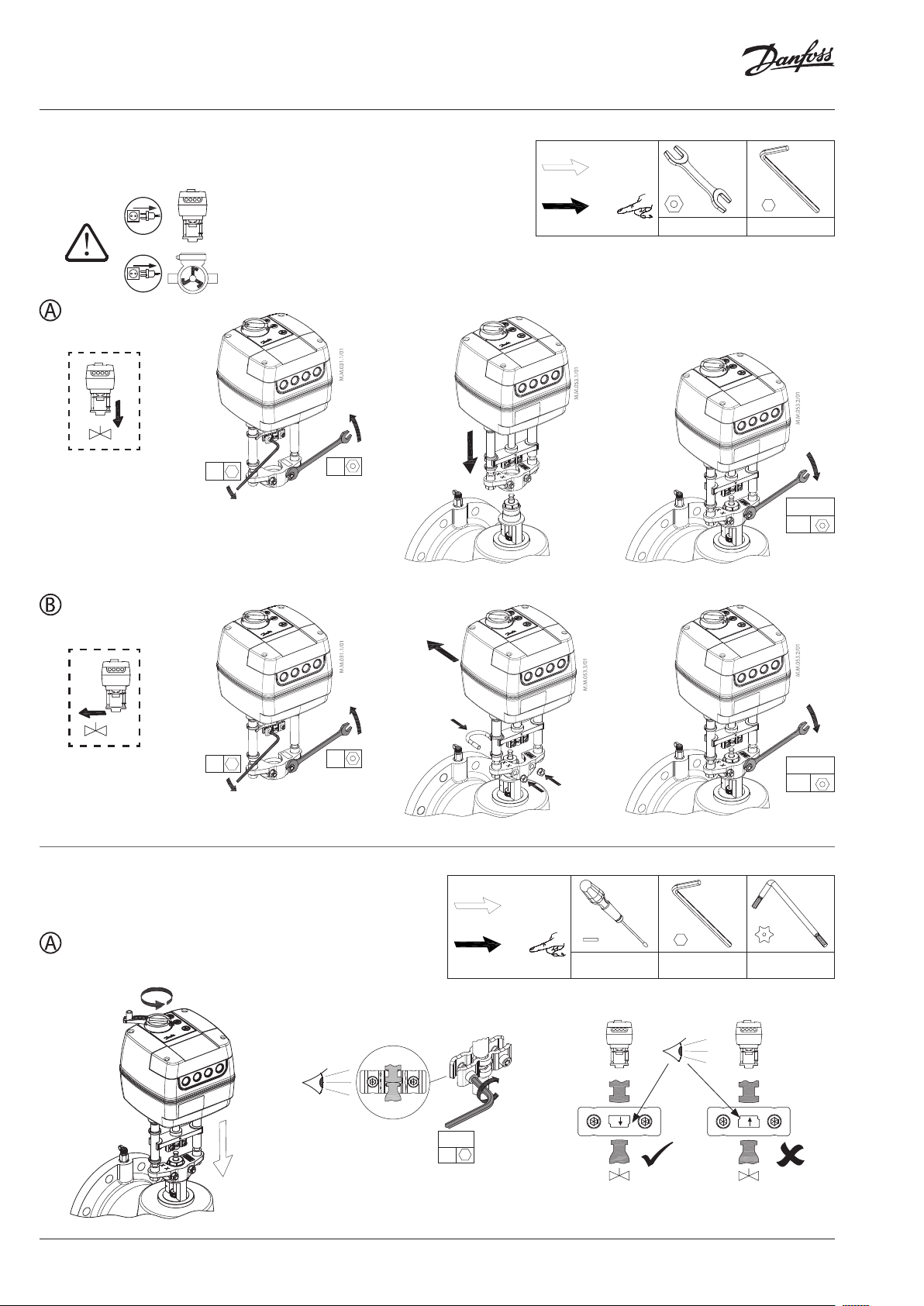

3-5 Nm

2×

AM E 655-1/658 S D-1/6 58 SU-1

❶

=

=

AUTO

13 mm 4 mm

①

③

④

2×

②

2×

2×

12-15 Nm

2×

①

③

2×

④

12-15 Nm

2×

②

❷

AM E 655-1

①

②

③

=

=

AUTO

3,5 - 4,5 mm

× 0,7mm

4 mm T 10

AQ323736153498en-000103 2 | © Danfoss | 2021.03

Page 3

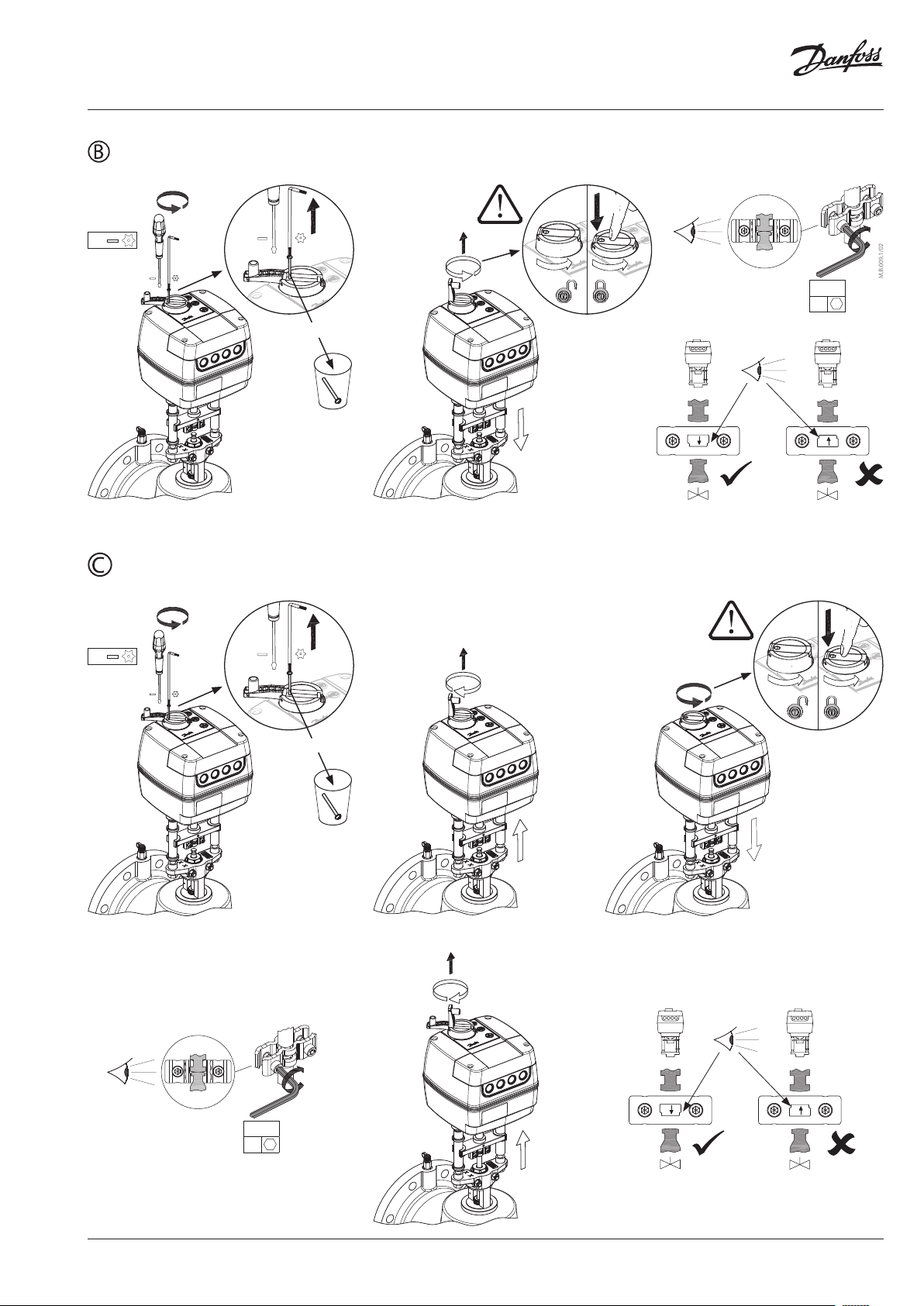

AME 655-1/658 SD-1/658 SU-1 & AME 685-1

3-5 Nm

2×

3-5 Nm

2×

AME 658 SD-1

1×

AME 658 SU-1

①

②

③

④

⑦

⑤

⑨

⑥

⑥

1×

③

①

④

②

⑧

⑤

⑦

© Danfoss | 2021.03 | 3AQ323736153498en-000103

Page 4

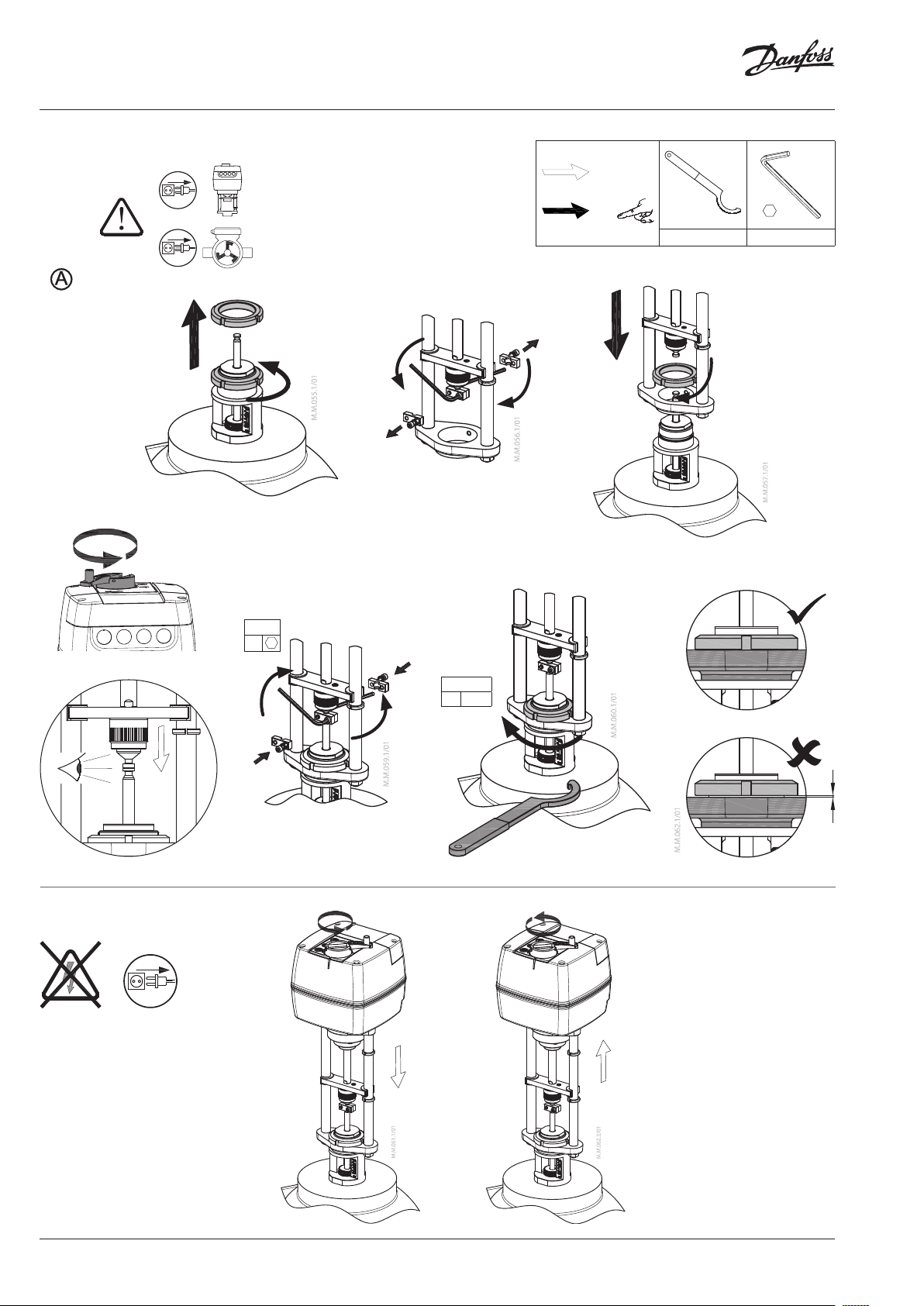

AME 655-1/658 SD-1/658 SU-1 & AME 685-1

3-5 Nm

2×

AM E 68 5-1

❸

⑥

=

=

AUTO

HN 10 5 mm

⑨

⑩

②

⑬

⑪

①

③

⑤

⑫

⑭

40 Nm

1×

⑦

⑧

④

HH10

⑮

❹

AM E 68 5-1

AQ323736153498en-000103 4 | © Danfoss | 2021.03

Page 5

AME 655-1/658 SD-1/658 SU-1 & AME 685-1

❺

=

AUTO

①

②

2×

③

④

⑥

AME 655-1/658 SD-1/658 SU-1 & AME 685-1 operating as modulating version

⑤

M16, M20 / MP16 1/2’’

=

3,5– 4,5 mm ×

0,7 mm

M16

M20

M16

1/2’’

⑦

SN 0 V Neutral

SP 24 V AC/DC

4

4, 5 SP (AC)

SP

5

Power

supply

SP output

-max 4 A

-min 3 W

T 10

AME 658 SD/SU-1

AME 655/685-1:

DIP 6 OFF (1a, 1b)

DIP 6 ON (2a, 2b)

⑧

AME 655/685-1 operating

as 3-point version

CONTROLLER

1

SP

3

GND 0 V Neutral

0(2 )-10 V

Y

0(4) -20 mA

0(2 )-10 V

X

0(4) -20 mA

Input

Input

Output

⑦

SN 0 V Neutral

1,3 24 V AC/DC

Y1

4, 5 SP(AC)

1

SP

3

K2

K4

Y2

Power

supply

24~ output

-max 4 A

-min 3 W

Input

AME655/685-1

© Danfoss | 2021.03 | 5AQ323736153498en-000103

Page 6

AME 655-1/658 SD-1/658 SU-1 & AME 685-1

❻

①

Actuator type AME 655-1 AME 658 SD-1 AME 658 SU-1 AME 685-1

Travel speed 2 or 6 s/m 4 or 6 s/m 3 or 6 s/m

T [sec] Travel speed × H

②

H

③

④

AQ323736153498en-000103 6 | © Danfoss | 2021.03

Page 7

AME 655-1/658 SD-1/658 SU-1 & AME 685-1

❻ ⑤

>5s = RESET

Max. retracted

Max. extended

=

=

AUTO

max. retracted

Set new retract

Set new extended

max. extended

>5s = RESET

Kv

>5s = RESET

Kv

© Danfoss | 2021.03 | 7AQ323736153498en-000103

Page 8

AME 655-1/658 SD-1/658 SU-1 & AME 685-1

S4

❻ ⑥

⑦

input

1 3

output

45

output

45

S5

V

❼

⑧

⑨

②

③

0,7 -1,1 Nm

2×

=

=

AUTO

3,5– 4,5 mm ×

0,7 mm

T 10

①

AQ323736153498en-000103 8 | © Danfoss | 2021.03

Page 9

AME 655-1/658 SD-1/658 SU-1 & AME 685-1

❽

LED Indication type Operating mode

Green LED:

Constantly lit Positioni ng mode - Actuator i s retracting th e stem

Constantly lit Positioni ng mode - Actuator i s extending the s tem

F lashing (1 s cycle) Self stro king mode - Actu ator is retracti ng the stem

F lashing (1 s cycle) Self stro king mode - Actu ator is extendin g the stem

Yellow LED:

Constantly lit Stationar y mode - Actuato r has reached upp er end position (ret racted stem)

Constantly lit Stationar y mode - Actuato r has reached bot tom end position (e xtended stem)

Red LED:

Red/ Yellow LE D

Dark

❾

F lashing

Constantly lit Stand-By mode

F lashing Error Mode

F lashing (1 s cycle)

F lashing (1 s cycle)

No indication No power sup ply

Stationar y mode - Single bl ink when Y signal is pr esents and doub le blinks when Y

signal is no t connected)

Set up stro ke limitation (ret racted stem)

Set up stro ke limitation (ex tended stem)

①

>5s = RESET

F lashing

(1 s cycle)

AUTO

=

=

②

F lashing

(1 s cycle)

LED : Green

F lashing

LED : Yellow

© Danfoss | 2021.03 | 9AQ323736153498en-000103

Page 10

AME 655-1/658 SD-1/658 SU-1 & AME 685-1

❿

AM E 68 5-1AM E 655-1/658 S D-1/6 58 SU-1

②

①

(1)

1s = STAND BY−ON

STAND BY−O FF

Constantly lit

LED : Red

AM E 68 5-1AM E 655-1/658 S D-1/6 58 SU-1

AQ323736153498en-000103 10 | © Danfoss | 2021.03

Page 11

AME 655-1/658 SD-1/658 SU-1 & AME 685-1

operation

operation

AM E 655-1

AME 658 SD/SU-1

AM E 685 -1

ENGLISH

Safety Notes

To avoid personal injury and damage

to devices, it is absolutely essential for

be read carefully and reviewed prior to

assembly and use.

Do not dismantle actuator with the safety spring

function! There is risk of injury and death in the

event of improper handling!

Switch off the pump and power line before

mounting and wiring the actuator.

The actuator is heavy. Handle with care to avoid

injury or product damage.

Wiring

and SW2 (INV/DIR) are active when is no power

supply on terminal SP and AME actuator operated

as AM V.

Actuator mounting to valve AME 655-1/

658 SD-1/ 658 SU-1 ❶

Stem connections AME 658 SD-1/ AME

658 SU-1 ❷

Actuator mounting to valve AME 685-1 ❸

Stem connections

Electrical connection ❺

DIP switch setting ❻

SW1: FAST/SLOW – Speed selection ①

- FA S T;

- SLOW;

SW2: DIR/INV – Direct or inverse acting

- DIR; the actuator is directly reacting to input

- INV; the actuator is inversely reacting to

SW3: 2-10V/0-10V – Input/output ③

- 2-10V; the input signal ranges from 2-10 V

- 0-10V; the input signal ranges from 0-10 V

Signal range selector sets Y & X signals.

SW4: LIN/MDF – Characteristic modification

- LIN; linear correlation between Y signal and

- MDF (Modified); enables modified

The function enables to change MCV (Motorised

Control Valve) characteristic (for example

linear to logarithmic and logarithmic to linear)

and works with all combinations of DIP switch

settings.

these instructions and safety notes to

Do not touch anythin g on the PCB! Do

not remove the servi ce cover before

the power supply is fu lly switched off.

termina ls 4 and 5 is 4 A. M in. power is 3W.

Max. al lowed curre nt output on

NOTE: Only basic function as SW1 (Fast/Slow)

AM E 685 -1

selector ②

signal

input signal

(voltage input) or 4-20 mA (current input)

(voltage input) or 0 -20 mA (current input)

function ④

stem position

correlation between Y signal and stem

position. Degree of modification depends on

setting of potentiometer CM.

❹

SW5: 100 %/95 % – Stroke limitation ⑤

Adjustable stroke limitation of retracted or

extended actuator stem position.

DIP 5 needs to be reset prior to procedure (5.2)

to 100 % (5.1) and set to 95 % (5.3) until the

self-stroking procedure has concluded (5.4).

Retracted icon (5.5) on actuator will blink redyellow when actuator stops at max. retracted

stem position (5.5) and will blink as long as it

is not set to a new retracted position (5.6) by

pressing buttons to set the required

position (observe flow on flow meter). Press and

hold reset button for 5 seconds (5.7) and then

set new extended stem position by pressing

buttons .

Extended icon (5.8) will blink red-yellow as long

as it is not set to new extended position by

pressing and holding reset button for 5 seconds.

SW6: C/P – Output signal mode selector ⑥

① An output signal is present on terminal 4

when the position of the actuator is equal

to or lower than the S4 set point. An output

signal is present on terminal 5 when the

position of the actuator is equal to or higher

than the S5 set point.

SW6: C; provides a constant output signal on

terminals 4&5, regardless of the input signal.

SW6: P; provides a pulse signal through parallel

or cascade electrical wiring input 1 & 3

dependents from the controller to output

terminals 4&5.

SW7: Smart function selector: ⑦

- OFF; the actuator does not try to detect

oscillations in the system

- ON; the actuator enables special antioscillation algorithm – In case control signal

Y on certain point oscillates looking from

time perspective, algorithm starts to lower

the amplification of the output to the valve.

Instead of having static characteristics

actuator changes to dynamic characteristics.

After the control signal does not oscillate

anymore, output to the valve slowly returns

back to static characteristics.

SW8: Uy/Iy – Input signal type selector: ⑧

- Uy; input signal Y is set to voltage (V)

- Iy; input signal Y is set to current (mA)

SW9: Ux/Ix – Output signal type selector: ⑨

- Ux; output signal X is set to voltage (V)

- Ix; output signal X is set to current (mA)

NOTE: Y detection is disabled if SW8 is set to

ON position and SW3 is set to OFF position.

Functions accessible from cover

RESET button

The actuators has an external RESET button,

which is located on the top cover of the actuator

next to the LED indicators. With this button

you can enable or disable standby mode (press

once) or self-stroking mode (press and hold for 5

seconds). See next paragraph for more details.

Final step of electrical connection ❼

LED signalisation ❽

Calibration mode ❾

Calibration mode begins automatically the first

time the actuator is powered on. To start the

self-stroking procedure, press and hold the

RESET button for 5 seconds ① until the green

light starts flashing. End positions of the valve

are automatically set and the actuator goes into

stationary mode ② and starts responding to the

control signal.

Manual Operation ❿

Mechanical and electrical operation

must not be used at the same tim e!

AME 655-1/658 SD-1/658 SU-1 and AME 685-1

actuators can be manually positioned when in

standby mode or when there is no power supply

(mechanically).

Actuator type

Stand-By mode

Press the RESET button ① to enter standby

mode. The actuator stops in the current position

and stops responding to any control signal. A

red light remains constantly lit. You can now

manually operate the actuator ②.

Mechanical manual operation

AME 655-1/658 SD-1/658 SU-1 and AME 685-1

actuators have a knob & crank on the top of the

housing which enables manual positioning of

the actuator.

same time!

Electrical manual operation

AME 655-1/658 SD-1/658 SU-1 and AME 685-1

actuators have two buttons on the top of the

housing that are used for electrical manual

positioning (up or down) if the actuator is

in standby mode. First, press and hold the

RESET button ① until the actuator goes to

standby mode (red LED is lit). By pressing the

button, the stem will be extended and

by pressing the button, the stem will be

retracted.

Mechanical

Use Mechanical manual operation

only when the power is d isconnected.

Mechanical and electrical operation

are not allowed to be used at the

Electrical

© Danfoss | 2021.03 | 11AQ323736153498en-000103

Page 12

AME 655-1/658 SD-1/658 SU-1 & AME 685-1

Part Nam e / 部件名称

Motor / 电机 X O O O O O

Beari ng cover / 轴承盖

Nut inse rt / 插入螺母

O: Indica tes that this hazar dous substance con tained in all of the h omogeneous ma terial for this par t is below the limi t requirement in GB /T 26572;

O: 表示该 有害物质在该部件所有均质材 料中的含量均在GB/ T 26572规定 的限量要求以下。

X: Indica tes that this hazar dous substance co ntained in at least o ne of the homogen eous material fo r this part is above th e limit requirem entw in GB/T 26572;

X: 表示该有害物质至少在该部件的某一均质材料中的含量超出GB /T 26572规定的限量 要求。

PB / 铅 Hg / 汞 Cd / 镉 Cr( VI) / 六价铬 PBB / 多溴联苯 PBDE / 多溴二 苯醚

X O O O O O

X O O O O O

Hazardous Substances Table / 有害物质表

73694850 / AQ323736153498en-00010312 | © Danfoss | DHS-SDBT/SI | 2021.03

Loading...

Loading...