Page 1

OPERATION MANUAL

CONVENI-PACK

Outdoor Unit

(LRYEQ16AY1(E))

Operation manual

CONVENI-PACK

Betriebsanweisung

CONVENI-PACK

Manuel d’utilisation

CONVENI-PACK

Manual de operación

CONVENI-PACK

Manuale d’uso

CONVENI-PACK

Gebruiksaanwijzing

CONVENI-PACK

Manual de funcionamento

CONVENI-PACK

English

Deutsch

Français

Español

Italiano

Nederlands

Portugues

Booster Unit

(LCBKQ3AV1(E))

Page 2

Thank you for purchasing this Daikin CONVENI-PACK. Carefully read this operation

manual before using the CONVENI-PACK.

It will tell you how to use the unit properly

and help you if any trouble occurs. After

reading the manual, keep it in your custody

for future reference. If the user changes,

be sure to hand over the operation manual

to the next user. After receiving the warranty card from the dealer, store it in a safe

place.

Wir danken Ihnen dafür, dass Sie sich für

dieses Daikin-Kondensatorgerät

entschieden haben. Lesen Sie diese Bedienungsanleitung sorgfältig durch, bevor

Sie das Kondensatorgerät in Betrieb nehmen. Sie erfahren hier, wie die Einheit korrekt genutzt wird, und es ist lhnen bei

Störungen behilflich. Lesen Sie das Handbuch sorgfältig und bewahren Sie es für

den späteren Gebrauch sorgfältig auf.

Wenn Sie das Gerät einem neuen

Benutzer übergeben, händigen Sie ihm

auch unbedingt die Bedienungsanleitung

aus. Bewahren Sie die Garantiekarte, die

Sie von Ihrem Händler erhalten haben,

ebenfalls an einem sicheren Ort auf.

Nous vous remercions d’avoir acheté cette

unité de condensation Daikin. Avant d’utiliser l’unité de condensation, veuillez lire

attentivement ce manuel d’utilisation. Il

vous enseignera à utiliser correctement

l’unité et vous aidera en cas de panne.

Après lecture du manuel, veuillez le conserver à des fins de consultation

ultérieure. Si l’utilisateur change, veillez à

confier ce manuel d’utilisation à l’utilisateur

suivant. Après réception de la carte de

garantie transmise par le revendeur, conservez-la dans un endroit sûr.

Gracias por adquirir haber adquirido esta

unidad de condensación Daikin. Lea

cuidadosamente este manual de operación antes de usar la unidad de condensación. El manual explica cómo usar la

unidad correctamente, proporcionándole

información de y lo ayuda en caso de que

surjan problemas. Una vez leído el manual, consérvelo en lugar seguro para futuras referencias.

Si el usuario cambia, En caso de cambio

de ususario, asegúrese de entregar el

manual de operación al próximo éste

último. usuario. Cuando reciba la tarjeta de

garantía del distribuidor, guárdela en un

lugar seguro.

Vi ringraziamo per aver acquistato questa

unità condensante Daikin. Leggere attentamente il presente manuale d’uso prima

di utilizzare l’unità condensante. Contiene

le istruzioni per usare correttamente l’unità

e per rimediare ad eventuali problemi di

funzionamento. Dopo aver letto il manuale,

conservatelo per il futuro. Se il prodotto

dovesse essere usato da un altro utente,

assicurarsi di consegnare il manuale d’uso

al nuovo utente. Dopo aver ricevuto la

scheda di garanzia dal vostro rivenditore,

conservatela in un luogo sicuro.

Hartelijk dank voor de aanschaf van deze

Daikin condensatie-unit. Lees deze

gebruiksaanwijzing aandachtig door voordat u de condensatie-unit gebruikt. In de

gebruiksaanwijzing kunt u lezen hoe u het

apparaat op de juiste manier gebruikt en

wat u kunt doen bij storingen. Nadat u de

handleiding heeft gelezen, dient u deze te

bewaren om hem in toekomst te kunnen

raadplegen. Als het apparaat overgedragen wordt aan een nieuwe gebruiker,

dient u ook de gebruiksaanwijzing mee te

geven. Berg de garantiekaart op een

veilige plek op, zodra u deze van de dealer

heeft ontvangen.

Obrigado por escolher esta unidade de

condensação Daikin. Leia este manual de

operação antes de utilizar a unidade de

condensação. Nele obterá O manual

contém informações sobre o modo de utilizar correctamente o aparelho e ajuda na

eventualidade de ocorrência de problemas. Após ler a leitura do manual, guardeo para futura referência. Se houver

mudança de usuário, não esqueça de

entregar-lhe o manual de operaçãoEm

caso de mudança do utilizador, garanta

que o manual de operação é entregue ao

novo utilizador.

Após receber o cartão de garantia do revendedor, guarde-o em num lugar seguro.

Page 3

LRYEQ16AY1(E)

LCBKQ3AV1(E)

CONVENI-PACK

Operation manual

CONTENTS

1. SAFETY PRECAUTIONS ...............................1

2. NAME OF PART.............................................. 4

3. WHAT TO DO BEFORE OPERATION ............ 4

4. REMOTE CONTROLLER AND COOL/HEAT

SELECTOR: NAME AND FUNCTION OF

EACH SWITCH AND DISPLAY....................... 5

5. OPERATION PROCEDURE ........................... 6

6. OPTIMUM OPERATION ................................. 9

7. CARE AND CLEANING METHOD................ 10

8. TROUBLESHOOTING .................................. 10

9. INSPECTION ................................................ 12

10. PRODUCT MODELS AND

MAIN SPECIFICATIONS............................... 13

11. AFTER-SALE SERVICE AND

WARRANTY.................................................. 14

Important information regarding the refrigerant

used

This product contains fluorinated greenhouse gases

covered by the Kyoto Protocol.

Refrigerant type R410A

(1)

GWP

(1)

GWP = global warming potential

value

1975

∗ Values are indicated in F-gas regulations (EC)

No.842/2006, Annex I, Parts 1 and 2.

Periodical inspections for refrigerant leaks may be

required depending on European or local legislation.

Please contact your local dealer for more information.

1. SAFETY PRECAUTIONS

To gain full advantage of the CONVENI-PACK’s

functions and to avoid malfunction due to mishandling, we recommend that you read this instruction

manual carefully before use.

This CONVENI-PACK is classified under “appliances not accessible to the general public”.

• The precautions described herein are classi-

fied as WARNING and CAUTION. They both

contain important information regarding

safety. Be sure to observe all precautions

without fail.

WAR NING ....... Failure to follow these instruc-

tions properly may result in personal injury or loss of life.

CAUTION ........ Failure to observe these

instructions properly may result

in property damage or personal

injury, which may be serious

depending on the circumstances.

• After reading, keep this manual in a conve-

nient place so that you can refer to it whenever

necessary. If the equipment is transferred to a

new user, be sure also to hand over the manual.

WARNING

Be aware that prolonged, direct exposure to

cool or warm air from the air conditioner, or

to air that is too cool or too warm can be

harmful to your physical condition and

health.

When the CONVENI-PACK is malfunctioning

(giving off a burning odour, etc.) turn off

power to the unit and contact your local

dealer.

Continued operation under such circumstances

may result in a failure, electric shocks or fire hazards.

Consult your local dealer about installation

work.

Doing the work yourself may result in water leakage, electric shocks or fire hazards.

Consult your local dealer regarding modification, repair and maintenance of the CONVENI-PACK.

Improper workmanship may result in water leakage, electric shocks or fire hazards.

Do not place objects, including rods, your fingers, etc., in the air inlet or outlet.

Injury may result due to contact with the CONVENI-PACK’s high-speed fan blades.

Never touch the air outlet or the horizontal

blades while the swing flap is in operation.

Fingers may become caught or the unit may break

down.

Beware of fire in case of refrigerant leakage.

If the CONVENI-PACK is not operating correctly

(i.e. the interior temperature of the CONVENIPACK does not drop efficiently), refrigerant leakage could be the cause.

Consult your dealer for assistance.

The refrigerant within the CONVENI-PACK is

safe and normally does not leak.

However, in the event of a leakage, contact with

a naked burner, heater or cooker may result in

generation of noxious gas.

English 1

Page 4

Do not longer use the CONVENI-PACK until a

qualified service person confirms that the leakage has been repaired.

Consult your local dealer regarding what to

do in case of refrigerant leakage.

When the CONVENI-PACK is to be installed in a

small room, it is necessary to take proper measures so that the amount of any leaked refrigerant does not exceed the concentration limit in the

event of a leakage. Otherwise, this may lead to

an accident due to oxygen depletion.

Contact professional personnel about

attachment of accessories and be sure to

use only accessories specified by the manufacturer.

If a defect results from your own workmanship, it

may result in water leaks, electric shock or fire.

Consult your local dealer regarding relocation and reinstallation of the CONVENIPACK.

Improper installation work may result in leakage,

electric shocks or fire hazards.

Do not replace fuses.

Do not use improper fuses, copper or other wires

as a substitute, as this may result in electric

shock, fire, injury or damage to the unit.

Be sure to earth the unit.

Do not earth the unit to a utility pipe, lightning

conductor or telephone earth lead. Imperfect

earthing may result in electric shocks or fire.

A high surge current from lightning or other

sources may cause damage to the CONVENIPAC K.

Be sure to install an earth leakage breaker.

Failure to install an earth leakage breaker may

result in electric shocks or fire.

Consult the dealer if the CONVENI-PACK submerges owing to a natural disaster, such as a

flood or typhoon.

Do not operate the CONVENI-PACK in that

case, or otherwise a malfunction, electric shock,

or fire may result.

Do not start or stop operating the CONVENIPACK with the power supply breaker turned ON

or OFF.

Otherwise, fire or water leakage may result. Furthermore, because power failure compensation

is set, the fan will rotate abruptly, which may

result in injury.

Do not use the product in the atmosphere contaminated with oil vapor, such as cooking oil or

machine oil vapor.

Oil vapor may cause crack damage, electric

shocks, or fire.

Do not use the product in places with excessive oily smoke, such as cooking rooms, or in

places with flammable gas, corrosive gas, or

metal dust.

Using the product in such places may cause fire

or product failures.

Do not use flammable materials (e.g., hairspray

or insecticide) near the product.

Do not clean the product with organic solvents such as paint thinner.

The use of organic solvents may cause crack

damage to the product, electric shocks, or fire.

Do not keep in the unit anything volatile or

flammable.

Doing so may result in explosion or fire.

Be sure to use a dedicated power supply for

the CONVENI-PACK.

The use of any other power supply may cause

heat generation, fire, or product failures.

CAUTION

Do not use the CONVENI-PACK for purposes

other than those for which it is intended.

Do not use the CONVENI-PACK for cooling precision instruments, works of art as this may

adversely affect the performance, quality and/or

longevity of the object concerned.

Do not use the unit for water cooling use.

Freezing may result.

Do not remove the unit’s fan guard.

The guard protects against the unit’s high speed

fan, which may cause injury.

Do not place objects that are susceptible to

moisture directly beneath the indoor or outdoor units.

Under certain conditions, condensation on the

main unit or refrigerant pipes, air filter dirt or drain

blockage may cause dripping, resulting in fouling

or failure of the object concerned.

To avoid oxygen depletion, ensure that the

room is adequately ventilated if equipment

such as a burner is used together with the

CONVENI-PACK.

After prolonged use, check the unit stand

and its mounts for damage.

If left in a damaged condition, the unit may fall and

cause injury.

Do not place flammable sprays or operate

spray containers near the unit as this may

result in fire.

Be sure to stop the operation of the unit and

turn off the power circuit breaker at the time

of cleaning, maintenance and inspection.

Otherwise, electric shock or injury may result.

Turn off the power supply if the unit is not

used for a long time.

Otherwise, dust gathered may result in heat generation or ignition.

To avoid electric shocks, do not operate with

wet hands.

Do not place appliances that produce naked

flames in places exposed to the air flow from

the unit as this may impair combustion of the

burner.

2 English

Page 5

Do not place heaters directly below the unit,

as resulting heat can cause deformation.

Do not allow a child to mount on the outdoor

unit or avoid placing any object on it.

Falling or tumbling may result in injury.

Do not block air inlets nor outlets.

Impaired air flow may result in insufficient perfor-

mance or trouble.

Do not wash the unit or the remote controller

with water.

Doing so may result in electric shock or ignition.

Do not install the CONVENI-PACK at any

place where there is a danger of flammable

gas leakage.

In the event of a gas leakage, build-up of gas near

the CONVENI-PACK may result in fire hazards.

Do not put flammable containers, such as

spray cans, within 1 m from the blow-off

mouth.

The containers may explode because the warm air

output of the indoor or outdoor unit will affect them.

Perform drain piping to ensure perfect drain-

age.

Imperfect drainage may result in water leakage.

Do not place the controller exposed to direct

sunlight.

The LCD display may get discolored, failing to dis-

play the data.

Do not wipe the controller operation panel

with benzine, thinner, chemical dustcloth,

etc.

The panel may get discolored or the coating

peeled off. If it is heavily dirty, soak a cloth in

water-diluted neutral detergent, squeeze it well

and wipe the panel clean. And wipe it with another

dry cloth.

The appliance is not intended for use by unat-

tended young children or infirm persons.

Impairment of bodily functions and harm to health

may result.

Children should be supervised to ensure that

they do not play with the unit or its remote con-

troller.

Accidental operation by a child may result in

impairment of bodily functions and harm health.

Do not let children play on or around the out-

door unit.

If they touch the unit carelessly, injury may be

caused.

Do not place water containers (flower vases,

flowerpot, etc.) on the unit, as this may result

in electric shocks or fire.

To avoid injury, do not touch the air inlet or

aluminium fins of the unit.

Do not touch the aluminium fin directly at the

time of cleaning.

Doing so may result in injury.

Do not place objects in direct proximity of the

unit and do not let leaves and other debris

accumulate around the unit.

Leaves are a hotbed for small animals which can

enter the unit. Once in the unit, such animals can

cause malfunctions, smoke or fire when making

contact with electrical parts.

Consult your dealer regarding cleaning the

inside of the CONVENI-PACK.

Improper cleaning may cause breakage of plastic

parts, water leakage and other damage as well as

electric shocks.

Do not operate the CONVENI-PACK when

using a room fumigation - type insecticide.

Failure to observe could cause the chemicals to

become deposited in the unit, which could endanger the health of those who are hypersensitive to

chemicals.

Never press the button of the remote controller with a hard, pointed object.

The remote controller may be damaged.

Never pull or twist the electric wire of a

remote controller.

It may cause the unit to malfunction.

Never touch the internal parts of the controller.

Do not remove the front panel. Touching certain

internal parts will cause electric shocks and damage to the unit. Please consult your dealer about

checking and adjustment of internal parts.

Do not leave the remote controller wherever

there is a risk of wetting.

If water gets into the remote controller there is a

risk of electrical leakage and damage to electronic

components.

Watch your steps at the time of air filter

cleaning or inspection.

High-place work is required, to which utmost

attention must be paid.

If the scaffold is unstable, you may fall or topple

down, thus causing injury.

There is a possibility that periodic inspections for refrigerant leakage are scheduled. Consult your local dealer for more

information.

[Installation site]

Is the unit installed in a well-ventilated place

with no obstacles around?

Do not use the product in the following places.

a. Places with mineral oil, such as cutting oil.

b. Places directly exposed to seawater spray and

briny air.

c. Places where sulphide gas is generated, such as

hot springs.

d. Places with radical voltage fluctuations, such as

factories.

e. In vehicles or on board ships.

English 3

Page 6

f. Places with sprays of oil or excessive steam, such

as kitchens.

g. Places with machines generating electromagnetic

waves.

h. Places with acid gas, alkaline gas, or steam.

i. Places with poor drainage.

j. Places in potentially explosive atmosphere.

Install the unit, power supply wiring, transmission wiring and refrigerant piping at least

1 meter away from televisions, radios and stereo sets.

Otherwise, the picture and sound may be interfered with noise.

Are snow protection measures taken?

For detailed arrangements, such as the installation

of a snow protection hood, consult your dealer.

Is there no clearance around the through hole

between the internal and external units?

The chilled air will leak from the clearance and the

cooling efficiency of the unit will be degraded.

Is service space secured?

[Electrical work]

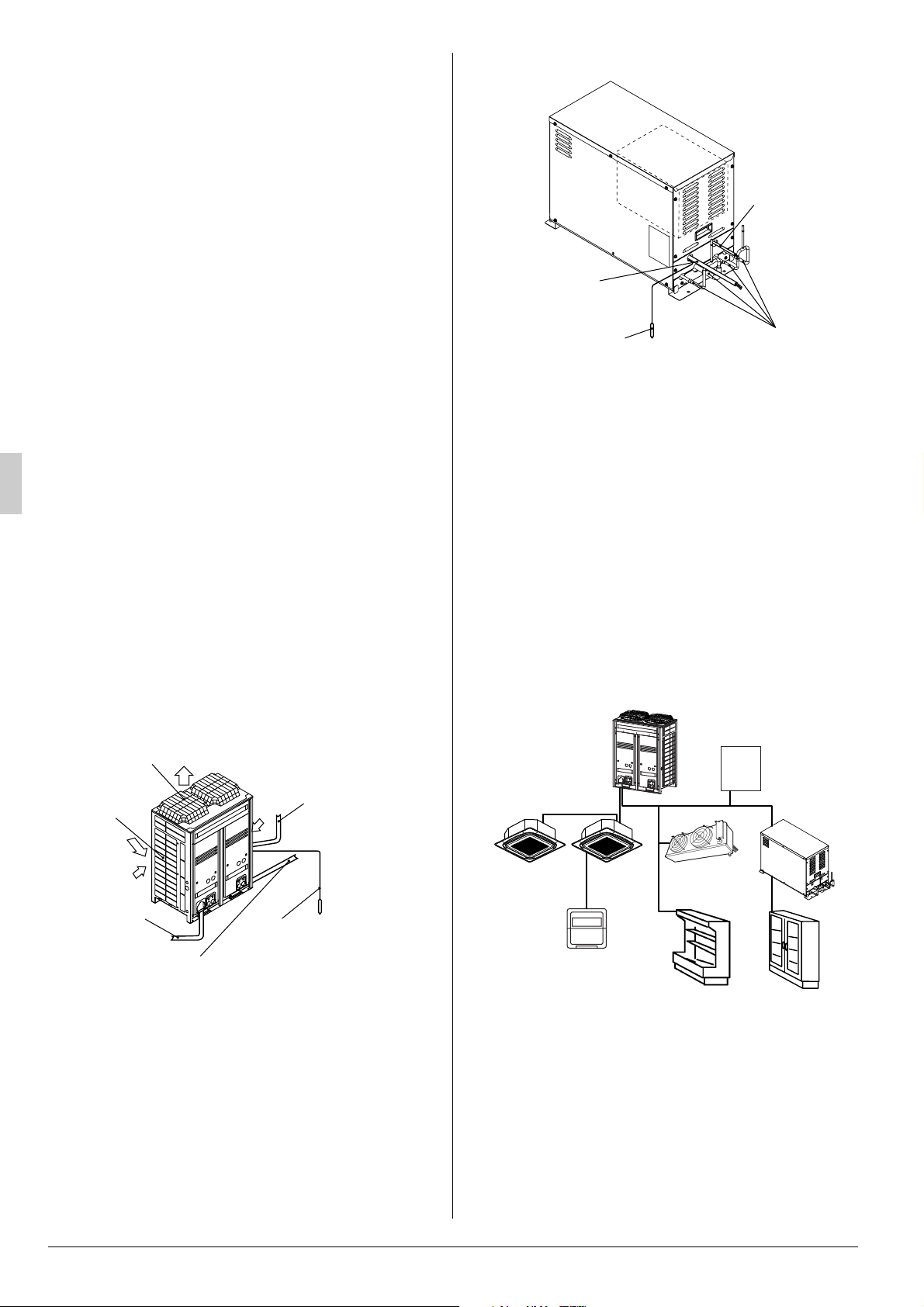

2-2 In the case of LCBKQ3AV1(E)

Power supply wires

(to dedicated earth

leakage breaker)

Earth wire

A wire that makes the system

safe by connecting the outdoor

unit to the ground for the

prevention of electric shocks

or fire resulting from electric

leakage.

Transmission

wiring

Refrigerant

piping

Do not attempt to conduct electrical work or

grounding work unless you are licensed to do

so.

Consult with your dealer for electrical work and

grounding work.

Check that the power supply is suitable to the

unit and that an exclusive circuit is provided to

the unit.

Check the electric capacity and voltage.

2. NAME OF PART

2-1

In the case of LRYEQ16AY1(E)

Air outlet

Fan

Air inlet

Heat exchanger

(aluminium fin)

Transmission

wiring

Refrigerant

piping

Earth wire

A wire that makes the system

safe by connecting the outdoor

unit to the ground for the

prevention of electric shocks

or fire resulting from electric

leakage.

Power supply wires

(to dedicated earth

leakage breaker)

3. WHAT TO DO BEFORE OPERATION

This operation manual is for the following system with standard control. Before initiating

operation, contact your Daikin dealer for the

operation that corresponds to your system type

and mark.

If your installation has a customized control

system, ask your Daikin dealer for the operation

that corresponds to your system.

Example of connecting system

1

3

4

1 Outdoor unit

2 Booster unit

3 Indoor unit for air-conditioning

4 Remote controller

5 Blower coil (Indoor unit for refrigerating)

6 Showcase (Indoor unit for refrigerating)

7 Showcase (Indoor unit for freezing)

8 Defrost control panel

5

6

8

2

7

For the device except outdoor unit and booster unit,

refer to the Operation Manuals of the respective

pieces of equipment.

4 English

Page 7

4. REMOTE CONTROLLER AND

COOL/HEAT SELECTOR: NAME

AND FUNCTION OF EACH SWITCH

AND DISPLAY

Refer to the operation manual attached with the

remote controller if a remote controller is

BRC1E51A. (This manual assumes that a

remote controller is BRC1C62.)

Fig.1

1. On/off button

Press the button and the system will start. Press

the button again and the system will stop.

2. Operation lamp (red)

The lamp lights up during operation.

3.

Display

It is impossible to changeover heat/cool with the

remote controller which display this icon.

4. Display “ ” (air flow flap)

Refer to the chapter “Operation procedure Adjusting the air flow direction”.

5. Display “ ” (ventilation/air cleaning)

This display shows that the ventilation unit are in

operation. (these are optional accessories)

6. Display “ ” (set temperature)

This display shows the temperature you have

set.

7.Display “” “” “” “” “” (operation mode)

This display shows the current operation mode.

8. Display “ ” (programmed time)

This display shows the programmed time of the

system start or stop.

9. Display “ ” (inspection/test operation)

When the inspection/test operation button is

pressed, the display shows the mode in which

the system actually is.

“”

TEST

(changeover under control)

C

10.Display “ ” (under centralized control)

When this display shows, the system is under

centralized control. (This is not a standard specification.)

11.Display “ ” (fan speed)

This display shows the fan speed you have

selected.

12.Display “ ” (time to clean air filter)

Refer to the operation manual of indoor unit.

13.Display “ ” (defrost/hot start)

Refer to the chapter “Operation procedure Explanation of heating operation.”

14.Timer mode start/stop button

Refer to the chapter “Operation procedure - Programming start and stop of the system with

timer.”

15.Timer on/off button

Refer to the chapter “Operation procedure - Programming start and stop of the system with

timer.”

16.Inspection/test operation button

This button is only used by qualified service persons for maintenance purposes.

17.Programming time button

Use this button for setting the programming start

and/or stop time.

18.Temperature setting button

Use this button for setting the desired temperature.

19.Filter sign reset button

Refer to the operation manual of indoor unit.

20.Fan speed control button

Press this button to select the fan speed of your

preference.

21.Operation mode selector button

Press this button to select the operation mode of

your preference.

22.Air flow direction adjust button

Refer to the chapter “Operation procedure Adjusting the air flow direction”.

23.Fan only/air conditioning selector switch

Set the switch to “ ” for fan only operation or to

“ ” for heating or cooling operation.

24.Cool/heat changeover switch

Set the switch to “ ” for cooling operation or to

“ ” for heating operation.

25.Thermistor

It sense the room temperature around the

remote controller.

English 5

Page 8

26.These button are used when the ventilation

unit are installed (These are optional accessories)

Refer to the operation manual of the ventilation

unit.

NOTE

• In contradistinction to actual operating situations,

the display on figure 2 shows all possible indications.

• Figure 1 shows the remote controller which is

opened the cover.

5. OPERATION PROCEDURE

• Operation procedure varies according to the combination of outdoor unit and remote controller.

Read the chapter “What to do before operation”.

• To protect the unit, turn on the main power switch

6 hours before operation.

• And do not turn off the power supply during the air

conditioning season because of smoothly start

up.

• If the main power supply is turned off during operation, operation will restart automatically after the

power turns back on again.

5-1 COOLING, HEATING , AUTOMATIC AND

FAN ONLY OPERATION

• The fan may keep on running for about 1 minute

after the heating operation stops for removing the

heat in the indoor unit.

• The air flow rate may be adjusted automatically

depending on the room temperature or the fan

may stop immediately. This is not a malfunction.

• For machine protection the system may control

the air flow rate automatically.

• It may take sometime for finishing to change the

air flow rate.

This is normal operation.

ADJUSTMENT (Refer to Fig.2)

For adjustment the desired temperature, fan

speed and air flow direction (only for the

remote controller: FXC, FXF, FXH), follow the

procedure shown below.

Press the temperature setting button and set

3

the desired temperature.

Each time this button is pressed, the

temperature setting rises or lowers 1°C.

NOTE

• Set the temperature within the operation

range.

• The temperature setting is impossible for fan

only operation.

Press the fan speed control button and select

4

the fan speed of your preference.

Fig.2

Press the operation mode selector button sev-

1

eral times and select the operation mode of

your choice;

• “ ” Cooling operation

• “ ” Heating operation

• “ ” Fan only operation

Press the on/off button.

2

The operation lamp lights up and the system

starts operation.

• The operation mode cannot be changed with the

remote controller whose display shows

“ ” (changeover under control).

Change the operation mode with the remote controller whose display does not show “ ”.

• When the display “ ” (changeover under

control) flashes, refer to the chapter “Operation

procedure - Setting the master remote controller”.

Press air flow direction adjust button.

5

Refer to the chapter “Adjusting the air flow

direction” for details.

STOPPING THE SYSTEM (Refer to Fig.2)

Press the on/off button once again.

6

The operation lamp goes off and the system

stops operation.

NOTE

• Do not turn off the power immediately after

the unit stops.

• The system need at least 5 minutes for

residual operation of drain pump device.

Turning off the power immediately will cause

water leak or trouble.

EXPLANATION OF HEATING OPERATION

• For general heating operation, it may take longer

to reach the set temperature than in cooling operation.

We recommend starting the operation which was

used before using timer operation.

• The following operation is performed in order to

prevent the heating capacity from dropping or

cold air from blowing.

6 English

Page 9

Defrost operation

• In heating operation, freezing of the outdoor

unit heat exchanger increases. Heating

capability decreases and the system goes

into defrost operation.

• The indoor unit fan stops and the remote

controller displays “ ”.

• After maximum 10 minutes of defrost operation, the system returns to heating operation

again.

Hot start

• In order to prevent cold air from blowing out

of an indoor unit at the start of heating operation, the indoor fan is automatically

stopped. The display of the remote controller

shows “ ”.

NOTE

• The heating capacity drops as the outside temperature falls. If this happens, use another heating device together with the unit. (When using the

appliances which produce open fire together, ventilate a room constantly.)

Do not place appliances which produce open fire

in places exposed to the air flow from the unit or

under the unit.

• It takes some time for the room to warm up from

the time the unit is started since the unit uses a

hot-air circulatory system to warm the entire

room.

• If the hot air rises to the ceiling, leaving the area

above the floor cold, we recommend using the circulator (the indoor fan for circulating air). Contact

your dealer for details.

5-2 PROGRAM DRY OPERATION

• The function of this operation is to decrease the

humidity in your room with a minimum temperature decrease.

• The micro computer automatically determines

temperature and fan speed.

• The system does not go into operation if the room

temperature is low.

• The microcomputer automatically controls the

temperature and fan speed, so these cannot be

set using the remote controller.

• This function is not available if the room temperature is 20°C or lower.

Fig.3

Press the operation mode selector button sev-

1

eral times and select “ ” (program dry operation).

Press the on/off button.

2

The operation lamp lights up and the system

starts operation.

Press the air flow direction adjust button (only

3

for FXC, FXF, FXH). Refer to the chapter

“Adjusting the air flow direction” for details.

Press the on/off button once again.

4

The operation lamp goes off and the system

stops operation.

NOTE

• Do not turn off the power immediately after

the unit stops.

• The system need at least 5 minutes for

residual operation of drain pump device.

Turning off the power immediately will cause

water leak or trouble.

5-3 ADJUSTING THE AIR FLOW DIRECTION

(only for Double-flow, Multi-flow, Ceilingsuspended)

Fig.4

Press the air flow direction button to

1

select the air direction.

The air flow flap display swings as

shown right and the air flow direction

continuously varies. (Automatic swing

setting)

English 7

Page 10

Press the air flow direction adjust but-

2

ton to select the air direction of your

choice.

The air flow flap display stops swinging and the air flow direction is fixed.

(Fixed air flow direction setting)

MOVEMENT OF THE AIR FLOW FLAP

For the following conditions, a micro computer controls the air flow direction which may be different

from the display.

COOLING HEATING

• When starting operation.

• When the room temperature is

higher than the set temperature.

• At defrost operation.

• When operating continuously at horizontal air flow direction.

• When continuous operation with downward air flow is performed at the

time of cooling with a ceiling-suspended or a wall-mounted unit, the

micro-computer may control the flow direction, and then the remote control indication also will change.

The air flow direction can be adjusted in one of the

following ways.

• The air flow flap itself adjusts its position.

• The air flow direction can be fixed by the user.

Automatic “ ” or desired position “ ”.

5-4 PROGRAMMING START AND STOP OF

THE SYSTEM WITH TIMER

• The timer is operated in the following two ways.

Programming the stop time “ ”. The system

stops operating after the set time has elapsed.

Programming the start time “ ”. The system

starts operating after the set time has elapsed.

• The timer can be programmed for a maximum of

72 hours.

• The start and the stop time can be simultaneously

programmed.

Fig.6

Press the timer mode start/stop button several

1

times and select the mode on the display.

NOTE

• The movable limit of the flap is changeable.

Contact your Daikin dealer for details. (Only

for Double-flow, Multi-flow, Corner, Ceilingsuspended and Wall-mounted.)

• Avoid operating in the horizontal direction

“ ”. It may cause dew or dust to settle on

the ceiling.

Double-flow

Ceiling Suspended

Multi-flow

Fig.5

The display flashes.

• For setting the timer stop “ ”

• For setting the timer start “ ”

Press the programming time button and set

2

the time for stopping or starting the system.

Each time this button is pressed, the

time advances or goes backward by 1

hour.

Press the timer on/off button.

3

The timer setting procedure ends. The display

“ ” or “ ” changes from flashing

light to constant light.

NOTE

• When setting the timer off and on at the

same time, repeat the above procedure

(from “ ” to “ ”) once again.

1 2

• After the timer is programmed, the display

shows the remaining time.

• Press the timer on/off button once again to

cancel programming. The display vanishes.

8 English

Page 11

For example:

When the timer is programmed to stop the system after 3 hours and start the system after 4

hours, the system will stop after 3 hours and

start 1 hour later.

Fig.7

5-5 PRECAUTIONS FOR GROUP CON-

TROL SYSTEM OR TWO REMOTE CONTROLLER CONTROL SYSTEM

This system provides two other control systems

beside individual control (one remote controller controls one indoor unit) system. Confirm about your

system to Daikin dealer.

• Group control system

One remote controller controls up to 16 indoor

units. All indoor units are equally set.

• Two remote controller control system

Two remote controllers control one indoor unit (in

case of group control system, one group of indoor

units). The unit is individually operated.

NOTE

• Contact your Daikin dealer in case of changing the combination or setting of group control and two remote controller control

systems.

6. OPTIMUM OPERATION

Observe the following precautions to ensure the

system operates properly.

• Turn off the power if the unit is not operated for a

long time.

The unit will consume a power of several watts to

several tens of watts if the power is on (see note).

For the purpose of machine protection, however, be

sure to turn on the power at least 6 hours before

resuming the operation of the unit.

OFF

• Install an alarm if operational errors are likely to

degrade the commodities in storage.

The unit is provided with a terminal to output an

alarm signal.

If the system should malfunction and there is no

alarm, the operation of the unit will be interrupted for

a long time and damage to the commodities in storage may result.

The installation of an alarm is recommended in

order to take appropriate measures promptly in such

cases.

For details, consult your dealer.

• Adjust the air outlet properly and avoid direct air

flow to room inhabitants.

• Adjust the room temperature properly for a comfortable environment. Avoid excessive heating or

cooling.

• Prevent direct sunlight from entering a room during cooling operation by using curtains or blinds.

• Ventilate often.

Extended use requires special attention to ventilation.

• Do not keep doors and windows opened. If the

doors and windows remain open, air will flow out

of your room causing a decrease in the cooling or

heating effect.

• Never place objects near the air inlet or the air

outlet of the unit. It may cause deterioration in the

effect or stop the operation.

• Turn off the main power supply switch to the unit

when the unit is not used for longer periods of

time. If the switch is on, it uses electricity. Before

restarting the unit, turn on the main power supply

switch 6 hours before operation to ensure smooth

running. (Refer to the chapter “Maintenance” in

the indoor unit manual.)

• When the display shows “ ” (time to clean the

air filter), ask a qualified service person to clean

the filters. (Refer to the chapter “Maintenance” in

the indoor unit manual.)

• Keep the indoor unit and remote control at least 1

m away from televisions, radios, stereos, and

other similar equipment.

Failing to do so may cause static or distorted pictures.

• Do not use other heating devices directly beneath

the indoor unit.

If you do, they might get deformed by the heat.

• It takes time for the room temperature to reach the

set temperature.

We recommend starting the operation in advance

using timer operation.

Note: The power consumption of the unit varies with

the operating factors, such as the CONVENIPAC K mo d el .

English 9

Page 12

7. CARE AND CLEANING METHOD

Be sure to stop the operation of the unit with the

power switch and turn off the power (i.e., turn off

the earth leakage breaker) before starting the

maintenance of the unit.

CAUTION

Do not touch the aluminium fin directly at the

time of cleaning.

Doing so may result in injury.

Do not wash the unit with water.

Doing so may result in electric shock or ignition.

Be sure to stop the operation of the unit and

turn off the power circuit breaker at the time

of cleaning, maintenance and inspection.

Otherwise, electric shock or injury may result.

Cleaning the outdoor unit

• Consult your local dealer.

Cleaning the indoor unit

• As the system is an all-in-one air-conditioner and

refrigerator, the fan may rotate in a heating mode

even if operation is stopped with the remote controller.

Be sure to stop operation with the remote controller and cut off the power breaker before cleaning.

Refer to the operation manual attached to the

indoor unit for details.

Cleaning the showcase and the unit cooler

• Refer to the operation manual attached to the

showcase and the unit cooler for details.

Cleaning the drain pan (Optional accessory)

• Clean the drain pan so that it does not become

clogged and dusty.

• Turn off the power (i.e., turn off the earth leakage

breaker) if the unit is not used for a long time.

8. TROUBLESHOOTING

8-1 The following cases are not malfunc-

tions.

1. The unit does not operate.

• The air conditioner does not start immediately when restart the operation after stop

the operation or change operation mode

after set the operation mode.

If the operation lamp lights, the system is in

normal condition.

To prevent overloading of the compressor

motor, the air conditioner starts 5 minutes after

it is turned ON again in case it was turned OFF

just before.

• If “Centralized Control” is displayed on the

remote controller and pressing the operation button causes the display to blink for a

few seconds.

This indicates that the central device is controlling the unit.

The blinking display indicates that the remote

control cannot be used.

• The system does not start immediately

after the power supply is turned on.

Wait one minute until the micro computer is

prepared for operation.

2. It stops sometimes

• The remote controller display reads “U4” or

“U5” and stops but then restarts after a few

minutes.

This is because the remote control is intercepting noise from electrical appliances other than

the air conditioner, and this prevents communication between the units, causing them to stop.

Operation automatically restarts when the

noise goes away.

3. COOL/HEAT cannot be changed over.

• When the display shows “ ”

(changeover under control).

It shows that this is a slave remote controller.

Refer to “Setting the master remote controller”.

• When the cool/heat selector switch is

installed and the display shows

“ ” (changeover under control).

This is because cool/heat changeover is controlled by the cool/heat selector. Ask your

Daikin dealer where the remote control switch

is installed.

4. Fan operation is possible, but cooling and

heating do not work.

• Immediately after the power is turned on.

The micro computer is getting ready to operate.

Wait 10 minutes.

5. The fan strength does not correspond to the

setting.

• The fan strength does no change even if the

fan strength adjustment button in pressed.

During heating operation, when the room temperature reaches the set temperature, the outdoor unit goes off and the indoor unit changes

to whisper fan strength.

This is to prevent cold air blowing directly on

occupants of the room.

The fan strength will not change even if the button is changed, when another indoor unit is in

heating operation.

10 English

Page 13

6. White mist comes out of a unit.

<Indoor unit for air conditioning>

• When humidity is high during cooling operation.

If the interior of an indoor unit is extremely contaminated, the temperature distribution inside

a room becomes uneven. It is necessary to

clean the interior of the indoor unit. Ask your

Daikin dealer for details on cleaning the unit.

This operation requires a qualified service person.

• Immediately after the cooling operation

stops and if the room temperature and

humidity are low.

This is because warm refrigerant gas flows

back into the indoor unit and generates steam.

<Indoor unit for air-conditioning, outdoor

unit>

• When the system is changed over to heating operation after defrost operation.

Moisture generated by defrost becomes steam

and is exhausted.

7. Noise of air-conditioners.

<Indoor unit for air-conditioning>

• A continuous low “shah” sound is heard

when the system is in cooling operation or

at a stop.

When the drain pump (optional accessories) is

in operation, this noise is heard.

• A low “sah”, “choro-choro” sound is heard

while the indoor unit is stopped.

When the other indoor unit is in operation, this

noise is heard. In order to prevent oil and

refrigerant from remaining in the system, a

small amount of refrigerant is kept flowing.

<Outdoor unit, booster unit>

• When the tone of operating noise changes.

This noise is caused by the change of frequency.

<Indoor unit for air-conditioning, outdoor

unit, booster unit>

• A continuous low hissing sound is heard

when the system is in cooling or defrost

operation.

This is the sound of refrigerant gas flowing

through both indoor and outdoor units.

• A hissing sound which is heard at the start

or immediately after stopping operation or

defrost operation.

This is the noise of refrigerant caused by flow

stop or flow change.

8. Dust comes out of the unit.

• When the unit is used after stopping for a

long time.

This is because dust has gotten into the unit.

9. The units can give off odours.

• During operation.

The unit can absorb the smell of rooms, furniture, cigarettes, etc., and then emit it again.

10.The outdoor unit fan does not spin.

• During operation.

The speed of the fan is controlled in order to

optimize product operation.

11.The display shows “ ”

• This is the case immediately after the main

power supply switch is turned on.

This means that the remote controller is in normal condition. This continues for one minute.

12.The compressor or fan in the outdoor unit

does not stop.

• This is to prevent oil and refrigerant from

remaining in the compressor. The unit will

stop after 5 to 10 minutes.

13.Hot air is emitted even though the unit is

stopped.

• Hot air can be felt when the unit is stopped.

Several different indoor units are being run on

the same system, so if another unit is running,

some refrigerant will still flow through the unit.

14.Does not cool very well.

• Program dry operation.

Program dry operation is designed to lower the

room temperature as little as possible.

Refer to page 7.

15.The indoor fan may rotate while the unit

stops.

• The fan rotates even if the operation is

stopped with the remote controller.

As the system operates as an all-in-one airconditioner and refrigerator, the fan works to

prevent oil and refrigerant from accumulating

on the air conditioner during operation of the

showcase.

8-2 Check before Requesting Servicing.

1. The unit does not operate at all.

• Has the power supply fuse not blown out?

Turn off the power. (Consult your dealer for the

replacement of the power supply fuse.)

• Is the power circuit breaker not turned off?

Turn on the power if the knob of the power circuit breaker is set to the OFF position.

Do not turn on the

power if the knob of

the power circuit

breaker is set to the

trip position. (Consult

your dealer.)

Breaker

ON

OFF

Switch

Trip position

English 11

Page 14

• Is there no blackout?

Wait until power is restored. If power failure

occurs during operation, the system automatically restarts immediately after the power supply is recovered.

• Are all the power supplies turned on?

Turn all the power on.

2. The unit comes to a stop soon after the unit

starts operating.

• Do obstacles not block the air inlet or outlet of

the outdoor unit or indoor unit?

Remove the obstacles.

• Check if the remote controller display shows

“ ” (time to clean the air filter);

Refer to the operation manual of the indoor unit

for air-conditioning. And clean the air filter.

3. The system operates but cooling or heating

is insufficient (Air-conditioning).

• Check if air inlet or outlet of outdoor or indoor

unit is not blocked by obstacles.

Remove any obstacle and make it well-ventilated.

• Check if the remote controller display shows

“ ” (time to clean the air filter);

Refer to the operation manual of the indoor unit.

And clean the air filter.

• Check the temperature setting.

Refer to “Operation procedure”.

• Check the fan speed setting on your remote

controller.

Refer to “Operation procedure”.

• Check for open doors or windows.

Shut doors and windows to prevent wind from

coming in.

• Check if there are too many occupants in the

room during cooling operation.

• Check if the heat source of the room is excessive during cooling operation.

• Check if direct sunlight enters the room during

cooling operation.

Use curtains or blinds.

• Check if the air flow angle is not proper.

Refer to “Operation procedure”.

4. The cooling operation of the unit is bad.

• Does the indoor unit (unit cooler and showcase) not have much frost?

Defrost manually or shorten the cycle of

defrosting operation.

• Are there not too many articles inside?

Reduce the number of articles.

• Is the circulation of cold air in the indoor unit

(unit cooler and showcase) smooth?

Change the allocation of the articles.

• Is there not much dust on the heat exchanger of

the outdoor unit?

Remove the dust with a brush or vacuum

cleaner without using water or consult your

dealer.

• Is cold air not leaking outside?

Stop the leakage of cold air.

• Is the set temperature in the indoor unit (unit

cooler and showcase) not too high?

Set the temperature appropriately.

• Are high-temperature articles not stored?

Store them after they are once cooled off.

• Is the opening time of the door not long?

Minimize the opening time of the door.

8-3 Consult your dealer in the following

cases.

WARNING

When the CONVENI-PACK is malfunctioning

(giving off a burning odour, etc.) turn off

power to the unit and contact your local

dealer.

Continued operation under such circumstances

may result in a failure, electric shocks or fire hazards.

1. Safety devices, such as the fuse, breaker, and

earth leakage breaker, frequently operate or

the operation of the RUN switch is not stable.

Contact your dealer after turning the power off.

2. Turn off the power and consult your dealer if

symptoms other than the above are noticed

or the equipment does not go into normal

operation after taking the steps specified in

8-2.

9. INSPECTION

The preventive maintenance of the unit is

required in order not to damage commercial

products. Request a contractor authorized by

our dealer for inspection.

Refer to information on maintenance inspection on

page 14 for maintenance inspection.

12 English

Page 15

10. PRODUCT MODELS AND MAIN SPECIFICATIONS

10-1Models and Main Specifications.

Model LRYEQ16AY1 (E) LCBKQ3AV1 (E)

Power supply 3 phase 380~415V 50Hz 1 phase 220~240V 50Hz

Refrigerant R410A

Operating condition

Capacity (kW)

Outer dimensions (HxWxD) (mm) 1680×1240×765 480×680×310

Product mass (kg) 370 47

Sound pressure level (dB(A)) 62 49

Design pressure

Note:

• Operating conditions:

Outdoor unit

(Air-conditioning side) Indoor temperature: 27ºCDB/19ºCWB, Outdoor temperature: 32ºCDB, Piping

length: 7.5m, Level difference: 0m (In cooling priority mode)

(Cooling equipment side) Evaporating temperature: -10ºC, Outdoor temperature: 32ºCDB, Suction SH:

10ºC (In cooling priority mode)

(Heating conditions)Indoor temperature: 20ºCDB, Outdoor temperature: 7ºCDB/6ºCWB, Cooling equipment load: 18 kW,

Piping length: 7.5 m, Level difference: 0 m

Saturated temperature equivalent to suction pressure (Cooling equipment side) : -10ºC (Under chilled condition),

Connection capacity for indoor air-conditioner: 10HP, When heat recovery is 100%

Evaporating temperature -20ºC~10ºC (Refrigeration) -45ºC~-20ºC

Refrigeration -15ºC~43ºCDB

Outdoor

temperature

Cool

Heat

High-pressure

side

Low-pressure

side

Cool -5ºC~43ºCDB

Heat

Air-conditioning 14 -

Refrigerating 21.8 -

Free zing - 3.35

Air-conditioning 27 -

Refrigerating 21.8 -

Free zing - 3.35

(bar) 38 38

(MPa) 3.8 3.8

(bar) 25 25

(MPa) 2.5 2.5

-15ºC~21ºCDB

-15ºC~15.5ºCWB

-15ºC~43ºCDB

Booster unit

Evaporating temperature: -35ºC, Outdoor temperature: 32ºC, Suction SH: 10ºC, Saturated temperature to

discharge pressure of booster unit: -10ºC

• The figures for the outside unit models show values measured at a distance of 1 m in the front and a height

of 1.5 m.

Values measured with the models actually installed are usually larger then the values shown as a result of

ambient noise and reflections.

When the outdoor temperature is low, the temperature reading may be below the target evaporating temperature set for the protection of the unit.

• Values are subject to change without notice for product improvements.

• The "E" suffix indicates anti-corrosion models.

English 13

Page 16

11. AFTER-SALE SERVICE AND

WARRANTY

11-1 After-sale Service

WARNING

Consult your local dealer regarding modification, repair and maintenance of the CONVENI-PACK.

Improper workmanship may result in water leakage, electric shocks or fire hazards.

Consult your local dealer regarding relocation

and reinstallation of the CONVENI-PACK.

Improper installation work may result in leakage,

electric shocks or fire hazards.

Beware of fire in case of refrigerant leakage.

If the CONVENI-PACK is not operating correctly

(i.e. the interior temperature of the CONVENIPACK does not drop efficiently), refrigerant leakage could be the cause.

Consult your dealer for assistance.

The refrigerant within the CONVENI-PACK is safe

and normally does not leak.

However, in the event of a leakage, contact with a

naked burner, heater or cooker may result in generation of noxious gas.

Do not longer use the CONVENI-PACK until a

qualified service person confirms that the leakage

has been repaired.

4. Relocation and Disposal

• Contact your dealer for removing and reinstalling the system CONVENI-PACK since they

require technical expertise.

• The system CONVENI-PACK uses fluorocarbon refrigerant.

Contact your dealer for discarding the system

CONVENI-PACK since it is required by law to

collect, transport and discard the refrigerant in

accordance with relevant local and national

regulations.

• In either case, consult your dealer.

5. Inquiries

Contact your dealer for after-sale services.

11-2 Warranty Card

1. This product comes with a warranty card.

Your dealer will deliver you the warranty card

filled out with the necessary items. Check the

details and have the administrative person in

charge of the heat source unit for refrigeration

system keep the warranty card carefully.

2. When requesting repairs for free during the warranty period, contact your dealer and be sure to

present the warranty card.

Repair services may be charged during the warranty period if the warranty card is not presented.

Be sure to keep the warranty card carefully.

1. Inform your dealer of the following items

when you request repairs.

• Model name Described in the warranty card.

• Serial number and date of installation

Described in the warranty card.

• Defective condition

• Your address, name, and telephone number

2. Repairs after Expiration of Warranty Period

Consult your dealer. Onerous repairs will be possible if the unit can maintain its original functions

after the repairs are made.

3. Maintenance Inspection

The interior of the refrigeration CONVENI-PACK

will become dirty and its performance may be

degraded if it is used for several seasons.

The disassembly and internal cleaning of the unit

requires specialized techniques. Therefore, our

dealer recommends an onerous maintenance

inspection besides usual maintenance services.

For details, consult your dealer.

Keep in mind that our dealer’s warranty may not

cover malfunctions resulting from the disassembly or internal cleaning of the unit conducted by

contractors not authorized by our dealer.

–

as precise as possible

Warranty period: 1 year counting from the date

of installation.

For details, read through the warranty card.

3. Secondary Warranties

Our dealer will not provide secondary warranties,

such as compensation for chilled product damage or business loss, resulting from failures in

the product.

Perform regular temperature control if secondary

disaster is feared. Besides, consult your dealer

and take appropriate measures, such as the

installation of an alarm system or auxiliary equipment.

In addition, take out accident insurance.

14 English

Page 17

11-3 Onerous Repairs (Outside Scope of

Warranty Coverage)

11-3-1 Accidents Resulting from Use

beyond Standards for Use

• Use beyond Limits

• Applications other than its designed purpose of

use or modification.

Standards for Use

Standards for Use

Item

Power supply Voltage

fluctuation

Outdoor temperature

range (Cool)

Outdoor temperature

range (Heat)

Connecting piping

length

Height difference

between inside and

outside units

Height difference

between outside unit

and booster unit

Height difference

between inside units

(Air-condition side)

Height difference

between inside units

(Showcase side)

Outdoor unit Booster unit

Within ±10% of rated voltage

ºC~

+43ºCDB

-5

ºC~21ºC

ºC~

15.5ºCWB

DB

-15

-15

Within 130 m

(Piping length

between Indoor and

Outdoor unit)

Within 35 m

(within 10 m if the out-

side unit is lower)

Within 35 m (within 10 m if the outside unit is

lower)

Within 0.5 m

Within 5 m

-15

ºC

~+43ºCDB

Within 30 m

(Piping length

between Indoor and

Booster unit)

Within 10 m

(within 0 m if the

booster unit is lower)

11-3-2 Selection, Installation, Work Failures

Specified below and Other Failures

Note: Asterisk-marked items show concrete exam-

ples.

1. Model selection failures

• A model not suitable for storage applications is

selected.

∗ The cooling of products not reaching the tar-

get storage temperatures.

• Cooling overloading or underloading judged by

our dealer.

∗ The frequency of stoppage is 6 or more times

per hour or the set cooling temperature is not

attained.

2. Installation failure (Installation and environmental problems)

• The unit is not installed on a stable horizontal

plane.

∗ The unit is not fixed securely.

• The environmental conditions of the place of

installation differ from normal atmospheric conditions.

∗ Briny air environment, shore side, oil mist

environment, kitchen exhaust side, other corrosive gas and adhesive mist environment.

• The place of installation had poor ventilation

and heat dissipation.

∗ The machine took in exhausted air again.

3. Work failure

• The interior of the piping was not vacuum dried

sufficiently.

∗ The clogging of the thin areas of the piping

caused by icing.

• The interior of the piping was not sufficiently airtight.

∗ Leakage of refrigerant gas.

• The interior of the piping was contaminated

with foreign substance.

∗ The clogging of the thin areas of the piping.

• The unit was adversely affected by on-site

modification work.

∗

The use of the unit beyond the operating temperature range as a result of on-site modification.

• An accident resulted from the improper handling of the unit under installation work.

∗ The loosening or wobbling of the outer panel

or broken or bent damage to the piping.

4. Operational failure

• Temperature settings for stored objects were

wrong.

∗ The storage of vegetables at temperatures

below 0°C.

• The periodical maintenance of the unit was

neglected.

∗ The clogging of the air heat exchanger, rust

generation from each part, gas leakage, and

icing of the indoor unit (showcase and unit

cooler).

5. Others

• Improvements recommended by our dealer in

advance were not accomplished.

∗ The simultaneous starting and stopping of a

number of units.

• Accidents were caused by natural disaster or

fire.

∗

Damage to electrical parts caused by lightning.

• There were other installation and operational

problems beyond common sense.

∗ The use of the unit without heat insulation

work on the piping.

• Work was conducted without keeping the following showcase restrictions.

<Showcase restrictions>

· The design pressure for the indoor unit is 2.5

MPa or more.

· The installation of the thermostatic expansion

valve and liquid supply solenoid valve (both of

which are for R410A) on a showcase basis.

Thermal insulation of feeler tube of thermostatic expansion valve must be thermal insulated.

·

Install showcases on the same floor if the showcases are connected to a single outdoor unit.

English 15

Page 18

· Make sure that the outlet of piping used for

the heat exchanger is located downward (as

shown on the following figure).

Inlet

(upper side)

Outlet

Heat exchanger

(lower side)

16 English

Page 19

3P248411-3B EM09A054

(1002) FS

Loading...

Loading...