Daikin LRMEQ3AY1, LRMEQ4AY1 Installer reference guide

Installer and user

reference guide

Air-cooled refrigeration condensing unit

LRMEQ3AY1

LRMEQ4AY1

Installer and user reference guide

Air-cooled refrigeration condensing unit

English

Table of Contents

Table of Contents

1 General safety precautions 3

1.1 About the documentation .......................................................... 3

1.1.1 Meaning of warnings and symbols.............................. 3

1.2 For the user ............................................................................... 3

1.3 For the installer.......................................................................... 4

1.3.1 General ....................................................................... 4

1.3.2 Installation site ............................................................ 4

1.3.3 Refrigerant .................................................................. 4

1.3.4 Brine............................................................................ 5

1.3.5 Water .......................................................................... 5

1.3.6 Electrical ..................................................................... 5

2 About the documentation 6

2.1 About this document.................................................................. 6

For the installer 6

3 About the box 6

3.1 Overview: About the box ........................................................... 6

3.2 Outdoor unit............................................................................... 7

3.2.1 To unpack the outdoor unit ......................................... 7

3.2.2 To handle the outdoor unit.......................................... 7

3.2.3 To remove the accessories from the outdoor unit....... 7

4 About the units 7

4.1 Overview: About the units ......................................................... 7

4.2 Identification .............................................................................. 7

4.2.1 Identification label: Outdoor unit ................................. 8

4.3 About the outdoor unit ............................................................... 8

4.4 System layout............................................................................ 8

4.5 About the indoor units ............................................................... 8

4.5.1 About reusing existing indoor heat exchangers.......... 8

5 Preparation 8

5.1 Overview: Preparation............................................................... 8

5.2 Preparing installation site .......................................................... 8

5.2.1 Installation site requirements of the outdoor unit ........ 9

5.2.2 Additional installation site requirements of the

outdoor unit in cold climates ....................................... 10

5.2.3 Securing safety against refrigerant leaks.................... 10

5.3 Preparing refrigerant piping....................................................... 11

5.3.1 About reusing existing piping...................................... 11

5.3.2 Refrigerant piping requirements.................................. 11

5.3.3 Refrigerant piping material.......................................... 11

5.3.4 To select the piping size ............................................. 11

5.3.5 Refrigerant piping length and height difference .......... 12

5.4 Preparing electrical wiring ......................................................... 12

5.4.1 Safety device requirements ........................................ 12

6 Installation 13

6.1 Overview: Installation ................................................................ 13

6.2 Opening the units ...................................................................... 13

6.2.1 About opening the units .............................................. 13

6.2.2 To open the outdoor unit............................................. 13

6.3 Mounting the outdoor unit.......................................................... 13

6.3.1 About mounting the outdoor unit................................. 13

6.3.2 Precautions when mounting the outdoor unit.............. 13

6.3.3 To provide the installation structure............................ 13

6.3.4 To install the outdoor unit............................................ 14

6.3.5 To prevent the outdoor unit from falling over .............. 14

6.4 Connecting the refrigerant piping .............................................. 14

6.4.1 About connecting the refrigerant piping ...................... 14

6.4.2 Precautions when connecting the refrigerant piping... 14

6.4.3 Guidelines when connecting the refrigerant piping..... 14

6.4.4 Pipe bending guidelines.............................................. 15

6.4.5 To flare the pipe end .................................................... 15

6.4.6 To braze the pipe end .................................................. 15

6.4.7 Using the stop valve and service port .......................... 15

6.4.8 Guidelines when installing a sight glass ...................... 16

6.4.9 Guidelines when installing a dryer ............................... 17

6.4.10 To connect the refrigerant piping to the outdoor unit ... 17

6.4.11 Guidelines when connecting piping branching............. 17

6.5 Checking the refrigerant piping .................................................. 18

6.5.1 About checking the refrigerant piping .......................... 18

6.5.2 Checking refrigerant piping: General guidelines.......... 18

6.5.3 Checking refrigerant piping: Setup............................... 18

6.5.4 To perform a leak test .................................................. 18

6.5.5 To perform vacuum drying ........................................... 19

6.6 To insulate the refrigerant piping................................................ 19

6.7 Charging refrigerant ................................................................... 19

6.7.1 About charging refrigerant ........................................... 19

6.7.2 Precautions when charging refrigerant ........................ 19

6.7.3 To determine the additional refrigerant amount........... 20

6.7.4 To charge refrigerant ................................................... 20

6.7.5 Error codes when charging refrigerant......................... 21

6.7.6 To fix the fluorinated greenhouse gases label ............. 21

6.8 Connecting the electrical wiring.................................................. 22

6.8.1 About connecting the electrical wiring.......................... 22

6.8.2 Precautions when connecting electrical wiring ............ 22

6.8.3 Guidelines when knocking out knockout holes ............ 23

6.8.4 Guidelines when connecting the electrical wiring ........ 23

6.8.5 To connect the electrical wiring on the outdoor unit..... 23

6.9 Finishing the outdoor unit installation ......................................... 24

6.9.1 To close the outdoor unit ............................................. 24

7 Configuration 25

7.1 Overview: Configuration ............................................................. 25

7.2 Making field settings................................................................... 25

7.2.1 About making field settings .......................................... 25

7.2.2 To access the field setting components....................... 25

7.2.3 Field setting components ............................................. 25

7.2.4 To access mode 1 or 2 ................................................ 25

7.2.5 To use mode 1 ............................................................. 26

7.2.6 To use mode 2 ............................................................. 26

7.2.7 Mode 1 (and default situation): Monitoring settings ..... 26

7.2.8 Mode 2: Field settings.................................................. 27

8 Commissioning 27

8.1 Overview: Commissioning.......................................................... 27

8.2 Precautions when commissioning .............................................. 27

8.3 Checklist before commissioning................................................. 28

8.4 Checklist during commissioning ................................................. 28

8.4.1 About test run............................................................... 28

8.4.2 To perform a test run (7-LEDs display)........................ 28

8.4.3 Correcting after abnormal completion of the test run... 29

8.4.4 Operating the unit ........................................................ 29

9 Hand-over to the user 29

10 Maintenance and service 29

10.1 Overview: Maintenance and service .......................................... 29

10.2 Maintenance safety precautions................................................. 29

10.2.1 To prevent electrical hazards ....................................... 29

10.3 Checklist for yearly maintenance of the outdoor unit ................. 30

10.4 About service mode operation.................................................... 30

10.4.1 To use vacuum mode .................................................. 30

10.4.2 To recover refrigerant .................................................. 30

11 Troubleshooting 30

11.1 Overview: Troubleshooting......................................................... 30

11.2 Precautions when troubleshooting ............................................. 30

11.3 Solving problems based on error codes ..................................... 30

11.3.1 To display the error codes of the latest malfunctions... 30

11.3.2 Error codes: Overview ................................................. 31

12 Disposal 32

Installer and user reference guide

2

Air-cooled refrigeration condensing unit

LRMEQ3+4AY1

4P442131-1 – 2016.03

1 General safety precautions

13 Technical data 33

13.1 Overview: Technical data .......................................................... 33

13.2 Dimensions: Outdoor unit .......................................................... 33

13.3 Service space: Outdoor unit ...................................................... 34

13.4 Components: Outdoor unit ........................................................ 36

13.5 Piping diagram: Outdoor unit..................................................... 37

13.6 Wiring diagram: Outdoor unit .................................................... 38

13.7 Technical specifications: Outdoor unit....................................... 40

For the user 41

14 About the system 41

14.1 System layout ............................................................................ 41

15 Before operation 41

16 Operation 41

16.1 Operation range ........................................................................ 41

16.2 Operating the system ................................................................ 41

16.2.1 About operating the system ........................................ 41

17 Energy saving and optimum operation 42

18 Maintenance and service 42

18.1 Maintenance after a long stop period ........................................ 42

18.2 About the refrigerant.................................................................. 42

18.3 After-sales service and warranty ............................................... 42

18.3.1 Warranty period .......................................................... 42

18.3.2 Recommended maintenance and inspection .............. 42

19 Troubleshooting 43

19.1 Symptoms that are NOT system malfunctions .......................... 43

19.1.1 Symptom: The system does not operate .................... 43

19.1.2 Symptom: The unit does not stop immediately when

operation is stopped.................................................... 43

19.1.3 Symptom: Noise (Outdoor unit) .................................. 43

19.1.4 Symptom: Dust comes out of the unit ......................... 44

19.1.5 Symptom: The outdoor unit fan does not spin ............ 44

19.1.6 Symptom: The inside of an outdoor unit is warm

even when the unit has stopped ................................. 44

20 Relocation 44

21 Disposal 44

22 Glossary 44

1 General safety precautions

DANGER: RISK OF BURNING

Indicates a situation that could result in burning because of

extreme hot or cold temperatures.

WARNING: FLAMMABLE MATERIAL

WARNING

Indicates a situation that could result in death or serious

injury.

CAUTION

Indicates a situation that could result in minor or moderate

injury.

NOTICE

Indicates a situation that could result in equipment or

property damage.

INFORMATION

Indicates useful tips or additional information.

1.2 For the user

▪ If you are not sure how to operate the unit, contact your installer.

▪ This appliance can be used by children aged from 8 years and

above and persons with reduced physical, sensory or mental

capabilities or lack of experience and knowledge if they have been

given supervision or instruction concerning use of the appliance in

a safe way and understand the hazards involved. Children shall

not play with the appliance. Cleaning and user maintenance shall

not be made by children without supervision.

WARNING

To prevent electric shocks or fire:

▪ Do NOT rinse the unit.

▪ Do NOT operate the unit with wet hands.

▪ Do NOT place any objects containing water on the unit.

NOTICE

▪ Do NOT place any objects or equipment on top of the

unit.

▪ Do NOT sit, climb or stand on the unit.

▪ Units are marked with the following symbol:

1.1 About the documentation

▪ The original documentation is written in English. All other

languages are translations.

▪ The precautions described in this document cover very important

topics, follow them carefully.

▪ The installation of the system, and all activities described in the

installation manual and the installer reference guide must be

performed by an authorized installer.

1.1.1 Meaning of warnings and symbols

DANGER

Indicates a situation that results in death or serious injury.

DANGER: RISK OF ELECTROCUTION

Indicates a situation that could result in electrocution.

LRMEQ3+4AY1

Air-cooled refrigeration condensing unit

4P442131-1 – 2016.03

This means that electrical and electronic products may not be

mixed with unsorted household waste. Do NOT try to dismantle

the system yourself: the dismantling of the system, treatment of

the refrigerant, of oil and of other parts must be done by an

authorized installer and must comply with applicable legislation.

Units must be treated at a specialized treatment facility for reuse,

recycling and recovery. By ensuring this product is disposed of

correctly, you will help to prevent potential negative consequences

for the environment and human health. For more information,

contact your installer or local authority.

Installer and user reference guide

3

1 General safety precautions

▪ Batteries are marked with the following symbol:

This means that the batteries may not be mixed with unsorted

household waste. If a chemical symbol is printed beneath the

symbol, this chemical symbol means that the battery contains a

heavy metal above a certain concentration.

Possible chemical symbols are: Pb: lead (>0.004%).

Waste batteries must be treated at a specialized treatment facility

for reuse. By ensuring waste batteries are disposed of correctly,

you will help to prevent potential negative consequences for the

environment and human health.

1.3 For the installer

1.3.1 General

If you are not sure how to install or operate the unit, contact your

dealer.

NOTICE

Improper installation or attachment of equipment or

accessories could result in electric shock, short-circuit,

leaks, fire or other damage to the equipment. Only use

accessories, optional equipment and spare parts made or

approved by Daikin.

WARNING

Make sure installation, testing and applied materials

comply with applicable legislation (on top of the

instructions described in the Daikin documentation).

CAUTION

Wear adequate personal protective equipment (protective

gloves, safety glasses,…) when installing, maintaining or

servicing the system.

WARNING

Tear apart and throw away plastic packaging bags so that

nobody, especially children, can play with them. Possible

risk: suffocation.

DANGER: RISK OF BURNING

▪ Do NOT touch the refrigerant piping, water piping or

internal parts during and immediately after operation. It

could be too hot or too cold. Give it time to return to

normal temperature. If you must touch it, wear

protective gloves.

▪ Do NOT touch any accidental leaking refrigerant.

WARNING

Provide adequate measures to prevent that the unit can be

used as a shelter by small animals. Small animals that

make contact with electrical parts can cause malfunctions,

smoke or fire.

CAUTION

Do NOT touch the air inlet or aluminum fins of the unit.

NOTICE

▪ Do NOT place any objects or equipment on top of the

unit.

▪ Do NOT sit, climb or stand on the unit.

In accordance with the applicable legislation, it might be necessary

to provide a logbook with the product containing at least: information

on maintenance, repair work, results of tests, stand-by periods,…

Also, at least, following information must be provided at an

accessible place at the product:

▪ Instructions for shutting down the system in case of an emergency

▪ Name and address of fire department, police and hospital

▪ Name, address and day and night telephone numbers for

obtaining service

In Europe, EN378 provides the necessary guidance for this logbook.

1.3.2 Installation site

▪ Provide sufficient space around the unit for servicing and air

circulation.

▪ Make sure the installation site withstands the unit's weight and

vibration.

▪ Make sure the area is well ventilated. Do NOT block any

ventilation openings.

▪ Make sure the unit is level.

Do NOT install the unit in the following places:

▪ In potentially explosive atmospheres.

▪ In places where there is machinery that emits electromagnetic

waves. Electromagnetic waves may disturb the control system,

and cause malfunction of the equipment.

▪ In places where there is a risk of fire due to the leakage of

flammable gases (example: thinner or gasoline), carbon fibre,

ignitable dust.

▪ In places where corrosive gas (example: sulphurous acid gas) is

produced. Corrosion of copper pipes or soldered parts may cause

the refrigerant to leak.

1.3.3 Refrigerant

If applicable. See the installation manual or installer reference guide

of your application for more information.

NOTICE

Make sure refrigerant piping installation complies with

applicable legislation. In Europe, EN378 is the applicable

standard.

NOTICE

Make sure the field piping and connections are not

subjected to stress.

WARNING

During tests, NEVER pressurize the product with a

pressure higher than the maximum allowable pressure (as

indicated on the nameplate of the unit).

WARNING

Take sufficient precautions in case of refrigerant leakage. If

refrigerant gas leaks, ventilate the area immediately.

Possible risks:

▪ Excessive refrigerant concentrations in a closed room

can lead to oxygen deficiency.

▪ Toxic gas may be produced if refrigerant gas comes

into contact with fire.

NOTICE

Works executed on the outdoor unit are best done under

dry weather conditions to avoid water ingress.

Installer and user reference guide

4

Air-cooled refrigeration condensing unit

LRMEQ3+4AY1

4P442131-1 – 2016.03

1 General safety precautions

WARNING

Always recover the refrigerant. Do NOT release them

directly into the environment. Use a vacuum pump to

evacuate the installation.

NOTICE

After all the piping has been connected, make sure there is

no gas leak. Use nitrogen to perform a gas leak detection.

NOTICE

▪ To avoid compressor breakdown, do NOT charge more

than the specified amount of refrigerant.

▪ When the refrigerant system is to be opened,

refrigerant must be treated according to the applicable

legislation.

WARNING

Make sure there is no oxygen in the system. Refrigerant

may only be charged after performing the leak test and the

vacuum drying.

▪ In case re-charge is required, refer to the nameplate of the unit. It

states the type of refrigerant and necessary amount.

▪ The unit is factory charged with refrigerant and depending on pipe

sizes and pipe lengths some systems require additional charging

of refrigerant.

▪ Only use tools exclusively for the refrigerant type used in the

system, this to ensure pressure resistance and prevent foreign

materials from entering into the system.

▪ Charge the liquid refrigerant as follows:

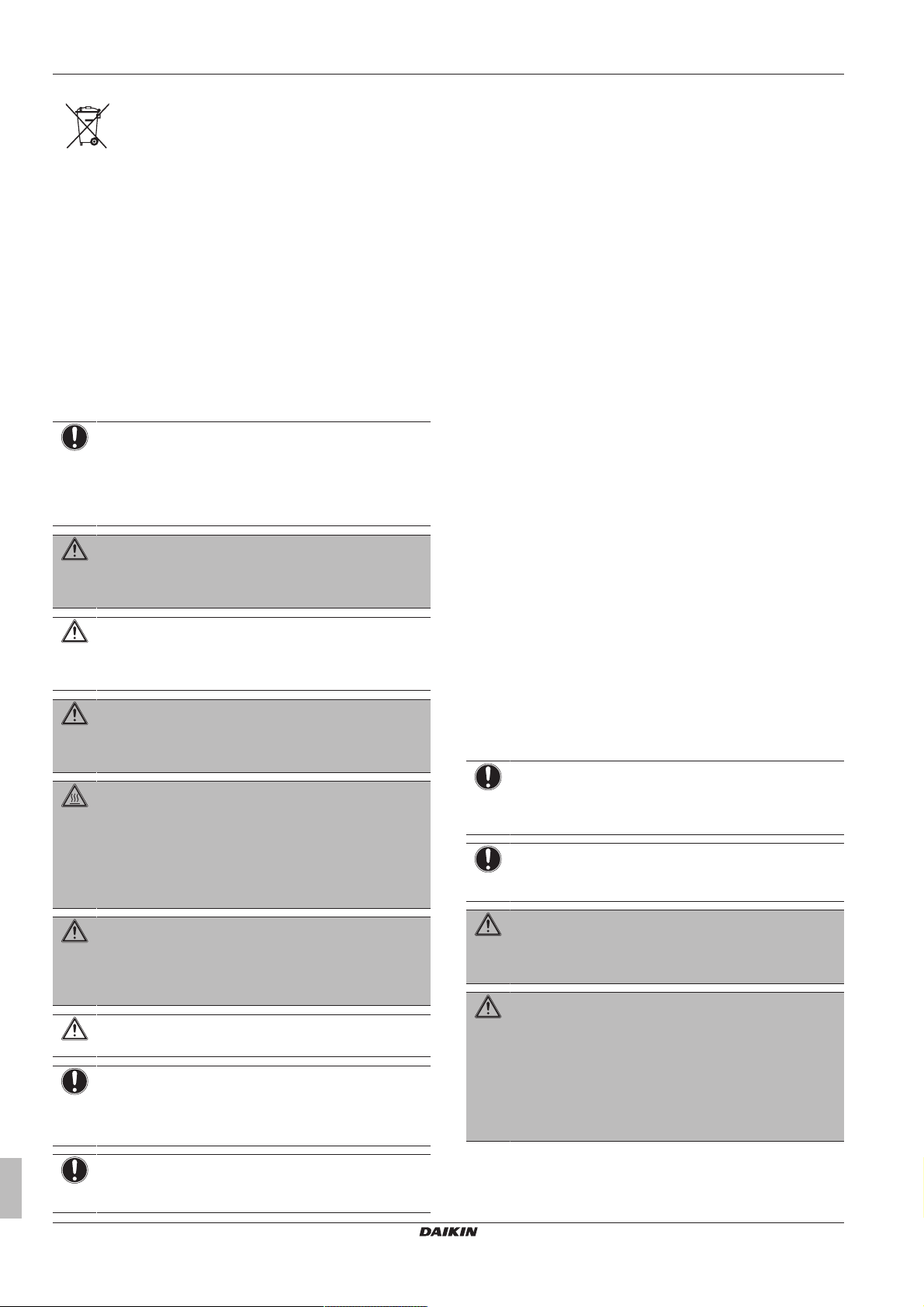

If Then

A siphon tube is present

(i.e., the cylinder is marked with

"Liquid filling siphon attached")

A siphon tube is NOT present Charge with the cylinder upside

Charge with the cylinder upright.

down.

WARNING

Take sufficient precautions in case of brine leakage. If

brine leaks, ventilate the area immediately and contact

your local dealer.

WARNING

The ambient temperature inside the unit can get much

higher than that of the room, e.g. 70°C. In case of a brine

leak, hot parts inside the unit can create a hazardous

situation.

WARNING

The use and installation of the application MUST comply

with the safety and environmental precautions specified in

the applicable legislation.

1.3.5 Water

If applicable. See the installation manual or installer reference guide

of your application for more information.

NOTICE

Make sure water quality complies with EU directive

98/83EC.

1.3.6 Electrical

DANGER: RISK OF ELECTROCUTION

▪ Turn OFF all power supply before removing the

switch box cover, connecting electrical wiring or

touching electrical parts.

▪ Disconnect the power supply for more than 1minute,

and measure the voltage at the terminals of main circuit

capacitors or electrical components before servicing.

The voltage MUST be less than 50 V DC before you

can touch electrical components. For the location of the

terminals, see the wiring diagram.

▪ Do NOT touch electrical components with wet hands.

▪ Do NOT leave the unit unattended when the service

cover is removed.

▪ Open refrigerant cylinders slowly.

▪ Charge the refrigerant in liquid form. Adding it in gas form may

prevent normal operation.

CAUTION

When the refrigerant charging procedure is done or when

pausing, close the valve of the refrigerant tank

immediately. If the valve is not closed immediately,

remaining pressure might charge additional refrigerant.

Possible consequence: Incorrect refrigerant amount.

1.3.4 Brine

If applicable. See the installation manual or installer reference guide

of your application for more information.

WARNING

The selection of the brine MUST be in accordance with the

applicable legislation.

WARNING

If NOT factory installed, a main switch or other means for

disconnection, having a contact separation in all poles

providing full disconnection under overvoltage category III

condition, shall be installed in the fixed wiring.

LRMEQ3+4AY1

Air-cooled refrigeration condensing unit

4P442131-1 – 2016.03

Installer and user reference guide

5

2 About the documentation

WARNING

▪ ONLY use copper wires.

▪ Make sure the field wiring complies with the applicable

legislation.

▪ All field wiring must be performed in accordance with

the wiring diagram supplied with the product.

▪ NEVER squeeze bundled cables and make sure they

do not come in contact with the piping and sharp

edges. Make sure no external pressure is applied to the

terminal connections.

▪ Make sure to install earth wiring. Do NOT earth the unit

to a utility pipe, surge absorber, or telephone earth.

Incomplete earth may cause electrical shock.

▪ Make sure to use a dedicated power circuit. NEVER

use a power supply shared by another appliance.

▪ Make sure to install the required fuses or circuit

breakers.

▪ Make sure to install an earth leakage protector. Failure

to do so may cause electric shock or fire.

▪ When installing the earth leakage protector, make sure

it is compatible with the inverter (resistant to high

frequency electric noise) to avoid unnecessary opening

of the earth leakage protector.

NOTICE

Precautions when laying power wiring:

▪ Do not connect wiring of different thicknesses to the

power terminal block (slack in the power wiring may

cause abnormal heat).

▪ When connecting wiring which is the same thickness,

do as shown in the figure below.

▪ For wiring, use the designated power wire and connect

firmly, then secure to prevent outside pressure being

exerted on the terminal board.

▪ Use an appropriate screwdriver for tightening the

terminal screws. A screwdriver with a small head will

damage the head and make proper tightening

impossible.

▪ Over-tightening the terminal screws may break them.

Install power cables at least 1metre away from televisions or radios

to prevent interference. Depending on the radio waves, a distance of

1metre may not be sufficient.

WARNING

▪ After finishing the electrical work, confirm that each

electrical component and terminal inside the electrical

components box is connected securely.

▪ Make sure all covers are closed before starting up the

unit.

NOTICE

Only applicable if the power supply is three‑phase, and the

compressor has an ON/OFF starting method.

If there exists the possibility of reversed phase after a

momentary black out and the power goes on and off while

the product is operating, attach a reversed phase

protection circuit locally. Running the product in reversed

phase can break the compressor and other parts.

2 About the documentation

2.1 About this document

Target audience

Authorised installers + end users

INFORMATION

This appliance is intended to be used by expert or trained

users in shops, in light industry and on farms, or for

commercial use by lay persons.

Documentation set

This document is part of a documentation set. The complete set

consists of:

▪ General safety precautions:

▪ Safety instructions that you must read before installing

▪ Format: Paper (in the box of the outdoor unit)

▪ Outdoor unit installation and operation manual:

▪ Installation and operation instructions

▪ Format: Paper (in the box of the outdoor unit)

▪ Installer and user reference guide:

▪ Preparation of the installation, technical specifications,

reference data,…

▪ Detailed step-by-step instructions and background information

for basic and advanced usage

▪ Format: Digital files on http://www.daikineurope.com/support-

and-manuals/product-information/

Latest revisions of the supplied documentation may be available on

the regional Daikin website or via your dealer.

The original documentation is written in English. All other languages

are translations.

For the installer

3 About the box

3.1 Overview: About the box

This chapter describes what you have to do after the box with the

outdoor unit is delivered on-site.

Installer and user reference guide

6

It contains information about:

▪ Unpacking and handling the units

▪ Removing the accessories from the units

Keep the following in mind:

LRMEQ3+4AY1

Air-cooled refrigeration condensing unit

4P442131-1 – 2016.03

▪ At delivery, the unit must be checked for damage. Any damage

21

a

1×

b

1×

c

1×

d

1×

must be reported immediately to the carrier's claims agent.

▪ Bring the packed unit as close as possible to its final installation

position to prevent damage during transport.

▪ When handling the unit, take into account the following:

Fragile, handle the unit with care.

Keep the unit upright in order to avoid compressor

damage.

▪ Choose on beforehand the path along which the unit is to be

brought in.

3.2 Outdoor unit

3.2.1 To unpack the outdoor unit

4 About the units

3.2.3 To remove the accessories from the outdoor unit

1 Remove the service cover. See "6.2.2 To open the outdoor

unit"on page13.

2 Remove the accessories.

3.2.2 To handle the outdoor unit

Carry the unit slowly as shown:

CAUTION

To avoid injury, do NOT touch the air inlet or aluminum fins

of the unit.

Forklift. As long as the unit remains on its pallet, you can also use a

forklift.

a General safety precautions

b Outdoor unit installation and operation manual

c Fluorinated greenhouse gases label

d Multilingual fluorinated greenhouse gases label

4 About the units

4.1 Overview: About the units

This chapter contains information about:

▪ Identification of the outdoor unit.

▪ Where the outdoor unit fits in the system layout.

▪ With which indoor units you can combine the outdoor units.

4.2 Identification

NOTICE

When installing or servicing several units at the same time,

make sure NOT to switch the service panels between

different models.

LRMEQ3+4AY1

Air-cooled refrigeration condensing unit

4P442131-1 – 2016.03

Installer and user reference guide

7

5 Preparation

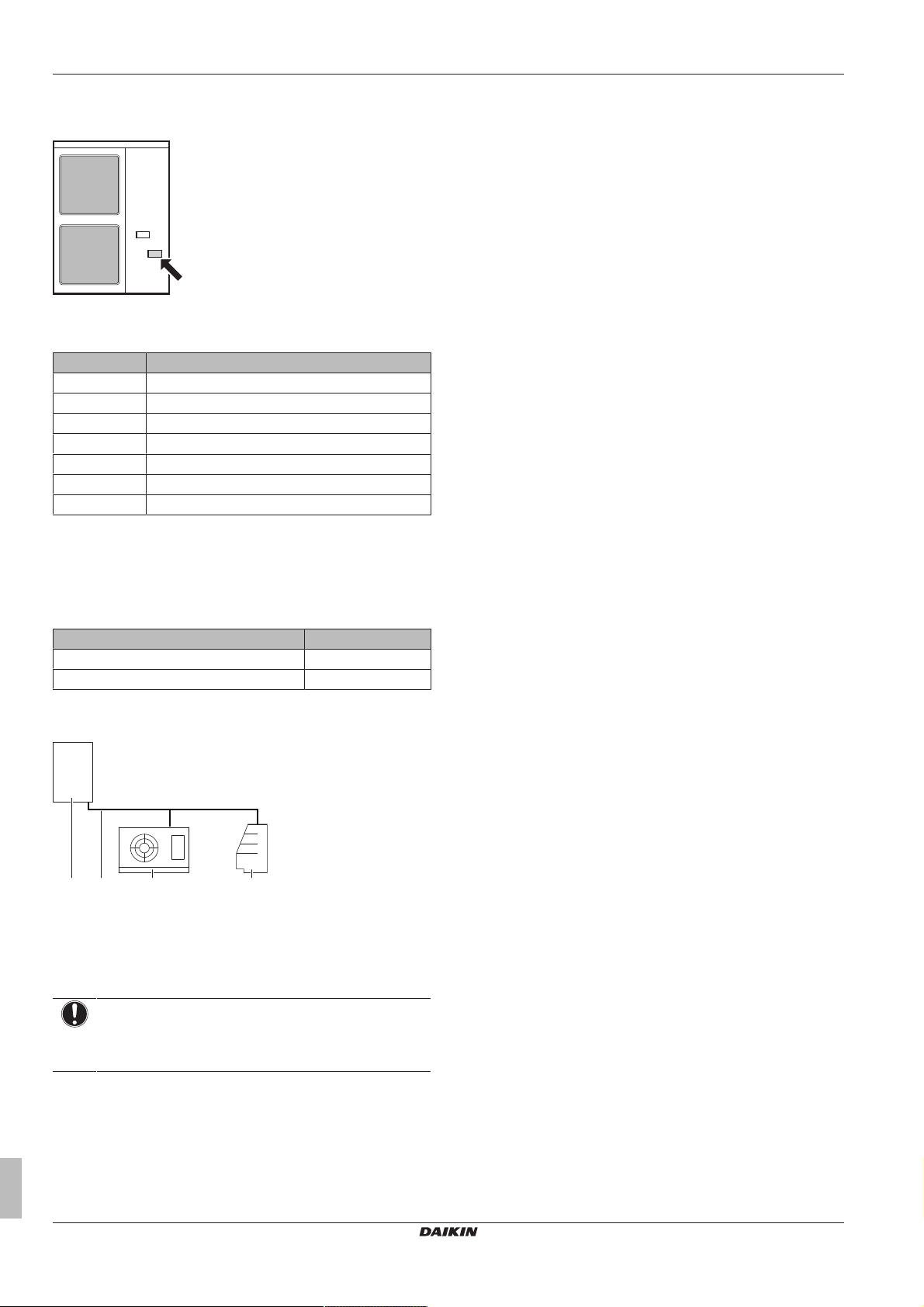

cb da

4.2.1 Identification label: Outdoor unit

Location

Model identification

Example: LR ME Q 4 A Y1 [*]

Code Explanation

LR ZEAS condensing unit

ME Medium temperature refrigeration

Q Refrigerant R410A

3+4 Capacity class

A Model series

Y1 Power supply

[*] Minor model change indication

4.3 About the outdoor unit

This installation manual concerns the ZEAS condensing unit.

This unit is intended for outdoor installation and aimed for air to air

cooling applications.

Specification LRMEQ3+4

Capacity (cooling) 5.90~8.40kW

Ambient design temperature (cooling) –10~43°CDB

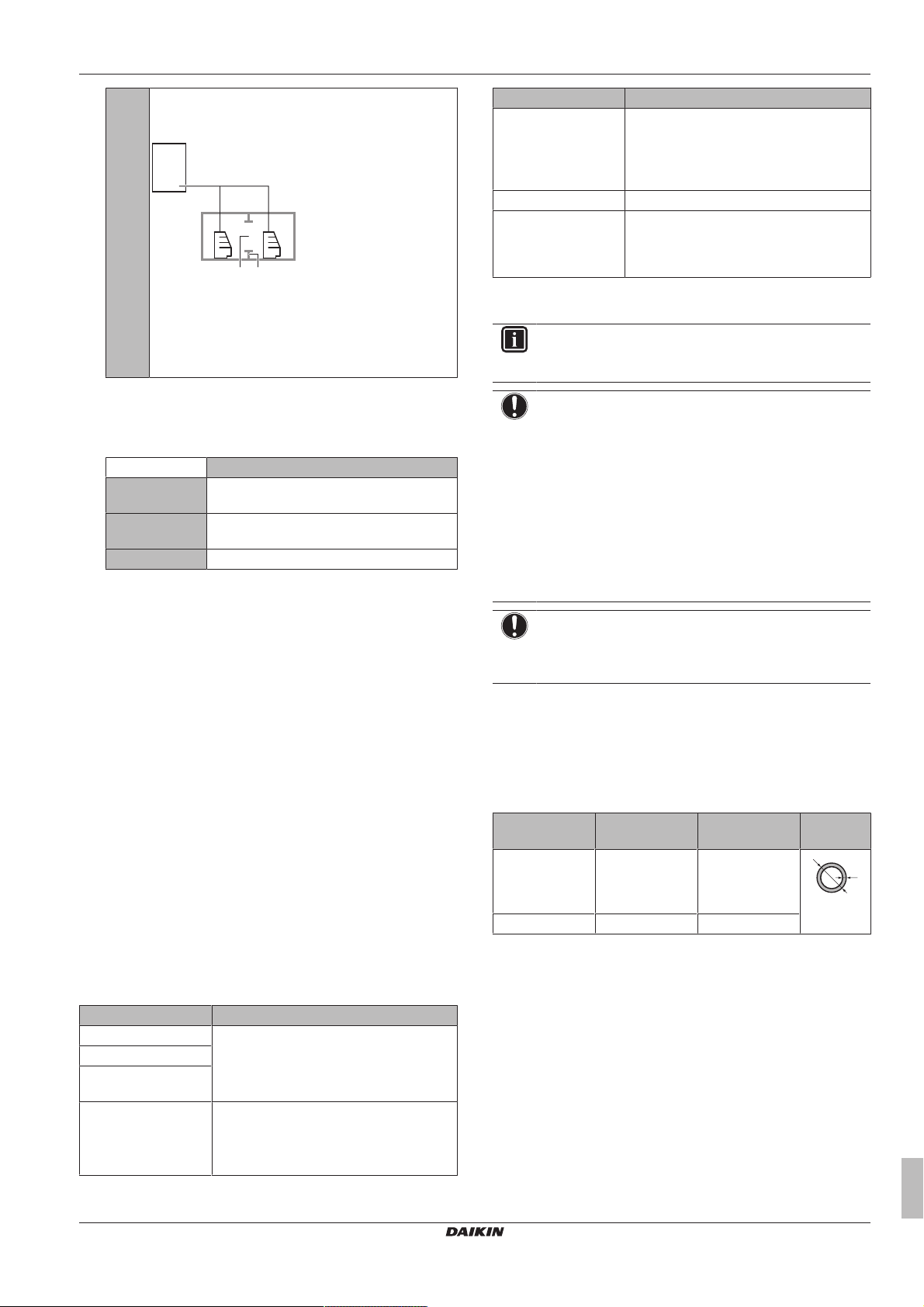

4.4 System layout

▪ Solenoid valve. Install an R410A solenoid valve (with an

operating differential pressure of 3.5MPa [35bar] or more) on the

primary side of the mechanical thermostatic expansion valve for

each indoor unit.

▪ Filter. Install a filter on the primary side of the solenoid valve for

each indoor unit. Determine the filter mesh count based on the

size specified by the solenoid valve and the mechanical

thermostatic expansion valve being used.

▪ Refrigerant flow. Route the path to the indoor unit heat

exchanger so that the refrigerant flow is from top to bottom.

▪ Multiple indoor units. When installing multiple indoor units,

install them at the same level. A combination of showcases and

blower coils is allowed if they are installed on the same floor.

▪ Defrosting type. Use either off-cycle defrosting or electric heater

defrosting models. Do NOT use hot-gas defrosting models.

4.5.1 About reusing existing indoor heat exchangers

In some cases you may reuse existing indoor heat exchangers, in

other cases not.

Reuse not allowed

You may not reuse existing indoor heat exchangers in the following

cases:

▪ When the design pressure is insufficient. (minimum design

pressure = 2.5MPa [25bar])

▪ When the path to the heat exchanger has been routed so that the

flow of refrigerant is from bottom to top.

▪ When the copper piping or fan is corroded.

▪ When the heat exchanger is contaminated. Foreign materials

(including oils for fabrication) must be ≤30mg/10m.

Reuse allowed

In other cases than above, you may reuse existing indoor heat

exchangers. However, if the old condensing unit did NOT use the

same refrigerant (R410A) and the same oil (FVC68D) as the new

one, you must clean the heat exchanger tubes to remove any

residue.

If the old condensing unit did NOT use the same refrigerant (R410A)

as the new one, make sure the mechanical thermostatic expansion

valve is compatible with R410A.

a Outdoor unit (ZEAS condensing unit)

b Refrigerant piping

c Indoor unit (Blower coil)

d Indoor unit (Showcase)

4.5 About the indoor units

NOTICE

To be sure your system setup (outdoor unit+indoor unit(s))

will work, you have to consult the latest technical

engineering data for ZEAS condensing unit.

The ZEAS condensing unit can be combined with several types of

third party indoor units and is intended for R410A use only.

When installing indoor units, mind the following:

▪ Expansion valve. Install an R410A mechanical thermostatic

expansion valve on each indoor unit. Insulate the feeler block of

the mechanical thermostatic expansion valve.

Installer and user reference guide

8

5 Preparation

5.1 Overview: Preparation

This chapter describes what you have to do and know before going

on-site.

It contains information about:

▪ Preparing the installation site

▪ Preparing the refrigerant piping

▪ Preparing the electrical wiring

5.2 Preparing installation site

Do NOT install the unit in places often used as work place. In case

of construction works (e.g. grinding works) where a lot of dust is

created, the unit must be covered.

Choose the installation location with sufficient place for carrying the

unit in and out of the site.

LRMEQ3+4AY1

Air-cooled refrigeration condensing unit

4P442131-1 – 2016.03

5 Preparation

≥1500

≥1500

≥1500

≥1500

(mm)

a b c ga b e f a b

d

b

c

a

a

b

c

d

c

d

5.2.1 Installation site requirements of the outdoor unit

INFORMATION

Also read the following requirements:

▪ General installation site requirements. See the

"General safety precautions" chapter.

▪ Service space requirements. See the "Technical data"

chapter.

▪ Refrigerant piping requirements (length, height

difference). See further in this "Preparation" chapter.

CAUTION

Appliance not accessible to the general public, install it in a

secured area, protected from easy access.

This unit, both indoor and outdoor, is suitable for

installation in a commercial and light industrial

environment.

NOTICE

This is a class A product. In a domestic environment this

product may cause radio interference in which case the

user may be required to take adequate measures.

NOTICE

The equipment described in this manual may cause

electronic noise generated from radio-frequency energy.

The equipment complies to specifications that are

designed to provide reasonable protection against such

interference. However, there is no guarantee that

interference will not occur in a particular installation.

It is therefore recommended to install the equipment and

electric wires keeping proper distances away from stereo

equipment, personal computers, etc.

Do NOT install the unit in the following places:

▪ Sound sensitive areas (e.g. near a bedroom and the like), so that

the operation noise will cause no trouble.

Note: If the sound is measured under actual installation

conditions, the measured value might be higher than the sound

pressure level mentioned in Sound spectrum in the data book due

to environmental noise and sound reflections.

▪ In places where a mineral oil mist, spray or vapour may be

present in the atmosphere. Plastic parts may deteriorate and fall

off or cause water leakage.

It is NOT recommended to install the unit in the following places

because it may shorten the life of the unit:

▪ Where the voltage fluctuates a lot

▪ In vehicles or vessels

▪ Where acidic or alkaline vapour is present

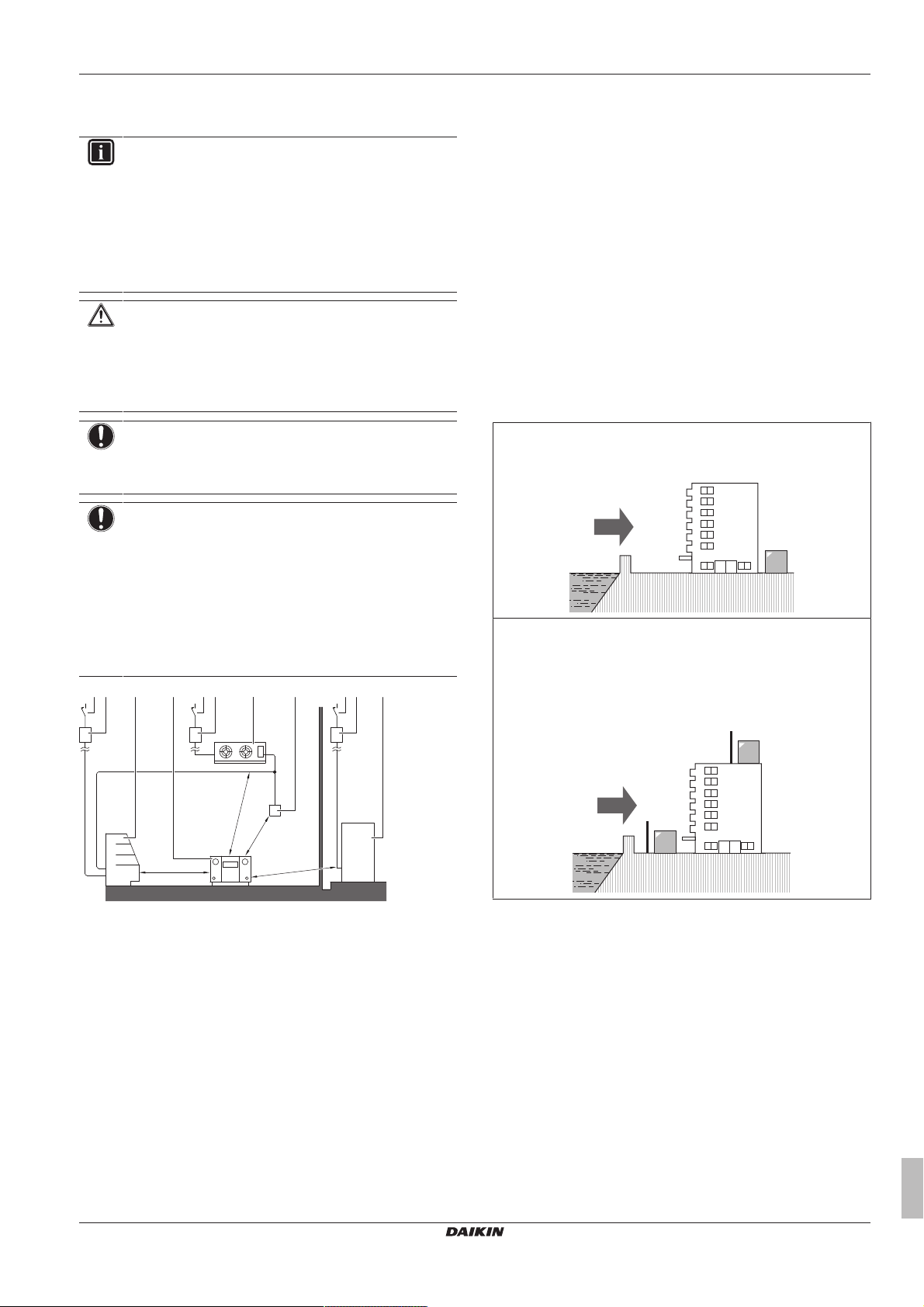

Seaside installation. Make sure the outdoor unit is NOT directly

exposed to sea winds. This is to prevent corrosion caused by high

levels of salt in the air, which might shorten the life of the unit.

Install the outdoor unit away from direct sea winds.

Example: Behind the building.

If the outdoor unit is exposed to direct sea winds, install a

windbreaker.

▪ Height of windbreaker≥1.5×height of outdoor unit

▪ Mind the service space requirements when installing the

windbreaker.

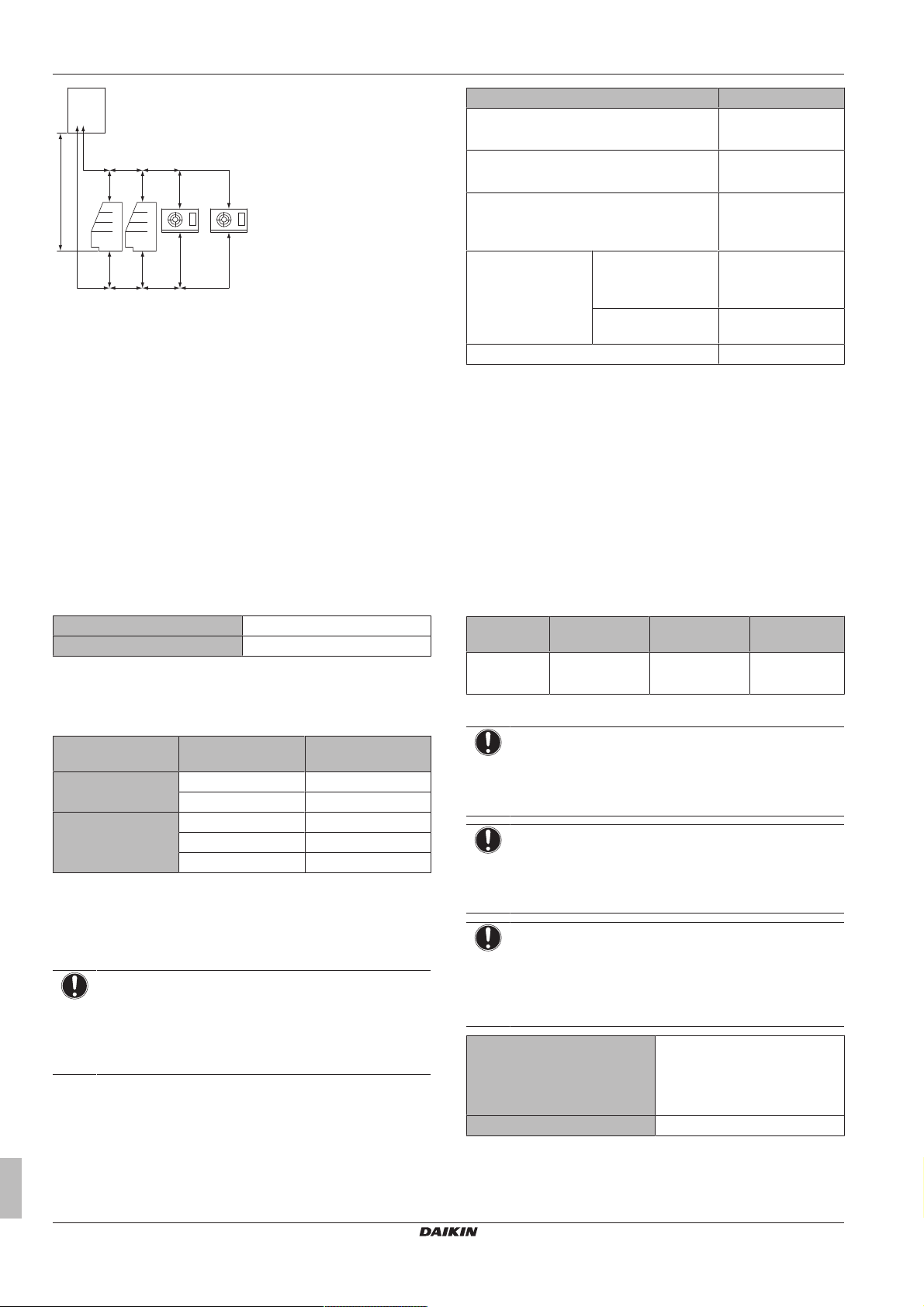

a Earth leakage protector

b Fuse

c Indoor unit (Showcase)

d Personal computer or radio

e Indoor unit (Blower coil)

f User interface

g Outdoor unit

In places with weak reception, keep distances of 3 m or more to

avoid electromagnetic disturbance of other equipment and use

conduit tubes for power and transmission lines.

▪ Select a place where rain can be avoided as much as possible.

▪ Take care that in the event of a water leak, water cannot cause

any damage to the installation space and surroundings.

▪ Choose a location where the hot/cold air discharged from the unit

or the operation noise, will NOT disturb anyone.

▪ Heat exchanger fins are sharp and injury is possible. Choose an

installation location where there is no risk for injury (especially in

areas where children play).

LRMEQ3+4AY1

Air-cooled refrigeration condensing unit

4P442131-1 – 2016.03

a Sea wind

b Building

c Outdoor unit

d Windbreaker

Strong winds (≥18 km/h) blowing against the outdoor unit’s air outlet

causes short circuit (suction of discharge air). This may result in:

▪ deterioration of the operational capacity;

▪ disruption of operation due to decrease of low pressure or

increase of high pressure;

▪ a broken fan (if a strong wind blows continuously on the fan, it

may start rotating very fast, until it breaks).

It is recommended to install a baffle plate when the air outlet is

exposed to wind.

Turn the air outlet side towards the building's wall, fence or screen.

Installer and user reference guide

9

5 Preparation

a

a

a

b

a

b

c

c

d

a b

a Make sure there is enough installation space

Set the air outlet side at a right angle to the direction of the wind.

This system uses R410A as refrigerant. R410A itself is an entirely

safe non-toxic, non-combustible refrigerant. Nevertheless care must

be taken to ensure that the system is installed in a room which is

sufficiently large. This assures that the maximum concentration level

of refrigerant gas is not exceeded, in the unlikely event of major leak

in the system and this in accordance to the local applicable

regulations and standards.

About the maximum concentration level

The maximum charge of refrigerant and the calculation of the

maximum concentration of refrigerant is directly related to the

humanly occupied space in to which it could leak.

The unit of measurement of the concentration is kg/m3 (the weight in

kg of the refrigerant gas in 1m3 volume of the occupied space).

Compliance to the local applicable regulations and standards for the

maximum allowable concentration level is required.

According to the appropriate European Standard, the maximum

allowed concentration level of refrigerant to a humanly space for

R410A is limited to 0.44 kg/m3.

a Prevailing wind direction

b Air outlet

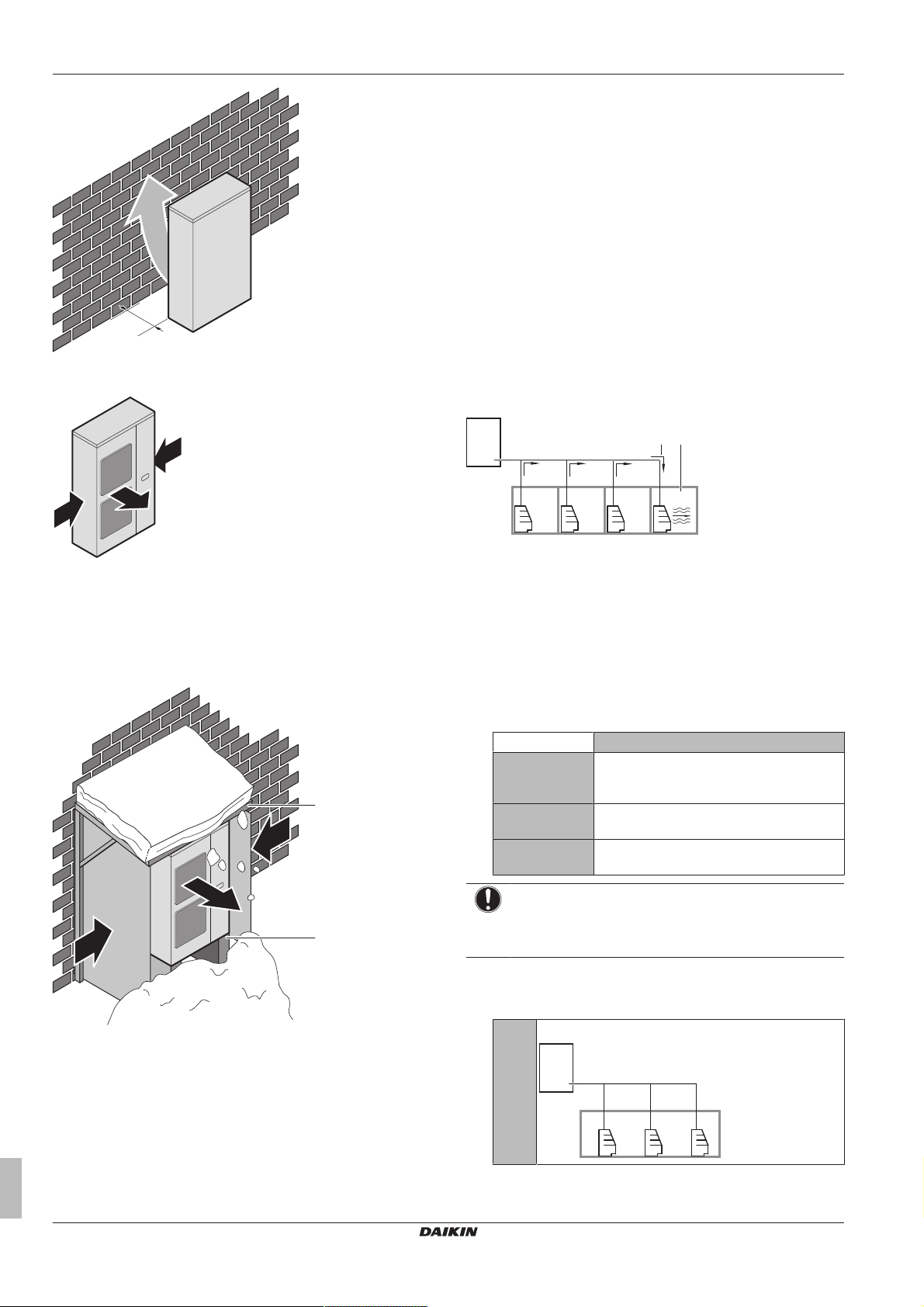

5.2.2 Additional installation site requirements of the outdoor unit in cold climates

Protect the outdoor unit against direct snowfall and take care that the

outdoor unit is NEVER snowed up.

a Direction of the refrigerant flow

b Room where refrigerant leak has occurred (outflow of all

the refrigerant from the system)

Pay special attention to places, such as basements etc., where

refrigerant can stay, since refrigerant is heavier than air.

To check the maximum concentration level

Check the maximum concentration level in accordance with steps 1

to 4 below and take whatever action is necessary to comply.

1 Calculate the amount of refrigerant (kg) charged to each system

separately.

Formula A+B=C

A Amount of refrigerant in a single unit system

(amount of refrigerant with which the system

is charged before leaving the factory)

B Additional charging amount (amount of

refrigerant added locally)

C Total amount of refrigerant (kg) in the

system

NOTICE

Where a single refrigerant facility is divided into 2 entirely

independent refrigerant systems, use the amount of

refrigerant with which each separate system is charged.

2 Calculate the volume of the room (m3) where the indoor unit is

installed. In a case such as the following, calculate the volume

of (D), (E) as a single room or as the smallest room.

a Snow cover or shed

b Pedestal (minimum height = 150mm)

c Prevailing wind direction

d Air outlet

5.2.3 Securing safety against refrigerant leaks

About safety against refrigerant leaks

The installer and system specialist shall secure safety against

leakage according to local regulations or standards. The following

standards may be applicable if local regulations are not available.

Installer and user reference guide

10

D Where there are no smaller room divisions:

LRMEQ3+4AY1

Air-cooled refrigeration condensing unit

4P442131-1 – 2016.03

5 Preparation

a b

t

Ø

E Where there is a room division, but there is an opening

between the rooms sufficiently large to permit a free

flow of air back and forth.

a Opening between the rooms

b Partition (Where there is an opening without a door

or where there are openings above and below the door

which are each equivalent in size to 0.15% or more of

the floor area.)

3 Calculate the refrigerant density using the results of the

calculations in steps 1 and 2 above. If the result of the above

calculation exceeds the maximum concentration level, a

ventilation opening to the adjacent room shall be made.

Formula F/G≤H

F Total volume of refrigerant in the refrigerant

system

G Size (m3) of smallest room in which there is

an indoor unit installed

H Maximum concentration level (kg/m3)

4 Calculate the refrigerant density taking the volume of the room

where the indoor unit is installed and the adjacent room. Install

ventilation openings in the door of adjacent rooms until the

refrigerant density is smaller than the maximum concentration

level.

5.3 Preparing refrigerant piping

5.3.1 About reusing existing piping

In some cases you may reuse existing piping, in other cases not.

Reuse not allowed

You may not reuse existing piping in the following cases:

▪ When the compressor in the old installation had problems

(example: breakdown). Possible consequence: oxidised coolant

oil, scale residue and other adverse effects.

▪ When the indoor and outdoor units were disconnected from the

piping for a long time. Possible consequence: water and dirt in

the piping.

▪ When the copper piping is corroded.

Reuse allowed

In other cases than above, you may reuse existing piping but keep

the following in mind:

Item Description

Piping diameter Must comply with requirements. See

Piping material

Piping length and

height difference

Piping insulation If deteriorated, must be replaced.

"5.3.2Refrigerant piping requirements"on

page11.

Must comply with requirements. See

"6.6To insulate the refrigerant piping"on

page19.

Item Description

Flare connections May not be reused. Make new ones to

prevent leaks. See "6.4.3Guidelines when

connecting the refrigerant piping"on

page14 and "6.4.5To flare the pipe

end"on page15.

Welded connections Must be checked for gas leaks.

Cleaning piping If the old condensing unit did NOT use the

same refrigerant (R410A) and the same oil

(FVC68D) as the new one, you must clean

the piping to remove any residue.

5.3.2 Refrigerant piping requirements

INFORMATION

Also read the precautions and requirements in the

"General safety precautions" chapter.

NOTICE

The refrigerant R410A requires strict cautions for keeping

the system clean, dry and tight.

▪ Clean and dry: foreign materials (including mineral oils

or moisture) should be prevented from getting mixed

into the system.

▪ Tight: R410A does not contain any chlorine, does not

destroy the ozone layer, and does not reduce earth's

protection against harmful ultraviolet radiation. R410A

can contribute slightly to the greenhouse effect if it is

released. Therefore we should take special attention to

check the tightness of the installation.

NOTICE

The piping and other pressure-containing parts shall be

suitable for refrigerant. Use phosphoric acid deoxidised

seamless copper for refrigerant.

▪ Foreign materials inside pipes (including oils for fabrication) must

be ≤30 mg/10 m.

5.3.3 Refrigerant piping material

▪ Piping material: Phosphoric acid deoxidised seamless copper.

▪ Piping temper grade and thickness:

Outer diameter

(Ø)

6.4mm (1/4")

9.5mm (3/8")

12.7mm (1/2")

15.9mm (5/8") Annealed (O) ≥0.99mm

(a) Depending on the applicable legislation and the unit's

▪ Flare connections: Only use annealed material.

Temper grade Thickness (t)

Annealed (O) ≥0.80mm

maximum working pressure (see "PS High" on the unit

name plate), larger piping thickness might be required.

(a)

5.3.4 To select the piping size

Determine the proper size referring to following tables and reference

figure (only for indication).

LRMEQ3+4AY1

Air-cooled refrigeration condensing unit

4P442131-1 – 2016.03

Installer and user reference guide

11

5 Preparation

F

A

1

2 3 3

d1

e

B

d2

C

c

D1

E

f

D2

ba

H

2

Requirement Limit

Maximum actual piping length

▪ Example: a+b+c+d2≤Limit

Maximum total piping length

▪ Example: a+b+c+d1+d2+e+f≤Limit

Maximum length first branch kit-indoor

unit

▪ Example: b+c+d2≤Limit

1 Outdoor unit

2 Indoor unit (Showcase)

3 Indoor unit (Blower coil)

A~F Liquid piping

a~f Gas piping

H Height difference outdoor-indoor

In case the required pipe sizes (inch sizes) are not available, it is

also allowed to use other diameters (mm sizes), taken the following

into account:

▪ Select the pipe size nearest to the required size.

▪ Use the suitable adapters for the change-over from inch to mm

pipes (field supply).

▪ The additional refrigerant calculation has to be adjusted as

mentioned in "6.7.3 To determine the additional refrigerant

amount"on page20.

A/a: Piping between outdoor unit and piping branching

Use the same diameters as the connections on the outdoor units:

Liquid piping Ø9.5 mm

Gas piping Ø15.9 mm

Maximum height

difference outdoorindoor

Maximum height difference indoor-indoor 0m

(a) A combination of showcases and blower coils is allowed if

5.4 Preparing electrical wiring

5.4.1 Safety device requirements

Power supply

The power supply must be protected with the required safety

devices, i.e. a main switch, a slow blow fuse on each phase and an

earth leakage protector in accordance with the applicable legislation.

Selection and sizing of the wiring should be done in accordance with

the applicable legislation based on the information mentioned in the

table below.

Model Minimum circuit

LRMEQ3+4 13.5A 16A 3N~ 50Hz

Outdoor higher than

indoor

▪ Example: H≤Limit

Outdoor lower than

indoor

they are installed on the same floor.

Recommended

ampacity

fuses

B+C/b+c: Piping between piping branching

Use diameters depending on the total capacity of the indoor units

connected downstream.

Capacity Piping outer

diameter

Liquid piping <4.0kW Ø6.4mm

4.0≤x<8.4kW Ø9.5mm

Gas piping <1.0kW Ø9.5mm

1.0≤x<6.0kW Ø12.7mm

6.0≤x<8.4kW Ø15.9mm

D~F/d~f: Piping between piping branching and indoor unit

Use the same diameters as the connections (liquid, gas) on the

indoor units.

NOTICE

If only 1 indoor unit is connected to the outdoor unit, and

the connections on the outdoor unit are different from

those on the indoor unit, then use the same piping

diameter as the connections on the outdoor unit, and install

suitable adapters as near to the indoor unit as possible.

5.3.5 Refrigerant piping length and height difference

The piping lengths and height differences must comply with the

following requirements.

(see example in "5.3.4To select the piping size"on page11)

Operation switch, low-noise switch and error output wiring

NOTICE

Operation switch. An operation switch is required to turn

outdoor unit operation ON/OFF. The outdoor unit cannot

operate without it. Use a voltage-free contact for

microcurrent (≤1mA, 12VDC).

NOTICE

Low-noise switch. If you want to remotely turn ON/OFF

low-noise operation (see setting [2‑25]), you must install a

low-noise switch. Use a voltage-free contact for

microcurrent (≤1mA, 12VDC).

NOTICE

Error output. If system malfunctions are likely to degrade

the articles in the room/showcase, you can install an alarm

(example: lamp). If a malfunction occurs, a signal

(220-240 VAC) is given to the error output (X2M/E1/E2).

Use an alarm with a maximum load of 0.5A.

Wiring Sheathed + shielded cable (2

Vinyl cords

0.75~1.25mm²

Maximum wiring length 130m

30m

30m

10m

5m

0m

(a)

Power supply

380-415V

wires)

Installer and user reference guide

12

Air-cooled refrigeration condensing unit

LRMEQ3+4AY1

4P442131-1 – 2016.03

6 Installation

1×

1

2

(mm)

>150

620

350

(345-355)

4× M12

a

20

6 Installation

6.1 Overview: Installation

This chapter describes what you have to do and know on-site to

install the system.

Typical workflow

Installation typically consists of the following stages:

▪ Mounting the outdoor unit.

▪ Mounting the indoor units.

▪ Connecting the refrigerant piping.

▪ Checking the refrigerant piping.

▪ Charging refrigerant.

▪ Connecting the electrical wiring.

▪ Finishing the outdoor installation.

▪ Finishing the indoor installation.

INFORMATION

For installation of the indoor unit (mounting the indoor unit,

connecting the refrigerant piping to the indoor unit,

connecting the electrical wiring to the indoor unit …), see

the installation manual of the indoor unit.

6.2 Opening the units

6.2.1 About opening the units

At certain times, you have to open the unit. Example:

▪ When connecting the refrigerant piping

▪ When connecting the electrical wiring

▪ When maintaining or servicing the unit

6.3 Mounting the outdoor unit

6.3.1 About mounting the outdoor unit

Typical workflow

Mounting the outdoor unit typically consists of the following stages:

1 Providing the installation structure.

2 Installing the outdoor unit.

3 Preventing the outdoor unit from falling over.

4 Protecting the unit against snow and wind by installing a snow

cover and baffle plates. See "Preparing installation site" in

"5Preparation"on page8.

6.3.2 Precautions when mounting the outdoor unit

INFORMATION

Also read the precautions and requirements in the

following chapters:

▪ General safety precautions

▪ Preparation

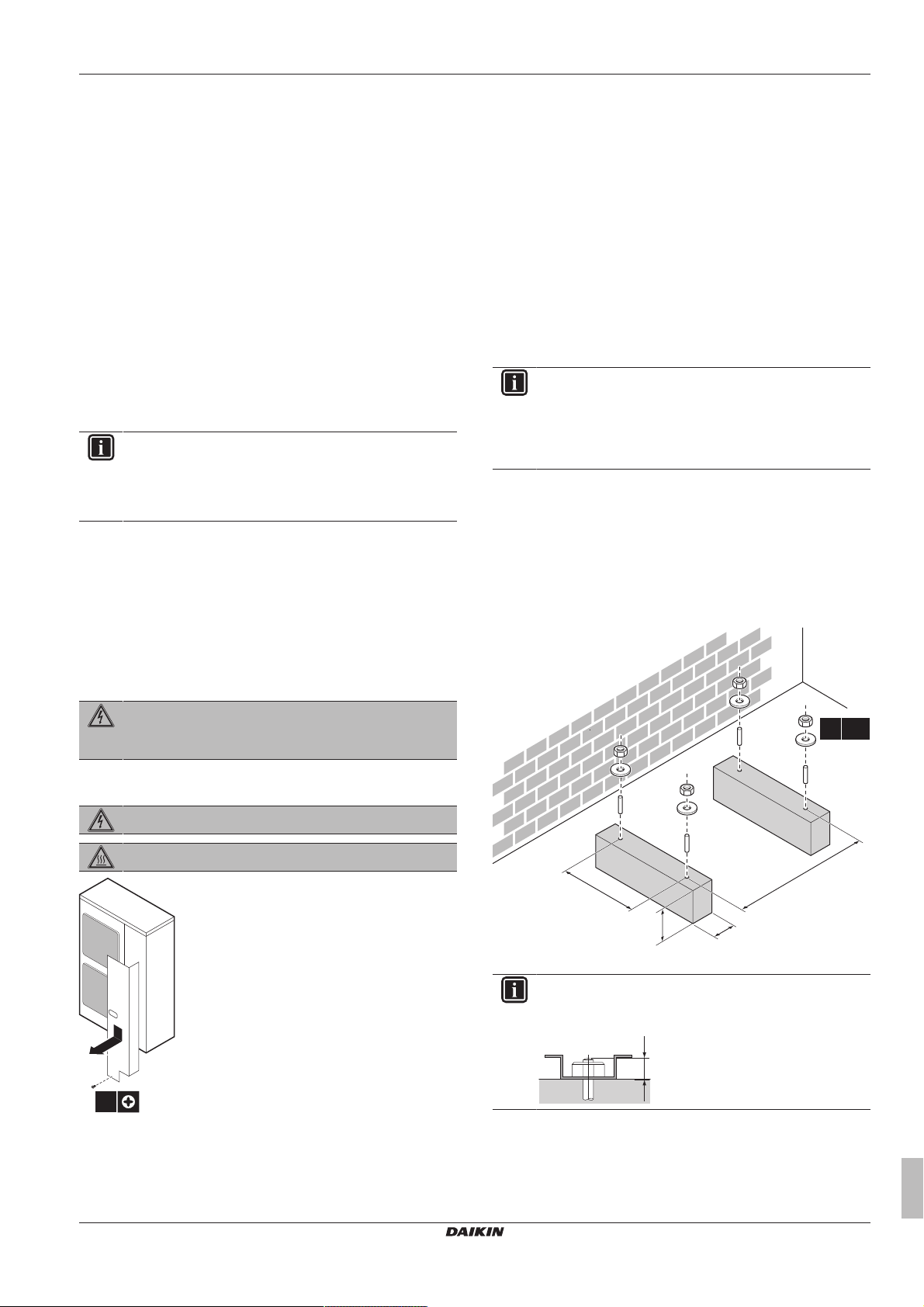

6.3.3 To provide the installation structure

Check the strength and level of the installation ground so that the

unit will not cause any operating vibration or noise.

Fix the unit securely by means of foundation bolts in accordance

with the foundation drawing.

Prepare 4 sets of anchor bolts, nuts and washers (field supply) as

follows:

DANGER: RISK OF ELECTROCUTION

Do NOT leave the unit unattended when the service cover

is removed.

6.2.2 To open the outdoor unit

DANGER: RISK OF ELECTROCUTION

DANGER: RISK OF BURNING

a Make sure not to cover the drain holes.

INFORMATION

The recommended height of the upper protruding part of

the bolts is 20mm.

LRMEQ3+4AY1

Air-cooled refrigeration condensing unit

4P442131-1 – 2016.03

Installer and user reference guide

13

6 Installation

a

4× M12

NOTICE

Fix the outdoor unit to the foundation bolts using nuts with

resin washers (a). If the coating on the fastening area is

stripped off, the nuts rust easily.

6.3.4 To install the outdoor unit

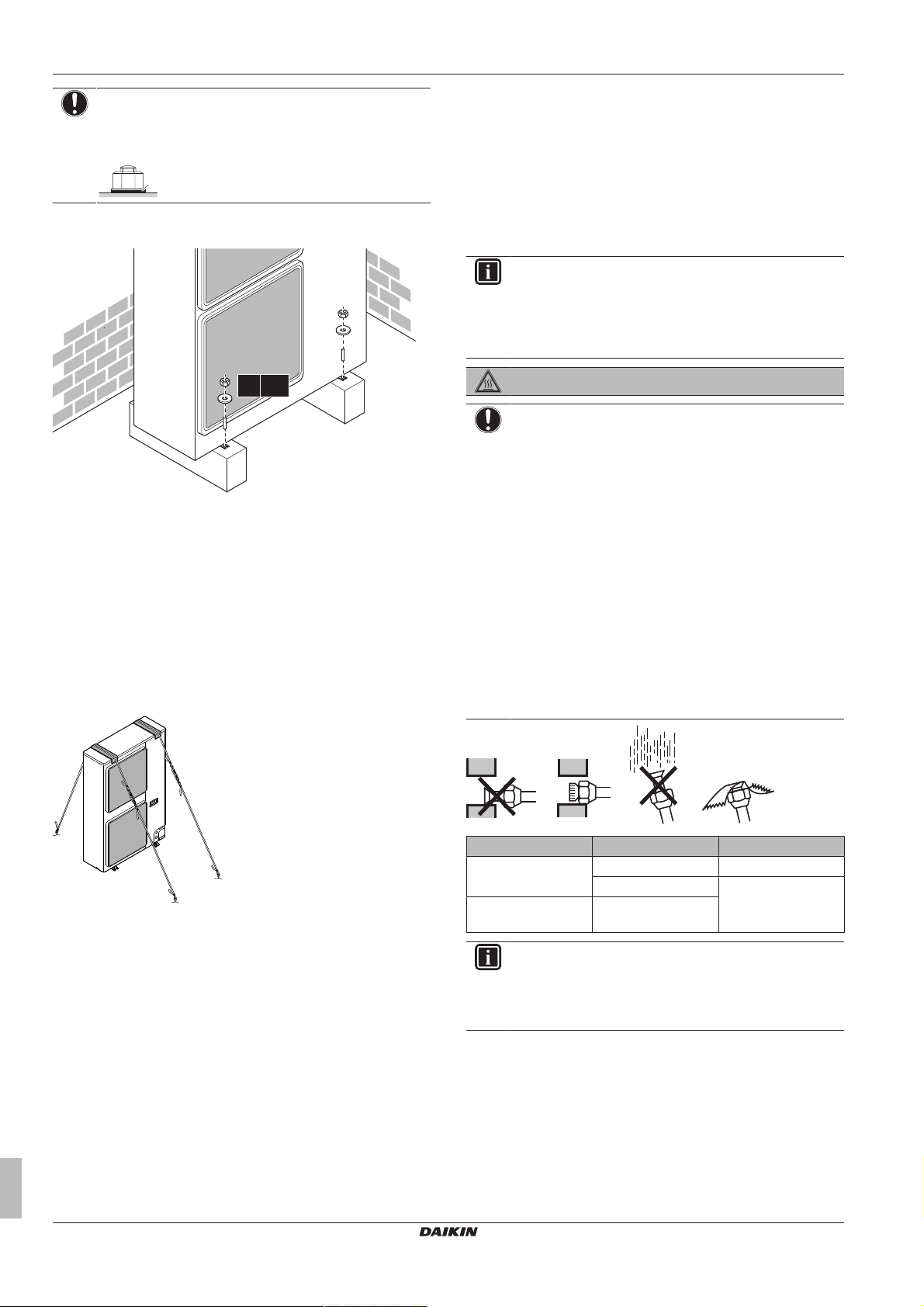

6.3.5 To prevent the outdoor unit from falling over

In case the unit is installed in places where strong wind can tilt the

unit, take following measure:

1 Prepare 2 cables as indicated in the following illustration (field

supply).

2 Place the 2 cables over the outdoor unit.

3 Insert a rubber sheet between the cables and the outdoor unit

to prevent the cable from scratching the paint (field supply).

4 Attach the cable’s ends. Tighten those ends.

▪ Keeping in mind the guidelines for:

▪ Pipe bending

▪ Flaring pipe ends

▪ Brazing

▪ Using the stop valves

6.4.2 Precautions when connecting the refrigerant piping

INFORMATION

Also read the precautions and requirements in the

following chapters:

▪ General safety precautions

▪ Preparation

DANGER: RISK OF BURNING

NOTICE

Take the following precautions on refrigerant piping into

account:

▪ Avoid anything but the designated refrigerant to get

mixed into the refrigerant cycle (e.g. air).

▪ Only use R410A when adding refrigerant.

▪ Only use installation tools (e.g. manifold gauge set) that

are exclusively used for R410A installations to

withstand the pressure and to prevent foreign materials

(e.g. mineral oils and moisture) from mixing into the

system.

▪ Install the piping so that the flare is NOT subjected to

mechanical stress

▪ Protect the piping as described in the following table to

prevent dirt, liquid or dust from entering the piping.

▪ Use caution when passing copper tubes through walls

(see figure below).

6.4 Connecting the refrigerant piping

6.4.1 About connecting the refrigerant piping

Before connecting the refrigerant piping

Make sure the outdoor and indoor units are mounted.

Typical workflow

Connecting the refrigerant piping involves:

▪ Connecting the refrigerant piping to the outdoor unit

▪ Connecting the dryer and sight glass

▪ Connecting refrigerant piping branching

▪ Connecting the refrigerant piping to the indoor units (see the

installation manual of the indoor units)

▪ Insulating the refrigerant piping

Installer and user reference guide

14

Unit Installation period Protection method

Outdoor unit >1month Pinch the pipe

<1month Pinch or tape the pipe

Indoor unit Regardless of the

period

INFORMATION

Do NOT open the refrigerant stop valve before checking

the refrigerant piping. When you need to charge additional

refrigerant it is recommended to open the refrigerant stop

valve after charging.

6.4.3 Guidelines when connecting the refrigerant piping

Take the following guidelines into account when connecting pipes:

▪ Coat the flare inner surface with ether oil or ester oil when

connecting a flare nut. Tighten 3 or 4 turns by hand, before

tightening firmly.

LRMEQ3+4AY1

Air-cooled refrigeration condensing unit

4P442131-1 – 2016.03

6 Installation

a

b

c

d

R=0.4~0.8

45°

±2

90°

±2

A

a b

A

a b

c

1

1

≤Ø25.4

a b c d e

f

f

c

d

a

b

▪ Always use two wrenches together when loosening a flare nut.

▪ Always use a spanner and torque wrench together to tighten the

flare nut when connecting the piping. This to prevent nut cracking

and leaks.

a Torque wrench

b Spanner

c Piping union

d Flare nut

Piping size

(mm)

Tightening

torque (N•m)

Flare

dimensions (A)

Flare shape

(mm)

(mm)

Ø6.4 15~17 8.7~9.1

Ø9.5 33~39 12.8~13.2

Ø12.7 50~60 16.2~16.6

Ø15.9 63~75 19.3~19.7

6.4.4 Pipe bending guidelines

Use a pipe bender for bending. All pipe bends should be as gentle

as possible (bending radius should be 30~40mm or larger).

a Flare’s inner surface must be flawless.

b The pipe end must be evenly flared in a perfect circle.

c Make sure the flare nut is fitted.

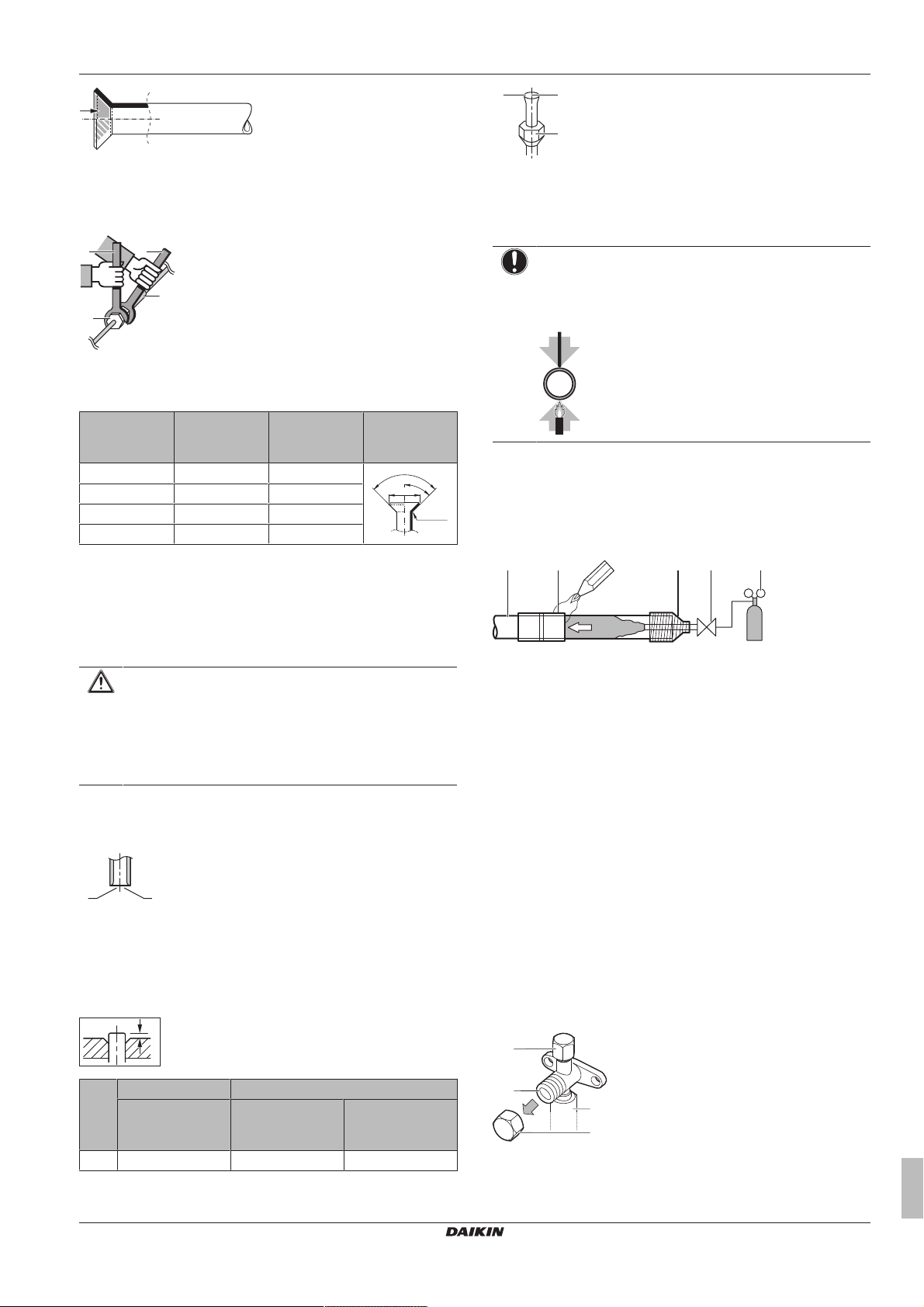

6.4.6 To braze the pipe end

NOTICE

Precautions when connecting field piping. Add brazing

material as shown in the figure.

▪ When brazing, blow through with nitrogen to prevent creation of

large quantities of oxidised film on the inside of the piping. This

film adversely affects valves and compressors in the refrigerating

system and prevents proper operation.

▪ Set the nitrogen pressure to 20kPa (just enough so it can be felt

on the skin) with a pressure-reducing valve.

6.4.5 To flare the pipe end

CAUTION

▪ Incomplete flaring may cause refrigerant gas leakage.

▪ Do NOT re-use flares. Use new flares to prevent

refrigerant gas leakage.

▪ Use flare nuts that are included with the unit. Using

different flare nuts may cause refrigerant gas leakage.

1 Cut the pipe end with a pipe cutter.

2 Remove burrs with the cut surface facing downward so that the

chips do not enter the pipe.

a Cut exactly at right angles.

b Remove burrs.

3 Remove the flare nut from the stop valve and put the flare nut

on the pipe.

4 Flare the pipe. Set exactly at the position as shown in the

following illustration.

Flare tool for

R410A (clutch

type)

A 0~0.5mm 1.0~1.5mm 1.5~2.0mm

5 Check that the flaring is properly made.

LRMEQ3+4AY1

Air-cooled refrigeration condensing unit

4P442131-1 – 2016.03

Conventional flare tool

Clutch type

(Ridgid-type)

a Refrigerant piping

b Part to be brazed

c Taping

d Manual valve

e Pressure-reducing valve

f Nitrogen

▪ Do NOT use anti-oxidants when brazing pipe joints.

Residue can clog pipes and break equipment.

▪ Do NOT use flux when brazing copper-to-copper refrigerant

piping. Use phosphor copper brazing filler alloy (BCuP), which

does not require flux.

Flux has an extremely harmful influence on refrigerant piping

systems. For instance, if chlorine based flux is used, it will cause

pipe corrosion or, in particular, if the flux contains fluorine, it will

deteriorate the refrigerant oil.

6.4.7 Using the stop valve and service port

To handle the stop valve

▪ Make sure to keep all stop valves open during operation.

▪ The figure below shows the name of each part required in

handling the stop valve.

▪ The stop valve is factory closed.

Wing nut type

(Imperial-type)

a Service port and service port cover

b Stop valve

c Field piping connection

d Stop valve cover

Installer and user reference guide

15

Loading...

Loading...