Daikin FWG05AATNMV1, FWG08AATNMV1, FWG11AATNMV1, FWG05AAFNMV1, FWG08AAFNMV1 Installation manuals

...

INSTALLATION

MANUAL

CEILING CASSETTE

CHILLED WATER FAN COIL UNIT

MODELS

FWG05AATNMV1

FWG08AATNMV1

FWG11AATNMV1

FWG05AAFNMV1

Installation Manual

Chilled Water Fan Coil Units

Installationsmanual

Kylda vattenfl äktspolenheter

English

Svenska

FWG08AAFNMV1

FWG11AAFNMV1

IM-CKEW(DC)-1013(5)-DAIKIN

Part No.:R08019039336E

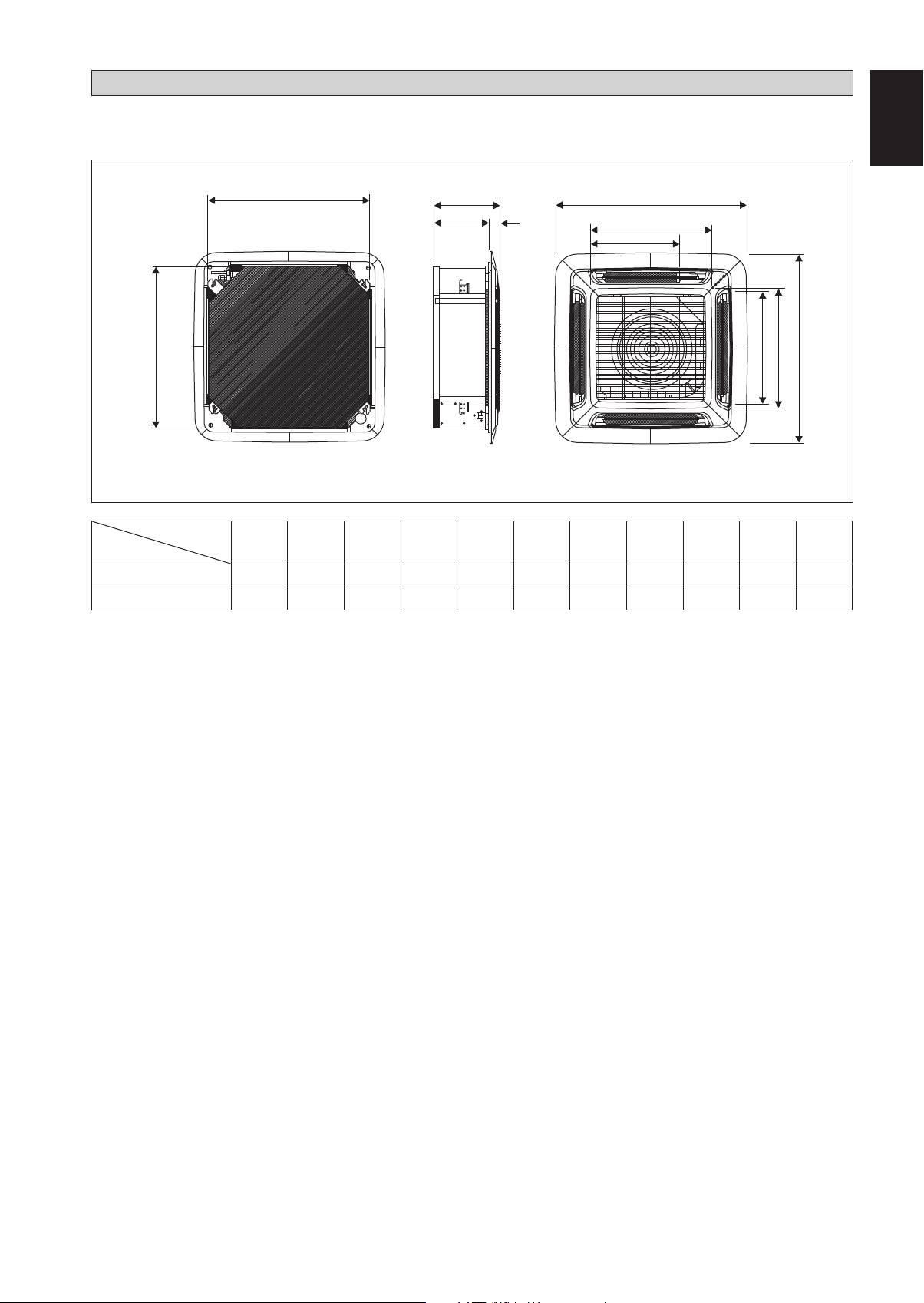

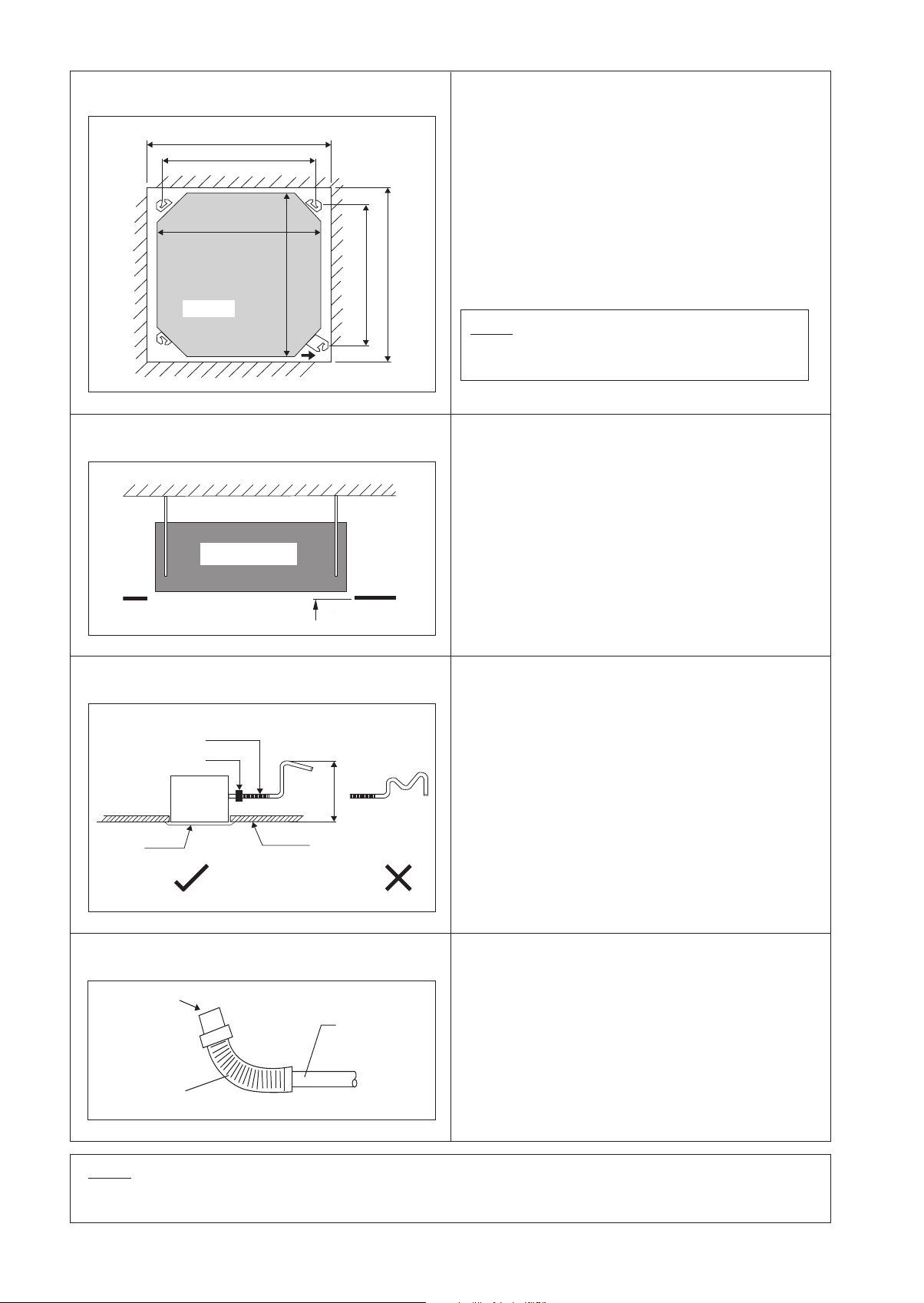

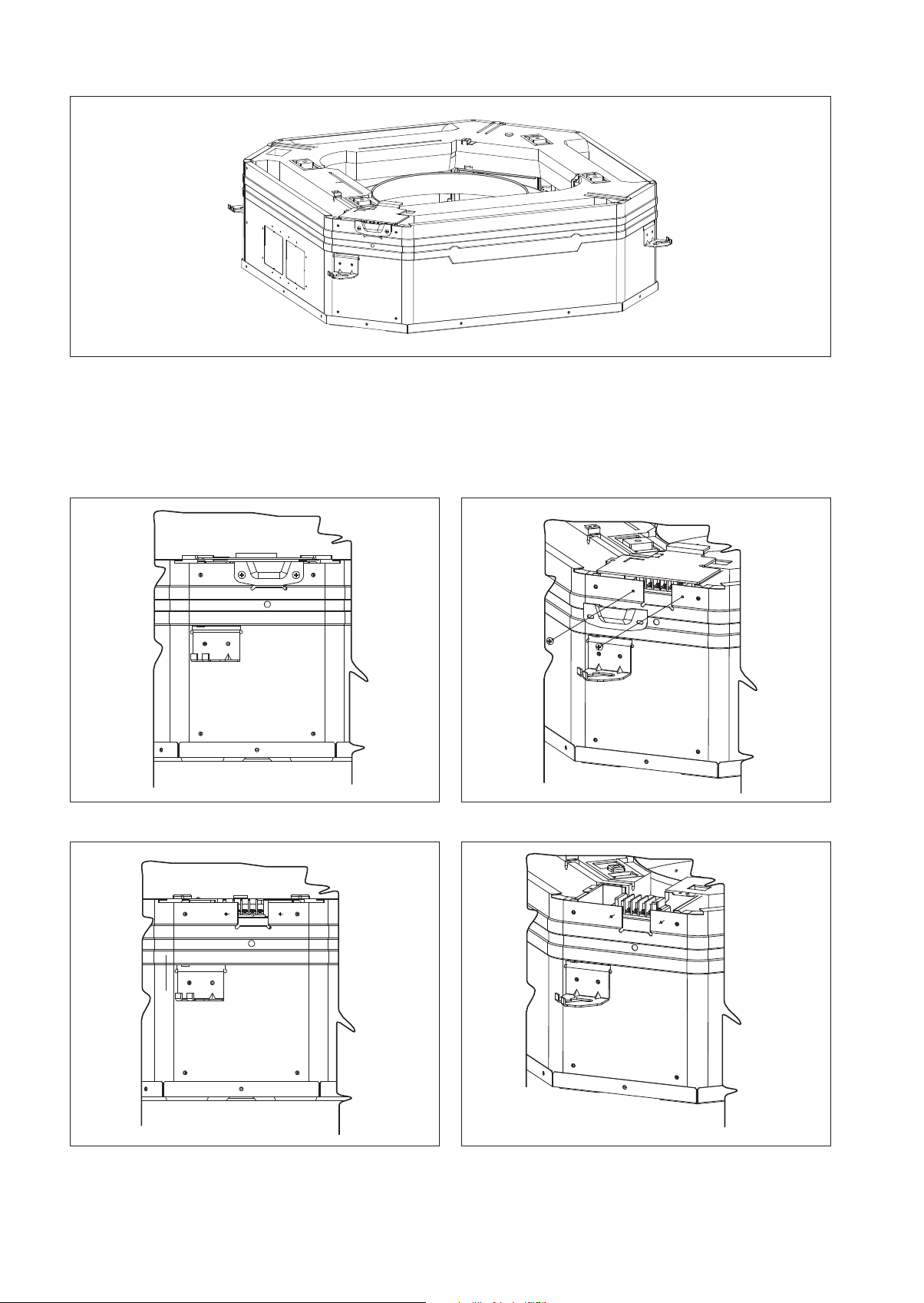

OUTLINE AND DIMENSIONS

Indoor Unit FWG05/08/11AAT(F) Series

• (With Wireless Remote Control & With Wired Remote Control)

English

A

Dimension

Model

FWG05/08AAT(F)

FWG11AAT(F)

B

C

D

E

F

H

K

I

J

G

All dimensions are in mm

ABCDEFGHI JK

820 820 340 300 40 990 990 627 627 607 430

820 820 375 335 40 990 990 627 627 607 430

Original Instruction

1-1

INSTALLATION MANUAL

This manual provides the procedures of installation to ensure a safe and good standard of operation for the air conditioner unit.

Special adjustment may be necessary to suit local requirement.

Before using your air conditioner, please read this instruction manual carefully and keep it for future reference.

This appliance is intended to be used by expert or trained users in shops, in light industry and on farms, or for commercial use by

lay persons.

This appliance is not intended for use by persons, including children, with reduced physical, sensory or mental capabilities, or lack

of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person

responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

SAFETY PRECAUTIONS

WARNING CAUTION

• Installation and maintenance should be performed by qualified

persons who are familiar with local code and regulation, and

experienced with this type of appliance.

• All field wiring must be installed in accordance with the

national wiring regulation.

• Ensure that the rated voltage of the unit corresponds to that

of the name plate before commencing wiring work according

to the wiring diagram.

• The unit must be GROUNDED to prevent possible hazard

due to insulation failure.

• All electrical wiring must not touch the refrigerant piping, or

any moving parts of the fan motors.

• Confirm that the unit has been switched OFF before installing

or servicing the unit.

• Disconnect from the main power supply before servicing the

air conditioner unit.

• DO NOT pull out the power cord when the power is ON.

This may cause serious electrical shocks which may result

in fire hazards.

• Keep the indoor and outdoor units, power cable and

transmission wiring, at least 1m from TVs and radios, to

prevent distorted pictures and static. {Depending on the type

and source of the electrical waves, static may be heard even

when more than 1m away}.

Please take note of the following important points when installing.

• Ensure that the drainage piping is connected properly.

If the drainage piping is not connected properly, it may

cause water leakage which will dampen the furniture.

• Ensure that the unit’s panel is closed after service or

installation.

Unsecured panels will cause the unit to operate noisily.

• Sharp edges and coil surfaces are potential locations which

may cause injury hazards.

Avoid from being in contact with these places.

• Before turning off the power supply set the remote

controller’s ON/OFF switch to the “OFF” position to

prevent the nuisance tripping of the unit. If this is not done,

the unit’s fans will start turning automatically when power

resumes, posing a hazard to service personnel or the user.

• Do not install the units at or near doorway.

• Do not operate any heating apparatus too close to the

air conditioner unit or use in room where mineral oil, oil

vapour or oil steam exist, this may cause plastic part to melt

or deform as a result of excessive heat or chemical reaction.

• When the unit is used in kitchen, keep flour away from

going into suction of the unit.

• This unit is not suitable for factory used where cutting

oil mist or iron powder exist or voltage fluctuates greatly.

• Do not install the units at area like hot spring or oil refinery

plant where sulphide gas exists.

• Ensure the color of wires of the outdoor unit and the

terminal markings are same to the indoors respectively.

• IMPORTANT : DO NOT INSTALL OR USE THE AIR

CONDITIONER UNIT IN A LAUNDRY ROOM.

• Don’t use joined and twisted wires for incoming power

supply.

• The equipment is not intended for use in a potentially

explosive atmosphere.

NOTICE

Disposal requirement [For European Union (EU) only]

Your air conditioning product is marked with this symbol. This means that electrical and electronic products shall

not be mixed with unsorted household waste.

Do not try to dismantle the system yourself: the dismantling of the air conditioning system, treatment of the

refrigerant, of oil and other parts must be done by a qualified installer in accordance with relevant local and national

legislation.

Air conditioners must be treated at a specialized treatment facility for re-use, recycling and recovery. By ensuring

correct disposal, you will help to prevent potential negative consequences for the environment and human health.

Please contact the installer or local authority for more information.

Batteries must be removed from the remote controller and disposed of separately in accordance with relevant local

and national legislation.

1-2

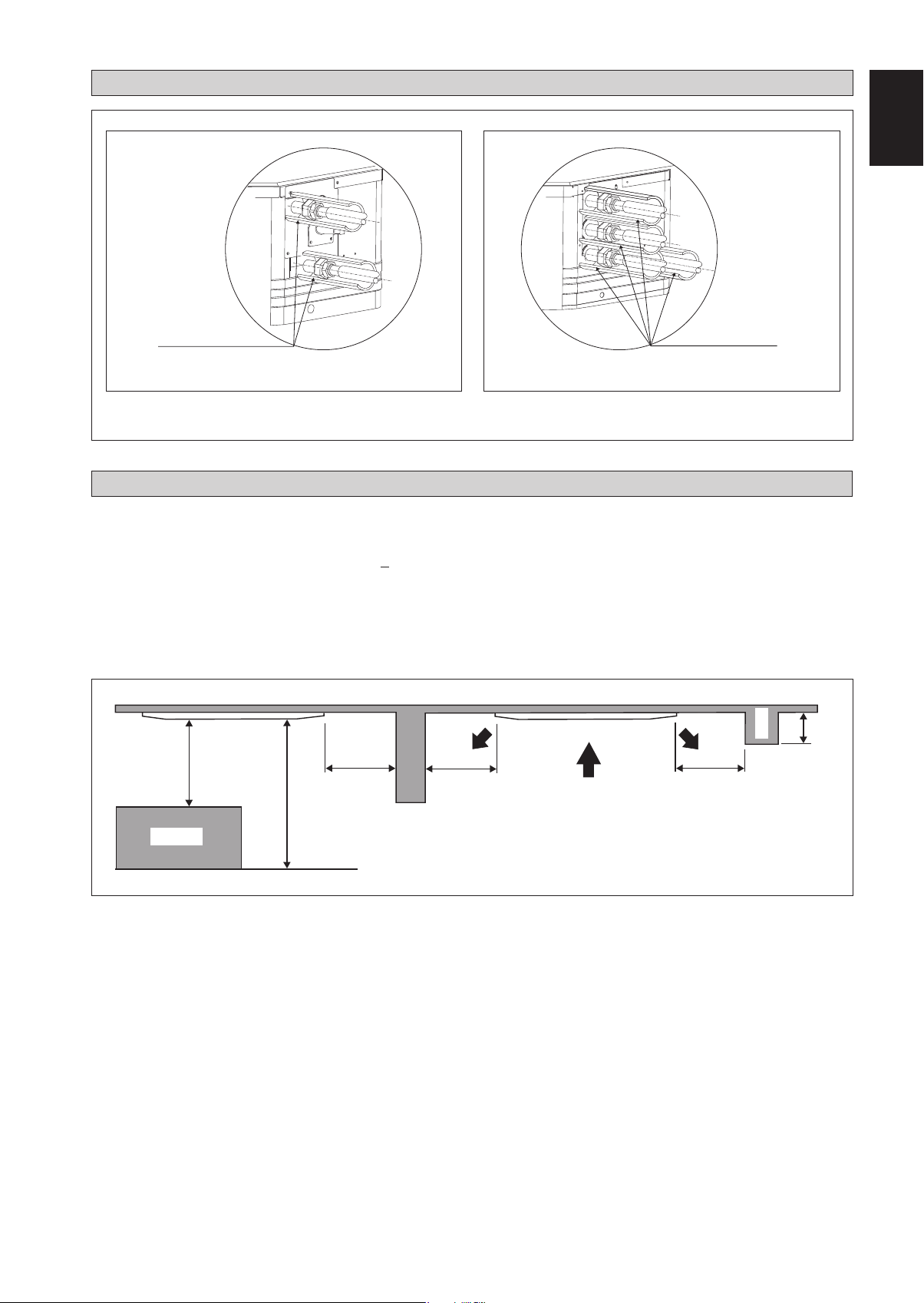

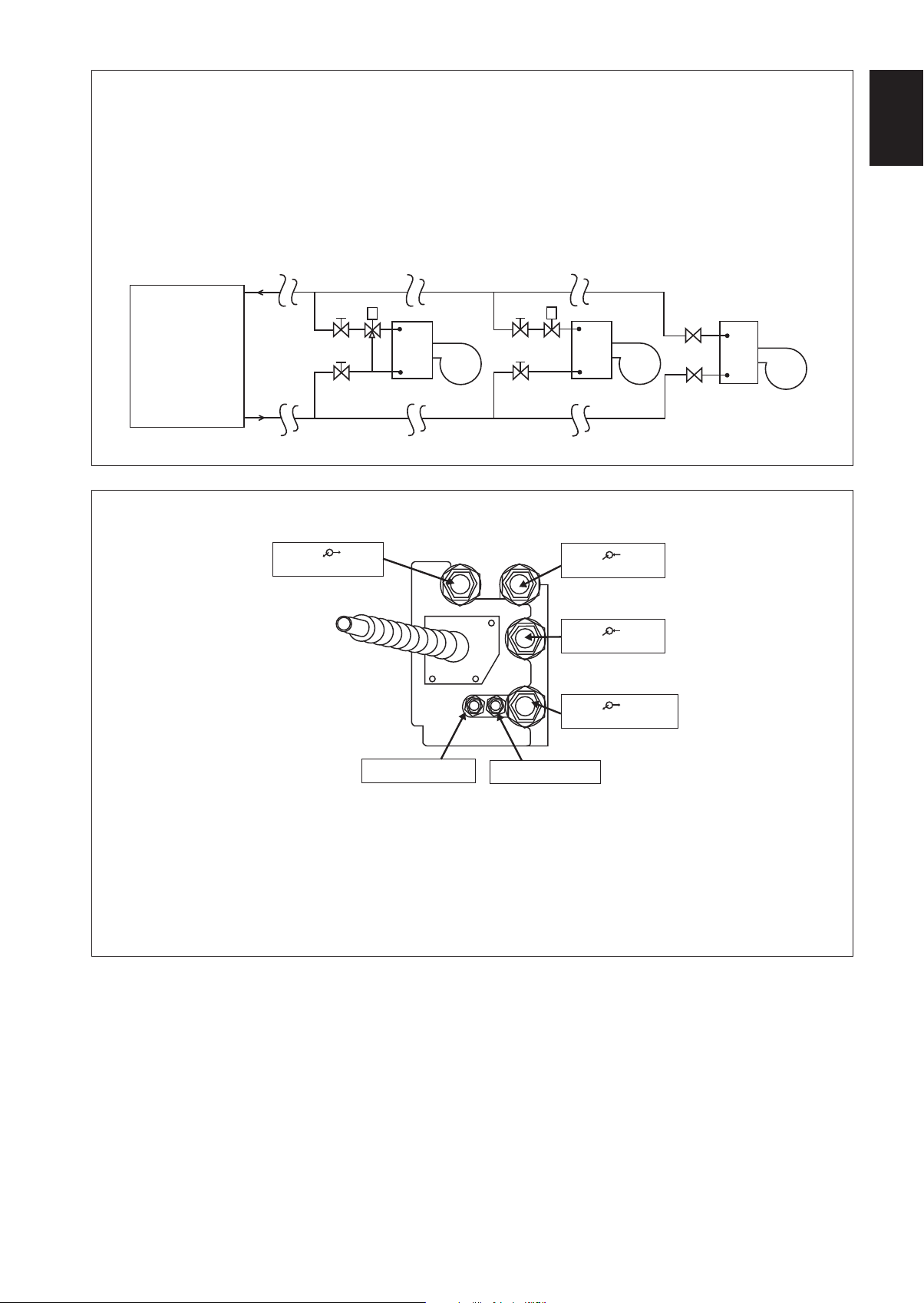

INSTALLATION DIAGRAM

English

CORK TAPE FULLY INSULATED

INSULATION THROUGH OUT CHILLED WATER PIPING

INSULATION THROUGH OUT CHILLED WATER PIPING

CORK TAPE FULLY INSULATED

2 Pipes System 4 Pipes System

INSTALLATION OF THE INDOOR UNIT

1. Preliminary Site Survey

Be sure to read this manual before installing the air-conditioner indoor unit.

• Voltage supply fluctuation must not exceed +10% of rated voltage. Electricity supply lines must be independent of

welding transformers which can cause high supply fluctuation.

• Ensure that the location is convenient for wiring, piping and drainage.

• Do not exert pressure on the resin parts when opening the unit or when moving it after opening.

• Do not move the unit from packaging while moving, until it reaches the installation site. Use safe material or protection

plates when unpacking it or lifting it to avoid damage or scratches to the unit.

Beam

3m or more

1m or more

0.5m or more 0.5m or more 0.5m or more

Obstacle

3m or more

Floor

• Ensure a location where:

a) Drainage can be done easily.

b) Convenient for wiring and piping.

c) Which have enough space for installation and service work.

d) Where no risk of flammable gas leakage.

e) When free from any obstacles in path of cool air discharge and warm air return and must allow spreading of air

throughout the room (near the center of the room).

f) Must be provided clearance for indoor unit from the wall and obstacles as shown in figure below.

g) The installation place must be strong enough to support a load 4 times the indoor unit weight to avoid amplifying

noise and vibration.

h) The installation place (hanging ceiling surface) must be assuring levelness and the height in the ceiling is 350mm or

more.

i) The indoor unit must be away from heat and steam sources (avoid installing it near an entrance).

1-3

Unit Installation

Unit Hanging

Ceiling Opening Site = 890mm

Hanging Rod Site = 790mm

Unit size 820mm

Unit

Indoor Unit

Indoor Unit

Unit size 820mm

Hanging Rod Site = 621mm

Ceiling Opening Site = 890mm

Piping Direction

Ceiling

Ceiling

Board

Board

35mm

35.0 mm

• Measure and mark the position for the hanging rod.

Drill the hole for the angle nut on the ceiling and fix

the hanging rod.

• The installation template is extended according to

temperature and humidity. Check on dimensions in

use.

• The dimensions of the installation template are the

same as those of the ceiling opening dimensions.

• Before ceiling laminating work is covmpleted, be

sure to fit the installation template to the indoor unit.

NOTE

Be sure to discuss the ceiling drilling work with the

installers concerned.

• Confirm the pitch of the hanging rod.

• Hold the unit and hang it on the hanging rod with the

nut and washer.

• Adjust the unit height to 35mm between the indoor

unit bottom surface and the ceiling surface.

• Confirm with a level gauge that the unit is installed

horizontally and tighten the nut and bolt to prevent

unit failing and vibration.

• Open the ceiling board along the outer edge of the

paper installation template.

Drain Piping Work

Flexible Hose

Pipe Clamp

Indoor

Unit

Panel

Drain Test

Feed Water

Flexible Drain Hose

Ceiling

or less

700mm

Main Drain Pipe

• Drain pipe must be in downward gradient for smooth

drainage.

• Avoid installing the drain pipe in up and down slope

to prevent reversed water flow.

• During the drain pipe connection, be careful not to

exert extra force on the drain connector at indoor unit.

• The outside diameter of the drain connection at the

flexible drain hose is 20mm.

• Be sure to execute heat insulation (polyethylene foam

with thickness more than 8mm) on the drain piping to

avoid the condensed water dripping inside the room.

• Connect the main drain pipe to the flexible drain.

• Feed water from flexible drain hose to check the piping

for leakage.

• When the test is completed, connect the flexible drain

hose to the drain connector on the indoor unit.

NOTE

This Indoor Unit uses a drain pump for condensed water drainage. Install the unit horizontally to prevent water leakage

or condensation around the air outlet.

1-4

6. Water Piping Connection

• The indoor unit is equipped with water outlet and inlet connection. There is an air-vent that is fitted along with the

connection for air purging.

• 3 ways valve is required for cycling off or bypass the chilled water.

• Black steel pipe, polyethrene pipe and copper tube are recommended in the field installation. All types of piping and

connection must be insulated with polyethrene (ARMAFLEX type or equivalent) to avoid condensation.

• Do not used contaminated or damaged pipe and fitting for installation.

• Some main fitting components are needed in the system to enhance the capacity and ease the service, such as gate

valve, balancing valve, 2 ways or 3 ways valve, filter, strainer and etc.

English

Chiller

7. 4 Pipe system

Gate Valve

Gate Valve

Good Control Bad Control

WATER OUTLET 1

3 Way Valve

FCU

Gate Valve

Gate Valve

2 Way Valve

FCU

WATER INLET 1

WATER INLET 2

WATER OUTLET 2

Gate Valve

FCU

Gate Valve

Worst Control

ACCESS VALVE 1

ACCESS VALVE 2

Note :

• Water Inlet 1* must couple with Water Outlet 1 and Access Valve 1. (*1 connection to chiller)

• Water Inlet 2* must couple with Water Outlet 2 and Access Valve 2. (*2 connection to Boiler)

• Valve cap of Access Valve 1 is painted red for identification.

• All union joints are to be screwed in together with an “O” -ring. Apply Teflon white tape on the screw threads to ensure

leak proof joints.

• Secure all screw connection tightly to prevent leakage.

1-5

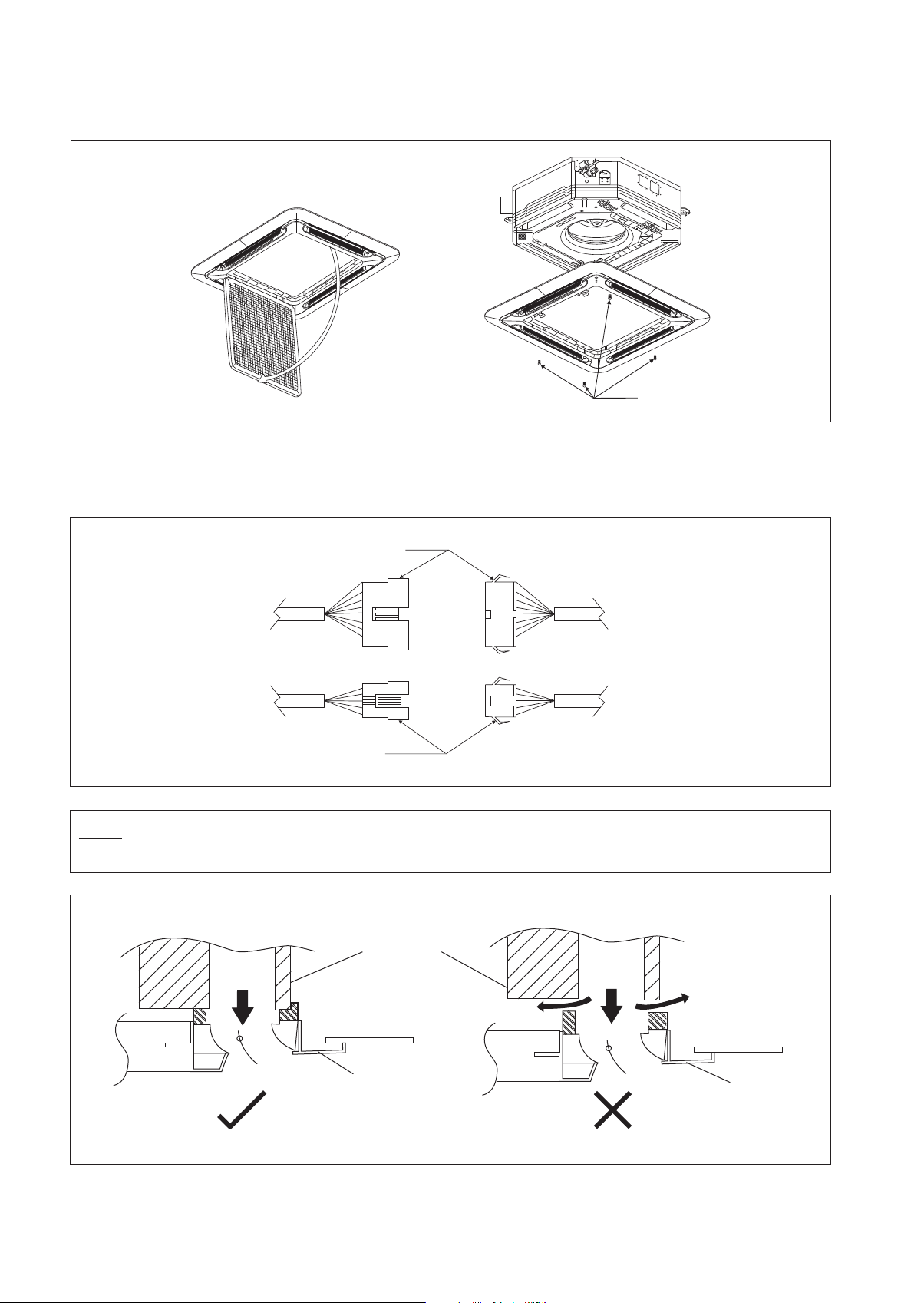

8. Panel Installation

• The front panel can only be fitted in one direction, follow the piping direction. (Follow piping arrow sticker on front panel)

• Be sure to remove the installation template before installing the front panel.

Open

Screw

• Open the air intake grille by pulling back the catchers and removing it together with filter from panel.

• Install the front frame panel onto the indoor unit by 4 screws and tighten it completely to prevent cool air leakage.

• Connect the LED wire and air swing wire to the indoor unit.

• The air swing connector must put inside the control box after connected.

LED Wire

From Front

Panel

Air Swing Wire

From Unit

Control Box

NOTE

Install the front frame panel firmly to prevent cool air leakage which will cause condensation and water dripping.

Indoor Unit

Cool

Air

Air Leak

Ceiling Board

Cool

Air

Air Leak

Ceiling Board

Panel

Panel

1-6

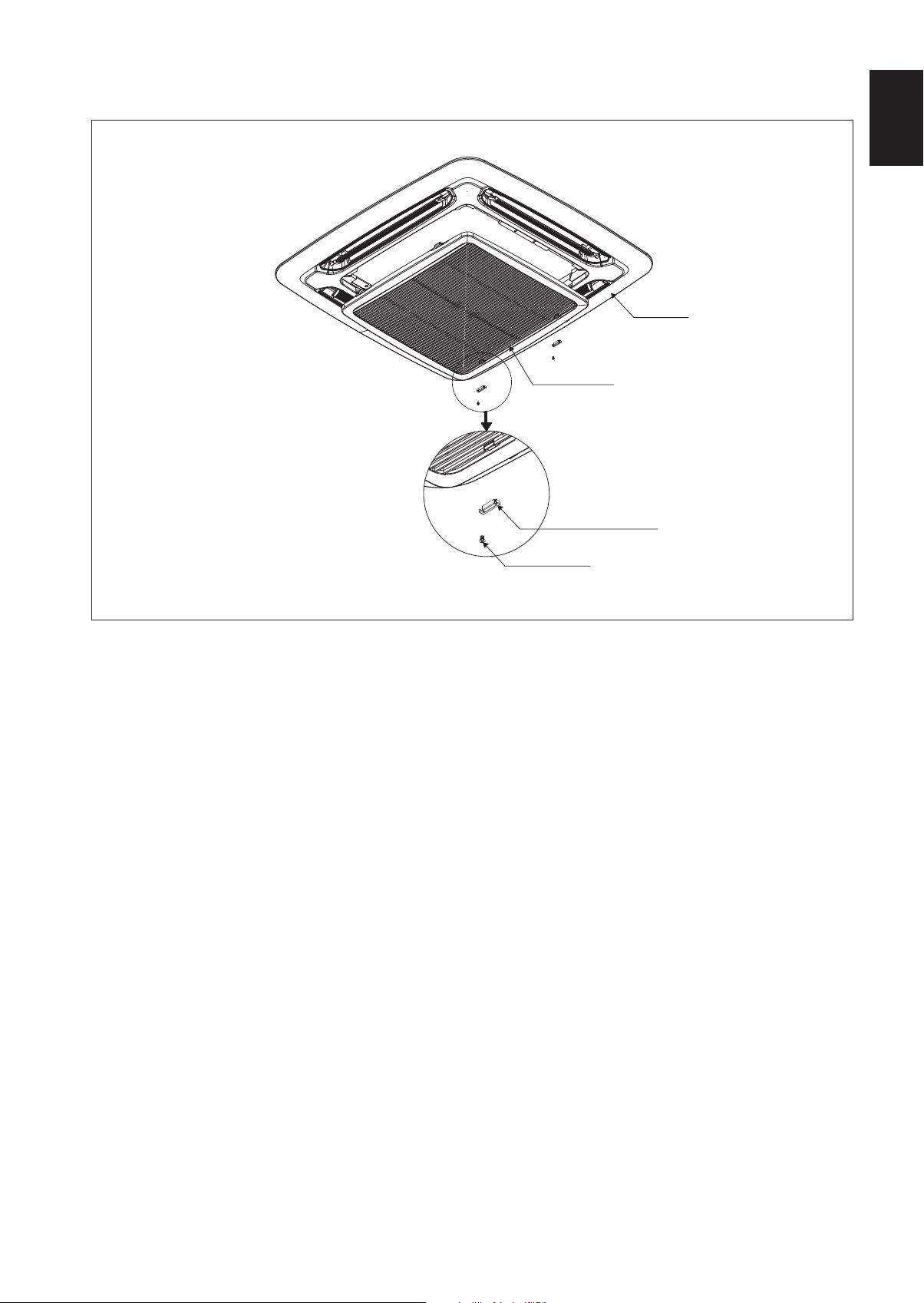

9. Cover Lock Grille (The moving part protection for user direct touching)

Cover lock grille must be installed as the figure below.

Intake Grille

Cover Lock Grille

(2pcs)

Screw M4 x 6

(2pcs)

English

Frame

If the unit need to be service, steps below shall be followed:

1. Confirm that the unit had been switched off before servicing the unit.

2. Use screwdriver to unlock the screw on the cover lock grille.

3. Remove the cover lock grille and open the intake grille for the service purpose.

4. Install the intake grille and screw the cover lock grille after service and make sure the unit is proper install.

1-7

10. Wires Installation

Figure A

Figure A and Figure B shows the location of cover wire in indoor unit.

Steps to install power supply wires and wires from outdoor unit.

1. Remove wire cover by removing screws as shown in Figure C.

2. Wires will go through the hole as shown in Figure D and E respectively without crossing the height of the hole.

3. After that, wire cover will be assembled back to close the wire.

Figure B Figure C

Figure D Figure E

1-8

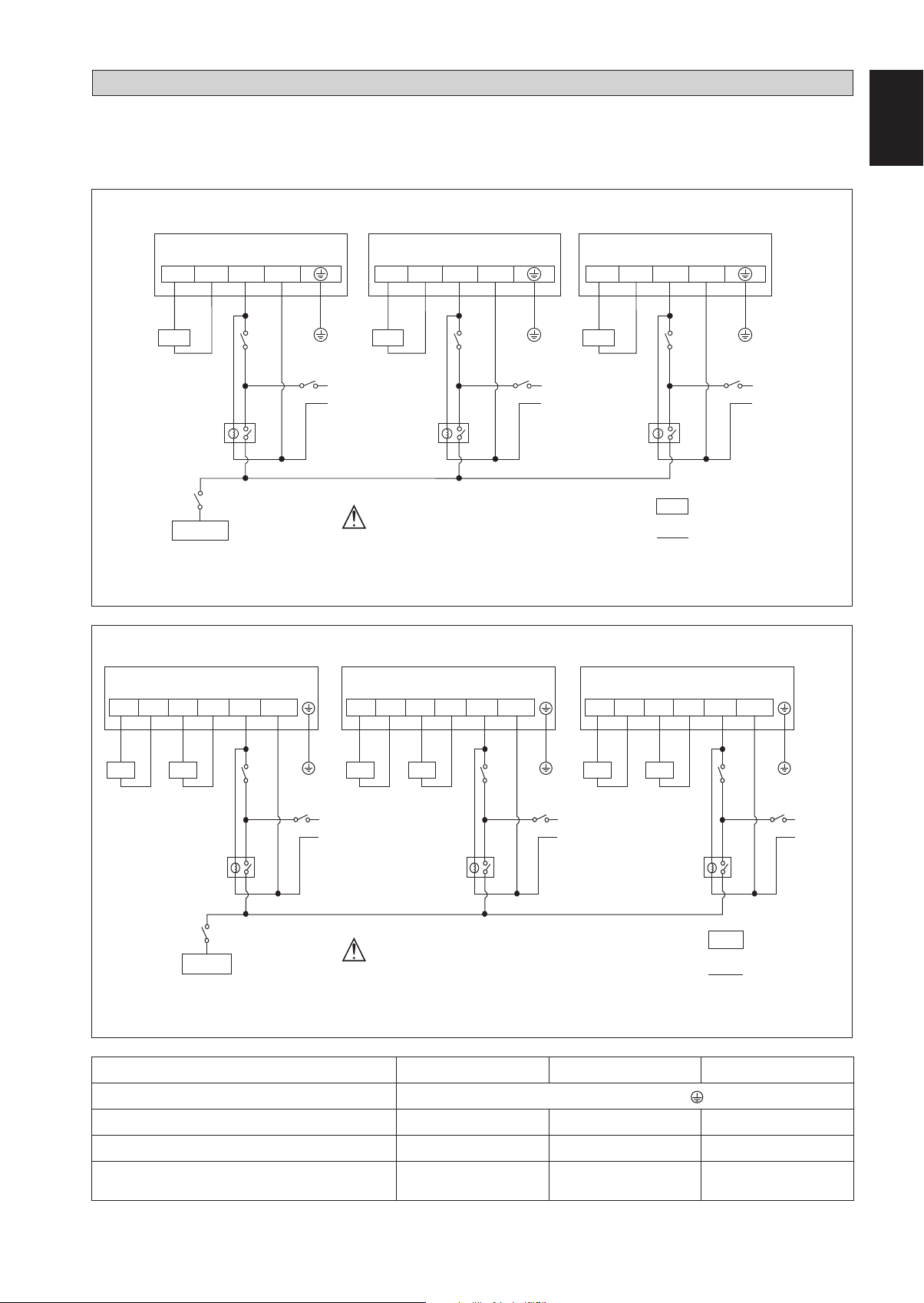

ELECTRICAL WIRING CONNECTION

IMPORTANT: * These values are for information only. They should be checked and selected to comply with local and/or

national codes and regulations. They are also subject to the type of installation and size of conductors.

** The appropriate voltage range should be checked with label data on the unit.

There must be an all pole disconnection in the supply mains with a contact separation of at least 3mm.

Model: FWG05/08/11AAT

English

FCU 1 FCU 2

LN1CVLV

X1

CHILLER

Model: FWG05/08/11AAF

FCU 1

HVLV

N1 CVLV N2 L N

NLN1CVLV N

3WV3WV

L

N

X2

There must be an all pole

disconnection in the supply

mains with a contact separation

of at least 3mm.

All power line must be from the

same phase.

FCU 2

HVLV N1 CVLV N2 L N

FCU 3

3WV

L

N

X1, X2,X3

HVLV N1 CVLV N2 L N

LN1CVLV N

X3

3 Way Valve

3WV

Relay

Field Supply Wire

FCU 3

L

N

3WV

3WV

L

N

X1

CHILLER

3WV3WV

X2

There must be an all pole

disconnection in the supply

mains with a contact separation

3WV3WV

L

N

X3

3 Way Valve

3WV

X1, X2,X3

Relay

Field Supply Wire

L

N

of at least 3mm.

All power line must be from the

same phase.

Model FWG05AAT(F) FWG08AAT(F) FWG11AAT(F)

Voltage Range**

Recommended time delay fuse* (A)

Power Supply Cable* (mm2)

Interconnection cable size* (mm2)

Number of conductors

220V-240V/~/50Hz +

222

1.5 1.5 1.5

333

1-9

• All wires must be firmly connected.

• Make sure all the wire not touching the refrigerant piping, compressor or any moving parts of the fan motor.

• The connecting wire between the indoor unit and the outdoor unit must be clamped on the wire clamps.

• The power supply cord must be equivalent to H07RN-F which is the minimum requirement.

• When attaching the terminal box lid, make sure do not pinch any wires.

• After all the wiring connections are done, fill in any gaps/holes with insulation (procured locally) to prevent small animals

and insects entering the unit from outside.

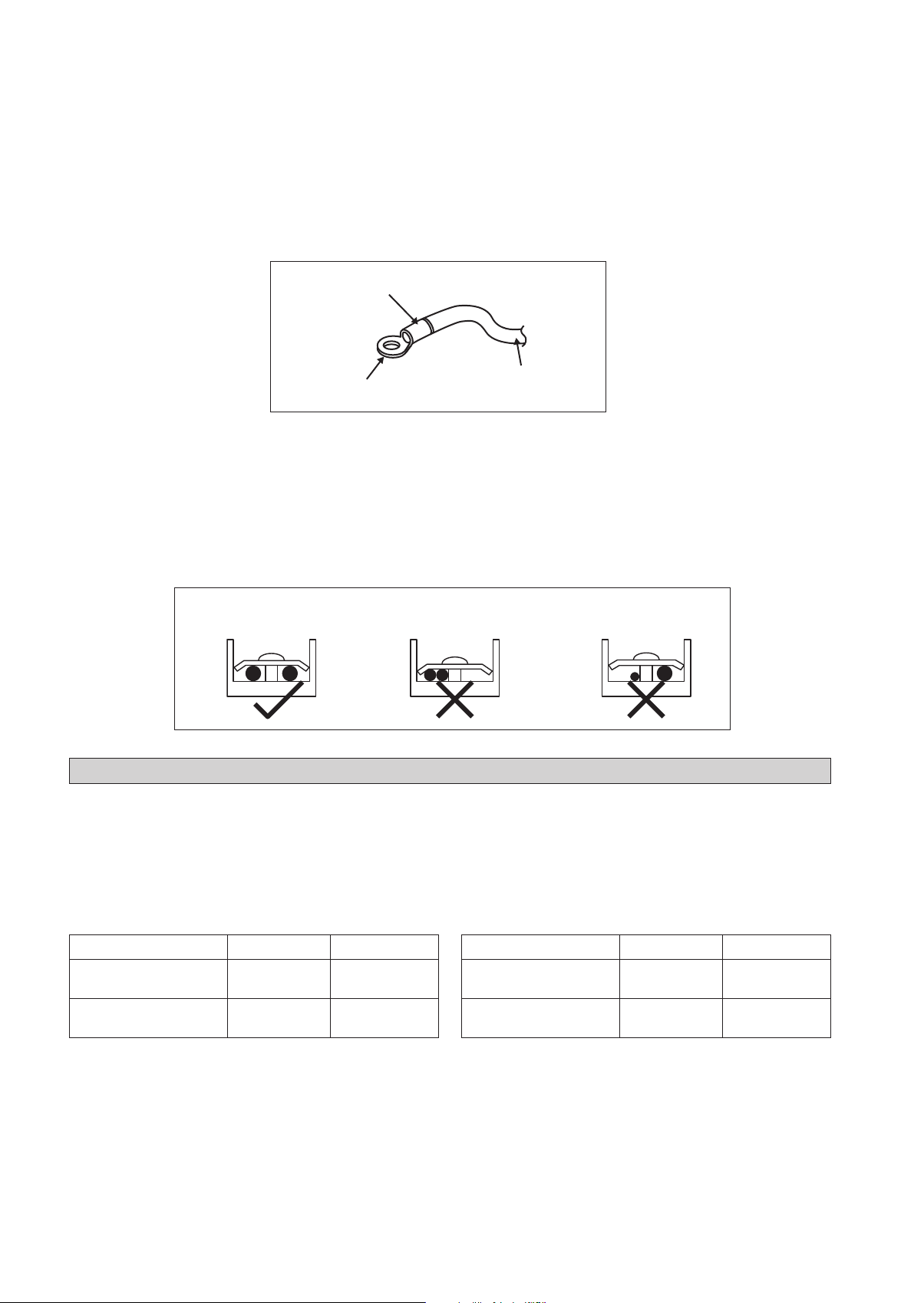

• Use round crimp-style terminal for connecting wires to the power supply terminal block. Connect the wires by matching

to the indication on terminal block. (Refer to the wiring diagram attached on the unit).

Attach insulation sleeve

Round crimp-style terminal

Electric wire

Step to connect the installation wire:

• Used the correct screwdriver for tightening the terminal screws. If the block is too small, the mad of the screw might be

damaged and the screw will not be properly tightened. If tightening too hard, screw might be damaged.

• Do not connect wire at different gauge to the same proper supply terminal.

• Use specified electric wire. Connect the wire securely to the terminal. Lock the wire down without applying excessive

force to the terminal.

• Keep wiring in mat order and not to obstruct other equipment such as popping open the terminal box lid.

Connect wires of the

same gauge to both side.

Do not connect wires of the

same gauge to one side.

Do not connect wires

of different gauges.

OPERATING RANGE

Operating Limits:

Thermal carrier : Water

Water temperature : 4°C ~ 10°C (Cooling), 35°C ~ 50°C (2 Pipes), 35°C ~ 70°C (4 Pipes),

Maximum water pressure : 16 bar

Air temperature : (as below)

Cooling Unit Heating Unit

Temperature Ts °C/°F Th °C/°F

Minimum indoor

temperature

Maximum indoor

temperature

16.0 / 60.8 11.0 / 51.8

32.0 / 89.6 23.0 / 73.4

Temperature Ts °C/°F Th °C/°F

Minimum indoor

temperature

Maximum indoor

temperature

Ts: Dry bulb temperature. Th: Wet bulb temperature.

1-10

16.0 / 60.8 -

30.0 / 86.0 -

Loading...

Loading...